Page 1

Ei’YDMkiI-C?AT/M

o

Page 2

TABLE OF CONTENTS

General Information

General information . . . . . .. . . . . . . . . . . . . . . . . . . . . . . .. . . . . 2

Howthe System Works . . . . . . . . . . . . . . . 2

Machine Specifications, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Spare Parts Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . ...2

Howto Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Parts Orders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purchaser’s Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Sales Representative’s Responsibility . . . . . . . . . . . . . . . . . . . . . . 3

Truck Preparation

Truck Preparation&illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Placement of Unitin Vehicle . . . . . . . . ., . . . . . . . . . . . . . . . . . . . . ...4

Machine installation . . . . . . . . . . . . . . .,, . . . . . . . . . . . . . . . . . . . . ...5

PropaneTank Location&Plumbing . . . . . . . . . . . . . . . . . . . . . 5

Water Softening

Hard Water Area Map& Water Softener . . . . . . . . . . . . . . . . . . . . 6

Hydra-Cat Operation

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning and Chemical Precautions . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning Stroke Procedure/Over-Wetting . . . . . . . . . . . . . . . . 8

Water and Chemical Flow Operation . . . . . . . . . . . . . . . . . . . . . . . 9

Water Flow illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9

Chemical Proportioning and Level Control illustration . . . . . . . . . 9

ChemicalTankTroubleShooting Guide . . . . . . . . . . . . . . . . . . . . 10

Valve Assembly illustration, . . . . . . . . . ., . . . . . . . . . . . . . . . . . ...11

Jet Assembly illustration . . . . . . . . . . . . . . . . . . 11

Wand Assembly illustration ...,..... . . . . . . . . . . . . . . . . . . . . . . 11

Stem Assembly illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bypass Valve &Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flow Water Trouble Shooting Guide.. . ...,................,,12

Vacuum System

Vacuum System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...13

Vacuum Flow illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,13

Vacuum Tank Filter Bags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...13

Blower Lubricant illustration ...,... . . . . . . . . . . . . . . . . . . . . . . ...13

Vacuum Blower Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...14

Vacuum Blower Lubrication...,,.. . . . . . . . . . . . . . . . . . . . . . . ...14

Vacuum BlowerTrouble Shooting Guide . . . . . . . . . . . . . . . . . . ...15

Heating System

Heating System information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...16

Heater Operating Instructions ...,. . . . . . . . . . . . . . . . . . . . . . . ...16

Heater Trouble Shooting Guide .,,... . . . . . . . . . . . . . . . . . . . . ...17

Cat Pump Model 290

Cat Pump Mode12900perating instructions , . . . . . . . . . . . . . ...17

Cat Pump Specifications . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . ...17

Cat Pump Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...18

General Information for Cat Pump Repair . . . . . . . . ...18

Piston Mode1290Exploded View &Parts List , . . . . . . . . . . . . ...19

Pumping Section Cutaway illustration . . . . . . . . . . . . . . . . . . . . ...20

Servicing the Pumping Section . . . , . . . . . . . . . . . . . . . . . . . . . . ...21

Servicing Sleeves and Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...21

Servicing Crankcase Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...21

Cat Pump Troubleshooting Guide . . . . . . . . . ...22.23

Hydra-Cat Electrical System

Electrical System Troubleshooting

HydraCat S/Series Electrical Diagram

Hydra-Cat M/Series Electrical Diagram

........ .......

. . . . . . . . . . . . . . .

,, . . . . . . . . . . . . .

CCKB Engine

Service Guide, Hydra-Cat S/Series. . . .

Specifications . . . . . . . . . . . . . . . . . . . . . .

Outof Service Protection . . . . . . . . . . .

Pre-Start . . . . . . . . . . . . . . . . . . . . . . . . .

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...26

Crankcase Breather illustration . . . . . . . . . . . . . . . . . . . . . . . . . . ...27

Spark Plug Gaplllustration ..,,... . . . . . . . . . . . . . . . . . . . . . . . ...27

Air Cleaner illustration . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . ...27

Oil Filter illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...27

Adjustments, Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...28

Engine Safety Precautions . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . ...28

Periodic Service Guide & Maintenance Schedule , . . . . . . . . . ...29

. . . . . . . . . . . .. . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Kohler Engine

Service Guide, Hydra-Cat M/Series . . . . . . . . . . . . . . . . ..3o

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...30

Periodic Maintenance.......,,.. . . . . . . . . . . . . . . . . . . . . . . . ...30

Oil . . . . . . . . . . . . . . . . . . . . . . . . . ,,, ,,. . ... ,,, . . . . . . ,,

Air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...31

Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...32

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...32

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...32

Cylinder Heads.................,,.. . . . . . . . . . . . . . . . . . ...33

Valve Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...33

Kohler Engine Trouble Shooting Guide ,, . . . . . . . . . . . . . . . . . ...34

Kohler Engine Carburetor

Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...35

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...35

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...35

Carburetor Troubleshooting Guide . . . . . . . . . . . . . . . . . . . ...37

Kohler Engine Lubrication System

Operation & Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...38

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . ., . . . . . . . . . . . . . . . . . ...38

Kohler Engine Electrical Systems

Systems and Components ...,.... . . . . . . . . . . . . . . . . . . . . . . ...39

Ignition System Trouble Shooting Guide . . . . . . . . . . . . . . . . . ...41

Spark Plug Condition Diagnosis., . . . . . . . . . . . . . . . . . . . . . . . ...42

Battery Charging System . . . . . . . . . ., . . . . . . . . . . . . . . . . . . . . ...43

Electric Starter illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..44

Trouble Shooting Guide, 15 Amp Battery Charging System . ..44

Maintenance

Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...45

Overall Careof Unit, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...45

Maintenance Log............,.. . . . . . . . . . . . . . . . . . . . . . . . ...46

Warranty

Warranty Information . . . . . . . . . . . . . . . . . . . . . .Inside back cover

24

24

24

25

25

25

25

26

30

Page 3

GENERAL INFORMATION

This manual contains installation and operation instructions as

well as information required for proper maintenance, adjustment

and repair of thki unit. Since the first and most important part of

repair work is the correct diagnosis of the trouble, a general

troubleshooting section and component manual troubleshooting

charts have been included for your convenience.

Unlike the garden tractor, Iawnmower and cement mixer, all having

one or two functions to perform, the truck-mounted carpet cleaning

plant has many functions to perform simultaneously.

● Engine has to run consistent RPM,

● Vacuum has to pull air and dirty water back from cleaning site.

* Water pump provides stable pra%sure at proper water flow for

cleaning.

● Chemical has to be injected into the water stream at the right

ccmsistency.

* Heater must maintain proper heat.

* Vacuum tank must store dirty water until drained.

As you can see, it is not just a turn key operation with only one

thing to worry about, Does it start?!

HOW THE SYSTEM WORKS

The water system takes incoming water at tap (low) pressure,

combines it with chemical from the chemical system automatically,

pumps it under high pressure through the heating system and out

to the cleaning tool. After being sprayed into the carpet being

cleaned, the water/chemical/soil solution is extracted by the

vacuum system and returned to the waste recovery tank.

As there is no guess work in the manufacture of these highly advanced cleaning plants, there must be none in preparing it to get

the job done in the field. It is the purpose of this manual to help you

properly understand, maintain and service your cleaning plant.

Follow the directions carefully and you will be rewarded with years

of profitable trouble-free operation.

it is imperative that no section be overlooked when preparing for

operation of this equipment.

The manufacturer uses this

symbol throughout the manual to

warn of possible injury or death.

This symbol is used to warn of

possible equipment damage.

MACHINE SPECIFICA~ONS

FRAME: 21 “W, 56”L, 34”H. Steel with Baked-on Epoxy Finish.

WEIGHT: 800 pounds.

COWLING: Steel with Baked-on Epoxy Finish.

ENGINE: M/Series 20 BHP Kohler M20 Electronic Ignition.

S/Series CCKB 20BHP Onan Opposed, Two Cylinder, Four

Cycle.

IGNITION: Standard Points (Kohler-Electronic), Keystart,

HI-PRESSURE PUMP: Tri-Plex Piston - Cat 290- 3.5GPM -1200

PSI - @ 1200 RPM.

VACUUM BLOWER: 4MF Sutorbuilt W/14 Hg Safety Relief.

CHEM. SYSTEM: Auto Proportioning Flow Meter Controlled.

HEATER: Propane Fired, Thermostatically Controlled.

(180,000 BTU).

INSTRUMENTS: 1-1000 High Pressure Gauge, Temp. Gauge,

Vacuum Gauge, Hour Meter, Chemical Flow Meter, Ignition Key

Start and on lnd. Lights.

RECOVERY TANK: 65 Gallon Aluminum Epoxy Finish,

CLEANING WAND: Stainless Steel w/Heat SMeld Grip and

Replaceable Vacuum Lips.

HI-PRESSURE HOSE: M“ High Temp LinedNinyl Covered,

Hose rated to 2750 PSI, Q.C. rated to 800 PSI

VACUUM HOSE: 2“ Reinforced, 11/2”Reinforced.

STANDARD FEATURES: Basic Console, 65 Gallon Vacuum Tank;

11” S1S Cleaning Wand; 100’ 2“ Vacuum Hose; 50’ 11~2Vacuum

Hose; 150’ H.P. M“ Solution Hose; Battery Box; Through Floor

Connections for Gasoline and Propane Hook-up; Tie Down

Cleats; Vacuum Hose Connections; Operation Manual; Steel

Legs with Casters; Clutch; Freeze Guard,

OPTIONAL FEATURES: Stair Tool, Additional 2“ Vacuum Hose in

50’ Lengths; additional

1/4” Pressure Hose in 50’ Lengths; Rotary

Jet Extractor.

SPARE PARTS RECOMMENDATION

Because your truck-mounted unit is capabte of generating several

hundred dollars per day, down-time on the unit can be very

expensive.

In order to minimize such down-time, it is strongly recommended

by the manufacturer that you purchase and keep in you truck the

following spare parts:

PART NO. DESCRIPTION

000-078-015

000-078-019

000-078-034

000-076-007

000-049-029 ‘

000-078-001

000-078-004

000-049-023

000-052-050 . .. .... .

000-052-051

000-052-052

000-052-053

000-11 -)6- 04?I

------ ---

010-022

010-017

Flow Meter Kit

Wand Valve Plunger Kit

Pressure Bypass ~alve Kit

Soray Jet 8008E

Recovery Tank Filter Ba~

Cat 290 ‘Short CUP Kit S~andard

Cat 290 Hot Cup Kit ~mntifin=~~

Scr,

_-.”een Garden Hose

44o Male Quick Connect

44o Fer

660 Mal~

66o Ferr---- _-,.

Fnnin~ Snark PII

_,, =...-

nale Quick Connect

Ie Quick Connect

nab C)L;ickconnect

-r -.. .

Pump Drive Belt, m-!3elt

S Cat Belt

,-,- ..-..-.,

.Ug 2

QTY.

1

1

1

1

2

_——

1

1

6

1

7

1

1

1

1

Page 4

HOW TO ORDER

—

To obtain a proper diagnosis of your malfunction, and to order

warranty replacement parts, it is important that you proceed in the

following manner

1. Call HydraMaster Warranty/Service Dept. at (206) 775-7275.

2. Give the Warranty/Service Representative the following

information:

A. Name of your company and your address.

B. Equipment Model (i.e. Hydra-Cat, Bobcat 2, etc.).

C. Date of purchase.

D. Hours on the unit.

E. Serial number of unit.

F. Name of person authorized to order parts.

G. Salesman unit purchased from.

H. Description of malfunction.

1. Pressure readings on high pressure gauge with wand turned

on and off.

3. If warranty replacement parts are needed, please specify

method of shipment desired. NOTE: All replacement parts are

sent freight collect, via:

A. U.P.S.

B, Air Freight

C. Air Mail

D. Air Express

E. Auto Freight

Do not give malfunctioning parts to a HydraMaster Sales or

4,

Service Representative. All parts must be returned directly

to HydraMaster, freight prepaid.

PARTSORDERS

To expedite your parts needs, please call your sales representative. In most instances, he either stocks or has access to parts

through a regional service center.

In the event parts are unavailable locally, contact the factory and

coordinate your needs. If this becomes necessary, always indicate

the method of shipment you desire, i.e. U.P.S. Blue Label, Air

Freight, Air Express, etc.

HydraMaster Parts Dept. phone (206) 775-7276.

ONE FINAL NOTE

Any questions you have regarding the warranty program should be

directed to the Warranty/Service Dept. Personnel at HydraMaster

Corporation.

We shall always endeavor to be fair in our evaluation of your

warranty claim, and shall provide you with a complete analysis of

our findings.

PURCHASER’SRESPONSIBILITY

PRIOR TO ARRIVAL OF UNIT:

● Install 5/8” exterior plywood flooring in vehicle and cover with

artificial turf.

● Have belly mounted propane tank installed on vehicle. Tank

must be propane vapor type.

● Caution Purchase heavy duty 42-60 amp hour battery and have

battery ‘slow’ charged if new. If battery is not fully charged

damage can occur to the engine charging regulator.

READING OF OWNERS MANUAL:

Itis the purchaser’s responsibility to read the unit operation

o

manual and to familiarize himself with the information contained

therein.

SALESREPRESENTATIVE’S

RESPONSIBILITY

ACCEPTANCE OF SHIPMENT:

If unit shows any outward signs of damage, do not sign the

*

delivery receipt until you have closely inspected the unit and

noted any damage on the delivery receipt. Have the freight company representative acknowledge the damage by signing the

notation of damage on the delivery receipt.

