Hydrim L110W Training Manual

Hydrim L110W

Training Manual

Training Manual

Table of Contents

Table of Contents 2

Description & Cycle Times 3

Installation 4

Quick Reference Guide 5-6

Water Flow & Backflow Protection 7

Sequence of Operation P0 Cycle Revision 2.02 Software 8-9

Sequence of Operation P1 & P2 Cycle Revision 2.02 Software 10-11

Sequence of Operation P3 & P4 Cycle Revision 2.02 Software 12-14

Control Panel & Fault Codes 15

Troubleshooting E1 Error Codes 16

Troubleshooting E2 Error Codes 17

Troubleshooting E4 Error Codes 18

Troubleshooting ED & EF Error Codes & Chemical Light ON Steady 19

Flow Switch Configurations & Dryer Check Valve Location 20

Master Controller Replacement 21

Slave Controller Replacement 22

Master Controller Wiring Diagram & Picture 23

Slave Controller Wiring Diagram & Picture 24

Checking & Programming Control Module 25

Programming for HIP Cleaning Solution Revision 2.02 Software 26

Water Test Kit 27

Preventative Maintenance Kit 28

Preventative Maintenance Kit Installation 29-34

Draining the Hydrim L110W for Shipping 35

Parts Front View Door Closed 36

Parts Front View Door Open 37

Parts Left Side No Cover 38

Parts Right Side No Cover 39

Parts Water Inlet Valve, Inlet Temp Sensor & Controllers 40

Hydrim L110W Preventative Maintenance Kit 41

2

