Page 1

HudraCat

HYDl?A&#ASREZ.

Corporation

Page 2

I

1

I

I1319W HydraMaster Corp.

Printed in U.S.A.

Page 3

GENERAL INFORMATION

Howlhe System Works..............................................................................2

Spare Parts Recommendation ..................................................................2

Machine S~cifi~tions .............................................................................2

Warning and Caution.................................................................................2

HowtoOrder ..............................................................................................3

PatisOrders ..............................................................................................3

One Final Note..........................................................................................3

Purchaser’s Responsititi~ ........................................................................3

Sales Representative’s Responsitili~ ......................................................3

TwckSelection ..........................................................................................4

TmckPre~ration ......................................................................................4

Tmck Pre~ration illustration .....................................................................4

Placementof Unitin Vehicle.......................................................................4

Machine installation ...................................................................................4

Propane Tank Location.............................................................................5

HardWaterArea Map................................................................................5

WaterSofiener ..........................................................................................5

Wastewater Disposal AdviwW ..................................................................6

Mactine A~ustments ................................................................................6

OPERATING INSTRUCTIONS & PRECAUTIONS

shdup . ....... ................... ................. ................... ........................ ...............6

ShutDom .................................................................................................6

Cautions and Warnings .............................................................................7

Freeze Protection......................................................................................8

Alternative Protection Using Anti.Freeeze .................................................8

Cleaning and Chemical Precautions ..........................................................8

Cleaning Stroke Procedure/Over.wetiing .................................................8

Water and Chemical Flow Operation .........................................................9

Chemical System Maintenance .................................................................9

Chemical Tank Trouble Shooting Guide..................................................lQ

Water Flow Trouble Shooting Guide

Vacuum System Information

VacuumTankfilter Bags.........................................................................l2

Vacuum Blower Wanan~ ........................................................................l3

~,,..:VacuumBlower Lubri~tion .....................................................................l3

Vacuum Blower Trouble Shooting Guide

Heating System Information

HeaterOperating lnstmctions ..................................................................15

HeaterTroubleShmtingGuide...................................................................l5

CatPump Mode12900prating lnstwctions ............................................l6

Cat Pump Wman~ .................................................................................l6

Mode1290PartsList

General Information forCatPump Repair................................................l8

Servicing the ValveAswmblies ...............................................................l8

Servicing the Pumping Section ................................................................l9

Servicing Sleeves and Seals...................................................................l9

Servicing Crankcase Section..................................................................l9

Cat Pump Trouble Shooting Guide..........................................................2O

HydraCat Electrical System

Onan Performer Engine

General Information about Onan

ENGINEMAINTENANCE

OilSystem

...............................................................................................25

.................................................................................l7

.....................................................................22

SPCS . ..... .................. ................................. .. ....23

........................................................................25

........................................................ll

...................................................................l2

............................................. ...

.....................................................................l4

.............................................................24

%--14

ignition....................................................................................................27

Cooling System

Exhaust System

AirCleaner

Batie~ .........................................................................................................28

Periodic Maintenance Stiedule ................................................................29

Engine Trouble Shooting

Maintenance Procedures........................................................................32

Overall Care ofUnit..................................................................................32

Maintenance Logs

Warranty Information

Warran~Pro~dure ................................................................................36

Limited Warranty Plan.....................................................lnside back cover

.......................................................................................27

.......................................................................................27

...............................................................................................27

.. .......... ...................... ............. ................... .......3o

....................................................................................33

...............................................................................36

LIST OF ILLUSTRATIONS

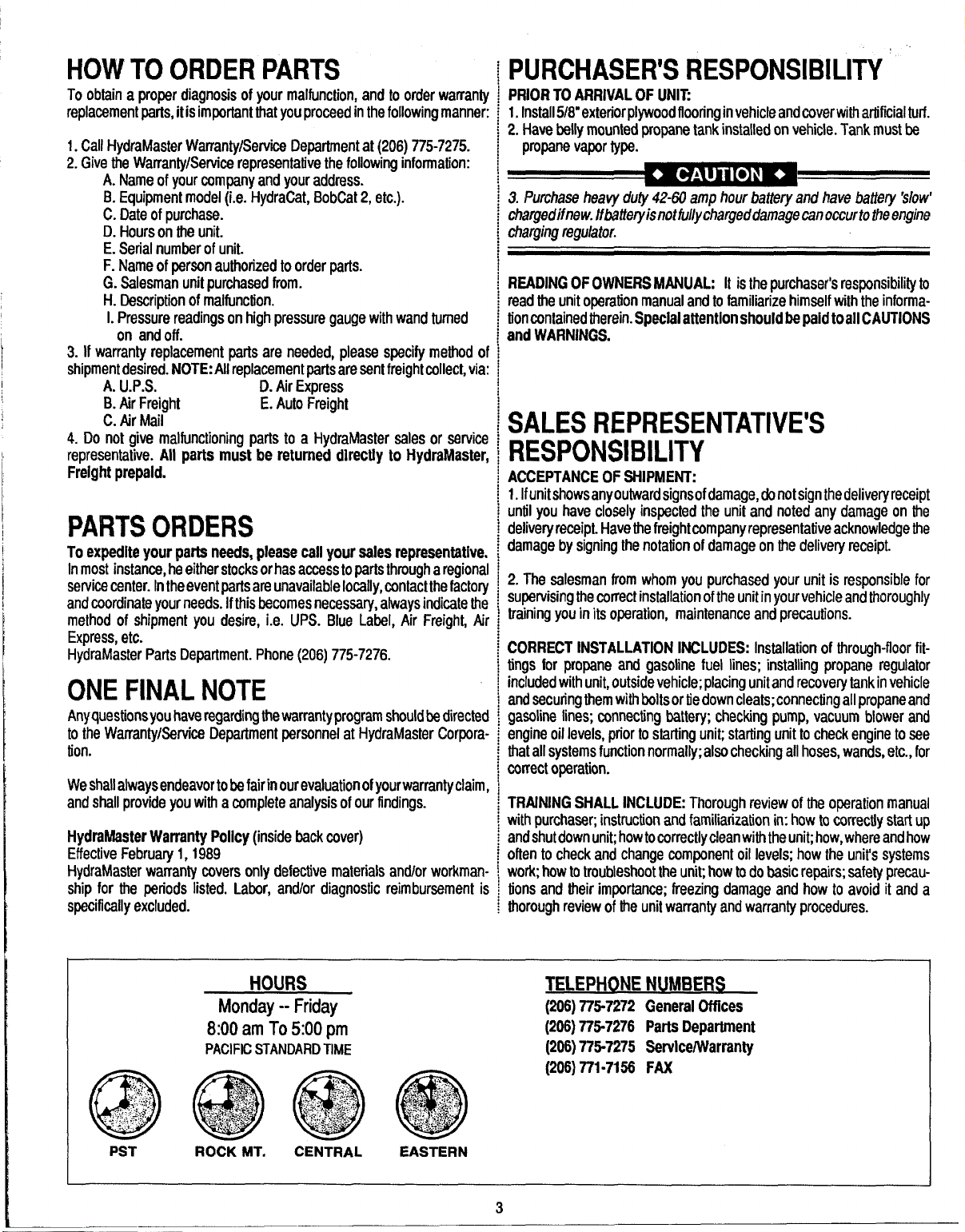

Plywood lnstallation(ontwck &d) ..............................................................4

AstiotudandRoof Vent...............................................................................4

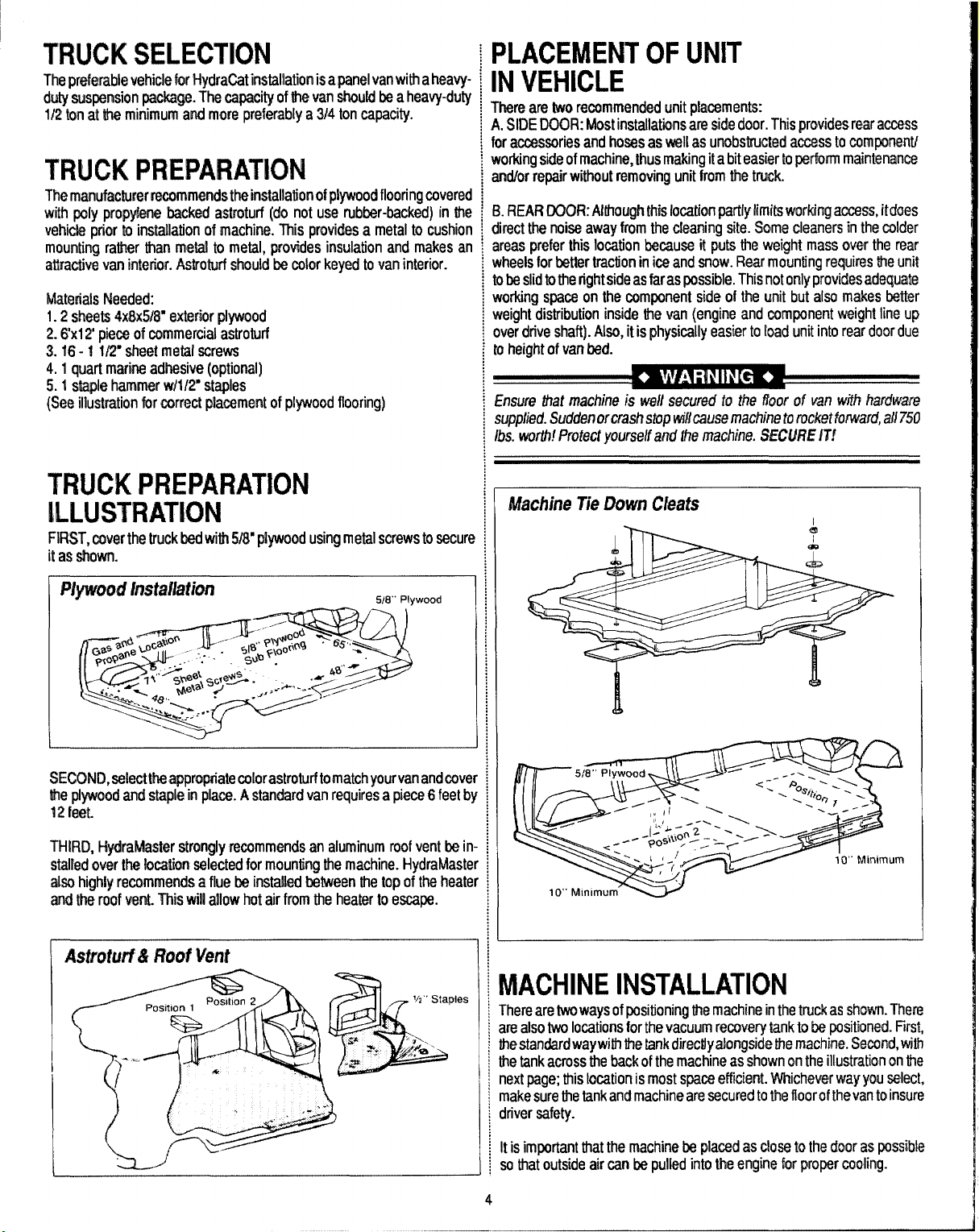

Machine XeDow Cleats...........................................................................4

~chine Configuration ...............................................................................5

Pro~neTankPlumting .............................................................................5

