Hydra-Cell T100S Installation, Operation & Maintenance Manual

Installation, Operation & Maintenance

177-998D

T100 Series High Pressure

Model: T100S

1204 Chestnut Avenue, Minneapolis, MN 55403

Tel: (612) 332-5681 Fax: (612) 332-6937

Toll-free fax [US only]: (800) 332-6812

www.hydra-cell.com/metering

email: sales@wannereng.com

W0542B

T100 Series High Pressure - Contents

W0542B

Page

Component Identication ........................................................2

Specications ..........................................................................2

Dimensions .............................................................................4

Installation ...............................................................................6

Maintenance ............................................................................9

Service (Fluid End) ................................................................10

Service (Hydraulic Section) ...................................................11

Service (Power End) .............................................................14

Troubleshooting .....................................................................16

Oil Level Monitor ...................................................................17

Fluid End Parts ......................................................................18

Hydraulic Section Parts ........................................................ 20

Power End Parts .................................................................. 22

Torque Specications ............................................................24

T100S Tool Kit Parts .............................................................25

Pump Storage .......................................................................25

Replacement Parts Kits ....................................................... 26

Warranty ................................................................................27

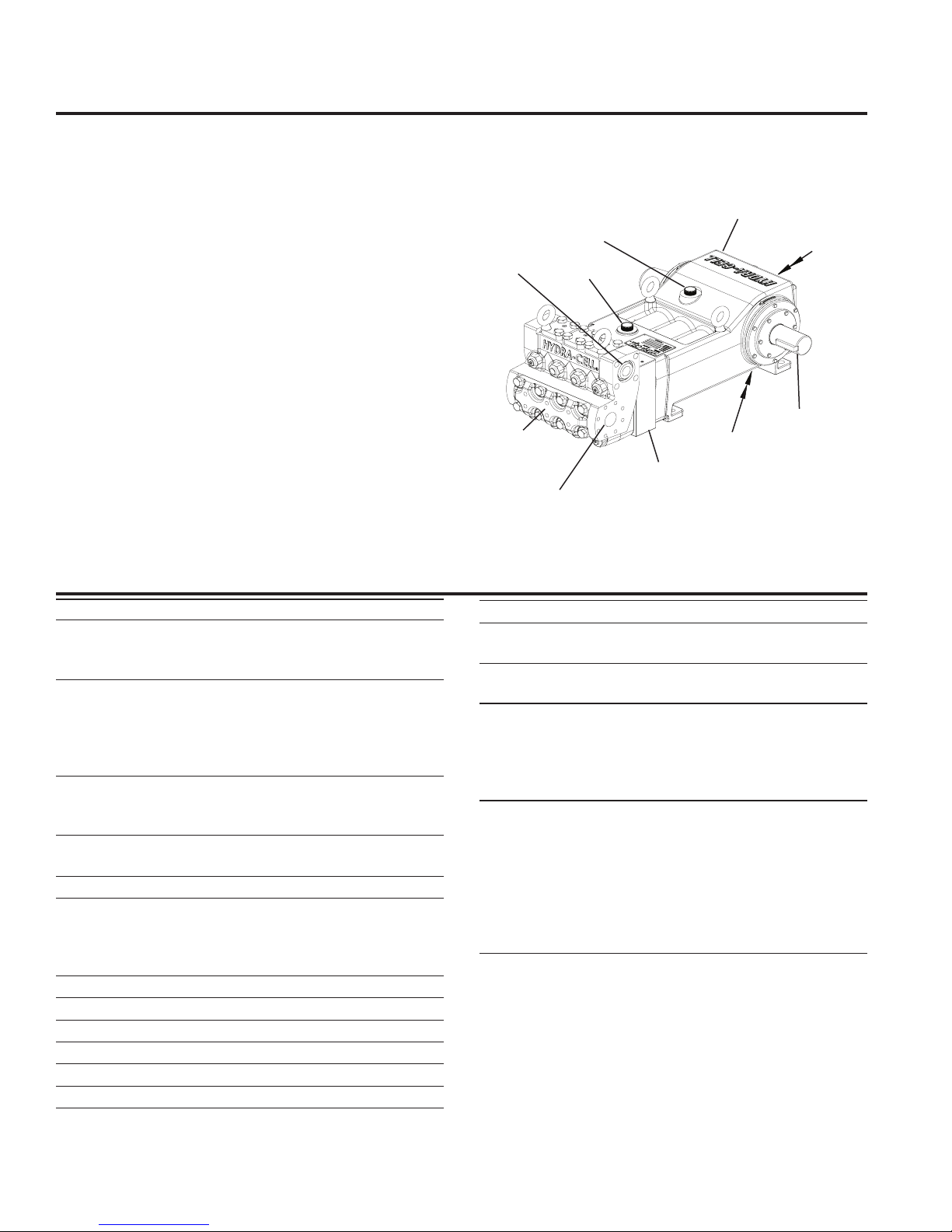

Component Identication

Oil Fill Cap

with Dipstick

Outlet

Fluid End

Oil Fill Cap

Hydraulic Section

Inlet

T100 Series High - Specications

Power End

Float Switch &

Sight Glass

Crankshaft

Oil Drain Plug

Maximum Pressure: 5000 psi (345 bar)

