Page 1

CARPET SCOUT

and

SEAHA WK

12 Gallon Extractors

.

ISSAE::

on Cleaning and Maintenance

Page 2

6321 204th Street SW, Lynnwood, WA 98036

SCOUT

and

SEAHAWK

Table of Contents

Machine Specifications . . . . . . . . . . . . . . . . . . . 1

Precautions . . . . . . . . . . . . . . . . . . . . . . . . ...2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . ...4

Machine Parts . . . . . . . . . . . . . . . . . . . . . . . ..5

Cleaning Wand Parts . . . . . . . . . . . . . . . . . . ...15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . ..17

Troubleshooting Guide . . . . . . . . . . . . . . . . . ...18

Repair Guide . . . . . . . . . . . . . . . . . . . . . . . . ..21

Warranty Repair Policy . . . . . . . . . . . . . . . . . ...22

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . ...23

Machine Serial Number

Page

Copyright @1996

CLEANMASTER@ Corporation

Lynnwood, Washington

182-401

No part of this manual may be reproduced or used in any form or by any means (i.e. graphic, electronic, photocopying or

electronic retrieval systems) without the express written permission of the CLEAN MASTER@ Corporation. All rights reserved.

Revised July 2, 1996

Page 3

SCOUT and SEAHAWK

Machine Specifications

Page 1

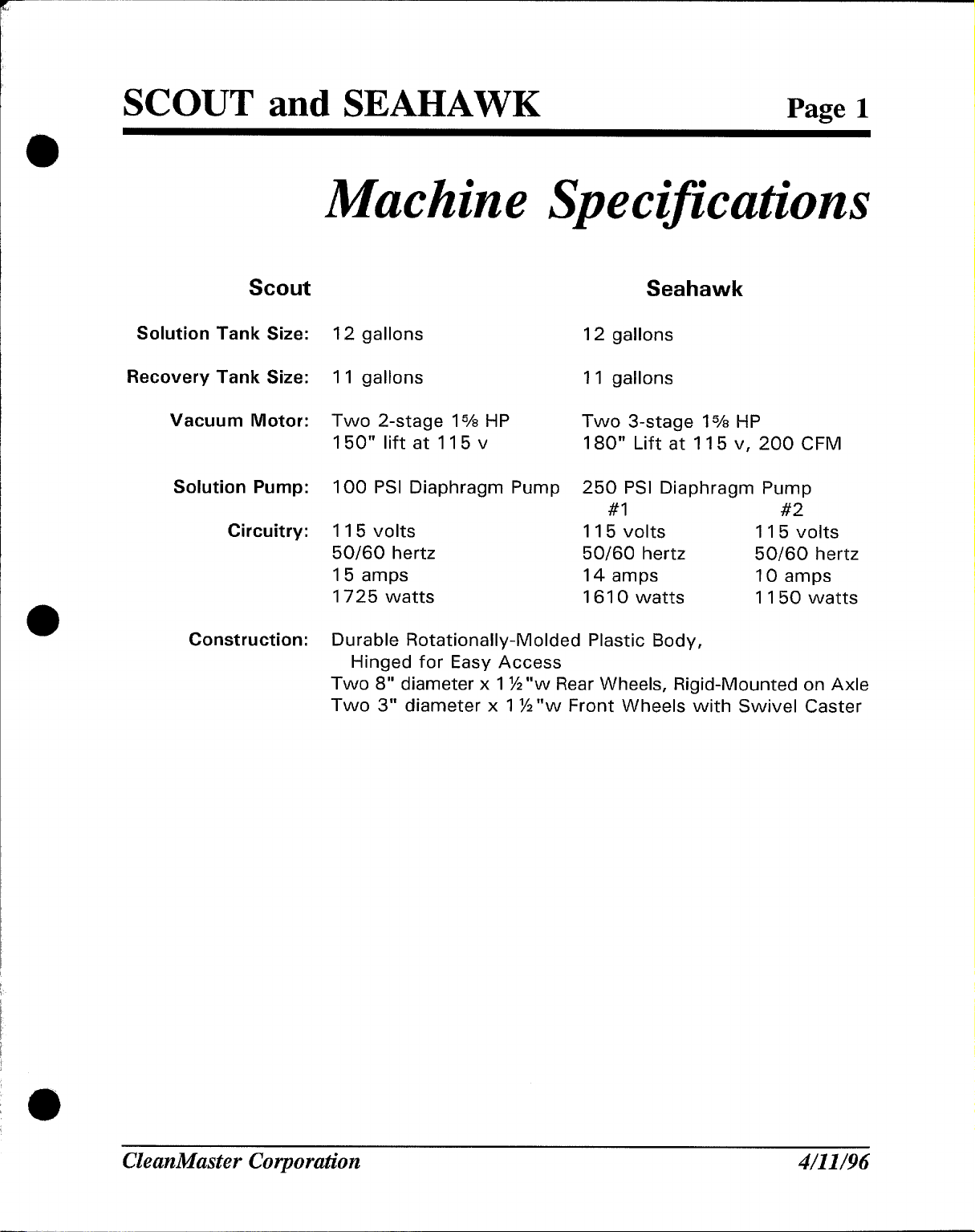

scout

Solution Tank Size:

Recovery Tank Size:

Vacuum Motor:

Solution Pump:

Circuitry:

Construction: Durable Rotationally-Molded Plastic Body,

Seahawk

12 gallons

11 gallons

Two 2-stage 1

150” lift at 115 v

100 PSI Diaphragm Pump

115 volts

50/60 hertz

15 amps

1725 watts

Hinged for Easy Access

Two 8“ diameter x 1 !4“w Rear Wheels, Rigid-Mounted on Axle

Two 3“ diameter x 1 ?4“w Front Wheels with Swivel Caster

5/8 HP

12

gallons

11 gallons

Two 3-stage 1

180” Lift at 115 v, 200 CFM

250 PSI Diaphragm Pump

#1

115 volts

50/60 hertz

14 amps

1610 watts

5/8 HP

#2

115 volts

50/60 hertz

10 amps

1150 watts

@

CleanMaster Corporation

4/11/96

Page 4

SCOUT and SEAHAWK Page 2

9

Precautions

To avoid hazardous conditions, do not use your machine in areas where

1.

flammable and/or explosive vapors or dust are present.

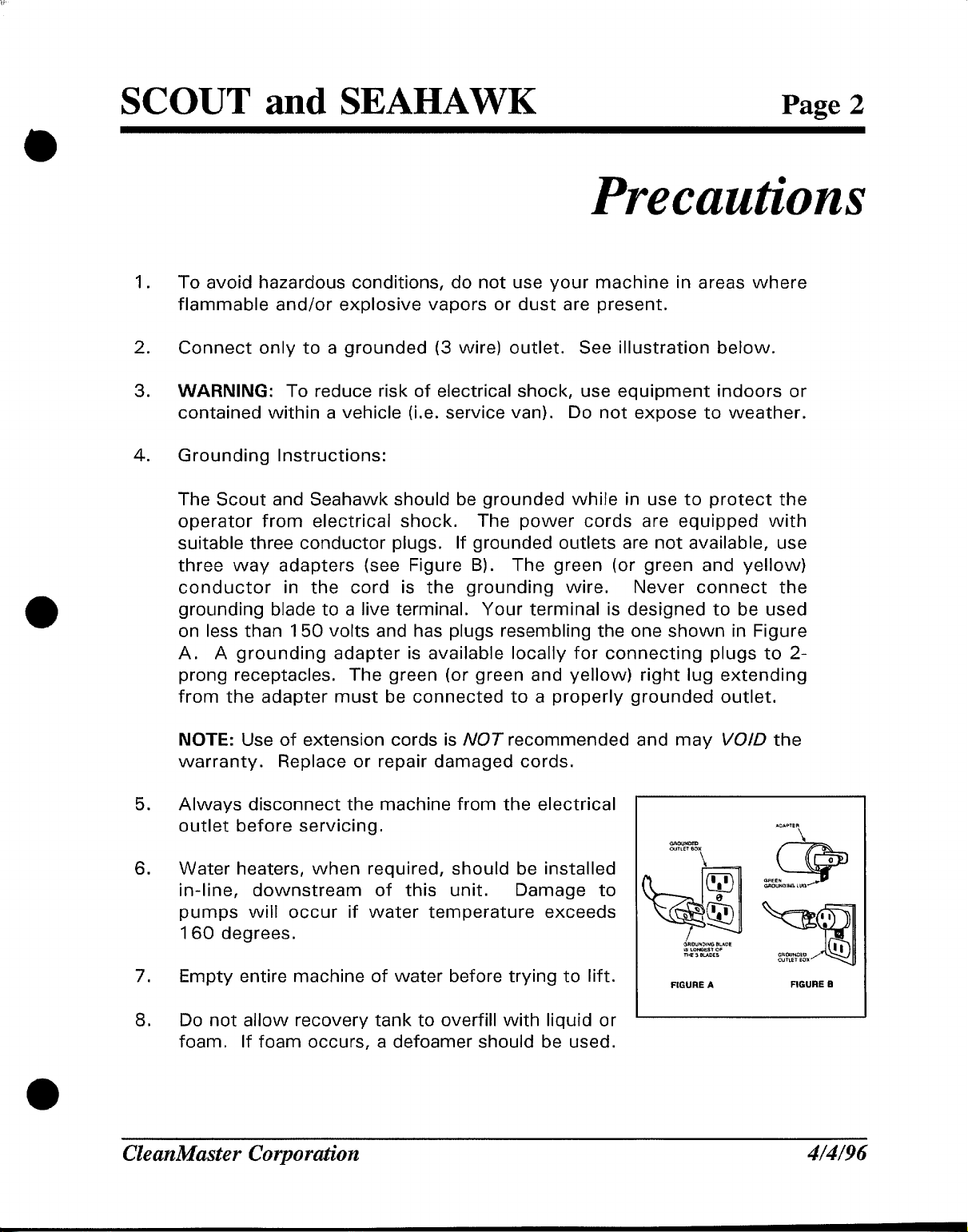

Connect only to a grounded (3 wire) outlet. See illustration below.

2.

WARNING: To reduce risk of electrical shock, use equipment indoors or

3.

contained within a vehicle (i.e. service van).

4.

Grounding Instructions:

The Scout and Seahawk should be grounded while in use to protect the

operator from electrical shock.

suitable three conductor plugs. If grounded outlets are not available, use

three way adapters (see Figure B).

conductor in the cord is the grounding wire.

grounding blade to a live terminal. Your terminal is designed to be used

on less than 150 volts and has plugs resembling the one shown in Figure

A. A grounding adapter is available locally for connecting plugs to 2-

prong receptacles. The green (or green and yellow) right lug extending

from the adapter must be connected to a properly grounded outlet,

The power cords are equipped with

The green (or green and yellow)

Do not expose to weather.

Never connect the

NOTE: Use of extension cords is NOT recommended and may VO/D the

warranty. Replace or repair damaged cords,

5.

Always disconnect the machine from the electrical

outlet before servicing.

6.

Water heaters, when required, should be installed

in-line, downstream of this unit.

pumps will occur if water temperature exceeds

160 degrees.

7.

Empty entire machine of water before trying to lift.