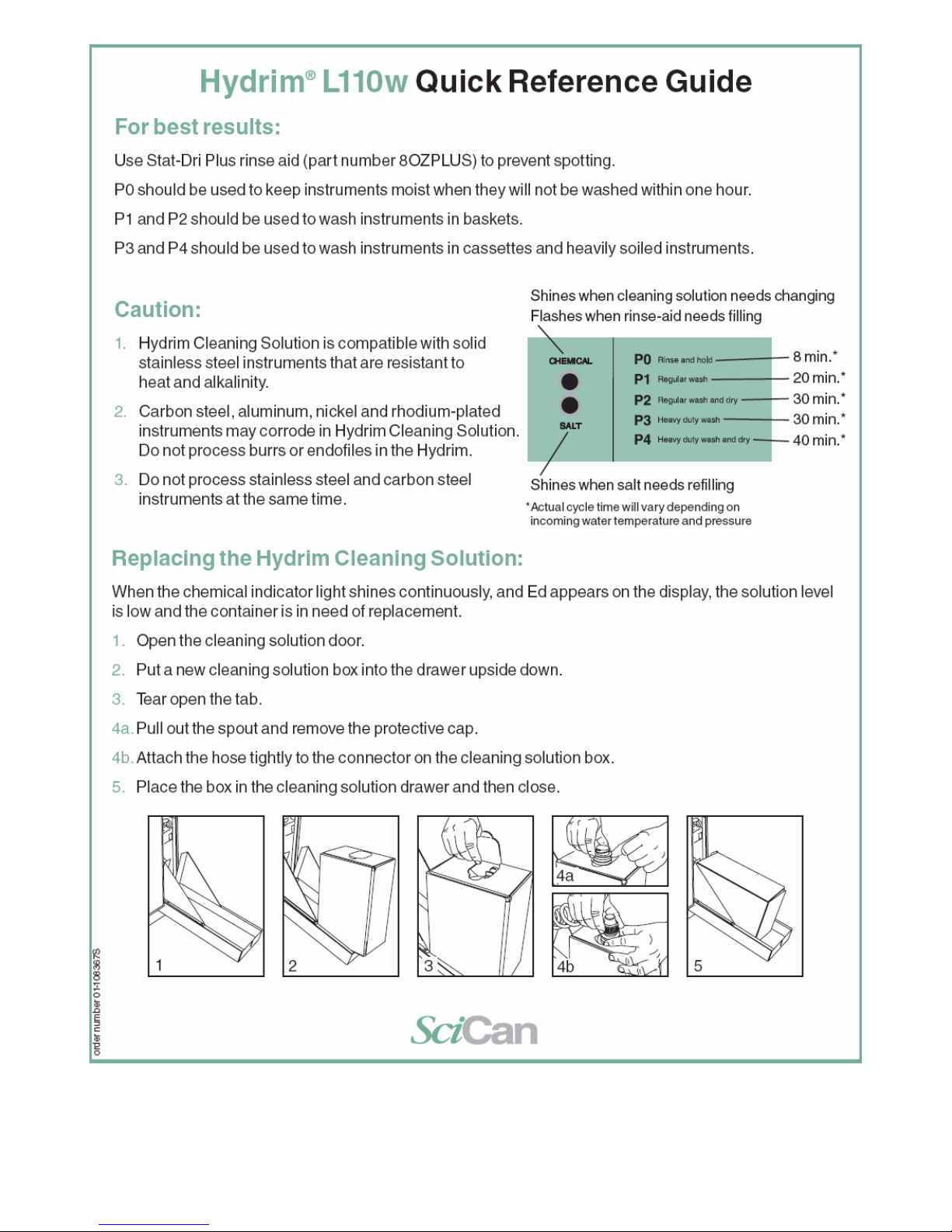

Description & Cycle Times

The Hydrim L110W Instrument Washer is designed to help you achieve an exceptional level of

cleanliness while providing a simplified method of washing dental instruments. There is no need to

pre-soak items but cement and composites still need to be removed from instruments. Note: Burs and

handpieces should not be placed in the Hydrim.

Cycle Times

Program Wash

Time*

Water Usage

Temperature

P0-Rinse and Hold

P1-Regular Wash

P2-Regular Wash with Dry

P3-Heavy Duty Wash

P4-Heavy Duty Wash with Dry

50°C/122°F

50°C/122°F

50°C/122°F

50°C/122°F

50°C/122°F

10 Minutes

20 Minutes 3 Gallons

30 Minutes 3 Gallons

30 Minutes 4 Gallons

40 Minutes 4 Gallons

2 Gallons

*Actual cycle time will vary depending on incoming water temperature. SciCan recommends setting

hot water supply temperatures to 60°C/140°F.

The Hydrim cleaning solution is HIP (Hydrim Instrument Protection), which coats the instruments

during the Rinse and Hold cycle and during prewash and final rinse portions of the Regular and Heavy

Duty Wash cycles, to protect the instruments.

A box of soap will last approximately 45 cycles.

3

4

Note: Rinse Aid is not required when using HIP solution with revision 2.02 software. See Checking &

Programming Control Module to check software revision.

