Hydro-Force SX-15 User Manual

1

SX-15

R

evised: 0

7/02/14

HARD SURFACE CLEANING TOOL

AW105

LMANAW105

Hydro-Force Manufacturing

4282 South 590 West

Salt Lake City, UT 84123

801-268-2673

801-268-3856 FAX

2

INTRODUCTION

Congratulations on your purchase of the SX-15 hard surface cleaning tool.

Years of experience, engineering, and planning have gone into the design and manufacturing

of the SX-15. We take a great deal of pride in the SX-15; our goal is no less than your

complete satisfaction.

The SX-15 can be used with portable or truck mounted extractors to clean tile, concrete and

stone floors. The larger cleaning area and superior water recovery of the SX-15 will make your

tile cleaning faster and more efficient.

This manual will provide users with the knowledge to operate and maintain the SX-15.

Any questions pertaining to the operating or servicing of this unit should be directed to your

nearest Hydro-Force distributor.

This manual is written specifically for the SX-15 tile cleaning tool manufactured by:

Hydro-Force Manufacturing

4282 South 590 West

Salt Lake City, UT 84123

801-268-2673

801-268-3856 FAX

Information in this manual is subject to change without notice and does not represent a

commitment on the part of Hydro-Force, its parent or affiliated companies.

3

SPECIFICATIONS

Model AW105 SX-15 Tile Cleaning Tool:

Cleaning Head: Width: 15 inches

Cleaning Head: Height: 3.13” w/ Hard Boot & 3.50” w/ Brush Ring

Total Height with Handle: 51 inches

Weight: 15.5 lbs.

Shell Construction: Polycarbonate

Hard Boot: HDPE

Brush Bristles: Nylon

Handle Construction: Stainless Steel

Maximum Solution Pressure: 2500psi

Minimum Solution Pressure: 700psi

SX-15 MAINTENANCE

Your SX-15 requires very little maintenance. To keep your SX-15 looking and

working its best for the longest period of use:

After each use rinse the Inner Shell of the SX-15 to remove accumulated dirt &

debris. The Inner Shell can be separated from the Outer Shell to clean the air flow

channel between the two shells. (See instructions for changing the Hard Boot &

Brush Ring for procedure to separate Outer and Inner Shells on Pages 5-7.)

Rinse & wipe down top of head assembly & handle.

Rinse & wipe clean the Hard Boot or the Brush Ring if used.

Examine Hard Boot - Replace the Hard Boot if worn down or deep gouges and

embedded debris are found.

Examine the Brush Ring – Replace Brush ring if bristles are excessively bent, worn or

if too many bristles are missing.

Check and clean the stainless steel mesh filter between the quick connect and valve to

prevent a reduction in water flow and tool efficiency. See item NA0803 in the parts

diagram on Page 16.

Check the spray pattern of the jets and clean or replace the jets as needed to assure

even spray pattern.

Check vacuum hose for holes or cracks. Replace Vacuum hose as needed.

