Hydra-Flex Pressure Booster Pumps User Manual

Operating Instructions & Parts Manual

5.28

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Pressure Booster Pumps

FW0154

0813

Supersedes

0113

Description

Pressure booster pumps increase water pressure from city mains or private water systems. Applications include providing high water pressure for washing buildings, dairy

walls or floors, hog parlors, poultry houses, rinsing or spray cooling equipment, lawn

sprinkling and insecticide spraying.

Single-phase models are equipped with a capacitor start, thermal protected motor.

Three-phase models require separate overload protection.

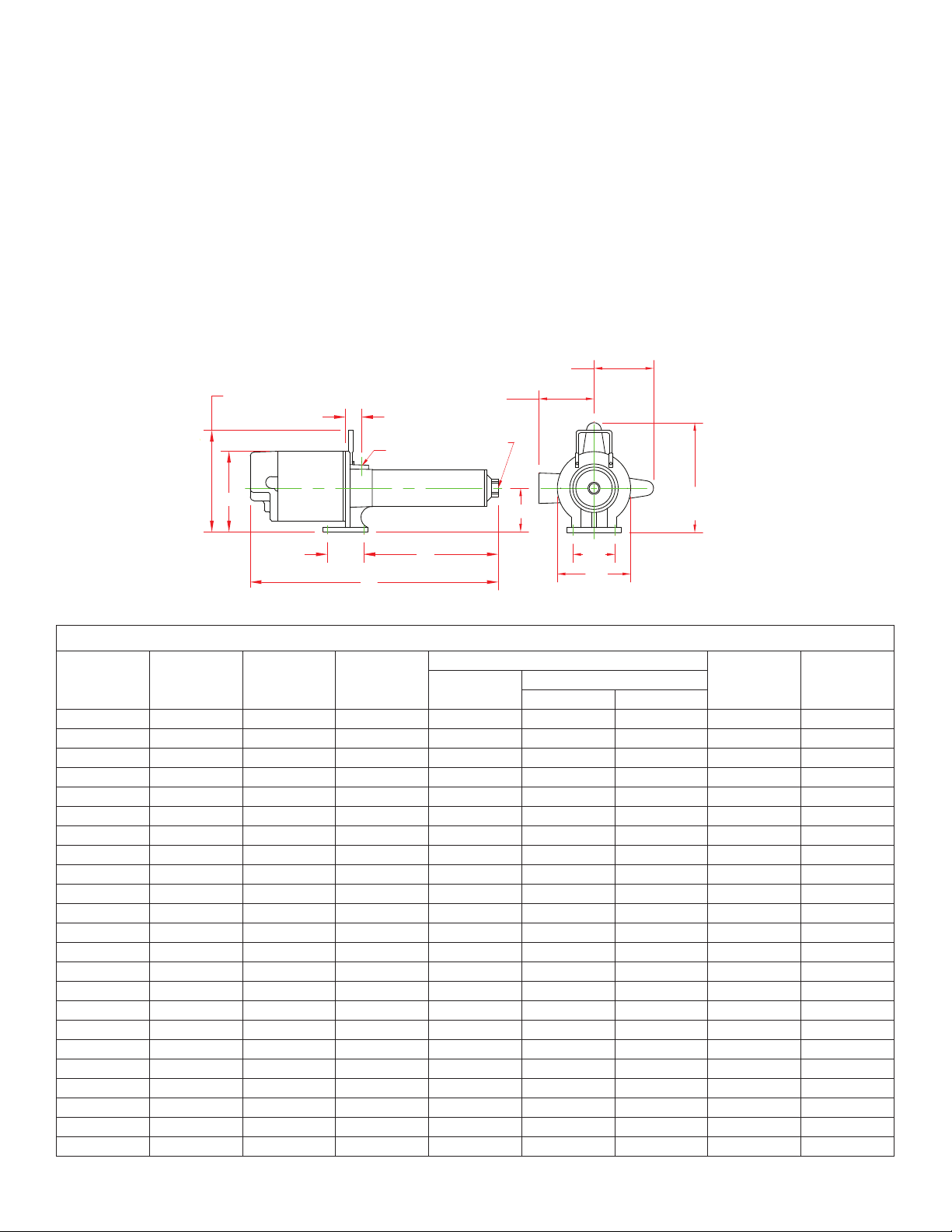

2 & 3HP

4.88

TEFC ONLY

3.88

1Ø TEFC ONLY

3.75

6.50

Figure 1

(MODELS WITH HANDLES)

7.15

9.00

1.44

"H" INLET

3.25 "C"

"F"

"J" DISCHARGE

Unpacking

When unpacking the unit, inspect carefully for any damage that may have

occurred during transit.

