Page 1

I

I

@

Page 2

INDEX

PAGE

General Information

Warranty ............................................................................................................................... 2

a

Warranty Information

Warranty Procedure

...............................................................................................................

.............................................................................................................

..............................................................................................................

2

3

3

I

a

Purchaser’s Responsibility

Truck Preparation Information ...............................................................................................

Truck Preparation Illustration

Propane Tank Location/illustration

Hard Water Area Map

Machine Specifications

Spare Parts Fiecommendation/Parts Orders

Water %1Chemical Flow Operation

Water Flow Diagram

Chemical Flow Diagram

High Pressure Pump Information

Bypass Valve Assembly Illustration

High Pressure Pump/Chemical System Troubleshooting

Model 290 Cat Pump Operating Instructions

Chemical Proportioning and Level Control Illustration .........................................................

Chemical Tank Troubleshooting

Heating System Information

bleater Operating Instruction

Heater Troubleshooting

Vacuum System Information

Vacuum Flow Diagram

Vacuum Tank Filter Bag

Vacuum Blower Lubrication (Diagram)

Vacuum System Warranty ...................................................................................................

Vacuum System Troubleshooting

............................................................................................................

..............................................................................................................

................................................................................................

.................................................................................................

........................................................................................

.......................................................................................................

....................................................................

.....................................................................................

.........................................................................................................

.........................................................................................

.......................................................................................

.............................................

.................................................................. 8-15

..........................................................................................

...............................................................................................

................................................................................................ 17

....................................................................................................... 17

..............................................................................................

........................................................................................................

......................................................................................................

................................................................................

........................................................................................

5-6

7&16

4

4

4

5

5

5

6

6

6

7

7

16

16

16

18

18

18

18

19

20

Engine Manual/Warranty

Engine Troubleshooting

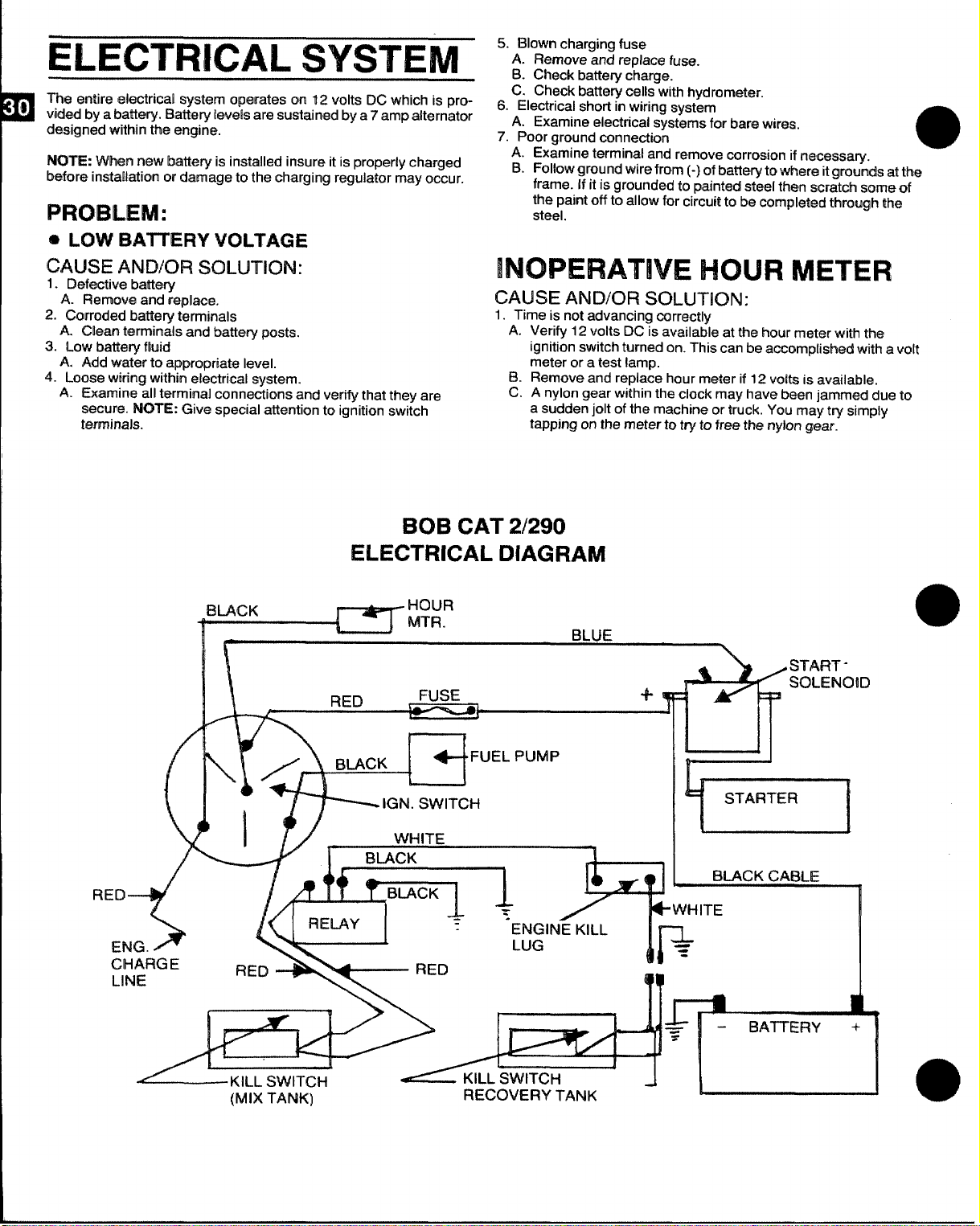

Electrical Diagram

Electrical Troubleshooting

Machine Installation Information

w

0

Machine Tie Down Cleat Information

Propane Hook-Up Illustration

Gas Hook-Up Illustration

Water Softener Information

Jet Assembly

Wand Assembly

Valve Assembly

Machine Operation Instructions

Control Panel

Operation Precautions

Freeze Protection

Cleaning and Chemical Precautions and Information ......................................................... 34

Cleaning Stroke Procedure/Over-Wetting

Maintenance Procedures

Overall Care of Machine

Maintenance Log

....................................................................................................................... 32

................................................................................................................... 32

................................................................................................................... 32

.......................................................................................................................

...@............................................................................................................ 34

................................................................................................................. 36

.............................................................................................

.......................................................................................................

............................................................................................................. 30

................................................................................................... 30

....................................................................................... 31

............$...................................................................... 31

............................................................................................... 31

...................................................................................................... 31

.................................................................................................. 32

......................................................................................... 33

......................................................................................................... 33

...........................................................................

.................................................................................................. 35

.......$.............................................................................................. 35

21-28

29

33

34

—

Page 3

GENERAL

INFORMATION

This manual contains installation and operation instructions as well

as information required for proper maintenance, adjustment and repair of this

isttw cm’rectd[agnasis ofthe trouble, a general troubleshooting section and cm”ryxment manual troubleshooting charts have beert included far yaur oortvermiencxa

Unlike the garden tractor, Iavvnmower and cement mixer, all having

one or two functions to perform, the truck-mounted carpet cleaning

plant has many functions to perform simultaneously.

@ Engine has to run crmsistent RPM.

@

e Water pump provides stable pressure at proper water flow for

@ Chemical has to be injected into the water stream at the right

@ Heater must maintain proper heat.

a Vacuum tank must store dirty water until drained.

As you can see, it is not just

ta worry about, Dcmmit start?!

In-E SYSTEMS WORK As

FOLLOWS:

The water system takes incoming water at tap (low) pressure, combines it with chemical from the chemical system automatically,

pumps it under high pressure through the heating system and out to

the chsaning toQ:l.After being sprayed into the carpet being cleaned,

the wtMer/chwmical/soil solution is extracted by the vacuum system

and returned to th@waste recovery tank.

As there is no guess work in the manufacture of these highly advanced cleaning plants, there must be none inpreparing itto get the

job done in the field. It isthe purpose ofthis manual to help you

erly understand, maintain and service your cleaning plant. Follow

the directions carefully and

ble trauble-frwe operation.

is imperativ~ that no section be overlooked when preparing forop-

It

@ratienof this equipment.

Uink. Wrkcm the first and most important part of repair work

VWUUrn has to pull air and dirtywater back from cleaning site.

cleaning.

consistency.

a turn key operation with only one thing

prop-

you wil~be rewarded with years of profita-

The manufacturer uses this symbol

throughout the

manual to warn of

possible injury or death.

HYDRA=MASTER

WARRANTY IPOLNXf

Effective October 1, 19$31

HYDRA-MASTER warranty covers only defective rnatawkalssmhr

workmanship for the periods listed. Labor,

andfor diagnostic reim-

bursement is specifically excluded.

LIMITED WARRANTY

HYDRA-MASTER warrantsproductsof itsmanufactureto be free

from defects in material and workmanship if properly rw.tailed, maintained, and operated under normal conditions with competent supervwiion. No person, agent, representative or dealer is authorized to

give any warranties on behalf o?HYDRA-MASTER nor to assume for

HYDRA-MASTER any other liability m connection with any of

HYDRA-MASTER’S products. This warranty shall extend for tlm

periods listed by component below from date of installation. Ifrepaws

or replacements are made by the Purchaser without HYDflA-MASTER’S written consent, HYDRA-MASTER’S warranty shall cease to

be in effect. No allowance will be granted for any repairs or alttwations made by the Purchaser without HYDRA-MASTER’S prior written consent.

Machinery, equipment and accessories furnished by l-fYf2FlA-MASTER, but manufactured by others, are warranted only to the extent of

the original manufacturer’s warranty to HYDRA-MASTER.

HYDRA-MASTER agrees at its option to repair at the p@int of shipment or to replace without charge f.o. b. point of shipment, any parts

or parts of products of HYDRA-MASTER’S manufacture, which with-

in the specified warranty period shall be proved to PiYD RA-M.4STER’S satisfaction to have been defective when shipped, provided

the Purchaser promptly notifies HYDRA-MASTER, in writing, of

such alleged defect,

HYDRA-MASTER’S liability to Purchaser, whether in contract or in

tori arising out of warranties, representation, instructions, or d@fwXs

from any cause shall be limited to repafring or replacing of the the r.$e-

factive part or parts as aforesaid, f,o.b. point of shipment.

No liaMlity whatsoever shall attach to HYDRA-MASTER un~[ said

products have been paid for.

Except as stated in this section and in the prwcedhtg aractlon

titled ‘Warranty” andexcept astotitle, thare are no $wmrarmtwm

orwarrantiesofmrarchantabiHty,fitness, prwformanoeorWver- (

wise, express, implied or statuatmy, and WW3RA-MASTER ~ ‘{

shall have no liability for consequential, im%drmtalor othsr I ~

damages, howsoever caused.

ENGINE: (Thru ongmal Manufacturer See 13nggs

& Stratton Warranty)

VACIJtJM BLOWER: (Thru original Manufacturer.

See Fuller warranty)

PROPANE HEATER:

VACUUM RECOVERY TAMtWCkfEMICAL MIX TANKS:

FRAME/Ct3VEFt ASSIEMB!JES:

HIGH PRESSURE PtJMP: (Thru ongmal Manufacturer

See Cat Pump warranty)

HIGH PRESSURE BY PASS VALVE:

CHEMICAL PROPORTIONING SYSTEM:

GAUGES, METERS, SWITCHES, WIRE HARNESS,

FUEL PUMP: 90 days 1~,

INTERNAL MACHINE HOSE:

EXTERNAL VACUUM HOSE, SOLI,JTION HOSE,

QUICK CON NECTOf?S:

SS CLEANING WAND: (Except valve& let assembly)

BELTS, FITTINGS, O RINGS, FILTER SCREENS:

FILTER BAGS:

Freezing of any one water or chem!cal related component WIII VOID I@ —

all other implied warranty on all water or chemical related comPo- E~

nents. internal or external, of this equipment

.- -# .-

$iwi.m!iiiriii

/ ~ @;3.’,m.7’rL-m —7F.F%-m.titijrm

.---, --’-.--’ -.-..--++- -+- 4..-.

Not Covered by Warranty ~~j

d

1 year

1 year

1

year -,

1 year -}

1 year “j

1year

90 days

90 days ““

‘odays ‘~$

2.Odavs ,~?

6 montk ~~

30 days iq’

a

1$’

~~,

I

‘t

!? .

1

F

~

o

y!

Page 4

WARRANTYINFORMATION

To-avoid misunderstandings which might occur between machine

owners and manufacturer, we are listing causes of component failure that specifically voids warranty coverage. Such causes as listed

below shall constitute abuse or neglect.

