Page 1

DOE

Compliant

KPM SERIES - INSTALLATION AND OPERATION MANUAL - V0

Page 2

MVP GROUP CORPORATION

5659 Royalmount Ave.

Montreal, QC, Canada

Telephone: (514) 737-9701

Toll Free Telephone: (888) 275-4538

Toll Free Fax: (877) 453-8832

Email: sales@mvpgroupcorp.com

Website: www.mvpgroupcorp.com

H4P 2P9

Fax: (514) 342-3854

2

Page 3

1 General information 5

1.1 Case description 5

2 Getting started with your KFM series 26

2.1 Location 26

2.2 Uncrating

2.2.1 Front and sides assemblies 27

2.3 Check for damage 28

2.4 Control panel and main features 29

2.5 Check serial, model numbers and requested options 33

2.6 Warning/Caution labels 35

2.7 Check your electrical installation 41

2.8 Electrical, drain and refrigeration connections (remotes only) 41

2.9 Joining 42

2.10 Plugging and start 48

3 Refrigeration 52

3.1 Self contained refrigeration equipment and defrost 52

3.2 Refrigeration loads (remotes only) 54

INDEX

4 Electrical 54

4.1. Electrical specifications data 54

4.2. Electrical service receptacles (optional)

4.3. Electrical diagrams 56

4.4. Electronic controller 96

5 Maintenance 99

5.1 Exterior cleaning 99

5.2 Interior cleaning

5.3 Shelf removing 99

5.4 Back Sliding doors removal

5.5 Light substitution 100

5.6 Panels and protection grille removal 101

5.7 Condenser cleaning 102

5.8 Evaporator cleaning 102

5.9 Evap Pan cleaning 104

5.10 Fish pans cleaning

5.11 Drain inspection 105

5.12 Glass type conversion model

6 Troubleshooting/Service 106

6.1 Troubleshooting 106

6.2 Service 108

7 Warranty 110

8 Notes 111

3

Page 4

This page has been left blank intentionally.

4

Page 5

1 General information

1.1 Case description

KPM series model (number) system.

KPM CG 40 S

AAA BB CC D

AAA

Basic model

BB

Model variation

|

CG-Curved glass tilt forward

|

FG-Flat glass tilt forward

|

OF-Open front

|

|

|

|

|

CC

Length

60''

80''

100''

D

Type of Unit.

|

S-Self Contained

|

R-Remote

|

D-Dry

|

5

Page 6

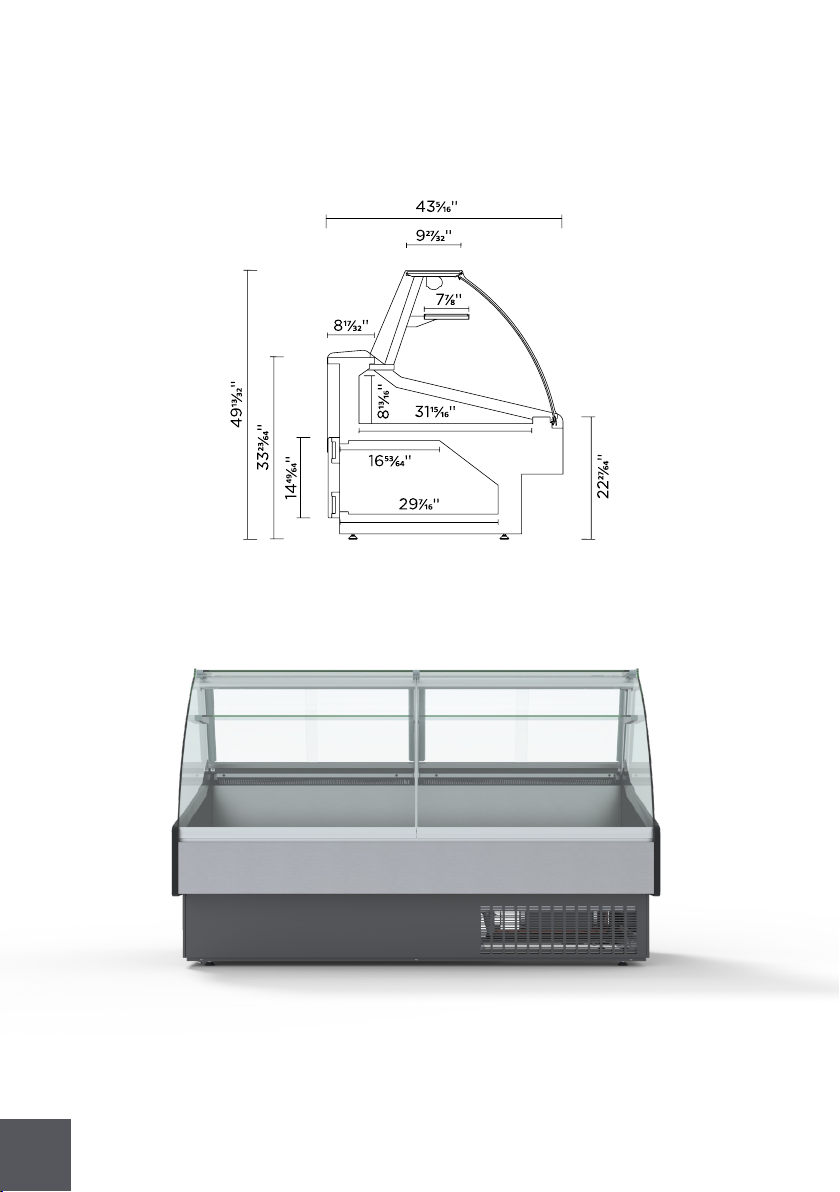

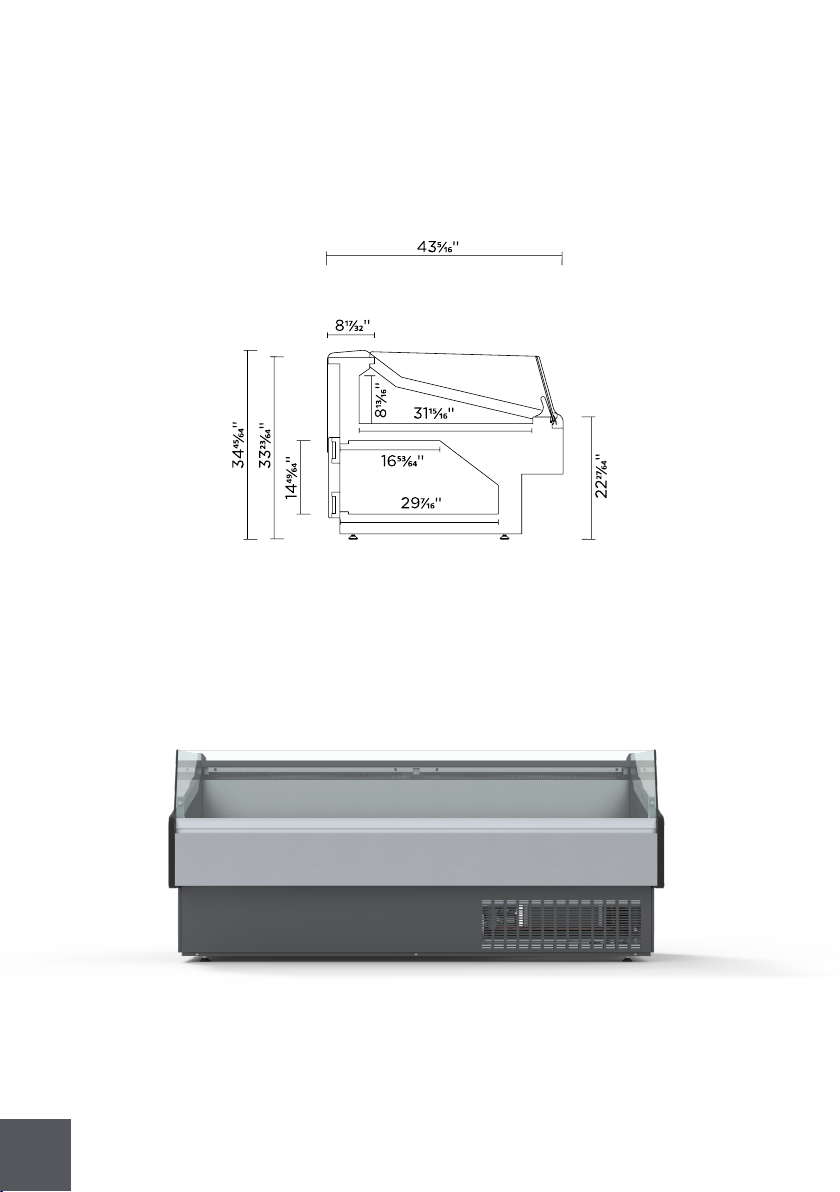

KPM SERIES

KPM-CG-S(R)(D)

KPM-CG-S(R)(D)

6

Page 7

KPM-FG-S(R)(D)

KPM-FG-S(R)(D)

7

Page 8

KPM-OF-S(R)(D)

KPM-OF-S(R)(D)