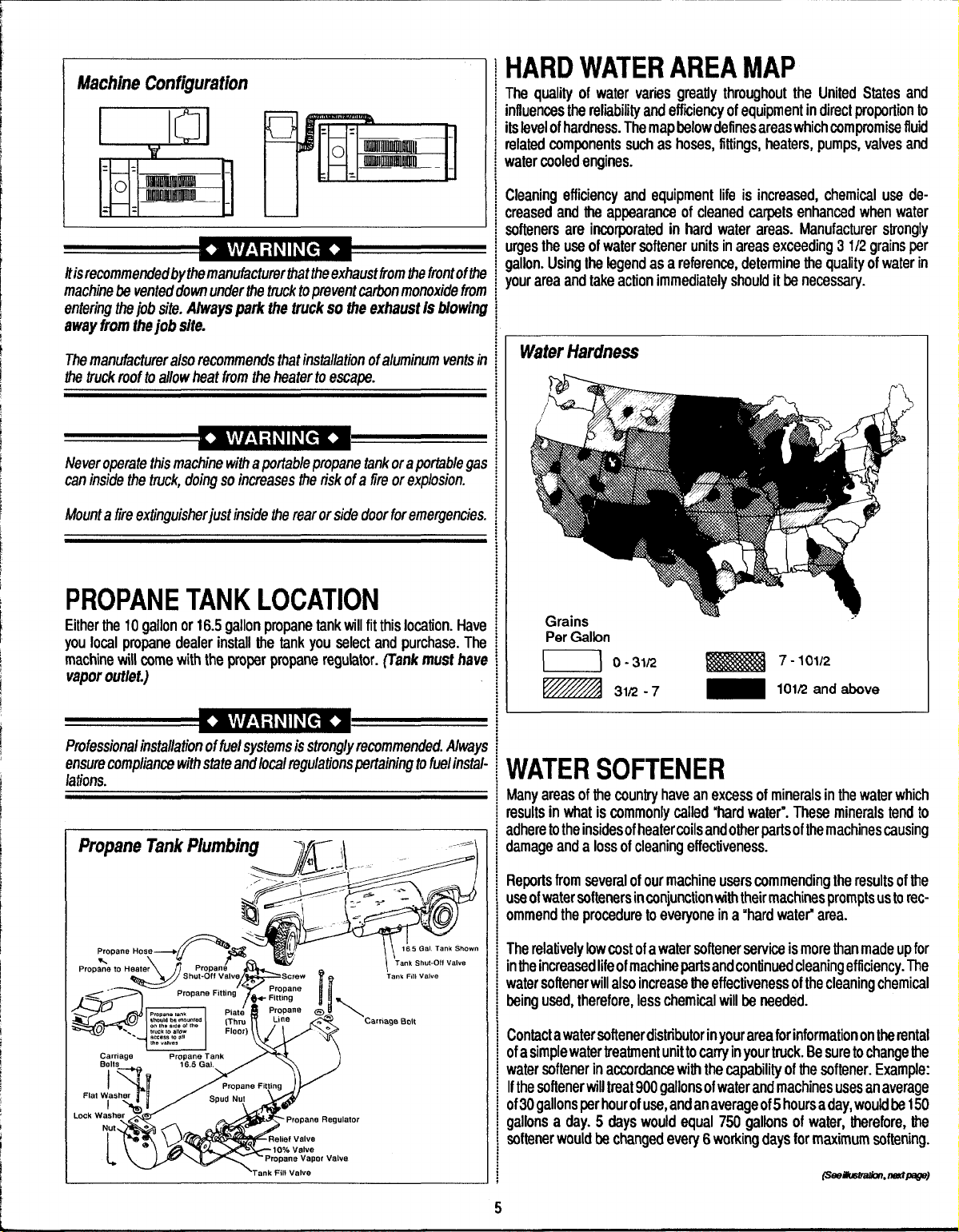

HardWakrMap .........................................................................................5

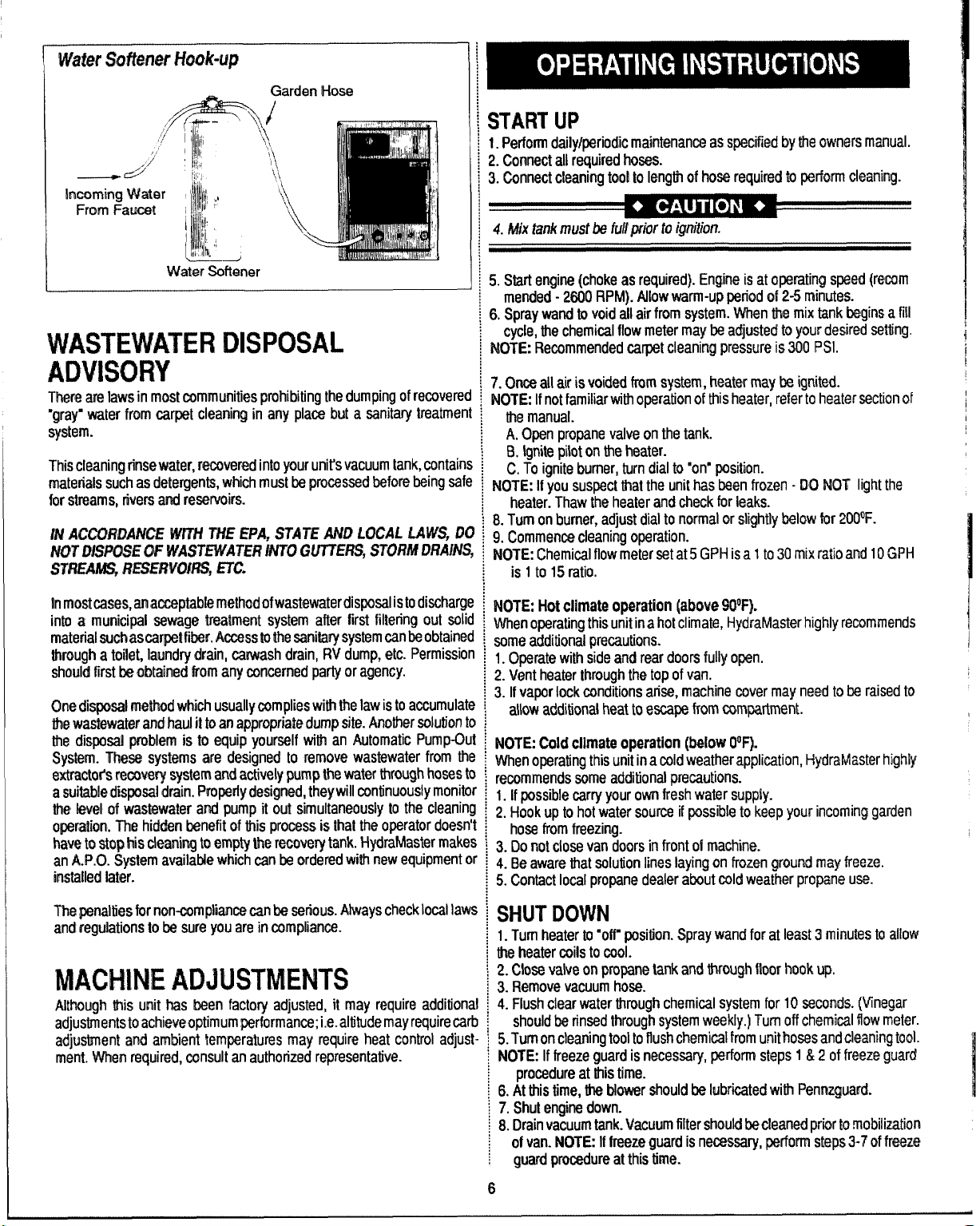

WaterSofienerHook.up .............................................................................6

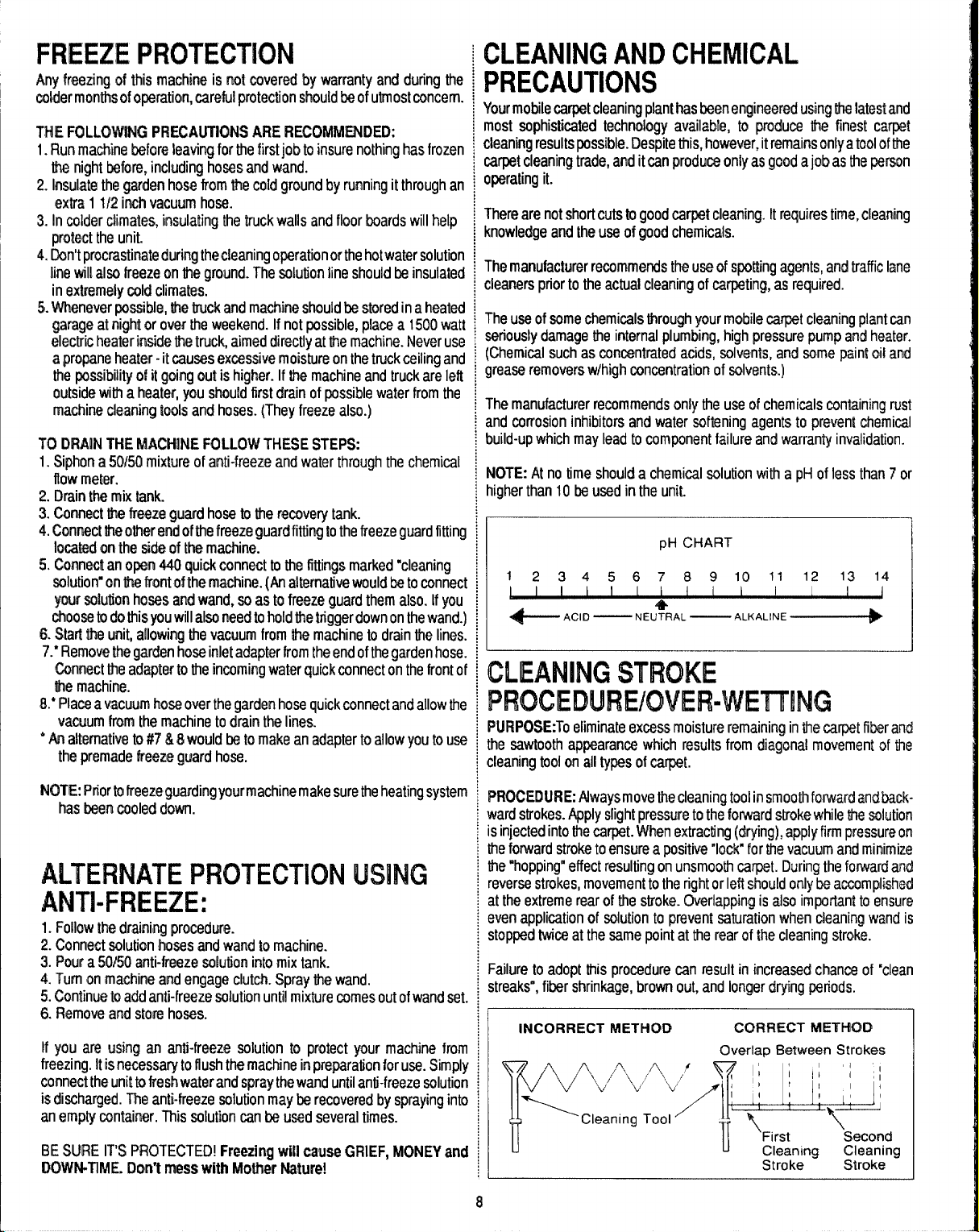

pHChati .....................................................................................................8

CleaningStroke Procedure........................................................................8

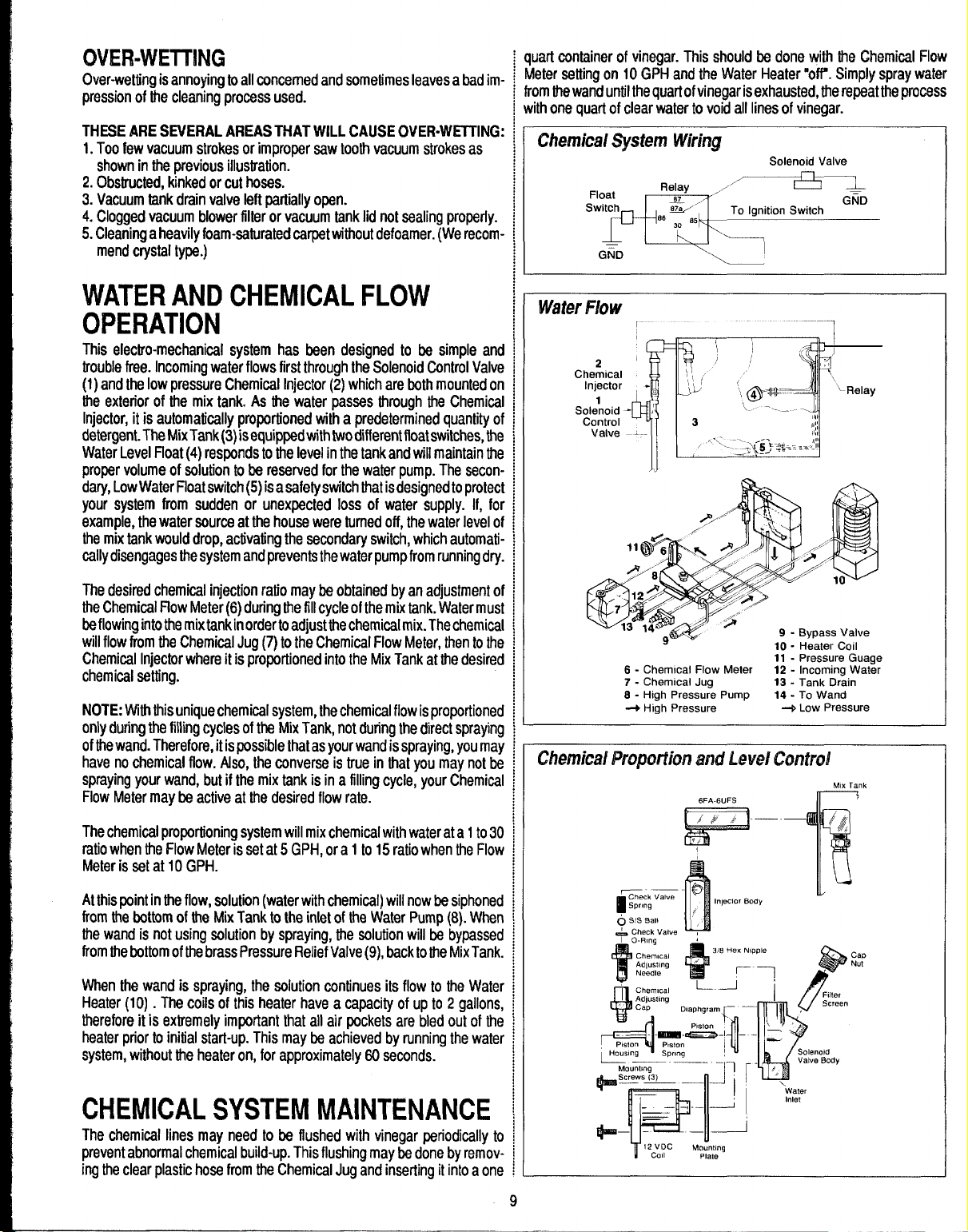

Chemiwl System Wring ............................................................................9