EN~fl~E: Operation at speed in excess of 2600 RPM. Failure to

maintain proper oil level (oil should be checked every 5 running

hours). Failure to use the proper oil viscosity and type (see engine

manual). Use of other than manufacturer’s recommended spark

plug in engines. Failure to perform recommended maintenance as

described on pages 3 and 4 of engine manual.

parts shipment will be sent to the customer for the

sent. The customer’s faulty parts must be returned forevalua-

parts

tion priorto the expiration of the thirty(30) day period. Upon warranty

approval, a credit will be issued the customer for the replacement

parts invoice. Werranty disapproval or faiiure to return the fauity

parts withhr the thirty (30) day period allowed will result In the

customer being charged for the replacement parts sent.

amount of the

HOW TO ORDER

To obtain a proper diagnosis of your malfunction, and to order warranty replacement parts, it is important you foiiow the below procedure:

9

~~~~~~: Failure to lubricate impellers daily with LPS-1 or

WD-40 lubricant. Failure to lubricate bearings as recommended in

blower manual. Failure to maintain proper oil levels in the blower.

Failure to use the correct oil grade and viscosity as recommended in

blower manual. Failure to properly maintain blower safeguard systems such as waste tank filter screen, vacuum safety relief valve in

vacuum tank lid and waste tank automatic shut-off system.

~1~1+

pressures over 1200 PSI. Failure to maintain proper oil level as recommended in pump manual. Failure to change oil inpump at recommended intervals. Failure to protect pump against freezing. Failure

to maintain pump protection shut-off system. Failure to use water

softener in hard water areas. Use of improper chemicals.

PRESSURE WATER PUMP: Operation of pump at

HEATER: Operation of heater without adequate water supply.

Changing factory set propane regulator. Operating heater without

proper ventilating. Failure to protect heater against freezing. Operating machine at water pressures over 1000 PSI. Overfilling of propane tank. Use of improper chemicals. Failure to use water softener

in hard water areas.

WACTANK: Failure to properly maintain filtering devices intank.

Failure to clean tank as recommended by manufacturer. Failure to

maintain vacuum safety release in tank lid. Use of improper chemicals.

~~~~. ~~~f%)~~~~~~~: Use of improper chemical. Failure

to use water softener inhard water area. Operating machine without

proper chemical filter screen. Failure to protect against freezing.

1. Call Hydra-Master Warranty/Service Dept. at (206) 775-7275

2. Give the Warranty/Service Representative the following information:

A.

Name of your company and your address.

Equipment Model (i.e. Hydra-Cat, Bobcat 2, etc.)

Date of purchase.

:.

Hours on the unit.

D.

Seriai number of unit.

E.

Name of person authorized to order parts.

F.

Salesman unit purchased from.

G.

H.

Description of malfunction.

i. Pressure readings on high pressure gauge with wand turned on

and off.

3. ifwarranty replacement parts are needed, piease specify method

of shipment desired. NOTE: Ail replacement parts are sent

freight coiiect, via:

A. U.P.S.

B. Airfreight

C. Air mail

D. Air express

E. Auto Freight

4. Do not give malfunctioning parts to a Hydra-Master Sales or Ser-

vice Representative. All parts must be returned directiy to HydraMaster, freight prepaid.

~ONTFlO~

pressure gauge against freezing.

PANEL: Failure to protect flow meter and water

VACUUM AND SOLUTION HOSES: Failure to protect

hoses against freezing. Failure to protect hoses against burns from

enginelblower exhaust. Damage to hoses from being run over by vehicles. Kinking or cracking from failure to store or unroll hoses correctly. Normal wear and tear from everyday use.

CLEANING WAND: Failure to protect against freezing. Obvi-

ous physical abuse of wand.

WARRANTY PROCEDURE

Warranty coverage is available to you ONLY through Hydra-Master

Corporation, 20309 64th Ave. West, Lynnwood, Washington 98036;

When warranty parts are needed, write Hydra-Master Warranty

Dept. at the above address, or call the Warranty/Service Dept. at

(206) 775-7275. No collect calls will be accepted. Hours of the

Warranty/Service Dept. are 8:00-11:30 am and 12:30-5:00 pm,

Pacific Time.

IMPORTANT

Hydra-Master’s warranty poiicy provides replacement parts without

charge forthirty (30) days to customers maintaining current account

status. An invoice dated thirty (30) days from date of replacement

ONE FINAL NOTE:

Any questions you have regarding the warranty program shouid be

directed to the Warranty/Service Dept. Personnel at Hydra-Master

Corporation.

We shall always endeavor to be fair in our evaluation of your warranty claim, and shall provide you with a compiete anaiysis of our

findings.

Page 5

PURCHASER’S

@3ESPONSlBlLlTY

PF$MWITo AFWWtfALOF WWT:

@ install %+”extmicwplywood flooring in vehicle and cover with I

artificial turf.

@ Have belly mounted pfioparretank installed on vehicle. Tank

must br3propane vapor type.

Materials Needed:

1. 2 sheets 4 x 8 x

2. 6’ x 12’ piece of commercial astroturf

3. 16-1

4. 1 quart marine adhesive (optional)

5. 1 staple hammer w/’/z” staples

(See

‘/2” sheet metal screws

illustration for correct placement of p!ywood ffooring)

5/a” exterior plywood

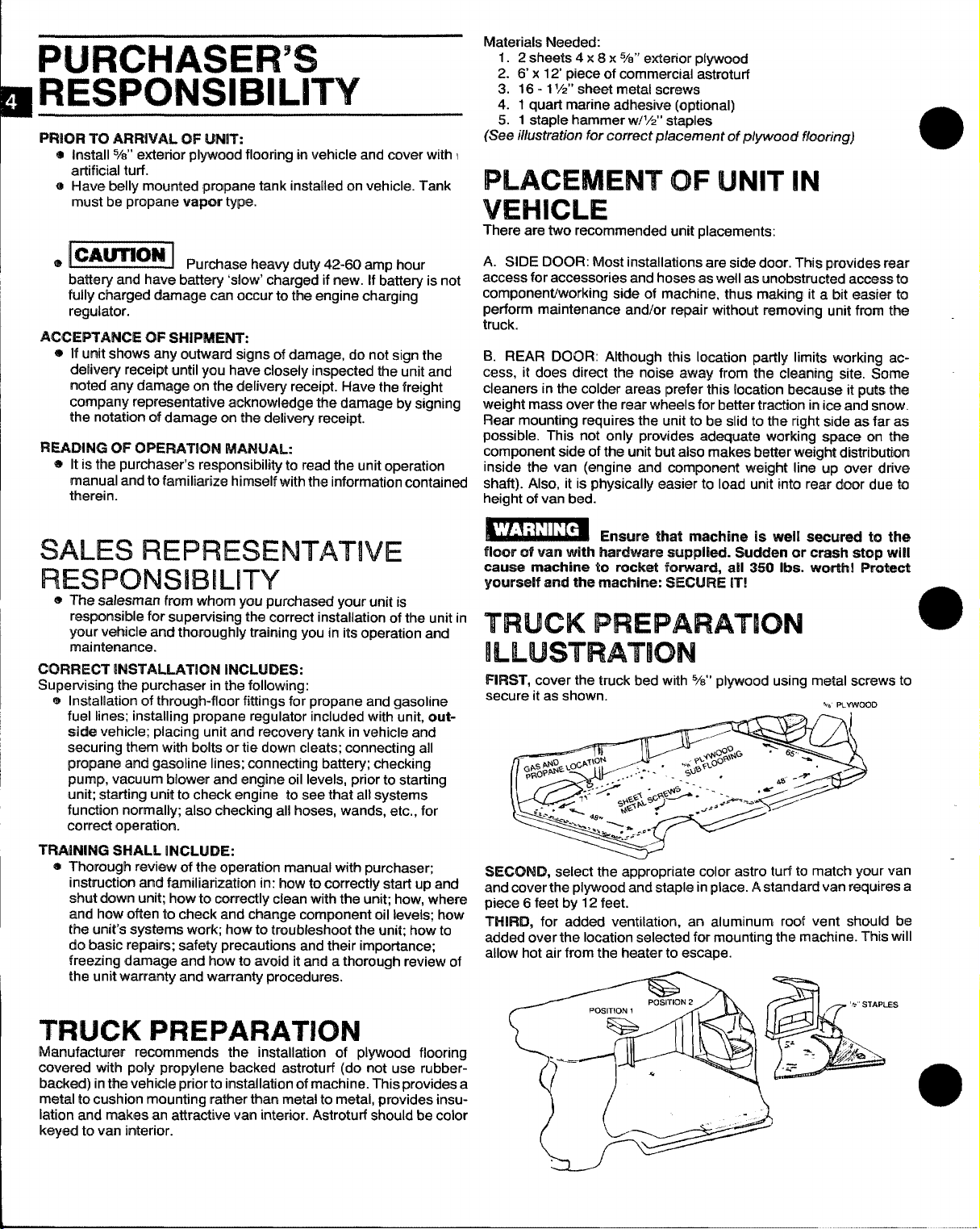

PLACEMENT OF UNIT’IN

VEHICLE

There are two recommended unit placements:

m

batte~ and have battery ‘slow’ ch&ge6 ifnew. If battery is not

fully charged damage can occur to the engine charging

regulator.

AWHHW,AFJCE OF S&l[PMENT:

@ If unit shows any outward signs of

delivery receipt until you have closely inspected the unit and

noted any damage on the delivery receipt. Have the freight

company representative acknowledge the damage by signing

the notation of damage on the delivery receipt.

EADING (W CIPERATIION MANUAL:

I%

@ It is the purchaser’s responsibility to read the unit operation

manual and to familiarize himself with the information contained

therein.

Purchase heavv dutv 42-60 amn hour

damage, do not sign the

SALES REPRESENTATIVE

RESPONSIBILITY

e The salesman from whom you purchased your unit is

responsible for supervising the correct installation of the unit in

your vehicle and thoroughly training you in itsoperation and

maintenance.

(X2RREGT INSTALLATION INCLUDES:

Supewising the purchaser in the following:

@ Installation of through-floor fittings for propane and gasoline

fuel lines: installing propane regulator included with unit, outside vehicle; placing unit and recovery tank in vehicle and

securing them with bolts or tie down cleats; connecting all

propane and

pump, vacuum Mower and engine oil levels, prior to starting

writ; starting I-NMto check engine to see that all systems

function normally; also checking ali hoses, wands, etc., for

correct operation.

TR%MNING SHALL INCLUDE:

Thorough revi~w of the operation manual with purchaser;

@

instruction arndfamiliarization in: how to correctly start up and

shut down unit; how to correctly clean with the unit; how, where

and how often to check and change component oil levels; how

the unit’s systems work; how to troubleshoot the unit; how to

do basic repairs; safety precautions and their importance;

freezing damage and how to avoid it and a thorough review of

the unit warranty and warranty procedures.

gasoline lines; connecting battery; checking

A. SIDE DOOR: Most installations are side door. This providw roar

access for accessories and hoses as well as unobstructed access to

componenffworking side of machine, thus making it a bit easier to

perform maintenance and/or repair without removing unit from the

truck.

B. REAR DOOR: Although this location partly limits working access, it does direct the noise away from the cleaning site. Some

cleaners in the colder areas prefer this location because it puts the

weight mass over the rear wheels for better traction in ice and snow.

Rear mounting requires the unit to be slid to the right side as far as

possible. This not only provides adequate working space on tlm

component side of the unit but also makes better weight distribution

inside the van (engine and component weight line up over drive

shaft). Also, it is physically easier to load unit into

height of van bed.

Ensure that machino is !R@l secured to tl’m

floor of van with hardwar@ supplied. %Miran m’

cause machine to rocket forward, all 350 lb. worth! Pratect

yourself and the machine: SECURE IT!

TRUCK PREPARATION

rem’ door due to

crash atop will

ILLUSTRATION

FIRST, cover the truck bed with

secure it as shown.

SECOND, select the appropriate color astro turf to match your van

and cover the plywood and staple inplace. A standard

piece 6 feet by 12 feet.

THIRD, for added ventilation, an aluminum roof vmt should be

added over the location selected for mounting the machine. This will

allow hot air from the heater to escape.

5/8” plywood using metal screws to

PLYWOOD

%

van requires a

a

TRUCK PREPARATION

Manufacturer recommends the installation of plywood flooring

covered with poly pnopylene backed astroturf (do not use rubber-

backed) in the vehicle pricwtoinstallation of machine. This provides a

metal to cushion mounting rather than metal to metal, provides insulation and makes an attractive van interior. Astroturf should be color

keyed to van interior.

Page 6

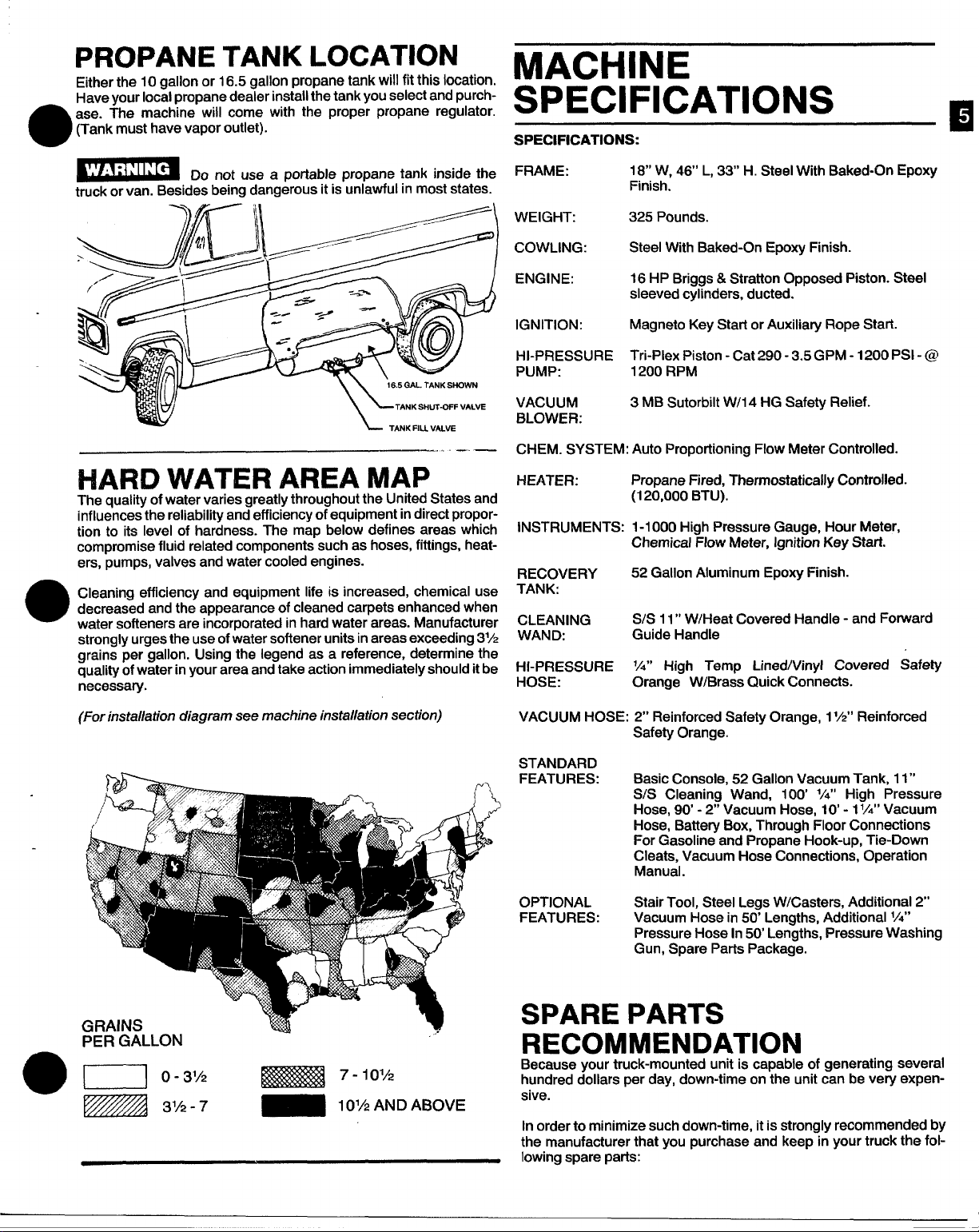

PROPANE TANK LOCATION

Either the 10 gallon or 16.5 gallon propane tank will fit this location.

