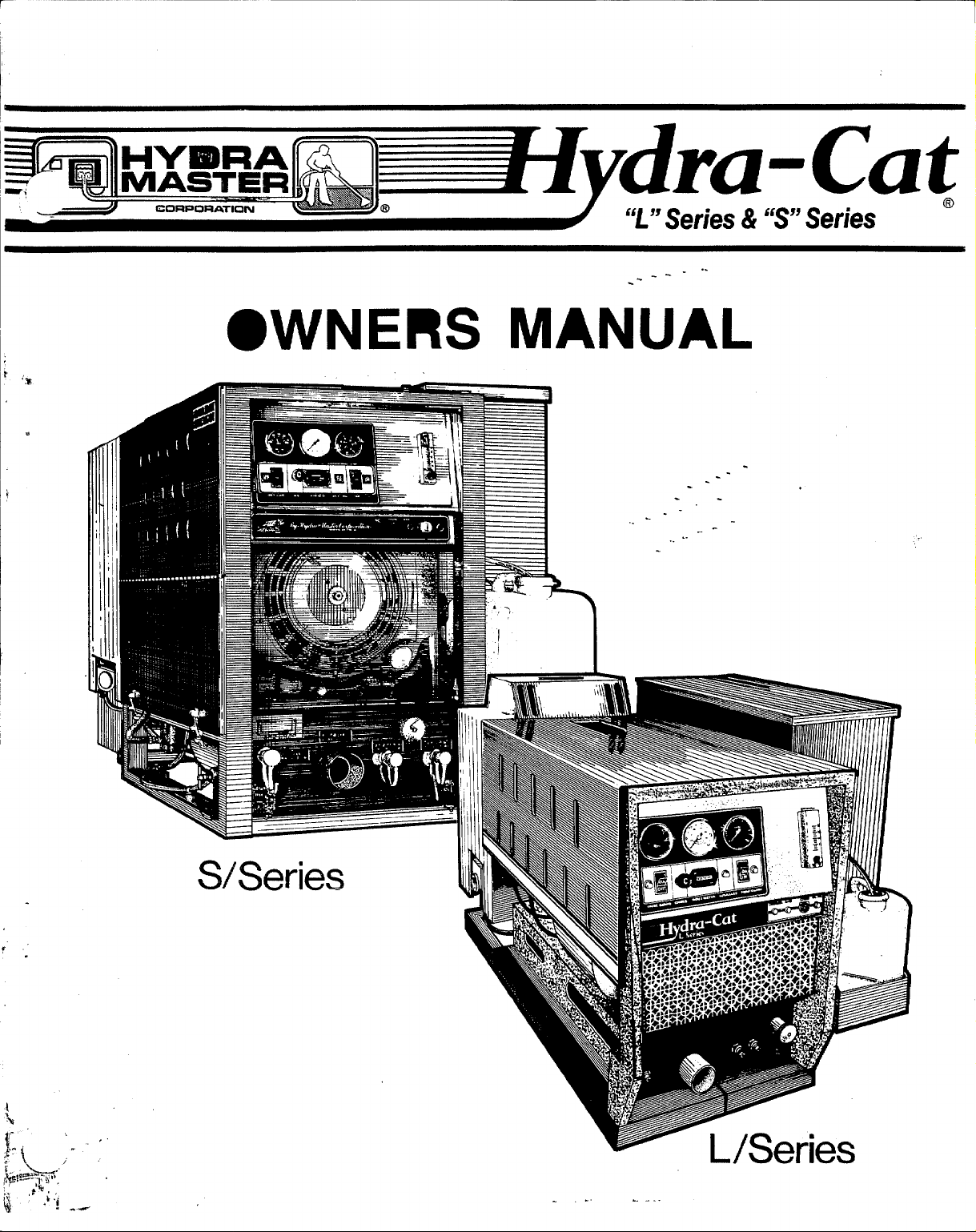

HYDRAMASTER Hydra-Cat L, Hydra-Cat S Owners Manual

r

1

-Ca

@

“S” Series

.

.-

,. .. -

..

.-

.

“-O-

WNERS MANUAL

‘.x

.

i

..-

.-. .. .

●

INDEX

PAGE

General Information .................................................................................................................. 2

Warranty

Warranty Information

Warranty Procedure .................................................................................................................. 3

Purchaser’s Responsibility .................................................................................................... 4

Truck Preparation Information

Truck Preparation ,Illustration

Propane Tank Location/illustration

Hard Water Area Map ...............................................................................................................

..................................................................................................................................

................................................................................................................

..................................................................................................

....................................................................................................

...........................................................................................

2

3

4

4

5

5

Machine Specifications

Spare Parts Recommendation/Parts Orders ......................................................................... 5-6

Water & Chemical Flow Operation

Water Flow Diagram

Chemical Flow Diagram ............................................................................................................

High Pressure Pump Information ............................................................................................ 7

Bypass Valve Assembly Illustration

High Pressure Pump/Chemical System Troubleshooting

Model 290 Cat Pump Operating Instructions

Chemical Proportioning and Level Control Illustration

Chemical Tank Troubleshooting16.............................................................................................

Heating System Information

Heater Operating Instruction

Heater Troubleshooting

Vacuum System Information

Vacuum Flow Diagram ............................................................................................................

Vacuum Tank Filter Bag

Vacuum Blower Lubrication (Diagram)

Vacuum System Warranty

Vacuum System Troubleshooting

Engine Manual/Warranty (S/Series)

Engine Manual/Warranty (L Series)

Engine Troubleshooting ..........................................................................................................

..........................................................................................................

........................................................................................

.................................................................................................................

..........................................................................................

.................................................

.......................................................................

............................................................

..................................................................................................

...................................................................................................

.......................................................................................................... 17

.................................................................................................

.........................................................................................................

...................................................................................

......................................................................................................

...........................................................................................

.................................................................................

.................................................................................

7&16

8-15

21-28

29-38

16

16

17

18

113

18

18

19

20

39

5

6

6

6

7

Electrical Diagrams (S/Series &USeries)” ............................................................................ 40

Electrical Troubleshooting

Machine Installation Information

Machine Tie Down Cleat Illustration

Propane Hook-Up Illustration

Gas Hook-Up Illustration

Water Softener Information

Jet Assembly

Wand Assembly

Valve Assembly

Machine Operation instructions

Control Panel ..........................................................................................................................

Operation Precautions ............................................................................................................

Freeze Protection

Cleaning and Chemical Precautions and Information

Cleaning Stroke Procedure/Over-Wetting

..........................................................................................................................

...................................................................................................................... 42

......................................................................................................................

...................................................................................................................

......................................................................................................

...........................................................................................

........................................................................................ 41

..................................................................................................

......................................................................................................... 41

..................................................................................................... 42

............................................................................................

.......................................................... 44

..........................................................................

43

43

43

43

44-45

40

41

41

42

42

GENERAL

INFORMATION

This manual rxmtains installation and operation instructions as well

as information required for proper maintenance, adjustment and repair of this unit. Since the first and most important part of repair work

isthe correct diagnosis ofthe trouble, a general troubleshooting section and component manual troubleshooting charts have been included for your convenience.

Unlike the garden tractor, Iawnmower and cement mixer, all having

one or two functions to perform, the truck-mounted carpet cleaning

plant has many funtilons to perform simultaneously.

Engine I?asto run consistent RPM.

Vacuum has to pull air and dirty water back from cleaning site.

Water pump provides stab~e pressure at proper water flow for

cleaning.

Chemical

consistency.

Heater must maintain proper heat.

Vacuum tank must store dirty water until drained.

As you can see, it is not just a turn key operation with only one thing

to worry abaut, EWes N start?!

THE SYSTEMS WORK AS

Fcmmws:

The water system takes incoming water at tap (low) pressure, combines it with chemical from the chemical system automatically,

pumps it under high pressure through the heating system and out to

the cleaning tool. After being sprayed into the carpet being cleaned,

the water/ch@micaI/soil solution is extracted by the vacuum system

and returned to the waste recove~ tank.

As there is no guess work in the manufacture of these highly advanced cleaning

job done in the field. It is the purpose of this manual to help you prop-

erly understand, maintain and service your cleaning plant. Follow

the directions carefully and youwill be rewarded with years of profita-

ble trouble-free operation.

is imperative that no section be overlooked when preparing forop-

It

eration of this equipment.

has to be injected into the water stream at the right

plants,there must be none in preparing itto get the

The manufacturer uses this symbol

throughout the manual to warn of

poss~ble injury or death.

HYDRA-MASTER WARRAIW’Y POLICY

Effective October 1, 1981

HYDRA-MASTER warranty covers only defective materials and/or

workmanship for the periods listed. Labor,

ancflor diagnostic reim- —

bursement is specifically excluded.

LIMITEDWARRANTY

HYDRA-MASTERwarrantsproductsof Its manufacture to be tree

fromdefectsin material and workmanship If properly installed. mam -

tained, and operated under normal conditions w[th competent supervision. No person, agent, representative or dealer IS authorized to

gwe any warranties on behalf of HYDRA-MASTER

HYDRA-MASTER any other l~abitityin connectmnwith any at

HYDRA-MASTER’Sproducts.This warrantyshall

periods listed by component below from date of mstallabon 1$repairs

or replacements are made by the Purchaser without HYDRA- k4ASTER’S written consent, HYDRA-MASTER’S warranty shall cease to

be m effect. No allowance will be granted for any repairs or alterations made by the Purchaser without HYDRA-MASTER’S prior writtenconsent.

Machinery, equipment and accessories fummhed

TER,butmanufacturedbyothers,arewarrantedonlytotheextentof

theoriginalmanufacturer’swarrantytoHYDRA-MASTER

HYDRA-MASTERagreesat itsopt(ontorepair

ment or to replace without charge f.o. b. pmnt of sh!pment, any parts

or parts of products of HYDRA-MASTER’S manufacture, which with-

in the specified warranty period shall be proved to

TER’S satisfaction

the Purchaser promptly notifies HYDRA-MASTER. m wntmq, of

such alleged defect.

HYDRA-MASTER’S Iiabdity to purchaser, whether m mntract or m

tort arising out of warranties, representation, instructions, or detects

from any cause shall be limited to repairing or replaclng of the the d@factive part or parts

No liability whatsoever shall attach to HYDRA-MASTER until sa~d

products have been paid for.

to have been detective when shipped. provided

asaforesa!d, f.o,b point of shipment

Except as stated in this section and in the preceding section

titled “Warrar’ity”andexcept as to title, there are noguarantees

orwarranties of merchantability, fitness, pwtorrnar$ceorotherwise, express, implied or

shall have no

Iiabllit y for consequential, incidental or other

statuato~, and HYDRA-MASTEI%

d~mages, howsoever caused.

