Page 1

DriMaster II HiFlo Stainless

Steel Upholstery Tool

Owner’s Manual

HydraMaster North America, Inc.

11015 47th Avenue West, Mukilteo, Washington 98275

MAN-33278 Rev. 0, December 31, 2009

No part of this manual may be reproduced or used in any form or by any means (i.e. graphic, electronic, photocopying

or electronic retrieval systems) without the express written permission of HydraMaster North America, Inc.

All rights reserved. © 2009 HydraMaster North America, Inc.

(182-803)

Page 2

Table of Contents

GENERAL INFORMATION ........................................................................... SECTION 1

Contact Information ................................................................................. 1-2

Warnings, Cautions and Notices ............................................................. 1-3

OPERATING INSTRUCTIONS ..................................................................... SECTION 2

Optional Accessory Handle Assembly..................................................... 2-1

Begin Cleaning ........................................................................................ 2-2

TOOL MAINTENANCE ................................................................................. SECTION 3

Removing and Re-installing the Clear Window Cover ............................ 3-1

Cleaning the Solution Bar Jet.................................................................. 3-2

Cleaning the Filter Cartridge and Orice Plate........................................ 3-3

ASSEMBLIES ANDPARTS LISTS ................................................................ SECTION 4

DriMaster II HiFlo Stainless Steel Upholstery Tool Assembly Parts List . 4-3

Accessory Handle Assembly Parts List ................................................... 4-4

Hide-A-Hose Stainless Steel Hose Assembly Parts List ......................... 4-7

HOW TO ORDER PARTS ............................................................................ SECTION 5

Warranty Parts Orders ............................................................................ 5-1

Parts Orders ............................................................................................ 5-1

Emergencies ........................................................................................... 5-1

