Page 1

Titan 875

Owner’s Manual

HydraMaster

11015 47th Avenue West

Mukilteo, Washington 98275

MAN-33180 Rev. 0 March 23, 2012

No part of this manual may be reproduced or used in any form or by any means (i.e. graphic, electronic, photocopying or electronic

retrieval systems) without the express written permission of HydraMaster. Specications and information in this document are

subject to change without prior notice.

(182-077-D)

All rights reserved. © 2012 HydraMaster

Page 2

Page 3

This document contains QR (Quick Response) tags, or

codes, like that shown in the illustration on this page.

QR tags can be scanned by smartphones or mobile

devices in which QR readers have been downloaded.

why use QR Tags

QR tags shown throughout this document contain links to

HydraMaster webpages or videos which explain specic

instructions for machine operations, maintenance or

troubleshooting.

http://www.

youtube.com/user/

One advantage of QR tags is that you do not need a

HydraMasterProducts#g/a

computer to access webpages or online videos. Also,

no typing is required; just select the QR reader, aim the

smartphone’s viewnder at the QR tag and select how to view the webpage or video.

To learn more about QR tags, access this link:

http://searchengineland.com/what-is-a-qr-code-and-why-do-you-need-one-27588

InsTRucTIOns

Download a QR tag reader from an app store or install the QR reader from this 1.

link:

http://www.i-nigma.com/Downloadi-nigmaReader.html

Follow instructions depending on whether you have a smartphone or a standard

2.

mobile device.

Scan the QR tag with your smartphone or mobile phone, and view the webpage or

3.

watch the video.

Links to other QR readers include:

http://reader.kaywa.co• m/

http://get.neoreader.co

• m

http://www.beetagg.com/supportedphones

• /

http://code.google.com/p/zxing/wiki/GettheReade

• r

i: Titan 875 Owner’s Manual

Page 4

Titan 875 Owner’s Manual: ii

Page 5

Table of Contents

GeNeRAL INFORMATION ...........................................................................SeCTION 1

System Concept ...................................................................................... 1-3

Contact Information ................................................................................. 1-4

Warnings, Cautions and Notices ............................................................. 1-5

Responsibilities .......................................................................................1-9

Machine Specications ...........................................................................1-12

Spare Parts List.......................................................................................1-14

High Altitude Operation ...........................................................................1-15

Local Water Precautions .........................................................................1-15

INSTALLATION INFORMATION ..................................................................SeCTION 2

Fuel Pump Installation Guidelines...........................................................2-1

Operating the Titan 875 In Hot Weather .................................................2-4

Setting Up the Titan 875..........................................................................2-7

CLeANING AND CHeMICALS .....................................................................SeCTION 3

Preparing the Carpet for extraction.........................................................3-2

Rinse and Recover..................................................................................3-3

Overwetting .............................................................................................3-3

Streaking .................................................................................................3-3

Cleaning Tool Tips ...................................................................................3-4

Severe Cleaning Situations ..................................................................... 3-9

MACHINe MAINTeNANCe ..........................................................................SeCTION 4

Operational Maintenance ........................................................................4-2

Overall Machine Maintenance.................................................................4-5

engine Maintenance ...............................................................................4-6

High Pressure Pump Maintenance .........................................................4-10

Vacuum System Maintenance .................................................................4-19

Descaling Procedure (Required) ............................................................. 4-20

Freeze Guarding .....................................................................................4-21

OPeRATING INSTRUCTIONS .....................................................................SeCTION 5

Start-Up Procedure .................................................................................5-3

Shut-Down Procedure ............................................................................. 5-5

Setting the Temperature ..........................................................................5-7

Machine Safeties.....................................................................................5-8

WATeR AND CHeMICAL SySTeM .............................................................SeCTION 6

Water and Chemical Flow Operation ......................................................6-1

iii: Titan 875 Owner’s Manual

Page 6

eLeCTRICAL SySTeM ................................................................................SeCTION 7

TROUbLeSHOOTING .................................................................................SeCTION 8

Heating System ....................................................................................... 8-2

Chemical System ....................................................................................8-3

engine .....................................................................................................8-4

High Pressure System

Vacuum System

......................................................................................8-9

............................................................................8-7

MACHINe ASSeMbLIeS AND PARTS LISTS .............................................SeCTION 9

Machine Assembly Parts List ..................................................................9-6

Frame Assembly Parts List

.....................................................................9-9

engine Assembly Parts List.....................................................................9-13

Solenoid Assembly Parts List ..................................................................9-14

Idler Pulley Tensioner Assembly Parts List ............................................. 9-15

blower Assembly Parts List .....................................................................9-18

Air Actuator Assembly Parts List ............................................................. 9-19

Pump and Silencer Assembly Parts List ................................................. 9-20

Pump Assembly Parts List ......................................................................9-23

exhaust Assembly Parts List ...................................................................9-25

blower Heat exchanger Assembly Parts List .......................................... 9-28

Coolant Heat exchanger Assembly Parts List.........................................9-30

Lower Instrument Panel Assembly Parts List ..........................................9-34

PSI Regulator Valve (0 - 3,200 psi) Assembly Parts List ........................9-35

Orice Manifold Assembly Parts List .......................................................9-36

Hi Pressure Out Manifold Assembly Parts List........................................ 9-37

3-Way Valve Assembly Parts List ............................................................ 9-38

2-Way Valve Assembly Parts List ............................................................ 9-39

Water box 8 Gallon Assembly Parts List .................................................9-41

Diffuser Assembly Parts List ...................................................................9-42

Upper Dash Assembly Parts List.............................................................9-43

Dash Gauge Panel Assembly Parts List ................................................. 9-45

Grill Assembly Parts List .........................................................................9-46

electrical Panel Assembly Parts List ....................................................... 9-48

Catalytic Cover Assembly Parts List

.......................................................9-50

Top Cover - Machine Assembly Parts List...............................................9-52

Left Side Cover - Machine Assembly Parts List

...................................... 9-53

Right Side Cover - Machine Assembly Parts List ....................................9-54

100 Gallon Universal Recovery Tank Assembly Parts List ......................9-56

100 Gallon Universal Recovery Cover Tank Assembly Parts List

Vacuum Relief Valve Assembly Parts List

...............................................9-59

........... 9-58

Machine Hose Routings ..........................................................................9-60

Titan 875 Owner’s Manual: iv

Page 7

HOW TO ORDeR PARTS ............................................................................SeCTION 10

Warranty Parts Orders ............................................................................10-1

Parts Orders ............................................................................................ 10-1

emergencies ...........................................................................................10-1

WARRANTy INFORMATION .......................................................................SeCTION 11

blower ....................................................................................................11-2

High Pressure Water Pump ...................................................................11-2

Vacuum Tank

Chemical System

Control Panel

Vacuum and Solution Hoses

.......................................................................................... 11-2

...................................................................................11-2

.........................................................................................11-2

.................................................................. 11-3

Cleaning Wand .......................................................................................11-3

Water Heating System

Hard Water Deposits

...........................................................................11-3

..............................................................................11-3

Warranty Procedure ................................................................................11-3

ACCeSSORIeS AND CHeMICAL SOLUTIONS ..........................................SeCTION 12

v: Titan 875 Owner’s Manual

Page 8

List of Figures

Figure 1-1. Hard Water Map of Continental United States ..........................................1-16

Figure 2-1. Fuel Pump Diagram ....................................................................................2-2

Figure 2-2. Location of Roof Vents in Vehicle ...............................................................2-3

Figure 2-3. Recommended Location of Titan 875 in Van ..............................................2-5

Figure 4-1. Remove Valve Cap and Valve Assembly .................................................4-11

Figure 4-2. Inspect Manifold and Old Valves .............................................................4-11

Figure 4-3. Replace Center Inlet Check Valve With Modied Check Valve .............. 4-12

Figure 4-4. Apply Grease and Install Valves .............................................................. 4-12

Figure 4-5. Replace Valve Cap and Torque to 95 ft lbs .............................................4-12

Figure 4-6. Separate Manifold from Crankcase......................................................... 4-13

Figure 4-7. Seal Assemblies May Come Off with Manifold ........................................ 4-13

Figure 4-8. examine Ceramic Plungers..................................................................... 4-13

Figure 4-9. Remove Stainless Steel Plunger bolt and Ceramic Plunger ................. 4-14

Figure 4-10. Install O-ring, Apply Sealant and Slide Plunger over Plunger Guide .... 4-14

Figure 4-11. extract Retainers and Seals ..................................................................4-15

Figure 4-12. Seal Kit and Insertion Tool for Seal Installation ..................................... 4-16

Figure 4-13. Install Seal Assembly Using O-Ring Grease ......................................... 4-16

Figure 4-14. Install Retainers into Cavities ................................................................ 4-17

Figure 4-15. Press Low Pressure Seal Assembly into Cavity.................................... 4-17

Figure 4-16. Re-install Manifold and Torque Fasteners ............................................. 4-18

Figure 4-17. Torque Sequence in “X” Pattern ............................................................ 4-18

Figure 4-18. Torque bolts to 22 ft lbs ......................................................................... 4-18

Figure 4-19. Recirculation Fitting............................................................................... 4-20

Figure 5-1. Titan 875 Upper Dash Assembly .................................................................5-1

Figure 5-2. Titan 875 Lower Dash Assembly .................................................................5-2

Figure 5-3. blower Port Located on Lower Dash Assembly ..........................................5-5

Figure 5-4. Set Heat Selector Valve ..............................................................................5-7

Figure 5-5. Rotate Thermostat Dial and Select engine rpm ..........................................5-7

Figure 6-1. Flow Diagram - View 1 of 3 .........................................................................6-3

Figure 6-2. Flow Diagram - View 2 of 3 .........................................................................6-4

Figure 6-3. Flow Diagram - View 3 of 3 .........................................................................6-5

Titan 875 Owner’s Manual: vi

Page 9

Figure 7-1. electrical Schematic ....................................................................................7-2

Figure 7-2. Wiring Diagram - View 1 of 3

Figure 7-3. Wiring Diagram - View 2 of 3

Figure 7-4. Wiring Diagram - View 3 of 3

......................................................................7-3

......................................................................7-4

......................................................................7-5

Figure 7-5. Schematic of Wire Harness -

Fuel Pump Manifold to Machine - View 1 of 2 ....................................................7-6