ENGINE: (Thru original Manufacturer. See

Onanwarranty)

VACUUM BLOWE6; (Thru onglnal Manufacturer

See Fuller warranty)

PROPANE HEATER:

VACUUM RECOVERY TANfG’CHEMICAL MIX TANKS:

FRAMEICOVER ASSEMBLIES:

HIGH PRESSURE PUMP: (Thru orlgmal Manufacturer

See Cat Pumu warranty)

HIGH

PRESSURE BY PASS VALVE:

CHEMICAL PROPORTIONING SYSTEM:

GAUGES. METERS. SWITCHES, WkRE btARNESS.

FUEL lWfMP:

INTERNAL MACHINE HOSE:

EXTERNAL VACUUM HOSE, SOLUTION HOSE.

QUICK CON NECTORS:

SS CLEANING WAND: (Except valve & let assembly)

BELTS, FllTtNGS, O RINGS, FILTER SCREENS:

FILTER BAGS:

Freezing oi any one water or chemical related component will VOID ‘~J

ail other lmDlted warrantv on all water or chemical related compo- [:)

nor to assume for

extend for the

byHYDFIA-MAS-

at the point of ship-

HYDRA-MAS-

—- ..—.. —_ —...—

1 year

1 year

1 year

1 year

1 year

1 year

:; :;;: i}

90 days ~)

90 days &

30): i~

30 days ~

Not Covered by Warranty [;;

m

z>

,.

o

parts shipment will be sent to the customer for the amount of the

WARRANTY lNFORMATK)N

To avoid misunderstandings which might occur between machine

owners and manufacturer, we are listing causes of component failure that specifically voids warranty coverage. Such causes as listed

below shall constitute abuse

0

ENGINE:

maintain proper oil level (oil should be checked every 5 running

hours). Failure to use the proper oil viscosity and type (see engine

manual). Use of other than manufacturer’s recommended spark

plug in engines. Failure to perform recommended maintenance as

described on pages 3 and 4 of engine manual.

Operation at speed in excess of 2600 RPM. Failure to

or neglect.

parts sent. The customer’s faulty parts

tion priorto the expiration of the thirty (30) day period. Upon warranty

approval, a credit will be issued the customer for the replacement

parts invoice. Warranty

within the thirty (30) day period allowed will result in the

perta

customer being charged for the replacement parts sent.

disapproval or failure to return the faulty

must be returned forevalua-

HOW TO ORDER

To obtain a proper diagnosis of your malfunction, and to order warranty replacement parts, it is important you follow the below procedure:

@

BLOWER: Failure to lubricate impellers daily with LPS-I or

WD-40 lubricant. Failure to lubricate bearings as recommended in

blowe; manual. Failure to maintain proper oil levels in the blower.

Failure to use the correct oil grade and viscosity as recommended in

blower manual. Failure to properly maintain blower safeguard systems such as waste tank filter screen, vacuum safety relief valve in

.

vacuum tank lid and waste tank

automatic shut-off system.

HIGH PRESSURE WATER PUMP: operation of pump at

pressures over 1200 PSI. Failure to maintain proper oil level as recommended in pump manual. Failure to change oil inpump at recommended intervals. Failure to protect pump against freezing. Failure

to maintain pump protection shut-off system. Failure to use water

softener in hard water areas. Use of improper chemicals.

1. Call Hydra-Master Warranty/Service Dept. at (206) 775-7275

2. Give the Warranty/Sewice Representative the following information:

Name of your company and your address.

A.

Equipment Model (i.e. Hydra-Cat, Bobcat 2, etc.)

B.

Date of purchase.

c.

Hours on the unit.

D.

E.

Serial number of unit.

Name of person authorized to order parts.

F.

G.

Salesman unitpurchased from.

1-1.

DescrirXion of malfunction.

1. Pressu~e readings on high pressure gauge with wand turned on

and off.

HEATER: Operation of heater without adequate water SUDDIV.

Changing factory set propane regulator. Operating heater without

proper ventilating. Failure to protect heater against freezing. Operating machine at water pressures over 1000 PSI. Overfilling of propane tank. Use of improper chemicals. Failure to use water softener

in hard water areas.

VAC TANK:

Failure to clean tank as recommended by manufacturer. Failure to

maintain vacuum safety release in tank lid. Use of improper chemicals.

Failure to properly maintain filtering devices in tank.

CHEM. PROPORTIONER: Use of improper chemical. Failure

to use water softener in hard water area. Operating machine without

proper chemical filter screen. Failure to protect against freezing.

3. Ifwarranty replacement parts are needed, please specify method

of shipment desired. NOTE: All replacement parts are sent

freight collect, via:

A. U.P.S.

B. Airfreight

C. Ak mail

D. Air express

E. Auto Freight

4. Do not give malfunctioning parts to a Hydra-Master Sales or Ser-

vice Representative. All parts must be returned efirectlyto HydraMaater, freight prepaid.

●

CONTROL PANEL: Failure to protect flow meter and water

pressure gauge against freezing.

VACUUM AND SOLUTION HOSES: Failure to protect

hoses against freezing. Failure to protect hoses against burns from

engineiblower exhaust. Damage to hoses from being run over byvehicles. Kinking or cracking from failure to store or unroll hoses correctly. Normal wear and tear from everyday use.

CLEANING WAND: Failure to protect against freezing. Obvi-

ous physical abuse of wand.

WARRANTY PROCEDURE

Warranty coverage is available to you ONLY through Hydra-Master

Corporation, 20309 64th Ave. West, Lynnwood, Washington 98036;

When warranty parts are needed, write Hydra-Master Warranty

Dept. at the above address, or call the Warranty/Service Dept. at

(206) 775-7275. No collect calls will be accepted. Hours of the

Warranty/Service Dept. are 8:00-11:30 am and 12:30-5:00 pm,

Pacific Time.

IMPORTANT

Hydra-Master’s warranty policy provides replacement parts without

charae for thirty (30) days.to customers maintaining current account

IONE FINAL NOTE:

Any questions you have regarding the warranty program should be

directed to the Warranty/Service Dept. Personnel at Hydra-Master

Corporation.

We shall always endeavor to be fair in our evaluation of your warranty claim, and shall provide you with a complete analysis of our

findings.

PURCHASER’S

~RESPONSIBILITY

IWWMt To AFWWM. W fJIdlT:

o Install %“ exterior plywood flooring in vehicle and cover with

atilficial turf.

e Have belly mounted propane tank installed on vehicle. Tank

must be propane vapor type.

Materials Needed:

1.

2 sheets 4 x 8 x 78” exterior plywood

2. 6’ x 12’ piece of commercial

3. 16- 11/,” sheet metal screws

4. 1 quart marine adhesive (optional)

5. 1 staple hammer

illustration for correct placement of plywood fkmring}

(See

w/1/2° staples

astroturf

IPLACEMENT OF UNIT IN

‘VEHICLE

There are two recummenc$ed unit placements:

a

*_ PurchaseheaWd.w42-60 ampho.r

battery and have battery ‘siow’ charged if new. If battery is not

ful!y charged damage can

regulator.

ACCEPTANCE t2F SHIPMENT:

If unit shows any outward signs of damage, do not sign the

*

delivery receipt until you have closely inspected the unit and

noted any damage on tt!e delive~ receipt. Have the freight

company representative acknowledge the damage by signing

the notation of damage on the delivwy receipt.

READING

* It is the purchaser’s responsibility to read the unit operation

OF t3PERATl(Ml MANUAL:

manual and to familiarize himseff withthe information contained

therein.

occur to the engine charging

SALES REPRESENTATIVE

RESPONSIBILITY

e The salesman from whom you purchased your unit is

responsible for supervising the correct installation of the unit in

your vehicie and thoroughly training ywJ in its operation and

maintenance.

CORRECT INSTALLATION INCLUDES:

Supervising the purchaser in the following:

o Installation of through-floor fittings for propane and gasoline

lines: installWCJpropane regulator included with unit, out-

fuel

side vehicle; placing unit and recove~ tank in vehicle and

securing them with bolts or tie down cleats; connecting all

propane and gasoline lines; connecting battery; checking

pump, vacuum blower and engine oil levels, priorto starting

writ; starting unit to check engine to see that all systems

function normally; also checking all hoses, wands, etc., for

correct operation.

TRAINING WALL INCLUDE:

Thorough review of the operation manual with purchaser;

*

instruction

shut down unit; how to correctly clean with the unit; how, where

and how often to check and change component oil levels; how

the unit’s systems work; trow to troubleshoot the unit; how to

do basic repairs; safety precautions and their importance;

freezing damage and how to avoid it and a thorough review of

the unit warranty and warranty procedures.

and familiarization in: how to correctly startup and

A. SIDE DOOR: Most installations are side door. This provides rear

access for accessories and hoses as well as unobstructed access to

componenffwork!ng side of mac~lne, thus making it a bit easier to

perform maintenance andlor repair without removing unit from the truck.

B. REAR DOOR: Although this location partly limits working ac- cess, it does direct the noise away from the cleaning site. Some

cleaners in the colder areas prefer this location because it puts the

weight mass over the rear wheels for better traction in ice and snow.

Rear mounting requires the unit to be slid to the right side as far as

possible. This not only provides adequate worktng space on the

component side of the unit but also makes better weight distribution

inside the van (engine and component weight !ine up over drive

Also, it is physically easier to load unit into rear door due to

shaft).

height of van bed.

floor at van with hardware

Ensure that machine is well secured to the

cause machine to racket forward, ail 3513 tbs. worth! Protmct

yourself and the machine: SECURE IT!

