Page 1

170 Series

Low Water Cut-Off

120 VAC Operating Voltage

Heavy-duty electro-mechanical design for long life.

Automatically shuts off burner in a low water condition to

prevent boiler damage.

Low maintenance. No moving parts to wear stick or hang up,

as in float devices.

Rugged construction. Designed for the heating professional.

WARNING: To prevent

electrical shock or equip-

ment damage, power must

be off during installation or servicing

of the control. To prevent serious

burns, the boiler should be thoroughly cooled before installing or servicing control. Only qualified personnel

may install or service the control in

accordance with local codes and

ordinances. Read instructions completely before proceeding.

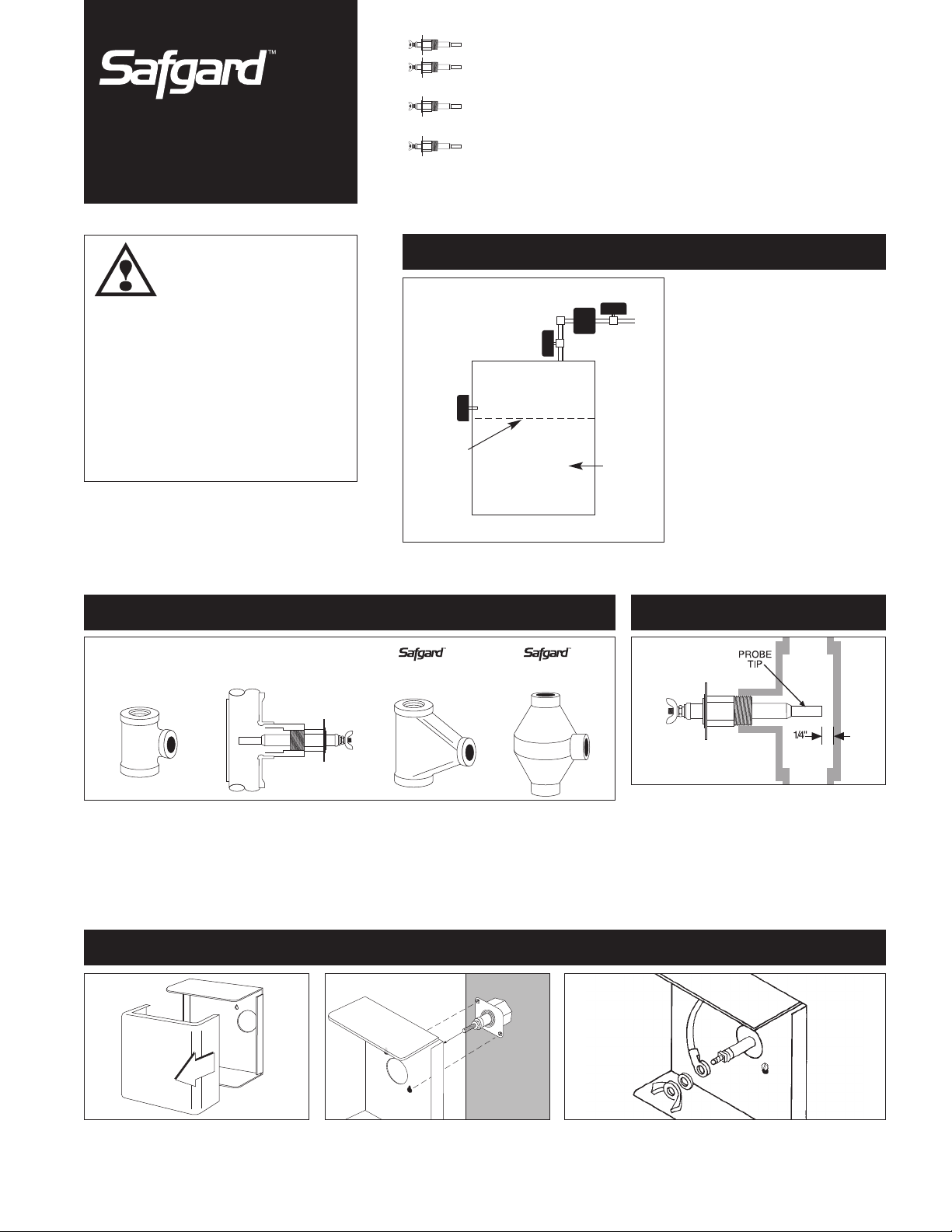

2. Tee Options

STANDARD

REDUCING TEE

(SV Models Only)

FABRICATED TEE

1. Where To Install

HOT WATER BOILER

INSTALLATIONS

B

A

MINIMUM

WATER LEVEL

FOEM-TEE

(160psi)

1214C-2 TEE

(250psi)

C

D

HOT WATER

BOILER

HOT WATER BOILERS: Probe must be

installed at or above the minimum safe

water level established by the boiler

manufacturer. The probe may be

installed directly in the boiler if a suitable tapping is available (A), in the riser

(B), or in the header (C) or (D).

