Hydra-Kool KBD-CG Owner’s Manual

DOE

Compliant

KBD SERIES - INSTALLATION AND OPERATION MANUAL - V0

MVP GROUP CORPORATION

5659 Royalmount Ave.

Montreal, QC, Canada

Telephone: (514) 737-9701

Toll Free Telephone: (888) 275-4538

Toll Free Fax: (877) 453-8832

Email: sales@mvpgroupcorp.com

Website: www.mvpgroupcorp.com

H4P 2P9

Fax: (514) 342-3854

2

1 General information 5

1.1 Case description 5

2 Getting started with your KBD series 18

2.1 Location 18

2.2 Uncrating 19

2.3 Check for damage 19

2.4 Control panel and main features 20

2.5 Check serial, model numbers and requested options 21

2.6 Warning/Caution labels 22

2.7 Check your electrical installation 26

2.8 Electrical, drain and refrigeration connections (remote only) 26

2.9 Joining 27

2.10 Plugging and start 35

3 Refrigeration 36

3.1 Self contained refrigeration equipment and defrost 36

3.2 Refrigeration loads (remotes only) 38

4 Electrical 38

INDEX

4.1. Electrical specifications data 38

4.2. Electrical service receptacles (optional) 39

4.3. Electrical diagrams 40

4.4. Electronic controller 48

5 Maintenance 51

5.1 Cleaning 51

5.2 Shelf removing/adjustment 52

5.3 Sliding doors removal 53

5.4 Light substitution 53

5.5 Panels and protection grille removal 54

5.6 Condenser cleaning 55

5.7 Evaporator cleaning 56

5.8 Evap Pan cleaning 57

5.9 Drain inspection 58

6 Troubleshooting/Service 58

6.1 Troubleshooting 58

6.2 Service 60

7 Warranty 62

8 Notes 63

Annex-A Dry KBD-Series 64

3

This page has been left blank intentionally.

4

1 General information

1.1 Case description

KBD series model (number) system.

KBD CG 40 S

AAA BB CC D

AAA

Basic model

BB

Model variation

|

CG-Curved Glass

|

FG-Front Glass

|

|

|

|

|

|

CC

Length

40''

50''

60''

D

Type of Unit.

|

S-Self Contained

|

R-Remote

|

D-Dry

|

5

KBD SERIES

35''

15''

12''

18''

54''

23''