Have your local propane dealer install

ase. The machine will come with the proper propane regulator.

(Tank must have vapor outlet).

0

the tank you select and purch-

MACHINE

SPECIFICATIONS

SPECIFICATIONS:

E

Do not use a portable propane tank inside the

truck or van. Besides being dangerous it is unlawful in most states.

-.. —

HARD WATER AREA MAP

The quality of water varies greatly throughout the United States and

influences the reliability and efficiency of equipment in direct proportion to its level of hardness. The map below defines areas which

compromise fluid related components such as hoses, fittings, heaters, pumps, valves and water cooled engines.

Cleaning efficiency and equipment life is increased, chemical use

decreased and the appearance of cleaned carpets enhanced when

water softeners are incorporated in hard water areas. Manufacturer

strongly urges the use of water softener units in areas exceeding 3%

grains per

quality ofwater inyour area and take action immediately should it be

necessary.

gallon. Using the legend as a reference, determine the

FRAME:

WEIGHT: 325 Pounds.

COWLING: Steel With Baked-On Epoxy Finish.

ENGINE:

IGNITION:

HI-PRESSURE Tri-Plex Piston - Cat 290- 3.5GPM -1200 PSI-@

PUMP:

VACUUM

BLOWER:

CHEM. SYSTEM: Auto Proportioning Flow Meter Controlled.

HEATER: Propane Fired, Thermostatically Controlled.

INSTRUMENTS: 1-1000 High Pressure Gauge, Hour Meter,

RECOVERY

TANK:

CLEANING

WAND:

HI-PRESSURE ‘A”

HOSE:

18“ W, 46’ L, 33’ H. Steel With Baked-On Epoxy

Finish.

16 HP Briggs & Stratton Opposed Pk3crn. Steel

sleeved cylinders, ducted.

Magneto Key Start or Auxiliary Rope Start

1200 RPM

3 MB Sutorbilt W/l 4 HG Safety Relief.

(120,000 BTU).

Chemical Flow Meter, Ignition Key Start.

52 Gallon Aluminum Epoxy Finish.

S1S 11” W/Heat Covered Handle - and Forward

Guide Handle

High Temp LinedlVinyl Covered Safety

Orange W/Brass Quick Connects.

(For installation diagram see machine installation section)

—..

PE-R--GALLON

,,.

u 0-31’2 E%E$%i37-’0”2

Izzzn “/2-7 - ‘01’2ANDAB0vE

VACUUM HOSE: 2“ Reinforced Safety Orange, 1%“ Reinforced

Safety Orange.

STANDARD

FEATURES:

OPTIONAL

FEATURES: Vacuum Hose in 50’ Lengths, Additional

Basic Console, 52 Gallon Vacuum Tank, 11”

S/S Cleaning Wand, 100’ lA” High Pressure

Hose, 90-2’ Vacuum Hose, 10’-1 l/.” Vacuum

Hose, Batte~ Box, Through Floor Connections

For Gasoline and Propane Hook-up, Tie-Down

Cleats, Vacuum Hose Connections, Operation

Manual.

Stair Tool, Steel Legs W/Casters, Additional 2’

Pressure

Gun, Spare Parts Package.

Hose In 50 Lengths, Pressure Washing

1/4”

SPARE PARTS

RECOMMENDATION

Because your truck-mounted unit is capable of generating several

hundred dollars per day, down-time on the unit can be very expensive.

In order to minimize such down-time, it is strongly recommended by

the manufacturer that you purchase and keep in your truck the following spare parts:

Page 7

CWANTITY

2

1

1

1

1

2

1

1

6

1

1

PAFIT NLMBER’i

000-0?8-015

000-07’$-024

000-078-034’

000-076-007’

000-049-028

000-078-001

000-078-004

000-049-023

000-052-050

000-052-051

DESGR!PT!OM

Engine Spark Plug

Flow Meter Kit

Wand Valve Plunger Kit

Press. Bypass Valve Kit

Spray Jet 800BE

Recovery Tank Filter Bag

Cat 290 Short Cup Kit

Standard

Cat 290 Hot Cup Kit

(Clpticmal)

Screen Gard@nHose

44o Male Quick Connect

440 Female Quick Connect

cycle of the mix tank. The chemical will flow from the chwrrical jug to

the chemical flow meter, then to the proportuonerwhere it is cWatributed intothe mix tank at your desired propo~lon. This line ~h~u~db~

flushed with vinegar weekly to prevent abnormal chemical build-up.

This may be done by removing the clear plastic hose from the c!wm+

cal jug and inserting it into

should be done with the chemical flow meter sisttirq on 10 GPl+ with

heater “off’. Simply spray the wand for the duration of the vinegar in

the one quart cantainer, then repeat the process

clear water to void all lines of vinegar.

NOTE: with this unique chemical system, your chemical flow is proportionedtothe filling cycles of the mix tank, nottha direct spraying af

the wand. Therefore, itispossible that as your wand is spraying, you

may have no chemical flow. Also, the converse is true in that you

may not be spraying your wand but, if the mix tank is ina fillingcycle,

your chemical flow meter may read your desired flow.

This chemical system will mix a 1to30 ratio when flow meter isset at “

5 GPH. Most chemical suppliers will recommend a 1 to 15 ratio,

therefore you can either set the flow meter at 10 GPH, giving you a 1

to 15 ratio of chemical to cleaning water, or double the recomm-

ended strength of chemical in the 5 gallon jug and set the flow

meter at 5 GPH, thereby attaining a 1to 15 ratio. (It is recommended

that you set the flow meter at 10 GPH for overall best results.)

a one quart container of vinegar. This

a

with one quart af

1

1

1

PARTS

To expoditrayour

In most instances, he either stocks or has access to parts through a

regional service center.

[nthe event parts are unavailable locally, contact the factoy and co-

ordinate your needs. Ifthis becomes necessary, always indicate the

method of shipment you desire, i.e. U.P.S., U.P.S. Blue Label, Air

Freight, Air Express, etc..

Hydra-fwfaster Parts Dept. phone (206) 775-7276.

MJO-052-052

000-052-053

4 L 280

ORDERS

parts newts, please call your sales representative.

660 Male Quick Connect

660 Female Quick Connect

Belt, Pump Drive.

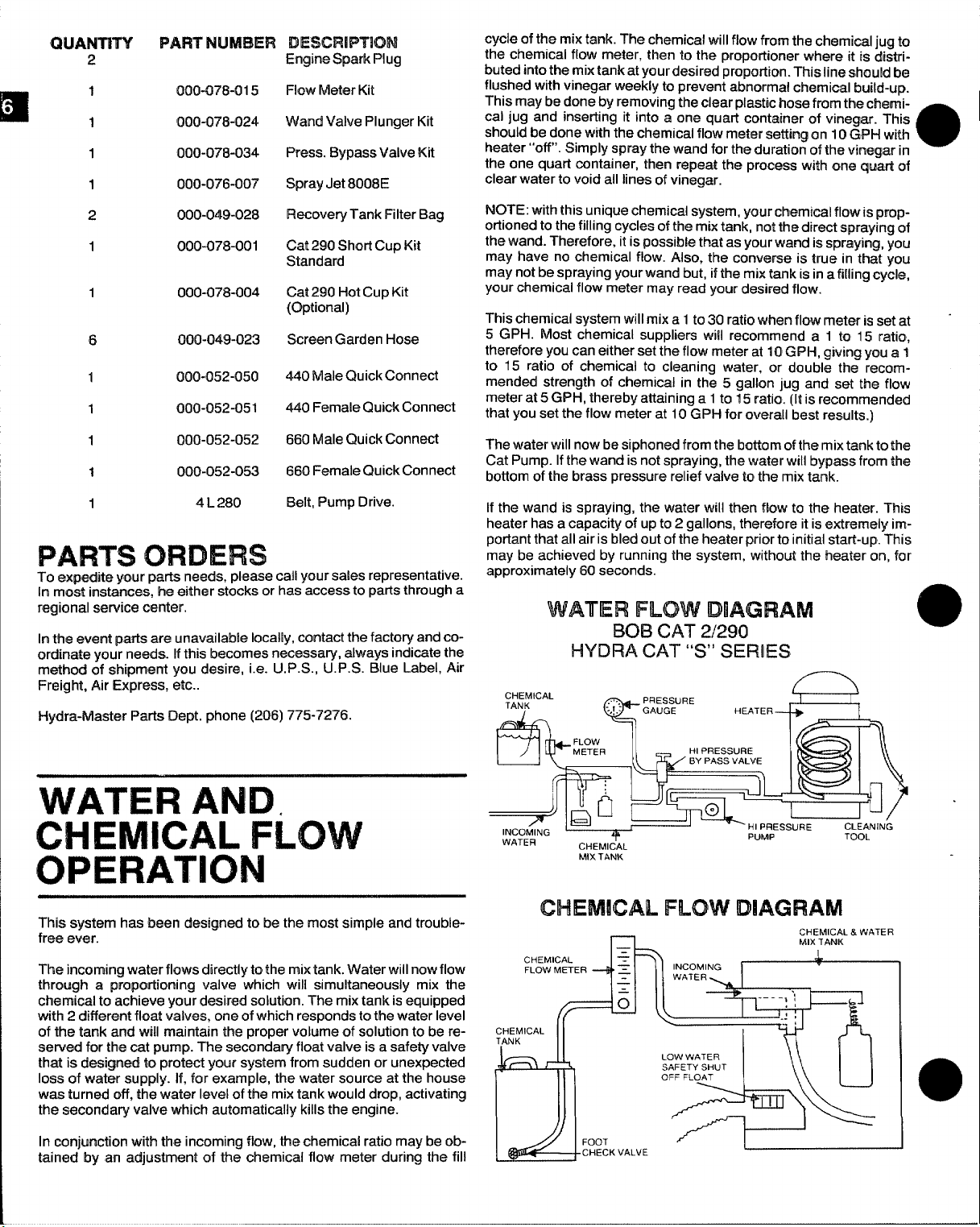

WATER AMID

ICHEMICAL FLOW

OPERATIONI

The water will now be siphoned from the bottom of the mixtank to the

Cat Pump. If the wand is not spraying, the water will bypass from the

bottom of the brass pressure relief

If the wand is spraying, the water will then flow to the heater. This

heater has a capacity of up to 2 gallons, therefore it isextremely important that all air is bled out of the heater prior to initial start-up. This

may be achieved by running the system, without the beater on, for

approximately 60 seconds.

valve tothe mix tank.

WATER FLOW DIAGRAM

BOB

CAT 2/290

WDRA CAT “S” SEFMES

CHEMICAL

TANK

& ‘;:

MIXTANK

PRESSURE

GAUGE HEATER

~

+

This systam has been designed to be the most simple and trouble-

frwe ever.

This incoming water flows directly tothe mix tank. Water will nowflow

through a pmpcwtioning valve which will simultaneously mix the

chemical to achiew your desired solution. The mix tank isequipped

with 2 different float valves, one of which responds to the water level

af the tank and will maintain the proper volume of solution to be re-

swwed for the cat pump. The secondary float valve is a safety valve

that is desigmsd to protect your system from sudden or unexpected

loss of water supply. if, for example, the water source at the house

was turned off, the water level of the mix tank would drop, activating

the secondary valve which automatically kills the engine.

[n conjunction with the incoming

tained by an adjustment crfthe chemical flow meter during the fill

flow, the chemical ratio maybe ob-

CHEMICAL FLOW DIAGRAM

v

CHEMICAL

FLOWMETER d

-IEMICAL

lNK

r - -K,

{~

1

v 7

.=

.

—

v

z

INCOMING

WATER

LOWWATER

SAFETYSHUT

OFF FLOAT

/-’---

t

CHEMICAL& WI%TE17

MIXTANK

&

I

.