TRUCK PREPARATION

supphd. Sudden or crash stop will

UMLISTRATK3N

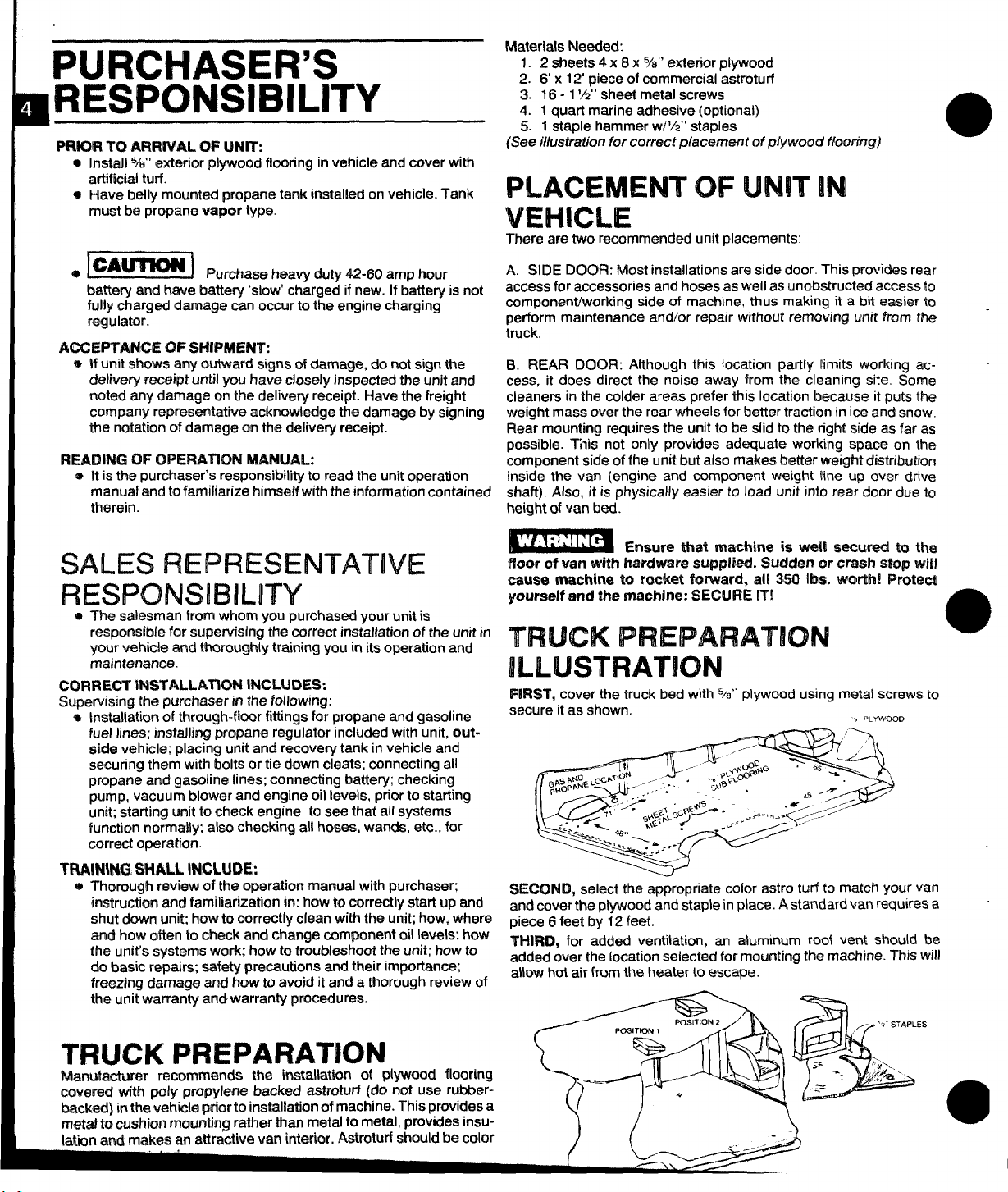

FIRST, cover the truck bed with 5A’ plywood using metal screws to

secure It as shown.

SECOND, select the appropriate color astro turf to match your van

and cover the plywood and stapie in place. A standard van requires a piece 6 feet by 12 feet.

THIRD, for added ventilation, an aiummum roof vent should be

added over the location selected for mounting the machine. This will

allow hot air from the heater to escape.

PLYWOOD

,,

Es

TRUCK PREPARATION

Manufacturer recommends the installation of plywood flooring

covered with poly propylene backed astroturf (do not use rubber-

b&cked) inthe vehicle priorto installation of machine. This provides a

metal to cushion mourrtina rather than metal

la~o~ and makes an attra~tive van interior. Astroturf should be color

to metal, provides insu-

L---

--

--

o

PROPANE TANK LOCATION

Either the 10 gallon or 16.5 gallon propane tank will fit this location.

Have your local propane dealer install the tank you select and purchase. The machine will come with the proper propane regulator.

(Tank must have vapor outlet).

@

Do not use a portable propane tank inside the

truck or van. Besides being dangerous it is unlawful in most states.

MACHINE

SPECIFICATIONS

SPECIFICATIONS:

FRAME:

WEIGHT: 475 Pounds.

18” W, 46” L, 33” H. Steel Wkh Baked-On Epoxy

Finish.

la

.

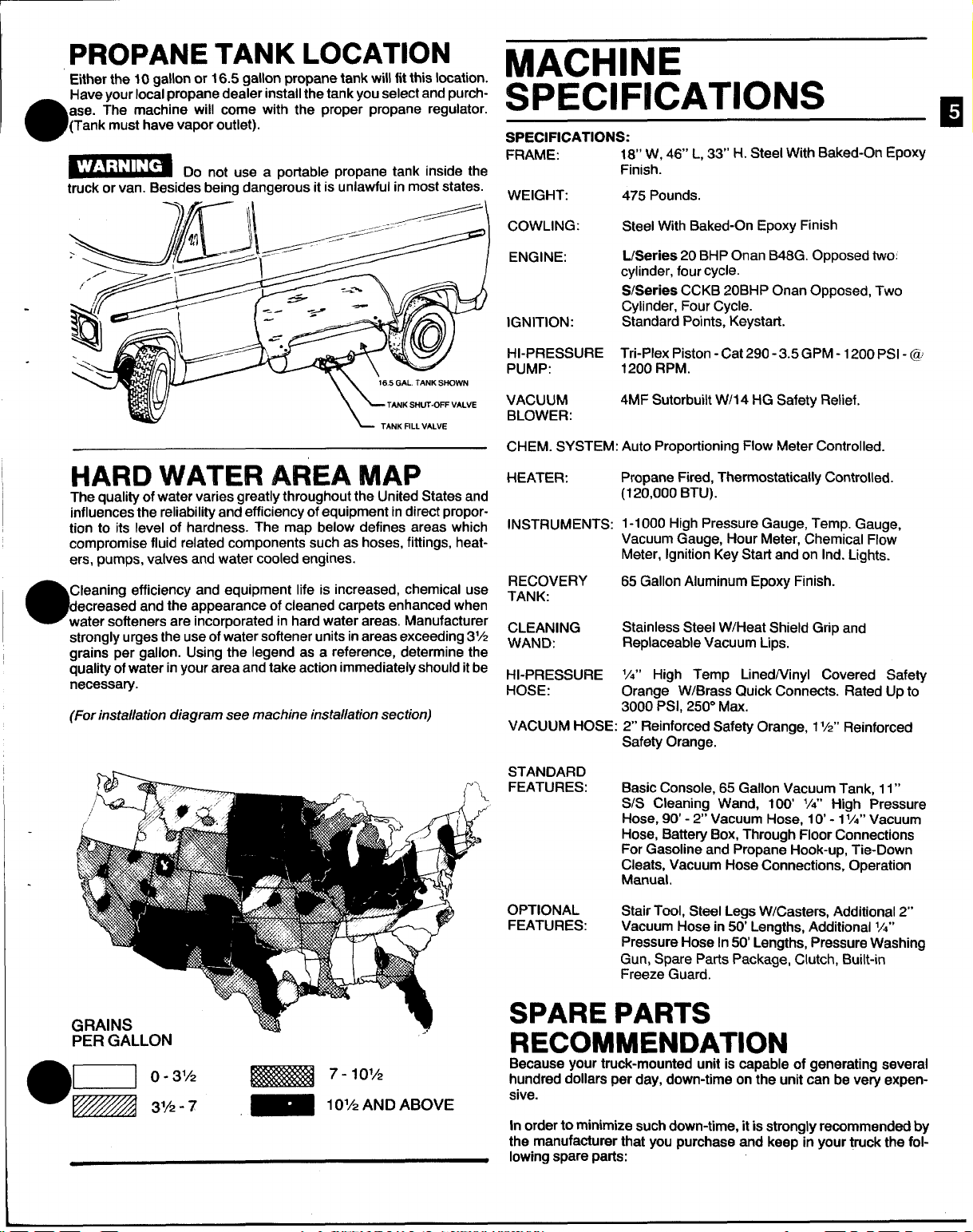

HARD WATER AREA MAP

The quality of water varies greatly throughout the United States and

influences the reliability and efficiency of equipment

tion to its level of hardness. The map below defines areas which

compromise fluid related components such as hoses, fittings, heaters, pumps, valves and water cooled engines.

Cleaning efficiency and equipment life is increased, chemical use

e

ecreased and the appearance of cleaned carpets enhanced when

water softeners are incorporated in hard water areas. Manufacturer

I StrOnglyurges the use OfWater SOftenerUnitSinareas exceeding 3%

grains per gallon. Using the legend as a reference, determine the

quality of water in your area and take action immediately should itbe

necessary.

(For installation diagram see machine installation section)

indirect propor-

COWLING:

ENGINE:

IGNITION:

HI-PRESSURE Tri-Plex Piston - Cat 290 -3.5GPM -1200 PSI - @

PUMP:

VACUUM

BLOWER:

CHEM. SYSTEM: Auto Proportioning Flow Meter Controlled.

HEATER:

INSTRUMENTS: 1-1000 High Pressure Gauge, Temp. Gauge,

RECOVERY 65 Gallon Aluminum Epoxy Finish.

TANK:

CLEANING

WAND:

HI-PRESSURE

HOSE:

VACUUM HOSE: 2 Reinforced Safetv Oranae. 1%“ Reinforced

Steel With Baked-On Epoxy Finish

L/Series 20 BHP Onan B48G. Opposed two!

cylinder, four cycle.

S/Series CCKB 20BHP Onan Opposed, Two

Cylinder, Four Cycle.

Standard Points, Keystart.

1200 RPM.

4MF Sutorbuilt W/l 4 HG Safety Relief.

Propane Fired, Thermostatically Controlled.

(120,000 BTU).

Vacuum Gauge, Hour Meter, Chemical Flow

Meter, Ignition Key Start and on Irrd.Lights.

Stainless Steel W/Heat Shield Grip and

Replaceable Vacuum Lips.

‘/,” High Temp LinedNinyl Covered Safety

Orange W/Brass Quick Connects. Rated Up to

3000 PSI, 250° Max.

Safety Orange. - “

~E”E--6-ALL0hI

STANDARD

FEATURES:

OPTIONAL

FEATURES:

-.

..

Basic Console, 65 Gallon Vacuum Tank, 11”

S/S Cleaning Wand, 100

Hose, 90’- 2“ Vacuum Hose, 10- 11/4”Vacuum

Hose, Battery Box, Through Floor Connections

For Gasoline and Propane Hook-up, Tie-Down

Cleats, Vacuum Hose Connections, Operation

Manual.

