Page 1

HGauaCat

HYDRA##!iiS-EY%

3+9

Corporation

Page 2

AquaCat(fiontview.featureslabeled).......................t.............................8

AquaCat(sideview.featureslabeled).............................................t.........8

CatPumpModel290

DismantlingCatPump

VanguardOHVEngine.........................................................................2l

.........................!.!..............................,,,,..!....,..........

....................................%...............<.....#...................

HOURS

Monday -- Friday

8:00 am To 5:00 pm

PACIFICSTANDARDTIME

GENERAL INFORMATION

'l~oodlnstallation (ontmckbed)..............................................................4

4strotuti installation..............................t.......................................c....l.4

Machinebnfiguration ........................................t......................................5

~ru.floorGas Hook.upandlnshllation...................................................5

WaterHardnessMap............................t................................................6

WaterSofienerMok.up.............................................................................6

WATER & CHEMICAL SYSTEMS

AquaGtWaterFlow ............................................................................lO

ChemicalPropotioningandLeveltintrol ..............................................lO

CAT PUMP

PumpingSectionCut.awy .................ll......4..c............l.......j....+o.4(..q4...l3

PistonModel290ExplodedMew...

BypassValveNsemb& .........................................................................l7

AquaGtWaterFlow ..........................................................................l7

VACUUM SYSTEM

Vacuum Flow............l..l...l.................4......c..........................c....l..l...l8

VacuumTankRlterBag...........t............................................................l8

BlowerLubePoR..................................................................................l8

VacuumBlowerMotorLubrication.........................................................2O

VANGUARD OHV ENGINE

OilMscos~Chti ...................................................................................~

OilRllandUpStick......................t.........................................................~

EngineComponenk..........................................................................~

EngineComponents(continued)

CarburetorAdjustmentScreW........t....................................................23

GovemedldleSpring...............................................................................23

Oil Filter/ Oil Drain

RoundDualArCleanerElement...........................................................24

SquarehalNrCleanerElement ...........................................................24

RoundDualElement.........t.................................................................25

CoolingSystem..

Sparkplug..............................................................................................25

FuelFilter................................................................................................25

ELECTRICAL SYSTEM

ElectricalElagram

.............................................................................24

.....................................................................................

............................,,,,..,.,,,,.... .... ....,,,...,,,.,,..,,,,!.,.....

...........................................................

.............................................................23

14

25

31

@@@@

,,,.y)!:,yiy’

PST

‘$@$&*:.

ROCK MT.

TELEPHONE NUMBERS

(206)775-7272

(206)775-7276

(206)775-7275

(206)771-7156

G 1991HydraMasterCorp.

Printedin U.S.A.

.~<jj$~.’

CENTRAL

GeneralOffices

Parts Department

ServlWarranty

FAX

“Yl:;j’%

EASTERN

CLEANING & CHEMICALS

pH~afl ..................................................................................................W

CleaningSkokeMethod.....................t.................................................~

CLEANING WAND

WandValve~sembly .......................................................................~

Jetksembly ..........................................t....t..........................................~

Wand%sembIy....................................................................................~

Page 3

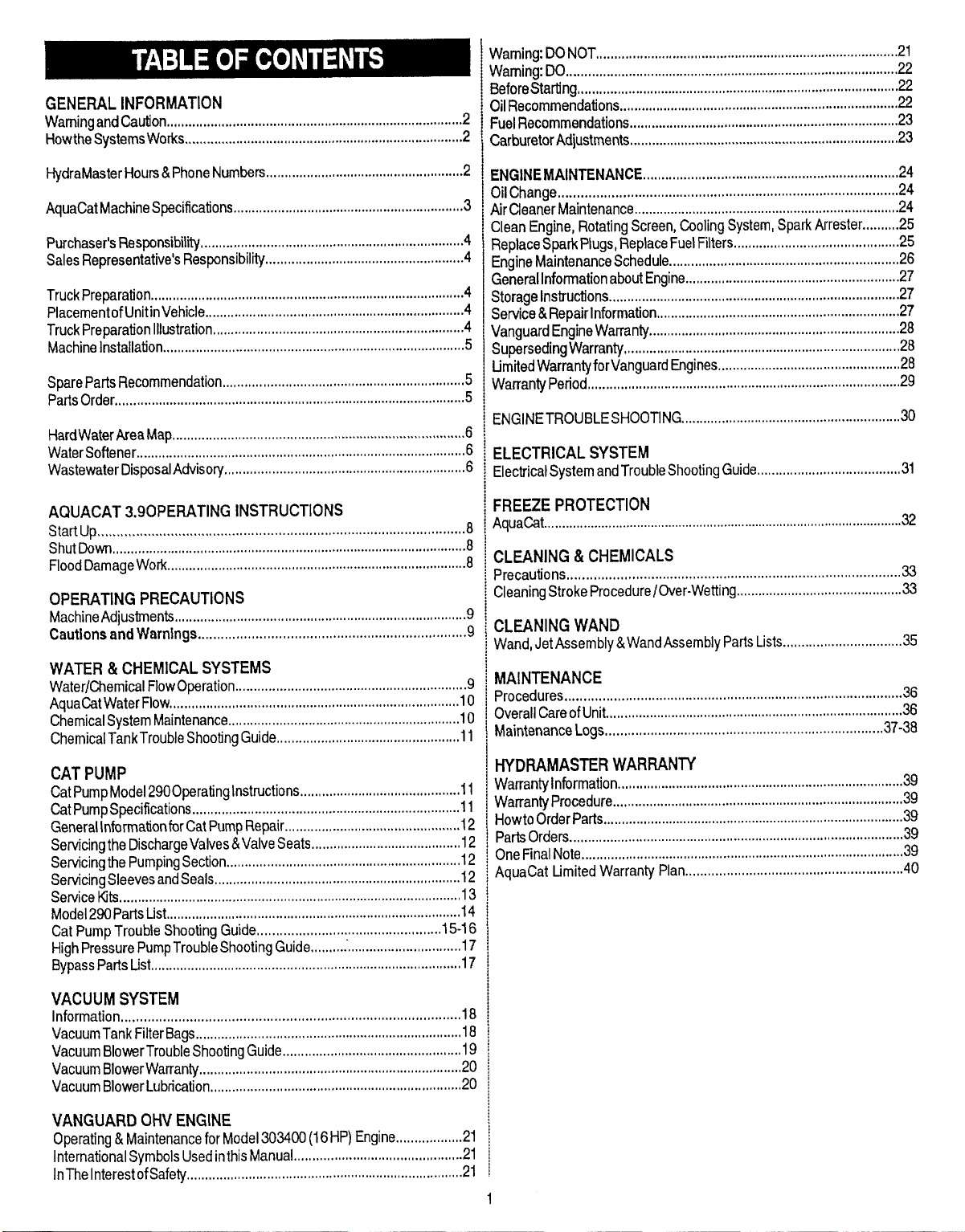

GENERAL INFORMATION

WarningandCaution

HowtheSystemsWoks ...........................................................................2

.,,,,...........................,,,,,,,,.,,,,....,,..,,,,,,.!,,,................#

Naming:DONOT

Naming:DO...........................................................................................

3eforeStartfng

2ilRecommendations.............................................................................

2

‘uel Recommendations

:arburetorAdjustments

,,,.,,,,,...,...,..................................................................

!....0......,,.......................................................................!...

..........................................................................23

..........................................................a.t.............23

21

22

E

~draMasterHoum& PhoneNumb~ ....................................................2

AquaCatMactine Spcifications ............................................................3

Purchaser’sResponsibiiii

SalesRepresentative'sResWnsibilw....................................................4

TruckPreparation

PlacementofUnitinVehicle......................................................................4

TruckPreparationillustration.................t.................................................4

Machineinstallation................................................................................5

S~re PaflsRecommendation..t...............................!.............................5

PartsOrder,.,,...4.....!..................................!,,......................!......................

HardWaterAreaMap

WaterSofiener.........................................................................................6

WastewaterUs~salAWlso~ .......t.........................................................6

AQUACAT 3.90 PERATING INSTRUCTIONS

Sta~Up. ...............................................................................................8

Shutmw ........................t......................................................................8

FloodDamageWork .

OPERATING PRECAUTIONS

MachineAdjus~enb .............................................................................9

Cautions and Warnings................................................................9

WATER & CHEMICAL SYSTEMS

Water/~emicai FlowO~ration ...............................................................g

AquaUtWaterFiow. t....t.....................................i...............................lO

ChemicalSystemMaintenance

ChemicalTankTroubleShootingGuide

.,..,,,,.,,.......................,,,,.,!,............................................

........................................................................

,................!!........................!....................................

.. ,.,.,.,!.....,,.................,,,,,...........................!..............

..#...........l...!..!...!.................##.....!......l...!.!lo

..........!......!.!..........t#...#..............ll

:NGiNEMAiNmNANcE .........l.....r$o...................................................24

3iiChange

Nr~eanerMaintenance ........................................................................24

:Iean Engine,RotatingScreen,CoolingSystem,SparkArrester..........25

4

~epiaceSparkPiugs,ReplaceFueiFilters

EngineMaintenanceSchedule

SeneraiInformationaboutEngine

4

3toragelnstiudons ................<......c......l..............c..l......l.......t.t.l....o...$(.27

3ewice& Repairinkrmation...................................t..............................27

UanguardEngineWarranty

SuprsedingWarran~ ....................................................................!28

UmtiedWarmn~forVanguard ~gines ..................................................28

Waran~Period .....................................................................................29

5

ENGINETROUBLESHOOTING............................................................W

6

ELECTRICAL SYSTEM

ElectricalSystemandTroubieShootingGuide

FREEZE PROTECTION

AquaCat

CLEANING & CHEMICALS

8

Precautions

CleaningStrokeProcedure/Over.Wetiing............................................W

CLEANING WAND

Wand,Jet%sembly&WandAsembiy Paflstists ................................W

MAINTENANCE

Procedures

OverallCareofUnit..................................l..................................o.....oct..

MaintenanceLogs........................................................................37.38

...........................................................................<..............24

..,,..,..,,,,,.,.,...........................25

...............................................................26

..,,<..,,,,.....................,,,,,............,,...!..0.

.....................................................................28

.,..............!......................31

..........................!...........................................................................

,,.,..,,,,,.,....................,,,,!,.,,,..............................!......,,.,!...

.,..............,!........................................................................

27

32

33

:

CAT PUMP

CatPumpMode12900~ ratinginstmctions...........................................ll

CatPumpSWcifiMtions ................t....cc..l..cc..c.........t........................l...ll

GeneraiinfimationhrCat PumpRepair................................................l2

SewicingtheDschargeValves& ValveSeats.........................................l2

Sewicingtie PumpingSection.........l.............................l.......................l2

SewicingSleevesandSeals..............................................................l2

SewiceKk...c.......c.(.......o...........r....cc...l............r..................l..............l3

Modei2WPafls Dst..............................................................................l4

CatPumpTroubie ShootingGuide...............................................l5.l6

HighPressurePumpTroubleshootingGuide

BypassPatistist ...................................................................................l7

VACUUM SYSTEM

Information

VacuumTankHlterBags..................................t.....................................l8

VacuumBlowrTrouble ShootingGuide..............................................ls

VacuumBiowerWaman~...................................................................2C

VacuumBiowerLubri@tion................................t.................................2C

VANGUARD OliV ENGiNE

Operating&MaintenanceforModel303400(16HP)Engine.......21........2l

internationalSymbolsUsedinthisManual...........................................2l

InTheInterestofSafety

....!.....l..<.!...........................................!c!.........c.....c...........la

.................................#).......!.!..........!....................2l

.........................................

HYDRAMASTER WARRANIY

Warrantyinformation

Waman~Procedure................................................................................39

HowtoOrderParts

PartsOrders

OneFinalNote

AquaCat LimitedWarranty Plan.................t......................................4O

17

1

,,,,,...!..,.,,,...........................!...............!!...............................

.................................................................,,............

,..................................................................................

,...,,,,.,,,,!..............,,$,..................................!.....................!

39

39

39

39

Page 4

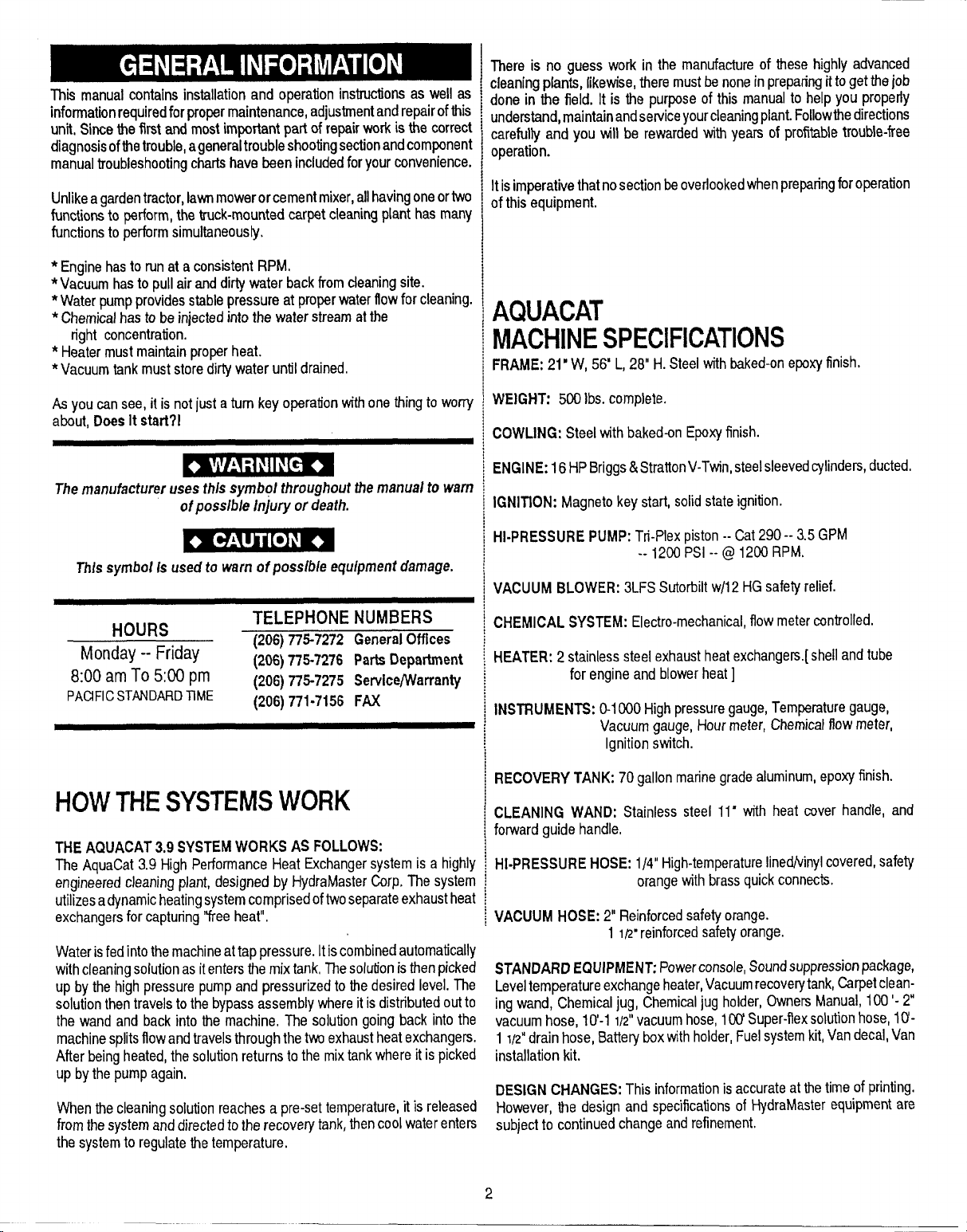

This manualcontains installationand operation instructionsas well as

informationrequiredforpropermaintenance,adjustmentandrepairofthis

unit, Sincethefirst and mostimportantpart of repairworkis the correct

diagnosisofthetrouble,ageneraltroubleshootingsectionandcomponent

manualtroubleshootingchartshave beenincludedforyour convenience.