Flow Capacities @ Maximum Pressure

rpm gpm I/min BPD

T100S 450 26.0 98.4 891

Delivery

Pressure psi (bar) gal/rev liter/rev

500 (34) 0.066 0.249

2500 (172) 0.063 0.237

5000 (345) 0.059 0.222

rpm

450 maximum

20 0 m ini mum (contact factory for speeds less than 200)

Maximum Discharge Pressure

Metallic Heads: 5000 psi (345 bar)

Maximum Inlet Pressure 500 psi (34 bar)

Operating Temperature

Maximum: 180 F (82.2 C)

Minimum: 40 F (4.4 C)

(consult factory for temperatures outside this range)

Maximum Solids Size 800 microns

Input Shaft Left or Right Side

Inlet Ports 2 inch Class 300 FF ANSI Flange

Discharge Ports 1-1/4 inch Class 2500 RTJ ANSI Flange

Shaft Diameter 3 inch (76.2 mm)

Shaft Rotation Uni-directional (see rotation arrows)

T100 Series High Specications (Cont’d)

Oil Capacity 18 US quarts (17 liters) - blank back cover

20.5 US quarts (19.4 liters) - oil level back cover

Weight (dry)

Metallic Heads: 1100 lbs (499 kg)

Fluid End Materials

Diaphragm Follower Screw: 316 Stainless Steel

Outlet Valve Retainer: 316 Stainless Steel

Plug-Outlet Valve Port: 316 Stainless Steel

Inlet Valve Retainer: 316 Stainless Steel

Power End Materials

Crankshaft: Forged Q&T Alloy Steel

Connecting Rods: Ductile Iron

Crossheads: 12L14 Steel

Crankcase: Ductile Iron

Bearings: Spherical Roller/Journal (main)

Steel Backed Babbit (crankpin)

Bronze (wristpin)