● The salesman from whom you purchased your unit is responsi-

ble for supervising the correct installation of the unit in your vehicle and thoroughly training you in its operation and

maintenance.

CORRECT INSTALLATION INCLUDES:

Supervising the purchaser in the following:

● Installation of through-floor fittings for propane and gasoline fuel

lines; installing propane regulator included with unit, outside

vehicle placing unit and recovery tank in vehicle and securing

them with bolts or tie down cleats; connecting all propane and

gasoline lines; connecting battery; checking pump, vacuum

blower and engine oil levels, prior to starting unit; starting unit to

check engine to see that all systems function normally also

checking all hoses, wands, etc., for correct operation.

TRAINING SHALL INCLUDE:

● Thorough review of the operation manual with purchaser; in-

struction and familiarization in: how to correctly start up and shut

down unit; how to correctly clean with the unit; how, where and

how often to check and change component oil levels; how the

unit’s systems work; how to troubleshoot the unit; how to do

basic repairs; safety precautions and their importance; freezing

damage and how to avoid it and a thorough review of the unit

warranty and warranty procedures.

HydraMaster warranty policy (Inside back cover)

Effective May 1, 1988

HydraMaster warranty covers only defective materials and/or

workmanship for the periods listed. Labor, and/or diagnostic

reimbursement is specifically excluded.

HOURS:

MONDAY THROUGH FRIDAY

am TO 6:00 pm

8:00

PACIFIC STANDARD TIME

@ @ @ @ ,AX ANDhIlARKETIt4G~~~~~

PST

..!:\;.::::*”..

ROCK MT.

CENTRAL

~:;;>;.$%,

EASTERN

TELEPHONE NUMBERS

GENERAL OFFICES:

PARTS DEPT

SERVICE/WARRANTY:

NEW EQUIPMENT SALES

(206) 775-7272

(206) 775-7276

Page 5

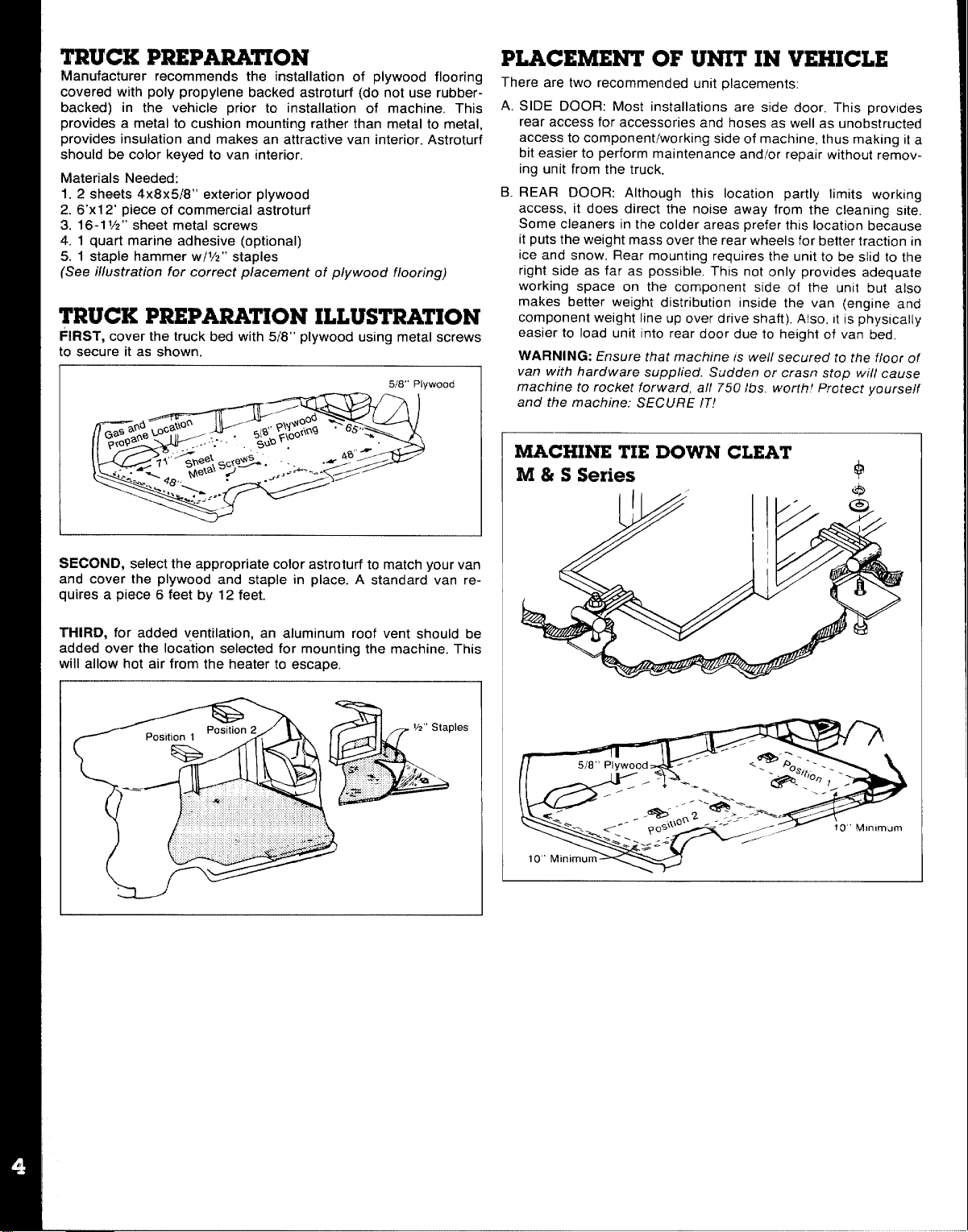

TRUCK PREPARATION

Manufacturer recommends the installation of plywood flooring

covered with poly propylene backed astroturf (do not use rubberbacked) in the vehicle prior to installation of machine, This

provides a metal to cushion mounting rather than metal to metal,

provides insulation and makes an attractive van interior. Astroturf

should be color keyed to van interior,

Materials Needed:

1.2 shaets 4x8x5f8° exterior plywood

2. 67X12’ piece of commercial astroturf

3. 16.1 VZ”sheet metal screws

4.1 quart marine adhesive (optional)

5.1 staple hammer w/VZ” staples

(See illustration for correct placement of plywood flooring)

TRUCK PREPARATION ILLUSTRATION

FIRST, cover the truck bed with 5/8” ~lvwood usmq metal screws

to secure it as shown.

.

PLACEMENT OF UNIT IN VEHICLE

There are two recommended unit placements:

A. SIDE DOOR: Most installations are side door. This provides

rear access for accessories and hoses as well as unobstructed

access to component/working side of machine, thus making it a

bit easier to perform maintenance andlor repair without removing unit from the truck.

B. REAR DOOR: Although this location partly limits workina

access, it does direct the noise away from the cleaning sit;

Some cleaners in the colder areas prefer this location because

it puts the weight mass over the rear wheels for better traction in

ice and snow, Rear mounting requires the unit to be slid to the

right side as far as possible. This not only provides adequate

working space on the component side of the unit but also

makes better weight distribution inside the van (engine and

component weight line up over drive shaft). Also, It is physically

easier to load unit into rear door due to height of van bed,

WARNING: Ensure that machine IS we// secured to the floor of

van with hardware supplied. Sudden or cra.sn stop will cause

machine to rocket forward, all 750 Ibs. worth I Protect yourself

and the machine: SECURE IT!

MACHINE TIE DOWN CLEAT

M & S Series

$

SECOND, select the appropriate color astroturf to match your van

and cover the plywood and staple in place. A standard van requires a piece 6 feet by 12 feet.

THIRD, for added ventilation, an aluminum roof vent should be

added over the location selected for mounting the machine. This

‘ill allow hot air from the heater to escape, -

&L--J

Page 6

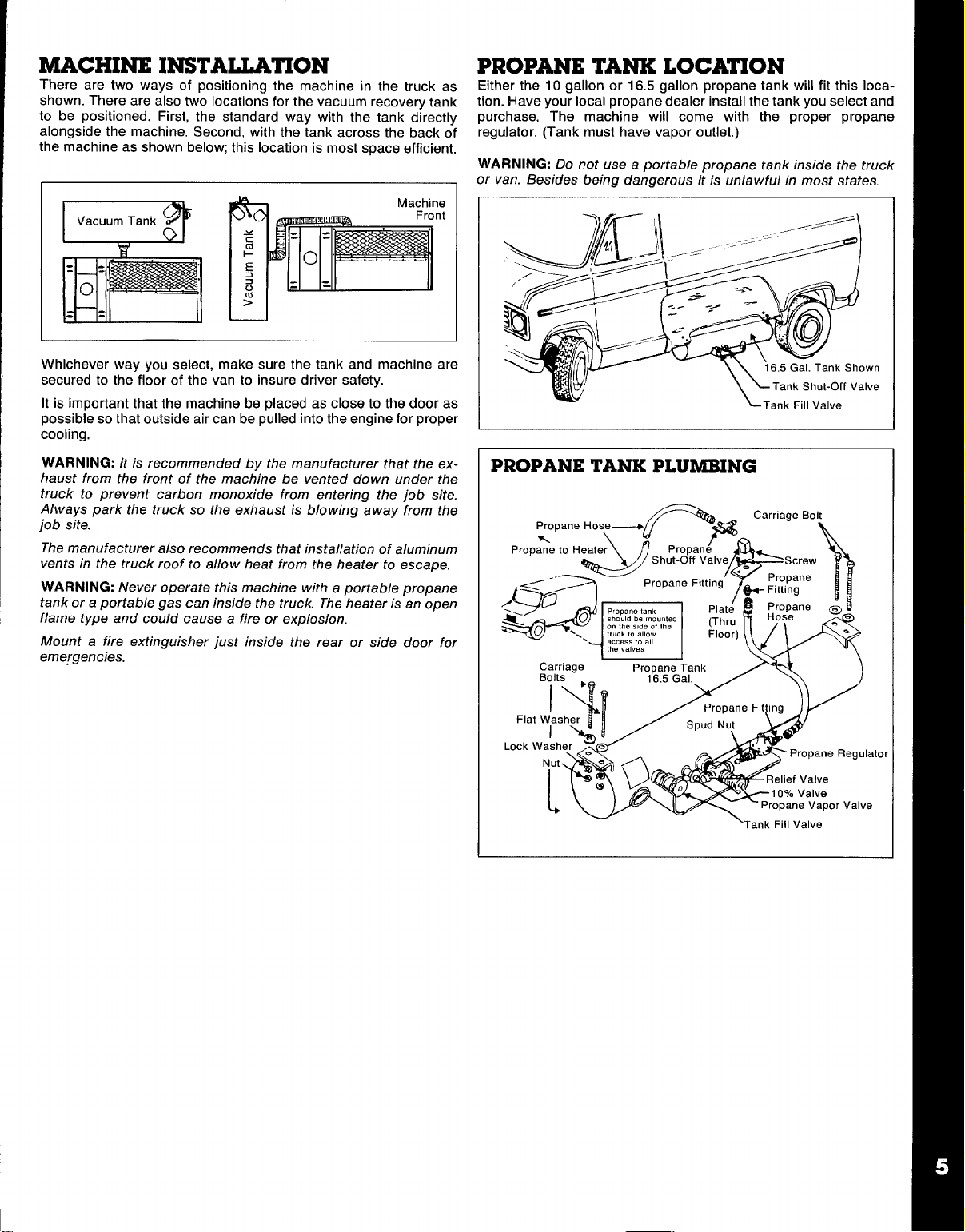

MACHINE INSTALLATION

There are two ways of positioning the machine in the truck as

shown. There are also two locations for the vacuum recovery tank

to be positioned. First, the standard way with the tank directly

alongside the machine, Second, with the tank across the back of

the machine as shown below; this location is most space efficient.

PROPANE TANK LOCATION

Either the 10 gallon or 16.5 gallon propane tank will fit this location. Have your local propane dealer install the tank you select and

purchase. The machine will come with the proper propane

regujator. (Tank must have vapor outlet.)

WARNING: Do not use a portable DroDane tank inside the truck

or van. Besides being dangerous ii is “unla wful in most states.

Whichever way you select, make sure the tank and machine are

secured to the floor of the van to insure driver safety.

I

It is important that the machine be placed as close to the door as

possible so that outside air can be pulled into the engine for proper

cooling.

WARNING:

haust from the front of the machine be vented down under the

truck to prevent carbon monoxide from entering the job site.

Always park the truck so the exhaust is blowing away from the

job site.

The manufacturer also recommends that installation of aluminum

vents in the truck roof to allow heat from the heater to escape.

WARNING: Never operate this machine with a portable propane

I

tank or a portable gas can inside the truck. The heater is an open

flame type and could cause a fire or explosion.

Mount a fire extinguisher just inside the rear or side door for

emergencies.