Figure 7-6. Schematic of Wire Harness -

Fuel Pump Manifold to Machine - View 2 of 2 ....................................................7-7

Figure 9-1. Machine Assembly - View 1 of 4 .................................................................9-2

Figure 9-2. Machine Assembly -View 2 of 4 ..................................................................9-3

Figure 9-3. Machine Assembly - View 3 of 4 .................................................................9-4

Figure 9-4. Machine Assembly -View 4 of 4 .................................................................9-5

Figure 9-5. Frame Assembly - View 1 of 2 ....................................................................9-7

Figure 9-6. Frame Assembly - View 2 of 2 ....................................................................9-8

Figure 9-7. engine Assembly - View 1 of 3 ..................................................................9-10

Figure 9-8. engine Assembly - View 2 of 3 ..................................................................9-11

Figure 9-9. engine Assembly - View 3 of 3 ..................................................................9-12

Figure 9-10. Solenoid Assembly ..................................................................................9-14

Figure 9-11. Idler Pulley Tensioner Assembly ..............................................................9-15

Figure 9-12. blower Assembly - View 1 of 2 ................................................................9-16

Figure 9-13. blower Assembly - View 2 of 2 ................................................................9-17

Figure 9-14. Air Actuator Assembly .............................................................................9-19

Figure 9-15. Pump and Silencer Assembly .................................................................9-20

Figure 9-16. Pump Assembly - View 1 of 2 .................................................................9-21

Figure 9-17. Pump Assembly - View 2 of 2 .................................................................9-22

Figure 9-18. exhaust Assembly ...................................................................................9-24

Figure 9-19. blower Heat exchanger Assembly - View 1 of 2 .....................................9-26

Figure 9-20. blower Heat exchanger Assembly - View 2 of 2 .....................................9-27

Figure 9-21. Coolant Heat exchanger Assembly.........................................................9-29

Figure 9-22. Lower Instrument Panel Assembly - View 1 of 3 .....................................9-31

Figure 9-23. Lower Instrument Panel Assembly - View 2 of 3 .....................................9-32

Figure 9-24. Lower Instrument Panel Assembly - View 3 of 3 .....................................9-33

Figure 9-25. PSI Regulator Valve (0 - 3,200 psi) Assembly .......................................9-35

Figure 9-26. Orice Manifold Assembly .......................................................................9-36

Figure 9-27. Hi Pressure Out Manifold Assembly........................................................9-37

Figure 9-28. 3-Way Valve Assembly ............................................................................9-38

Figure 9-29. 2-Way Valve Assembly ............................................................................9-39

vii: Titan 875 Owner’s Manual

Page 10

Figure 9-30. Water box 8 Gallon Assembly .................................................................9-40

Figure 9-31. Diffuser Assembly ...................................................................................9-42

Figure 9-32. Upper Dash Assembly.............................................................................9-43

Figure 9-33. Dash Gauge Panel Assembly .................................................................9-44

Figure 9-34. Grill Assembly .........................................................................................9-46

Figure 9-35. electrical Panel Assembly .......................................................................9-47

Figure 9-36. Catalytic Cover Assembly .......................................................................9-49

Figure 9-37. Top Cover - Machine Assembly ...............................................................9-51

Figure 9-38. Left Side Cover - Machine Assembly ......................................................9-53

Figure 9-39. Right Side Cover - Machine Assembly ....................................................9-54

Figure 9-40. 100 Gallon Universal Recovery Tank Assembly ......................................9-55

Figure 9-41. 100 Gallon Universal Recovery Tank Cover Assembly ...........................9-57

Figure 9-42. Vacuum Relief Valve Assembly ...............................................................9-59

Titan 875 Owner’s Manual: viii

Page 11

1- General Information

The Titan 875 truckmount carpet cleaning and restoration machine is powered by the 61

HP GM 4-cylinder, fuel injected engine and the Tuthill Competitor Plus™ 5009 Tri-Lobe

dual oil bath blower.

For superior carpet and upholstery cleaning, the Titan 875 provides temperatures up

to 270° F at 1,200 psi *. It also provides non-heated pressure washing at 3,000 psi for

cleaning hard surfaces.

* Patented Heat exchanger System - U.S. Patent No. 8,032,976

1-1: General Information

Page 12

The Titan 875 also features:

a simple 3-panel maintenance access•

keyless ignition•

last-step chemical injection which reduces scale buildup •

Standard equipment includes:

100 Gallon MaxAir™ Recovery Tank

•

5 gallon chemical jug•

150 ft long, 2” diameter vacuum hose•

150 ft long, 1/4” diameter solution hose•

Optional pieces of equipment available are:

Dura-Flow™ Automatic Pump Out (APO)

•

2.5” adaptor kit for triple wand capability•

It is the purpose of this manual to help you properly understand, maintain and service

the Titan 875. by following these guidelines carefully, you can expect years of reliable

operation.

Other topics covered in this section of the manual are:

Contact Informatio n

Warnings, Cautions and Notice s

Responsibilitie s

Machine Specication s

Spare Parts Lis t

High Altitude Operatio n

Local Water Precaution s

General Information: 1-2

Page 13

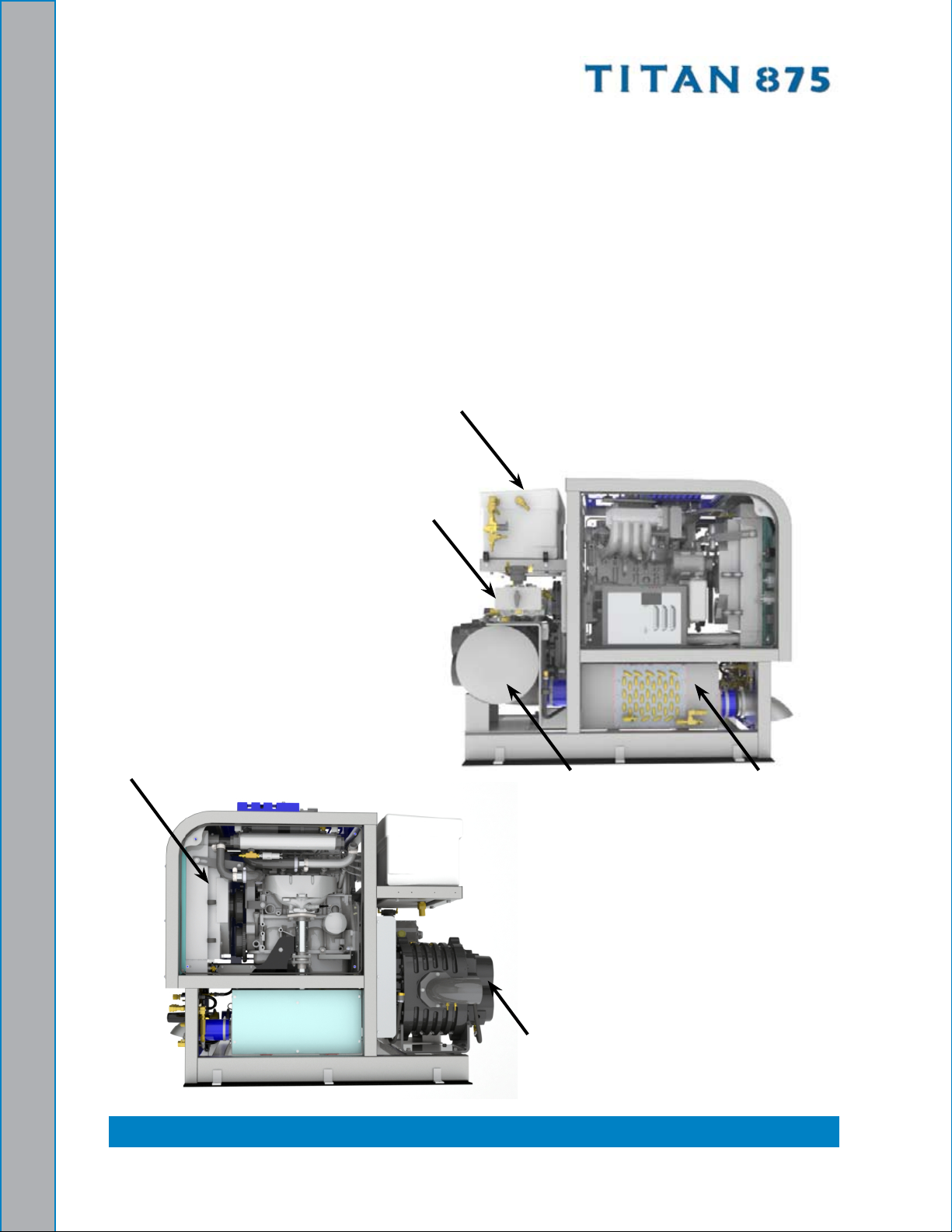

sysTeM cOncepT

The Titan 875’s system utilizes an internal combustion engine to provide the power

necessary to turn both the vacuum blower and the high pressure water pump.

The heat from the engine and blower exhausts is transferred to the high pressure water

in the nned tube heat exchanger and copper tube and shell of the system. Finally, the

chemical is injected into the pressurized water stream and the heated solution is delivered

to the cleaning tool.

Solution is recovered by the vacuum generated by the vacuum blower and is collected in

the recovery tank for proper disposal.

water Box

water

pump

engine

silencer

Vacuum

Blower

Finned Tube

heat exchanger

1-3: General Information

Page 14

cOnTacT InFORMaTIOn

If you have any questions regarding the operation, maintenance or repair of this machine,

please contact your local distributor.

To nd a local distributor, please visit our website at

http://hydramaster.com/HowTobuy/DealerLocator.aspx

If your question cannot be resolved by your distributor or by the information within

the Owner’s Manual, you may contact HydraMaster direct using the following phone

numbers.

