- 1 -

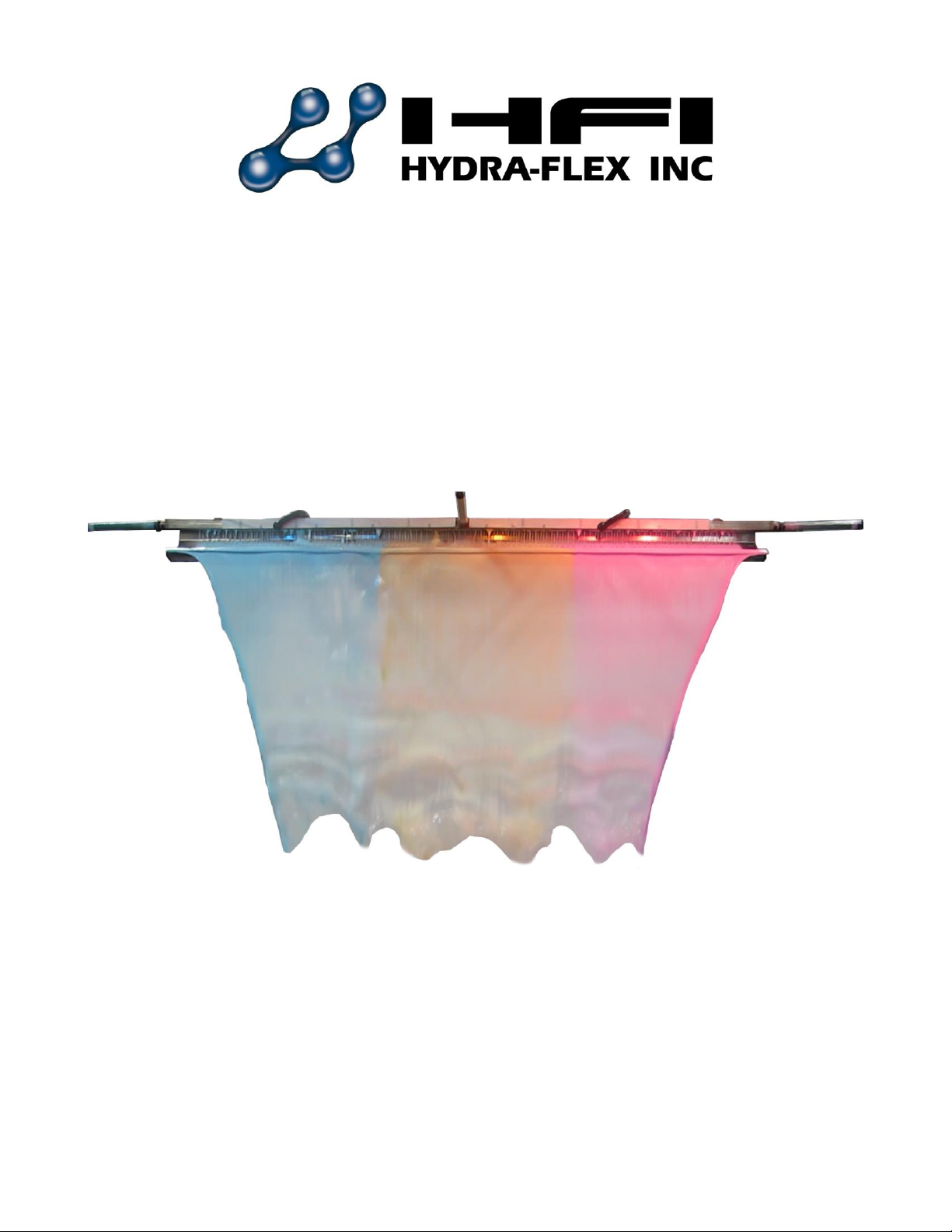

Tsunami™ Dispensing Arch

Using

™

AQUA-LAB

Chemical Dispensing System

REV A

© Hydra-Flex Inc 2011

- 2 -

Chemical Dispensing Specifications

1. Operating water pressure: 200 psi (Factory set)

2. Maximum water source temperature 140° F

3. Operating ambient temperature: 40-120° F

4. Electrical supply

a. 120 / 208 Single Phase

b. 1.5 hp pump 20 amps @ 120 volts or 10 amps @ 208

volts

5. Operate valves with 24VAC, 24VDC, 120VAC

a. < .5 amp

6. Water supply

a. 3/4” ID flooded inlet required

b. Inlet pressure: 2-60 psi

7. Air supply

a. Pneumatics inlet pressure: 60 - 100 psi

b. 3/8” feed per system

c. 20 CFM @ 100 psi supply

d. 3 x 3/8” poly lines to applicator

8. Chemical Solution lines

a. 3x ½” poly lines to applicator

9. Space requirements:

a. AQUA-LAB Systems

i. Valve panel – 1.5’ wide x 2’ tall

ii. Pump – 1’ wide x 4’ tall

b. Pump assemblies – pumps need to be within 6’ of the

system to allow connection with the connection hose

included (longer connections can be run with customer

supplied hose)

