Page 1

HYDRAMASTER

11015 47th Avenue W, Mukilteo, WA 98275

CDS 4.6

Overdrive

Corporation

Machine Serial Number________________________

Copyright© 2000

HYDRAMASTER© Corporation

Mukilteo, Washington

D-182-012

No part of this manual may be reproduced or used in any form or by any means (i.e. graphic, electronic, photocopying or

electronic retrieval systems) without the express written permission of the HYDRAMASTER© Corporation. All rights

reserved.

Revised January 25, 2001

Page 2

Clutch Drive System

Table of Contents

GENERAL INFORMATION .............................................................. Section 1

Telephone Numbers............................................................. 1-2

Precautions ........................................................................ 1-3

System Overview................................................................ 1-7

Machine Specifications ........................................................ 1-8

Spare Parts Recommendation ............................................... 1-11

Spare Parts List ......................................................... 1-11

Responsibilities ................................................................... 1-13

Local Water Precautions....................................................... 1-15

Wastewater Disposal Advisory..................................... 1-17

Map ......................................................................... 1-19

CLEANING AND CHEMICALS ........................................................ Section 2

pH Chart ............................................................................ 2-4

OPERATING INSTRUCTIONS ......................................................... Section 3

Start Up............................................................................. 3-2

Shut Down......................................................................... 3-3

FREEZE GUARD ........................................................................... Section 4

Vacuum Freeze Guard Procedure ........................................... 4-1

Freeze Protection of Pump-In System..................................... 4-3

HydraMaster Corporation

CDS 4.6

10/15/99

Page 3

Clutch Drive System

WATER AND CHEMICAL SYSTEM ........................................................ Section 5

Water Flow Diagram ...........................................................................5-3

Proportioner Diagram ..........................................................................5-4

Chemical Tank Troubleshooting ............................................................5-5

HIGH PRESSURE PUMP ...................................................................... Section 6

Pump Maintenance ............................................................................. 6-1

Service ............................................................................................6-3

Cat Pump Assembly Drawing and Parts List ............................................6-7

Pump Troubleshooting ...................................................................... 6-10

CDS MACHINE ASSEMBLIES AND PARTS ............................................. Section 7

Machine Assembly Drawings and Parts Lists ...........................................7-1

CDS Belts ....................................................................................... 7-26

Cleaning Wand Assembly Drawings and Parts Lists ................................ 7-28

Bypass Valve Assembly Drawing and Parts List ..................................... 7-31

VACUUM SYSTEM ............................................................................ Section 8

Lubrication Instructions .......................................................................8-4

Blower Troubleshooting....................................................................... 8-3

Roots Blower Instruction Booklet

ELECTRICAL SYSTEM ........................................................................ Section 9

Wiring Schematic ...............................................................................9-3

10/15/99

Wiring Diagrams ................................................................................9-5

HydraMaster Corporation

CDS 4.6

Page 4

Clutch Drive System

ELECTRICAL SYSTEM (cont.)

Electrical Troubleshooting ....................................................................9-7

MACHINE MAINTENANCE ............................................................... Section 10

Operational Maintenance ......................................................................10-2

Daily, Weekly .................................................................................10-2

Monthly, Quarterly, Yearly................................................................ 10-3

Appearance Maintenance......................................................................10-4

Daily, Weekly .................................................................................10-4

Long Term Maintenance Schedule..........................................................10-5

Drive Shaft Maintenance....................................................................... 10-6

Troubleshooting .................................................................................. 10-7

Maintenance Logs

HOW TO ORDER PARTS .................................................................. Section 11

WARRANTY INFORMATION ............................................................. Section 12

Golden Guarantee©

ACCESSORIES ............................................................................... Section 13

PRODUCT UPDATES ....................................................................... Section 14

HydraMaster Corporation

CDS 4.6

10/15/99

01/25/01

Page 5

Clutch Drive System

List of Figures

Fig 1-1 Location of Water Softener.......................................................... 1-17

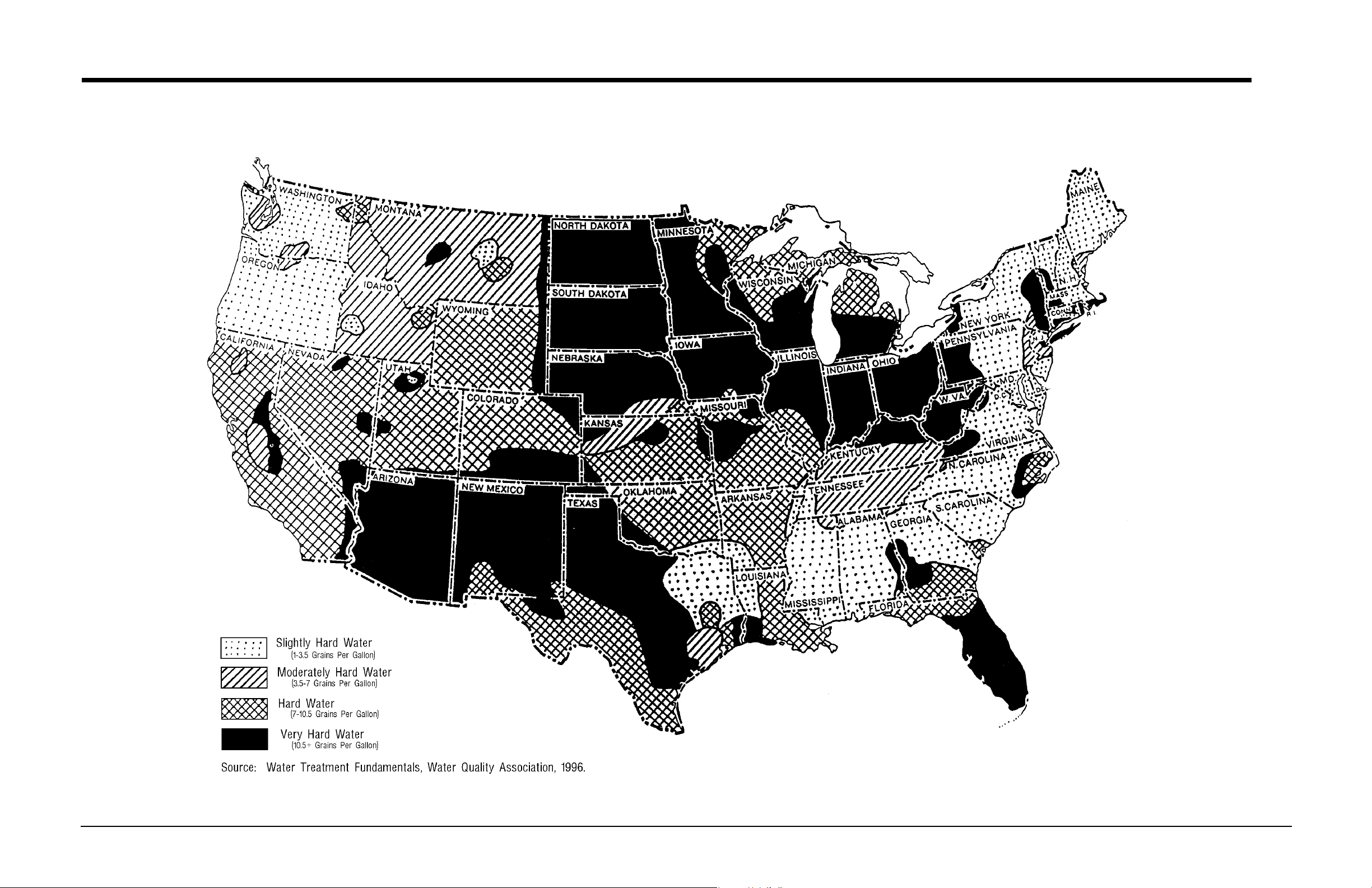

Fig 1-2 Hard Water Map ......................................................................... 1-19

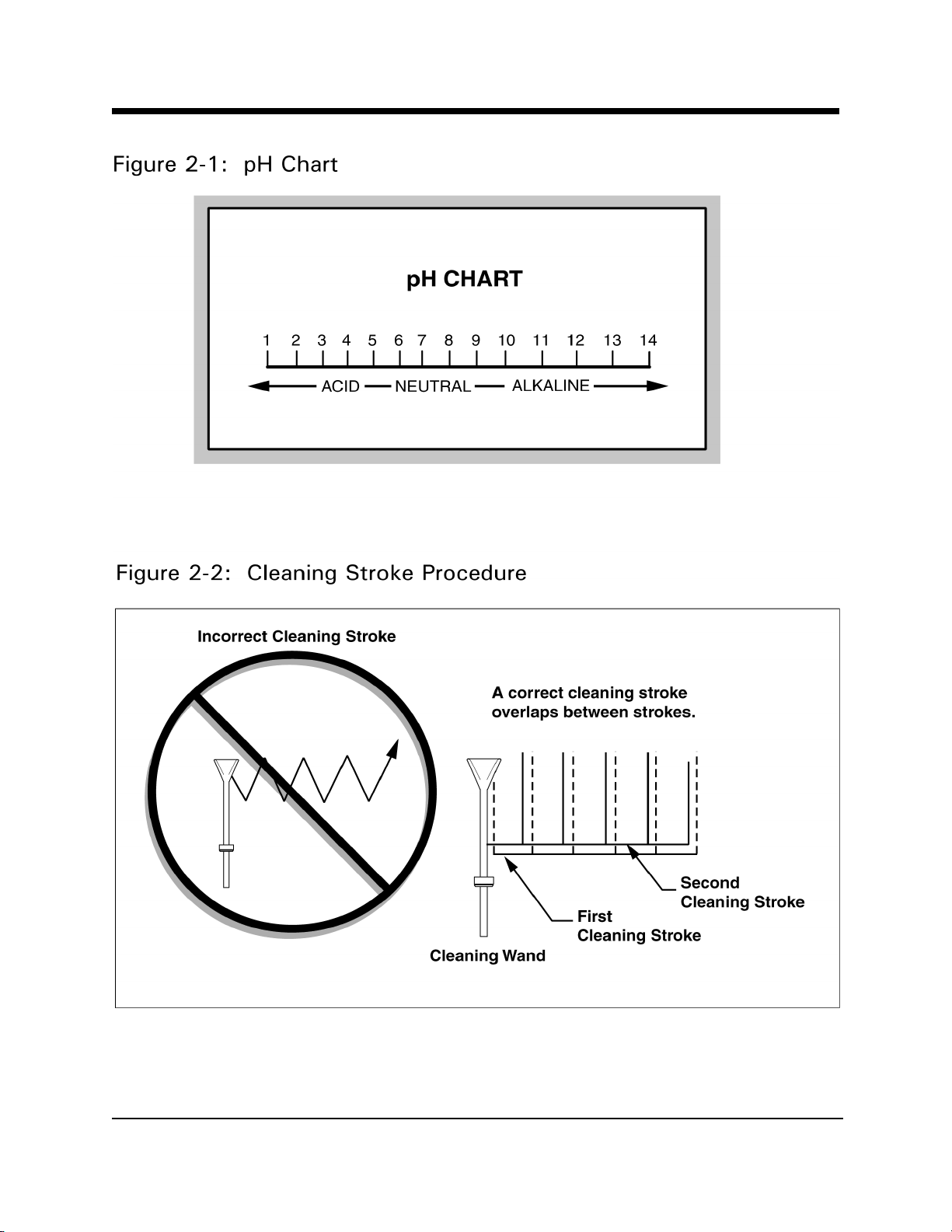

Fig 2-1 pH Chart .................................................................................... 2-4