8

Page 9

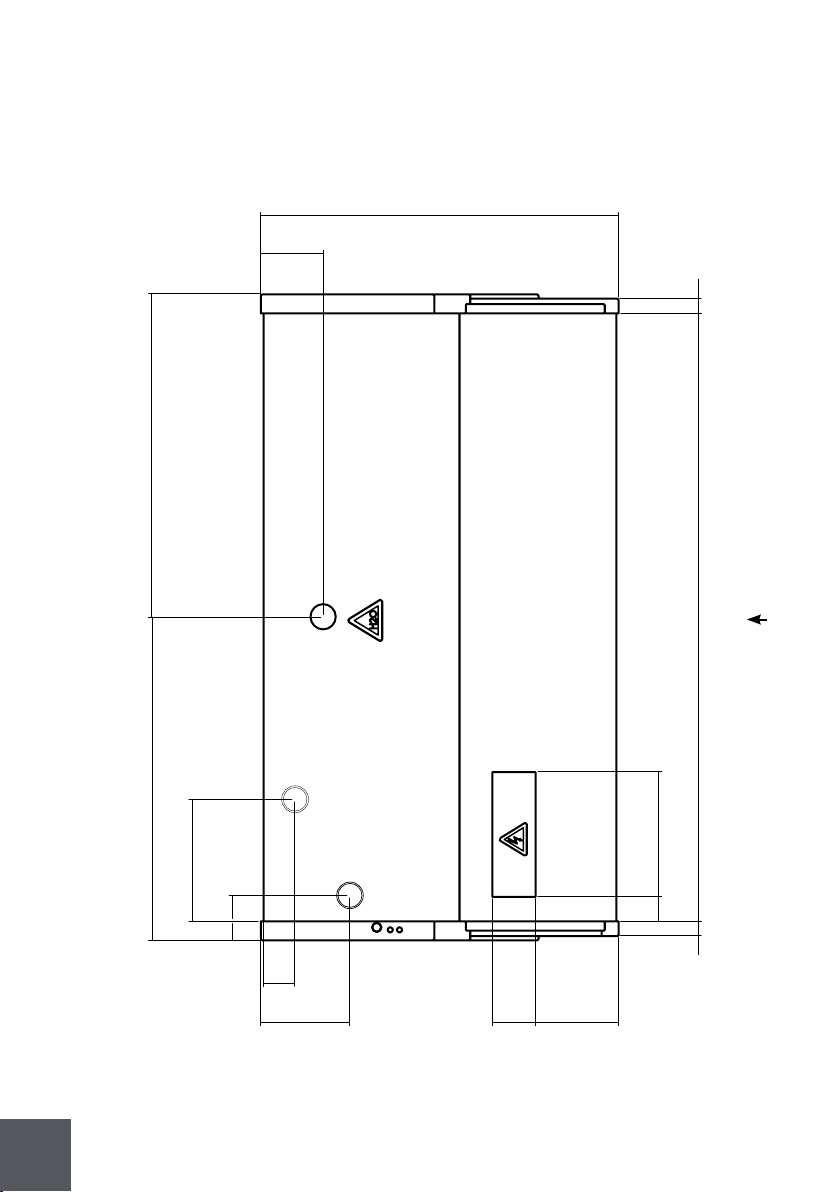

Implantation

Drain outlet

Electrical board

Refrigeration piping

21''

34''

6''

2''

38''

21''

5''

9''

5''

8''

12''

3''

2''

Front

KGL-OF-40-S(R)

9

Page 10

34''

6''

2''

47

Front

26'' 25''

12''

10

5''

5''

8''9''

3''

2''

KGL-OF-50-S(R)

Page 11

34''

6''

2''

31''

57''

31''

12''

5''

8''9'' 5''

3''

2''

Front

KGL-OF-60-S(R)

11

Page 12

Drain outlet

Electrical board

Refrigeration piping

Electrical wiring

6''

25''

34''

2''

38''

26''

2''

5''

4''

8''9'' 5''

8''

3''

2''

Front

KGL-RS/RM-40-S(R)

12

Page 13

34''

6''

2''

26'' 25''

47''

12''

2''

5''

4''

5''

8''9''

3''

2''

Front

KGL-RS/RM-50-S(R)

13

Page 14

34''

6''

2''

31''

57''

31''

12''

2''

5''

4''

8''9'' 5''

3''

2''

Front

KGL-RS/RM-60-S(R)

14

Page 15

Drain outlet

Electrical board

Refrigeration piping

6''

34''

2''

38''

21'' 21''

8''

5''

8''9'' 5''

3''

2''

Front

KGL-DL-40-S(R)

15

Page 16

6''

34''

2''

47''

25'' 26''

12''

5''

8''9'' 5''

3''

2''

Front

KGL-DL-50-S(R)

16

Page 17

6''

34''

2''

57''

31'' 31''

12''

5''

8''9'' 5''

3''

2''

Front

KGL-DL-60-S(R)

17

Page 18

Drain outlet

Electrical board

Refrigeration piping

Electrical wiring

6''

21''

34''

2''

38''

21''

2''

5''

3''

9''

5''

8''

12''

3''

2''

Front

KGL-OS-40-S(R)

18

Page 19

34''

6''

2''

26''

37''

25''

12''

7''

5''

3''

5''

8''9''

3''

2''

Front

KGL-OS-50-S(R)

19

Page 20

6''

34''

2''

20

57''

31'' 31''

12''

12''

5''

3''

8''9'' 5''

3''

2''

Front

KGL-OS-60-S(R)

Page 21

KPM series intended for deli, meat and fish are type 1 equipment - 75°F/55%RH.

Temperature of the deli and meat cases is set for 32°F.

The decks have a 31 lb/ft loading limit.

Glass shelves are for non refrigerated products only and have a 5,5 lb/ft loading limit.

Model

KPM-CG-60-S(R)(D)

KPM-CG-80-S(R)(D)

KPM-CG-100-S(R)(D)

KPM-FG-60-S(R)(D)

KPM-FG-80-S(R)(D)

KPM-FG-100-S(R)(D)

KPM-OF-60-S(R)(D)

KPM-OF-80-S(R)(D)

KPM-OF-100-S(R)(D)

2 Getting started with your KPM series

2.1 Location

To your new equipment perform well please respect the following warnings:

This is type 1 equipment, intended to work with 75°F / 55%RH.

This equipment is intended for maintaining temperature only.

Be sure products are not ambient temperature (must be cold)

This equipment must be located in an indoor environment.

Check for airdrafts and avoid them.

Air movement from ac units shouldn’t be directed to the equipment.

Dimensions

(LxDxH in inches)

601'' x 49'' x 61''

|

77'' x 49'' x 61''

|

60'' x 591'' x 33''

|

40³'' x 591'' x 35''

|

50'' x 591'' x 35''

|

60'' x 64'' x 35''

|

40³'' x 64'' x 33''

|

50'' x 64'' x 33''

|

60'' x 64'' x 33''

|

Service

dimensions

(LxDxH in inches)

601'' x 49'' x 75''

|

50'' x 591'' x 35''

|

60'' x 591'' x 35''

|

40³'' x 591'' x 51''

|

50'' x 591'' x 56''

|

60'' x 64'' x 61''

|

40³'' x 591'' x 35''

|

50'' x 591'' x 35''

|

60'' x 591'' x 35''

|

Volume (ft³)

13,0

|

19,9

|

16,2

|

13,0

|

19,9

|

16,2

|

13,0

|

19,9

|

16,2

|

The equipment must not be directly or indirectly exposed to the sun.

Check for rejected heat from another refrigeration units and avoid that.

Place the equipment in a levelled floor.

Do not obstruct the air way in front of the condenser.

Make sure there is a drain preparation (remotes and fish display cases only).

21

Page 22

Models to be positioned against a wall keep a safe distance of 2''.

After servicing always close the doors.

Make sure you have a suitable electrical installation.

This equipment should be handled by a qualified technician.

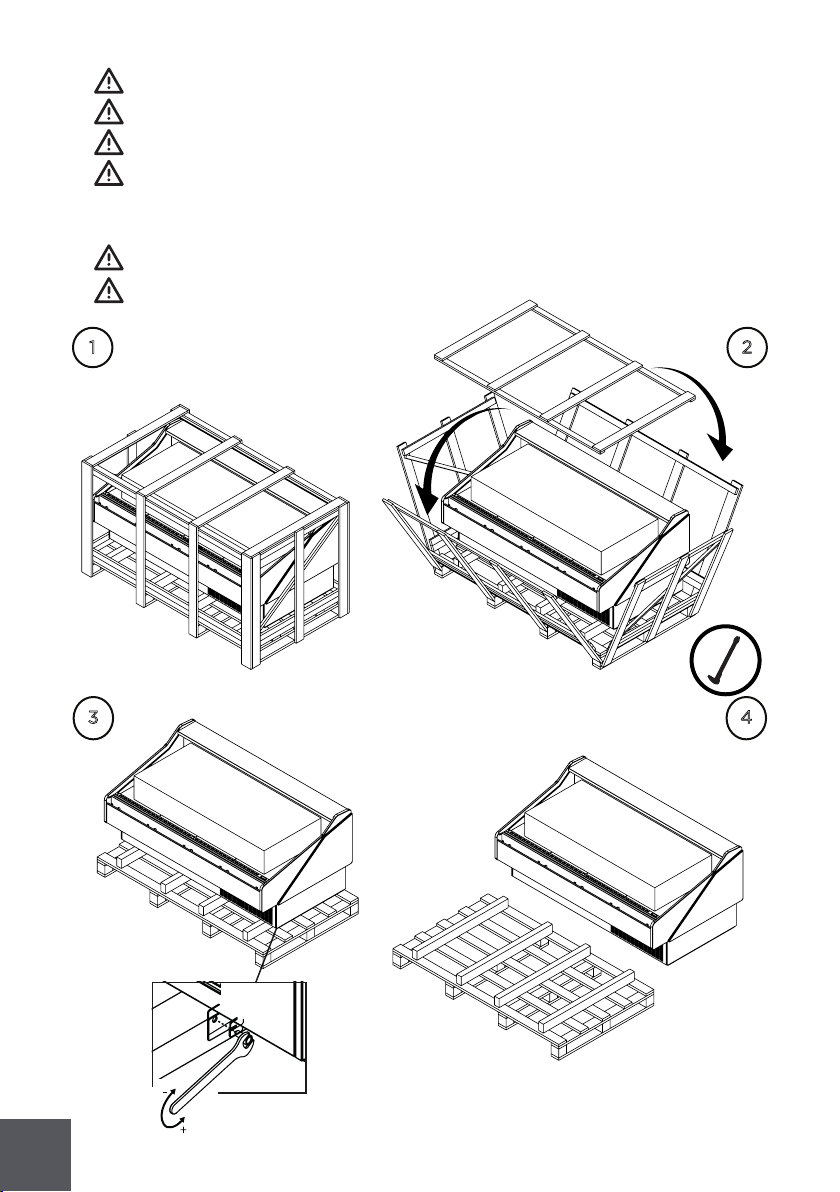

2.2 Uncrating

All operations must be done carefully.

All plastic protective films must be removed before using the equipment for

the first time.