c. Electrical enclosures

i. Motor starter – 12” wide x 6” tall

Tsunami Applicator Specifications

1. Operating water pressure: 100 psi max

2. Pneumatics inlet pressure: 0-60 psi

3. Maximum water source temperature 140° F

4. Operating ambient temperature: 40-120° F

5. Water supply

a. 4 – 10 GPM

b. Inlet pressure: 10-65 psi

6. Air supply

a. 3x 3/8” feed per system

b. ~20 CFM

7. Solution lines

a. 3x ½” poly lines to applicator

8. Mounting requirements

a. This Applicator requires an arch to mount to

b. Must be level

c. Recommend roughly centering on car or slightly favoring the driver’s side

© Hydra-Flex Inc 2011

- 3 -

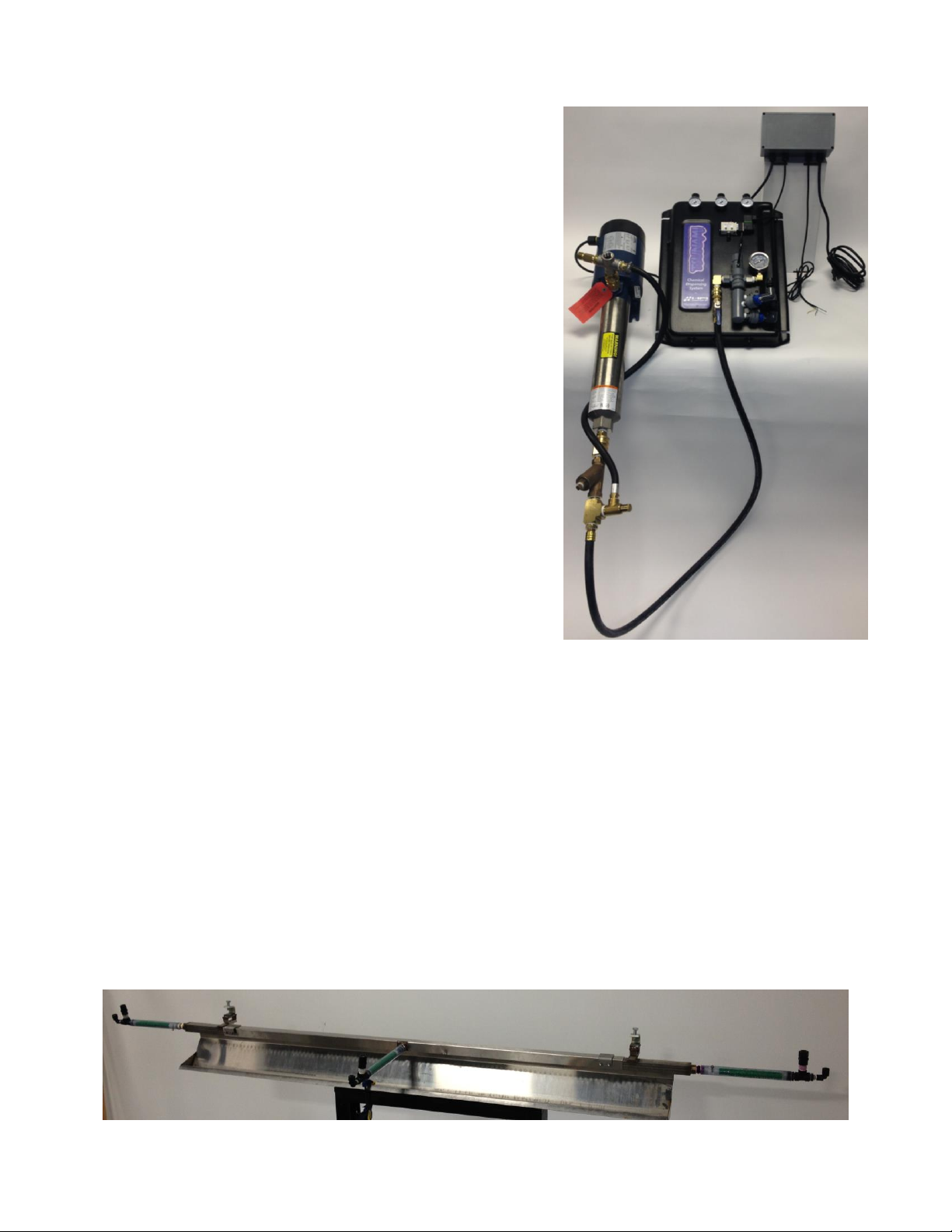

System Component Identification

Air Regulator 1, 2, 3

Air Solenoid

Valve Board Mounting Slots

Air Inlet

(3/8” Poly) Pneumatically

Actuated Valve

Water Feed

From Pump

(200psi)

Triple Foam

Manifold

Chemical

Injector

3x Outlet to Applicator

Air Outlet 1,

2, 3

© Hydra-Flex Inc 2011

- 4 -

1. Mount pump using 4x 3/8” wedge Anchors provided (3/8” hammer drill required)

a. Mounting slots 3.75”W x 3.38”H

2. Mount electrical box and delivery panel using Tapcon anchors provided (5/32” hammer drill

required)

a. Electrical Box – Hole spacing 7.4”W x 3.5”H

b. Panel – Slot spacing 17.5”W x 15”H

3. Run ¾” water line to the inlet of the pump

4. Close the ball valve on the pump outlet line and open the feed to the pump

5. Point the outlet line towards a drain or a container and open the ball valve until water is flowing

freely to prime the pump.

6. Close the ball valve and attach the quick connect to the chemical delivery panel and re-open

the ball valve

7. Run a 3/8” poly airline to the chemical panel and supply with at least 60psi of air pressure

8. Wire the signal wire from the provided electrical box to the box with the signal to fire the

application

9. Connect the DIN I solenoid cable from the electrical box to the air valve.

10. Check that relay installed in the electrical box corresponds with the signal voltage from the car

wash controller (120VAC relay is installed from the factory, 24 VAC and 24VDC relays are

included inside the electrical box)