Itis recommended by the manufacturer that the ex-

wn

Ive

PROPANE TANK PLUMBING

Iator

e

Page 7

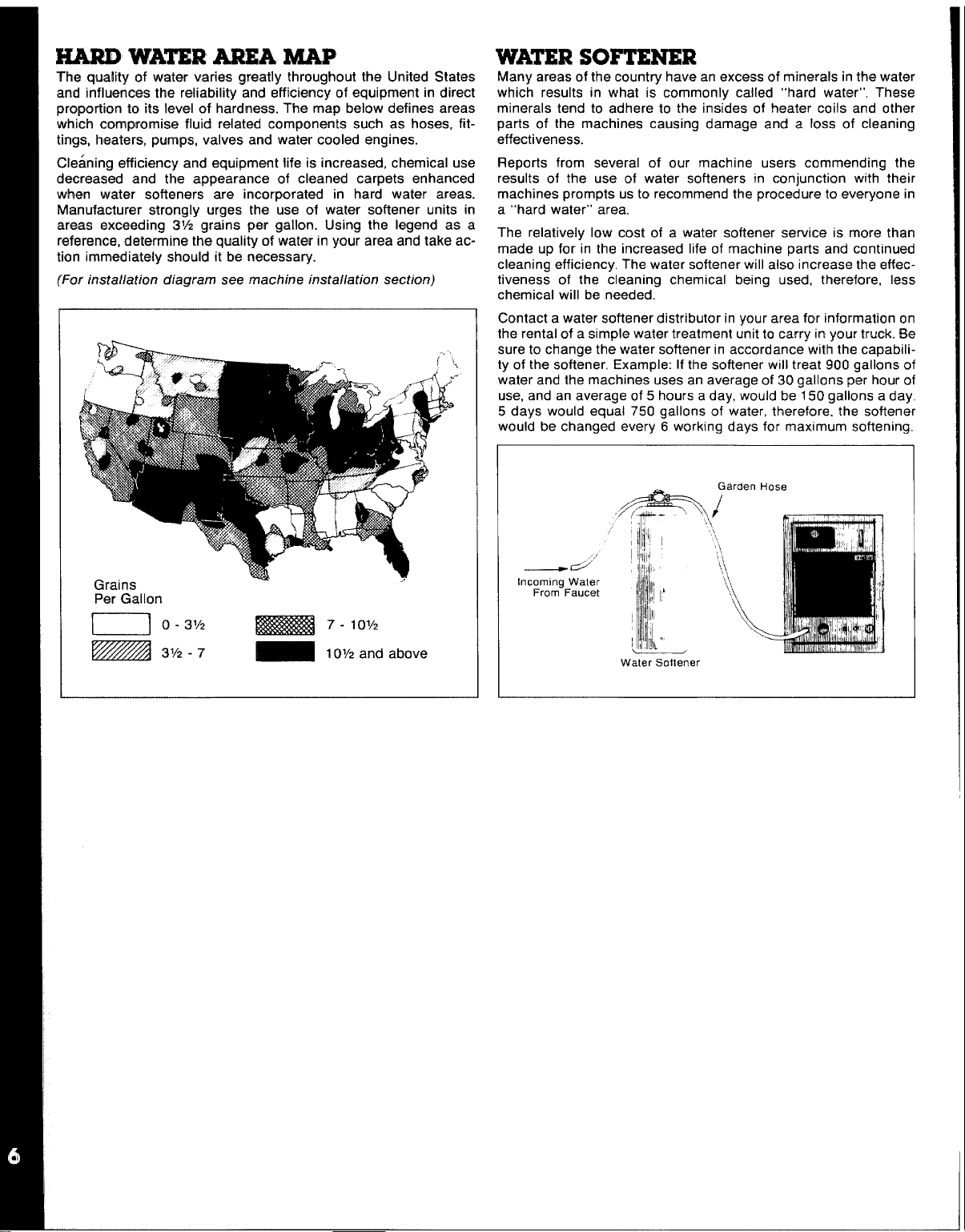

HARI) WA~R AREA MAP

The quality of water varies greatly throughout the United States

and influences the reliability and efficiency of equipment in direct

proportion to its level of hardness. The map below defines areas

which compromise fluid related components such as hoses, fittings, heaters, pumps, valves and water cooled engines.

Cleaning efficiency and equipment life is increased, chemical use

decreased and the appearance of cleaned carpets enhanced

when water softeners are incorporated in hard water areas.

Manufacturer strongly urges the use of water softener units in

areas exceeding 31A grains per gallon. Using the legend as a

reference. determine the cmalitv of water in vow area and take action imm~diately should ii be ~ecessary. ‘

(For installation diagram see machine installation section)

WATERSOFTENER

Many areas of the country have an excess of minerals in the water

which results in what is commonly called “hard water”, These

minerals tend to adhere to the insides of heater coils and other

parts of the machines causing damage and a loss of cleaning

effectiveness.

Reports from several of our machine users commending the

results of the use of water softeners in conjunction with their

machines prompts us to recommend the procedure to everyone in

a “hard water” area.

The relatively low cost of a water softener service is more than

made up for in the increased life of machine parts and continuad

cleaning efficiency, The water softener will also increase the effectiveness of the cleaning chemical being used, therefore, less

chemical will be needed.

Contact a water softener distributor in your area for information on

the rental of a simple water treatment unit to carry in your truck. Be

sure to change the water softener in accordance with the capability of the softener, Example: If the softener will treat 900 gallons of

water and the machines uses an average of 30 gallons per hour of

use, and an average of 5 hours a day, would be 150 gallons a day,

5 days would equal 750 gallons of water, therefore. the softener

would be changed every 6 working days for maximum softening.

Grains

Per Gallon

u 0-31’2

- 3% -7

..

= 7- 107/2

_ 101/2 and above

— d“

Incoming Water

From Faucet

Water Sottener

Page 8

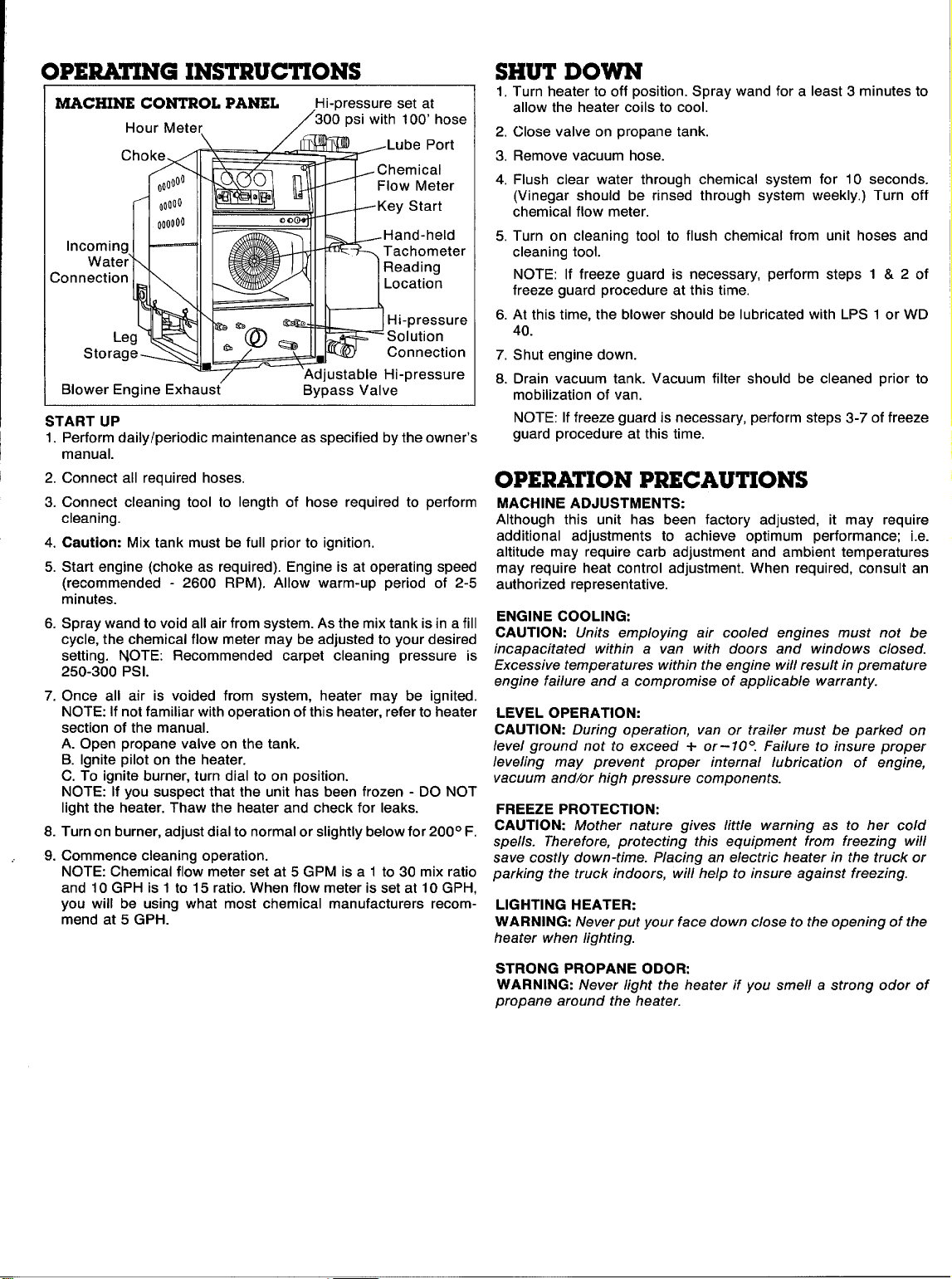

hPERATINGINSTRUCTIONS

MACHINE CONTROL PANEL

Hour Meter

In

;on

Blower Engine Exhaust’

START UP

1. Perform daily aperiodic maintenance as specified by the owner’s

manual.

2. Connect all required hoses.

3. Connect cleaning tool to length of hose required to perform

cleaning.

4. Caution: Mix tank must be full prior to ignition.

5. Start engine (choke as required). Engine is at operating speed

(recommended -2600 RPM). Allow warm-up period of 2-5

minutes.

6. Spray wand to void all air from system. As the mix tank is in a fill

cycle, the chemical flow meter may be adjusted to your desired

setting. NOTE: Recommended carpet cleaning pressure is

250-300 PSI.

7. Once all air is voided from system, heater may be ignited.

NOTE: If not familiar with operation of this heater, refer to heater

section of the manual.

A. Open propane valve on the tank.

B. Ignite pilot on the heater.

C. To ignite burner, turn dial to on position.

NOTE: If you suspect that the unit has been frozen - DO NOT

light the heater. Thaw the heater and check for leaks.

8. Turn on burner, adjust dial to normal or slightly below for 200° F.

9. Commence cleaning operation.

NOTE: Chemical flow meter set at 5 GPM is a 1 to 30 mix ratio

and 10 GPH is 1 to 15 ratio. When flow meter is set at 10 GPH,

you will be using what most chemical manufacturers recom-

mend at 5 GPH.

Hi-pressure set at

300 psi with 100’ hose

/

Bypass Valve

1. Turn heater to off position. Spray wand for a least 3 minutes to

allow the heater coils to cool.

2. Close valve on propane tank.

3. Remove vacuum hose.

4. Flush clear water through chemical system for 10 seconds.

(Vinegar should be rinsed through system weekly.) Turn off

chemical flow meter.

5. Turn on cleaning tool to flush chemical from unit hoses and

cleaning tool.

NOTE: If freeze guard is necessary, perform steps 1 & 2 of

freeze guard procedure at this time.

6. At this time, the blower should be lubricated with LPS 1 or WD

40.

7. Shut engine down.

8. Drain vacuum tank. Vacuum filter should be cleaned prior to

mobilization of van.

NOTE: If freeze guard is necessary, perform steps 3-7 of freeze

guard procedure at this time.

OPERATION PRECAUTIONS

MACHINE ADJUSTMENTS:

Although this unit has been factory adjusted, it may require

additional adjustments to achieve optimum performance; i.e.

altitude may require carb adjustment and ambient temperatures

may require heat control adjustment. When required, consult an

authorized representative.

ENGINE COOLING:

CAUTION: Units employing air cooled engines must not be

incapacitated within a van with doors and windows closed.

Excessive temperatures within the engine will result in premature

engine failure and a compromise of applicable warranty.

LEVEL OPERATION:

CAUTION: During operation, van or trailer must be parked on

level ground not to exceed i- or- 10°. Failure to insure proper

leveling may prevent proper internal lubrication of engine,

vacuum andlor high pressure components.

FREEZE PROTECTION:

CAUTION: Mother nature gives /itt/e warning as to her cold

spells. Therefore, protecting this equipment from freezing will

save costly down-time. Placing an electric heater in the truck or

parking the truck indoors, will help to insure against freezing.

LIGHTING HEATER:

WARNING: Never put your face down close to the opening of the

heater when lighting.

STRONG PROPANE ODOR:

WARNING: Never light the heater if you smell a strong odor of

propane around the heater.

Page 9

FREEZEPROTECTION

Any freezing of this machine is not covered by warranty and during the colder months of operation, careful protection should be of

utmost concern.

THE FOLLCWING PRECAUTIONS ARE RECOMMENDED:

1. Run machine before leaving for the first job to insure nothing

has frozen the night before, including hoses and wand.

2. Insulate the garden hose from the cold ground by running it

through an extra 1

3. Leave truck doors closed until time cleaning begins, then open

slightly.

4. on extremely cold days propane does not vaporize as quickly,

therefore, venting the warm exhaust over to blow on the propane tank will stabilize the propane flow. (This is necessary if

you notice a drop in heat or a low burning flame in the heater.)

5. In colder climates, insulating the truck walls and floor boards will

help protect the unit.

6. Don’t procrastinate during the cleaning operation or the hot

water solution line will also freeze on the ground. The solution

line should be insulated in extremely cold climates.

T. Whenever possible, the truck and machine should be stored in a

heated garage at night or over the weekend. If not possible,

place a 1500 watt electric heater inside the truck, aimed directly

at the machine. Never use a propane heater - it causes excessive moisture on the truck ceiling and the possibility of it

going out is higher. If the machine and truck are left outside with

a heater, you should first drain all possible water from the

machine cleaning tools and hoses. (They freeze also.)

