Page 1

Clutch Drive System

4.8 / 4.6 Owner’s Manual

HydraMaster North America, Inc. - 11015 47th Avenue West,

Mukilteo, Washington 98275

Copyright 2009 HydraMaster North America, Inc.

MAN-33149 Rev. 0

(182-038-D)

No part of this manual may be reproduced or used in any form or by any means (i.e. graphic, electronic, photocopying

or electronic retrieval systems) without the express written permission of

All rights reserved.

Revised July 10, 2009

HydraMaster North America, Inc.

Page 2

Table of Contents

GENERAL INFORMATION ........................................................................... SECTION 1

Contact Information ........................................................................... 1-2

Warnings, Cautions and Notices ....................................................... 1-3

Machine Specications ...................................................................... 1-6

Responsibilities .................................................................................. 1-8

Purchaser’s Responsibility ................................................................ 1-8

Sales Representative’s Responsibility ............................................... 1-8

Local Water Precautions .................................................................... 1-9

Hard Water Advisory .......................................................................... 1-9

Hard Water Area Map ........................................................................ 1-10

Water Softener ................................................................................... 1-11

Waste Water Disposal Advisory ......................................................... 1-12

CHEMICALS AND CLEANING .................................................................... SECTION 2

Cleaning Precautions......................................................................... 2-2

Cleaning Stroke Procedure................................................................ 2-2

Overwetting........................................................................................ 2-3

OPERATING INSTRUCTIONS ..................................................................... SECTION 3

Before Operating the CDS ................................................................. 3-1

CDS Start Up ..................................................................................... 3-2

CDS Flood Restoration Work ............................................................ 3-2

CDS Shut Down................................................................................. 3-3

3 Speed Throttle Control Function ..................................................... 3-4

FREEZE GUARD ......................................................................................... SECTION 4

Draining the CDS ............................................................................... 4-2

Freeze Protecting Pump-In System ................................................... 4-3

WATER AND CHEMICAL SYSTEM ............................................................. SECTION 5

Water and Chemical Flow Operation ................................................. 5-1

Chemical System Maintenance ......................................................... 5-2

Chemical System Troubleshooting .................................................... 5-3

1.0. System will not prime ........................................................... 5-3

2.0. Chemical ow is unstable or low .......................................... 5-3

3.0. Chemical jug lls with water ................................................. 5-4

i - CDS 4.8 / 4.6 Owner’s Manual

Page 3

WATER PUMP MAINTENANCE .................................................................. SECTION 6

Daily Maintenance ............................................................................. 6-1

Periodic Maintenance ........................................................................ 6-2

Water Pump Troubleshooting ............................................................ 6-3

1.0.Will not come up to normal cleaning pressure ...................... 6-3

2.0. No pressure reading on PSI gauge ...................................... 6-3

3.0. PSI gauge reads normal; low pressure from tool/wand ....... 6-4

4.0. Pressure pulsation ............................................................... 6-4

5.0.Water box empty or lls slowly .............................................. 6-4

6.0. Water box overows ............................................................. 6-5

ASSEMBLIES AND PARTS LISTS ............................................................... SECTION 7

CDS Machine Assembly Parts List .................................................... 7-3

CDS Recovery Tank Assembly Parts List .......................................... 7-6

CDS Recovery Tank Cover Assembly Parts List ............................... 7-7

CDS Instrument Panel Assembly Parts List....................................... 7-10

CDS Hi-PSI Manifold Assembly Parts List ......................................... 7-11

CDS By-Pass Valve Assembly Parts List ........................................... 7-12

CDS 4.8 Pump and Blower Assembly Parts List ............................... 7-15

CDS 4.6 Pump and Blower Assembly Parts List ............................... 7-18

CDS Pump Assembly Parts List ........................................................ 7-20

CDS DuraFlow Automatic Pump Out (APO) Assembly Parts List ..... 7-22

CDS Dash Box Assembly Parts List .................................................. 7-25

CDS Dash Panel Assembly Parts List ............................................... 7-27

CDS Water Box Assembly Parts List ................................................. 7-30

Diffuser Filter Assembly Parts List ..................................................... 7-31

CDS Vacuum Relief Valve Assembly Parts List ................................. 7-32

CDS Front End 2003 - 2009 GM Assembly Parts List ....................... 7-34

Horizontal Pump In Tank Assembly Parts List ................................... 7-37

Free Standing Tray Assembly Parts List ............................................ 7-38

85-Gallon Rotomolded Fresh Water Tank Assembly Parts List ......... 7-42

85-Gallon Rotomolded Fresh Water Tank

with Reel Assembly Parts List ................................................. 7-43

125-Gallon HydraCradle Tank Assembly Parts List * ......................... 7-47

CDS Pass Through Assembly Parts List ........................................... 7-48

CDS Standard Heat Exchanger Assembly Parts List ........................ 7-49

CDS Heat Exchanger Assembly Parts List ........................................ 7-50

CDS Salsa 2005 - 2009 Assembly Parts List..................................... 7-51

Ford Hush Kit Mufer Assembly Parts List - 4.8 ............................... 7-52

Chevy Hush Kit Mufer Assembly Parts List - 4.8 ............................ 7-53

Silencer Assembly Parts List - 4.6 ..................................................... 7-54

CDS Belts Parts List .......................................................................... 7-55

Cleaning Wand Valve Assembly Parts List ........................................ 7-56

CDS 4.8 / 4.6 Owner’s Manual - ii

Page 4

Cleaning Wand Solution Valve Assembly Parts List .......................... 7-57

Cleaning Wand Valve Stem Assembly Parts List ............................... 7-58

Hydra Hoe Wand Assembly Parts List ............................................... 7-60

GM Cowling Assembly, 2003 – 2009 Parts List (P/N 601-020-008) .. 7-61

2009 Ford Cowling Assembly Parts List (P/N 601-020-001) ............. 7-61

CDS Parts Kit List (P/N 000-078-069) ............................................... 7-61

2009 GM Throttle Kit Parts List (P/N 000-078-430) ........................... 7-62

2009 Ford Throttle Kit Parts List (P/N 000-078-405) ......................... 7-62

VACUUM BLOWER SYSTEM ...................................................................... SECTION 8

Vacuum Tank Inlet Filter .................................................................... 8-2

Vacuum Blower Lubrication ............................................................... 8-2

Vacuum Blower Troubleshooting ....................................................... 8-3

1.0. Weak vacuum at tool/wand. ............................................. 8-3

2.0. Vacuum gauge will not come up to 14” Hg ...................... 8-3

3.0. Vacuum gauge reads high with no hoses attached ......... 8-3

4.0. Noisy Vacuum Blower ...................................................... 8-4

5.0. Vacuum Blower is locked and will not turn ....................... 8-4

ELECTRICAL SYSTEM ................................................................................ SECTION 9

Electrical Troubleshooting.................................................................. 9-5

1.0. CDS will not turn on ......................................................... 9-5

2.0. CDS shuts off while in use ............................................... 9-5

MACHINE MAINTENANCE .......................................................................... SECTION 10

Operational Maintenance................................................................... 10-1

Appearance Maintenance .................................................................. 10-4

Long-Term Maintenance Schedule .................................................... 10-5

Drive Shaft Maintenance ................................................................... 10-6

Troubleshooting ................................................................................. 10-7

Heating System ................................................................................. 10-7

Miscellaneous .................................................................................... 10-8

HOW TO ORDER PARTS ............................................................................ SECTION 11

Warranty Parts Orders ....................................................................... 11-1

Parts Orders ...................................................................................... 11-1

Emergencies ...................................................................................... 11-1

One Final Note................................................................................... 11-1

iii - CDS 4.8 / 4.6 Owner’s Manual

Page 5

WARRANTY INFORMATION ....................................................................... SECTION 12

Blower ............................................................................................... 12-1

High Pressure Water Pump .............................................................. 12-1

Vacuum Tank .................................................................................... 12-1

Chemical System ............................................................................... 12-1

Control Panel .................................................................................... 12-1

Vacuum and Solution Hoses ............................................................. 12-2

Cleaning Wand and Tool .................................................................... 12-2

Water Heating System ....................................................................... 12-2

Hard Water Deposits ......................................................................... 12-2

Warranty Procedure ........................................................................... 12-2

ACCESSORIES AND CHEMICAL SOLUTIONS .......................................... SECTION 13

CDS 4.8 / 4.6 Owner’s Manual - iv

Page 6

List of Figures

Figure 1-1. Hard Water Map of Mainland United States ................................ 1-10

Figure 1-2. Conguration of Water Softener and CDS .................................. 1-11

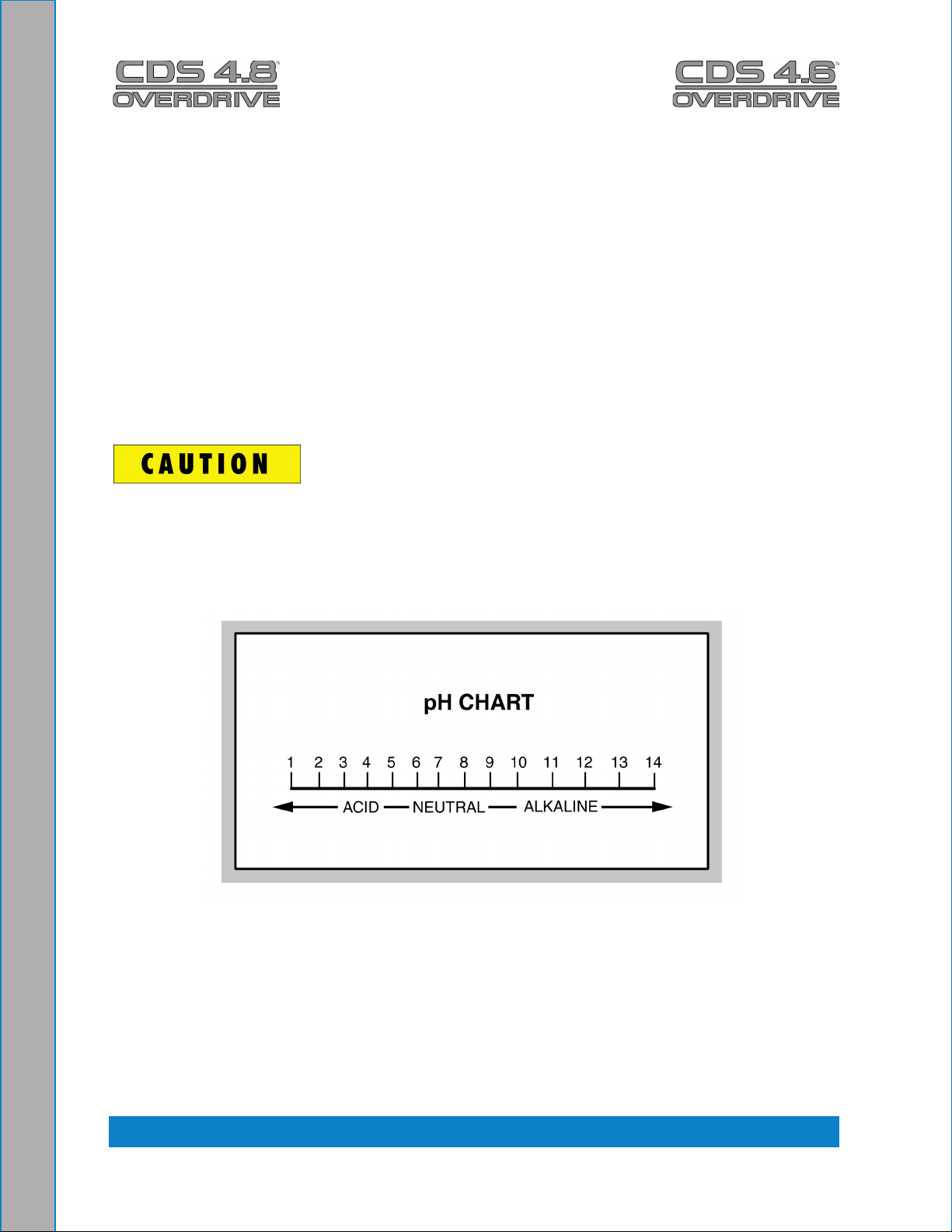

Figure 2-1. pH Chart ........................................................................................ 2-1

