Hydro Instruments HC-220 Operation And Maintenance Manual

HC-220 PID Controller

Operation and Maintenance Manual

The information contained in this manual was current at the time of printing. The most current versions of all

Hydro Instruments manuals can be found on our website: www.hydroinstruments.com

HC-220 Rev. 11/1/18

1

HC-220 PID Controller

Operation & Maintenance

Manual

Table of Contents

Safety Precautions .............................................................................................................3

I. Overview ...........................................................................................................................3

II. Control Features ................................................................................................................4

III. Confi guration Mode ..........................................................................................................7

IV. Input And Output Calibration ...........................................................................................9

V. Operation Mode ..............................................................................................................11

VI. Alarm & Output Features ................................................................................................12

VII. Reference Terms .............................................................................................................13

VIII. Troubleshooting ..............................................................................................................15

Flow Charts and Drawings

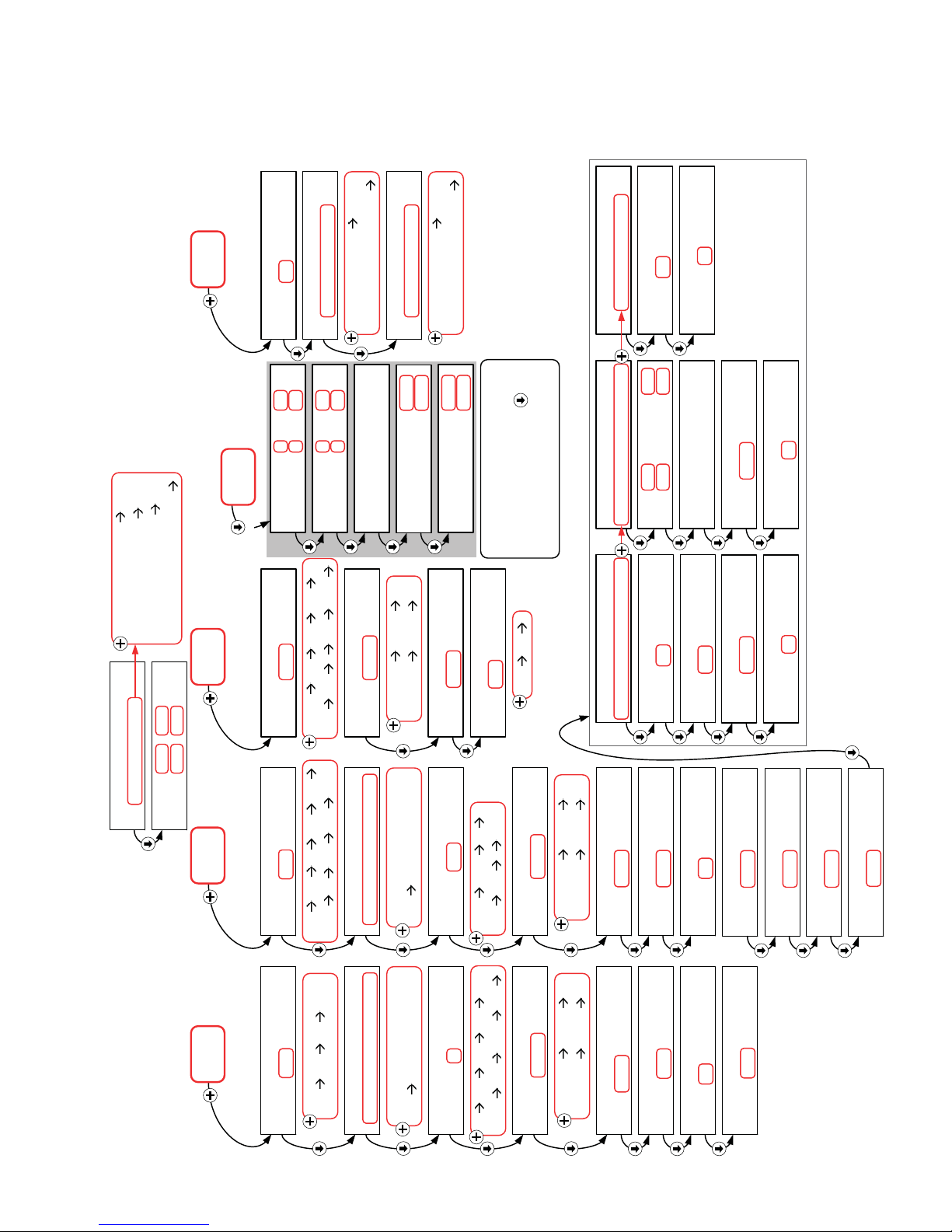

Figure 1 Confi guration Mode Flow Chart ...............................................................5