Unlikeagardentractor,lawnmowerorcementmixer,allhavingoneortwo

functionsto perform,the truck-mountedcarpetcleaningplanthas many

functionsto performsimultaneously.

*Engine hasto run ata consistentRPM,

*Vacuum hasto pullair anddirty water backfromcleaningsite.

*Water pumpprovidesstablepressure atproperwaterflowforcleaning.

* Chemicalhasto beinjectedinto the waterstreamat the

right concentration.

* Heatermustmaintainproperheat.

*Vacuum tank muststoredirtywater until drained.

l%ere is no guess work in the manufactureof these highly advanced

cleaningplants,Iikewke, theremustbenoneinpreparingitto getthejob

done in the field. It is the purpcse of this manualto help you properly

understand,maintainandserviceyourcleaningplant.Followthedirections

carefully and you will be rewardedwith years of profitabletrouble-free

operation.

Itisimperativethat nosectionbeoverlookedwhenpreparingforoperation

of thisequipment,

AQUACAT

MACHINESPECIFICATIONS

FRAME: 21”W, 56” L, 28” H.Steelwith baked-onepoxyfinish,

As youcan see,it is notjust aturn key operationwithone thingto wony

about,Does It start?l

The manufacturer uses this symbol throughout themanual to warn

of possible Injury or death.

Thki symbol k used to warn of possible equipment damage.

HOURS

Monday -- Friday

8:00 am To 5:(HI pm

PACIFICSTANDARDTIME

TELEPHONE NUMBERS

(206) 775-7272 General Offfces

(206)775-7276 Parts Department

(206)775-7275 ServiceAVarrantv

~20~ 771-7156 FAX “

HOWTHESYSTEMSWORK

THE AQLIACAT’3,9 SYSTEMWORKS AS FOLLOWS:

The AquaCat3.9 HighPerformanceHeat Exchangersystemis a highly

engineeredcleaningplant,designed by HydraMasterCorp.The system

utilizesadynamicheatingsystemcomprisedoftwoseparateexhaustheal

exchangersfor capturing“free heat”.

Waterisfedintothemachineattappressure.Itiscombinedautomatically

withcleaningsolutionasitentersthemixtank,Thesolutionisthenpicked

up by thehigh pressurepumpand pressurizedto the desiredlevel.The

solutionthentravelstothe bypassassemblywhereit isdistributedoutto

the wand and back into the machine, The solution goingback into the

machinesplitsflowandtravelsthroughthetvmexhaustheatexchangers.

After beingheated,the solutionreturnstothe mixtankwhere it is picked

up bythe pumpagain,

Whenthe cleaningsolutionreachesa pre-settemperature,it isreleased

fromthesystemanddirectedto the recoverytank,hen cool waterenters

the systemto regulatethetemperature,

WEIGHT: 500Ibs.complete.

COWLING: Steelwith baked-onEpoxyfinish.

ENGINE:16HPBriggs&StrattonV-Twin,steelsleevedcylinders,ducted.

IGNITION: Magnetokeystafl, solid stateignition.

HI-PRESSUREPUMP:Tri-Plexpiston--Cat290-- 3.5 GPM

--1200 PSI --(Q1200 RPM.

VACUUM BLOWER: 3LFSSutorbiltw/12HGsafetyrelief.

CHEMICAL SYSTEM: Electro-mechanical,flow metercontrolled.

HEATER: 2stainlesssteel exhaustheatexchangers.[shellandtube

for engineand blowerheat]

INSTRUMENTS:0-1000Highpressuregauge,Temperaturegauge,

Vacuumgauge, Hourmeter,Chemicalflowmeter,

Ignitionswitch.

RECOVERYTANK: 70 gallonmarinegradealuminum,epoxyfinish.

CLEANING WAND: Stainless steel 11” with heat cover handle, and

forwardguide handle,

HI-PRESSUREHOSE: 1/4”High-temperatureIinedvkrylcovered,safety

orangewithbrassquickconnects.

VACUUM HOSE:2“ Reinforcedsafetyorange.

1 It? reinforcedsafetyorange.

STANDARDEQUIPMENT Powerconsole,Soundsuppressionpackage,

Leveltemperatureexchangeheater,Vacuumrecoverytank,Carpetcleaning wand, Chemicaljug, Chemicaljug holder,OwnersManual,100’-2

vacuumhose, 10’-11/2”vacuumhose,1CQ’Super-flexsolutionhose,10-

1 1/2”drain hose,Batteryboxwithholder,Fuelsystemkit,Vandecal,Van

installationkit.

DESIGNCHANGES:This informationis accurateat thetimeof printing,

However, the design and specificationsof HydraMasterequipmentare

subjectto continuedchangeand refinement.

2

Page 5

PIACEMENTOFUNIT

INVEHICLE

THEREARETWO RECOMMENDEDUNITPLACEMENTS:

A.SIDEDOOR:Mostinstallationsaresidedoor,Thisprovidesrearaccess

for accessoriesandhosesaswell asunobstructedaccessto componenff

workingsideofmachine,thusmakingitabiteasiertoperformmaintenance

and/orrepairwithoutremovingunit fromthe truck,

B.REARDOOR:Althoughthislocationpartlylimitsworkingaccess,itdoes

directthenoiseawayfromthecleaningsite. Somecleanersinthecolder

areaspreferthis locationbecauseit puts the weight massover the rear

wheelsfor bettertractionin iceandsnow,Rearmountingrequiresthe unit

tobeslidtotherightsideasfaraspossible.l%isnotonlyprovidesadequate

workingspaceon the componentside of the unit but alsomakes better

weightdistributioninsidethe van (engineand componentweightline up

overdriveshaft).Also,itisphysicallyeasierto load unit into reardoordue

to heightofvan bed,

Ensure that machine is well secured to the floor of van with hardware

supplied. Sudden or crash stop willcause machine to sliderlmvard,,.. all

500 /bs.worth!Protect yourself and the machine. SECURE lTI

TRUCKPREPARATION

[ILLUSTRATION

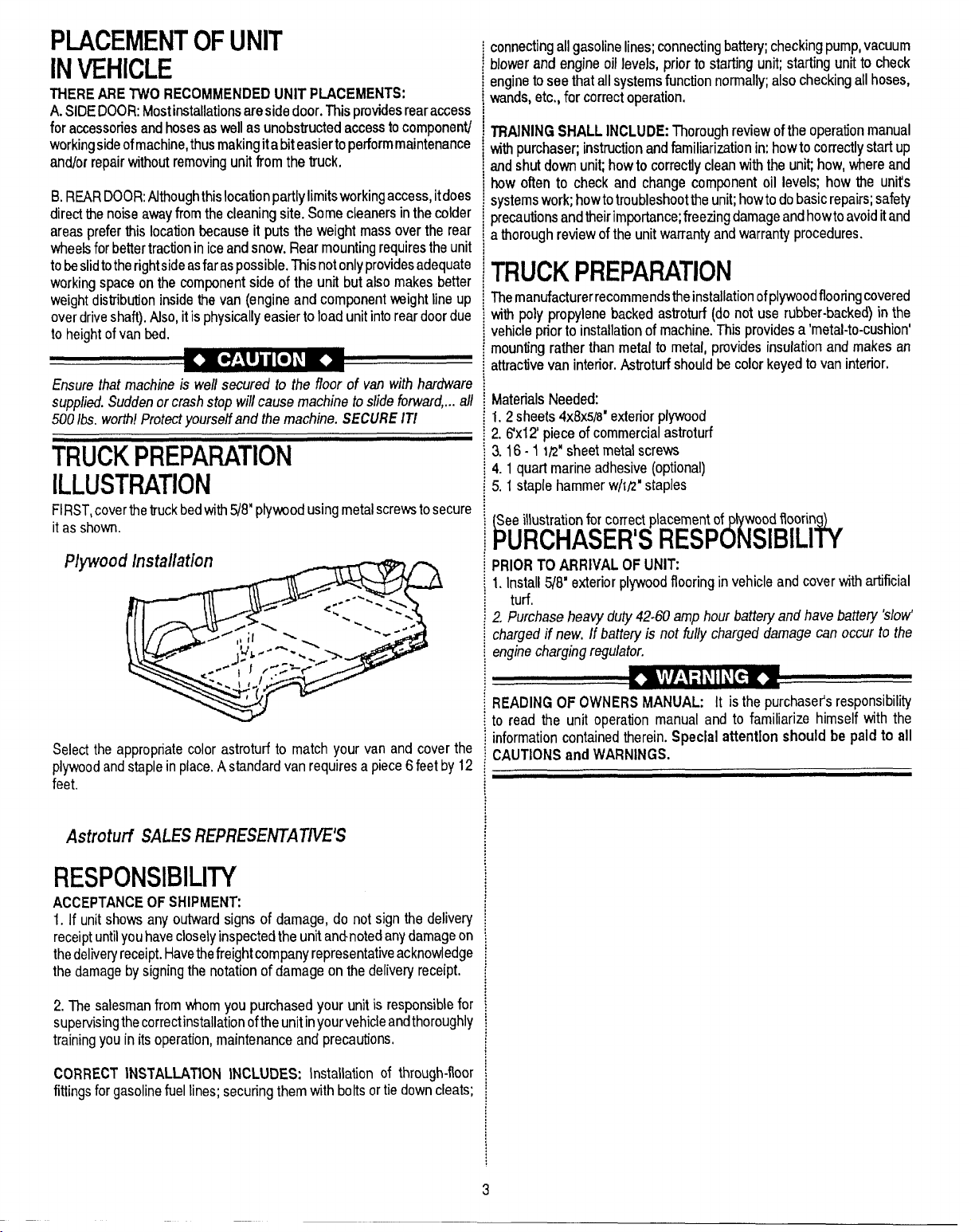

FIRST,coverthetruckbedwith!Y8”plywoodusingmetalscrewstosecure

it asshown.

PlyWoo

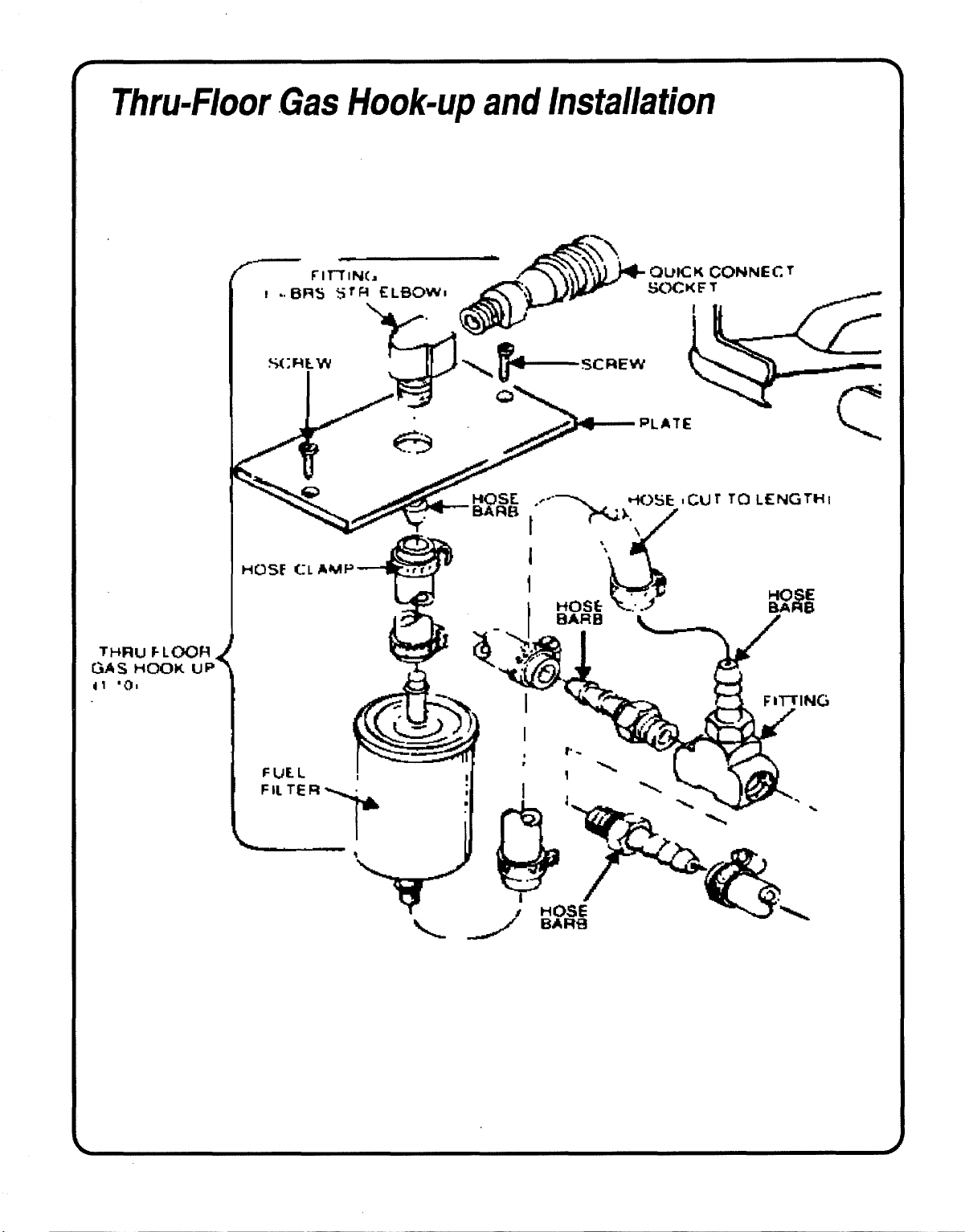

connectingallgasolinelines;connectingbattery;checkingpump,vacuum

dower and engineoil levels, prior to startingunit; startingunit to check

mgine toseethat allsystemsfunctionnormallfi alsocheckingallhoses,

wands,etc.,for correctoperation,

TRAININGSHALL INCLUDE:Thoroughreviewofthe operationmanual

NWpurchaser;instructionandfamiliarizationin:howto correctlystartup

andshut downunit howto correctlycleanwith the unit how, whereand

how often to check and change component oil levels; how the unit’s

systemswork;howtotroubleshoottheunit howtodobasicrepairs;safety

precautionsandtheirimportance;freezingdamageandhowto avoiditand

athoroughreviewofthe unitwarrantyandwarrantyprocedures.