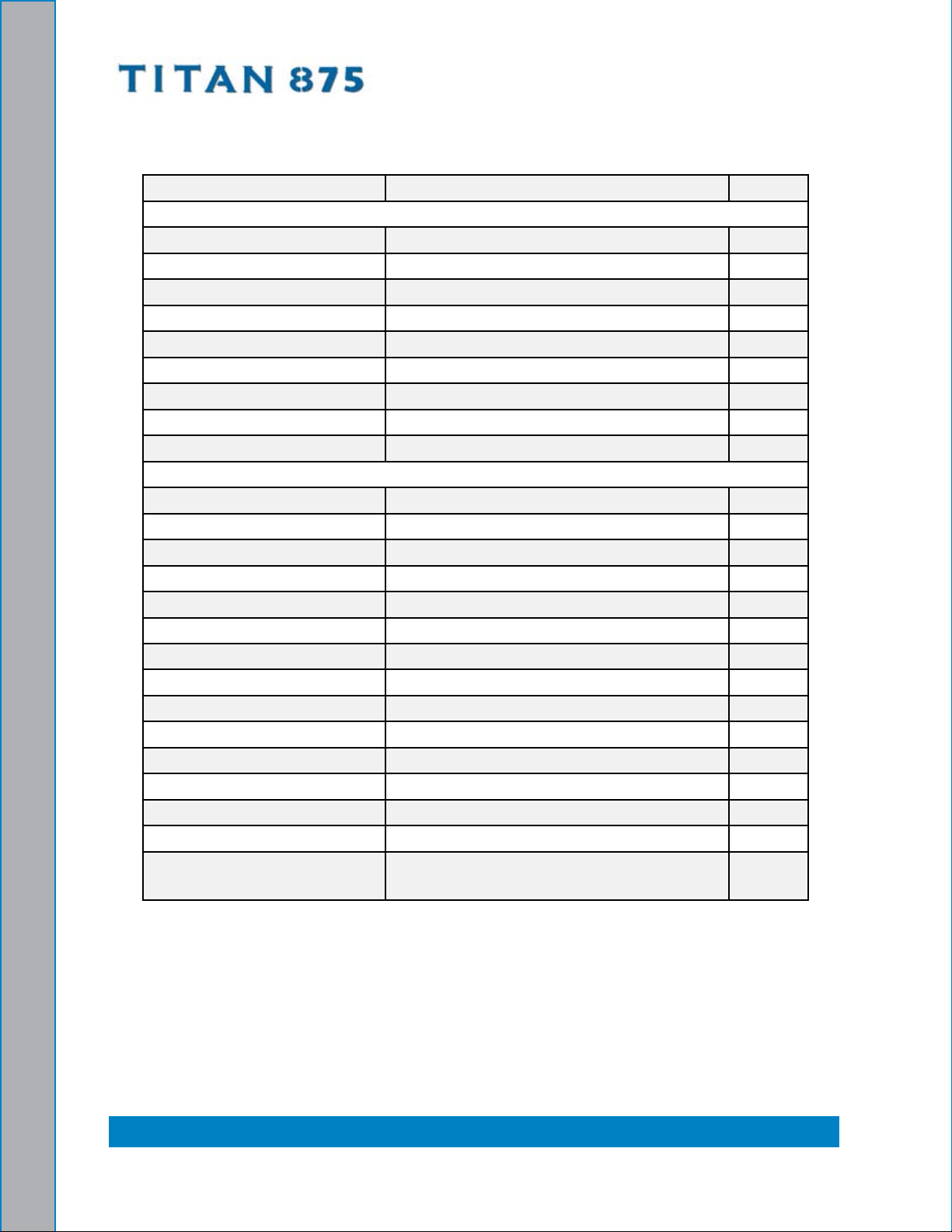

hOuRs TeLephOne nuMBeRs e-MaIL aDDResses

Monday-Friday

Technical support

(425) 775-7275

FAX : (800) 426-4225

techsupport@hydramaster.com

Technical support

7:00 a.m. to 5:00 p.m.

Pacic Standard Time

customer service/parts

(425) 775-7276

FAX: (425) 771-7156

customer service/parts

parts@hydramaster.com

When calling your distributor, be sure to reference the serial number and date of

purchase.

FOR yOUR ReFeReNCe:

Serial No. ____________________________________________________

Date of Purchase: _____________________________________________

Purchased From (Distributor): ____________________________________

General Information: 1-4

Page 15

waRnIngs, cauTIOns anD nOTIces

HydraMaster uses this WARNING symbol throughout the manual to warn of

possible injury or death.

This CAUTION symbol is used to warn of possible equipment damage.

This NOTICe symbol indicates that federal or state regulatory laws may apply,

and also emphasizes supplemental information.

1-5: General Information

Page 16

Warnings and Cautions specic to the Titan 875 include the following:

During the operation of the truckmount many components are in motion. Never

touch any part of the truckmount that is in motion. Serious injury may result.

During the operation of the truckmount many surfaces will become extremely hot.

Never touch hot surfaces. Serious injury may result.

The operation of this truckmount can produce noise levels exceeding 85 decibels

to a distance of 10 ft. The Occupational Safety and Health Administration (OSHA)

recommends the use of hearing protective equipment if a person is exposed

to an average of 85 decibels over an 8-hour period. Check with local and state

agencies concerning hearing conservation rules.

During the operation of the truckmount carbon monoxide and other toxic fumes

are produced. Position the vehicle so that any fumes produced will be directed

away from inhabited areas and any points of building entry (doors, windows, air

conditioning units, fans, etc.). Do not occupy the vehicle while the truckmount is

in operation. Serious injury may result.

During the operation of the truckmount, chemicals known to the State of California

to cause cancer, birth defects and other reproductive harm are produced by the

engine exhaust.

Never operate the truckmount with a portable gas container inside the vehicle.

Doing so will increase the risk of re and explosion. Serious injury or death may

result.

General Information: 1-6

Page 17

Transporting a vented fuel container that presently contains, or has ever contained

in the past, a ammable liquid is strictly forbidden by HydraMaster and by federal

and state regulations. Doing so will increase the risk of re and explosion. Serious

injury or death may result.

Never smoke in or around the truckmount. Doing so will increase the risk of re

and explosion. Serious injury or death may result.

During the operation of the truckmount the exhaust system will become extremely

hot. Keep all ammable materials away from the truckmount exhaust system.

Failure to do so will increase the risk of re and explosion. Serious personal injury

and property damage may result.

Never operate the truckmount when the vehicle is tilted more than 10 degrees in

any direction. Doing so will result in improper lubrication of the internal components,

and will increase the risk serious component or engine damage.

Never perform cleaning operations when the truckmount engine is running at the

IDLe throttle position. Failure to do so will increase the risk of serious component

or engine damage.

Never operate the truckmount with the vehicle doors closed. Doing so results in

extremely high temperatures inside the vehicle and will lead to serious component

or engine damage.

Never use concentrated acids or solvents (including d-limonene) in the truckmount

water system or chemical system. Use of these products will cause serious

component damage.

1-7: General Information

Page 18

Never operate the truckmount with a water hardness reading measuring 3.0

grains per gallon or higher. Using reading than 3.0 grains per gallon will cause

scale to build up inside the truckmount water system. Scale build up causes

serious component damage. Test all water prior to use and use water softening

equipment if necessary.

Never allow water to freeze inside the truckmount. Serious component damage

will occur. Perform all freeze guarding procedures as outlined in Section 4 of this

Owner’s Manual.

Many vehicles have critical components mounted directly below the oor that

can easily be damaged. Before drilling holes in the oor of the vehicle inspect

the underside of the vehicle for critical components. Failure to do so may result

in damage to the vehicle.

Use of the vacuum recovery system when stripping or otherwise removing wax

from oors is specically excluded as an approved use of the truckmount. Failure

to follow this exclusion may lead to component failure and will invalidate your

warranty.

Use of the vacuum recovery system for “dry cleaning”, without corresponding

solution application (i.e. duct cleaning), is specically excluded as an approved

use of the truckmount. Failure to follow this exclusion may lead to component

failure and will invalidate your warranty.

If concentrated acids or solvents are used to pre-treat surfaces before power

washing, do not recover them through the vacuum system. Failure to follow this

exclusion may lead to component failure and will invalidate your warranty.

General Information: 1-8

Page 19

RespOnsIBILITIes

purchaser’s Responsibilities

Prior to purchasing a van, ensure that the payload is suitable for all of the equipment •

that will be installed and transported. This includes and is not limited to: the truckmount,

recovery tanks, fresh water tanks, on-board water, hose reels, hoses, cleaning tools,

chemicals and drying equipment. Payload capacity information is available through

the auto dealer, the manufacturer’s web site, and is also located on the door pillar of

the driver’s side door.

Purchase a heavy duty Group 24 (500+ CC Amps) battery for this truckmount. This is

•

normally available from the installation dealer.

Prior to dropping your van off at the distributor for the truckmount to be installed, have

•

a spray-on bed liner applied to the oor such as Rhino Lining® or Line-X®.

Plywood and carpet are not recommended.

Prior to operating the truckmount, read this manual in its entirety and familiarize •

yourself with the information contained here. Special attention should be paid to all

Warnings and Cautions.

The distributor is responsible for the correct installation of the truckmount. The

•

distributor is also responsible to train you in the correct and proper operation and

maintenance of the truckmount.

Any modication of the truckmount may void the warranty.

1-9: General Information

Page 20

Distributor’s Responsibility

Acceptance of Shipment

before accepting the truckmount, check the following:

The truckmount should be free from any damage during shipping. Do not sign the 1.

delivery receipt until you have closely inspected the truckmount and noted any

damage on the delivery receipt. Hidden damage may be present even if the box looks

okay. It is recommended that the box be opened before you sign for the shipment.

Check the packing list and verify that all items are accounted for.

2.

Installation Responsibilities

ensure proper payload capacity. It is the distributor’s responsibility to verify that the •

equipment package does not exceed the vehicle capacity.

Ensure installation of a safe fuel tap system and through-oor ttings as provided by

•

HydraMaster.

ensure proper placement of the truckmount, recovery tank, fresh water tank, and •

accessories in the vehicle, and check that they are secured with bolts and back up

plates. The distributor should verify that the owner is in agreement with the layout.

ensure proper connection of the fuel lines.•

ensure proper connection and installation of the battery. Verify that the battery is in •

accordance with HydraMaster’s recommendation.

Check the pump, vacuum blower and engine oil levels prior to starting the

•

truckmount.

Start and run the truckmount and check that all systems function properly.

•

Test all hoses, wands and other accessories for correct operation.•

ensure timely return of the document package.•

General Information: 1-10

Page 21

Training

The distributor should provide a thorough review of the operation manual with the

purchaser along with instruction and familiarization in:

How all the truckmount’s systems function.

1.

All safety precautions and their importance.2.

How to correctly start and shut down the truckmount.3.

How to correctly clean with the truckmount.4.

Where and how often to check and change component oil levels.5.

Freezing damage and how to avoid it. This includes explaining proper freeze 6.

guarding procedures.