4

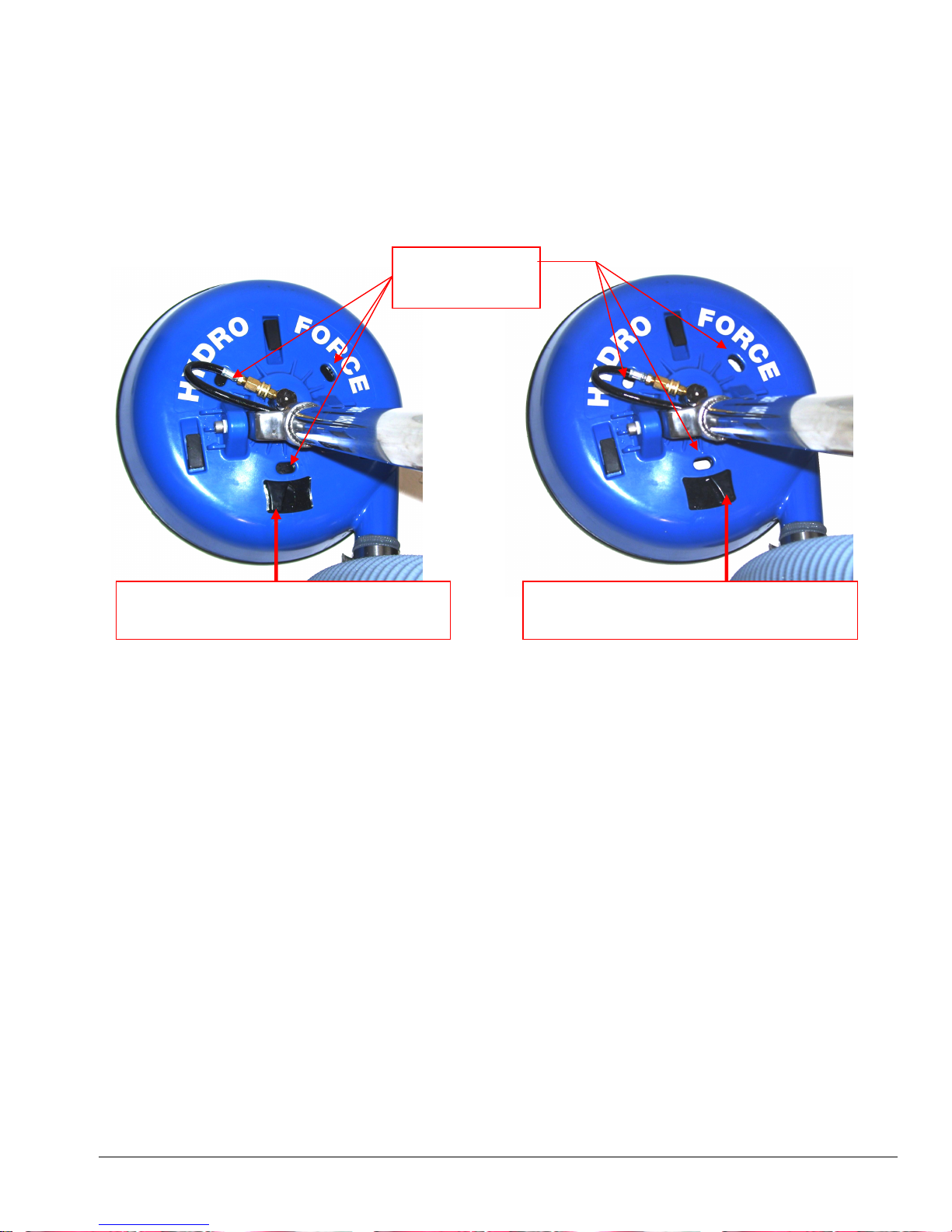

Vacuum Relief Vent Adjustment

Vacuum Relief Slide

–

Moved Left

Vacuum Relief

Vents

- CLOSED

Vacuum Relief Slide

–

Moved Right

Vacuum Relief

Vents

- OPEN

Vacuum

The SX-15 has vacuum relief vents on top of the head assembly. To increase the

water recovery, move the vacuum relief slide to the left to close the three vents. To

prevent the SX-15 from sticking to the floor and to make the SX-15 easier to move,

push the vacuum relief slide to the right to open the vents. Try different slide position

settings to get the best movement and recovery for your equipment and the type of

floor being cleaned.

Relief Vents

Using the SX-15 with extractors with higher air flow will generally require the vacuum

relief vents to be opened more.

Using the SX-15 with smaller portable extractors may require the vacuum relief vents

to be closed for the best water recovery.

When using the Hard Boot the vacuum relief vents will usually be opened more than

it is when using the Brush Ring with the same extractor.