WARRANTY INFORMATION ....................................................................... SECTION 6

DriMaster II HiFlo Stainless Steel Upholstery Tool Owner’s Manual - ii

Page 3

List of Figures

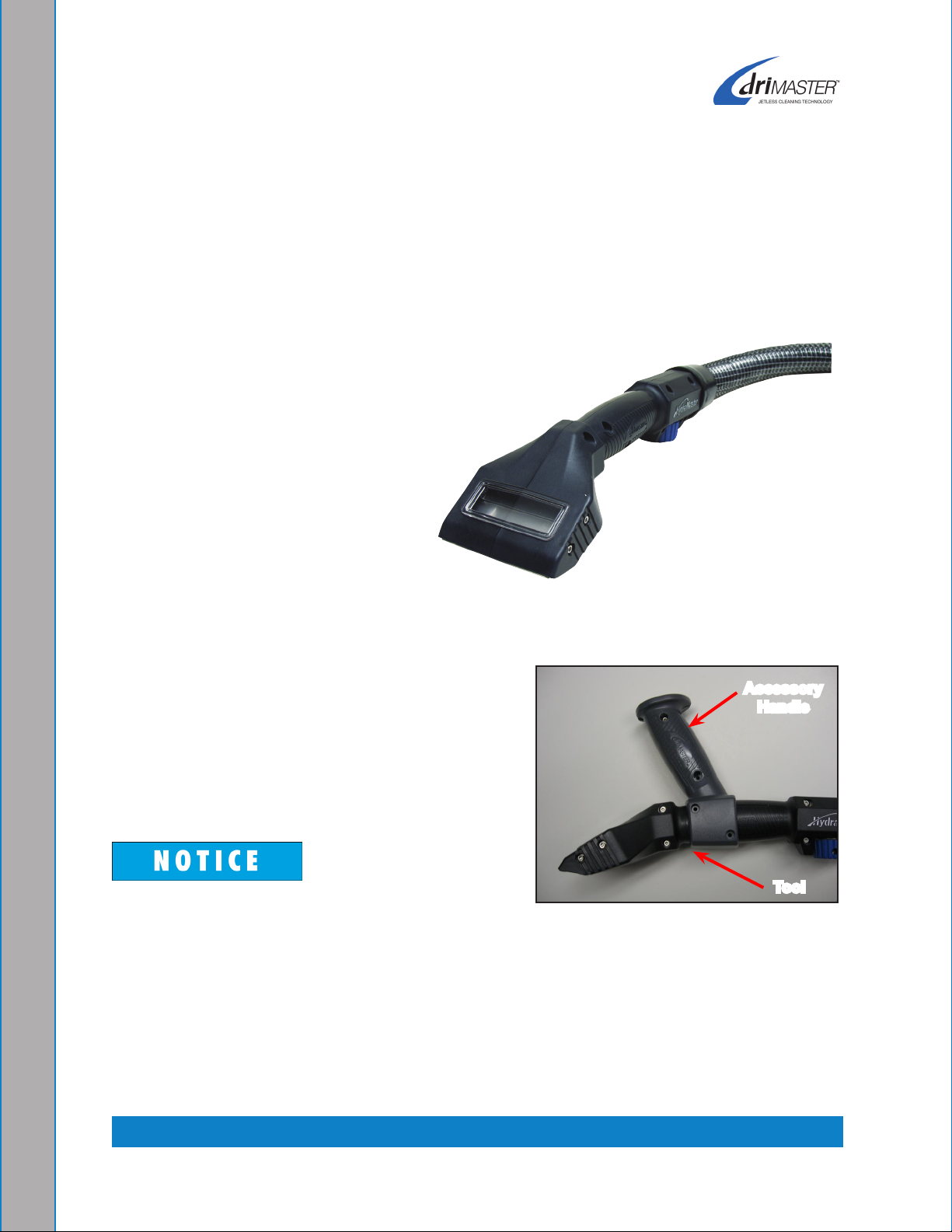

Figure 1-1. DriMaster II HiFlo Stainless Steel Upholstery Tool ..............................1-1

Figure 1-2. Optional Accessory Handle Attached to Tool .......................................1-1

Figure 2-1. Remove Tool Screws ...........................................................................2-1

Figure 2-2. Attach Accessory Handle .....................................................................2-1

Figure 2-3. Attach Solution Hose and Adjust Water Volume ..................................2-2

Figure 2-4. Turning Knob to “HiFlo” Position

Forms Sheet of Water Across Bar Jet .................................................2-3

Figure 3-1. Remove Tool from Hose ......................................................................3-1

Figure 3-2. Remove Solution Control Knob ...........................................................3-1

Figure 3-3. Remove All Screws on Tool .................................................................3-1

Figure 3-4. Separate Tool in Half ...........................................................................3-1

Figure 3-5. Re-install Clear Window Cover ............................................................3-2

Figure 3-6. Clean the Solution Bar Jet ...................................................................3-2

Figure 3-7. Disassemble Solution Quick Connect..................................................3-3

Figure 3-8. Remove Filter Cartridge and Plate Orice ...........................................3-3

Figure 3-9. Re-assemble Solution Quick Connect .................................................3-3

Figure 4-1. DriMaster II HiFlo Stainless Steel

Upholstery Tool Assembly - Overview .................................................4-1

Figure 4-2. DriMaster II HiFlo Stainless Steel

Upholstery Tool Assembly - Parts View ...............................................4-2

Figure 4-3. Accessory Handle Assembly................................................................4-4

Figure 4-4. Hide-A-Hose Stainless Steel Hose Assembly - Parts View 1 of 2 .......4-5

Figure 4-5. Hide-A-Hose Stainless Steel Hose Assembly - Parts View 2 of 2 .......4-6

iii - DriMaster II HiFlo Stainless Steel Upholstery Tool Owner’s Manual

Page 4

1 - General Information

Congratulations on purchasing the very latest in upholstery cleaning technology.

The patented DriMaster II HiFlo Stainless Steel Upholstery Tool, shown in Figure 1-1,

is perfect for cleaning upholstery, fabric and stairs. Because of its Jetless Cleaning

Technology, it has no trigger valve, no spray jet and never needs a separate dry pass.*

The tool’s new design incorporates

light weight, extremely durable

materials, giving the tool increased

levels of strength and comfort.