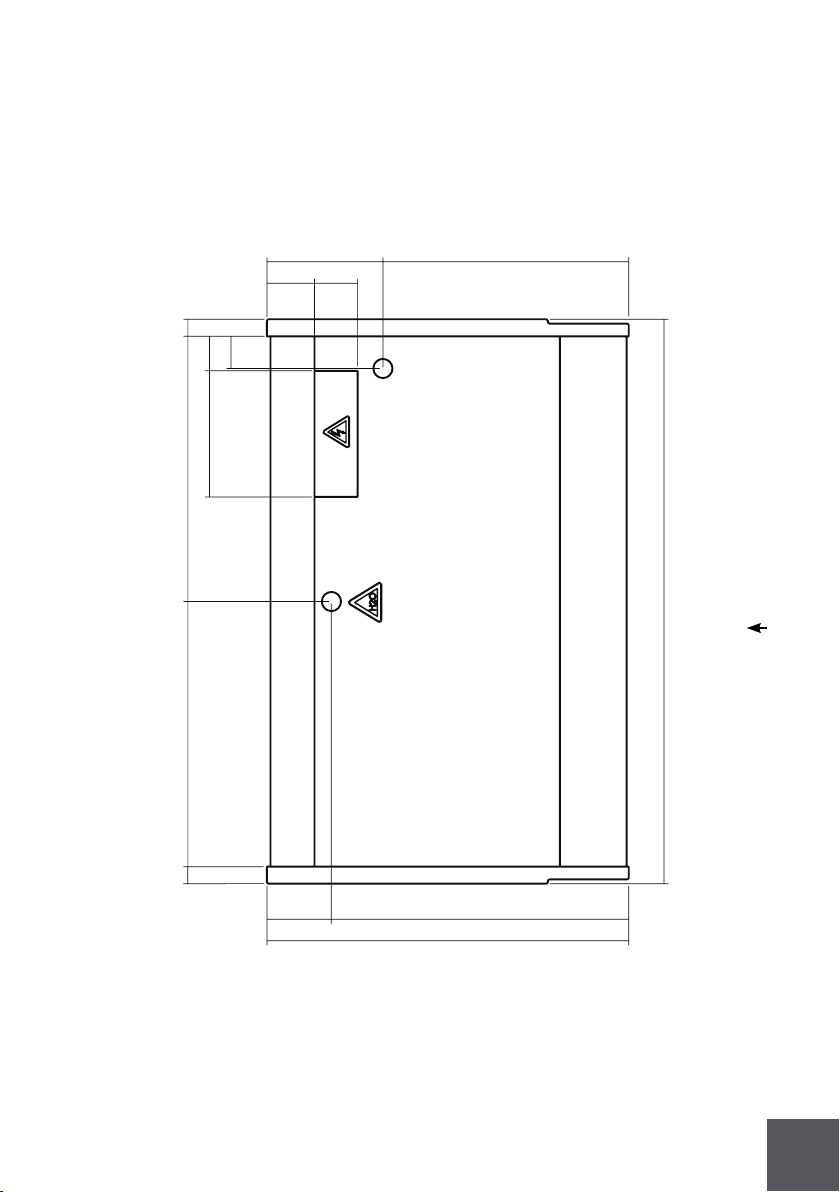

KBD-CG-XX-S(R)(D)

7''8''8''

8''

23''

39''

KBD-CG-40-S(R)(D)

6

51''

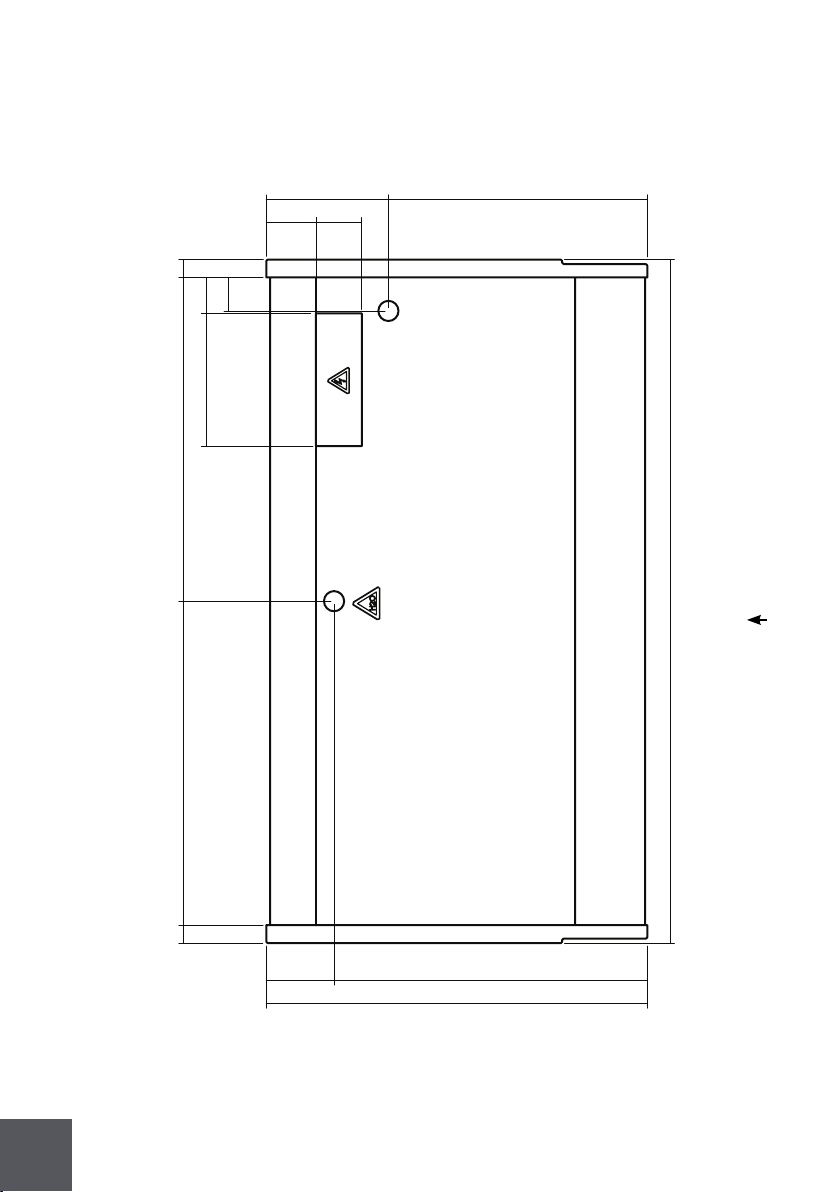

KBD-CG-50-S(R)(D)

59''

