Page 1

BmbCat/HmuaCat

Page 2

130bCat(frorit view, feaMresltiled) .........................................................'

BotICat (side tiew.featureslabled) ..........................................................'

AquaCat (front view, feaWreslabIed) .......................................................i

AquaCat (side view, featumslabled) ........................................................

Cat Pump Model 290 ................................................................................l

DWrrantiing Cat Pump .............................................................................l

Vanguad OHVEngine ............................................................................2

GENERAL lNFORMAllON

Piywood Instailatiin (ontwck&d) ..............................................................4

Aswot@and RmfVent ...............................................................................4

MactiwConfiguration ...............................................................................5

Machine Tie Down Cleats,BobCat Only ......................................................5

Propane Tank Piumbing, MbCatOnly ......................................................5

Thru-floor Gas Hook-upand lnshliation ....................................................5

.Nater Mrdww Map .................................................................................6

Water%fiewrHook.up .............................................................................6

WATER & CHEMICAL SYSTEMS

Bob&tWaterHow ..................................................................................lO

AquaCat Water Flow ...............................................................................l O

Chemiml ProWfiioningand Levei Conhoi ...............................................lO ,

CAT PUMP

Pumping Section Cut.awy .....................................................................l3

NstonMo&i~OExpbded Mew ..............................................................l4

Bypass Vaive A~mbly ..........................................................................l7

AquaCat Water Fiow ...............................................................................l7

VACUUM SYSTEM

Vawum Fbw ...........................................................................................l8

Va@um Tank fiiWrBag ...........................................................................l8

Blower Lube Pofl .....................................................................................l E

Vawum Blowr Motor Lubri~tion ...........................................................2O

PST

HOURS

Monday -- Friday

8:00 am To 5:00 pm

PACIFIC STANDARD TIME

ROCK MT.

TELEPHONE NUMBERS

(206) 776-7272 General Offices

(206) 776-7276 Parts Department

(206) 775-7275 ServiceA!Varranty

(206) 771-7156 FAX

CENTRAL

EASTERN

VANGUARDOHVENGINE

aiMm9~ckti ....................................................................................22

OiHliandDip Stick ..................................................................................22

Enghe Compnents ................................................................................22

Engine Compwnts(mntinued) .............................................................23

Carburetor Adjustment Screws ...............................................................23

Govemd idle Sping ...............................................................................23

Oii Filter/Oii Drain

Round Duai AirCieaner Element .......

Square Dual Air Cleaner Element ............

Round Dual Element ...............................................................................25

Coating System .......................................................................................25

s~kPiug ...............................................................................................25

Fuei Hlter ................................................................................................25

ELECTRICAL SYSTEM

Electrical Diagram ...................................................................................3l

CLEANING & CHEMICALS

pHChafi ..................................................................................................33

Cleaning Stroke Method ..........................................................................33

BOBCAT HEATING SYSTEM

Pro~ne Riot tight ..................................................................................34

....................................................................................24

.... .................................................24

................................................24

@1991 HydraMaster Corp.

Printed in LLS.A.

CLEANING WANI)

WandVaiveAswmbly .............................................................................35

Jet Assembly

Wand Aswmbly ......................................................................................35

...........................................................................................35

Page 3

Iacuum Biower Troub~ Shooting Guide .................................................l9

!acuum BlowerWarran~ ........................................................................2O

(acuum Blower Lubtitnn .....................................................................2O

GENERAL lNFOf?MAllON

Warning and Caution .................................................................................2

How the Systems Wotis ..............................................................................2

HydraMaster Hours&Phone Numhrs ......................................................2

BobCat Machine SWcifiMtions .................................................................3

AquaCat Machine S~cifimtions ...............................................................3

Purchaser’s Res~nsitili~ ........................................................................4

Sales Representative’s ResWnsitih~ ......................................................4

TwckPre~ration ......................................................................................4

Placement of Unit in Vehicle .......................................................................4

Truck Preparation lllustmtion .....................................................................4

Machine lnstdlation ...................................................................................5

Propane Tank Location, BobCatOnly ........................................................5

Spare Parts Recommendation ..................................................................5

PaflsOrder ................................................................................................5

Hard Water Area Map ................................................................................6

Water Sofiener ..........................................................................................6

Wastewater Disposal Advim~ ..................................................................6

BOBCAT OPERATING lNSTRUCTfONS

StaflUp ......................................................................................................7

ShutDoM .................................................................................................7

Flood Damage Work ..................................................................................7

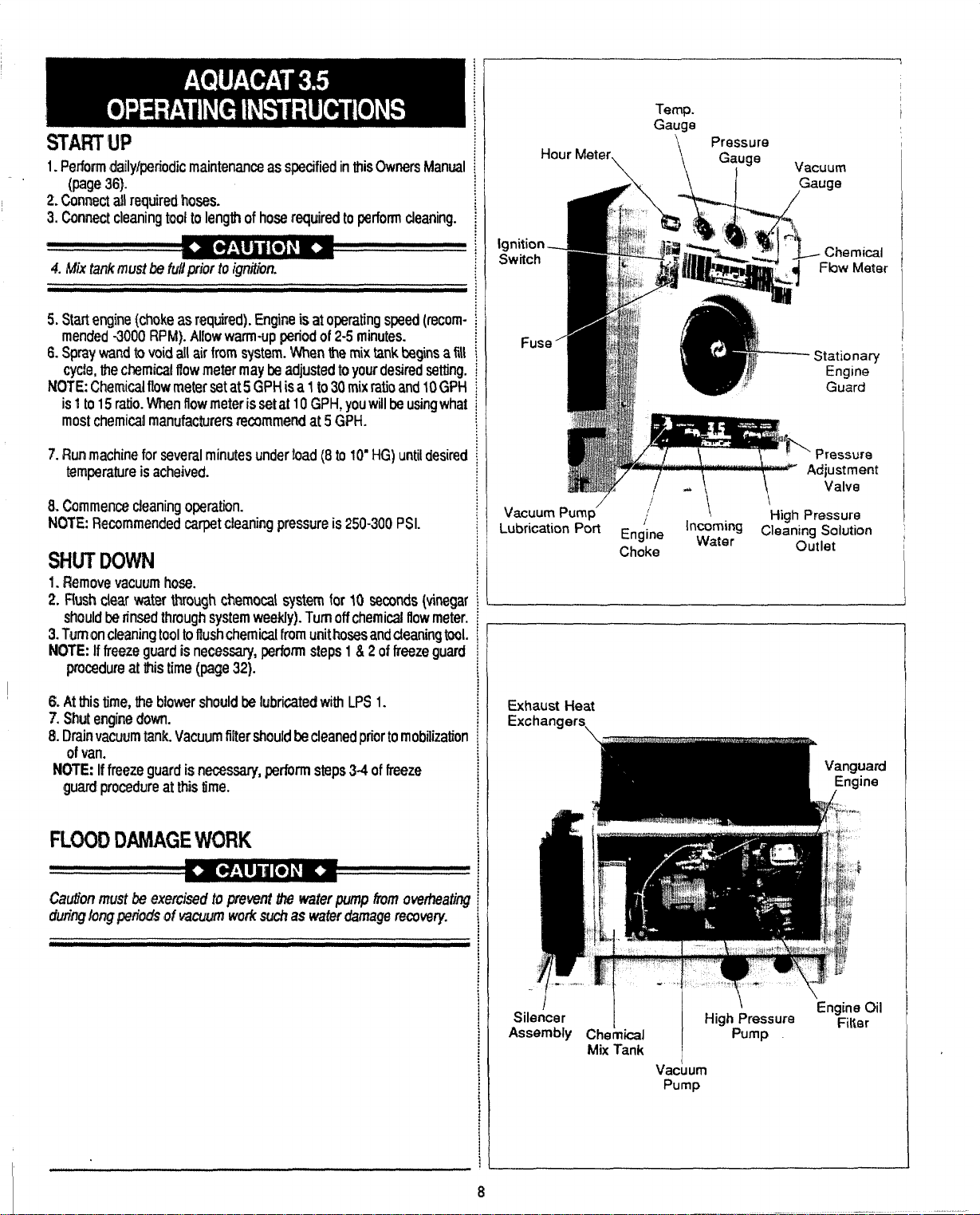

AQUACAT3.5 OPERATING INSTRUCTIONS

StatiUp ......................................................................................................8

Shut DoM .................................................................................................8

Flood Damage Work ..................................................................................8

OPERATING PRECAUTIONS

MactineAdjustments ................................................................................9

Cautionsand Warning% ............................................................................9

WATER&CHEMICAL SYSTEMS

Water/Chemical Fiow OWration ...............................................................9

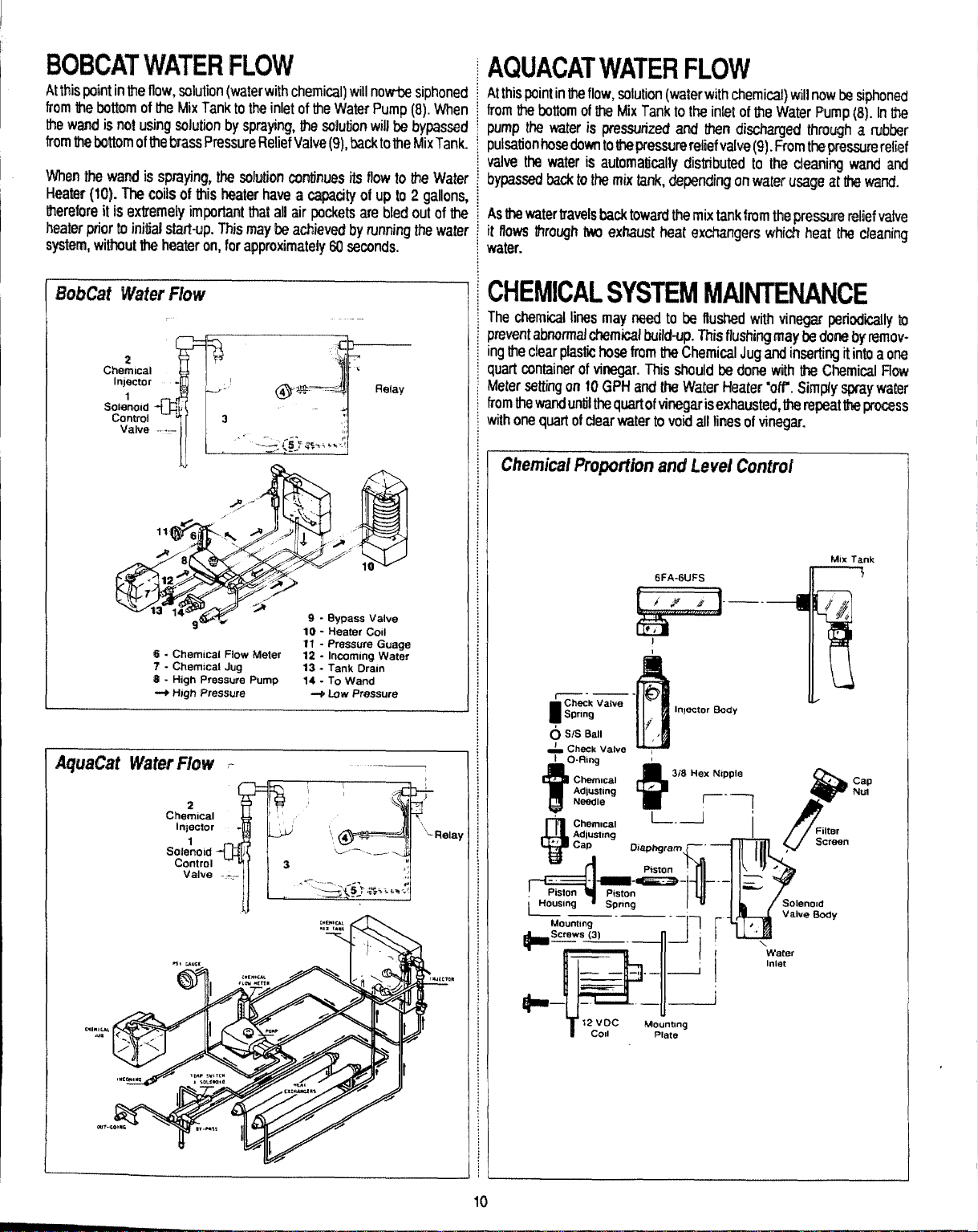

BobCat Water Flow ..................................................................................lO

AquaCat Water Fiow ...............................................................................lO

ChemiMiSystem Maintenance ................................................................lO

Chemical Tank Trouble Shooting Guide

CAT PUMP

\

Cat Pump Modei 2900perating instructions

Cat Pump S~cifiMtions .........................................................................l 1

General information for Cat Pump Re~ir ................................................l2

Servicing the Discharge Vaives& Valve Seats .........................................l2

Servicing the Pumping Section ................................................................l2

Servicing Sleeves and Seals ...................................................................l2

Sewice Nts ..............................................................................................l3

Modei290PartsList

Cat PumpTrouble Shooting Guide .....................................................l5.l6

High Pressure Pump Troubie Shooting Guide .........................................l 7

BypassPartsList .....................................................................................l7

VACUUMSYSTEM

infomation ................................................................................................l8

Vacuum Tank filter Bags .........................................................................l8

.................................................................................l4

..................................................l 1

............................................1 1

IANGUARDOHVENGINE

)perating & Maintenance for Modei 303400 (16 HP) Engine ..................2l

Iternatiinai Symbois Used in this Wnuai ..............................................2l

ntheinterestofSafety .............................................................................2l

Wrning: DO NOT ...................................................................................2l

Yarning: DO ...........................................................................................22

khmshti~ .........................................................................................22

)iI *mmetitbns .............................................................................22

‘uei Rwmmetitions ..........................................................................23

laWmtor Mjustments ..........................................................................23

ENGiNEMAiNTENANCE ........................................................................24

lil Change ...............................................................................................24

W Cieaner Maintenance .........................................................................24

lean Engine, Rotating Screen, Cooling System, Spark Arrester,. ........25

?epiace Spark Piugs, Repiace Fuel Riters .........................................25.26

~ngine Maintenance Scheduie ...............................................................26

;enerai information about Engine ...........................................................27

Storage instructions

;ervice & Repair information ...............