The DriMaster II HiFlo Stainless Steel

Upholstery Tool accommodates high

volume jobs where production rate is

important.

It is capable of solution ow rates

for jobs that require a ushing action

which makes the tool particularly

efcient for stair cleaning.

Figure 1-1. DriMaster II HiFlo

Stainless Steel Upholstery Tool

An optional accessory handle, shown attached

to the tool in Figure 1-2, is available to increase

comfort on long cleaning jobs.

We trust that you will enjoy many years of reliable

upholstery cleaning with the DriMaster II HiFlo

Stainless Steel Upholstery Tool.

The DriMaster II HiFlo Stainless Steel

Upholstery Tool can be used with a variety of

HydraMaster cleaning systems.

* U.S. Patent No. 6,243,914; 7,070,662; RE39,623; D590,111

New Zealand Patent No. 549645

Other U.S. and Foreign Patents Pending

Accessory

Handle

Tool

Figure 1-2. Optional Accessory

Handle Attached to Tool

1-1: General Information

Page 5

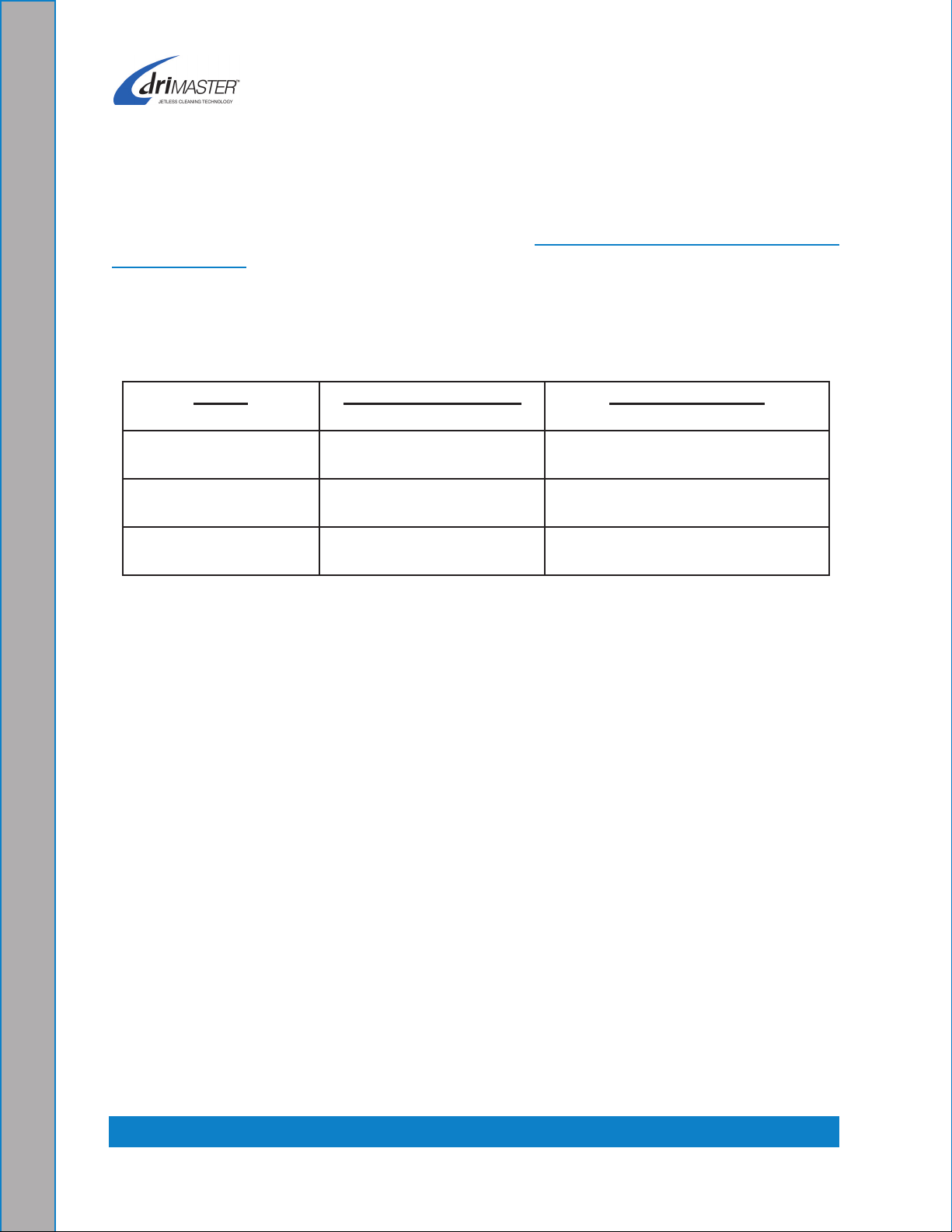

CONTACT INFORMATION

If you have any questions regarding the operation, maintenance or repair of this tool,

please contact your local distributor.

To nd a local distributor, please visit our website at http://www.hydramaster.com/owners/

locate/index.asp.

If your question cannot be resolved by your distributor or by the information within this

manual, you may contact HydraMaster Customer Service direct using the following phone