Page 8

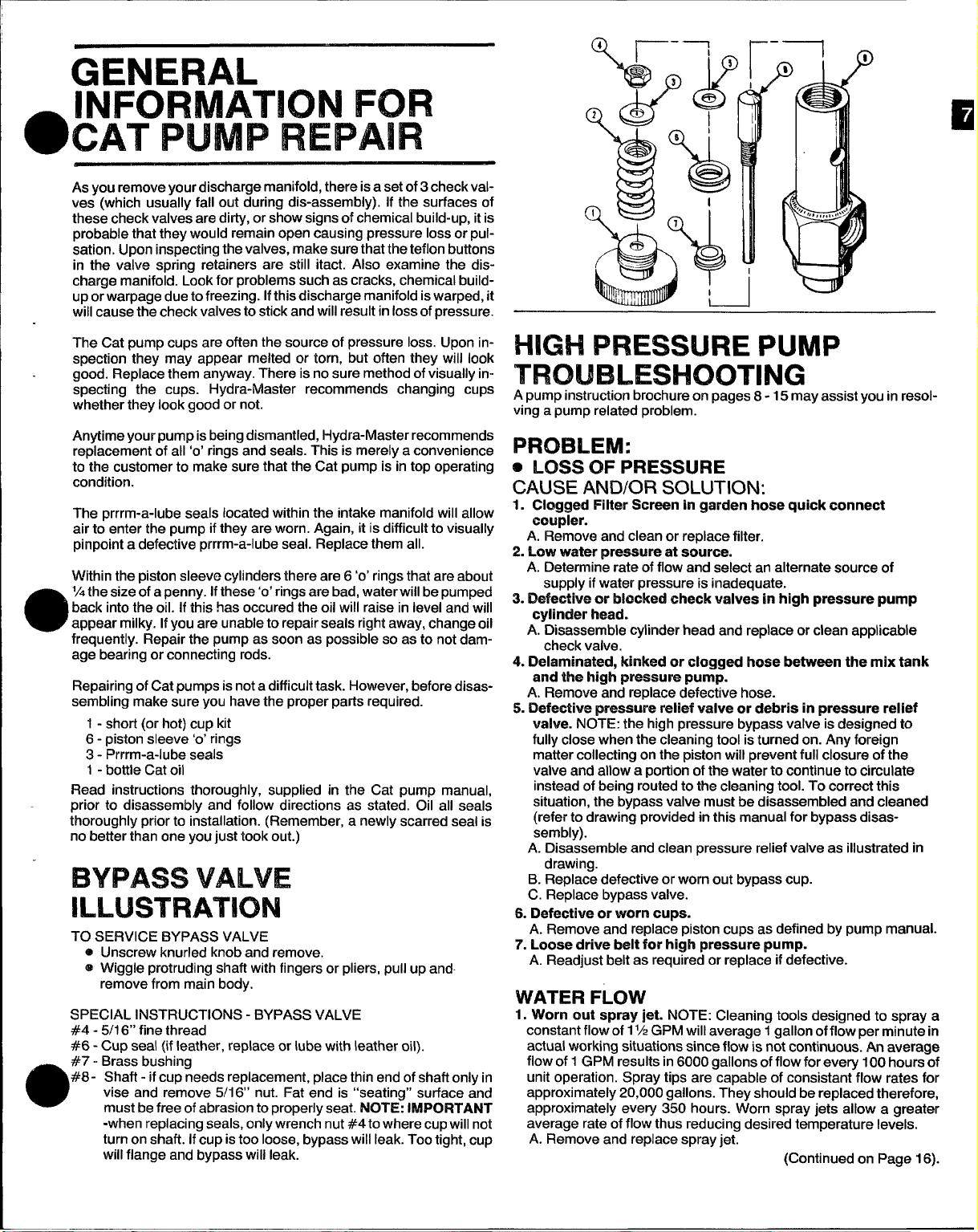

As you remove your discharge manifold, there isa set of 3 check valves (which usually fall out during dis-assembly). If the surfaces of

these check valves are dirty, or show signs of chemical build-up, it is

probable that they would remain open causing pressure loss or pul-

sation. Upon inspecting the valves, make sure that the teflon buttons

in the valve spring retainers are still itact. Also examine the discharge manifold. Look for problems such as cracks, chemical buildup or warpage due to freezing. Ifthis discharge manifold iswarped, it

will cause the check valves to stick and will result in lossofpressure.

The Cat pump cups are often the source of pressure loss. Upon inspection they may appear melted or torn, but often they will look

good. Replace them anyway. There is no sure method ofvisually in-

specting the cups. Hydra-Master recommends changing cups

whether they look good or not.

Anytime your’pump is being dismantled, Hydra-Master recommends

replacement of all ‘o’ rings and seals. This is merely a convenience

to the customer to make sure that the Cat pump is in top operating

condition.

The prrrm-a-lube seals located within the intake manifold will allow

air to enter the pump if they are worn. Again, it is difficult to visually

pinpoint a defective prrrm-a-lube seal. Replace them all.

Within the piston sleeve cylinders there are 6 ‘o’ rings that are about

‘/4 the size of a penny. If these ‘o’ ringsare bad, water will be pumped

back into the oil. If this has occured the oil will raise in level and will

appear milky. If you are unable to repair seals rightaway, change oil

e

frequently. Repair the pump as soon as possible so as to not dam-

age bearing or connecting rods.

Repairing of Cat pumps isnota difficulttask. However, before disassembling make sure you have the proper parts required.

1- short (or hot) cup kit

6- piston sleeve ‘o’ rings

3- Prrrm-a-lube seals

1- bottle Cat oil

Read instructions thoroughly, supplied in the Cat pump manual,

prior to disassembly and follow directions as stated. Oil all seals

thoroughly prior to installation. (Remember, a newly scarred seal is

no better than one you just took out.)

BYPASS VALVE

ILLUSTRATION

TO SERVICE BYPASS VALVE

@ Unscrew knurled knob and remove.

@ Wiggle protruding shaft with fingers or pliers, pull up and

remove from main body.

SPECIAL INSTRUCTIONS - BYPASS VALVE

#4 - 5/16“ fine thread

#6 - CUD seal {ifleather, redate or lube with leather oil).

#7 - Brass bushing

#8- Shaft - if cup needs replacement, place thin end of shaft only in

a

vise and remove 5/1 6“ nut. Fat end is “seating” surface and

must be free of abrasion to mo~erlv seat. NOTE: lMPORTANT

-when replacing seals, only”wrenc~ nut #4to where cup will not

turn on shaft. Ifcup is too loose, bypass will leak. Too tight, cup

will flange and bypass will leak.

HIGH PRESSURE PUMP

TROUBLESHOOTING

A pump instruction brochure on pages 8-15 may assist you in resolving a pump related problem.

Plmmmvl:

o LOSS OF PRESSURE

CAUSE AND/OR SOLUTION:

1. Clogged Filter Screen in garden hose quick connect

coupler.

A. Remove and clean or replace filter.

2. Low water pressure at source.

A. Determine rate of flow and select an alternate source of

supply if water pressure is inadequate.

3. Defective or blocked check valves in high pressure pump

cylinder head.

A. Ok-assemble cylinder head and replace or clean applicable

check valve.

4. Delaminated, kinked or clogged hose between the mix tank

and the high pressure pump.

A. Remove and replace defective hose.

5. Defective pressure relief valve or debris in pressure relief

valve. NOTE: the high pressure bypass valve is designed to

fully close when the cleaning tool is turned on. Any foreign

matter collecting on the piston will prevent full closure of the

valve and allow a potilon of the water to continue to circulate

instead of being routed to the cleaning tool. To correct this

situation, the bypass valve must be disassembled and cleaned

(refer to drawing provided in this manual for bypass disassembly).

A. Disassemble and clean pressure relief valve as illustrated in

drawing.

B. Replace defective or worn out bypass cup.

C. Replace bypass valve.

6. Defective or worn cups.

A. Remove and replace piston cups as defined by pump manual.

7’.Loose drive belt for high pressure pump.

A. Readjust belt as required or replace if defective.

WATER FLOW

1. Worn out spray jet. NOTE: Cleaning tools designed to spray a

constant flow of 1‘/2GPM will average 1 gallon of flow per minute in

actual working situations since flow is not continuous. An average

flow of 1 GPM results in 6000 gallons of flow for every 100 hours of

unit operation. Spray tips are capable of consistent flow rates for

approximately 20,000 gallons. They should be replaced therefore,

approximately every 350 hours. Worn spray jets allow a greater

average rate of flow thus reducing desired temperature levels.

A. Remove and replace spray jet.

(Continued on Page 16).

Page 9

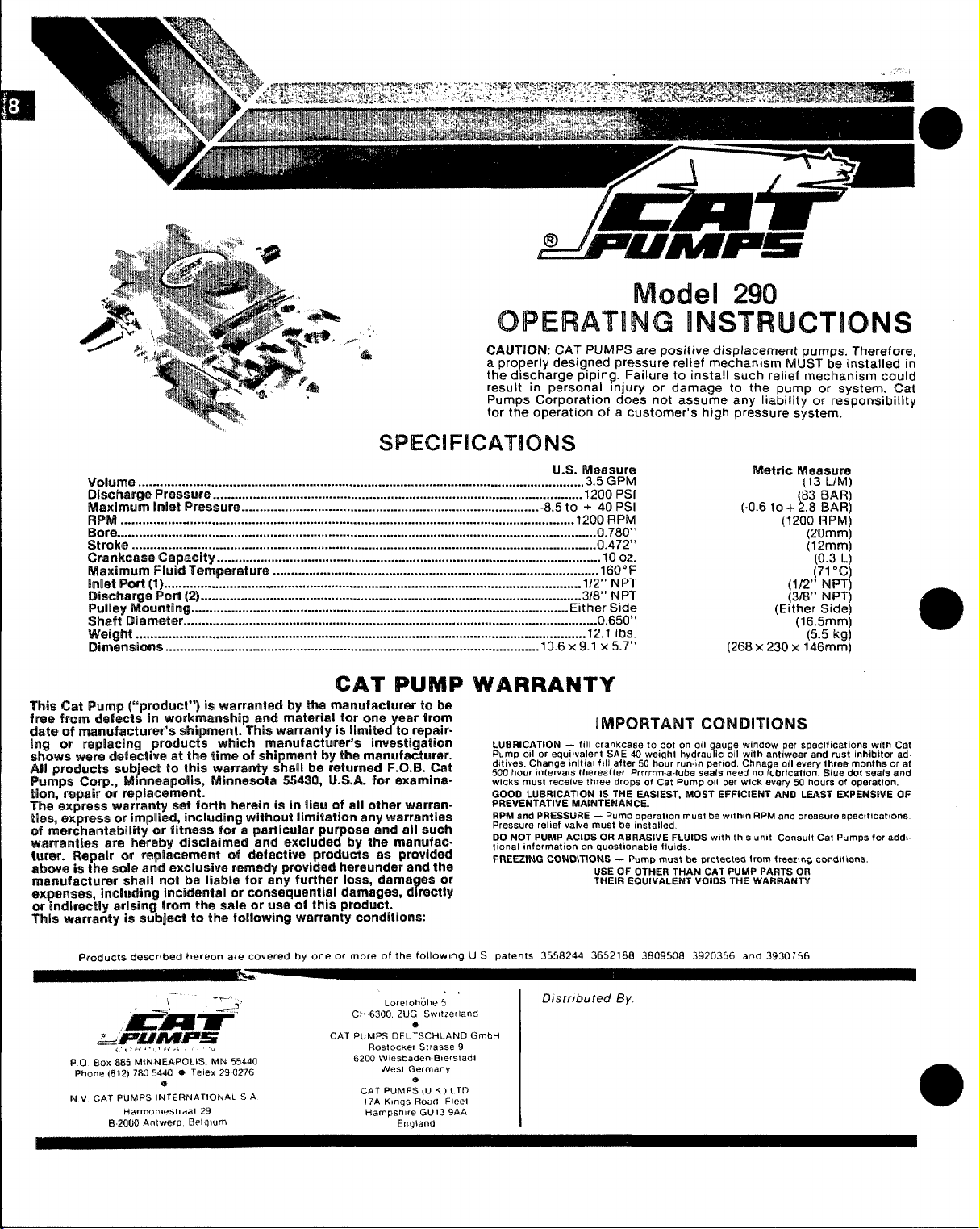

OPERATING INSTRUCTIONS

CAUTION: CAT PUMPS

a properly designed pressure reltef mechanism MUST’be installed in

the discharge piping. Failure to install

result in personal injury or damage to the pump or system. Cat

Pumps Corporation does not assume arty liability or responsibility

for the operation of a customer’s high pressure system.

SPECIFICATIONS

vdurrme ...........................................................................................................................3.5 Gf?M

lMdmarfJcr Pressur@......................................................................................................1200 PSI

#~m#num Ink$t Press ure ............................................................... .... .... . .......... -8.5 to + 40

.............................................................................................................................

................................................................................ ..... ..... .... ..... ......... ........ ................O.78O''

B’occr

Stroke .................................................................................... . ........ ..... .... . .... ..... .... .... ........O.472''

Crankcase Capacity ..........................................................................................................10 oz.

Maximum Fluid Tmpmtlm

Inlet Port (l) ............................" ................................................................... . ........ ......... 1/2” N

LNschargaPcwt

I%dky MQunting ........................................................................ .... ..... .... ................... Eit her Side

Shaft fJimmrt@r

Wtright ............................................................................................................................