11. Plug 120VAC power cord into a circuit with 20 amp available capacity

12. Install or identify an existing arch to mount the Tsunami applicator to

IMPORTANT!! The Tsunami applicator requires a level sturdy arch or other

mounting feature as it does not include one

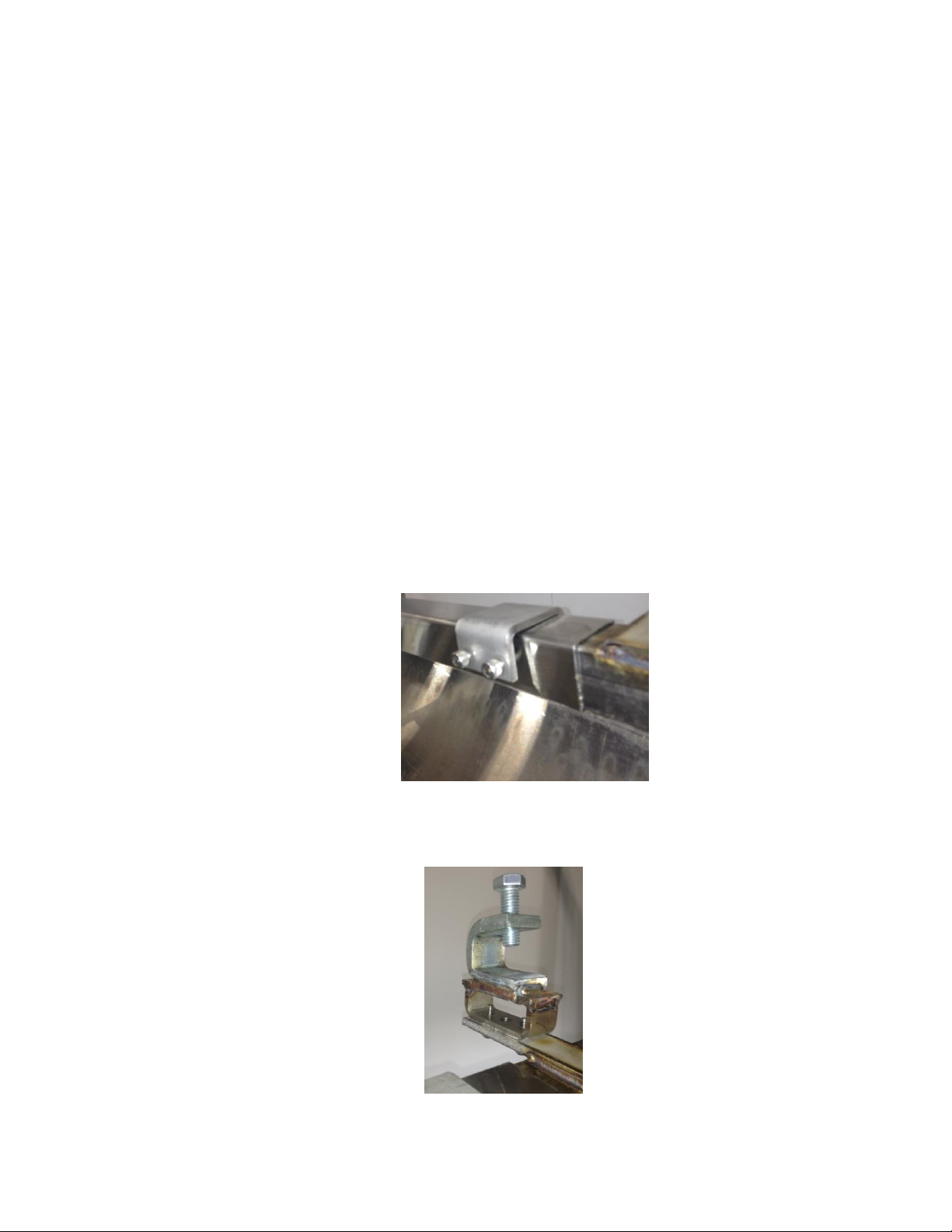

13. Clamp the rain bar into the trough using the provided clamps as shown

14. Center the applicator on the largest vehicle that can safely pass thru the tunnel

15. Make sure that the applicator is level side to side

16. Securely attach the applicator to the arch using the mounting tabs and / or the included

brackets.

17. Run and connect three ½” polyflow lines for the chemical solution and three 3/8” polyflow lines

for the foaming air from the chemical delivery panel to the foam generators on the applicator.

© Hydra-Flex Inc 2011

- 5 -

18. Run chemical lines with foot valves from the chemical barrels to the hose barbs on the

injectors and install metering tips according to desired chemical dilution ( see chemical dilution

ratio chart)

19. Using the car wash controller manually fire the signal for the application.

20. The pump, air valve and pneumatically actuated valve should all turn on.

21. Adjust the chemical ratio and air pressure until you get the desired results.

© Hydra-Flex Inc 2011

- 6 -

Optimizing the System

Consistently achieve the desired cleaning and presentation/performance

using the least amount of chemical and water

Injectors vs. Metering Tips

The key to optimizing the system is through trial and error.

Don’t be afraid to try these steps to achieve your ideal performance.