NOTE: Use pump with clear water

only.

9.75

1-1/2 & 2HP 1Ø TEFC

ALL 3HP 1Ø

IL0391B

Pump Dimensions 60 Hz Chart A

F

HP GPM Stage “C”

1/3 5 8 10.19 19.81 - - .75 .75

1/3* 5 8 10.19 20.06 22.04 - .75 .75

1/2 5 12 13.38 23.25 23.23 24.10 .75 .75

1/2* 5 14 14.97 25.34 26.82 25.69 .75 .75

3/4 5 16 16.54 26.91 28.77 27.51 .75 .75

3/4 7 12 13.38 23.75 25.61 24.35 .75 .75

3/4* 7 14 14.97 25.84 27.20 25.94 .75 .75

1 10 14 16.31 27.18 29.16 28.02 .75 .75

1-1/2 10 16 18.13 29.62 31.48 30.07 .75 .75

1* 10 20 21.69 33.18 34.54 33.40 .75 .75

1* 10 22 23.50 34.99 36.35 35.21 .75 .75

1* 10 23 24.38 35.87 37.73 36.09 .75 .75

2 19 14 17.89 29.88 32.12 30.87 .75 .75

1-1/2* 19 20 24.06 36.05 37.41 36.00 .75 .75

2* 19 22 26.13 38.12 40.36 39.11 .75 .75

2 27 11 15.38 27.37 29.61 28.36 1.00 1.00

3 27 14 18.50 30.49 33.85 33.35 1.00 1.00

2* 27 17 21.59 33.58 35.82 34.57 1.00 1.00

3 27 17 21.59 33.74 - - 1.00 1.00

2 35 6 13.94 25.93 28.17 26.92 1.00 1.00

3 35 8 17.13 29.12 32.48 31.98 1.00 1.00

1-1/2* 35 8 17.13 29.12 30.48 29.07 1.00 1.00

3* 35 14 26.86 38.85 42.21 41.71 1.00 1.00

F&W

1 Phase 3 Phase

TEFC

H J

Copyright © 2012 FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • flintandwalling.com