2

177- 9 9 8 D

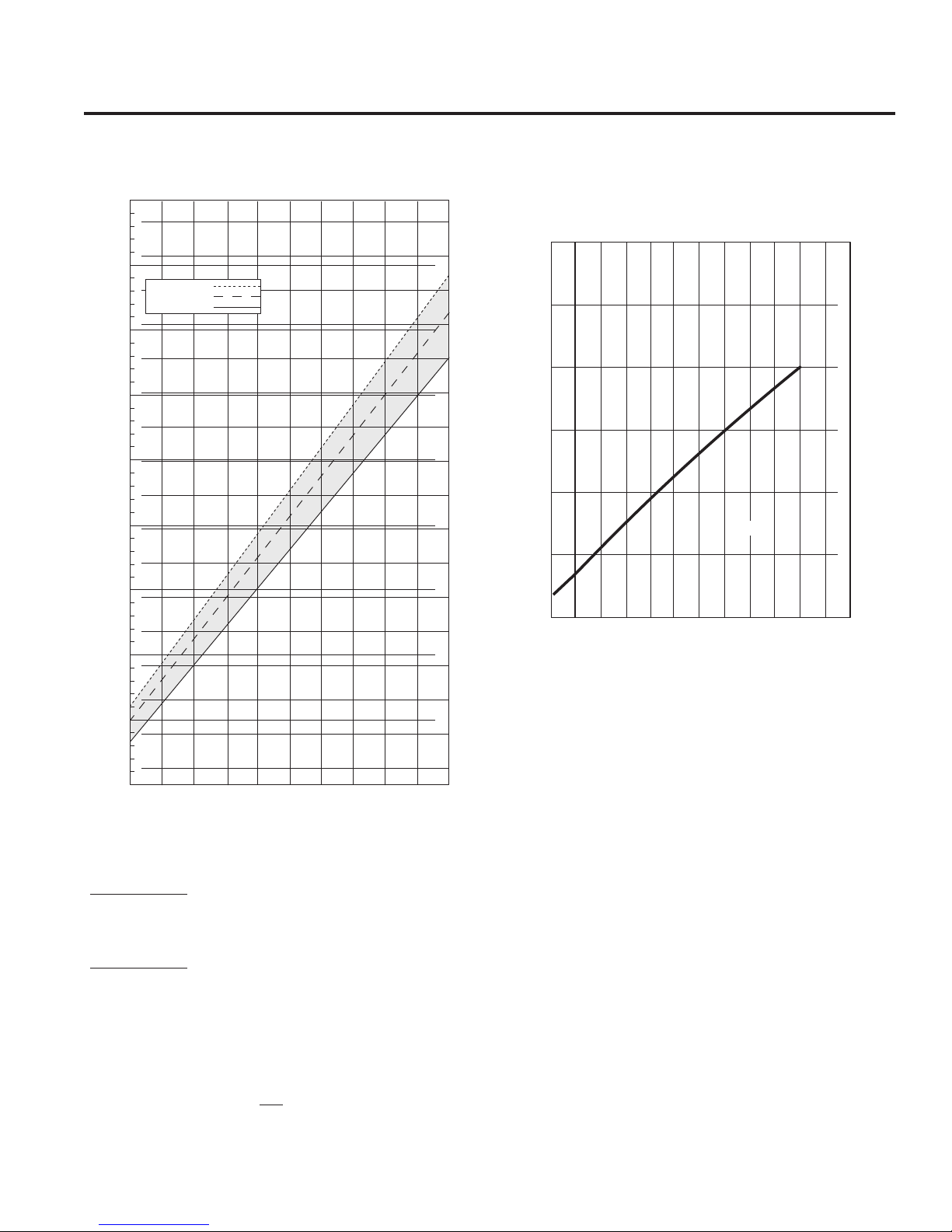

T100S

RPM

200 225 325 375 425 450

10.0

32.5

30.0

27.5

25.0

22.5

20.0

17.5

15.0

12.5

Liters Per Minute

Gallons Per Minute

35.9

W0540B

275 400350300250

75.0

80.0

85.0

90.0

95.0

70.0

40.0

45.0

50.0

55.0

60.0

65.0

100.0

110.0

115.0

120.0

105.0

500 psi (34 bar)

2500 psi (172 bar)

5000 psi (345 bar)

RPM

12

NPSHr (feet of water

)

NPSHr (meters of water)

13

14

15

16

17

18

3.75

4

4.25

4.5

4.75

5

5.25

W0541B

5.5

T100S

200 350 450300 400 500250

T100 Series - High Specications (Cont’d)

Performance

Net Positive Suction Head –

NPSHr

Calculating Required

Horsepower (kW)*

gpm x psi

1,460

l/min x bar

* HP/kW is required application power.

Attention!

511

=

electric motor HP*

=

electric motor kW*

When sizing motors with variable speed drives (VFDs), it is

very important to select a motor and a VFD rated for constant

torque inverter duty service and that the motor is rated to

meet the torque requirements of the pump throughout desired

speed range.

