Page 1

11015 47th Avenue W, Mukilteo, WA 98275

Boxxer H2O

Machine Serial Number________________________

Copyright© 2012

HYDRAMASTER© Corporation

Mukilteo, Washington

MAN-45052 Rev. 1

(182-136)

No part of this manual may be reproduced or used in any form or by any means (i.e. graphic,

electronic, photocopying or electronic retrieval systems) without the express written permission of the

HYDRAMASTER© Corporation. All rights reserved.

Revised May 25, 2012

Page 2

Boxxer H2O

Boxxer H2O Owner’s Manual

HydraMaster Corporation

Page 3

Boxxer H2O

Table of Contents

T able of Contents

List of Figures

Quick Reference

GENERAL INFORMATION......................................................................... Section 1

T elephone Numbers........................................................................... 1-2

Precautions....................................................................................... 1-3

Responsibilities..................................................................................1-5

Vehicle Prep aration............................................................................1-7

High Altitude Operation Preparation ...................................................1-11

Local Water Precautions ....................................................................1-12

MACHINE SPECIFICATIONS ..................................................................... Section 2

Machine Layout ................................................................................. 2-2

OPERATING INSTRUCTIONS ................................................................... Section 3

MACHINE MAINTENANCE ........................................................................ Section 4

Maintenance Log

MACHINE ASSEMBLIES AND PARTS LIST ............................................. Section 5

VACUUM SYSTEM ..................................................................................... Section 6

V acuum System Troubleshooting....................................................... 6-2

Miscellaneous Troubleshooting.......................................................... 6-3

Blower Manual

ELECTRICAL SYSTEM ............................................................................. Section 7

Wiring Diagrams ............................................................................... 7-3

Electrical Troubleshooting.................................................................. 7-5

ENGINE TROUBLESHOOTING................................................................. Section 8

HOW TO ORDER PARTS........................................................................... Section 9

WARRANTY INFORMA TION...................................................................... Section 10

Golden Guarantee®

Boxxer H2O Owner’s Manual

Page 4

Boxxer H2O

List of Figures

Fig. 1-1 Roof Vents............................................................................ 1-7

Fig. 1-2 Recommended Placement ................................................... 1-8

Fig. 1-3 Installation Using T ie-down Cleats......................................... 1-9

Machine Assemblies and Part s List s ................................................. 5-1

Fig. 5-1 Machine Assembly - Front View - Left Side........................... 5-1

Fig. 5-2 Machine Assembly - Front View - Right Side......................... 5-2

Fig. 5-3 Frame Assembly - Front View - Left Side.............................. 5-3

Fig. 5-4 Frame Assembly - Front View - Right Side............................ 5-4

Fig. 5-5 Engine Assembly.................................................................. 5-6

Fig. 5-6 Blower Assembly .................................................................. 5-8

Fig. 5-7 Dash Assembly..................................................................... 5-10

Fig. 5-8 Exhaust Assembly ................................................................ 5-12

Fig. 5-9 Machine Left Side Cover Assembly ...................................... 5-14

Fig. 5-10 Machine Right Side Cover Assembly .................................... 5-15

Fig. 5-11 100 Gallon Universal Recovery T ank Assembly ..................... 5-16

Fig. 5-12 100 Gallon Universal Recovery T ank Cover Assembly ........... 5-19

Fig. 5-13 Vacuum Relief V alve Assembly ............................................. 5-20

Fig. 5-14 Dura-Flow APO Pump Assembly .......................................... 5-21

Fig. 7-1 Wiring Schematic .................................................................. 7-3

Fig. 7-2 Wiring Diagram . ................................................................... 7-4

Boxxer H2O Owner’s Manual

HydraMaster Corporation

Page 5

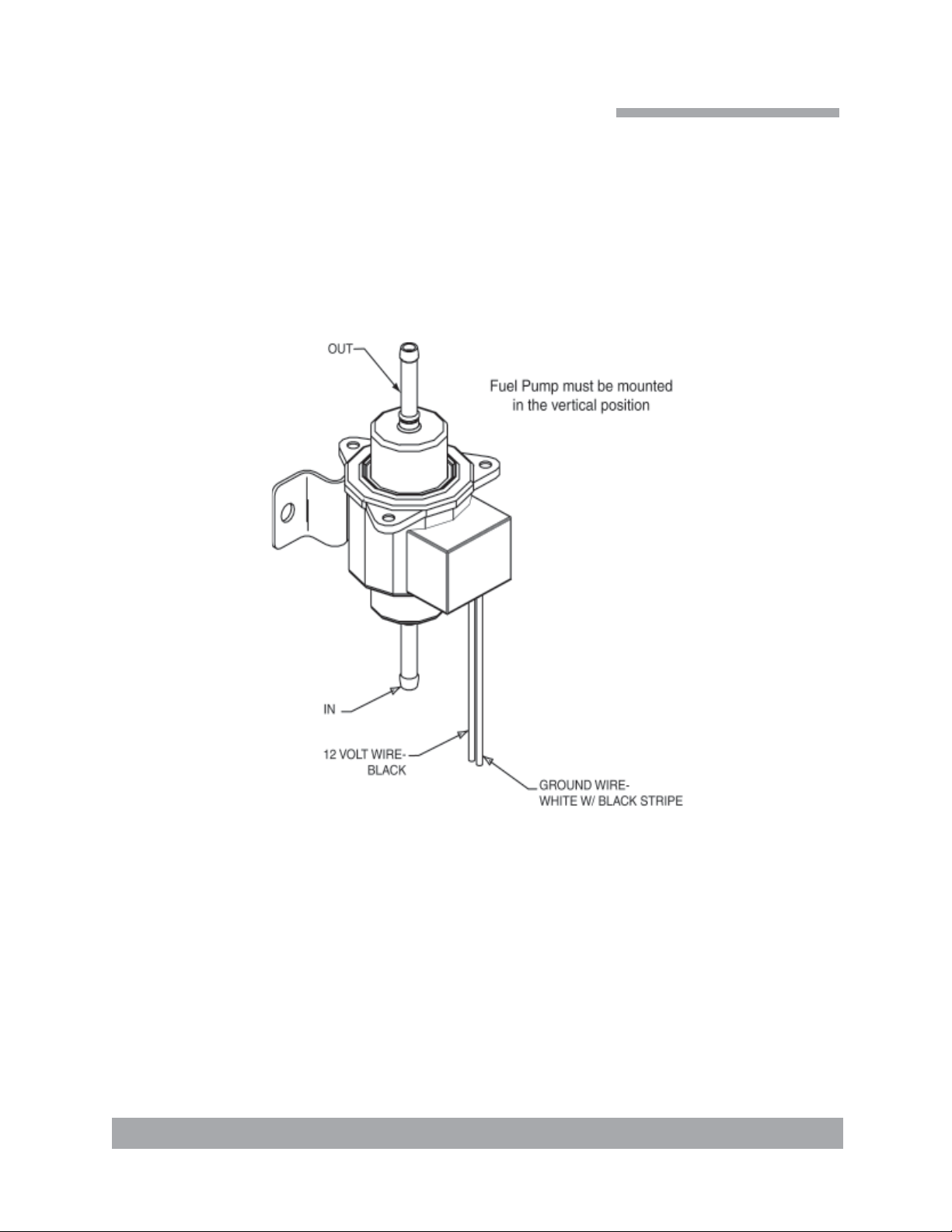

Fuel Pump Assembly

B-4627 Rev -

Boxxer H2O

Quick Refer ence

Boxxer H2O Owner’s Manual

Page 6

Boxxer H2O

This page intentionally left blank.

Boxxer H2O Owner’s Manual

HydraMaster Corporation

Page 7

Boxxer H2O

General Information

The HydraMaster Boxxer H20 is a purpose designed machine to accommodate the needs

of the Water Restoration Contractor who is extracting water and not cleaning carpet. The

basis of the machine is a 27 HP Liquid Cooled V Twin engine that is directly coupled via

the patented BUCS coupling system to a T uthill 4007 Dominator blower. This combination

produces over 400 CFM of air flow, more than enough to extract water with one or two

wands.

In addition to this high performance Power Pack, the Boxxer H20 comes with a 100 gallon

recovery tank. The reliable Dura-Flo Automatic Pump Out is an option which allows you

to extract water without the need to shut down and empty the recovered water.

In addition to the obvious performance aspects of this machine, it was designed to deliver

maximum reliability and to be easily serviced. All the major component s have been proven

in other HydraMaster Truckmounts and this new machine was put together with an eye

towards simple, quick maintenance. All service point s are conveniently located so routine

maintenance takes only a few minutes to perform.

As with any machine, it is important to use the Boxxer H2O correctly. Operating the machine is simple; just start the engine with the vacuum hoses disconnected, let it warm up

for two or three minutes, advance the throttle to the maximum operating position, connect

the vacuum hoses and you are ready to extract water. We strongly suggest that the operator of the machine be well acquainted with the IICRC guidelines for Flood Extraction

and with the various methods of carpet drying that are currently being used. It is also

recommended that the machine operator be familiar with the local municipality’s requirements for the proper disposal of waste water. Typically waste water is to be deposited in

the city sewer system and never in a gutter or storm drain where it would eventually find

it’s way into a stream, river, lake, ocean or public water supply system.

Page 1-1: General Information

Page 8

Boxxer H2O

The manufacturer uses this symbol throughout the manual to

warn of possible injury or death.

This symbol is used to warn of possible equipment damage.

This symbol is used to warn of regulatory or legal issues.

Monday - Friday (425) 775-7276 Parts

8:00 am to 5:00 pm (425) 775-7275 Service

PACIFIC STANDARD TIME (800) 426-4225 Parts / Service FAX

Page 1-2: General Information

Hours Telephone Numbers

HydraMaster Corporation

Page 9

Boxxer H2O

Precautions

ENGINE COOLING: Units employing internal combustion engines must not be enclosed

within a van with doors and windows closed. Excessive temperatures within the engine

will result in premature engine failure and a compromise of applicable warranty.

MOVING PARTS: Never touch any part of the machine that is in motion. Severe bodily

injury may result.

HOT SURF ACES: During the operation of this equipment, many surfaces on the machine

will become very hot. When near the van for any reason care must be taken not to touch

any hot surface, such as blower, engine, exhaust, etc.

HEARING PROTECTION: The Occupational Safety and Health Administration (OSHA)

recommends the use of hearing protection when a technician is exposed to an average of

85 decibels (this is an average of exposure over an 8 hour period). This equipment can

produce 85 decibels to a distance of 10 feet. Please check with your local state agencies

to see if OSHA standards apply to your application.