1

132934

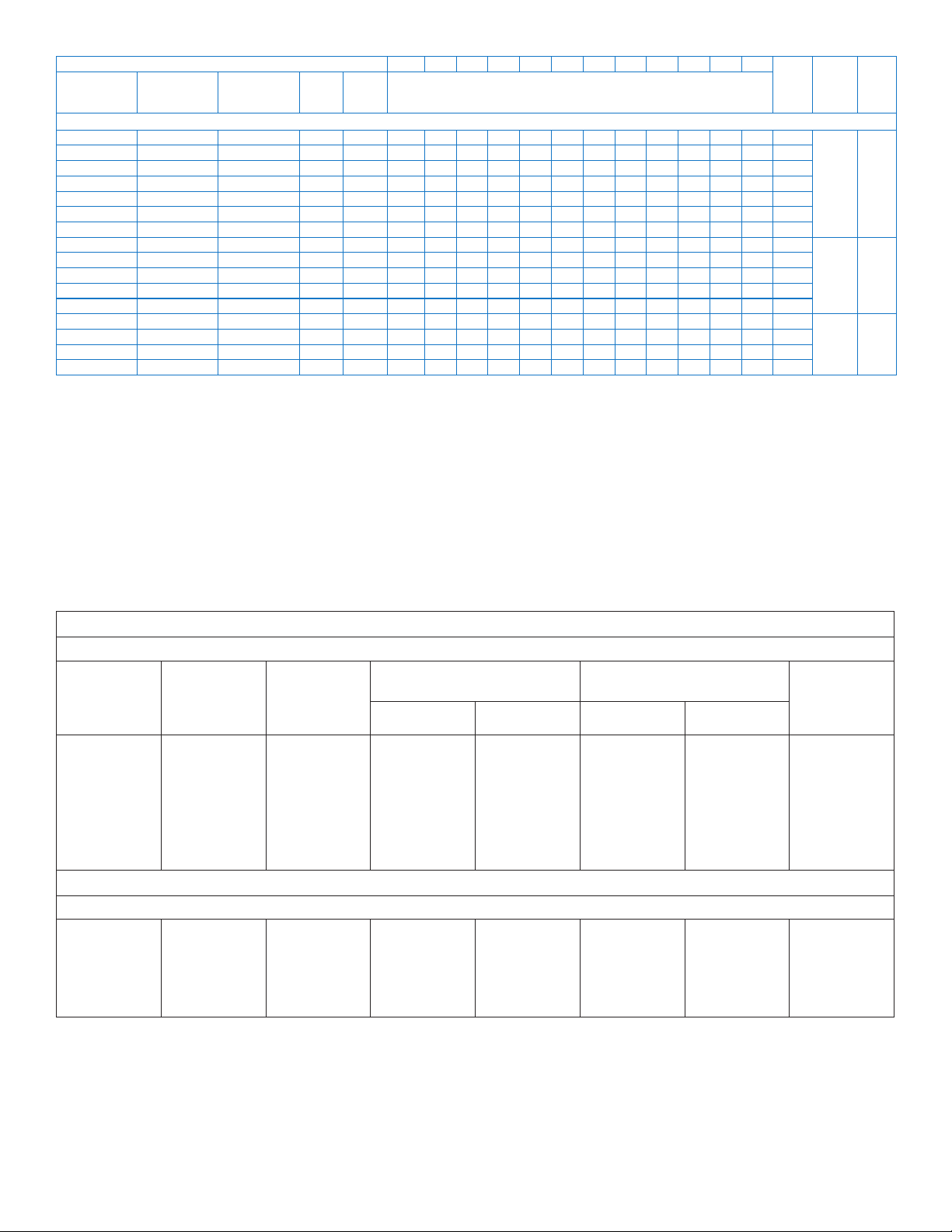

PRESSURE ADDED - PSI 10 20 40 60 80 100 120 140 160 180 200 220

Stainless Steel

Fitted

PB0508S031 PB0508C031 PB0508A031‡ 1/3 8 10.2 9.6 8.3 6.5 4.3 96

PB0512S051 PB0512C051 PB0512A051‡ 1/2 12 10.0 9.5 8.3 7.1 6.0 4.0 2.3 132

PB0516S071 PB0516C071 PB0516A071 3/4 16 10.2 9.7 9.1 8.3 7.5 6.6 5.8 4.6 3.3 189

PB0712S071 PB0712C071 PB0712A071 3/4 12 14.0 13.4 12.2 10.9 9.5 8.9 7.0 4.6 158

PB1014S101 PB1014C101 PB1014A101 1 14 * * 14.5 13.4 12.3 11.2 9.8 8.0 6.0 2.3 183

PB1016S151 PB1016C151 PB1016A151 1-1/2 16 * * 15.0 14.1 13.1 12.1 11.0 9.8 8.2 5.2 2.0 212

PB1914S201 PB1914C201 PB1914A201 2 14 27.6 27.0 25.7 24.2 22.6 20.8 18.7 16.2 12.9 7.7 190

PB3506S201 PB3506C201 PB3506A201 2 6 48.0 47.0 42.5 35.2 24.0 85

PB2711S201 PB2711C201 PB2711A201 2 11 * * 31.5 29.5 27.1 24.2 20.3 13.0 147

PB3508S301 PB3508C301 PB3508A301 3 8 48.0 47.5 44.0 40.0 35.2 27.5 118

PB2714S301 PB2714C301 PB2714A301 3 14 * * 33.0 31.5 29.8 27.9 25.6 22.8 18.9 11.1 187

PB2717S303** - - 3 17 * * * 34.1 32.3 30.5 28.3 25.8 23.1 20.0 16.6 11.4 225

- - PB5504A201 2 4 77.6 71.5 52.5 55

- - PB5506A301 3 6 77.8 74.4 65.0 51.1 31.9 83

- - PB8504A201 2 4 105.8 90.0 47.0 49

- - PB8505A301 3 5 108.8 98.8 60.0 25.0 60

‡ Equipped with carrying handle. 132079 handle available as an option for other models.