How to do basic troubleshooting of the truckmount.

7.

Hard water damage and how to avoid it. This includes how to determine if hard 8.

water exists in your area and the installation and use of water softening systems.

The truckmount’s warranty and warranty procedures.

9.

1-11: General Information

Page 22

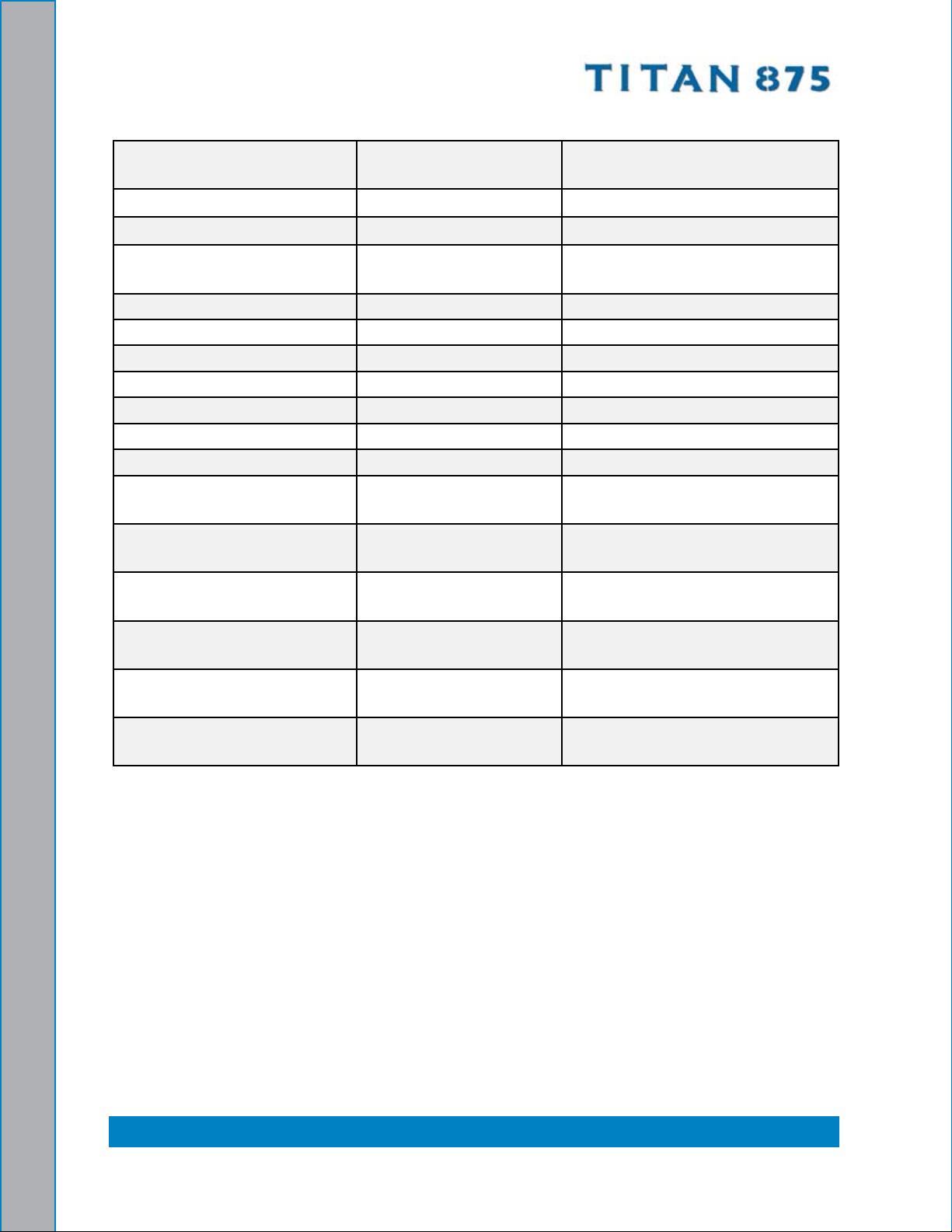

MachIne specIFIcaTIOns

Overall Dimensions

22" W x 29" D x 29" H

(Console Only)

Weight 1,187 lbs.

engine - GM, 1.6L, 4

Cylinder eFI, 61 HP

Oil Type 10W-30 (Synthetic not

recommended)

Capacity Approx. 4 quarts (128 oz.)

when changing oil and lter

engine rpm High 2,700 rpm

Mid 2,500 rpm

Low 2,150 rpm

Vacuum blower- Tuthill

5009 Competitor Plus SL

Oil Type PneuLube™ or other ISO 100

rating

(Dual Splash Lubrication)

Gear end Capacity Approx. 9.6 oz.

Drive end Capacity Approx. 7 oz.

blower rpm 2,250 rpm

Pump- General Pump Oil Type 15W-40

Capacity Approx. 40 oz.

Pump Rate 5.5 gallons per minute

Pump rpm 1,450 rpm

Operating Pressure 0-1,200 psi (heated) 0-3,000 (no heat)

Chemical System Last Step Chemical

Injection

Heating System Finned Tube Heat

Copper Tube and Shell

exchanger

General Information: 1-12

Page 23

Standard equipment High Pressure Hose 1/4" High Temperature Lined/

Vinyl Cover - 150 ft.

Vacuum Hose 2" Vacuum Hose - 150 ft.

1-1/2" Wand Whip Line - 10 ft.

Recovery Tank 100 gallon MaxAir Universal

Tank

Cleaning Wand Stainless Steel S-bend

Replaceable Grip

Rebuildable Solution Valve

Chemical Jug 5 gallon

battery box

Van Decal

Van Installation Kit

Owner’s Manual

(on CD)

Owner’s Guide

(printed)

Optional equipment Third Wand Adapter for

Recovery Tank

Automatic Pump Out

(APO)

2.5 Vacuum Port

(P/N 000-078-875)

Dura-Flow APO

(P/N 000-079-091)

Thru Floor exhaust 4” Thru Floor exhaust Kit

(P/N 000-079-129)

Pressure Washing Pressure Wash Kit

(P/N 000-079-123)

1-13: General Information

Page 24

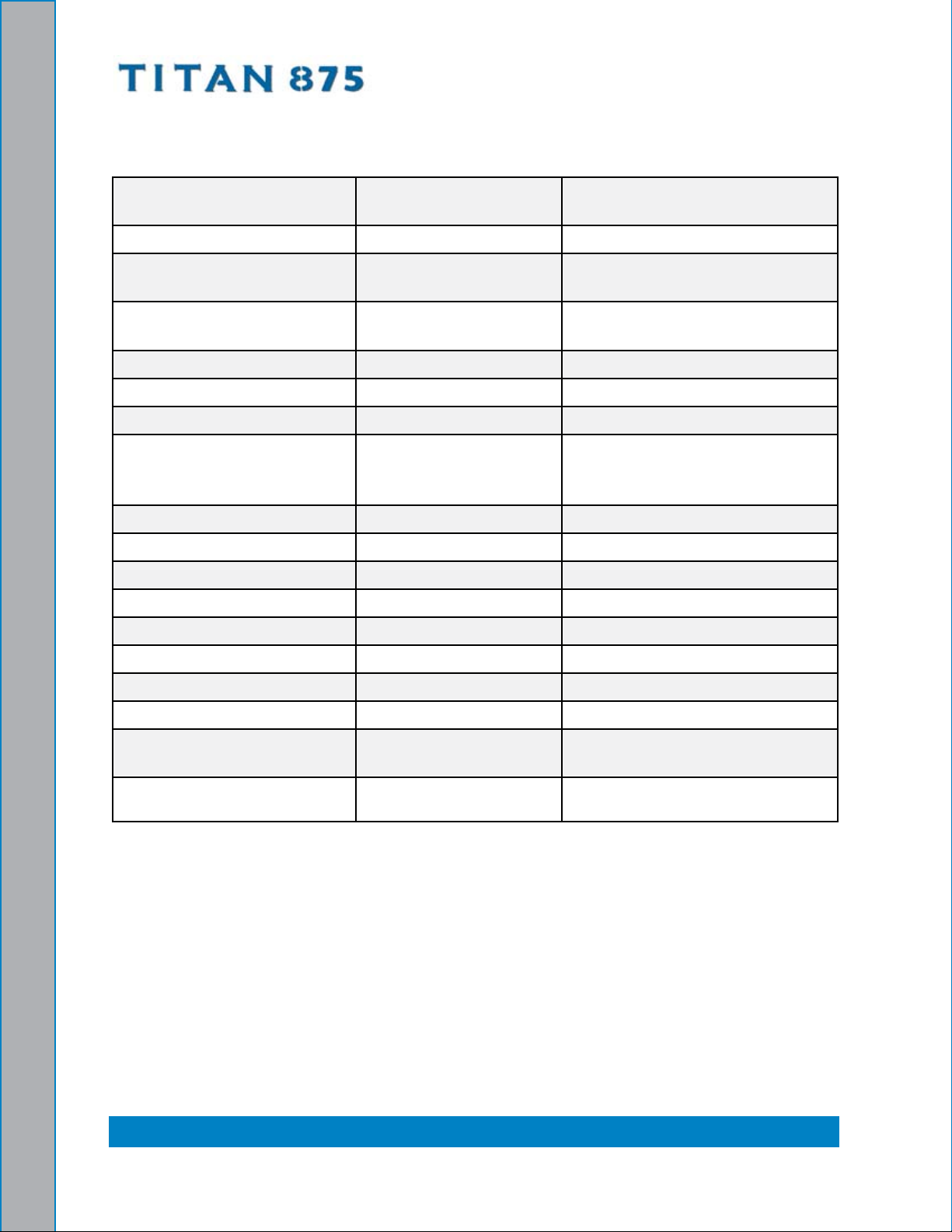

spaRe paRTs LIsT

part no. Description Qty

engine and Drivetrain Components

000-106-125 Plug, Spark 4

000-049-097 Filter, Fuel 1

000-049-250 Filter, Oil 1

000-049-251 Filter, Primary Air 1

000-049-252 Filter, Secondary Air 1

000-010-127

000-010-128

000-010-129

000-010-134

belt, 3VX464 Super HC 4

belt, HD 9330 2

belt, Timing 1

belt, Alternator 1

electrical Components

000-056-010 Fuse, 25 Amp 1

000-056-008 Fuse, 15 Amp 1

000-157-040 Switch, 20 Amp Rocker 2

000-157-022 Switch, Relay, 12 V 2

Hydraulic Components

000-052-050 Quick Connect, 440 Male 2

000-052-051 Quick Connect, 440 Female 2

000-052-052 Quick Connect, 660 Male 1

000-052-053 Quick Connect, 660 Female 1

000-046-011 Diaphragm, Chemical Pump 1

000-169-219 Valve, 80 psi, Last Step Chemical 1

000-180-003 Orice, 0.046 dia. 1

000-074-167 Gauge, High PSI (0 - 3,000) 1

000-049-023 Screen, Garden Hose 1

000-078-005 Kit, Seal, and Spring High PSI

Regulator

1

General Information: 1-14

Page 25

hIgh aLTITuDe OpeRaTIOn

It is not required to change or adjust the fuel system due to altitude differences. The engine

electronic control system constantly monitors the barometric pressure and fuel mixture in

the exhaust. Using these 2 inputs, the engine can compensate for any elevation. This will

be done each time the engine is turned on.