IMPORTANT: To assure proper

drainage, pipe diameter should be no

less than 1" on installations in vertical

piping and no less that 1

tions in horizontal piping.

3. Probe Installation

1

⁄4" on installa-

TEE MOUNTING: If a field fabricated tee is used, make sure that the tee drains thoroughly when the

water level falls below it, and that it conforms to the spacing requirements described in Step 3.

Models equipped with the shorter EL1214-SV probe can be installed in most standard reducing tees.

Safgard cast iron tees are also available to accommodate all probe models (See page 4).

4. Control Mounting

Loosen the two control box cover binding head screws and remove the cover.

Slide keyhole slots over probe mounting

screws and tighten screws (with either a

1/4" hex head driver or flat screwdriver).

Connect the ring terminal wire lead to the probe terminal

stud and secure with the lock washer and wing nut provided.

With the power removed, proceed with installation and

wiring according to Method A or B described on next page.

Check to insure 1/4" clearance from probe to

any surface within the boiler or tee. When

installed in a tee, the probe tip should extend

fully into the pipe run. Apply pipe sealing compound to threads.

Note: Use of Teflon tape is not recommended.

Page 2

P1 P2 A

+

0

LIMIT

CONTROLS

BURNER

CIRCUIT

NEUTRAL

HOT

2

1

ALARM

P1 P2 A

HOT

BURNER

CIRCUIT

NEUTRAL

2

1

BURNER

POWER

SOURCE

(

24 or

120VAC)