† Example: If PB0508A031 pump is connected to supply line of sufficient capacity, carrying water at 40 PSI, and the output of the pump is held to 7.3 GPM by a gate

valve, the pump will add 40 PSI to line pressure for a total output pressure of 80 PSI.

* Operation of pump in this range may result in reduced pump life and/or motor damage.

To keep pump and seal lubricated, a minimum flow of 1.5 GPM must always be maintained through the pump.

** Only available in 3 phase

Motor voltage: Open Drip Proof Totally Enclosed Fan Cooled

Powder-

Coated Cast

Iron Fitted

Single Phase 1/3 - 2 HP - 115/230; 3 HP - 230V 60 Hz.

Three Phase 1/2 - 2 HP - 208-230/460, 50/60Hz.

Three Phase 3 HP - 208-230/460, 60 HZ

For three phase models, use suffix “3” on the model no.

Example: PB0512A053

Cast Iron Fitted HP Stage Output - Gallons per Minute

60Hz Models

Single Phase: 1/2 thru 3 HP - 115/230V 60/50Hz

Three Phase: 1/2 thru 3 HP - 208/230/460V 60/50Hz

Max.

Press.

PSI

Suction

Pipe

Tap

NPT

3/4” 3/4”

1” 1”

2” 2”

Disch.

Pipe

Tap

NPT

Single Phase Motor Data 60HZ Chart C

Single Phase† 60 Hz 3450 RPM Capacitor Start

HP

1/3

1/2

3/4

1

1-1/2

2

3

Motor

Voltage

115/230

115/230

115/230

115/230

115/230

115/230

230

Factory

Connected

Motor

Voltage

115V

115V

115V

230V

230V

230V

230V

Service Factor Motor

Amps

Locked Rotor Motor

Amps

115V 230V 115V 230V

8.6

13.0

14.0

18.0

21.0

25.0

-

4.3

6.5

7.0

9.0

10.5

12.5

13.5

26.0

36.0

52.0

78.0

98.0

116.0

-

13.0

18.0

26.0

39.0

49.0

58.0

53.0

Code Letter

K

K

K

L

J

H

D

Single Phase Motor Data 50HZ

Single Phase† 50 Hz 2850 RPM Capacitor Start

1/2

3/4

1

1-1/2

2

†Thermal overload protector - automatic reset

115/230

115/230

115/230

115/230

230

115V

115V

230V

230V

230V

10.0

14.4

16.4

23.6

-

5.0

7.2

8.2

11.8

13.2

48.0

64.0

72.0

104.0

-

24.0

32.0

36.0

52.0

55.0

M

L

K

K

H

Copyright © 2012 FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • flintandwalling.com