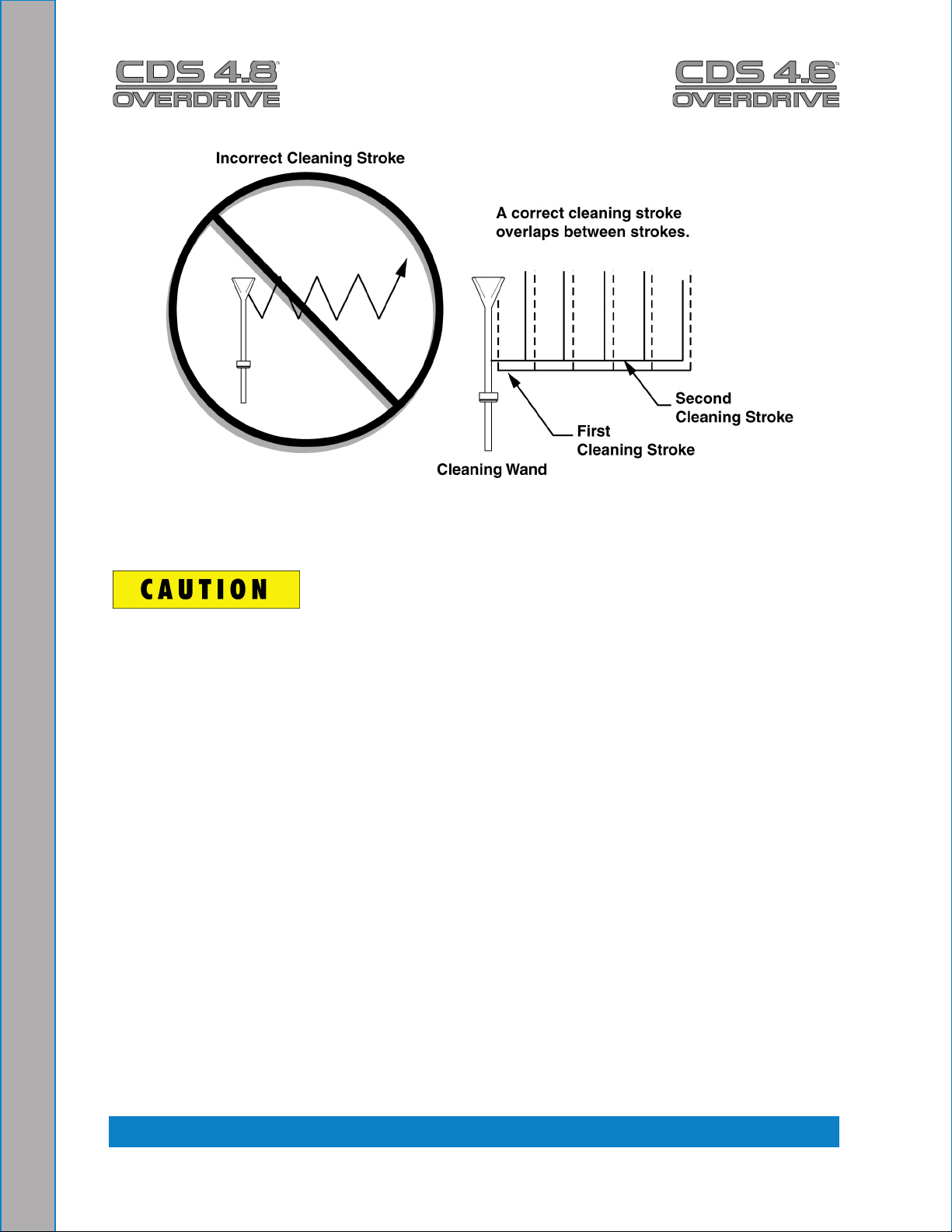

Figure 2-2. Cleaning Stroke Procedure ...........................................................2-3

Figure 3-1. Location of Controller’s LED Lights

with Labels and RPM Trim Potentiometers ............................................3-4

Figure 3-2. Location of 3 Lights on Throttle Control Assembly ........................3-6

Figure 7-1. CDS Machine Assembly - Front View ...........................................7-1

Figure 7-2. CDS Machine Assembly - Rear View ............................................7-2

Figure 7-2. CDS Recovery Tank Assembly - Front View ................................. 7-4

Figure 7-3. CDS Recovery Tank Assembly - Rear View .................................. 7-5

Figure 7-4. CDS Recovery Tank Cover Assembly ...........................................7-7

Figure 7-5. CDS Instrument Panel Assembly - Front View .............................. 7-8

Figure 7-6. CDS Instrument Panel Assembly - Rear View ..............................7-9

Figure 7-7. CDS Hi-PSI Manifold Assembly .................................................. 7-11

Figure 7-8. CDS By-Pass Valve Assembly ....................................................7-12

Figure 7-9. CDS 4.8 Pump and Blower Assembly - Overview .......................7-13

Figure 7-10. CDS 4.8 Pump and Blower Assembly - Parts View ................... 7-14

Figure 7-11. CDS 4.6 Pump and Blower Assembly - Overview ..................... 7-16

Figure 7-12. CDS 4.6 Pump and Blower Assembly - Parts View ................... 7-17

Figure 7-13. CDS Pump Assembly - Overview ..............................................7-19

Figure 7-14. CDS Pump Assembly - Parts View ............................................ 7-20

Figure 7-15. CDS DuraFlow Automatic Pump Out (APO) Assembly ............. 7-21

Figure 7-16. CDS Dash Box Assembly - Overall View ..................................7-23

Figure 7-17. CDS Dash Box Assembly - Rear View ......................................7-24

Figure 7-18. CDS Dash Panel Assembly - Overall View ...............................7-26

Figure 7-19. CDS Dash Panel Assembly - Rear View ...................................7-27

Figure 7-20. CDS Water Box Assembly - Overview ......................................7-28

Figure 7-21. CDS Water Box Assembly - Parts View .................................... 7-29

Figure 7-22. CDS Diffuser Filter Assembly ....................................................7-31

Figure 7-23. CDS Vacuum Relief Valve Assembly ........................................7-32

Figure 7-24. CDS Front End 2003 - 2009 GM Assembly - Overview ............7-33

Figure 7-25. CDS Front End 2003 - 2009 GM Assembly - Parts View .......... 7-33

Figure 7-26. Horizontal Pump In Tank Assembly - Front ............................... 7-35

Figure 7-27. Horizontal Pump In Tank Assembly - Rear ................................ 7-36

Figure 7-28. Free Standing Tray Assembly ................................................... 7-38

v - CDS 4.8 / 4.6 Owner’s Manual

Page 7

Figure 7-32. 85-Gallon Rotomolded Fresh Water Tank with Reel Assembly . 7-43

Figure 7-33. 125-Gallon HydraCradle™ Tank Assembly - Parts View 1 of 3 . 7-44

Figure 7-34. 125-Gallon HydraCradle Tank Assembly - Parts View 2 of 3 .... 7-45

Figure 7-35. 125-Gallon HydraCradle Tank Assembly - Parts View 3 of 3 .... 7-46

Figure 7-36. CDS Pass Though Assembly .................................................... 7-48

Figure 7-37. CDS Standard Heat Exchanger Assembly ................................ 7-49

Figure 7-38. CDS Heat Exchanger Assembly................................................ 7-50

Figure 7-39. CDS Salsa 2005- 2009 (Chevy) Assembly................................ 7-51

Figure 7-40. Ford Hush Kit Mufer Assembly - 4.8 ........................................7-52

Figure 7-41. Chevy Hush Kit Mufer Assembly - 4.8 ..................................... 7-53

Figure 7-42. Silencer Assembly - 4.6 .............................................................7-54

Figure 7-43. Cleaning Wand Valve Assembly ................................................7-56

Figure 7-44. Cleaning Wand Solution Valve Assembly ..................................7-57

Figure 7-45. Cleaning Wand Valve Stem Assembly ......................................7-58

Figure 7-46. Hydra Hoe Wand Assembly ......................................................7-59

Figure 9-1. CDS Electrical Schematic ............................................................. 9-2

Figure 9-2. CDS Wiring Diagram .....................................................................9-3

Figure 9-3. CDS Wiring Diagram .....................................................................9-4

Figure 10-1. Zerk Fittings and Spline Locations on Drive Shaft .................... 10-6

CDS 4.8 / 4.6 Owner’s Manual - vi

Page 8

List of Tables

Table 3-1. GM Throttle Controller LED Functions ............................. 3-5

Table 3-2. Ford Throttle Controller Light Functions .......................... 3-7

Table 8-1. Lubricants for Oil-Lubricated Gears and Bearings ........... 8-3

vii - CDS 4.8 / 4.6 Owner’s Manual

Page 9

1 - General Information

The Clutch Drive System (CDS) 4.8 and 4.6 Truckmounts are highly engineered carpet

cleaning machines developed, designed and manufactured by HydraMaster Corporation.

The systems utilize the most current technology available in water heating and water

recovery systems.

As there is no guess work in the manufacture of these highly advanced cleaning systems,

there must be none in preparing the CDS to get the job done in the eld. It is the purpose

of this manual to help you properly understand, maintain and service your cleaning plant.

Follow the directions carefully and you will be rewarded with years of protable, trouble-

free operation.

This Owner’s Manual contains installation and operation instructions as well as information

required for proper maintenance, adjustment and repair of the CDS 4.8 and 4.6. Component

troubleshooting guides have also been included for your convenience.

It is imperative that no section be overlooked when preparing for operation of this equipment.

Please read this Owner’s Manual to familiarize yourself with the operation of the 4.8 and

4.6 Truckmount Systems, paying special attention to all Warnings and Cautions.

This section of the manual contains the following helpful information:

Contact Information

Warnings, Cautions and Notices

Machine Specications

Responsibilities

Local Water Precautions

1-1: General Information

Page 10

Contact Information

If you have any questions regarding the operation, maintenance or repair of this machine,

please contact your local distributor.

To nd a local distributor, please visit our website at http://www.hydramaster.com/owners/

locate/index.asp.

If your question cannot be resolved by your distributor or by the information within this

manual, you may contact HydraMaster Customer Service direct using the following

phone numbers.

Hours Telephone Numbers

Monday-Friday (425) 775-7276 Parts

7:00 a.m. to 5:00 p.m. (425) 775-7275 Service

Pacic Standard Time (800) 426-4225 Parts / Service FAX

General Information: 1-2

Page 11

Warnings, Cautions and Notices

HydraMaster uses this WARNING symbol throughout the manual to warn of possible

injury or death.

This CAUTION symbol is used to warn of possible equipment damage.

This NOTICE symbol indicates that federal or state regulatory laws may apply, and also

emphasizes supplemental information.

1-3: General Information

Page 12

Warnings and Cautions specic to the CDS 4.8 / 4.6 include:

HOT SURFACES: During the operation of this equipment, many surfaces on the machine

will become very hot. When near the van for any reason care must be taken not to touch

any hot surface, such as the engine or the exhaust.

HEARING PROTECTION: The Occupational Safety and Health Administration (OSHA)

recommends the use of hearing protection when a technician is exposed to an average of

85 decibels (this is an average of exposure over an 8 hour period). This equipment can

produce 85 decibels to a distance of 10 feet. Please check with your local state agencies

to see if OSHA standards apply to your application.

NO SMOKING: It is unsafe to smoke in or around the vehicle. Do not allow any open

ames in or around the vehicle.

CARBON MONOXIDE: This unit generates toxic fumes. Position the vehicle so that the

fumes will be directed away from the job site. Do not park where exhaust fumes can enter

a building through open doors, windows, air conditioning units or kitchen fans.

TOXIC FUMES: Do not occupy the vehicle when the cleaning equipment is operating.

Toxic fumes may accumulate inside a stationary vehicle.

ENGINE EXHAUST: The engine exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

MOVING PARTS: Never touch any part of the machine that is in motion. Severe bodily

injury may result.

General Information: 1-4

Page 13

The use of some chemicals through your mobile carpet cleaning plant can seriously

damage the internal plumbing, high-pressure pump, chemical pump and heat exchangers.

These harmful chemicals include concentrated acid (see the pH chart in Figure 2-1),

solvents (including d-Limonene), and some paint, oil and grease removers with a high

concentration of solvents.

THROUGH-FLOOR DRILLING: Be cautious when drilling holes through the van oor.

Many vans have critical components mounted directly below the van oor that could be

damaged by a misplaced drill bit.

LEVEL OPERATION: During operation, the vehicle must be parked on level ground

not to exceed + or - 10 degrees. Failure to ensure proper leveling may prevent proper

internal lubrication of engine, vacuum and/or high pressure components.

ACID RINSE AGENTS: Some acid rinse products can cause damage to internal machine

components. Failure to take appropriate measures to prevent acidic corrosion can result

in system failure and loss of warranty on affected parts.

HARD WATER PROTECTION: Failure to take appropriate measures to prevent scale

build up can result in system failure and loss of warranty on affected parts. Test the water

in your immediate and surrounding areas with hard water test strips. Assume all water

obtained from wells is hard. If you are operating in a hard water area at 3.0 grains or more

per gallon, use a water softening system.