Fig 5-1 Water Flow Diagram ................................................................... 5-3

Fig 5-2 Proportioner Diagram .................................................................. 5-4

Fig 6-1 Servicing the Valves ................................................................... 6-3

Fig 6-2 Servicing the Low Pressure and High Pressure Seals ...................... 6-4

Fig 6-3 Cat Pump .................................................................................. 6-7

Machine Assemblies and Parts:

Fig 7-1 CDS 4.6 Machine Assembly - Front View ...................................... 7-1

Fig 7-2 CDS 4.6 Machine Assembly - Rear View....................................... 7-2

Fig 7-3 CDS 4.6 Machine Assembly - Top and Front Views........................ 7-3

Fig 7-4 Recovery Tank Assembly - Front View .......................................... 7-4

Fig 7-5 Recovery Tank Assembly - Rear View........................................... 7-5

Fig 7-6 Recovery Tank Lid Assembly ....................................................... 7-8

Fig 7-7 Instrument Panel Assembly .......................................................... 7-9

Fig 7-8 Dual Heat Exchanger Assembly .................................................... 7-12

Fig 7-9 Salsa X Assembly ....................................................................... 7-14

Fig 7-10 CDS 4.6 Pump and Blower Assembly ........................................... 7-16

Fig 7-11 Dash Box Assembly .................................................................... 7-20

Fig 7-12 Dash Panel Assembly .................................................................. 7-21

Fig 7-13 Mix Tank Assembly .................................................................... 7-22

Fig 7-14 Tachometer Sensor and Bracket Assembly .................................... 7-24

Fig 7-15 Horizontal Pump In Tank Assembly............................................... 7-25

Fig 7-16 Vacuum Relief Valve Assembly .................................................... 7-27

10/15/99

9/5/00

HydraMaster Corporation

CDS 4.6

Page 6

Clutch Drive System

Cleaning Wand Assemblies and Parts:

Fig 7-17 Valve Assembly .......................................................................... 7-30

Fig 7-18 Solution Valve Assembly ............................................................. 7-31

Fig 7-19 Valve Stem Assembly ................................................................. 7-32

Fig 7-20 Hydra Hoe Wand Assembly ......................................................... 7-33

Fig 7-21 Bypass Valve Assembly ............................................................... 7-35

Fig 9-1 Wiring Schematic ....................................................................... 9-3

Fig 9-2 Wiring Diagram, Sheet 1 ............................................................. 9-5

Fig 9-3 Wiring Diagram, Sheet 2 ............................................................. 9-6

Fig 10-1 Drive Shaft Assembly.................................................................. 10-6

HydraMaster Corporation

CDS 4.6

10/15/99

9/5/00

Page 7

Introduction

CDS 4.6

Section 1-1

his manual contains operating instructions as well as information required

T

for proper maintenance, adjustment and repair of this unit. Since the first

and most important part of repair work is the correct diagnosis of the problem,

component manual troubleshooting charts have been included for your convenience.

Unlike a garden tractor, lawn mower or cement mixer, all having one or two

functions to perform, the truckmounted carpet cleaning plant has many functions to perform simultaneously.

The engine has to run at a consistent RPM.

The vacuum has to pull air and dirty water back from cleaning site.

The water pump must provide a stable pressure at proper water flow

for cleaning.

The chemical has to be injected into the water stream at the right

concentration.

The heating system must provide a consistant water temperature.

The vacuum tank must store dirty water until drained.

As you can see, it is not just a turn-key operation with one thing to worry

about, Does it start?!

HydraMaster Corporation

10/20/99

Page 8

Page 1-2 Clutch Drive System

♦ WARNING ♦

The manufacturer uses this symbol throughout the manual to warn of possible

injury or death.

♦ CAUTION ♦

This symbol is used to warn of possible equipment damage.

10/20/99

Business Hours and Telephone Numbers

Monday - Friday (425) 775-7276 Parts

8:00 am to 5:00 pm (425) 775-7275 Service

PACIFIC STANDARD TIME 800) 426-4225 Parts / Service FAX

HydraMaster Corporation

CDS 4.6

Page 9

Clutch Drive System Page 1-3

Precautions

lthough this unit has been factory adjusted, it may require additional ad

adjustments to achieve optimum performance, for instance altitude may

A

require carburetor adjustment and ambient temperatures may require heat control adjustment. When required, consult an authorized representative.

♦ CAUTION ♦

THROUGH-FLOOR DRILLING: Be cautious when drilling holes through the van

floor. Many vans have critical components mounted directly below the van

floor that could be damaged by a misplaced drill bit. (See Product Support

Bulletins 92102, 94062 and 94063 at the end of the manual.)

♦ CAUTION ♦

LEVEL OPERATION: During operation, van or trailer must be parked on level

ground not to exceed + or - 10 degrees. Failure to insure proper leveling may

prevent proper internal lubrication of engine, vacuum and/or high pressure components.

♦ WARNING ♦

MOVING PARTS: Never touch any part of the machine that is in motion.

Severe bodily injury may result.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 10

Page 1-4 Clutch Drive System

♦ CAUTION ♦

ACID RINSE AGENTS: The increased demand for clear water rinsing results

in the need for special care when using these acid based chemicals in your

equipment. The negative side of these products is the corrosive effects the

acid can have on metals, including swivels, pumps, heat exchangers, etc.

HydraMasters ClearWater Rinse has been formulated to protect vital components. HydraMaster will not warranty parts that have been damaged from

using unprotected acid products that have obviously caused failures.

♦ CAUTION ♦

HARD WATER PROTECTION: Failure to take appropriate measures to prevent

scale build up can result in system failure and loss of warranty on affected

parts. Test the water in your immediate and surrounding areas with hard water

test strips. Assume all water obtained from wells is hard. If you are operating

in a Hard Water Area (3.5 grains or more per gallon), use a water softening

system.

♦ CAUTION ♦

FREEZE PROTECTION: There is often little warning before a cold spell. Therefore, not protecting this equipment from freezing will result in costly downtime. Placing an electric heater in the truck or parking the truck indoors will

help to insure against freezing, but should not be the primary method of freeze

protection.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 11

Clutch Drive System Page 1-5

♦ WARNING ♦

HOT SURFACES: During the operation of this equipment, many surfaces on

the machine will become very hot. When near the van for any reason care

must be taken not to touch any hot surface, such as heater, engine, exhaust,

etc.

♦ WARNING ♦

HEARING PROTECTION: The Occupational Safety and Health Administration

(OSHA) recommends the use of hearing protection when a technician is exposed to an average of 85 decibels (this is an average of exposure over an 8

hour period). This equipment can produce 85 decibels to a distance of 10 feet.

Please check with your local state agencies to see if OSHA standards apply to

your application.

♦ WARNING ♦

NO SMOKING: It is unsafe to smoke in or around the vehicle.

♦ WARNING ♦

CARBON MONOXIDE: This unit generates toxic fumes. Position the vehicle so

that the fumes will be directed away from the job site. Do not park where

exhaust fumes can enter a building through open doors, windows, air conditioning units or kitchen fans.

♦ WARNING ♦

TOXIC FUMES: Do not occupy the vehicle when the cleaning equipment is

operating. Toxic fumes may accumulate inside a stationary vehicle.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 12

Page 1-6 Clutch Drive System

♦ WARNING ♦

ENGINE EXHAUST: The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects or other reproductive harm.

♦ WARNING ♦

PORTABLE GAS TANK: Never operate this machine with a portable gas can

inside the truck. Doing so increases the risk of a fire or explosion.

♦ WARNING ♦

PORTABLE PROPANE TANK: Do not use a portable tank inside of the truck or

van. It is dangerous and illegal in most states.

♦ WARNING ♦

TRANSPORTATION OF FUEL CONTAINERS: Transportation in a vehicle of any

vented fuel container that presently has or has ever contained a flammable

liquid is strictly forbidden by HydraMaster Corporation and by federal and state

regulation.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 13

Clutch Drive System Page 1-7

System Overview

he HydraVan CDS machines are highly engineered cleaning plants designed

T

by HydraMaster Corporation. The system utilizes the most current

technology available in water heating and water recovery systems.

The water flow is as follows:

Water is fed into the machine under tap pressure. The water enters the

machine and is combined with cleaning solution as it enters the mix tank.

The cleaning solution is picked up from the mix tank by the high pressure

pump and pumped under pressure through the heating system and then

out to the cleaning tool.

After the water is applied to the carpet, it is recovered by the vacuum

system and carried back to the recovery tank.

As there is no guess work in the manufacture of these highly advanced cleaning plants, there must be none in preparing it to get the job done in the field. It

is the purpose of this manual to help you properly understand, maintain and

service your cleaning plant. Follow the directions carefully and you will be

rewarded with years of profitable, trouble-free operation.

It is imperative that no section be overlooked when preparing for operation of

this equipment.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 14

Page 1-8 Clutch Drive System

Machine Specifications

Frame: 13"W x 68"L x 38"H

Weight: 575 lbs.