.........................................................................................................3/8'' N

(2)

..................................................................................................................O.65O''

..........................................................................................1

Dim@n$iQn$.......................................................................................................10.6X 9.1 X 5.7”

U.S. Measuro

PSI

1200 RPM

k30”F

12.1 tbs.

PT

PT

Model 290

are positive displacement pumps. Therefore,

such relief mechanism could

Metric Measure

(-0.6 to+ !2!8::;;;

(268 x 230x 146mm)

[13 L./M)

(1200 RPM)

(20mm)

(12mm)

(0.3 L)

(71“c)

(1/2” NPT)

(3/8” NPT)

Side)

(Either

(l~5\mk~]

CAT IPUMP

This Cat Pump ($’prackt”) is warranted by the manufacturer to be

Moe from dttrf~ctsin

dat@of rmmufactumr’s

ing or ropltmhr~ products which manufacturer’s investigation

Mrcmrawara ddmtiv~ at the time of shipment by the manufacture.

AIUproducts sub@ to this warranty

Pumps

tkm,impairor raplacament.

Tim express

tkm, exprcmsor

d merdrmatrahility or

wwrarotle%+

turm’. Repsrtr cmI’E@WMIWtnt Qf defectiw products as provided

Corp., M mmnwpdis,Mhmeaota 55430, tJ.S.A. for axamina.

warranty set fcwthhwwin is IFIlhw of all other warren.

are Iwwekwdisclaitmatf and exc!uded by the mamdac-

la the501@ 8rIud exclusive remmty providad hereunder and tha

abwm

mmnufactumr shall mrt be liable for any further loss, dama ea or

tmfmnwwi, irmc!udim’u$Incktwrtal m consequential damages, d rectly

or irrdlrectly arisiq Irm the

Thla warranty it?

Products df3$Cr(b@dhereon are covered by one or more of the follo’w,og U S Patems 3558244 3652188 3809508 3920356 and 3930 T56

~Hq&g&”

,,!,f+,.,~f{.., ,,, >

BOX 885 MW4NEAPOLK. MN 55440

P O

Phone (612) 7805440 m Telex 290276

N V CAT PUMPS INTERNATIONAL SA

0.2000 Antwerp Belwum

workmanship and matr3rial for one year from

sh@’rmwTl. This warranty is I!mifed to repair-

/

hrmplid,hclmfhg without limitation any warranties

fitness for a particular purpose and all such

shall be retumad F.0.k%Cat

7

aub@ct tothe following warranty condition

.

Harmonteslraal 29

sale m trae o~ this product.

CH 6300. ZUG Switzerland

CAT PUMPS DEUTSCHLANO GmbH

Restocker Strasse 9

6200 Wlesbaden.Blersladl

CAT PUMPS (U K ) LTO

17A K,ngs RoaIY Fleet

Hampsh, re GU13 9AA

LorelohOhe 5

e

west Germany

e

England

WARRANTY

LUaFIICATION

Pump 011 or equivalent SAE 40 weight hydraulic 011with antlwear and rust Inhibitor ad.

dttives. Change mltml fill after 50 hour run.m parmd, Chwage O(I %V%Wibrme months or at

S00 hour lflterWdS thereafter. Prrrrrm.a-lube seals need no Iubrlcatton. Blu% dot WX3113and

wicks mu$t r9C91v9 three drops of Cat Pump 011 per wick every 54 hour8 of operation.

GOOD

PREVENTATIVE MAINTENANCE.

IIPMmd PRESSURE

Pressure relkef valve must be [nstalled,

DO NOT PUMPACIDS OR AL!RASIVEFUJIOS wdh this unit Consult Cat Pumps km addl.

tlonal #nf0rr17at10n on questionable flulds.

FREEZING CONDITIONS - Pump must be protectect 1rom iroez!ng cond!l

,.

IMPORTANT t2C)NKNTlCJNS

crankcase to dot on o(I gauge window per specifications with Cat

- fill

LUBRICATION IS WE EASIEST, MOST EFFfC!ENT AND LEAST EXPW4SWE OF

Pump oper@#o” must be wlthm RPM and pmasure specttlcat(ons

-

USE OF OTHER THAN CAT PUMP PARTSOr?

THEIR EQUIVALENT VOIOS THE WAWIAMIT

Ions.

Page 10

3/8’

1

\

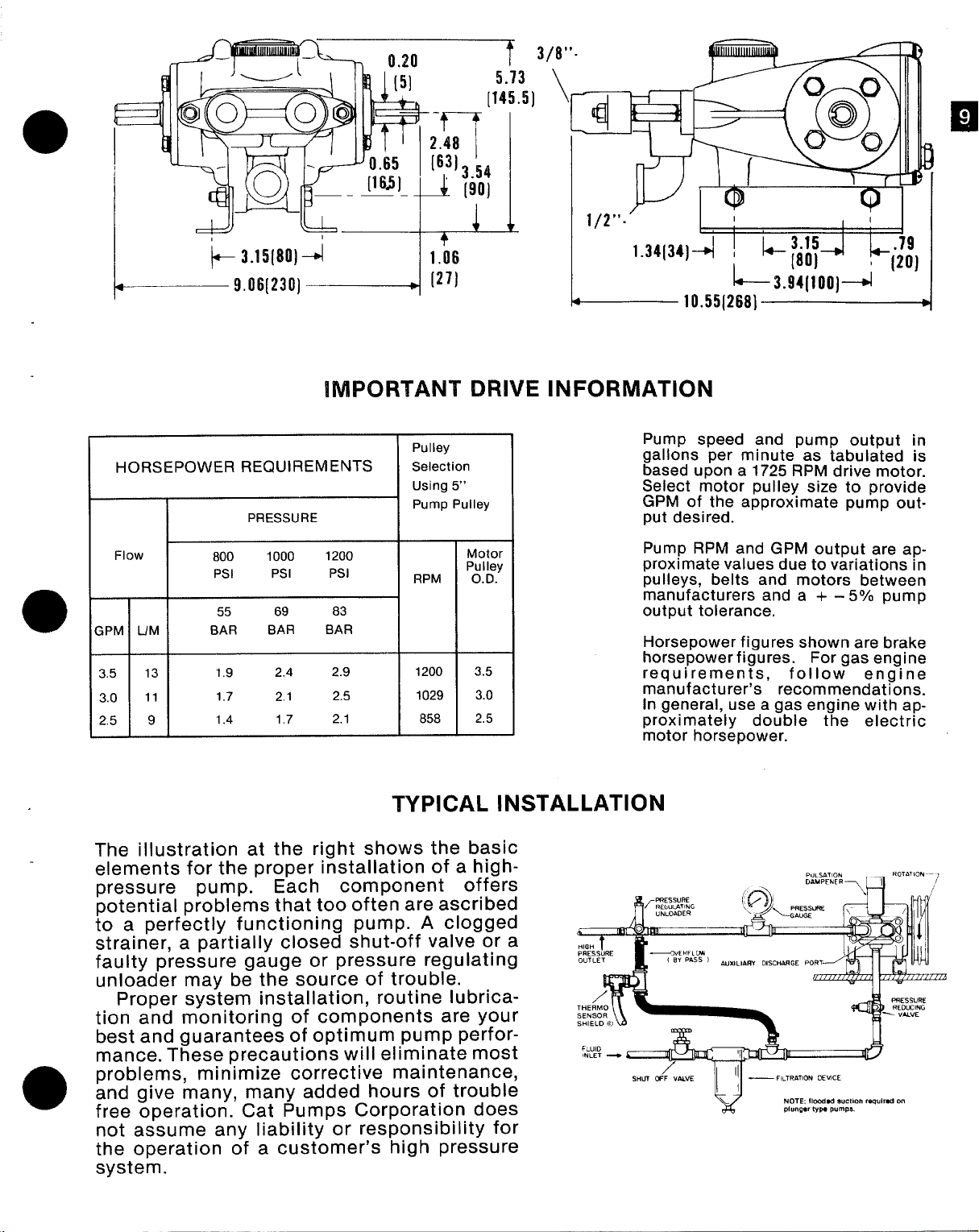

HORSEPOWER REQUIREMENTS

PRESSURE

Flow

LIM

;PM

3.5 13

3.0 11

2.5 9

800

Psl Psl

55

BAR

1.9 2.4

1.7

1.4

1000

69

BAR

2.1

1.7

1/2”-’

1.34[34]4 ! L- ~ap

IMPORTANT DRIVE INFORMATION

Pump speed and pump output in

gallons per minute as tabulated is

based upon a 1725 RPM drive motor.

Select motor pulley size to provide

GPfvl of the approximate pump output desired.

Pump RPM and GPM output are approximate values due to variations in

pulleys, belts and motors between

manufacturers and a + –

output tolerance.

Horsepower figures

horsepower figures. For gas engine

requirements,

manufacturer’s recommendations.

In general, use a gas engine with approximately double the electric

motor horsepower.

1200

Psl

83

BAR

2.9

2.5

2.1 858

Pulley

Selection

Using 5“

Pump Pulley

tblotor

RPM .

1200

1029

P; I&y

3.5

3.0

2,5

I

I

I

I

.79

k(20)

5°/0 pump

shown are brake

follow engine

TYPICAL INSTALLATION

The illustration at the right shows the basic

elements for the proper installation of a high-

-pressure pump. Each component offers

potential problems that too often are ascribed

to a perfectly functioning pump. A clogged

strainer, a partially closed shut-off valve or a

faulty pressure gauge or pressure regulating

unloader may be the source of trouble.

Proper system installation, routine lubrica-

tion and monitoring of components are your

best and guarantees of optimum pump perfor-

mance. These precautions will eliminate most

problems, minimize corrective maintenance,

a

and give many, many added hours of trouble

free operation. Cat Pumps Corporation does

not assume any liability or responsibility for

the operation of a customer’s high pressure

system.

Page 11

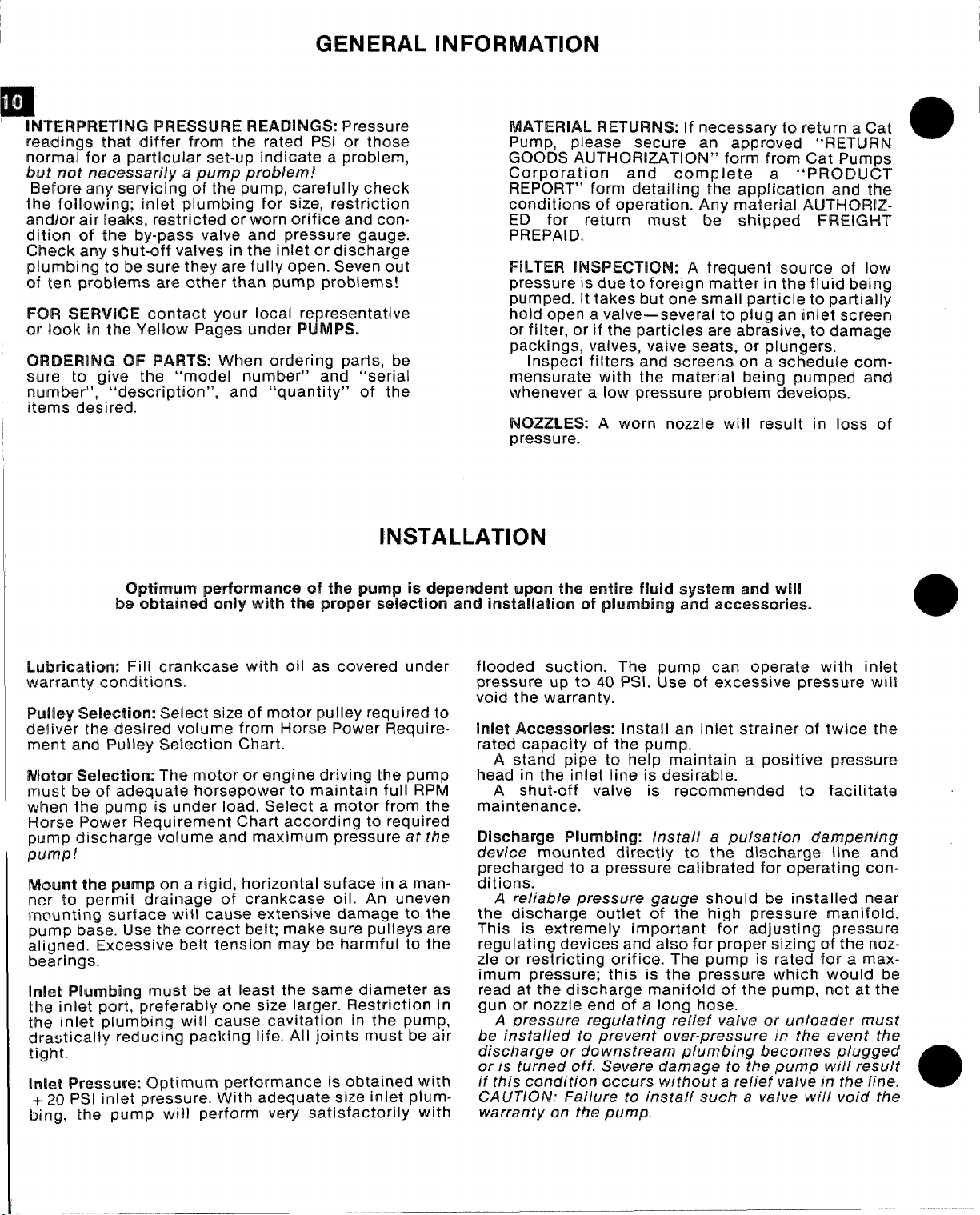

GENERAL IINFORMATIC)N

~

It

p

INTERPRETING PRESSURE READINGS: Pressure

readings that differ from the rated IISl or those

normal far a

buf not necessarily a pump probkem!