TO DRAIN THE MACHINE, FOLLOW THESE STEPS:

A. Before shutting off the machine, remove the chemical line from

the chemical jug and place in a mixture of 50/50 anti-freeze and

water. With the cleaning tool on, allow mixture to fill chemical

system back to the chemical mix tank.

B. Loosen the petcock valve on your bypass drain hose and allow

the water to drain thoroughly from the mix tank.

C. To remove the water from the heater and pump use the freeze

guard which is a small air compressor. Using the correct connectors, first blow air into the high pressure solution male quick

connect. This will force the water through the heater back

through the pump and into the chemical mix tank to be drained

out through the petcock valve to the ground. By loosening the

bypass knob, the air will be allowed to flow more freely through

the system. Next, blow the air into the incoming water quick

connect and force that water into the chemical mix tank to be

drained out.

D. Remember to close the drain valve prior to next operation of

your unit.

BE SURE ITS PROTECTED!

Freezing will cause GRIEF, MONEY and DOWN-TIME. Don’t

mess with Mother Nature!

V2 inch vacuum hose.

CAUTION: When c/caning cut-pile acri/an p/u.sh carpefs, using

high heat setting may result in fiber damage on this type of

carpet.

The use of some chemicals through your mobile carpet cleaning

plant can seriously damage the internal plumbing, high pressure

pump and heater. (Chemical such as concentrated acids and

some paint oil and grease removers w/high concentration of

solvents.)

Manufacturer recommends only the use of chemicals containing

rust and corrosion inhibitors and water softening agents to prevent

chemical build-up.

NOTE: At no time should a chemical solution with a Pti of less than

7 or higher than 10 be used in the unit,

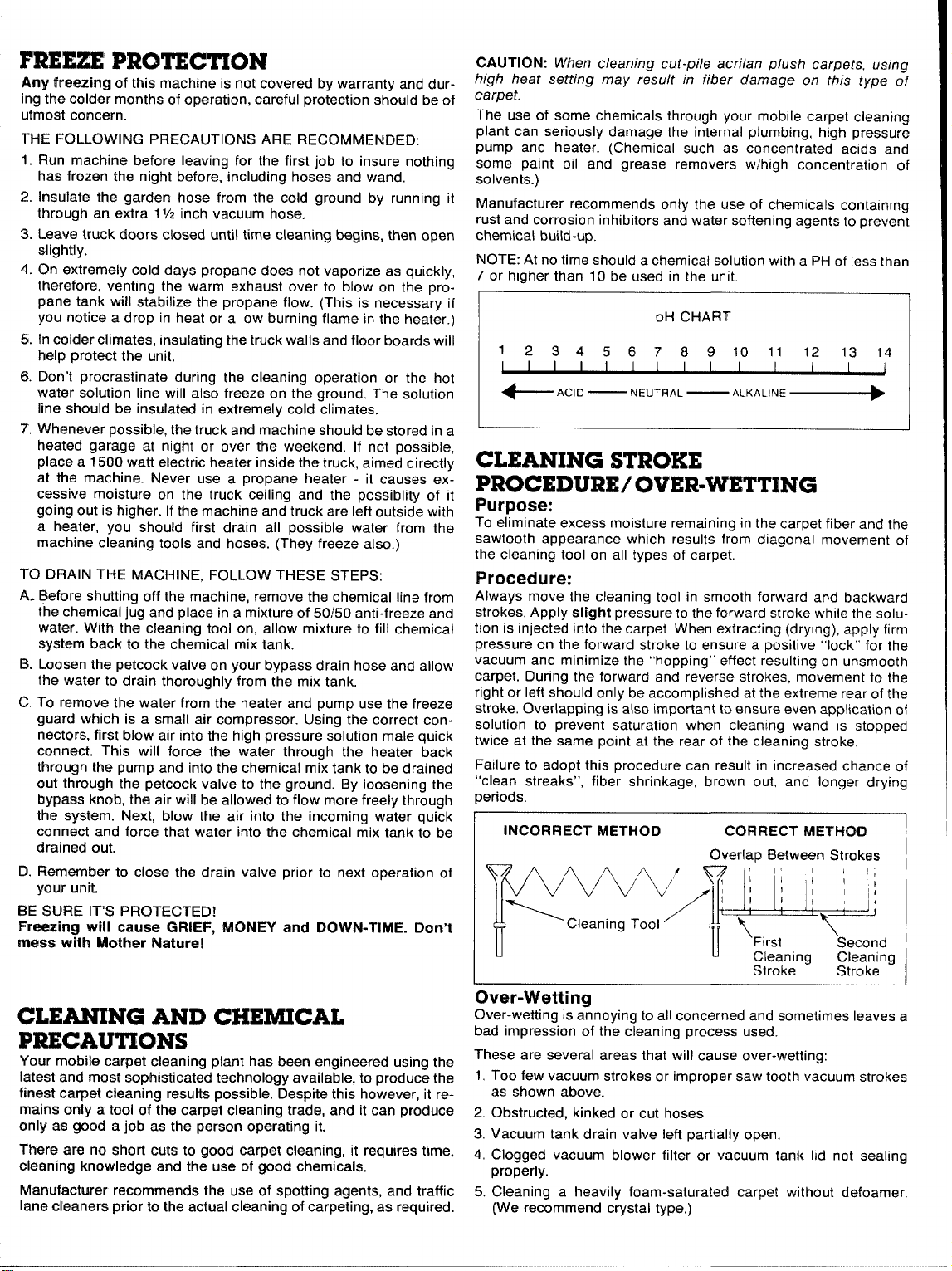

pli CHART

1

234567891011121314

I

+ACID

I I I I

— NEUTRAL

—“’’A””’ ~

I I

I

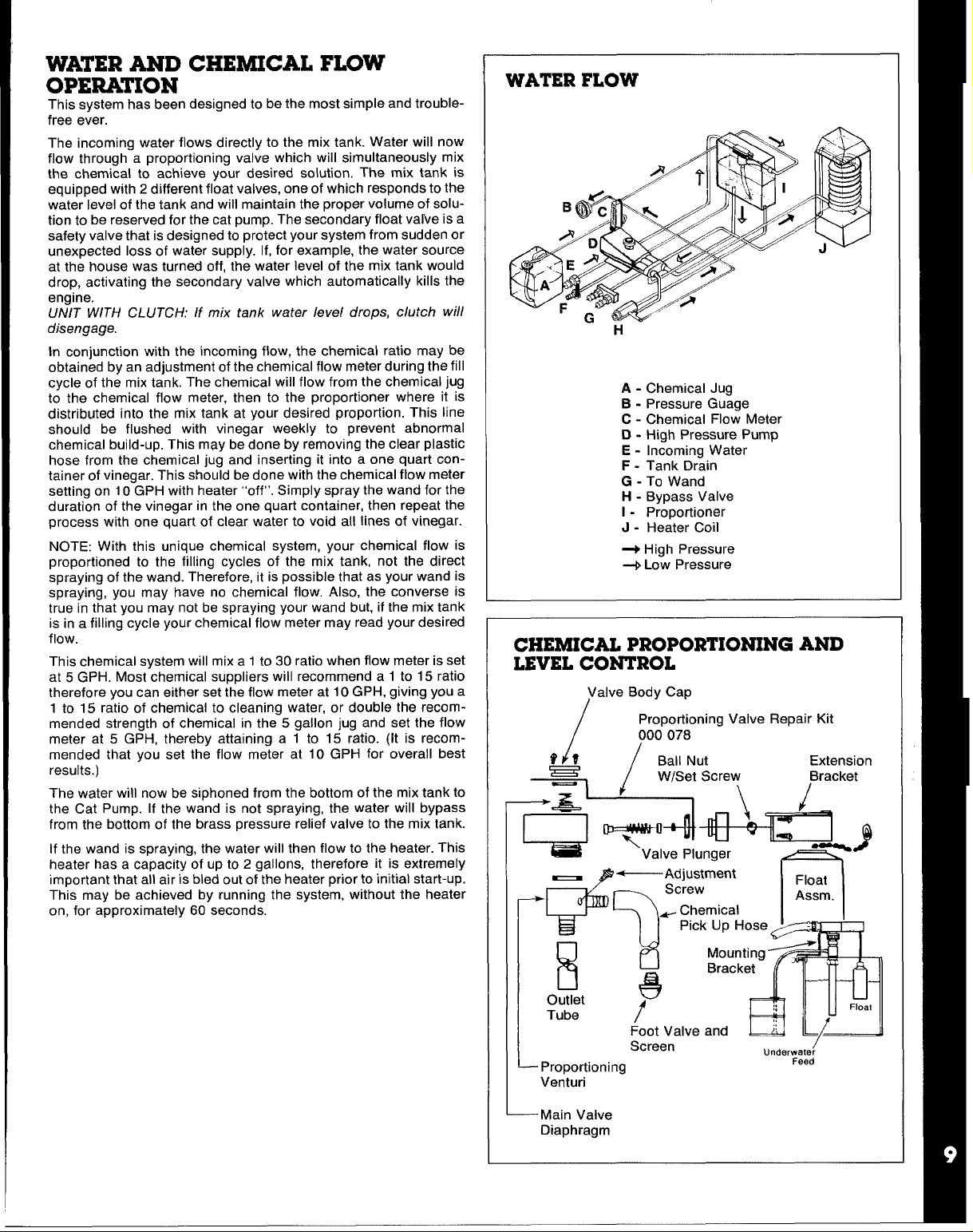

CLEANING STROKE

PROCEDURE/ OVER-WVETTING

Purpose:

To eliminate excess moisture remaining in the carpet fiber and the

sawtooth appearance which results from diagonal movement of

the cleaning tool on all types of carpet,

Procedure:

Always move the cleaning tool in smooth forward and backward

strokes. Apply slight pressure to the forward stroke while the solu-

tion is injected into the carpet. When extracting (drying), apply firm

pressure on the forward stroke to ensure a positive “lock” for the

vacuum and minimize the “hopping” effect resulting on unsmooth

carpet. During the forward and reverse strokes, movement to the

right or left should only be accomplished at the extreme rear of the

stroke, Overlapping is also important to ensure even application of

solution to prevent saturation when cleaning wand is stopped

twice at the same point at the rear of the cleaning stroke,

Failure to adopt this procedure can result in increased chance of

“clean streaks”, fiber shrinkage, brown out, and longer drying

periods.

INCORRECT METHOD CORRECT METHOfJ

\/

\cleaning Tool ‘

v“

Overlao Between Strokes

!

%

/-4

II

@ LJ ~:

u

11,1

First

““

Cleanina

Stroke -

Second

Cleaning

Stroke

‘1

CLEANING AND CHEMICAL

PRECAUTIONS

Your mobile carpet cleaning plant has been engineered using the

latest and most sophisticated technology available, to produce the

finest carpet cleaning results possible. Despite this however, it remains only a tool of the carpet cleaning trade, and it can produce

cmly as good a job as the person operating it.

There are no short cuts to good carpet cleaning, it requires time,

cleaning knowledge and the use of good chemicals.

Manufacturer recommends the use of spotting agents, and traffic

lane cleaners prior to the actual cleaning of carpeting, as required.

Over-Wetting

Over-wetting is annoying to all concerned and sometimes leaves a

bad impression of the cleaning process used.

These are several areas that will cause over-wetting:

1.

Too few vacuum strokes or improper saw tooth vacuum strokes

as shown above.

2,

Obstructed, kinked or cut hoses,

Vacuum tank drain valve left partially open.

3.

4,

Clogged vacuum blower filter or vacuum tank lid not sealing

properly.

Cleaning a heavily foam-saturated carpet without defoamer.

5.

(We recommend crystal type,)

Page 10

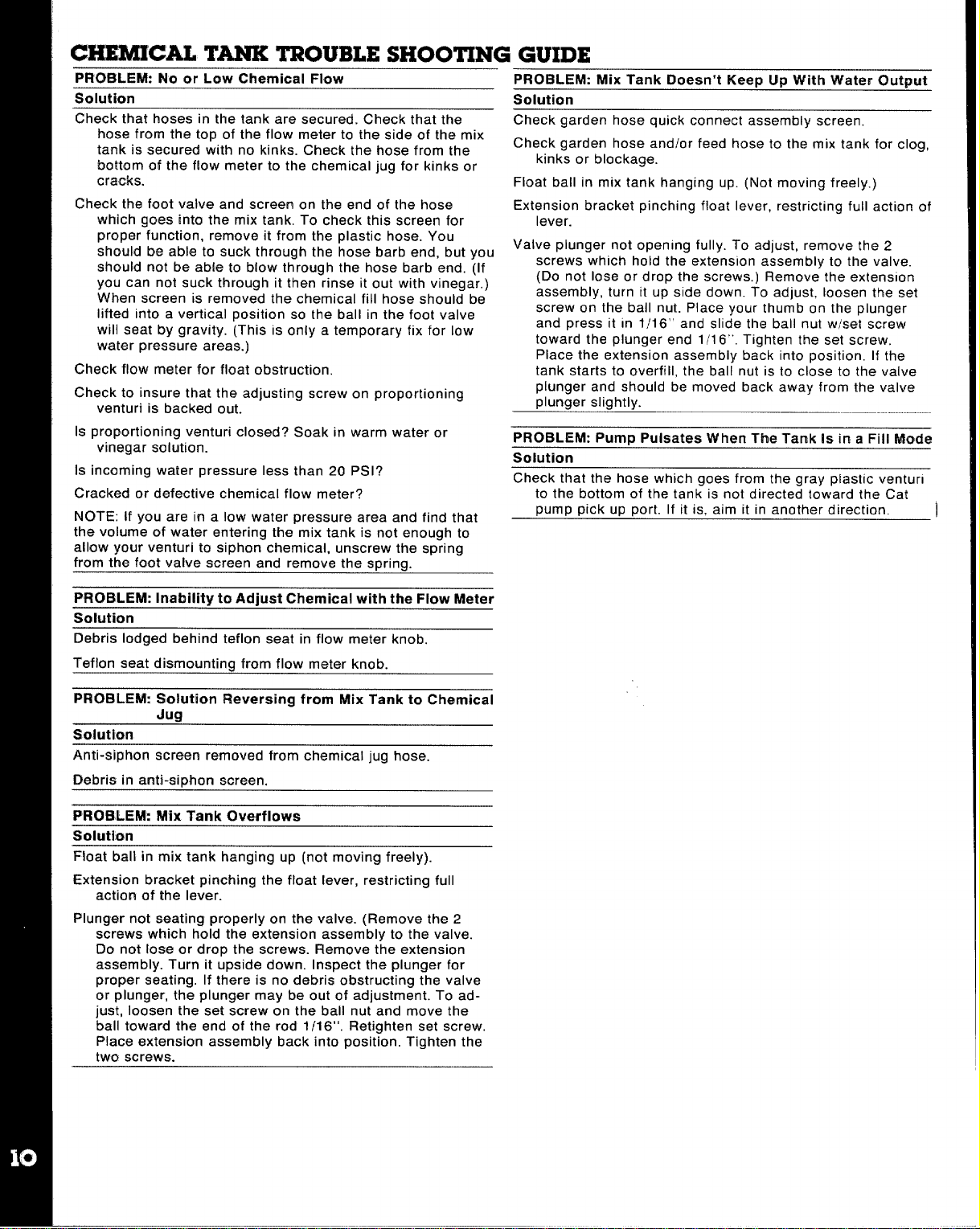

This system has been designed to be the most simple and troublefree ever.