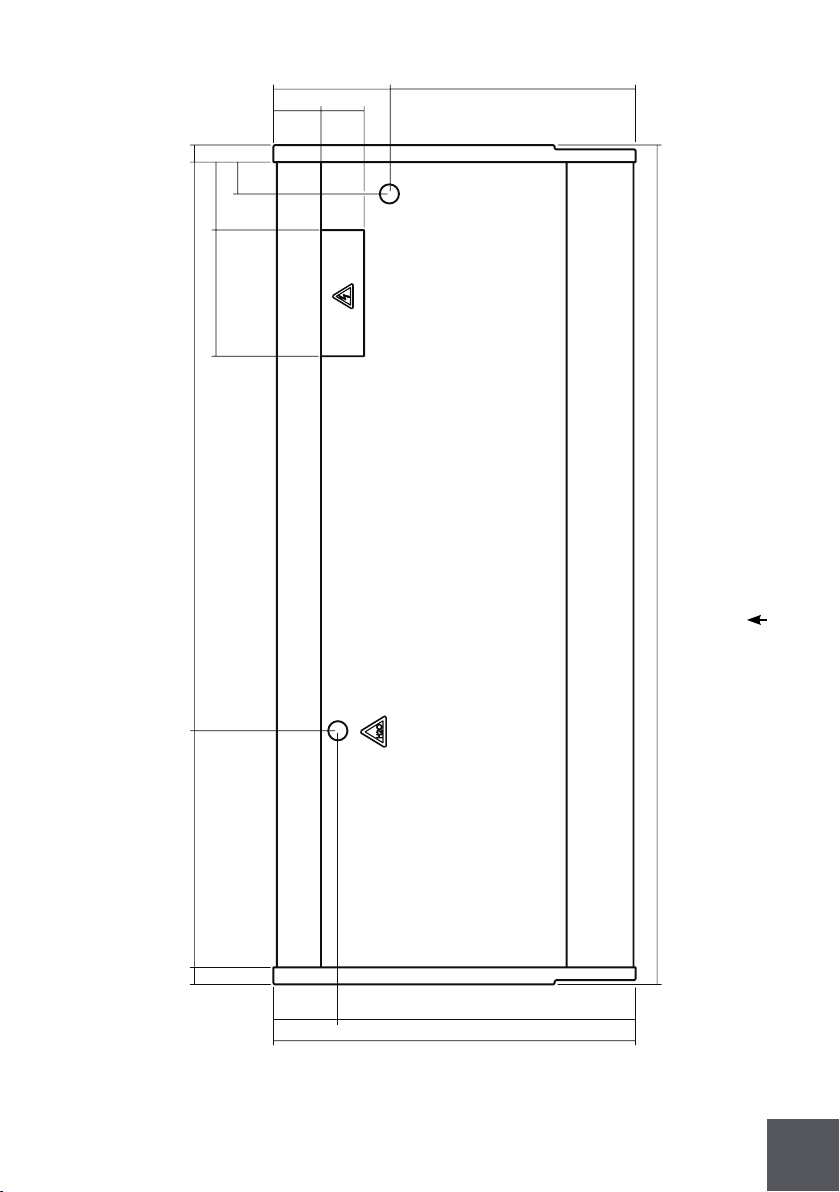

KBD-CG-60-S(R)(D)

78''