3

177- 9 9 8 D

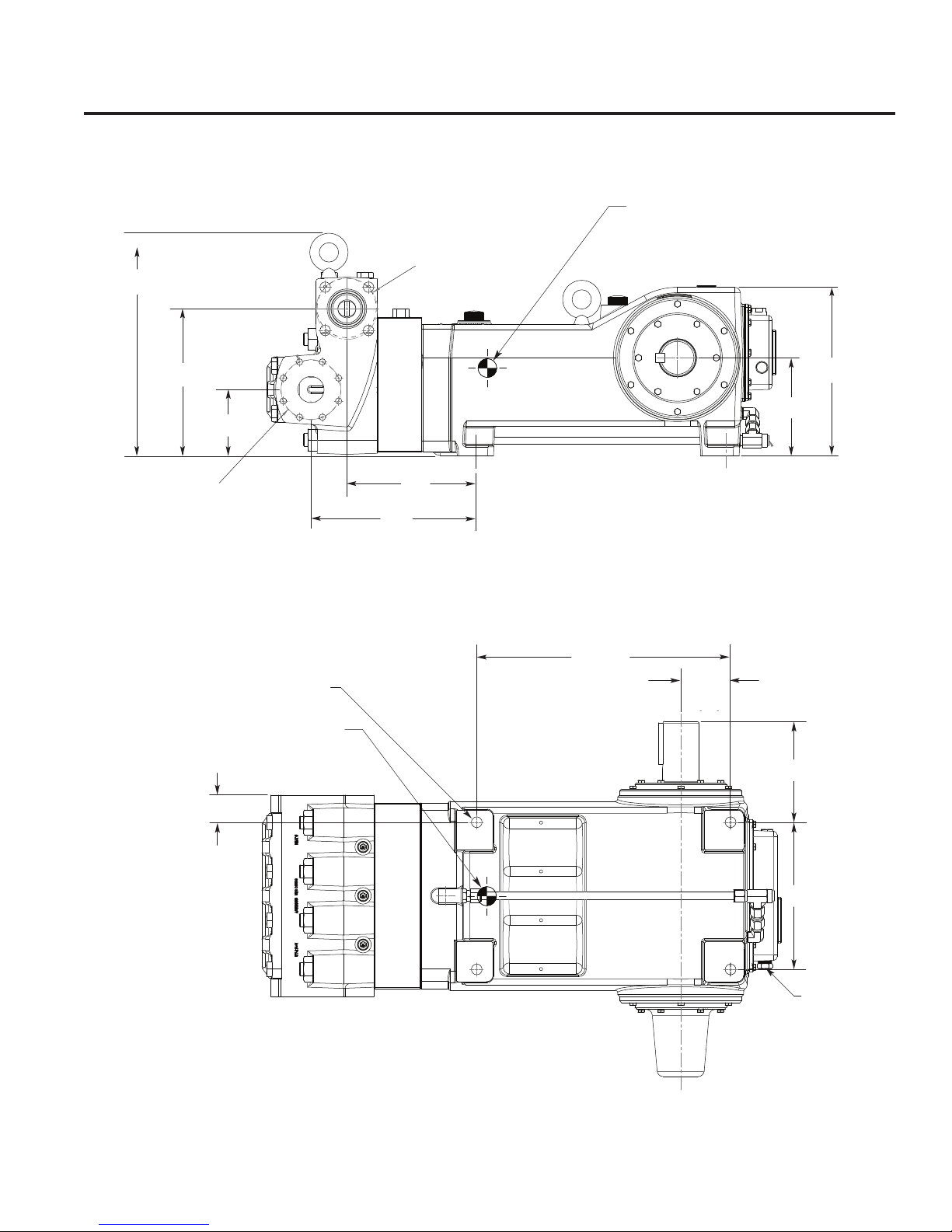

T100 Series High Pressure - Dimensions

W0529B

3.50

(89)

4.83

(123)

Ø 3.00

(76)

0.75 X 0.75 Keyway

(19.05 X 19.05)

Minimum full key

29.11

(739)

16.50

(419)

Center of mass

42.55 (1081)

W0530B

inches

(mm)

Front View

Top View

4

177- 9 9 8 D

T100 Series High - Dimensions (Cont’d)

Center of mass

Outlet:

ASME 16.5

18.6

(473)

1-1/4˝ Class 2500 lbs RTJ

(4X 1-8 UNC-2B)

Both Sides

inches

(mm)

12.30

(312)

5.54

(141)

Inlet:

ASME B16.5

2˝ Class 300 lbs FF

(8X 5/8-11 UNC-2B)

Both Sides

2.22

(56)

4 X Ø0.88

(22.23)

Mounting Holes

Center of mass

13.92

(354)

10.92

(277)

Side View

20.80

(528)

W0531B

4.09

(104)

8.2

(208)

8.27

(210)

14.1

(358)

Bottom View

5

W0532B

12.06

(306)

3/4-14 NPT

177- 9 9 8 D

T100 Series High Pressure - Installation

MINIMUM LIQUID LEVEL

VORTEX

BREAKER

WEIR

PLATE

FEED IN

LINE VELOCITY

5-15 FT/SEC.

LONG-RADIUS

ELBOW

SUCTION LINE

VELOCITY 1-3 FT/SEC.

FULL-OPENING

VALV E

ECCENTRIC REDUCER

W/ FLAT SIDE UP

(OPTIONAL)

SUCTION

STABILIZER

AMPLE NPSHA

PUMP FLUID

CYLINDER

LINE VELOCITY

3-10 FT/SEC.

MINIMUM NUMBER OF ELBOWS

WITH AMPLE PIPE SUPPORTS

(OPTIONAL)