FREEZE PROTECTION: Failure to take appropriate measures to prevent equipment

damage due to freezing can result in system failure and loss of warranty on affected

parts. Placing an electric heater in the vehicle or parking the vehicle indoors will help

ensure against freezing, but should not be the primary method of freeze protection.

1-5: General Information

Page 14

Machine Specications

Frame: 23” W x 41.5” H x 61.0” L

Weight: 912 lbs.

Construction: Tank: Marine Aluminum with Baked-on Epoxy Finish

Chassis: Painted Steel

Cowling: Fiberglass

Power Transfer: Electric Clutch-driven shaft, Key Activated

Vacuum Blower: 4.6 - 45 Tuthill/M-D Tri-Lobe

4.8 - 47 Tuthill/M-D Tri-Lobe

Water Pump: Plunger pump, 4.0 gpm (at high speed), 2,500 psi, electric clutch

control

Chemical System: Mechanical, Meter Controlled

Heating System: Multiple Heat Exchanger (1,200 psi pressure)

Dual Shell and Tube Exchangers

Optional Salsa Heat Package

Instruments:

Main Panel:

Electronic Tachometer, 0-3,000 rpm

Water Temperature Gauge, 0-320° F

Vacuum Gauge, 0-30” Hg

Hour Meter, Machine Run-Time

Keyed Ignition, Start/Stop

Electronic Circuit Protection Breaker, Re-settable

Machine Status Indicator Lamps

Chemical Flowmeter, 0-10 gph

Water Pressure Gauge, Liquid Filled, 0-1,500 psi

Side Panel:

Water Pressure Adjustment

Blower Lubrication Port

Water Temperature Adjustment Knob

High Pressure Solution Outlets, Quick-Disconnect

Fresh Water Inlet Fitting, Quick-Disconnect

Water Box Drain Valve

Chemical Controls

General Information: 1-6

Page 15

Recovery Tank: 100 gallon Aluminum

Cleaning Tool/

Wand: Stainless Steel

Replacement Grip

Rebuildable Solution Valve

High Pressure Hose:

1/4” High Temperature, Lined, Vinyl Covered

Hose rated to 2,200 psi, 250° F

Standard Equipment:

Power Transfer Package

Component Power Pack

Equipment Cowling

Vacuum Recovery Tank

Control Console

Dual Tool/Wand Hook-up

HydraMaster Heat Exchanger System

Freeze Guard System

Wheel Chock Set

Carpet Tool/Wand

150’ Solution Hose

150', 2" Vacuum Hose

10'. 1 ½” Vacuum Hose

50', Fresh Water Hose (Garden Hose)

10', 1 ½” Drain Line

5 gallon Chemical Jug

Chemical Jug Holder

Van Finish Package

Van Decal Package

Monogrammed Jacket

Owner’s Manual

Equipment Color Selection

Hushkit Silencer System (4.8)

1-7: General Information

Page 16

Responsibilities

Prior to the arrival of the unit, the van that it will be installed in should be delivered to the

installer.

Purchaser’s Responsibility

If you are the purchaser, it is the your responsibility to read the Owner’s Manual and to

familiarize yourself with the information contained herein, paying special attention to all

Warnings and Cautions.

Sales Representative’s Responsibility

Acceptance of Shipment

If the unit shows any outward signs of damage, do not sign the delivery receipt until 1.

you have closely inspected the unit and noted any damage on the delivery receipt.

The sales representative from whom you purchased your unit is responsible for 2.

supervising the correct installation of the unit in your vehicle and thoroughly training

you in its operation, maintenance and precautions.

Installation

Correctly installing the unit and recovery tank in your vehicle and securing them with •

bolts and tie down washers.

Checking the pump, vacuum blower and engine oil levels prior to starting the unit.•

Starting the unit to check the drive system and see that all other systems function •

normally.

Checking all hoses, tools/wands and accessories for correct operation.•

Training

A thorough review of the Owner’s Manual with the purchaser.•

Instruction in and familiarization with: •

How to correctly start up and shut down the unit1.

How to correctly clean with the unit2.

Where and how often to check and change component oil levels3.

How the unit’s systems work, how to troubleshoot the unit4.

How to do basic repairs5.

Safety precautions and their importance 6.

How to avoid freezing damage7.

How to avoid hard water damage8.

A thorough review of the unit warranty and warranty procedures.•

A thorough review of hard water precautions and warnings.•

How to determine hard water areas.•

Use of water softening systems.•

General Information: 1-8

Page 17

Local Water Precautions

The quality of water varies greatly. Many areas have an excess of minerals in the water

which results in what is commonly called “hard water.” These minerals tend to adhere to

the insides of heater coils and other parts of the machines causing damage and a loss of

cleaning effectiveness. This inuences the reliability and efciency of equipment in direct

proportion to the level of hardness.

HARD WATER ADVISORY

HydraMaster recognizes that any hard water deposits which might occur within the water

system of our truckmounts is a serious problem. The precision technology of truckmount

heat exchanger systems is intolerant of any foreign material. Hard water deposits will

ultimately decrease the performance of the system and are expected to seriously lower

the reliability of the machine.

To validate a machine’s warranty, HydraMaster requires that all machines operating in

designated “Hard Water Areas” (3.0 grains or more per gallon) be tted with a water

softening system, or a properly installed magnetic-type descaler must be used and

maintained. Periodic descaling or acid-rinsing alone is not adequate in these areas.

HydraMaster does not recommend any particular type or brand; however, the relative

effectiveness of some types of magnetic descalers or softeners may require additional

periodic use of descaling agents.

HydraMaster also recommends, in the strongest possible terms, that machines in all areas

be tted with a water softening system for improved operation and reliability.

Failure to take appropriate measures to prevent scale build up can result in system failure

and loss of warranty on affected parts.

1-9: General Information

Page 18

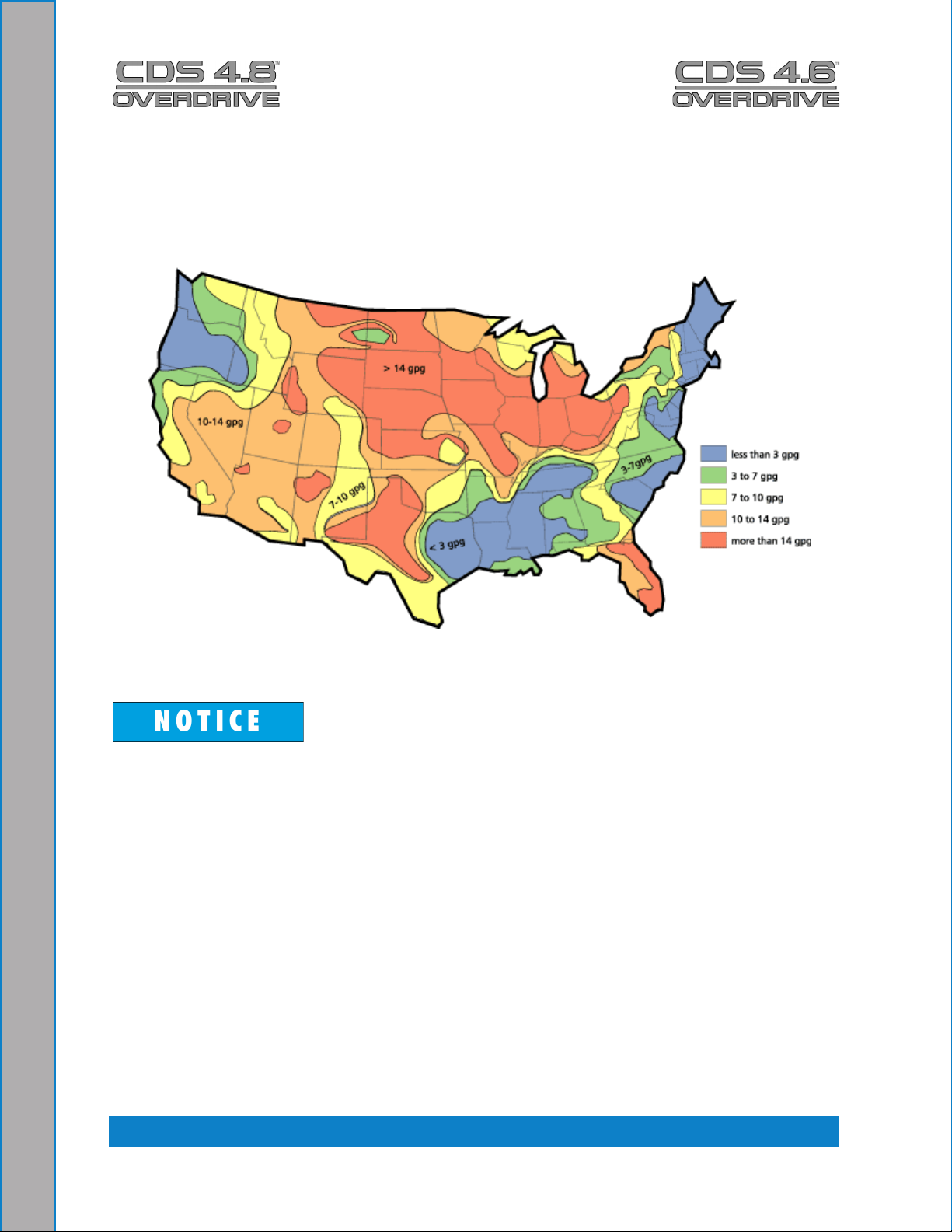

HARD WATER AREA MAP

The hard water map, shown in Figure 1-1, denes hard water areas in the lower 48 United

States which compromise uid related components such as hoses, ttings, heaters,

pumps, valves and water-cooled engines. For other countries, hard water area maps can

be obtained from geological societies.

Figure 1-1. Hard Water Map of Mainland United States

The map shown in Figure 1-1 is provided for general reference only. Water hardness in

your geographical location should be conrmed by testing.

General Information: 1-10

Page 19

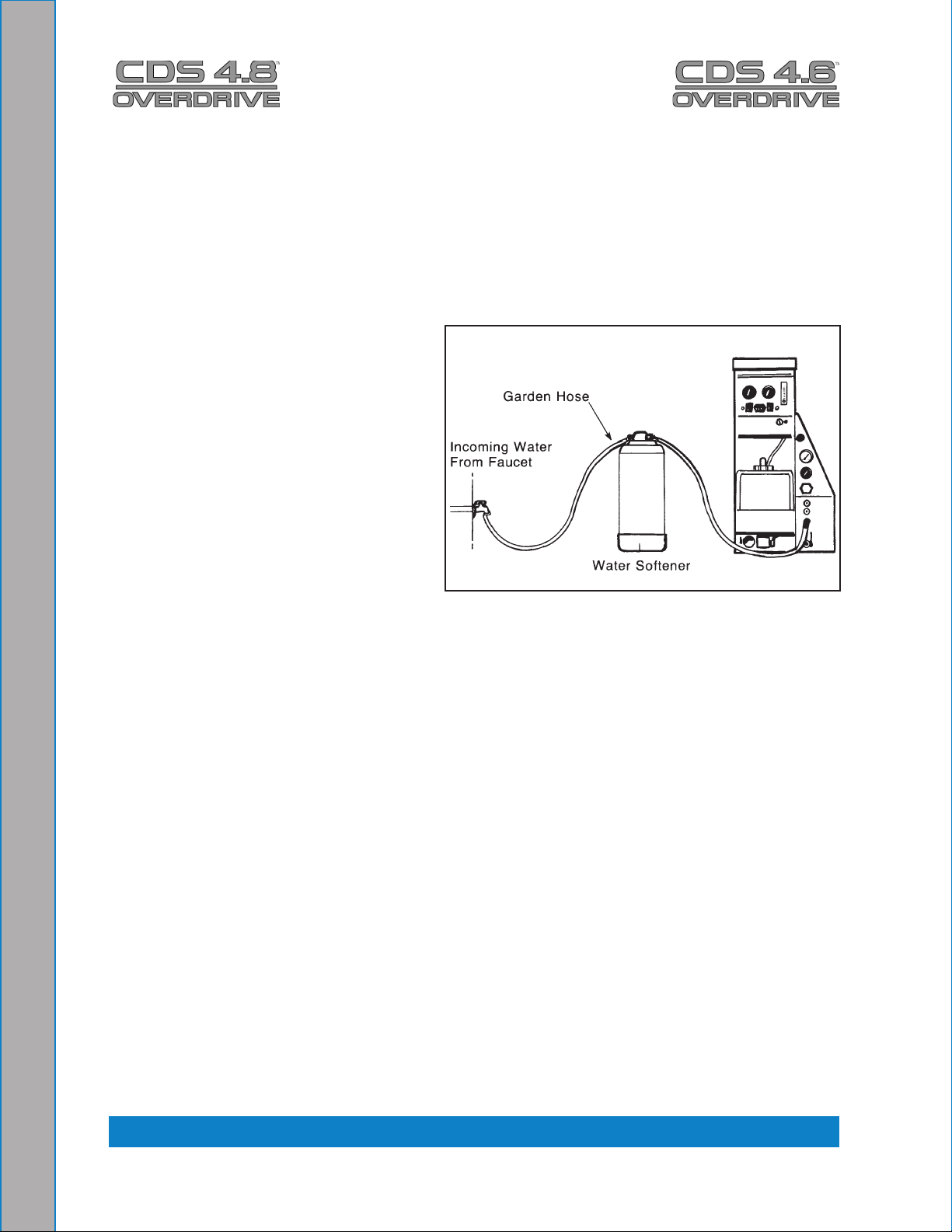

WATER SOFTENER

Cleaning efciency and equipment life is increased, chemical use decreased, and the

appearance of cleaned carpets enhanced when water softeners are incorporated in

hard water areas. HydraMaster strongly urges the use of water softener units with the

CDS 4.8/4.6 machines in areas exceeding 3.0 grains per gallon (see Figure 1-2).