1

3

2

4

22

Page 23

2.2.1 Front and sides assemblies

2x - VID24M01095

1x - BRA09M02000

1x - PRN00101002

DIN 916

6 x - CMS00101000

2x - VID07003000 1x - PRT01201190

2x - PAR00802002

DIN912 M5x12

1x - APO01101000 1x - PAR00902001

10 x - PAR11101001 1x - GAM13M01200

2x - ANL00101006

DIN 127

DIN7380 M5x12

2x- ANL00501006

DIN 9021

1x - PAR00902004

DIN7380 M4x10

4x - POR19M01100

2x - SUP17M01020

1x - PAR01002013 1x - PRT01301190

23

Page 24

1

2

3

5

4

6

24

Page 25

7 8

2.3 Check for damage

At the end of production HYDRA KOOL products are carefully inspected. No damaged

units are sent out.

HYDRA KOOL doesn’t take responsibility for damage between factory and client.

Possible damage on the unit must be checked to file a claim near the transportation

company.

The unit must be checked in the following points:

Exterior panels

Doors

Shelves

Glasses

Paint job

Door handles

Base structure

25

Page 26

2.4 Control panel and main features

The pictures below, shows the main features and all necessary controls.

Electronic controller

Light switch

Power signal

Condensing unit switch

Hot key connector

Electrical board

Self contained control panel (KPM-CG/FG/OF)

Electronic controller

Light switch

Power signal

Condensing unit switch

26

Electrical board

Remote control panel (KPM-CG/FG/OF)

Page 27

Light switch

Power signal

Power switch

Electrical board

Dry control panel (KPM-CG/FG/OF)

27

Page 28

Rear Storage

Rear doors Tilt down Front glass

Return air grille

Discharge air grille

2.5 Check serial, model numbers and requested options

Before starting your equipment, check the serial number, model numbers and

requested options. This inspection should be made visually in the following items:

28

Page 29

Self contained numbers

Remote numbers

29

Page 30

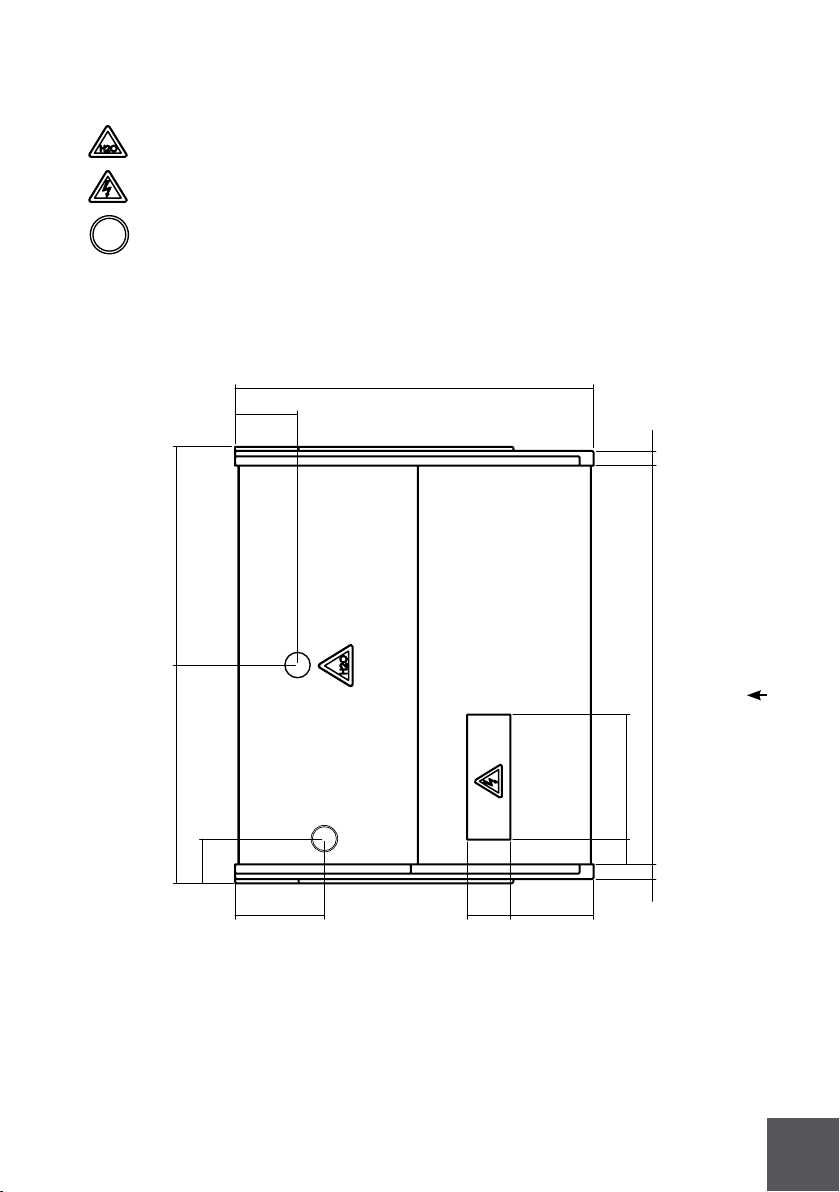

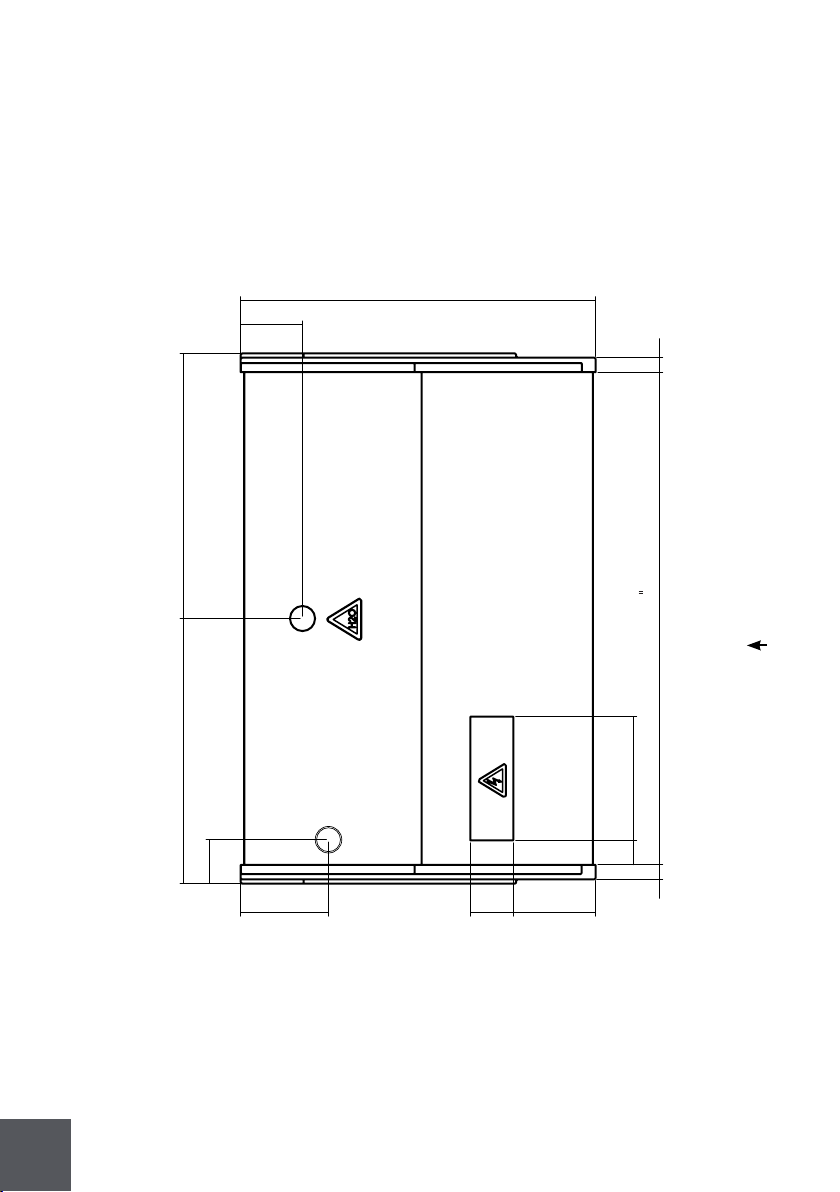

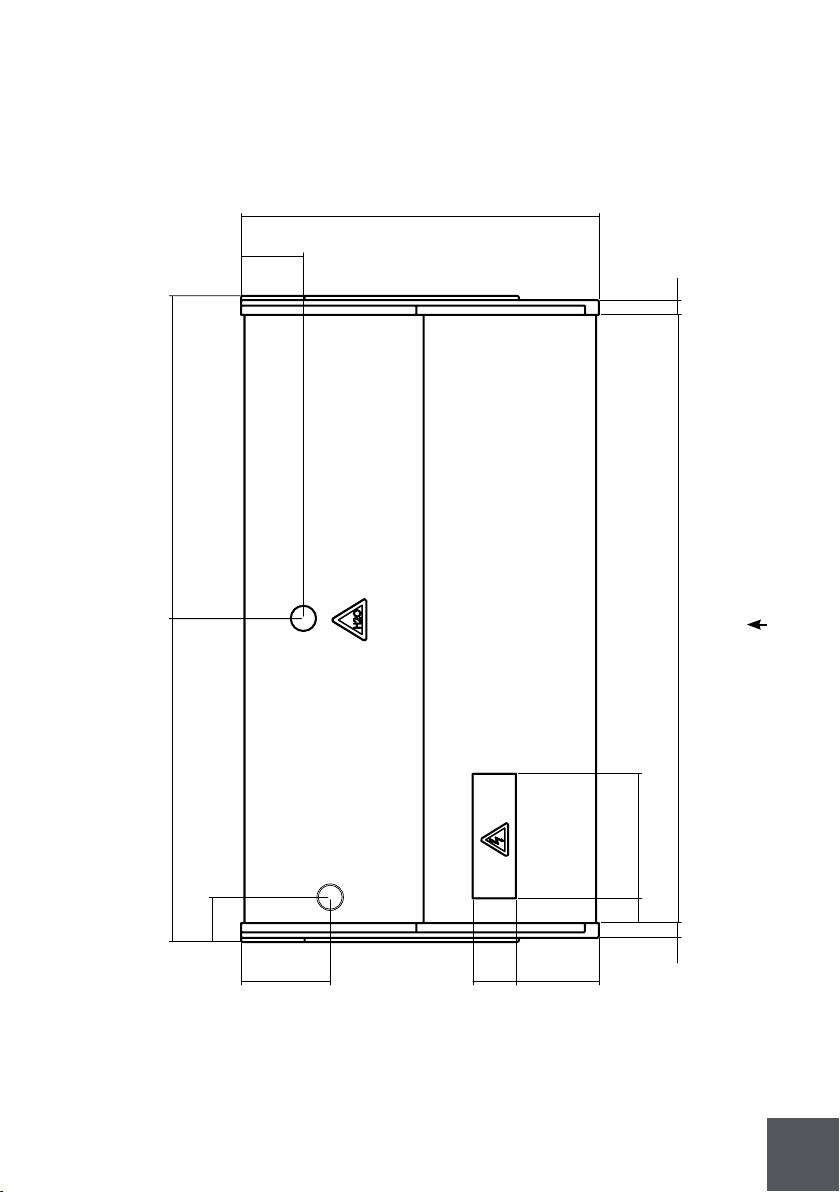

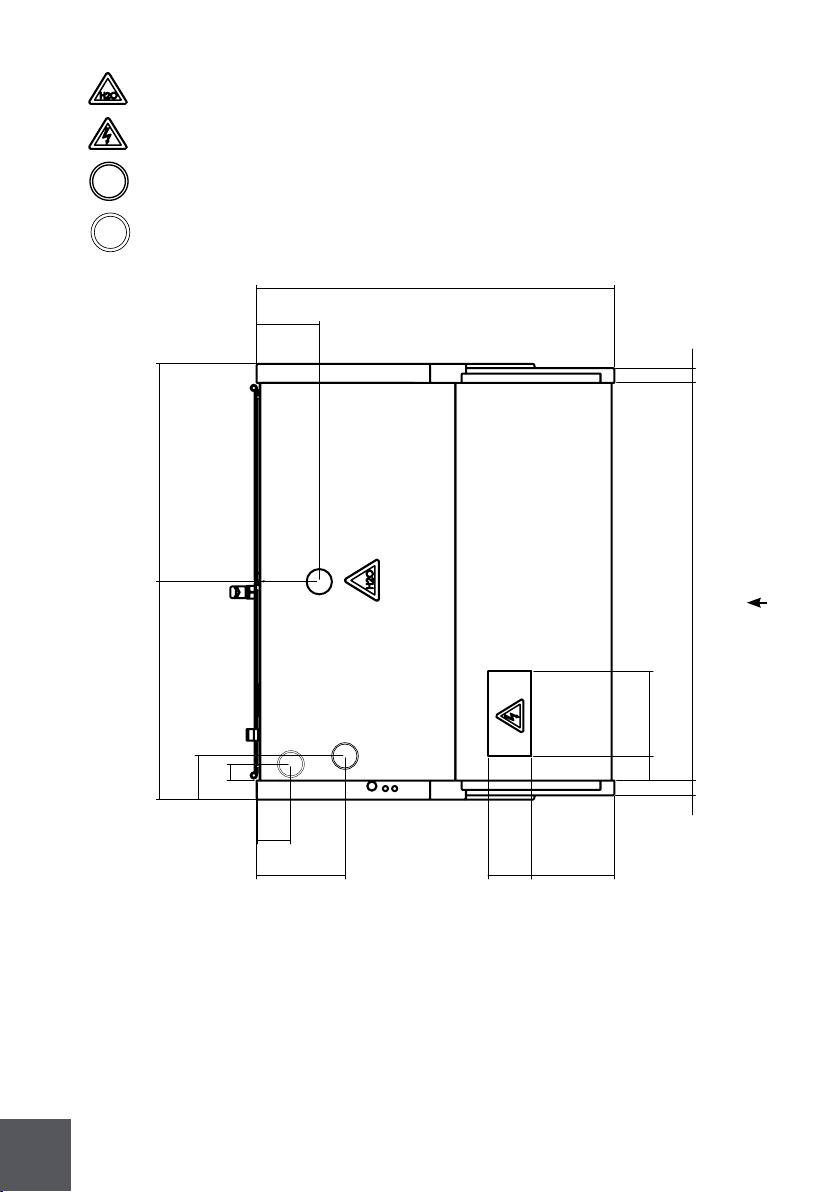

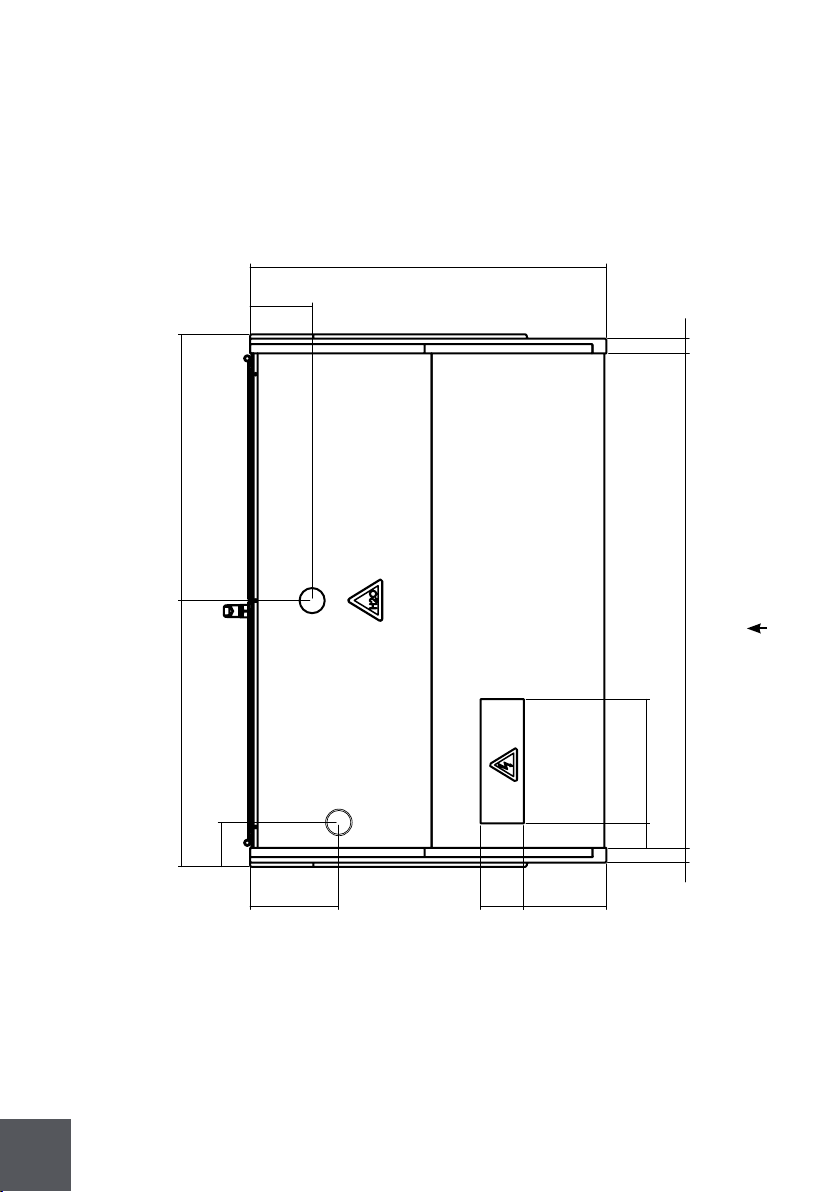

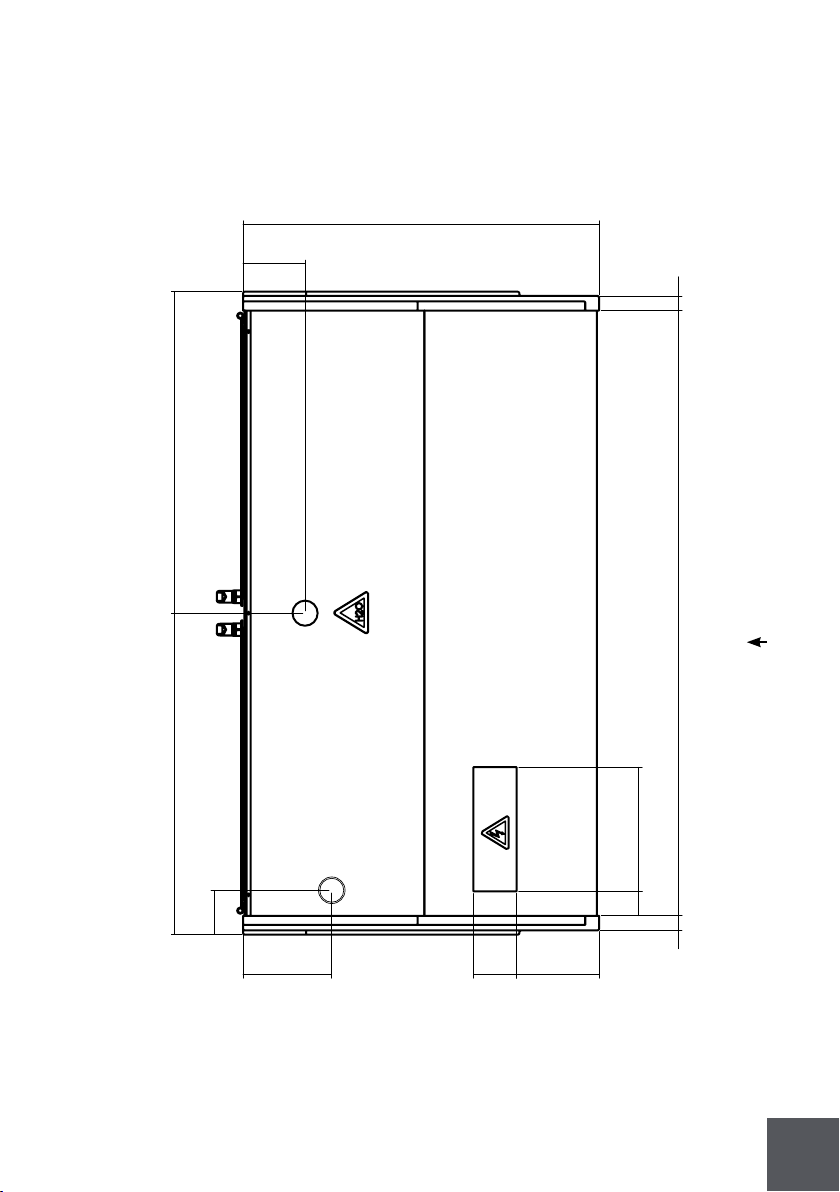

2.6 Warning/Caution labels

Before starting, HYDRA KOOL products have caution and warning labels to be

respected.