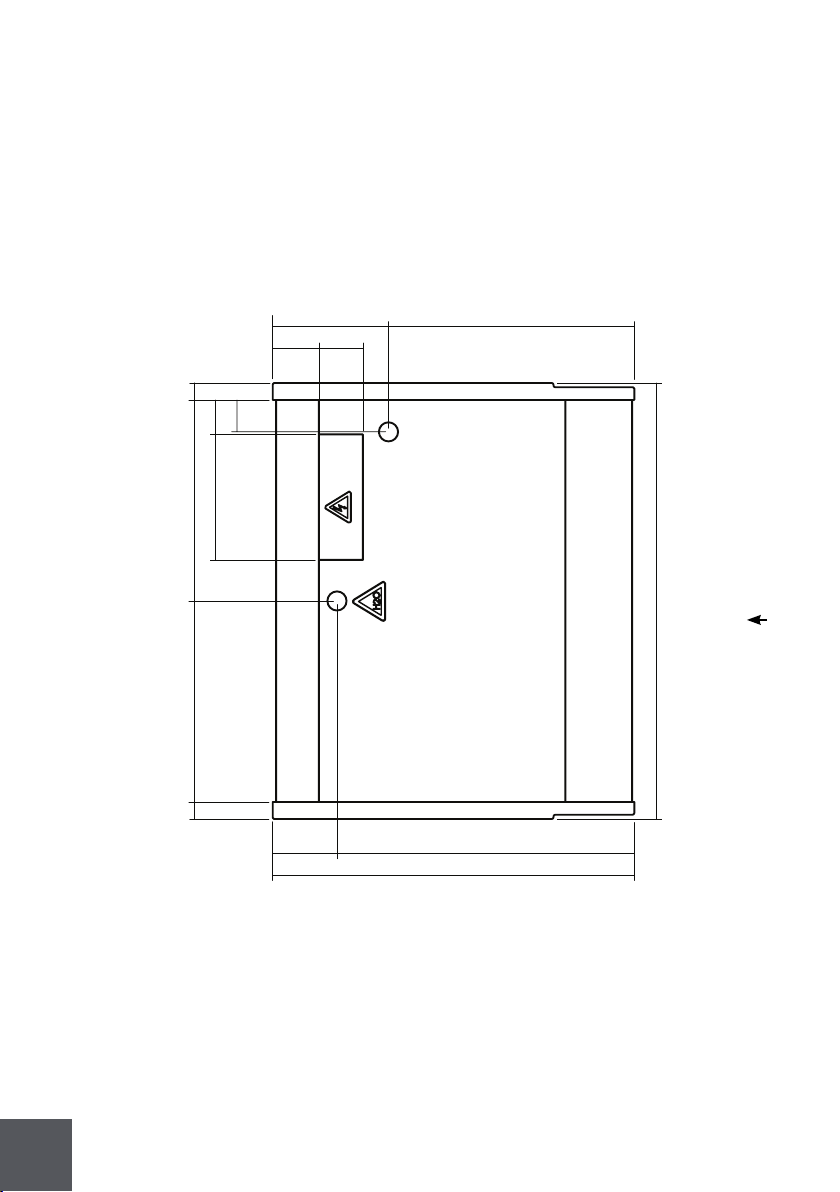

KBD-CG-80-S(R)(D)

7

20''

35''

18''

54''

23''

KBD-FG-XX-S(R)(D)

7''8''8''

8''

23''

39''

KBD-FG-40-S(R)(D)

8

51''

KBD-FG-50-S(R)(D)

59''

KBD-FG-60-S(R)(D)

78''

KBD-FG-80-S(R)(D)

9

Implantation

Drain outlet

Switchboard

Upper output

28''

23''

41''

Front11Front

11''

5'' 4''

2''

3''

4''12''

19''

19''2''

6''

34''

10

KBD-CG/FG-40-S(D)

11''

4''5''

2''

3''

12'' 4''

25''

23''

53''

2'' 25''

6'' 28''

34''

KBD-CG/FG-50-S(D)

11''

4''5''

2''

3''

12'' 4''

29''

23''

61''

29''

2''

6'' 28''

34''

Front

KBD-CG/FG-60-S(D)

12

11''

4''5''

2''

3''

12'' 7''

53''

23''

78''

Front

2'' 22''

6'' 28''

34''

KBD-CG/FG-80-S(D)

13

11'' 23''

5'' 4''

3''

4''12''

19''

41''

19''2'' 2''

6''

28''

34''

Front

KBD-CG/FG-40-R(D)

14

11''

5''5''

2''2'' 25''

3''

12'' 4''

25''

23''

6'' 28''

34''

KBD-CG/FG-50-R(D)

53''

Front

15

11''

4''5''

2''

3''

12'' 4''

29''

23''

61''

Front

29''

2''

6'' 28''

34''

KBD-CG/FG-60-R(D)

16

11''

5''5''

2''

3''

12'' 4''

53''

23''

78''

Front

2'' 22''

6'' 28''

34''

KBD-CG/FG-80-R(D)

17

KBD series intended for pastry and bakery are type 1 equipment - 75°F/55%RH.

Temperature of pastry and bakery cases is set for 39°F.

All glass shelves of the KBD series have a 5,5 lb/ft loading limit.

Model

KBD-CG/FG-40-S(R)(D)

KBD-CG/FG-50-S(R)(D)

KBD-CG/FG-60-S(R)(D)

KBD-CG/FG-80-S(R)(D)

2 Getting started with your KBD series

2.1 Location

To your new equipment perform well, please respect the following warnings:

This is type 1 equipment, intended to work with 75°F / 55%RH.

This equipment is intended for maintaining temperature only.

Be sure products are not ambient temperature (must be cold).

This equipment must be located in an indoor environment.

Check for airdrafts and avoid them.

Air movement from ac units shouldn’t be directed to the equipment.

The equipment must not be directly or indirectly exposed to the sun.

Check for rejected heat from another refrigeration units and avoid that.

Place the equipment in a levelled floor.

Do not obstruct the air way in front of the condenser.