Failure to use a water softener in these areas will invalidate the machine’s warranty.

Referring to the hard water area map shown Figure 1-1, determine the quality of water in

your area and take immediate action if

the water hardness exceeds 3.0 grains

per gallon.

The relatively low cost of a water

softener service is more than made up

for by an increased life of machine parts,

reduced chemical costs and continued

cleaning efciency. The water softener

will also increase the effectiveness of

the cleaning chemicals, therefore less

chemical will be needed.

Contact a water softener distributor in

your area for information on the rental

of a simple water treatment unit to

carry in your truck. Be sure to change

the water softener in accordance with the capability of the softener.

For example: If the softener will treat 900 gallons of water and the machine uses an

average of 30 gallons per hour, for an average of 5 hours a day, this equals 150 gallons

per day. In 6 days the machine would use 900 gallons of water. Therefore, the softener

would need to be changed every 6 working days for maximum softening.

Figure 1-2. Conguration of Water

Softener and CDS

1-11: General Information

Page 20

WASTE WATER DISPOSAL ADVISORY

There are laws in most communities prohibiting the dumping of recovered “gray” water

from carpet cleaning in any place but a sanitary treatment system.

The cleaning rinse water, recovered into your unit’s vacuum tank, contains materials

such as detergents, and must be safely processed before entering streams, rivers and

reservoirs.

In most cases, an acceptable method of waste water disposal is to discharge into a

municipal sewage treatment system after rst ltering out solid material such as carpet

ber. Access to the sanitary system can be obtained through a toilet, laundry drain, RV

dump, etc. Permission should rst be obtained from any concerned party or agency.

One disposal method which usually complies with the law is to accumulate the waste

water and haul it to an appropriate dump site. Another solution to the disposal problem

is to equip your CDS with an Automatic Pump-Out System (APO). These systems are

designed to remove waste water from the extractor’s recovery system and actively pump

the water through hoses to a suitable disposal drain.

HydraMaster makes an APO System which can be ordered with new equipment or

installed later.

When properly congured, the systems will continuously monitor the level of waste water

and pump it out simultaneously with the cleaning operation. The hidden benet of this

process is that the technician does not have to stop his/her cleaning to empty the recovery

tank.

IN ACCORDANCE WITH EPA, STATE AND LOCAL LAWS, DO NOT DISPOSE OF

WASTE WATER INTO GUTTERS, STORM DRAINS, STREAMS, RESERVOIRS, ETC.

The penalties for non-compliance can be serious. Always check local laws and regulations

to be sure you are in compliance.

General Information: 1-12

Page 21

2 - Chemicals and Cleaning

Your mobile carpet cleaning plant has been engineered using the latest and most

sophisticated technology available to produce the nest carpet cleaning results possible.

Despite this, it remains only a tool of the carpet cleaning trade and can produce only as a

good a job as the person operating it.

This section of the manual contains the following information:

Cleaning Precautions

Cleaning Stroke Procedure

Overwetting

The use of some chemicals through your mobile carpet cleaning plant can seriously

damage the internal plumbing, high-pressure pump, chemical pump and heat exchangers.

These harmful chemicals include concentrated acid, solvents (including d-Limonene),

and some paint, oil and grease removers with a high concentration of solvents (see pH

chart in Figure 2-1.

Figure 2-1. pH Chart

2-1: Chemicals and Cleaning

Page 22

CLEANING PRECAUTIONS

There are no short cuts to good carpet cleaning. It requires time, cleaning knowledge and

the use of good chemicals. Therefore, the manufacturer recommends the use of spotting

agents and trafc lane cleaners, as required, prior to the actual cleaning of carpeting.

HydraMaster also recommends only the use of chemicals containing rust and corrosion

inhibitors, and water softening agents to prevent chemical build-up which may lead to

component failure and warranty invalidation.

Some acid rinse products can cause damage to internal machine components. Failure

to take appropriate measures to prevent acidic corrosion can result in system failure and

loss of warranty on affected parts.

HydraMaster will not warranty parts that have been damaged from using acid products

that have obviously caused failures.

Avoid using detergents and chemicals which create foam when those products are

agitated because foam passing through the blower could lead to serious mechanical

failures. To ensure proper cleaning, use HydraMaster detergents and chemicals which

are formulated with built in anti-foaming agents. When cleaning surfaces with excessive

foaming residue, use HydraMaster de-foamer products as directed.

CLEANING STROKE PROCEDURE

To eliminate excess moisture remaining in the carpet ber and eliminate the sawtooth

appearance which results from diagonal movement of the cleaning tool, follow these

steps.

Always move the cleaning tool in smooth, forward and backward stroke1.

Apply slight pressure to the forward stroke while the solution is injected into the 2.

carpet.

When extracting (drying), apply rm pressure on the forward stroke to ensure a 3.

positive “lock” for the vacuum and minimize the “hopping” effect resulting on carpet

that is not smooth.

During the forward and reverse strokes, movement to the right or left should only be 4.

done at the extreme rear of the stroke.

Overlapping is also important to ensure even application of solution and prevent 5.

saturation when the cleaning tool is stopped twice at the same point at the rear of

the cleaning stroke Figure 2-2.

Chemicals and Cleaning: 2-2

Page 23

Figure 2-2. Cleaning Stroke Procedure

Failure to adopt the previous procedure can result in increased chance of “clean streaks,”

ber shrinkage, brown-out and longer drying periods.

OVERWETTING

Overwetting is annoying to all concerned, and sometimes leaves the customer with a bad

impression of the cleaning process used.

These are several conditions that will cause over-wetting

Too few vacuum strokes or improper saw-tooth vacuum strokes as shown in 1.

Figure 2-2.

Obstructed, cut or kinked hoses.2.

Vacuum tank drain valve left partially open.3.

Clogged vacuum blower lter or vacuum tank lid not sealing properly.4.

Cleaning a heavily foam-saturated carpet without defoamer. 5.

2-3: Chemicals and Cleaning

Page 24

3 - Operating Instructions

This section of the manual contains the following instructions:

Before Operating the CDS

CDS Start Up

CDS Flood Restoration Work

CDS Shut Down

3 Speed Throttle Control Function

BEFORE OPERATING THE CDS

Locate the unit and equipment in a well-ventilated area.1.

The CDS unit generates toxic fumes. Position the vehicle so that the fumes will be

directed away from the job site. Do not park where exhaust fumes can enter a building

through open doors, windows, air conditioning units or kitchen fans.

Check the fuel tank to be certain there is adequate fuel to complete the job.2.

Position the wheel chocks on one of the front tires.3.

If using a water supply hose which has not been used recently or if using a customer’s 4.

hose, rst connect the hose to the faucet and ush out any debris which may be in

the hose. Afterwards connect the hose to the unit.

Check the chemical jug to see if you have enough concentrated chemical to nish 5.

the job. If not, mix and ll a 5 gallon chemical jug.

Connect all required hoses.6.

When connecting the pressure hose to the pressure outlet connections at the front of 7.

the unit, go to the farthest area to be cleaned and connect to the cleaning tool. This

ensures that you have the proper length of hose required to perform the cleaning.

3-1: Operating Instructions

Page 25

CDS START UP

Make sure the vehicle’s gear select lever is in the Park position and the emergency 1.

brake is set

Start the vehicle’s engine.2.

Turn key on the CDS dash.3.

Select the cleaning speed appropriate for the cleaning job.4.

Turn on the PUMP CLUTCH switch. Adjust cleaning pressure to desired level.5.

Turn on the PUMP IN switch (if equipped).6.

Turn the heat control valve to “Max” only if you will be using water. Do not activate 7.

the heat exchanger during ood extraction work.

Turn the CHEMICAL SYSTEM valve to the “PRIME” position to purge any air from 8.

the system.

The prime hose is plumbed into the recovery tank. Leaving the valve in the “PRIME”

position will cause excessive chemical usage.

When the chemical begins to ow through the owmeter, with the ow indicator a.

reading maximum ow and the PRIME line pulsing, turn the CHEMICAL SYSTEM

valve to “ON”. Cap off vacuum if necessary.

While spraying the solution from the cleaning tool, adjust the chemical ow by b.

turning the CHEMICAL METERING CONTROL to the desired level.

Optional: Turn the APO switch ‘ON’ if using the Automatic Pump-Out feature.9.

The pump will not engage until the water level rises inside the recovery tank.

Now proceed with the cleaning operation.10.

The machine will automatically shut down when it reaches its full capacity due to the oat

switch located inside the recovery tank. When this occurs, turn the switch off and empty

the recovery tank. Then, turn the unit back on and continue to clean.

CDS FLOOD RESTORATION WORK

When using equipment for ood damage, adjust the high pressure pump to zero. This will

reduce the engine power load and save on fuel consumption.

Operating Instructions: 3-2

Page 26

CDS SHUT DOWN

Flush clear water through the chemical system for 10 seconds.1.

Open the water box drain and actuate the tool/wand valve to run fresh water through 2.

the water box, heat exchangers and cleaning tools.

If freeze guarding is necessary, perform the freeze guard procedure at this time. Draining

the water box to ½ full or less is recommended to reduce spillage inside the vehicle.

Rinse the system with vinegar on a weekly basis. Rinse the entire system with descaler

each month.

Lay vacuum hoses out in order for all moisture to be removed from the hoses. This 3.

prevents spillage of any dirty solution in your vehicle when storing the hoses.

Disconnect the hoses and put them away.4.

If you are using an outside water source, turn the water supply faucet off. Bleed 5.

pressure out of the supply hose by loosening the hose at the water supply. Unhook

the water supply hose and store it in the vehicle

Allow the unit to run for a few minutes with the vacuum hose disconnected in order 6.

to remove all moisture from the vacuum pump.

Plug the vacuum inlets. Spray lubricant into the lube port for about 5 to 10 seconds 7.

while the unit is running. This will lubricate the vacuum pump and prevent it from

rusting. (The lube port is located on the front panel above the pressure gauge.)

Remove the inlet plugs, then turn the 8. ignition “OFF” before draining the recovery

tank.

Turn the heat control valve to the ‘OFF’ position. This will help avoid engine overheat 9.

problems due to reduced coolant ow through the radiator.

Drain the recovery tank.10.

Do not dump waste in any area which might violate local, state or federal law. If

you have the optional Automatic Pump-Out (APO) system, drain the recovery tank into a

sanitary drain system.

When the recovery tank is drained, lift the recovery tank lid and remove the lter 11.

basket.

Clean out an12. y accumulated debris.

Rinse and re-install.13.

3-3: Operating Instructions

Page 27

3 speed Throttle Control function

▬ For GM Vans ▬

The GM Throttle Controller must meet certain “Chassis Ready” conditions to elevate the

engine rpm, which are as follows:

Parking Brake is set1.

Gear shift is in “Park”2.

Foot is off Service Brake (brake pedal)3.

Foot is off Accelerator Pedal4.

Vehicle is stationary (no speed)5.

Engine is started and idling6.

The A/C / Heater switch is in off position7.

The Throttle Controller must be initialized anytime the Data Link Cable (DLC) harness is

disconnected from the Data Link Connector. To initialize the system switch ignition key to

OFF position, plug in DLC harness, switch the ignition on, and then start the engine. This

allows the Throttle Controller to read the PCM engine computer.