WaterFlow .................................................................................................9

Chemical Proportioning and Level Control..................................................9

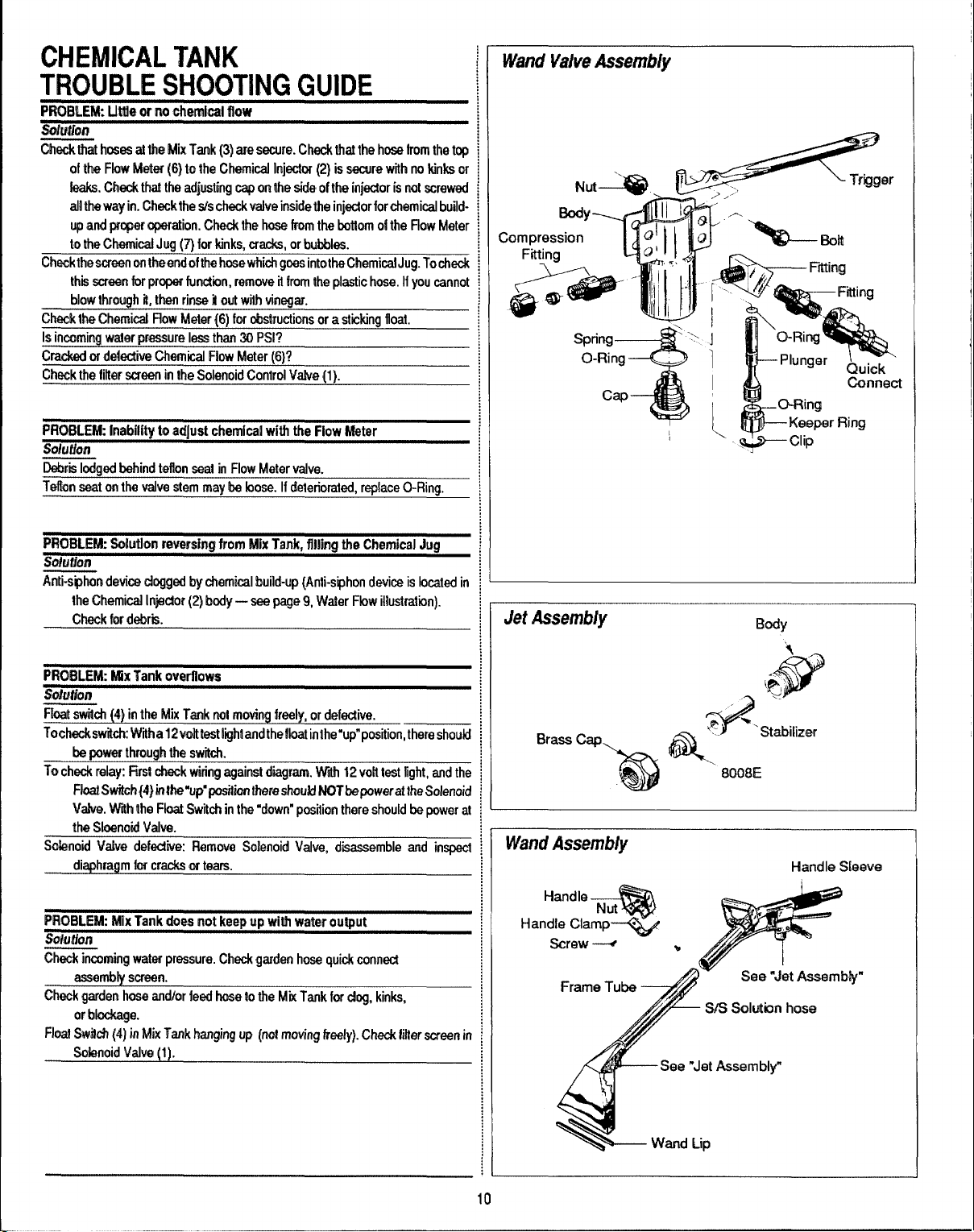

WandValveAssembly ..............................................................................lO

JetAswmbly ............................................................................................lO

WandAswmbly .......................................................................................ll

Wand Valve Stem Aswmbly ....................................................................ll

By~ss ValveAswmbly ...........................................................................ll

VacuumFlow............................................................................................l2

VacuumTankRlterBags ..........................................................................l2

BlowerLubPofi ......................................................................................l2

VacuumBlower Motor Lubrication............................................................l3

RlotBwnerAdjustment ............................................................................l5

Model 290 Exploded Mew.......................................................................l7

Pumping ~ction Cubway .......................................................................l8

HydraCat Electrical Diagram....................................................................22

BasicUmensions. P224..........................................................................23

Basic Dmensions. P220..........................................................................23

OIMmsi~ ..............................................................................................25

OlfilterLoMtion ......................................................................................26

P220CmnkMWBreather ........................................................................26

P224CmnkMWBreather ........................................................................26

SewicingS~rkPlug ................................................................................27

ArCleanerAswmbly ...............................................................................28

SWcificGravi~Test .................................................................................28

BatieqCaMeConnection .........................................................................28

LIST OF PHOTOS

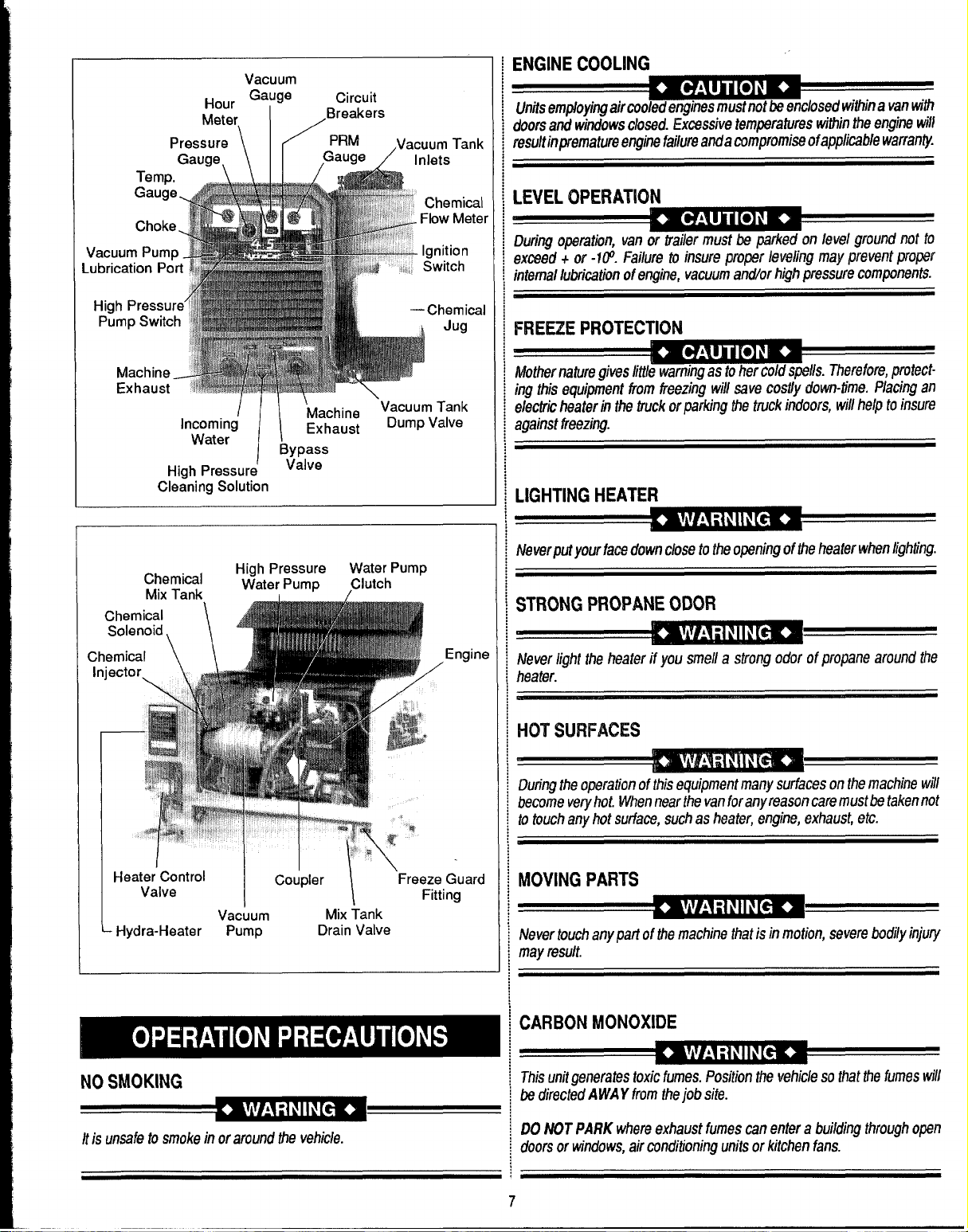

HydraCat (kontview.features labled) .......................................................7

HydraCat(sidetiew. featureslahled) .......................................................7

CatPumpMode1290 ................................................................................l6

Semicingtie Pump...................................................................................l9

Onan Performer Gasoline Engim .............................................................23

SparlrPlug Diagnosis

1

...............................................................................27

Page 4

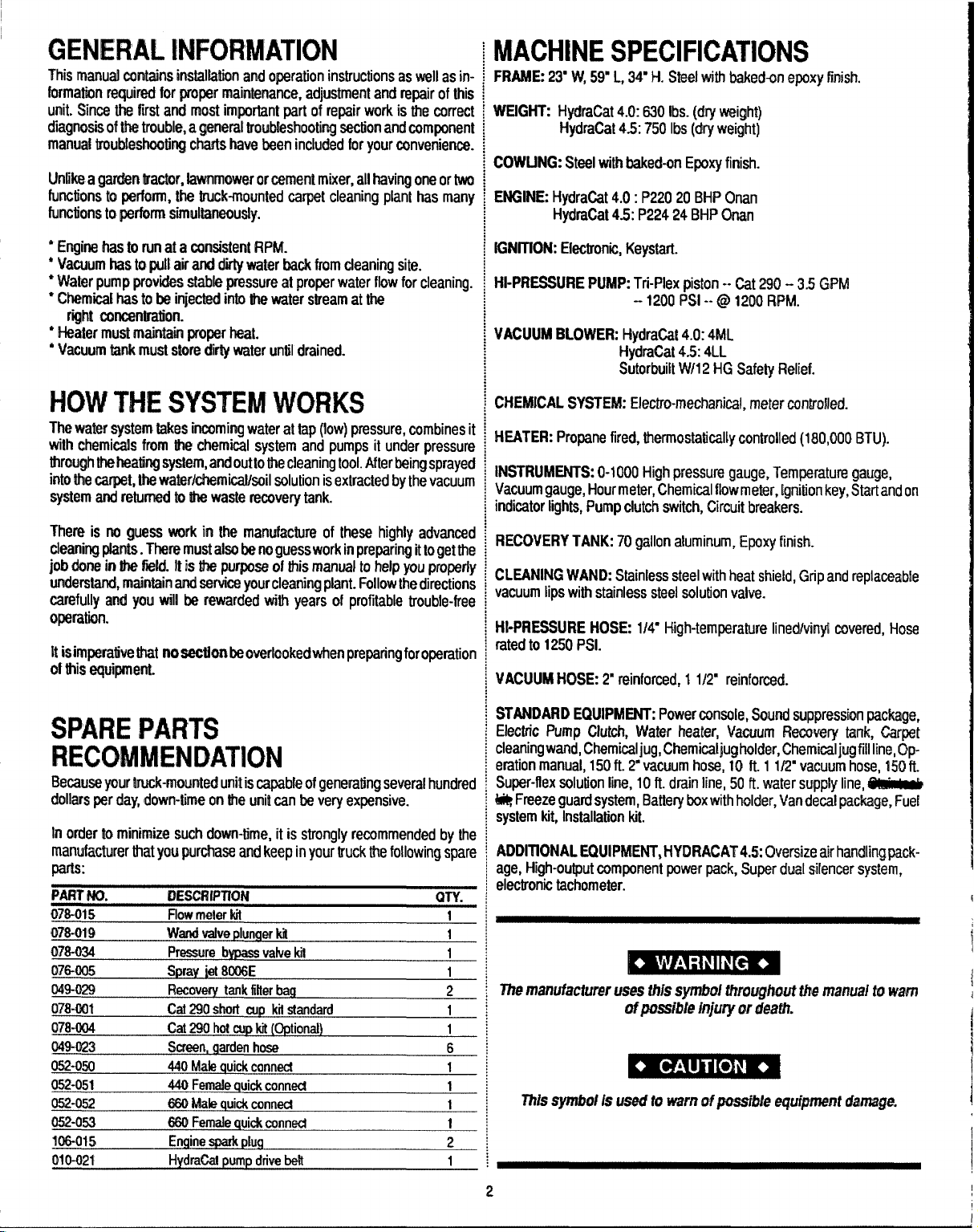

GENERAL UWWWIATION

T’hwmanual contains installation and operation instructions aswII as information rquired tar proper maintenance, adjustment and repair of this

unit. Since the first and mast important part of repair work is the correct

diagnosk of the trouble, ageneral troubleshooting section and component

manual troubleshooting charts have fxen included for your convenience.