/anguard Engine Wamany .....................................................................28

superseding Wamnty ............................................................................28

.imited Warranty for Vanguard Engines ..................................................28

rVarranty Period ......................................................................................29

ENGINE TROUBLE SH~TING ............................................................3O

SLECTRICALSYSTEM

3ectricaiSystemand TroubieShootingGuide

FREEZE PROTECTION

Bobcat .....................................................................................................32

*uaCat ......................................................................................................32

CLEANING & CHEMICALS

Prmutions ................................................................................................33

Cleaning Stroke Procedure / @er.Wetiing .............................................33

BOBCAT HEATING SYSTEM

infomation ................................................................................................33

HeaterOperating instructions

Heater Trouble Shooting Guide

CLEANING WAND

Wand, Jet Assembly &Wand Assembly Parts Lists ................................35

MAINTENANCE

Pr~dures .................................................................................................36

Overail Care of Unit..................................................................................36

Maintenam Logs ...............................................................................37.38

HYDRAMASTER WARRANTY

Warranty lnfomation ................................................................................39

Warranty Procedure

How to Order Pafls ...................................................................................39

PatisOrders ............................................................................................39

One Rnal Note .........................................................................................39

BobCat/AquaCat Limited Warranty Plan .................................................M

................................................................................27

....................................................27

.......................................31

..................................................................34

...................................................................34

................................................................................39

1

Page 4

This manual contains installation and opation instructions as well as

informaticm required for proper maintenance, adjustment and repair of this

unit Since the first and most important part of repair work is the correct

diagnosis otthe trouble, a gemwal trouble shooting section and component

manual trothlwahooting charts have been included for your convenierm.

HOW THE SYSTEMS WORK

THE BOBCAT SYSTEM WORKS AS FOLLOWS:

The water system takes incoming water at tap(!ow) pressure, automatically

combines it with chemicals from the chemical system, pumps it under

pressure tfmugh the heating syslern and out to the cleaning tcml. Afhw

being sprayed into the carp?~ the water/chemic-alhoil solution is extfacted

by the vacuum system and returned to the wasJe recmry tank.

Unlike a gamf%ntracfur, lawn mower or~ment mixer, al! hating one or W

functions M perform, tha truck-mounted carpet cleaning ptant has many

functions to pwform simuitaneouqy.

* Engine has to run at a consistent RPM.

‘ Vacuum has to pull air and dirty water baok from cleaning site.

* Waler pump provides stabte pressure at proper water flow for cleaning.

‘ Chemical has 10be injected into the water stream at the

right concentration.

* Heater must maintain proper heat.

*Vacuum tank must store dirty water until drained.

As you can see, it is not just a turn key operation with one ttlng to worry

about, Does H starl?!

TM manufacturer uses this

symfmi throughout themanual to warn

of possible Injury or death.

?’hissymbol k used ?0warn of

pxs!b!e equipment damage.

There is no guess work in the marwtacture of these highly adw%$d

chxrning ptants. There must also be no guess vmrk in prqwing it to g@tthe

job done in the field. It is the purfxm of this manual to fwlp YOUproperly

understand, maintain and service your cleaning plant. Follow tfmdirections

carefully and you will be rewarded witi years of profitable tro@le-f#e

operation.

Itis imperative that no sectirxr twoverfookecl when preparing foroperatirm

of this equipment.

THE AQUACAT 3.5 SYSTEM WOHKS AS FOLLOWS:

The AquaCat 3.5 High Perlorrnance Heat Exchanger system is

engineered cleaning plant, designed by HydraMaster Corp. The system

utilizes a dynamic heating system comprised of two separate exhaust h@at

exchangers for capturing ‘free heat=.

Water is fed into the machine at tap pressure. It is combined automatically

with cleaning solution as it enters the mix tank. The solution is then picked

up by the high pressure pump and pressurized to the desired level. Th8

solution then travels to the bypass assembly where it is distributed out to ttw

wand and back into the machine. The solution going back into the machine

splits flow and travels through the two exhaust heat exchangers. NW’ being

heated, the solution returns to the mixtankwhere it is picked up by the pump

again.

When the cleaning solution reaches a pre-sat high terrqwature, it is

released from the system and directed to the recovery tank, then cool water

enters the system to regulate the temperature.

a highly

As there is no guess work in the manufacture of these highly advanc%d

cleaning plants, there must lx?none in pre~”ng it to get tha job dons in the

field. It is the purpose of this manual to help you property urrcf$wskmt,

maintain and service your cleaning ptant. Follow the ciirectionscarefully and

you will 5e rewarded with years of protlfable trouble-free opxation.

[t is imperative that no section be overlooked when preparing for opmtion

of this equipment.

I

*

2

Page 5

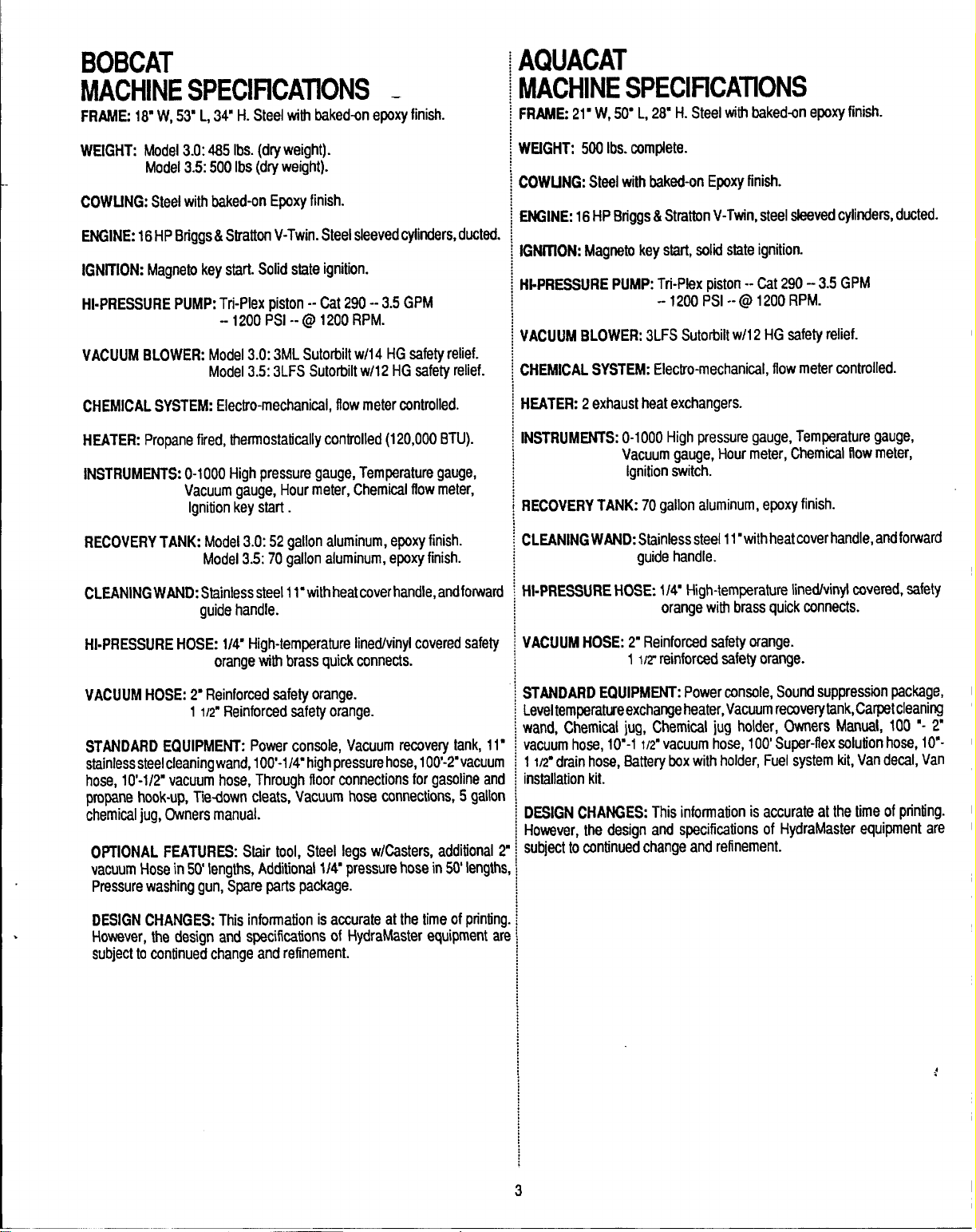

BOBCAT

hQUACAT

MACHINE SPECIFICATIONS .

FRAME: 16” W, 5~ L, 34’ H. Steel with baked-on epoxy finish.

WEIGHT: Model 3.0:465 Ibs. (dry weight).

Model 3.5:500 Ibs (dry weight).

COWUNG: Steel with baked-on Epoxy finish.

ENGINE: 16t-fP Briggs& Sfratton V-Twin. Steel sleeved cylinders, ducte(

IGNITION: Magneto key start. Solid state ignition.

HI-PRESSURE PUMP: Tri-Plex piston -- Cat 290-- 3.5 GPM

-1200 PSI -- @ 1200 RPM.

VACUUM BLOWER: Model 3.0: 3ML Sutorbilt w/14 HG safety relief.

Model 3.5: 3LFS Sutorbilt w/12 HG safety relief.

CHEMICAL SYSTEM: Electro-mechanical, flow meter controlled.

HEATER: Propane fired, thermostatically controlled (120,000 BTU).

INSTRUMENTS: 0-1000 High pressure gauge, Temperature gauge,

Vacuum gauge, Hour meter, Chemical flow meter,

Ignition key start.

RECOVERY TANK: Model 3.0:52 gallon aluminum, epoxy finish.

Model 3.5:70 gallon aluminum, epoxy finish.

llACtIllNE SPECIFiCATIONS

‘RAME 21” W, 5(Y L, 26’ H. Steel with baked+m epoxy finish.

lfEtGHT: 500 Ibs. complete.

)OWUNG: Steel with baked-on Epoxy finish.

MINE: 16 HP Briggs & Stratton V-Twin, steel sleeved cylinders, ducted.

GNfflON: Magneto key start, solid state ignition.

II-PRESSURE PUMP: Tri-Pk?x piston--(X290 -3.5 GPM

--1200 PSI -- @ 1200 RPM.

/ACUUM BLOWER:3LFSSutorbiltw/12 HG safety relief.

2HEMICAL SYSTEM: Electro-mechanical, flow meter controlled.

4EATER: 2 exhaust heat exchangers.

NSTRUMENTS: O-1000 High pressure gauge, Temperature gauge,

Vacuum gauge, Hour meter, Chemical flow meter,

ignition switch.

3ECOVERY TANK: 70 gallon aluminum, epoxy finish.