TRUCKPREPARATION

Themanufacturerrecommendstheinstallationofplywoodflooringcovered

withpoly propylene backedastroturf (donot use rubber-backed)in the

vehiclepriorto installationof machine,This providesa ‘metal-to-cushion’

mountingratherthan metal to metal,provides insulationand makesan

attractivevan interior.Astroturfshouldbe colorkeyedto vaninterior.

MaterialsNeeded:

1.2 sheets4x8x5B”exteriorplywood

2.flxl 2’piece ofcommercialastroturf

3.16-1 lPMsheetmetalscrews

4.1 quart marineadhesive(optional)

5.1 staple hammerwh’z” staples

Seeillustrationfor conectplacementof woodfloorin

lWRCHASERISREsPckIBILii

PRIORTOARRIVAL OF UNIT

1.Install5/8” exteriorplywoodflooring invehicleand coverwithartificial

turf.

2, Purchase heavy duty 42-60amp hour battery and have battery Wow’

charged if new, If baltery is not fully charged damage can occur to the

engine charging regu/ator.

Selectthe appropriatecolor astroturfto match your van and cover the

plywoodandstapleinplace.Astandardvanrequiresa piece6 feetby 12

feet.

AstrohIti SALES REPRESENTA7%’E’S

RESPONSIBILITY

ACCEPTANCEOF SHIPMEN’E

1. If unit showsany outwardsigns of damage, do not sign the delivery

receiptuntilyouhavecloselyinspectedthe unitandmotedanydamageon

thedeliveryreceipt.Havethefreightcompanyrepresentativeacknowledge

the damageby signingthe notationof damageon thedeliveryreceipt.

2. l%e salesmanfrom whomyou purchasedyour unit is responsiblefor

supervisingthecorrectinstallationoftheunitinyourvehicleandthoroughly

trainingyouin itsoperation,maintenanceand preca~”ons,

CORRECT INSTALLATION INCLUDES: Installation of through-floor

fittingsforgasolinefuellines; securingthem withbottsortie downcleats;

READINGOF OWNERSMANUAL: It is thepurchasers responsibility

to read the unit operation manual and to familiarize himself with the

informationcontainedtherein.Special attention should be paid to all

CAUTIONSand WARNINGS.

3

Page 6

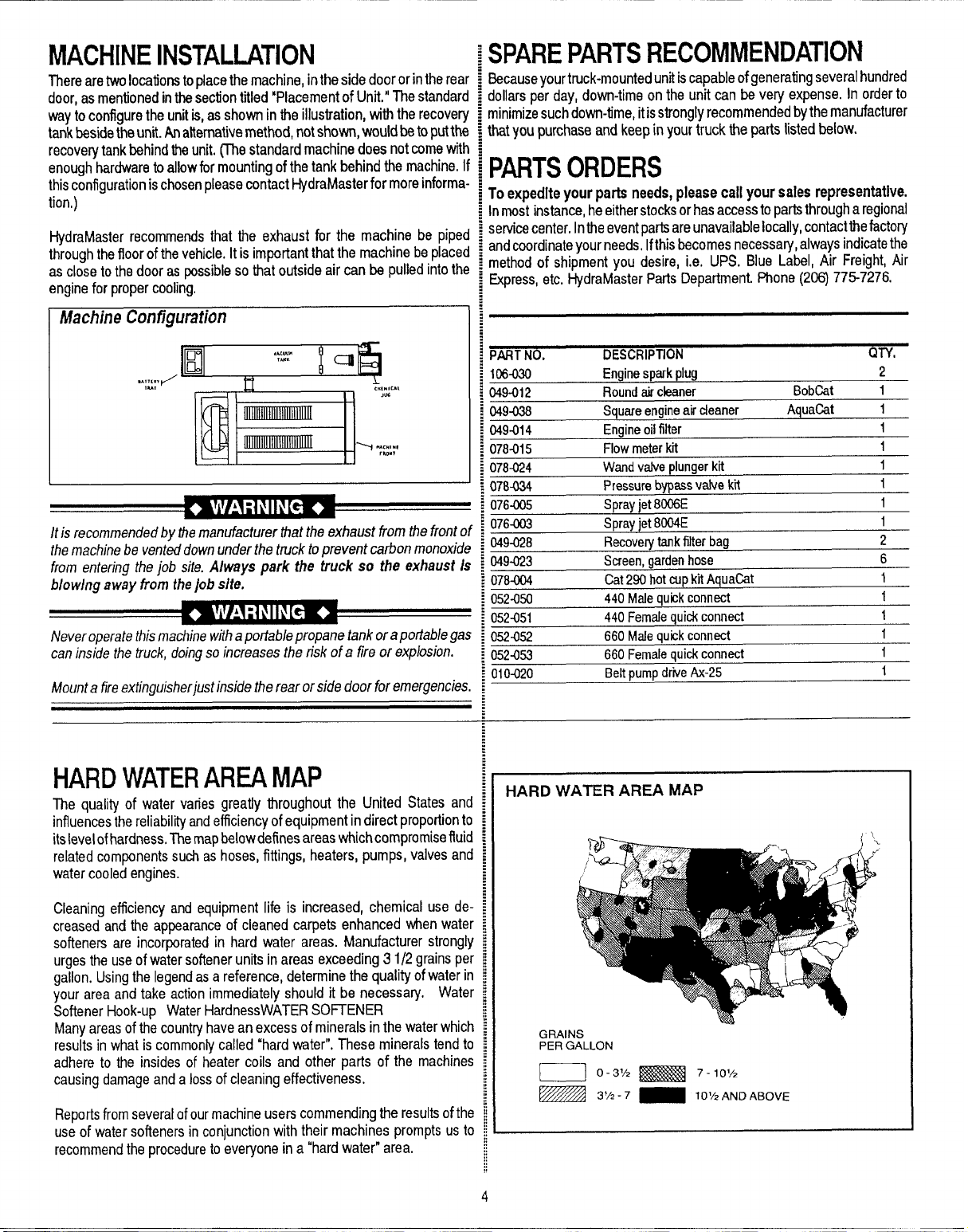

MACHINEINSTALLATION

Therearetwolocationstoplacethemachine,intheside door or intherea

door,asmentionedinthesectiontitled “Placementof Unit,”Thestandart

waytoconfiguretheunitis,asshown in theillustration,with therecove~

tankbesidetheunit.Analternativemethod,notshown,wouldbetoputttv

recoveqftankbehindtheunit.(Thestandardmachinedoes notcomewftl

enoughhardwaretoallowformountingofthetank behindthe machine.I

thisconfigurationischosenpleasecontactHydraMasterfor moreinforms

tion,)

HydraMasterrecommendsthat the exhaust for the machine be pipe{

throughthefloorofthevehicle.Itis importantthat the machine be place{

ascloseto thedoor aspossibleso that outside aircan be pulledintoth[

engineforpropercooling.

Machhe Configuration

;PAREPARTSRECOMMENDATION

?causeyourtruck-mountedunitiscapableofgeneratingseveralhundred

JIlarsper day,down-timeon the unit can bevery expense, Inorderto

inimizesuchdown-time,itisstronglyrecommendedbythemanufacturer

atyou purchaseand keepinyourtruck the partslistedbelow.

Jexpedite your parts needs, please call your sales representative.

Inmost instance,heeitherstocksorhasacce~stopartsthr~ugharegional

servicecenter.Intheeventpartsareunavailablelocally,contactthefactory

andcoordinateyourneeds,Ifthisbecomesnecessary,alwaysindicatethe

methodof shipment you desire, i.e. UPS. Blue Label, Air Freight,Air

Express,etc.HydraMasterPartsDepartment.Phone(206)775-7276.

/t is recommended by lhe manufacturer that the exhaust from the front c

the machine be vented down under the truck to prevent carbon monoxid,

from entering the job site. Always park the truck so the exhaust/.

blowhrg away from the job site.

Never operate thismachine withaportable propane tank oraportable ga

can inside the truck, doing so increases the risk of a tire or explosion.

Mount afire extinguisher just inside the rear or side door for emergencies

HARDWATERAREAMAP

The quality of water varies greatiy throughout the United States ant

influencesthereliabil”~andefficiencyofequipmentindirect proportiontf

itslevelofhardness,Themapbelowdefinesareaswhichcompromiseflui[

relatedcomponentssuchashoses,fittings, heaters, pumps,valvesan~

watercooledengines.

108-030 Enginespark plug

049-012

049438

049-014

078-015 Flow meter kfi

078-024 Wand valve plur

078434

076-005

0764)03

049-028

$9-023

784Q4 Cat 290 hot cup kit AquaCat

52-050

57-051

.. .. .

52452

52-053 660 F

1rmxl

.- ---

Round air cleaner

Square engine air cleaner

Ermine oil filter

ngerkit

Pressurebypassvaive kti

Spray jet 8006E

Spray jet 8004E

Recove~ tank filter b:

Screen, garden hose

440 Male auick conn~

Female quid connect

440

660 !

We quick connect

‘emale quick connect

Rdtrmmo driie Ax-25 1

--.. r-...r

—

ag

,,,,,-”.

HARD WATER AREA MAP

BobCat

AquaCat

2

1

1

1

1

1

1

1

1

2

6

1

f

1

1

1

Cleaningefficiency and equipmentlife is increased, chemical use de

creasedand the appearanceof cleaned carpets enhancedwhen wate

softeners are incorporatedin hard water areas. Manufacturer strongl

urgestheuseofwatersoftenerunits inareas exceeding31 /2 grainspe

gallon.Usingthe legendasa reference,determinethe qualityof wateri!

your areaand take actionimmediatelyshould it be necessary. Wate

SoftenerHook-up WaterHardnessWATERSOfTENER

Manyareasof thecountryhaveanexcessof mineralsin the waterwhicl

resultsinwhat is commonlycalled“hard water”,These mineralstend t[

adhere to the insides of heater coils and other parts of the machine

causingdamageand alossof cleaningeffectiveness.

Reportsfromseveralofourmachineuserscommendingtheresultsofth

useof watersoftenersin conjunctionwith their machines promptsust

recommendthe proceduretoeveryonein a “hardwater” area.

GRAINS

PERGALLON

~] 0-3/2 H 7-10/2

- ~/,-i’ _

10%ANDABOVE

4

Page 7

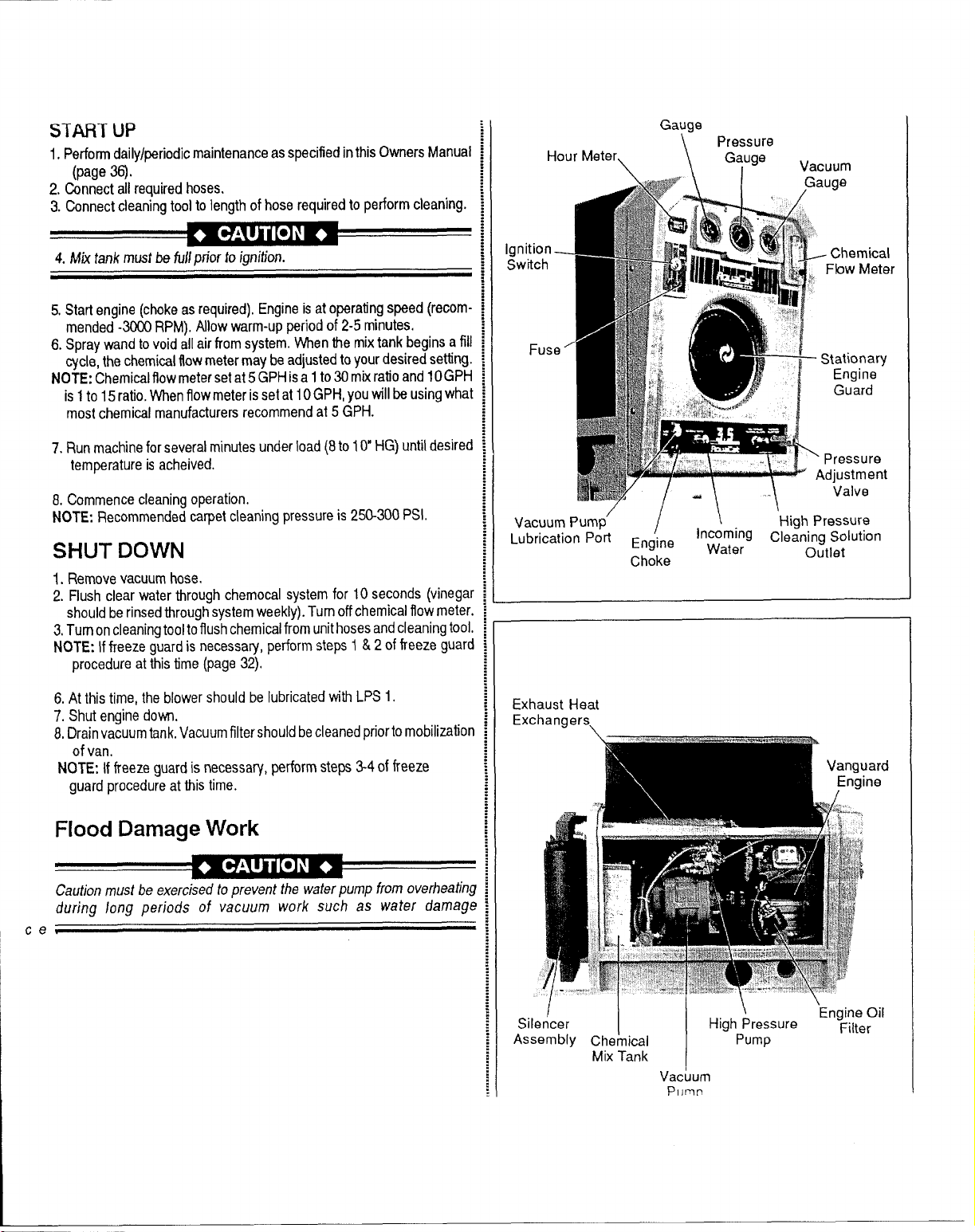

START UP

1,

Performdaily/periodicmaintenanceasspecifiedinthis OwnersManual

(page36).