The incoming water flows directly to the mix tank. Water will now

flow through a proportioning valve which will simultaneously mix

the chemical to achieve your desired solution, The mix tank is

equipped with 2 different float valves, one of which responds to the

water level of the tank and will maintain the proper volume of solution to be reserved for the cat pump. The secondary float vahe is a

safety valve that is designed to protect your system from sudden or

unexpected loss of water supply. If, for example, the water source

at the house was turned off, the water level of the mix tank would

drop, activating the secondary valve which automatically kills the

engine,

UNIT WITH CLUTCH: If mix tank water level drops, clutch will

disengage.

In conjunction with the incoming flow, the chemical ratio may be

obtained by an adjustment of the chemical flow meter during the fill

cycle of the mix tank. The chemical will flow from the chemical jug

to the chemical flow meter, then to the proportioner where it is

distributed into the mix tank at your desired proportion. This line

should be flushed with vinegar weekly to prevent abnormal

chemical build-up. This may be done by removing the clear plastic

hose from the chemical jug and inserting it into a one quart container of vinegar. This should be done with the chemical flow meter

setting on 10 GPH with heater “off”. Simply spray the wand for the

duration of the vinegar in the one quart container, then repeat the

process with one quart of clear water to void all lines of vinegar.

NOTE: With this unique chemical system, your chemical flow is

proportioned to the filling cycles of the mix tank, not the direct

spraying of the wand. Therefore, it is possible that as your wand is

spraying, you may have no chemical flow, Also, the converse is

true in that you may not be spraying your wand but, if the mix tank

is in a filling cycle your chemical flow meter may read your desired

flow.

This chemical system will mix a 1 to 30 ratio when flow meter is set

at 5 GPH. Most chemical suppliers will recommend a 1 to 15 ratio

therefore you can either set the flow meter at 10 GPH, giving you a

1 to 15 ratio of chemical to cleaning water, or double the recommended strength of chemical in the 5 gallon jug and set the flow

meter at 5 GPH, thereby attaining a 1 to 15 ratio. (It is recommended that you set the flow meter at 10 GPH for overall best

results.)

The water will now be siphoned from the bottom of the mix tank to

the Cat Pump. If the wand is not spraying, the water will bypass

from the bottom of the brass pressure relief valve to the mix tank.

If the wand is spraying, the water will then flow to the heater. This

heater has a capacity of up to 2 gallons, therefore it is extremely

important that all air is bled out of the heater prior to initial start-up.

This may be achieved by running the system, without the heater

on, for approximately 60 seconds.

WATER FLOW

H

A - Chemical Jug

B - Pressure Guage

C - Chemical Flow Meter

D - High Pressure Pump

E - Incoming Water

F - Tank Drain

G - To Wand

H - Bypass Valve

I - Proportioner

J - Heater Coil

-+ High Pressure

+ Low Pressure

CHEMICAL PROPORTIONING AND

LEVEL CONTROL

Diaphragm

Page 11

CHEMICAL TANK TROUBLESHOOTING GUIDE

PROBLEM: No or Low Chemical Flow

Solution

Check that hoses in the tank are secured. Check that the

hose from the top of the flow meter to the side of the mix

tank is secured with no kinks. Check the hose from the

bottom of the flow meter to the chemical jug for kinks or

cracks.

Check the foot valve and screen on the end of the hose

which goes into the mix tank. To check this screen for

proper function, remove it from the plastic hose. You

should be able to suck through the hose barb end, but you

should not be able to blow through the hose barb end. (If

you can not suck through it then rinse it out with vinegar, )

When screen is removed the chemical fill hose should be

lifted into a vertical position

will seat by gravity. (This is only a temporary fix for low

water pressure areas. )

Check flow meter for float obstruction.

Check to insure that the adjusting screw on proportioning

venturi is backed out.

Is proportioning venturi closed? Soak in warm water or

vinegar solution.

Is incoming water pressure less than 20 PSI?

Cracked or defective chemical flow meter?

NCITE: If you are in a low water pressure area and find that

volume of water entering the mix tank is not enough to

the

allow your venturi to siphon chemical, unscrew the spring

from the foot valve screen and remove the spring.

so the ball in the foot valve

PROBLEM: Mix Tank Doesn’t Keen UCIWith Water Outnut

Solution

Check garden hose quick connect assembly screen.

Check garden hose andlor feed hose to the mix tank for clog,

kinks or blockage.

Float ball in mix tank hanging up. (Not moving freely.)

Extension bracket pinching float lever, restricting full action of

lever.

Valve plunger not opening fully. To adjust, remove the 2

screws which hold the extension assembly to the valve.

(Do not lose or drop the screws. ) Remove the extension

assembly, turn it up side down. To adjust, loosen the set

screw on the ball nut. Place your thumb on the plunger

and press it In 1/16” and slide the ball nut w/set screw

toward the plunger end 1/1 6“’. Tighten the set screw.

Place the extension assembly back into position. If the

tank starts to overfill, the ball nut is to close to the valve

plunger and should be moved back away from the valve

olunaer sliahtlv.

PROBLEM: Pump Pulsates When The Tank Is in a Fill Mode

Solution

Check that the hose which goes from the gray plastic venturi

to the bottom of the tank is not directed toward the Cat

pump pick up port. If it is, aim it in another direction.

1

PROBLEM: Inability to Adjust Chemical with the Flow Meter

Solution

Debris lodged behind teflon seat in flow meter knob,

Teflon seat dismounting from flow meter knob.

PROBLEM: Solution Reversing from Mix Tank to Chemical

solution

Anti-siphon screen removed from chemical jug hose.

Debris in anti-siphon screen.

PRt3HLElW Mix Tank Overflows

solution

Float ball in mix tank hanging up (not moving freely).

Extension bracket pinching the float lever, restricting full

action of the lever.

Plunger not seating properly on the valve. (Remove the 2

screws which hold the extension assembly to the valve.

Do not lose or drop the screws. Remove the extension

assembly. Turn it upside down. Inspect the plunger for

proper seating. If there is no debris obstructing the valve

or plunger, the plunger may be out of adjustment. To ad-

just, loosen the se! screw on the ball nut and move the

ball toward the end of the rod 1/16”. Retighten set screw,

Place extension assembly back into position. Tighten the

two screws.

Jug

Page 12

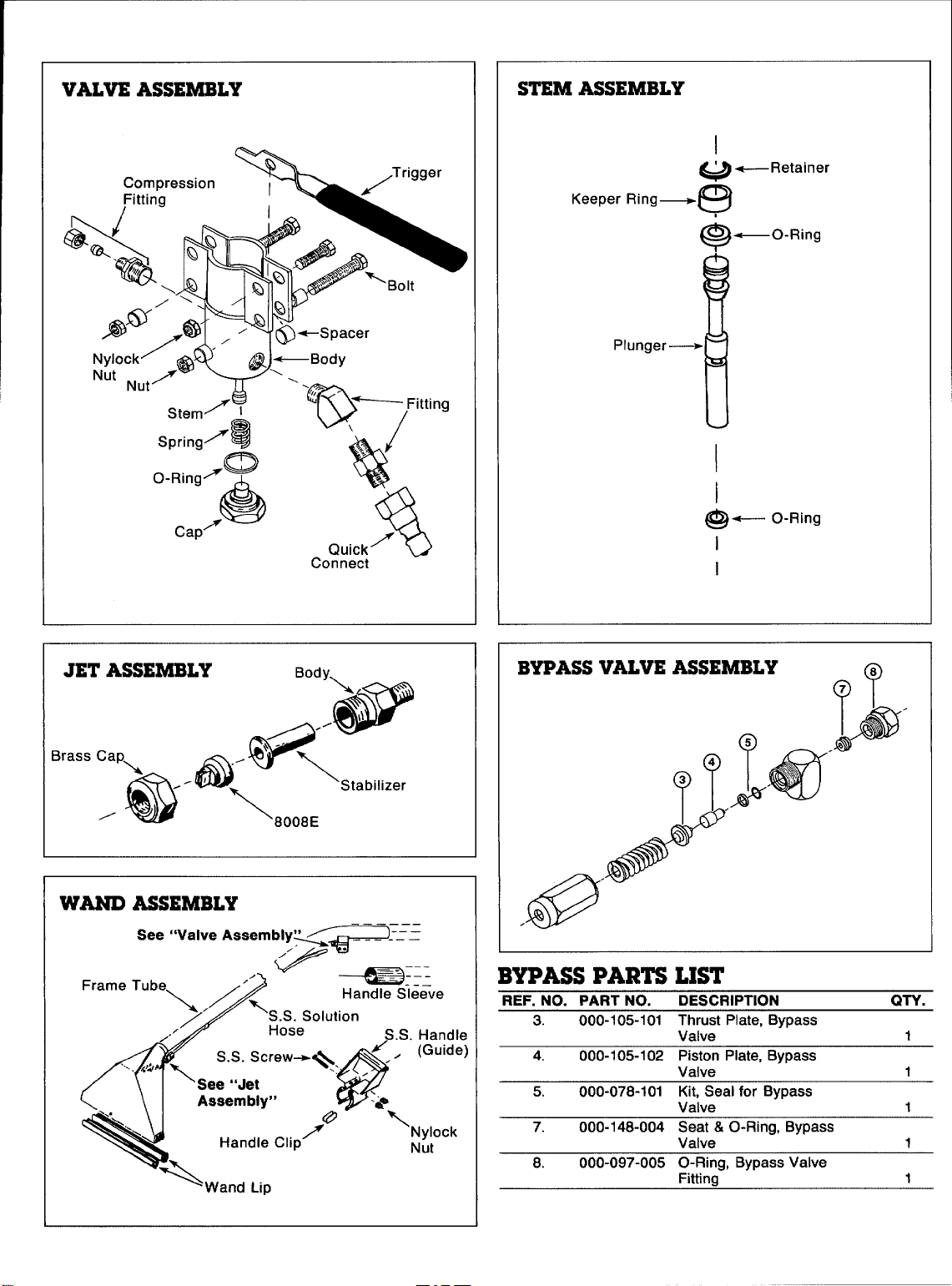

VALVE ASSEMBLY

STEM ASSEMBLY

Keeper Ring—

I

+--Retainer

w

~

_C)-Ring

I

I

@—

I

1

O-Ring

JET ASSEMBLY

Brass Cap

,a”0a<800~St~bilizer

WAND ASSEMBLY

See “Valve Assembly”

/

Body

‘--% “

@

P

BYPASS VALVE ASSEMBLY

?@8

.. ————

BYPASS PARTS LIST

S.S. Handle

REF. NO. PART NO. DESCRIPTION

3. 000-105-101 Thrust Plate, Bypass

4.

000-105-102 Piston Plate, Bypass

5.

000-078-101 Kit, Seal for Bypass

7.

000-148-004 Seat & O-Ring, Bypass

8. 000-097-005 O-Ring, Bypass Valve

Valve -‘

Valve

Valve

Valve

Fittina

QTV.

1

1

1

1

1

Page 13

FLOW WATER TROUBLESHOOTING

PROBLEM: Loss of Pressure

Cause

Defective or blocked check valves in hicfh pressure pump

cylinder head.

Delaminated, kinked or clogged hose between the mix tank

and the high pressure pump.

Defective pressure relief valve or debris in pressure relief

valve. NOTE: the high pressure bypass valve is designed drawing.

to fully close when the cleaning tool is turned on. Any

foreign matter collecting on the piston will prevent full

closure of the valve and allow a oortion of the water to

continue to circulate instead of being routed to the cleaning tool. To correct this situation, the bypass valve must

be disassembled and cleaned (refer to drawing provided

in this manual for bypass disassembly).

Defective or worn cups.

Loose drive belt for high pressure pump. Readjust belt as required or replace if defect!ve.

Loss of Pressure/Unit with clutch.