IMikea garden tractw, Iawmnower arcement mixer, all having one ortwo

functions 10fwrtarm,

functions to pwform simultaneously.

thebuck-mounted carpet cleaning plant has many

MACHINE SPECIFICATIONS

‘RAME: 2~ W, 59 L,3& H. Steef with baked-on epoxy finish.

VEIGWE HydraCat 4.0:630 tbs. (dry ‘might)

HydraCat 4.5:750 Ibs (dry weight)

;OWUNG: Steel with baked-on Epoxy finish.

NGINE: HydraCat 4.0: P22020 BHP Onan

HydraCat 4.5:P22424 BHP Onan

* Engine has to run at a consistent RPM.

‘ Vacuum has ta pull air and d@ water bad from cleaning site.

● Waler pump provides stable pressure at proper water flow for cleaning.

*Chemical has to be injected into the water stream at the

right cmcentration.

* Heater must maintain proper hsat.

Vacuum tank must store dirty water until drained.

*

HOW THE SYSTEM WORKS

The water system takes incoming water at tap (low) pressure, combines it

wilh chemicals from the chemical system and pumps it under pressure

through theheatingsystern, anctouttothec]eaning tool.After being sprayed

into the carpet, Ihe water/chemicaf/soil solution isextracted by the vacuum

system and returrwd to the waste recovery tank.

There is no guess wrk in the manufacture of these highly advanced

cleaning

pfmts.There must also be no guess work inpreparing ittoget the

job done in the field. his the purpose of this manual to help you prqwty

understand, maintain and service your cleaning pfant. Follow the directions

carefully and you will be rewarded with years of profitable trouble-free

operation.

It isimperatfvethat nw$eclfonbeoverlookedwhen preparing for operation

of this equipment.

SPARE PARTS

RECOMMENDATION

Because your truck-mounted unit is capabfe of generating several hundred

dollars Wr day,

In order to minimize such down-time, it is strongly recommended by the

marwfacturcx that PU pumhase and keep in your truck the following spare

palls:

PART NO.

078-015 Flow

4178-(119 Wand vafve dunger kit 1

Wlf4XJ4 Pressurebypass

076-005 Spray @ W06E

048-029 Recovwv

078-001 cat 290

078-004 f%t 290 hoi CUPkit (~ tionat) 1

048-023

0624W0 440

052-051

052-052

a52-a53 660 F@mafequick mned

106-015

010-021

down-time on the unit can be very expensive.

0ESC13fPTKIN

meterkit

vafvekti

tankfitterbag

short cqp kdstandard 1

Screen, qarden hose

Mafequick conned 1

440 Femete quick conned 1

660 Male quick conned 1

Ermine@plug 2

HydraCalpumpdrivebelt

WY.

1

1

1

2

6

1

1

GNfTfON: Electronic, Keystart.

ii-PRESSURE

PUMP: Tri-Plex piston -- Cat 290- 3.5 W%!

-1200 PSI -- @ 1200 RPM.

fACUUM BLOWER: HydraCat 4.0: 4ML

HydraCat 4.5: 4LL

Sutorbuift W/l 2 HG Safety Relief.

:HEM[CAL SYSTEM: Electro-mechanical, meter Conlro!l@d.

WATER: Propane fired, thermostatically controlled (180,000 BTU).

NSTRUMENTS: 0-1000 High pressure gauge, Temperature

gauge,

/acuum gauge, Hour meter, Chemical flowmeter, ignition key, Start andon

ndicator fights, Pump clutch switch, Circuit breakers.

?ECOVERY TANK: 70 gallon aluminum, Epoxy finish.

;LEANING WAND: Stahless steel with heat shield, Gripand replaceable

racuum fips with stainless steel solution valve.

+f-PRESSURE HOSE I/& High-temperature linecflvin~ covered, Hose

ated to 1250 PSI.

IACUUM HOSE: 2’ reinforced, 1 1/2’ reinforced.

STANDARD EQUIPMENT: Power conso!e, Sound suppression Packagq

Electric Pump Clutch, Water heater, Vacuum Recovery tank, Carpet

cleaning wand, Chemical jug, Chemicafjugholder, Chemkal@gfill line,(lp

eration manuaf, 150ft. 2’ vacuum hose, 10 ft. 1 1/2” vacuum hose, 150ft.

Super-flex solution fine, 10 ft. drain line, 50 ft. water supply line, ~

!d! Freeze guard system, Battery boxwithholder, Vandeca! package, Fuel

system kit, Installation kit.

ADDITtONAL EQUIPMENT, HYDRACAT4.5: Oversize air handling package, High-output component power pack, Super dual silencer system,

electronic tachometer.

The manufacturer uses this symbol throughout We rnarwai to wwrr

Qfposslbie injury ardt?alh.

This symbol is used 10warn of possible ei@gme?rMdamage.

2

Page 5

HOW TO ORDER PARTS

To obtain a proper diagnosis of your malfunction, and to order warranty

replacement parts, it is important that you proceed inthe following mannec

1. Call HydraMaster Warranty/Service Department at (206) 775-7275.

2. Give the Warranty/SeM”ce representative the following information:

A. Name of your company and your address.

B. Equipment model (i.e. HydraCat, Bobcat 2, etc.).

C. Date of purchase.

D. Hours on the unit.

E. Serial number of unit.

F. Name of person authorized to order parts.

G. Salesman unit purchased from.

H. Description of malfunction.

1.Pressure readings on high pressure gauge with wand turned

on and off.

3. If warranty replacement parts are needed, please specify method of

shipment desired. NOTE: All replacement partsare sent freight collect, via:

A. U.P.S.

B. Air Freight

C. Air Mail

4. Do not give malfunctioning parts to a HydraMaster sales or service

representative. All parts must be returned dlrectfy to HydraMaster,

Freight prepaid.

D. Air Express

E. Auto Freight

PARTS ORDERS

To expedite your parts needs, please caii your saies representative.

Inmost instance, he either stocks orhas access toparts through aregionai

service center. Inthe event parts are unavailable iocaliy, contact the factory

and coordinate your needs. ifthis becomes necessary, always indicate the

method of shipment you desire, i.e. UPS. Blue Label, Air Freight, Air

Express, etc.

HydraMaster Parts Department. Phone (206) 775-7276.

ONE FINAL NOTE

Anyquestionsyou have regarding the warranty program shouid bedirected

to the Warranty/Servkxr Department personnei at HydraMaster Corporation.

We shallalwaysendeavorto befairinourevaiuationof yourwarrantyclaim,

and shali provide you with a complete analysis of our findings.

HydraMaster Warranty Poiicy (inside back cover)

Effective February 1,1989

HydraMaster warranty covers oniy defective materiais andlor workmanship for the periods listed. Labor, and/or diagnostic reimbursement is

specifically excluded.

PURCHASER’S RESPONSIBILITY

PRiOR TO ARRIVAL OF UNiT

1.lnstali 5/8” extenorplywoodflooring invehicle and cover with artificial turf.

2. Have beiiy mounted propane tank installed on vehicie. Tank must be

propane vapor type.

3. Purchase heavy duty 42-60 amp hour battery and have battery ‘slow’

chargedjfnew. Ifbatteryisnotfully chargeddamage can occurto tie engine

charging regulator.

READiNG OF OWNERS MANUAL: it is the purchaser’s responsibility to

read the unit operation manuai and to familiarize himself with the informafioncontainedtherein. Speciai attention shouidbepaidtoaii Cautions

and WARNINGS.

SALES REPRESENTATIVE’S

RESPONSIBILITY

ACCEPTANCE OF SHiPMENT:

1.ifunit showsanyoutward signsof damage, do not signthedeiiveryreceipt

untii you have closely inspected the unit and noted any damage on the

deiiveryreceipt. Have thefreightcompanyrepresentativeacknowledgethe

damage by signing the notation of damage on the delivery receipt.

2. The salesman from whom you purchased your unit is responsible for

supervising thecomectinstallation ofthe unit inyour vehicle and thoroughly

training you in its operation, maintenance and precautions.

CORRECT iNSTALLATION iNCLUOES: Installation of through-floor fittings for propane and gasoline fuel lines; installing propane regulator

included with unit, outside vehicie; placing unitand recovery tank invehicle

and securing them with bolts or tiedown cleats ;connecting all propane and

gasoline Iinew connecting battery; checking pump, vacuum biower and

engine oil ieveis, prior to starting unit; starting unit to check engine to see

that ail systems function normaily; aiw checking ail hoses, wands, etc., for

carect operatiin.

TRAfNiNG SHALL iNCLUDE: Thorough review of the operation manual

with purchase~ instruction and familiarization in: how to correctiy start up

andshut down unit; howtocorrectiyciean withthe unit; how,where andhow

often to check and change component oil ievels; how the unit’s systems

worlc how to troubleshoot the unib how to do basic repairs; safety precautions and their importance; freezing damage and how to avoid it and a

thorough review ~ the unit warran~ and w&ranty procedures.

HOURS

Monday -- Friday

8:00 am To 5:00 pm

PACIFICSTANDARDTIME

TELEPHONE NUMBERS

(206) 775-7272 Generai offices

(206) 775-7276 Parts Department

(206) 775-7275 Service/Warranty

(206) 771-7156 FAX

3

Page 6

TRUCK SELECTION

The preferable vtllclefor HydraCat iristallationis apam?lvanwith aheavyduty swyx?nsirm package. The capacity ofIho van should be a heavy-duty

1/2 ton at ttm minimum and more preferably a 3/4 ton o&pacity.

TRUCK PREPARATION

The manufacmrarmmmmands theinslallation ofpl~od flooring covered

wiftr paly propylene backed astroturf (do not use rubber-backed) in the

vehicl~ prior to installation of machine. This provides a metal to cushion

mounting rather than metal to metal, provides insulation and makes an

attractive van interior. Aslroturf should be color keyed to van interior.

Materials Needed:

1.2 sheets 4x8x5/fY exterior plywood

2. &xl 2’ piwe of commercial astrotwf

3. 16-f lM sheet metal screws

4.1 quart marine adhesive (optional)

5.1 staple hammar wII12” staples

(See illustration for correct placement of plywood flooring)

ILACEMENT OF UNIT

4VEHICLE

we are two recommended unit placements:

SIDE DOOR: Most installations are side door. This provides rearamss

p accessories and hoses as well as unobstructed access to compmwnti

]rfdngside of machirw, thus making it abiteasiw’ io perform maintenance

IWorrepair without removing unit from the truck.

REARDOOf%Afthaugh this location partly limits working access, itdoes

wet the noise away from the cleaning site. Some cleaners in the colder

eas prefer this location because if puts the weight mass ow?rthe rear

~eelsfor better traction in ice and snow. Rear mounting requires ttw unit

beslid tothe right side as faras possible. This not only provides adequate

xking space on the component side of the unit but also makes better

sight distribution inside the van (engine and cornponer?tweight line up

~erdrive shaft). Also, it is physically easier to load unit into rear door due

height of van bed.

rrsure that machine is well secured to the floor of van with hwchvafe

~pplied.Sudden orwash stop Wlcause machine torocket foru%wd,all 750

s. wrth! Protect yourself and the machimz SECURE lT#

TRUCK PREPARATION

ILLUSTRATION

FIRST, covtwth~ truck kd with 5/8’ p@vood using metal screws tosecure

it as shown.

Plywood Immlwcm

SECOND, wlecttWappro@ate coloras!roturfto match yourvan andcm

tie plywood and staple in place. A standard van requires a piece 6 feet b]

12feet.

THIRD, Hydrafdasler strongly recommends an aluminum roof vent be in

stalIed over Ihe location selected for mounting the machine. HydraMaste

alsohighly recommends a flue be installed between the lop of the heate

and the roof vent.

Thiswillallow hot air from the heater to escape.