Make sure there is a drain preparation (remotes only).

After servicing always close the doors.

This equipment should be handled by a qualified technician.

Dimensions

(LxDxH in inches)

393''x331''x53''

|

511''x331''x53''

|

59''x331''x53''

|

783''x331''x53''

|

Service dimensions

(LxDxH in inches)

393''x461''(551'')x53''

|

511''x461''(551'')x53''

|

59''x461''(551'')x53''

|

783''x461''(551'')x53''

|

Volume (ft)

13,3/15,6

|

17,5/20,5

|

20,3/23,8

|

26,6/31,1

|

18

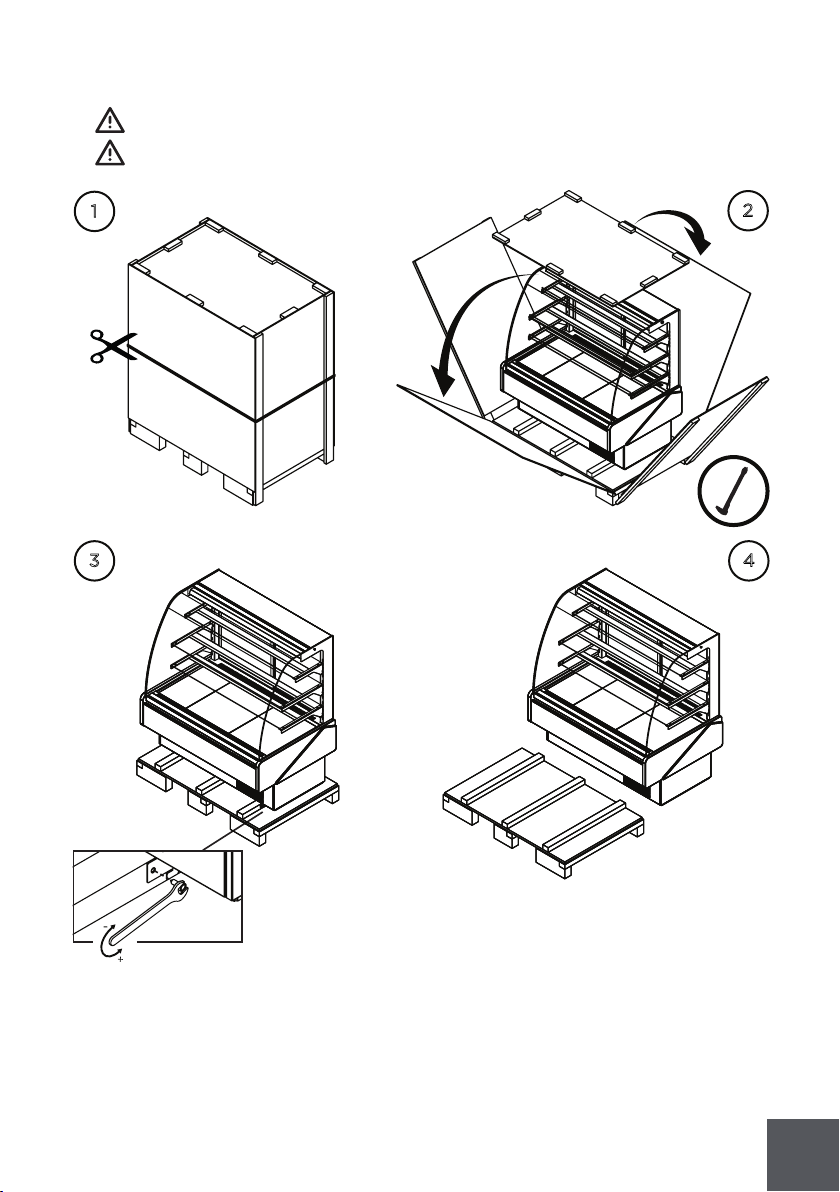

2.2 Uncrating

All operations must be done carefully.

All plastic protective films must be removed before using the equipment for

the first time.

1

3

2

4

2.3 Check for damage

At the end of production HYDRA KOOL products are carefully inspected. No damaged

units are sent out. HYDRA KOOL doesn’t take responsibility for damage between factory and client.

19

Possible damage on the unit must be checked to file a claim near the transportation

company.