5

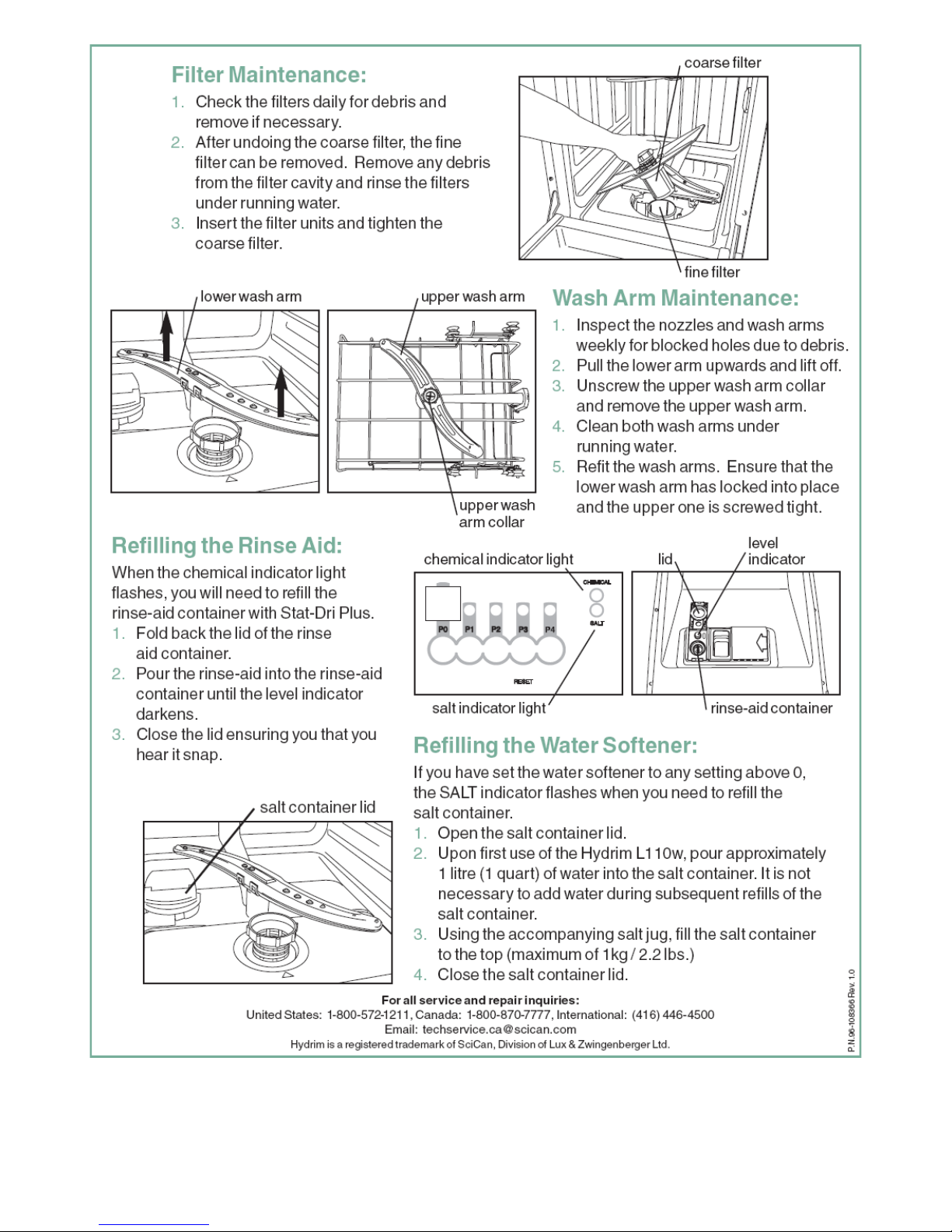

Installation

Cold Water Hot Water

Water, Drain & Power Connections

The unit is supplied with two water intake hoses, which are 6.5 ft. long, and they connect to ¾ “ garden

hose fittings.

The unit is supplied with a 5ft. flexible drain hose with an inner diameter of ¾”. It should be connected

to a drain point no more than 14” above the floor.

The power cord is 6ft. long with a 6-15 NEMA plug. A power outlet of 208-240V is required.