Stair Tool, Steel Legs W/Casters, Additional 2“

Vacuum Hose in 50’ Lengths, Additional 1/,”

Pressure Hose In 50’ Lengths, Pressure Washing

Gun, Spare Parts Package, Clutch, Built-in

Freeze Guard.

‘/4” High Pressure

RECOMMENDATION

Because your truck-mounted unit is capable of generating several

hundred dollars per day, down-time on the unit can be very expensive.

In order to minimize such down-time, it is strongly recommended by

the manufacturer that you purchase and keep in your truck the fol-

lowing spare parts:

QwwTm

2

1

B

a

1

1

1

2

1

1

6

1

1

1

1

1

PAFITNW4HER IXSCFWJTN2N

Engine Spark Plug

000-078-01!5

000-078-024

000-078-034

000-076-007

000-049-028

000-078-001

000-078-004

000-049-023

000-052-050

000-052-051

000-052-052

000-0!52-053

5L3WII-VL

Flow Meter Kit

Wand Valve Plunger Kit

Press. Bypass Valve Kit

Spray Jet 8008E

Recovery Tank Filter Elag

Cat 290 Short Cup Kit

Standard

Cat 290 Hot Cup Kit

(C)ptional)

Screen Garden l-lose

440 Male Quick Connect

440 Female Qwck Connect

660 Male Quick Connect

660 Female Qwck Connect

Belt, Pump Drive.

5L390tl’s

PARTS ORDERS

To expedite you?’parts rwmds,please call your sales representative.

in most instances, he either stocks or has access to parts through a

regional service center.

in the event parts are unavailable iocally, contact the factory and coordinate your needs. {fthis becomes n@cessary, always indicate the

method of shipment you desire, i.e. U.P.S., U.P. S. Blue Label, Air

Freight, Air Express, etc..

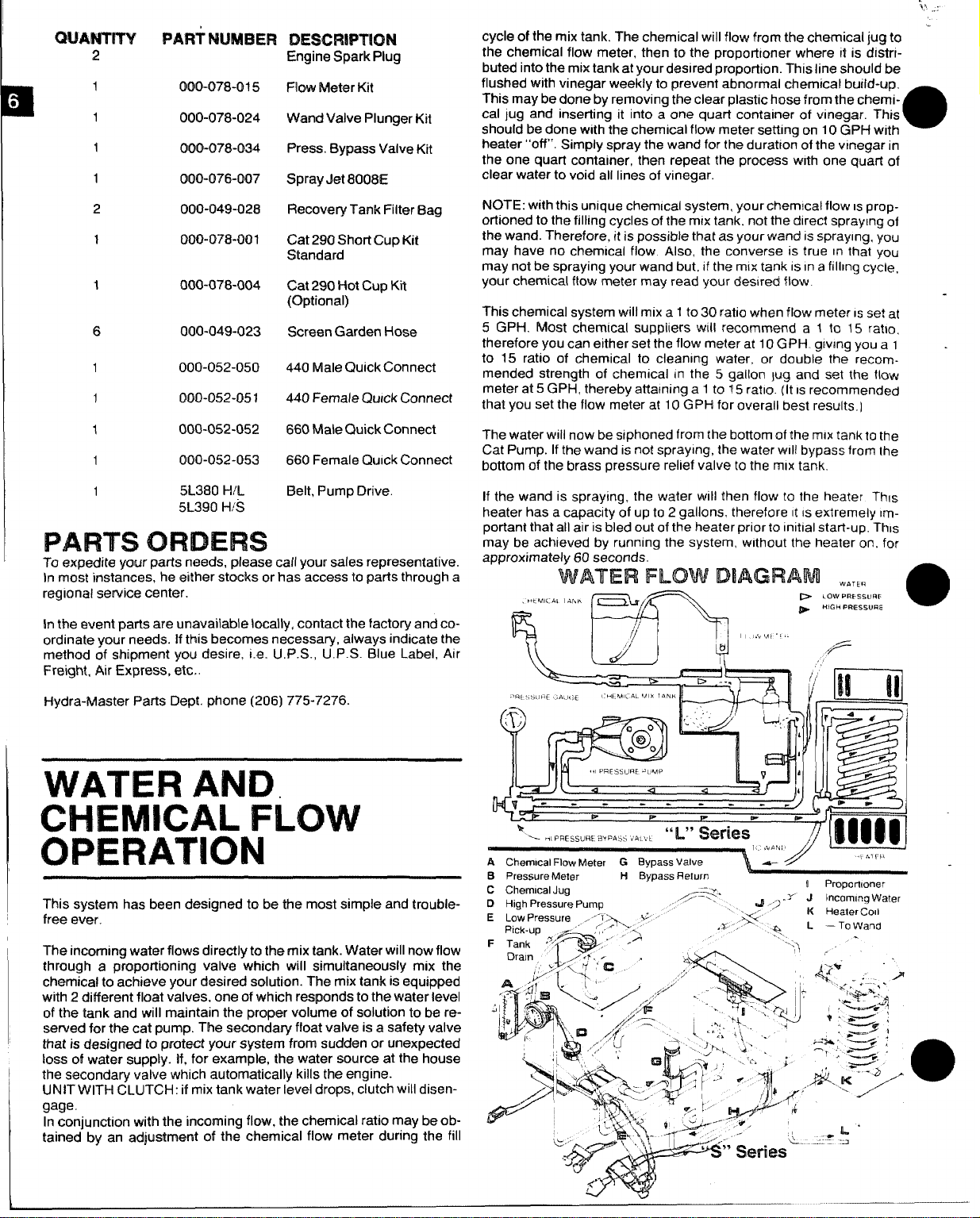

cycle of the mix tank. The chemical will flow from the chemical jug to

the chemical flow meter, then to the proporhoner where it is distributed into the mix tank at your desired proportion. This line should be

flushed with vinegar weekly to prevent abnormal chemical budd-up.

This may be done by removing the clear plastic hose from the chemical jug and inserting it into a one quart container of vinegar. This

should be done with the chemical flow meter setting on 10 GPf-1with

heater “off’. Simply spray the wand for the duratfon of the vinegar in

the one

clear water to void all lines of vinegar.

NOTE: with this unique chemical system, your cbem~cal flow

ortioned to the fillingcycles of the m!x tank. not the direct spraying of

the wand. Therefore, it is possible that as your wand ISspraying, you

may have no chemical flow Also, the converse is true m that you

may not be spraying your wand but. If the mix tank ISIn a filhngcycle.

your chemical flow meter may read your desired flow

This chemical system will mix a 1 to 30 ratio when flow meter

5 GPH. Most chemical suppliers will

therefore you can either set the flow meter at 10 GPH gkung you a 1 .

to 15 ratio of chemical to cleaning water. or double the recommended strength of chemical In the 5 gallon Jug and set the flow

meter at 5

that you set the flow meter at 10 GPi-i for overall best results. ]

The water will now be siphoned from the bottom of the mlx tank to the

Cat Pump. Ifthe wand is not spraying, the water WIIIbypass from the

bottom of the brass pressure rellef valve to the mix tank.

If the wand is spraying, the water will then flow to the heater Thm

heater has a capacity of up to 2 gallons, therefore If ISextremely im-

portant that all air is bled out of the heater prior to initial start-up. This

may be achieved by runnlnclthe system, without the heater on. for

aptiroximately 60 seconds. - -

quart container, then repeat the process with one quart of

IS prop-

IS set at

recommend a 1 10 15 ratio,

GPH, thereby attaining a 1 to 15 ratio. (It ISrecommended

m

WATER FLOW DIAGRAM .,,,,,

a

Fik”(c””” m E “=’

.

I-lydra-fvlaster Parts Dept. phone (206) 775-7276.

WATER AND

CHEMICAL FLOW

OPERATION

This system has been designed to be the most simple and troublefree ever.

The incoming water flows directly to the mix tank. Water will now flow

through a propcmtirmingvalve which will simultaneously mix the

cfwwnicalto achieve your desired solution. The mix tank is equipped

with 2 different float valves, one of which responds to the water level

of the tank and will maintain the proper volume of solution to be reserved for the cat pump.

that is designed to protect your system from sudden or unexpected

loss of water supply. If, for example, the water source at the house

the secondary valve which automatically kills the engine.

IJN!T W ITH CLUTCH: if mix tank water level drops, clutch will disengage.

In conjunction with the incoming flow, the chemical ratio maybe obtained by an adjustment of the chemical flow meter during the fill

The secondary float valve is a safety valve

A

. 1 ‘“’AN //

B

c

D

E

F

o

I

,.

GENERAL

INFORMATION FOR

a

CAT PUMP REPAIR

As you remove your discharge manifold, there is a set of3 check valves (which usually fall out during dis-assembly). If the surfaces of

these check valves are dirty, or show signs of chemical build-up, itis

probable that they would remain open causing pressure loss or pulsation. Upon inspecting the valves, make sure that the teflon buttons

in the valve spring retainers are still itact. Also examine the discharge manifold. Look for problems such as cracks, chemical buildup or warpage due to freezing. Ifthis discharge manifold iswarped, it

will cause the check valves to stick and will result in loss of pressure.

HIGH PRESSURE PUMP

The Cat pump cups are often the source of pressure loss. Upon in-

spection they may appear melted or torn, but often they will look

good. Replace them anyway. There is no sure method of visually

specting the cups. Hydra-Master recommends changing cups

whether they look good or not.

Anytime your pump is being dismantled, Hydra-Master recommends

replacement of all ‘o’ rings and seals. This is merely a convenience

to the customer to make sure that the Cat pump is in top operating

condition.

The prrrm-a-lube seals located within the intake manifold will allow

air to enter the pump if they are worn. Again, it is difficult to visually

pinpoint a defective prrrm-a-lube seal. Replace them all.

Within the piston sleeve cylinders there are 6 ‘o’ rings that are about

1/4the size of a penny. If these ‘o’ rings are bad, water will be pumped

back into the oil. If this has occured the oil will raise in level and will

a

appear milky. If you are unable to repair seals right away, change oil

frequently. Repair the pump as soon as possible so as to not damage bearing or connecting rods.

Repairing of Cat pumps is not a difficulttask. However, before disassembling make sure you have the proper parts required,

1- short (or hot) cup kit

6- piston sleeve ‘o’ rings

3- Prrrm-a-lube seals

1- bottle Cat oil

Read instructions thoroughly, supplied in the Cat pump manual,

prior to disassembly and follow directions as stated. Oil all seals

thoroughly prior to installation. (Remember, a newly scarred seal is

no better than one you just took out.)