Self contained labels

Label 5

Label 3

Label 1

Label 11

Label 12

Label 2

Label 4

Label 6

Remote labels

Label 5

Label 3

Label 4

Label 6

30

Dry labels

Label 5

Label 3

Label 4

Label 6

Page 31

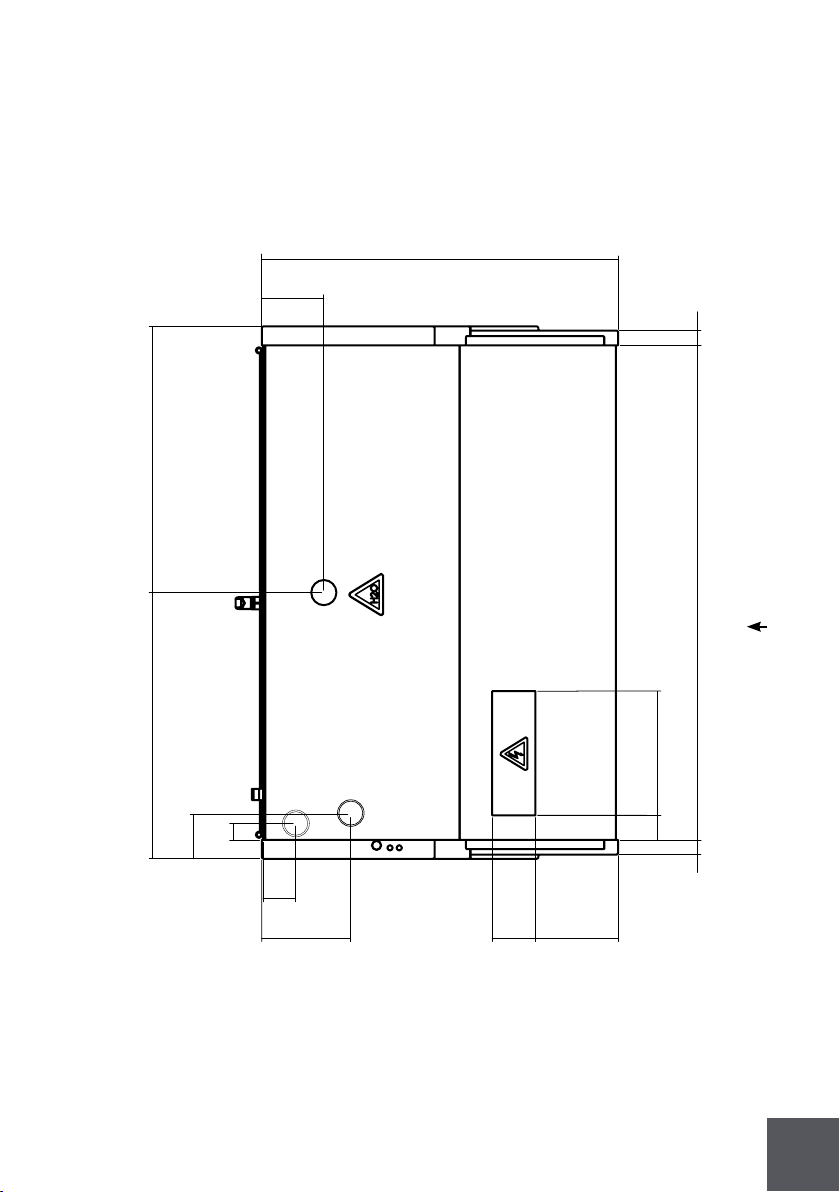

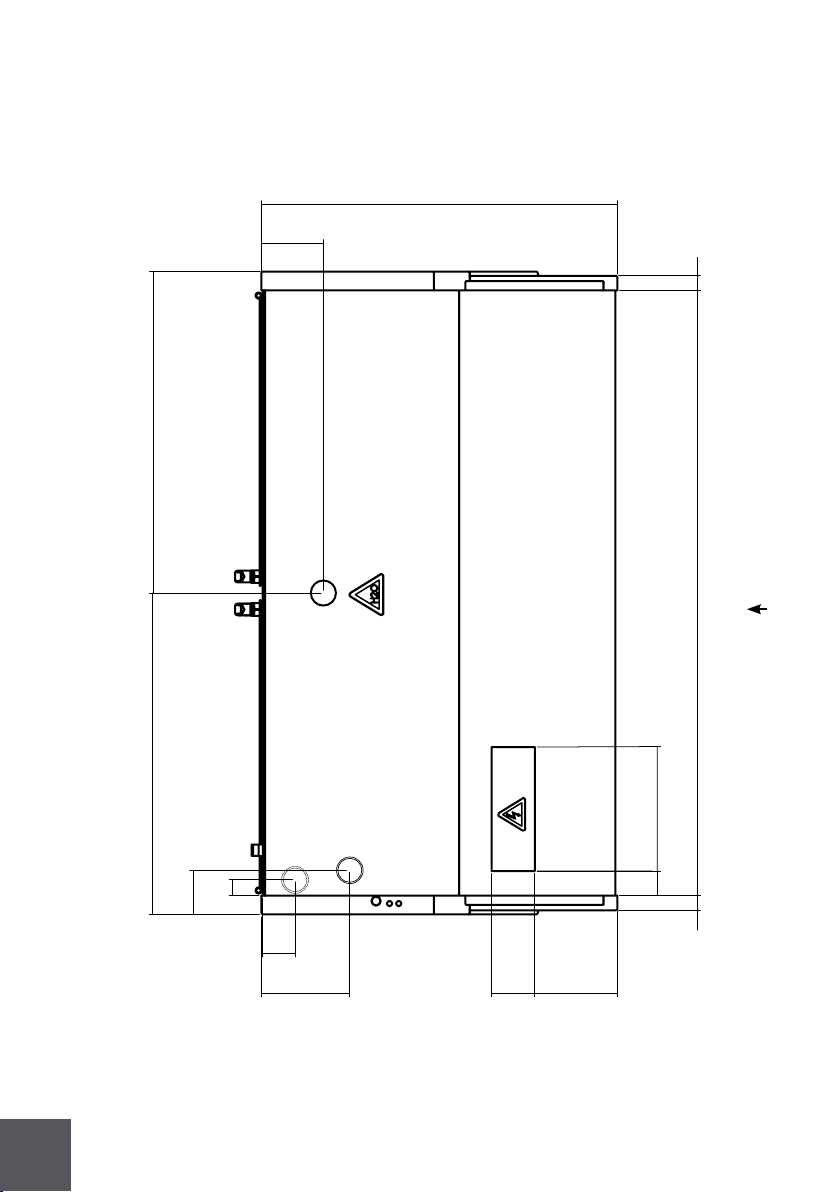

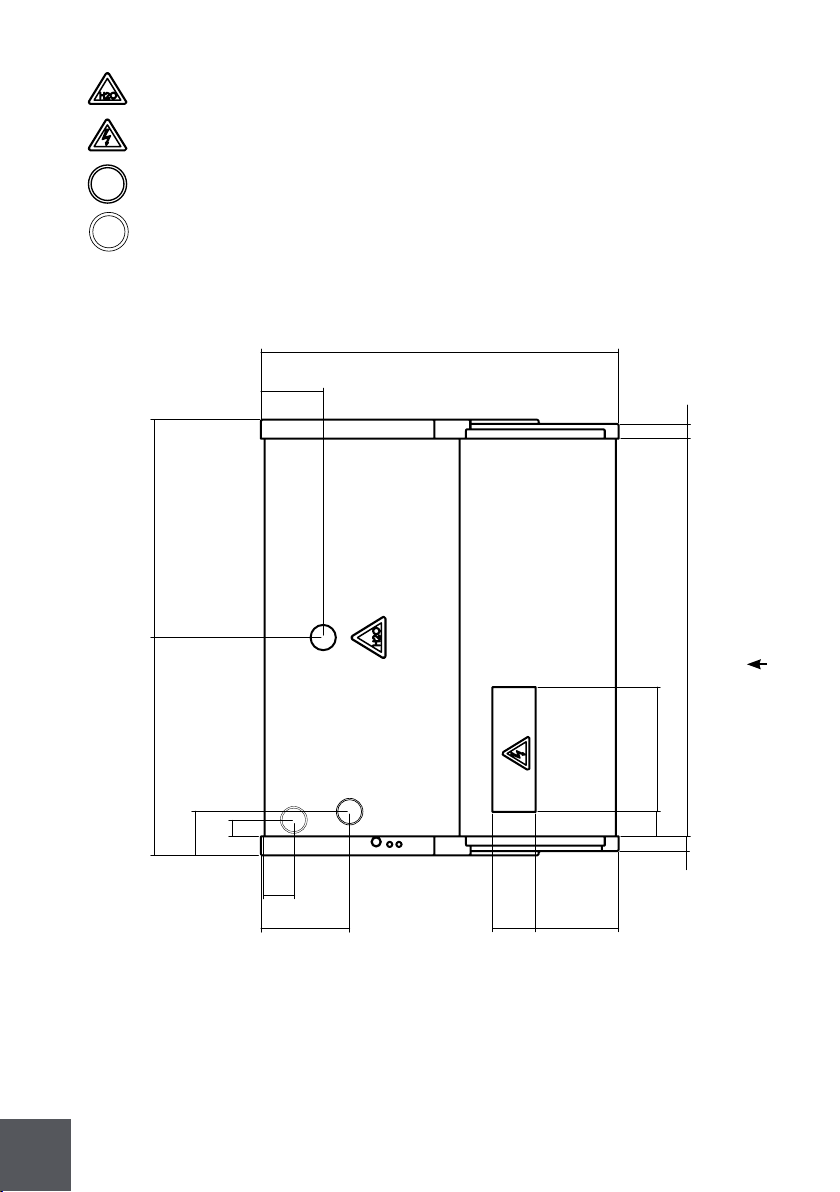

Self contained labels

Label 9

Label 7

Label 8

Label 10

Remote labels

Label 9

Label 7

Label 8

Label 10

Dry labels

Label 9

Label 7

Label 8

Label 10

31

Page 32

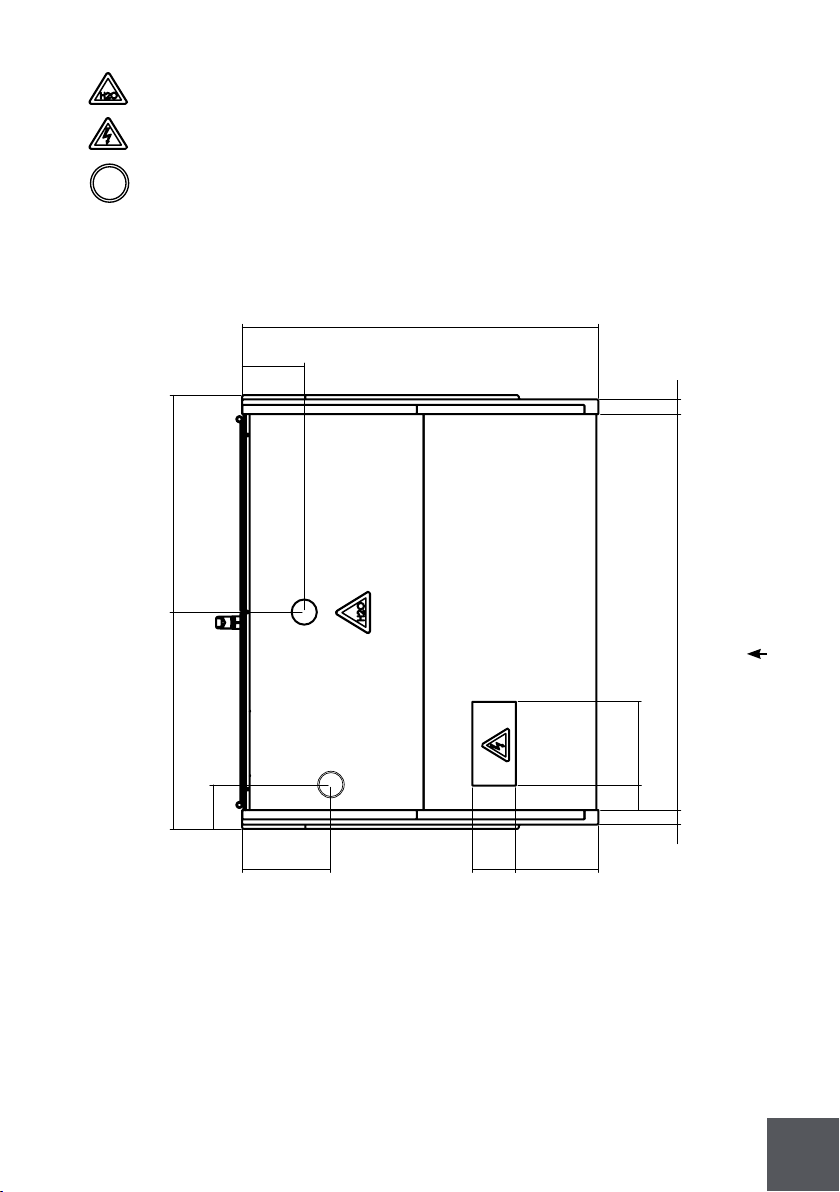

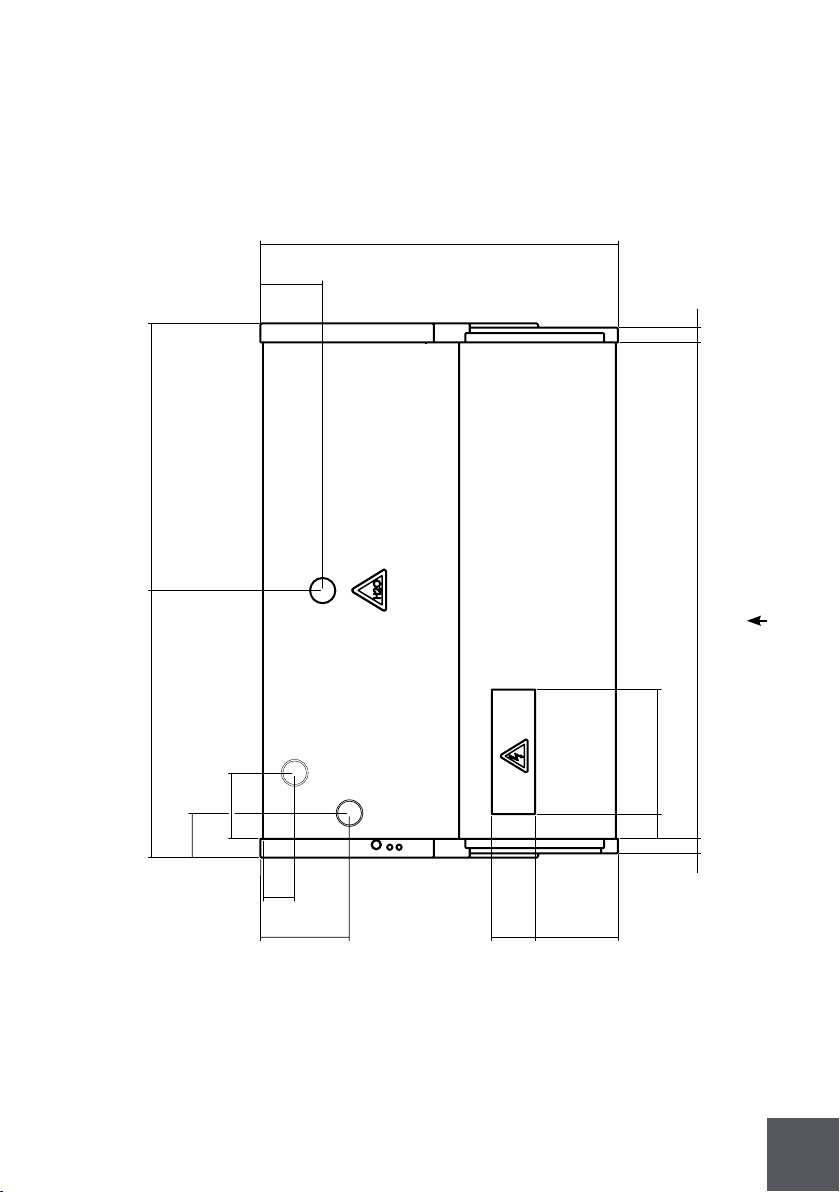

Self contained, Remote and Dry labels (evaporator)

Label 13

Label 14

Label 1

CAUTION

MOVING PARTS.

DO NOT OPERATE UNIT

WITH (PART) REMOVED

Label 3

-NOTE-

THIS A TYPE 1 CASE AND IS

DESIGNED TO OPERATE AT

THE FOLLOWING STORE

CONDITIONS THAT DOES NOT

EXCEED

75 F AND 55% R.H.

Label 2

ATTENTION

PIÈCES MOBILES.

NE FAIRE PAS

FONCTIONNER AVEC

DES PIÈCES ENLEVER

Label 4

-NOTE-

CETTE VITRINE TYPE 1 EST

CONÇUE POUR FONCTIONNER

SELON LES CONDITIONS DU

MAGASIN ET NE DOIT

DÉPASSER

75 F AND 55% R.H.

32

Page 33

Label 5 Label 6

-NOTE-

THIS EQUIPMENT IS INTENDED

FOR THE STORAGE

AND DISPLAY OF PACKAGED

FOOD PRODUCTS ONLY

CET EQUIPEMENT EST PREVU

UNIQUEMENT POUR LE

STOCKAGE ET EXPOSITION DE