6

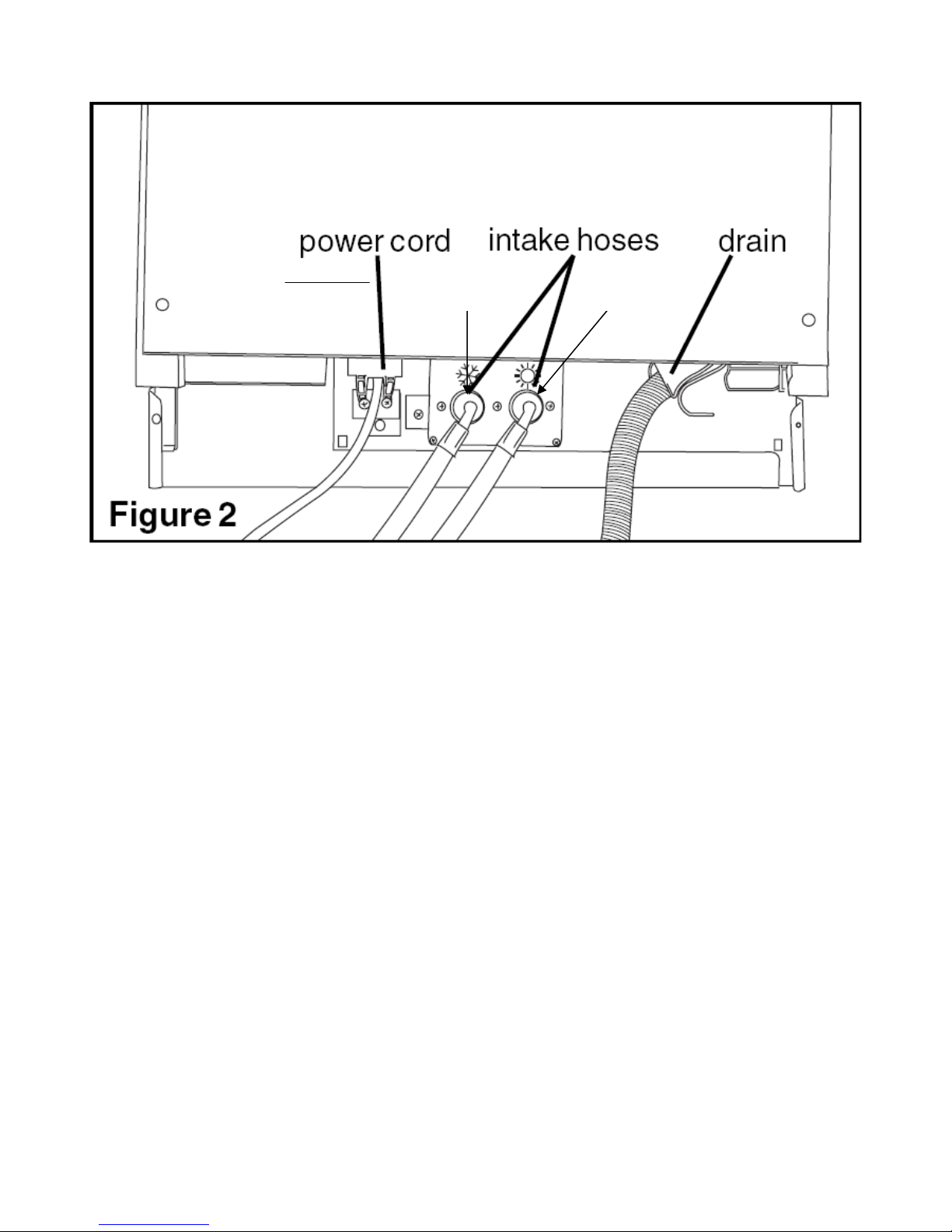

Water Flow & Backflow Protection

Water Inlet

When the hot or cold-water inlet valve is open, the water flows to Water Inlet Channel 1 of the

Sidebag. From there it flows up to the Air Gap. The Air Gap 3 is between Channel 1 and 2. The water

under pressure shoots over the Air Gap. Channel 2 takes water down to the Water Softener 4.

From the Water Softener, water flows to Channel 5. Channel 5 is connected with the Sidebag 8 and

they fill simultaneously. When water reaches the top of Channel 5 (Sidebag is full) it overflows, filling

Regeneration Channel 6 and Overflow Channel 7.

Regeneration Channel 6 takes water to the Salt Reservoir. Regeneration Valve 13 controls filling the

Salt Reservoir.

Overflow Channel 7 takes water to the Membrane Sensor that activates Switch 12.

At that time the Controller opens Drain Valve 14, releasing water from Channel 5 and the Sidebag

through Channel 9 and the Chamber Inlet into the Wash Chamber.