LOcaL waTeR pRecauTIOns

The quality of water varies greatly. Many areas have an excess of minerals in the water

which results in what is commonly called “hard water.” These minerals tend to adhere to

the insides of heater coils and other parts of the machines causing damage and a loss of

cleaning effectiveness. This inuences the reliability and efciency of equipment in direct

proportion to the level of hardness.

hard water advisory

HydraMaster recognizes that any hard water deposits which might occur within the water

system of our truckmounts is a serious problem. The precision technology of truckmount

heat exchanger systems is intolerant of any foreign material. Hard water deposits will

ultimately decrease the performance of the system and are expected to seriously lower

the reliability of the machine.

To validate a machine’s warranty, HydraMaster requires that all machines operating in

designated “Hard Water Areas” (3.0 grains or more per gallon) be tted with a water

softening system, or a properly installed magnetic-type descaler must be used and

maintained. Periodic descaling or acid-rinsing alone is not adequate in these areas.

HydraMaster does not recommend any particular type or brand; however, the relative

effectiveness of some types of magnetic descalers or softeners may require additional

periodic use of descaling agents.

HydraMaster also recommends, in the strongest possible terms, that machines in all areas

be tted with a water softening system for improved operation and reliability.

Failure to take appropriate measures to prevent scale build up can result in

system failure and loss of warranty on affected parts.

1-15: General Information

Page 26

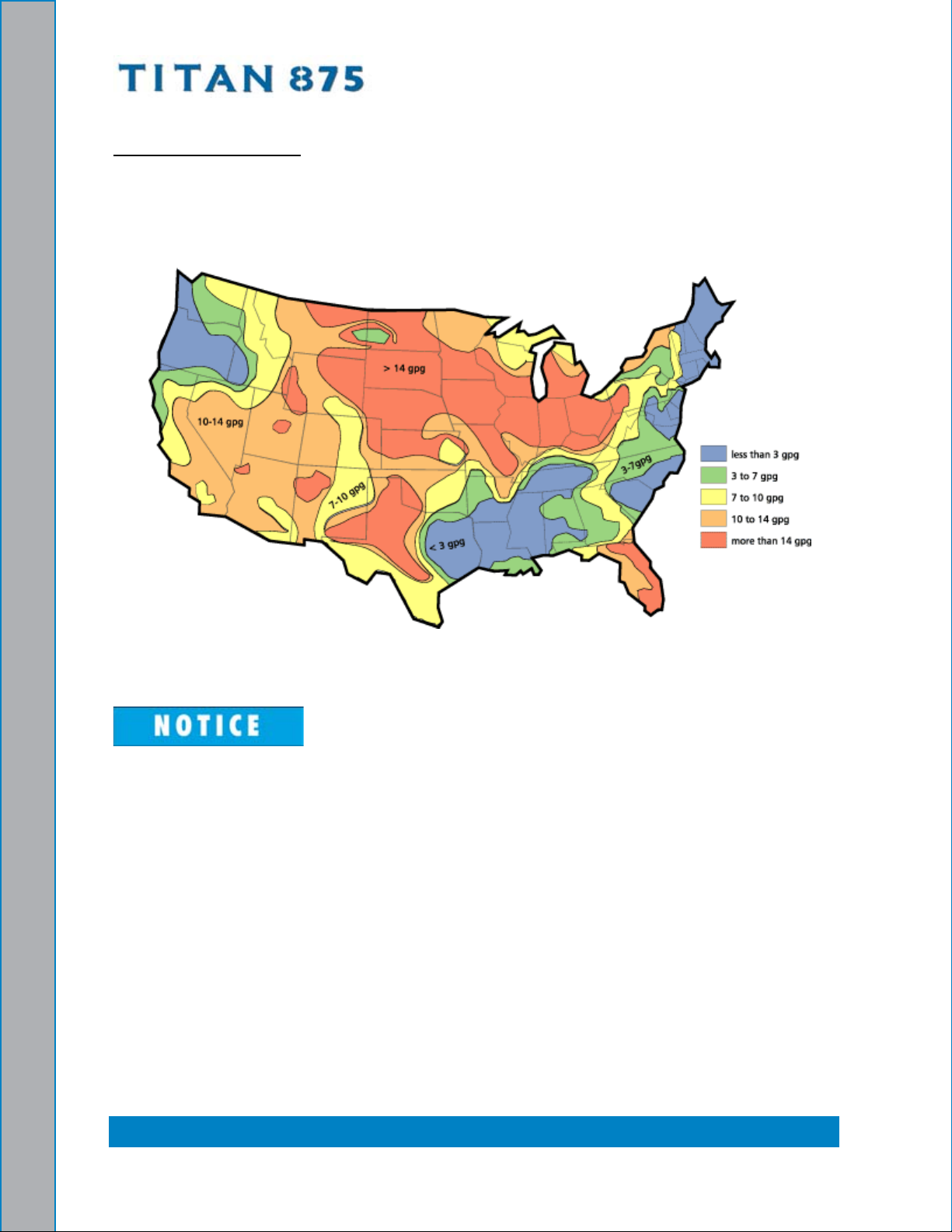

hard water area Map

The hard water map, shown in Figure 1-1, denes hard water areas in the continental

United States which compromise uid related components such as hoses, ttings, heaters,

pumps, valves and water-cooled engines. For other countries, hard water area maps can

be obtained from geological societies.

hard water Map of continental united statesFigure 1-1.

The map shown in Figure 1-1 is provided for general reference only. Water

hardness in your geographical location should be conrmed by testing.

General Information: 1-16

Page 27

water softener

Cleaning efciency and equipment life is increased, chemical use decreased, and the

appearance of cleaned carpets enhanced when water softeners are incorporated in hard

water areas. HydraMaster strongly urges the use of water softener units with the Titan 875

in areas exceeding 3.0 grains per gallon.

Failure to use a water softener in these areas will invalidate the machine’s warranty.

Referring to the hard water area map shown Figure 1-1, determine the quality of water

in your area and take immediate action if the water hardness exceeds 3.0 grains per

gallon.

The relatively low cost of a water softener service is more than made up for by an increased

life of machine parts, reduced chemical costs and continued cleaning efciency. The

water softener will also increase the effectiveness of the cleaning chemicals, therefore

less chemical will be needed.

Contact a water softener distributor in your area for information on the rental of a simple

water treatment unit to carry in your truck. be sure to charge the water softener in

accordance with the capability of the softener.

For example: If the softener will treat 900 gallons of water and the machine uses an

average of 30 gallons/hour, for an average of 5 hours a day, this equals 150 gallons per

day. In 6 days the machine would use 900 gallons of water. Therefore, the softener would

need to be charged every 6 working days for maximum softening.

1-17: General Information

Page 28

waste water Disposal advisory

There are laws in most communities prohibiting the dumping of recovered “gray” water

from carpet cleaning in any place but a sanitary treatment system.

The cleaning rinse water, recovered into your unit’s vacuum tank, contains materials

such as detergents, and must be safely processed before entering streams, rivers and

reservoirs.

In most cases, an acceptable method of waste water disposal is to discharge into a

municipal sewage treatment system after rst ltering out solid material such as carpet

ber. Access to the sanitary system can be obtained through a toilet, laundry drain, RV

dump, etc. Permission should rst be obtained from any concerned party or agency.

One disposal method which usually complies with the law is to accumulate the waste

water and haul it to an appropriate dump site. Another solution to the disposal problem is

to equip your Titan 875 with an Automatic Pump-Out System (APO). These systems are

designed to remove waste water from the extractor’s recovery system and actively pump

the water through hoses to a suitable disposal drain.

HydraMaster makes an APO System which can be ordered with new equipment or

installed later.

When properly congured, the systems will continuously monitor the level of waste water

and pump it out simultaneously with the cleaning operation. The hidden benet of this

process is that the technician does not have to stop his/her cleaning to empty the recovery

tank.

IN ACCORDANCe WITH ePA, STATe AND LOCAL LAWS, DO NOT DISPOSe OF

WASTe WATeR INTO GUTTeRS, STORM DRAINS, STReAMS, ReSeRVOIRS,

eTC.

The penalties for non-compliance can be serious. Always check local laws and

regulations to be sure you are in compliance.