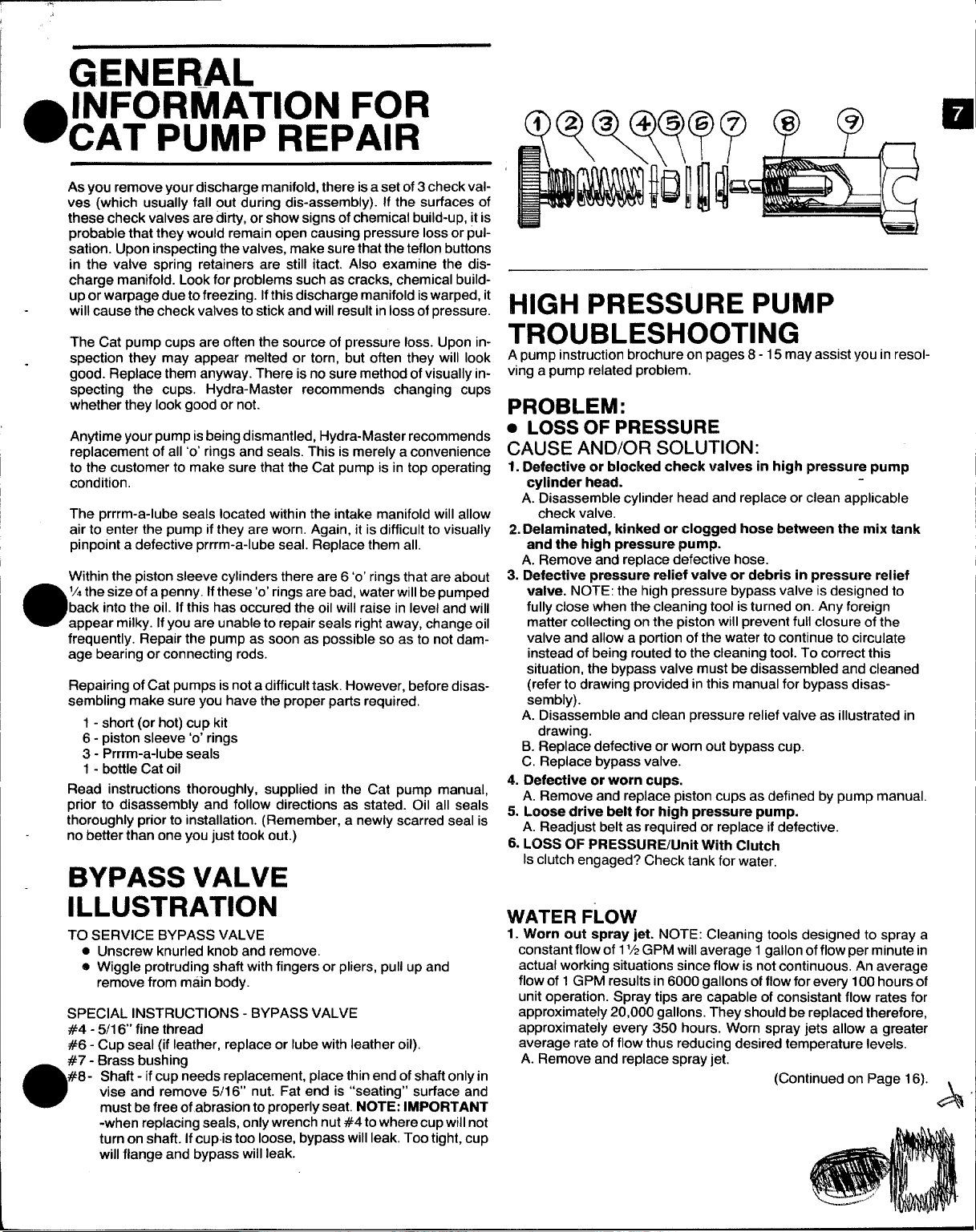

BYPASS VALVE

TROUBLESHOOTING

A pump instruction brochure on pages 8-15 may assist you m resolving a pump related problem.

in-

PROBLEM:

● U)ss OF PRESSURE

CAUSE AND/OR SOLUTION:

1. Defective or blocked check valves in high pressure pump

cylinder head.

A. Disassemble cylinder head and replace or clean applicable

check valve.

2. 13elarnirrated, kinked or clogged hose between the mix tank

and the high pressure pump.

A. Remove and replace defective hose.

3. Defective pressure relief valve or debris in pressure relief

valve. NOTE: the high pressure bypass valve is designed to

fully close when the cleaning tool is turned on. Any foreign

matter collecting on the piston will prevent full closure of the

valve and allow a portion of the water to continue to circulate

instead of being routed to the cleaning tool. To correct this

situation, the bypass valve must be disassembled and cleaned

(refer to drawing provided in this manual for bypass disas-

sembly).

A. Disassemble and clean pressure relief valve as illustrated in

drawing.

B. Replace defective or worn out bypass cup.

C. Replace bypass valve.

4. Defective or worn cups.

A. Remove and replace piston cups as defined by pump manual.

5. Loose drive belt for high pressure pump.

A. Readjust belt as required or replace if defective.

6. LOSS OF PRESSURE/Unit With Clutch

Is clutch engaged? Check tank for water,

ILLUSTRATION

TO SERVICE BYPASS VALVE

o Unscrew knurled knob and remove.

o Wiggle protruding shaft with fingers or pliers, pull up and

remove from mtin body.

SPECIAL INSTRUCTIONS - BYPASS VALVE

#4 - 5/16“ fine thread

#6 - Cup seal (if leather, replace or lube with leather oil)

#7 - Brass bushing

#8- Shaft - ifcup needs replacement, place thin end of shaft only in

a

vise and remove 5116’ nut. Fat end is “seating” surface and

must be free of,abrasion to properly seat. NOTE: IMPORTANT

-when replacing seals, only wrench nut #4to where cup willnot

turn on shaft. If cupis too loose, bypass will leak.

will flange and bypass will leak.

WATER FLOW

1. Worn out spray jet. NOTE: Cleaning tools designed to spray a

constant flow of 11/2GPM will average 1 gallon of flow per minute in

actual working situations since flow is not continuous, An average

flow of 1 GPM results in 6000 gallons of flow for every 100 hours of

unit operation. Spray tips are capable of consistent flow rates for

approximately 20,000 gallons. They should be replaced therefore,

approximately every 350 hours. Worn spray jets allow a greater

average rate of flow thus reducing desired temperature levels.

A. Remove and replace spray jet.

(Continued on Page 16). I

Too tight, cup

k

4%

SPECIFUCA-V’IONS

Vdurnsz

Discharge Pmzss’ure

Maximum Irmlet!%3ssum

RPM .............................................................................................................................

Bore

W roktr

Crankcase Capacity

Maximum Fluid Temperature

Inlet Port (1)

Dischar e Port (2)

Pulley

Shaft Diametm

we6ght

Dimensions

This Cat @ump (“product”) is warrantmf by the manufacturer to be

fmm horn def~cfs in workrnanahip and material tor one year

rnanufacturrw’s shipment. This warranty is Ilmitod to repair.

date d

kq or replacing products which manufacturer’s inveatlgation

shows were defecthw at the time of

All pmfuct$ sub @et to this warranty shall bo

rrrpalr“orraplacainermt.

tion,-

Tha axpmso warranty $@tforth herein Is in

Ws, axpress or

of merchantability or fitness for a particular purpose and all such

warrarrtles am hamby disclaimed and excluded by the marrufac.

turer. Rr!pah or mphcmtmt of Clefocilwr products as provided

atwm is tkmSOIQand exciuskm ramady provided hereunder and the

manufacturer shall not be ilable for any further kzsa, darma as or

expenaea, including [rmidenttd or consequential damages, d rwctly

or Indlrectiy adsirig horn the ssrieor use of this product.

Th}s warranty is

...........................................................................................................................

...................................................................................................... 1200

...................................................................................8.5 to + 40 Psl

....................................................................................................................................O.78O''

................................................................................................................................O.472''

............................. ..................................................................................... 1/2” N PT

ouniing

$

............................................................................................................................l 2.1 Ibs.

.......................................................................................................

..........................................................................................................

..........................................................................................

.........................................................................................................3/8'' N

........................................................................................................

..................................................................................................................O.65O''

CAT PUMP

from

ahlpment by the manufacturer.

nneaoolis, Mhmesot a 55430, U.S.A. for examina-

/PumK3sCorp., M

$mmplld, inciuding without Iimitatlcm any warranties

subject to the following warranty conditions

returned F.O.B. Cat

lieu of all crtherwarran.

f

CNJTIQN: CAT PUMPS are positive displacement pumps. Therefore,

a properly designed pressure reliet mechanism MUST be ~nstalled in

the discharge piping. Failure to Install such relief mechanism could

result in personal injury or damage to the pump or system. Cat

Pumps Corporation does not assume any liability or responsibility

for the operation of a customer’s high pressure system.

U.S. Measure

3.5

GPM

Psl

1200 RPM

10oz.

160” F

Either Side

10,6 x9,1 x5.7”

PT

(268 x 230x ?46mm)

(1200 RPMj

(20mm)

(12mm)

(0.3 L)

(71 “c)

(1/2” NPT)

(3/8”’ N PT)

(Either S!de)

(1~5:5mk~~

WARRANTY

IMPORTANT CQNDIT’IONS

LUBRICATION — 1111crankcase to dot on 011 gauge wtndow per ?.pecrilcat#ons wtlh CaI

Pump 011or equllvalent SAE 40 welghl hydraultc 011wtth antlwear and rust ,nhtb)tor ad.

dd!ves. Change Indlal 11(1aller 50 hour run., n period Chna@e 011every three momhs or aI

500 hour !ntewals thereafter Prrrrrm.a.lube seals need no Iubrrcatmn Blue dot seals and

wtcks must receive three drops of Cat Pump 011 per iwck every 50 hours of Operatmn

LU~131CAT10NIS THE EASIEST, fAOSTEFFICIENT AND LEAST EXPENSIVE OF

(3000

PREVENTATIVEMAINTENANCE.