The unit must be checked in the following points:

Exterior panels

Doors

Shelves

Glasses

Paint job

Door handles

Base structure

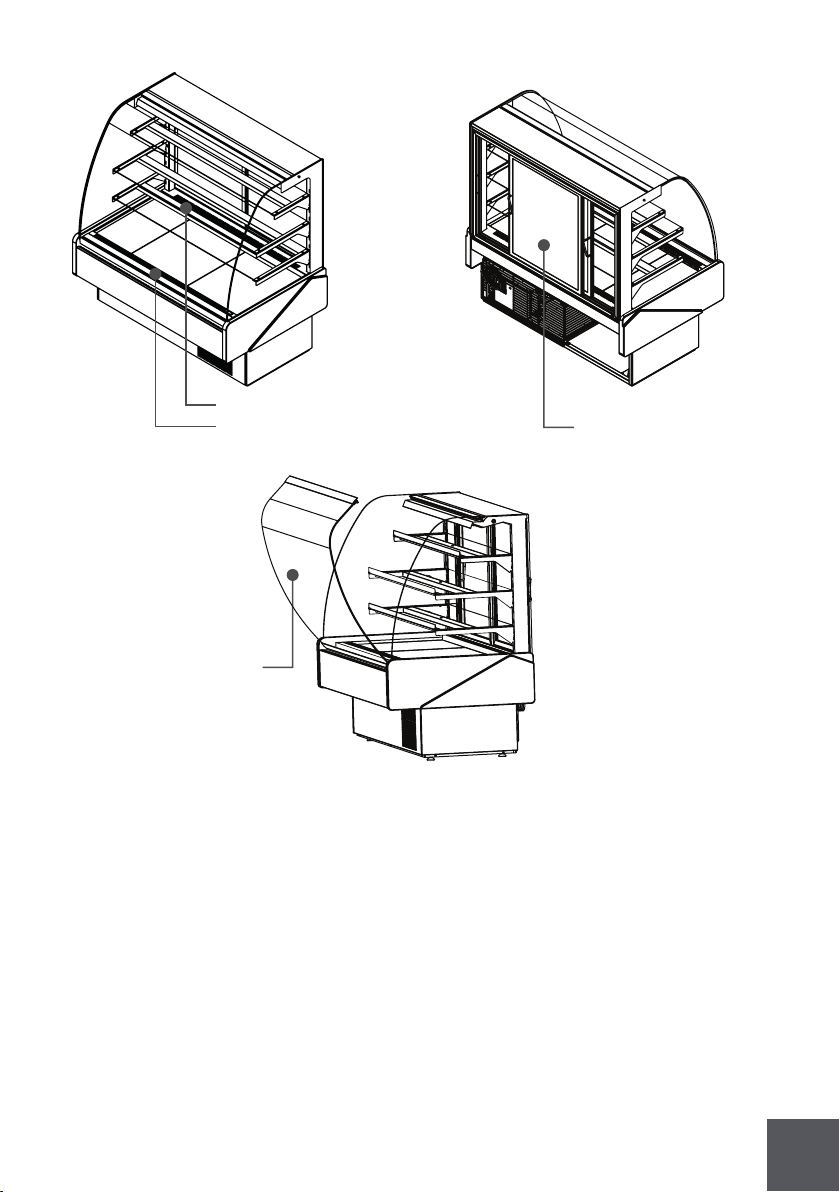

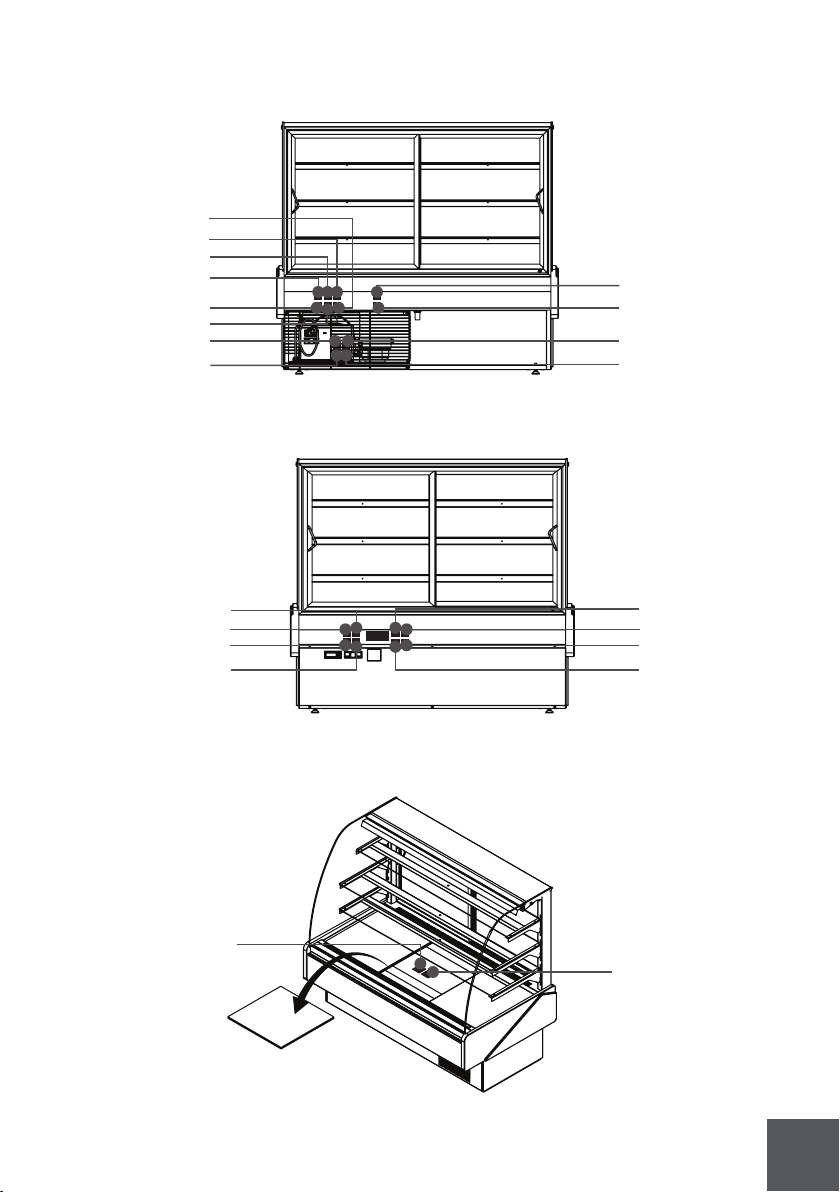

2.4 Control panel and main features

The pictures under, shows the main features and all necessary controls.