General Information: 1-18

Page 29

2 - Installation Information

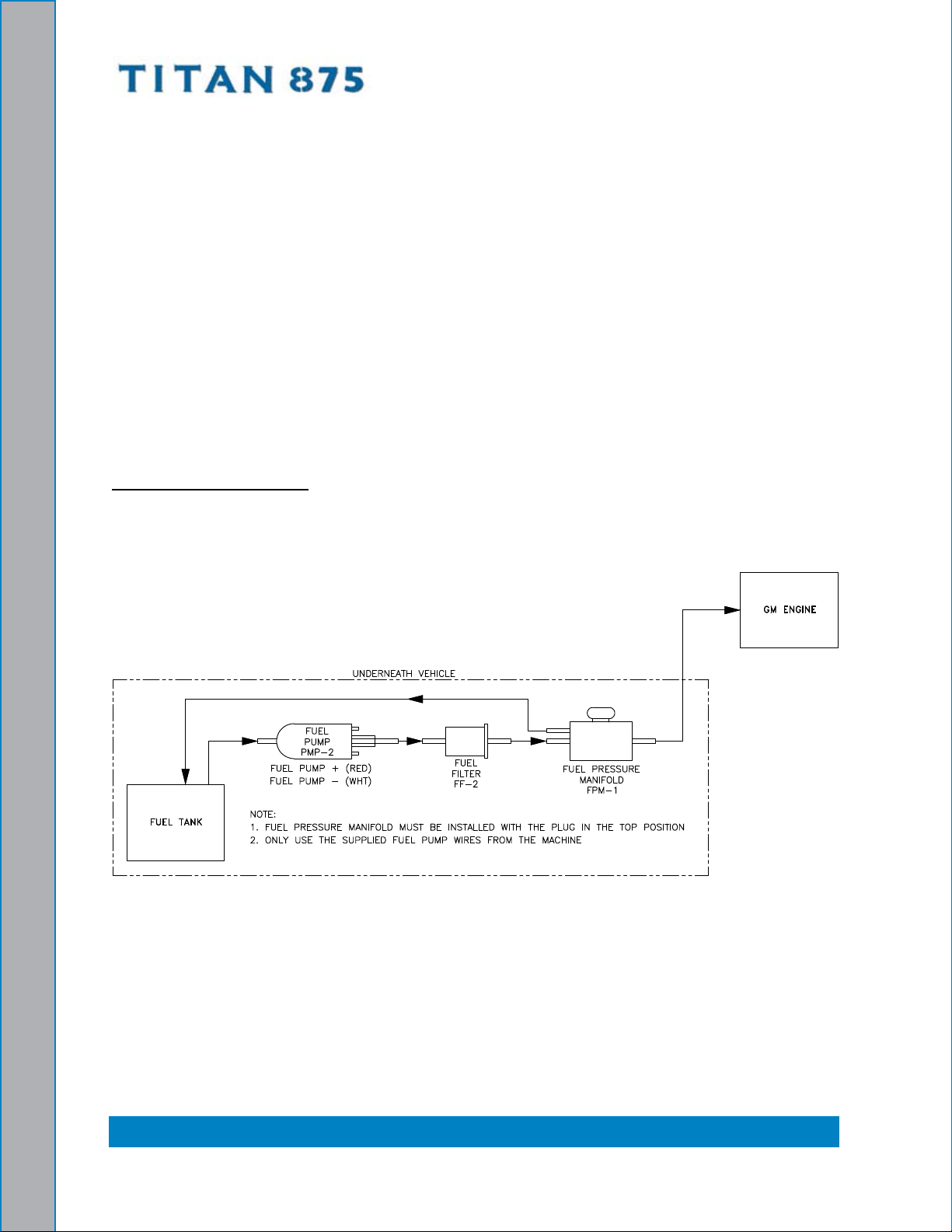

FueL puMp InsTaLLaTIOn guIDeLInes

general

The 1.6L GM engine on the Titan 875 is fuel injected. This is a high pressure system and

requires approved components and hose to operate within the specications. The average

operating pressure at the fuel rail should be 40 - 50 psi. This pressure is controlled via

an pressure manifold that is placed inline with the fuel pump. The fuel system should be

hooked up in the following order:

Fuel Tank Tap

1.

Fuel Pump2.

Fuel Filter3.

Fuel Pressure Manifold4.

Thru Floor Kit5.

Machine6.

Failure to use the specied fuel hose can result in equipment failure or bodily

injury. Fuel hose specication: Fuel injection hose carb no. C-4-06-002 SAE

30R9 180 psi.

Failure to use this hose can result in non-compliance nes set forth by the EPA.

The fuel lter must be on the outlet side of the pump, failure to do so may cause

the engine to run poorly.

It is important that the order of the fuel supply components are installed correctly,

failure to do so may cause the engine or fuel components may not function

properly or be damaged.

All components should be replaced with approved OeM parts.

2-1: Installation Information

Page 30

The fuel pump has a “domed” end and an end with the electrical terminations. The “domed”

end is the inlet of the pump and the side with the terminations is the output.

The fuel pressure manifold has three ports. The side with the two ports is the return and

the inlet, the side with the single port is the output. The dual port side has one connection

almost in the center of the block; this is the inlet. The connection that is slightly offset is

the return to the fuel tank.

The electrical plug must be positioned at the top when the manifold is installed.

The supplied fuel quick connects are required per the engine certication requirements.

The fuel hose is specic to the Titan 875, this is required by the EPA to maintain the

engine certication as well as the pressure requirements.

Locating components

The Titan 875 is equipped with a fuel pump mounting bracket assembly. This bracket

should be located as close to the fuel source as possible. It should be oriented so the

fuel pressure manifold plug is oriented upwards (see Figure 2-1).

Installation Information: 2-2

Figure 2-1. Fuel pump Diagram

Page 31

Although there are many different heavy duty vehicles used for carpet cleaning equipment,

the preferable vehicle for a Titan 875 installation is a cargo van with a heavy-duty

suspension package and a 3/4 HD ton capacity. If a fresh water tank is added, a one ton

or larger capacity van is required.

Prior to installing the Titan 875, HydraMaster recommends installing a spray-on bed liner

in the vehicle. This provides ‘metal to cushion’ mounting rather than ‘metal to metal’ and

makes for an attractive van interior.

HydraMaster also recommends installing roof vents in

vehicles operated in hot weather locations. Roof vent

positions are shown in Figure 2-2. Consult your local RV

distributor about selection and/or installation of powered

roof vents.

For best results, the fan should draw air into the vehicle

which will supply cooler air to the air cleaner intake.

Location of Figure 2-2.

Roof Vents in Vehicle

2-3: Installation Information

Page 32

OpeRaTIng The TITan 875 In hOT weaTheR

HydraMaster recommends the following steps when operating the Titan 875 during periods

of hot weather (95º F or higher). This will help ensure that your Titan 875 continues to run

at 100% capacity during even the hottest days.

A minimum of 9” of clearance is required on both sides of the Titan 875, when

1.

installed. ensure that additional equipment or other materials are not stored at the

sides or on top of the Titan. Unobstructed airow around the unit is critical for cooling

the engine and other components. The covers must be on the machine at all times

to ensure proper cooling.

For side-door vans with “barn doors”, open the doors as wide as their construction

2.

will allow. be sure to open the doors beyond their standard “straight-out” position,

if possible, by releasing the stops and putting the doors in their fully extended

position.

Provide cross-ventilation. When possible, keeping the rear doors open while the

3.

Titan is running will substantially reduce the temperature inside the van and will

provide a path for cooling air ow. For rear-mount installations, open up the other

doors in the van.

Consider adding powered roof vents to the vehicle (if not already installed). These

4.

vents can signicantly reduce interior temperatures and will result in much cooler

operation.

Run the Titan 875 in HOT mode when outdoor temperatures are high. Running the

5.

Titan in WARM mode is not “easier” on the machine. In fact, it cuts the coolant heat

exchanger out of the cleaning solution loop, in effect reducing the engine-cooling

capacity. The Titan was designed to deliver solution at the optimum temperature

to clean carpets when in the HOT mode. The WARM mode is intended for delicate

materials like upholstery.

Installation Information: 2-4

Page 33

Use caution when drilling any holes through the van oor. Many vans have critical

components mounted directly below the vehicle oor that could be damaged by

a misplaced drill bit.

LOcaTIng The TITan 875 In VehIcLe

There are two recommended entry points on the vehicle for the Titan 875 installation: the

side door or the rear doors.

Most installations are through the side door. This provides rear access for accessories

and hoses as well as unobstructed access to the component/working side of the machine,

thus making it a bit easier to perform maintenance and/or repair without removing the unit

from the truck.

Rear mounting requires the unit to be slid to the right side as far as possible Although

installing the Titan 875 through the rear door partly limits working access, it does direct

the noise away from the cleaning site.

In addition, rear mounting not only provides adequate working space on the component

side of the unit but also improves weight distribution inside the van (engine and component

weight line up over drive shaft). Some cleaners in colder geographical areas prefer this

placement for better traction in ice and snow. Also, it is physically easier to load the unit

into the rear door due to the height of the vehicle bed.

Recommended Location of Titan 875 in VanFigure 2-3.

secure Installation

No matter how the unit is installed, check to see if the Titan 875 is properly secured to

the oor of the van with the hardware provided. This safety measure will ensure that the

machine will not slide inside the van. See Figure 2-3 for the correct installation.

2-5: Installation Information

Page 34

A sudden or crash stop will cause the machine to rocket forward if not properly

secured. To prevent serious personal injury, ensure that the Titan 875 is well

secured to the oor of the vehicle with the hardware supplied. Protect yourself

and the machine.

HydraMaster strongly recommends that the exhaust from the front of the machine

be vented down under the truck to prevent carbon monoxide from entering the

job site. always park the truck so the exhaust is blowing away from the job

site.

Never operate this machine with a portable gas can inside the truck. Doing so

increases the risk of a re or explosion.

Mount a re extinguisher just inside the rear or side door for emergencies.

Do not use a portable propane tank inside of the truck or van. It is dangerous and

illegal in most states.

Transporting any vented fuel container that presently holds or has ever held

a ammable liquid in a vehicle containing the Titan 875 is strictly forbidden by

HydraMaster Corporation and by federal and state regulation.

The engine exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Installation Information: 2-6

Page 35

seTTIng up The TITan 875

Prior to operating the Titan 875, follow these steps:

Adjust the vacuum relief located on the recovery tank by capping all the vacuum

1.

inlets (the full throttle condition). The machine should be set to 14” Hg maximum.

Setting the vacuum level higher than the recommended value can result in an

increased risk of serious component damage.

The Titan 875 is shipped from the factory with antifreeze added to the solution system.

Recover this antifreeze and dispose of the recovered antifreeze as stated in the local laws

and regulations.

KeeP ANTIFReeZe OUT OF ReACH OF CHILDReN AND ANIMALS. Drinking

antifreeze can cause death.

If required, dispose of antifreeze at facilities licensed to accept household

hazardous waste. If permitted, dispose of antifreeze in sanitary sewer systems.

Do not pour antifreeze into storm sewers, septic systems, or onto the ground.

Doing so causes health and environmental dangers.

ensure the antifreeze is completely drained from the solution system. If any

antifreeze remains in the system, it could damage machine components and

damage fabric.