RPMandPRESSURE— Pumpoperaf!anmustbew,lh!n WW andprm$me

Pressure retlef

00 NOT PUMP ACIOS OR ASRASIVE FLuIDS W,thIbIS Umf Consul!cat PurnPsfor ado,

teonalunformat[onon quesho”able fl”lds

FREEZIMGCONDITIOPJS-

valve rn”w be m~talled

Pumpmmt b%protectedTromfr~~zln~ Condltmns

USEOF OTliER TtiAfIJCAT PLJf4PPAI?TS0$1

THEIR E13LflVALElYTvOI12ST(4EWARRANTY

speed Icat Ions

Products described hereon ace covered by one or more 01 lhe follow!ng U S Pal@nfS 3S58244 3652188 3809508 3920356 ano 3930:56

> ---- -t-4

~;uwmp~=

&

,., .,,?,,,+,! ,,, Roslocker Strasse 9

P O 60X 885 MINNEAPOLIS MN 55440

Phone (6121 7805440 @ Telex 29-0276

CAT PuMPS INTERNATIONAL S A

N V

!3 2000 AntWelD 8@qlUM

9

Hatmon#eslraal 29

CH 6300 ZUG Switzerland

CAT PUMPS OEUTSCHLAND GmbH

6200 Wtesbaden B,erstadt

Lofelohtihe 5

0

West Germany

CAT PUMPS (U K I LTD

@

17A U,ngs Road Fleel

Hampshire GU13 9AA

Englana

Distrlbufed By

HYDRA MASTER CORP.

20309- 64th AvEm

LYNNWOOD, WA. 98036

w.

@

0.20

I

I

I

t

5.73

145.5)

3/8’

\

~3.15[80)d

_——

1-

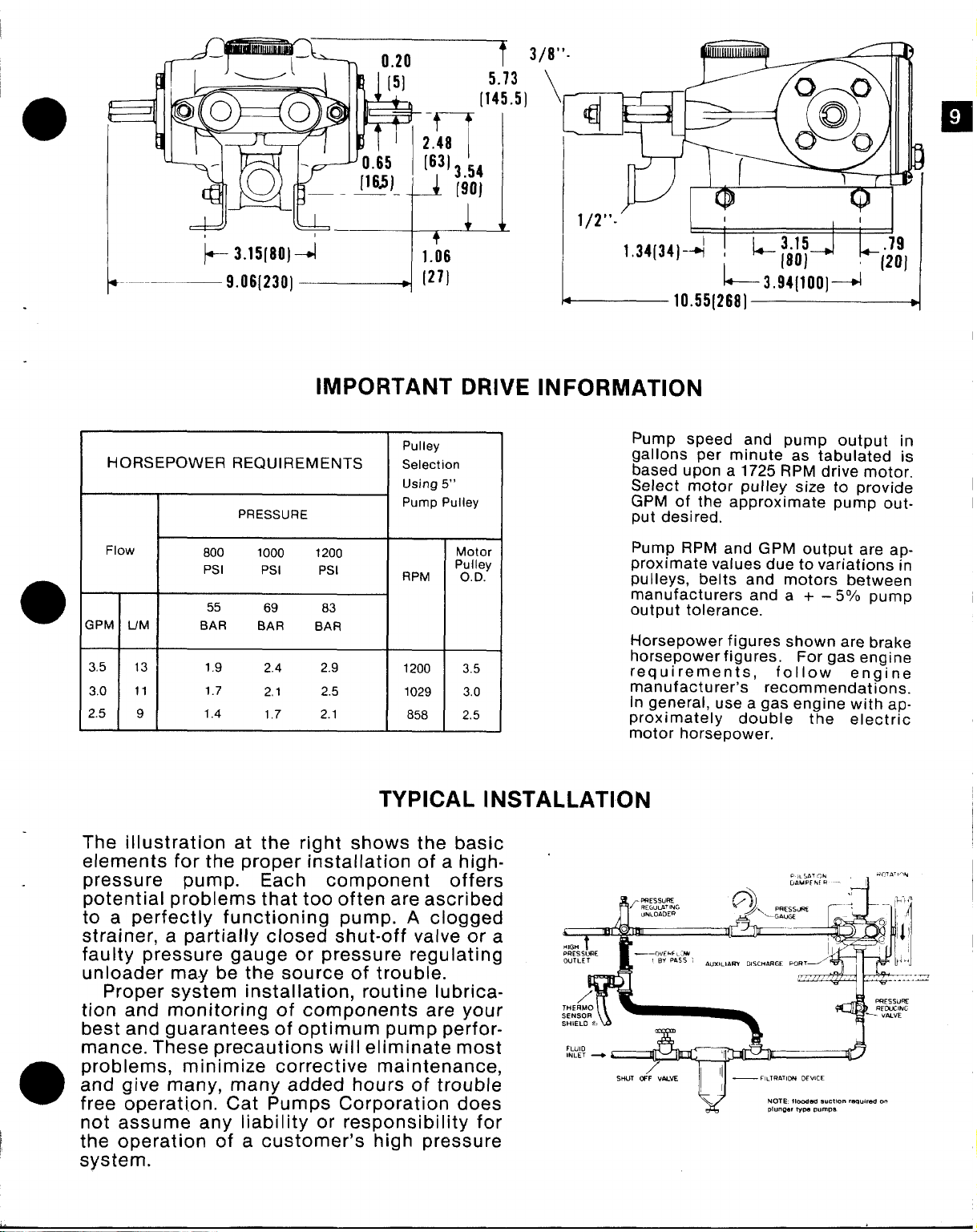

HORSEPOWER REQUIREMENTS

Flow

M IJM

3.5

I

3.C

2.5

[

–9.06123014:$

PRESSURE

800

Psl

55

BAR BAR

13

11

9

1.9

1.7

1.4

1000

Psl

69 83

2.4

2.1

1.7 2.1 858 2.5

IMPORTANT DRIVE

Pulley

Selection

Using 5“

Pump Pulley

1200

Psl

BAR

2.9 1200

2.5

RPM

1029 3.0

Motor

P:lH&y

3.5

“2’’-:.34(34,-+=7;,

INFORMATION

Pump speed and pump output in

gallons per minute as tabulated is

based upon a 1725 RPM drive motor.

Select motor pulley size to provide

GPM of the approximate pump output desired.

Pump RPM and GPM output are approximate values due to variations in

pulleys, belts and motors between

manufacturers and a + –

output tolerance.

Horsepower figures shown are brake

horsepower figures. For gas engine

requirements,

manufacturer’s recommendations.

In general, use a gas engine with approximately double the electric

motor horsepower.

W*k~

follow

5°/0 pump

engine

1

TYPICAL INSTALLATION

The illustration at the right shows the basic

elements for the proper installation of a high- ‘

pressure pump. Each component offers

potential problems that too often are ascribed

to a perfectly functioning pump. A clogged

strainer, a partially closed shut-off valve or a

faulty pressure gauge or pressure regulating

unloader may be the source of trouble.

.._T

Proper system installation, routine lubrication and monitoring of components are your

best and guarantees of optimum pump performance. These precautions will eliminate most

problems, minimize corrective maintenance,

and give many, many added hours of trouble

a

free operation. Cat Pumps Corporation does

not assume anv Iiabilitv or res~onsibilitv for

the operation 6f a cus~omer’s high pres-sure

system.

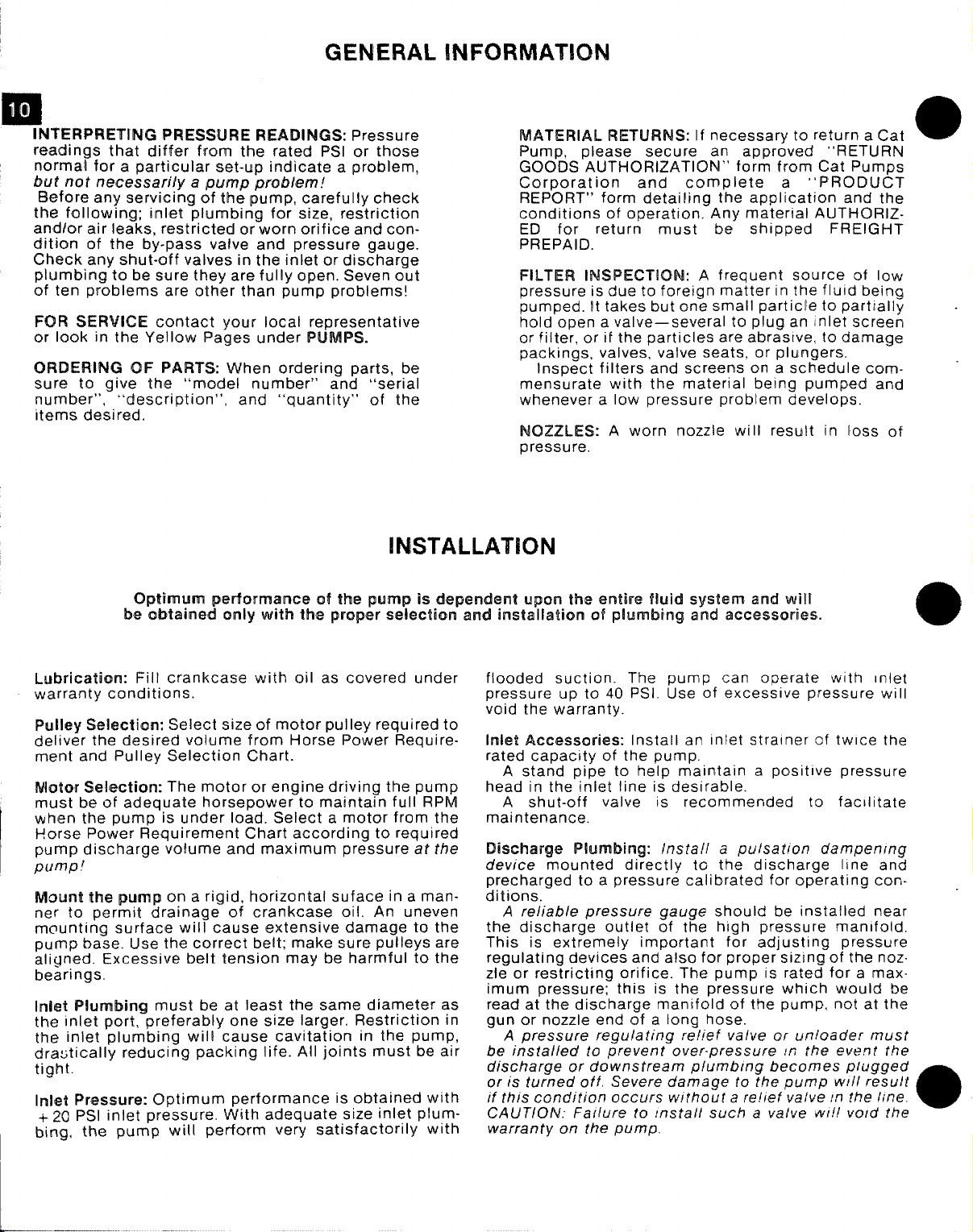

GENERAL INFORMATION

‘a

m

INTERPRETING PRESSURE READINGS: Pressure

readings that differ from the rated PSI or those

normal for a particular set-up indicate a problem,

buf not

Before any servicing of the pump, carefully check

the following; inlet plumbing for size, restriction

andlor air leaks, restricted or worn orifice arid condition of the bypass valve and pressure gauge.