PULSATION

DAMPENER

RELIEF VALVE W/

10 PERCENT MAX.

PRESSURE

ACCUMULATION

PRESSURE

GAUGE

PRESSURE

GAUGE

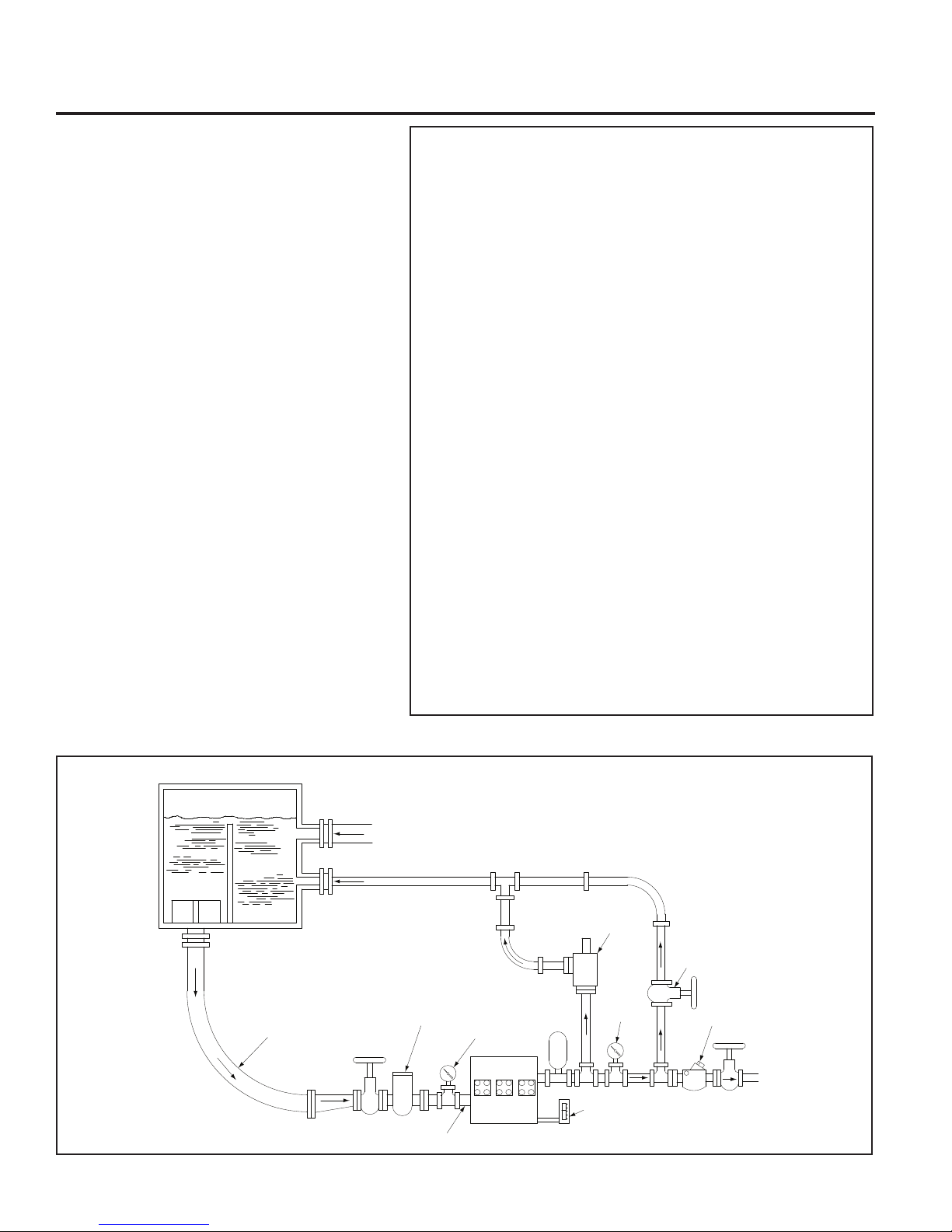

Typical Installation

START-UP AND

CAPACITY-CONTROL

VALV E

W0511A

CHECK VALVE

65 psi cracking pressure

OIL LEVEL

MONITOR

Location

Locate the pump as close to the uid supply source as

possible.

Install it in a lighted clean space where it will be easy

to inspect and maintain. Allow room for checking the oil

level, changing the oil (drain plug on the bottom of pump),

and removing the pump head components (inlet and

discharge retainer plates, manifold, and related items).

Rigging Provisions and

Procedures

Lift pump by attaching rigging to all four eyebolts (14).

Adjust attachment lengths to keep pump level during lifting.

CA UTION: Ey e b o l t s ar e ra t e d to lif t th e we i g h t of the

pump only. Also see center of mass references in

the Dimension Drawings Section.

Mounting

CAUTION: The pump shaft rotation direction is

indicated by arrows on the pump housing.

To prevent vibration, mount the pump and motor securely

on a level rigid base.

On a belt-drive system, align the sheaves accurately;

poor alignment wastes horsepower and shortens the

belt and bearing life. Make sure the belts are properly

tightened, as specied by the belt manufacturer.

On a direct-drive system, align the shafts accurately.

Unless otherwise specied by the coupling manufacturer,

maximum parallel misalignment should not exceed 0.015

in. (0.4 mm) and angular misalignment should be held

to 1° maximum. Careful alignment extends life of the

coupling, pump, shafts, and support bearings. Consult

coupling manufacturer for exact alignment tolerances.

Important Precautions

Adequate Fluid Supply. To avoid cavitation and premature pump failure,

be sure that the pump will have an adequate uid supply and that the inlet

line will not be obstructed. See “Inlet Piping” and consult NPSH chart.

Positive Displacement. This is a positive-displacement pump. Install a

relief valve downstream from the pump. See “Discharge Piping”.

Safety Guards. Install adequate safety guards over all pulleys, belts, and

couplings. Follow all local codes and regulations regarding installation

and operation of the pumping system.

Shut- O Valves. Never install shut-o valves between the pump and

discharge pressure regulator, relief valve, or in the regulator bypass line.

Freezing Conditions. Protect the pump from freezing. See also the

Maintenance Section.

Vacuum at Outlet. Do not allow a vacuum at the pump outlet during

shutdown. A vacuum can damage the diaphragm at start-up. If there is a

vacuum at the pump outlet, allow atmospheric pressure at the outlet for

30 minutes before starting. Wanner Engineering recommends installing

an outlet check valve with a 65 psi (4.5 bar) cracking pressure to prevent

a vacuum condition during shutdown.