What do injectors do?

o Increases or decreases the amount of water

in the solution

What do metering tips do?

o Increases or decreases the amount of

chemical in the solution

Application Optimization (repeat for each

application)

View Performance at Arch with Decision Maker

Application too wet

o Increase air

o Reduce injector size (decreases water)

o Increase metering tip (increases chemical)

Application too dry

o Decrease air

o Increase injector size (increases water)

o Decrease metering tip (decreases chemical)

Too much chemical used

o Decrease metering tip

o Decrease metering tip and injector size (to maintain desired ratio)

No chemical

o Check vacuum of injector (see instructions on page 9)

o Check foot valve

o Check metering tip

© Hydra-Flex Inc 2011

- 7 -

Chemical Usage Measuring

Verify titration of chemicals before proceeding

1. Setup lab scale with small bucket of chemical to be measured.

2. Put the suction line into the bucket.

3. Run the application being tested to “prime” the line. (All air bubbles must be removed for accuracy)

4. Record the Initial Weight from the scale. (Tarring the scale with weight on the scale can affect accuracy)

5. Run the application for 6 vehicles (or manually for the same it would be on for 6 vehicles).

6. Record the Final Weight from the scale.

7. Subtract the Initial Weight from the Final Weight to determine the weight of used product.

8. Divide this Used Weight by 6 to get a per car weight.

9. Divide the Per Car Weight in grams by the specific gravity of the chemical to determine the milliliters of chemical

used per vehicle.

10. Repeat for each chemical application.

Recommended Maintenance

The recommended service and maintenance on the AQUA-LAB System are as follows.

Monthly

Check water filter and replace as needed (if installed)

Semi-Annually

Check and replace injector metering tips

Check and clean Y strainer

Inspect and replace chemical lines as needed

Annually

Clean water regulator

Inspect motor starter for corrosion, if identified order replacement/spare parts

2 Years

Inspect and replace injectors

Rebuild valves

Rebuild water regulator

© Hydra-Flex Inc 2011

- 8 -

Troubleshooting

Injector Vacuum Check (for troubleshooting injectors)

1. At the ChemFlex injector, remove the chemical feed line from the injector hose barb.

2. Attach the tubing of the vacuum gauge to the ChemFlex hose barb

3. With the pump(s) on, manually activate the chemical that is to be tested at the main car wash control cabinet. An

injector that is working properly will have a reading greater than or equal to (≥) 20 in Hg

4. If injector is not functioning:

a) Check metering tip for clogs (can be tested with no metering tip to ensure injector is performing)

b) Try smaller injector (this will produce less flow and thus less backpressure)

5. Repeat steps 2-4 for each chemical lane that a vacuum reading is needed for.

6. Once testing is complete, turn off the AQUA-LAB pump from the main car wash control cabinet.

There is a variation of performance in the injectors that comes from slight variations in the dimensions of the parts and in assembly that are

unavoidable. It is common to see the resultant vacuum range from 20 in Hg all the way up to 28. There is also variation in the through hole size on the

meter tips from Dema (within their manufacturing tolerances). Using the same tip color from site to site is a good starting point. However with the

potential for variation from part to part it is reasonable to still need to do some adjustments from there.

© Hydra-Flex Inc 2011

- 9 -

Inlet Restriction

Check all in-line filters and inlet plumbing for restrictions. Check

valves and backflow preventers

Inadequate water supply

Check pressure on inlet side of pump to be sure positive

pressure is maintained

Undersized piping Replace with larger piping

Leak on the Inlet side Make sure connections are tight

Worn or defective pump parts Replace worn parts or entire pump, Clean parts if required

Blown fuse or circuit breaker Replaced fuses or close circuit breaker

Defective Motor Starter

contactor

Replaced motor starter contactor

Incorrect Motor Voltage Voltage must be within 10% of motor rated voltage

Defective motor Replace motor

Pump components damaged Replace worn part or entire pump

Not Primed Reprime pump

Pump not secured firmly Secure properly

Restricted Inlet Clean or correct restriction

Water regulator fluttering

Try to adjust regulator down and then back up or replace

regulator

Cavitation (Sounds like marbles

in pump)

Increase inlet size

Worn mechanical seal Replace shaft seal

Worn o-ring seals Replace

Injector is not

drawing chemical -

Passes Vacuum

Pressure check

Clogged chemical feed

Check chemical hose, foot valve, metering tip and hose barb

for debris or clogs

Too much back pressure on

injector

Perform back pressure check test outlined in Section IV if this

manual. If the result is higher than 66 psi then, use larger

tubing, or use a smaller flow injector

Clogged injector check valve

Blow compressed air through the chemical hose barb on the

injector to remove debris

Clogged injector nozzle Remove injector and blow out any debris with compressed air