Water Exhaust

The Drain Pump, pumps water to Channel 10. Channel 10 leads to Channel 11 that is connected to the

exhaust hose and to the drain.

Sidebag

Regeneration Valve

Drain Valve

Resin

7

Hydrim L110W P0 Cycle with Revision 2.02 Software

1. Preparation drain pump runs

When the P0 cycle button is pressed the drain pump turns ON. The Hydrim will drain the

wash chamber and the sidebag. If the previous cycle was interrupted when the cycle is

started the drain pump will run for 80 seconds. If the previous cycle was a complete cycle

the drain pump will run for 20 seconds. If the unit fails to drain an E4 code will appear on

the display.

2. Sidebag fills with cold water target temperature 28°C/82.4°F

Turn ON Y1 cold water valve. Start timer whenever valve is open to calculate the Water

Debit Constant and Error Timer for filling sidebag. If water does not close pressure switch

B1 within 130 seconds Hydrim fails with an E2 code. When the pressure switch closes

calculate the Water Debit Constant time for filling up 2.7 liters.

3. Fill wash chamber target temperature 28°C/82.4°F

When sidebag is full and pressure switch B1 activates (blue arm moves out) turn ON Y6

sidebag drain valve to allow sidebag to drain into the chamber. Pressure switch will

deactivate when sidebag starts draining into chamber. After approximately 45 seconds turn

ON circulation pump M1 and Y1 cold-water valve. The on time for the cold water inlet

valve depends on the “Water Debit Constant” that was calculated previously. The chamber

capacity is 4 liters, 2.7 liters from the sidebag and 1.3 liters from the cold water inlet valve,

resulting valve Y6 is on for approximately 75 seconds and valve Y1 is on for 1.3/Water

Debit Constant. When water inlet valves timer expires add 10 seconds to the sidebag drain

valve Y6 before closing. Failure to fill chamber will cause an E2 code.

4. Circulation

Turn ON circulation pump M1 for 180 seconds/3 minutes. Fill sidebag bag with water

target temperature 80°C/176°F.

5. Circulation and evacuation 10 seconds

Circulation pump M1 remains ON. Turn ON drain pump M2.

6. Evacuation 20 seconds

Circulation pump M1 turns OFF. Drain pump M2 remains ON for 20 seconds.

7. Wait until sidebag is full target temperature 80°C/176°F

8. Fill wash chamber target temperature 80°C/176°F

When sidebag is full and pressure switch B1 activates turn ON Y6 sidebag drain valve to

allow sidebag to drain into the chamber. Pressure switch will deactivate when sidebag starts

draining into chamber. After approximately 45 seconds turn ON circulation pump M1 and

Y7 hot water valve. The on time for the hot water inlet valve depends on the “Water Debit

Constant” that was calculated previously. The chamber capacity is 4 liters, 2.7 liters from

the sidebag and 1.3 liters from the hot water inlet valve, resulting valve Y6 is on for

approximately 75 seconds and valve Y7 is on for 1.3/Water Debit Constant. When water

inlet valves timer expires add 10 seconds to the sidebag drain valve Y6 before closing.

Failure to fill chamber will cause an E2 code.

9. Circulation, heating and dosing

Start circulation pump M1, dosing pump M4 and turn ON water heater R1 if water

temperature in chamber is below target temperature. Start heating and dosing error timers.

Dosing pump runs for 5 seconds. If flow switch does not detect dosing before the dosing

error timer ends (30 seconds), the Hydrim fails with an ED code. Once selected dosing time

is achieved the dosing pump will turn OFF.

10. Circulation and heating target temperature 50°C/122°F

Circulation pump continues to run and water heater remains turned ON. If the heating error

timer ends and the chamber water temperature is below the target temperature, the Hydrim

fails with an E1 code.

8

Hydrim L110W P0 Cycle with Revision 2.02 Software (Cond.)

11. Circulation

Circulation pump M1 remains ON for 60 seconds/1 minute.