NO SMOKING: It is unsafe to smoke in or around the vehicle.

CARBON MONOXIDE: This unit generates toxic fumes. Position the vehicle so that the

fumes will be directed away from the job site. Do not park where exhaust fumes can enter

a building through open doors, windows, air conditioning units or kitchen fans.

Page 1-3: General Information

Page 10

Boxxer H2O

TOXIC FUMES: Do not occupy the vehicle when the cleaning equipment is operating.

Toxic fumes may accumulate inside a stationary vehicle.

ENGINE EXHAUST: The engine exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

PORTABLE GAS TANK: Never operate this machine with a portable gas can inside the

truck. Doing so increases the risk of a fire or explosion.

TRANSPORTA TION OF FUEL CONTAINERS: Transportation in a vehicle of any vented

fuel container that presently has or has ever contained a flammable liquid is strictly forbidden by HydraMaster Corporation and by federal and state regulation.

THROUGH-FLOOR DRILLING: Be cautious when drilling holes through the van floor.

Many vans have critical components mounted directly below the van floor that could be

damaged by a misplaced drill bit. (See Product Support Bulletins 92102, 94062 and 94063

at the end of the manual.)

LEVEL OPERATION: During operation, van or trailer must be parked on level ground not

to exceed + or - 10 degrees. Failure to insure proper leveling may prevent proper internal

lubrication of engine and vacuum blower.

The machine cannot be run in the IDLE position for carpet or floor extraction. This will void

the warranty.

EXHAUST SYSTEM: Do not allow flammable material (i.e. oil, fuel, plastic or wood products) to come in contact with the exhaust system.

Page 1-4: General Information

HydraMaster Corporation

Page 11

Boxxer H2O

Responsibilities

In Dodge vans the fuel tanks are located directly against the floor . Caution must be used

when drilling any holes through the floor. (See Product Support Bulletin 94062 at the end

of this manual.)

T o purchase heavy duty 24- 60 amp hour battery and have the battery ‘slow’ charge if new .

If the battery is not fully charged, damage can occur to the engine charging regulator.

Reading of owner’s manual: It is the purchaser’s responsibility to read the unit opera-

tion manual and to familiarize himself with the information contained therein.

Special attention should be paid to all Cautions and Warnings.

The Sales Representative’s responsibilities are:

ACCEPTANCE OF SHIPMENT:

1. If the unit shows any outward signs of damage, do not sign the delivery

receipt until you have closely inspected the unit and noted any damage

on the delivery receipt.

2. The salesman from whom you purchased your unit is responsible for

supervising the correct installation of the unit in your vehicle and thoroughly training you in its operation, maintenance and precautions.

CORRECT INSTALLATION INCLUDES:

• Vehicle of proper load carrying capacity (recommendation: 3/4 ton).

• Installation of through-floor fittings for gasoline fuel lines.

Page 1-5: General Information

Page 12

Boxxer H2O

• Placing the unit and recovery tank in your vehicle and securing them

with bolts or tie down cleats.

• Connecting gasoline lines.

• Connecting the battery.

• Checking the vacuum blower and engine oil levels prior to

staring the unit.

• Starting the unit to check the engine and see that all systems

function normally.

• Checking all hoses, wands, etc. for correct operation.

TRAINING:

• A thorough review of the operation manual with purchaser.

Instruction and familiarization in:

• How to correctly start up and shut down the unit.

• How to correctly recover with the unit.

• Where and how often to check and change component oil levels.

• How the unit’s systems work.

• How to troubleshoot the unit.

• How to do basic repairs.

• Safety precautions and their importance.

• A thorough review of the unit warranty and warranty procedures.

.

Page 1-6: General Information

HydraMaster Corporation

Page 13

Boxxer H2O

Vehicle Preparation

When selecting a truck, remember the preferable vehicle for a Boxxer H2O installation is a

cargo van with a heavy-duty suspension package and a 3/4 capacity. A 3/4 ton or larger

capacity van, with a 2,400 pound payload capacity, is required.

TRUCK PREP ARATION

The manufacturer recommends the installation of a spray-on bed liner in the vehicle prior

to installation of machine.

Be cautious when drilling any holes through the van floor. Many vans have

critical components mounted directly below the van floor that could be damaged by a misplaced drill bit. (See Product Support Bulletins 92101, 94062,

and 94063 at the end of this manual.)

This provides ‘metal to cushion’ mounting rather than ‘metal to metal’ and makes for an

attractive van interior . It is highly recommended to install roof vents in vehicles operated in

hot weather locations. Roof vent positions are shown in Figure 1-1.