Construction: Tank: Marine Aluminum with Baked-on Epoxy Finish

Chassis: Painted Steel

Cowling: Fiberglass

Power Transfer: Electric Clutch-driven shaft, Key Activated

TM

Vacuum Blower: 45 WhispAir

Water Pump: CAT® Triple Plunger 4 gallons per minute

Chemical System: Electro-mechanical, Meter Controlled

Heating System: Multiple Heat Exchanger (600 PSI pressure)

Dual Shell and Tube Exchangers

Instruments:

Main Panel:

Electronic Tachometer, 0-3000 RPM

Water Temperature Gauge, 0-320° F

Vacuum Gauge, 0-30 in Hg

Hour Meter, Machine Run-Time

Keyed Ignition, Start/Stop

, Dual Shaft

10/20/99

Electronic Circuit Protection Breaker, Re-settable

Machine Status Indicator Lamps

HydraMaster Corporation

CDS 4.6

Page 15

Clutch Drive System Page 1-9

Side Panel: Chemical Flowmeter, 0-10 GPH

Water Pressure Gauge, Liquid Filled, 0-1000 PSI

Water Pressure Adjustment

Blower Lubrication Port

Water Temperature Adjustment Knob and

(Exchanger By-pass)

High Pressure Solution Outlets, Quick-

Disconnect (2)

Fresh Water Inlet Fitting, Quick-Disconnect

Mix Tank Drain Valve

Recovery Tank: 120 gallon Aluminum

Cleaning Wand: Stainless Steel Wand.

Stainless Steel Solution Valve and Tube

Jet Splash Guards Insulated Handle Sleeves

Height Adjustable Handles

Standard Equipment: Power Transfer Package

Component Power Pack

Equipment Cowling with Armrests

Vacuum Recovery Tank

Control Console

Dual Wand Hook-up

HydraMaster Heat Exchanger System

Freeze Guard System

Wheel Chock Set

Carpet Wand

150', 2" Vacuum Hose

10' 1½ Vacuum Hose

HydraMaster Corporation

CDS 4.6

150', HP Solution Line

50' Fresh Water Hose

10' 1½ Drain Line

10/20/99

Page 16

Page 1-10 Clutch Drive System

Standard Equipment (cont.):

5 gallon Chemical Jug

Chemical Jug Holder

Chemical Jug Fill Line

Van Finish Package

Van-Sentry Package

Van Decal Package

Monogrammed Jacket

Operation Manual

Custom Equipment Color

Oversize Air Handling Package

Expanded Vacuum Recovery Tank Capacity

10/20/99

HydraMaster Corporation

CDS 4.6

Page 17

Clutch Drive System Page 1-11

Spare Parts

own-time on the unit can be very expensive, because your truck-mounted

D

unit is capable of generating several hundred dollars per day. In order to

minimize such down-time, it is strongly recommended by the manufacturer

that you purchase and keep in your truck the parts listed below.

Parts Orders

To expedite your parts needs, please call your sales representative. In most

instances, he either stocks or has access to parts through a regional service

center. If further assistance is needed, contact the factory and coordinate your

needs. If this becomes necessary, always indicate the method of shipment you

desire, i.e. UPS, Blue Label, Air Freight, Air Express, etc.

HydraMaster Parts Dept. Phone ............. (425) 775-7276

HydraMaster Parts Dept. Toll Free Fax .... 1-800-426-4225

CDS 4.6 Spare Parts List

PART NO DESCRIPTION QTY

049-023 Screen, Garden Hose 6

052-050 Quick Connect, 440 Male 2

052-051 Quick Connect, 440 Female 2

052-052 Quick Connect, 660 Male 1

052-053 Quick Connect, 660 Female 1

076-005 Spray Jet 8006E 1

078-015 Kit, Flow Meter 1

078-019 Kit, Wand Valve Plunger 1

HydraMaster Corporation

CDS 4.6

10/20/99

Page 18

Page 1-12 Clutch Drive System

CDS 4.6 Spare Parts List

PART NO DESCRIPTION QTY

078-102 Kit, Pressure By-pass Valve 1

078-270 Kit, Valve for 3CP Cat Pump 2

078-271 Kit, Seals for 3CP Cat Pump 1

157-0012 Switch, Tethered Float

157-022 Switch, Relay 1

157-040 Switch, 12 VDC Lighted 2

169-022 Valve, 1½ Full Port Ball 1

10/20/99

HydraMaster Corporation

CDS 4.6

Page 19

Clutch Drive System Page 1-13

Responsibilities

rior to the arrival of the unit, the van that it will be installed in should be

P

delivered to the installer.

Purchasers Responsibility:

It is the purchasers responsibility to Read the Owners Manual and to familiar-

ize yourself with the information contained therein. Special attention should be

paid to all Cautions and Warnings.

Sales Representatives Responsibility:

Acceptance of Shipment

1. If the unit shows any outward signs of damage, do not sign the

delivery receipt until you have closely inspected the unit and noted any

damage on the delivery receipt.

2. The salesman from whom you purchased your unit is responsible for

supervising the correct installation of the unit in your vehicle and

thoroughly training you in its operation, maintenance and precautions.

Installation

Correctly installing the unit and recovery tank in your vehicle and

securing them with bolts and tie down washers.

Checking the pump, vacuum blower and engine oil levels prior to starting

the unit.

Starting the unit to check the drive system and see that all other

systems function normally.

Checking all hoses, wands, etc. for correct operation.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 20

Page 1-14 Clutch Drive System

Training

A thorough review of the operation manual with the purchaser.

Instruction and familiarization in: how to correctly start up and shut

down the unit, how to correctly clean with the unit, where and how often

to check and change component oil levels, how the units systems work,

how to troubleshoot the unit, how to do basic repairs, safety precautions

and their importance, freezing damage and how to avoid it, hard water

damage and how to avoid it.

A thorough review of the unit warranty and warranty procedures.

A thorough review of hard water precautions and warnings.

How to determine hard water areas.

Use of water softening systems.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 21

Clutch Drive System Page 1-15

Local Water Precautions

he quality of water varies greatly. Many areas have an excess of minerals

T

in the water which results in what is commonly called hard water. These

minerals tend to adhere to the insides of heater coils and other parts of the

machines causing damage and a loss of cleaning effectiveness. This influences

the reliability and efficiency of equipment in direct proportion to the level of

hardness.

HARD WATER ADVISORY

HydraMaster recognizes that any hard water deposits which might occur within

the water system of our truckmounts is a serious problem. The precision

technology of truckmount heat exchanger systems is intolerant of any foreign

material. Hard water deposits will ultimately decrease the performance of the

system and are expected to seriously lower the reliability of the machine.

To validate a machines warranty, HydraMaster requires that all machines operating in designated Hard Water Areas (3.5 grains or more per gallon) be fitted

with a water softening system or a properly installed magnetic-type de-scaler

must be used and maintained. Periodic de-scaling or acid-rinsing alone is not

adequate in these areas. HydraMaster does not recommend any particular type

or brand, however the relative effectiveness of some types of magnetic descalers or softeners may require additional periodic use of de-scaling agents.

HydraMaster also recommends, in the strongest possible terms, that machines

in all areas be fitted with a water softening system for improved operation and

reliability.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 22

Page 1-16 Clutch Drive System

HydraMaster has included five hard water test strips with your machine. These

can be used to test the water in your immediate and surrounding areas as they

can vary greatly. Assume all water obtained from wells is hard.

♦ CAUTION ♦

Failure to take appropriate measures to prevent scale build up can result in

system failure and loss of warranty on affected parts.

HARD WATER AREA MAP

The following map defines areas in the United States which compromise fluid

related components such as hoses, fittings, heaters, pumps, valves and water

cooled engines. For other countries, hard water area maps can be obtained

from geological societies.

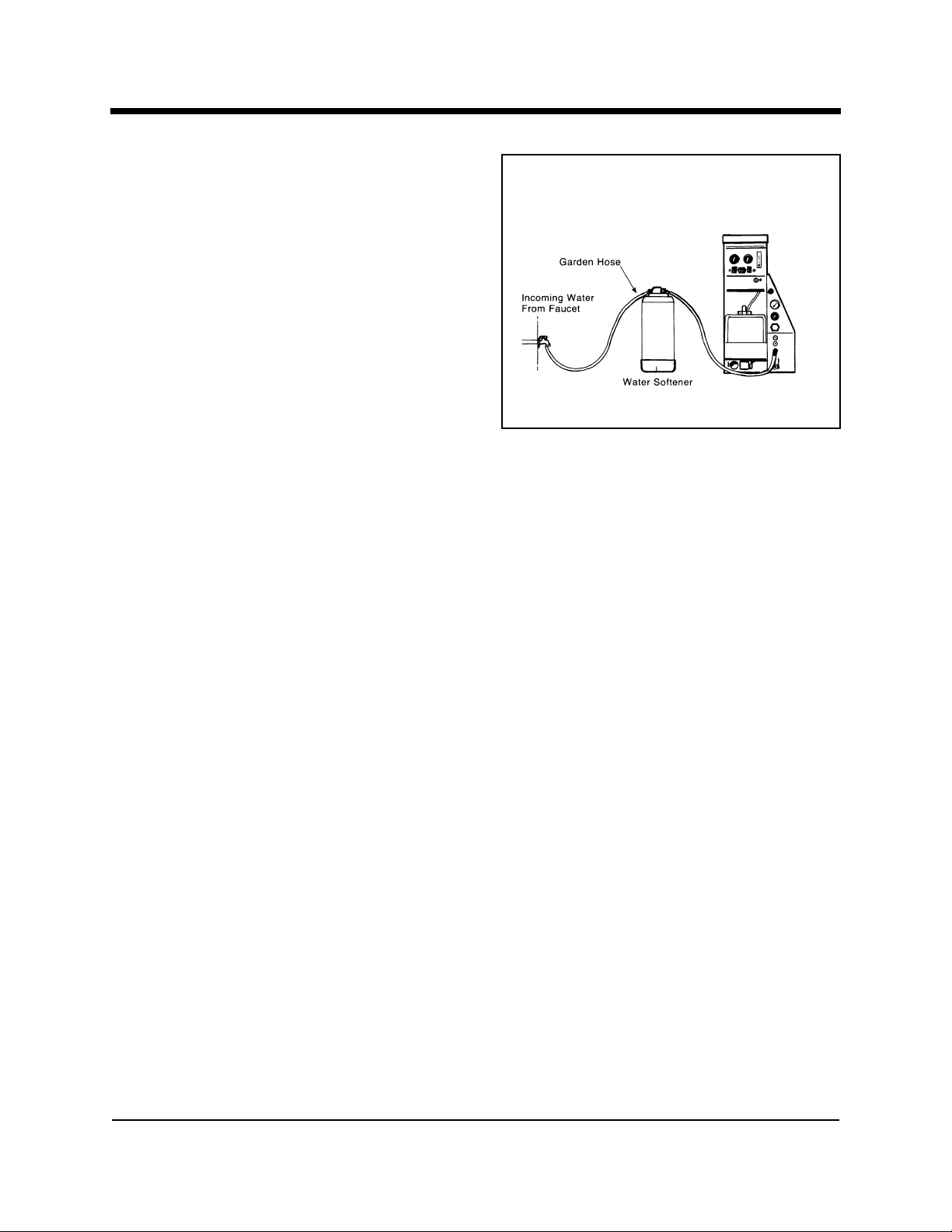

WATER SOFTENER

Cleaning efficiency and equipment life is increased, chemical use decreased,

and the appearance of cleaned carpets enhanced when water softeners are

incorporated in hard water areas. The manufacturer strongly urges the use of

water softener units in areas exceeding 3½ grains per gallon. Failure to use a

water softener in these areas will invalidate the machines warranty. Using a

hard water area map as a reference, determine the quality of water in your area

and take action immediately, if necessary.

