Page 1

No moving parts to stick, wear or hang-up.

250 Series

Pump Control Low Water

Cut-Off Combination

120 VAC Operating Voltage

Max. Pressure 250 psi

LISTED

HOW TO INSTALL

WARNING!

1

WARNING: To prevent electrical shock

and equipment damage, power must

be off during installation or servicing of

the control. To prevent serious burns

the boiler should be thoroughly cooled

before installing or servicing control.

Only qualified personnel may install or service the control

in accordance with local codes and ordinances.

Read instructions completely before proceeding.

No replacement or rebuilding of floats or

mechanical parts.

Reliable Electronic Design

Made in the U.S.A

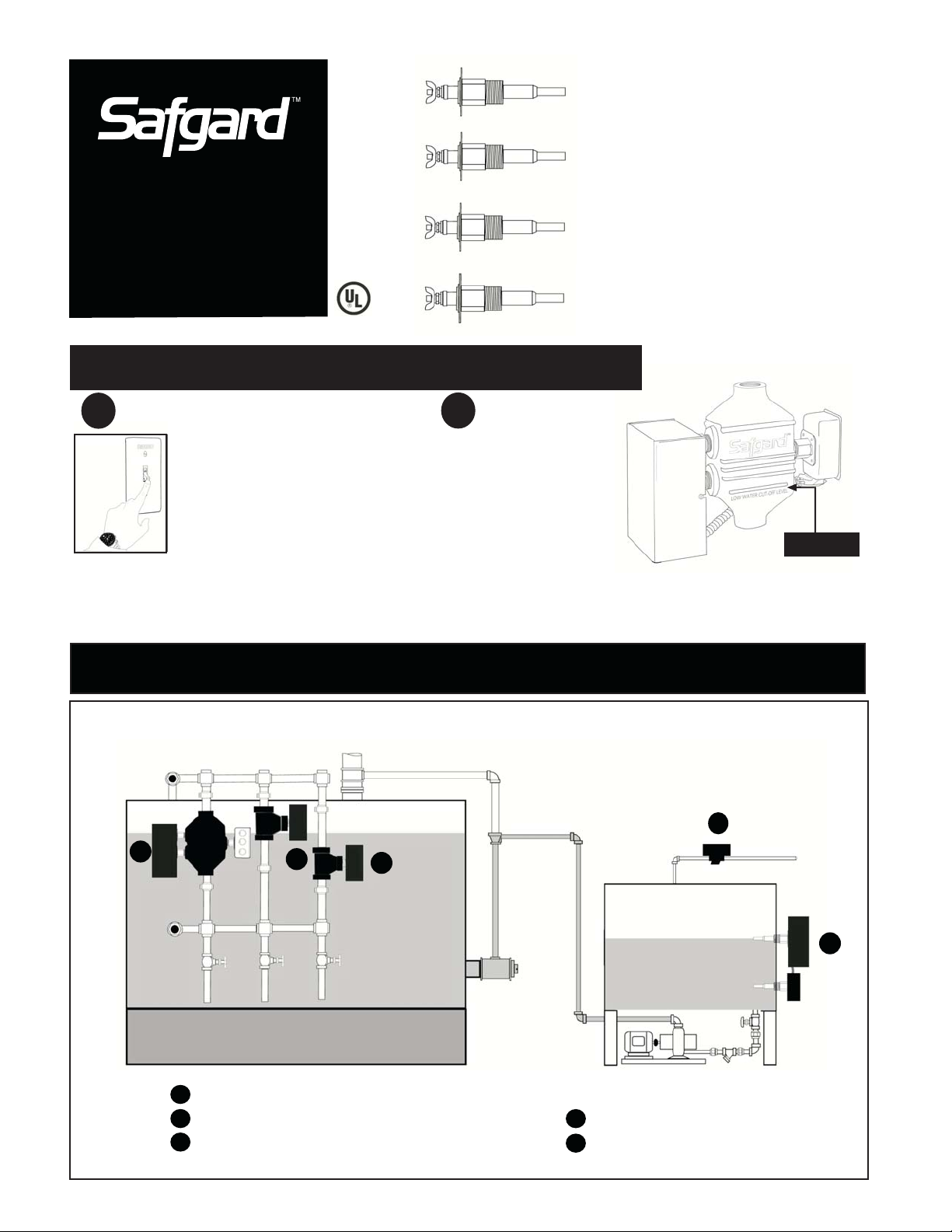

LOCATION

2

Install the Safgard 250 in a

1" equalizing line equipped

with a blow-down valve

meeting applicable state

and local codes. The control

should be located so that

the "LOW WATER CUT-OFF LEVEL marked on the control casting

is at least 1/2 above the lowest permissible water level as specified

by the boiler manufacturer.