2LEANING WAND: Stainless steel 11“with heat cover handle, and fo~ard

guide handle.

CLEANING WAND: Stainless steel 1l“withheat cover handle, andforwai

guide handle.

HI-PRESSURE HOSE: l/V High-temperature Iinedhinyl covered safe!

orange with brass quick connects.

VACUUM HOSE: 2“ Reinforced safety orange.

1/2” Reinforced safety orange.

1

STANDARD EQUIPMENT: Power consale, Vacuum recoveiy tank, 1

stainless steel cleaning wand, 100’-1/4’ high pressure hose, 100’-2”vacuu

hose, 10’-1/2” vacuum hose, Through floor connections for gasoline al

propane hook-up, Tiedown cleats, Vacuum hose connections, 5 galk

chemical jug, Cwners manual.

OPTIONAL FEATURES: Stair tool, Steel legs w/Casters, additional

vacuum Hose in 50’ lengths, Additional 11~ pressure hose in 50’ lengt

Prwsure washing gun, Spare parts package.

>

DESIGN CHANGES: This information is accurate at the time of printi

However, the design and specifications of HydraMaster equipment ~

subject to continued change and refinement.

rll-PRESSURE HOSE: 1/4’ High-temperature Iinedlvinyl covered, safety

orange with brass quick connects.

VACUUM HOSE: 2“ Reinforced safety orange.

1 M? reinforced safety orange.

STANDARD EQUIPMENT: Power console, Sound suppression package,

Level temperatureexchange heater, Vacuum recovery tank, Carpet cleani~

wand, Chemical jug, Chemical jug holder, Owners Manual, 100 ‘- 2“

vacuum hose, l(Y-1

IL? drain hose, Battery box with holder, Fuel system kit, Van decal, Van

1

installation kit.

DESIGN CHANGES: This information is accurate at the time of printing.

However, the design and specifications of HydraMaster equipment are

subject to continued change and refinement.

1/2” vacuum hose, 100’ Super-flex solution hose, 10’-

*

3

Page 6

PLIWWER’S RESPONSIBILITY

PRIOR T(3 ARRIVAL OF UNIT:

1. lrMal15N’ ~xteriorplywood flooring invehicie andcoverwi~ artificial turf.

2. Have belly mmmt~d propane tank installed on vehicle. Tank must be

propane vapor typ4 (for BobCat only).

3. Purchase heavy duty 42-6d amp hour battery arrd have battery ‘slow’

ct?argedifrww. lfhti~~isnotblty chargeddamagemfl occurfo the engine

charging mgulakw.

WADING OF QWERS MANUAL: it is the purchaser’s responsibility to

read the unit operation manual and to familiarize himself with the informs

tion contained therein. Special attention sf?ouldbe paldtoail CAUTIONS

and WARMNGS.

SALES REPRESENTATIVE’S

RESPQNW31UTY

ACCEPTANCE OF WIPMEm

f. Ifunit shows any outward signs of damage, do not sign the delivery receipt

until you have closely inspecied the unit and noted any damage on the

delivery rewipt. Have the freight company representative acknowledge the

damage by signing Me notation of damage on the delivery receipt.

2. Tim salesman from whom you purchased your unit is responsible for

Supawising tfm Wrrect installation of the unit in your vehicle and thoroughly

training you in its operation, maintenarwa and precautions.

LACENIENT OF LINIT

4VEHICLE

IERE ARE TWO RECOMMENDED UNIT PLACEMENTS:

SIDE DOOR: Most installations are side door. This provides rear

‘accessories

Mng side of machine, thus making it a bit easier to perform maintenance

!d/or repair without removing unit from the truck.

REAR DOOR: Afthough this location partly limits working access, itdoes

rect the noisa away from the cleaning site. Some cleane~ in the colder

aas prefer this location twcause it puts the weight mass over the rear

Ieels for better traction in ice and snow. Rear mounting requires+tt%?unit

b slid 10the right side as faraspossible.This not only provides adequate

inking space on the component side of the unit but al~ makes better

sight distribution inside the van (engine and component weight line up

Ier drive shaft). Also, it is physically easier to load unit into rear door due

height of van bad.

nsure that machine is well secured to the floor of van with hardware

Jpp/ied. Sudden or crash stop wili cause machine 10rocket forward, d

70 lbs. worth! Protect yourself and the maclrirw. SEC(N?E IT?

and hoses as well as unobstructed access to cornpmntf

access

“IWCK PREPARATION

lmLWTRATION

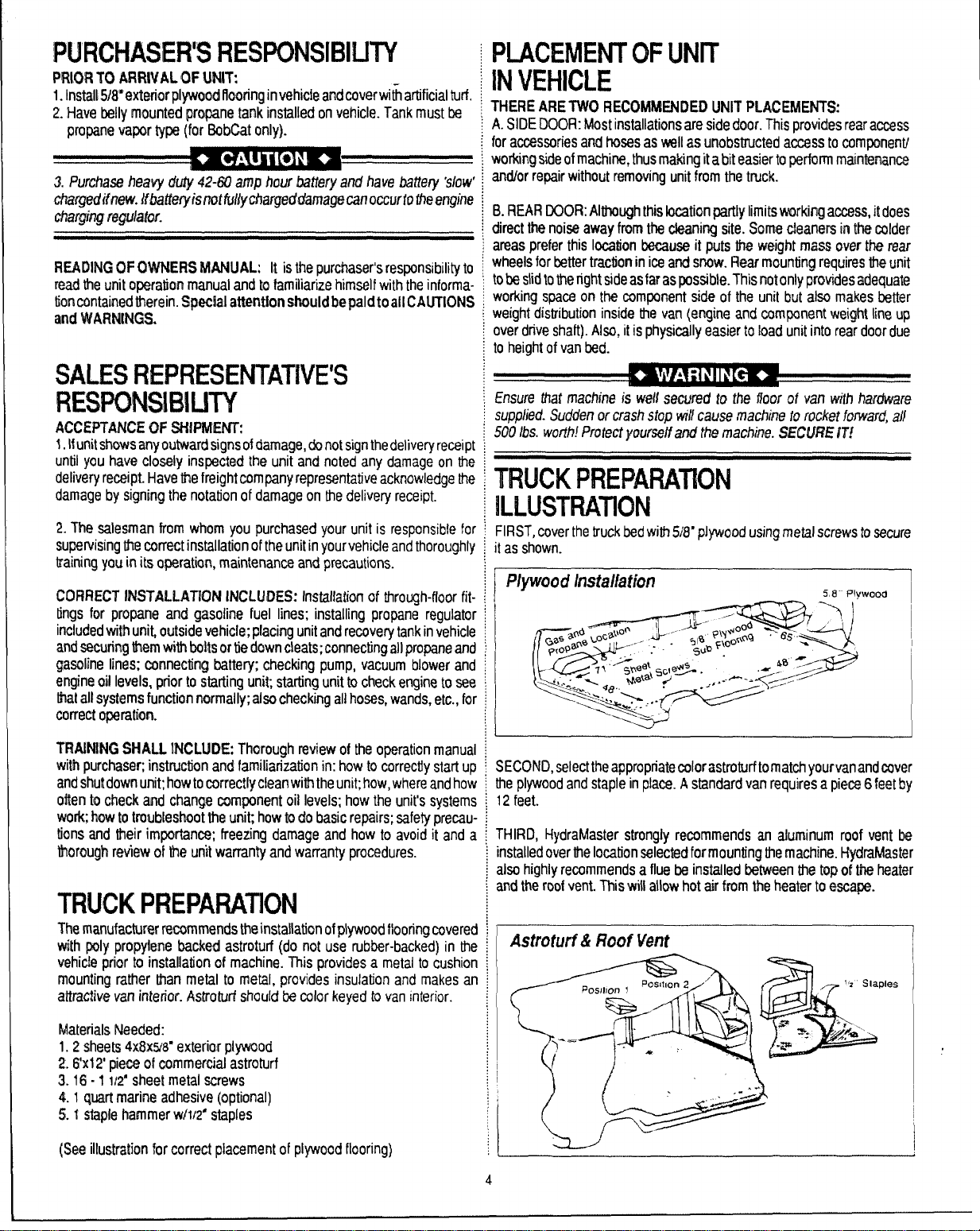

IRST, cover the truck bed with 5/8mpJywood using metal screws to secure

as shown.

CORRECT’ INSTALLATION INCLUDES: Installation of through-floor fit-

tings for propane and gasoline fuel lines; installing propane regulator

included with unit, outside vehicle; placing unit and recovery tank in vehicle

and securing them with bolts or tie down cleats; connecting all propane and

gasoline lines; carmecting battery; checking pump, vacuum blower and

engine oil levels, prior to starting unit starting unit to check engine to see

that all systems function normally; also checking all hoses, wands, etc., for

correct opwation.

TRAINING SHALL INCLUDE: Thorough review of the operation manual

with purchawq instruction and familiarization in: how to correctly startup

and shutdown unit; how to cwrec!lyclean with the unit; how, where and how

often to check and change component oil levels; how the unit’s systems

work how to troubleshoot the unit how to do basic repairs; safety precau

lions and their imporfanoe; freezing damage and how to avoid it and a

ihorough review crl the unit warranty and warranty procedures.

TRLICK PREPARATION

Th~ manufacture recommends the installation of plywood flooring covered

with poly propylene backed astroturf (do not use rubber-backed) in the

vehiclo prior to installation of machine. This provides a metal to cushion

mOunting rather than metal to metal, provides insulation and makes an

attractive van interior. Astroturf should be color keyed to van interior.

Materials Needed:

1.2 sheets 4x8x9$* exterior plywood

2. 6x12’ piew of commwcial astroturf

3.16-1112” sheet metal screws

4.1 quart marim! adhesiv~ (optional)

5. f staple hammer w/1/2” staples

ECOhfD, select the appropriate colorastroturfto match yourvanandcover

Ie plywood and staple in place. A standard van requires a pieca 6 feet by

2 feet.

HIRD, HydraMaster strongly recommends an aluminum roof vent be

lstalled over the location selected for mounting the machine. I-fydrafdaster

Iso highly recommends a flue be installed between the tap of the heater

nd the roof vent. ~is will allow hot air from the heater to escape.

Astrowrf& Roof Venf

pies

1

(See illustration for correct placement of plywood flooring)