Do not allow recovery tank to overfill with liquid or

8.

foam, If foam occurs, a defoamer should be used,

CleanMaster Cm-por&”on

Damage to

Gnouwom

OUTLET w.

\

m

~QII

G)

w

c.mumw BLAm

. LOWEST .$

mums

ml, 3

FIGURE A

1

FIGURE B

4/4/96

Page 5

SCOUT and

After each use of the machine, rinse out and empty the recovery tank.

9.

Then, with the recovery lid open and the vacuum hose off, run the

vacuum motor to allow to dry.

SEAHAWK

Page 3

10. When adding a heater to the Scout, the solution hose must be upgraded

higher temperature hose.

to a

CleanMaster Corporation

7/2/’96

Page 6

SCOUT and SEAHAWK

1.

Remove the power cord and solution hose from the solution tank.

2.

Check to be sure the Empty slide valve is closed.

3.

Fill the solution side of the tank with warm water (not to exceed 160° F).

4.

Put in the proper amount of cleaning solution for ten gallons of water.

CAUTION: Only non-foaming cleaning solutions can be used and absolutely

harsh solvents or petroleum products,

gaskets, diaphragms and seals.

5.

Close the recovery tank lid,

6,

Hook up both the solution hose and the vacuum flex hose to their appropriate

connections, Connect the other end to cleaning wand or tool,

Page 4

Operation

no

They will decrease the life of rubber

7.

Turn on the solution pump and depress the water valve on the wand until all air

is pumped out of the system, and the pump is primed. Turn on the vacuum.

8,

For carpet:

Place the wand on the carpet.

back toward the operator at a moderate rate for about an arm’s length at a

time. Move the wand to the right or left, slightly overlapping until you cover

a five foot square floor area,

may be vacuumed a second time without using spray solution,

Note: At the first sign of foam in the recovery tank, a defoamer should be

used.

For upholstery:

Place tool on upholstery.

toward the operator at a moderate rate for about an arm’s length at a time.

Move the tool to the right or left, slightly overlapping until you cover the soiled

area.

second time without using spray solution,

Note: At the first sign of foam in the recovery tank, a defoamer should be

used.

9.

Repeat Step 8 until the solution tank is empty or until the job is completed.