LOW WATER CUT-OFF

LEVEL INDICATOR

TYPICAL APPLICATIONS

1

Safgard 250 Pump Controller LWCO Combination

1

Safgard 270 High Water Limit/Alarm

2

3

Safgard 550 or 750 as Secondary LWCO

2

3

Safgard VF-120 Solenoid Valve

4

5

Safgard 727 Tank Control

4

INCOMING WATER LINE

5

Page 2

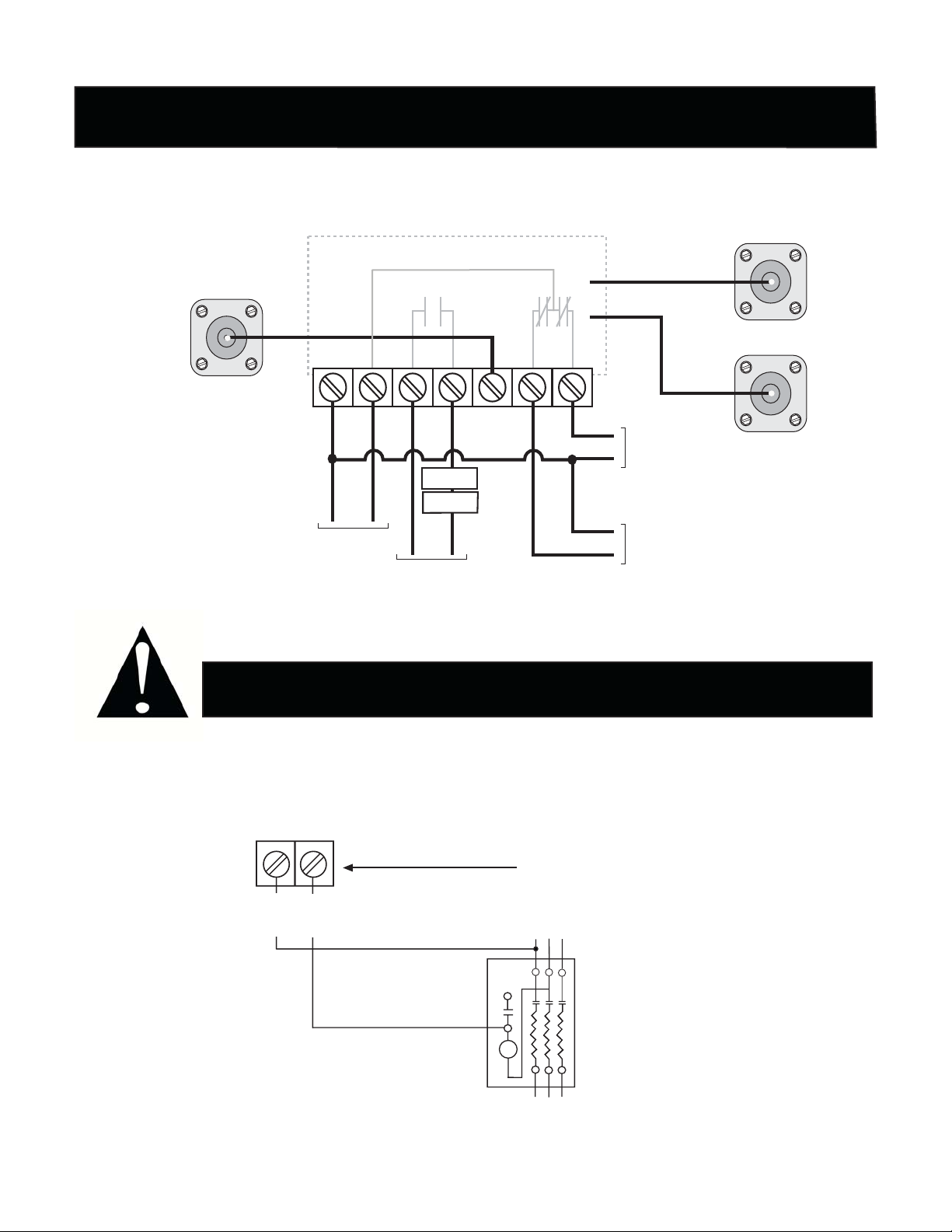

WIRING

HOTHOT

COMMONCOMMON

HOTHOT

NEUTRALNEUTRAL

H H

PP

PPPFEFEFEAA

VV

MODEL 250 Low Water Cut-Off and Pump Control

ALL WIRING SHALL

BE NEC CLASS I

OPEN CIRCUIT

VOLTAGE TO PROBE

140 VAC

FEED

PROBE

(FEED ON)

MAXIMUM PRESSURE: 250 PSI

INTERNAL WIRING

GGG

NEUTRAL

H

HOT

120 VAC 60 HZ

INCOMING

POWER

P

LIMIT

BURNER

HOT

COMMON

BURNER POWER

SOURCE

5.8 FLA 34.8 LRA

BLUE

WHITE

UPPER PROBE

(FEED OFF)

A

V

TO FEED

PUMP CONTROL

CIRCUIT

125 VA PILOT DUTY

TO ALARM CIRCUIT

120 VA, 60 HZ, 10A

LOWER

PROBE

(LWCO)

The Safgard 250 requires connection to a 120VAC power source to enable the control to operate.

IMPORTANT!

The Safgard 250 is intended as a pilot control only and must be installed with a relay

between it and both the condensate pump and burner circuit. Direct wiring of the control

to either the burner circuit or condensate pump can result in failure of the control.

250 PUMP TERMINALS

A

V

LINE

TYPICAL PUMP STARTER WIRING. SEE RELAY MANUFACTURERS

INSTRUCTIONS FOR MORE COMPLETE INFORMATION.