Figure 1-1 Roof Vents

Page 1-7: General Information

Page 14

Boxxer H2O

PLACEMENT OF UNIT IN VEHICLE

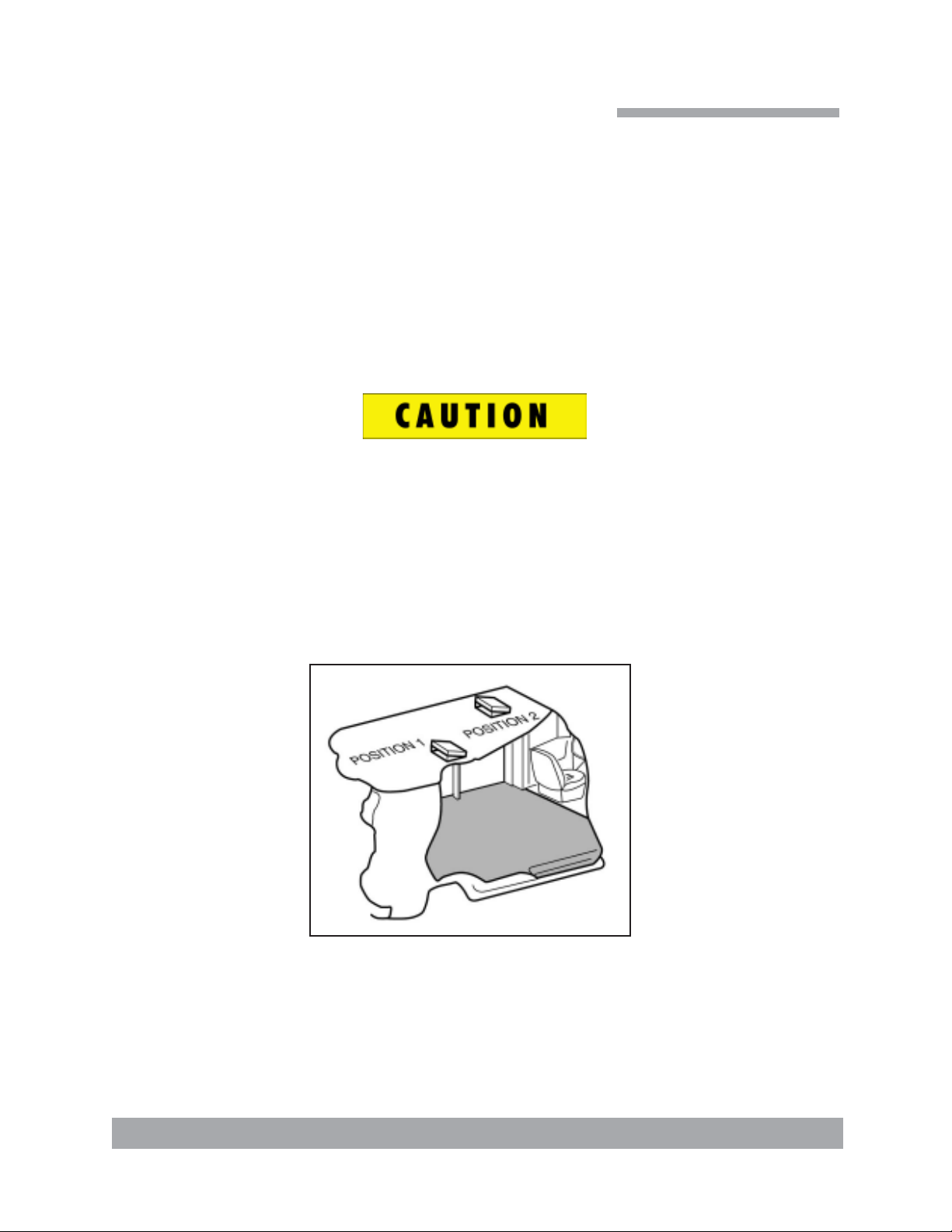

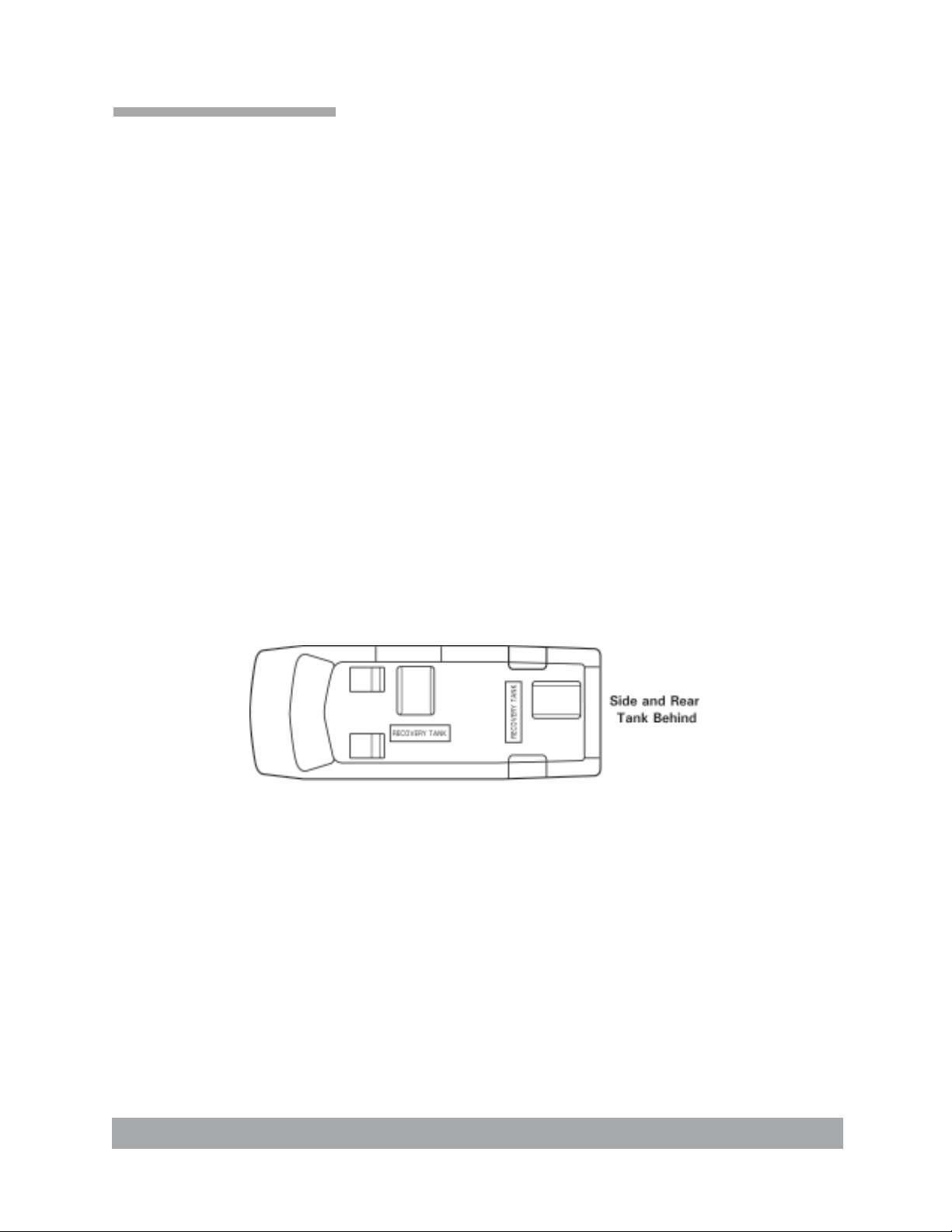

There are two recommended unit placements (shown in Figure 1-2):

SIDE DOOR:

Most installations are side door. This provides rear access for accessories and hoses as

well as unobstructed access to the component/working side of the machine, thus making

it a bit easier to perform maintenance and/or repair without removing the unit from the

truck.

REAR DOOR:

Although this location partly limits working access, it does direct the noise away from the

cleaning site. Some cleaners in the colder areas prefer this location because it puts the

weight over the rear wheels for better traction in ice and snow. Rear mounting requires the

unit to be slid to the right side as far as possible.

This not only provides adequate working space on the component side of the unit but also

improves weight distribution inside the van (engine and component weight line up over

drive shaft). Also, it is physically easier to load the unit into the rear door due to the height

of the van bed.

Figure 1-2 Recommended Placement

Page 1-8: General Information

HydraMaster Corporation

Page 15

Boxxer H2O

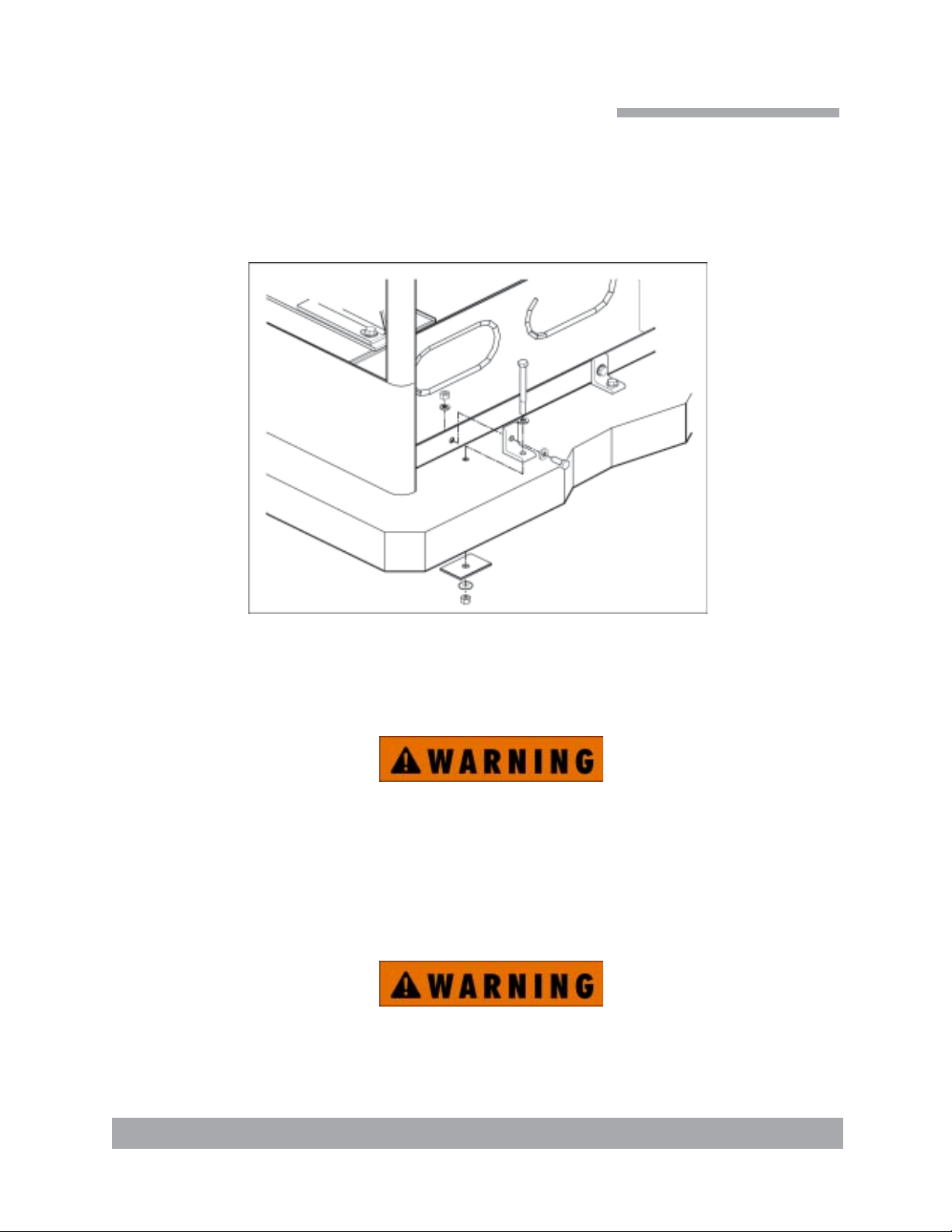

Machine Tie Down Cleats

Secure the machine to the floor of the van with the four tie down cleats provided. This

safety measure will ensure that the machine will not slide inside the van. See the following illustration for the correct installation.

Figure 1-4 Installation Using Tie-down Cleats

Ensure that the machine is well secured to the floor of the van with the hardware

supplied. A sudden stop or crash will cause the machine to rocket forward. Protect

yourself and the machine. SECURE IT!

It is recommended by the manufacturer that the exhaust from the front

of the machine be vented down under the truck to prevent carbon monoxide from entering the job site. Always park the truck so the exhaust is

blowing away from the job site.

The manufacturer also recommends the installation of aluminum vents in

the truck roof to allow heat to escape.

Never operate this machine with a portable gas can inside the truck. Doing

so increases the risk of a fire or explosion.

Mount a fire extinguisher just inside the rear or side door for emergencies.

Page 1-9: General Information

Page 16

Boxxer H2O

Do not use a portable propane tank inside of the truck or van. Doing so may

increase risk of fire or explosion.

Transportation in a vehicle of any vented fuel cont ainer that presently holds

or has ever held a flammable liquid is strictly forbidden by HydraMaster Corporation and by federal and state regulation.

The engine exhaust from this product contains chemicals known to the St ate

of California to cause cancer, birth defects or other reproductive harm.

Page 1-10: General Information

HydraMaster Corporation

Page 17

Boxxer H2O

High Altitude Operation

Preparation

Although this unit has been factory adjusted, it may require additional adjustments

to achieve optimum performance, for instance higher altitudes may require carburetor

adjustment. When required, consult an authorized representative. Elevation plays a key

role in how the machine will operate.

The factory setting of the machine is set for elevations from 0—3,000 feet. Any time the

machine is operated above 3,000 feet there are two areas on the machine the may need

adjustment.

The first area is the carburetor jet. The higher the elevation, the less air is provided to the

fuel mixture. This will make the engine run ‘rich’, and, in turn will result in the loss of

power , excessive heat in the exhaust, and carbon buildup in the exhaust system. The jet

sizes vary per engine and elevation. Consult HydraMaster to obtain proper jet size.

Page 1-11: General Information

Page 18

Boxxer H2O

Local Water Precautions

WASTE WATER DISPOSAL ADVISORY

There are laws in most communities prohibiting the dumping of recovered “gray” water

from carpet cleaning in any place but a sanitary treatment system.

The extracted water recovered into your unit’s vacuum tank must be processed before

being safe for streams, rivers and reservoirs.

IN ACCORDANCE WITH THE EPA, ST A TE AND LOCAL LA WS, DO NOT DISPOSE OF

WASTE WATER INTO GUTTERS, STORM DRAINS, STREAMS, RESERVOIRS, ETC.

In most cases, an acceptable method of waste water disposal is to discharge into a municipal sewage treatment system after first filtering out solid material such as carpet fiber.

Access to the sanitary system can be obtained through a toilet, laundry drain, RV dump,

etc. Permission should first be obtained from any concerned party or agency.

One disposal method which usually complies with the law is to accumulate the waste

water and haul it to an appropriate dump site. Another solution to the disposal problem is

to equip your machine with an Automatic Pump-Out System. These systems are designed to remove waste water from the extractor’s recovery system and actively pump the

water through hoses to a suitable disposal drain. Properly designed, they will continuously monitor the level of waste water and pump it out simultaneously to the cleaning

operation. The hidden benefit of this process is that the technician does not have to stop

his cleaning to empty the recovery tank.

HydraMaster produces an A.P.O. System available which can be ordered with new equipment or installed later.

The penalties for noncompliance can be serious. Always check local laws and regulations

to be sure you are in compliance.

Page 1-12: General Information

HydraMaster Corporation

Page 19

Machine Specifications

Frame: Welded Steel

Weight: 572 lbs.

Engine: Vanguard 27HP Briggs and Stratton

Pressurized Oil System

Spin-on Filter and Oil Cooler

Ignition: Electronic, Keystart

Vacuum Blower: Dominator 4007, Tuthill/M-D Tri-Lobe,

Instruments: Hour Meter, Machine Runtime

Keyed Ignition, Start/Stop

Vacuum Gauge

APO Switch

Recovery Tank “Full” Light

Boxxer H2O

Recovery T ank: 100 Gallon Aluminum, Epoxy Finish

Cleaning Wand: Stainless Steel

Replaceable Grip

Vacuum Hose: 2" Reinforced, 1-1/2" Reinforced.