numbers.

Hours Telephone Numbers E-mail Addresses

Monday-Friday (425) 775-7275 Service

7:00 a.m. to 5:00 p.m. (425) 775-7276 Parts

Pacic Standard Time

(800) 426-4225 Parts /

Service FAX

FOR YOUR REFERENCE:

Date of Purchase:_____________________________________________

Purchased From (Distributor): __________________________________

Tech Support:

techsupport@hydramaster.com

Parts Support:

partssupport@hydramaster.com

General Information: 1-2

Page 6

WARNINGS, CAUTIONS AND NOTICES

HydraMaster uses this WARNING symbol throughout the manual to warn of

possible injury or death.

This CAUTION symbol is used to warn of possible equipment damage.

This NOTICE symbol indicates that federal or state regulatory laws may apply,

and also emphasizes supplemental information.

1-3: General Information

Page 7

2 - Operating Instructions

Your DriMaster II HiFlo Stainless Steel Upholstery Cleaning Tool has been engineered

using the latest and most sophisticated technology available to produce the nest

upholstery cleaning results possible. Despite this, it remains only a tool of the upholstery

cleaning trade and can produce only as a good a job as the person operating it.

HydraMaster strongly recommends attending an Institute of Inspection, Cleaning

and Restoration Certication (IICRC) approved Upholstery Cleaning course as

soon as possible and to always follow the IICRC guidelines when cleaning.