Ehefore any servicing of the pump, carefully check

the following; inlet plumbing for size, restriction

andlor air leaks, restricted or worn orifice and condition of the by-pass valve and pressure gauge.

Ch@ck any shut-off valves in the inlet or discharge

plumbing to be sure they are fully open. Seven out

of ten problems are other than pump problems!

FOR SERVICE contact your local representative

cw look in the Yellow Pages under PUMPS.

ORDERING OF PARTS: When ordering parts, be

sure to give the

number”,

items desired.

particular set-up indicate a problem,

“model number” and “serial

“description”, and “quantity” of the

MATERIAL RETURNS: If necessary to return a Cat

Pump, please secure an approved “RETLfRN

GOODS AUTHORIZATION” form

from Cat Purnrm

Corporation and complete a “PRODUCT

REPORT” form detailing the application and th~

conditions of operation. Any material AIJTHQRIZED for return must be shipped FREIGHT

PREPAID.

FILTER INSPECTION: A frequent source of low

pressure is due to foreign matter in the fluid being

pumped. It takes but one small particle to partially

hold open a valve—

or filter, or if the particles are

several to plug an inlet screen

abrasive,to damage

packings, valves, valve seats, or plungers.

Inspect filters and screens on a schedule comm-

ensurate with the material being pumped and

whenever a low pressure problem develops.

NOZZLES: A worn nozzle will result in loss of

pressure.

a

INSTALLATION

Optimum ptwfomantm at tfw pump is dependent upon ths entire fluid system and will

obtained only with NM?properselection and installation of plumb!ngand acmassories.

be

Lubrication: Fill crankcase with oil as covered under

warranty conditions.

PIuil@y $elactitm: Select size of motor pulley required to

deliver the desired volume from Horse Power Require-

ment and Pulley Selection Chart.

Wutar Sel@cticm: The motor or engine driving the pump

must be of adequate horsepower to maintain full RPM

when the

Horse Power Requirement Chart according to required

pIJrYIP discharge volume and maximum pressure at tfre

pump!

MourIt tl’m pump cm a rigid, horizontal suface in a

ner to permit drainage of crankcase oil.

mounting surface will cause extensive damage to the

pump base. Use the correct belt; make sure pulleys are

aligned. Excessive belt tension may be harmful to the

bearings.

Inlat Plumbing must be at least the same diameter as

the inlet port, preferably one size larger. Restriction in

the inlet plumbing will

di”autically reducing packing life. All joints must be air

tight.

Inhat

+ 20 PSI inlet. pressure. With adequate size inlet plum-

bing, the pump will perform very satisfactorily with

pump is under load. Select a motor from the

man-

An uneven

cause cavitation in the pump,

Prmwwm%x Optimum performance is obtained with

flooded suction. The pump can operate with inlet

pressure up to 40 PSI. Use of excessive pressure will

void the warranty.

Inlet Accessories: Install an inlet strainer of twice the

rated capacity of the pump.

A stand pipe to help maintain a positive pressure

head in the inlet line is desirable.

A shut-off valve is recommended to facilitate

maintenance.

Discharge Plumbing: Install a puisatian dampening

device mounted directly to the discharge line and

precharged to a pressure calibrated for operating con-

ditions.

A re/iab/e pressure gauge should be installed near

the discharge outlet of the high pressure manifold.

This is extremely important for adjusting pressure

regulating devices and also for proper sizing of the noz-

zle or restricting orifice. The pump is rated for a

max-

imum pressure; this is the pressure which would be

read at the discharge manifold of the pump, not at the

gun or nozzle end of a long hose.

A pressure regulating relief valve or unloader must

be installed to prevent over-pressure in the event the

discharge or downstream plumbing becomes plugged

or is turned off. Severe damage to the pump wif[ result

if this condition occurs without a rslief valve in the line.

CA UTIOIV: Failure to install such a valve wtil void the

warranty on the pump.

@

a

Page 12

I

—

58

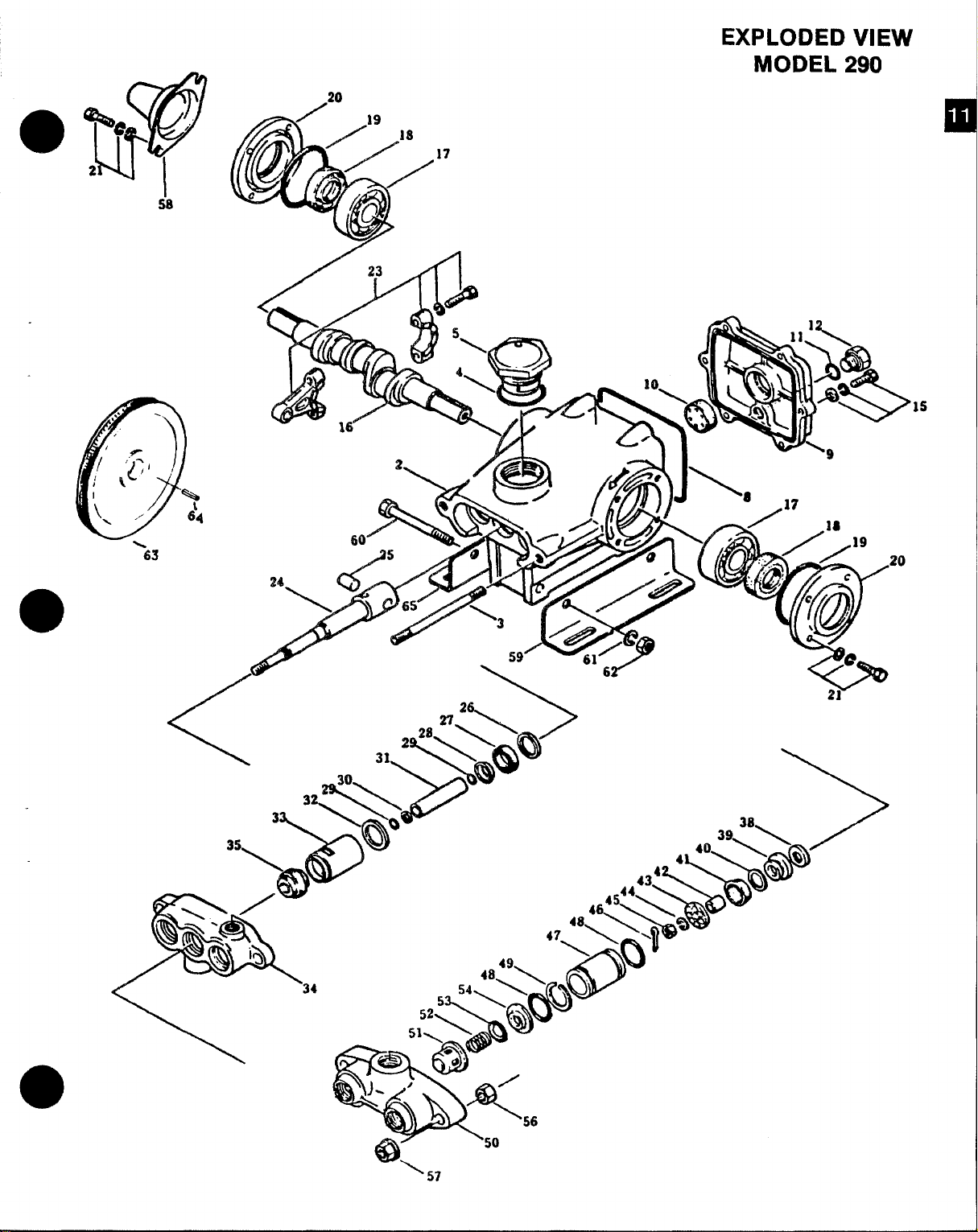

EXPLODED VIEW

MODEL 290

20

❑

17

’15

‘ 57

Page 13

ITEM

PARTS LIST

CAT PUMP MODEL 290

2

3

4

5

8

9

10

11

12

15

16

17

18

19

2’0

21

23

24

25

26

X

2!2

3’0

31

32

33

34

35

PART No

28766

856W)

14177

43211

26(M37

26105

22289

23170

25625

%2520

43804

14487

24159

26536

27950

92519

101799

101‘Boo

16948

20017

25301

25327

25392

28771

29003

29614

26854

28597

25128

25635

30315

30325

Dmclllm’lc)l’i!

QTY.

Crankcase

Stud (M8 x 82)

Cl-Ring, Oil Filler Cap

Oil Filler Cap

O-Ring, Crarrkcase Cover

Crankcase Cover

Oil Gauge

O-Ring, Drain Plug

Drain Plug

Sems Comb l-lead

Screw (IM6 x 20)

Crankshaft

Rearing

Oil Seal

Q. Ring, Oil Seal Case

Oil Seal Case

Semrs

Comb. Head

Screw (M6 x 16)

Confecting Rod

Piston Rod

Piston Pin

Seal Washer

Oil Sea!

Harrier Slinger

O-Ring, Sleeve

O-Rina, Sleeve (Viton)

Back-U”p Ring, Sleeve

Sleeve (29743 Lfnchrorned) 3

Seal Washer

Seal Retainer 3

Inlet Manifold

Inlet Manifold-Stainless

Steel

Prrrrrm-A-Lube Seal

Prrrrrm-A-Lube Seal(Viton) 3

PART NO.

ITEM

3a

;

1

39

40

27004

30543

30544

1

1

1

1

1

1

41

42

43

44

45

46

6

1

47

4a

2

2

2

49

50

2

43172

27983

27002

27006

18956

14158

101802

23172

11377

21985

24459

25634

DESCFUPTIC)N

Inlet Valve

f3ac-Cup Piston

Bat-Cup Ring

(Teflon)

Cup (Viton}

Piston Spacer

Piston Retairw

Conical Washer-SS (M6)

Nut-SS (M6)

Cotterpin

Cylinder (43834 Unch)

O-Ring, Cylinder

O-Ring, Cylinder (Viton]

Bat-Up Ring, Cylinder

Discharge Manifold

Discharge Manifold-

3

3

3

3

3’

3

3

3

3

6

6

3

1

Stainless Steel

8

3

3

3

3

3

3

3

3

51

52

53

54

56

57

58

59

60

3

61

3

62

1

63

64

43442

43360

43723

43434

81109

101804

25130

26246

30901

30920

30910

30032

30047

Valve Spring Retainer

Valve Spring

Valve

Discharge Valve

Seat

Hex Nut (MS)

Hex Flange Nut (M8)

Shaft Protector

Angle Rail

Hex Cao Screw

1

(5/16 x23A)

Split Lockwasher

(5116 US)

I’-lex Nu~ (5/16 LfS)~

Pulley 5“ w{2

Set screws

Key (M5)

J

30612

Mk,ng

30246

Pulley

Asbly

;

3

3

3

2

2

;

2

a

2

2

1

1

:

30023

3

6

3

1

1

3’0305

3

3

2

1

30431

3

3

3

i

1

Cup Kit

cup

O-Ring, Cylinder

Cotterpin

Instruction Sheet

Cup Inserter

Seal Kit

Prrrrrm-A-Lube Seal

Cotterpin

Abrasive Paper

Instruction Sheet

Slt?eve

and Seal Kit

Prrrrrm-A-Lube Seal

Barrier Slinger

Cotterpin

Sleeve

O-Ring, Sleeve

instruction Shee’

SERVICE KITS

30686

3

3

3

3

3

1

30860

6

3

:

3

Vahm Kit

Valve Spring Retainer

Valve Spring

Valve

Valve Seat

O-Ring, Cylinder

Instruction Sheet

Piston Kit

O-Ring, Cylinder

Back-Up Ring, Cylinder

Bat-Cup Piston

i3ac-Cup Ring

cup

Piston Spacer

3

Piston Retain@r

3

3

Conical Washer (M6)

Nut (!v16)

3

3

Cotterpin

Inlet Valves

3

1

Instruction Shr3e!