Defective Injector

If Vacuum check fails but Back Pressure is less than 66 psi,

replace the injector

Pump won't start or

run at full speed

Pump Operates, but

delivers little or no

water

Injector is not

drawing chemical -

Fails Vacuum

Pressure check

test

Pump Leaks

Excessive Noise from

Pump

© Hydra-Flex Inc 2011

- 10 -

PROBLEM POTENTIAL CAUSES SOLUTIONS

Pump not primed Follow priming instructions

Debris in regulator Remove regulator and clean out debris

Defective Check Valve Replace check valve if broken

Defective Regulator Replace Regulator

Defective Pump Replace Pump

Incorrect Injector Flow Rate

Selection

Replace with desired injector size

System pressure too low Ensure system pressure is set at 200 psi

Foam Generator Plugged Ensure cleaned and clear

Downstream pluming restrictive

Perform Back pressure test outlined in Section IV of this

manual, if over 66 psi, increase tube size and reduce elbows,

turns or other restrictive plumbing

Valve malfunction Ensure valve is receiving at least 60 psi

Valve may be assembled incorrectly

Disassemble valve and clean out debris (See valve

replacement instructions)

Clogged Injector Remove injector and blow out debris with compressed air

No water supply Check that the system has a supply of water

Valve stuck open –

Staying open when

signal is off

Debris in valve seat Remove and clean valve (See valve replacement instructions)

Starter Tripping

Incorrect Overload Setting

Verify overload setting versus settings found in specs page of

this document

Flow at arch is too

low

System won't

regulate up to 200

psi

No flow from injector

© Hydra-Flex Inc 2011

- 11 -

Appendix

© Hydra-Flex Inc 2011

- 12 -

Chem-Flex Injector Listing

Aqua-Lab Chem Flex Injector Listing

Part Number

#

Barbs

GPM

618029

1

0.25

618040

1

0.50

618051

1

0.75

618057

1

1.00

618070

1

1.50

618083

1

2.00

618086

1

2.30

618098

1

3.20

618125

1

5.40

629029

2

0.25

629040

2

0.50

629051

2

0.75

629057

2

1.00

629070

2

1.50

629083

2

2.00

629086

2

2.30

629098

2

3.20

629125

2

5.40

© Hydra-Flex Inc 2011

- 13 -

AQUA-LAB WARRANTY

Factory Limited

Hydra-Flex Inc warrants its equipment to be free from defect in material or workmanship under proper

normal proper use for a period of one (1) year beginning the date of purchase.

The Hydra-Flex Inc’s liability shall be limited to repair or replacement of parts found to be defective

within the warranty period and following Hydra-Flex Inc’s inspection. Hydra-Flex Inc shall have the

option requiring the return of defective material to establish the purchaser’s claim. In the event of

repair or replacement this limited warranty is non-cumulative. Neither labor nor transportation charges

are included in this warranty.

This warranty is based upon the proper care and maintenance of the warranted equipment. Warranty

does not apply if the merchandise is altered or modified in any way. Warranty does not apply to any

equipment which has been subject to misuse, inappropriate use of tools, including exposure to harsh

chemicals, neglect, lack of maintenance, freezing, fluid hammer, accident, third party damage, fluid

impurities such as sand or minerals, acts of God or acts of war. Nor does it apply to any equipment

which has been repaired or altered by anyone not so authorized by Hydra-Flex Inc. All equipment

must be properly installed in accordance with specified plumbing, electrical, and mechanical

requirements. The warranty does not apply to normal wear and tear or routine maintenance

components as described in the equipment manual.

Except as expressly stated herein, Hydra-Flex Inc shall not be liable for damages of any kind in

connection with the purchase, maintenance, or use of this equipment including loss of profits and all

claims for consequential damages. This limited warranty is in lieu of all other warranties expressed or

implied. Hydra-Flex Inc neither assumes nor authorizes any person to assume for it any other

obligation or liability in connection herewith. This warranty is neither assignable nor transferable.

Transportation damage claims are to be submitted to the carrier of the damaged material.

© Hydra-Flex Inc 2011

Loading...

Loading...