Standard Equipment: Machine Power Console

Full Instrumentation

Vacuum Recovery Tank

100 ft, 2" Vacuum Hose

10 ft, 1-1/2" Wand Whip Line

Battery Box

Van Decal Package

Van Installation Kit

Operation Manual

HydraMaster Jacket

Page 2-1: Machine Specifications

Page 20

Boxxer H2O

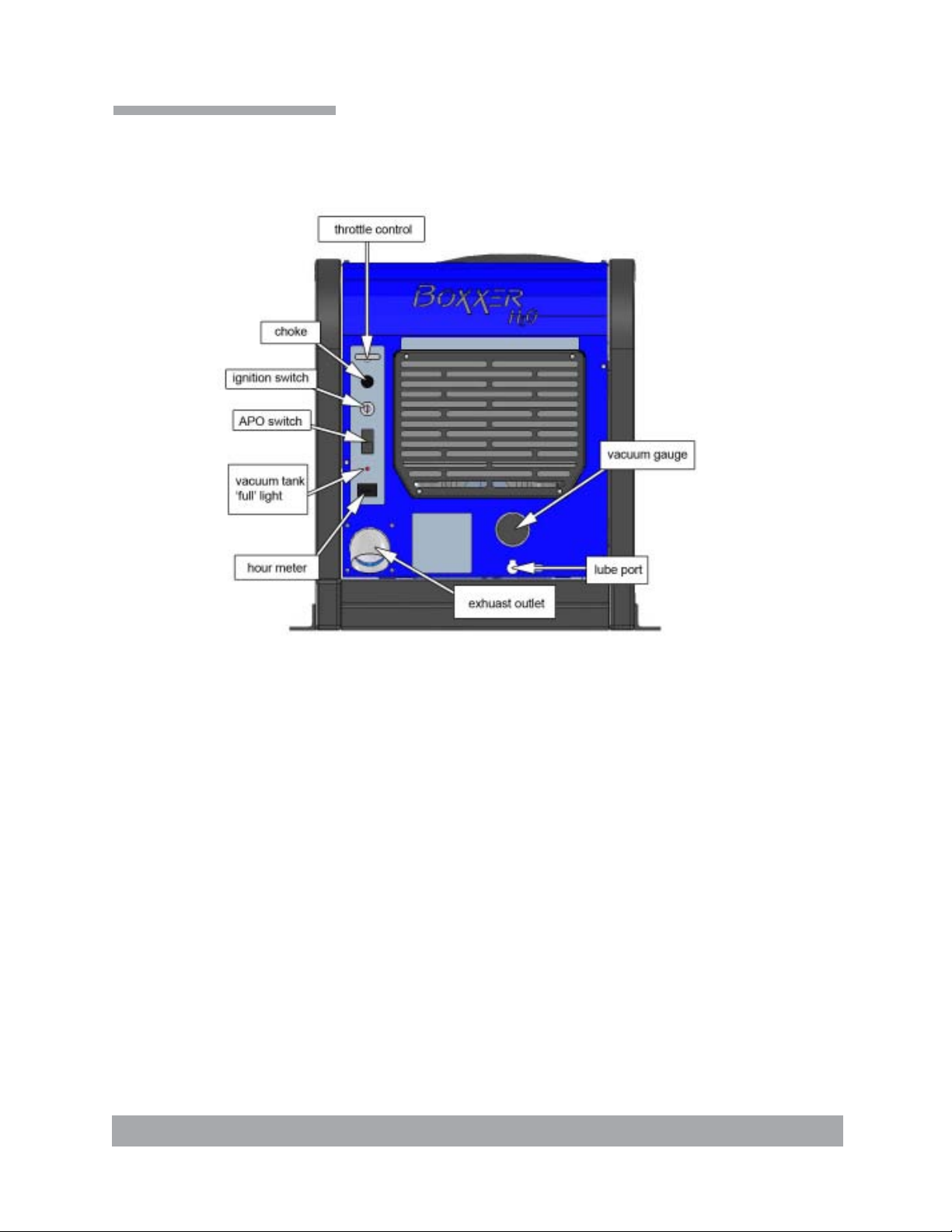

Machine Layout

Throttle Control - Controls the speed of the engine.

Choke - Pull style cable for cold starts.

Ignition Switch - Main power control to the machine.

APO Switch - Activates/Deactivates Automatic Pump Out.

Vacuum Tank ‘Full’ Light - Lights up when vacuum tank is full.

Hour Meter - Displays total number of hours machine has been run during its lifetime.

Exhaust Outlet - Engine and blower exhaust outlet.

Lube Port - Allows blower to be lubricated.

Vacuum Gauge - Displays engine temperature and vacuum.

Page 2-2: Machine Specifications

HydraMaster Corporation

Page 21

Perform daily and periodic maintenance as specified in this Owner’s Manual.

The machine cannot be run in the “IDLE” position for water recovery. This

will void the warranty.

Never run the machine on any speed other than full throttle during water

extraction. Extracting at any other speed will void the warranty.

Start Up

Boxxer H2O

Operating Instructions

Flood Extraction

1. Start the engine with the THROTTLE cable to the “IDLE” position.

Allow the machine to run in idle for 2 - 3 minutes to warm up.

2. Connect required length of hoses.

3. Connect wand or tool.

4. Pull the THROTTLE cable to the “HIGH” position.

5. If used, turn PUMP OUT switch to “ON” .

6. Commence water extraction.

Shut Down

1. Remove the vacuum hose.

2. At this time, the blower should be lubricated with an oil-based lubricant. See

the blower manufacturer’s manual or the maintenance section for lubrication

information.

3. Lower the engine RPMs to idle.

4. Turn the key off.

5. Drain the vacuum tank. The vacuum filter should be cleaned prior to mobilization of the van.

In accordance with the EPA, state and local laws, do not dispose of waste water

into gutters, storm drains, streams, reservoirs, etc.

6. Perform daily maintenance as prescribed in this manual.

Page 3-1: Operating Instructions

Page 22

Boxxer H2O

This page intentionally left blank

Page 3-2: Operating Instructions

HydraMaster Corporation

Page 23

Boxxer H2O

Machine Maintenance

To avoid costly repairs and downtime, it is imperative to develop and practice

good maintenance procedures from the beginning. These procedures fall into daily , weekly ,

monthly and quarterly increments, and are outlined below. All recommended maintenance must be performed by competent service personnel.

Important: Record the date and machine hours on the maintenance log.

We have provided a maintenance log for your convenience at the end of this section.

Records of maintenance must be kept and copies may be required to be furnished to

HydraMaster before the warranty is honored. It is recommended that you affix a copy of

the log on the vehicle door near your unit for convenience and to serve as a maintenance

reminder.

OPERATIONAL MAINTENANCE

DAILY:

• Check engine oil level.

• Visually inspect machine for loose wires, oil leaks, etc.

• Lubricate blower with an oil based lubricant through blower inlet.

WEEKLY:

• Inspect vacuum tank s/s filter and filter basket for tears, holes, etc.

Clean, repair or replace as needed.

• One time change of oil and oil filter after first 50 hours of use.

• Check oil level in blower.

• Check drive system screws. Tighten as needed.

• Check all nuts and bolts. Tighten as needed.

• Inspect vacuum relief valve. Clean and lubricate as necessary.

• Clean vacuum tank thoroughly with high pressure washer.

• Check wiring for chafing.

• Change engine oil (every 100 hrs.).

Page 4-1: Machine Maintenance

Page 24

Boxxer H2O

MONTHLY:

• Change oil filter (every other oil change).

It is important to use only Briggs oil filters. Even though an

aftermarket filter may fit, the internal by-pass system may not be

compatible with the Briggs engine resulting in low oil pressure.

• Check engine air cleaner filter. Clean as necessary.

• Check water level in battery. Clean connections as needed.

QUARTERLY:

• Check fuel lines.

• Clean and gap spark plugs.

• Check drive coupler for cracks or wear. Replace as necessary.

• Change oil in blower.

500 HOURS:

• Check coupler element between the engine and the blower, replace as necessary.

OVERALL MACHINE MAINTENANCE

Maintaining the original appearance of your unit is import ant for two reasons:

1. It represents a big dollar investment for your recovery business and its appearance

should reflect that fact. A dirty machine is not professional.

2. Maintenance, troubleshooting, and repair is much easier to accomplish on a clean,

well maintained unit. Regular cleaning of the machine offers you an opportunity to

visually inspect all facets of the machine and spot potential problems before they

occur.

Page 4-2: Machine Maintenance

HydraMaster Corporation

Page 25

Boxxer H2O

The following maintenance is recommended by the manufacturer at the frequency indicated.

AFTER EACH JOB

• Check recovery tank, s/s filter and filter basket as required.

DAILY

• Wipe machine down thoroughly with a damp cloth.

• Flush recovery tank out thoroughly.

• Empty filter basket and inspect for rips, tears, etc. Replace as needed.

• Remove, thoroughly clean and reinstall stainless steel filter screen in

recovery tank.

• Inspect and clean vacuum slot on recovery wand.

• Check wand head for sharp edges that could tear carpet. File down

as needed.

• Clean wand to maintain original appearance.

• Wipe down vacuum hoses as needed.

• Visually inspect hoses for cuts, etc.

WEEKLY

• Wipe down entire unit as needed.

• Apply good coat of auto wax to all painted surfaces inside and out, and

to control panel.

• Thoroughly clean recovery tank using high pressure water.

• Remove stainless steel filter in recovery tank and thoroughly clean, removing

all lint buildup. Inspect for damage and reinstall.

• Remove filter basket. Thoroughly clean and reinstall.

• Apply light coat of auto wax to wand.

• Thoroughly clean vacuum hoses including hose cuffs.

• Inspect for wear or damage to hoses and quick connect fittings.

Page 4-3: Machine Maintenance

Page 26

Boxxer H2O

This page intentionally left blank

Page 4-4: Machine Maintenance

HydraMaster Corporation

Page 27

BOXXER H2O MAINTENANCE LOG

MAX

HRS

8

8

8

8

See Note

25

25

25

25

25

25

DAILY SERVICE

ENGINE OIL - check

MACHINE - general inspection

VACUUM TANK FILTER BAG - clean

BLOWER INLET - spray with lubricant

WEEKLY SERVICE

OIL - change with filter

BLOWER - check oil level

DRIVE SYSTEM - tighten screws

NUTS & BOLTS - check tightness

VAC. RELIEF VALVE - inspect, clean, lube

VACUUM TANK - clean

WIRING - check for chafing

BLOWER

ENGINE

OIL RECOMMENDATIONS

40 weight non-detergent

See Briggs engine manual

DATE & HOURS

Note: Break-in period determined by manufacturer. Refer to engine manual.