12. Circulation and evacuation 10 seconds

Circulation pump M1 remains ON. Turn ON drain pump M2.

13. Evacuation 20 seconds

Circulation pump M1 turns OFF. Drain pump M2 remains ON for 20 seconds.

9

Hydrim L110W P1 & P2 Cycle with Revision 2.02 Software

1. Preparation drain pump runs

When the P1 or P2 cycle button is pressed the drain pump turns ON. The Hydrim will drain

the wash chamber and the sidebag. If the previous cycle was interrupted when the cycle is

started the drain pump will run for 80 seconds. If the previous cycle was a complete cycle

the drain pump will run for 20 seconds. If the unit fails to drain an E4 code will appear on

the display.

2. Sidebag fills with hot water target temperature 50°C/122°F

Turn ON Y7 hot water valve. Start timer whenever valve is open to calculate the Water

Debit Constant and Error Timer for filling sidebag. If water does not close pressure switch

B1 within 130 seconds declare “no hot water” and use just cold water. If pressure switch

does not close after another 130 seconds Hydrim fails with an E2 code. When the pressure

switch closes calculate the Water Debit Constant time for filling up 2.7 liters.

3. Fill wash chamber target temperature 28°C/82.4°F

When sidebag is full and pressure switch B1 activates (blue arm moves out) turning ON Y6

sidebag drain valve to allow sidebag to drain into the chamber. Pressure switch will

deactivate when sidebag starts draining into chamber. After approximately 45 seconds turn

ON circulation pump M1 and Y7 hot water valve. The on time for the hot water inlet valve

depends on the “Water Debit Constant” that was calculated previously. The chamber

capacity is 4 liters, 2.7 liters from the sidebag and 1.3 liters from the hot water inlet valve,

resulting valve Y6 is on for approximately 75 seconds and valve Y7 is on for 1.3/Water

Debit Constant. When water inlet valves timer expires add 10 seconds to the sidebag drain

valve Y6 before closing. Failure to fill chamber will cause an E2 code.

4. Circulation, heating and dosing

Start circulation pump M1, dosing pump M4 and turn ON water heater R1 if water

temperature in chamber is below target temperature. Start heating and dosing error timers.

Dosing pump runs for 7 seconds. If flow switch does not detect dosing before the dosing

error timer ends (30 seconds), the Hydrim fails with an ED code. Once selected dosing time

is achieved the dosing pump will turn OFF.

5. Circulation and heating target temperature 50°C/122°F

Circulation pump continues to run and water heater remains turned ON. If the heating error

timer ends and the chamber water temperature is below the target temperature, the Hydrim

fails with an E1 code.

6. Circulation, heating and dosing target temperature 50°C/122°F

Circulation pump continues to run, and water heater remains turned ON. When water

temperature in chamber reaches target temperature start dosing error timer. The dosing

pump runs for 7 seconds. If flow switch does not detect dosing before the dosing error timer

ends (30 seconds), the Hydrim fails with an ED code. Once selected dosing time is

achieved the dosing pump will turn OFF.

7. Circulation

Circulation pump M1 remains ON for 300 seconds/5 minutes.

8. Circulation and evacuation 10 seconds

Circulation pump M1 remains ON. Turn ON drain pump M2.

9. Evacuation 20 seconds

Circulation pump M1 turns OFF. Drain pump M2 remains ON for 20 seconds.

10. Fill wash chamber target temperature 40°C/104°F without filling sidebag

Turn ON valve Y6 and valve Y7 target temperature 40°C/104°F. The ON time for the water

inlet valve depends on the “Water Debit Constant” that was calculated previously. Turn

valve Y7 ON for 3/Water Debit Constant and Y6 for 3/Water Debit Constant + 10 seconds.

When water inlet valves timer expires add 10 seconds to the sidebag drain valve Y6.

10

Hydrim L110W P1 & P2 Cycle with Revision 2.02 Software (Cond.)