Consult the Factory for the following situations:

• Fluid temperature applications – above 180° F (82° C) or below 40° F (4.4° C)

• Pressure feeding of pumps over 500 psig (34.5 bar)

• Viscous uid applications above 100 Cps

• Chemical compatibility problems

• Hot ambient temperatures – above 110° F (43° C)

• Conditions where pump oil may exceed 200° F (93° C) because of a

combination of hot ambient temperatures, hot uid temperature, and

full horsepower load — an oil cooler may be required

• Pump rpm less than 200

6

177- 9 9 8 D

T100 Series High - Installation (Cont’d)

Accessories

Consult installation drawing below for typical system components.

Contact Wanner Engineering or the distributor in your area for

more details.

Inlet Piping (Suction Feed)

Install drain cocks at any low points of the suction line, to permit

draining in freezing conditions.

Provide for permanent or temporary installation of a vacuum

gauge to monitor the inlet suction. To maintain maximum ow,

NPSHA must exceed NPSHR (See chart in Specications

Section). D o no t supply more than one pump fr o m th e sa m e

inlet line if possible.

Supply Tank

Use a supply tank that is large enough to provide time for any

trapped air in the uid to escape. The tank size should be at

least ve times the maximum pump ow rate (in gpm or lpm).

For example: at a maximum rate of 45 gpm, since trapped air

takes ve minutes to escape from water, 5 x 45 = 225 gallons

for a recommended supply tank size.

Isolate the pump and motor stand from the supply tank, and

support them separately.

Install a separate inlet line from the supply tank to each pump.

Install the inlet and bypass lines so they empty into the supply

tank below the lowest water level, on the opposite side of the

bae from the pump suction line.

If a line strainer is used in the system install it in the inlet line

to the supply tank.

To reduce aeration and turbulence, install a completely submerged

bae plate to separate the incoming and outgoing liquids.

Install a vortex breaker in the supply tank, over the outlet port

to the pump.

Place a cover over the supply tank, to prevent foreign objects

from falling into it.

Hose and Routing

Size the suction line at least one size larger than the pump inlet,

and so that the velocity will be 1-3 ft/sec (0.3 to 0.9 m/s):

For pipe in inches: Velocity (ft/sec) = 0.408 x GPM/Pipe ID2

For pipe in mm: Velocity (m/sec) = 21.2 x LPM/Pipe ID2

Keep the suction line as short and direct as possible.

Use exible hose and/or expansion joints to absorb vibration,

expansion, or contraction.

If possible, keep suction line level. Do not have any high points

collecting vapor unless high points are vented.

To reduce turbulence and resistance, do not use 90° elbows.

If turns are necessary in the suction line, use 45° elbows or

arrange sweeping curves in the exible inlet hose.

If a block valve is used, be sure it is fully opened so that the ow

to the pump is not restricted. The opening should be at least the

same diameter as the inlet plumbing ID.

Do not use a line strainer or lter in the suction line unless

regular maintenance is assured. If used, choose a top loading

basket. It should have a free-ow area of at least three times

the free-ow area of the inlet.

Install piping supports where necessary to relieve strain on the

inlet line and to minimize vibration.

Inlet Piping (Pressure Feed)

Provide for permanent or temporary installation of a vacuum/

pressure gauge to monitor the inlet vacuum or pressure.

Pressure at the pump inlet should not exceed 500 psi (34.5 bar);

if it could get higher, install an inlet pressure reducing regulator.

Do no t su p p l y more than one pu m p fr o m th e same inlet li n e .

Inlet Calculations

Acceleration Head

Calculating the Acceleration Head

Use the following formula to calculate acceleration head losses.

Subtract this gure from the NPSHa, and compare the result to

the NPSHr of the Hydra-Cell pump.

Ha = (L x V x N x C) ÷ (K x G)

where:

Ha = Acceleration head (ft of liquid)

L = Actual length of suction line (ft) — not equivalent length

V = Velocity of liquid in suction line (ft/sec) [V = GPM x (0.408

÷ pipe ID

N = RPM of crank shaft

C = Constant determined by type of pump — use 0.066 for

the T100S Hydra-Cell pumps

K = Constant to compensate for compressibility of the uid —

use: 1.4 for de-aerated or hot water; 1.5 for most liquids;

2.5 for hydrocarbons with high compressibility

G = Gravitational constant (32.2 ft /sec

Friction Losses

Calculating Friction Losses in Suction Piping

When following the above recommendations (under “Inlet

Piping”) for minimum hose/pipe I. D. and maximum length,

frictional losses in the suction piping are negligible (i.e., Hf = 0)

if you are pumping a water-like uid.

When pumping more-viscous uids such as lubricating oils,

sealants, adhesives, syrups, varnishes, etc., frictional losses in

the su c t i o n piping ma y bec ome signi c an t . As Hf increase s , th e

available NPSH (NPSHa) will decrease, and cavitation will occur.