2-7: Installation Information

Page 36

Installation Information: 2-8

Page 37

3 - Cleaning and Chemicals

your HydraMaster truckmount has been engineered using the latest and most sophisticated

technology available to produce the nest carpet cleaning results possible. Despite this,

it remains only a tool of the carpet cleaning trade and can produce only as a good a job

as the person operating it.

hydraMaster strongly recommends attending the clean Trust (formerly known as

as possible and to always follow the clean Trust guidelines when cleaning carpets

and hard surfaces.

This section describes the carpet cleaning procedure in the following areas:

Precaution

s

Preparing the Carpet for extractio n

Rinse and Recove r

Over-Wettin g

Streakin g

Cleaning Tool Tip s

Severe Cleaning Situation s

The use of some chemicals (such as concentrated acids and/or solvents) in

your truckmount can seriously damage the internal plumbing and high pressure

pump.

HydraMaster strongly recommends purchasing a water softener system to prevent the

buildup of scale and hard water deposits in your truckmount.

HydraMaster also recommends only the use of chemicals containing rust and corrosion

inhibitors and water softening agents to prevent chemical buildup which may lead to

component failure and warranty invalidation.

3-1: Cleaning and Chemicals

Page 38

Increased demand for a neutralizing rinse results in the need for special care

when using these acid based chemicals in your truckmount The negative side

of these products is the corrosive effects the acid can have on metals, including

ttings, pumps, heat exchangers, etc.

HydraMaster’s ClearWater Rinse™ has been formulated to protect vital components.

HydraMaster will not warranty parts that have been damaged from using acid products

that have obviously caused failures.

pRepaRIng The caRpeT FOR exTRacTIOn

pre-vacuum the carpet

Whether you instruct the customer to pre-vacuum or you offer it as part of your service,

proper vacuuming will make your job easier with superior end results. The more time

spent removing loose particulate soil, the easier it will be to remove the oily soil stuck to

the bers.

pre-treat the carpet

This process of applying trafc lane type chemicals to the carpet (whether by sprayer or

rotary scrubber) is essential prior to extraction with your truckmount.

by applying cleaning agents to the carpet and letting them dwell 10-20 minutes prior to

rinsing, you allow the product to dissolve and emulsify the oily, sticky binders holding the

soil to the ber. This will allow more soil to be removed in one or two cleaning passes and

help prevent over-wetting.

Remember the solution coming out of your cleaning tool is only in contact with the carpet

ber for a few seconds. Relying on the rinse detergent to do the majority of the cleaning

will result in overly long dry times and excess detergent residue left in the carpet.

HydraMaster recommends the use of our pre-sprays: Fastbreak™ for residential carpet

and Blitz™ for commercial carpet needs.

Cleaning and Chemicals: 3-2

Page 39

RInse anD RecOVeR

Whether you are using a wand or an RX-20™, you should clean an area approximately

3 ft. x 3 ft. with the solution valve open then immediately go over that area with vacuum

only to remove any excess moisture.

Olen ber is becoming more popular, particularly in commercial installations. The

process mentioned above can leave excessive residual moisture because olen bers

will not absorb any of the cleaning solution. you must only apply solution during the

backward stroke of the wand so it can be immediately captured by the vacuum head.

RX-20™ users should follow each pass with a dry pass. Failure to follow this procedure

will cause solution to ow to the back of the carpet along with some of the soil. This, along

with any soil imbedded in the backing, will be wicked to the surface of the bers as the

carpet dries.

HydraMaster recommends the following rinse aids: Alkaline - Hydra-Dri Powder™ or

Hydra-CleanLiquid™. Acid - Clear Water Rinse™.

OVeRweTTIng

Overwetting is an annoyance to all concerned. extended drying times will leave the

customer with a negative impression of both the cleaning company and the process

used.

There are several factors that will cause over-wetting:

Too few vacuum strokes.

1.

Clogged vacuum blower lter or vacuum tank lid not sealing properly.2.

Vacuum tank drain valve left partially open.3.

Obstructed, cut or kinked vacuum hoses.4.

Obstructed vacuum hoses while cleaning a heavily foam-saturated carpet (it is 5.

recommended to use a crystal type defoamer distributed evenly over the carpet).

sTReakIng

Streaks in the carpet can appear in both clean or dirty areas and normally appear in

heavily soiled, light colored carpets.

Possible reasons of streaking may include:

Clogged or improperly angled spray nozzles.

1.

Spray nozzles that overlap, concentrating the solution.2.

A partially clogged vacuum head.3.

Inconsistent solution temperature.4.

3-3: Cleaning and Chemicals

Page 40

cLeanIng TOOL TIps

wands

With a wand, keep cleaning strokes short, front to back, and run a “dry pass”.

After pulling the wand for a strip of 3 or 4 ft (0.9 m or 1.2 m) long with the solution trigger

activated, go back up to the top of the stroke, and make a “dry “ pass [i.e. no solution

owing]. This gives the wand a second chance to pick up the solution on the carpet.

If you do not run a dry pass, the carpet can take longer to dry, and, possibly, the pad under

the carpet can become saturated.

be aware of the carpet seams; try to use strokes that are parallel with the seam. Avoid

pulling the want across the seam. every stroke can peel the seam connection and pull

the carpet off the oor.

Also, tilt the wand handle down [head up] to move the tool forward, and away from you,

on the carpet. This means less pull on the carpet and less work for you.

Cleaning and Chemicals: 3-4

Page 41

3-5: Cleaning and Chemicals

Page 42

Cleaning and Chemicals: 3-6

Page 43

Rotary Tool: Rx-20

Rotary tools are easier to move on the carpet, but harder to control at rst. With a rotary

tool, remember to keep strokes short and side-to-side.

before turning on the RX-20, adjust the handle; it should rest right below or even with the

bottom of your pants’ front pockets, with the tool resting at on the oor. Take your time

in adjusting the tool’s height; make sure the head of the tool is at with the oor while you

are holding the handle. Relax your posture; the more difcult it is to hold the tool’s head

at on the oor surface, the more quickly you will tire.

While the tool is running, control the left and right movements of the tool by tilting the head

to the front and back, and lifting the handles up and pushing the handles down. The tool

can be driven to the forward and backward by tilting the head of the unit to the left and

right. The head must be turning to use the self driving feature of the tool, and only requires

a slight bit of pressure to handles to get the head to move the tool across the oor.

As with the wand, drying times will be improved if you run a dry pass between wet passes.

Hold down the solution trigger and move the unit left or right across the oor 3 or 4 ft, then

immediately back across the same pass, without the solution owing, to make the dry

pass. Make the next pass half-overlapping the previous pass.

Use the RX-20 in very heavily trafcked areas or if it has been a long time since the carpet

has been cleaned. beware of the seam edges of carpets and transition edges between

oor surfaces. Use extreme caution when cleaning these areas.

Sometimes it is necessary to use an edge tool or wand to run the perimeter of the room

on in difcult-to-reach areas where the circular head of the rotary units will not reach.

3-7: Cleaning and Chemicals

Page 44

upholstery Tool: DriMaster

Upholstery Tool

Part #000-163-012

Grip

Part #000-061-144

Use the upholstery tool on small rugs and furniture. When you clean rugs, be sure that the

temperature and chemicals are safe for that particular type of rug.

As with the larger tools, do not leave the surface of the upholstery too wet. Adjust the

volume of water on the tool without it touching any surface: the water should just barely

come out of the tool before the vacuum pulls it back in. The water will only just spray the

top layer of the furniture and the vacuum will pull the dirty water back into the tool.

If you nd it necessary to do a dry pass, keep strokes short to limit the amount of water

that comes into contact with the fabric surface.

Cleaning and Chemicals: 3-8

Page 45

seVeRe cLeanIng sITuaTIOns

When your truckmount is used for hard-surface cleaning or pressure washing, some jobs

may involve severe cleaning situations. In these cases, certain precautions will need to

be taken in order to ensure that the recovery tank and various internal components are

not damaged

The following are examples of severe cleaning situations. (This list is not intended to be

complete.)

Concrete cleaning

•

Concrete stripping•

Parking lot cleaning•

Extremely greasy oors•

Cleaning that results in the recovery of extensive particulate residue•

Cleaning that results in extensive foam production•

When your truckmount is used in severe cleaning situations:

A pre-lter must be used on the vacuum hose. A ne-mesh lter (i.e. nylon) should be

•

installed into the pre-lter. Contact your distributor for more information.

The recovery tank should be inspected and cleaned daily.

•

The recovery tank inlet lter screen should be rinsed after every job.•

The rectangular blower lter should be rinsed after every job.•

Special care should be taken to clean debris from the recovery tank oat switches; •

they should be inspected daily to ensure that they are fully operational.

Any cleaning job that induces excessive foam production should be halted until an

•

approved de-foaming agent can be added to the tank.

Failure to follow these recommendations may lead to component failure and

warranty invalidation.

Use of the vacuum recovery system when stripping or otherwise removing wax

from oors is specically excluded as an approved use of the truckmount. Failure

to follow this exclusion may lead to component failure and will invalidate your

warranty.

3-9: Cleaning and Chemicals

Page 46

Use of the vacuum recovery system for “dry cleaning”, without corresponding

solution application (i.e. duct cleaning), is specically excluded as an approved

use of the truckmount. Failure to follow this exclusion may lead to component

failure and will invalidate your warranty.

If concentrated acids or solvents are used to pre-treat surfaces before power

washing, do not recover them through the vacuum system. Failure to follow this

exclusion may lead to component failure and will invalidate your warranty.

Cleaning and Chemicals: 3-10

Page 47

4 - Machine Maintenance

To avoid costly repairs and downtime, it is imperative to develop and practice good

maintenance procedures. These procedures fall into daily, weekly, monthly and quarterly

increments and are outlined below. All maintenance must be performed by qualied

service personnel.

A maintenance log is provided in the Owner’s Guide. This log must be maintained and

may be required to be furnished to hydraMaster before a warranty claim is honored.

It is recommended that the log be afxed to the vehicle door near the truckmount for

convenience and to serve as a maintenance reminder.

This section describes how to properly maintain the truckmount in the following areas:

Operational Maintenance

Overall Machine Maintenance

High Pressure Pump Maintenance

Vacuum System Maintenance

Descaling Procedure (Required)

Freeze Guarding

4-1: Machine Maintenance

Page 48

OpeRaTIOnaL MaInTenance

Daily Maintenance:

Check the engine oil level. Add oil (non-synthetic

•

only) if needed.

Check the high pressure pump oil. Add oil if

•

needed.

Check the oil level in the blower. Add oil if needed.