For further moisture recovery, the cleaned area may be vacuumed a

Depress the water valve and draw the wand

For further moisture recovery, the cleaned area

Depress the water valve and draw the tool back

CleanMaster Corporation

4/4/96

(

Page 7

SCOUT and SEAHAWK

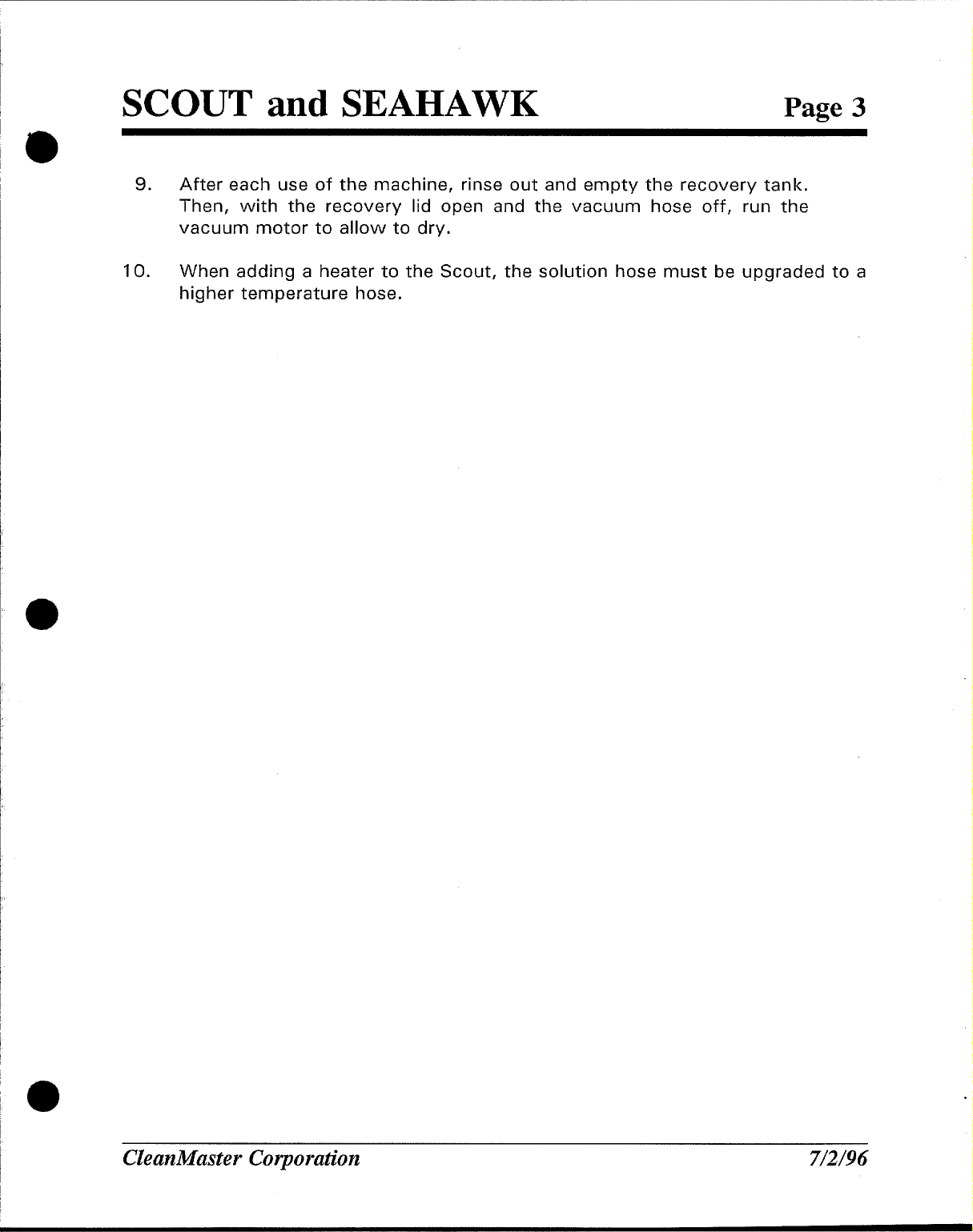

Vacuum Lid

Page 5

Machine Parts

ITEM

1

2

3 P704 Lid

4

PART NO DESCRIPTION

H245

H208

GO05

CleanMaster Corpor@”on

i

QTY

8-32 Stud (lid) x 1” 1

8-32 x 1 ?4 Socket

Lid Gasket

Head

4/4/96

1

1

1

Page 8

SCOUT and SEAHAWK

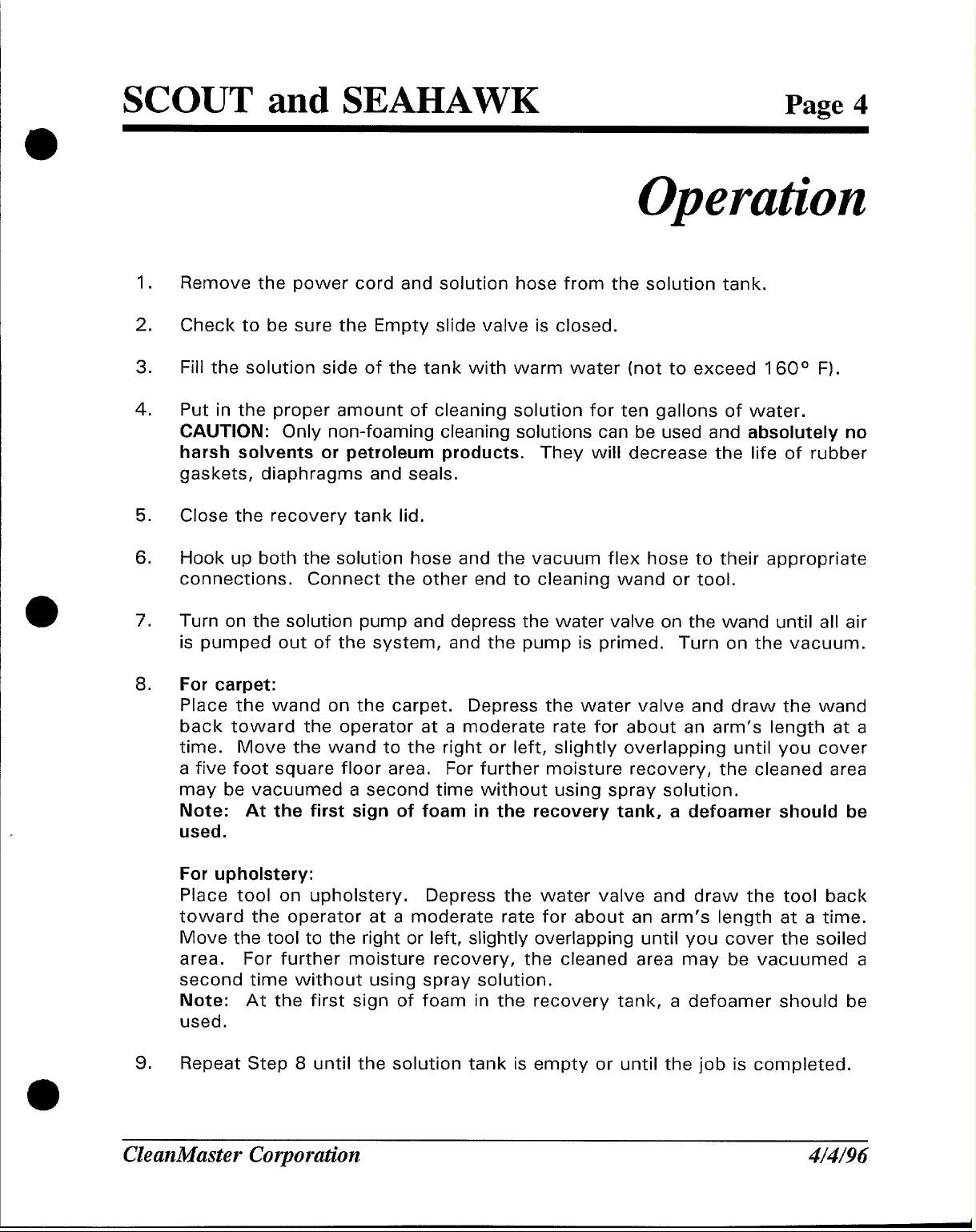

Solution Tank

Page 6

(“n

,

FOR DETAIL SE

PUMP & HEATER LAYOUT ,/

/’

‘ ,.

-.

. ----

,.

---

FOR DETAIL SEE

,--- PUMP & HEATER LAYOUT

.

I

i

I

)

i

I

I

‘7!)

5

ITEM

1 P713

2 BIOI

3 P702

4

!5 H204

PART NO DESCRIPTION

H203

CleanMaster Corporafk”on

QTY

Lid (Solution Tank)

% Male QD 1

Solution Tank

14-20 xl% Bolts/s 2

y4 - 20 X 1 3A Bolt

4/4/96

1

1

2

Page 9

SCOUT and SEAHAWK

Base

Page 7

.—. — ._. —

r-

1

I

i-

25’ POWER CABLE

PRONG CONNECTOR

w/ 3

CleanMaster Corporation

4/4/96

Page 10

SCOUT and SEAHAWK Page 8

a

Base Parts

ITEM PART NO DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

e

H202

H205

H210

H216

H219

H222

H223

H224

H238

H239

P701

E534

H220

H221

E512

H212

74 - 20 x 3A” Bolt

5/16 18 3“ Blk Bolt

‘!4 Flat Washer

!4 - 20 Locknut

Axle Caps

Rubber Sleeve Hinge Pins

Hinge Pin Set

Axle

3“ Castors

8“ Wheels

Base

30’ 16/3 Gray

Strain Relief

Locknut

Indicator Light

9/16” ID X 1 %“ OD F.W.