In general, frictional losses increase with increasing viscosity,

increasing suction-line length, increasing pump ow rate, and

decreasing suction-line diameter. Changes in suction-line

diameter have the greatest impact on frictional losses: a 25%

increase in suction-line diameter cuts losses by more than two

times, and a 50% increase cuts losses by a factor of ve times.

Consult the factory before pumping viscous uids.

Minimizing Acceleration Head and Frictional Losses

To minimize the acceleration head and frictional losses:

• Keep inlet lines less than 6 ft (1.8 m) or as short as possible

2

)]

2

)

7

177- 9 9 8 D

T100 Series High - Installation (Cont’d)

• Use at least 2.5 in. (63 mm) I.D. inlet hose

• Use suction hose (low-pressure hose, non collapsing) for

the inlet lines

• Minimize ttings (elbows, valves, tees, etc.)

• Use a suction stabilizer on the inlet.

Net Positive Suction Head

NPSHa must be equal to or greater than NPSHr. If not, the

pressure in the pump inlet will be lower than the vapor pressure

of the uid — and cavitation will occur.

Calculating the NPSHa

Use the following formula to calculate the NPSHa:

NPSHa = Pt + Hz - Hf - Ha - Pvp

where:

Pt = Atmospheric pressure

Hz = Vertical distance from liquid surface to pump center line

(if liquid is below pump center line, the Hz is negative)

Hf = Friction losses in suction piping

Ha = Acceleration head at pump suction

Pvp = Absolute vapor pressure of liquid at pumping temperature

Notes:

• In good practice, NPSHa should be 2 ft greater than NPSHr

• All values must be expressed in feet of liquid

Atmospheric Pressure at Various Altitudes

Altitude Pressure Altitude Pressure

(ft) (ft of H

0 33.9 1500 32.1

500 33.3 2000 31.5

1000 32.8 5000 28.2

O) (ft) (ft of H2O)

2

Discharge Piping

Hose and Routing

Use the shortest, most-direct route for the discharge line.

Select pipe or hose with a working pressure rating of at least

1.5 times the maximum system pressure. EX AMPLE: Select

a 1500 psi W.P.-rated hose for systems to be operated at 1000

psi-gauge pressure.

Use exible hose between the pump and rigid piping to absorb

vibration, expansion or contraction.

Support the pump and piping independently. Size the discharge line

so that the velocity of the uid will be 3-10 ft/sec (1-3 m/sec):

For pipe in inches: Velocity (ft/sec) = 0.408 x GPM/Pipe ID2

2

For pipe in mm: Velocity (m/sec) = 21.2 x LPM/Pipe ID

Pressure Relief

In stal l a pressure relie f val ve in th e disc harg e line . Bypass

pressure must not exceed the pressure limit of the pump.

Size the relief valve so that, when fully open, it will be large

enough to relieve the full capacity of the pump without

overpressurizing the system.

Locate the valve as close to the pump as possible and ahead

of any other valves.

Adjust the pressure relief valve to no more than 10% over the

maximum working pressure of the system.

Route the bypass line to the supply tank. See the diagram showing

a typical installation at the beginning of the Installation Section.

If the pump may be run for a long time with the discharge closed

and uid bypassing, install a thermal protector in the bypass line

(to prevent severe temperature buildup in the bypassed uid).

CAUTION: Never install shuto valves in the bypass line

or between the pump and pressure relief valve.

Install a pressure gauge in the discharge line.

Va c uum at Ou t l e t . Do not allow a vacuum at the pump outlet during

shutdown. A vacuum can damage the diaphragm at start-up. If

there is a vacuum at the pump outlet, allow atmospheric pressure

at the outlet for 30 minutes before starting. Wanner Engineering

recommends installing an outlet check valve with a 65 psi cracking

pressure to prevent a vacuum condition during shutdown.

Oil Level Monitoring. Oil level is sensed by the back cover

oat switch (48) and can be used to control the pump system

operation.

Before Initial Start-Up

Before you start the pump, be sure that:

• Pump is stored at a temperature between 40-180 F (4.4-82.2 C)

for a minimum of 24 hours before start up.

• All shuto valves are open, and the pump has an adequate

supply of uid.

• All connections are tight.

• The oil level is within the marking on the dipstick. Add oil as

needed. The oil level can also be viewed through the sight

glass (42) on the back cover (12). The oil level is OK when

the oat (48) is in the middle of the sight glass.

• Connect the oat switch (if used). See Float Switch Section.

• Test the oat switch by removing the side port plug (50) and

manipulating the oat up and down using a suitable tool

(screwdriver). Reinstall side port plug (50).

CAUTION: Take care not to drop tool inside pump.

• The relief valve on the pump outlet is adjusted so the pump

starts under minimum pressure.

• All shaft couplings or drive pulleys have adequate safety guards.