2

Three Phase Motor Data Chart D

Three Phase† 60/50 Hz 3450/2850 RPM Capacitor Start

HP

3/4

1

1-1/2

2

3

Motor

Voltage

208-230/460

208-230/460

208-230/460

208-230/460

208-230/460

Factory

Connected

Motor

Voltage

230V

230V

230V

230V

230V

Service Factor Motor

Amps

Locked Rotor Motor

Amps

230V 460V 230V 460V

3.5

4.5

5.7

7.4

9.8

1.75

2.25

2.85

3.70

4.90

19.0

26.9

33.5

44.0

48.0

13.5

16.8

22.0

24.0

9.5

Code Letter

K

K

K

K

D

3 HP, 3 Phase motor operable on 60Hz only.

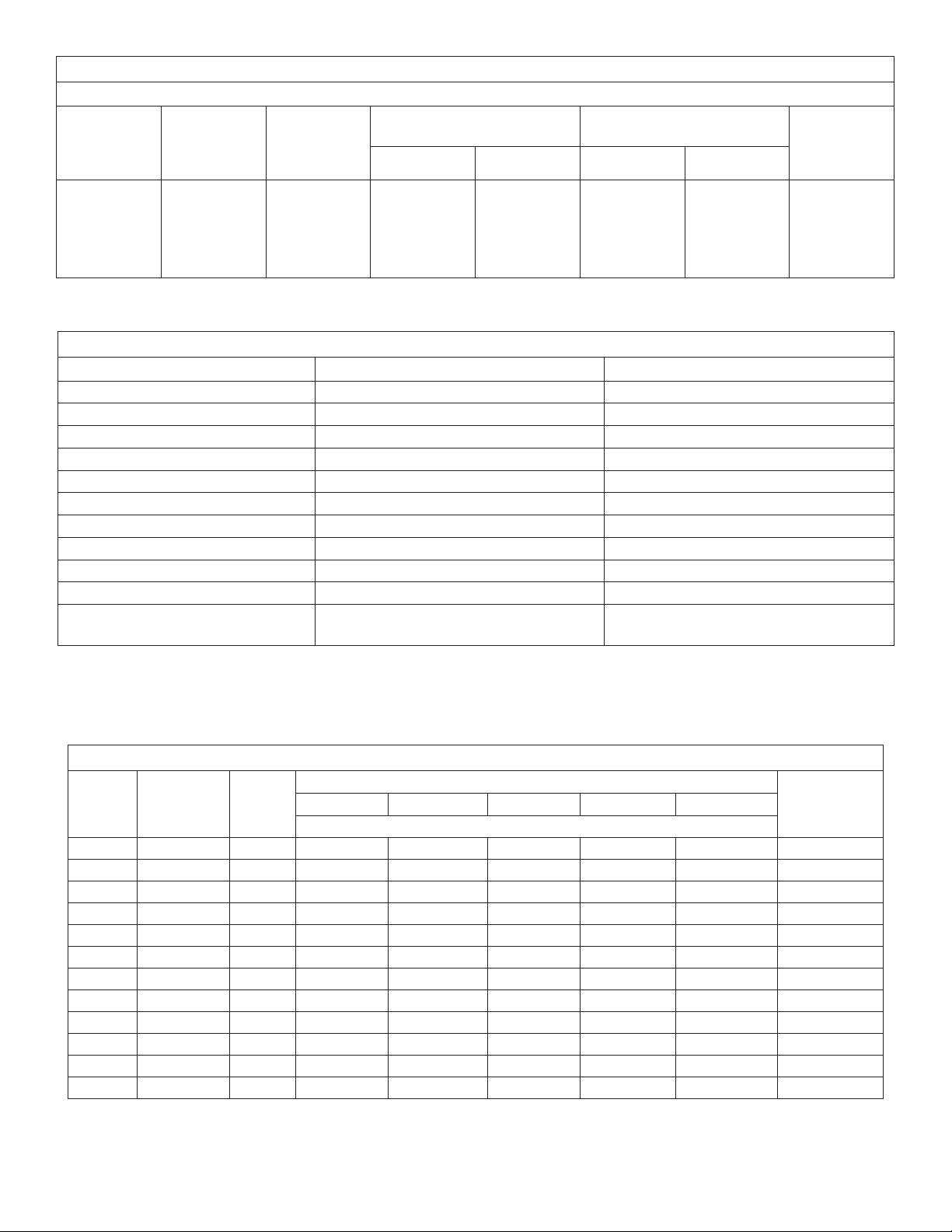

Material Construction Chart E

Component Standard Models* Stainless Steel Models

Motor Rear access - Nema 56J face Rear access - Nema 56J face

Bearings Ball-ball, permanently lubricated Ball-ball, permanently lubricated

Impellers Noryl with 304 stainless steel bearing insert Noryl with 304 stainless steel bearing insert

Diffuser Noryl Noryl

Diffuser plates Delrin Delrin

Pump shaft 416 Stainless steel 304 Stainless steel

Pump shaft coupling 316 Stainless steel 316 Stainless steel

Pump shell 304 Stainless steel 304 Stainless steel

Discharge & inlet casting Cast iron 304 Stainless steel

O-Rings Buna-N Viton

Seal composition Carbon-silicon carbide, stainless steel spring

and Buna-N

*Models with powder coated inlet & discharge also available.