4

Page 7

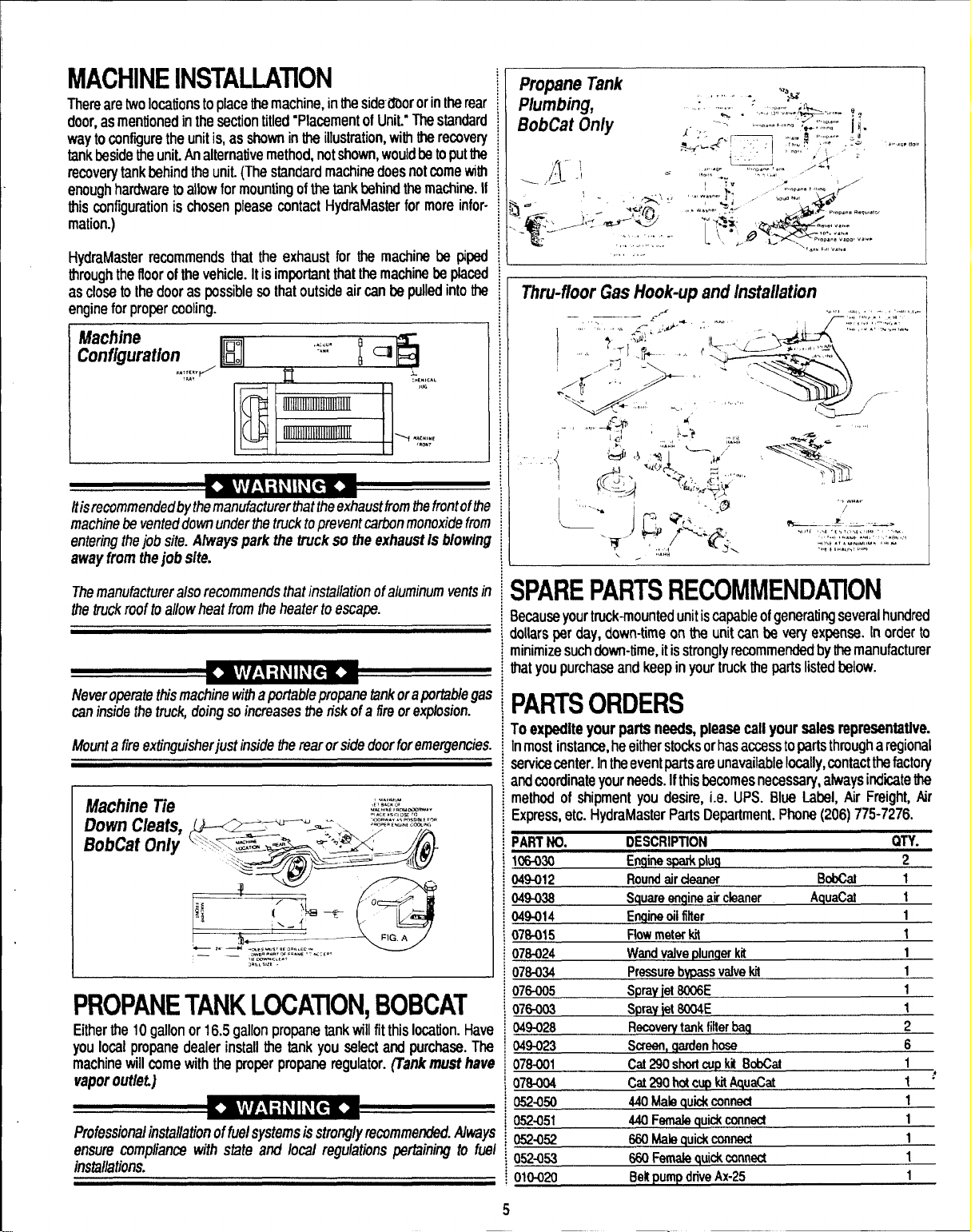

MACHINE INSTALLATION

There are two locations to place the machine, in the side duor or in the real

door, as mentioned in the section titled “Placement of Unit.” The standara

way to configure the unit is, as shown in the illustration, with the recoveq

tank beside the unit. An alternative method, not shown, would be to put tfw

recovery tank behind the unit. (The standard machine does not come witt

enough hardware to allow for mounting of the tank behind the mactrhe. I

this configuration is chosen please contact HydraMaster for more infer

mation.)

HydraMaster recommends that the exhaust for the machine be P@

through the floor of the vehicle. It is important that the machine be placw

as cfose to the door as possible so that outside air can be pulled into tlw

engine for proper cooling.

Machjne

Conflguraflon

ltisrecommendedbvthe marrufacturerthatthe exhaustkom the frontoffh

machine be vented down under the truck to prevent carbon monoxide frofi

entering lhe job site. Afways

away from the job site.

,,,,,””

,*,r’”

park the truck so the exfrauat Is &/ow/nj

Thru-iloor Gas Hook-up and h?stallafjon

The manufacturer also recommends lhat insta/iation of aluminum vents i

the truck roof to allow heat from the heater to escape.

Never operate this machine with aporlablepropane tank oraportabie ga

can inside Ihe truck, doing so increases zhe risk of a fire or expfosion.

Mount afire extinguisher just inside the rear or side door foremergencie:

Machh?e Tie

Down Cleats,

BobCat On/y

PROPANE TANK LOCAnON, BOBCAT

Either the 10 gallon or 16.5 gallon proparw tank till fit this location. Hav

you local propane dealer install the tank you select and purchase. Th

machine will come with the proper propane regulator. (Tank must

vapor outlet)

Professional installation of fuel systems is strorrglyremmmerrdad. Alwaj

ensure compliance with state and local regulations pertaining to fu

installations.

hat

SPARE PARTS RECOMMENDATION

Because your truck-mounted unit is capable of generating several hundred

dollars per day, down-time on the unit can be very expense. [n order to

minimize such down-time, it is strongly recommended by the manufacturer

that you purchase and keep in your truck the parts listed Mow.

PARTS ORDERS

To expedite your parts needs, please call your sales representative.

Inmost instance, he either stocks or has access to parts through a regional

service center. In the event parts are unavailable locally, contact the factory

and coordinate your needs. Ifthis Eecomes necessaty, always indite the

method of shipment you desire, i.e. UPS. Blue Label, Air Freight, Ar

Express, etc. HydraMaster Parts Department. Phone (206) 775-7276.

PART NO.

106-030 Ermine spark pluq

)49-012 Round air cleaner

)49036 Square emaineair cleaner

)4%014

)7s-015 Flow meter M

)7S-024 Wand

07s-034

076-005 Spray iel 6CX16E

076-003 SPraYiet 6004E

049-028

049-023

07a-ool

07s-004 Cat 290 hot CUPkitAquaCa!

052aw

052451

052-052

052453 660 Female quick conned

010-020 Belt pump drive Ax-25

DESCRIPTfON

Erwrineoil fifter

VSk3 r)iuntler kit

Preswre bvpas

Recoverv tank filler baq

%merr, mrden hcse

Cat 29o shorr

440 Male @ck conned

440 Female quick conned

W Male Quid conned

s valve M

CUP kt BobCar

BobCaI

A(auaCat

QTY.

2

1

1

1

1

1

1

1

1

2

6

1

1:

1

1

1

1

1

5

Page 8

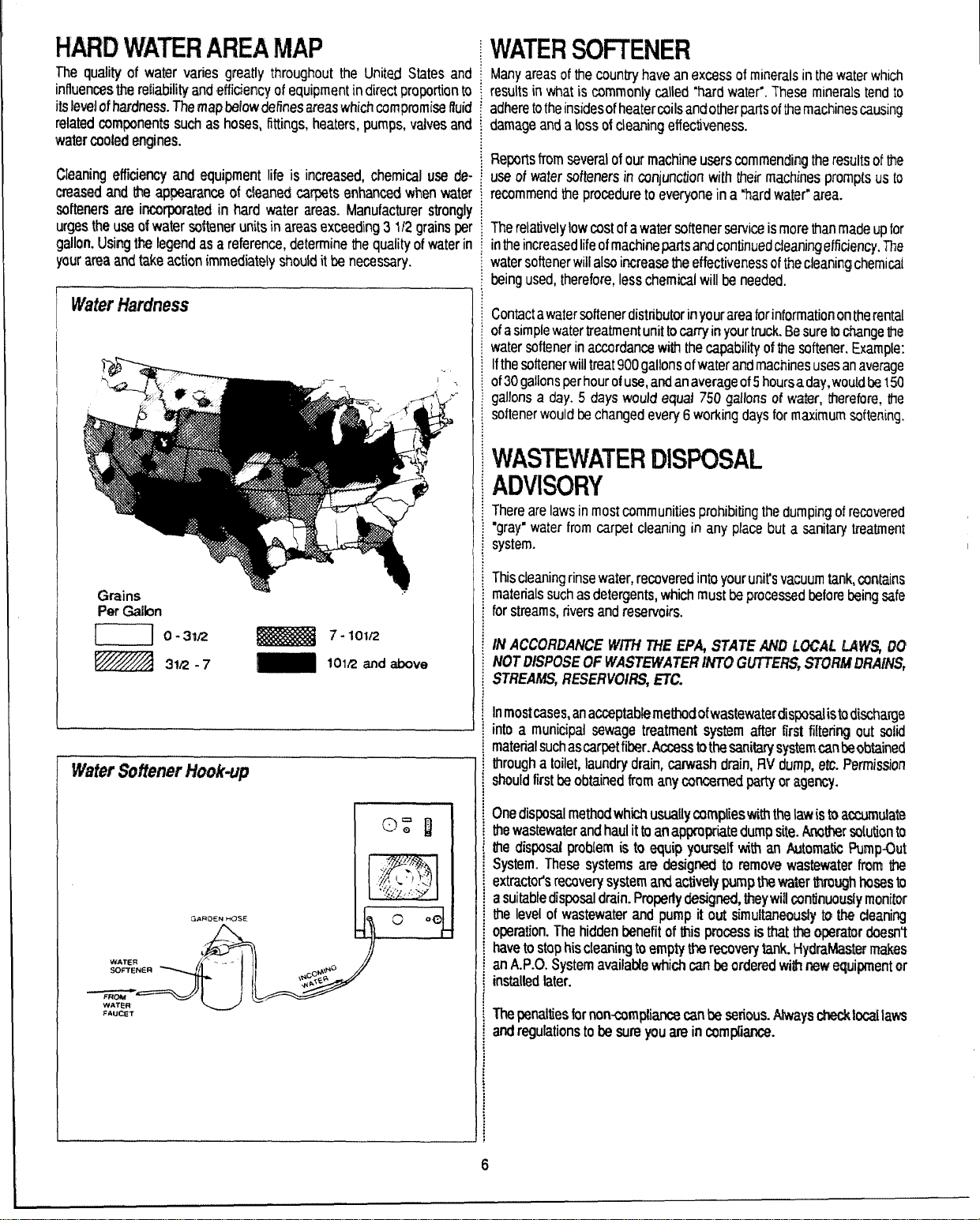

HAM) WATER AREA MAP

The quality of vvatw varies greatly throughout the United States an{

influences the reliability and efficiency of equipment in direct proportion t{

its leve~of hardness. The map bdowdefines areas which compromise flui(

related cwmfxmwms such as hoses, fittings, heaters, pumps, valves an~

water cooled engines.

Cleaning dficioncy and equipment life is increased, chemical use de

crwumd and the appearance cd cleaned carpets enhanced when wate

softeners are incaporated in hard water areas. Manufacturer strong!

urges the use of watr3r softener units in areas exceeding 3 1/2 grains pe

gallon. Using We legend as a reference, determine tie quality of water ii

your arm and tak~ action immediately should it be necessary.

INATEI?SOFTENER

dany areas of the country have an excess of minerals in the watw which

esults in what is commonly called ‘hard water”. These minerals t~nd to

idhere to the insides of heaterwils and other pans of the machines causing

!amage and a loss of cleaning effectiveness.

?e~rts from several of our machine usk+rscommending the rwx.dts of Me

Ise of water softeners in conjunction with their machines prompts us to

ecommencf the procedure to everyone in a “hard watw’” area.

~herelatively low crestof a water Wtener service is mor~ than made up for

nfhe increaw+d life of machine parts and continu@d deaningefficiemcy. The

vater softener will also increase the effectiveness of the cleaning chemical

wing used, therefore, less chemical will be needed.

;Ontact a water softener distributor in your area for information cmthe rental

]f a simple water treatment unit to carry in your truck. Be sure to change ttw

vater softener in accordance with the capability of the softener. Example:

fthe softener will treat 900 gal!ons of water and machines uses an average

}f30 gallons per hour of use, and an average of 5 hoursa day,woukf be 150

]allons a day. 5 days would equaf 750 gallons of water, therefore, the

;oftener would be changed every 6 working days for maximum softening.

WASTEVIATER IDISPOSAL

ADVISORY

rhere are laws in most communities prohibiting the dumping of recovered

‘gray” water from carpet cleaning in any place but a sanitary treatrrmt

;ystem.

Per Gdbn

W’MerSiMttM9erMwk-up

G.iROEN HOSE

&~.,

::____J=’~w

FAUCET

Wriscleaning rinse water, recovered into your unit’s vacuum tank, contains

naterials such as detergents, which must be processed txfore being safe

br streams, rivers and reservoirs.

N ACCO171?ANCE W/TH 77iE EPA STATE Al@ LOCAL LAW% IX?

NOT DiSPOSE OF WASTEWATEI? Mf7TJ GU?TKUS, STCiFfMOl?A#dS,

STREAMS, RESERVOIRS, ETC.

n mostcases, an arxx?ptablerrtrathodofwastwvaterdisposalistodwharge

nto a municipal sewage treatment system after ftrst filtering out sofii

natenal such ascar@fiber.Access @the sanitary systerncanbeobtain~d

through a toilet, laundry drain, carwash drain, flV dump, etc. Permission

]hould first be obtained from any cmcerned party or agwwy.

One disposal method whti usuatly complies witf’i the law is to accumulate

he wastewater and haul it to an appropriate dump site. Anather solution to

he disposal problem is to equip yourself with an Automatii Pump.Qut

System. These systems are designed to remove wastewater from the

Wactot% recovery system and actively pump the water Wugh hoses to

asuitable disposal drain. Properiy designed, they will continuously monitor

the level of wastewater and pump it ouf simultarwously to thre ckaaning

opmtion. The hidden benefit of fhis process is that the operator doesn’t

have to stop his cleaning to empty the recovery tank. Hydrah%tstm makes

an A.P.O. System availakle which can M ordered wifh rww equipment or

installed later.