2. Connectall requiredhoses.

3. Connectcleaningtool tolength ofhose requiredto performcleaning.

Hour Meterl

Gauge

Pressure

\

Gauge

\

.JM#%#\ 1

Vacuum

,Gauge

4. Mixtank musfbe fullm’iortoiar?ition.

5.Startengine (chokeasrequired),Engineis atoperatingspeed (recommended-3000RPM).Allowwarm-upperiodof 2-5 minutes.

6. Spraywandtovoid allairfromsystem.Whenthe mixtankbeginsa fill

cycle,thechemicalflowmetermaybeadjustedto yourdesiredsetting.

NOTE:Chemicalflowmetersetat5GPHisa 1to 30mixratioand 10GPH

is 1to 15ratio.Whenflowmeteris setatIOGPH, you will beusingwhat

mostchemicalmanufacturersrecommendat 5 GPH.

Run machine for severalminutesunderload(8to10“ HG)until desired

7.

temperatureisacheived.

& Commencecleaningoperation,

NOTE: Recommendedcarpetcleaningpressureis 250-300PSI.

SHUT DOWN

1. Removevacuumhose.

2. Flushclear water throughchemocalsystem for 10 seconds (vinegar

shouldberinsedthroughsystemweekly).Turnoffchemicalflowmeter.

3.Turnoncleaningtooltoflushchemicalfromunithosesandcleaningtool.

NOTE: Iffreezeguardis necessary,performsteps1 &2 offreeze guard

procedureatthis time(page32)

6.At thistime, the blowershouldbe lubricatedwith LPS1.

7. Shutenginedown.

8.Drainvacuumtank.Vacuumfiltershouldbecleanedpriortomobilization

of van.

NCITE;Iffreezeguardis necessary,performsteps 3-4offreeze

guardprocedureatthis time.

gnition _

Switch

Fuse

## X?//...

‘7/-\\

Vacuum Pump’

‘Lubrication ‘on Engine

Choke

Exhaust Heat

Exchangers,

; Stationary

:\

Pressure

Adjustment

Outlet

Engine

Guard

Valve

!!

:’1

..,

&

i~

Incoming

Water

High Pressure

cleaning Solution

Flood Damage Work

Caution must be exercised to prevent the water pump from overheating

during long periods of vacuum work such as water damage

\

ce

/

Silencer

Assembly Chemical

I

Mix Tank

Vacuum

Pomn

\

High Pressure

Pump

\

Engine Oil

Filter

Page 8

ThrwF/oor Gas Hook-up and Installation

-c.-.

1’

Page 9

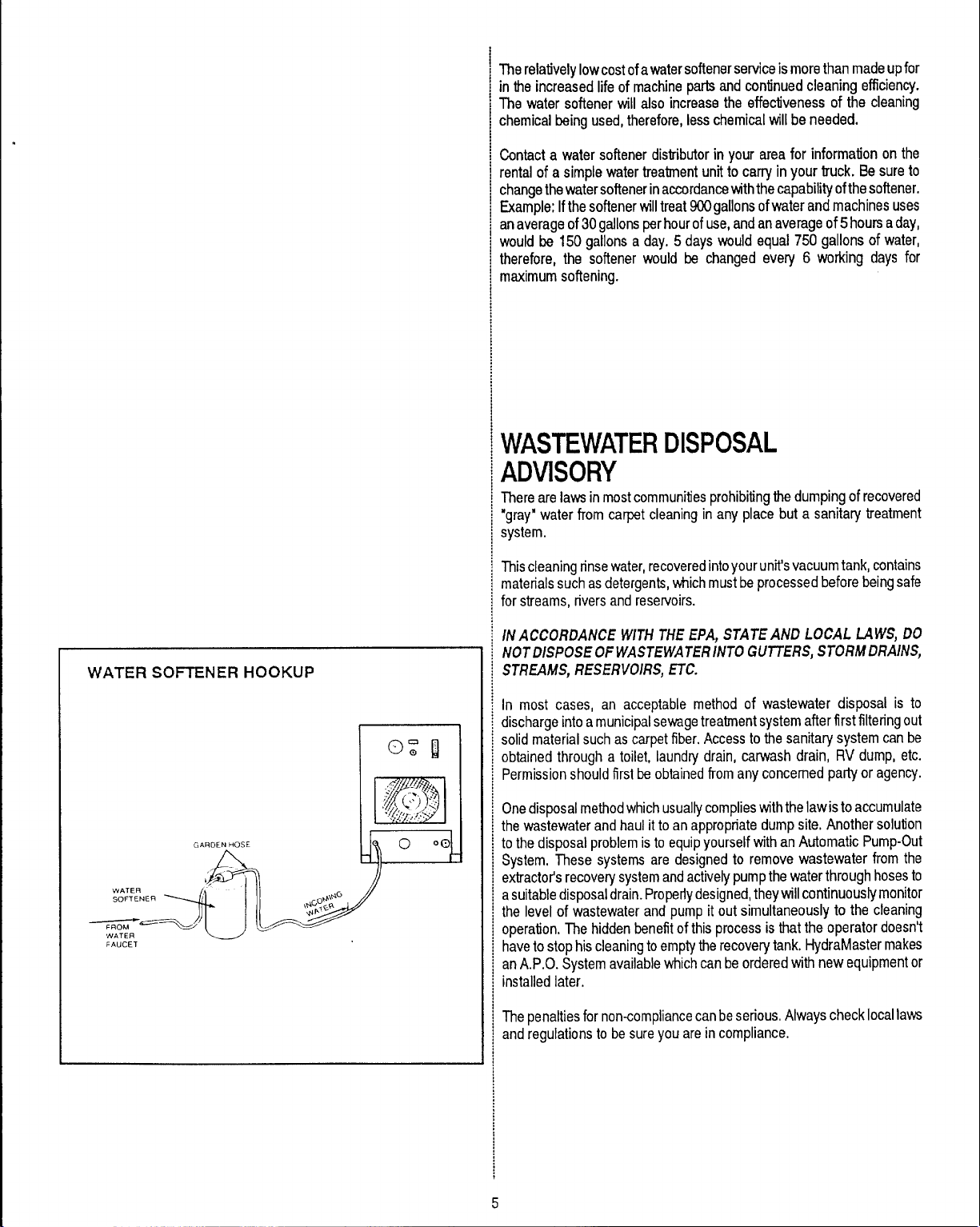

TherelativelyIowcost of awater softenerserviceismorethan madeupfor

in theincreasedlife of machinepartsand continuedcleaningefficiency.

The water softener will also increasethe effectivenessof the cleaning

chemicalbeingused,therefore,lesschemicalwillbe needed.

.

Contacta water softenerdistributorin your area for information onthe

rentalof a simple watertreatmentunitto carry inyour truck. Be sureto

changethewatersoftenerinaccordancewiththecapabilityofthesoftener.

Example:IfthesoftenerwilltreatWOgallonsofwaterandmachinesuses

anaverageof30gallonsperhourofuse,andanaverageof 5hoursaday,

would be 150 gallonsa day, 5 dayswould equal 750 gallons of water,

therefore, the softener would be changed every 6 worldng days for

maximumsoftening.

WASTEWATERDISPOSAL

ADVISORY

Therearelawsinmostcommunitiesprohibitingthedumpingofrecovered

“gray”water from carpetcleaningin any place but a sanitarytreatment

system.

WATER SOFTENER HOOKUP

GAROkN HOSE

,., -

,&

‘1

Thiscleaningrinsewater,recoveredintoyourunit’svacuumtank,contains

materialssuchasdetergents,whichmustbeprocessedbeforebeingsafe

for streams,riversand reservoirs.

IN ACCORDANCE WITHTHE EPA, STATE AND LOCAL LAWS, DO

NOTDLSPOSE OF WASTEWATER INTO GUTTERS, STORM DRAINS,

STREAMS, RESERVOIRS, ETC.

In most cases, an acceptable method of wastewater disposal is to

dischargeintoamunicipalsewagetreatmentsystemafterfirst filteringout

solidmaterialsuchas carpetfiber,Accesstothe sanitarysystemcan be

obtainedthrough a toilet, laundrydrain, carwash drain, RV dump, etc.

Permissionshouldfirstbeobtainedfromanyconcernedpartyor agency.

OnedisposalmethodwhichusuallycomplieswiththeIawis toaccumulate

thewastewaterandhaul itto anappropriatedump site. Anothersolution

to thedisposalproblemisto equipyourselfwithanAutomatic Pump-Out

System, These systemsare designedto remove wastewater from the

extractor’srecoverysystemandactivelypumpthewaterthroughhosesto

asuitabledisposaldrain.Properlydesigned,theywillcontinuouslymonitor

the level of wastewaterand pumpit out simultaneouslyto the cleaning

operation,Thehiddenbenefitof thisprocessis thatthe operatordoesn’t

haveto stophiscleaningtoemptytherecoverytank. HydraMastermakes

anA.P,O.Systemavailablewhichcanbeorderedwith newequipmentor

installedlater,

Thepenaltiesfornon-compliancecanbeserious.Alwayschecklocallaws

andregulationsto besureyouarein compliance,

Page 10

MACHINEADJUSTMENTS

Although this unit has been factory adjusted, it may require additional

adjustmentsto achieve optimum performance;i.e. attitudemay require

carb adjustment and ambient temperatures may require heat control

adjustment.Whenrequired,consult anauthorizedrepresentative.

ENGINECOOLING

Units employing air cooled engines musinot be enclosed within a van with

doors and windowsclosed. Excessive temperatures within the engine will

r~ult in premature engine failure and a compromise of applicable war-

ranty,

LEVEL OPERATtON

Dunhg operation, van or trailer must be parked on level ground not to

exceed + or -10’. F~”lure to insure proper leveling may prevent proper

internal /ubricetion of engine, vacuum arroYorhigh pressure components,

FREEZEPROTECTtON

Mother nature gives litf/e warning as to her cold spelk. Therefore,

protecting thisequipment from freezing willsave costly down-time, Placing

electric heaferin the truckor parking the truck indoors, wi//he/p to insure

an

against

freezing.

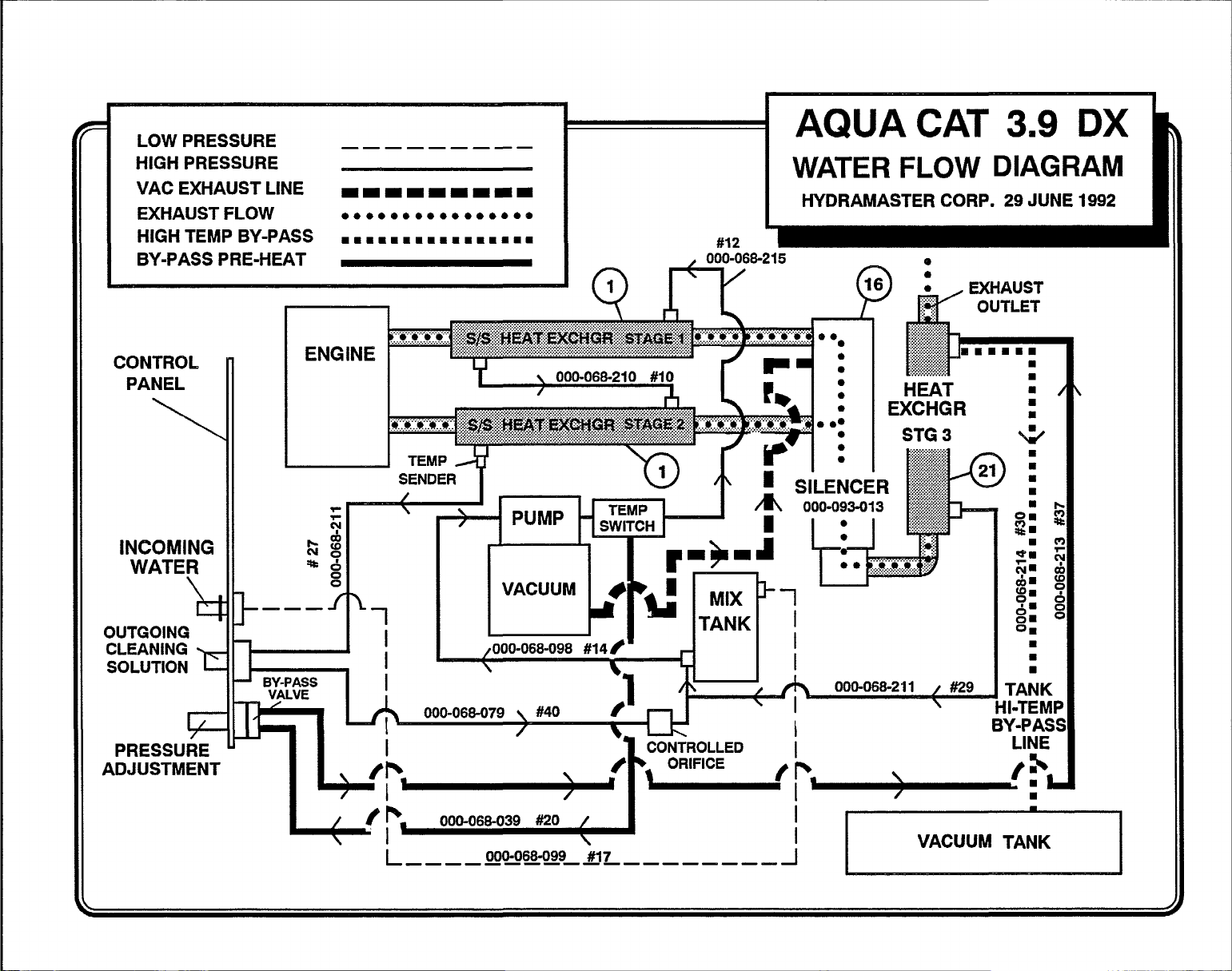

WATER/CHEMICALFLOWOPERATION

This electro-mechanicalsystem has been designedto be simple and

troublefree. IncomingwaterflowsfirstthroughtheSolenoidControlValve

(1)(seeillustrationonnext page)andthe lowpressureChemicalInjector

(2)whichare both mountedonthe exteriorofthe mix tank. As thewater

passesthroughthe ChemicalInjector,itisautomaticallyproportionedwith

a predeterminedquantityofdetergent.The MixTank(3)is equippedwith

twodifferentfloatswitches,theWaterLevelFloat(4)respondstothelevel

inthe tankandwill maintainthepropervolumeof solutionto be resewed

forthewaterpump.Thesecondary,LowWater Floatswitch(5)isasafety

switchthat isdesignedto protectyoursystemfromsuddenorunexpected

lossof watersupp~. If,for example,thewatersourceatthe housewere

turned off, the water level of the mix tank would drop, activating the

secondaryswitch,which automaticallydisengagesthe systemand pre-

ventsthe waterpumpfrom runningdry.