•

Check coolant overow bottle level. Add coolant if •

needed.

Check the blower drive belt.

•

Inspect and clean the recovery tank lters.•

Inspect and clean the orice and lter.•

HydraMasterProducts#p/u/4/

Daily Inspection

http://www.

youtube.com/user/

qowVchMnrGA

Inspect and clean the garden hose screen.•

Inspect the truckmount for water and oil leaks, loose •

electrical connections, etc. and repair as needed.

Lubricate the blower with a HydraMaster-recommended spray lubricant.

•

weekly Maintenance:

Inspect the recovery tank lters for tears, holes, etc. Repair or replace as needed.•

Inspect the vacuum relief valve. Clean and lubricate •

as necessary.

Clean the recovery tank thoroughly with pressure

•

washer.

Check the pump drive belt and blower drive belt for

•

wear and proper tension. Tighten as needed.

Check all the hoses and wiring for wear and chang.

•

Secure as needed.

Flush the water and chemical systems with solution

•

of equal parts white vinegar and water.

Check all the nuts and bolts. Tighten as needed.

•

One time change of the high pressure pump oil •

after 50 hours of operation. (every 500 hours

thereafter.)

One time change of the engine oil after 25 hours of

•

engine Oil Change

Procedure

http://www.

youtube.com/user/

HydraMasterProducts#p/u/9/

dT2p3o80dJs

operation.

QR Tag:

QR Tag:

Machine Maintenance: 4-2

Page 49

Monthly Maintenance:

Change the engine oil every 150 hours. (every 100 •

hours if operating in high ambient temperatures.)

Change the oil lter every oil change.

Check the engine primary air lter. Clean or replace

•

as necessary.

Check the water level in battery. Fill as needed.

•

Clean the battery terminals as needed.•

Change the blower oil after rst 100 hours of use; •

change every 500 hours thereafter.

Quarterly Maintenance:

Check the fuel lines. Repair or replace as needed.

•

Clean and gap the spark plugs to 0.031” - 0.035”. •

Replace if excessive carbon buildup is visible.

Replace the high pressure pump drive belt.

•

QR Tag:

Air Filter Maintenance

http://www.

youtube.com/user/

HydraMasterProducts#p/u/8/

waeAGFmpbDe

QR Tag:

Vacuum blower

Maintenance

http://www.

youtube.com/user/

HydraMasterProducts#p/u/0/

pL9rDyHn6JA

QR Tag:

Spark Plug Maintenance

http://www.

youtube.com/user/

HydraMasterProducts#p/

u/7/c_HZiXZehPs

4-3: Machine Maintenance

Page 50

500 hours:

Change the blower oil.•

Replace the blower drive belt•

Change the high pressure pump oil.•

Replace spark plugs.•

Change primary fuel lter.•

Check the engine fan belt.•

800 hours:

Change engine coolant.•

1,000 hours:

Replace spark plugs.•

Change secondary air lter.•

Clean and inspect the blower heat exchanger.•

Replace the engine fan belt.•

Refer to the Interval in Hours Maintenance Chart

in the Owner’s Guide or on HydraMaster’s website

for more information.

Machine Maintenance: 4-4

QR Tag:

Interval Maintenance

Schedule

http://hydramaster.com/

Portals/0/Manuals/Titan_875/

Maint_Schedule_Titan_875.

pdf

Page 51

OVeRaLL MachIne MaInTenance

Maintenance, troubleshooting and repair are much easier tasks to accomplish on a clean

truckmount. Regular cleaning of the truckmount offers the user an opportunity to visually

inspect all facets of the truckmount and spot potential problems before they occur. In

addition to the operational maintenance the following “housekeeping” duties should be

performed.

after each job

Check the recovery tank and the recovery tank lters. Empty and clean as •

necessary.

Daily

Wipe the truckmount down thoroughly with a damp cloth.

•

Wipe down the vacuum and high pressure hoses as needed.•

Inspect and clean the vacuum slot on the cleaning wand.•

Check the wand head for sharp edges that could tear carpet. File down as needed.•

Clean the wand to maintain original appearance.•

Visually inspect the hoses for abrasions, cuts, etc. Repair or replace as needed.•

weekly

empty the chemical container. Wash out thoroughly to remove any chemical buildup.•

Inspect the chemical feed line strainer and use solution of equal parts white vinegar •

and water to remove any chemical buildup.

Thoroughly clean the wand and inspect for clogged jets, debris in vacuum slot and

•

leaking ttings at valve.

Thoroughly clean the vacuum and high pressure hoses including quick releases and

•

cuffs.

4-5: Machine Maintenance

Page 52

engIne MaInTenance

engine Oil

engine Oil Level Check

The engine oil level should be checked daily. It is recommended that the oil be checked

just before the engine is started for the rst time for that day. The oil level should be

between the ‘Add’ and the ‘Full’ marks on the dipstick.

Do not operate the engine with the oil level below the bottom of the ‘Add’ mark on

the dipstick, or above the top of the ‘Full’ mark.

Adding engine Oil

It is normal to add some oil in the period of time between oil changes. The amount will

vary with the severity of operation. When adding or replacing engine oil, be sure the oil

meets or exceeds the recommended specication.

Changing engine Oil and Filter

The engine oil and lter must be changed every 150 hours or every three months whichever

occurs rst. The oil and lter should be changed more often if the engine is operating in

dusty or extremely dirty areas, or during cold weather.

engine Oil Quality

To achieve proper engine performance and durability, it is important that you use only

engine lubricating oils of the correct quality in you engine. Proper quality oils also provide

maximum efciency for crankcase ventilation systems, which reduces pollution.

Use only engine oils displaying the American Petroleum Institute (API) “starburst”

certication mark ‘FOR GASOLINE ENGINES’ on the container.

engine Oil Recommendation

Multi-viscosity oils are recommended. SAe 10W-30 is recommended for your engine from

0° F or above. If ambient temperatures are consistently below 0° F, SAe 5W-30 oil should

be used. Synthetic oils are not recommended for industrial or stationary engines.

Machine Maintenance: 4-6

Page 53

Oil Filter

The GM powertrain engines use a AC Delco oil lter as the original equipment. An

equivalent or better oil lter must be used when servicing the engine.

To replace the lter, use a proper lter wrench to remove the lter.

Clean the lter mounting base and lightly coat the gasket surface of the new lter with

engine oil. Hand tighten the lter until the gasket contacts the base, then tighten another

½ turn. Fill the engine with the correct amount of oil, run the engine and check for oil leaks

at the drain plug and oil lter gasket.

spark plugs

Always use the recommended spark plugs for your engine. Hotter or colder plugs, or similar

plugs that are not exact equivalents to the recommended plugs, can cause permanent

engine damage, reduce the engines useful life, and cause many other problems such as

hard starting, spark knock and run-on. Installing new spark plugs regularly is one of the

best ways to keep your engine at peak performance.

air cleaner

Air that contains dirt and grit produces an abrasive fuel mixture and can cause severe

damage to the cylinder walls and piston rings. Damage to the cylinder walls and piston

rings will cause high oil consumption and shorten engine life.

A restricted or dirty air cleaner will also cause a rich fuel mixture. Thus, it is extremely

important that the air cleaner be serviced properly at the recommended intervals.

Service the air cleaner more frequently under severe dusty or dirty conditions.

Failure to do so can result in machine failure.

Remove the primary air cleaner element from the air cleaner assembly and inspect

1.

the element for foreign material restrictions or signs of excessive wear or damage.

Replace the element if necessary.

2.

Remove all dust and foreign matter from the air cleaner housing. 3.

Re-install the air cleaner element. 4.

Re-install the air cleaner cup, and securely fasten the retaining clips.5.

Safety element

If your engine is equipped with an air cleaner which utilizes a safety element, ensure that

the element is properly in place before installing the primary element.

Change the safety element annually.

4-7: Machine Maintenance

Page 54

cooling system

Coolant Level

Check the coolant level of the radiator daily and only when the engine is cool. Generally

a good time to do this is just prior to starting the engine for the rst time each day.

Maintain the coolant level at 3/4 to 1 1/2” below the ller neck seat of the radiator when

the coolant is cold. Whenever coolant level checks are made, inspect the condition of the

radiator cap rubber seal. Make sure it is clean and free of any dirt particles which would

keep it from seating on the ller neck seat. Rinse off with clean water if necessary. Also

make sure that the ller neck seat is free of any dirt particles.

Never remove the radiator cap under any conditions while the engine is operating.

Failure to follow these instructions could result in damage to the cooling system,

engine, or cause personal injury. To avoid having scalding hot coolant or steam

blowout of the radiator, use extreme caution when removing the radiator cap

from a hot radiator. If possible, wait until the engine has cooled, then wrap a thick

cloth around the radiator cap and turn slowly to the rst stop. Step back while the

pressure is released from the cooling system. When all the pressure has been

released, press down on the cap and remove it slowly.

The engine manufacturer recommends the cooling system be lled with a 50/50

mixture of antifreeze and water. The use of DexCool® “Long Life” or equivalent

type coolant is required. This antifreeze is typically bright orange in color and

should meet requirements issued by the engine supplier. Failure to use this type

of antifreeze may result in corrosion of the cooling system.

DO NOT add coolant to any engine that has become overheated until the engine

cools. Adding coolant to an extremely hot engine can result in a cracked block or

cylinder head.

Machine Maintenance: 4-8

Page 55

bleeding Air from Cooling System

It is necessary to remove all of the air from the engine to prevent overheating. If the coolant

has been drained for any reason, it will be necessary to follow the bleed procedure.

When the engine is cold, remove the radiator cap.

1.

Fill the radiator until it is to the top of the ller neck. 2.

Start the engine and run in the low rpm position, pump clutch off, and no vacuum 3.

load.

Allow the engine coolant to heat up and open the thermostat several times. As all

4.

the air is removed from the system, the level of the radiator should lower below the

internal tubes. This process should take approximately 5 - 10 minutes.

Top off the coolant and install the cap.

5.

In the event you experience a coolant shutdown due to overheat, allow the machine 6.

to cool down and repeat this procedure.

A kit is available which allows you to add a valve to the radiator to improve bleeding

the air. Ask HydraMaster Technical Support for P/N 000-078-891 Titan Coolant

bleed Valve Kit (INS-33141).

Radiator

Inspect the exterior of the radiator for obstructions. Remove all debris with a soft brush or

cloth. Use care to avoid damaging the core ns.