The penalties for non-camptiance can be serious. Always ctwk$ocallaws

and regulations to h sure you are in czrmpilarrrx.

6

Page 9

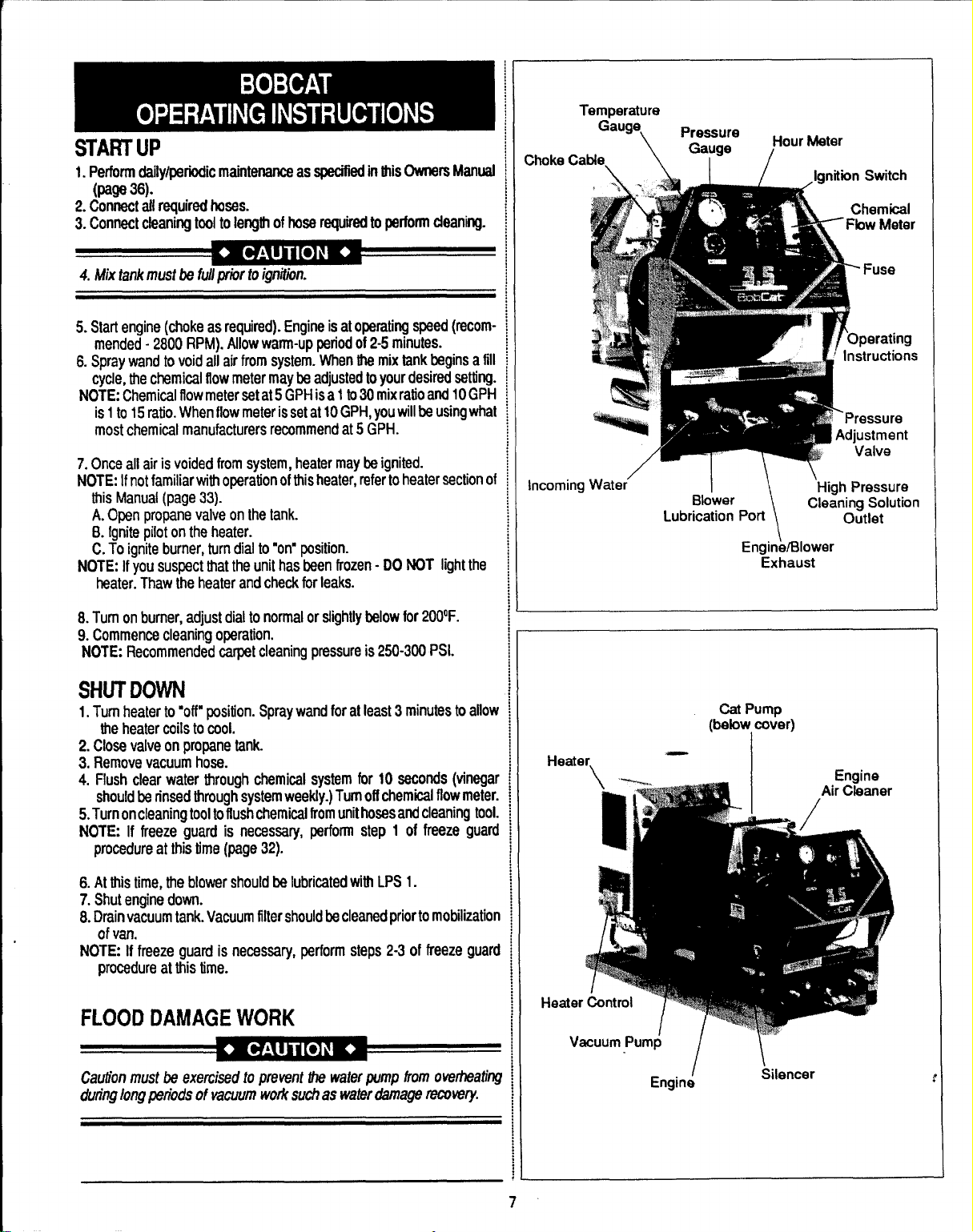

START UP

1.

Perform daily/periodic maintenance as specified in tMs Owners Manual

(WW 36).

2. Connect atl required hoses.

3. Connect cleaning tool to length of hose required to perform dearring.

r~

4. Mix tankmust be ful/priortoignition.

5. Start engine (choke as required). Engine is at operating speed (recommended -2800 RPM). Allow warm-up period of 2-5 minutes.

6. Spray wand to void all air from system. When the mix tank begins a fill

cycle, the chemical flow meter may be adjusted to your desired setting.

NOTE: Chemical flow meter set at 5

is 1to 15 ratio. When flow meter is set at 10 GPH, you will be using what

most chemical manufacturers recommend at 5 GPH.

A

●

GPHisa 1 to 30 mix ratio and 10 GPH

;hoke Cable.

Gauge

\ L I / ,ignition Switch

t%ssure

\

Ga~ge

Hour Meter

/

~

Chemical

~ Fbw Meter

- Fuse

7. Once all air is voided from system, heater maybe ignited.

NOTE: Ifnot familiar with operation of this heater, ~fer to healer =ction of

this Manual (page 33).

A. Open propane valve on the tank.

6. Ignite pilot on the heater.

C. To ignite burner, turn dial to “on” position.

NOTE: If you suspect that the unit has been frozen-DO NOT light the

heater. Thaw the heater and check for leaks.

8. Turn on burner, adjust dial to normal or slightly below for 200QF.

9. Commence cleaning operation.

NOTE: Recommended carpet cleaning pressure is 250-300 PSI.

SHUT DOWN

1.

Turn heater to “off’ position. Spray wand for at least 3 minutes to allow

the heater coils to cool.

2. Close valve on propane tank.

3. Remove vacuum hose.

4. Flush clear water through chemical system for 10 seconds (vinegar

should be rinsed through system weekty.) Turn off chemical flow meter.

5. Turn oncleaningtool to flush chemical from unit hosesarrd cleaning tool.

NOTE: If freeze guard is necessary, perform step 1 of freeze guard

procedure at this time (page 32).

6. At this time, the blower should be lubricated with LPS 1.

7. Shut engine down.

8. Drain vacuum tank. Vacuum filter should be cleaned prior to mobilization

of van.

NOTE: If freeze guard is necessary, perform steps 2-3 of freeze guard

procedure at this time.

incoming Water’

Heater.

Blower

Lubrication Port

‘\

Engink310wer

Cat Pump

(below, cover)

—

Exhaust

1

I

\

High Pressure

Cleaning Solution

Outlet

FLOOD DAMAGE WORK

Cauthn must be exercised to prevent the waterpump from owheatiq

dutinglongptwbds of vacuumworksuchas waterdamage recovery

Heatei

Vacuum Pump

Engine

-. .

/\

Silencer

Page 10

\

START w

1. Perform dailylp@riodic maintenance as specified in this OwrMrs Manual

(page 36].

2. Connrxt afl r~quired hosas.

3. Connect cleaning toot to I@ngti of hose required to perform cleaning.

4. Mix tank r?wttw tiilpriur to @tiort

5. Start engine (choke as required). Engine is at operating speed (recom-

mended -3000 RPM). Allow warmup period of 2-5 minutes.

6. Spray wand to void all air from system. When the mix tank begins a fill

cycle, the chemical ffow meter may k adjusted to your desired setting.

N(ITE Chemical flow meter set at 5 GPH is a 11030 mix ratio and 10 GPtl

is 1to 15 ratio. When flow meter is set at 10 GPH, you will be using what

most chemicai manufacturers recummend at 5 GPH.

Run machine for several minutes under toad (8 to 10” HG) until desired

7.

t~mperalure is acheived.

8. Commence cleaning operation.

NOTE: Recommended carpet cieaning pressure is 250-300 PSI.

Swn’DCNMN

1. Fh3move vacuum hose.

2. Flush ck?ar water through chemacal system for 10 smcmds (vinegar

should M timed through system weekly). Turnoff chemical flow meter.

3. Turmon cleaning tool to f?ush chemical from unit hosmand cleaning tool.

NOTE: If freezo guard is necessary, perform steps 1 & 2 of freeze guard

procedure at this time (page 32).

Temp.

Gauge

Hour Meter

Ignition.

Switch

Fuse

Vacuum PumD’ ~ i

Lubrication Port Eng’lne

\

Choke

\ Pressure

\

‘n~a~~g Cle;ning Solution ,

Gauge

F;.

Vacuum

w!.

II

Hiah Pressure

outlet

1

Stationary

Engine

Guard

6. At this time, the blower should be Iubrfcatecf with LPS 1.

7. Shut engine down.

& Drain vacuum tank. Vacuum filter should&e dearted prior to mobilization

d van.

fWITE: If freeze guard is necessary, perform steps 3-4 of freeze

guard procedure at this time.

FLOOD DAMAGE WORK

Caution must b exercised to prwmt thewaterpump hvn overheati~

dwirq long pfiads M

Kscwrn work suctr aswater damage recovery.

Exhaust l-feat

Exchangers,

I

Silencer

Assembly Chem&J Pump

Mix Tank

Vacuum

Pump

\

High Pressure

‘Engine CM

Filter

Page 11

MACHINE ADJUSTMENTS

Although this unit has been factory adjusted, it may require additional

adjustments to achieve optimum performance;i.e. altitude may require carb

adjustment and ambient temperatures may require heat control adjustment. When required, consult an authorized representative.

ENGINE COOLING

Units emp/o@gaircootedengin+?s must not &? enclosed w“thina van with

doors and windows closed. Excwssive temperatures within the engine will

resultinpremafure engine failure andacompromise ofappkable warranty.

LEVEL OPERATION

During operation, van or trailer must be parked on /eve/ ground noi to

exceed + or -1P. Failure to insure proper leveling may prevent proper

internal lubrication of engine, vacuum ancVor high pressure components,

FREEZE PROTECTION

Mothernafuregives/ittie wamingasto hercoldspelis. There fore, protecting

this equipment t70m freezing will save costfydown-time. Placingane/ectric

heater in the truck or parking the truck indoors, will hefp to insure against

freezing.

NO SMOKING

It is unsafe to smoke in or around the vehicle.

MOVING PARTS

Never touch any part of the machine that is in motrnn, sewn? bodily injury

may resuft.

CARBON MONOXIDE

This unit generates toxic fumes. Position the vehicie so that the fumes will

be directed AWAY from the jot) site.

DO NOT PARK where exhaust fumes can enter a building through open

doors or windows, air conditioning units or kitchen fans.

TOXIC FLUMES

Do not occupy the vehicle when tie cleaning equipment is operating. Toxic

times may accumulate inside a stationary vehicle.

WATEFUCHEMICAL FLOW OPERA~ON

HEATER

Never pile things aroundi%e heater, i.e. hoses, boxes, chemicaljugs, etc.,

as this will block the flow of air required for a clean burning heater.

OPEN FLAME

Remember that this heater is an open flame, therefore, do not remove

engine gasiine whi/e trouble shootingorstore any flammable materiaiin the

truck w“th heater operating.

STRONG PROPANE ODOR

Never light fhe heater if you smell a strong odor of propane around

the heater.

HOT SURFACES

During the operation of this equipment many surfaces on the machine will

tk?come veryhot. When near the van foranyreasoncare must be taken not

to touch any hot surface, such as heater, engine, exhaust, etc.

LIGkfTfNG HEATER

Neverputyourface down close to the opening of the heater when bghting.

I

This electro-mechanical system has been designed to be simple and

trouble free. Incoming water flows first through the Solenoid Control Valve

(I)(seeillustration on next page) andthelowpressure Chemical injector(2)

which are both mounted on the extenorof the mix tank. As the water passes

through the Chemical Injector, it is automatically proponioned with a

predetermined quantity of detergent. The Mix Tank(3) is equipped with two

different float switches, the Water Level Float (4) respmcfsto the !evel in the

tank and will maintain the proper volume of solution to be reserved for the

water pump. The secondary, Low Water Float switch (5) is a safety switch

that is designed to protect your system from sudden or unexpected loss of

water supply. If, for example, the waler source at the house were turned off,

the water level of the mix tank would drop, activating the secondary switch,

which automatically disengages the system and prevents the water pump

from running dry.

The desired chemical injection ratio may be obtained by an adjustment of

the Chemical Flow Meter (6) during flw fill cycle of the mix tank. Water must

be flowing into the mix lank inorderto adjust the chemical mix. The chemical

will flow from the Chemical Jug (7) to the Chemical F{ow Meter, then to the

Chemical Injector where it is Proportioned into the Mix Tank at the desired

chem”~l setting.