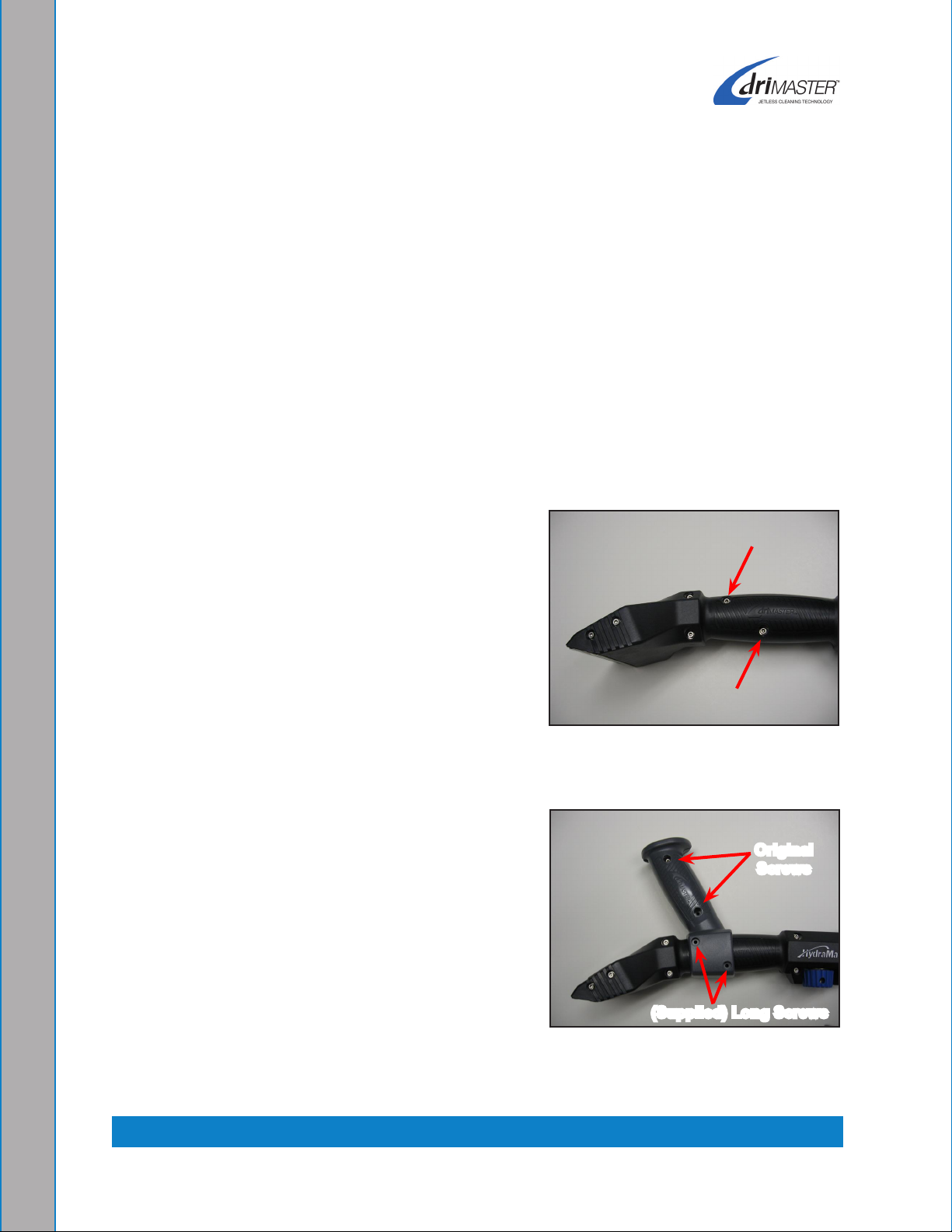

OPTIONAL ACCESSORY HANDLE ASSEMBLY

The DriMaster II HiFlo Stainless Steel tool can be equipped with an optional accessory

handle (purchased separately) to increase comfort and control during difcult or extended

repetitious use of the upholstery tool.

Remove the two screws, nuts, and washers 1.

found on the handle grip portion of the tool

(Figure 2-1). These parts will be reused in

fastening the handle.

Attach the accessory handle as shown in 2.

Figure 2-2. The original shorter screws, nuts,

and washers are used on the upper handle.

The longer supplied screws, nuts and washers

are used to connect the handle to the tool

body.

Figure 2-1. Remove Tool

Screws

Original

Screws

(Supplied) Long Screws

Figure 2-2. Attach Accessory

Handle

2-1: Operating Instructions

Page 8

BEGIN CLEANING

Solution Bar Jet

Solution Control Knob

Solution Quick

Connect

Vac Hose Manifold

Do not use the DriMaster II HiFlo Stainless Steel Upholstery Tool on a machine

exceeding 14” Hg vacuum and 500 psi solution pressure. Personal injury could

result.

Attach the solution hose to the solution quick connect. A 1 ½” - 2” vacuum hose can 1.

be attached to the vac hose manifold (see Figure 2-3).

Figure 2-3. Attach Solution Hose and Adjust Water Volume

Adjust the water volume by turning the solution control knob. Turning the knob 2.

counterclockwise increase the water volume; turning the knob clockwise decreases

the water volume. The amount of water volume you need will vary with the type of

machine you are cleaning with and the type of material you are cleaning.

To begin adjustment, make sure the cleaning machine is running and both vacuum 3.

and solution hoses are connected.

Slowly open the solution control knob until water is owing across the entire bar jet 4.

(without overspray).