Electronic controller

Light switch

Power signal

Power switch

Electrical board

Hot key connector

Evap pan outlet

Self contained control panel

20

Electronic controller

Light switch

Power signal

Power switch

Remote control panel

Discharge air grille

Return air grille

Tilt down front glass

Sliding doors

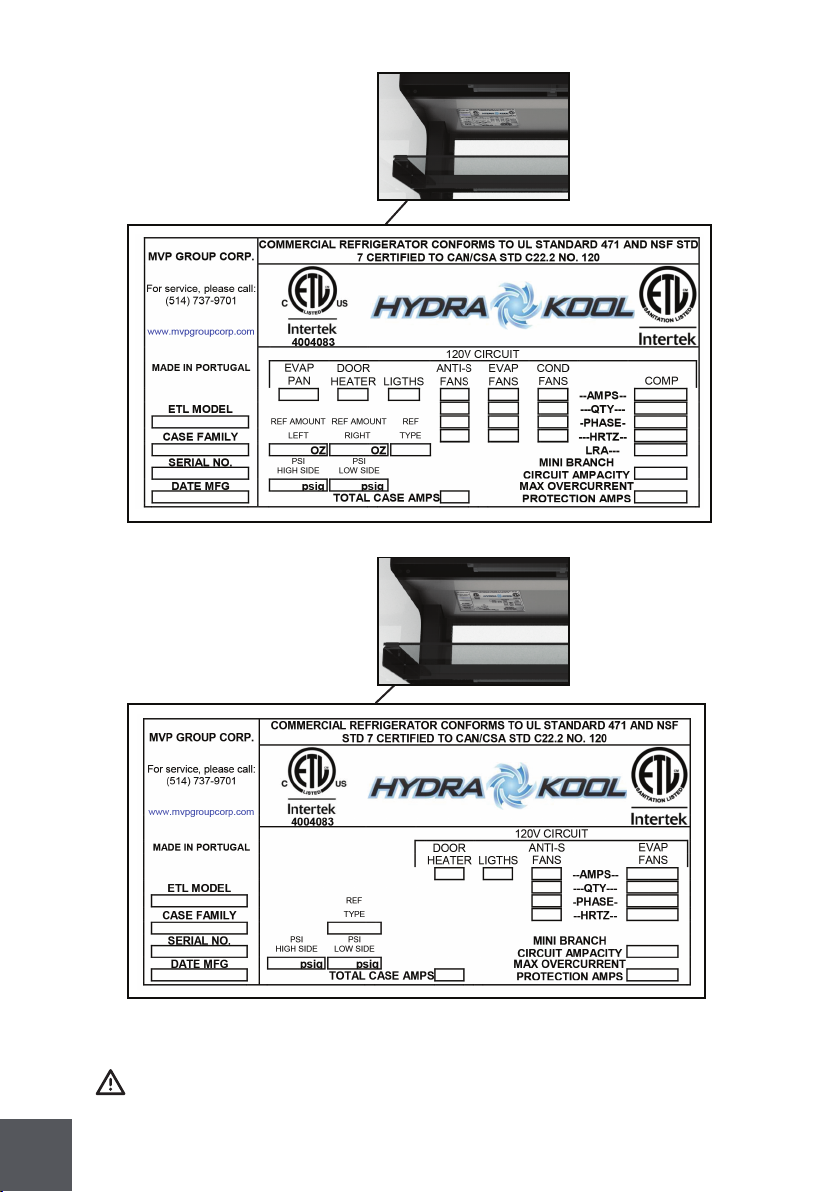

2.5 Check serial, model numbers and requested options

Before start your equipment, check the serial number, model numbers and requested

options. This inspection should be made visually in the following items:

21

Self contained numbers

Remote name plate

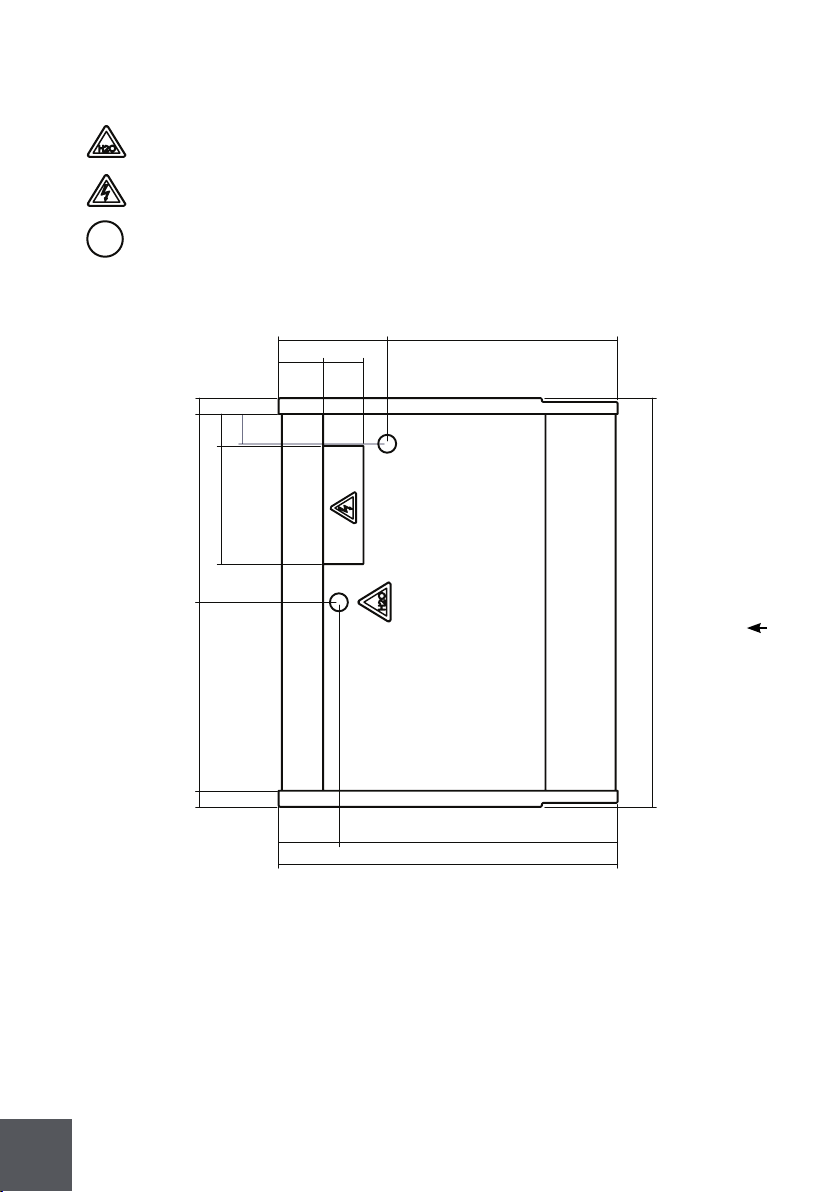

2.6 Warning/Caution labels

Before starting, HYDRA KOOL products have caution and warning labels to be

respected.

22

Self contained labels

Label 1

Label 2

Label 3

Label 4

Label 5

Label 6

Label 7

Label 8

Remote labels

Label 9

Label 10

Label 11

Label 12

Label 11

Label 2

Label 8

Label 12

Self contained and remote labels (evaporator)

Label 13

Label 4

Label 3

Label 6

Label 5

Label 14

23

Loading...

Loading...