100

100

100

300

300

300

400

MONTHLY SERVICE

ENGINE OIL & FILTER - change

ENGINE AIR CLEANER - clean

BATTERY WATER LEVELS - check

QUARTERLY SERVICE

(3 MONTHS)

FUEL LINES - check

SPARK PLUGS - clean and gap

DRIVE COUPLER - check for wear

BLOWER OIL - change

Page 28

Page 29

Machine Assemblies

and Parts Lists

Figure 5-1 Machine Assembly - Front V iew - Lef t Side

D-6800 Rev -

Boxxer H2O

2

3

1

Page 5-1: Machine Assemblies and Parts List

Page 30

Boxxer H2O

Figure 5-2 Machine Assembly - Front View - Right Side

D-6800 Rev -

Machine Assembly Parts List

Item Part Number Description Qty

1 610-001-036 Assembly, Frame - Boxxer H2O (Fig. 5-3 & 5-5) 1

2 610-050-033 Assembly, Machine Left Side Cover (Fig. 5-9) 1

3 610-050-033 Assembly, Machine Right Side Cover (Fig. 5-10) 1

Page 5-2: Machine Assemblies and Parts List

HydraMaster Corporation

Page 31

Figure 5-3 Frame Assembly - Front View - Lef t Side

D-6801 Rev -

21

Boxxer H2O

10

3

19

20

5

2

6

1

11

12

10

16

4

16

Page 5-3: Machine Assemblies and Parts List

Page 32

Boxxer H2O

Figure 5-4 Frame Assembly - Front View - Right Side

D-6801 Rev -

21

6

11

12

8

13

14

15

10

17

18

8

13

14

HIDDEN

HIDDEN

14

15

9

10

7

9

HIDDEN

HIDDEN

HIDDEN

HIDDEN

15

6

8

13

HIDDEN

HIDDEN

HIDDEN

HIDDEN

Page 5-4: Machine Assemblies and Parts List

HydraMaster Corporation

Page 33

Boxxer H2O

Frame Assembly Parts List

Item Part Number Description Qty

1 000-055-186 Frame, Weldment - Boxxer H2O 1

2 610-003-036 Assembly, Engine - Boxxer H2O (Fig. 5-5) 1

3 610-002-036 Assembly, Blower - Boxxer H2O (Fig. 5-6) 1

4 610-020-036 Assembly, Dash Boxxer H2O (Fig. 5-7) 1

5 601-003-036 Assembly, Exhaust - Boxxer H2O (Fig. 5-8) 1

6 000-092-017 Mount, Rubber Isolator - Boxxer H2O 3

7 000-105-012 Plate, Machine Serial I.D. 1

8 000-033-053 Clamp, 1-1/2" Cushion Loop 3

9 000-140-015 Rivet, 1/8" x 1/4" Lg. Pop 2

10 000-020-063 Bushing, Snap, 0.55" O.D. x 0.312" I.D. 4

11 000-143-013 Screw, 5/16"-18UNC x 1.00" Lg. Grade 8 12

12 000-174-018 Washer, 5/16" Lock 12

13 000-174-001 Washer , #10 Flat 3

14 000-174-014 Washer, #10 Lock 3

15 000-143-126 Screw, #10-24UNC x 0.50" Lg. Hex Head 3

16 000-027-033 Cap, Frame End - Raw 2

17 000-068-660 Hose, 1/4" I.D. Trident Fuel - Bulk 1

18 000-131-055 Insulation, Hi T emp Sleeving - Bulk 1

19 000-068-030 Hose, 5/32" I.D. Vacuum - Bulk 1

20 000-068-030 Hose, 5/32" I.D. Vacuum - Bulk 1

21 000-081-036 Label, ANSI Warning Text Only 2

Page 5-5: Machine Assemblies and Parts List

Page 34

Boxxer H2O

Figure 5-5 Engine Assembly

D-6802 Rev A

26

15

6

5

4

21

25

19

20

2

16

1

18

19

11

12

14

23

8

7

1322

Page 5-6: Machine Assemblies and Parts List

17

24

7

10

9

10

7

3

10

11

8

HydraMaster Corporation

Page 35

Boxxer H2O

Engine Assembly Parts List

Item Part Number Description Qty

1 000-047-026 Engine, Briggs & Stratton 27HP 1

2 000-047-026 Air Cleaner - Daihatsu Engine 1

3 000-092-011 Mount, Engine 27 B&S 1

4 000-057-050 Gasket, Thermostat Housing Daihatsu Engine 1

5 000-047-026 Thermostat, Stock B&S 27HP 1

6 000-047-026 Thermostat Housing, B&S 27 HP Stock 1

7 000-174-007 Washer, 1/2" Flat 4

8 000-094-037 Nut, 1/2"-13UNC Hex 2-Way Locking - z/p 2

9 000-143-568 Screw, 5/16"-18UNC x 2.50" Lg. Hex Head Grade 8 4

10 000-174-004 Washer , 5/16" Flat 8

11 000-094-081 Nut, 5/16"-18UNC Hex 2-Way Locking 5

12 000-033-117 Clamp, 1" Cushion Loop w/ 7/16" Mount Hole 1

13 000-052-063 Bushing, 14mm x 1/4" NPT Engine Oil Drain Adapter 1

14 000-068-221 Hose, Engine Oil Drain 1

15 000-068-595 Hose, 1.75" x 18.25" x 90 Molded Radiator 1

16 - - - Screw, 8mm x 25mm Lg. Hex Head W asher 2

17 000-049-014 Filter, 16HP Oil - All B & S 1

18 000-1 11-171 Pump, B&S 27 HP W ater 1

19 000-056-006 Fuse Holder, Inline Weather Proof 2

20 000-056-011 Fuse, 30 AMP Plug In 1

21 000-113-007 Radiator, 27 HP B & S Engine 1

22 000-052-082 Elbow, 1/4" NPT Street x 45° 2

23 000-143-155 Screw, 1/2"-13UNC x 3.50" Lg. Hex Head 2

24 000-077-010 Key, 1/4" x 1-1/2" Lg. Class 2 Fit 1

25 000-056-005 Fuse, 25 AMP Plug In 1

26 000-049-063 Filter, Replacement - Engine Air Daihat su 1

Page 5-7: Machine Assemblies and Parts List

Page 36

Boxxer H2O

Figure 5-6 Blower Assembly

D-6803 Rev A

13

6

5

23

8

18

20

21

20

16

15

30

14

1

23

8 13

10

3

8

8

13

29

2

5

12

7

22

26

25

19

Page 5-8: Machine Assemblies and Parts List

27

28

4

9

8

11

29

12

7

17

23

8

24

HydraMaster Corporation

Page 37

Boxxer H2O

Blower Assembly Parts List

Item Part Number Description Qty

1 000-1 1 1-167 Blower , MD 4007 C-Face Dual Shaft 1

2 000-015-814 Bracket, Dominator Mounting 1

3 000-042-063 Housing, Bell - Modified 1

4 000-039-053 Coupler, 50 Series 1

5 000-174-007 Washer, 1/2" Flat 2

6 000-094-037 Nut, 1/2"-13UNC Hex 2-Way Locking - Z/P 1

7 000-052-142 Elbow, 3/8" FPT x FPT 2

8 000-174-021 Washer, 3/8" Lock 19

9 000-143-025 Screw, 3/8"-16UNC x 1.25" Lg. Hex Head Grd 8 4

10 000-143-200 Screw, 3/8"-16UNC x 1.50" Lg. Grade 8 4

11 000-174-004 Washer , 5/16" Flat 4

12 000-052-077 Nipple, 3/8" NPT Close 2

13 000-143-018 Screw, 3/8"-16UNC x 1.00" Lg. Grade 8 7

14 000-001-115 Adapter, Blower Flange T o 3" M Slip 1

15 000-174-019 Washer, 1/4" Lock 6

16 000-143-001 Screw, 1/4"-20UNC x 0.75" Lg. Hex Head 6

17 000-013-069 Box, Blower Collector - Weldment 1

18 000-093-104 Silencer, Weldment 1

19 000-052-106 Insert, 1/8" NPT x 5/32" Barb x 90° 2

20 000-033-013 Clamp, Size #48 Hose 2

21 000-068-398 Hose, 3" I.D. x 3 Ply Silicone 1

22 000-143-155 Screw, 1/2"-13UNC x 3.50" Lg. Hex Head 1

23 000-174-005 Washer, 3/8" Flat 8

24 000-143-139 Screw, 3/8"-16UNC x 4.00 Lg. Grd 8 4

25 000-068-219 Hose, Drain 1

26 000-068-219 Hose, Drain 1

27 000-078-424 Kit, Metal Ring Retainer 3 Pc. (Replacement) 1

28 000-152-010 Sleeve, 50 Series S plit (Replacement) 1

29 000-027-112 Plug, Oil Sight Glass Tuthill Blower 2

30 000-174-003 Washer, 1/4" Flat 6

Page 5-9: Machine Assemblies and Parts List

Page 38

Boxxer H2O

Figure 5-7 Dash Assembly

D-6804 Rev A

13

12

11

1

14

2

11

19

18

6

5

3

7

23

22

4

12

13

21

12

11

23

22

11

12

21

10

17

Page 5-10: Machine Assemblies and Parts List

16

15

20

9

8

HydraMaster Corporation

Page 39

Boxxer H2O

Dash Assembly Parts List

Item Part Number Description Qty

1 000-100-163 Panel, Dash 1

2 000-100-145 Panel, Grill 1

3 000-157-008 Switch, Ignition 1

4 000-074-018 Meter, Rectangular w/o Bezel 1

5 000-025-002 Cable, Choke (3 Foot) 1

6 000-025-030 Cable, Throttle 1

7 000-157-040 Switch, 20 AMP Rocker 1

8 000-074-017 Gauge, 0-30” Hg Vac. 2 1/2” HydraMaster Face 1

9 000-052-272 Cup, Gravity Feed Oil Blower Lubrication Port 1

10 000-084-011 Light, Red Led Indicator Mini 1

11 000-174-001 Washer, #10 Flat 13

12 000-174-014 Washer, #10 Lock 13

13 000-143-126 Screw, #10-24UNC x 0.50” Lg. Hex Head 9

14 000-131-131 Trimlock, 3/8” x 1/8” Groove - Bulk 1

15 000-174-032 Washer, 3/8” Flat 2

16 000-052-096 Insert, #F23 (1/8” FPT x 3/16” Barb) 1

17 000-081-036 Label, ANSI Warning 1

18 000-081-036 Label, Dash Controls 1

19 000-081-036 Label, Water Recovery System 1

20 000-081-036 Label, Lube Port - Boxxer H2O 1

21 000-143-133 Screw, #10-24UNC x 1.50” Lg. Hex Head 4

22 000-033-057 Clamp, 1” Cushion Loop 2

23 000-094-034 Nut, #10-24UNC Nylock 2

Page 5-11: Machine Assemblies and Parts List

Page 40

Boxxer H2O

Figure 5-8 Exhaust Assembly

D-6805 Rev -

2

13

18

16

17

5

13

14

11

1

9

8

7

10

171615

3 13

11

12

6

12

413

11

Page 5-12: Machine Assemblies and Parts List

HydraMaster Corporation

Page 41