Thedesiredchemicalinjectionratiomaybeobtainedbyanadjustmentof

theChemicalFlowMeter(6)duringthefillcycleofthemixtank.Watermust

be flowing into the mix tank in order to adjust the chemical mix. The

chemicalwill flowfrom theChemicalJug (7)to theChemicalFlowMeter,

thentothe ChemicalInjectorwhereit is proportionedintothe MixTankat

thedesired chemicalsetting.

NOTE: Wih this unique chemical system,the chemicalflow is proportionedonly duringthe filling cyclesofthe MixTank,notduringthe direct

sprayingofthewand,Therefore,itispossiblethatasyourwandisspraying,

youmayhavenochemicalflow,Also,theconverseistrueinthatyoumay

not be sprayingyour wand, but if the mix tank is in a filling cycle,your

ChemicalFlowMeter maybe activeatthe desiredflowrate.

HOTSURFACES

During the operation of this equipment many suriaces on the machine will

become veryhot, When near the van foranyreason care must be takennol

to /ouch any hot surface,such as heater, engine, exhaust, etc.

NOSMOKING

It is unsafe to smoke in or around the vehicle.

MOVINGPARTS

Never touch anypari of the machine that is in motion, severe bodily injury

may result.

CARBONMONOXIDE

77risunitgenerates toxic fumes, Position the vehicleso thatfhe rl.imes will

be directed A WAY from the job site.

DO NOT PARK where exhausf fumes can enfer a bui)ding through open

doors or windows, air conditioning unifs or kifchen fans.

TOXICFLUMES

Do not occupy the vehicle when the cleaning equipmentis opera fing, Toxic

fumes may accumu/afe inside a stationary vehic/e.

The chemicalproportioningsystemwillmix chemicalwithwaterat a 1to

ratio when the Flow Meteris setat 5GPH,ora 1to 15ratiowhenthe

30

FlowMeter isset at 10 GPH.

nextpage)

@nliwes,

9

Page 11

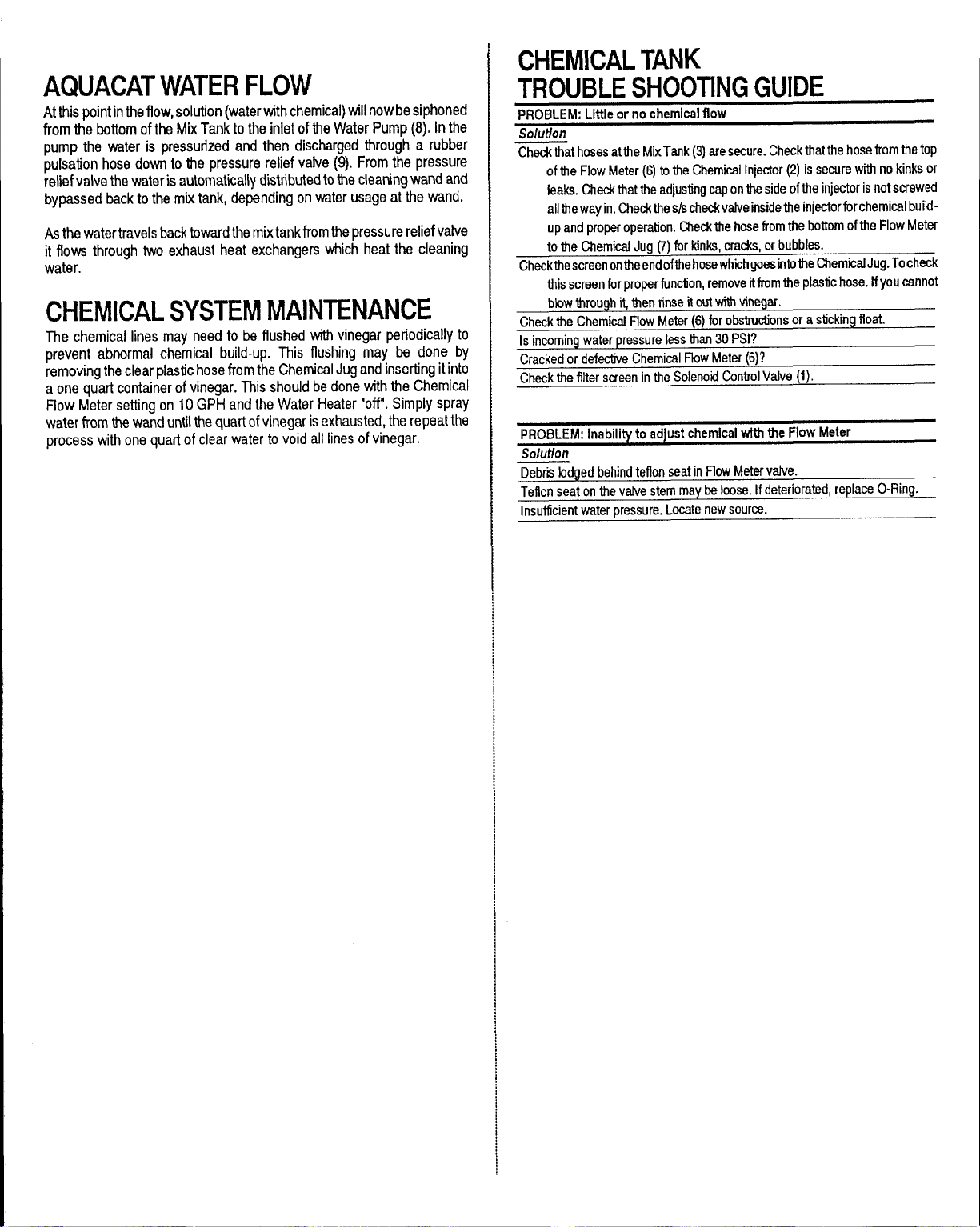

AQUACATWATERFLOW

Atthis pointintheflow,solution(waterwithchemical)willnowbesiphoned

from the bottomof theMixTankto the inletoftheWater Pump(8),In the

pump the water is pressurizedand then dischargedthrough a rubber

pulsationhose downto the pressurereliefvalve (9), Fromthe pressure

reliefvalvethewaterisautomaticallydistributedtothecleaningwand and

bypassedbackto the mixtank,dependingon water usageat the wand.

Asthewatertravelsbacktowardthe mixtankfromthepressurereliefvalve

it flows through two exhaust heat exchangerswhich heat the cleaning

water.

CHEMICALSYSTEMMAINTENANCE

The chemical lines may needto be flushed withvinegar periodicallyto

prevent abnormal chemical build-up. This flushing may be done by

removingtheclearplastichosefromthe ChemicalJugandinsertingitinto

a one quartcontainerof vinegar.This shouldbedonewiththe Chemical

Flow Metersettingon 10 GPHandthe Water Heater‘off”. Simplyspray

waterfromthewanduntilthequartofvinegarisexhausted,therepeatthe

process with one quart of clear water to void all lines of vinegar.

CHEMICALTANK

TROUBLESHOOTINGGUIDE

PROBLEM:Llttieor nochemicalflow

Sotution

Check that hoses at tie Mix Tank (3) are secure. Check that the hose from the top

of the Flow Meter(6)tothe ChemicaJInjector(2)issecurewith no kinks or

leaks. Chad that the adjustingcap onthe side of the injector is notscrewed

alithe way in.Check the sls checkvalve insidethe injectorfor chemical buikf-

up and proper operation. Check the hosefrom the bottom of the Flow Meter

to the Chemical Jug (7’)for kinks, crad(s, or bubbles.

Checkthescreen ontheendofthehose whiihgoe.sintothe Chemical Jug.Tocheck

tMs screen for properfunction,remove itfrom the plastic hose. Ifyou cannot

b!ow through i$ then rinse itout with vinegar.

Check the Chemical Flow Meter (6) for obstructionsor a sticking float.

Is incoming water pressure iess than 30

Cracked or defective Chemical Flow Meter (6)?

Check the fiiter semenin the SolenoidContioi Valve (1).

PROBLEM: inabiiity to adjust chemical with tie Flow Meter

Solution

Debrii lodgedbehindteflon seatin flow Metervaive.

Teflon seat on the valve stem maybe loose. If deteriorated, repiaca O-Ring.

Insufficient water pressure. Locate new source.

PSI?

Page 12

LOW PRESSURE

HIGH PRESSURE

VAC EXHAUST LINE

EXHAUST FLOW

HIGH TEMP BY-PASS mm=mmmmmmmmnnaam

BY-PASS PRE-HEAT

CONTROL

PANEL

INCOMING

WATER

1

———

OUTGOING

CLEANING

SOLUTION

!k

, I&= L

PRESSURE u

ADJUSTMENT

,—

BY-PASS

.... ..-

——— ——— ———

-W------=

● **e*o**e ****e ● 9

SENDER

1

‘1

I

I

1

I

:::::::::................-...* .:$.+.>-..-..+..:.:.-..:?:?..:?-:.:

...............................................

............. .........

VACUUM

4

n’

/000-068-098 #14 /

#12

AQUA CAT 3.9 DX

WATER FLOW DIAGRAM

HYDRAMASTER CORP. 29 JUNE 1992

e

HEAT ~ /

EXCHGR

STG 3

i

A ooo-068-2~1 , #29

m

N

m

m

L

TANK

11-TEMP

Y-PASS

LINE

+Z r’ 00’0’’03’‘o <

.—— — ———— ———. ———— ———

L

000-088-099 #17

I

J

‘~

Page 13

PROBLEM: Mix Tank Overflows

Solution

Float switch (4) in the mix tank not moving freely, or defective.

To Check Switch: With a 12volttest Iightand the floatinthe ‘up’ position, there

should be power through the switch.

To Check Relay First, check wiring against diagram. Wti 12 volt test light

and the float switch (4)

solenoid valve. Wtth the

power at the

solenoid valve.

Solenoid valve defective: Remove solenoid valve, dsassamble and inspect

diaphragm

for cracks or tears.

in the ‘up’ position, there should NOT be power at the

float switch in the ‘down’ position, there should be

CATPUMPMODELZ9(I

OPERATINGINSTRUCTIONS

PROBLEM: Mix Tank Does Not Keep Up With Water Output

Solutlon:

Check Incoming water pressure. Check garden hose quick cannect assembly

screen.

Check garden hosesmd/orfeed hose tothe mix tankforclog,kinks or blockage.

float switch (4) inmix tank hanging up (notmoving freely). Check filterscreen

in Solenoid valve (1).

Products described hereon are covered by

oneor more ofthe follovnng

US. patents:3558244,3652188,3809508, 3920356,and3930756

c CAT PUMPS – A G. ●

LorelohcebO 5

CH+3W zuo. swnzerland

J&&p

CORPORATION

PO. Box LW5 MINNEAPOLIS, MN 55440

Phone (6 12) 7@0.s440 – Telex 290276

4N V CAT PuMPS INTERNATIONAL S A.*

Harmooleslraal 29 27 Slallon Inoustr,al E31ale, Fleet

B 2C4N Antwerp, Belgium

Phom (03) 237.72-24 — Telex 33947

Ph+ne (42) 21.3140 — Telex S65 160

9 CAT WMPS DEuTSCHLAND GmbH ●

RoslochIx Stmsse 9

6X0 W!es&9den-Bmrsladl, Wesl Germany

Phooe GB12.560301i2 – Telex 41 M713

PuMPS (U K) LTD ●

● CAT

Harwsh$w GU13 80Y, En.#and

PIIO,WJ F!ec,l 22o31 - Telex 85fL998

CPWJ ch

;PECIFICATIONS

,,,..,.,,.,,.,,,,,...,..,..,,..,3,5GPM(l3uM)

olume

ischargePressure..............1200PSI(83EAR)

IaximumInlet Pressure......-

PM,.,,,,,,,,.,..,,....................l2~

,.,,,.,,,,.,,,,,.,,.,.,..,...,......0.787’ (20mm)

ore

,,,,,,,,,,,.,,.,,.................0<472”(12mm)

troke

rankcaseCapacity.............10 oz. (.3L)

IletPort (l),...l ....................l/2” NPT(l/2’ NPT)

heroical Iniection Port (1),., 1/4” NPT(1/4’ NPT)

ischarge Ports (2) ....18. NPT (3/8’ Npq (1):~...2”2”NpT (1/2” NpT)

ulley Mounting

haft Diameter

,.,,..,..,,.,..,...,,.,,..,......12.1 Ibs.(5.5kg)

Ieight

,,.,,,,,.,,,.,.....Eitherside(Eitherside)

....................0.650” (16.5mm)

imensions.....l................l...