Page 3

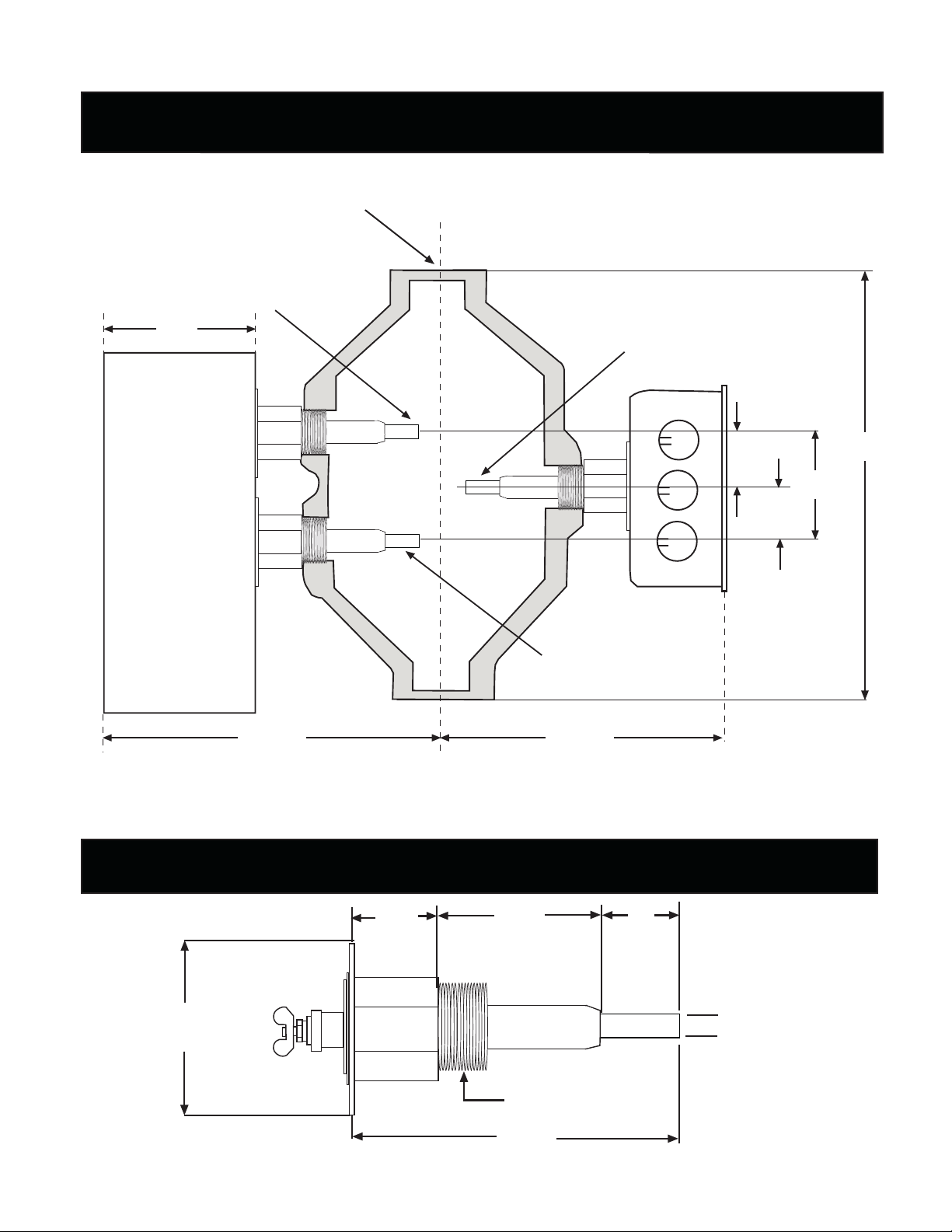

DIMENSIONAL DATA

1 NPT (BOTH ENDS)

PUMP OFF

1/4

3

PUMP ON

1

1/16

1

3/16

1/2

8

1/4

2

7 MAX

PROBE DATA

2

SQUARE

LOW WATER CUT-OFF

6 MAX

Maximum Steam Pressure 250 PSI

15/16

7/8

1

3/4 NPT

1

5/16

13/16

3

Probe Test Pressure 1000 PSI

Page 4

BLOW-DOWN & TEST PROCEDURE

CAUTION!- Blow down valve should be piped to a proper drain connection to avoid exposure to

steam discharge. Severe injury could result from failure to follow these instructions.

Blow down the 250 Series control when the water level is at its normal operating level (between middle and upper

probe) - with the the burner on.

Slowly open the column blow-down valve. The water level should begin to drop in the site glass. When water falls below

the middle probe, the pump or valve should energize. Continue draining the blow down column until water has fallen

below the bottom probe. Boiler should shut down immediately. Close the blow-down valve. Water should begin to rise

in the site glass. The burner should refire after covering the bottom probe and water should continue to rise in the site

glass. When water reaches the top probe the burner should continue to fire and the pump or valve should de-energize.

If the control fails to react as described above recheck wiring and/or probes for sludge or sediment buildup.

MAINTENANCE

In addition to the blow-down and test procedure above, the probes should be removed and examined annually. The

probes can usually be cleaned with a soft cloth although they are rugged enough to be cleaned with steel wool or a

scouring pad if a more crystaline or solid buildup is present. Probes should be inspected and cleaned more often on

systems with high make-up water or untreated boiler water.

MANUAL RESET FEATURE (Model 250M)

The Safgard 250M manual reset incorporates a 90-second time delay that prevents nuisance lockouts. During

temporary low water conditions such as column blow-down, excessive surge or slow condensate return, the burner

will shut down immediately but will not lock out for 90 seconds. The burner will restart automatically if the water

returns to a safe level within 90 seconds. The manual reset does not require resetting after a power failure.