5

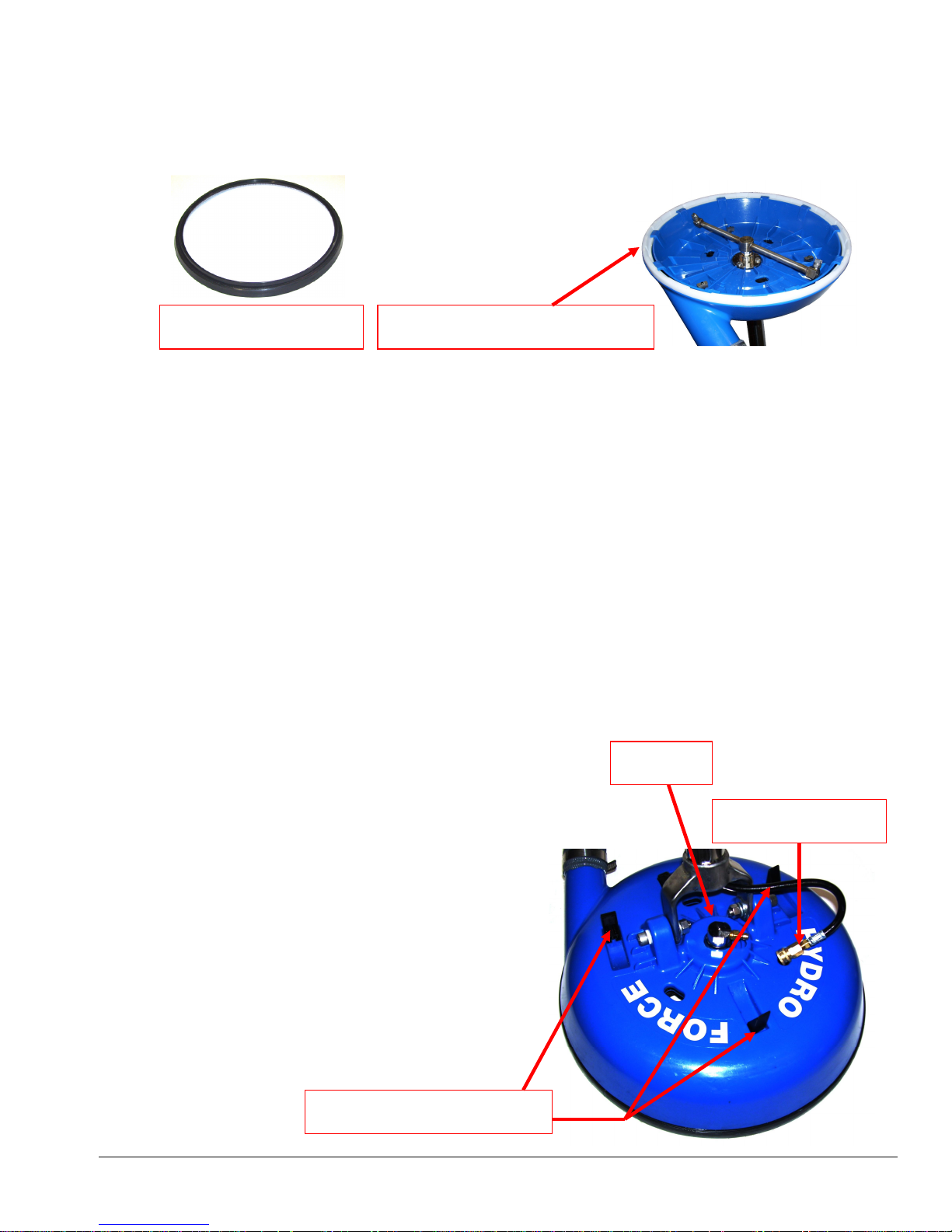

Hard Boot & Brush Ring Use

The SX-15 comes with a Hard Boot and Brush Ring. You have the option to choose

to install either for the type of floor being cleaned and the equipment used.

Brush Ring – AB53 Hard Boot – NM5772

Use of the Hard Boot should be limited to durable surfaces such as ceramic tile.

Do not use the Hard Boot on Soft Surfaces such as marble. The Hard Boot may

scratch soft surfaces.

Use of the Brush Ring will help prevent scratching of soft surfaces.

When using portable extractors with lower air flow the Hard Boot will provide

improved recovery compared to the Brush Ring.

Truck mounts with higher air flow will get excellent recovery with Brush Ring or

Hard Boot.

With a high air flow truck mount extractor, the tight seal of the Hard Boot on

smooth surfaces such as concrete may prevent the SX-15 from being moved

properly across the floor.

Swivel

Changing the Hard Boot & Brush Ring

Changing between the Hard Boot and Brush

Ring can be done quickly and easily without

tools.

1. Disconnect the solution hose from the

swivel.

2. Lift the three retainer levers on top of

the SX-15 head to release the retainers.