QTY

12

2

24

12

2

2

1

1

2

2

1

1

1

1

1

4

CleanMaster Corporation 4/4/96

Page 11

a

SCOUT and SEAHAWK

Vacuum Tank

/1 —

Page 9

—

13

20

a

20

7

R

CleanMaster Corpor&”on

4/4/96

Page 12

SCOUT and SEAHAWK

Page 10

e

Vacuum Tank Parts

ITEM

1

2

3

4

!5

6

7

8

9

10

11

12

13

14

15

16

a

17

18

19

20

21

22

PART NO DESCRIPTION

GO02

GO03

H230

H231

H244

H227

H234

H235

H236

H237

PH622

H243

P714

H229

GOOI

H228

P703

H225

H226

E525

E501

H246

Float Flapper

1.88 Filter Foam

10-32 %“ Screw

10-32 1 Screw

PVC FM.S

lYz” PVC Pipe 12X”

1 % ABS Sleeve

Float

Lever Float

Clamping Ring

Metal Screen

PVC Elbow

Blue Elbow

1 YZ M,T, x M.S. Inlet

Thin Rubber Gasket

1 k Steel Locknut

Vacuum Tank

1 % Drain Valve

45° Drain Spout

Four Hole Switch Plate

Waterproof Switches

8-32 x

3/8” Socket Head

X FM.T

QTY

1

1

1

1

1

1

1

1

1

1

1

1

0

2

2

1

1

2

1

1

3

4

CleanMaster Corpor&”on

4/4/96

Page 13

● ●

e

Page 14

SCOUT and SEAHAWK Page 12

e

Pump and Heater Parts

ITEM PART NO DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Bill

BI06

B130

A910

A912

BI18

BI13

BI03

BI07

BI19

BI04

C305

C306

E526

E527

H273

A909

H272

A91 1

Ya Extender Adapter

M Close Nipple

45” Mx%M

18” H.P. Hose

23” H,P. Hose

Relief Valve

% Tee

90”?4’’x?4M

Ya Hex Nipple

Filter Strainer

l/Bx % Bushing

100 PSI Pump, 115 Volts

100 PSI Pump, 230 Volts

192° Thermostat (Automatic)

275° Thermostat (Manual)

Heater Casting

7“ H,P. Hose

Heater Clamp, 6%”

14” H,P. Hose

QTY

3

1

1

1

2

1

1

4

3

1

1

1

0

0

0

0

0

0

~

CleanMaster Corporation 4/4/96

Page 15

I

SCOUT and SEAHAWK

Vacuum Motors

n

@---

Page 13

(2)

(2Ka

5

0-’

(6)

CleanMaster Corporah”on

4/4/96

Page 16

,

SCOUT and SEAHAWK

*

Page 14

Vacuum Motor Parts

ITEM PART NO

1

2

3

4

5 H247 1 %” Vacuum Hose, 20”

6

7

8

9

10

11

12

13

14

C301 Two Stage Vacuum Motor, 115 Volts

C303 Two Stage Vacuum Motor, 230 Volts

H248 2“ Vacuum Hose, 4“

GO04

H249

PH629

H217

H216

H218

H201

H210

P705

H202

H253

DESCRIPTION

Vacuum Gasket

2“ Vacuum Hose, 9“

Blk Hose Cuff

Hose Clamps

U -20 Locknut

Springs

% -20

U Flat Washer

Manifold

X - 20x %“ Bolt

Vacuum Mounting

X M Bolts

QTY

2

1

4

1

1

1

3

2

6

6

4

2

2

Plate 1

CleanMaster Corpordion

4/4/96

Page 17

SCOUT and SEAHAWK

Page 15

CleanMaster Corporation

5/16/96

Page 18

SCOUT and SEAHAWK Page 16

Wand Parts List

ITEM PART NO. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

Handle Assembly (Item #1 O):

061-007

015-203

167-018

052-082

052-072

052-050

169-074

052-152

168-001

061-024

052-450

076-004

094-035

143-012 Bolt, 5/1 6-18

061-006

Handle Grip 1

Bracket, Low Pressure Wand Valve Holder 1

Trigger, Wand Low PSI 1

Elbow, %” Brass 45 Street 1

Nipple, % Brass Close 1

Quick Connect, 440 Male with Viton

Valve, High PSI Brass 1

Compression, H”

Tube, HydraHoe Solution %“ OD s/s 1

Handle Kit, Wand - Pressure Guide (see below) 1

Elbow, For Jet Assembly Wands 1

Jet, #1 1004 %“ VV s/s

Nut, 5/1 6-18 s/s Nylock Half

Handle, Pressure Guide

Male HydraHoe Fitting 2

X %“ HHC S/S

QTY

1

1

2

2

1

CleanMaster Corporah”on

5/16/96

Page 19

SCOUT and SEAHAWK

Page 17

Maintenance

Depending upon the frequency of use, the Pump/Spray/Heater system of your Scout

or Seahawk should be cleaned with a solution of two gallons of water and one quart

of white vinegar, or an anti-browning solution mixed according to the manufacturer’s

directions. This will prevent a buildup of alkaline deposits in the pump and spray jet

of your floor wand,

Make sure that all excess cleaning solution has been drained from the solution

1.

tank.