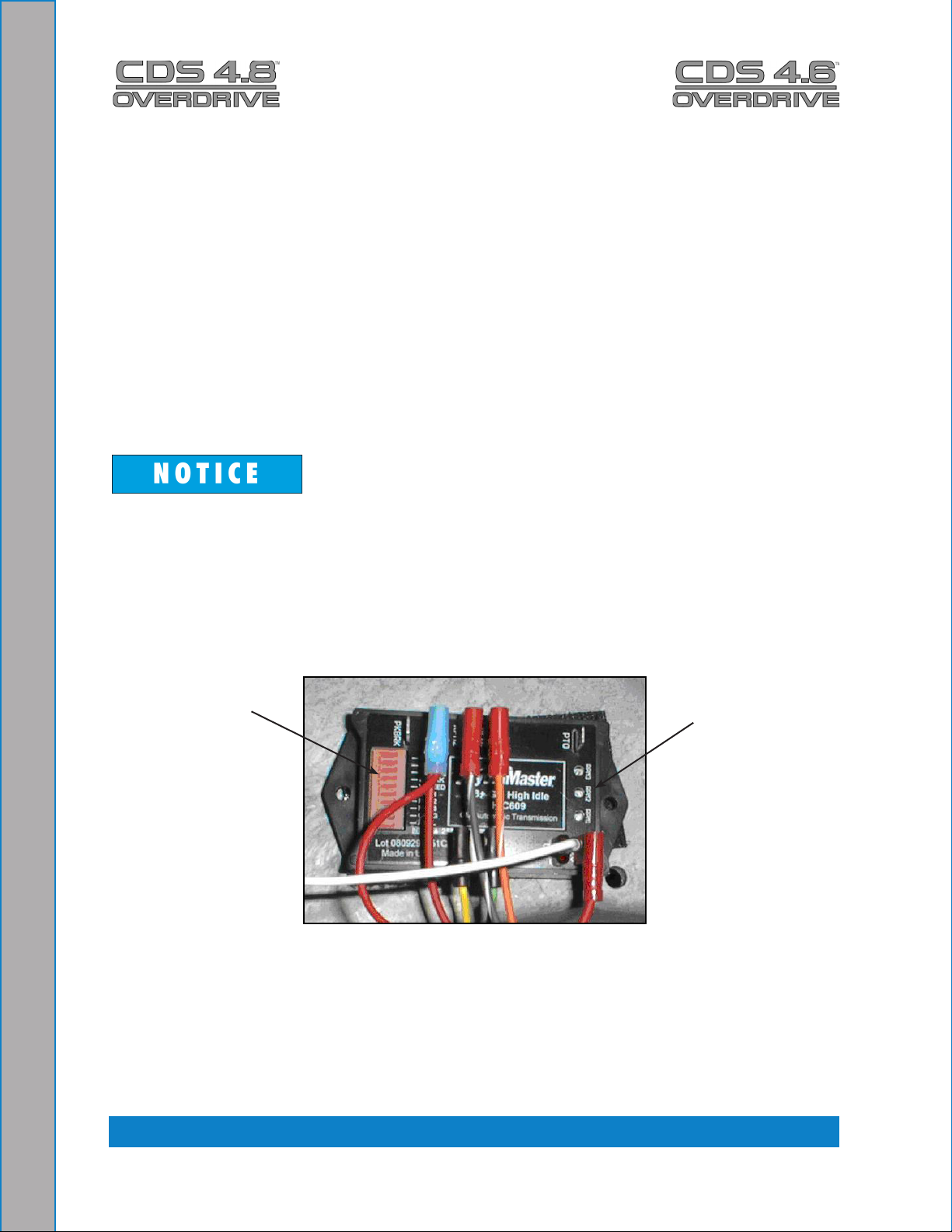

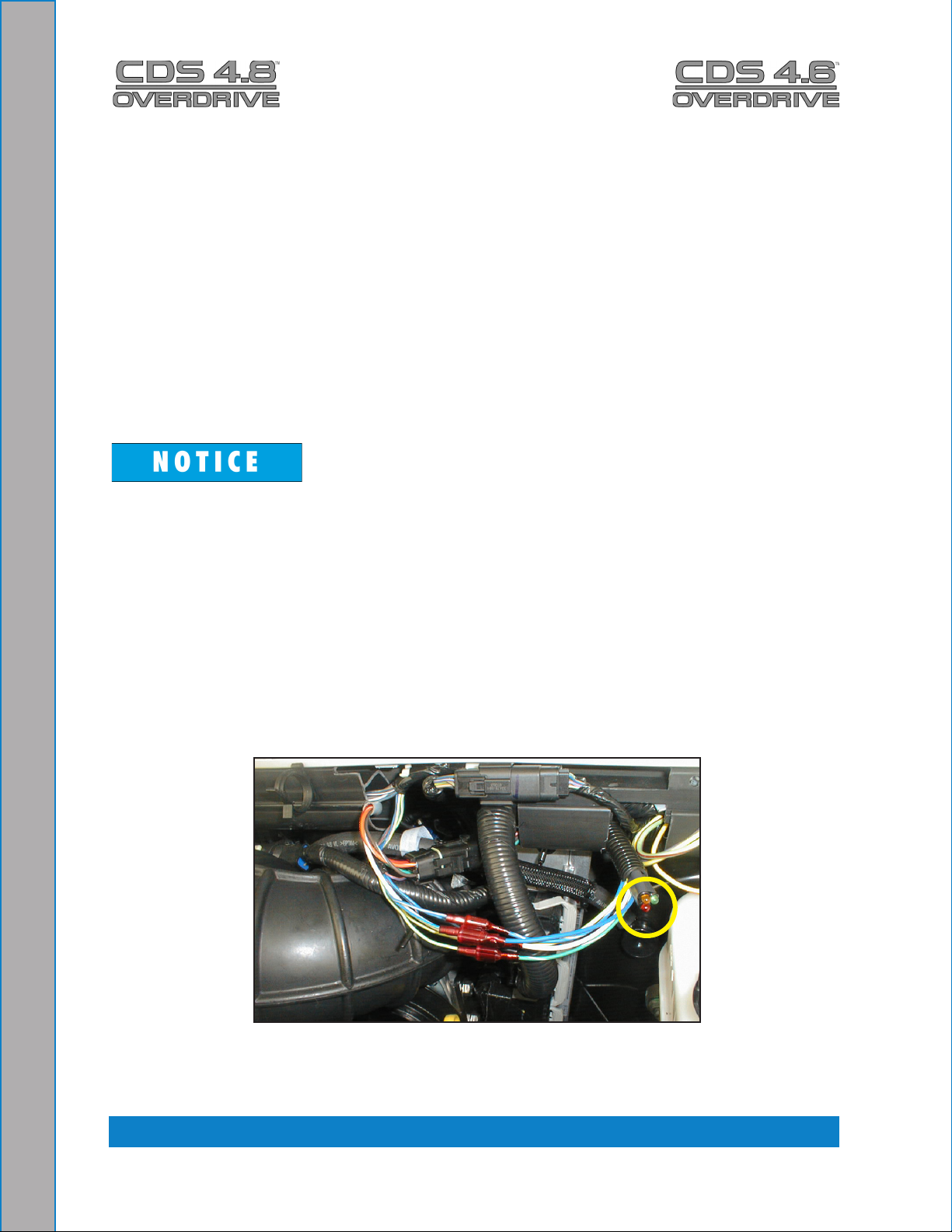

On the Throttle Controller, there are LED lights with corresponding labels to provide status

and problem detection information (refer to Figure 3-1 and Table 3-1).

LED LIGHTS WITH

LABELS

Location of Controller’s LED Lights Figure 3-1.

with Labels and RPM Trim Potentiometers

3 TRIM POTS

Operating Instructions: 3-4

Page 28

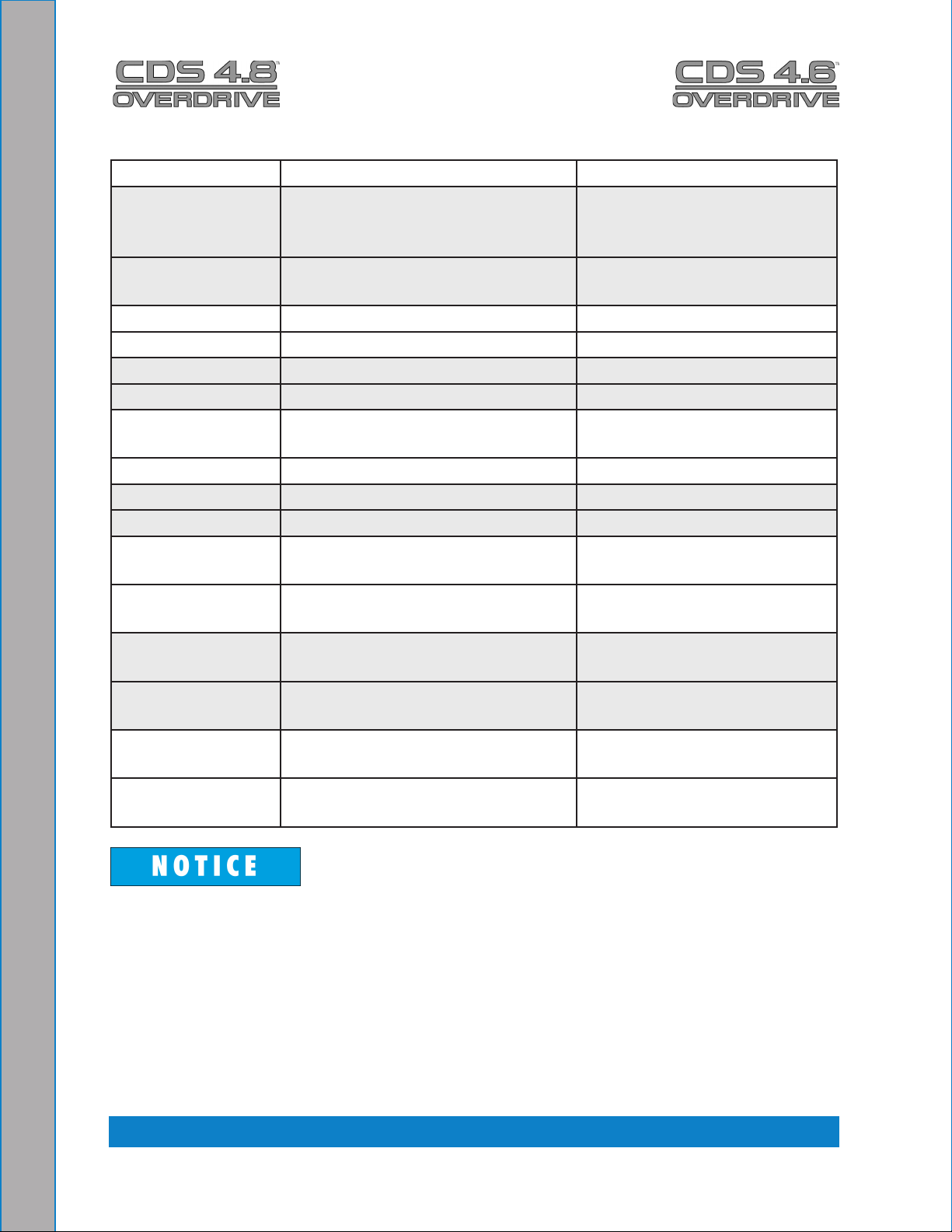

GM Throttle Controller LED FunctionsTable 3-1.

LED STATUS INDICATION

BUSS On Solid Unit ON and functioning

(harness connected to data

link)

BUSS Flashing Unit ON, but a problem was

detected

GEAR On Solid Transmission in PARK

GEAR Flashing Transmission NOT in Park

PK BRK On Solid Parking Brake Set

PK BRK Flashing Parking Brake is NOT set

SR BRK On Solid Service Brake is set (not

being used)

SR BRK Flashing Service Brake is NOT set

VSPEED On Solid Vehicle is stationary

VSPEED Flashing Vehicle is moving

RPM1 On Solid RPM1 mode selected, engine

at fast idle

RPM1 Flashing RPM1 mode selected, engine

not at fast idle

RPM2 On Solid RPM2 mode selected, engine

at fast idle

RPM2 Flashing RPM2 mode selected, engine

not at fast idle

RPM3 On Solid RPM3 mode selected, engine

at fast idle

RPM3 Flashing RPM3 mode selected, engine

not at fast idle

On GM gas engine vehicles, the PCM engine computer will cause the engine speed to

momentarily drop back to normal idle speed every time the air conditioner pump cycles on

or off. Make sure the operator of the CDS understands that the AC / HEAT switch needs

to be in the OFF position before activating the CDS unit.

3-5: Operating Instructions

Page 29

▬ For Ford Vans ▬

The Ford 3 Speed Throttle Controller must meet certain “Chassis Ready” conditions to

elevate the engine rpm, which are:

Parking Brake is set.1.

Gear shift is in “Park”.2.

Foot is off Service Brake (brake pedal).3.

Foot is off Accelerator Pedal.4.

Vehicle is stationary (no speed).5.