P1 P2 A

NEUTRAL

HOT

BURNER

+

0

LIMIT

CONTROLS

2

1

2

P1 P2

A

BURNER

POWER

SOURCE

24 V

AC

1

NEUTRAL

HOT

FACTORY

INSTALLED

JUMPER

1

P1P2 A

ALARM

2

P2 A

24V

AC

1

NEUTRAL

HOT

P1

P1 P2 A

+

0

LIMIT

CONTROLS

BURNER

CIRCUIT

HOT

NEUTRAL

2

1

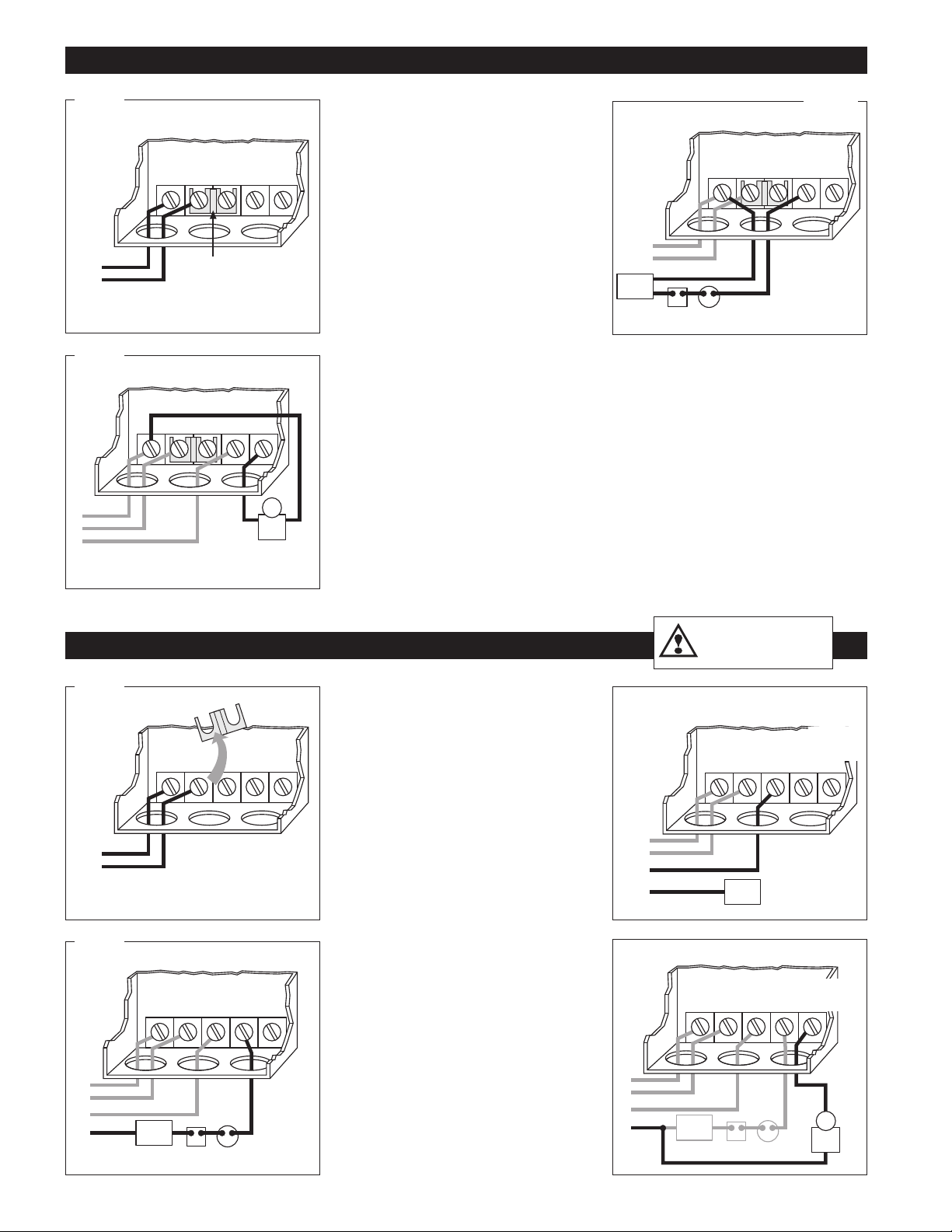

WIRING METHOD A: SAME POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.

A1

A3

䊴

A1 Connect the hot lead of the input volt-

age (24 VAC, 60 HZ) to terminal 1. Connect the

neutral lead to terminal 2. 24 VAC, 60 HZ must

be supplied to terminals 1 and 2 for internal

operation of the control.

䊳䊳

Connect terminal 2 to burner

A2

circuit neutral. Connect terminal P2 to burner

circuit in series with other limit controls.

Consult boiler manufacturer instructions for

proper terminal connections. Control should be

wired in series with and before other circuits.

䊴

A3 Optional alarm connection. Connect

alarm common to terminal 2. Connect alarm hot

to terminal A.

Upon completion of wiring, replace control

box cover.

A2

WIRING METHOD B: SEPARATE POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.

B1

B3

䊴

B1 WARNING! Remove the jumper

between 1 and P1. Connect the hot lead of the

input voltage (24 VAC, 60 HZ) to terminal 1.

Connect the neutral lead to terminal 2. 24 VAC,

60 HZ must be supplied to terminals 1 and 2 for

internal operation of the control.

Connect hot lead from the 24 VAC

B2

䊳䊳

or 120 VAC burner power source to terminal P1.

This terminal supplies power to terminal P2 in

normal operating conditions when water is at

the probe. Connect neutral to burner circuit.

Note: consult boiler manufacturer instructions

for proper terminal connections.

䊴

B3 Connect terminal P2 to burner

circuit in series with and before other limit controls.

Optional alarm connection. Connect

B4

䊳䊳

alarm hot to terminal A. Connect alarm common

to neutral of the burner power source.

Upon completion of wiring, replace control

box cover.

WARNING: Be sure to

remove the jumper

between 1 and P1.

B2

B4

Page 3

OPERATIONAL TEST PROCEDURE

Important: Do not run boiler unattended until the following procedure is completed.

1. After wiring is complete and prior to raising the water level above the probe set the thermostat to call for heat. The burner should not fire. IMPORTANT:

If the boiler fires with no water at the probe, immediately shut down the boiler and refer to Trouble Shooting Instructions below.

2. Proceed to fill the system with water. When water reaches probe position burner should fire. If burner does not fire with water at the probe refer to

Trouble Shooting Instructions below.

MAINTENANCE

When installed on a residential hot water heating system, the probe should be removed and cleaned every five years. When installed on a commercial

application, the probe should be removed and cleaned annually. After cleaning the probe, perform the Operational Test Procedure described above.

TROUBLE SHOOTING

IF THE BURNER DOES NOT SHUT DOWN WHEN WATER DROPS BELOW THE PROBE.