PRODUITS ALIMENTAIRES

-NOTE-

EMBALLER

Label 7 Label 8

CAUTION

DISCONNET ALL POWER.

MAY HAVE MORE THEN

ONE DISCONNET SWITCH

IL PEUT AVOIR PLUS D’UN

ATTENTION

DEBRANCHER TOUTE

COURANT.

INTERRUPTEUR

Label 9 Label 10

CAUTION

ATTENTION

RISK OF ELECTRIC SHOK.

DISCONNECT ALL

POWER BEFORE

SERVICING UNIT

Label 11 Label 12

CAUTION

HOT PARTS.

DO NOT OPERATE UNIT

WITH (PART) REMOVED

RISQUE DE CHOC

ELECTRIQUE.

AVANT TOUT TRAVAIL

COUPER LE COURANT

ATTENTION

PIÈCES BRULANTES.

NE FAIRE PAS

FONCTIONNER AVEC LES

PIÈCES ENLEVER

33

Page 34

Label 13 Label 14

CAUTION

HAZARDOUS MOVING PARTS.

DO NOT OPERATE UNIT

WITH DECK PANS

DANGEREUSES. NE FAIRE

PAS FONCTIONNER AVEC

ATTENTION

PIÈCES MOBILES

DES PIÈCES ENLEVER

2.7 Check your electrical installation

This equipment is intended to be connected to an outlet with 115V/ 60Hz/ 1

phase.

Nema-5-15P

2.8 Electrical, drain and refrigeration connections (remotes only)

Installation and service must be performed by a qualified technician.

Prepare a drain installation

All electrical connections must be

done from the electrical board

Equipments for remote installation

come with nitrogen under

pressure and an easy prep kit

(tubing connections needed only)

for installation.

34

Page 35

2.9 Joining

For joining follow the steps described.