PROBLEM: Water Flow

Cause Solution

Worn out spray jet. NOTE: Cleaning tools designed to spray

a constant flow of 1V2GPM will average 1 gallon of flow

per minute in actual working situations since flow is not

continuous. An average flow of 1 GPM results in 6000

gallons of flow for every 100 hours of unit operation.

Spray tips are capable of consistent flow rates for

approximately 20,000 gallons. They should be replaced

therefore, approximately every 350 hours. Worn spray jets

allow a greater average rate of flow thus reducing desired

temperature levels.

Reduction of Flow.

Solution

Disassemble cylinder head and replace or clean applicable

check valve,

Remove and replace defective hose,

—

Disassemble and clean pressure relief valve as illustrated in

Replace defective or worn out bypass cup.

Replace bypass valve.

Remove and replace piston cups as defined by pump manual.

Is clutch engaged? Check tank for water,

Remove and replace spray jet.

Due to increased iength of solution hose NOTE: For every

50 feet of hose, beyond 100 feet in total length, a

measurable loss of flow is experienced. This condition is a

result of the increased friction experienced by the water

as it passes through the hose. Therefore, it is necessary

to increase the pressure at the machine 40 PSI for every

additional 50 feet of cleaning solution hose over 100 feet,

Page 14

VACUUM SYSTEMINFORMATION

—

The vacuum blower incorporated in this machine is a positive

displacement lobe type, manufactured by Cooper Industries. The

performance and life of this unit is greatly dependent on the care

and proper maintenance it receives.

Because of the close tolerances between the lobes and housing of

the vacuum blower, solid objects entering the inlet will damage the

internal lobes, gears and bearing or direct drive coupler.

To prevent this, a stainless steel filter screen has been placed at

the vacuum inlet inside the vacuum recovery tank. This stainless

steel screen is finger tight and should be removed for cleaning

weekly.

CAUTION: Should be used when machine is be~ng run for test

purpose and the vacuum inlet on top of machine is open.

To protect the vacuum blower from overloading and damaging

itself, there is a vacuum relief system installed on the vac tank lid.

When the vacuum tank inlet is completely sealed off, a maximum

of 14 HG will be attained. A hole on the top blower pipe elbow acts

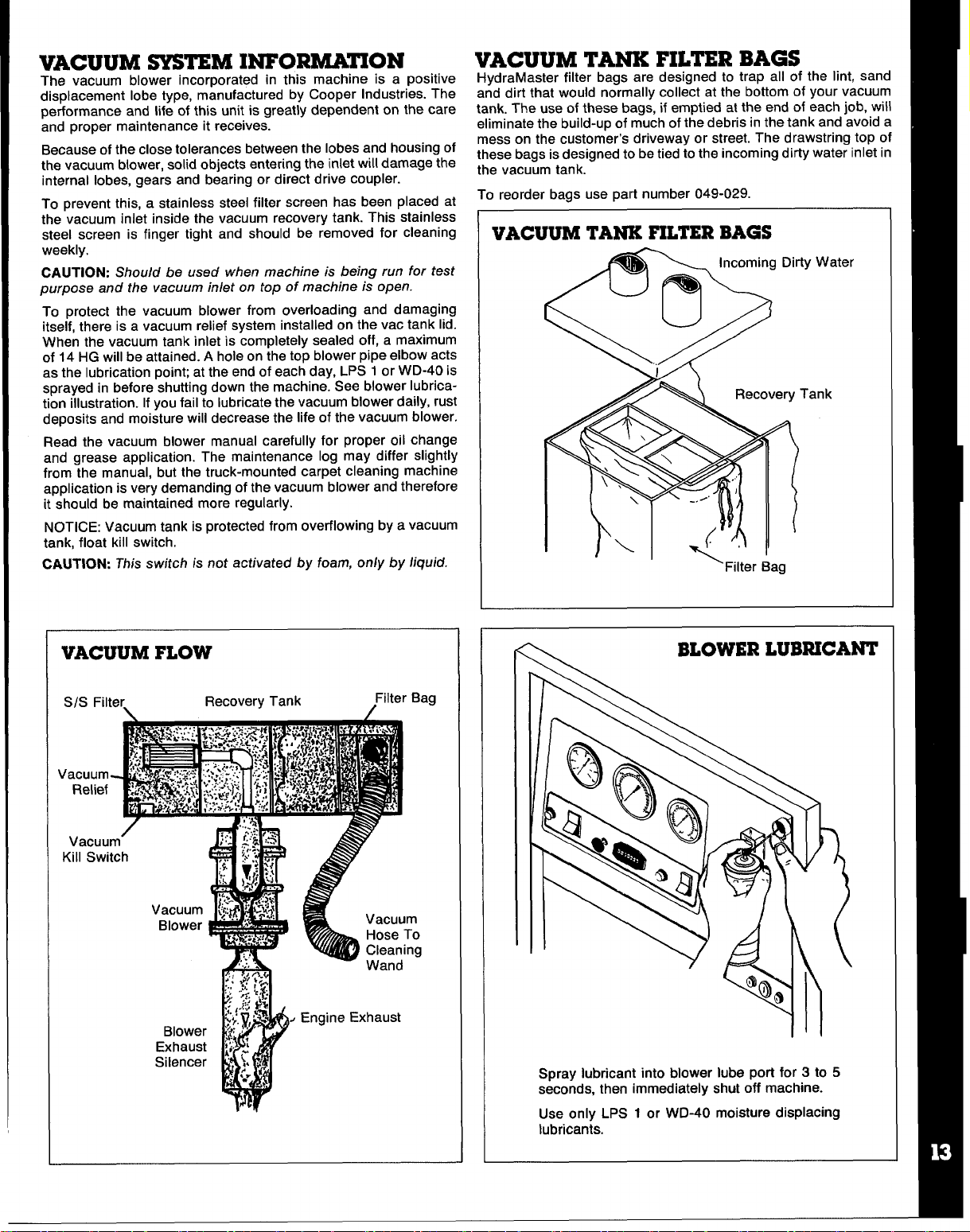

as the lubrication point at the end of each day, LPS 1 or WD-40 is

sprayed in before shutting down the machine. See blower lubrication illustration. Ifyou fail to lubricate the vacuum blower daily, rust

deposits and moisture will decrease the life of the vacuum blower.

Read the vacuum blower manual carefully for proper oil change

and grease application. The maintenance log may differ slightly

from the manual, but the truck-mounted carpet cleaning machine

application is very demanding of the vacuum blower and therefore

it should be maintained more regularly.

NOTICE: Vacuum tank is protected from overflowing by a vacuum

tank, float kill switch,

CAUTION: This switch is not activated by foam, only by liquid.

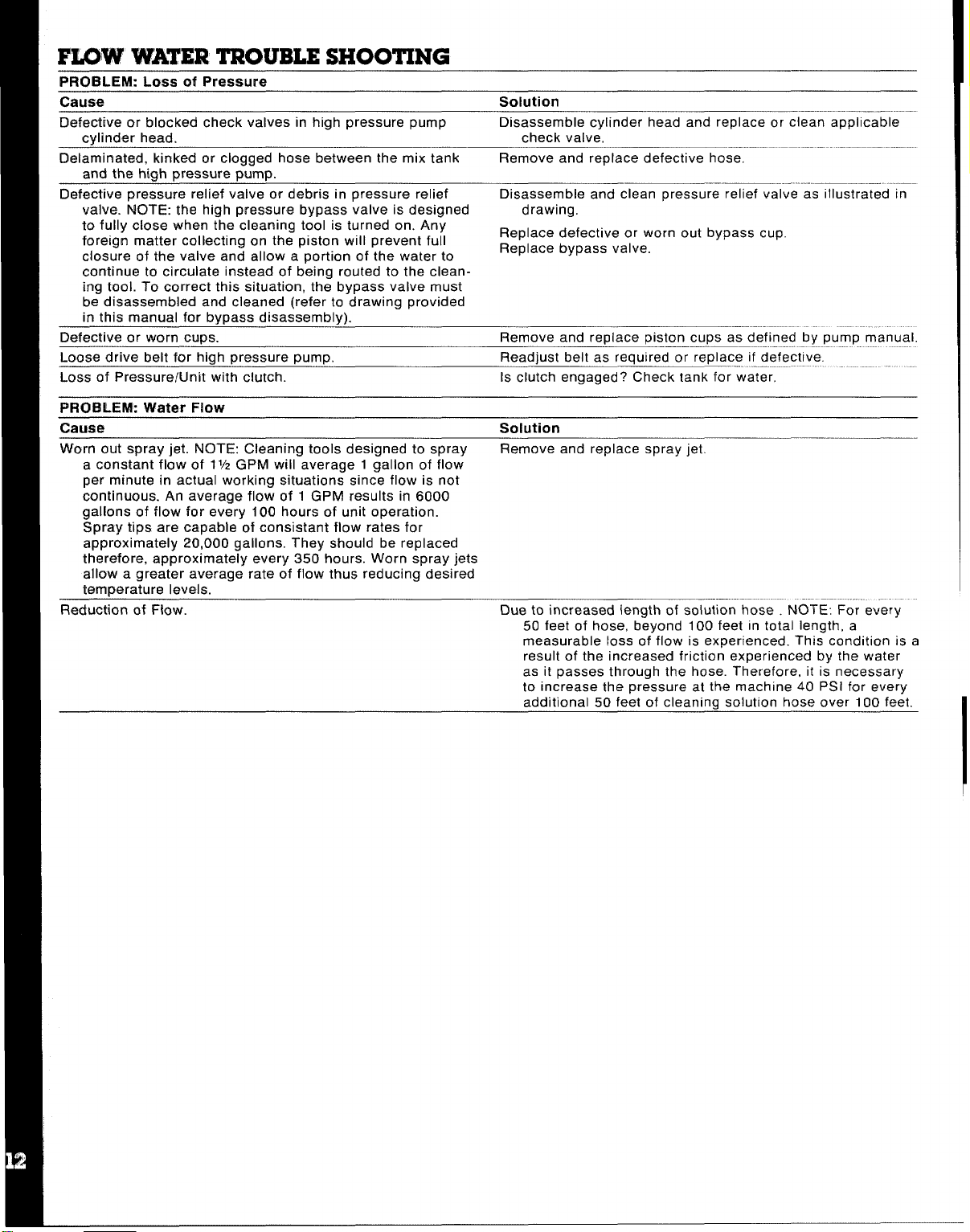

VACUUM TANK FILTBRBAGS

liydraMaster filter bags are designed to trap all of the lint, sand

and dirt that would normally collect at the bottom of your vacuum

tank. The use of these bags, if emptied at the end of each job, will

eliminate the build-up of much of the debris in the tank and avoid a

mess on the customer’s driveway or street. The drawstring top of

these bags is designed to be tied to the incoming dirty water inlet in

the vacuum tank.

To reorder bags use part number 049-029.

VACUUM TANK FILTER BAGS

ter

VACUUM FLOW

S/S Filter

\ /

Recovery Tank

Filter Bag

Spray lubricant into blower lube port for 3 to 5

seconds, then immediately shut off machine.

Use only LPS 1 or WD-40 moisture displacing

lubricants.

Page 15

1. All Sutorbilt California Series ‘F’ blowers are covered by this warranty.

2. Warranty period is 24 months from date of shipment, or 18 months from date of installation, whichever occurs first.

3. Sutorbilt will replace or repair any unit covered by this warranty without regard for the cause of failure.

4. Customers claiming relief under this warranty shall issue a Purchase Order to Sutorbilt for a replacement unit.

5. Customer must obtain a Return Goods Authorization number from the factory and return blower prepaid to an Authorized

Factory Repair Center, as directed.

6. On receipt of the blower a credit memo will be issued to offset the P.O. issued Der (4} above.

7. Replacement unit will be shipped to customer at Sutorbilt’s expense to any destination in the US or Canada.

8. SUTORBILT reserves the right to withdraw the Uncontested Warranty where evidence indicates application outside the

manufacturer’s stated performance area, or where there is evidence of abuse.

CONTACT SUTOR81LT FOR THE LOCATION OF THE

1

FACTORY AUTHORIZED SERVICE CENTER NEAREST YOIJ

.,

Ila

-.