NOTE: With this unique chemical system, the chemical flow isproportioned

only during the filling cycles of the MIX Tank, not during the direct spraying

of the wand. Therefore, it is possible that as your wand is spraying, you may

have no chemical flow. Also, the converse is true in that you may not 1#

spraying your wand, but if the mix tank is in a filling cycle, your Chemical

Flow Meter may be active at the desired flow rate.

The chemical profmlioning system will mix chemical with water at a 1to 30

ratio when the Flow Meter is set at 5 GPH, or a 1 to 15 ratio when the Flow

Meter is set at 10 GPI-I.

9

(cuntilXls,mxtpage)

Page 12

BOBCAT WATER FLOW

— .————— .-

At this paint in ttw flow, solution (water with chemical) will no’ar@ siphoned ~

from M@bcdtom of lt’m Mix Tank to W inlet of tie Water Pump (8). When ~

tfw wand is no! using salution by sprayh& the solution will be bypassed ~

from the bottom of the brass Pressure Relief Valve(9), back to the MixTank. ~

Wfwn the wand is spraying, the solution continues its flow to the Water

HtMar (10). The coils of MS twaler have a capacity of up to 2 gallons,

therefore it is extremely important that all air pockets are bled out of the

heater pricw 10 initial start-up. This maybe achieved by running the waler

systtxn, wilfwut th% heater on, for approximately 60 seconds.

Valve .-.-–

1!~ Ii

AQUACAT WATER FLOW

At this point in the flow, solution (wakw with chemicat) will now be siphorwd

from the bottom of the Mix Tank to the inlet of the Water Pump (8). In ttw

pump the water is pressurized and then discharged through a rubber

pulsation hose down to Uiepressureretief valve (9). From tfwpressure relief

valve the water is automatically distributed to the cleaning wand and

bypawd back to the mix tank, depending on water usage at tfw wand.

As the water travels back toward the mix tank from the Wessum relk?f vatve

it flows through M exhaust heat exchangers which heat the cleaning

water.

CHEMICAL SYSTEM MAINTENANCE

The chemical lines may need to be flushed with vinegar wriodiily to

prevent abnormal chemical build-up. This flushing may be dom by removingthe clear pfastic hose from the Chemical Jug and inserting it into a one

quart cmtainer of ki’wgar. This should k done with the Chemical flow

Meter setting on 10 GPH and the Water Heater ‘off’. Simply spray water

from the wand until the quart of vinegar isexhausted, the repeat W pmc$ss

with one quart of dear water to void all fines of vinegar.

Chemical Proportion i3m#Level Control

AquaCat Water Flow .

Che&lcal

ln~ac!or

SW!totd

Control

Valve

-—-—

1!

O S/S Ball

= Check

Housing

Mounting

‘—-—-–11

+Smnvs {3,

ValV13

...... , .,;;.9

——

——.,.—

1J+

*–

‘7 ‘—

12 Voc

T

Cd

6FA-6UFS

I

-0

Inpctor Body

f’

/’

(II

/w

r .

‘1

u

k40unong

Plate

!!-+(

L+i

Soleno[d

Valvo@Qdy

water

Inlet

II

MIX Tank

\

10

Page 13

CHEMICAL TANK

TROUBLE SHOOTING GUIDE -

PROBLEM Lfttfe or no chemical flow

Solution

------- .

Check that hoses at the Mix Tank(3) are secure. Check that the hose from the top

of the Flow Meter (6)10 the Chemical Injector (2) is secure with no idnks or

leaks. Check that the adjusting cap on the

atllhe way in. Check the s/s chedr valve insidethe injeciorfor chemicatbuiidup and proper cperafkm. Chac+Ithe hose from the Mtom of the flow Meter

10the Chemical Jug (7) for kinks, cmcAs, or bubbles.

Checkthescmenontheendofthehosewhichgo eaintolheChemicaJJug. Tocheck

thisscfeen for proper function, remove kfrom the plastic hose. If you cannot

blow through d,

Check the Chemical flow Meter (6)

Is incoming water pressure tees than 30 PSI?

Cracked or defective Chemkai Ftow Meter (6)?

Check the filter screen in the Solenoid Controf Vafve (l).

then rinse it out with vinegar.

for obstructions or a sticking float.

PROBLEM Inabilitv to adiust chemicai with the Flow Meter

Ilsbrii iodged behind teflon seat in Flow Meter valve.

Teflon seat on the vafve stem mav be Icase. if deteriorated. reoiace O-Rina.

insufficientwafer mssura. Locate new

side of the injector is not screwed

source.

CAT PUMP MODEL 290

OPERATING iNSTRUCTIONS

Products described hereon are covered by one or more of the foiiowrtg

U.S. patents: 3558244,3652188, 3809W”, 3920358, and 3930756 -

—

Aiu#

&MM-

C017P0 RATION

PO Box S85 MINNEAPOLIS, MN 5S440

Phone 161 2) 7S0.5440 – Telex 290276

● N V CAT PUMPS tNTERNfi TIONAL S A ●

Hfmno”mstraat 29

0 261M An!vmp,

Phone 1031237.72.24 – Telex 33947

13dawm

● CAT PuMPS - A G. ●

Loretohcmhe5

CH.WOO 2uG, SwtzeNanO

21.3140- T$Jlm SS5 160 CPmO M

Plm”e (42)

PUMPS DEUTSCHLAND GmLIHG

● cAT

Roe.! ocker Strms. 9

8200 Wlesbaaen.fllamtadt, West Germany

PhO”e C812560001i2 — Tela, 41 @S713

● CAT PUMPS (U K ) LTO ●

27 Stat(O” +“dustrlal Estate. Fleet

l+arnPshl<eGU13 6QY England

Pho”eI F!mt 22031 — Totem 65SSSS

PROBLEM: Soiutfon reversing from Mix Tank, fflling the Chemicai Jug

Solution

Anti-siphondevics dogged by chemicai buiid-up (Anti-siphon device is bcated in

the Chemical Injector (2) body — seepage 10, Water Fiow illustration).

Check for debrii.

PROBLEW. MIx Tank overflows

Solution

Fioat swifdr (4) in the Mix Tank not moving freeiy, or defedive.

Tochackswifch Wrha 12voiftast iightandtheffoat inthe”up”positiirr, thereshoukf

be oower throuoh the swkfr.

To check raiay First“deck wiring against diagram. Wtih 12 volt test light, and the

FioafSwifch (4) inthe’up”position there should NOT bepowerattheSoienoid

Valve. Wtih the Fioat Switch inthe “down”positian there should be power at

the Sofenoid Valve.

Solenoid Veive defedive Remove Soienoid Valve, d~assembie and inspect

diaphragm forcracks or tears.

PR08LEkk Mix Tank does not keep up with water output

Soiution

Check irmming water pressure. Check garden hose quick connect

assembly screen.

Check garden hose ardor feed hose to the Mix Tank for dog, kinks,

or bfockage.

Float Switch (4) in Mix Tank hanging up (not moving freely). Check fitterscreen in

Solenoid Wdve (l).

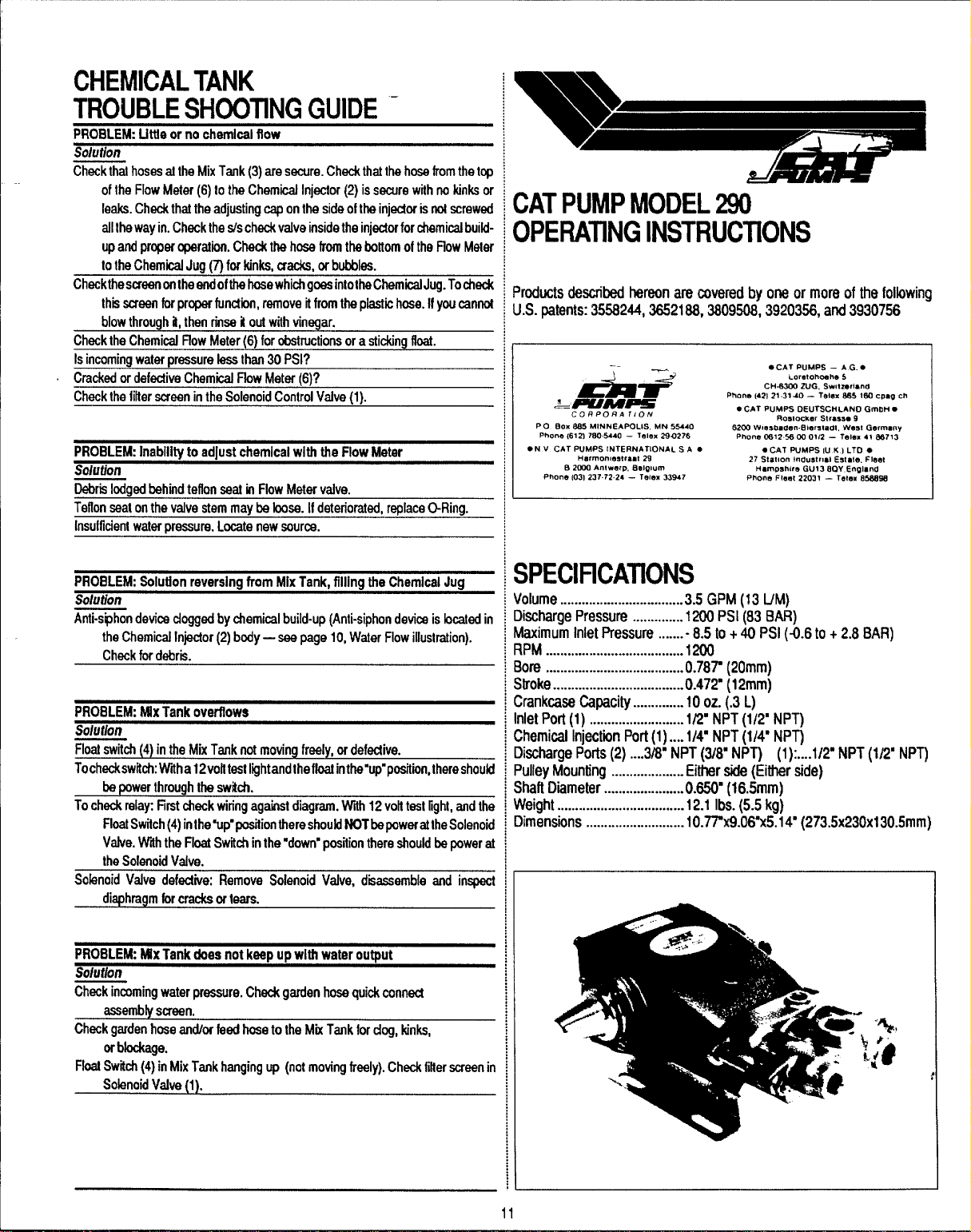

SPECIFICATIONS

oiume

..................................3.5 GPM (13 lfM)

ischarge Pressure

i~imum iniet Pressure .......-

PM ......................................1200

ore ......................................0.787 (20mm)

troke

....................................0.472 (12mm)

rankcase Capacity .............. 10 oz. (.3 L)

liet Port(1) ..........................

heroical Injectiin Port (1).... 1/4” NPT (l/# NPT)

ischarge Ports(2) ....3hY NPT (3/8’ NPT) (1 ):....1/? NPT (1/2’ NPT

uiiey Mounting

halt Diameter

/eiaht ...................................12.1 ibs. (5.5 ka)

lim%ions ...........................10.77W9~O&x51{# (273.5x230x130.5mm)

..............1200 Psi (83 BAR)

8.5 to+ 40 PSI (-0.6 tO + 2.8 BAR)

1/2’ NPT (1/2’ NPT)

.................... Either side (Either side)

...................... O.6!W (16.5mm)

11

Page 14

GENERAL INFORMATION FOl?

CAT lWMp IWIW? -

As you rwnove your dischargra manifold, there is a set of 3 check valves

(which usually fall out during dismantling]. If the sudaces of the%e check

valves am dirty, or show signs of chemical build-up, it is probable that they

would rwnainopen causing pressur~ loss orpu!sation. Upon inqwcting the

valves, make sure that the tef!on button in the valve spring retainers are still

intact. Also t?xarnine the discharge manifold. Look for problems such as

cracks, chwnical buildup or warping due ta freezing. If this discharge

manifold is warp@d, it will cauwl the check valves to stick and will result in

[0ss of pressure.