8.5to+ 40 PSI(-0.6to +2.8 BAR)

10,77”x9.06’x5,14“ (273.5x230x130,5mm)

10

Page 14

GENERALINFORMATIONFOR

CATPUMPREPAIR

Asyou removeyourdischargemanifold,there isa set of 3 checkvalves

(whichusuallyfall out duringdismantling),Ifthe surfacesofthese check

valvesaredirty,orshowsignsofchemicalbuild-up,itisprobablethatthey

wouldremainopencausingpressurelossorpulsation,Uponinspectingthe

valves,makesurethatthetetlon buttoninthevalvespringretainersareSW

intact,Also examinethe dischargemanifold,Lookfbr problemssuch as

cracks, chemical buildup or warping due to freezing. If this discharge

manifoldiswarped,itwill causethe checkvalvesto stickandwill resultin

lossof pressure,

TheCatpumpcupsareoftenthesourceofpressureloss.Uponinspection

theymayappearmeltedortorn,butoftentheywillIookgood,Replacethem

anyway. Thereis no sure method of visually inspectingthe cups, HydraMasterrecommendschanging

cupswhetherthey lookgoodor not.

.

When restarting thepump, check tosee that there isno cylindermotion as

this will causepremature failure of the cy/inder o-rings. Center cylinder

motion can be eliminated by switching withone of the end cylinders.

SERVICINGTHEPUMPINGSECTION

DISMANTLING

1, Removedischargemanifoldas describedinthe lastsection.

2,Slipcylindersoutofinletmanifold,NOTE: Identifycylinderssotheywill

bereplacedin theiroriginalposition(frontto back),

3. Removecotterpin,nut,andwasher.

4, Nextremovepistonretainer,spacer,and pistonassembly.

5, Removeinlet valve

Anytimeyour pump is being dismantled,HydraMasterrecommendsreplacementof ail ‘o’ ringsand seals.This is merelyaconvenienceto the

customerto makesure thatthe Catpumpis intop operatingcondition,

The Prrrrrm-A-Lubeseals locatedwithinthe intakemanifoldwill allowair

to enterthe pumpif theyareworn,Again, it is difficulttovisuallypinpoint

a defectivePrrrrrm-A-Lubeseal,Replacethemall,

RepairingofCatpumpsisnotadifficulttask. However,beforedismantling

makesureyouhavethe properpartsrequired.

1- short (orhot)cut kit 6- pistonsleeve ‘o’rings

3- Prrrrrm-A-Lubeseals

Readinstructionsthoroughly,suppliedin the Cat pumpmanual priorto

dismantlingandfollowdirectionsasstated.Oilallsealsthoroughlypriorto

installation.(Remember,anewlyscarredsealisnobetterthanoneyoujust

tookout.)

1- bottle Catoil

SERVICINGDISCHARGEVALVES

&VALVESEATS

DISMANTLING

1. Loosenthe 2 (M8)lockingnuts approximatelyoneturn.

2, Thenremovethe 2 (M8)flangenuts.

3, Graspthe dischargemanifoldwith3 fingersonthe undersideandtap

with

a softmalletto remove,

4. Valveassemblieswill remainwiththe manifold,Invertmanifoldand

dischargevalve assembliesshouldfall out,

5,Inspectdischargevalvesforwearor ridges,(Sphericalvalvesduetotheir

shapemustbe replacedwhenworn.)

REASSEMBLY

1. Placeretainerin manifoldchamber,

2. Nextinsertspringintocenterof retainer,

3, Placevalveover springwithspherical(mooned)sideup.

4, Nextinsertthe valveseat,

5, Positionmanifoldbackonto pump.

NOTE:Exercisecautionwheninsertingcylindersinto manifoldto avoid

damagingcylindero-rings,

6,Replaceflangenutsonstudsandhandtightenbothsides,Thentorque

eachsideto 125 inchpounds.

7. Handtighten lockingnut.

REASSEMBLY

1.Examineinletvalvesurfaceandreverseifdamaged(bothsidesarelap

surfaces).

2. Examinepistonassemblyfor clean inletsurface,If damaged,replace

and lubricate,

NOTECUPINSTALLATION: Wipecupinserter lightlywithoil. Slip bac-

cupring ontopiston.Forcecupover inserterandsquarew“thall

surfaces.Fauhycup installationcausesprematurefdure.

3, Nextreplacepistonspacerand retainer.

4.Slipwasher ontorod,screwon nutandtorque to 60 inch pounds.

NOTE:ALWAYS REPLACE WITH NEW C071ERPlN.

5, Examinecylinderwallsfor scoringoretching,Theseconditionswill

causeprematurewear ofyour pistonassemblies.Replaceifworn

ordamaged,

6, Lubricatecylinderand replaceo-ringsand backuprings(if defective),

7, Positioncylindersintheiroriginal orderintomanifoldchambersand

carefullyiip over rodends;nto the pump.

8.Replaceflangenutsonstudsandhandtighten bothsides,Thentorque

eachsideto 125inchpounds.

9. Handtighten lockingnuts,

SERVICINGTHESEALSANDSLEEVES

DISMANTLING

1,Removedischargemanifoldandpistonassembliesasdescribed,

2.Removeboth(M8)lockingnutsfrom studs,

3,Wtihsoft mallet,tap inletmanifoldloosefrom crankcase.

4,Placeinletmanifoldon pair ofclearance blockswith crankcaseside

downanddriveout seals,

5,Invertinlet manifoldwith CRANKCASE SIDE UP.

6. Lubricatecircumferenceofnew Prnwrn-A-Lubeseals,positionin

manifoldwith GARTER SPRING DOWN and driveinto place,

7,Examinesleevesforscoringor otherdamagebeforeremoving,

6.Ifworn, graspsleevewith pliers andpull off.

NOTE:This procedurewill marthesleeve souse onlyif sleeveis

to be replaced.

\ 9, Removeo-ringand back-upringsfrompistonrod.

Page 15

REASSEMBLY

1, Placebarrierslingeron rod,

2, Lubricatenewo-ringsandback-uprings,Installfirst o-ringintheo-ring

grooveon thepistonrod. Positionback-upringagainsttheshoulderin

flont of thefirst o-ring,thenthe second o-ring.Becarefulto avoid

damagingthe o-ringswhenslipping themoverthe pistonrod

threadedends.

3. Immersesleevein oil carefuliytwistand pushonto rod(machined

counterboreendfirst).

4, Replaceseal retainers.

5,Exercisecautionwtrenreplacinginletmanifold,sothe inletsealsarenot

damagedby thethreadedrod ends.

6, Replacelockingnuts onstuds,

7, Reassemblepistonassembliesanddischargemanifoldas described.

Consultfactoryfor yourlocal distributorfor crankcaseservicing,

DISMANTLINGCATPUMP

Page 16

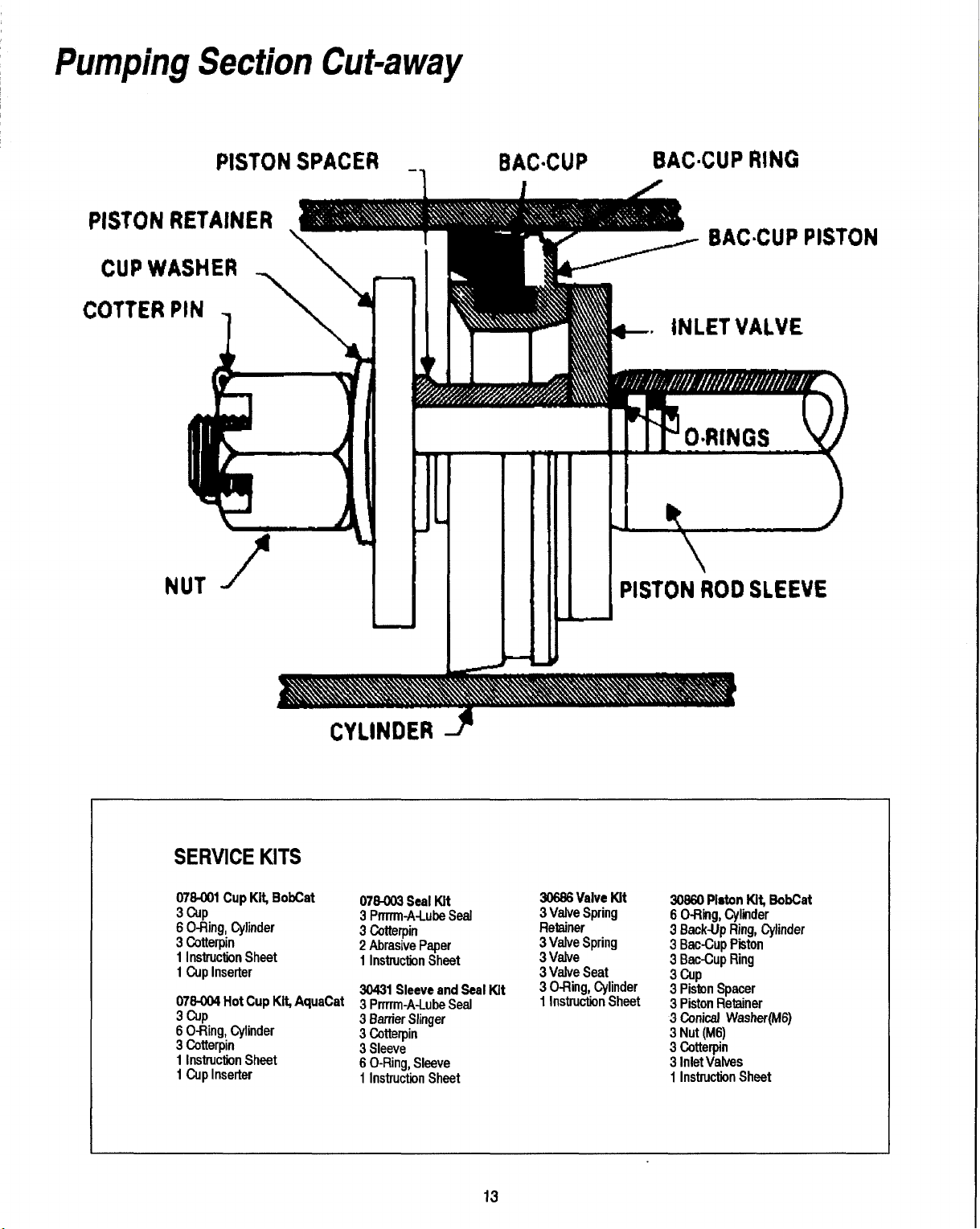

Pumping Section Cut-away

PISTON

PISTON RETAINER \

CUP WASHER

COTTER PIN

1

NUT -f

SPACER _,

BACSCUP

BAC~CUP RING

IN

PISTON ROD SLEEVE

J

SERVICEKITS

07S-001 Cup Kit BobCat

3cup

Ofling, Cylinder

6

CotterPin

3

1 Instruction Sheet

t Cup Inserter

076-004 Hot

3 cup

6 O-Ring, Cylinder

3 Cotterpin

1 Instruction Sheet

1 Cup inserter

Cup Ki$ AquaCat 3 prmm.A~u@ Sed 1 Instruction Sheet

CYLINDER Y

076-003SealKit

3Prrrrm-A.LubeSeai

3CotterPin

2Abrasive

1 Instruction Sheet

30431 Sleeve and Seal Kit

3 Barrier Siinger

3 CotterPin

3 Sieeve

6 O-Ring, Sleeve

1 instruction Sheet

Paper

13

30666ValveKit

3ValveSpring

Retainer

3 Valve Spring

3 Valve

3 Valve Seat

3 O-Ring, Cylinder

30660PistonKit BobCat

6 O-Riig,

3 Back-UpRing,Cylinder

3 Bat-Cup P~ton

3 Bat-Cup Ring

3 Cup

3 Piston Spacer

3 Piston Retainer

3 Conical Washer(M6)

3 Nut (M6)

3 Cotterpin

3 Inlet Valves

1 instruction Sheet

Cyliider

Page 17

PISTON MODEL 290 Exploded View

d

●-

‘ 57

14

Page 18

PARTSLISTMODEL290

ITEM

10

11

12

15

16 43804 Crankshaft

17 14487 Rearing

18

t9 0974107 O-Ring, oil seal case

20

21

23 101799 Connecting rod

24 101800

25

26 20017 Seal washer 3

27 147-006 Oil seal 3

28

29 097408 O-Rina. sleeve 3

30 29003

31

32 26654 Seal washer 3

33 1384)01 Seal rea”ner 3

34 25128

35

35

PARTNO, DESCRIPTION QTY.

1 20285 Ofling (Buns-N)

44274 Crankcase

2

3 156408 Stud(M8X

4 097404 O-Ring, oil tillercap

5 027-007

8 43340

43339 Crankcasa cover 1

9

074-021 Bubble oilgauge

23170 O-Ring,drainplug

25625 Drain plug 1

92520 Sems comb head screw (M6 x 20) 6

1474Q5 Oil seal (Buns-N) 2

041-021 Oilseal case 2

92519 Sems comb head screw (M6 x 16) 8

16948 Piston pin 3

25327 Barriir slinger 3

28771 O-Ring, sleeve (WOn) 3

29614 Sleeve (29743 Unchromed)

25635 Inlet man”tild - stainless steel 1

147-008 Pm’rrm-A-Lube seal 3

30325 Prrrrrm-A-Lube seal (Vrron] 3

Oil fillercap 1

O-Ring, crankcase cover 1

Piston rod 3

Back-up ring, Sleeve (Teflon)

Inlet manifold 1

82)

ITEM

1

1

2

1

1

1

1

2

2

3

3

3

38

39

40

41

39-41

39-41

42 27963

43

44

45

46

47

46

49

50 090-005

51 43442

52

53

54

56

57

58

Electric Clutch Aesembly

59 152-005

60

61 036-005

62 143464

63 174034 Flat washer (5/t6 US)

64

PARTNO.

27004

30543

0974)25 Bat-Cupring(Teflon)

044-001

43474

078401 BobCat CUpkii

0781U34

27002

27006

27000

14156 Cotterpin

0454X)4

097-012 O-Ring, cylinder (Buns-N)

11377

097~24 Bat-Cup ring, cylinder

25&4

43360 Valve spring

43723 Valve

43434 Discharge valve seal

81109 Hex nut (M8)

101804 Hex ffange nut (M8)

108403 Shaft protector

077-005 Key, electric clutch

174-018 Lock washer (5/16 US)

DESCRIPTION

Inletvalve

Bat-Cuppiston

Cup (t4ton)

Bat-Cup assembly

AquaCat cup kti

Piston spacer

Piston retainer

Conical washer - SIS(M6)

S/S(M6)

Nut -

Cylinder(43634 Unch)

O-Ring, cyIinder win)

Discharge manifold

Discharge manifold - SIS

Valve spring retainer

Tapered sleeve

6’ electric clutch

8~ mm socket head screw

Q-W.