Brake light circuit is functional.6.

Engine coolant is above 140° F.7.

Transmission Oil Temperature is below 240° F.8.

Maximum Catalytic Temperature has not been met.9.

SEIC (Stationary Elevated Idle Control)* will be terminated by a safety condition violation.

For instance, the SEIC will be terminated if the service brake is depressed at any time

during its operation.

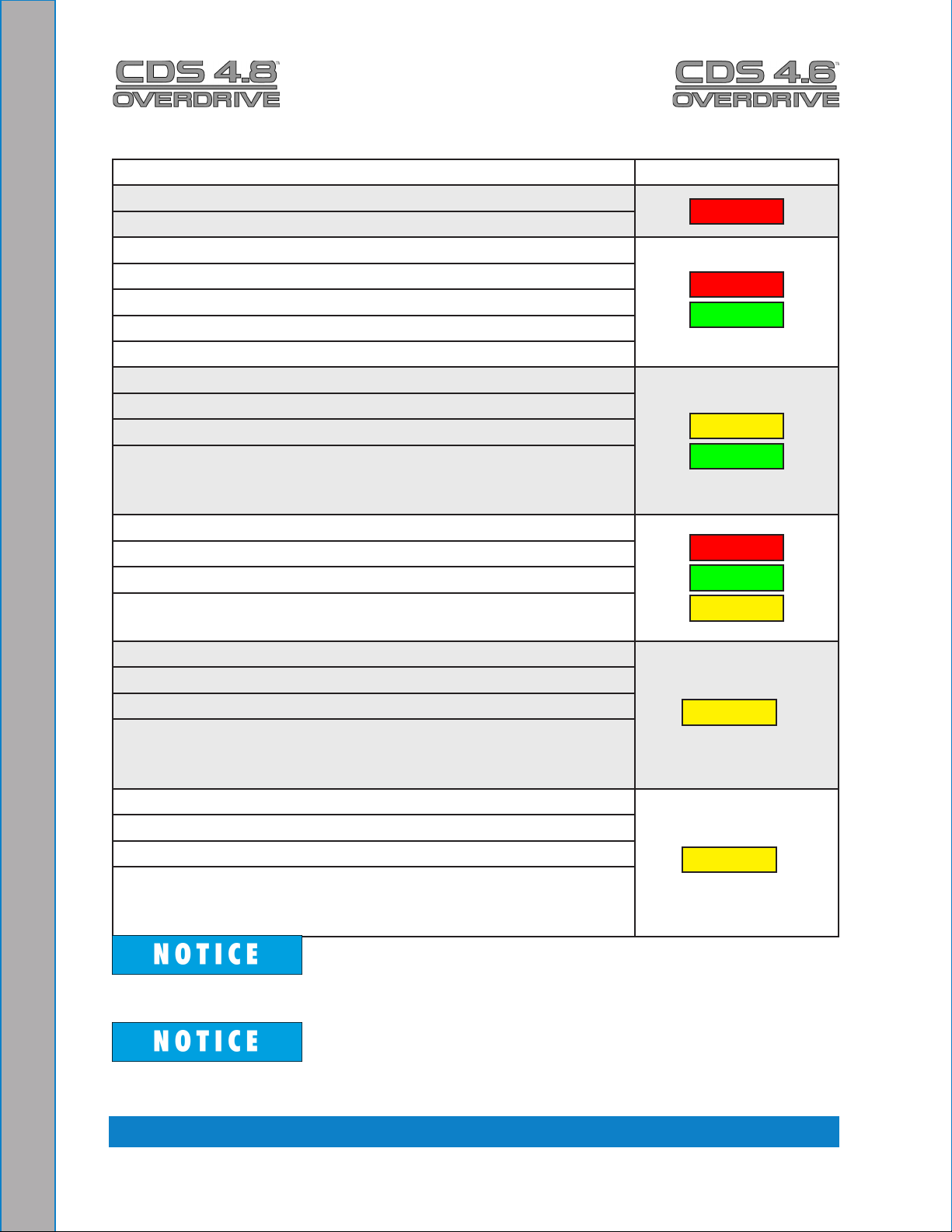

The 3 lights on the Throttle Control assembly indicate the following conditions (refer to

Figure 3-2 and Table 3-2):

RED LIGHT: the Throttle Control assembly is receiving power from the vehicle, but 1.

the SEIC process has not been initiated.

YELLOW LIGHT: all the “Chassis Ready” conditions have been met and the SEIC 2.

process has been initiated.

GREEN LIGHT: the Throttle Control assembly is receiving power from the CDS and 3.

the SEIC process is operational.

Location of 3 Lights on Throttle Control AssemblyFigure 3-2.

* SEIC is Ford’s onboard computer throttle control strategy.

Operating Instructions: 3-6

Page 30

1.Van ignition ‘ON’

2.CDS ignition ‘OFF’

1.Van ignition ‘ON’

2.CDS ignition ‘ON’

3.Recovery tank NOT full

4.SEIC NOT active

“Chassis ready” conditions HAVE NOT been meta.

1.Van ignition ‘ON’

2.CDS ignition ‘ON’

3.Recovery tank NOT full

4.SEIC IS active

“Chassis ready” conditions HAVE NOT been a.

violated

1.Van ignition ‘ON’

2.CDS ignition ‘ON’

3.Recovery tank NOT full

4.SEIC IS active

“Chassis ready” conditions HAVE been violateda.

1.Van ignition ‘ON’

2.CDS ignition ‘ON’

3.Recovery tank IS full *

4.SEIC IS active

“Chassis ready” conditions HAVE NOT been a.

violated

1.Van ignition ‘ON’

2.CDS ignition ‘OFF’

3.Recovery tank NOT full *

4.SEIC IS active

“Chassis ready” conditions HAVE NOT been a.

violated

Ford Throttle Controller Light FunctionsTable 3-2.

WHEN… CONTROL LIGHT(S)

Red

Red

Green

Yellow

Green

Red

Green

Yellow

Yellow

Yellow

**

**

*Turn CDS ignition “OFF” before draining recovery tank.

**SEIC process will continue until a “chassis ready” condition has been violated. To clear

single yellow light conditions, van ignition needs to be turned “OFF”.

3-7: Operating Instructions

Page 31

4 - Freeze Guard

When operating the CDS 4.8 / 4.6 during the colder months of the year, ensure that

you properly freeze guard the system. No part of the CDS 4.6/4.8 System is covered by

warranty if machine damage occurs because of freezing.

This section of the manual includes information concerning:

Draining the CDS

Freeze Protecting Pump-In System

BE SURE YOUR MACHINE IS PROTECTED! Freezing will cause GRIEF, LOST MONEY,

and DOWN-TIME.

The following precautions are recommended prior to and during cleaning:

Run the machine before leaving for the rst job to ensure nothing has frozen the 1.

night before, including hoses and tool/wand.

Insulate the fresh water (garden) hose from the cold ground by running it through an 2.

extra 1½” vacuum hose.

Leave vehicle doors closed until you begin cleaning; afterwards, open slightly.3.

In colder climates, insulating the vehicle walls and oor boards will help protect the unit.

Do not procrastinate during the cleaning operation or the hot water solution line will 4.

also freeze on the ground. The solution line should be insulated in extremely cold

climates.

Whenever possible, store the van in a heated garage at night or over the weekend. 5.

If not possible, place a 1,500 Watt electric heater inside the vehicle, aimed directly

at the machine.

Never use a propane heater. It causes excessive moisture on the vehicle ceiling and the

possibility of it going out is higher.

If the machine and vehicle are left outside with a heater, drain water from the machine 6.

cleaning tools and hoses because they can be freeze-damaged also.

4-1: Freeze Guard

Page 32

DRAININg THE CDS

To drain the machine, follow these steps:

Before shutting off the machine, remove the chemical line from the chemical jug and 1.

place in a mixture of 50/50 antifreeze and water. Turn the CHEMICAL SYSTEM

valve to the “PRIME” position until coolant registers in the ow meter. With the

cleaning tool on, allow mixture to ll the remainder of the chemical system.

Open the water box drain valve and allow the water to drain thoroughly from the 2.

water box.

Close the water box drain and ll the water box with 50 / 50 antifreeze and water 3.

mixture. Run the unit for 1 minute to circulate the mixture through the machines

low-pressure hoses. Spray through the wand or other tool into a suitable container

until the water box shut-off switch activates (pump stops). This freeze guards the

high-pressure circuit

Open the water box drain and drain out the residual uid into a suitable container. 4.

This antifreeze solution may be retained for reuse (attach freeze guard tting to inlet

quick connect and vacuum water out of the inlet line).

One manufacturer of antifreeze cautions:

“WHEN DISPOSING OF USED ANTIFREEZE COOLANT: Follow local laws and

regulations. If required, dispose at facilities licensed to accept household hazardous

waste. If permitted, dispose in sanitary sewer systems. Do not discard into storm sewers,

septic systems, or onto the ground.”

This warning appears on the label of one brand of antifreeze:

“HARMFUL OR FATAL IF SWALLOWED. Do not drink antifreeze coolant or solution. If

swallowed, induce vomiting immediately. Call a physician. Contains Ethylene Glycol which

caused birth defects in animal studies. Do not store in open or unlabeled containers.

“KEEP OUT OF REACH OF CHILDREN AND ANIMALS.”

Freeze Guard: 4-2

Page 33

FREEZE PROTECTINg PUMP-IN SYSTEM

Drain the fresh water tank.1.

Remove the fresh water (garden) hose adapter from the pump-in pump hose and 2.

position the hose so it is pointing outside the van.

Turn on the pump-in pump and run for 1 - 2 minutes until all the water is purged from 3.

the hose.

The next time the CDS is used, it may take a few minutes before the water box begins to

ll.

4-3: Freeze Guard

Page 34

5 - Water and Chemical

System

The CDS 4.8 / 4.6 high-pressure water and chemical system has been designed to be

simple and trouble free.

This section of the manual explains:

Water and Chemical Flow Operation

Chemical System Maintenance

Chemical System Troubleshooting

WATER AND CHEMICAL FLOW OPERATION

The general concept of the water and chemical ow is as follows:

Water is fed into the CDS under tap pressure to the water box.•

The water is then pumped from the water box through the heating system, mixed with •

the chemical and then that mixed solution is pumped out to the cleaning tool/wand.

After the solution is applied to the carpet, it is recovered by the vacuum system and •

carried back to the recovery tank.

The chemical pump draws the chemical from the inlet lter which is in the chemical

container. The chemical solution ows through the owmeter, indicating the ow of

chemical being used in gallons/hour. The chemical then ows through the chemical pump

to the chemical selector valve. The CHEMICAL SYSTEM valve can be used to prime the

pump (evacuate air from the system), inject chemical into the system or turn the chemical

ow off. When the CHEMICAL SYSTEM valve is in the “ON” position, chemical ows

through the metering valve, and is injected into the heated water path just prior to its

leaving the machine.

The low water oat switch in the water box is a safety switch that is designed to protect

your system from sudden or unexpected loss of water supply. If, for example, the water

source at the house were turned off, the water level of the water box would drop, activating

the low water oat switch, which automatically disengages the system and prevents the

water pump from running dry.

The desired chemical injection ratio may be obtained by adjusting the chemical metering

valve when spraying of water through the cleaning tool.

5-1: Water and Chemical System

Page 35

CHEMICAL SYSTEM MAINTENANCE

The chemical lines may need to be ushed with vinegar periodically to prevent abnormal

chemical build-up.

To ush the chemical system:

Set the CHEMICAL FLOWMETER to10 gph.1.

Remove the clear plastic hose from the chemical jug and insert it into a 1-quart 2.

container of vinegar.

Spray water from the tool/wand until the vinegar is gone.3.

Repeat the process with 1 quart of clear water to void all lines of vinegar.4.

Water and Chemical System: 5-2

Page 36

Chemical System Troubleshooting

1.0. SYSTEM WILL NOT PRIME

1.1. Check valves in

chemical pump are faulty.

1.2. Chemical pump

diaphragm is faulty.

1.3. Check valve in high

pressure pump (the one that

the chemical pump attaches

to) is faulty.

1.4. Filter on feed line in

chemical jug is clogged.

1.5. Feed line from chemical

jug is loose, pinched or cut.

1.6. Three-way prime valve

is faulty.

If the chemical system has been run dry, it may be necessary to prime the chemical

system to purge all of the air from the system.

Remove valves and inspect. Clean or replace as

necessary.

Remove and inspect. Replace as necessary.

Remove valve and inspect. Clean or replace as

necessary.

Inspect and clean.

Inspect and repair.

Check valve for leaks between ports. Replace as

necessary.

2.0. CHEMICAL FLOW IS UNSTAbLE OR LOW

2.1. Air in lines. Check that all ttings and connections are tight and in

good condition. Repair or replace as necessary.