The Cat pump cups are often the source of pressure loss. I@m inspection

they may appear melted or torn, but often they will look good. Replam them

anyway. There isno sur’ernethodofvisual lyinspecting the cups. HydraMaster recommends changing cups whether they look good or not.

SERVICING THE PUMPING SECTION

IISMANTUNG

1.Remov@ discharge manifoti as described in the last ser%on.

L Slip cylinders out of inlet manifold. N(2TE: Identify cylinders so they will

be repiaced in their original position (front to back).

1.Remove cotterpm, nu~ and washer.

L Next remove piston retainer, spacer, and ptston as~mbly.

i Remove inlet valve

WEASSEMBLY

1.Examine inlet valve surface and reverse if damaged (both sides are lap

surfaces).

L Examine piston assembly for clean inlet surface. Ifdamaged, replace and

lubricate.

UOTECUPINSTALLATiON: Wipe cup inserter Iightiywtth od. Slip batxup

ring onto piston. Force cup over inserter and square with al surfaces.

Faulty cup installation causes premature failure.

Anytime your pump is being dismantled, HydraMaster recommends replacem~nt of all ‘o’ rings and saals. This is mereiy a convenience to the

customer to make sure that the Cat pump is in top operating condition.

The Prm-A-Lube seafs located within the intake manifold will allow air to

@nter fhe pump if they are worn. Again, it is difficult to visually pinpoint a

dilft?ctfve Prrmrn-A-Lube seai. Replace them all.

Repairing of Cat pumps is not a difficuh task.

make sure you have the profwr parts required.

1- short (or hot) cut kit

3- Wrmrn-A-Lube seals

Read instructions thoroughly, supplied in the Cat pump manual prior to

dismantling and follow directions as stated. Oil all seals thoroughly prior to

installation. (Remember, a newly scarred seal isno better than one you just

took out.)

6- piston sleeve ‘o’ rings

1- txlt?fe Cat oil

However, before dismantling

SERVICING DISCHARGE VALVES

a VALVE SEATS

DISMANTLING

1. Loosen ttm 2 (M8) locking nuts approxirnataly one turn.

2. Then remove the 2 (M8) flange nuts.

3. Graspthedischarge manifoldwi~3tingerson the underside andtapwith

a sdt mallet to remove.

4. Valve as~mblies will remain with the manifold. Invert manifold and

discharge valve assemblies should fall out.

5. Inspectdischarge vaivesforwwarorridges. (Spherical valves due to their

shape must be replaced when worn.)

REASSEMBLY

1. Place rwtainer in manifold chamber.

2. Next insert spring intD center of retainer.

Macevalve over spring with spherical (mooned) side up.

3.

4. M3xt inswt the valve wdat.

5. Position manifold back onto pump.

MOTE Exrwckm caution Men inserting cylinders into manifold to avoid

damaging cylinder o-rings.

6. Replaca fkmge nu!s on studs and hand tighten both sides. Then torque

each side to 125 inch paunds.

7. Hand tigh!en locking nut.

When re.starfirg tie pump, check fo .%Mthat there Lsno cylihdermofiona$

this will cause flremahxe failure of the cvlirmfer o-firm. Center ctiincfe~

mtkm cm be &imtha?ed by SwiMing wi~hor?eof the-endcy~inde;s.

1 Next replace piston spacw and retainer.

$. Slip washer onto rod, screw on nut and torque to 60 inch pounds.

NOTE AL WAYS REPLACE WITH MEW CCWTE6?PN

j. Examine cylinder wails for scoring or etching. These ccmditions will causa

premature wear of your piston assemblies. Replace ifworn ordamag@d.

5. Lubricate cylinder and replace o-rings and backup rings (if defective).

7. Position cylinders in their original order into manifold chambers and

carefully slip over rod ends onto the pump.

3. Replace flange nuts on studs and hand tighten both sides. Then torque

each side to 125 inch pounds.

9. Hand tighten locking nuts.

SERVICING THE SEALS AND SLEEVES

DISMANTUNG

1. Remove discharge manifold and piston assemblies as described.

2. Remove fxIth (M8) locking nuts from studs.

3. With soft mallet, tap inlet manifold loose from crankcasa

4. Place inlet manifold onpairof clearance blocks with crankcase side down

and drive out seals.

5. Invert inlet manifold with CRANKCASE SUE UP.

&Lubricate circumference of new Prrrrrm-A-Lube seats, position inrnanifold

with GARTER SPR/AfG i)UWPJ and drive into place.

7. Examine sfeevw for scoring or other damage before removfng.

3. Ifworn, grasp sfeeve with pliers and pull off.

NOTE This procedure will mar the sleeve SQuse onfy if sleeve is

to be replaced.

9. t7emove o-ring and back-up rings from piston rod.

REASSEMBLY

1. Placa barrier slinger on rod.

2. Lubricate new o-rings and back-up rings. Install first o-ring in the o-ring

groove on the piston rod. Position back-up ring against the shoulder

front of the first o-ring, then the secxmcf o-ring. Be careful to awoid

damaging the o-rings when Qipping them over the piston rod

threaded ends.

3. Immerse sleeve in oil carefully lwist and pushonto rod (machim?d counter

bora eti first).

4. Repface seal retainers.

5. ExerciW caution wmn replacing inlet manifold, w the inlet seals are not

damaged by the fhreaded rod ends.

6. Replace Iockhg nuts on studs.

7. Reassemble piston assemblies and discharge manifold as described.

Consult factory for your loud distritwtor for crankcase servidrrg.

in

12

Page 15

DISMANTLING CAT PUMP

Pumping Sect~on Cut-away

P!ston Spacer

Bat-cup

/

Bee-Cup Rmg

‘“t”-“ROds’eeve

;ERVICE KITS

78-001 Cup Kit BobCat

cup

O-Ring, Cylinder

COtterpin

Instruction Sheet

Cup Inserter

Hot Cup Kitj AquaCat

7S404

cup

0-Ring, Cylinder

Cotlerpin

InstructionSheet

Cup Inserter

78-003 Seal Kit

Prrrrm-A-Lube S&d

Cotterpin

Abrssive Paper

Instrudion Shed

0431 Sleeve

IPrrnm-A-Lube Seal

BarrierSlinger

I

I Colterpin

ISleeve

iO-Ring, Sleeve

Instruction Sheat

and Saal Klt

Cyhnder

,7

/

30666 Valve

3 Valve Spring Retainer

3 Valve Spring

3 Valve

3 Valve Seat

3 O-Ring, Cylinder

1 Instruction Sheet

30660 Piston Kit BobCat

6 0-Ring, Cyiinder

3 Back-Up Ring, Cylinder

3 Bat-Cup Piston

3 Bat-Cup Ring

3 cup

3 Piston Spacer

3 Piston Reltiner

3 Conical

3 Nut (M6)

3 COlterpin

3 Inlet Valves

1 Instrudion Sheet

Kit

Washer (M6)

a

.d

13

Page 16

PISTON Mcmil 290 Explod@ View _

PARTS LIST MODEL 290

ITEM

10

11

12

15

PART NO.

1

2Q285

2 44274

3 1!%-OOa

4

097-004 O-Ring, 01 fi~l~ ~

5

027-007

843340 O-Fiing, mankcase cover

9

43-324 Crenkcas.e rover

074-021 Wkbte oilgaug+3

23170

25625

92520 Sem$ comb head screw (M6 x 20) 6

m 43fw4

17 144a7

la

19

20

21

23

25 1’6948

26

27 147406

2a

29

Wm Back-up riig, Sleeve {Teffon)

31

32 26864

32

34

35 147-008

35 30325

1

A7JWW

!-r, w“” Oil ad @ma-N)

097-007

041-021

19

9251

3n1709

.“. .-”

W180Q

2#?7

25327

097-008

2a771

29614

1%-001 SW retainer

25na

25S35

DESCRIPTION

O-Ring (Buns-hl)

Crankcase

Stud (M8

oil fillfwI-s 1

O-Ring, drab plug

X 62)

. ......

--r

l%ain plug

Crarlkshafl 1

Rearino 7

O’l?irlg, Oifseal case

al s{

WI case

Sems comb head screw (M6 x 16] 8

Cannedng md

Piiton KM 3

PEttm pin

Seal washer

oil Snd 3

Wnier sfingef

Wing,

sleeve

Ming, sle9ve (Won)

Sleeve (%4743 Unchmwd)

Seal washer

Met

manifold

Met manifold - stainless steel

hrrm-A-Lu& seal

Prmrrm-A-Lube seal (Won)

QTY.

1

1

2

f

1

1

1

1

f

22

2

3

3

3

3

3

3

3

3

3

3

1

1

3

3

ITEM

36

39

40

41 044-ool

39-41

39-41

42

43

44

45

46

47 045-004

46

49

500WO05

51 43442 Vatve spring r~tainer

5243360 Valve spring

53 43723 Valve

5443434 tlk.charge valve seal

56

57

58 108-OO3 Shafl pramctor

PART NO. DESCRIPTICIN

27004

30543 Bat-Cup piston

097425 I&Cup ring (Tefkm]

43474

001

0784

004 AauaCat

0784

33 PiitonSOacw 3

2796

27002

27066 Oomicalwasher -s& (M6]

27000

14158

097-012

11377

097424

Inlet vaJve

cup (Won)

Bac-(hm assamblv 3

M&t Cuokii

Clla kti t

Piiton retainep

S/S (M6)

Nut C@erpin

cylinder (434334Unch]

O-Rhg, cyiinder (WM-N]

O-Ring, cyfinder (Won)

Bao-Cup

ring, cyfindw

Discharge

25634 Di*ge manifold - sls

81109 Hex nut (MB)

101604 Hex flange nut (M8)

EIactrfc Clutch AesembW

59 152-005 “ Tapered sl~ve

60

61

62

63

64

077-005

036-005

143-084

174-004

174-018 f-cd washw (5/16 US) 1

Key, Wcfric clutch

6“ elec$ncclutch

8-30 mm sacket head sww

Ret wash~ (5/tLI US}

manifold

my.

3

3

3

3

3

3

3

3

3

6

6

3

1

1

3

3

3

3

2

2

1

1

f

1

1

1

14

Page 17

CAT PUMP TROUBLE SHOOTING GUIDE

PROBLEM Pulsation

cause So{utforr

Dabrii in discharge valves of pump.

Worn Prrrrrm-A-Lube seats.

Exrxssive temperature.

PROBLEM: Low pressure

cause Soluffon

Worn nozzle, Re+kca nozzle of proper size.

Belt sfippage.

Air leak in inlet plumbing.

Relief vafve stuck, partiafly plugged or improperly adjustad; vafve seat worn.

Infaf suction strainer dogged or improper size.

Worn piston assembly. Abrasives inpumped fluidor serve cavitation. Inadequate Instaflpraperfifter. Sudion at inletmanifoldmust be fimifedfofiffing less than 20 feet

water suf@y.

Fouled or dirty inlet or discharge vafves.

Leaky dscharge hose. Rapfaca worn valves, vafve seats.

PROBLEM: Pump runs extremefy rough, pressure is very low

cause

Restricted inlet or air entering the

Infet restridions arrd/orair leaks. Damaged cup or stuck inlet or discharge vafve.

Worn inlet manifold seats. Prrrrrm-A-Lubes. Replace worn seek.

inlet plumbing. Proper size inlel plumbing; check forairtight seal.

Ctean or replaca discharge valves.

Replace.

Check pump sofenod.

Tighten or r~lace; use corrad heft.

Dismantle, reseaf, and reassemble.

Clean and adjust refief valve; check for worn and diriy valve seats. Kitavailable.

Clean. Use adequate size. Check more frequently.

of water or -8.5 PSI vacwm.

Clean infetand discharge vafve assemblies.

Replace discharge hose.

Solution

Replace worn cup or cups, dean out foreign material, replace worn vafves.

PROBLEM: cylinder O.Rings blown next to dischsrge manifofd

Cause

Pressures

Warped manifold. Freezing.

PROBLEM: Leskage at the cyflnder O-Rkrgs st the discharge manifold snd

inexcess of rated PSI.

bfack, powdery substance fn the area of the O-Ring

cause

Loose cyfinders. Cylinder motion caused by improper torque on the &charge Retighten, Donottightentoomud ortheeiwsof the manifoldwiilbebwed,causing

manifold.

PROBLEM: Water Ieakaae from under the infet manifold

cause

-et manifofdseals.Prrmm-A-Lube.LeakingsfeeveO-Ring.