Carbon-silicon carbide, stainless steel spring

and Viton

Minimum Wire Size Chart (Gauge) Chart F

Motor

HP

1/3 115/230 1 14/14 14/14 14/14 12/14 12/14 15/15

1/2 115/230 1 12/14 12/14 12/14 12/14 10/14 15/15

3/4 115/230 1 12/14 12/14 10/14 10/12 8/12 15/15

1 115/230 1 10/14 10/14 10/12 8/12 6/10 20/15

11/2 115/230 1 10/12 8/12 6/12 */10 */10 30/15

2 115/230 1 10/12 8/12 6/12 */10 */10 30/15

3 230 1 10 10 10 10 8 20

3/4 230/460 3 14/14 14/14 14/14 14/14 14/14 15/15

1 230/460 3 14/14 14/14 14/14 14/14 12/14 15/15

11/2 230/460 3 14/14 14/14 14/14 12/14 12/14 15/15

2 230/460 3 14/14 14/14 14/14 12/14 10/12 15/15

3 230/460 3 14/14 14/14 14/14 12/14 10/12 15/15

(*) Not economical to run in 115V, use 230V.

Volts Phase

Copyright © 2012 FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • flintandwalling.com

0-50 50-100 100-150 150-200 200-300

Distance In Feet From Motor To Service Panel

Breaker Size

(Amps)

Wire Size

3

General Safety Information

!

!

!

!

!

!

Carefully read and follow all safety instructions in

this manual and on pump. Keep safety labels in good

condition. Replace missing or damaged safety labels.

9. Do not insert finger or any object into pump or motor

openings.

10. Secure the discharge line before starting the pump. An

unsecured discharge line will whip, possibly causing personal injury and/or property damage or puncture.

symbol on the pump or in the manual, look for one of the

following signal words and be alert to the potential for personal injury or property damage.

personal injury, death or major property damage if ignored.

personal injury or death, if ignored.

personal injury, product or property damage if ignored.

This is a SAFETY ALERT SYMBOL. When you see this

Warns of hazards that WILL cause serious

Warns of hazards that CAN cause serious

Warns of hazards that MAY cause minor

IMPORTANT: Indicates factors concerned with operation,

installation, assembly or maintenance which could result in

damage to the machine or equipment if ignored.

NOTE: Indicates special instructions which are important but

are not related to hazards.

Wire motor for correct voltage. See

“Electrical” section and Motor Data Charts

C&D of this manual, and motor nameplate.

Ground motor before connecting to

power supply.

Hazardous voltage. Can shock,

burn or cause

death. Ground

pump before connecting to power

supply.

Meet United States National Electrical

Code and local codes for all wiring.

Do not handle a pump or pump motor

with wet hands or when standing on a wet

or damp surface or in water.

engine. They are designed to operate at high temperatures.

the State of California to cause cancer and birth defects or

other reproductive harm.

been investigated for use in swimming pool areas.

NOTE: Pumps with the “CSA-CUS” mark are tested to UL standard UL778 and certified to CSA standard C22.2 No. 108.

Pre-Installation

HANDLING

1. Use handle supplied to lift pump.

2. Avoid impact on pump or motor. In particular, avoid

impact on discharge end of pump or rear motor access

cover.

LOCATION

age and/or personal injury might result from an inoperative

or leaking pump due to power outages, discharge line blockage, or any other reason, a backup system(s) should be used.

1. Locate pump as close to the fluid source as possible, keeping the inlet pipe short as possible.

2. Place unit where the pump and piping are protected from

the weather and extremes of heat, humidity and below

freezing temperatures.

3. Mount unit in a dry location that is easily accessible for

inspection and maintenance. If a dry location is not available, mount it on a foundation well above the wet floor.