Check any shut-off valves in the inlet or discharge

plumbing

of ten problems are other than pump problems!

FOR SERVICE contact your local representative

or look

QRDERING

sure to give the

number”,

items desired.

necessarily a pump problem!

to be sure they are fully open. Seven out

in the Yellow Pages under PUMPS.

CtF PARTS: When ordering parts, be

“model number” and “serial

“description”, and “quantity” of the

MATERIAL RETURNS: If necessarv to return a Cat

Pump, please secure an approved “RETURN

GOODS AUTHORIZATION” form from Cat Pumps

Corporation

REPORT” form detailing the application and the

conditions of operation. Any material AUTHORIZ-

ED for return must be shipped FREIGHT

PREPAID.

FILTER INSPECTION: A frequent source of low

pressure

pumped. It takes but one small particle to partially

hold open a valve—several to plug an Inlet screen

or filter, or if the particles are abras~ve, to damage

packings, valves, valve seats, or plungers.

Inspect filters and screens on a schedule commensurate with the material be]ng pumped and

whenever a low pressure problem develops.

NOZZLES: A worn nozzle will result

pressure.

and complete a

is due to foreign matter in the fluid being

“PRODIJCT

in loss of

e

INSTALLATION

Optimum performance of the pump is dependent upon the entire fluid system and will

obtained only with the proper selection and installation of plumbing and acccw3cwit35.

be

Lubrication: Fill crankcase with oil as covered under

warranty conditions.

Pulh?y %?hacticm: Select size of motor pulley required to

deliver the desired voiume from Horse Power Require-

ment and Pulley Selection Chart.

Motor Selection: The motor or engine driving the pump

must be of adequate horsepower to maintain full RPM

when the pump is under load. Select a motor from the

Horse Power Requirement Chart according to required

pump discharge volume and maximum pressure at the

pump!

Mount

ner to permit drainage of crankcase oil. An uneven

mounting surface will cause extensive damage to the

pump base. Use the correct belt; make sure pulleys are

aligned. Excessive belt tension may be harmful to the

bearings.

Inbst Plumbing must be at least the same diameter as

the inlet port, preferably one size larger, Restriction in

the inlet plumbing will cause cavitation in the pump,

drastically reducing packing life. All joints must be air

tight.

Inlet Pressure: Optimum performance is obtained with

+ 20 PSI inlet pressure. With adequate size inlet plum-

bing, the pump will perform very satisfactorily with

the pump on a rigid, horizontal suface in a man-

flooded suction. The ~um~ can o~erate with Inlet

pressure up to

void the warranty.

Accessories: Install an inlet strainer of twice the

Inlet

rated capacity of the pump.

A stand ~iDe to helo maintain a ~ositive Dressure

head in the’i~let line is desirable. ‘

A shut-off valve is recommended to facilitate

maintenance.

Discharge Plumbing: Install a pu/saf[on dampen(ng

device mounted directly to the discharge I!ne and

precharged to a pressure calibrated for operating con- -

ditions.

A re/iab/e pressure gauge should be installed near

the discharge outlet of the high pressure manifold,

This is extremely important for adjust~ng pressure

regulating devices and also for proper sizing of the noz.

zle or restricting orifice. The pump is rated for a max-

imum pressure; this is the pressure which would be

read at the discharge manifold of the pump, not at the

gun or nozzle end of a long hose.

A pressure regulating relief valve or unloader must

be installed to prevent over-pressure In the event the

discharge or downstream piumblng becomes plugged

or is turned off Severe damage to the pump WIII result

it this condition occurs withour a relief va/ve /n the /(rre.