Figure 2 Hidden Screens .........................................................................................6

Figure 3 Operation Mode Flow Chart ...................................................................10

Figure 4 Circuit Board Drawing ............................................................................16

RIGHT TO REVISE: Hydro Instruments reserves the right to make engineering

revisions and improvements at any time. Please contact Hydro Instruments if there

is any discrepancy between the literature and the product provided.

2

SAFETY PRECAUTIONS

GENERAL: Be sure to follow all applicable and prudent safety precautions when working with chemicals

and electrical equipment.

ELECTRICAL: The circuit board and incoming A/C power line do include electrical shock risk. Take care

to avoid electrical shocks and do not touch any part of the circuit board or A/C power line unless you are certain

that A/C power has been disconnected from the system.

When connecting A/C power to the instrument, it is imperative that the A/C source be well grounded. Insuffi cient

A/C grounding will disrupt proper operation of the instrument.

CHECK FOR DAMAGE: Before removing the product from the shipping packaging, carefully check the

equipment for damage. If any product is found damaged, do not put it into operation or install it. Contact

Hydro Instruments to discuss repair or replacement of the damaged equipment.

I. OVERVIEW

1. Modes of the HC-220 – The HC-220 PID Controller has 2 modes that can be accessed. These modes are

as follows:

a. Confi guration Mode – This mode is used to set up the control and display parameters. (Flow Meter

range, Control type, Display units, alarms, etc…)

b. Operation Mode – This is the mode used during operation of the HC-220 PID Controller. It allows for

Dosage and Set Point Adjustments as well as manual control of the chemical feed rate.

2. Switching Between Modes – The Confi guration Mode is password protected. The password is 220.

This can be entered by using the

a. Operation Mode – This is the HC-220 standard mode. This can be reached from either of the other

two modes by repeatedly pressing the “up arrow”

b. Confi guration Mode – This mode is accessed from the Operation Mode by pressing the “down arrow”

key until the password screen is reached. Then enter the password “220” and then press the “down

arrow”

3. Menus & Display – Within each “Mode” there is a set of “Parameters”. Parameters are represented by

the blocks in the following fl ow charts. To move between these parameters, use the “up arrow” and

“down arrow”

4. Control Methods – The HC-220 offers four different control methods. They are Flow Pacing (Propor-

tional), Residual/ORP, Compound Loop Control, and Manual Control. The method is selected within the

“Confi guration Mode”. (See Section III.)

key.

keys.

and buttons.

key.

5. Electrical Inputs – The HC-220 offers two analog input channels standard. The PV1 input channel is

used only for a Flow (e.g. proportional) signal. The PV2 input channel is used only for a Residual (e.g.

set point) signal. A third, optional analog input is sometimes included. The optional PV3 input channel is

used only for remote adjustment of the Set Point setting. Each channel can be set to accept either 4-20mA

or Modbus RS-485 signals. Each of the process variable inputs are individually selectable to be read over

any of the four analog input channels AI1, AI2, AI3, or AI4 and also over Modbus.

3

NOTE: The HC-220 can power the 4-20mA source via 24VDC for both the PV1 and PV2 inputs (e.g.

loop powered input). This will change how these inputs are connected. Refer to Figure 3 for additional

details.

PV1(Flow)

AI1/V- = Source powered 4-20mA input.

AI1/V+ = Loop powered 4-20mA input.

PV2 (Residual)

AI2/V- = Source powered 4-20mA input.

AI2/V+ = Loop powered 4-20mA input.

6. Electrical Outputs – The following outputs are available:

a. The HC-220 includes two (2) SPDT alarm relays. Each relay can be independently selected as either

representing normal alarms or whether the HC-220 is in AUTO or Manual mode.

b. 4-20mA Output – The HC-220 is equipped with two (2) 4-20mA outputs which are used to control

chemical feed rate.