Boxxer H2O

Exhaust Assembly Parts List

Item Part Number Description Qty

1 000-125-223 Tube, Lower Exhaust - Boxxer H2O 1

2 000-093-103 Muffler , Weldment - Boxxer H2O 1

3 000-015-931 Bracket, Exhaust Support - Boxxer H2O 1

4 000-001-098 Adapter, Exhaust Turndown - W eldment 1

5 000-068-398 Hose, 3" I.D. x 3 Ply Silicone - Bulk 1

6 000-068-398 Hose, 3" I.D. x 3 Ply Silicone - Bulk 1

7 000-057-177 Gasket, Exhaust Donut 1.50" 1

8 000-125-128 Tube, 1-3/8" O.D. x 1/8" Wall x 7/8" Long 1

9 000-143-124 Screw, 5/16"-18UNC x 1.75" Lg. Hex Head 2

10 000-094-081 Nut, 5/16"-18UNC Hex 2-Way Locking 2

11 000-174-003 Washer , 1/4" Flat 8

12 000-094-009 Nut, 1/4"-20UNC Hex Nylock 6

13 000-033-013 Clamp, Size #48 Hose 4

14 000-143-001 Screw, 1/4"-20UNC x 0.75" Lg. Hex Head 2

15 000-143-013 Screw, 5/16"-18UNC x 1.00" Lg. Grade 8 2

16 000-174-018 Washer, 5/16" Lock 4

17 000-174-004 Washer , 5/16" Flat 4

18 000-143-187 Screw, 8mm x 25mm Lg. Grade. 10.9 Hex Head 2

Page 5-13: Machine Assemblies and Parts List

Page 42

Boxxer H2O

Figure 5-9 Machine Left Side Cover Assembly

D-5587 Rev -

5

6

1

6

5

4

3

2

4

3

Machine Left Side Cover Assembly Parts List

Item Part Number Description Qty

1 000-041-417 Cover, Left Side Machine - Boxxer 427 1

2 000-105-313 Plate, Hydramaster Name- Roto T ank 1

3 000-174-001 Washer, #10 Flat 2

4 000-143-166 Screw, #10-24UNC x 0.38" Lg. Hex Head 2

5 000-094-034 Nut, #10-24UNC Nylock 2

6 000-089-003 Magnet, Treadmaster 2

Page 5-14: Machine Assemblies and Parts List

HydraMaster Corporation

Page 43

Figure 5-10 Machine Right Side Cover Assembly

D-5762 Rev -

1

6

5

Boxxer H2O

6

5

4

2

3

4

3

Machine Right Side Cover Assembly Part s List

Item Part Number Description Qty

1 000-041-419 Cover, Right Side Machine - Boxxer 427 1

2 000-105-313 Plate, Hydramaster Name- Roto T ank 1

3 000-174-001 Washer , #10 Flat 2

4 000-143-166 Screw, #10-24UNC x 0.38" Lg. Hex Head 2

5 000-094-034 Nut, #10-24UNC Nylock 2

6 000-089-003 Magnet, Treadmaster 2

Page 5-15: Machine Assemblies and Parts List

Page 44

Boxxer H2O

Figure 5-1 1 100 Gallon Universal Recovery Tank Assembly

D-7149 Rev A

12

11

HIDDEN

HIDDEN

HIDDEN

2

26

19

20

9

7

27

20

30

20

29

5

33

37

20

29

6

27

15

HIDDEN

18

HIDDEN

28

13

16

17

8

14

36

35

29

31

4

38

25

10

32

HIDDEN

28

HIDDEN

13

3

HIDDEN

32

28

HIDDEN

21

24 23 22

34

10

13

3

1

Page 5-16: Machine Assemblies and Parts List

HydraMaster Corporation

Page 45

Boxxer H2O

100 Gallon Universal Recovery T ank Assembly Parts List

Item Part Number Description Qty

1 000-159-129 Tank, 100 Gallon Universal Recovery - Weldment 1

2 Fig. 5-12 Assembly, Recovery Tank Cover - 100 Gallon 1

3 000-157-090 Float, Lever Switch 2

4 000-079-091 Kit, Dura-Flow APO - Production (Fig. 5-14) 1

5 Fig. 5-13 Assembly, V acuum Relief V alve 1

6 000-049-152 Filter, Recovery Tank Basket 1

7 000-049-153 Filter, Flat - Recovery Tank 1

8 000-012-002 Block, 6 Post T erminal 1

9 000-015-932 Bracket, Flat Filter Securing - Universal Recovery T ank 1

10 000-033-023 Clamp, 3/4" Nylon Hose 2

11 000-049-154 Deflector, Air - Univeral Recovery Tank 1

12 000-140-023 Rivet, AB8-6A Aluminum Pop 6

13 000-143-126 Screw, #10-24UNC x 0.50" Lg. Hex Head 5

14 000-143-051 Screw, #8-32UNC x 0.75" Lg. Binder Head Phillips 2

15 000-094-059 Nut, #8-32UNF Nylock 2

16 000-086-008 Latch, Bungie 1

17 000-143-539 Screw, #6-32UNC x 0.50" Lg. Button Head Allen 2

18 000-094-063 Nut, #6-32UNC Nylock 2

19 000-174-019 Washer, 1/4" Lock 2

20 000-174-003 Washer, 1/4" Flat 18

21 000-106-019 Plug, 1-1/2" NPT 1

22 000-052-763 Nipple, 1-1/2" IPS Close s/s 1

23 000-169-022 Valve, 1-1/2" Full Port Ball 1

24 000-052-226 Insert,1-1/2" NPT x 1-1/2" Barb (Grey) 1

25 000-081-036 Label, Maintenace And Lubrication Schedule 1

26 000-143-333 Screw, 1/4"-20UNC x 0.50" Lg. Hex Head 2

27 000-174-029 Washer, 3/8" Rubber Back 2

28 000-174-036 Washer, #10 Flat Rubber Backed 5

29 000-143-002 Screw, 1/4"-20UNC x 1.00" Lg. Hex Head 12

30 000-094-009 Nut, 1/4"-20UNC Hex Nylock 8

Page 5-17: Machine Assemblies and Parts List

Page 46

Boxxer H2O

100 Gallon Universal Recovery T ank Assembly Parts List

Item Part Number Description Qty

31 000-166-002 Tray, Soap Jug - Weldment 1

32 000-094-034 Nut, #10-24UNC Nylock 2

33 000-057-206 Gasket, Adapter - Universal Recovery T ank 2

34 000-106-049 Plug, 1" NPT Allen Head 1

35 000-174-060 Washer, 1/4" Flat Rubber Backed 4

36 000-094-113 Nut, 1/4"-20UNC Neoprene Wellnut 4

37 000-001-135 Adapter, Tank T o Ø3.0" x 90° Blower Hose - Universal Recov 1

38 000-106-007 Plug, 1/4" NPT Allen Head 1

Page 5-18: Machine Assemblies and Parts List

HydraMaster Corporation

Page 47

Boxxer H2O

Figure 5-12 100 Gallon Universal Recovery Tank Cover Assembly

D-6919 Rev -

8

2

5

6

7

9

1

3

4

10

11

9

100 Gallon Universal Recovery Tank Cover Assembly Parts List

Item Part Number Description Qty

1 000-041-447 Cover, 100 Gallon Universal Recovery Tank - Weldment 1

2 000-078-039 Vacuum Inlet Stopper Assembly - Recovery Tank 1

3 000-057-015 Gasket, 1-1/2" Bulkhead Fitting 2

4 000-052-219 Adapter, 2" NPT x 2" F Slip 2

5 000-143-539 Screw, #6-32UNC x 0.50" Lg. Button Head Allen 2

6 000-086-008 Latch, Bungie - Strike 1

7 000-094-063 Nut, #6-32UNC Nylock 2

8 000-052-222 Elbow, 2" Barb x 2" FPT 2

9 000-057-202 Gasket, End - Recovery Tank 2

10 000-057-203 Gasket, Middle - Recovery Tank 3

11 000-057-205 Gasket, Side - Recovery Tank - 100 Gallon 2

Page 5-19: Machine Assemblies and Parts List

Page 48

Boxxer H2O

Figure 5-13 Vacuum Relief Valve Assembly

C-6894 Rev -

7

5

3

1

4

8 2

6

V acuum Relief Valve Assembly Part s List

Item Part Number Description Qty

1 000-015-182 Bracket, Vacuum Relief V alve 1

2 000-027-032 Cap, V acuum Releif V alve 1

3 000-125-111 Pipe, V acuum Relief S pring Guide 1

4 000-105-332 Plate, Vacuum Relief V alve Mounting - Universal Recovery T 1

5 000-155-026 Spring, V acuum Relief 1

6 000-143-198 Screw, 3/8"-16UNC x 4" Lg. Hex Head Full Thread 1

7 000-094-077 Nut, 3/8"-16UNC x 1.00" O.D. Knurled 2

8 000-094-101 Nut, 3/8"-16UNC Hex Jam 1

Page 5-20: Machine Assemblies and Parts List

HydraMaster Corporation

Page 49

Figure 5-14 Dura-Flow APO Assembly

D-5654 Rev E

Boxxer H2O

2

38

5

6

7

7

6

13

4

8

6

12

14

4

16

17

15

22

1

5

16

17

9

18

10

19

21

20

Page 5-21: Machine Assemblies and Parts List

Page 50

Boxxer H2O

Dura-Flow APO Assembly Parts List

Item Part Number Description Qty

1 000-1 1 1-169 Assembly , APO Pump - Jabsco 1

2 000-091-042 Motor, Bison 438 Series 1

3 000-015-891 Bracket, APO Clamp 1

4 000-015-890 Bracket, T ank Mounted APO Support 1

5 000-143-566 Screw, 1/4-28UNF x 0.75" Lg. Socket Head 4

6 000-143-074 Screw, 1/4"-20UNC x 0.50" Lg. Hex Head Self-T apping 4

7 000-174-002 Washer, 1/4" Flat 4

8 000-061-131 Knob, Handle - Rdm 2

9 000-052-723 Fitting, 1" NPT Cam Lock - Banjo 100F 1

10 000-052-724 Fitting, 1" NPT Cam Lock - Banjo 100B 1

11 000-157-022 Switch, Relay 1

12 000-012-011 Block, 6 Post 1

13 000-094-027 Nut, #10-24UNC Hex 1

14 000-143-532 Screw,#6-32UNC x 5/8" Lg. Socket Head 2

15 000-068-069 Hose, 3/4" I.D. Weatherhead - Blue - Bulk. 1

16 000-033-026 Clamp, Size #10 Hose 2

17 000-052-338 Insert, #1212 (3/4" NPT x 3/4" Barb) 2

18 000-169-009 Valve, 3/4" FPT Swing Check 1

19 000-052-281 Nipple, 3/4" NPT x 3/4" Male Garden Hose 1

20 000-057-055 Gasket, Garden Hose 1

21 000-027-014 Cap, Garden Hose 1

22 000-052-425 Bushing, 1" NPT x 3/4" FPT 1

Page 5-22: Machine Assemblies and Parts List

HydraMaster Corporation

Page 51

(To be Added)