Reports from several of our machine users commending the results of the use

of water softeners in conjunction with their machines prompts us to recommend the procedure to everyone in a hard water area.

The relatively low cost of a water softener service is more than made up for by

an increased life of machine parts, reduced chemical costs and continued cleaning

efficiency. The water softener will also increase the effectiveness of the cleaning chemicals, therefore less chemical will be needed.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 23

Clutch Drive System Page 1-17

Contact a water softener distributor in

your area for information on the rental

of a simple water treatment unit to carry

in your truck. Be sure to change the

water softener in accordance with the

capability of the softener. For example:

If the softener will treat 900 gallons of

water and the machine uses an average of 30 gallons per hour, for an average of 5 hours a day, this equals 150

gallons per day. In 6 days the machine would use 900 gallons of water.

Therefore, the softener would need to be changed every 6 working days for

maximum softening.

Figure 1-1 Location of Water

Softener

WASTE WATER DISPOSAL ADVISORY

There are laws in most communities prohibiting the dumping of recovered gray

water from carpet cleaning in any place but a sanitary treatment system.

This cleaning rinse water, recovered into your units vacuum tank, contains

materials such as detergents. These must be processed before being safe for

streams, rivers and reservoirs.

IN ACCORDANCE WITH THE EPA, STATE AND LOCAL LAWS, DO NOT

DISPOSE OF WASTE WATER INTO GUTTERS, STORM DRAINS, STREAMS,

RESERVOIRS, ETC.

In most cases, an acceptable method of waste water disposal is to discharge

into a municipal sewage treatment system after first filtering out solid material

such as carpet fiber. Access to the sanitary system can be obtained through a

toilet, laundry drain, RV dump, etc. Permission should first be obtained from

any concerned party or agency. One disposal method which usually complies

HydraMaster Corporation

CDS 4.6

10/20/99

Page 24

Page 1-18 Clutch Drive System

with the law is to accumulate the waste water and haul it to an appropriate

dump site. Another solution to the disposal problem is to equip yourself with an

Automatic Pump-Out System. These systems are designed to remove waste

water from the extractors recovery system and actively pump the water through

hoses to a suitable disposal drain. Properly designed, they will continuously

monitor the level of waste water and pump it out simultaneously to the cleaning operation. The hidden benefit of this process is that the technician does not

have to stop his cleaning to empty the recovery tank. HydraMaster makes an

A.P.O. System available which can be ordered with new equipment or installed

later.

The penalties for non-compliance can be serious. Always check local laws and

regulations to be sure you are in compliance.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 25

Clutch Drive System Page 1-19

Figure 1-2 Hard Water Map

HydraMaster Corporation

CDS 4.6

10/15/99

Page 26

Cleaning and Chemicals

CDS 4.6

Section 2-1

our mobile carpet cleaning plant has been engineered using the latest

Y

and most sophisticated technology available to produce the finest carpet

cleaning results possible. Despite this, however, it remains only a tool of the

carpet cleaning trade, and it can produce only as good a job as the person

operating it.

PRECAUTIONS

There are no short cuts to good carpet cleaning. It requires time, cleaning

knowledge and the use of good chemicals. Therefore, the manufacturer recommends the use of spotting agents and traffic lane cleaners, as required, prior

to the actual cleaning of carpeting.

The use of some chemicals through your mobile carpet cleaning plant can

seriously damage the internal plumbing, high pressure pump and heater.

These harmful chemicals include concentrated acid (see the pH chart at the

end of this section), solvents, and some paint, oil, and grease removers with

a high concentration of solvents.

The manufacturer recommends only the use of chemicals containing rust and

corrosion inhibitors and water softening agents to prevent chemical build-up

which may lead to component failure and warranty invalidation.

♦ CAUTION ♦

The increased demand for clear water rinsing results in the need for special

care when using these acid based chemicals in your equipment. The negative

side of these products is the corrosive effects the acid can have on metals,

including swivels, pumps, heat exchangers, etc.

HydraMaster Corporation

10/20/99

Page 27

Page 2-2 Clutch Drive System

HydraMasters ClearWater Rinse has been formulated to protect vital components. HydraMaster will not warranty parts that have been damaged from

using unprotected acid products that have obviously caused failures.

The use of detergents and chemicals which create foam when agitated should

be avoided. Foam passing through the blower could lead to serious problems.

HydraMaster and SafeClean chemicals are formulated with built in anti-foaming

agents. When cleaning surfaces with excessive foaming residue use HydraMaster Powder Defoam as directed.

CLEANING STROKE PROCEDURE

Purpose:

To eliminate excess moisture remaining in the carpet fiber and the sawtooth

appearance which results from diagonal movement of the cleaning tool on all

types of carpet.

Procedure:

Always move the cleaning tool in smooth, forward and backward strokes.

Apply slight pressure to the forward stroke while the solution is injected into

the carpet. When extracting (drying), apply firm pressure on the forward stroke

to ensure a positive lock for the vacuum and minimize the hopping effect

resulting on carpet that is not smooth. During the forward and reverse strokes,

movement to the right or left should only be accomplished at the extreme rear

of the stroke. Overlapping is also important to ensure even application of

solution and prevent saturation when cleaning wand is stopped twice at the

same point at the rear of the cleaning stroke. This is illustrated at the end of

this section.

Failure to adopt this procedure can result in increased chance of clean streaks,

fiber shrinkage, brown-out and longer drying periods.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 28

Clutch Drive System Page 2-3

OVER-WETTING

Over-wetting is annoying to all concerned, and sometimes leaves a bad impression of the cleaning process used.

These are Several Areas That Will Cause Over-wetting:

1. Too few vacuum strokes or improper saw-tooth vacuum strokes as shown

in the following illustration.

2. Obstructed, cut or kinked hoses.

3. Vacuum tank drain valve left partially open.

4. Clogged vacuum blower filter or vacuum tank lid not sealing properly.

5. Cleaning a heavily foam-saturated carpet without defoamer.

(We recommend crystal type.)

HydraMaster Corporation

CDS 4.6

10/20/99

Page 29

Page 2-4 Clutch Drive System

10/20/99

HydraMaster Corporation

CDS 4.6

Page 30

Operating Instructions

CDS 4.6

Section 3-1

BEFORE OPERATING THE UNIT

1. Operate the unit and equipment only in a well ventilated area.

♦ CAUTION ♦

Exhaust fumes contain carbon monoxide and may be hazardous to your health.

Do not operate this truck where the exhaust may enter any building doorway,

window, vent, or opening of any kind.

2. Check the fuel tank to be certain there is adequate fuel to complete

the job.

3. Position the wheel chocks on one of the front tires.

4. If using a water supply hose which has not been used recently or if

using a customers hose, first connect the hose to the faucet and flush

out any debris which may be in the hose. Afterwards connect the hose

the unit.

5. Check your chemical jug to see if you have enough concentrated

chemical to finish the job. If not, mix and fill a five gallon chemical jug.

6. Connect all required hoses.

7. When connecting the pressure hose to the pressure outlet connections

at the front of the unit, go to the farthest area to be cleaned and

connect to the cleaning tool. This insures that you have the proper

length of hose required to perform the cleaning.

HydraMaster Corporation

10/20/99

Page 31

Page 3-2 Clutch Drive System

START UP

1. Make sure the van gear select lever is in the Park position and

the emergency brake is set.

2. Start the van engine.

3. Turn key on CDS Dash. The RPM will automatically increase to

the proper running speed. Engine RPM should be as noted in the

Maintenance Section.

4. Pull the heat control valve open only if you will be using water.

Do not activate the heat exchanger during flood extraction work.

When the mix tank begins a fill cycle, the chemical flowmeter may

be adjusted to your desired setting. Set your cleaning pressure at

300 PSI.

NOTE: A chemical flowmeter set at 5 GPH is a 1 to 30 mix ratio

and 10 GPH is a 1 to 15 ratio.

5. Turn the APO switch ON if using the auto pump-out feature.

6. Now proceed with the cleaning operation.

NOTE: The machine will automatically shut down when it reaches

its full capacity due to the float switch located inside the

waste tank. When this occurs, turn the switch off and empty

the waste tank. Then turn the unit back on and continue to

clean.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 32

Clutch Drive System Page 3-3

FLOOD DAMAGE WORK

When using equipment for flood damage, turn the cleaning water pressure

down to zero. This will reduce the engine power load and save on fuel consumption. Also, de-activate the heat exchangers to help prevent engine overheat problems.

SHUT DOWN

1. Shut off the knob on the chemical flowmeter. NOTE: If freeze guarding

is necessary, perform the freeze guard procedure at this time. Draining

the mix tank to ½ full or less is recommended to reduce spillage inside

the vehicle.

2. Open the mix tank drain and actuate the wand valve to run fresh water

through the chemical mix tank, heat exchangers and cleaning tools.

NOTE: Vinegar should be rinsed through the system weekly. De-scaler

should be rinsed through the entire system monthly.

3. Lay vacuum hoses out in order for all moisture to be removed from the

hoses. This prevents spillage of any dirty solution in your vehicle when

storing the hoses.