Do not touch an operating motor or

This product contains chemicals known to

Risk of Electric Shock. This pump has not

In any installation where property dam-

4. Allow ample clearance around unit for free air circulation.

Follow wiring instructions in this manual when connect-

ing to power lines.

SUCTION LIMITATIONS

1. Units are non self-priming.

2. Pressure booster pumps are not recommended for suction

performing any work on or near the motor or its connected

Always disconnect power source before

load.

lift applications.

PIPING

1. Use galvanized piping, rigid plastic or other suitable pipe

that will not collapse under suction or rupture due to pressure.

such as gasoline, fuel oil, kerosene, etc. Do not use in flam-

Do not use to pump flammable or explosive fluids

mable and/or explosive atmospheres.

forced industrial type that is rated higher than the shutoff

pressure of the system. Ordinary garden hose will collapse

and starve the pump of water.

If hose is used, make sure it is the rein-

2. The diameter of the inlet and discharge pipe should be

discharge pipe. Release all pressure on system before work-

Hazardous pressure! Install pressure relief valve in

ing on any component.

1. Make workshop child proof - use padlocks, master

switches; remove starter keys.

2. Wear safety glasses when working with pumps.

3. Wear a face shield and proper apparel when pumping

hazardous chemicals.

4. Keep work area clean, uncluttered and properly lighted;

replace all unused tools and equipment.

no smaller than the corresponding ports of the pump (See

Figure 1). Smaller pipe will reduce the capacity of the

pump. Increase pipe size on long runs.

3. Avoid air pockets in inlet piping or air will accumulate at

high points, making priming difficult.

4. Use pipe compound on all joints and connections. Use

Teflon tape or plastic joint stik, on plastic pipe. Draw all

pipe up tightly.

IMPORTANT: The entire system must be air and water tight

for efficient/proper operation.

5. Provide guarding around moving parts.

6. Keep visitors at a safe distance from the work area.

7. Periodically inspect pump and system components.

8. Protect electrical cord. Replace or repair damaged or

worn cords immediately.

Copyright © 2012 FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • flintandwalling.com

4

IL0418

IL0420

IL0421

Installation

!

PUMP INSTALLATION

IMPORTANT: Pump is built to handle

clear water only; it is not designed to

handle water containing sand, silt or

other abrasives.

1.Refer to Figures 6, 7, and 8 for typical installations.

No Sags

Sags Allow Air Pockets

No Air Leaks In

Inlet Pipe

If Air Flows

Water

Won’t

Pipe Joint Compound

Will Damage Plastic

IL0419

piping when assembling and when

Support pump and

installed. Failure to do so may cause

piping to break, pump to fail, motor

bearing failures, etc.

2. If the pump is used as part of a permanent installation, bolt to a rigid

foundation.

Use only components that are rated for maximum pressure pump can produce when used in

boosting system or any other system.

Do not exceed the total maximum

pressure boost as listed per model in

Performance Charts B.

PRESSURE BOOST SYSTEMS

1. On pressure boost systems, locate

the pump so that there will always

be a positive supply of water to the

pump (See Figures 6, 7 and 8).

2. For service convenience, install a

gate valve and union in the inlet

and discharge line.

Do not use a globe

valve or other restricting type of valve

that will seriously restrict the pumps

discharge capacity.

3. Install a check valve as shown in

Figure 6. Be sure check valve flow

arrows point in the direction of

water flow.

4. Whenever dirt, sand or debris is

present in the supply water, install a

strainer or filter on the inlet side of

the pump (See Figure 7).

NOTE: For heavy amounts of sediment, install a trap filter on the inlet

side of the pump (See Figure 5).

NOTE: Pressure gauges installed

before and after the filter will show

pressure differential indicating the

need for filter replacement or cleaning.