PROBLEM: Oil leak between crankcase and pumplrtg section

cause

Worn crankcase piston rod seats.

PROBLEW Off leaking In tha area of the crankshaft

cause

Worn cmkshaft seat or imprcpa rfy ins!aflad oil seal.

Bad b+mring.

Solution

Check forplugged nozzle, dosad vafves or imprcp

Replace marrilofd.

so/uffon

fooseness in the canter cylinder.

Solution

Installseats.

Ifpiston rod sleeves are scared, rapfaca sleeves and sleeve O-Rings.

Solution

Replace crankcase piston rod seafs,

Solution

Remove oifseat retainer and reptace damaged gas

Replace bearing.

rfyadjusted bypass vafve.

ket andhr seats.

rmnknws. next me)

(

15

Page 18

CAT Pwiwmowx wmrw GUIDE

PROBLEM Excasslva play In the rmd of Ma crankshaft puilwy

CalIsa

ITXiGil bearing tmmnexrxrs.sivetension on drive belt.

Solution

Replace ball bswing. Prcprty twrsion belt.

PHtXM.Efk

Cause

=causad by humid tir mrrdensirq interwater insido Ihe wankcase.

Linkage of maniiold inlet seafs andlor piston rod sieaves O-Ring.

PRcIEILEiW Oil leaking from undsrsida of crankcase

Cause

Worn crankcase piston rod seals.

PRQfM,.Ehk Oli ieaking

Cause Solution

-d or improperly irwXaJiedoii gauge orcrankcase rear cover O-Ring, and

Water In crankcase

Solution

Change oil at 3

approved oiievery month or 200 hours).

Replace seals, sleeves and O-flings.

Soiution

Rapiace seals, sleeve and O-flings.

at the roar portion of the crankcase

Repiaw oii gauge or cover O-Ring, and drain

drain duo O-f?irm.

WWWfk.Eh%Oil Ioakage from drain piug

Cause

=rain piug or worn drtin pfug O-Ring.

PHCIHLEhk Loud knockirtg noise in pump

Solution

dram piug or repiace O-Ring.

Tighten

cause Solution

Pulfey Ioase on mrrkshatt.

fMoken worn baring, Replace lmrirrgs.

Check key and tighten set screw.

manth m 500 hour intervals usinq Cat pump cmrittraw oil (othw

plug O%ing.

fWOHLEM Frequent or premature

Cause

Smred r9ds

CIWMpressure to inlet manifold.

or sieews.

faiiweof the inlet manifold aeais

Solution

Replace rods and sleeves.

Reduce iniel pressure ~

Cau$$ Sohrtion

Abrasive matisriai in the fluid king pumped.

Excessive pressure andfor temWrature of fluid being pumped.

pressure of pumps. Rs&rw pressure.

Over

Running pump dry.

Front edge of piston sharp. flqhce with new pkton.

WN3HLEht SVongt surging at the iniet and iowpt’esaura

Cause So!ution

Foreignparticles intheiniet ordischarge vaJveorwom inletmd/wtiwhwgevdves.

on thedischargeside

Irrstatlproper filtration onpump inlet pfurnbing.

Check pressuresandffuid intettemperamre;be suretheyarewithii s@ftirangw

Ca not runpump withoutwater.

Check forsmooth lap surfaces on irrle4and discharge valwe saats. Diw%arge valve

seals, and iniet valve ssata may be iapped on a vwy fine oilstone; darnag@d :

cups and disc+wge valves cannot be !appsd but muet b replac.ad.

16

inslruc$ions.

Page 19

HIGH PRESSURE PUMP

TROUBLE SHOOTING GUIDE -

PROBLEM: Loss of pressure

Cause/Solution

-- —.. . ..— .

1. Clogged fitter screen in garden hose quick conned coupler.

A. Remove and clean or replace fiker.

2, Low waler pressure at source.

A. Determine rate 01 flow and select an alternative source of supply if water

pressure is inadequate.

3. Defective or blocked check valves inhigh pressure pump cylinder head.

A. Dsmantle cyfinder head and replace or c!ean applicable check valve.

4. Delaminated, kinked or dogged hose betw~n the mix

pressure pump,

tank and the high

I

~BYPASS PARTS UST

7

Q?

8

5. Defedivepressure refiefvalve ordabris inpressure reliefvalve. NOTE The high

pressure bWass valve is desgnad to fully dose when the cleaning tool is

turnedon. Any foregn matter colleding on the pistonwill prevent full cbsure

ofthe valve and allow a portion of the water to continue 10circulate instead of

being routed to the cfaaning tool. To correct !his situation, the bypass valve

must be dsmantled and deanad (refer to illustration provided for bypass

dismantling),

A. Dismantle and clean pressure relief valve as shown in illustration.

ELReplace defedive or worn out bypass cup.

C. Replace bypass valve.

6. Defective or worn cups.

A, Remove and replace piston cups as defined by pump section of this manual.

7. Loose drive bait for high pressure pump.

A. Readjust baft as required or raplaca if defective.

PROBLEM Irtsufffclent or excessive water flow

Ceuse/So/ution

1. Wornout sprayjet. NOTE: Cleaning toois desgned to spray a constant flow of 1

IL? GPM willaverage 1 gation of flow par minute in aduai working situations

since flow isnot continuous. An average flowof 1GPM resultsin6000 gallons

of fbw for every 100 hours of unit operation. Spray tips are capabie of

consistent flow rates for approximately 20,000 gafions. They should be

replaced therefore approximately every 3541hours. Worn spray jets ailow a

greater average rate of flow thus reduang desired temperature Ieveis.

A. Remove and repfaca sprayjet.

~ REF. NO. PART NO.

OOO-105-1OI

3

4 NJO-105-1O2 Piston date. Bypass valve

cOo-076-lol

5

7 000-146-004

Q nrllr?n7.MK n 0:. ” n,-..

~ - —v-~-.J

DESCRIPTfON

Thmst plate, Bypass valve

.-.-. ~.-.–,—

seal for By

Kit,

Seat & O-Ring

-nllly, Uywss valve fitting

AquaCat Water Fjow

~..

Chekcal

Iniector

Sol~noid

Control

_

Valve

QTY.

pass valve

I, Bypass valve 1

...—

I

,,,

,(,,

,,::

1

1

1

1

2. Reductkm of flow.

A. Due to increased iengfh of solution hose. NOTE For every 50 feet of hose

beyond 100 feet intotal length, a measurable iossof flowis experienced. This

condition is a

passas through the hose. Therefore, itis necessary to increase the pressure

at ihe machine 40 PSi for every additional 50 feet of cleaning solution hose

over 100 feet.

resultof the increased frictionexperienced by the water as it

17

Page 20

WIFORMATICN

Ttm vacuum blowor irmorporated in tiki machine is a positive displatx?ment lobe type, manufacttmd by Coqwr Industries. Tle performance and

Iifa of this unit is gfieatiy dependent on tha care and pro~r maintwwrwe

it receives.

. . . . ... --—. .--. —-- ———— -—-.

‘ACUUM TANK FIL~Ell 5AC3S

/draMaster filter bags are designed to traQ all of tho lint, that would

rrnaily colleot at the tmttom of your vacuum tank. Tlm use of these bags,

wnptied at the end of each job, till elirninab? tfw budd-up of muoh of 8W

;Ms in the tank. The drawstring top of these bags is designed to be tiwl

the incoming dirty water inlet in the vacuum tank.

Jreotder bags use part number 049-028.

Hecausa of the clowa talwances between Me lobes and housing of the

vacuum Mower, solid objects entering the ink?t will damage the internal

lobes, gears and bearing or direct drive caupler.

To prevent this, a stainless steel filter screen has keen placed at he

vacuum inlet insido the vacuum recovery tank. This stainless steel screen

is finger tight and should be removed for cleaning weekly.

When machine is being nm tar test purposes and the vacuum in~ef on top

of machine ix iJp@n,cautr’oi? should be used.

To prot(?ct the vacuum blower from overloading and damaging itself, there

is a vacuum retief system installed on the vac tank. When the vacuum tank

inliilt is completely sealed off, a maximum of 12 HG will I-Eattained. A hole

on the top blower pipe elbawacts as the lubrication point. At the end of each

day, LR31 or Pennzguard should be sprayed in before shutting down the

machine. See blower lubrication illustration. If you fail to lubricate the

vacuum blower daily, rust depusits and moisture will decrease the life of

the vacuum blower.

Read the vacuum blower manual carefuilyfor proper oilchange andgreasa

application. The maintenance log may differ slightly from the manual, but

the buck-mounted carpet c!eaning machine application is very demanding

of Uaevacuum blower and therefore it should k maintained more regulatfy.

Vacuum Tank FNimI Bags

HOSE

C>FC

f310wer Lube PM

V?.CUUM

“0s E

NOTE: Vacuum tank isprotectt?dfnxn avefllowingbya vacuum tank, flea

MI switch. This switch is not activated by foam, only by liquid.

vacuum Fi(?w

S/S Filterk

Blower

Exhaust

Silencer

Recovery Tank

. Engine

Filter Bag

/

Exhaust

c)

I

Spray Iubriit into blower IUIN port for 3 to 5 seconds,

then immediately shut off machine. Use only LPS 1

moisture displacing Iuiwioant.

I

18

Page 21

VACUUM BLOWER TROUBLE SHOOTING GUIDE

PROBLEM Loss of pressure

Cause

-d vacuum hose between bbwer and

vaczrumtank.

Clogged stainless steel timer.

Defective

Defaciive or “open’ vacuum tank dump valve.

vacuum tank seat,

Fractured weld on vacuum tank.

Collapsed or kinked vacuum hose.

Plugged vacuum hose.

Restriction in

Worn end plates or Ides

cfeaning tool,

in vacuum blower.

Defective relief vafve.

PR06LEW. Blower is seized

Cause

Rust.

Foreignmatter.

77reatrovementioned, rust, rbreign matterandseizingare often causedrhrn

Note:

foam traveling through theblower.

Soiutfon

I%rnove and replace hose.

for repfacem

Remove and dean w repke stakdess steal filter.

I%mova and rsplaca

Cbsa valve.

Repfaca valve.

Rwekf as required or rapface tank.

Rash

apahosaifpass

Remove obstructionsby reversing tfw vacuum hose.

Remove obstmction.

Replace worncomponents.

Inspect and replace ifnecessary.

Solution

Spray rust dissolving lubricant onto lobes to emulsify rust and attempt to rotate

vacuumlobes.

Dismantle and remove foreign matter and repair as required. NOTE: Dismantling

must be accompfishad by qualified taohnican.

NOTE A qwial reinfomd hose is r@md

ant.

vacuum tank seal.

We andhr eliminate kinks.

NOTE Mustbeaccompfishedbyaquafifiidtechnican.

PROBLEM Noise in vacuum blower

Cause

ViRijears.

Lack of lubrication. NOTE: Permanent damage may have resuftad from lack

solution

Remove and replace gears. NOTE: Replacement of gears must be acmmplisfwd

by quafifii technican.

Timing of vacuum blower has been changed due to worn components. NOTE

Replacement ofcmmporrentsmust be amompfishad by quafiied tachrr”ban.

Lubriieas specifiedbyapplicabiavacuum blowermanuaf. SaeTabla ofConlanls.

of lubrication.

Worn be~”ngs.

Debrii and/or foreign material build-up.

vacuum inlet located in vacuum blower components. k accomplished by qualifii tachnican only. Replacement of worn parts is

NOTE A stainless stael filter isprovided in

Remove and

Dismantle vacuum bbwerand remove foreign materiil.

replace trwings as required. NOTE: Must be accomplished by

quaMiad technican.

NOTE Dismantling should

necessary.

Tighten

Loose or missing mounting bofts.

or reinstall mounting bolts.

19

Page 22

VACUUM BLOWER WARRAtW’Y

FULLER warrants products of its manufacture to h free from defects in matf?riil and workmanship if properly installed, maintained, and oporated

undw normal cwrditions with competent supervision.

No lx!rsan,

in ccmrmction with any of FLILLEF3’S products.

This wmranty sha~i extend for two (2) years from date of installation provided this equipment has been put into sm’vice within six morMhs aftw

shipment from tie FULLER factory. If repairs or replacements are made by the Purchaser without FULLER’S prior written consent, FULLER’S

warranty shali cease to he in effect. No allowance wili be granted for any repairs or alterations made by the Purchaser without FULLER’s@rwritten

consent.

Machinery, equipment and accessmies furnished by FULLER, but manufactured by others, are warmrted only to the extent of the original