4. Disconnect the hoses and put them away.

5. If you are using an outside water source, turn the water supply faucet

off. Bleed pressure out of the supply hose by loosening the hose at the

water supply. Unhook the water supply hose and store it in the vehicle.

6. Allow the unit to run for a few minutes with the vacuum hose disconnected in order to remove all moisture from the vacuum pump. Next

plug the vacuum inlets. Spray lubricant into the lube port located on the

front panel above the pressure gauge while the unit is running.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 33

Page 3-4 Clutch Drive System

Spray for about 5 to 10 seconds. This will lubricate the vacuum pump

and prevent it from rusting.

7. Remove the inlet plugs, then turn the machine off.

8. Before draining, it is recommended that the heat control knob be moved

to the OFF position. This will help to avoid potential engine overheat

problems due to reduced coolant flow through the radiator.

9. Drain the waste tank. Do not dump waste in any area which might

violate local, state or federal law. The pump-out system may be used

to drain the waste tank into a sanitary drain system. When the waste

tank is drained, lift waste tank lid and remove the filter screens. Clean

out any accumulated debris. Rinse. Re-install.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 34

Freeze Guard

CDS 4.6

Section 4-1

ny freezing of this machine is not covered by warranty and during

A

the colder months of operation, careful protection should be of utmost

concern.

The following precautions are recommended prior to and during cleaning:

1. Run the machine before leaving for the first job to insure nothing has

frozen the night before, including hoses and wand.

2. Insulate the garden hose from the cold ground by running it through an

extra 1½ inch vacuum hose.

3. Leave truck doors closed until time cleaning begins, afterwards open

slightly.

4. In colder climates, insulating the truck walls and floor boards will help

protect the unit.

5. Do not procrastinate during the cleaning operation or the hot water

solution line will also freeze on the ground. The solution line should be

insulated in extremely cold climates.

6. Whenever possible, the truck should be stored in a heated garage at night

or over the weekend. If not possible, place a 1500 watt electric heater

inside the truck, aimed directly at the machine. Never use a propane

heater. It causes excessive moisture on the truck ceiling and the

possibility of it going out is higher. If the machine and truck are left

outside with a heater, you should drain water from the machine cleaning

tools and hoses. (They freeze also.)

HydraMaster Corporation

10/20/99

Page 35

Page 4-2 Clutch Drive System

To Drain the Machine, Follow These Steps:

A. Before shutting off the machine, remove the chemical line from the

chemical jug and place in a mixture of 50/50 antifreeze and water.

With the cleaning tool on, allow mixture to fill chemical system back

to the chemical mix tank.

B. Open the mix tank drain valve and allow the water to drain thoroughly

from the mix tank.

C. Close the mix tank drain and fill the mix tank with 50/50 antifreeze

and water mixture. Run the unit for 1 minute to circulate the mixture

through the machines low-pressure hoses. Spray through the wand

or other tool into a suitable container until the mix tank shut-off switch

activates (pump stops). This freeze guards the high-pressure circuit.

D. Open the mix tank drain and drain out the residual fluid into a suitable

container. This antifreeze solution may be retained for reuse (attach

freeze guard fitting to inlet quick connect and vacuum water out of the

inlet line).

♦ CAUTION ♦

One manufacturer of antifreeze cautions: WHEN DISPOSING OF USED ANTIFREEZE COOLANT: Follow local laws and regulations. If required, dispose at

facilities licensed to accept household hazardous waste. If permitted, dispose

in sanitary sewer systems. Do not discard into storm sewers, septic systems,

or onto the ground.

♦ WARNING ♦

This warning appears on the label of one brand of antifreeze: HARMFUL OR

FATAL IF SWALLOWED. Do not drink antifreeze coolant or solution. If

swallowed, induce vomiting immediately. Call a physician. Contains Ethylene

Glycol which caused birth defects in animal studies. Do not store in open or

unlabeled containers.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 36

Clutch Drive System Page 4-3

KEEP OUT OF REACH OF CHILDREN AND ANIMALS.

BE SURE YOUR MACHINE IS PROTECTED!

Freezing will cause GRIEF, MONEY, and DOWN-TIME.

FREEZE PROTECTION OF THE PUMP-IN SYSTEM

1. Drain the fresh water tank.

2. Remove the garden hose adapter from the pump-in pump hose and

position the hose so it is pointing outside the van.

3. Turn on the pump-in pump and run for 1-2 minutes till all the water

is purged from the hose.

NOTE: The next time the unit is used it may take a few minutes before

the mix tank begins to fill.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 37

Water and

Chemical System

CDS 4.6

Section 5-1

his electro-mechanical system has been designed to be simple and

T

trouble free.

WATER AND CHEMICAL FLOW OPERATION

Incoming water flows first through the solenoid control valve and the low pressure chemical injector which are both mounted on the exterior of the mix tank.

As the water passes through the chemical injector, it is automatically proportioned with a quantity of detergent that is adjusted with the flowmeter knob.

The mix tank is equipped with two different float switches, the water level float

responds to the level in the tank and will maintain the proper volume of solution

to be reserved for the water pump. The secondary, low water float switch is a

safety switch that is designed to protect your system from sudden or unexpected loss of water supply. If, for example, the water source at the house

were turned off, the water level of the mix tank would drop, activating the

secondary switch, which automatically disengages the system and prevents

the water pump from running dry.

The desired chemical injection ratio may be obtained by an adjustment of the

chemical flowmeter during the fill cycle of the mix tank. Water must be

flowing into the mix tank in order to adjust the chemical mix. The chemical will

flow from the chemical jug to the chemical flowmeter, then to the chemical

injector where it is proportioned into the mix tank at the desired chemical

setting.

HydraMaster Corporation

10/15/99

Page 38

Page 5-2 Clutch Drive System

NOTE: With this unique chemical system, the chemical flow is proportioned

only during the filling cycles of the mix tank, not during the direct spraying of

the wand. Therefore, it is possible that as your wand is spraying, you may

have no chemical flow. Also, the converse is true in that you may not be

spraying your wand, but if the mix tank is in a filling cycle, your chemical

flowmeter may be active at the desired flow rate.

The chemical proportioning system will mix chemical with water at a 1 to 30

ratio when the flowmeter is set at 5 GPH, or a 1 to 15 ratio when the flowmeter is set at 10 GPH.

CHEMICAL SYSTEM MAINTENANCE

The chemical lines may need to be flushed with vinegar periodically to prevent

abnormal chemical build-up. This flushing may be done by removing the clear

plastic hose from the chemical jug and inserting it into a one quart container of

vinegar. This should be done with the chemical flowmeter setting 10 GPH.

Simply spray water from the wand until the quart of vinegar is exhausted.

Then repeat the process with one quart of clear water to void all lines of

vinegar.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 39

Clutch Drive System Page 5-3

Figure 5-1 Water Flow Diagram

D4497 Rev A

HydraMaster Corporation

CDS 4.6

9/5/00

Page 40

Page 5-4 Clutch Drive System

Figure 5-2 Proportioner Diagram

10/20/99

HydraMaster Corporation

CDS 4.6

Page 41

Clutch Drive System Page 5-5

Chemical Tank

Troubleshooting

HydraMaster Corporation

CDS 4.6

10/20/99

Page 42

Page 5-6 Clutch Drive System

10/20/99

HydraMaster Corporation

CDS 4.6

Page 43

Pump Maintenance

CDS 4.6

Section 6-1

DAILY

1. Check the oil level and the condition of the oil. The oil level

should be up to the center of the sight glass on the back of the

pump.

Use a 30 weight, non-detergent oil.

♦ CAUTION ♦

If the oil becomes discolored and contaminated, one of the oil seals may be

damaged. Refer to the Service Section.

Do not operate the pump if the crankcase has been contaminated with water.

♦ CAUTION ♦

Do not leave contaminated oil in the pump housing or leave the housing empty.

Remove contaminated oil as soon as it is discovered and replace it with clean

oil.

PERIODICALLY

1. Change the oil after the first 100 hours of operation, and every

400 operating hours thereafter. When changing, remove the

drain plug on the oil drain hose so all oil and accumulated

sediment will drain out.

HydraMaster Corporation

10/20/99

Page 44

Page 6-2 Clutch Drive System

♦ CAUTION ♦

Do not turn the drive shaft while the oil reservoir is empty.

♦ CAUTION ♦

Protect the pump from freezing.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 45

Clutch Drive System Page 6-3

Pump Service

he next few pages explain how to disassemble and inspect all easily

serviceable parts of the pump.

T

♦ CAUTION ♦

Do not disassemble the hydraulic end unless you are a skilled mechanic. For

assistance, contact HydraMaster (425-775-7275) or the distributor in your area.

1.0 Servicing the Valves (See illustrations above.)

A.Remove the hex valve plugs (top-discharge, bottom-inlet).

B. Unthread the valve plug and examine the o-ring under the plug for cuts or

distortion. Replace it if it is worn. Lubricate new o-rings before installing.

C. Grasp the valve retainer by the tab at the top with needle-nose pliers,

then remove the o-ring at the bottom of the valve chamber.

D. Inspect all valve parts for pitting, gouges, or wear. If wear is excessive,

replace valve assembly.

E. Reinstall valve assemblies:

1. Using a clean towel, clean the valve chamber.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 46

Page 6-4 Clutch Drive System

2. Install the o-ring into the high pressure manifold.

3. Install the valve assemblies into the high pressure manifold

(the metal side of the valve faces the manifold).

4. Replace the o-ring on the hex valve plug.

5. Torque the plug to 72 foot pounds.

2.0 Removing the High Pressure Manifold

A. Using an M6 allen wrench, remove all eight of the socket head bolts.

B. Rotate the crankshaft by hand to start separation of the manifold head

from the crankshaft.

C. Insert two flat-head screwdrivers on opposite sides to further separate

the manifold from the crankshaft.

♦ CAUTION ♦

To avoid damage to either plunger or seal, keep the manifold properly aligned

with the ceramic plungers when removing it.

D. Remove the seal retainer from the manifold and inspect for wear.

E. Examine the ceramic plunger for cracks or scoring (refer to Servicing the

Plungers for replacement).

3.0 Servicing the Low Pressure Seals and High Pressure Seals

(See illustrations above.)

A. Remove the low pressure seal from the seal retainer using a 90 degree

pick tool.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 47

Clutch Drive System Page 6-5

B. Remove the high pressure seal from the manifold.

C. Inspect the low pressure seal and high pressure seal for wear and replace

if necessary.