Operating Instructions: 2-2

Page 9

When the solution knob is turned toward the

“HiFlo” position, the water will form a sheet across

the solution bar jet (see Figure 2-4).

The amount of vacuum and pressure produced

by your machine will determine the overspray

on the solution bar jet. The patented solution

bar jet makes a trigger valve unnecessary.

Figure 2-4. Turning Knob to

“HiFlo” Position Forms Sheet of

Do not touch the solution bar jet during

Water Across Bar Jet

operation or immediately afterward; doing so

may cause severe burns!

When cleaning stairs, do not allow the tool to come into contact with the tack strip

along the edges of the stairs. The tool’s cleaning surface will be damaged by the

tack strip. Equipment damage such as this is not covered by warranty.

It may be necessary to periodically clean the inside of the tool, hose and manifold.

Debris can build up over time, restricting the vacuum ow (see Figure 3-6).

2-3: Operating Instructions

Page 10

3 - Tool Maintenance

REMOVING AND RE-INSTALLING THE CLEAR WINDOW COVER

Remove vacuum hose cuff from 1. DriMaster II HiFlo Stainless Steel Upholstery Tool

and disconnect the solution hose quick connect as shown in Figure 3-1.

Lightly heating the “cuff” with a heat gun will make the cuff easier to remove and

install.

Remove the solution control knob by removing the 8/32” Allen head screw as shown 2.

in Figure 3-2.

Figure 3-1. Remove Tool from

Hose

Loosen, but do not remove, the valve retention nut (see arrow in 3. Figure 3-3).

Remove all screws from both sides of the tool (see 4. Figure 3-3) and carefully separate

the tool halves (see Figure 3-4).

Valve Retention Nut

Figure 3-3. Remove All Screws

on Tool

Figure 3-2. Remove Solution

Control Knob

Figure 3-4. Separate Tool in Half

3-1: Tool Maintenance

Page 11

Slide the clear window cover off of the tool 5.

body.

To re-install the clear window cover, slide it 6.

into one half of the tool body (see Figure 3-5).

Then slide the other half of the body into the

window.

The clear window has grooves on either side that slide

onto the edges of the cutouts in the tool bodies.

Figure 3-5. Re-install Clear

Window Cover

The wear plates must be aligned and slid onto the tool half at the same time as

the cover.

The window cover may come out if not installed properly.

Continue to assemble the two halves of the tool together, with the clear window 7.

being captured in the cutouts. Careful attention must be paid when sliding the two

body halves together.

Re-install the screws.8.

Tighten the valve retention nut. Do not 9.

overtighten.

CLEANING THE SOLUTION BAR JET

The solution bar jet needs to be cleaned with a .020”

feeler gauge.

Slide the feeler gauge into the small slot.1.

Gently slide the gauge back and forth to clear 2.

any debris from the opening (see Figure 3-6).

Figure 3-6. Clean the

Solution Bar Jet

Use only a feeler gauge to clean the slot in the bar

jet. Use of any other implement (paper clip, knife blade) may damage the opening

and seriously reduce the cleaning effectiveness of the upholstery tool.

Tool Maintenance: 3-2

Page 12

HydraMaster recommends you clean the lter

cartridge and orice plate on a periodic basis

to eliminate hard water deposit buildup. Both

components are conveniently located in the

solution quick connect subassembly.

Disassemble the solution quick connect to gain access

to the lter cartridge and orice plate (see Figure 3-7

and Figure 3-8).

CLEANING THE FILTER CARTRIDGE

AND ORIFICE PLATE

Remove the lter cartridge and orice plate, place 1.

them in a cup full of white vinegar and soak for

30 minutes.

Clean the orice plate’s opening with a wooden 2.

skewer or similar tool such as a plastic pick.

Do not use a metal object to clean the opening of

the orice plate; doing so can damage the plate.

Remove both parts from the vinegar and 3.

thoroughly rinse them with clear water.

Re-assemble the solution quick connect, re-4.

installing the lter cartridge and orice plate in the

proper order (see arrows in Figure 3-9).