Boxxer H2O

Page 5-23: Machine Assemblies and Parts List

Page 52

Boxxer H2O

(To be Added)

Page 5-24: Machine Assemblies and Parts List

HydraMaster Corporation

Page 53

Boxxer H2O

This page intentionally left blank

Page 5-25: Machine Assemblies and Parts List

Page 54

Boxxer H2O

Vacuum System

The vacuum pump in this machine is commonly referred to as a ‘positive displacement lobe’

type blower. The performance and life of this unit is greatly dependent on the care and proper

maintenance it receives.

Because of the close tolerances between the lobes and housing of the vacuum blower, solid

objects entering the inlet will damage the internal lobes, gears, bearings or drive system.

T o prevent this, a stainless steel filter screen has been placed at the vacuum inlet inside the

vacuum recovery tank. This stainless steel screen is ‘finger’ tight and should be removed

for cleaning weekly .

T o protect the vacuum blower from overloading and damaging itself, there is a vacuum relief

system installed on the vacuum tank. When the vacuum tank inlet is completely sealed off, a

maximum of 12 HG will be attained.

At the end of each day , an oil based lubricant should be sprayed into the blower lubrication

port before shutting down the machine. Lubricate the vacuum blower daily to prevent rust

deposits and moisture that will decrease the life of the vacuum blower .

Foam passing through the blower could lead to serious problems.

It is important to keep the vacuum tank foam free.

Read the vacuum blower manual carefully for proper oil change. The maintenance log may

differ slightly from the manual, but the truck-mounted carpet cleaning machine application is

very demanding of the vacuum blower and therefore it should be maintained more regularly .

The vacuum tank is protected from overflowing by a vacuum tank float kill switch. The switch

is not activated by foam, only by liquid.

VACUUM TANK FILTER BASKETS

HydraMaster filter baskets are designed to trap lint, sand and dirt that would normally collect

at the bottom of your vacuum tank. The use of these filters, if emptied at the end of each job,

will eliminate the build-up of much of the debris in the tank.

Page 6-1: Vacuum System

Page 55

Boxxer H2O

Vacuum System

Troubleshooting

1.0. Weak vacuum at wand. Gauge reads normal (10" to 12" with hoses & wand

attached)

1.1. Clogged hoses or wand tube. Disconnect hoses and check carefully for an obstruction.

1.2. Excessive length of hoses connected to machine. Make sure machine is rated

for the conditions under which it is being operated.

2.0. V acuum gauge will not come up to 12" hg

2.1. There is an air leak somewhere in the vacuum system. Check vacuum relief

valve for proper adjustment. Carefully check all vacuum hoses for a cut or break.

Check recovery tank lid gasket. Make sure recovery tank drain valve is fully closed.

2.2. V acuum blower is turning too slowly. Check engine RPM. Adjust as necessary

to 3000RPM.

2.3. The vacuum gauge is defective. Test gauge and replace as necessary .

3.0. V acuum gauge reads too high with no hoses attached

3.1. Filter in recovery t ank is clogged. Remove and clean or replace as necessary .

3.2. Hose from vacuum blower to recovery tank is collapsed internally. Inspect

and replace as necessary .

4.0. Noisy vacuum blower

4.1. Vacuum blower is low on oil. Inspect oil level and replenish as necessary . Note:

Running vacuum blower low on oil can cause severe mechanical damage. If this

situation occurs, it should be inspected by a qualified service technician.

4.2. V acuum blower has internal damage. Refer to qualified service technician.

Page 6-2: Vacuum System

HydraMaster Corporation

Page 56

Boxxer H2O

5.0. Vacuum blower is locked and will not turn.

5.1. The machine has been unused for a period on time and the blower was not

properly lubricated when it was shut down, causing rust to build up on internal surfaces. Spray penetrating oil into blower inlet and let sit for at least one hour .

Then very carefully use pipe wrench on outer diameter of pulley on blower shaft and

attempt to free up blower . Do not use wrench directly on blower shaft. If unable to free

up blower in this manner , refer to qualified service technician.

5.2. There is internal damage to the blower. Refer to qualified service technician.

Miscellaneous

Troubleshooting

1.0. W ater from exhaust

1.1. The recovery t ank has been filled with foam or overfilled with water. Remove

recovery tank lid and inspect. If full, drain tank then inspect high-level shutoff switch for

proper operation. Clean or replace switch as necessary .

1.1.1. If foam is observed in recovery tank, use defoamer.

1.2. Condensation. This will be more pronounced in cool weather and humid climates.

Observe how long this condition persists after starting machine. If it is only until the

machine warms up, it is normal.

Page 6-3: Vacuum System

Page 57

Boxxer H2O

This page intentionally left blank.

Page 6-4: Vacuum System

HydraMaster Corporation

Page 58

Boxxer H2O

Electrical System

The Boxxer electrical system, in keeping with the entire machine concept, has

been kept to a minimum so as to keep any necessary troubleshooting as easy as possible.

The entire electrical system operates on 12 volts DC which is provided by a battery. Battery levels are sustained by a 16 amp alternator inside the engine.

NOTE: When a new battery is installed, check that it is properly charged

before installation or damage to the charging regulator may occur.

Page 7-1: Electrical System

Page 59

Boxxer H2O

This page intentionally left blank

Page 7-2: Electrical System

HydraMaster Corporation

Page 60

Boxxer H2O

Figure 7-1 Wiring Schematic

D-6838 Rev -

Page 7-3: Electrical System

HydraMaster Corporation

Page 61

Boxxer H2O

21(BRN) 14 GA.

6

F

E

D

C

18(ORG/BLK)

B

A

J-4

P-4

17(ORG)

5

4

3

2

1

(WHT)

(GRN)

TB1

HIGH WATER FLOAT

FS-1

PS-1

12V BATTERY

EXISTING

+

-

FUEL PUMP

PMP-1

BRIGGS AND STRATTON ENGINE

MTR-1

(YEL)

(YEL)

10(ORG)

11(RED) 12GA.

(ORG)

B-2

(ORG)

6(RED)

(BLK)

2(RED) 4 GA.

1(BLK) 4 GA.

5(WHT/GRN)

(WHT/BLK)

14(ORG/BLK)

16(BRN) 14 GA.

4(WHT) 14 GA.

J-2

P-2

J-3

P-3

10(ORG)

30A IN-LINE FUSE

19(WHT) 14 GA.

4(WHT) 14 GA.

P-1

ENGINE

PLUG

(RED)

(GRY)

(YEL)

9(YEL)

(GRY)

7(RED) 12 GA.

(GRN)

(WHT)

FS-2

APO FLOAT

22(WHT)-14 GA.

(BLK)

PMP-2

(RED)

(BLK)

J-4

B

A

P-4

TB-2

APO TERMINAL

BLOCK

(WHT)

5

6

2

4

3

1

(BLK)

(WHT)

RELAY

APO PUMP

CR-1

27(WHT/RED)

28(WHT/BLU)

29(BLK)-14 GA.

26(WHT)-14 GA.

87

87A

85

30

86

27(WHT/RED)

25(WHT)-14 GA.

24(BLK)-14 GA.

PUMP

APO

23(BLK)-14 GA.

26(WHT)-14 GA.

AUTO PUMP OUT OPTION

B-1

FU-1

(BLK)

(BLK)

15(RED/WHT)

20(RED/WHT)

8(BLK) 12 GA.

3(WHT) 18 GA.

ST

BAT

ACC

IGN

SWITCH

SW-2

IGNITION

+

HOUR METER

HI-1

12(BRN)-14 GA.

13(BRN)-14 GA.

2

3

SWITCH

APO

SW-1

L-1

RECOVERY

TANK FULL

LIGHT

(BLK)

(RED)

25A IN-LINE FUSE

FU-2

B-3

B-4

B-5

(RED)

16(BRN) 14 GA.

15(RED/WHT)

3(WHT) 18 GA.

8(BLK) 12 GA.

9(YEL)

11(RED) 12GA.

6(RED)

14(ORG/BLK)

12(BRN)-14 GA.

(BLK)

ENGINE

SIDE

MACHINE

SIDE

CARB SOLENOID

V-1

CHARGING COIL

(INTERNAL)

STARTER

SOLENOID

SOL-1

GND-1

VOLTAGE

REGULATOR

VR-1

RECOVERY TANK ASSEMBLY

C

Wiring DiagramFigure 7-2.

6837 Rev. C

Page 7-4: Electrical System

HydraMaster Corporation

Page 62

Boxxer H2O

Electrical Troubleshooting

No. Problem/Possible Cause Solution

1.0

1.1 The regulator/rectifier is bad. Check the B+ voltage from the

1.2 The stator winding is bad.

The engine is not charging the battery.

regulator/rectifier to ground. With

the engine running at normal RPM

the voltage should be 12.5 to 14.5

DC volts. If necessary, replace the

regulator/rectifier.

Check for AC voltage at the regulator/

rectifier. The stator should be producing an AC voltage of around 25 to

40 volts. Check your Owner’s manual

for the exact voltage. If necessary,

replace the stator winding.

