Hydra-Cell P300 Installation Service

T M

P300 Metering Pump

W0000A

Installation & Service

P300-991-2400B

1204 Chestnut Avenue, Minneapolis, MN 55403

TEL: (612) 332- 56 81 FAX: (612) 332- 69 37

TOLL-FREE FAX [US only]: (800) 332-6812

www.hydra-cell.com/metering

email: sales@wannereng.com

P300 Contents

W0000A

Page

Specifications ..........................................................................2

Dimensions .............................................................................3

Installation ...............................................................................5

Maintenance ............................................................................7

Fluid End

Service ..................................................................................8

Parts List ............................................................................10

Hydraulic End Parts List .......................................................11

Reducer Parts List ................................................................12

Troubleshooting.....................................................................14

Replacement Parts Kits ........................................................15

Warranty ................................................................................16

P300 Specifications

Steady State Accuracy ±1%

Linearity ±3%

Repeatability ±3%

Maximum Pressure

Metallic Head: 2500 psi (173 bar)

Maximum Inlet Pressure 500 psi (35 bar)

Maximum Temperature

Metallic Head: 250°F (121°C) – consult factory for

temperatures above 160°F (71°C)

Component Identification

Pump Assembly

Hydraulic End

Reducer

Outlet

Inlet Port 1/2 inch NPT or BSPT

Discharge Port 1/2 inch NPT or BSPT

Shaft Rotation Bi-directional

Oil Capacity 1.1 US quart (1.05 liters)

Weight

Metallic Head: 51 lbs (23.1 kg)

Metallic Head with motor adapter: 57 lbs (25.9 kg)