Solution Hose

Three Retainer Levers

6

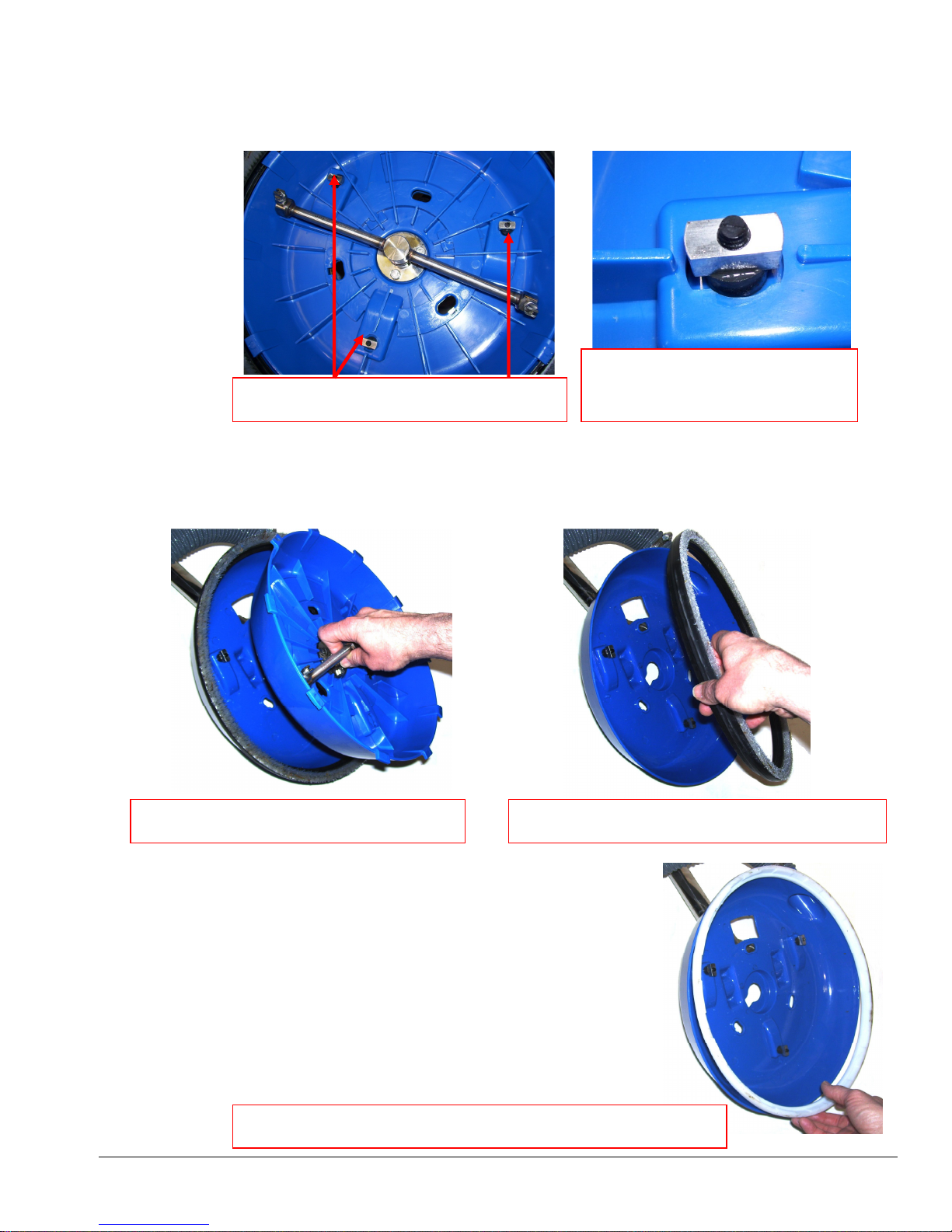

3. Turn the deck over and turn the three rectangular retaining nuts on the

Retaining

Nut

Aligned for

retainers to align with the holes in the bottom of the Inner Shell, so they can

pass through the holes.

Three Rectangular Retaining Nuts

Inner Shell Removal

4. Pull and separate the Inner Shell from the Outer Shell.

5. Lift up and remove the current Hard Boot or Brush Ring from the bottom lip

of the Outer Shell.

Remove the Brush Ring or Hard Boot Separate the Outer & Inner Shells

6. Place the desired Brush Ring or Hard Boot back

onto the bottom lip of the Outer Shell.

7. Place the Inner Shell back onto the Outer Shell

with the rectangular retaining nuts going through

the openings in the Inner Shell. The flanges on the

Inner Shell set on the edge of the Hard Boot or

Brush Ring to hold it in place.

Place the Brush Ring or Hard Boot on the Outer Shell

Loading...

Loading...