2,

Add water and vinegar or anti-browning solution.

3,

Attach the solution hose and wand. Turn on the pump and the heater,

4.

Allow the water and vinegar or anti-browning solution to circulate through the

pump, heater, solution hose and floor wand.

appropriate area for this operation. )

5.

As soon as it is apparent that the solution (not residual water or cleaning

chemicals) is being sprayed out of the jets, turn off the pump and allow the unit

to sit for approximately five minutes to allow any alkaline residues to dissolve.

Empty the solution through the wand,

6.

7.

Rinse the system with one gallon of clear water by pumping through the wand.

NOTE: If your machine is used on a daily basis or several t[mes each week you

should follow the above procedure every two to four weeks. If the unit is used

once per month or less frequently.

(Make sure that you are in an

CAUTION: When a portable in-line water heater is in use, always use approved high

temperature hose. This hose connects the machine’s pump to the cold water inlet of

the heater and the hot water outlet of the heater to the wand. This hose, so

connected, increases the life of the pumps.

At least once each month inspect all of the vacuum hoses, filters and electrical cords

for cracking or fraying.

At least every week apply silicone lubricate to all pressure fittings.

CleanMaster Corpora.h”on

Defective parts should be repaired or replaced,

5/’16/96

Page 20

SCOUT and SEAHAWK Page 18

Troubleshooting Guide

No Problem / Possible Cause

%ibtihrn **&ei:iEi:&O&~~: :!’~.:’::~“’~j

:“!.i; ;;’;::

~

,: ~~... ........ ..... ..... .... ..,,..,,.,..,,..,,.

1,1 Lint on top of the automatic shut- Remove any lint.

off screen in the recovery tank,

1!2 The vacuum hoses are not securely Push the vacuum hose cuff further

attached.

1.3 The slide dump valve is open, Close the valve securely.

1,4 The flex hose is clogged or broken,

onto the extractor hose connector.

Check and/or replace the hose,

No Problem / Possible Cause

,..,..

;;}}s:}:}::

2.1 The circuit breakers are tripped,

:’*&tig&ti::mhitii. i#:;*tii;;:::’;:::”i,::,.;.:;“::

,.

:.j ::~g@@~@~=:’:”:!’:::’”:;//“:”’;:‘;‘;::’:.;::’::’;:}’:}::;;:::;’;”:;

Locate a heavier circuit or reduce

the load.

Solution

Solution

2.2 The electrical connections are not

secure. connections.

2.3 A switch is burned out. Remove and replace the switch.

2.4 Field armature is shorted out.

2,5 The motor is burned out.

Recheck all of the electrical

Remove and replace the motor.

Remove and replace the motor.

CleanMaster Corporatz”on 5/16/96

Page 21

SCOUT and SEAHAWK

Page 19

3.1

3.2 The water level is high.

3,3 I The foam level is high.

No

4.1 The suction hose is loose.

4s2 The suction hose filter is clogged,

4,3 The front screws on the pump are

4.4 I There is debris in the pump. I Clean the pump.

4.5 I The valve assembly is worn out.

The recovery tank automatic shutoff is not operating properly.

I

Problem / Possible Cause

unevenly tightened.

Check for proper water level in the

float. Clean the filter,

Reduce the water level in the

vacuum tank.

I Add defoamer to the solution tank,

I

Tighten the hose clamp,

Clean the filter,

Retighten the screws uniformly.

I Remove and replace the valve.

Solution

No

‘Q:: ,“:

,.

5!1

5,2 There is an obstruction in the

Problem / Possible Cause

“:$ke’’:;i’~$ iii:~iisiifii:g; ::”::’!.”.; :! ‘*/:’;

This is normal when using the

hand upholstery tool.

pump, hoses, quick coupler or

CleanMaster Corpor@”on

Solution

Use a larger v-jet.

Check and clean the hoses, quick

coupler and/or v-jet.

5/’16/96

I

Page 22

SCOUT and SEAHAWK

Page 20

No

‘g;’

:::,

:;:::::

601 The quick coupler is loose.

6.2 The pressure switch is open.

6.3 The rectifier is open,

6,4 The motor is burned out,

6,5 The panel switch is burned out,

6.6 This is normal when the hand

6.7 There is an obstruction in the

Problem / Possible Cause

;,,,,.::..: :,.:.::.::,::,.::,,,, ,,:!:::

:ThHiapEia#& ~urnp:.rn’ottx ! ::‘

~j~:,. '.:.::::::::,*::,::::.:.,,.:,,:,.,:.,.,..:::.,:,:

::naf:f~~~l~gr:::”,: : ;:;::;“;::.:: ; ~:.:;:; :.:

trigger valve is closed.

pump discharge hoses quick

coupler and/or v-jet.