5/8” Plywood

Machine Tie f?own Cleats

I

UIACHINE INSTALLATION

‘hereare twoways of positioning the machine inthe truck as shown.Thwu

re also two locations for the vacuum recovw’y tank to be pasitiom?d.l%%

w?standard waywith fhe tankdirectly alongside the machine. %?cond,with

Ie tank across the back of the machine as shown on the illustration on the

Iextpage; this location is most spaca eflicient. Whichew?rway YOUsdect,

lake sure the tank and machirm aresecured tothe tloorof thevan to insure

Iriver safety.

tis important that the machine lx?placed as close to the door as possibh?

o that outside air can b pulled into the engine for proper cooling.

4

Page 7

Machine Configuration

::

———

0 .UrloidB----

:

E

Iiisrecommendedbyfhe manufacturerthatthe exhaustfi’om thefrontofth

machine be venfeddown under the truck toprevent carbon monoxide frof

I

I

entering ihspb We.

away torn Ihejob site.

Aiwaysparkthe fruckso theexhaustis bfowiq

HARD WATER AREA MAP

quality of water variis greatly throughout the United States and

The

influences the reiiibility and effiiienoy of equipment in direct proportion to

its !evelof hardness. The map below detinesareas which cornprumise fluid

related components such as hoses, fittings, heaters, pumps, valves and

water cooled engines.

Cleaning efficiency and equipment life is increased, chemical use decreased and the appearance of cleaned carpets enhanced when water

softeners are incorporated in hard water areas. Manufacturer strongly

urges the use of water softener units in areas exceeding 3 1/2 grains per

oallon. Using the legend as a reference, determine the quality of water in

~our area aid take ;ction immediately should it be nece&a~.

The

manufactureraiso recommends that instillation of aluminum vents i

$

the truck roof to a//ow heat from the heater to escape.

Never operate this machine

can inside the truck, doing so increases the risk of a fire or explosion.

Mount afire extinguisherjusf inside the rear or side door foremergencie:

with aportable propane tank oraportable ga

PROPANE TANK LOCATION

Either the 10 gallon or 16.5 gallon propane tank will fit this location. Hav

t

you local propane dealer install the tank you select and purchase. Th

machine will come with the proper propane regulator. fTank must hav

vaporoutiet.)

Professions/insta//ation offudsystems is strongly recommended. Aiwq

ensure compliance withstite andlocdregulations pertaining to fueiinsta

Iations.

Water Hardness

I

Grains

Per Galbn

n ‘-3iQ

Izzzz 31/2-7

=

_ 101/2 and above

7-101/2

..

WATER SOFTENER

Many areas of the country have an excess of minerals in the water which

results in what is commonly called “hard water”. These minerals tend to

adhere tothe insides ofheater coils andotherpartsof themachines causing

damage and a loss of cleaning effectiveness.

Reports from several of our machine users commending the results of the

useofwater softeners inconjunctionwith their machines prompts usto recommend the procedure to everyone ina “hard water” area.

The relatively lowcost of awater softener service is more than made upfor

inthe increased Iifeof machine parts andcontinuedcleaning efficiency. The

water softener will also increase fhe effectiveness of thecleaning chemical

being used, therefore, less chemical will be needed.

Contactawatersoftener distributor inyour area forinformationon therental

ofa simple water treatment unit to carry in your truck. Be sure tochange the

water softener in accordance with the capability of the softener. Example:

Ifthe softener will treat 900 gallons ofwater and machines uses anaverage

of30gallons perhourof use,andanaverageof 5 hours aday, wouidbe 150

gallons a day. 5 days would equal 750 gallons of water, therefore, the

softener would be changed every 6working days for maximum softening.

(s6eil@laum,wpi?#e)

5

Page 8

Garden I-fose

— C#

h-morning VVatar

From Faucet

Softener

Water

WASTEWATER DISPOSAL

START UP

1.Perform daily/periodic mainttrnance as specifbd by the owrws manual.

2. Connect all required hws.

, 3. Connect c!eaning tool to length of hose required to perform clwaning.

tankmust&M/priorto @rithmr.

L Mix

. Start engine (choke as required}. Engine is at operating speed (r@cam

mended -2600 RPM). Allow

I 6. Spray wand to void al air from system: When the mix tank tmgins a fill

cycle, the chemical flow meter may be adjusted to your desired setting.

NOTE: Recommended carpet cleaning pressure is 300 PSI.

warm-uP period of 2-5 minutes.

ADVISORY

Them are laws inmost communities prohibiting the dumping of recovers

‘gray” water from carpet cleaning in any place but a sanitary treatmel

system.

This cleaning rinse water, reccwred intoyour unit%vacuum tank, contair

materials such as dete~ents, which must be procwed before being se

for streams, rivers and reservoirs.

IN ACCCMM2AMCEWITtf THE EPA, STATE AND LOCAL MWS, D

MM MWW$f OF WASTEWATER MK7 GUTTERS, ST0f?h4 DRAIN

STllEAA@ RESEJ?Vt’WS, ETC.

Inmost cases, anacoep!ab[e method ofwastewaterdisposal istodischarf

into a municipal sewage treatment syst@mafter first filtering out sol

material suctwmrrpetfiber. Access tothe sanifwy system can beobtaim

through a toilet, laundry drain, carwash drain,

should first be obtained from any concerned party or agency.

One dis~sal rmtfwd which usually complies with the law is to accumula

the wastewater and haul it toan appropriate dump site. Another solution

the disposal pmblam is !0 equip yourself with an Automatic Pump-O

System. Thetm systems afie designed 10 remove wastewater from tl

tixtractor’s rwooverysystem and actively pump the water through hoses

asuitable disposal drain. Properfydesignecf, theywill continuously monii

tie Iml of wasttwvaler and pump it out simultaneously to the cleanil

operalion. Tim hidden benefit of this procm is

have to stop his cleaning to empty the recovery tank. HydraMaster mak

an A.P.O. System available which can be ordered with new equipment

installed Iat@r.

RV dump, etc. Permissi[

thatthe operator does

7. Once all air is voided frum system, heatw may be ignited.

NOTE: Ifnot familiar with operation of this healer, refer to heater section of

the manual.

A. Open propane valve on the tank.

B. Ignite pilot on the heater.

C. To ignite burner, turn dial to “on” position.

NOTE: Ifyou suspect that the unit has been frozen -DO NOT light the

heater. Thaw the heater and check for leaks.

8. Turn on burner, adjust dial to normal or slightly below for 200W.

9. Commence cleaning operation.

NOTE: Chemical flow meter set at 5 GPH isa 1to 30 mix ratio and 10GPH

is 1 to 15ratio.

NOTE: Hot cfbnate opw’ation [above 90°F].

When operating this unit ina hot climate, HydraMaster highly recommends

some additional precautions.

1. Operate with side and rear doors fully open.

2. Vent heater through the top of van.

3. Ifvapor lock conditions arise, machine cover may need to be raised to

allow additional heat to escape from canpwtmt?nt.

NOTE: Cold cfimate operation (below O°F).

When operating this unit in a cold weather application, HydraMaster highly

recommends some additional precautions.

1. If nossible carrv Yourown fresh water SUDDI%

2. Hookup to ho~wkder source if possible to’keep your incoming garden

hose ~m freezing.

3. Do not close van doors in front of machine.

4. Beaware that solution lines laying on frozm ground may frewe.

5. Contact local propane dealer about cold weather propane use.

Thi?penalties for nwr+ompliance can be serious. Always check local la’

and n?gufaticmsM be sum you are in compliance.

I

MACHINE AthKISTMENTS

Although MS unit has been factory adjusted, it may require additiol

adjustmentsto achieve optimum performance; i.e.altitude may require u

adjustment and ambient temperatures may require heat control adju

ment. When required, cansult an authorized ~epresentative.

SHUT DOWN

1.

Turn heater to ‘off” position. Spray wand for at least 3 minutes to allow

the heater coils to cool.

2. Close valve on propane tank and through floor hookup.

3. Remove vacuum hose.

4. Flush clear water through chemical system for 10 seconds. (Vinegar

should be rinsed through system weekly.] Turnoff chemical flow meter.

5.Tumon cleaning tool toflush chemical from unithoses andcleaning tool.

NOTE If freeze guard is necessary, perform steps 1 & 2 of freeze guard

procedure at tlls time.

6. At this time, the blower should be lubricated with Pennz@xwd.

7. Shut engine down.

8. Drain vacuum tank. Vacuum filter should @cleaned prior 10mobilization

of van. NOTE Iffreeze guard is necessary, pwtorm st~ps 3-7 of fr@ez@

guard procedure at this time.

6

Page 9

Pressure

Gauge,

Temp.

Gauge ,,

Choke “

Vacuum Pump ;J

Lubrication Port &;

High Pressure ~]

Pump Switch ‘~l

Machine _

Exhaust

I

)

Incoming

Hiah Pressure’

Cle%ing Solution

Vacuum

Hour Gauge

Meter,

\

I

I1’,J:ue/va:%Tank

/

Circuit

Breakers

\\l l/~

~’

#

I

!!

$;

‘/

#

/ ‘Machine‘vacuum‘ank

Water

/1

Exhaust

Bv~ass

Valve

Dump Valve

ENGINE COOLING

Units employingaircooledengines mustnotln? enclosed withina van with

doors and ~ndows closed. Excessive temperatures within the engine will

resultinpremature engine failure anda compromise ofappiicable warranty.

LEVEL OPERATION

During operation, van or tiailer must be parked on /eve/ ground not to

excwed + or -1P. Failure to insure proper leveling may prevent proper

internal lubrication of engine, vacuum anoYorhigh pressure components.

FREEZE PROTECTION

Mother nature oives little wamin~ as to her cold s@ls. Therefore, wtect-

irrg this equifient from fi’eezing will save cosfly down-time. Placing an

electric heater in the Puck or parking the truck indoors, will help to insure

against fleezing.

LIGHTING HEATER

Chemical

. . — Water PumD Clutch

Heater Control

Valve

Hydra-Heater

High Pressure Water Pump

Coupler

Vacuum

Pump Drain Valve

\

Mix Tank

Engin6

/’

‘Freeze Guard

Fitting

Neverputyourface down close to the opening of the heater when lighting.

STRONG PROPANE ODOR

Never light the heater if you smell a strong odor of propane around the

heater.

HOT SURFACES

During the operation of this equipment many surfaces on the machine wili

become vetyhot. Whennear the vanforanyreason care mustbe takennot

to touch any hot sudace, such as heater, engine, exhaust, etc.

MOVING PARTS

Never touch any pad of tie machine that is in motion, severe bodily injury

may result.

NO SMOKING

ft

is unsafe to smoke in or around the vehicle.

CARBON MONOXIDE

This unit generates toxic fumes. Position the vehic/e so that the fumes will

be directed

DO NOT PARK where exhaust fumes can enter a bui/dif?gthrough open

doors or windows, air conditioning units or kitchen fans.

7

AWAYfrom thejob site.

Page 10

FREEZE PROTECTION

pfl~q-!,ir!‘<!,.

Any frw~zing of this machine is not covefied by warranty and during the

~ldelrmantisofo~mtion, careful protection should be of utmost

THE FQLLWW4G PRECAUTIONS ARE RECOMMENDED:

1.Run machine befcm leaving for the first job to insure nothing

ha night lmfore, including hoses and wand.

2. Insulak the gafidt?nhose from the cold ground by running it through an

extra 1 1/2 inch vacuum hose.

3. In colder dirnates, insulating the truck walls and floorboards will help

prutoct the unit.

4, Don’tprocrastinate during thec!eaning operation or the hotwater solution

line will alw freeze an the ground. The solution iine should be insulated

in exlrerrmly cold climates.

!$.Whenever ~ssible, the truck and machine should be stored in a heated

garage at night or over the weekend. If not possible, place a 1500 watt

electric heater inside the truck, aimed directly at the machine. Never use

a propane heater-it causes excessive moisture on the truck ceiling and

the possibility of it going out is higher. Ifthe machine and truck are left

outside with a heater, you should first drain of possible water from the

machine cleaning tools and hoses. (They freeze also.)

TO DRAIN THE MACHINE FOLLOW THESE STEPS

1. Siphon a50150 mixture of anti-freeze and water through the chemical

ftow meter.

2. Drain the mix tank.

3. Connect Ma freeze

4.Connect Ihecdher ond of the freeze guard fitting tothe freeze guard fitting

Iocatfid on the sido of the machine.

5. Connect an open 440 quick connect to the fittings marked “cleaning

solution” on the front oithe machine. (An alternative would be to connect

your solution hww and wand, w as to freeze guard them also. Ifyou

choose to do thisycw will also need tohold the!riggerdown onthe wand.)

6. Start the unit, allowing the vacuum from the machine to drain the lines.

7.* Remove tfre garden hose inlet adapter from the end ofthe garden hose.

Conrmct the adapter to the incoming water quick connect on the front of

9hemachine.

8.’ Place a vacuum hose over the garden hose quick connect and allow the

vacuum from the machine to drain the lines.