D. Reinstall the low pressure seal:

1. Install the low pressure seal into the seal retainers with the garter

spring down.

E. Reinstall the high pressure seal:

1. Lubricate the seal chamber in the manifold.

2. Carefully square the high pressure seal into position by hand with the

grooved side down (metal back facing out).

3. Examine the seal retainers o-ring and replace if worn. Lubricate the

new o-ring before installing.

4. Next, press the seal retainers into the manifold until completely seated.

4.0 Servicing the Plungers (See illustrations above Step 3.)

A. Using a hex tool, loosen the plunger retainer about three to four turns.

Push the plunger back to separate it from the retainer and finish unthreading

the plunger retainer by hand.

B. Unthread the plunger retainer with sealing washer.

C. Remove the ceramic plunger, keyhole washer and barrier slinger from the

plunger rod.

D. Reinstall the ceramic plungers:

1. Examine the sealing washer on the plunger retainer and replace it if it

is cut or worn. Lubricate the new sealing washer for ease of installation and to avoid damage.

2. Apply Loctite 242 to the threads of the plunger retainer and press it

into the ceramic plunger. Thread hand tight, then torque the bolt to

4.4 foot pounds.

3. Install the seal retainer with holes to the top and bottom, and forward.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 48

Page 6-6 Clutch Drive System

5.0 Reinstall High Pressure Manifold

A. Slip the seal retainer over the ceramic plungers with the holes to the top

and bottom and forward.

B. Turn the shaft by hand to line up the plungers so that the end plungers

are parallel.

C. Lightly lubricate the plungers and carefully slide the manifold head onto

the plungers while supporting it from the underside to avoid damaging

the plungers.

D. Reinstall the socket head bolts and torque to 4.4 foot pounds.

6.0 Servicing the Crankcase

A. While manifold, plungers, and seal retainers are removed, examine the

crankcase seals for wear.

B. Rotate the crankshaft oil seal externally for drying, cracking or leaking.

C. Consult your HydraMaster distributor if crankcase servicing is

necessary.

Torque Chart

Torque

Pump Item Thread Inch Pounds Foot Pounds Nm

Plunger Retainer M6 55 4.4 6.2

Manifold Bolt M6 55 4.4 6.2

Valve Plugs M22 870 72.3 100.0

Bearing Case Screws M6 50 4.0 6.0

Crankcase Cover M6 50 4.0 6.0

Bubble Oil Gauge M28 45 3.6 5.0

Mounting Bolts M8 115 9.4 13.0

10/20/99

HydraMaster Corporation

CDS 4.6

Page 49

Clutch Drive System Page 6-7

Figure 6-3 Cat Pump

HydraMaster Corporation

CDS 4.6

10/20/99

Page 50

Page 6-8 Clutch Drive System

Cat Pump Parts List

ITEM PART NO. DESCRIPTION QTY

2 30057 Key (M6) 1

5 96031 Screw, Sems HHC, Bearing Cover (M8x16) 8

8 46910 Cover, Bearing 2

10 14028 O-Ring, Bearing Cover 1

11 43222 Seal, Oil, Crankshaft 2

15 14480 Bearing

20 46743 Rod, Connecting, Assembly 2

25 46928 Crankshaft, Dual End 3

32 46798 Cap, Oil Filler 1

33 14179 O-Ring, Oil Filler Cap 1

37 43987 Gauge, Oil, Bubble 1

38 44428 Gasket, Flat, Oil Gauge 1

40 92519 Screw, Sems HHC, Crankcase Cover (M6x16) 4

1

48 25625 Plug, Drain (

49 23170 O-Ring, Drain Plug 1

50 46940 Cover, Crankcase 1

51 14044 O-Ring, Crankcase Cover 1

53 46912 Crankcase 1

64 46746 Pin, Plunger Rod 3

65 46747 Rod, Plunger 3

70 147-013 Seal, Crankcase Oil for 3CP Cat Pump 3

75 43900 Slinger, Barrier 3

88 45697 Washer, Keyhole 3

90 46893 Plunger (M50) 3

/4 x 11) 1

98 46730 Seal, Washer 3

99 46729 Retainer, Plunger with Stud (M7) 3

100 46749 Retainer, Seal 3

10/20/99

HydraMaster Corporation

CDS 4.6

Page 51

Clutch Drive System Page 6-9

ITEM PART NO. DESCRIPTION QTY

106 43243 Seal, LPS with Spring 3

120 46896 Case, Seal

121 13976 O-Ring, Seal case 3

127 44549 V Packing 6

128 44548 Adapter, Male 3

139 22179 Plug, Inlet ½ 1

163 17547 O-Ring 85, Valve Seat 6

164 46658 Seat 6

166 46429 Valve 6

167 43750 Spring 6

168 46583 Retainer, Spring 6

172 17549 O-Ring, Valve Plug 6

173 48365 Back up Ring, Valve Plug 6

174 45900 Plug, Valve 6

185 46895 Manifold, Head 1

193 87872 Bolt, HSH, Manifold Head (M8x70) 8

196 22187 Plug, Discharge

129 814843 Complete Head 1

300 078-271 Kit, Seal for 3CP Cat Pump 1

310 078-270 Kit, Valve for 3CP Cat Pump 1

350 30696 Valve Seal Removal Tool 1

3

/81

HydraMaster Corporation

CDS 4.6

10/20/99

Page 52

Page 6-10 Clutch Drive System

Pump Troubleshooting

Cavitation

l Inadequate fluid supply because of:

-Inlet line collapsed or clogged.

-Air leak in inlet line.

-Worn or damaged inlet hose.

l Fluid too hot for inlet suction piping system.

l Air entrained in fluid piping system.

l Aeration and turbulence in supply tank.

l High pressure seals worn.

Symptoms of Cavitation:

l Excessive pump valve noise (chattering)

l Premature failure of spring or retainer

l Volume or pressure drop

l Rough-running pump.

Drop in Volume or Pressure

l Air leak in suction piping.

l Clogged suction line.

l Pressure gauge inoperative or not registering accurate.

l Suction line inlet above fluid level in tank.

l Inadequate fluid supply.

l Pump not operating at proper RPM.

l Worn pump valve parts.

l Foreign material in inlet or outlet valves.

l Worn low pressure seals.

l Cavitation.

l Belt slippage.

10/20/99

HydraMaster Corporation

CDS 4.6

Page 53

Clutch Drive System Page 6-11

Water Pulsations

l Foreign object lodged in pump valve.

l Air in suction line.

l Valve spring broken.

l Cavitation.

l Aeration or turbulence in supply tank.

l Stuck inlet or discharge valve.

Valve Wear

l Normal wear.

Loss of Oil

l External seepage.

l Frozen pump.

l Worn crankshaft seal.

l Oil drain piping or fill cap loose.

Premature Failure of Valves or Seals

l Excessive cavitation.

l Foreign object in the pump.

l Pump running too fast.

l Valve or seal material incompatible with fluid being pumped.

l Excessive inlet pressure.

l Scored plungers.

l Running pump dry for excessive periods of time.

l Excessive temperatures of fluid being pumped.

HydraMaster Corporation

CDS 4.6

10/20/99

Page 54

Machine Assemblies

CDS 4.6

Section 7-1

Figure 7-1 CDS 4.6 Machine Assembly

D4429 Sht 1, Rev A

and Parts Lists

HydraMaster Corporation

10/20/99

Page 55

Page 7-2 Clutch Drive System

Figure 7-2 CDS 4.6 Machine Assembly-Rear View

D4429 Sht 2, Rev A

10/20/99

HydraMaster Corporation

CDS 4.6

Page 56

Clutch Drive System Page 7-3

Figure 7-3 CDS 4.6 Machine Assembly-Top and Front Views

D4429 Sht 3 & 4, Rev A

HydraMaster Corporation

CDS 4.6

10/20/99

Page 57

Page 7-4 Clutch Drive System

Figure 7-4: Recovery Tank Assembly - Front View

D4430 Sht 1, Rev

10/20/99

HydraMaster Corporation

CDS 4.6

Page 58

Clutch Drive System Page 7-5

Figure 7-5 Recovery Tank Assembly-Rear View

D4430 Sht 1, Rev

HydraMaster Corporation

CDS 4.6

10/20/99

Page 59

Page 7-6 Clutch Drive System

Recovery Tank Assembly Parts List

REF. NO. PART NO. DESCRIPTION QTY

1 159-031 Recovery Tank 1

2 Dash Box Assembly 1

3 Instrument Panel Assembly 1

4 Mix Tank Assembly 1

5 Dual Heat Exchanger Assembly 1

6 Cover Assembly, Recovery Tank 1

7 166-002 Soap Jug Tray 1

8 601-013-001 Instrument Panel to Vacuum Tank Stabilizer 1

9 105-011 Plate, Filter Bag Support 1

10 068-152 Hose Assembly, Mix Tank Control Panel 2

11 068-150 Hose Assembly, Bypass 1

3

12 068-089 Hose Assembly,

13 068-094 Hose Assembly,

14 068-025 Hose, 1.4 Clear A/R

5

15 068-030 Hose,

/

Vacuum A/R

32

16 063-007 Harness, CDS Wire-Primary 1

/

x24 Lg Teflon 1

8

3

/

x16 Lg. Teflon 1

8

17 063-008 Wire Harness Wrap, Split Seam A/R

18 081-070 Label, Small CAUTION 1

1

19 033-021 Clamp,

20 033-023 Clamp,

/

Nylon Hose 3

4

3

/

Nylon Hose 5

4

21 049-013 Filter, Vacuum Pump Blower 1

22 159-016 Jug, 5 Gallon Chemical 1

23 052-182 Nipple, 1.50 NPT Close Galvinized 1

24 125-111 Pipe, Vacuum Relief Spring Guide 1

25 155-026 Spring, Vacuum Relief 1

26 157-012 Switch, Heavy Duty Liquid Level Float 1

3

27 131-027 Trimlok, Crossfire Brow Trim

28 131-028 Trimlok, Recovery Tank Gasket

3

29 131-003 Trimlok, CDS Trim

/

A/R

4

/

A/R

8

3

/

A/R

4

30 169-022 Valve, 1.50 NPT Full Port 1

10/20/99

HydraMaster Corporation

CDS 4.6

Page 60

Clutch Drive System Page 7-7

Recovery Tank Assembly Parts List

REF. NO. PART NO. DESCRIPTION QTY

31 143-114 Flat Head Machine Screw,

#10-24UNC x 0.50 LG. 1

32 143-132 Hex Head Machine Screw 2

#10-24UNC x 0.75 LG.