Solution

Reconnect the quick coupler.

Remove and replace the switch.

Remove and replace the rectifier.

Remove and replace the motor.

Remove and replace the panel

switch,

Activate the trigger valve.

Check and clean the hoses, quick

coupler and/or v-jet.

o

CleanMaster Corpor&”on 5/16/96

Page 23

SCOUT and SEAHAWK

Removal of Vacuum Motor:

1.

2.

3,

4.

Reinstallation of Vacuum Motor:

1,

2, Install gasket around vacuum horn.

3.

4.

5.

Disconnect unit from power source.

Disconnect wiring,

Loosen vacuum hoses.

Remove vacuum motor.

Carefully seat motor against mounting plate.

Reconnect wiring.

CAUTION: Ground wire must be reconnected to insure operator safety.

Reconnect vacuum hoses.

Tighten motor bolts.

Page 21

Repair Guide

Removal of Diaphragm Pump and Motor:

1.

2.

3.

4,

5.

Reinstallation of Diaphragm Pump and Motor:

1.

2.

3.

Removal of Diaphragm Pump From Motor:

1, Remove two (2) screws.

2.

3.

4.

Replacement of Diaphragm Pump Parts:

1. Remove pump and motor per instructions above.

2. See pump breakdown.

Disconnect unit from power source.

Disconnect wiring.

Remove two (2) screws.

Remove pump by moving forward and up.

Remove hose fitting.

new pump,

Install hoses and fittings.

Install pump using two (2) screws.

Reconnect wiring.

CAUTION: Ground wire must be reconnected to insure operator safety.

Hoses and fittings to be used on reinstallation of

Pry off top bearing.

Remove pump.

Reverse procedure for installation.

CleanMaster Ckwporatk”on

5/16/96

Page 24

SCOUT and SEAHAWK

Page 22

Warranty Repair Policy

When requesting warranty information, call or write and provide the following

information:

1,

2,

3.

4,

Upon receipt of the above information, a Material Return Authorization will be issued.

All packages should be prepaid and clearly marked with the Material Return

Authorization number. If these conditions are not met, shipment will be refused.

After evaluation, the item(s) will be repaired or replaced at our discretion.

If failure or defect is the result of physical

repairs will be charged to the customer.

For service, contact the distributor

When and where the equipment in question was purchased.

Model and serial number of machine.

Part number and description of part.

Description of failure or defect.

abuse, or if the warranty period has expired,

where the machine was purchased or

call our Customer

Monday through Friday

Parts:

Service:

Parts and Service FAX:

Service Department.

● 8:00 am To 5:00 pm PST

(206) 775-7276

(206) 775-7275

(800) 426-4225

PST ROCK MT.

CleanMaster Corpor&”on

CENTRAL EASTERN

5/16/96

Page 25

SCOUT and SEAHAWK

5 -3-1 WARRANTY

Page 23

CleanMaster products are warranted

either 5 years, 3 years, or 1 year as noted below:

* 5 Years on Roto Cast Molded Tanks

* 3 Years Prorated on Drive Motor Gearbox Assembly (RX-Express Only)

* 1 Year on Vacuum Motors, Pumps, Switches, Fittings, Etc.

* 1 Year on HushhVac Vacuums

During this warranty period, we will repair or replace, at our sole option, free of charge,

any parts shown to be defective in either material or workmanship, Said parts must be

returned with postage or freight pre-paid. Specific parts, such as switches, vacuum

motors, pumps, fittings, etc., are also warranted for a period of 1 year from date of

original purchase.

This warranty is for replacement of defective parts or workmanship only. IT DOES NOT

PROVIDE FOR REPLACEMENT OF COMPLETE UNITS DUE TO DEFECTIVE PARTS. It

does NOT cover normal wear items such as hoses, power cords, bumpers, carbon

brushes, gaskets, etc., which require replacement as a result of ordinary usage. Also,

failures caused by abuse, neglect, alterations or operation contrary to manufacturer’s

recommendations are not warranted.

Replacements parts are warranted only for the remainder of the original warranty

period.

This warranty does not cover labor or other charges in connection with replacement

parts. NO LOCAL SERVICE OR REPAIR CHARGES ARE ALLOWED UNLESS PRIOR

AUTHORIZATION IS OBTAINED.

to be free of defects in material for a period of

There are no other warranties, expressed or implied, made with respect to this

equipment. The manufacturer assumes no responsibility for damages resulting from the

use or misuse of this equipment.

6321 204th SW . Lynnwood, WA 98036

CleanMaster Corporation

c .

5/16/96

Loading...

Loading...