No. Problem/Possible Cause Solution

2.0 The fuse is blown.

2.1 There is an electrical short Check for a loose wire or a wire that

in the system. has rubbed it’s insulation off and is

shorting out to ground. Unscrew each

individual wire (except the white wires)

one at a time until the fuse does not

trip. Then trace that circuit.

Page 7-5: Electrical System

Page 63

Boxxer H2O

This page intentionally left blank.

Page 7-6: Electrical System

HydraMaster Corporation

Page 64

Boxxer H2O

Engine Troubleshooting

1.0.Will not turn over

1.1. There is a loose or corroded battery terminal. Clean and tighten the battery terminal

connections.

1.2. The battery is dead. Recharge or replace the battery. Test the charging system.

Repair if necessary.

Do not attempt to jump-start this machine from a running vehicle. The

amperage output froman automobile will damage the charging system of the

truckmount.

1.3. The 25 amp main power fuse in the electrical panel has blown. Inspect the wiring

thoroughly to locate shorted or damaged wires.

1.4. The vacuum blower has seized. Attempt to turn the engine by hand. If it will not turn,

refer to Vacuum System section.

1.5. The ignition switch is defective. Test to see if there is 12 volts to the switch. If there

is, but there is not 12 volts going from the switch, replace the switch.

1.6. There is a problem with the starter solenoid. If there is 12 volts at the battery

connection and at the key switch connection with the key in the start position but there is

not 12 volts on the starter connection of the solenoid, replace the solenoid.

1.7. The starter motor is defective. Check to see if the engine can be turned over by

hand. If it can and if there is 12 volts from the starter solenoid to the starter, replace the

starter.

1.8. There is a mechanical problem with the engine. If the engine can be turned over by

hand and the vacuum blower is not locked, refer the engine to a qualified service

technician to determine the cause of the problem.

Page 8-1: Engine Troubleshooting

Page 65

Boxxer H2O

2.0. Turns over but will not start. There is no spark

Note: To check for spark, use the following procedure. Remove a spark plug

from the engine. Attach the lead wire back onto the plug. Ground the threaded

part of the spark plug to an unpainted engine surface. While holding the plug and

wire assembly by the insulated wire, crank the engine over by turning the ignition

switch to the “start” position. Y ou should observe a blue spark between the two

electrodes of the spark plug.)

2.1. The spark plugs are faulty. Remove and inspect. Replace as necessary.

2.2. The engine ignition system is malfunctioning. Refer to a qualified engine service

technician for inspection.

3.0. Turns over but will not start. There is spark.

3.1. Fuel is not reaching the carburetor inlet. Check the fuel pump. If the pump is

working, inspect the fuel lines between the fuel source and the carburetor. Repair or

replace any faulty parts as necessary.

3.1.1. If the pump is not working, check for 12 volts and a ground at the pump.

3.1.2. If 12 volts is not present at the pump, check the wiring to the pump, including the fuse.

Repair or replace as necessary. Note: If the fuse has blown, carefully inspect the wiring

for a shorted or damaged wire. Repair immediately.

3.1.3. If 12 volts is present at the pump and the ground is good, replace the pump.

3.2. Recovery tank is full. Empty the tank.

3.3. Recovery tank float is defective. Disconnect float. If engine starts, replace the float.

3.4. The carb solenoid is malfunctioning. Test for 12 volts and proper ground at solenoid.

If both test okay , replace the solenoid.

3.5. The engine is flooded. Wait for a few minutes and attempt to start with the choke

open. Note: If the engine has been flooded, it may be necessary to remove and clean

the spark plugs.

3.6. The spark plugs are dirty or worn. Inspect and replace as necessary.

3.7. There is a mechanical problem with the engine. Have engine inspected by a

qualified engine service technician.

Page 8-2: Engine Troubleshooting

04/20/04

HydraMaster Corporation

Page 66

Boxxer H2O

4.0. Will not come up to normal operating RPM

4.1. Throttle linkage is out of adjustment. Inspect for broken or loose linkage. Repair or

replace as necessary and adjust to proper RPM. Note: It is important to use an

accurate tachometer to adjust engine speed to 3000 RPM while it is under a vacuum

load of between 10"hg and 14"hg. Too high or too low will cause severe damage to

machine components.

4.2. There is excessive load on the engine due to the blower-to-recovery tank hose

becoming delaminated. Remove and inspect the inside of the hose. Replace as

necessary.

4.3. There is excessive back-pressure on the engine or blower exhaust. Check for

clogged blower heat exchanger.

5.0. Runs rough at medium or high speed

5.1. One or both spark plugs are defective. Remove and inspect spark plugs. Replace

as necessary.

5.2. A spark plug wire is loose at the spark plug or has been damaged. Inspect wire.

Replace wire and coil as necessary.

5.3. Low compression on one or both cylinders. Check compression. If low, check

valve adjustment. If incorrect, adjust to proper specs. This operation should be

performed by a qualified service technician.

5.3.1. If adjustment is okay, there is a possibility of burned valves, burned head gasket or worn

cylinders. Refer to qualified engine service technician.

5.4. Poor spark on one or both cylinders. Refer to qualified engine service technician.

5.5. Inadequate fuel supply to the carburetor. Test the fuel volume at the carburetor by

removing the fuel line from the carburetor inlet and placing the line in a metal container with

a minimum of 16 oz. capacity. Turn on the ignition switch to operate the fuel pump. The

fuel flow volume should be 12 oz. / minute. Check for clogged filter or obstructed fuel line.

Also check to make sure the fuel pump is mounted vertically and is close to the fuel

source. Repair as necessary.

Page 8-3: Engine Troubleshooting

Page 67

Boxxer H2O

6.0.Runs rich (Black smoke)

6.1. Dirty air filter. Inspect and replace as necessary.

6.2. Choke is partially closed. Inspect and adjust or repair as necessary.

6.3. Excessive fuel to carburetor. Insure that fuel pump is proper PSI rating. A fuel pump

with a psi rating in excess of that of the pump supplied with the machine could overpower

the inlet valve in the carburetor, causing excessive fuel to be supplied to the carburetor.

7.0.Engine overheats

7.1. Poor ventilation in vehicle. All cargo area doors must be open for proper ventilation.

Roof vents are strongly recommended for machines that are operated in hot climates. Any

item that might restrict air flow to the machine such as other equipment or a solid divider

should be moved or modified to permit proper air flow.

7.2. Low engine oil level. Check oil level and replenish as necessary.

7.3. Engine RPM too high. Check RPM with an accurate tachometer. Adjust as necessary

to 3000 RPM.

7.4. Restricted engine or blower exhaust. Disassemble exhaust components to locate

restriction. Repair as necessary.

Page 8-4: Engine Troubleshooting

04/20/04

HydraMaster Corporation

Page 68

Boxxer H2O

How to Order Parts

To obtain a proper diagnosis of your malfunction, and to order warranty replacement parts

or repairs, it is important that you proceed in the following manner:

WARRANTY PARTS ORDERS

1. Call the local distributor where you purchased your equipment and ask for

the Service Department.

2. Have the following information ready:

A. Equipment Model

B. Date of Purchase

C. Hours on the Unit

D. Unit Serial Number

E. Description of Malfunction

3. Once it has been determined which parts are needed to correct the problem with

your machine, make arrangements with your distributor to either perform the repairs or ship the parts to you.

P ARTS ORDERS

Call your local distributor. In most instances, they either stock or have access to parts

through a regional service center.

EMERGENCIES

If, for any reason, your distributor is unable to supply you with the necessary parts, they

may call us and arrange for expedited shipping.

HydraMaster sells parts only through authorized distributors and service centers.

Page 9-1: How to Order Parts

Page 69

Boxxer H2O

ONE FINAL NOTE

Any questions you have regarding the warranty program should be directed to the:

HydraMaster Customer Service Department

(425) 775-7275,

8 a.m. to 5 p.m.

Monday through Friday (PST).

We shall always endeavor to be fair in our evaluation of your warranty claim, and shall

provide you with a complete analysis of our findings.

HydraMaster warranty covers only defective materials and/or workmanship for the periods listed. Labor and/or diagnostic reimbursement is specifically excluded.

Page 9-2: How to Order Parts

HydraMaster Corporation

Page 70

Boxxer H2O

Warranty Information

To avoid misunderstandings which might occur between machine owners and

manufacturer, we are listing causes of component failure that specifically voids warranty

coverage. Such causes as listed below shall constitute abuse or neglect.

BLOWER:

• Failure to lubricate impellers daily with an oil based lubricant.

• Failure to lubricate bearings as recommended in blower manual.

• Failure to maintain proper oil levels in the blower.

• Failure to use the correct oil grade and viscosity as recommended in

blower manual.

• Failure to properly maintain blower safeguard systems such as waste tank

filter screen, vacuum safety relief valve and waste tank automatic shut-off

system.

• Allowing foam to pass through blower.

V ACUUM T ANK:

• Failure to properly maintain filtering devices in tank.

• Failure to clean tank as recommended by manufacturer.

• Failure to maintain vacuum safety release in tank.

VACUUM HOSES:

• Failure to protect hoses against burns from engine and blower exhaust.

• Damage to hoses from being run over by vehicles.

• Kinking or cracking from failure to store or unroll hoses correctly.

• Normal wear and tear from everyday use.

RECOVERY WAND:

• Obvious physical abuse of wand.

Page 10-1: Warranty Information

Page 71

Boxxer H2O

WARRANTY PROCEDURE

Warranty coverage is available to you through your local Distributor.

If you have moved to a new area or have purchased a used machine and need informa-

tion regarding your local distributor, call HydraMaster at (425) 775-7272 or email us at

custsvc@hydramaster.com.

When calling your distributor, be sure to have the machine’ s information; model and serial

number, ready for the service representative.

IMPORTANT: HydraMaster’s warranty policy provides replacement parts without charge

for thirty (30) days to distributors maintaining current account status. An invoice will be

sent to the distributor for the amount of the parts sent. The customer’s faulty parts must

be returned for evaluation prior to the expiration of the thirty (30) day period. Upon warranty approval, a credit will be issued the distributor for the replacement parts invoice.

Warranty disapproval or failure to return the faulty parts within the thirty (30) day

period allowed will result in the customer being charged for the replacement parts

sent.

FOR YOUR REFERENCE:

Model No._____________________________________________________

Serial No._____________________________________________________

Date of Purchase:_______________________________________________

Purchased From (Distributor):_____________________________________

Page 10-2: Warranty Information

HydraMaster Corporation

Loading...

Loading...