Page 14

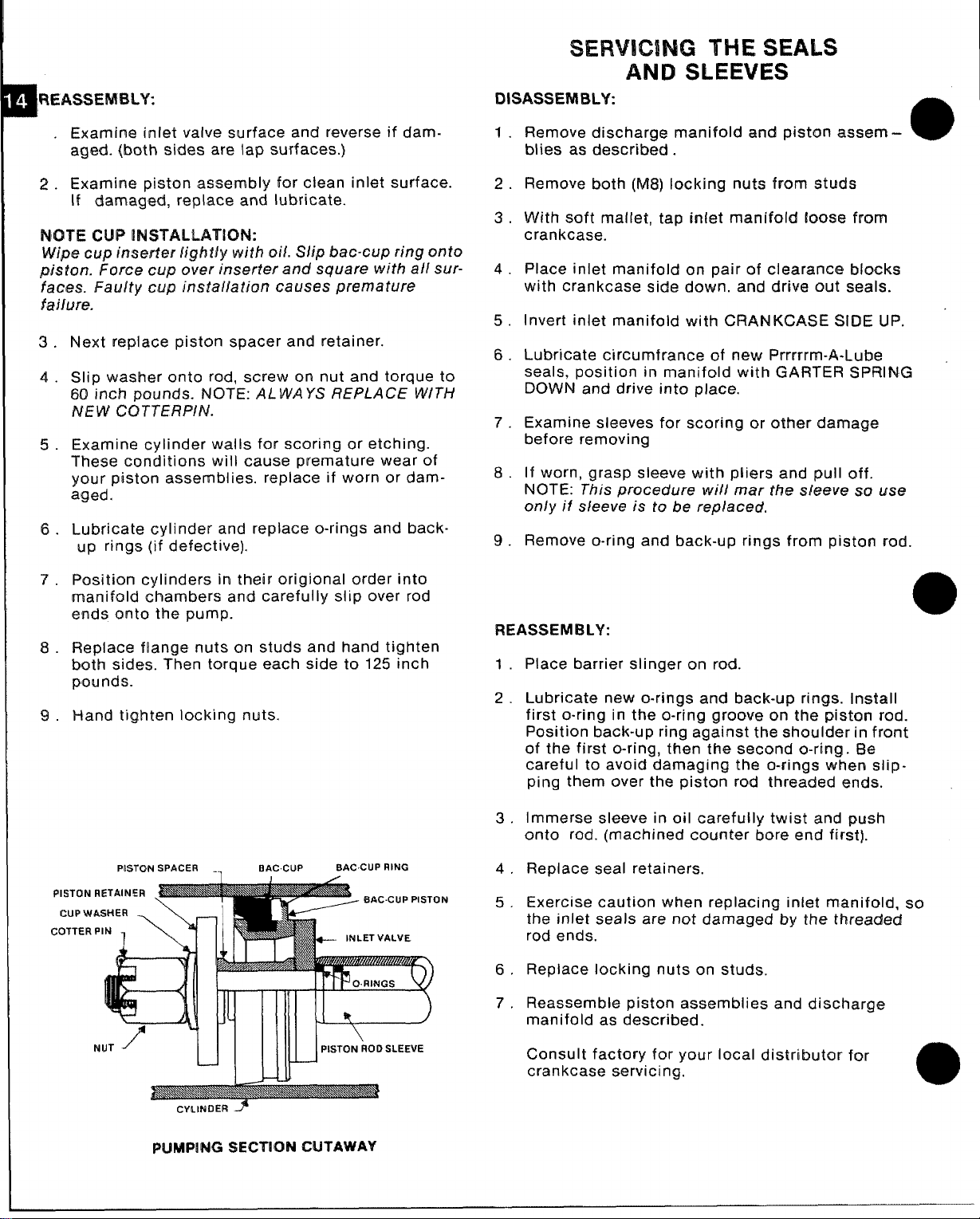

SERVICING DISCHARGE VALVES

& VALVE SEATS

e%

DISASSEMBLY

1.

Loosen the 2 (M8) locking nuts approximately one

turn.

2.

Then remove the 2 (M8) flange nuts.

3.

Grasp the discharge manifold with 3 fingers on

the underside and tap with a soft mallet to remove

Valve assemblies will remain with the manifold. in-

4.

vert manifold and discharge valve assemblies

should fall out.

Inspect discharge valves for wear or ridges.

5.

(Sperical valves due to their shape must be replac-

ed when worn.)

REASSEMBLY:

1.

Place retainer in manifold chamber.

2.

Next insert spring into center of retainer

3.

Place valve over spring with spherical (mooned)

side down.

4.

Next insert the valve seat.

Position manifold back onto pump. NOTE: Exer-

5.

cise caution when inserting cylinders into manifold

to avoid damaging cylinder o-rings.

Replace flange nuts on studs and hand tighten

6.

both sides. Then torque each side to

pounds.

Hand tighten locking nut.

7.

CAUTION: When restarting the pump, check to see

that there is no cy/inder motion as this will

cause premature failure of the cylinder o-rings.

Center cy/inder motion canbe eliminated by switching with one of the endcylinders,

125 inch

SERVICING THE PUMPING SECTION

DISASSEMBLY:

1.

Remove discharge manifold as described above.

2.

Slip cylinders out of inlet manifold.

NOTE: Identify cylinders so they will be re/apced in

their origional position. (Front to back)

3.

Remove cotterpin, nut, and washer.

4.

Next remove piston retainer, spacer, and piston

assembly.

Remove inlet valve.

5.

Page 15

A WEASSEMBLY:

m

Exarnirm inlet valve surface and reverse if damaged. {both sides are lap surf aces.)

Examine piston assembly for clean inlet surface.

2.

If damag~d, replace and lubricate.

lWITE CUP INW”M.LAT[QN:

Wipe cup Inswfer Iight/y with oii. Slip Me-cup ring onto

pisfon. Force cup over inserter and square with all sur-

faces. Faulty cup installation causes premature

fa)lure.

Next replace piston spacer and retainer.

3.

4.

Slip washer onto rod, screw on nut and torque to

60 inch pounds. NOTE: ALWAYS REPLACE WITH

NEW CQT7ERPIN.

5.

Examine cylinder walls for scoring or etching.

These conditions will cause premature wear of

your piston assemblies. replace if worn or dam-

aged.

6.

Lubricate cylinder and replace o-rings and back-

up rings (if defective).

SERVICING THE SEALS

AND SLEEVES

DISASSEMBLY:

Remove discharge manifold and piston a.sst?m -

1.

blies as describ~d .

Remove both (M8) locking nuts from studs

2.

With soft ma[let, tap inlet manifcdd lcms@ from

3.

crankcase.

Place inlet manifold on pair of clearance Mocks

4.

with crankcase side down. and drive out seals.

Invert inlet manifold with CRANKCASE SIDE UP.

5.

Lubricate circumfrance of new Prrmrrn-A-Lube

6.

seals, position in manifold with GARTER SPRING

DOWN and drive into place.

Examine sleeves for scoring or other damage

7.

before removing

If worn, grasp sleeve with pliers

8.

NOTE: This procedure will mar the s[et?ve so LJiW

only it sleeve is to be replaced,

Remove o-ring and back-up rings from piston rod.

9.

and pull off.

a

7.

Position cylinders in their origional order into

manifold chambers and carefully slip over rod

ends onto the pump.

Replace flange nuts on studs and hand tighten

%.

both sides. Then torque each side to 125 inch

pounds.

Hand tighten locking nuts.

9.

PISTON SPACER . . EIAC.CUP

coTTER”N1 \Y

BAC.CUP RING

+--- INLET VALVE

IliE--4l

REASSEMBLY:

Place barrier slinger on rod.

1

2

Lubricate new o-rings and back-up rings. Install

first o-ring in the o-ring groove on the piston rod.

Position back-up ring against the shoulder in front

of the first o-ring, then the second o-ring. lilt?

careful to avoid damaging the o-rings whtan slip-

ping them over the piston rod threaded ends.

Immerse sleeve in oil carefully twist and push

3

onto rod. (machined counter bore end first].

Replace seal retainers.

4

Exercise caution when replacing inlet manifold, so

5

the inlet seals are not damaged by the threaded

rod ends.

Replace locking nuts on studs.

6

Reassemble piston assemblies and discharge

7

manifold as described.

CYLINDER ~

PUMPING SEGTION CUTAWAY

Consult factory for your local distributor for

crankcase servicing.

a

Page 16

●

DIAGNOSIS AND MAINTENANCE

PROBLEM

Pulsation Faulty PulsationDampener Check Precharge

Pressure

Low

Wmps runs axtremely rough,

wessure very low

:yfinder O.rings blown nexf to

iacharge manifold

Warped manifold

eakage atthe cylinder O.rings Loose cyl!nders. Cylinder motion

t fhe discharge manifold and

lack, powdery substanca in fhe discharge manifold

rea of the O.rings

later leakage from under the Worn Inlet manifold seala. Leaking Installaeals If piston rodsleevea prescored,

det manifold

ii leak between crankcase

nd pumping section

il leaking in the area of

rankahaft

cau5ed by improper shrmming of the

sIeeve O-ring

Worn crankcase piston rod seals

Excess 011 from wicks

Worn crankshaft seal or Improperly

Installed oil seal retainer packing gasket andlor seala

Bad bearing

PROBABLECAUSE

new one

Worn nozzle Replace nozzle, of proper alze May be caused by humid ah Change oIl at 3 month or 500 hour intervals

Belt Sllppage

Alrleakir inlet plumbing

Pressuregaugeinoperativeor not Check

registering accurately

Relief valvestuck, partiallypluggedor

Improperlyadjusted;valve seat worn

Inlet suctionstrainerclogged or

Impropersize

Worn p]ston assembly Abrasivesin

pumped fluid or severe cavitation. must be Iimited to lifting less than 20 feet of

Inadequate water supply. water or -8.5 PSI vacuum.

Fouled or dirty inlet or discharge Clean inlet and discharge valve assemblies.

valves

Worn Inlet or discharge valves

Leaky discharge hose

Restricted !nlet or air entering the inlet

plumbing

Inlet restnctionsa ndlorair leaks. Replace worn cup or cups, clean out foreign

Damaged cup or stuck inlet or

discharge valve

Worn Inlet manifold seala Replace worn seals.

Worn Inlet seals allow pump to draw Install new inlat manifold seals.

air.

Preaaures In excesaof rated PSI Check for plugged nozzle, closed valves or

Tighten or replace; use correct belt

Disassemble,reseal, andreassemflle

with new gaugq replace worn or

damaged gauge, P.N. 06090 Oil leaking from underside of Worn crankcase piston rod seals

Clean, andadjusl reliefvalve;check for worn

and dirtyvalveseata. KitAvailable. Damagedor improperlyinstalledod

Clean. Useadquatesize. Checkmore frequently.

Install proper falter. Suction at inlet manifold

Replace worn valves, valve seats andlor

discharge hose.

Proper size inlet plumbing; check for air tight

seal

material, replace worn valves

—

!mproperly adjusted bypass valve Chrome plating of cylinders damaged

Replace manifold

Remove spacer shims on manifold studs. Do not Strong surging at the inlet and

remove too many shims orthe ears of the

manifold will be bowed when the manifold is side discharge valves

retightened, causing looseness in the center

cylinder

replace sleeves and aleeve O.rings.

RePIaCe crankcase piston rod Seak

Reduce quantity of oil per oiling

Remove oil seal retainer and replace damaged

Replace bearing

SOLUTION

if low recharge it or install a

PROBLEM PROBABLECAUSE SOLUTION

Excessiva play in the end of tha

crankshaft pulley

Water in crankcase crankcase oil every month or200houra) P.N. 06100,

Worn main ball bearing from excessive

tension on drive belt

condensing into water inside the

Leakageof manifold inletseals andlm Replace seals,sleeve andO.mgs,

piston rod sleeve O.nng

Replace ball bearing. Properly tenaion belt.

using Cat Pump Crankcase Oil (other approved

crankcase

Replaceoil gaugeor coverO-ring,and drainplu

Oil leakingat tha rear portionof

the crankcase

Oil leakage from drain plug

Loud knocking noise in pump

Frequent or premature failure of

the inlat manifold seals

Shortcup life

low preaaure on

the discharge

gaugeor crankcaaerear coverO.ring,

anddrain plug

Loose drain plug or worn drain plug

O.ring

Pulley Ioose on crankshaft Check key and tighten set screw.

Broken or worn bearing

Scored mds or sleeves

Over preaaure to inlet manifold

Damaged or worn chrome plating of Replace cylinders

the cylinders

Abraswe material mthe fluid being Install proper filtration on pump inlet plumbing

pumped

Excassive pressure andlor

temperature of fluid being pumped

Over pressure of pumps Reduce pressure

Running Pump dry Do not run pump without water

Front edge of piston sharp

causing excessive wear of cups. Maybe compatible with chrome

caused by pumping acid solution.

Foreign particles in the inlet or

discharge valve or worn inlet andlm

O.ring

O-ring

Tighten drain plug or replace O.ring

Replace bearings

Replace rods and sleeves.

Reduce inlet pressure per instructions

Check pressures and fluid inlat temperature; be

Sure they arewithinapecified range

Replace with new piston

Install new cups and cylinders. Pump only fluld

check for smooth lap surfaces on inlet and

discharge valve seats. Discharge valve seats

a nd inlet Valve seats may belapped on a very

fine oil stone; damaged cups and discharge

valves cannot ba lapped but must be replaced.

Page 17

as it passes thrcwgh”thahose. Therefore, it is

necessary to increase the pwwsure at the

machine 40 PSI for eve~ additional 50 feet of

cleaning

solution hos~ over 1100feet.

CHEMICAL PROPORTIONING AND

LEVEL CONTROL ILLUSTRATION

PROI=QRTIONING VALVE REPAIR KIT

Pm

VE

MIX

TANK OVERFL~W$

1. Float ball in mix tank hanging up (not moving frissdy).

2. Extension bracket pinching the float lever, restricting full a@km of

the lever.

3. Plunger not seating properly cmthe vakm. (Remove the 2 screws

which hold the extension assembly to th~ valve. Do not Iasti or

drop thisscrews. Remove the wtmwion assembly. Turn itupsk.ka

down. Inspect the plunger for proper seating. If tl%ra is no

obstructing the vahm or plunger, the plunger maybe nut of adj,ustme.nt. To adjust, loosen thes@ screw on ths ball nut rarncfmow

tho ball toward the end of the rod 1/16“. Retighten set scxww.

Place wtension assembly back into position. Tighten the two

screws.

MIX TANK DOESN’T’ KEEP UP WITH WATER CM$TPWF

1.

Check garden hose quick connect assembly screen.

Check garden hose

2.

kinks or blockage.

3.

Float ball in mix tank hanging up. (Not moving freely).

4.

Extension bracket pinching float lever, restricting full action of

lever.

5.

Valve plunger not o~eninq fullv. To adiust, remmm tlm

which “hold-theextension >sse-mbly to ‘the‘valve. (Do not lose w

drop the screws). Remove the extension assemb[y, turn it upside

down. To adjust, loosen the setscrew on tho bait nut. Place your

thumb on the plunger and pressitin1/16“ and siide the ball nut WI

set screw toward the plunger end 1/16“, Tighhan the s~t screw.