3

3

3

3

3

1

3

3

3

3

3

3

6

6

3

1

1

3

3

3

3

2

2

1

1

1

1

1

1

1

Page 19

—

CATPUMPTROUBLESHOOTINGGUIDE

PROBLEM: Pulsatlon

Cause

-n discharge valves of pump.

Worn Prrrrrm-A-Lube seals.

Excessive temperature.

Soiution

Clean or replace discharge valves.

Replace.

Check pump solenoid.

PROBLEM:

Cause

Worn nozzle.

Belt slippage.

Air leak in inletplumbing,

Relief valve stuck, partially plugged or improperly adjusted; valve seat worn.

Inlet suction strainer clogged

Worn piston assembly. Abrasives in pumped fluid or serve cavitation. Inadequate

Fouled or ditty inletor discharge valves.

Leaky discharge hose. Replace worn valves, valve seats.

PROBLEM: Pump runs extremely rough,

Cause

Restricted inlet orair entering the inlet plumbing. Proper size inlet plumbing; check for air tight seal.

Inlet restrictions and/or air leaks, Damaged cup or stuck inlet or discharge valve. Replace worn cup or cups, clean out foreign materiel, replace worn valves.

Worn inlet manifold seals. Prrrrrrn-A-Lubes, Replace worn seals.

PROBLEM: Cylinder O-Rings biown next to discharge manifoid

Cause

Pressures in excess of rated PSI, Check for piugged nozzle, closed valves or imprope

Warped manifold. Freezing. Replace manifold.

LOWpt%SSU~

water supply,

orimproper size.

Solution

Replace nozzksof proper size.

lighten or replacw use correct belt.

Dismantle, reseal, and reassemble.

Clean and adjust relief vaivq check for worn and dirty valve seats. Kit available.

Clean. Use adequate size. Check more fraquemty.

Install properfiiter. Suction at inlet manifold must be limited to liftingless than 20

feet of water or -B.5 PSI vacuum.

Clean inlet and discharge valve assemblies.

Replace discharge hose,

prassurwis verylow

Solution

Soiution

rlyadjusted bypass valve.

PROBLEM: Leakage at the cyiinder O-Rings at the discharge manifoid and

powderysubetancein the area of the O-Ring

biack,

Cause

Loose cylinders Cylinder motion caused by improper torque on the discharge Retighten. ~nottighbntmmuch ortieemoftiemmtioidwill be~wed,causing

manifoid.

PROBLEM: Water ieakage from under the inlet manifoid

Solution

looseness in the center cylinder.

Cause Soiution

Worn iniet manifold seals. Prrrrrm-A-Lube. Leaking sleave O-Ring. installseals. If piston rod sleeves are scored, repiace sieeves and sleeve O-Rings.

PROBLEM: Oii ieak betwean crankcase and pumping section

Cause Soiution

Worn crankcase piston rodseais.

PROBLEM: Oil ieaking in the area of the crankshaft

Cause

Worn crankshaft seal or improperly instaiied oil seal, Remove oil seal retainer and repiace damaged gasket and/or seals.

Bad bearing.

Repiace crankcase piston rod seals.

Soiution

Repiace bearing.

(cmthues, nextpsge)

15

Page 20

CATPUMPTROUBLESHOOTINGGUIDE

PROBLEM Excessive play in the end of the crankshaft puliey

Cause

Worn ball bearing from excessive tension on drive beit.

PROBLEM: Water in crankcase

Cause

May be caused by humid air mndensing intowater inside the crankcase.

Leakage of manifold inlet seals and/or piston rodsleeves O-Ring.

PROBLEM: Oil leaking from underside of crankcase

Cause

Worn crankcase piston rod seals.

PROBLEM: 011 leaking at ths rear portion of the crankcase

Cause

Damaged or improperly installed oilgauge or crankcase rear cover O-Ring, and

drain plug O-Ring.

PROBLEM Oil leakage from drain plug

Cause

Loosedrain

plugor worndrainplugOfling.

solution

Replam ball bearing. Properly tension belt.

Solution

Change oil at 3 month or 500 hour intervals using Cat pump crankcase oil (other

approved oilevery month or 200 hours).

Replace seals, sleeves and O-Rings.

Solution

Replace seals, sleeve end O-Rings.

SoMion

Replace oil gauge or cover O-Ring, and drain plug O-Ring.

solution

Tighten drain plug

orreplace O-Ring.

PROBLEM: Loud knocking noise

in pump

Cause Solution

Pulley loose on crankshaft,

Broken worn bearing. Replace bearings.

PROBLEM: Frequent or premature faiiura of the inlet manifold seals

Check key end tighten set screw.

Cause So/ution

Scored rods or sleeves.

Over pressure to inlet manifold,

PROBLEM: Short cup life

Cause

Abrasive materiel in the fluid being pumped.

Excessive pressure and/or temperature of fluid being pumped. Check pressures endfluid inlettemperetur~ besuretheyare withinspecifiedrange.

Over pressure of pumps. Reduce pressure.

Running pump dry.

Front edge of piston sharp,

PROBLEM: Strong surging attheinletandlow preasureonthedischargeside

Replace rods end sleeves.

Reduce inlet pressure per kvmmtions.

Solution

Install proper filtration on pump inlet plumbing,

Do not run pump wiihout water.

Replace with new piston,

Cause Soiution

Foreignparticles intie in!etordischargevalve orworn inletand/ordischergevalves.

Check forsmooth lapsurfaces oninletand discharge valve seats. Discharge velve

seats, and inletvalve seats may be lapped on a very fine oilston% damaged

cups and discharge valves cannot be lapped but must be replaced.

16

Page 21

HIGHPRESSUREPUMP

TROUBLESHOOTINGGUIDE

PROBLEM: LOSS of D1’eSSUi’e

Qi4MWd@

1.Cloggedfilterscreen ingarden hose quick connect coupler.

A. Remove and clean or replace filter.

2. Low water pressure at sourcs.

A.Determine rate of flow end select an alternative source of supply ifwater

pressure is inadequate.

3. Defective or blocked check vatves in high pressure pump cylinder head.

A.Dismantlecylinder head andreplaceordeanapplicablecheckvalve,

4.Delaminated,kinkedorcloggedhosebetweenthemixtankandthe high

pressurepump.

5.Defectivepressurereliefvalve

h!@pressure bypassvafve isdesigned tofullyclose when thedeaningtool

isturned on. Any foreign matter collecting on the piston will prevent full

closure ofthe valve and allow a partianofthewaterta continueto circulate

instead of being routed to tie cleaning tool. To correct this situation, the

bypass valve mustbedismantled and cleaned (referto illustiationprovided

for bypass dismantling),

A. Dismantle and dean pressure relief valve as shown in illustration.

B. Replace defective or worn out bypass cup.

C, Replace bypass valve.

6. Defective or worn cups.

A. Remove endreplace piston cups as defined by pump section of this

manual.

7. Loose driie belt for high pressure pump.

A. Readjust belt as required or replace if defective.

or debris in pressure reliefvalve. NOIE: The

Bypass Valve Assembly

‘?(D”

IYPASSPARTSLIST

IEF. NO.

PART NO, DESCRIPTION

3 000-105-101

000-105-102 Piston plate: Bypass valve

4

5 000-076-101 Kfl, seal for Bypass valve

7 COO-I48-004

8 000-0974)05 O-Rirra. Bvr)ass valve fittina

Thrust date, Bvr)ass valve

Seat & O-Ring, Bypass valve

QTY,

1

1

1

1

1

INFORMATION

Thevacuum blowerincorporatedin Urismachineis a positivedisplacementlobetype,manufacturedbyCooperIndustries.Theperformanceand

lifeofthis unitis greatlydependenton the care and proper maintenance

t receives,

PROBLEM: Insufficient or excessive water flow

Cause/Solution

Wornout spray jet. NOTE: Cleaning tools designed to spray a canstant flow of

1.

11/2 GPM will average 1gallon offiowperminute inactual workingsituations

sinceflow isnoncontinuous.Anaverage fbwof 1GPM results in6000 gallons

of fbw for evey 100 hours of unit operation. Spray tips are capable of

consistent flow rates for epproximatety 20,000 gallons. They should be

replaced therefore approximately every 350 hours. Worn spray jeis albw a

greater average rate of fbw thus reduang

A, Remove andreplacesprayjet.

2. Redur%on offlow.

A. Due to increased length of solutionhose. NOTE: For every 50 feet of hose

beyond 100 feet intotal length,a measurable !css offlow is experienced. This

cond~on is a result of the increased friction experienced by the water as it

passes through the hose. Therefore, itis necwssaiyto increase the pressure

at the machine 40 PSI for every additional 50 feet of cleaning solution hose

over 100 feet.

desiredtemperaturelevels.

3ecauseof the closetolerances betweenthe lobes and housingofthe

~acuumblower,solid objectsenteringthe inlet will damagethe internal

obes,gearsandbearingordirect drivecoupler.

To preventthis, a stainless steel filter screen has been placed at the

#acuuminletinsidethevacuumrecoverytank.This stainlesssteelscreen

s fingertightandshould beremovedforcleaningweekly.

When machine is being run fortestpuposes and the vacuum inlet on top

ofmachine b open, caution should be used.

Toprotectthevacuumblowerfromoverloadinganddamagingitself,there

savacuumreliefsysteminstalledonthevactank,Whenthevacuumtank

nletiscompletelysealedoff,a maximumof12HGwillbeattained.A hole

mthetop blowerpipeelbowactsasthelubricationpoint.Attheendofeach

jay, LPS 1or Pennzguardshouldbesprayedin beforeshuttingdownthe

machine.See blower lubrication illustration, If you fail to lubricatethe

iacuum blowerdaily,rustdepositsand moisturewill decreasethelife of

thevacuumblower.

Readthevacuumblowermanualcarefullyforproperoilchangeandgrease

application.Themaintenancelogmaydifferslightlyfromthe manual,but

:hetruck-mountedcarpetcleaningmachineapplicationisverydemanding

)fthe vacuumblowerandthereforeitshouldbemaintainedmoreregularly,

MOTE: Vacuum tankisprotacted from ovetiowingbya vacuum tank, frbat

W switch. This switch is not activated by foam,only by ijquid.

17

Page 22

Blower Lube Port

Spray lubricant into blower lube port for 3to 5 seconds,

then immediatelyshutoff machine.Useonly LPS 1

moisturedisplacinglubricant,

VACUUMTANKFILTERBAGS

HydraMasterfilter bags are designedto trap all of the lint, that would

normallycollectatthebottomofyourvacuumtank.The useofthesebags,

ifemptiedatthe endofeachjob, will eliminatetie build-upof muchof the

debrisinthetank.

the incomingdirtywater inlet~nke vacuum~~k. -

to

To reorderbagsusepart number049-028.

Vacuum Tank Filter Bags

PROTECTIV

HOLDING RECOVERY

The drawstring top of these bags is designed to b tied

R

TANK

Vacuum Flow

S/S Fil

Vacuum

Relief

Vacuu

Kill Swi

ag

Page 23

VACUUMBLOWERTROUBLESHOOTINGGUIDE

PROBLEM:

Cause solution

Collapsed

Cloggedstainless steel finer,

Defective vacuum tank seal.

Defectiveor“open”vacuumtankdumpvafve.

Fracturedwekfonvacuumtank.

Collapsed or kinked vacuum hose.

Pluggedvacuumhose.

Restiiclion in cleaning tool.

Worn end plates or lobes in vacuum b!ower.

Defectivereliefvalve.

PROBLEM:Blower Isseized

Cause

Rust.

Foreignmatter.

Note: Theabovementioned, rust foreignmatterandseizing areoftencaused from

Loss of pressure

vacuum hose between blower and vacuumtank. Remove and replace hose. NOTE: A special reinforcxxfhoseisrequired

for replacement.

Remove end clean or replace stainless steel filter.

Removeand replacevacuumtank seal.

Closevalve,

Replacevalve.

Re-weld as required or replace tank.

Reshapehose if possibleand/oreliminatekinks.

Remove obstructionsbyreversingthevacuumhose.

Remove obstruction.

Replaceworncomponents.NOTE:Mustbeaccompliihedbyaqualifiedtechnican.

Inspectand replaceifnecessary.

Solution

Sprayrustdissolvinglubricantonto lobesto emulsifyrustandattempt to rotate

vacuumlobes.

Dismantfeandremoveforeign mattarand repairas required.NOTE:Dismantling

mustbeaccomplishedbyqualifledtechnican.

foamLwvehrgthroughthe Mower.

PROBLEM:NoiseIn vacuum blower

Cause

Worngears.

Lackoflubrication.NOTE:Permanentdarnagemayhaveresultedfrom lack

of lubrication.

Wornbearings.

Debrisand/orforeignmaterialbuild-up.NOTE:A stainlesssteelfilter isprovided

in vacuuminletlocatedin vacuum blower components.

Lcoseormissingmountingbofts.

Solutlon

Removeandreplacegears.NOTE:Replacementofgearsmustbeaccomplished

byqualifiedtechnican.

Timing of vacuum blowerhas beenchanged dueto worncomponents.NOTE:

Replacementofcomponentsmustbeaccamplihed byqualifiedtechnican.

Lubricateasspecifiedbyapplicablevecuumblowermanual.SeeTableofContents.

Removeand replace bearings as required. NOTE:Must be acmmplished by

qualifiedtechnican.

Dismantfevacuumblowerandremoveforeignmaterial.NOTE:Ilsmantfingshould

beaccomplishedby quafifi+s-dtechnicanonty.Replacementofwornpartsis

necessary.

or reinstallmounting bofts.

Tighten

Page 24

VACUUMBLOWERWARRANTY

COOPERwarrantsproductsofitsmanufacturetobefreefromdefectsinmaterialandworkmanshipifproperlyinstalled,maintained,andoperated

undernormalcondtiionswith competentsupervision.

Noperson,agent,representativeordealeris authorizedtogiveanywarrantiesonbehalfofCOOPERnortoassumeforCOOPER anyotherliability

in connectionwithany of COOPERSproducts.