33 143-064 Flat Head Machine Screw, 5

#10-24UNC x 1.00 LG

34 143-115 Hex Head Machine Screw, 2

1

/

-20UNC x 0.75 LG

4

35 143-198 Hex Head Machine Screw,

3

/

-16UNC x 4 LG. 1

8

36 143-143 Hex Head Machine Screw,

5

/

18UNC x 1.00 LG 2

16

37 094-004 Hex Nut, #10-24UNC 11

38 094-034 Hex Nut, #10-24UNC Nylock 2

3

39 094-077 Nut,

/

-18UNC x

8

1.00 O.D. Knurled 2

1

40 094-007 Whiz Nut,

41 094-023 Whiz Nut,

/

-20UNC 2

4

5

/

-18UNC 2

16

42 174-015 Washer, #10 Outside Star 11

43 174-001 Washer, #10 Flat 1

1

44 174-003 Washer,

/

Flat 4

4

45 052-360 Adapter, 3 FPT x 3 M Slip 1

46 052-361 Elbow, 3 F Slip x 3 M Slip 1

47 015-182 Bracket, Vacuum Relief Valve 1

48 027-031 Cap, Vacuum Relief 1

49 081-056 Label, H/M Lubrication Schedule 1

50 103-028 Locking Pin Assembly 1

3

51 174-032 Washer,

/

Flat 1

8

52 143-126 Hex Head Machine Screw

#10-24UNC x 0.50 LG. 1

HydraMaster Corporation

CDS 4.6

10/20/99

Page 61

Page 7-8 Clutch Drive System

Figure 7-6 Recovery Tank Lid Assembly

D4456, Rev

REF. NO. PART NO. DESCRIPTION QTY

1 052-219 Adapter, 2NPT x 2 S Slip 2

2 052-404 Adapter, 3 F Slip x 2 F Slip 2

3 041-228 Cover, Recovery Tank-Painted 1

4 052-222 Elbow, 2 Barb x 2 FPT 2

5 049-030 Filter Bag 2

1

6 052-015 Gasket, 17 125-052 Tube, 2x1.5 Lg. Filter Bag

Adapter Sleeve 2

8 078-039 Vacuum Inlet Stopper Assembly 1

9 143-158 Button Head Machine Screw

#10-25UNC x .63 Lg 1

10/20/99

/

Bulkhead Fitting 2

2

HydraMaster Corporation

CDS 4.6

Page 62

Clutch Drive System Page 7-9

Figure 7-7 Instrument Panel Assembly

D4149, Rev B

HydraMaster Corporation

CDS 4.6

10/20/99

Page 63

Page 7-10 Clutch Drive System

Instrument Panel Assembly Parts List

REF. NO. PART NO. DESCRIPTION QTY

1 052-010 4FA-2UFS 1

2

3 052-019 6M-6UFS 5

3

4 052-060

/

NPT x

8

5 025-002 Choke 3 Cable 1

6 027-014 Garden Hose Cap 1

7 052-272 Gravity Feed Oil Blower

Lubrication Port Cup 1

3

8 052-086

/

NPT Street Elbow 1

8

9 131-003 CDS Trim ¾ Gasket 4

10 057-055 Garden Hose Gasket 1

11 074-003 HI PSI (0-1000) Gauge 1

1

/

NPT Bushing 1

8

12 060-002 Large Wiring Grommet 1

13 090-008 High Pressure Manifold 1

3

14 068-285

/

x 8.5 Lg Teflon Hose Assembly 1

16

15 052-096 No. F23 Insert 1

16 052-487 No. 24 Modified Insert 1

17 052-097 No. 24 Insert 2

18 052-104 No. 66 Insert 1

19 052-338 No. 1212 Insert 1

20 074-020 Chemical Flow Meter 1

21 052-071 ¼ NPT Hex Nipple 2

22 052-281 ¾ NPT x ¾ M Garden Hose Nipple 1

23 100-173 Instrument Panel 1

24 105-012 Machine Serial I.D. Plate 1

25 106-029 1 Hole Plug 1

26 052-050 440 Male Quick Connect 2

27 052-052 660 Male Quick Connect 1

28 135-052 Hi PSI Snubber Regulator 1

1

29 140-015 1

/

x ¼ LG Pop Rivet 2

8

10/20/99

HydraMaster Corporation

CDS 4.6

Page 64

Clutch Drive System Page 7-11

Instrument Panel Assembly Parts List

REF. NO. PART NO. DESCRIPTION QTY

30 149-039 Water Temperature Sender 1

3

31 052-023

32 169-064

33 169-009 ¾ FPT Swing Check Valve 1

34 169-101 By-Pass Valve 1

35 174-005

36 174-040

37 174-040

38 174-050 1 Flat Washer 1

39 081-099 Label Set 1

40 105-020 HydraMaster Cast Name Plate 1

41 139-023 Push-on Retainer Ring 2

/

NPT Male Street Tee 1

8

3

/

NPT Full Port Ball Valve 1

8

3

/

Flat Washer 1

8

9

/

Flat Washer 4

16

5

/

Flat Washer 4

8

HydraMaster Corporation

CDS 4.6

10/20/99

Page 65

Page 7-12 Clutch Drive System

Figure 7-8 Dual Heat Exchanger Assembly

D3803, Rev B

10/20/99

HydraMaster Corporation

CDS 4.6

Page 66

Clutch Drive System Page 7-13

Dual Heat Exchanger Assembly Parts List

ITEM PART NO DESCRIPTION QTY

1 038-011 Heat Exchanger Core 2

2 015-171 Bracket, Dual Heat

Exchanger Mounting-R/H 1

3 015-172 Bracket, Dual Heat

Exchanger Mounting-l/H 1

4 052-477 Elbow, Heat Exchanger Connector 2

5

6 068-071 Hose Assembly, 3/8 x 12 Lg 1

7 068-087 1 X 1.5 Lg Red Hose 1

8

9 052-033 8MA-6UFS 2

10 052-064 1/2 NPT x 3/8 FPT Bushing 2

11 052-259 3/4 NPT x 3/8 FPT Bushing 1

12 033-020 No. 16 Hose Clamp 2

13 052-086 3/8 NPT Street Elbow 2

14 052-340 3/4 NPT Street Elbow 1

15 052-338 No. 1212 Insert 2

16 131-042 4.13 I.D. x .50 Wall x 33 Lg

Insulation 1

17 052-330 3/4 NPT Hex Nipple 1

18 149-021 Hi Temp Limit 218° F Sensor 1

19 052-447 3/8 NPT Male Branch Tee 1

20 052-336 3/4FPT x FPT x FPT Tee 1

21 162-006 15.5 Lg Tie Wrap 6

22 143-115 Lg Hex Head Machine Screw

1/420UNC x 3/4 8

23 174-019 1/4 Lock Washer 8

HydraMaster Corporation

CDS 4.6

10/20/99

Page 67

Page 7-14 Clutch Drive System

Figure 7-9 Salsa X Assembly

D4801 Rev C

9/5/00

HydraMaster Corporation

CDS 4.6

Page 68

Clutch Drive System Page 7-15

Salsa X Assembly Parts List

ITEM PART NO DESCRIPTION QTY

1 052-528 Nipple,

3

/

M JIC x

8

3

/

NPT 4

8

2 169-172 Valve, 3-Way 3/8 NPT 1

3

3 052-086 Elbow,

4 052-023 Tee,

5 068-245 Hose,

6 052-064 Bushing, ½ x

/

NPT Street 3

8

3

/

NPT Male Street 3

8

3

/

x 12 Teflon 1

8

3

/

FPT 2

8

7 169-027 Valve, Thermal Relief 1

3

8 068-257 Hose,

9 068-017 Hose,

10 052-586 Nipple,

/

Teflon x 24 1

16

3

/

x 32 1

8

1

/

FPT x ¼ SAE 1

8

11 052-585 Nipple, Tee Jet Modified 1

12 094-028 Nut, Brass Jet Assembly 1

13 052-153 Housing, Stabilizer Nozzle 1

14 049-052 Filter Cartridge, ¼ 1

15 180-007 Orifice, Salsa X 1

16 052-104 Insert #66 1

17 033-004 Clamp, Size 6 2

18 052-099 Insert #26 1

19 108-111 Protector, Insulation Blanket, Salsa X x 36 1

20 038-052 Core Assembly, Salsa X 1

21 052-669 Coupler, ½ FPT 2

22 052-675 Elbow, 3 Steel Modified 1

23 052-674 Elbow, 3 Rubber Assembly 2

24 068-617 Hose, 3 Silicone x 7 Assembly 1

25 068-616 Hose, 3: Nitrile x 9 Assembly 1

3

26 052-061 Bushing,

27 052-172 Insert, ¼ NPT x

28 068-618 Hose,

/

NPT x ¼ FPT 1

8

3

/

Hose 1

16

3

/

x 19 Teflon 2

8

29 001-094 Adapter, Blower to Salsa X 1

HydraMaster Corporation

CDS 4.6

9/5/00

Page 69

Page 7-16 Clutch Drive System

Figure 7-10 CDS 4.6 Pump and Blower Assembly

D4431, Rev B

9/5/00

HydraMaster Corporation

CDS 4.6

Page 70

Clutch Drive System Page 7-17

Pump and Blower Assembly Parts List

ITEM PART NO DESCRIPTION QTY

1 001-041 Adapter, Blower Inlet 1

2 001-042 Adapter, Blower Outlet 1

3 015-173 Bracket, Cat Pump Tensioner Plate 1

4 015-174 Bracket, Hose Holding 1

5 Drive Shaft Assembly 1

6 055-037 Frame, Pump and Blower 1

7 108-061 Protector, Cat Pump Belt Guard 1

8 108-060 Protector, Cat Pump Head 1

9 150-040 Shaft, Drive Sprocket 1

10 052-019 6M-6UFS 1

11 052-038 8M-UFS 1

12 010-052 Belt, Polychain GT Blower Drive 1

13 010-012 Belt, Pump Drive Gates #9325 1

14 111-012 Blower, 4.2 Hydra Whisper 1

7

15 020-019 Bushing, #H x

16 020-036 Bushing, SDS 117 052-062 Bushing, ¼ NPT x

3

18 020-001 Bushing,

/

/

1

8

1

/

1

8

3

/

FPT 1

8

Vac Pump Hub 1