2.2. Filter screen in

chemical jug is partially

clogged.

2.3. Three-way chemical

valve is faulty.

2.4. Chemical metering

valve is faulty or partially

obstructed.

2.5. High pressure check

valve is faulty.

Inspect and clean.

Inspect valve for leaks between ports. Replace as

necessary.

Inspect valve and clean or replace as necessary.

Remove and inspect. Clean or replace as necessary.

5-3: Water and Chemical System

Page 37

3.0. CHEMICAL jUg FILLS WITH WATER

3.1. Three-way chemical

valve is defective.

3.2. Inlet check valve in

chemical pump is faulty.

Inspect valve for leaks between ports. Replace as

necessary.

Remove and inspect valve. Clean or replace as

necessary.

4.0. CHEMICAL IN WATER BOX

4.1. Chemical pump

diaphragm is faulty.

4.2. High-pressure check

valve is faulty.

Remove and inspect. Replace as necessary.

Remove and inspect. Clean or replace as necessary.

Water and Chemical System: 5-4

Page 38

6 - Water Pump Maintenance

The CDS’ water pump features a dynamic low-pressure seal retainer, an innovative

intermediate ring, and superior low-pressure and high-pressure seals. With its ceramic

plungers and nickel-plated forged brass manifold, this high-temperature pump is ideal for

use in carpet cleaning.

You must perform daily and periodic maintenance

on the pump to maintain maximum performance

of seals and valves.

This section of the manual explains:

Daily Maintenance

Periodic Maintenance

Water Pump Troubleshooting

DAILY MAINTENANCE

Check the oil level and the condition of the 1.

oil. The oil level should be up to the center

of the sight glass on the back of the pump.

Use a SAE15W40 oil.2.

If the oil becomes discolored and contaminated, one of the oil seals may be damaged.

Refer to the Pump Owner’s Manual, included with the CDS 4.8 / 4.6 Owner’s Manual, for

more information.

Do not operate the pump if the crankcase has been contaminated with water.

Do not leave contaminated oil in the pump housing or leave the housing empty. Remove

contaminated oil as soon as it is discovered and replace it with clean oil.

Do not turn the drive shaft while the oil reservoir is empty.

Protect the pump from freezing.

6-1: Water Pump Maintenance

Page 39

PERIODIC MAINTENANCE

Change the oil after the rst 50 hours of operation, with the pump stopped and the oil still

warm, and after every 300 operating hours or 3 months of operation. When changing the

oil, remove the drain plug on the oil drain hose so all oil and accumulated sediment will

drain out.

The initial oil change is recommended for no other reason than to eliminate impurities that

may be in the oil during the running-in phase. If these impurities are not removed, but are

allowed to remain in the oil, they may cause premature wear to the moving parts and the

oil seals.

If the pump works in conditions with high humidity and with sharp temperature changes,

condensation may appear inside the crankcase. Condensation mixing with the oil can

change the oil’s properties, which is easy to detect because the oil changes to a white,

milky color.

If the pump does not have excessive water leaking from the packings, and the oil becomes

milky, the oil has to be changed more frequently.

Water Pump Maintenance: 6-2

Page 40

Water Pump Troubleshooting

1.0.WILL NOT COME UP TO NORMAL CLEANINg PRESSURE

1.1.Pressure adjusting valve

is defective or dirty.

1.2.Worn seals or valves in

pump.

1.3. Pump rpm is too low. Check engine rpm and adjust as necessary. Check for

1.4. Primary system control

orice is missing or loose*.

1.5. Primary orice is worn.* Measure orice size and replace as necessary.

*Applies to SALSA option only.

Disassemble valve. Repair or replace as necessary.

Test pump output volume directly from pump at normal

operating rpm. If volume is below manufacturers

specications, replace seals and inspect for defective

valves.

loose pump belt. Adjust tension as necessary.

Remove lter and inspect. Tighten or replace as

necessary.

2.0. NO PRESSURE READINg ON PSI gAUgE

2.1. Pump switch is not

turned on.

2.2. No water in water box. Refer to section 5 of this manual.

2.3. Pump belt is broken. Replace belt.

2.4. Pump clutch is not

activated. There is no water

in water box

2.5. Pump clutch is not

activated. There is water in

the water box.

Turn on switch

Check system back to source to locate cause of

interruption to water ow.

2.5.1. Check for 12 volts at clutch. If 12 volts is present,

replace clutch.

2.5.2. If 12 volts is not present, check power to the lowwater relay. If there is 12 volts at the relay, check low

water switch in water box.

2.5.3. If low water switch has no continuity when oat is

up, replace the switch. If switch is good, replace the low

water relay.

6-3: Water Pump Maintenance

Page 41

3.0. PSI gAUgE READS NORMAL; LOW PRESSURE FROM TOOL/

WAND

3.1. There is a restriction in

the cleaning tool/wand.

3.2. There is a defective quick

connect in the system.

3.3. There is a restriction in

one of the solution hoses.

3.4. There are hard water

deposits restricting the

system between the heat

exchanger and the highpressure solution connection

at the front of the machine.

Inspect tool jet and clean or replace as necessary.

Inspect any lters in the cleaning tool and clean or

replace as necessary.

Inspect each quick connect and replace as necessary.

Remove quick connects and inspect hoses. Clean or

replace as necessary.

Descale the machine. If this doesn’t solve the problem,

disassemble this portion of the system and locate

restriction.

4.0. PRESSURE PULSATION

4.1. Water in the water-box

is too hot and is approaching

boiling point.

4.2. There is an air leak

between the water box outlet

and the pump inlet.

4.3. One of the intake or outlet

valves in the high-pressure

pump is defective or is being

held open by debris.

Check temperature of water in the water-box.

Physically check all hoses and ttings for cuts, breaks,

cracks or tightness. Repair as necessary.

Remove each valve and inspect for correct operation.

5.0.WATER bOx EMPTY OR FILLS SLOWLY

5.1. There is a restriction in

the water supply system.

5.2. The oat valve in the

water box is defective

Water Pump Maintenance: 6-4

Inspect the supply system from the source through the

incoming quick connect for kinks, clogs or restricted

lters. Clean or repair as necessary.

Replace.

Page 42

6.0. WATER bOx OvERFLOWS

6.1. There is either debris

caught in the valve or the

valve seal is bad.

6.2. The oat has absorbed

water and has lost buoyancy.

6.3. The oat has come out

of adjustment.

Replace.

Replace.

Re-adjust oat as necessary.

6-5: Water Pump Maintenance

Page 43

7145 Rev. C

7 - Assemblies and Parts Lists

CDS Machine Assembly - Front ViewFigure 7-1.

7-1: Assemblies and Parts Lists

Page 44

7145 Rev. C

CDS Machine Assembly - Rear ViewFigure 7-2.

Assemblies and Parts Lists: 7-2

Page 45

CDS Machine Assembly Parts List

Item Part Number Description Qty Item Part Number Description Qty

1 - - - Assembly, Recovery Tank - CDS 4.8 1

2 - - - Pump & Blower Assembly - CDS 4.8 1

3 000-068-588 Hose, 3/8" X 36" Lg. Throb - CDS 1

4 000-068-030 Hose, 5/32" ID Vacuum - Bulk 10 ft

5 000-068-459 Hose, 3/4" ID Green Stripe - Bulk 18 ft

6 000-068-085 Hose, 3/8" Hi Temp Black - Bulk 73"

7 000-068-706 Hose, 3/16" X 70" Lg. Teon W/ F JIC Ends 1

8 000-033-005 Clamp, Size #5 Hose 2

9 000-033-020 Clamp, Size #16 Hose 2

10 000-033-013 Clamp, #48 Hose (3") 2

11 000-068-764 Hose, Ø3.0" X 15 Lg. Flexible Wire Reinforce 34"

12 000-068-777 Hose, 1" X 45" Lg. Suction 1

13 000-033-132 Clamp, 1-1/2" T-Bolt 2

7-3: Assemblies and Parts Lists

Page 46

6977 Rev. B

CDS Recovery Tank Assembly - Front ViewFigure 7-2.

Assemblies and Parts Lists: 7-4

Page 47

6977 Rev. B

CDS Recovery Tank Assembly - Rear ViewFigure 7-3.

7-5: Assemblies and Parts Lists

Page 48

CDS Recovery Tank Assembly Parts List

Item Part Number Description Qty Item Part Number Description Qty

1 000-159-130 Tank, 100 Gallon Universal Recovery - Weldment 1

2 Assembly, Recovery Tank Cover - 100 Gallon 1

3 000-001-135 Adapter, Tank To Ø3.0 X 90° Blower Hose 1

4 000-049-152 Filter, Recovery Tank Basket 1

5 See Notes Assembly, Vacuum Relief Valve - URT 1

6 000-049-153 Filter, Flat - Universal Recovery Tank 1

7 000-015-932 Bracket, Flat Filter Securing 1

8 000-049-154 Deector, Air - Universal Recovery Tank 1

9 000-057-206 Gasket, Adapter - URT 2

10 000-140-023 Rivet, Ab8-6a Aluminum Pop 6

11 000-106-046 Plug, 1-1/4" NPT 1

12 000-157-091 Float, Lever Switch 1

13 000-033-023 Clamp, 3/4" Nylon Hose 4

14 000-143-126 Screw, #10-24UNC X 0.50" Lg. Hex Head 6

15 See Notes Label, Set CDS 4.6/4.8 Common 1

16 000-086-008 Latch, Bungie 1

31 601-050-105 Assembly, Water Box 1

32 000-166-002 Assembly, Soap Jug Tray 1

33 601-050-111 Assembly, Dual Heat Exchanger 1

34 000-174-001 Washer, #10 Flat 6

35 000-067-031 Hinge, Dash Box 1

36 000-094-113 Nut, 1/4"-20UNC Neoprene Wellnut 4

37 000-143-166 Screw, #10-24UNC X 3/8" Lg. Hex Head 3

38 000-174-060 Washer, 1/4" Rubber Backed 4

39 000-106-049 Plug,1" NPT Black Nylon 1

40 000-143-002 Screw, 1/4"-20UNC X 1.00" Lg. Hex Head 8

41 000-094-009 Nut, 1/4"-20UNC Nylock 8

42 000-174-036 Washer, #10 Flat Rubber Backed 3

43 000-094-034 Nut, #10-24UNC Nylock S/S 3

44 000-174-015 Washer, #10 Outside Star 5

45 000-094-004 Nut, #10-24UNC Hex 5

46 000-143-064 Screw, #10-24UNC X 050" Lg. Flat Head 4

17 000-143-539 Screw, #6-32UNC X 0.50" Lg. Button Head 2

18 000-094-063 Nut, #6-32UNC Nylock 2

19 000-174-019 Washer, 1/4" Lock 2

20 000-174-003 Washer, 1/4" Flat 18

21 000-106-019 Plug, 1-1/2" NPT 1

22 000-052-763 Nipple, 1-1/2" IPS Close S/S 1

23 000-169-022 Valve, 1-1/2" Full Port Ball 1

24 000-052-226 Insert, 1-1/2" NPT X 1-1/2" Barb (Grey) 1

25 000-052-082 Elbow, 1/4" NPT Street X 45° 1

26 000-052-102 Insert, #46 (1/4" NPT X 3/8" Barb) 3

27 000-052-085 Elbow, 1/4" NPT Street 1

28 See Notes Label, Maintenance & Lube Schedule 1

29 000-143-333 Screw, 1/4"-20UNC X 0.50" Lg. Hex Head 2

30 000-174-029 Washer, 3/8" Rubber Backed 2

Assemblies and Parts Lists: 7-6

47 000-068-459 Hose, 3/4" ID Green Stripe 1

48 000-033-020 Clamp, Size #16 Hose 2

49 000-068-017 Hose, 3/8" Bulk 3.5 ft

50 000-033-005 Clamp, Size #5 Hose 2

51 000-143-114 Screw, #10-24UNC X 0.50" Lg. Flat Head 2

52 601-013-001 Stabilizer, Instrument Panel To Recovery Tank 1

53 000-068-018 Hose, 1/2" ID Rubber - Bulk 3.75 ft

54 000-068-734 Hose, 1/2" X 42.5 Lg. W/ 3/8" NPT & 3/8" SAE F Ends 1

55 000-068-326 Hose, 3/8" Id. Clear W/ Braid 1

56 - - - Assembly, Dash Box 1

57 000-068-203 Hose, 3/16" X 34" Lg. 1/4" FJIC X 1/4" FJIC 1

58 - - - Assembly, Instrument Panel 1

59 000-049-118 Filter, Chemical Inlet High Pressure 1

Page 49

8

1

7

6

3

4

9

10

11

9

5

2

7151

CDS Recovery Tank Cover AssemblyFigure 7-4.