1

ZJ

$puggyL;

~

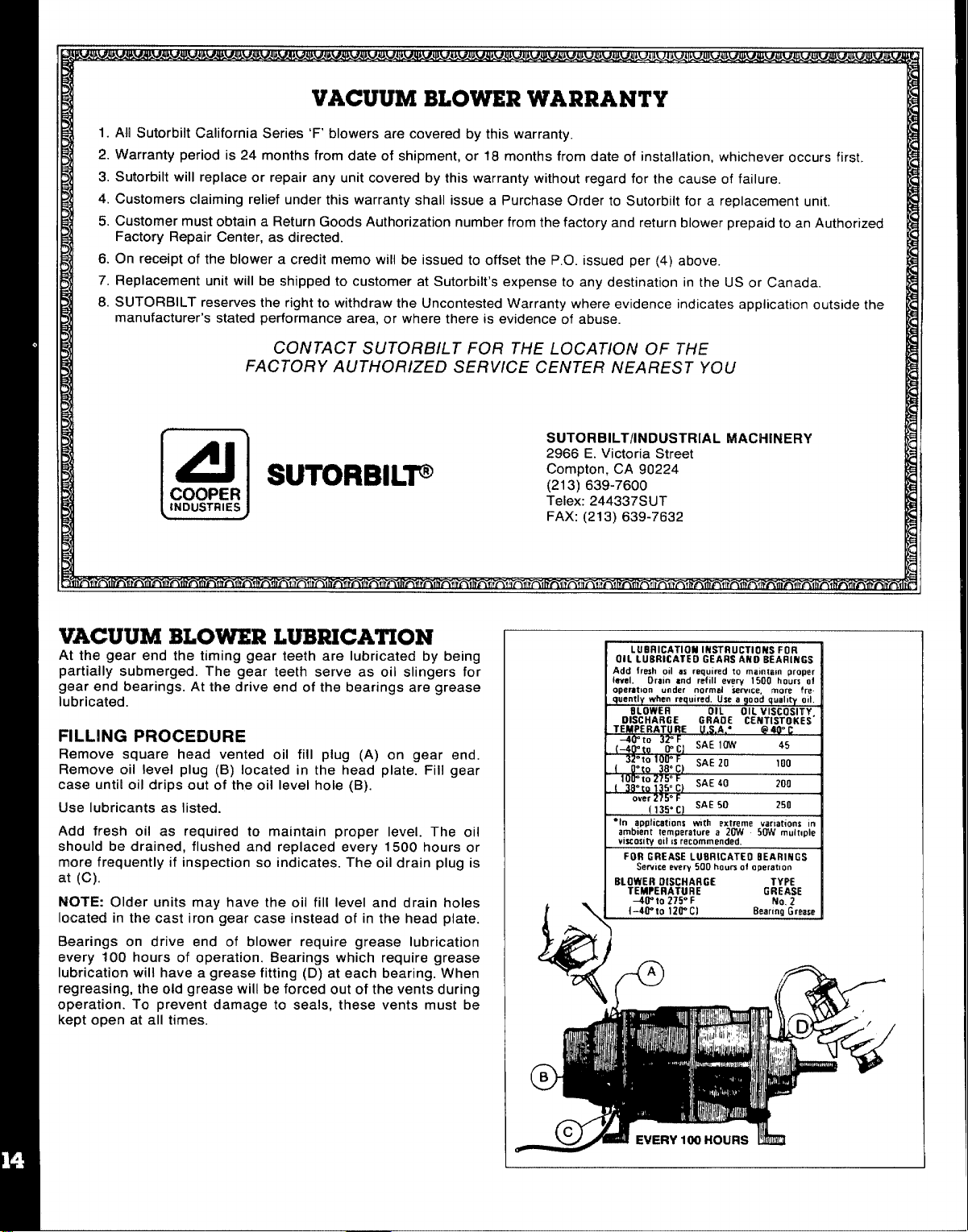

VACUUM BLOWER LUBRICATION

At the gear end the timing gear teeth are lubricated by being

partially submerged. The gear teeth serve as oil slingers for

gear end bearings. At the drive end of the bearings are grease

lubricated.

FILLING PROCEDURE

Remove square head vented oil fill plug (A) on gear end.

Remove oil level plug (B) located in the head plate. Fill gear

case until oil drips out of the oil level hole (B).

Use lubricants as listed.

Add fresh oil as required to maintain proper level. The oil

should be drained, flushed and replaced every 1500 hours or

more frequently if inspection so indicates. The oil drain plug is

at (C).

NOTE: Older units may have the oil fill level and drain holes

located in the cast iron gear case instead of in the head plate.

Bearings on drive end of blower require grease lubrication

Wery 100 hours of operation. Bearings which require grease

lubrication will have a grease fitting (D) at each bearing. When

regressing, the old grease will be forced out of the vents during

operation. To prevent damage to seals, these vents must be

kept open at all times.

=n m7fiC2~lL’”

1 wu E vnu

:lx

cc I

SUTORBILT/industrial MACHINERY

2966 E. Victoria Street

Compton, CA 90224

(213) 639-7600

Telex: 244337SUT

FAX: (21 3) 639-7632

LUBRICATION IN~RUCTiONSFOR

OILLUERICATEOGEARSAMOB~ARIR~S

Add fresh od m roqulmd to mamtam proper

Ieval. Dram cnd refill every 1500 hours oi

cmeratbon under normal kwice. more fm.

qbently when reqwred, U$e a good qualmy

BLOWER

OISCHARGE

TEhlPER+lTUBE

~!: %;, SAE1OW

%

W

over

=~!, SAE 50

‘In appficat(on$ w!th extreme varmt!om In

ambient temperature a 20w 50w mulrmle

viscosl~ oil ISrecommended.

FOR GREASE LUBRICATE EEARINGS

Sefwce every 500 houm of operatnon

OIL OILVISCOSl~~,

GRA#$ CENTISTOKES

F

SAE 20 100

c)

SAE 40 ?Iln

-,.,

)

o

45

250

1

Ott.

1

I

Page 16

VACUUM BLOWER TROUBLESHOOTING GUIDE

PROBLEM: Loss of Vacuum

Cause

Collapsed vacuum hose between blower and vacuum tank.

Clogged stainless steel filter.

Defective vacuum tank seal.

Defective or ‘open’ vacuum tank dump valve.

Fractured weld on vacuum tank.

Collapsed or kinked vacuum hose.

Plugged vacuum hose.

Restriction in cleaning tool.

Worn end plates or lobes in vacuum blower.

Loose drive shaft between clutch and blower.

PROBLEM: Blower is Seized

Cause

Rust.

Foreign matter.

NOTE: The above mentioned, rust, foreign matter and seizing are often caused from foam traveling through the blower.

Solution

Remove and replace hose. NOTE: A special reinforced hose

is reauired for replacement.

Remove and clean or replace stainless steel filter.

Remove and replace vacuum tank seal.

Close valve.

Replace valve.

Re-weld as required or replace tank.

Reshape hose if possible and/or eliminate kinks.

Remove obstruction by reversing the vacuum hose.

Remove obstruction.

Replace worn components. NOTE: Must be accomplished by

a qualified technician.

The set “screws may come loose causing blower to stand still

while engine may be turning properly. NOTE: Unless the

blower is seized or making a knocking noise, your vacuum

loss is not caused by a bad blower.

Solution

Spray rust dissolving lubricant onto lobes to emulsify rust and

attempt to rotate vacuum lobes.

Disassemble and remove foreign matter and repair as

required. NOTE: Disassembly must be accomplished by

aualified technician.

PROBLEM: Noise in Vacuum Blower

Cause

Worn Gears.

Lack of Lubrication. NOTE: Permanent damage may have

resulted from lack of lubrication.

Worn bearings.

Debris and/or foreign material build-up. NOTE: A stainless

steel filter is provided in vacuum inlet located in vacuum

blower components.

Loose or missina mountina bolts. Tiahten or reinstall mountina baits.

Solution

Remove and replace gears. NOTE: Replacement of gears

must be accomplished by a qualified technician.

Timing of vacuum blower has been changed due to worn

components. Replacement of components must be

accomplished by a qualified technican.

Lubricate as specified by applicable vacuum blower manual.

See index.

Remove and replace bearings as required. Must be

accomplished bv aualified technician.

Disassemble vacuum blower and remove foreign material.

NOTE: Disassembly should be accomplished by qualified

technician only. Replacement of worn parts is recommended is this procedure is necessary.

Page 17

HEATING SYSTEM INFORMATION

The propane heater incorporated in this equipment is a special

design for use in the carpet cleaning industry. It’s high pressure

coils and thermostatic temperature control make it simple to

operate and reliable. Once the desired temperature is set, the

heater will then go ‘on’ and ‘off’ according to the water temperature

within the heater. As water is used through the cleaning tool, cold

water entering the heater will activate the thermostatically controlled propane valve thereby firing the heater to maintain a con-

skitant flow of hot water. Cmce the cleaning wand is shut off and

the flow of water through the heater stops, the heater will continue

to burn until the set temperature is attained.

It is possible then with this design that the flame may be on when

the wand is off, likewise, it is possible the flame may be off when

the wand is on.

CAUTION: This heater is designed to burn vapor propane gas

only. ArJy liquid propane entering the heater may cause damage

to the control valve on the heater. it will also cause improper

burning and a soot build-up on the coils. Therefore, it is

necessary to shut off the heater and c/ose the valve at the tank

bet ween cleaning locations. Failure to do this allows sloshing li-

quid to enter the vapor feed line to the heater.

IMPORTANT Overfilling of the propane tank will cause many

problems. To avoid this, advise the attendant filling the tank not

to fill the tank over 80%. When filling the tank, watch the 10%

valve and immediately stop filling when white liquid starts spurt-

ing from th@ 10°4 valve. To prevent damage to the propane

regulator’, always close the vaive on the tank before filling.

The propane regulator is pre-set at the factory at 6 oz. of propane.

This reading is taken at the control valve on the heater (see figure

A -No. 6). To prevent road dust and moisture from entering the pro-

pane regulator, keep the white plastic cover (supplied) on the

regulator at all times.

To avoid restriction of air flow at base of heater, keep articles such

as chemical containers, hose, boxes, etc. from within 18 inches of

base of heater. NOTE: This restricted situation also creates an

over rich condition which results in soot build-up.

IMPORTANT If a new propane tank has been installed or hoses

have been disconnected, air may enter propane hoses and must

be purged prior to attempting to light the pilot burner. Should this

condition exist, operator must depress the pilot button for 1-5

minutes and attempt to ignite the pilot light at 15 second intervals.

A very slight hissing noise should be evident while performing this

operation.

CAUTION: Check heater for propane leaks regularly as loading

and unloading hoses, too/s, etc., may accidentally bump against

heater fittings or pipes.

HEATER- OPERATING INSTRUCTIONS

CAUTION: Heater must be fi//ed with water prior to igniting.

A. TO START PILOT

1. Adjust thermostat control knob on unitrol to desired setting.

2. Adjust upper dial to pilot position.

3. Depress pilot button.

4. Depress sparking button to light pilot.

IF PILOT FAILS TO LIGHT:

Is propane tank full?

Is propane tank valve open?

Has air been properly bled from propane line?

WHEN PILOT LIGHTS:

Wait ten seconds, depressing button manually, then release

button.

CAUTION: Always keep face away from main burner opening to

avoid ignition flash burn.

B. TO LIGHT MAIN BURNER:

1. Turn upper knob to “on” position. Flame will come on.

If you do not get the burner to flame, the pilot has expired. You

must turn upper dial to “off” position. Do not attempt to re-light

the pilot for 60 seconds. To light the main burner, repeat instructions as above (TO START PILOT), 1 through 4.

OR,

Water may already be at controlled temperature.

Flame will turn off when thermostat senses maximum

temperature.

C. TO ACHIEVE PROPER CARPET CLEANING

TEMPERATURE

1. Complete procedures A & B.

2. With 100’ of hose, turn cleaning wand on for 5 minutes and the

temperature should stabilize.

3. Once a constant temperature is established, turn cleaning

The flame on the heater burner should remain on for 10-15

‘off’.

seconds.

A. If the flame expires prior to 10 seconds, turn the thermostat

dial to a higher reading, then repeat C 1-3.

B. If the flame remains lit after 15 seconds, turn the thermostat

dial to a lower reading, then repeat C 1-3.

D. TO SHUT DOWN HEATER:

1. Turn upper dial #1 to ‘off’ position.

2. CAUTION: Turn cleaning wand on for 3 to 5 minutes to cool

heater core. If heater core is not cooled, it is possib(e that the

heat retained in the core will cause boiling back into a

chemical mix tank.

3. Close propane tank valve While wand IS on and heater w

cooling.

wand

PILOT BURNER ADJUSTMENT

1. Remove pilot adjustment cap #5.

2. Adjust pilot key to provide

properly sized flame.

3. Replace pilot adjustment cap.

Allen head pipe plug #6 can be

removed for monometer insertion

to read propane ounces.

@

@l’@

Page 18

HEATER TROUBLESHOOTING

PROBLEM: Excessive Heat

Flames Proturding Outside The Lower Openings

Cause lSolution:

1. Thermostatic control dial set too high.

A. Turn dial to lower setting.

2. Maladjustment of propane regulator. NOTE: Propane regulators

are factory preset and may be readjusted by authorized

personnel.

A. Contact manufacturer to determine correct procedure.

B. Have your local propane dealer use a monometer at the

unitrol to reset the propane regulator to 7 oz. maximum.

3. Overfilled propane tank. NOTE: Propane heater is designed to

operate on vapor propane only. Over-filling a propane tank

allows liquid propane to enter all heater related components

and permits an over-rich burning condition to occur. This condition usually requires the heater core to be cleaned of soot and

carbon deposits. Cleaning is a messy, dirty job and very

inconvenient, so don’t let it ha~~en to you!

PROBLEM: Pilot Light

Cause lSolution:

1. Pilot light will not ignite. NOTE: Do not use a needle or pin to

clean pilot orifice - use compressed air or solvent only.

A. Verify propane reaching igniter. NOTE: A kinked or crushed

hose may impede propane flow.

B. Remove and clean orifice.

C. Verify iqnitor spark is operating correctly.

CAT PUMP Model 290

OPERATING INSTRUCTIONS

CAUTION: CAT PUMPS are positive displacement pumps.

Therefore, a properly designed pressure relief mechanism MUST

be installed in the discharge piping. Failure to install such relief

mechanism could result in personal injury or damage to the pump

or system. Cat Pumps Corporation does not assume any liability or

responsibility for the operation of a customer’s high pressure

system.