CAUTION: Fa{lure to /rrsta// such a valve WIII void the

warranty on the pump,

40 PSI. Use of excessive pressure will

a

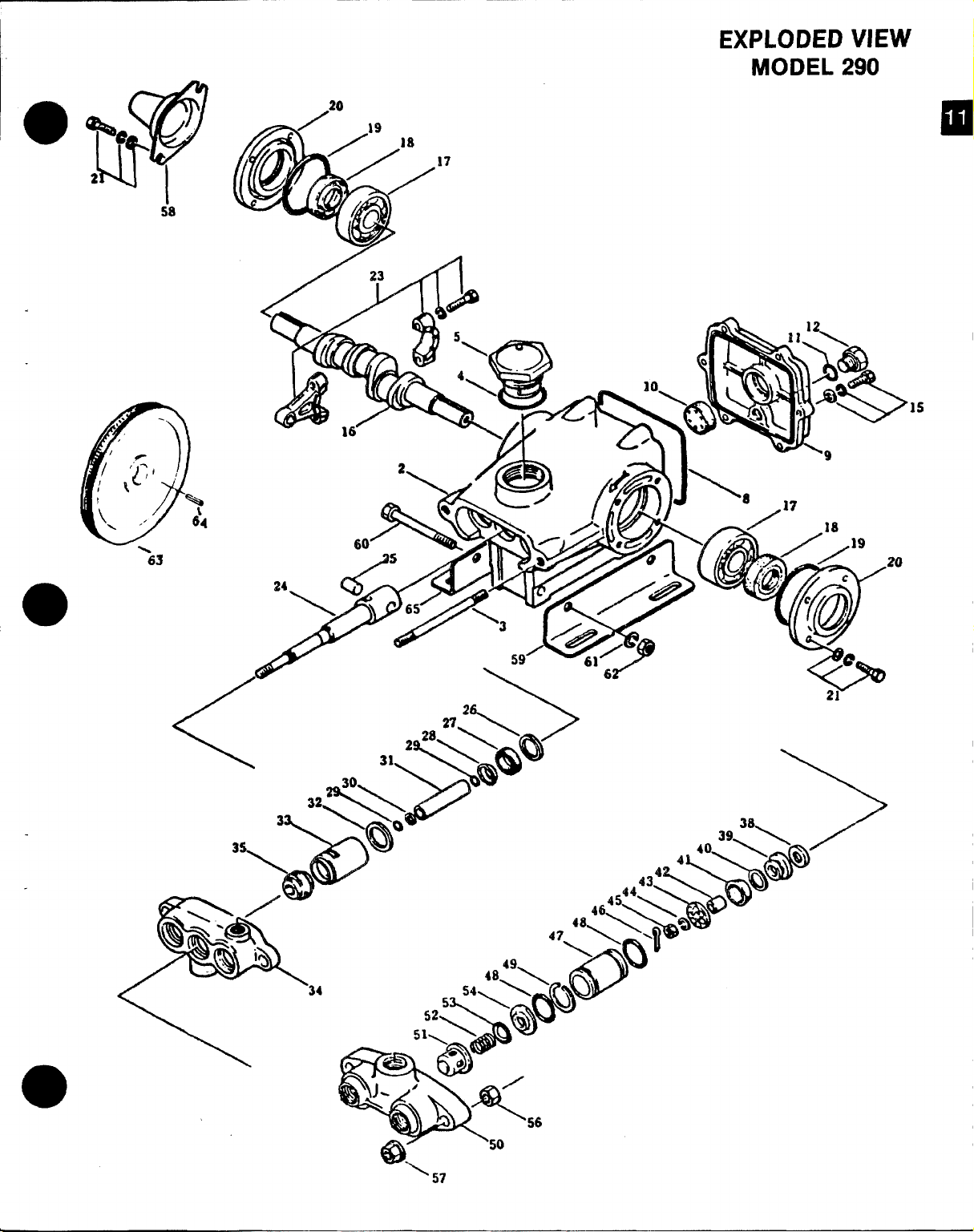

EXPLODED VIEW

m

MODEL 290

15

lTf!M

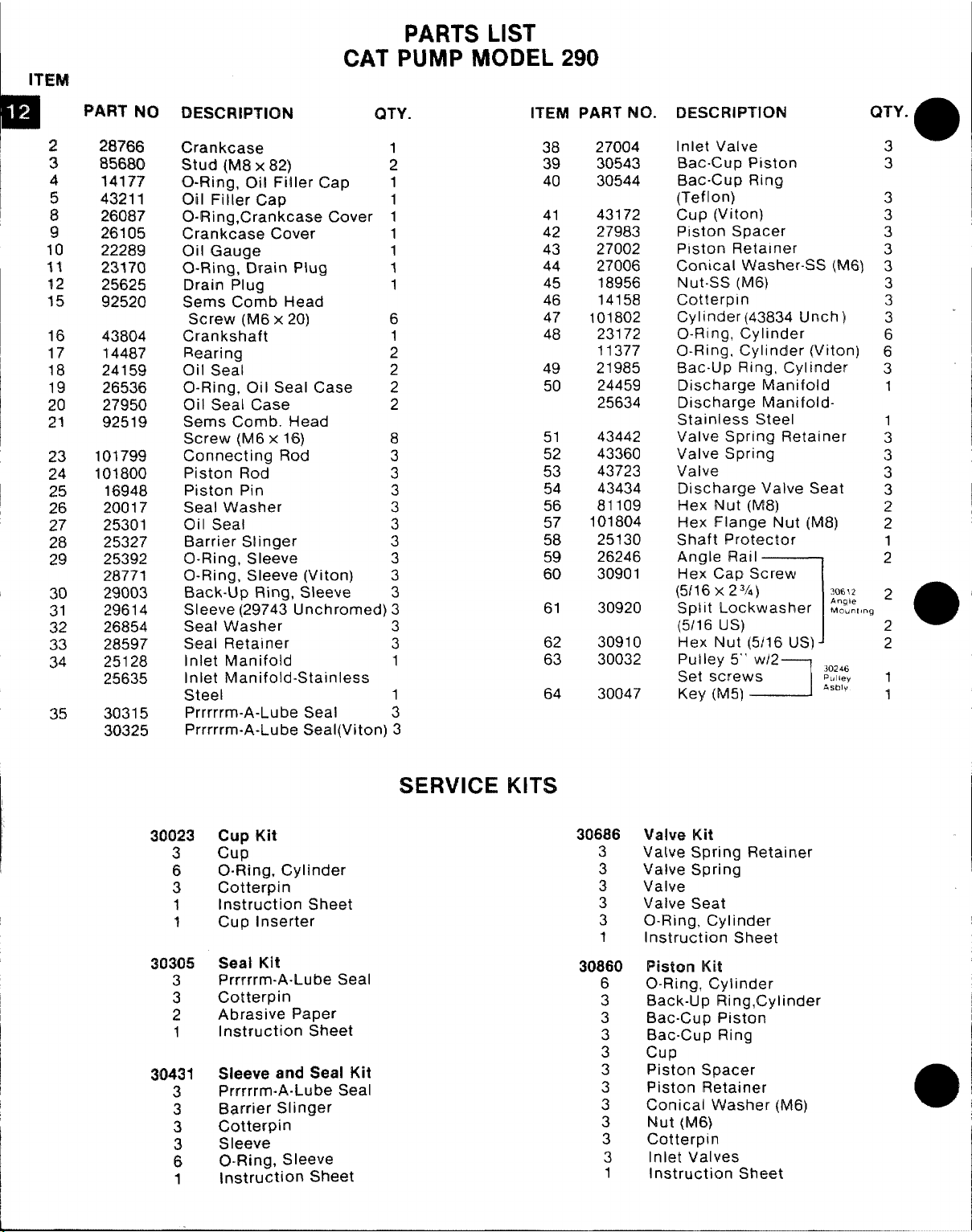

PARTS LIST

CAT PUMP MODEL 290

PART

2

3

4

5

8

9

10

11

12

15

16

17

18

19

20

21

23

24

I

25

26

27

28

29

30

31

32

33

34

35

28766

856ao

14177

43211

26087

26105

22289

23170

25625

92520

43804

14487

24159

26536

27950

92519

101799

101800

16948

20017

25301

25327

25392

28771

29003

29614

26854

28597

25128

25635

30315

30325

No

13ESCRIPTI(IN

Crankcase

stud (M8

X 82)

Q-Ring, oil Filler Cap

Oil Filler Cap

0-Fling, Crankcase Cover

Crankcase Cover

Oil Gauge

O-Ring, Drain Plug

Drain Plug

Serns Comb Head

Screw (M6 x 20)

Crankshaft

Rearing

Oil Seal

O-Ring, Oil Seal Case

Oil Seal Case

Serns Comb. Head

Screw (M6 x 16)

Connecting Rod

Piston Rod

Piston Pin

Seal Washer

Oil Seal

Barrier Slinger

O-Ring, Sleeve

O-Ring, Sleeve (Viton)

Back-LID Rina. Sleeve

Sleeve ~2974~’Unchromed) 3

Seal Washer 3

Seal Retainer 3

Inlet Manifold 1

Inlet Nfanifold-Stain less

Steel

Prrrrrm-A-Lube Seal ;

Prrrrrm-A-Lube Seal(Viton) 3

QTY.

6

1

2

2

2

2

8

3

3

3

3

3

3

3

3

3

ITEM PART NO

38

39

40

41

42

43

44

45

46

47

48

27004

30543

30544

43172

27983

27002

27006

18956

14158

101802

23172

11377

49

50

21985

24459

25634

51

52

53

54

56

57

58

59

60

61

62

63

64

43442

43360

43723

43434

81109

101804

25130

26246

30901

30920

30910

30032

30047

DESCRIPTION

Inlet Valve

Bat-Cup Piston

Bat-Cup Ring

(Teflon)

Cup (Viton)

Piston Spacer

Piston Reta!ner

Conical Washer-SS (Mf5)

Nut-SS (M6)

Cotterpin

Cylinder (43834 Unch)

O-fling, Cylinder

O-Ring, Cylinder (Viton)

Bat-Up Ring, Cylinder

Discharge Manifold

Discharge ManifoldStainless Steel

Valve Spring Retainer

Valve Spring

Valve

Discharge Valve Seat

Hex Nut (M8)

Hex Flange Nut (M8)

Shaft Protector

Angle Rail

Hex Ca~ Screw

(5/16x23/4)

Split I_ockwasher

:10612

Y/;:,,”g

(5/16 US)

Hex Nut (5/16 LIS)J

Pulley 5“ w/2

Set screws

Key (M5)

J

J0246

Pl,lte”

Asbly

Q-r’Y.

3

3

3

3

3

3

3

3

3

3’

6

6

3

1

1

3

3

3

3

2

2

1

2

2

2

2

1

1

e

m

30023 Cup Kit

cup

3

O. Ring, Cylinder

6

3 Cotterpin

Instruction Sheet

1

1

Cuo Inserter

30305 Seal

3

3

2

1

Kit

Prrrrrm-A-Lube Seal

Cotterpin

Abrasive Paper

Instruction Sheet

30431 Sleeve and Seal Kit

Prrrrrm-A-Lube Seal

3

Barrier Slinger

3

Cotterpin

3

Sleeve

3

O-Ring, sleeve

6

Instruction Sheet

1

SERVICE KITS

30686

3

3

3

3

3

1

30860

6

3

3

3

3

3

3

3

3

Valve Kit

Valve Spring Retainer

Valve Spring

Valve

Seat

Valve

O-Ring, Cylinder

Instruction Sheet

Piston Kit

0-Ring, Cylinder

Back-Up Ring, Cylinder

Bat-Cup Piston

Bat-Cup Ring

cup

Piston Spacer

Piston Retainer

YY(’%washer (ME)

3

Cotterpin

Inlet Valves

3

1

Instruction Sheet

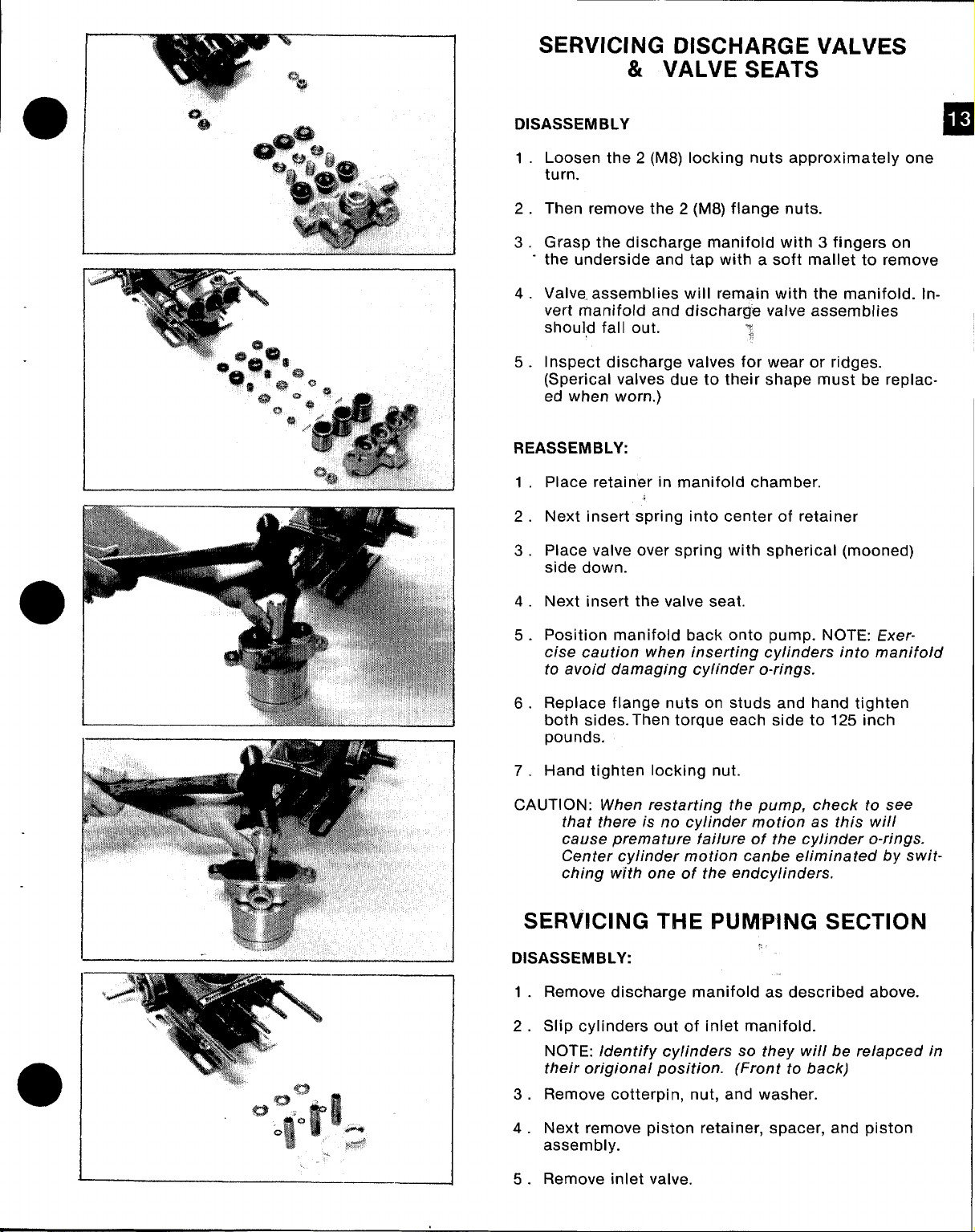

SERVICING DISCHARGE VALVES

&

VALVE SEATS

DISASSEMBLY

Loosen the 2

1.

turn.

2.

Then remove

Grasp the discharge manifold with 3 fingers on

3.

the underside and tap with a soft mallet to remove

Valve. assemblies will remain with the manifold. in-

4.

vert manifold and discharge valve assemblies

shoul,d fall out.

Inspect discharge valves for wear or rid~es.

5.

(Sperical valves-due to their shape mus; be replaced when worn.)

REASSEMBLY:

Place retainer in manifold chamber.

1.

Next insert spring into center of retainer

2.

Place valve over spring with spherical (mooned)

3.

side down.

Next insert the valve seat.

4.

(M8) locking nuts approximately one

the 2 (M8) flange nuts.

,~~

,~

Position manifold back onto pump. NOTE: Exer-

5.

cise caution when inserting cylinders into manifold

to avoid damaging cyiinder o-rings.

Replace flange nuts on studs and hand tighten

6.

both sides. Then torque each side to 125 inch

pounds.

Hand tighten locking nut.

7.

CAUTION: When restarting the pump, check to see

that there is no cylinder motion as this will

cause premature failure of the cylinder o-rings.

Center cylinder motion canbe eliminated by switching with one of the endcylinders.

SERVICING THE PUMPING SECTION

DISASSEMBLY:

1.

Remove discharge manifold as described above.

Slip cylinders out of inlet manifold.

2.

NOTE: Identify cylinders so they will be relapced in

their origional position. (Front to back)

Remove cotterpin, nut, and washer.

3.

4.

Next remove piston retainer, spacer, and piston

assembly.

Remove inlet valve.

5.

Loading...

Loading...