*i4n alternative to #7 & 8 would be lo make an adapter to allow you to us@

the premade freeze guard hose.

guardhow?to the rwxwery tank.

concern.

hasfrozen

CLEANING AND CHEMICAL

PRECAUTIONS

Yourmobile carpet cleaning plant has been engineered using the!at@stand

nest sophisticated technology available, to produce the finest carp@t

~eaning results possible. Despite this, however, itremains onlya toolofthe

xpet cleaning trade, and it can produce only as good a job as Me person

]Perating it.

Thereare not short cuts to good ca~t cleaning. Itrequirws time, cleaning

mowledge and the use of good chemicals.

Themanufacturer recommends the use of spotting agents, and traffic lane

nleaners prior to the actual cleaning of carpeting, as required.

Theuse of some chemicals through your mobile carpet cleaning plant can

seriously damage the internal plumbing, high pressure pump and heater.

(Chemical such as concentrated acids, solvents, and some paint oil and

grease removers w/high cwwentration of solvents.)

The manufacturer recommends only the use of chemicals containing rust

and corrosion inhibitors and water softening agents to prevent chemical

build-up which may lead to component failure and warranty invalidation.

NOTE: At no time should a chemical solution with a pH of less than 7 or

higher than 10 be used in the unit.

pH CHART

I

1234567891O 1?12

I 1

)

+AOD - *

I I

I

I

NEUTRAL

I I

‘ALKALINE~

I

I

CLEANING STROKE

PROCEDUREIOVER-WEUING

PIJRPOSE:TOeliminate excess moisture rernainirrg in the carpet fiberand

the sawtooth appearanw? which results from diagonal movement of the

cleaning tool on all types of carpet.

I

13 14

I

I

NQTE: Prior tofreezo guarding your rnachinemake surethe heating system

has been cooled down.

ALTERNATE PROTECTION USING

ANTI-FREEZE:

1. Follow We draining procedure.

2. Cmnect solution hoses and wand

3. Pour a 50/50 ariti-$reeze sokJtion into mix tank.

4. Turn on machine and engage clutch. Spray the wand.

5.Continue to add anti-freeze solution until mixture comes out ofwand set.

6. Remove and store hoses.

If you are using an

freezing. 1[isne~ssary to flush the machine in preparation for use. Simply

connect the unit tofresh water and spray the wand until anti-freeze solution

is discharged. The anti-freeze soiution maybe recovered by spraying into

an empty container. This solution can be used several times.

BE SURE IT’S PROTECTED! Freezing will cause GRIEF, MONEY and

DOWF&TIME. Don’t mess with Mother Nature!

anti-freeze solution to protect your machine from

tomachine.

PROCEDURE: Always move the cleaning toolin smooth foward anciMck-

ward strokes. Apply slight

is injected into the carpet.

the foiward stroke to ensure a positive “lock” for the vacuum and minimize

the “hopping” effect resulting on unsmooth carpet. During the forward and

reverse strokes, movement to the right or left should only be a~omplishexi

at the extreme rear of the stroke. Overlapping is also important to ensure

even application of solution to prevent saturation when cleaning wand is

stopped twice at the same point at tie rear of the cleaning stroke.

Failure to adoot this mocedure can result in increased chance of “clean

streaks”, fiber’shrinkage, brown out, and longer drying pdods.

INCORRECT METHOD

pressureto the forward stroke while the solution

When extracting (drying), applyfirm pressure on

CORRECT MEWMN2

Overla~ Between Strokes

Cbanmg

Stroke Stroke

8

Cleaning

Page 11

OVm”wmmlci

Over-wetting isannoying toall concerned and sometimes leaves a bad impression of the cleaning process used.

THESE ARE SEVERAL AREAS THAT WILL CAUSE OVER”WEITING:

1.Too Iew vacuum strokes or improper sawtooth vacuum strokes as

shown in the previous illustration.

2. Obstructed, kinked or cut hoses.

3. Vacuum tank drain valve left partially open.

4. Clogged vacuum blower filter or vacuum tank lid not sealing propxly.

5.Cleaning a heavily foam-saturated carpet without defoamer. (Werecommend crystal type.)

uart container of vinegar. This should be done with the Chemical Flow

!eter setting on 10 GPH and the Water Heater “off’. Simply spray water

om thewa~d until thequart of vinegar isexhausted, the repeat the @wess

ith one quart of clear water to void all lines of vinegar.

Chemical System Wiring

Solenoid Valve

Float

Switch

G~D

Relay

88

E ,.~

X!/’

~. 85

h.

,.~

To Ignition Switch

‘--l

‘..

GND

WATER AND CHEMICAL FLOW

OPERATION

This electro-mechanical system has been designed to be simple and

trouble free. Incoming water flows first through the Solenoid Control Valve

(1)and the low pressure Chemical Injector (2)which are both mounted on

the exterior of the mix tank. As the water passes through the Chemical

Injector, it is automatically proportioned with a predetermined quantity of

detergent. The MixTank(3)isequippedwith twodifferent float switches, the

Water Level Float (4) responds to the level in the tank and will maintain the

proper volume of solution to be reserved for the water pump. The secondary, LowWater Float switch(5) isasafetyswitch thatisdesignedto protect

your system from sudden or unexpected loss of water supply. If, for

example, thewater source at the house were turned off, the water level of

the mix tank would drop, activating the secondary switch, which automaticallydisengages thesystem and pn?ventsthewater pump from running dry.

The desired chemical injection ratio may be obtained by an adjustment of

the Chemical Flow Meter (6)during the fill cycle ofthe mix tank. Water must

beflowing into themixtankinorderto adjustthechemical mix. Thechemical

will flow from the Chemical Jug (7) to the Chemical Flow Meter, then to the

Chemical Injector where it is proportioned into the Mix Tank at the desired

chemical setting.

NOTE: %Mththisuniquechemical system, thechemicalflow isproportioned

only during the filling cycles of the MIXTank, not during the direct spraying

ofthewand. Therefore, itispossible that asyour wand is spraying, you may

have no chemical flow. Also, the converse is true in that you may not be

spraying your wand, but if the mix tank is in a filling cycle, your Chemical

Flow Meter may be active at the desired flow rate.

Water Flow

6- Chemical Flow Meter 12- Incoming Water

7- Chemical Jug 13- Tank Drain

8- High Pressure Pump 14- To Wand

+ High Pressure

11 - Pressure Guage

+ Low Pressure

Chemical Proportion and Level Contra\

6FA-6UFS

I

M,, Tank

$

The chemical proportioning system will mix chemical with water at a 1to30

ratiowhen the Flow Meter is set at 5 GPH, or a 1to 15 ratio when the Flow

Meter is set at 10 GPH.

Atthis point in the flow, solution (water with chemical) will now be siphoned

from the

bottom of the Mix Tank to the inlet of the Water Pump (8). When

the wand is not using solution by spraying, the solution will be bypassed

fromthe bottom ofthe brass Pressure Relief Valve(9), back to the MixTank.

When the wand is spraying, the solution continues its flow to the Water

Heater (10). The coils of this heater have a capacity of up to 2 gallons,

therefore it is extremely important that all air pockets are bled out of the

heater prior to initial start-up. This maybe achieved by running the water

system, without the heater on, for approximately 80 seconds.

CHEMICAL SYSTEM MAINTENANCE

The chemical lines may need to be flushed with vinegar periodically to

prevent abnormal chemical build-up. This flushing may be done by remov-

ing the clear plastic hose from the Chemical Jug and inserting it into a one

=eCk=

Swng

B . ‘“’W’”’ B””’

o SIs Ball

& Check valve ;

-0

fl

~u

*:5$3’’HeFj~jii$

g;zj_:Dlen;n

Mo.n!tng

+wJw ,3)

—-, .— -

—.

+-=” –d

(la ‘

12 Voc

cm

9

q~

Mo.ntlng

Plato

,-,4, va,vech,y

Water

Idet

Page 12

I

I

I

~

I

CHEMICAL TANK

TROUBLE SHOOTING GUIDE

PRQHLEW. Uttla

%hldon

Chackthtat hoses af the Mix Tank(3) are secure. Check that the hose fromthe top

of tkw Flow MrXar (6) to the Chemical lnject~ (2) is seam with no kinks or

leaks, (M& thal the ad~ustingcap on tho side ofthe injectoris INI! screwed

af!ttw way in. Clmcklhe $/s check vafveirw.idethe injedorforchemical buildup and pqer qwration. Chec& the hose from the botiom of the Ffow Meter

to the Ctmrnicaf Jug (7) for kinks, cracks, or bubbles.

Cf’mckthwxraen ontheemdof the hose which gces intotheChemicaf Jug.Tochack

thii scram forproper function, remove itkom Itw plastic hose. If you csnnot

blow Ihrough if, tti rinse if out with vinegar.

Check the Chemical flow Meter (6) for obstructions or a sticking float.

Is incoming waler pressura less than 30 PSI?

Cracked w cle!ective Chemical Flow Meter (6)?

Check the fitterwren inthe Solenoid Control Valve(1).

PROBLEM frmbillty to adjust chemical with the Flow Meter

Sahtion

Debrii Iodued &hind Mlon %at in Flow Meter valve.

Tdhm seat on the valve stem maybe hose. Ifdeteriorated, replace O-Ring.

or no chemical flow

Wand Valve Asswnbfy

Ekldy

Compression

Fitting

~?

*

--~;~’

-T

Spring

O-Ring

cap

3’L%

II I *C

QI *

I

=*I6

:11“?’<F~@

\

.\

i

[

\

O-Ring

Plunger Quick

Connect

Cl-Ring

Keeper Ring

I

I

PHCWLEM: Solution rmmrsbrg from Mix Tank, ffllhrg the Chemical Jug

Sohlfk?n

Anti-siphon dwice cfogged by chemical build-up (Anti-siphon device is bcated in

the Chemical Injedor (2) body — see page 9, Water F!aw illustrakon).

Check fordebrii.

PRQBLEM FAxTank overflows

mlution

Float awitc+r(4) inthe Mix Tank nd moving ireely, or d~fadive.

TochmckswitctrWNma 12voht@[ghiandtheilut inthe”up”position, there should

b power through the swhh.

To check relay: First check wiring against dmgram. W* 12 volt lest fight, and the

FloafSw%ch(4} in Ifre”up”posilierr there sf?cmklNOT@owerat !heSolenoid

Vahw. Wth !he Float Switch in the “down”position there should be power af

the SIoarwid Vafve.

EKderroidValve defectiwx Remove Solenoid Vafve, disassemble and inspect

diaphragm Iw cracks w tears.

PRQ5LE~ Mix Tank does not keep up with water output

SOlufhltl

Check incoming water pressure. Check gaden hoaa quick conned

assembfy screen.

Check garden hose ardor feed hose 10the Mix Tank for dog, kinks,

or blockage.

Float Swifd (4) in Mix Tank hanging up (rmf moving freely). Check fifterscmn in

Solenoid Vafve (1).

Jet Assembly

Wand Assembly

Ha

Ekdy

‘b”

10

Page 13

Wand Valve Stem Assembly

I

Keeper Ring ———+

Plunger —

I

@

~

(

Bypass Valve Assembly

+— Retainer

O-Ring

u

I

@—

I

O-Ring

BYPASS PARTS LIST

REF. NO. PART NO.

3

OOO-105-1OI

4 OOO-105-1O2 Piilon plate,Bypassvalve

5 OOO-O78-1O1 Kt, seal

7 000-14B-oo4 Seat & C43ing, Bypass vafve

8 000-097-005 O-Ring, Bypass valve fitting

DESCRIPTfON QTY.

Thrustplate,Bypassvatve 1

for Bypass vafve

WATER FLOW TROUBLE SHOOTING GUIDE

PRoBLEkk

Cslrse

=ve or blocked check vafves in high pressure pump cyfinder head.

Delaminated, Idnked or dogged hose between the mix lank and fhe high Remove and replace defective hose.

Defective pressure refief valve or debris in pressure reliefvalve. NOTE lle high Disassemble and clean pressure relief valve as illustrated in drawing above.

Oelective or worn cups. Remove and replace piston cups as defined by pump manuat.

Loose driie belt Ior high pressure pump. Readjust belt as required or replaos if defective.

Pump inletYstrainer dogged Check lank for water. Clean strainer. Clutch disengaged?

LOSSof pressure

solution

Disassemble cylinder head and replace or cfean applicabfa check valve.

pressure pump,

pressure bypass vafve is desgned to fully dose when the cleaning teal is

turned on. Any foregn matter colleding onthe piston willprevent iull closure

offhe valve id allow a portionof the water to continue to circulate instead of

being routed to the ciaaning tool. To correct this situation, the bypass vafve Replace bypass valve.

must be disassembled and dearrad (refer to illustrationprovided abve for

bypass disassembly).

Replace defective or worn out bypass cup.

1

1

1

1

PROBLEM: Excessive water flow

cause

Worn out spray jet. NOTE: Cleaning tools designed to spray a constant fbw of Remove and replace spray jet.