11. Evacuation 30 seconds fill sidebag target temperature 45°C/113°F

Drain pump remains ON and sidebag starts filling target temperature 45°C/113°F.

12. Wait until sidebag is full target temperature 45°C/113°F

13. Fill wash chamber target temperature 45°C/113°F

14. Circulation 60 seconds/1 minute target temperature 45°C/113°F fill sidebag

15. Circulation and evacuation 10 seconds

16. Evacuation 20 seconds

17. Wait until sidebag is full target temperature 80°C/176°F

18. Fill wash chamber target temperature 80°C/176°F

19. Circulation, heating and dosing

Start circulation pump M1, dosing pump M4 and turn ON water heater R1 if water

temperature in chamber is below target temperature. Start heating and dosing error timers.

Dosing pump runs for 5 seconds. If flow switch does not detect dosing before the dosing

error timer ends (30 seconds), the Hydrim fails with an ED code. Once selected dosing time

is achieved the dosing pump will turn OFF.

20. Circulation and heating target temperature 65°C/149°F

Circulation pump continues to run and water heater remains turned ON. If the heating error

timer ends and the chamber water temperature is below the target temperature, the Hydrim

fails with an E1 code.

21. Circulation 180 seconds/3 minutes

22. Circulation and evacuation 10 seconds

23. Evacuation 20 seconds

24. Drying (P2 cycle only)

Dryer time factory set to 10 minutes. May be increased to 20 minutes in 1-minute

increments. Dryer will run at slower speed for 1 minute then increase to high speed.

11

Hydrim L110W P3 & P4 Cycle with Revision 2.02 Software

1. Preparation drain pump runs

When the P3 or P4 cycle button is pressed the drain pump turns ON. The Hydrim will drain

the wash chamber and the sidebag. If the previous cycle was interrupted when the cycle is

started the drain pump will run for 80 seconds. If the previous cycle was a complete cycle

the drain pump will run for 20 seconds. If the unit fails to drain an E4 code will appear on

the display.

2. Sidebag fills with cold water target temperature 28°C/82.4°F

Turn ON Y1 cold water valve. Start timer whenever valve is open to calculate the Water

Debit Constant and Error Timer for filling sidebag. If water does not close pressure switch

B1 within 130 seconds Hydrim fails with an E2 code. When the pressure switch closes

calculate the Water Debit Constant time for filling up 2.7 liters.

3. Fill wash chamber target temperature 28°C/82.4°F

When sidebag is full and pressure switch B1 activates (blue arm moves out) turning ON Y6

sidebag drain valve to allow sidebag to drain into the chamber. Pressure switch will

deactivate when sidebag starts draining into chamber. After approximately 45 seconds turn

ON circulation pump M1 and Y1 cold-water valve. The on time for the cold water inlet

valve depends on the “Water Debit Constant” that was calculated previously. The chamber

capacity is 4 liters, 2.7 liters from the sidebag and 1.3 liters from the cold water inlet valve,

resulting valve Y6 is on for approximately 75 seconds and valve Y1 is on for 1.3/Water

Debit Constant. When water inlet valves timer expires add 10 seconds to the sidebag drain

valve Y6 before closing. Failure to fill chamber will cause an E2 code.

4. Circulation, heating and dosing target temperature 28°C/82.4°F

Start circulation pump M1, dosing pump M4 and turn ON water heater R1 if water

temperature in chamber is below target temperature. Start heating and dosing error timers.

Dosing pump runs for 2 seconds. If flow switch does not detect dosing before the dosing

error timer ends (30 seconds), the Hydrim fails with an ED code. Once selected dosing time

is achieved the dosing pump will turn OFF.

5. Circulation

Circulation pump M1 remains ON for 240 seconds/4 minutes. Turn ON Y7 hot water valve

and fill sidebag, target temperature 50°C/122°F.

6. Circulation and evacuation 10 seconds

Circulation pump M1 remains ON. Turn ON drain pump M2.