Thiswarrantyshallextendfortwo (2)yearsfrom dateof installationprovidedthis equipmenthas beenput into servicewithin six monthsafter

shipmentfromtheCOOPERfactory,IfrepairsorreplacementsaremadebythePurchaserWithoutCOOPER’Spriorwrittenconsent,COOPER’S

warrantyshallceaseto beineffect. No allowancewillbegrantedfor anyrepairsor alterationsmadebythe PurchaserwithoutCOOPER’Sprior

vwittenconsent,

Machinery,equipmentand accessoriesfurnishedby COOPER,but manufacturedbyothers, arewarrantedonly to the extentof the original

manufacturer’swarrantyto COOPER,

COOPERagreesatitsoptionto repairatthe pointofshipmentortoreplacewithoutchargef.o,b.pointofshipment,anyparl orpartsofproducts

of COOPER’Smanufacture,whichwithinthe specifiedwarrantyperiodshallbeprovedto COOPER’Ssatisfactiontohavebeendefectivewhen

shipped,providedthe PurchaserpromptlynotifiesCOOPER,inwriting,ofsuch alleged defect

COOPER’Sliabilityto Purchaser,whetherincontractorintori arisingoutofwarranties,representations,instructions,ordefectsfromanycause

shallbe limitedto repairingor replacingofthe defectivepartor partsasaforesaid,f.o.b, pointof shipment.

NoliabilitywhatsoevershallattachtoCOOPERuntilsaidproductshavebeenpaidfor, EXCEPTASSTATEDINTHISSECTIONANDINTHE

PRECEDINGSECTION TITLED ‘WARRANTY’AND EXCEPTAS TO TITLE, THERE ARE NO GUARANTEEDOR WARRANTIESOF

MERCHANTABILITY,FITNESS,PERFORMANCEOROTHERWISE,EXPRESS,IMPLIEDORSTATUTORY,AND COOPERSHALLHAVE

NOLIABILITYFORCONSEQUENTIAL,INCIDENTALOROTHERDAMAGES,HOWSOEVERCAUSED.

DATEINSTALLED

MOD~

COOPER/GARDENER-DENVER1800GardenerExpway Quincy,IL 62305-4024

VACUUMBLOWERLUBRICATION

At the gear end the timing gear teeth are lubricatedby being partially

hoursor moretlequentiy ifinspectionso indicates,The oildrainplugis

at (C),

submerged,Thegearteethserveasoilslingersfor gearendbearings.At

the driveendofthe bearingsaregreaselubricated.

NOTE:Olderunitsmayhavetheoilfilllevelanddrainholeslocatedinthe

castirongearcaseinsteadofinthe headplate.Bearingsondriveendof

FILLING PROCEDURE

Removesquareheadventedoilfillplug (A)on gearend. Removeoillevel

plug(B)locatedinthe headplate.Fill gearcaseuntiloildripsoutofthe oil

levelhole(B),Uselubricantsaslisted.Addfreshoilasreuuiredtomaintain

blowerrequiregreaselubricationevery100hoursofoperation.Bearings

which requiregrease lubricationwill have a greasefitting (D)at each

bearing.Whenregressing,the oldgreasewillbeforcedoutof the vents

duringoperation,Topreventdamagetoseals,theseventsmustbekept

properle~el:Theoil should bedrained,flushedand replacedevery300 ~ open}t all times. -

Vacuum Blower Motor Lubrication

‘In ●pplicstiorts with extreme variations. in

qnbiertt t.rnpwsture 8 20W - 50W multtplc

wscosi

-LOWER DISCHARGE

SERl~

;!

SAE10W

n)” SAE40

Uw ZVJ- F

/**C*PI

w 011ISracommend~d.

FOR GREASE LUBRICATED BEARINGS

Ssrviccsverv 600 hours of oporstion

TEMPERATURE

-400 to 275*

(-4@ to

12rPc)

SAE50

F

6;:A~E

B-=ri

45

200

250

TVPE

ng.Groins

20

Page 25

INTHEINTERESTOFSAFETY

BEFORE STARTING ENGINE,READ AND UNDERSTAND

THE “OPERATING AND MAINTENANCE INSTRUCTIONS. ‘

OPERATINGANDMAINTENANCE

INSTRUCTIONSFORMODELSERIES

303400(16HP)

#+

@

A

,...................................Read Operator’s Manual

..............................,!...!.

..................................!.

..!!..,,.,,...............,,,,,....!.

B

Warning/Caution

oil

Fuel

THIS SYMBOL M&4NS WARNING OR CAUTION.

DEATH, PERSONAL lNJURYAND/OR PROPERWDAMAGE

A

MAY OCCUR UNLESS INSTRUCTIONS ARE FOLLOWED

CAREFUUY.

[WARNING: Do NOT...

1A

1, DONOTrun engine in an enclosedarea,Exhaustgasescontaincarbon

monoxide,an odorlessanddeadtypoison.

2,D0 NOTplacehandsor feetnear movingorrotatingparts.

3,DO NOTstore,spill,or usegasolinenearan open flame,or devicessuch

as astove,furnace,or waterheaterwtich usea pilot light ordevices

whichcan createaspark

4.DO NOTrefuel

refueling is preferred.

NOTfill fueltankwhile engineis running,Allowengineto coolfor

5.DO

2 minutesbeforerefueling.Storefuel in approvedsafetycontainers.

NOT remove fuel tank capwhileengineis running.

6,DO

NOT operate engine when smellof gasolineis presentor other

7.DO

explosiveconditionsexist.

8,DO NOToperateengine ifgasolineis spilled.Movemachineawayfrom

thespill andavoidcreatingany ignitionuntilthe gasolinehas evaporated.

9.DONOTtransportenginewith fuel in tank.

10.DONOTsmokewhenfilling fueltank.

11,DO NOT choke carburetor to stop engine. Whenever possible,gradually

reduceenginespeed beforestopping.

12.DONOTrun engineat excessivespeeds.This mayresult ininjufyt

13.DONOTtamperwith governorsprings,governorlinksor otherpatis

whichmay increasethe governedenginespeed.

14.DONOTtamperwiththe enginespeedselectedbythe original

equipmentmanufacturer.

15,DONOTcheckforspafi withspark plug or spark plug wireremoved.

Usean approvedtester.

16.DONOTcrankenginewith sparkplugremoved.If engineisflooded,

placethrottlein

17.DONOTstrikeffywheelwitha hardobjector metaltool asthis maycause

flywheelto shatterinoperation.Usepropertoolsto serviceengine.

18,D0 NOToperateenginewithouta muffler,Inspectperiodicallyand

replace,ifnecessary.If engineisequippedwith muffferdeflector,inspect

periodicallyand replace,ifnecessary,with correctdeflector.

19.DONOToperateenginewithan accumulationof grass, leaves,dirt or

othercombustiblematerialinthe mufflerarea,

20. DONOTusethis engineonanyforest covered,brush covered,orgrass

coveredunimprovedland unlessa sparkarresteris installedonthe

mufffer,The arrestermustbemaintainedin effectiveworkingorderby

theoperator.In theState ofCaliforniathe above is requiredby law

(Section4442of the CaliforniaPublicResourcesCode).Otherstates

mayhavesimilarlaws. Federallawsapplyon Federallands,

21,DONOTtouchhot muffler,cylinder,orfins becausecontactmay

indoors where area is not well ventilated, Outdoor

“FAST” position and crank until enginestarts.

A

. .. . .. ,.,,.,.,..,..,.,.....AirCleaner......Air Cleaner

,.

.:.

Q

21

Page 26

WARNING: DO

1.ALWAYSDOremovethe wirefrom the sparkplugwhen servicingthe

engineor equipmentTO PREVENT ACCIDENTAL STARTING.

Disconnectthe negativewirefromthe batteryterminalifequippedwith

a 12volt startingsystem.

2, DOkeepcylinderfinsandgovernorpartsfreeofgrassandotherdebris

whichcanaffectenginespeed.

3. DOpullstartercordslowlyuntilresistanceif fett. Then pullcordrapidly

to avoidkickbackandpreventhand or arminjury.

4. DOexaminemufflerperiodicallyto be sure itis functioningeffectively.

Awornorleakingmuffiershouldberepairedorreplacedasnecessary.

5.DOusefreshgasoline.Stalefuelcangumcarburetorandcauseleakage.

6. DOcheckfuellinesandfittingsfrequentlyfor cracksor leaks.Replace

if necessaty.

NOTE:UseOriginalBriggs& Stratton Service ReplacementPartswhen

servicingyour engine, Briggs& Stratton AuthorizedServiceCenters

carryastockofsuchparts.TheuseofBriggs&StrattonPartspreserves

the oriiinal designof your engine. Imitation replacementparts offer

potentialriskincludingtheriskof personalinjury.Cantactany Briggs&

StrattonAuthorizedServiceCenterfor OriginalBriggs& StrattonReplacementParts,

DFILL CRANKCASEWITH OIL

lace enginelevel.Cleanareaaroundoilfill.Removedipstick.POUR OIL

LOWLY. Fill to FULLmark ondipstick, DO NOT OVERFILL

0Ti5 Afterstartingengine,stopafter30seconds.Checkoillevelandadd

if necessary, Without filter, oil capacity is approximately 1-1/2 q~.

(48OZS.or 1,42Itrs),With oilfilter, oil capacityisapproximately1-3/4

k.

(560zs. or 1,65Itrs.

0 CHECKOIL LEV L

laceenginelevel.Removedipstickandwipe oil fromit with cleancloth.

crewdipstickintotube untilcapbottomsontube.Removeandcheckoil

vel, Dipstickmustbe firmlyscrewed intotubewhenengineis running.

2

Oii Fill and Dip Stick

BEFORESTARTING

READ THE OPERATING INSTRUCTIONS OF THE

EQUIPMENT THISENGINE POWERS.

OIL RECOMMENDATIONS

We recommenduseofahigh qualitydetergentoil “ForServiceSC,SD,SE,

SF,orSG,”suchas Briggs&Strattonhigh qualitydetergent30weight oil

(partno.1CC005),or 10W-30weight oil (partno.272001). Detergentoils

keeptheenginecleanerandretardformationofgumandvarnishdeposits.

Use no special additives with recommendedoils.

RECOMMENDEDSAE VISCOSITYGRADES

*

**

.20 0

‘F

‘c -30

* UseSAE30 oilin hightemperature,high loadapplications.

w 10W-40oil maybesubstitutedif 10W-30is not available.

* Use synthetic oil having 5W-20, 5W-30 or 5W-40 viscosity, If not

.20

TEMPERATURERANGEANTICIPATEDBEFORENEXTOILCHANGE

available,a petroleum-basedmulti-grade oil may be used having

5W-20 or 5W-30viscosity.

20 40 60 80

-lo 0

10

20 30

100

40

Engine Components

1,Air Cleaner

2. FuelShut-offValve

3. Carburetor

4. RewindStarter

5. BlowerHousing

6, OilDrain Plug

r-d

7,12 Veil ElectricStarter

8, Model,Type and

CodeNumbers

9, SparkPlug

10,ValveCover

Fuel Tank (Optional)

11,

NOTE:Using multigradeoils (5W-20, 5W-30, 5W-40,and 10W-30)will

increaseoil consumption.Check oil level more frequently when using

them.

22

Page 27

FUELRECOMMENDATIONS

Carburetor Ao’justment Screws

Thisenginewilloperatesatisfactorilyonanygasolineintendedforautomo- ‘

tive use. A minimum of 85 octane is recommended.DO NOT MIX OIL

W/Tf-l GASOL/NE.

I

Useclean,fresh,lead-freegasoline,We recommendtheuse of Briggs&

StrattonGasolineAdditive,partno.5041.Purchasefuelinquantitythatcan

beusedwithin30days.This willassurefuelfreshnessandvolatilitytailored

tothe season,Leadedgasolinemaybe usedif lead-freeis notavailable.

Useof lead-freegasolineresultsin fewercombustiondepositsand longer

valvelife,

NOTE: We DO NOT recommend the use of gasoline which contains

alcohol, such as gasohol.

MUST NOT contain more than 10 percent Ethanol and MUST be \

removed from the engine during storage. DO NOT use gasoline i

contain-

ing Methanol.See STORAGEINSTRUCTIONS(page27),

DO/vC)7’REMOVEfuel~ while engineisrunning. DO ~O~~lLL fuelfank j idje stop, turn idle mi~ure screw W clockwise (lean)untilspeed~

topointofoveflowing. A1/owapproximately 1/4 in. (5mm) of tank space for ~

tiel expansion.

However,if gasolinewith alcoholis used, it ~

I

I

\ FINALADJUSTMENT

~Start engine and place equipmentspeed controlin ‘IDLE” or “SLOW

~position.Hold carburetorthrottle lever againstidle stop and adjust idle

~speedscrewtoobtain1300to1500RPM.Stillholdingthroffleleveragainst

~ startstoslowandthenWcounterclockwise (rich)untilenginejuststarts

~to slow.Finally,turnscrewto midpointbetweenrichand lean.

--l

IDLE

SPEED

SCREW

I

IDLE

MIXTURE

SCREW

/

~ng~fle Co~~Ofle~ts

12.Fuel Pump

13, Dipstick

14,Exhaust Manifold1

15.Crankshaft

16.Oil Filter

17,Air Cleaner

CARBURETORADJUSTMENTS

Minor carburetor adjustment may be required to compensate

encesinfuel,temperature,altitudeorload.Aircleanerandaircleanercover

mustbe assembledto carburetorwhen runningengine,

TWIN CYLINDER CARBURETOR ADJUSTMENT IS UNIQUE.

ADJUST CARBURETOR FUEL MIXTURE IN THE ORDER STATED

AS FOLLOWS:

INITIALADJUSTMENT

Gentlyturn idlemixturescrewclockwiseuntilitjustcloses.Turningscrew

in too far may damage it, Then turn idle mixture screw 1-1/2 turns

counterclockwise.This initial adjustment will permit the engine to be

startedandwarmedup(approximately5minutes)priortofinaladjustment.

for differ-

adjust idle speed screw to obtain 1200 RPM, if governed idle spring

~Now

~isred,or900 RPM,ifgovernedidlespringisvhite. Releasethrottle lever,

If engine does not accelerate smoothly, readjust idle mixture screw

approximately1/8turncounterclockwise(rich).

NOTE:Enginesoperatedataltitudesof approximately3000to 5000fee

(900to1500meters)orhighermayrequiretheinstallationofahighaltitude

carburetormainjet to achievebestengineperformance.Ifematicperfor-