Place the extension assembly back into position. Ifthe tank

to overfill, the ball nut is too c[ose to the valvo plunger and should

be moved back away from the valve plunger slightly.

mdlor feed hose to the mix tank far clog,

ckbris

2 screws

starts

@

iaw

CHEMICAL TANK

TROUBLESHOOTING

WIm LawCHEMICALFmw

1.

Chack that hoses in the tank are secured. Check that the hose

from the top of the flow

with no kinks, Check the hose from ttm bottom ofthe flow meter to

the them. Jug for

2.

ICheck th~ foot valve and

goes into the mix tank. To check Wis screw for proper function,

remove it fmrm the plastic hose. You should ba able to suck

through the hcwmbarb end, but you should

through the hose barb end. (If you

rinso it out with vinegar). When screen is removed the chemical

bsl hose should kmIifkadinto a vertical position so the ball in the

foot valve will seat by gravity. (This isonly a tempora~ fix for low

watfiwfwessuns areas.)

3. Check flmv metcwfor float obstruction.

4. Check ta h’ummethat the adjusting screw on proportioning venturi

is ‘b~cked out.

5. ls proportioning wimturiclmsed? Soak in warm water or vinegar

Soh.ltkm.

& Is incoming waihwpressure lIsss

7. Cracked or defective ch@micalflow meter?

IWITE!: If YOUam in a low water pressure area and find that the volumo of water entering the mixtank is notenough to allow yourventuri

to siphon chemical, unsc~ew the spring

and rwmmmthe

IEMJ3MJW To ADJUST CWWKL5L WITH THE

1,

Debris lodged L@tincfteflon seat inflow meter knob.

2. TIMlcmsaat dismcmnting from flow meter knob.

spring.

mieterto the sid~ of the mix tank issecured

kinks or cracks.

screen on the end of the hose which

not be able to blow

can not suck through it then

than 20 PSI.?

from the foot valve screen

mow METER

PUMP PULSATES WHEN W-METANK [$ IN

1.Check that the hose which goes from the gray plastic venturi to

the bottom of the tank is not directed toward the Cat pump pickup

port. If it is, aim it in another direction.

HEATIN

INFOR

The propane heater incoporatad in this equipment is of special d@sign for use in the carpet cleaning industry. [t’s high pressure coils

and thermostatic temperature control make it simple to operate and

reliable. One@tlw desired temperature is set, the heater’ will then go

‘on’and ‘off according tothe water temperature within the heater. As

water is used through the cleaning tool, cold water entering tlw heater will ati]vate the thermostatically controlled

firing the heater to maintain a consistent fiow of hot water. One@tho

cleaning wand is shut off and the flow of water through the heatfw

stops, the heater will continue to burn until the set tempimatwe is at-

tained.

It ispossible th~n with this design that the flame maybe on when tlm

wand is off, likewise, it is possible the flame may be off when the

wand is on.

~ This beater is desicmed to burn warm mopane

gas only. Any liquid propane entering tke heater may c~use damage

to the control valve on the heater. Itwill also

and a soot build-upon the coils. Therefore, itis necessary to shut off

the heater and close the valve at the tank bfftween cleaning locations. Failure to do this allows sloshing liquid to enter

line to the heater.

G SYSTEM

MATION

A FM. MODE

propane valve thereby

cause improptmburning

t17E3vapor feed

o

W31JJTiClN REVERSlklG FIWWd MM TANK To CHEMICAL JUG

1. Anti-siphon scnwanremoved from chemical jug hose.

2. Debris in anti-siphon wmsen.

Overfilling of the propane tank will

this, advise the attendant filling the tank rmt W fftil We t$snk tmmr

!307.. When filling the tank, watch the 10?6 valve and imm~diately

cause many problems. To avoid

Page 18

stop filling when whke liquid starts spurting from the 107. valve. To

prevent damage to the propane regulator, always close the valve on

the tank before filling.

When venting the heater through the roof of the van, it is necessary

to install a draft diverter on top of the heater. This will prevent down

drafts from blowing out the pilot light.

The propane regulator is pre-set at the factory at 6 oz. of propane.

This reading is taken at the control valve on the heater (see figure A

#6). To prevent road dust and moisture from entering the propane

regulator, keep the white Tupperware cover (supplied) on the regulator at all times.

To avoid restriction of airflowat base of heater, keep articles such as

chemical containers, hose, boxes, etc. from within 18 inches of base

of heater. NOTE: This restricted situation also creates an over rich

condition which results in soot build-up.

IMPORTANT: If a new propane tank has been installed or hoses

have been disconnected, air may enter propane hoses and must be

purged prior to attempting to light the pilot burner. Should this condi-

tion exist, operator must depress the pilot buttonfor 1-5 minutes and

attempt to ignite the pilot light at 15 second intervals. A very slight

hissing noise should be evident while performing this operation.

HEATER - OPERATING

INSTRUCTIONS

Heater must be Wed with water

mm!z!ilpriortoignmg.

A. TO START PILOT:

1. Adjust thermostat control knob on unitrolto ‘normal’. @ Fig. A.

2. Adjust upper dial to ‘pilot’position. @Fig. A.

3. Depress pilot button. @Fig. A.

4. While pilot button is depressed with the left hand, use

your right hand forefinger to depress the electric spark pilot

igniter button several times in rapid succession, then look to

see if pilot is lit. If not, depress in rapid succession again until

lit. If this fails, use the resourceful match.

NOTE: Whenever ignitingpilot, hold litmatch in front of pilotsight

opening before inspection. Move lit match toward pilot

burner. The pilot should ignite.

IF HEATER FAILS TO LIGHT:

Is propane tank full?

Is propane tank valve open?

Has air been properly bled from propane line?

Once pilot is litcontinue depressing button for 10 seconds to

insure thermo coupler has been heated.

B. TO LIGHT MAIN BURNER:

1. Turn upper knob to ‘on’ position. Flame will come on.

IF NOT: Pilot has expired.

Turn upper dial to ‘off position. @Fig. A.

Do not attempt to relight pilot for 60 seconds.

Then repeat instructions A -#1 -4.

Water may already beat controlled temperature.

IF YES: Flame will turn off when thermostat senses maximum temp.

C. TO ACHIEVE PROPER CARPET CLEANING

TEMPERATURE:

1. Complete procedures A & B

2. With 100’ of hose, turn cleaning wand on for 5 minutes and

the temperature should stabilize.

3. Once a constant temperature is established, turn cleaning

wand ‘off. The flame on the heater burner should remain on

for 10-15 seconds.

A. If the flame expires priorto 10 seconds, turn the

thermostat dial to a higher reading, then repeat C 1-3.

B. If the flame remains lit after 15 seconds, turn the

thermostat dial to a lower reading, then repeat C 1-3.

D. W SHUT 12N3WWNHEATER:

1. Turn upper dial to ‘off position. @ Fig. A.

_ 2. Turncleaningwandonfor3 t05min.testo

cool heater core. If heater core is not cooled, it is impossible

that the heat retained in the core will cause boiling back into

the chemical mix tank.

3. Close propane tank valve while

wand is on and heater is cooling.

PILOT BURNER

FIG

ADJUSTMENT

1. Remove pilot adjustment cap@

2. Adjust pilot key to provide

properly sized flame

3. Replace pilot adjustment cap

ALLEN HEAD PIPE PLUG ~

CAN BE REMOVED

FOR MONOMETER INSERTION

TO HEAD PROPANE OUNCES.

o

HEATER

TROUBLESHOOTING

o EXCESSWE HEAT

o FLAMES PROTRUDING OUTSIDE

THE ILOWER OPENINGS

CAUSE ANDOR SOLUTION:

1.

Thermostatic control dial set too high

A. Turn dial to lower setting

2. Maladjustment of propane regulator. NOTE: Propane regulators

are facto~ preset and maybe readjusted by authorized

personnel.

A. Contact manufacturer to determine correct procedure.

B. Have your local propane dealer use a monometer at the

unitroi to re-set the propane regulator to 7 oz. maximum.

3. Overfilled propane tank. NOTE: Propane heater is designed to

operate on vapor propane only. Over-filling a propane tank

allows liquid propane to enter all heater related components

and permits an over-rich burning condition to occur. This

condition usually requires the heater core to be cleaned of soot

and carbon deposits. Cleaning is a messy, dirty job and very

inconvenient, so don’t let it happen to you!

PROBLEM:

● PILOT LIGHT

CAUSE AND/OR SOLUTION:

1. Pilot lightwillnot ignite. NOTE: Do not use a needle or pinto clean

pilot orifice - use compressed air or solvent only.

A. Veri@ propane reaching igriitor. NOTE: A kinked or crushed

hose may impede propane flow.

B. Remove and clean orifice.

C. Verify igniter spark isoperating correctly.

B

Page 19

VACUUM SYSTEM

~lNFORMATIoN

Tlw vacuum Mcwwwincorporated in this machine is a positive dis-

placement

marwmand lifeofthis unit isgreatly dependent on the care and propisrmaintiarnancait mtmives.

lobe type, manufactured byFuller Company. The perfor-

‘VACUUMTANK FILTER BAGS ‘

Hydra-fwlashsrfilter bags are

dirt that would normally

The use ofthese bags, if

the build-up of much ofthe debris inthe tank and

customer’s driveway or street. The drawstring top of thwse bags is

designed to be tied to the incominq dirtv water irrlet in the vacuum

tank.

Tore-order bags use part numbw

designed to trap all c#tfm lint, sand and

collect at the bottom of your vacmmrntank.

emptied at the end of @achjob, will fflimhvata

avoid a moss on th~

-.

049-02$

a

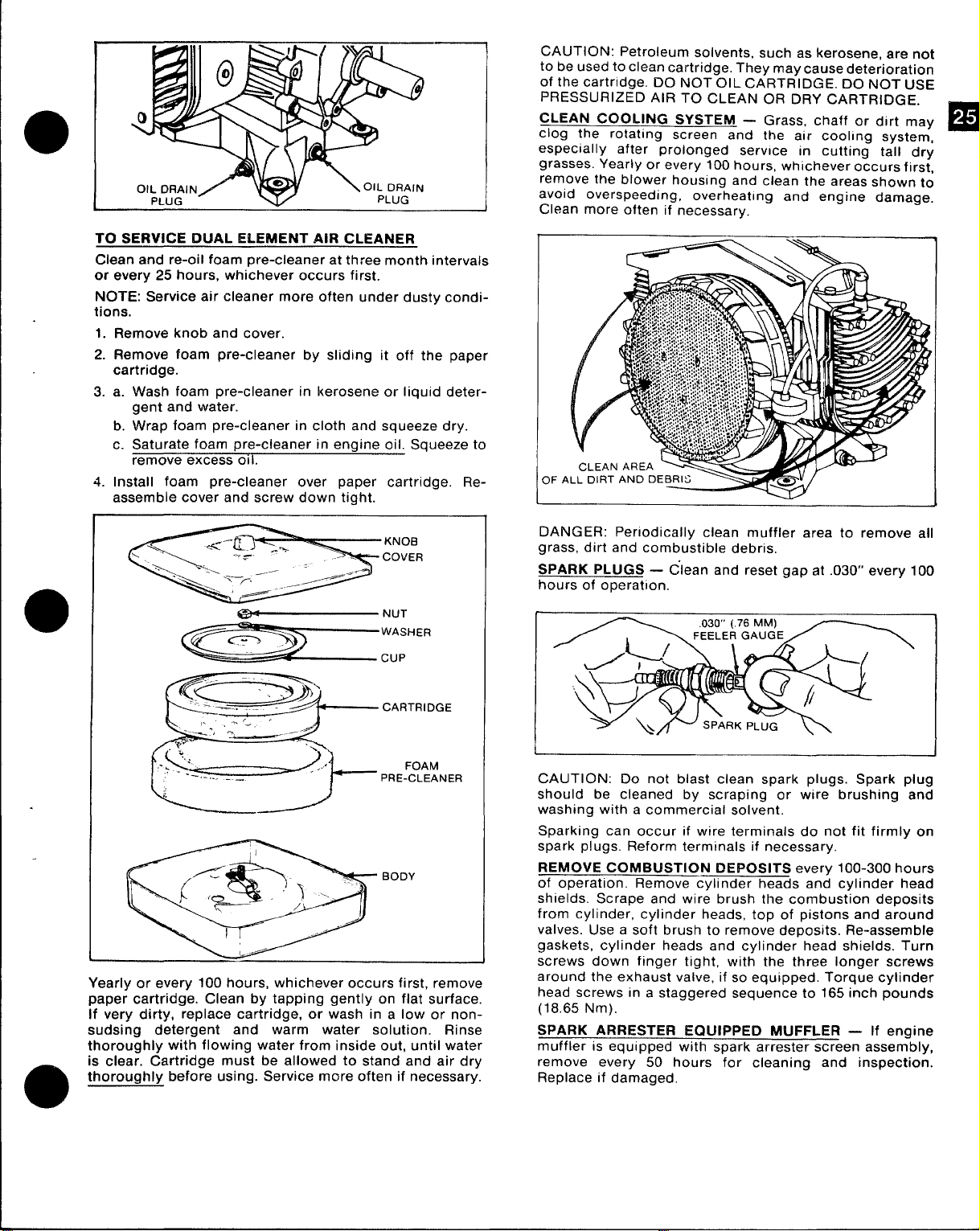

Bacausa of ti’mclose tolerances between the lobes and housing of