35

Page 36

3x - PAR00601013 DIN933 M6x80

2x - PAR00902003 DIN 7380 M5x10

2x - PAR00902007 DIN 7380 M5x502x - PAR00601007 DIN933 M6x20

14x- ANL00501006 DIN9021 M6

5x - PRC00101006 DIN934 M6

2X FIT00000427 A100 04 (91)

2X PRN00101002 DIN916 M6x16

13 10

4x - PAR00801102 DIN912 8.8

4x - ANL00101006 DIN 127-B

2x - BRA09M02000 VA 71

36

1x

1x

1x DIN911 - 3/4

Page 37

2x KPM-CG

KIT0012U02000

37

Page 38

38

Page 39

10

10

G

G

G

2X - FIT00000427 (91 )

G

39

Page 40

DIN911 - 3

DIN911 - 4

10

10

C

F

E

C

+/-0

13

13

C

10

10

D

D

D

E

C

C

C

+/-0

1x - DIN912 8.8 M6x30

1x - DIN127-B

1x - DIN9021 M6

1x - DIN933 M6x80

D

+

-

2x - DIN9021 M6

1x - DIN934 M6

1x - DIN933 M6x20

E

2x - DIN9021 M6

1x - DIN934 M6

40

F

1x - DIN916 M6x16

Page 41

DIN911 - 3

H

I

G

H

I

1x - DIN7380 M5x50

1x - DIN7380 M5x10

1x - DIN912 M4x12

G

41

Page 42

10

10

42

Page 43

2.10 Plugging and start

To start your equipment follow the steps:

1 - Check for page with parameters inside the manual.

2 - After uncrating and placed the equipment respecting all warnings set in 2.1 chapter,

and all switches are set to off position, connect the equipment.

Make sure you have the correct outlet!

Nema-5-15P

3 - Check lights, using button referenced on chapter 2.4. If not working consult the

maintenance chapter.

4 - Turn ON power button referenced in 2.4 chapter.

Noise will be heard when compressor starts! If compressor doesn’t start, call a

technician!

5 - Open the door and check for air movement in the discharge air grille.

43

Page 44

6 - Check air movement in the anti condensation system.

7 - Before loading, leave the equipment working for about 2h.

8 - Load your KPM-Series.

Loading must be done respecting loading limits and weight per square foot

mentioned in page xx. This equipment is intended for maintaining

temperature, be sure the products are cold, and not ambient temperature.

After loading check for any obstruction in the discharge and return air grilles.

44

Page 45

1''

Maintain doors closed after servicing.

9 - If any problem encountered, see troubleshooting or call a qualified technician!

3 Refrigeration

3.1 Self contained refrigeration equipment and defrost

The refrigeration equipment it’s laid out in the base of the equipment.

45

Page 46

Filter

Condenser

Compressor

Fan

Controller

Evap pan

46

Page 47

All self contained KPM series use the following equipment: capillary tube, finned coil

ventilated systems (condenser/evaporator), hermetic compressor, electrical water

evaporation system.

Model

KPM-CG/FG/OF-60-S

KPM-CG/FG/OF-80-S

KPM-CG/FG/OF-100-S

3.2 Refrigeration loads (remotes only)

Installation of remote equipment must be done by a qualified technician.

Model

KPM-CG/SC/FG/SF/OF/SO-60-R

KPM-CG/SC/FG/SF/OF/SO-80-R

KPM-CG/SC/FG/SF/OF/SO-100-R

*values presented are indicative for 14°F evap, and 90°F ambient.

4 Electrical

4.1. Electrical specifications data

Electrical data can be found on the marking plate.

Circuit

pressure

(psig)

High side Low side

331

|

331

|

331

|

174

174

174

|

|

|

2959

3253

4372

Refrigerant

and charge

R 404A 19,40

|

R 404A 25,39

|

R 404A 37,74

|

BTU*/h

TS2

|

TS2

|

TS2

|

(OZ)

Expansion

valve type

Defrost

Automatic 3/day

|

Automatic 3/day

|

Automatic 3/day

|

00

00

00

Standard equipment include led lighting and anti condensation system.

47

Page 48

115V/60Hz/1 phase

Model

KPM-CG/FG-60-S

KPM-CG/FG-80-S

KPM-CG/FG-100-S

KPM-OF-60-S

KPM-OF-80-S

KPM-OF-100-S

The data regards to standard options only.

Model

KPM-CG/FG-60-R

KPM-CG/FG-80-R

KPM-CG/FG-100-R

KPM-OF-60-R

KPM-OF-80-R

KPM-OF-100-R

Compressor

F.L.A./L.R.A.

9,6/49

|

8,9/47

|

16/64

|

9,6/49

|

8,9/47

|

16/64

|

Total amps

(remotes

0,97

|

1,14

|

1,55

|

0,7

|

0,7

|

1,05

|

0,14

|

0,18

|

0,24

|

|

|

|

only)

Lights

EVP CND

|

|

|

|

|

|

Fans

0,70

0,70

1,05

0,70

0,70

1,05

0,45

0,45

0,45

0,45

0,45

0,45

|

|

|

|

|

|

3,33

3,33

3,33

3,33

3,33

3,33

Evap pan

0,13

|

0,26

|

0,26

|

|

|

|

Anti condensation

system

|

|

|

|

|

|

Total amps

(self contained)

14,35

14,52

14,23

14,08

14,08

13,73

48

Page 49

4.2. Electrical service receptacles (optional)

Service receptacles are not intended nor suitable for large motors or other

external appliances. Only for scales and lighted displays.

Receptacle ampacity

Type

GFCI

Max. amps

2

|

49

Page 50

4.3. Electrical diagrams

KPM-CG/FG-80-S

50

Page 51

4

5

6

7

8

9

11

12

13

20

21

22

29

30

36

31

41

1

2

3

Nº

Discription

Compressor

|

Overload

|

Relay

|

Start capacitor

|

Condenser fan

|

Controller

|

Temperature probe

|

Earth two pin plug

|

Terminal block

|

Ground connection

|

Evaporator fan

|

Compressor relay

|

Light switch

|

Pilot light

|

Switch

|

Transformer

|

Led lighting

|

Fan anti-condensation

|

Socket

|

Evaporative condensate pan

|

51

Page 52

KPM-CG/FG-80-R

52

Page 53

Nº

Discription

6

7

9

11

12

20

21

22

29

30

36

39

Controller

|

Temperature probe

|

Terminal block

|

Ground connection

|

Evaporator fan

|

Light switch

|

Pilot light

|

Switch

|

Transformer

|

Led lighting

|

Fan anti-condensation

|

Solenoide valve

|

53

Page 54

KPM-CG/FG-80-D

54

Page 55

9

12

20

21

22

29

30

Nº

Terminal block

|

Evaporator fan

|

Light switch

|

Pilot light

|

Switch

|

Transformer

|

Led lighting

|

Discription

55

Page 56

4.4. Electronic controller

TECHNICAL SPECIFICATIONS

Model Voltage Power

Power supply

Insulation

guaranteed

by the power

supply

Inputs

Probe type

IRxxxxExxxx

IRxxxxAxxxx

IRxxxxHxxxx

IRxxxxLxxxx

IRxxxx0xxxx

IRxxxxExxxx

IRxxxxAxxxx

IRxxxxHxxxx

IRxxxxLxxxx

IRxxxx0xxxx

S1 (probe 1)

S2 (probe 2)

DI 1

S3 (probe 3)

DI 2

S4 (probe 4)

Maximum ditance of probes and digital inputs less than 10 m.

Note: during installation keep the power and loads connection separate from probe cables,

digital inputs, repeater display and supervisory system.

Std. CAREL NTC

NTC high

temperature

PTC std. CAREL

(specic model)

230 V~, 50/60 Hz 3 VA, 25 mA~max.

115V~, 50/60 Hz 3 VA, 50 mA~max.

115 to 230 V~, 50/60 Hz 6 VA, 50 mA~max.

12 to 24V~, 50/60 Hz, 12 to 30 Vdc

12V~, 50/60 Hz, 12 to 18 Vdc

insulation in reference

to very low voltage par ts

insulation from relay outputs

insulation in reference

to very low voltage par ts

insulation from relay outputs

NTC (IRxxx0xxxxx) o NTC e PTC (IRxxx7xxxxx)

NTC (IRxxx0xxxxx) o NTC e PTC (IRxxx7xxxxx)

free contact, contact resistance < 10 Ω, closing current 6 mA

NTC (IRxxx0xxxxx) o NTC e PTC (IRxxx7xxxxx)

free contact, contact resistance < 10 Ω, closing current 6 mA

NTC (IRxxx0xxxxx) o NTC e PTC (IRxxx7xxxxx)

Carel - IR33F0AHE0

3 VA, 300 mA~/mAdc max.

Use only SELV power supply

reinforced

6mm clearance, 8 mm creepage

3750 V insulation

basic

3mm clearance, 4 mm creepage

1250V insulation

externally guaranteed by safety

transformer (SELV power supply)

reinforced

6mm clearance, 8 mm creepage

3750 V insulation

10 kΩ at 25 ºC , - 50T90 ºC range

measurement error:

50 kΩ at 25 ºC, - 40T150 ºC range

measurement error:

985 Ω a 25 ºC , range da - 50T150 ºC

measurement error:

1 ºC in the - 50T50 ºC range

3 ºC in the - 50T90 ºC range

1,5 ºC in the - 20T115 ºC range

4 ºC in the - 20T115 ºC range

2 ºC in the - 50T50 ºC range

4 ºC in the - 50T150 ºC range

56

Page 57

Relay outputs

SSR outputs

(*): Relay not suitable for uorescent loads (neon lights, ...) that use starters (ballasts) with phase-shift

capacitors. Fluorescent lamps with electronic control devices or without phase-shift capacitors can be used,

within the operating limits specied for each type of relay.