1. Remove power immediately and re-check wiring.

2. Remove power and check for adequate clearance from the probe to any surface within the boiler or tee.

IF THE BURNER DOES NOT FIRE.

1. Make sure water is at the probe and probe lead wire is properly secured to probe.

2. Check for proper ground between probe and boiler shell. Excessive use of Teflon tape or sealing compound may insulate the probe from the

boiler shell.

3. Check to insure probe is not surrounded by an air pocket. Slowly loosen, but do not remove, the probe with a wrench. Allow any air to escape.

When water begins to seep past probe threads, retighten probe.

4. Re-check wiring and test for correct incoming voltage.

A

NEW

VXT Water Feeder with

Digital Feed Counter

D

B

Hydrolevel...

The Safe Choice

C

E

for Every Boiler!

Hydrolevel offers a complete line of electronic

low water cut-offs and liquid level controls,

including the NEW VXT water feeder with

digital feed counter… everything to give you

peace of mind on all

Whether it’s hot water or steam, residential or

commercial, Hydrolevel makes the right control

to complete your installation with safety.

P.O. Box 1847 • New Haven, CT 06508

(203) 776-0473 • Fax (203) 773-1019

TOLL FREE 800-654-0768

www.hydrolevel.com

AA..

el 550 Low Water Cut-Off for hot water boilers,

Mod

dential hot water boilers,

DD..

el VXT-24 Programmable Water Feeder,

Mod

your installations.

BB..

CC..

CG400 foam-compensating Low Water Cut-Off for steam boilers,

Model

Model 170SV Low Water Cut-Off for resi-

EE ..

Model 250WC Pump Contoller/Low Water Cut-Off.

Page 4

FITTINGS

2"

SQUARE

17/8"

313/16"

15

/16"

1"

3

/4" NPT

5

/16"

2"

SQUARE

11/16"

3"

15

/16"

1"

3

/4" NPT

5

/16"

2"

SQUARE

17/8"

49/16"

1"

3

/4" NPT

5

/16"

111/16"

59/16

11/16

51/2

31/16

BACK

37/8

15/8

11/8

15/8

23/8

BOTTOM

Controls equipped with the EL1214-SV Probe can be mounted in standard reducing tees (supplied by others). Safgard manifolds, listed below, can be used

with all probe models.

MODEL PSI SIZE

FOEM-1 160 1 1/2" x 1 1/2" x 3/4"NPT

FOEM-2 160 1" x 1" x 3/4"NPT

FOEM-3 160 1 1/4" x 1 1/4" x 3/4"NPT

1214C-2 TEE 250 1" x 1" x 3/4"NPT

FOEM MANIFOLD 1214C-2 TEE

PROBE DATA

Test Pressure: 1000 PSI, All Models

EL1214 – STANDARD MODEL – 3/4" NPT

For 1/2", order Model EL1220

EL1214-SV – 3/4" NPT

For 1/2", order No. EL1220-SV

EL1214-P – 3/4" NPT

CAUTION: When installing probe, make sure there is a minimum of 1/4" clearance from probe tip to any surface.

DIMENSIONS SPECIFICATIONS

MAXIMUM PRESSURE: 160 PSI

INPUT VOLTAGE: 24 VAC, 60 HZ

SWITCH RATINGS: 5.8 FLA, 34.8 LRA

SWITCH CONTACTS: SPDT

ALARM CIRCUIT: 50 VA @ 24 VAC

LIMITED MANUFACTURERʼS WARRANTY

We wa rra nt pro duc ts man ufa ctu red by

Hydrolevel Company to be free from defects in

material and workmanship for a period of two

years from the date of manufacture or one year

from the date of installation, whichever occurs

first. In the event of any claim under this warranty or otherwise with respect to our products

which is made within such period, we will, at our

option, repair or replace such products or refund

the purchase price paid to us by you for such

products. In no event shall Hydrolevel Company

be liable for any other loss or damage, whether

direct, indirect, incidental or consequential. This

warranty is your EXCLUSIVE remedy and shall be

IN PLACE OF any other warranty or guarantee,

express or implied, including, without limitation,

any warranty of MERCHANTABILITY or fitness

for a particular purpose. This warranty may not

be assigned or transferred and any unauthorized

transfer or assignment thereof shall be void and

of no force or effect.

P.O. Box 1847

New Haven, CT 06508

Phone: (203) 776-0473

FAX: (203) 773-1019

Pilot Duty

45-2400

Loading...

Loading...