Figure 3-7. Disassemble

Solution Quick Connect

Orice Plate

Filter

Cartridge

Figure 3-8. Remove Filter

Cartridge and Plate Orice

Do not operate the DriMaster II HiFlo Stainless

Steel Upholstery Tool without the orice plate. If

you do not properly re-install the orice plate in the

solution quick connect (see Figure 3-9), equipment

damage could result. Such equipment damage is

not covered by warranty.

Figure 3-9. Re-assemble

Solution Quick Connect

3-3: Tool Maintenance

Page 13

Overview

7332

4 - Assemblies and

Parts Lists

DriMaster II HiFlo Stainless Steel Upholstery Tool AssemblyFigure 4-1. -

4-1: Assemblies and Parts Lists

Page 14

DriMaster II HiFlo Stainless Steel Upholstery Figure 4-2.

1

3

2

7

9

14

9

16

15

9

16

9

9

10

10

10

11

14

9

13

6

5

8

4

12

17

7

6

5

4

17

REVISIONS

LTR

REVISION

CODE

5

4

3

2

Tool Assembly - Parts View

7332

Assemblies and Parts Lists: 4-2

Page 15

DriMaster II HiFlo Stainless Steel Upholstery Tool

Assembly Parts List

Item Part Number Description Qty

1 000-076-088 Jet, DriMaster S/S HiFlo Bar Assembly 1

2 000-105-533 Plate, Wear DriMaster 2

3 000-061-138 Handle, Handpiece, Left, DriMaster HiFlo 1

4 000-169-222 Valve, Ball S/S 1

5 000-052-782 1/8” NPT X 1.5 S. S. 1

6 000-052-783 Quick Disconnect, Male 1/8” NPT 1

7 000-061-139 Handle, Handpiece, Right, DriMaster HiFlo 1

8 000-174-768 Washer, Flat, .875 O.D. X .515 I.D X .035 Thk 1

9 000-174-167 Washer, Flat, .248 O.D. X .128 I.D. X .029 Thk 12

10 000-094-063 Nut, Nylon Lock 6-32 8

11 000-041-445 Cover, DriMaster HiFlo, Window 1

12 000-052-781 1/8” NPT X .1875” O.D. 1

13 000-061-146 Assembly, Knob Custom Insert With Label 1

14 000-143-576 Capscrew, Socket Head, 6-32 X 5/16 4

15 000-143-577 Capscrew, Socket Head, 6-32 X 3/4 2

16 000-143-578 Capscrew, Socket Head, 6-32 X 7/8 6

17 000-068-810 Hose, Hide-A-Hose S/S Assembly 1

4-3: Assemblies and Parts Lists

Page 16

6958 Rev. B

Accessory Handle AssemblyFigure 4-3.

Accessory Handle Assembly Parts List

Item Part Number Description Qty

1 000-061-142 Handle, Accessory, Right 1

2 000-061-141 Handle, Accessory, Left 1

3 000-174-167 Washer, Flat, 0.248” O.D. x 0.128” I.D. x 0.029” Thk 2

4 000-094-063 Nut, #6-32 Nyloc 2

5 000-143-579 Screw, #6-32UNC x 2” Lg. Socket Head 2

P/N 000-164-030 Allen wrench also included with the Accessory Handle Assembly.

Assemblies and Parts Lists: 4-4

Page 17

7331 Rev. D

13

11

12

4

4.00

±0.25

1.500

DETAIL C

SCALE 1 : 1

REVISIONS

LTR

REVISION

CODE

C

CORRECTED ORDER OF HARDWARE

IN EXPLODED VIEW. ADDED .217 NPT

THREAD ENGAGEMENT DIMENSION IN

MODEL BETWEEN ITEM 6 AND 7.

LRIP

D

CORRECTED ITEM 7 NPT DIMENSION.

LRIP

8

7

6

5

4

3

2

Hide-A-Hose Stainless Steel Hose Assembly - Parts View 1 of 2Figure 4-4.