SPECIFICA~ONS

Volume:3.5 GPM (13 L/M)

DischargePressure:1200 PSI (83 BAR)

MaximumInlet Pressure -8.5 to + 40 PSI (-0.6 to + 2.8

RPM: 1200 RPM (1200 RPM)

Bore: 0,787” (20mm)

Stroke 0.472” (12mm)

Crankcase Capacity: 10 oz. (.3 L)

Maximum Fluid Temperature: 180”F (71 “C)

Inlet Port (l): 1/2’: NPT (1/2” NPT)

Chemical Injection Port (1): 1/4” NPT (1/4” NPT)

Discharge Ports (2): 3/8” NPT (3/8” NPT)

(l): 1/2” NPT (1/2” NPT)

Pulley Mounting: Either side (Either side)

Shaft Diameter 0.650” (16.5mm)

Weight: 12.1 Ibs. (5.5 kg)

Dimensions: 10.77’’x9.O6’’XI.I 4“ (273,5 x230x130.5 mm)

BAR)

Products described hereon are covered by one or more of

the following U.S. patents: 3558244, 3652188, 3809508,

3920356, and 3930756

—-. _

JP*-*+

.3

CO RPOF7ATION

SS5 MINNEAPOLIS, MN 55440

PO. Box

Phone (612) 780.5440 – Telex 294276 Phone 0612.56000112 — Telex 41 ffi713

● N V CAT PuMPS INTERNATIONAL S.A. s

Harmonlestraat 29

S 2000 Antwerp, Belglum

Pho”e (03] 237.72.24 — Telex 33947

● CAT PUMPS — A,G.0

Loretohoehe 5

CH.6300 ZUG, Switzerland

Phone (42) 21.3140 — Telex S$5 160 cpag ch

9

CAT PuM’PS DEuTSCH LAND GmbH ●

Restocker SIrasse 9

6200 Wlesbaden.Blerstadt, West Germany

● CAT PUMPS (u.K ) LTO 9

27 StatIon Industrial Estate, Fleet

Hampshtre GU13 80Y, England

Phone Fleet 22031 — Telex S5SS9S

Page 19

CAT PUMP WARRANTY

This Cat Pump (“product”) is warranted by the manufacturer to

be free from defects in workmanship and material for one year

from date of manufacturer’s shipment. This warranty is limited

to repairing or replacing products which manufacturer’s in-

vestigation shows were defective at the time of shipment by the

manufacturer. All products subject to this warranty shall be

returned F.O.B. Cat Pumps Corp., Minneapolis, Minnesota

55430, U.S.A. for examination, repair or replacement.

The express warranty set forth herein is in lieu of all other war-

ranties, express or implied, includingwithout limitationany war-

ranties of merchantability or fitnessfor a particularpurpose and

all such warranties are hereby disclaimed and excluded by the

manufacturer. Repair or replacement of defective products as

provided above is the sole and exclusive remedy provided

hereunder and the manufacturer shall not be liable for any fur-

ther loss, damages or expenses, including incidental or conse-

quential damages, directly or indirectly arising from the sale or

use of this product.

This warranty is subject to the following warranty conditions:

Important Ccmditions

LUBRICATION - fill crankcase

per specifications with Cat Pump oil or equivalent SAE 40

to the top of oil gauge window

weight hydraulic oil with antiwear and rust inhibitor additives,

Change initial fill after 50 hour run-in period. Change oil every

three months or at 500 hour intervals thereafter. Prrrrrm-a-lube

seals need no lubrication. Blue dot seals and wicks must

receive three drops of Cat Pump oil per wick every 50 hours of

operation.

GOOD LUBRICATION IS THE EASIEST, MOST EFFICIENT

AND LEAST EXPENSIVE OF PREVENTATIVE

MAINTENANCE.

RPM and PRESSURE - Pump operation must be wltttin RPM

and pressure specifications. Pressure relief valve must be

installed.

DO NOT PUMP ACIDS OR ABRASIVE FLUIDS with this unit.

Consult Cat Pumps for additional information on questionable

fluids.

FREEZING CONDITIONS - Pump must be protected from

freezing conditions.

USE OF OTHER THAN CAT PUMP PARTS OR THEIR

EQUIVALENT

VC)IDS THE WARRANTY

GENERAL INFORMATION FOR CAT PUMP REPAIR

As you remove your discharge manifold, there is a set of 3 check

valves (which usually fall out during dis-assembly). If the surfaces

of these check valves are dirty, or show signs of chemical build-up,

it is probable that they would remain open causing pressure loss

or pulsation. Upon inspecting the valves, make sure that the teflon

buttons in the valve spring retainers are still intact. Also examine

the discharge manifold. Look for problems such as cracks,

chemical buildup or warpage due to freezing. If this discharge

manifold is warped, it will cause the check valves to stick and will

result in loss of pressure.

The Cat pump cups are often the source of pressure loss. Upon inspection they may appear melted or torn, but often they will look

goad. Replace them anyway. There is no sure method of visually

inspecting the cups. HydraMaster recommends changing cups

whether they look gaod or not.

Anytime your pump is being dismantled, HydraMaster recommends replacement of all ‘o’ rings and seals. This is merely a convenience to the customer to make sure that the Cat pump is in top

operating condition.

The prrm-a-lube seals located within the intake manifold will allow

air to enter the pump ifthey are worn. Again, it is difficult to visually

pinpoint a defective prrrm-a-lube seal. Replace them all.

Within the piston sleeve cylinders there are 6 ‘o’ rings that are

1/4 the size of a penny. If these ‘o’ rings are bad, water will be

about

pumped back into the oil. If this has occurred the oil will raise in

level and appear milky. If you are unable to repair seals right away,

change oil frequently. Repair the pump as soon as possible so as

to not damage bearing or connecting rods.

Repairing of Cat pumps is not a difficult task, However, before

disassembling make sure you have the proper parts required.

1 - short (or hot) cup kit 3- Prrrm-a-lube seals

6- piston sleeve ‘o’ rings

Read instructions thoroughly, supplied in the Cat pump manual,

prior to disassembly and follow directions as stated. Oil all seals

thoroughly prior to installation. (Remember, a newly scarred seal

is no better than one you just took out.)

1 - bottle Cat oil

Page 20

PISTON MODEL 290 Exploded View

PARTS LISTModel 290

ITEM PART NO. DESCRIPTION

1 20285 O-Ring (Buns-N) 1

2 44274 Crankcase 1

3 85660 Stud (M8

4 44377 O-Ring, Oil Filler Cap 1

5

8

9

10 43987 Bubble Oil Gauge 1

11

12

15

4R Aannd

,“ . . . . .

17 14467

18

19 26536

20

21

23

24

25

26 20017 Seal Washer 3

27 25301 Oil Seal 3

28 25327 Barrier Slinger 3

29 25392 O-Ring, SIeeva 3

30

31

32

33

34

44374

43340 O-Ring, Crankcase Cover 1

43339

23170

25625 Drain Plug

92520 Sems Comb Head Screw

Oil Filler Cap

Crankcase Cover 1

O-Ring, Drain Plug 1

(M6 x

Crankshaft

Rearing 2

~il Seal (Buns-N) 2

24159

27950

92519

101799

101800 Piston Rod

16946 Ptston Pin

28771 O-Ring, Sleeve (Viton) 3

u

)-Ring, Oil Seal Case 2

o

Oil Seal Case 2

Sems Comb. Head Screw

(M6x 16) 8

Connecting Rod 3

29003 Back-UpRing,Sleeve (Teflon) 3

29614 Sleeve (29743 Unchromed) 3

26854 Seal Washer 3

28597 Seal Retainer 3

25126 Inlet Manifold

25635

Inlet Manifold-StainlessSteel 1

X 62)

20) 6

QTY.

2

1

1

1

3

3

1

ITEM

35 30315

38

39 30543

40

41 43172

42

43

44 27006 Conical Washar-SS (M6)

45

46 14158 Cotterpin

47 101602

48

49 21985 Bat-Up Ring, Cylinder

50 24459 Discharge Manifold

51 43442 Valve Spring Retainer

52 43360 Valve Spring

53 43723 Valve

54 43434 Discharge Valve Seat

56 81109

57

58 25130

PART NO. DESCRIPTION

Prrrrrm-A-Lube Seal

30325

27004 Inlet Valve 3

30544

Prrrrrm-A-Lube Seal (Viton)

Bat-Cup Piston

Bat-Cup Ring (Teflon)

Cup (Viton)

43474

27983 Piston Spacer 3

27002 Piston Retainer 3

27000 Nut-SS (M6)

23172

11377 O-Ring, Cylinder (Viton)

25634 Discharge Manifold-S.S.

101804 Hex Flange Nut (M8)

Bat-Cup Assembly 3

Cylinder (43634 Unch) 3

O-Ring, Cylinder (Buns-N)

Hex Nut (M6)

Shaft Protector 1

Electrlc Clutch Assembly

59 152-005 Tapered Sleeve 1

60 077-005

61 036-005 6“ Electric Clutch

62 143-084

63

ii

174-004

174-0;8 Lock Washer (5/1 6 US)

Key, Electric Clutch

8-30 mm Socket H

Flat-Washer (5/16 US)

. . . . . .Iead Screw 1

Wry.

3

3

3

3

3

3

3

3

6

6

3

1

1

3

3

3

3

2

2

1

1

1

1

Page 21

PUMPING SECTION CUTAWAY

\

6ac-Cup

Piston Spacer

I /

/

Nut

078-001 cup Kit

3

cup

6 O-Ring, Cylinder

3 Cotterpin

1 Instruction Sheet

1

Cup Inserter

078-003 Seal Kit

30431

Prrrrrm-A-Lube Seal

3

3

Cotterpin

2

Abrasive Paper

1

Instruction Sheet

Sleeve and Seal Kit

Prrrrrm-A-Lube Seal

3

3

Barrier Slinger

3

Cotterpin

3

Sleeve

O-fling, Sleeve

6

1

Instruction Sheet

l-l

Cylinde~

I 11P

/

078-006 Valve Kit

3

;

3

3

1

30860

6

3

3

3

3

3

3

3

3

3

3

1

Bat-Cup Ring

/

iston

Piston Rod Sleev~

Valve Spring Retainer

Valve Spring

Valve

Valve Seat

O-Ring, Cylinder

instruction Sheet

Piston Kit

O-Ring, Cylinder

Back-Up Ring, Cylinder

Bat-Cup Piston

Bat-Cup Ring

cup

Piston Spacer

Piston Retainer

Conical Washer (M6)

Nut (M6)

Cotterpin

Inlet Valves

Instruction Sheet

SERVICING THE VALVE ASSEMBLIES

DISASSEMBLY

1. Remove the fasteners securing the discharge manifold to the

crankcase of the pump.

2. Support the discharge manifold and tap from the backside

and a soft mallet to separate from the crankcase and

gradually work free from cylinders.

3. Valve assemblies will remain in the manifold. Pump madt?ls

with the o-ring groove on the outside of the

require the assistance of a reverse pliers to remove th~

valve seat. The valve, spring and retainer will then fall out

when the manifold is inverted.

Pump models without the o-ring groove on the outside of the

valve seat permit the seat, valve, spring and retainer all to fall

out when manifold is inverted,

REASSEMBLY:

1, Place retainers in manifold chambers

2. Next insert spring into center of retainer

3. Inspect the valves for wear, ridges or pitting and replace if

necessary.

NOTE: Seating side of fiat valves maybe lapped on flat

face using 240 grit paper. Quiet valves due to their shape

must be replaced.

Insert valve over spring with recessed (dish) side down.

4

Next examine the seating surface of the flat valve seats and

lap with 240 grit paper ;r replace if evidence of excessive

wear. Quiet valve seats should be replaced if worn, Lap new

quiet valve and seat to assure positive seal.

5. Some pump models have o-rings and back-up rings on the

valve seat, Examine and replace if worn. Always lubricate

o-rings for ease of installation and to avoid damaging

elastomers.

NOTE: First install o-ring in groove on seat (towards seating

surface), then back-up ring.

NOTE: Models without outer groove on seat require the

o-ring to be placed on lip of retainer.

6. Insert valve seats into manifold chambers.

7

Position manifold back onto pump.

NOTE: Lubricate o-rings on cylinder and exercise caution

when slipping manifold over cylinders to avoid damaging

cylinder o-rings.

Replace fasteners and torque per specification chart.

8.

NOTE: Replace ali original shims when used. When new

manifold is used reshim pump.

CAUTION: When starting the pump, check to see (hat there IS ‘

no cylinder motion as this will cause premature failure of the

cylinder o-rings. Center cylinder motion can be eliminated by

switching with one of the end cylinders.

va!ve seat

sur-

Page 22

SERVICING THE PUMPING SECTION

DISASSEMBLY:

1.

Remove discharge manifold as described.

2.

Grasp cylinders by hand and with an up and down motion,

pull cylinders from inlet manifold.

3.

Remove cotterpin, nut, and washer from piston rod.

4.

Next remove retainer, spacer, and piston/cup assembly.

5.

Remove inlet valve.

REASSEMBLY:

1. Examine inlet valve surfaces for pitting, scale or grooves.

Reverse valve and sand inlet side of valve using 240 grit

paper for clean surface or replace if evidence of excessive

wear. Slip onto rod.

2. Examine piston seating surfaces and sand clean on flat surface using 240 grit paper. If extreme pitting or sharp edges,

replace piston.

3, Examine cup for wear, cracking, tearing or separation from

the piston. If worn replace and lubricate before installing on

piston.

NOTE CUP INSTALLATION: Wipe cup inserter with oil. Slip

bat-cup ring (when used) onto piston. Push cup over inserter and square with all surfaces. Faulty cup installation

causes premature cup failure.

4. Next replace piston spacer and retainer on rod.

5. Replace washer, thread on nut and torque per specification

chart.

NOTE: Always replace with new Stainless Steel Cotterpin

and turn ends under.

6. Examine cylinder walls for scoring or etching which causes

premature wear of cups and replace if worn.

7. Lubricate cylinder walls for scoring or etching which causes