CDS Recovery Tank Cover Assembly Parts List

Item Part Number Description Qty Item Part Number Description Qty

1 000-041-447 Cover, 100 Gallon Universal Recovery Tank - Weldment 1

2 000-078-039 Vacuum Inlet Stopper Assembly - Recovery Tank 1

3 000-057-015 Gasket, 1-1/2” Bulkhead Fitting 2

4 000-052-219 Adapter, 2” NPT x 2” F Slip 2

5 000-143-539 Screw, #6-32UNC x 0.50” Lg. Button Head Allen 2

6 000-086-008 Latch, Bungie - Strike 1

7 000-094-063 Nut, #6-32UNC Nylock 2

8 000-052-222 Elbow, 2” Barb x 2” FPT 2

9 000-057-202 Gasket, End - Recovery Tank 2

10 000-057-203 Gasket, Middle - Recovery Tank 3

11 000-057-205 Gasket, Side - Recovery Tank - 100 Gallon 2

7-7: Assemblies and Parts Lists

Page 50

6988 Rev. C

CDS Instrument Panel Assembly - Front ViewFigure 7-5.

Assemblies and Parts Lists: 7-8

Page 51

6988 Rev. C

CDS Instrument Panel Assembly - Rear ViewFigure 7-6.

7-9: Assemblies and Parts Lists

Page 52

CDS Instrument Panel Assembly Parts List

Item Part Number Description Qty

1 000-100-168 Panel, Instrument 1

2 See Notes Assembly, Hi-psi Manifold 1

3 See Notes Assembly, By-Pass Valve 1

4 000-105-012 Plate, Machine Serial ID 1

5 000-074-030 Meter, Chemical Flow Raw 1

6 000-174-008 Washer, 5/8" Flat 4

7 000-169-064 Valve, 3/8" NPT Full Port Ball 1

8 000-052-051 Quick Connect, 440 Female w/ EPDM O-Ring 2

9 000-106-029 Plug, 1" Hole 1

10 000-052-052 Quick Connect, 660 3/8" Brass w/ EPDM O-Ring 1

11 000-052-281 Nipple, 3/4" NPT X 3/4" Male Garden Hose 1

12 000-052-104 Insert, #66 (3/8" NPT X 3/8" Barb) 1

13 000-052-096 Insert, #F23 (1/8" FPT X 3/16" Barb) 1

14 000-060-002 Grommet, Large Wiring 1

15 000-057-055 Gasket, Garden Hose 1

Item Part Number Description Qty

32 000-169-160 Valve, Chemical Metering 1

33 000-052-069 Nipple, 1/8" NPT Hex 2

34 000-174-030 Washer, 5/8" Id X 7/8" OD X 0.010" Thk 1

35 000-094-098 Nut, 7/16"-24 UNF - 2 watt Metering Valve 1

36 000-052-531 Elbow, 1/8" NPT X 1/4" SAE 1

37 000-052-084 Elbow, 1/8" NPT Street 1

38 000-052-099 Insert, #26 (1/8" NPT X 3/8" Barb) 3

39 000-068-491 Hose, 3/16" X 10" Lg Teon 1/4" NPT X 1/4" JIC F 1

40 000-068-518 Hose, 3/16" X 18.25" Lg. Teon w/FJIC Ends 1

41 000-052-022 Tee, 3/8" Insert 1

42 000-052-089 Elbow, 1/8" NPT Female 1

43 000-174-001 Washer, #10 Flat 6

44 000-143-166 Screw, #10-24 UNC X 3/8" Lg. Hex Head 2

45 000-068-017 Hose, 3/8" Bulk 1

46 000-068-017 Hose, 3/8" Bulk 1

16 000-074-007 Gauge, Pressure 0 -1500 psi 1

17 000-052-272 Cup, Gravity Feed Oil Blower Lube Port 1

18 000-027-014 Cap, Garden Hose 1

19 000-174-050 Washer, 1" Flat 1

20 000-135-052 Regulator, Hi psi Snubber 1

21 000-169-009 Valve, 3/4" FPT Swing Check 1

22 000-052-338 Insert, #1212 (3/4" NPT X 3/4" Barb) 1

23 000-052-088 Elbow, 1/4" FPT X FPT 1

24 000-174-005 Washer, 3/8" Flat 2

25 000-052-128 Nipple, 3/8" NPT X 3/8" M Propane 2

26 000-174-063 Washer, 1.5" OD. X 1.073" ID X 0.075" Thk. 1

27 000-174-012 Washer, 1/2 SAE H/D 2

28 000-140-015 Rivet, 1/8" X 1/4" Lg. Pop 2

29 000-169-201 Valve, 3/4" Heater Panel Mount 1

30 000-052-756 Insert, 3/4" NPT X 3/4" Elbow 2

31 000-169-017 Valve, 3-Way Ball O-Ring Style 1

47 000-033-005 Clamp, Size #5 Hose 4

48 000-052-530 Nipple, 1/4" SAE X 1/8" NPT 1

49 000-131-027 Trimlok, 1/8" X 3/16" Lg. 1

50 000-174-014 Washer, #10 Lock 2

51 000-174-007 Washer, 1/2" Flat 1

52 000-143-327 Screw, #10-32UNF X 0.50" Lg. Hex Head 2

53 Label, Instrument Panel-CDS 4.6/4.8 1

54 Label, Bottom-Instrument Panel-CDS 4.6/4.8 1

55 000-068-757 Hose, 1/2" X 20.5" Lg. Rubber W/3/8" NPT X 3/8" S 1

Assemblies and Parts Lists: 7-10

Page 53

2

43

5

6

7

6

10

1

11

13

1217

1614

15

8

9

6091 Rev. B

CDS Hi-PSI Manifold AssemblyFigure 7-7.

CDS Hi-PSI Manifold Assembly Parts List

Item Part Number Description Qty Item Part Number Description Qty

1 000-052-528 Nipple, 3/8” MJIC x 3/8” NPT 1

2 000-052-071 Nipple, 1/4” NPT Hex 2

3 000-090-008 Manifold, Hi Pressure 1

4 000-106-002 Plug, 1/4” NPT Hex 1

5 000-052-530 Nipple, 1/8” MNPT x 1/4” SAE 1

6 000-052-074 Nipple, 3/8” NPT Hex 2

7 000-169-186 Valve, 3/8” FPT x 3/8” FPT 100 PSI Check 1

8 000-149-039 Sender, Temperature 1

10 000-052-113 Cross, 3/8” FPT 1

11 000-050-060 Bushing, 3/8” NPT x 1/8” FPT 1

12 000-052-582 Nipple, Tee Jet Style Collar x 1/8” NPT 1

13 000-094-028 Nut, Brass Jet Assembly 1

14 000-052-153 Housing, Stabilizer Nozzle 1

15 000-052-586 Nipple, 1/8” FPT x 1/4” SAE 1

16 000-049-052 Filter Cartridge, 1/4” 1

17 000-180-009 Orice, 0.027” Plate 1

9 000-052-061 Bushing, 3/8” NPT x 1/4” FPT 1

7-11: Assemblies and Parts Lists

Page 54

CDS By-Pass Valve AssemblyFigure 7-8.

3

2

10

5

6

9

7

11

4

1

5

8

12

14

13

CDS By-Pass Valve Assembly Parts List

6989 Rev. A

Item Part Number Description Qty

1 000-169-188 Valve, PSI Regulator 0-1500 psi - Modied 1

2 000-015-515 Bracket, By-Pass Valve Mounting 1

3 000-027-008 Cap, 3/8” FPT 1

4 000-052-764 Elbow, 1/4” SAE x 3/8” MNPT x 90° 1

5 000-052-023 Tee, 3/8” NPT Male Street 3

6 000-052-528 Nipple, 3/8” M JIC x 3/8” NPT 1

7 000-052-105 Insert, #68 (3/8” NPT x 1/2” Barb) 1

8 000-169-027 Valve, Thermal Relief 165° F 1

9 000-052-099 Insert, #26 (1/8” NPT x 3/8” Barb) 1

10 000-106-008 Plug, 3/8” NPT Allen Head 1

11 000-143-126 Screw, #10-24UNC x 0.50” Lg. Hex Head 2

12 000-052-128 Nipple, 3/8” NPT x 3/8” Male Propane 1

13 000-174-001 Washer, #10 Flat 2

14 000-174-014 Washer, #10 Lock 2

Assemblies and Parts Lists: 7-12

Page 55

3802 Rev. N

CDS 4.8 Pump and Blower Assembly - OverviewFigure 7-9.

7-13: Assemblies and Parts Lists

Page 56

CDS 4.8 Pump and Blower Figure 7-10.

Assembly - Parts View

3802 Rev. N

Assemblies and Parts Lists: 7-14

Page 57

CDS 4.8 Pump and Blower Assembly Parts List

Item Part Number Description QtyItem Part Number Description Qty

1 000-055-028 Frame Pump And Blower 1

2 000-008-020 Bearing, Pillow Block - 1-3/16" Bore 2

3 000-020-019 Bushing, #H X 7/8" Bore 1

4 000-052-505 Zerk Fitting, 1/8" MPT Grease Fitting - Straight 2

5 000-094-100 Nut, 3/8-16, Nylock 5

6 000-111-147 Blower, 4007 Dominator 1

7 000-139-021 Snap Ring, 1-3/16" Shaft 2

8 000-143-018 Screw, 3/8-16UNC X 1" Hex Head - Grade 8 4

9 000-174-004 Washer, 5/16" Flat 12

10 000-001-042 Adapter, Blower Outlet - CDS 4.8 1

11 000-150-040 Shaft, Drive Sprocket - CDS 4.8 1

12 000-108-065 Protector, Cat Pump Belt Shield 1

13 000-154-146 Spacer, Powerpack - Front - CDS 4.8 Ford 2 1

14 000-154-147 Spacer, Powerpack - Rear - CDS 4.8 Ford 200 1

15 000-033-057 Clamp, 1" Cushion Loop 1

16 000-052-061 Bushing, 3/8" NPT X 1/4" FPT 2

32 000-174-001 Washer, #10 Flat 1

33 000-143-132 Screw, #10-24UNC X 0.75" Lg. Hex Head 1

34 000-077-010 Key, 1/4" X 1-1/2" Lg. 1

35 000-020-020 Bushing, 7/8" Taper-Lock 1

36 000-020-026 Bushing, 1-1/8" Taper-Lock 1

37 000-077-012 Key, 3/16" X 2.5" Lg. Class 2 Fit 1

38 000-109-057 Pulley, 40 Tooth Gt2 8mx-10s-21 Engine & Blower 1

39 000-109-058 Pulley, 56 Tooth Gt2 8mx-56s-21 Engine & Blower 1

40 000-143-373 Screw, 1/4"-20UNC X 2"G. Hex Head Grd 5 1

41 000-143-548 Screw, 1/4"-20UNC X 2.00" Lg. Hex Head 1

42 000-149-010 Sensor, CDS Magnetic Tach 1

43 000-154-153 Spacer, Tach, Sensor - CDS 4.8 1

44 000-109-009 Pulley, 2.75" X 0.88" Pump Drive 1

45 000-015-801 Bracket, Blower Mounting - CDS 4.8 2

46 000-015-930 Bracket, Tach, Magnetic Extension N/S - CDS 1

47 000-010-052 Belt, Polychain Gt 1

17 000-052-083 Elbow, 3/8" NPT Street X 45° 1

18 000-052-084 Elbow, 1/8" NPT Street 1

19 000-052-293 Insert, #23 (1/8" NPT X 3/16" Barb) 2

20 000-094-010 Nut, 1/4"-20UNC Hex S/S 2

21 000-143-096 Screw, 3/8"-16UNC X 1.00" Lg. Hex Head 2

22 000-143-260 Screw, 3/8"-16UNC X 8.00" Lg. Hex Head W/ 6" Thr 1

23 000-174-021 Washer, 3/8" Lock 7

24 000-143-025 Screw, 3/8"-16UNC. X 1.25" Lg. Hex Head Gr. 8 4

25 000-143-013 Screw, 5/16"-18UNC X 1.00" Lg. Grade 8 5

26 000-174-018 Washer, 5/16" S/S Lock 5

27 000-174-002 Washer, 1/4" Flat 6

28 000-174-017 Washer, 1/4" Lock 2

29 000-143-240 Screw, 1/2"-13UNC X 1.75" Lg. Hex Head - Grade 4

30 000-174-012 Washer, 1/2 SAE H/D 4

31 000-094-037 Nut, 1/2-13 UNC. 2 Way Locking 4

48 000-068-149 Hose, CDS Blower Oil Drain 2

49 000-077-001 Key, #3 & #4 Vacuum Pump Drive 2