Likewise, power interruptions will not reset the manual reset once engaged. With the Safgard manual reset design,

a genuine low water condition must be detected before reset is actuated and the only procedure for resetting a

tripped reset involves operator contact.

LIMITED MANUFACTURERS WARRANTY

We warrant products manufactured by

Hydrolevel Company to be free from defects

in material and workmanship for a period of

two years from the date of manufacture or

one year from the date of installation,

whichever occurs first. In the event of any

claim under this warranty or otherwise with

respect to our products which is made within

such period, we will, at our option, repair or

replace such products or refund the purchase

price paid to us by you for such products

FRONT

Top of Control

SLIDE MANUAL RESET TOWARD FRONT OF CONTROL TO RESET

In no event shall Hydrolevel Company be liable

for any other loss or damage, whether direct,

indirect, incidental or consequential. This

warranty is your EXCLUSIVE remedy and shall

be IN PLACE OF any other warranty or

guarantee, express or implied, including, without

limitation, any warranty of MERCHANTIBILITY

or fitness for a particular purpose. This warranty

may not be assigned or transferred and any

unauthorized transfer or assignment thereof

shall be void and of no force or effect.

.

MANUAL

RESET

BUTTON

.

P.O. Box 1847

New Haven, CT 06508

Phone: (203) 776-0473

Fax: (203) 773-1019

www.hydrolevel.com

Page 5

No moving parts to stick, wear or hang-up.

250WC Series

Pump Control Low Water

Cut-Off Combination

120 VAC Operating Voltage

Max. Pressure 250 psi

LISTED

HOW TO INSTALL

WARNING!

1

To prevent electrical shock and

equipment damage, power must be off

during installation, inspection or servicing

of the control.

To prevent serious burns the boiler

should be thoroughly cooled before

installing or servicing control.

Only qualified personnel may install or service the control

in accordance with local codes and ordinances. Read

instructions completely before proceeding.

No replacement or rebuilding of floats or

mechanical parts.

Reliable electronic design.

Made in the U.S.A.

LOCATION

2

Install the Safgard 250WC

in a 1" equalizing line

equipped with a blow-down

valve meeting applicable

state and local codes. The

control should be located

so that the "LOW WATER CUT-OFF LEVEL marked on the control

casting is at least 1/2 above the lowest permissible water level as

specified by the boiler manufacturer.

LOW WATER CUT-OFF

LEVEL INDICATOR

TYPICAL APPLICATIONS

1

2

Safgard 250 Pump Controller LWCO Combination

1

Safgard 270 High Water Alarm

2

3

Safgard 550 or 750 as Secondary LWCO

3

Safgard VF-120 Solenoid Valve

4

5

Safgard 727 Tank Control

4

Incoming Water Line

5

Page 6

WIRING

HOTHOT

COMMONCOMMON

HOTHOT

NEUTRALNEUTRAL

H H

PP

PPPFEFEFEAAAVV

MODEL 250WC Low Water Cut-Off and Pump Control

MAXIMUM PRESSURE: 250 PSI

INTERNAL WIRING

BLUE

WHITE

FEED

PROBE

(FEED ON)

ALL WIRING SHALL

BE NEC CLASS I

OPEN CIRCUIT

VOLTAGE TO PROBE

140 VAC

GGG

NEUTRAL

120 VAC 60 HZ

INCOMING

POWER

H

HOT

P

LIMIT

BURNER

HOT

COMMON

BURNER POWER

SOURCE

5.8 FLA 34.8 LRA

V

TO FEED

PUMP CONTROL

CIRCUIT

125 VA PILOT DUTY

TO ALARM CIRCUIT

120 VA, 60 HZ, 10A

UPPER PROBE

(FEED OFF)

LOWER

PROBE

(LWCO)

The Safgard 250WC requires connection to a 120VAC power source to enable the control to operate.

IMPORTANT!

The Safgard 250WC is intended as a pilot control only and must be installed with a relay

between it and both the condensate pump and burner circuit. Direct wiring of the control

to either the burner circuit or condensate pump can result in failure of the control.

