Hydrajaws 2008 Operating Instructions Manual

Operating Instructions

HYDR A J AWS

LIMITED

2008 Model Tester

Hole 26mm

diameter

3

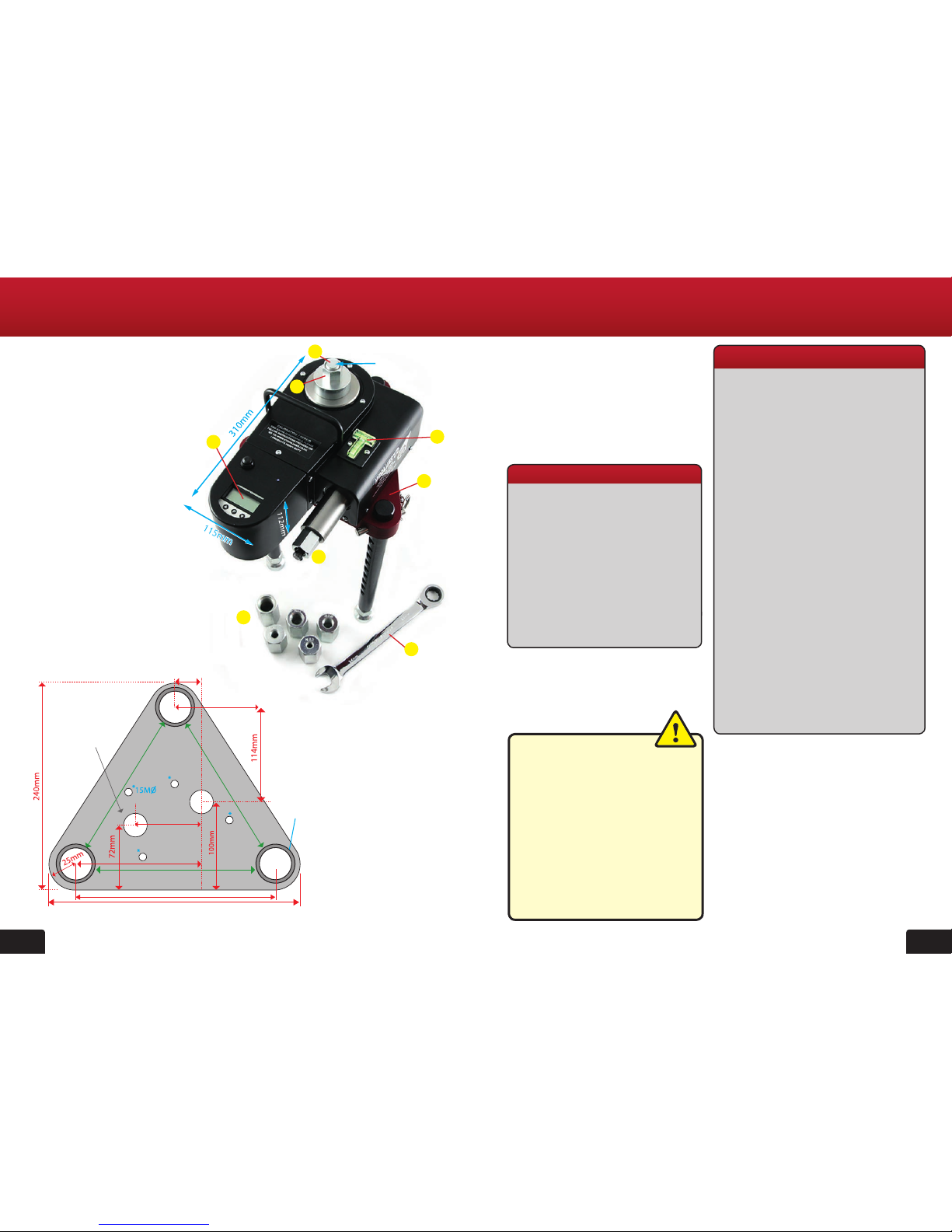

Model 2008 Tester Parts

1. Operating Nut

2. Digital Gauge

3. Load Spreading Bridge

4. M20 Connecting Rod

5. M20 Adjustable Nut

6. 22mm Ratchet Spanner

7. Threaded Adaptors M12-M30

8. Spirit Level

Model 2008 Bridge Footprint

2

SAFETY RULES

• Modication of the tester, or tampering

with it’s parts is not permissible.