If Air Pockets Form,

Water Won’t Flow

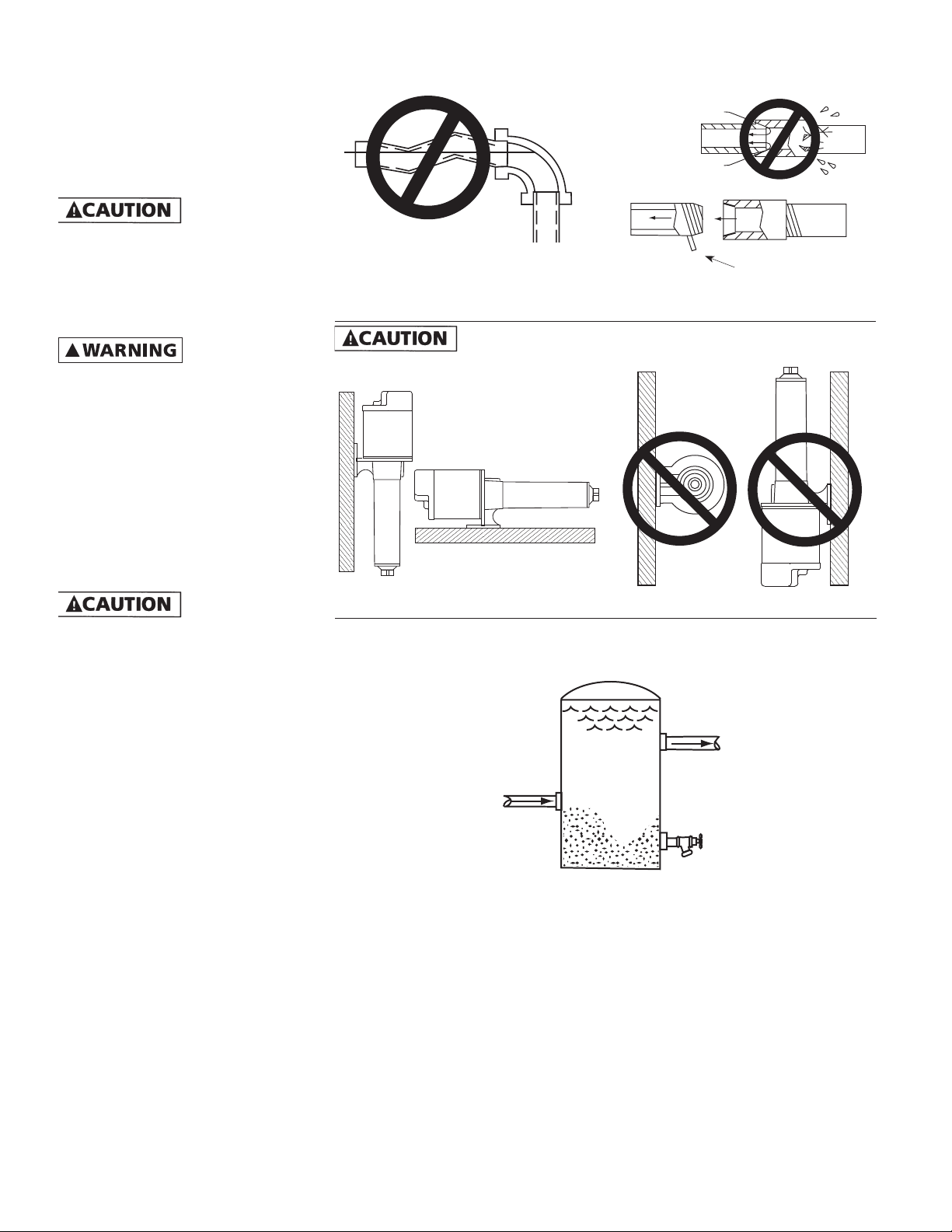

Figure 2 - No Air Pockets in Inlet Pipe

Mount pump in correct position or pump failure will result.

Correct

Figure 4A Figure 4B

IL1013

Figure 3 - Inlet Pipe Must Not Leak

Use Teflon Tape

Incorrect

SAND AND SEDIMENT TRAP FILTER

Standard Pressure

Tank - 42 Gallon Or

Larger

Outlet

Inlet

Sand Settles To The Bottom

Figure 5

Clean Out

IMPORTANT: Clean all filters and strainers on a regular schedule.

IL1014

Copyright © 2012 FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • flintandwalling.com

5

Loading...

Loading...