Initial Start-Up

1. Pump must be at or above 40 F (4.4 C) for 24 hours prior to

starting.

2. Open the bypass line start-up and capacity-control valve so the

pump may be started against negligible discharge pressure.

3. Turn on power to the pump motor.

4. Ch e c k the inlet pressure or va c u um. To maint a i n maximu m ow,

inlet vacuum must not exceed 7 in. Hg at 70° F (180 mm Hg at

21° C). Inlet pressure must not exceed 500 psi (34.5 bar).

5. Listen for any erratic noise, and look for unsteady ow. If the

pump does not clear, refer to the Troubleshooting Section.

6. If the system has an air lock and the pump fails to prime:

a. Turn o the power.

b. Remove the pressure gauge from the tee tting at the

pump outlet (see installation diagram).

8

177- 9 9 8 D

T100 Series High - Installation/Maintenance

Initial Start-Up (Cont’d)

Note: Fluid may come out of this port when the plug

is removed. Provide an adequate catch basin for uid

spillage, if required. Fluid will come out of this port

when the pump is started, so we recommend that you

attach adequate plumbing from this port so uid will

not be sprayed or lost. Use high-pressure-rated hose

and ttings from this por t. Take all safety precautions

to assure safe handling of the uid being pumped.

c. Jog the system on and o until the uid coming from this

port is air-free.

d. Turn o the power.

e. Remove the plumbing that was temporarily installed, and

reinstall the pressure gauge or plug.

7. Adjust the bypass line valve to the desired operating pressure.

Do not exceed the maximum pressure rating of the pump.

8. After the system pressure is adjusted, verify the safety relief

valve setting by closing the bypass line valve until the relief

valve opens.

Note: Fluid may come out of the safety relief valve.

Provide an adequate catch basin for uid spillage. Take

all safety precautions to assure safe handling of the

spillage.

9. Reset the bypass line valve to obtain the desired system pressure.

10. Provide a return line from the relief valve to the supply tank,

similar to the bypass line.

Maintenance

Note: The numbers in parentheses are the Reference

Numbers shown in the Parts Section of the manual.

Daily

Check the oil level and the condition of the oil with the pump

turned o. The oil level should be within the marking on the

dipstick or when the oat is in the middle of the sight glass. Add

oil as needed or use continuous monitor.

Use the appropriate Hydra-Oil for the application (contact

Wanner Engineering if in doubt).

CAUTION: If you are losing oil but don’t see any external

leakage, or if the oil becomes discolored and contaminated,

one of the diaphragms (73) may be damaged. Refer to the

Fluid-End Service Section. Do not operate the pump with

a damaged diaphragm.

Do no t le a ve contaminated oil in th e pu m p ho u sing or leav e

the housing empty. Remove contaminated oil as soon as

discovered, and replace it with clean oil.

Periodically

Change the oil after the rst 500 hours of operation;

and then every 2000 hours or six months, whichever

comes rst.

Note: Hydra-Cell T100S Series Pumps come standard with

10W30 motor oil.

Minimum oil viscosity for proper hydraulic end lubrication

is 10-20 cST at 212°F (100°C).

Use of an oil cooler is recommended when process uid

and/or hydraulic end oil exceeds 180°F (82°C).

When changing oil, remove drain plug (40) at the bottom of the

pump so all oil and accumulated sediment will drain out.

Check the inlet pressure or vacuum periodically with a gauge. If

vacuum at the pump inlet exceeds NPSHR, check the inlet piping

system for blockages. If the pump inlet is located above the

su p p l y tank, chec k th e u i d supply le vel and re p l enish if to o lo w.

Inspect pump for hydraulic oil or process uid leaks.

Shutdown Procedure During

Freezing Temperatures

Take all safety precautions to assure safe handling of the

ui d be i n g pu m p e d . Prov i d e ad e q u a t e ca t c h basins for u i d

drainage and use appropriate plumbing from drain ports,

etc., wh e n u shing the pump an d system with a co m p a t i b l e

antifreeze. Drain ports are located in the manifold.

Recommended Tools and

Supplies

The following tools and supplies are recommended for servicing

the T100S Pump:

10 mm hex socket with extension

30 mm hex socket

46 mm hex socket

3/4 in. hex socket

8 mm box-end wrench

13 mm open-end wrench

9/16 in. box-end wrench

3 mm hex wrench

4 mm hex wrench

6 mm hex wrench

8 mm hex wrench

3/8 in. hex wrench

Torx T30

Flathead screwdriver

No. 3 Phillips-head screwdriver

Internal retaining ring pliers

8 in. adjustable wrench

Torque wrench, adjustable from 250 to 450 ft-lbs (339 to 610 N-m)

Pipe wrench

Loctite 242

New Hydra-Oil

Wanner T100S Tool Kit (see T100S Tool Kit Parts)

9

177- 9 9 8 D

Loading...

Loading...