• Observe the information printed in the

operating instructions applicable to

operation care and maintenance.

• The tester and its accessories may

present hazards when used incorrectly

by untrained personnel or not as

directed.

• Use only the genuine Hydrajaws

accessories or ancillary equipment

listed in the operating instructions.

The Hydrajaws model 2008

Heavy Duty Tester is designed

for establishing linear loading of

mechanical and resin anchors, eye

type anchors, threaded bar, re-bar

and structural bolts and xings to a

maximum load of 145kN.

USE OF THE TESTER AS DIRECTED

The tester is intended for use by skilled

personnel with the appropriate training

and knowledge of the applicable

safety precautions.

GENERAL DESCRIPTION

It is essential that the

operating instructions

are read before the tester is

operated for the rst time.

Always keep these operating

instructions together with

the tester.

Ensure that the operating

instructions are with the

tester when it is given to

other persons.

TECHNICAL SPECIFICATIONS

Intelligent digital pressure gauge

• 0-145kN (4 segment LCD display)

• Accurate to +/-2.5% FSD

• Indication of pull-out load

• Rise and fall output

• Maximum load achieved function

• Calibration in kN

• Traceable Calibration Certicate

supplied valid for 1 year

• Material: stainless steel and ceramic

• Battery Powered (PP3)

2008 Model Tester

1

7

8

3

6

2

4

5

26mm

* Mounting

Holes

Feet Outer

Edge

x 2 proles for

dierent

edge distance

75m

230mm

290mm

173mm

173mm

188mm

35mm

Dia

40mm Dia

CONTENTS

Page

2008 Model Tester Parts 2

General description 3

Technical Specications 3

Kit contents 4

1. LOAD SPREADING

BRIDGE - set up 5

2. General Testing

Procedure - set up 6

3. General Testing

Procedure - Operating the tester 7

4. Eyebolt Testing 8

5. Re-bar operating instructions 9

6. 2008 MODEL TESTER ASSEMBLY

TO 12.5 TON LOAD SPREADING

BRIDGE 11

6. GENERAL GUIDELINES

FOR TESTING 11

7. Operating the digital gauge 12

8. Operating instructions for

optional Bluetooth Digital Gauge 13

9. Changing the gauge battery 14

10. Calibration/Repair/

Replacement of gauge 14

11. Bluetooth Digital Option Cable removal 15

4 5

1. Model 2008 Tester Body

2. 22mm Operating Nut

3. 0-145kN Digital Gauge

(Bluetooth version optional for recording

data via suitable mobile device)

4. Offset Load Spreading Bridge plate with

10mm eye hook

5. 3 Telescopic legs with fully adjustable

swivel feet

6. M20 Connecting Rod 400mm

7. M20 Adjustable Nut

8. M24 Ratchet Spanner

9. 5 Threaded Adaptors

M20 > M12, M16, M20, M24, M30

10. Spirit level

11. Allen Keys

12. Spare screws

13. Carry Case with Foam Filler

14. Operating Instructions

15. Calibration Certicate

KIT CONTENTS

1

2

12

11

8

5

5

5

6

7

9

13

3

4

10

1. LOAD SPREADING BRIDGE - set up

Operating Instructions

HYDRAJ AWS

LIMITED

2008 Model Tester

14

Fig 1

Fig 2

Fig 4Fig 3

15

The bridge has been designed specically

for the model 2008 tester and directs

reaction loads away from the xing (g 1).

The lightweight aluminium load spreading

bridge ts in the carry case disassembled

(g 2). The bridge is simple to assemble

and adjust. Three fully adjustable telescopic

legs offer 11 height positions 25mm apart

(g 3). The legs are held in place with

steel ball pins.

The swivel feet offer 30mm of ne

adjustment.

The triangular shape bridge plate is

deliberately offset to offer two different

close to edge testing distances in

relationship to the xing under test.

The tester can be secured to the bridge

plate in two positions with the supplied

cap screws (g 4). Securing the tester

to the plate is not crucial when the tester

is being operated in a horizontal position

however is essential when the tester is in

a vertical position or inverted.

Loading...

Loading...