1112GPM will average 1 gafbn of flow per minute inadual workingsituations

since lbwis not continuous.An average flowof 1GPM resultsin6000gallons

offbwforevery 100hoursof unito~ration. Spray tipsarecapableof fbwrates

forapproximately 20,000 gallons. They should beraplacedtherefore, approximately every 350 hours,Worn spray jets allow a greater average rate of flow

thus reducing desired temperature fevels.

Reduction of flow.

Solution

Due to increased length of sloutionhose. NOTE For every 50feat ofhose, bevond

100faet intotdlength,ame~urtile losoffbwisexpenencd. Ttiscondition

is a result of the increased fridion experienced by the water as it passes

through the hose. Therelore, if is necessary to increase the pressure at the

machine 40 PSI for every additional 50 feet of cleaning solution hose over

100feat.

11

,

Page 14

VACUUM SYSTEM INFORMATION

The vacuum blcwwrincmporated inthis machine is apositive displacement

Iokwtype, manufactured by Cooper Industries. The performance and fifeoi

this unit is gfieatiy dependent on the care and proper maintenance it re

Ceiv@$.

Becauw?of the CIOWtcdmum.esbetween the lobes and housing ofthe vac

uum blower, did objects entwing the inlet will damage the internal lobes,

g~ars and bearing or direct drhm coupler.

To p~event this, a stainless steel filter screen has been placed at the vac

uurn inlet inside the vacuum recovery tank. This stainless steel screen is

finger tight and should be removed forcleaning weekly.

When machine is Ming run fir iesi purposes and the vacuum inlef on fo~

of machine is open, caution should h? used.

To protect Ih@vacuum blower from overloading and damaging itself, thert

isa vacuum rdi~f sys!em installed on the vac tank. When the vacuum tan}

inlet is completely sealed off, a maximum of 14

on thetop blower pipe eltmw acts as the lubrication point. Atthe end ofeact

day, LPS 1or Pennzguard should be sprayed in before shutting down th[

machine. See blower lubrication W4ration. If you fail 10 Iubricaie tfw

vacuum blower daily, rust doposils and moisture will decrea~ the life ofttw

vacuum Mower.

HG will be attained. A hok

—

MXIUM TANK FILTER BAGS

/drafdasler filter bags are designed totrap all ofthe lint, sand anddirltha!

wld normally collect at the bottom of your vacuum tank. The w? ofthese

lgs, if emptiid at the end of each job; will eliminate the build-up cd

thedebt%

d to the incoming dirty water inlet in the vacuum tank.

Jreorder bags use part number 049-029.

Vacuum Tank Filf@r Bags

inthe tank. Th@drawstring top of these bags is ckmigrwdto be

.Vacuum Tank MM

much

Read thevacuum blower rnanualcarefully forpmperoil change and greaw

application. The maintmarm log may differ slightly from the manual, bu

the truck-mounted carpet cleaning machine application isvery demandiry

of thevacuum

NOTE: Vacuum tank isprotecfedfrom ow?rflowirrgbya vacuum tank, flea

kill swi[ch. This swiich is

blowerandtherefore itshould bemaintained more regularly

not acfiwated byfoam, only byliquid.

vacuumFlow

S/S Filter

\

Recovery Tank

Filter Bag

/

\:7

Blower Lube Port

I

\/

L

Spray lubricant into bloww’ lube port for 3 to 5 seconds,

then immediately shut off machine. Use only LPS 1or

Pennzguard moisture displacing lubricants.

12

Page 15

VACUUM BLOWER WARRANTY

FULLERwarrants products of its manufacture tobe free from defects in malerial and workmanship ifproperly installed, maintained, arid operated

under normal conditions with competent supervision.

Noperson, agent, representative or dealer isauthorized togive any warranties on behalf of FULLER nor toassume for FULLER any other liability

in connection with any of FULLER’S products.

This warranty shall extend for two (2) years from date of installation provided this equipment has been put into servicw within six months after

shipment from tie FULLER factory. Ifrepairs or replacements are made by the Purchaser without FULLER’S prior Mitten consent, FULLER’S

warranfyshall cease to beineffect. Noallowance will begranted forany repairs or alterations made bythe Purchaser without FULLER’s prior written

consent.

Machinery, equipment and accessories furnished by FULLER, but manufactured by others, are warranted only to the extent of the original

manufacturer’s warranty to FULLER.

FULLER agrees at its option to repair at the point of shipment or to replace without charge f.o.b. point of shipment, any part or parts of products

of FULLER’S manufacture, which within the specified warranty period shall be proved to FULLER’S satisfaction to have been defective

shipped, provided the Purchaser promptly notifies FULLER, in writing, of

FULLER’S liability to Purchaser, whether in contract or in tort arising out of warranties, representations, instructions, or defects from any cause

shall be limited to repairing or replacing of the defective part or parts as aforesaid, f.o.b. point of shipment.

No liability whatsoever shall attach to FULLER until said products have been paid for. EXCEPT AS STATED IN THIS SECTION AND IN THE

PRECEDING SECTION TITLED ‘WARRANTY’ AND EXCEPT AS TO TITLE, THERE ARE NO GUARANTEED OR WARRANTIES OF

MERCHANTABILITY, FITNESS, PERFORMANCE OR OTHERWISE, EXPRESS, IMPLIED OR STATUTORY, AND FULLER SHALL HAVE NO

LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR OTHER DAMAGES, HOWSOEVER CAUSED.

such alleged defect.

when

DATE INSTALLED MODEL SERIAL #

FULLER COMPANY 2966 East victoria Street Compton, California 90224

VACUUM BLOWER LUBRICATION

At the gear end the timing gear teeth are lubricated by being partially

submerged. The gear teeth serve as oil slingers for gear end bearings. At

the drive end of the bearings are grease lubricated.

FILLING PROCEDURE

Remove square head vented oil fill plug (A) on gear end. Remove oil level

plug (B) located in the head plate. Fill gear case until oil drips out of the oil

level hole (B). Use lubricants aslisted. Add fresh oil as required to maintain

proper level. The oil should be drained, flushed and replaced every 1500

hours or more frequently ifinspection so indicates. The oil drain

at(C).

NOTE: Older units may have the oil fill level and drain holes located in the

cast iron gear case instead of in the head plate. Bearings on drive end of

blower require grease lubrication every 100 hours of operation. Bearings

which require grease lubrication will have a grease fitting (D) at each

bearing. When regressing, the old grease will be forced out of the vents

during operation. To prevent damage to seals, these vents must be kept

open at all times.

plug is

Vacuum Blower Motor Lubrication

.

13

1

Page 16

VACIKJM BLOWER TROUBLE SHOOTING GUIDE

PIW5LEM Loss cd prw$si.irn

Carkm

Collapsed vacuum hose between blowm and vacuum kink.

Chfjgad skddese steel

IMwAive vacuum lank seat.

Dekctive or %p@ vacuum tank pump valve.

Fraclured weld on vacuum tank.

Gallapsed w kinked vacuum hmw.

vacwn hose. Remove obstructionsby reversing the vacuum hose.

P%Jgged

Restriction in cleaning tool. Remove obstruction.

Worn @nd plates or lobes in vacuum blower.

IM3ctive relief valve.

WNIBLEW B!mver k+seized

Cause Solution

Rust. Spray rusI dissolving lubricant onto lobes to emulsify rust and attwnpt to ro$at~

Foreign matter.

tite: fie

ahvernwrtiorred, Nst foreignrmaftt?rarrdseizingare oftencausal from

foam traveling through

Ikmr,

the Mewer.

Solution

Remove and replam hose. NOTil A .speckdr@irrfcmd hose is requirwd

for replacement.

Remove and dean or replaca stainless steel filter.

Remove and raplw vacuum lank seal.

Close valve.

Replace valve.

Re-weld as required or replace tank.

Reshape h= ifpo~ibla andlor eliminate kinks.

Replace worn components. NOTE Must be accomplished bya qualifiedtechnical,

Inspect and replace ifnecessary.

vacuum lobes.

Disassambieand remove foreign matter and reptiras r~quired. NOTE: Disassem-

bly must be accomplished by qualified tedrrrican.

lWOtN.EW Nab in

vacuum blower

calm

Worn gears.

Lack of lubrication. NOTE Permanent damage may have resulted from lack

of lubrication.

wormbwing$.

Ikbris and/or foreign materii build-up. NOTE: A sfahdess steel filter isprovided in

vacuum inlel located in vanmm blower carnpcments.

Lcme ar missirmgmmm[ing bats.

I-IEAIING SYSTEM INFORMATION

The propane

WM?inthe carpet cleaning industry. It’shigh pressure coils andthermostatic

temperature control make itsimple tooperate and reliable. Once thedwired

temp%ratumis set,the heater willthen go ‘em’ and‘off’according tothe water

terrpwatum within the heater. As water is wed through the cleaning tool,

cold water entwing the heater will

propane valve thereby firing the heater to maintain a consistent flow of hot

wattw. Once the cleaning wand is shut off and the flow ofwater through the

kmater stop% the treater will continue to burn until the set temperature is

attainfid.

Itis pwsible with this design thatthe flame may be on when the wand is off,

likewise, it is passible the flame may be off when the wand is on.

heater incorporated in tfls equipment is a special design for

activate the thermostatically controlled

Soiutfon

Remove and rap[~ gears. NOTE: Replacement of gears must be accoinplishwl

by qualifii tedrnicarr.

Timingofvacuumblowerhasbeen changed duetow-orncomprmnts. Replacement

of components must be accomp!iihad by qualified technican.

Lubriite as specified by applicable vacuum blower manual. Sea index.

and replace bearings as required. Must be accmpliihad by qutified

Remove

technican.

Disassemble vacuum blower and remove foregn materii. NOTE: DkmssomMy

should be accampliihsd by qualified $echnkxrr only, Replacemwrt of worn

parts is nwssay.

Tighten or reinstall mounting bolts.

Thisheaferis designedfo &urrJvaporproparreg’as oniy Anyiiquidpropar?e

entering the healer may cause damage to tfm contmi valve on the heater.

tt wili also cause improper burning and a soot buiki-up on the coil,%

Therefore, if is necessary to shutoff fhe h@a@rand close tho waiveat th@

tarrkbetween ciearring icmations.Failure todo ff?isaliows sloshing /iquid fo

enfer the vapor feed iine to the heater.

IMPORTANT: Overfilling ofthe propane tankwill caus$ many problems.

To

avoid this, advise the attendant filling the tank not tcttill the tank mrer$tl%.

When filling thetank, watch the 10% valve and immediately stop fillirtgwhen

14

Page 17

white fiquid starts spurting from the 10% valve. To prevent damage to the

propane regulator, always cfose the valve on the tank before fflfing.

The propane regulator is pre-set at the factory at 6 oz. of propane. This

reading is taken at the control valve on the heater (see figure A No. 6). To

prevent road dust and moisture from entering the propane regulator, keep

the white plastic cover (supplied) on the regulator at all times.

To avoid restriction of air flow at base of heater, keep articles such as

chemical containers, hose, boxes, etc. from within 18 inches of base of

heater. NOTE This restricted situation also creates an over rich condition

which results in soot build-up.

lMPORTANf7 Ifa newpropanetank hasbeen installed or hoses have been

disconnected, air may enter propane hoses and must be purged prior to

attempting to light thepilot burner. Should this condition exist, operator must

depress the pilot button for 1-5 minutes and attempt to ignite the pilot light

at 15 second intervals. Avery slight hissing noise should be evident while

performing this operation.

Check heater forpropane leaks regularly as loading andunioadinghoses,

tools, etc., mayaccidentally bump against heater fitting or pipes.

To fight the main burner, repeat instructions asabove (TO START PILOT),

1through 4.

OR,

Water may already beat controlled temperature.

Flame will turn off when thermostat senses maximum temperature.

C. TO ACHIEVE PROPER CARP~ CLEANING TEMPERATURE:

1. Complete procedures A& B.

2. with 100’of hose, turn cleaning wand on for 5 minutes and the

temperature should stabilize.

3.Oncea constant temperature isestablished, turncleaning wand ‘off’.The

flame on the heater burner should remain on for 10-15 seconds.

A. Ifthe flame expires prior to 10 seconds, turn the thermostat dial to

a higher reading, then repeat C 1-3.

B. If the ffame remains lit after 15 seconds, turn the thermostat dial to

a lower reading, then repeat C 1-3.

D.TO SHUT DOWN HEATER:

1.Turn upper dial #1 to ‘off’ position.

2. Tumcieaning wandon for3 to5minutestocoo/heatercore. Ifi?eafercore

isnotcooled, itispossible tha(theheat retainedin thecore wiilcause boiling

back into a chemical mix tank. This results in damages to Cat pump.

3. Close propane tank valve while

wand is on the heater is coofing.

HEATER OPERATING

INSTRUCTIONS

Heater must be fi)led with water prior to igniting.