250WC PUMP TERMINALS

A

V

LINE

TYPICAL PUMP STARTER WIRING. SEE RELAY MANUFACTURERS

INSTRUCTIONS FOR MORE COMPLETE INFORMATION.

Page 7

DIMENSIONAL DATA

UPPER PROBE

(PUMP OFF)

LOW WATER CUT-OFF PROBE

7/8”

10

1/8”

8

3/8”

7

3/4”

5

LOW

WATER

LEVEL

1” NPT

(TYP. BOTH ENDS)

1/2” NPT

(TYP 2 PLACES)

FOR SIGHT GLASS

(NOT SUPPLIED)

1/2”

9

15/16”

6

15

3/4”

1/2” NPT

TYP. 3 PLACES

ON FAR SIDE

FOR TRI-COCKS

PROBE DATA

2”

SQUARE

7/8”

3

1/8”

3

6”

MAX

6”

MAX

LOWER PROBE

250 PSI Steam Pressure

7/8

15/16”

1 ”

1”

(PUMP ON)

5/16”

3/4” NPT

13/16

3 ”

Probe Test Pressure 1000 PSI

Page 8

BLOW-DOWN & TEST PROCEDURE

CAUTION!- Blow down valve should be piped to a proper drain connection to avoid exposure to

steam discharge. Severe injury could result from failure to follow these instructions.

Blow down the 250WC Series control when the water level is at its normal operating level (between middle and upper

probe) - with the the burner on.

Slowly open the column blow-down valve. The water level should begin to drop in the site glass. When water falls

below the middle probe, the pump or valve should energize. Continue draining the blow down column until water has

fallen below the bottom probe. Boiler should shut down immediately. Close the blow-down valve. Water should begin

to rise in the site glass. The burner should refire after covering the bottom probe and water should continue to rise in

the site glass. When water reaches the top probe the burner should continue to fire and the pump or valve should deenergize. If the control fails to react as described above recheck wiring and/or probes for sludge or sediment buildup.

MAINTENANCE

In addition to the blow-down and test procedure above, the probes should be removed and examined annually. The

probes can usually be cleaned with a soft cloth although they are rugged enough to be cleaned with steel wool or a

scouring pad if a more crystaline or solid buildup is present. Probes should be inspected and cleaned more often on

systems with high make-up water or untreated boiler water.

MANUAL RESET FEATURE (Model 250MWC)

The Safgard 250MWC manual reset incorporates a 90-second time delay that prevents nuisance lockouts. During

temporary low water conditions such as column blow-down, excessive surge or slow condensate return, the burner

will shut down immediately but will not lock out for 90 seconds. The burner will restart automatically if the water

returns to a safe level within 90 seconds. The manual reset does not require resetting after a power failure.

Likewise, power interruptions will not reset the manual reset once engaged. With the Safgard manual reset design,

a genuine low water condition must be detected before reset is actuated and the only procedure for resetting a

tripped reset involves operator contact.

LIMITED MANUFACTURER’S WARRANTY

We warrant products manufactured by

Hydrolevel Company to be free from defects

in material and workmanship for a period of

two years from the date of manufacture or

one year from the date of installation,

whichever occurs first. In the event of any

claim under this warranty or otherwise with

respect to our products which is made within

such period, we will, at our option, repair or

replace such products or refund the purchase

price paid to us by you for such products.

FRONT

Top of Control

SLIDE MANUAL RESET TOWARD FRONT OF CONTROL TO RESET.

In no event shall Hydrolevel Company be liable

for any other loss or damage, whether direct,

indirect, incidental or consequential. This

warranty is your EXCLUSIVE remedy and shall

be IN PLACE OF any other warranty or

guarantee, express or implied, including, without

limitation, any warranty of MERCHANTIBILITY

or fitness for a particular purpose. This warranty

may not be assigned or transferred and any

unauthorized transfer or assignment thereof

shall be void and of no force or effect.

MANUAL

RESET

BUTTON

P.O. Box 1847

New Haven, CT 06508

Phone: (203) 776-0473

Fax: (203) 773-1019

www.hydrolevel.com

Loading...

Loading...