7. RS-485 Modbus Communication – This feature allows the HC-220 to be monitored and controlled by a

computer. See Hydro Instruments’ Modbus Communication Setup document for further details.

II. CONTROL FEATURES

1. Keypad Operation – The keypad is used in all three modes of the HC-220. Generally the keys are used

as outlined here below. However, detailed instructions will follow.

a.

b.

2. Dip Switches – These switches are used to select whether the analog input channels are to be used for

0-10 Volts or 4-20mA.

a. Switches 1 and 2 on the MB124 circuit board are used for the PV1 (Flow) input channel.

4-20mA: 1 = On, 2 = Off

0-10V: 1 = Off, 2 = On

b. Switches 3 and 4 on the MB124 circuit board are used for the PV2 (Residual) input channel.

4-20mA: 3 = On, 4 = Off

0-10V: 3 = Off, 4 = On

& keys – These keys are used to cycle through the various display screens. These keys will be

referred to as “up arrow” and “down arrow”.

& keys – These keys are generally used to adjust settings and values within the screen being

displayed. These keys will be referred to as “plus” and “minus”.

4

ALM

OUT

HOLD

Alarm Delay Time

AI1 Cal: 4 mA 20 mA

FIGURE 1

CONFIGURATION MODE

Normal Alarms

10 secs

AI2 Cal: 4 mA 20 mA

Output Relay 1 Usage

AI3 Cal: 4 mA 20 mA

Auto(Off)/Manl(On)

Normal Alarms

Input Value

Was Changed!

AI4 Cal: 4 mA 20 mA

Output Relay 2 Usage

Normal Alarms

A01 Cal: 4mA= 803

20mA= 3992

Normal Alarms

A02 Cal: 4mA= 800

Auto(Off)/Manl(On)

20mA= 4000

are hidden screens,

accessed by holding -

Screens shown with grey border

at the appropriate screen

nd

to last in the branch)

(typically 2

Lag Time Mode

Lag Time Mode

Fixed Lag Time

Res Lag Time

60 secs

Res Reset Value

0 GPM

2 Point Var Lag Time

FA1= 50% TA1= 60s

FA2= 75% TA2= 40s

A= 0.0 F= 0

B= 0.0 T= 60

Maximum Lag Time

1800 secs

Res Reset Value

0 GPM

Flow Pacing

Control Type

Residual/ORP

Compound Loop

Dual Input Feed Fwd

10.0 KG/H

PPM

Out Gas Feed Type

PPM MG/L mV

2

Cl

pH NTU %

Cl2 SO2

Res Decimal Posn

Lag Time Mode

1 Point Var Lag Time

00.00 0.000

00000 000.0

00.00

Res Full Scale

5.00 PPM

Flow at Variable Lag

60 secs

0.00 PPM

Res Filter Time

500 GPM

10 secs

Maximum Lag Time

Res Low Set

1800 secs

0.00 PPM

Res Reset Value

Res High Set

0 GPM

5.00 PPM

Res Dead Band

0.10 PPM

Res Integral Value

20.0 %

Res Lag Time

Res Minimum Value

OUT

000.0 00.00

Output Units

KG/H

SETUP: FLO RES

OUT ALM

Flow Pacing

Res Input Name

RES

KG/H GPH GPM GPD

RES ORP pH Ch1 SCM

O PRO

Output Decimal Posn

LPM LPH % PPD GR/H

TDS DO CON TUR PV2

Input Signal Loss

2

0.000 00000

000.0

Maintain Valve Posn

Maintain Valve Posn

Output Full Scale

Close Valve

Res Units

FLO RES

Flow Input Name

FLO

Close Valve

FLO PV1 H

Maintain Valve Posn

Input Signal Loss

Maintain Valve Posn

Flow Input Units

%

% GPM MGD LPM

MLD GPD M3/H LPH

Flow Decimal Posn

000.0

000.0 00.00

0.000 00000

Flow Full Scale

10.0 %

Flow Threshold

0.0 %

Flow Filter Time

10 secs

Flow Low Set

0.0 %

5

Loading...

Loading...