A. TO START PILOll

1.Adjust thermostat control knob on unitrol to desired setting (#3).

2. Adjust upper dial to pilot position (#l).

3. Depress pilot button (#2).

4. Depress sparking button to fight pilot (#4).

IF PILOT FAILS TO LfGfiT:

Is propane tank full?

Is propane tank valve open?

Has air Men properly bled from propane line?

Is igniter system working?

WHEN PiLOTUGH7S:

Wait ten seconds, depressing button manually, then release button.

PILOT BURNER ADJUSlllENT:

1. Remove pilot adjustment cap #5.

2. Adjust pilot key to provide properly

sized flame.

3. Replace pilot adjustment cap.

Allen head pipe pfug #6 can be

removed for monometer insertion

to read propane ounces.

HEATER TROUBLE SHOOTING

PROBLEM: Excessive

Csuee/So/ution

Maladjustment of propane regulator. tWTE Propane regulators are factory

1.

preset and may be readjusted by authoriiad personnei.

A. Contact manufacturer to determine correct procedure.

B. Have your local prcpane deafer use a marromeler at the Unitrolto reset the

propane ragufafor to 7 oz. maximum.

2. Overfilled propane tank. Propane heaters are designed to operate on vapor

propane only. Overfilling a propane tank affows ~quid propane to enter ail

heater reiatad components and permits an over-rich burning condition to

occur. This condiion usually requires the core to be deaned of soot and

carbon dapadts. Cleaning is a messy, dirtyjob and very inconvenient, so do

not iet if happen to you!

heat. Flamesprotruding outside theiower openings.

Always keep face away from main burner opening to avoid ignition

flash bum.

B. TO UGHT MAIN BURNER:

1.Turn up~r knob to “on” position. Flame will come on.

Ifyou do not get the burner to flame, the pilot has expired. You must turn

upWrdial to“or position. Donotattempt to re-light the pilot fort24seconds.

PROBLEM Pilot

Cause/Solution

1. Pibt lightwill notignite. NOTE: Do not use a naedleorpin to dean pilotorifii—

use compressed air or solvent only.

A. Verify propane reaching igniter. NOTE A tinkad orcrushed hose may

impede

B. Remove and clean orifii.

C. Verify igniter spark is operating correctly.

light

propaneflow.

15

Page 18

CAT PUMP MODEL 290

—

OPERATING Ihlsmwmolw

CAT PUMPS am positive dispkwrmti pumps. Therefore, a properfy

desigr?edprt?ssurt?relief mffchanisrn IUUST be irstalled in Me discharge

piping. Fajlure toinstall suchmliefmechanism ~uidmsultin~rsonalinju~

ordamage toffwpwnparsystwn. Cat Pumps CorporabOndoesnot assume

afly liability ormsfxmsibility for the operatiorr of a customer’s high pressure

system.

Pracfuctsdescribed hereon ar~covered byone or more ofthe following U.S.

patr?rls: 3558244,3652188,3809508, 3920356, and 3930756

SPECIFICATIONS

Volume: 3.5 GPM (13 UM)

Discharge Pressure: 1200 PSI (83 BAR)

Maximum inlet Pressure: -8.5 to+ 40 PSI (-0.6 to + 2.8 BAR)

RPM: 1200

Bore: 0.78~ (20mm)

Stroke: 0.472’ (12rnrn)

Crankcase Capacity: 10 oz. (.3 L)

Maximum Fluid Temperature: 1800F(71°C)

Inlet Port (1): 1/2” NPT (1/2” NPT)

Chemical Injection Port (l): 1/4” NPT (1/4” NPT)

Discharge Ports (2): 3/8” h!PT(3/8” NPT)

Pulley Mounting: Either side (Either side)

Shaft Diameter: 0.65(Y (16.5mm)

Weigh& 12.1 Ibs. (5.5 kg)

Dimensions: 10.77’’x9.08’’x14n4n(273.5x230x130 .5rnm)

(l): 1/2’ NPT(1/2’ NPT)

.~..

p#ziltH3ilm*y

,.

C0F7P0RArt0N

P O 130KBS5 MINNEAPOLIS MN 5S440

PbmIfI (6 12) 780.s440 — Telex 290278

a N V CAT PUMPS INTERNATIONAL S A *

Hmmonmstraat 29

8 2LlQtJAntwerp, 13elgwm

Phone (03) 2377224 - T@E,x 33947

*CAT PUMPS — AG 0

LorelohOelIe 5

CH.63CQ ZUG. Swtzerlana

Phone (42) 213140 – Telex 865 160 CPag ch

OCAT PUMPS DEuTSCHLAND Grnot+@

ROSlocker Sttesse g

62L12 Wlesbaden BIef3tadl West Germany

Phone 0612.5600 01(2 – Telex 41 86713

-CAT PuMPS [U K) LTD 0

27 Stallon Ina.strml Estets, Flee!

H.9MD9hW3 Gu13 8QY.EnglamJ

Phone Fbl 22021 – Telex 8SSS93

CAT IPUMP WARRANTY

This Cat Pump (“product”) is warranted by the manufacturer to be free from defects in workmanship and material for orw year hum dat~ of

manufacturer’s shipment. This warranty is limited to repairing or replacing products which manufacturers investigation shows were defective

al the time of shipment by the manufacturer. All products subject to this warranty shall bt?returned F,O.B. Cat Pumps Corp., Minneapolis,

Minnesata 55430, U.S.A. for examination, repair or replacement

The express warranty set forth herein

merchantability or fitness for a particular purpose and all such warranties are hereby disclaimed and excluded by the manufacturer. Repair or

replacement of defective products as provided above is the sole and exclusive remedy provided hereunder and the manufacturer shall not be

Iiablo for any further 10ss,damages or expenses, including incidental or consequential damages, directiy or

use of this product.

This warranty is subject to the following warranty conditions:

impmlant Conditions- LUBRICATION -fill crankcase tothe top of oil gauge window per specifications with Cat Pump oil or equivalent SAE

40 weight hydraulic ailwith antiiear and rust inhibitor additives. Change initial fill after 50 hour run-in period. Change oil every three months

or at 500 hour intervals thereafter. FWrrrn-a-lube seals need no lubrication. Bluedot seals and wick must receive three drops of Cat Pump oil

per wick every 50 hours of operation.

is in fieu of all other warranties, express or implied, incfuding without limitation any warranties of

indirectlyarising from the sale or

GCXMILUBR1CATK3NISTHE EASIEST, MOST EFFICIENT AND LEAST EXPENSIVE OF PREVENTATIVE MAINTENANCE.

RPM and PRESSURE - Pump operation must be within RPM and pressure specifications. Pressure relief valve must tw installed.

00 NOT PUMP ACIDS OR ABRASh/E FLUIDS with this unit. Consult Cat Pumps for additional information on questionable fluids.

FREEZING CONDITIONS - Pump must be protected from freezing conditions.

USE CWOTHER THAN CAT PUMP PARTS OR THEIR EQUIVALENT VOIDS THE WARRANTY

16

Page 19

PISTON MODEL 290 Exploded View

——— .——

—.

———

PARTS LIST MODEL 290

fTEM PART NO.

1 202e5

44274

2

385880 Stud (M8

4

44377

5

44374 Oil filler cap

43340 O-Ring, crankcase cover

8

9 43339 Crankcase cover 1

10

11 23170 O-Ring, drain plug t

12 25625 Drain plug

15

16 438o4 Crankshaft

17 14487 Rearing 2

18 24159 Oil seat (Buns-N) 2

19

20

21 92519 Sems comb head screw (M6 x 16) 8

23 101789

24

,

25

26

27 25301 oil seal 3

28 25327 Barrier slinger

29

30 29003 Back-up ring, Sleeve (Teflon)

31 29614

32 26854

33

34 25128

43987 Bubble oil gauge

92520

2653$ O-Ring, oil seal case 2

27950 oil seal case 2

Iolmo

lMkUt

20017

25392 O-Ring, sleeve

28771

28597

25635

DESCRIPTION

O-Rino (Buns-N\

Crankcaee

X82) 2

O-Ring, oilfillercap 1

Sems comb head screw (M6 x 20) 6

Conneding rod

Pston rod 3

Pston pin

Seal washer

O-Ring, sleeve (Viion) 3

Sleeve (28743 Unchromed) 3

Seal washer

Seat relainer

Inlet manifold

Inlet manifold - stainless steel

QTY.

1

1

1

1

1

1

1

3

3

3

3

3

3

3

3

1

1

fTEM PART NO. DESCRIPTION QTY.

35 30315 Prrrrrm-A-Luba seat 3

30325 Prrrrrm-A-Lube seal (Won) 3

38 27004

39 30543 Bat$-Cup piston

40 30544

41 43172 Cup (Viton)

43474

42

43 27002

44 27006 Conical washer - s/s (M6) 3

45 270Q0 Nut 46 14156 Cotterpin 3

47 101802 Cylinder (43834 Unch) 3

48 23172

49

50

51 43442

52 43360 Valve spring

53 43723 Valve

5443434 Discharge vatve seal

58 81108 Hex nut (M8)

57 101804 Hex flange nut (M8)

58 25130 Shaft protector

Electric Clutch Assembly

59 152-005

80 077-005 Key, electric clutch

61 036-005 8’ elednc clutch

62 143-084 8-30 mm socket head screw

63 174-004

64 174-018

27983 Piston spacer

11377 O-Ring, cylinder (Viton)

21985 Bat-Cup ring, cylinder 3

24459 Discharge manifold

25634

Intel valve 3

Bat-Cup ring (Teflon) 3

t3ac-Cup assembly 3

Pston retainer

S/S(tvf6) 3

O-Ring, cylinder (Buns-N)

Discharge manifold - SIS

Vaive spring retainer

Tapered sleeve

Flat washer (5/16 US)

Lock washer (5/16 US)

3

3

3.

3—

6

6

1

1

3

3

3

3

2

2

1

1

1

1

1

1

1

17

Page 20

GENERAL INFORMATION

FOR CAT PUMP REPAIR

As you mwnow!ym.trdischarge manifold, there is a set of 3 check valves

{which usually fall OUIduring dis-assarnbly). Ifthe surfaces of these check

vtives am dirty, OFshow signs of chemical build-up, it is pmbahle that they

would mrnain awn causing pmssum Iossc!r pulsation. Upon inspecting the

valwas,make sum Ihatthe tefkm button inthe valve spring retainers are still

intact. Also examine the discharge manifold. Look for problems such as

cracks, chwnical buildup or warpage ch.mM hewing. If this discharge

manifold is warped, it will cause th~ check valves to stick and will result in

loss of pnlssure.

Nextexamine the seating surface of the flalvalve seats and lapwith ?.40

grit paper or replace if evicklnco of excessivw wow. (Met valve

S43ats

should be replatwd if vmrn. Lap new quiet valve and seat to assure

seal.

positive

Some pump models have o-rings for easa of installation and to avoid

damaging elastomers.

DTE First install o-ring ingroove on sea! (towards seating surface), then

back-up ring.

Modelswithout outer groove onmat require the o-ring to be placed

DTE:

on lip of retainer.

The Cat pump cups am Men the source of pressure loss. Upon inspection

they rnayappearmeked ortorn, butoften they will look good. Replace them

anyway. Thereisrw surernethodofvisualfyinspecting thecups. HydraMas-

tw recommends changing cups whether they look good or not.

Anytim@your pump is being dismantled, HydraMaster recommends re-

placermnt d all ‘o’ rings and seals. This is merely a convenience to the

customer to make sure that the Cat pump is in top operating condition.

The Prmwm-A-Lube Mals located within the intake manifold will atlowair to

@nt@rthe pump if they are vmrn. Again, it is difficult to visually pinpoint a

defective Prrrrrm-A-Lutw seal. Replace them al.

Repairing of Cat pumps is not a difficult task. However, before disassem-

Ming make swa you hava tie proper parts required.

ShOti (Of hot) CLd kit

13- Prmrrn-A-Lube seals

6-piston

sleeve ‘o’ rings

1- bottle Cat oil

Readinstructions thoroughly, suppfied in the Cat pump manual prior todisassernbly and fallow directions as stated. Oil all seals thoroughly ~“or toinstallation. (Remember, a newiy scarred seal is no better than one you just

took aut.)

SERVICING THE VALVE

ASSEMBLIES

DISASSEMBLY

1.Remove th@ fastmers securing the discharge manifold tothe crankcase

of the pump.

2. Support ~ discharge manifold and tap from the bac~lde and a soft

mallet to separate hum the crankcase and gradually work free from

qdh’ld$rs.

3. Valve assemblies will remain in the manifold. Pump models with the

o-ring groove an lhe outside of the valve seat require the assistanw of

a reverse pliers to remove thevalve seat. The valve, spring and retainer

will then fall out wlwn the manifold is inverted.

Pump models without the o-ring groove on the outside of the valve seat

pwmii the s@a~valve, spring and retainer all to fall out wf’ten manifold is

inwwted.