8

19 033-023 Clamp, ¾ Hose 1

3

20 052-079 Cross,

21 052-084 Elbow,

/

FPT 1

8

3

/

NPT Street 1

8

22 052-085 Elbow, ¼ Street 2

3

23 052-086 Elbow,

/

NPT Street 1

8

24 052-087 Elbow, ½ NPT Street 1

25 068-149 Hose Assembly, CDS Blower Oil Drain 2

26 052-293 Insert, #23 3

27 077-001 Key, #3 and #4 Vacuum Pump Drive 4

28 077-006 Key, Blower Drive x ¼ 1

29 Magnet, Tachometer Sensor 2

3

30 052-057 Nipple,

/

” NPT Close 1

8

HydraMaster Corporation

CDS 4.6

9/5/00

Page 71

Page 7-18 Clutch Drive System

Pump and Blower Assembly Parts List

ITEM PART NO DESCRIPTION QTY

3

31 088-020 Pillow Block Bearing, 132 Tachometer Sensor/Bracket Assembly 1

3

33 106-003 Plug,

/

NPT 1

8

34 106-004 Plug, ½ NPT 1

35 109-022 Pulley, #AK 54 H 1

7

36 109-009 Pulley, 2¾ x

/

Pump

8

Drive-Modified 1

37 109-055 Pulley, 40 Tooth Sprocket Poly Chain 1

38 109-056 Pulley, 56 Tooth Sprocket Poly Chain 1

39 109-042 Pulley, 5 Pump 1

40 108-055 Protector, 3CP Cat Pump Shaft 1

/

Bore 2

16

41 111-070 Pump, 4GPM Cat Hi Temp, Plunger 1

42 114-003 Pail, Angle, 3CP Cat Pump (Set) 1

43 139-021 Snap Ring, 1¾ I.D. Drive Shaft 2

1

44 052-505 Zerk Grease Fitting,

/

NPT Straight 4

8

45 143-126 Hex Head Machine Screw,

#1020UNC x 0,50 Lg. 1

46 143-115 Hex Head Machine Screw,

¼20UNC x 0.74 Lg. 1

47 143-002 Hex Head Machine Screw,

¼20UNC x 1.00 Lg. 2

48 143-148 Hex Head Machine Screw,

5

/

18UNC x 0.50 Lg. 4

16

49 143-013 Hex Head Machine Screw,

5

/

18UNC x 1.00 Lg. 1

16

50 143-016 Hex Head Machine Screw,

5

/

18UNC x 2.50 Lg. 2

16

51 143-094 Socket Head Machine Screw,

3

/

16UNC x 0.75 Lg. 4

8

52 143-096 Hex Head Machine Screw,

3

/

16UNC x 1.00 Lg. 5

8

9/5/00

HydraMaster Corporation

CDS 4.6

Page 72

Clutch Drive System Page 7-19

Pump and Blower Assembly Parts List

ITEM PART NO DESCRIPTION QTY

53 143-260 Hex Head Machine Screw,

3

/

16UNC x 8.00 Lg. 1

8

54 143-240 Hex Head Machine Screw,

½13UNC x 1.75 Lg. Grade 5 5

5

55 094-012 Nut,

56 094-015 Nut,

57 094-016 Nut,

58 094-020 Nut, ½13UNC Whiz 4

59 174-001 Washer, #10 Flat 1

60 174-017 Washer, ¼ Lock 1

61 174-004 Washer,

62 174-020 Washer,

63 174-018 Washer,

64 174-032 Washer,

65 174-057 Washer,

66 174-007 Washer, ½ Flat 4

/

18UNC Hex 2

16

3

/

16UNC, Two-Way Locking 1

8

3

/

16UNC Whiz 2

8

5

/

Flat 1

16

5

/

Cam Lock 4

16

5

/

Lock 2

16

3

/

Flat 1

8

3

/

Lock 4

8

HydraMaster Corporation

CDS 4.6

9/5/00

Page 73

Page 7-20 Clutch Drive System

Figure 7-11 Dash Box Assembly

C2712, C3466, Rev B

ITEM PART NO DESCRIPTION QTY

1 013-006 Box, CDS Dash 1

2 Figure 7-11 Dash Panel Assembly 1

4 060-002 Grommet, Large Wiring 1

5 131-003 Gasket, CDS Trim 45

1

6 143-114 Screw, 1024 x

/

FHM Phillips s/s 8

2

7 094-034 Nut, 10-24 s/s Nylock 8

1

8 169-062 Valve,

9 068-025 Hose,

10 068-025 Hose,

/

Anti-Siphon 1

4

1

/

Clear 30

4

1

/

Clear 30

4

Not Shown:

178-090 Wire Assembly, Vanguard High

Temp. Switch 1

9/5/00

HydraMaster Corporation

CDS 4.6

Page 74

Clutch Drive System Page 7-21

Figure 7-12 Dash Panel Assembly

C3465, Rev B

ITEM PART NO DESCRIPTION QTY

1 018-004 25 AMP Circuit Breaker 1

2 100-071 Painted Dash Panel 1

3 074-019 Engine Tachometer Gauge 1

4 074-018 Rectangular Hour Meter Gauge 1

5 074-016 Temperature Gauge 1

6 074-006 Vacuum Gauge 1

7 084-015 12V, 2W Round Red Indicator Lamp 5

8 084-004 Replacement Gauge Lamp 3

9 084-009 Socket-Dashboard Lamp 3

10 157-040 20 AMP Rocker Switch 3

11 157-008 Ignition Switch 1

12 033-049 Indicator Light Clamp 5

1

13 052-084

/

NPT Street Elbow 1

8

14 052-096 No. F23 Insert 1

1

15 174-052

/

Flat Washer 1

8

HydraMaster Corporation

CDS 4.6

10/20/99

Page 75

Page 7-22 Clutch Drive System

Figure 7-13 Mix Tank Assembly

D4457, Rev A

9/5/00

HydraMaster Corporation

CDS 4.6

Page 76

Clutch Drive System Page 7-23

Mix Tank Assembly Parts List

ITEM PART NO DESCRIPTION QTY

1 159-032 Tank, CDS Chemical Mix 1

2 041-038 Cover, CDS Chemical Mix Tank 1

3 Part Deleted 4 169-120 Valve, Chemical System Solenoid - 12 Volt 1

5 157-012 Switch, Side Mount w/ Bulkhead Fitting 2

6 Part Deleted 7 Part Deleted -

1

8 068-327 Hose,

9 181-008 Venturi, Low Pressure Injector-Modified 1

10 052-074 Nipple,

11 052-086 Elbow,

12 052-026 6FA-6UFS 1

13 052-142 Elbow,

14 052-105 Insert, #68 1

15 052-087 Elbow,

16 131-027 Trimlok, 12.75 Lg. CrossFire Brow 1

/

x 69.5 Lg. Clear Braid 1

2

3

/

NPT Hex 1

8

3

/

NPT Street 2

8

3

/

NPT Female 1

8

1

/

NPT Street 1

2

17 Part Deleted 18 Part Deleted 19 Part Deleted 20 Part Deleted -

HydraMaster Corporation

CDS 4.6

9/5/00

Page 77

Page 7-24 Clutch Drive System

Figure 7-14 Tachometer Sensor and Bracket Assembly

B3237, Rev

ITEM PART NO DESCRIPTION QTY

1 015-060 Bracket, CDS Tachometer Magnet Extension1

2 149-010 Sensor, CDS Magnet Tachometer

(only parts shown are used here) 1

3

3 037-017 Terminal,

Vinyl Insulated 1

4 037-012 Terminal, Fully Insulated Female QC 1

9/5/00

/

Stud, 10GA Wire,

8

HydraMaster Corporation

CDS 4.6

Page 78

Clutch Drive System Page 7-25

Figure 7-15 Horizontal Pump in Tank Assembly

D3700, Rev A

HydraMaster Corporation

CDS 4.6

9/5/00

Page 79

Page 7-26 Clutch Drive System

Horizontal Pump in Tank Assembly Parts List

ITEM PART NO DESCRIPTION QTY

1 159-005 Tank, 120 Gallon Horizontal 1

2 033-004 Clamp, #6 Mini Hose 2

3 041-005 Cover, 6" Pump-In Tank 2

4 052-086 Elbow, = Brass Street 1

5 052-143 Elbow, ½ F x F Brass 1

6 049-006 Filter, ½ Inline Y - Cat Pump 1

7 068-025 Hose, ¼ Clear 9I

8 068-327 Hose, ½ Clear Braid 6½

9 068-165 Hose, Pump-In Overflow 1

10 052-103 Insert, #64 2

11 052-107 Insert, #88 1

12 052-313 Insert, ½ Plastic Swivel Straight 2

13 052-226 Insert, 1½ NPT x 1½ Barb 1

14 081-173 Label, HydraMaster Accessory 1

15 052-074 Nipple, = Brass Hex 1

16 052-076 Nipple, ½ Brass Hex 2

17 052-182 Nipple, 1½ Close - Galv. Steel 1

18 111-010 Pump, 35 PSI Elect. Pump-In with M Threads 1

19 052-052 Quick Connect, 660 Male with Viton 1

20 052-023 Tee, ? Male Street - Brass 1

21 169-022 Valve, 1½ Full Port Brass Dump 1

22 143-114 Screw, 10-24 x ½ FHM Phillips s/s 12

23 143-113 Screw, 10-24 x 1½ FHM s/s 4

24 094-034 Nut, 10-24 s/s Nylock 4

25 174-001 Washer, #10 s/s Flat 4

26 166-012 Tray, Air Mover - Removable 2

27 166-014 Tray, 4-Bin Storage - Removable 1

28 083-002 Leg, Tray Support 2

29 143-019 Screw, =- 16 x 1¼ HHC Grade 5 Zinc 16

30 094-014 Nut, = - 16 Hex 16

31 174-005 Washer, = Flat 32

32 174-021 Washer, Lock 16

9/5/00

HydraMaster Corporation

CDS 4.6

Page 80

Clutch Drive System Page 7-27

Figure 7-16 Vacuum Relief Valve Assembly

C4237, Rev

ITEM PART NO DESCRIPTION QTY

1 015-182 Bracket, Vacuum Relief 1

2 027-031 Cap, Vacuum Relief 1