7. Evacuation 20 seconds

Circulation pump M1 turns OFF. Drain pump M2 remains ON for 20 seconds.

8. Wait until sidebag is full target temperature 50°C/122°F

Y7 the hot water valve remains ON. If water temperature is higher than the target

temperature then turn ON Y1 cold-water valve. Start timer whenever valve is open to

calculate the Water Debit Constant and Error Timer for filling sidebag. If water does not

close pressure switch B1 within 130 seconds declare “no hot water” and use just cold water.

If pressure switch does not close after another 130 seconds Hydrim fails with an E2 code.

When the pressure switch closes calculate the Water Debit Constant time for filling up 2.7

liters.

12

Hydrim L110W P3 & P4 Cycle with Revision 2.02 Software (Cond.)

9. Fill wash chamber target temperature 50°C/122°F

When sidebag is full and pressure switch B1 activates turn ON Y6 sidebag drain valve to

allow sidebag to drain into the chamber. Pressure switch will deactivate when sidebag starts

draining into chamber. After approximately 45 seconds turn ON circulation pump M1 and

Y7 hot water valve. The on time for the hot water inlet valve depends on the “Water Debit

Constant” that was calculated previously. The chamber capacity is 4 liters, 2.7 liters from

the sidebag and 1.3 liters from the hot water inlet valve, resulting valve Y6 is on for

approximately 75 seconds and valve Y7 is on for 1.3/Water Debit Constant. When water

inlet valves timer expires add 10 seconds to the sidebag drain valve Y6 before closing.

Failure to fill chamber will cause an E2 code.

10. Circulation, heating and dosing target temperature 50°C/122°F

Start circulation pump M1, dosing pump M4 and turn ON water heater R1 if water

temperature in chamber is below target temperature. Start heating and dosing error timers.

Dosing pump runs for 7 seconds. If flow switch does not detect dosing before the dosing

error timer ends (30 seconds), the Hydrim fails with an ED code. Once selected dosing time

is achieved the dosing pump will turn OFF.

11. Circulation and heating target temperature 50°C/122°F

Circulation pump continues to run and water heater remains turned ON. If the heating error

timer ends and the chamber water temperature is below the target temperature, the Hydrim

fails with an E1 code.

12. Circulation, heating and dosing

Circulation pump continues to run, and water heater remains turned ON. When water

temperature in chamber reaches target temperature start dosing error timer. The dosing

pump runs for 7 seconds. If flow switch does not detect dosing before the dosing error timer

ends (30 seconds), the Hydrim fails with an ED code. Once selected dosing time is

achieved the dosing pump will turn OFF.

13. Circulation

Circulation pump M1 remains ON for 360 seconds/6 minutes.

14. Circulation and evacuation 10 seconds

Circulation pump M1 remains ON. Turn ON drain pump M2.

15. Evacuation 20 seconds

Circulation pump M1 turns OFF. Drain pump M2 remains ON for 20 seconds.

16. Fill wash chamber target temperature 40°C/104°F without filling sidebag

Turn ON valve Y6 and valve Y1 or Y7 (depending on water inlet temperature and the target

temperature). The ON time for the water inlet valve depends on the “Water Debit Constant”

that was calculated previously. Turn valve Y1 or Y7 ON for 3/Water Debit Constant and

Y6 for 3/Water Debit Constant + 10 seconds. When water inlet valves timer expires add 10

seconds to the sidebag drain valve Y6.

17. Evacuation 30 seconds fill sidebag

Drain pump remains ON and sidebag starts filling target temperature 45°C/113°F.

18. Wait until sidebag is full target temperature 45

°C/113°F

19. Fill wash chamber target temperature 45°C/113°F

20. Circulation 60 seconds/1 minute target temperature 45°C/113°F fill sidebag

21. Circulation and evacuation 10 seconds

22. Evacuation 20 seconds

23. Wait until sidebag is full target temperature 80°C/176°F

24. Fill wash chamber target temperature 80°C/176°F

13

Loading...

Loading...