See Figure 4-5 for details

4-5: Assemblies and Parts Lists

Page 18

Figure 4-5. Hide-A-Hose Stainless Steel Hose Assembly - Parts View 2 of 2

13

C

C

10

8

7

5

3

6

1

2

9

1

2.50

±0.25

C

1 1

2

1

DETAIL B

11

12

4

NOTES:

BOND WITH ADHESIVE, 3M

1.

SCOTCH WELD, DP 100

000-146-018

SWAGE, SYNFLEX

2.

PUSHER, 4599-MP-026

DIE, 4540-30200

SWAGE, SYNFLEX

3.

PUSHER, 4599-MP023

DIE, 4540-30200

D

13 1

12 1

11 1

10 1

9 1

8 1

7 1

6 1

5 1

4 1

3 1

2 1

1 1

ITEM NO.

Defaul

t/QTY.

A

B

C

D

8

7

6

5

4

E

F

UNLESS OTHERWISE NOTED

DIMENSIONS ARE IN INCHES

BREAK ALL SHARP EDGES 0.005-.015

TOLERANCES

.X= .1

.XX= .03

.XXX= .010

ANGULAR= 1°

APPVD

CHECKED

DRAWN

KJW

LRK

LRK

7332

- - - - - -

7331 Rev. D

Assemblies and Parts Lists: 4-6

Page 19

Hide-A-Hose Stainless Steel Hose Assembly Parts List

Item Part Number Description Qty

1 000-052-803 Housing, 1/4" S/S. Filter 1

2 000-052-516 Quick Connect, 440 Male W/ Viton Std 1

3 000-049-253 Filter Cartridge, 1/4" S/S 1

4 000-052-805 Quick Connect, Female, 1/8" - Open 1

5 000-180-024 Orice, Plate 0.067" 1

6 000-052-804 Adapter, S/S. Jet X 1/4" FNPT 1

7 000-052-811 Insert, 1/8" Hose X 1/4" MNPT S/S 1

8 000-068-811 Hose, 1/8" USP 540n-2 1

9 000-052-807 Cuff - Solution Hose 1/4" Thru 1

10 000-125-248 Tube, 1.5" S/S - Hide-A-Hose 1

11 000-052-806 Swivel Cuff - Half 1

12 000-052-810 Insert, 1/8" Hose X 1/8" MNPT S/S 1

13 000-068-036 Hose - Gray, 1.5” Vac 1

4-7: Assemblies and Parts Lists

Page 20

5 - How to Order Parts

From time to time, cleaning equipment may wear out or malfunction. To obtain a proper

diagnosis of your malfunction, and to order warranty replacement parts or arrange for

repairs, it is important that you proceed in the following manner:

WARRANTY PARTS ORDERS

Call the local distributor where you purchased your equipment and ask for the 1.

Service Department.

Have the following information ready: 2.

Equipment Model a.

Date of Purchase b.

Description of Malfunctionc.

Once it has been determined which parts are needed to correct the problem with 3.

your tool, make arrangements with your distributor to either perform the repairs or

ship the parts to you.

PARTS ORDERS

Call your local distributor. In most instances, they either stock or have access to parts

through a regional service center.

EMERGENCIES

If, for any reason, your distributor is unable to supply you with the necessary parts, they

may call us and arrange for expedited shipping.

HydraMaster sells parts only through authorized distributors and service centers.

We shall always endeavor to be fair in our evaluation of your warranty claim, and shall

provide you with a complete analysis of our ndings.

5-1: How to Order Parts:

Page 21

6 - Warranty Information

All parts of the DriMaster II HiFlo Stainless Steel Upholstery Tool are warranted against

defects for 1 year.

Freezing, hard water, the use of unapproved solvents and/or abuse will void the

warranty.

HydraMaster warranty covers only defective materials and/or workmanship for the period

listed. Labor and/or diagnostic reimbursement is specically excluded.

If you have moved to a new area or have purchased a used machine and need information

regarding your local distributor, call HydraMaster at (425) 775-7272 or email us at:

custsvc@hydramaster.com.

6-1: Warranty Information:

Loading...

Loading...