Connessioni

the installer has to provide the correct dimensioning of the power supply and cable connection between the

instruments and the loads. Depending on the model, the maximum current in the common terminals 1, 3 or 5 is

12 A. When using the controller at maximum operating temperature and full load, use cables featuring a

maximum operating temperature of 105 ºC at least.

depending on the model

model

IRxxxx(E,A)

(P,Q,S,U,V,X,Y,Z)xxx

IRxxxx(E,A)

(N,R,C,B,A,M,L,T)xxx

IRxxxx(E,A)

(N,R,C,B,A,M,L,T)xxx

IRxxxx(O,L,H)

(N,R,C,B,A,M,L,T)xxx

IRxxxx(E,A)

(P,Q,S,U,V,X,Y,Z)xxx

IRxxxx(O,L,H)

(N,R,C,B,A,M,L,T)xxx

insulation between the relay outputs indipendent

Max output voltage : 12 Vdc, Output resistance: 600 Ω, Max output current: 20 mA

Model Relay P. Supply Probes for wires from 12 A

IRxxxxxx0xx screw screw screw 0.5 a 2.5 mm²

IRxxxx(E,A)x1xx faston faston removable

IRxxxxxx2xx removable removable removable

IRxxxx(E,A)x3xx faston faston screw

IRxxxx(E,A)x5xx vertical screw vertical screw vertical screw

relay

R2 (*)

R3 (*)

R1,R2

R2,R3

R4 (*)

R1

R1 (*)

EN 60730 -1 UL 873

250 V~ 250 V~

5(1)A 5 A resistive 1FLA

5(1)A

8 (4)A N.O.

6 (4)A N.C. 12 LR A

2 (2)A N.O./N.C. C300

12 (2)A N.O./N.C.

Type of connection

operating operating

cycles cycles

100000 300000

100000 300000

100000 300000

100000 300000

reinforced

6 mm clearance, 8 mm creepageinsulation from very low voltage parts

3750 V insulation

basic

3 mm clearance, 4 mm creepage

1250 V insulation

6 LRA C 300

5 A resistive 1FLA

6 LRA C 300

8 A resistive 2FLA

12 A resistive 5FL A

30 LRA C300

Cross-section Max. current

Controller must be handled by a qualified technician.

57

Page 58

Signals on the display

The blinking status indicates a request for activatuin that cannot be implemented until the end of

the corresponding delay times.

AUX

sent

HACCP

Function

COMPRESS.

FAN

DEFROST

AUX

CLOCK

LIGHT

SERVICE

HACCP

CONTINUOUS

CYCLE

ONIcon OFF blink Startup

compressor ON comp. OFF compressor request

fan ON fan OFF fan request

defrost in progress

auxiliary output

AUX acti v e AUX not active

delayed externalALARM

alarm (before the

expiry of the time

“A7“)

at least one timed

defrost has been

set

auxiliary output auxiliary output

LIGHT ACTIVE LIGHT NOT ACTIVE

enabled

defrost not required defrost request

auxiliary output anti-sweat heater function active

no alarm present

no timed defrost is ON if Real-Timeclock alarm

present Clock present

no malfunction

HACCP functi o n HACCP alarm ( HA a n d/o r HF)HACCP functi o n

enabled

not enabled request

alarms in normal operation (eg.

high/low temp.) or alarm from

ext. digital input immediate or

delayed

anti-sweat heater function active

malfunction (eg. EEPROM error

or probe fault)

not enabled

Controller must be handled by a qualified technician.

Buttons on the keypad

Button Press. the button alone Pressing together with other buttons

· if pressed for more than

5 s accessed the menu

for setting type “F”

Prg

(frequent) parameters

· in the event of alarm:

mute

silences the audible · if pressed for more than 5 s together

alarm (buzzer) and with the UP/AUX button resets any

disables the alarm relay alarm with manual reset

if pressed for more than

1 s, enables/disables

the auxiliary output

aux

if pressed for more than

def

5 s, enables/disables a

manual defrost

if pressed for more than

1 s, displays and/or set

the set point

Set

Normal operation

· if pressed for more than 5 s together

with the SET button, accesses the

menu for setting the type “C“

(configuration) or downloading the

parameters

· if pressed for more than 5 s together with DOWN/DEF button, enables/disables

the continuous cycle operation

· if pressed for more than 5 s with SET button, starts the procedure for printing

the repor ts (function available, with management to be implemented)

· if pressed for more than 5 s together with PRG/MUTE button, resets any

active alarm with manual reset

· if pressed for more than 5 s together with UP/AUX button, enables/disables

the continuous cycle operation

· if pressed for more than 1 s together with SET button, displays a submenu

with the HACCP alarm parameters (HA, HAn, HF, HFn)

· if pressed for more than 5 s together with PRG/MUTE button, accesses the

menu for setting the type “C“ parameters “C“ (configuration) or downloading

the parameters

· if pressed for more than 1 s together with DOWN/DEF button, displays a

submenu with the HACCP alarm parameters (HA, HAn, HF, HFn)

· if pressed for more than 5 s together with UP/AUX , starts the procedure for

printing the report (function available, with management to be implemented)

Star t-up : if Automatic address

pressed for assignment:

more than if pressed for 1 s enters

5 s at start-up, the automatic serial

start s the address assigning

default procedure

parameter

setting

58

Page 59

Main parameters

Symbol Code Parameter Models UOM Type Min Max Def.

/3 Probe display response MSYF

/5

Select ºC or ºF

0: ºC

1: ºF

/A2

Conguration of probe 2 (S2)

0: Probe absent

1: Product probe (display only)

2: Defrost probe

3: Condenser probe

4: Antifreeze probe

/c1

Calibration of probe 1

Temperature set point

St

Control delta

rd

Minimum compressor OFF time

c2

Interval between defrosts

dl

Maximum defrost duration, evaporator

dP1

MSYF

YF

MS

MSYF

MSYF

SYF

SYF

SYF

SYF

-

ag

-

-

ºC/ºF

ºC/ºF

ºC/ºF

min

hours

min

C

0

15

C

0

1

C

0

C

C

-20

F

F

0,1

C

F

F

4

0

4

20

rl

r2

20

0

15

0

250

1

250

5 Maintenance

5.1 Exterior cleaning

All operations must be done with the unit disconnected.

Clean surfaces (glass/metal/plastic) with soft detergents or warm water. Do not use

abrasive cleanser.

0

0

2

2

0,0

0,0

2,0

0

8

30

59

Page 60

For easier cleaning remove the front glass (instructions below).

5.2 Interior cleaning

All operations must be done with the unit disconnected.

Clean surfaces (glass/metal/plastic) with soft detergent or warm water. Do not use

abrasive cleanser.

5.3 Shelf removing

All operations must be done with the unit disconnected.

To remove or adjust shelves take care with light connections.

60

Page 61

1

3

5.4. Back Sliding doors removal

2

Back sliding doors are easy to take off.

- Grab door push up and then tilt the bottom towards you.

To put the door back on, just reverse the previous step.

61

Page 62

5.5 Light substitution

To replace lights follow the steps:

All operations must be done with the unit disconnected.

- Disconnect the light

- Unscrew the light holder and remove the light

- Insert a new light in the same place of the old one, screw the holder connect it

- Screw the light and connect it

- Plug and turn on the light

1

62

2

Page 63

5.6 Panels and protection grille removal

5.7 Condenser cleaning

This operation must be performed by a qualified technician.

All operations must be done with the unit disconnected.

Condenser must be regularly cleaned (every month). Use a brush or vacuum it.

To get to the condenser must remove frontal panel.

63

Page 64

5.8 Evaporator cleaning

This operation must be performed by a qualified technician.

All operations must be done with the unit disconnected.

To access the evaporator:

- Open your unit

- Lift and remove exposition panels

- Use tool for the screws and clean

1

3 4

2

5.9 Evap Pan cleaning

This operation must be performed by a qualified technician.

All operations must be done with the unit disconnected.

Pan can be hot!

This operation must be done weekly.

64

Page 65

To access the evap pan:

- Remove protection grille.

- Unplug the evap pan.

- Relieve the screws and take the evap pan off.

- Clean with soft detergent or warm water.

5.11 Drain inspection

Check for drain obstruction and correct position every month (Remotes only).

5.12 Glass type conversion model

This operation must be performed by a qualified technician.

Contact distributor for specific manual to assist in conversion.

65

Page 66

6 Troubleshooting/Service

6.1 Troubleshooting

Service must be performed by a qualified technician.

Doors not closing:

Check for leveled floor.

Check for obstruction.

Remove doors and check the bearings.

Lights not working:

Check light switch position.

Check light connections.

Warm case temperature:

Check for air return grille obstruction.

Check for air drafts.

Check store temperature.

Check for condenser obstruction and cleaning.

Check for frozen evaporator.

Check set point.

Display area is over filled.

Fans not working:

Check electrical connections.

Check for any debris.

Case not aligning:

Check for leveled floor.

Check instructions for joining.

Display not working:

Check main power switch position..

Check electrical connections.

Compressor not starting:

Disconnect switch open.

Blown fuse.

Overload protective tripped.

Low charge of refrigerant.

Relay defective.

66

Page 67

Equipment runs constantly:

Condenser dirty.

Condenser fan malfunction.

Temperature and relative humidity too high.

Starting relay burns out:

Low voltage.

High voltage.

Compressor short cycles.

Incorrect running capacitor.

Incorrect relay.

Head pressure too high:

Unit overcharged.

Air or other non condensable gases in the system.

Clogged condenser.

Defective condenser fan motor.

Unit location too hot.

Restriction in charge line.

Head pressure too low:

Insufficient refrigerant charge.

Leak in the system.

Cold location.

Noisy unit:

Compressor oil charge low.

Fan blade causing vibrations.

Tube rattle.

Loose parts.

Case not leveled.

6.2 Service

This operation must be performed by a qualified technician.

For spare parts, contact your distributor.

67

Page 68

Service by

Service by

Type of

action

Date

Serial

number and

model

68

Page 69

7 Warranty

12 month warranty for all parts from the invoice date. A new part will be provided free

of charge. Defective part must be returned to the manufacturer.

Warranty claims: All claims must include model number, serial number, date of

purchase, date of installation and additional information about the supposed defect.

All service work must be authorized by MVP group.

MVP group reserves the right to select the service company.

Loss of food or other damages caused by faulty equipment aren’t covered by this

warranty.

Warranty does not cover damage when uncrating.

Work made necessary, by lack of maintenance or cleaning are not covered by this

warranty.

Warranty does not cover damage or malfunction result of improper use or installation.

Warranty does not cover negligence, misuse and operation on wrong voltage.

Warranty does not apply if the serial number is altered or defaced.

Failure to comply with the instructions in this manual shall avoid warranty.

69

Page 70

8 Notes

70

Page 71

This page has been left blank intentionally.

71

Page 72

MVP GROUP CORPORATION

www.mvpgroupcorp.com

Loading...

Loading...