Oil Fill Cap

Pump Assembly

Fluid End

ID Plate

Inlet

Gallons Per Hour (GPH) Maximum Flow at Designated Pressure

GPH Metallic Pump Heads

100 PSI (*) 500 PSI (*) 1500 PSI (*) 2500 PSI (*)

(¼) 1.85 (¼) 1.50 (¼) 1.15 (¼) 18 100:1

2.00

2.51

(¼) 2.36 (¼) 1.98 (¼) 1.60 (¼) 22.5 80:1

3.37 (¼) 3.21 (¼) 2.79 (¼) 2.36 (¼) 30 60:1

4.06 (¼) 3.88 (¼) 3.43 (¼) 2.97 (¼) 36 50:1

5.09 (¼) 4.89 (¼) 4.40 (¼) 3.88 (¼) 45 40:1

6.80 (¼) 6.58 (¼) 6.01 (¼) 5.39 (¼) 60 30:1

8.17 (¼) 7.94 (¼) 7.30 (¼) 6.60 (¼) 72 25:1

(¼) 9.62 (¼) 9.23 (¼) 8.41 (½) 90 20:1

10.23

13.66 (¼) 13.34 (¼) 12.46 (½) 11.44 (½) 120 15:1

(¼) 20.10 (¼) 18.90 (½) 17.50 (¾) 180 10:1

20.52

(¼) 26.86 (¼) 25.35 (½) 23.55 (1) 240 7.5:1

27.38

41.10 (¼) 40.37 (½) 38.24 (¾) 35.67 (1½) 360 5:1

(¼) 53.89 (½) 51.13 (1) 47.78 (2) 480 7.5:1

54.82

(¼) 80.91 (¾) 76.91 (1½) 72.00 (3) 720 5:1

82.26

*Required Motor HP

2

Pump

RPM

Gear

Ratio

Motor

RPM

1800

3600

P300-991-2400B

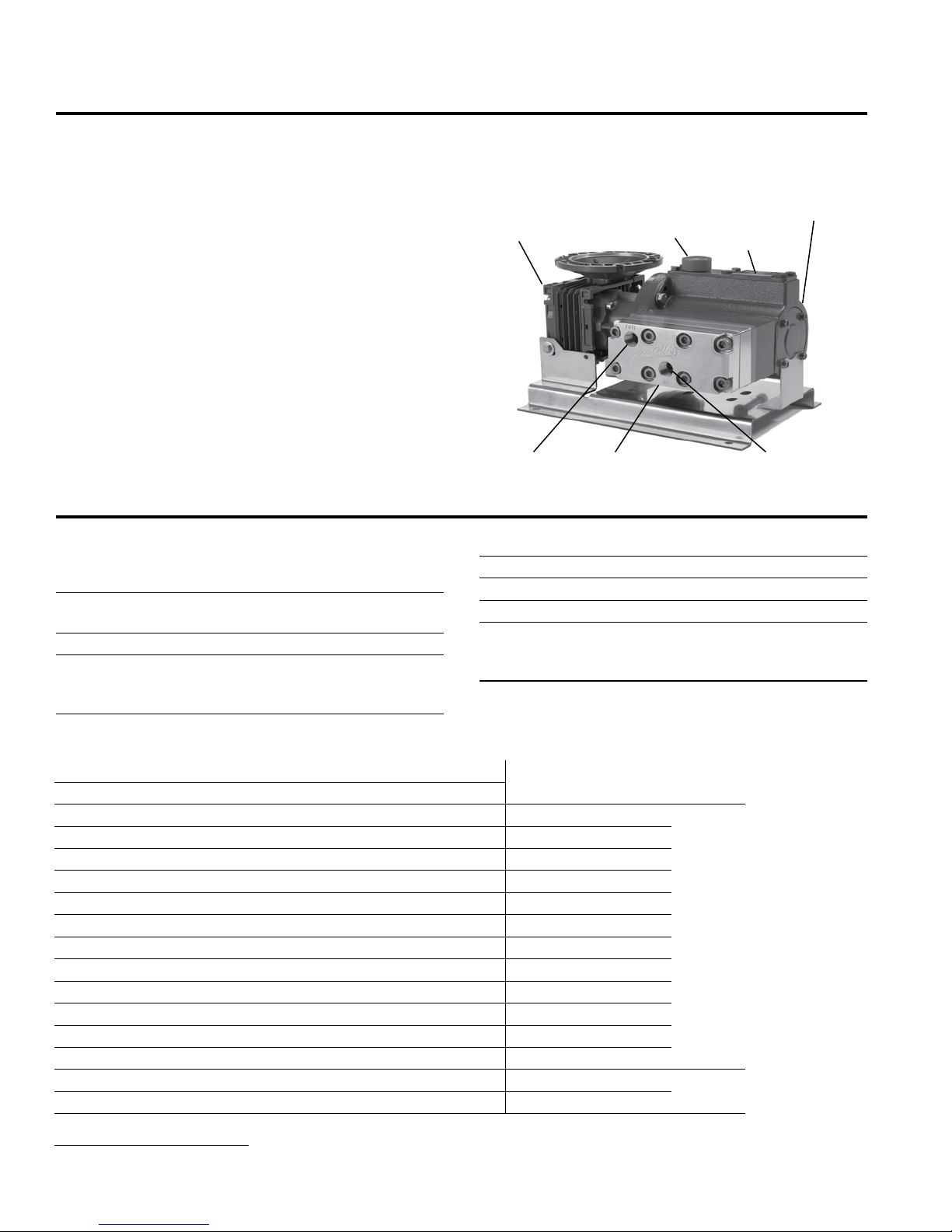

P300 Dimensions

OUT

IN

8.68

(220.5)

0.24

(6.1)

9.38

(238.3)

11.38

(289.1)

14.50

(368.3)

14.75

(374.6)

4.52

(114.8)

5.86

(148.8)

1.37

(34.8)

1

1/2" NPT or

1/2" BSPT

16.02

(406.9)

0.24

(6.1)

1/2" NPT or 1/2" BSPT

1

Note:

Worm Gear Reducer available

in the following ratios: 5:1, 7.5:1,

10:1, 15:1, 20:1, 25:1, 30:1, 40:1,

50:1, 60:1, 80:1, 100:1.

4.65

(118.1)

2.36

(59.9)

5.13

(130.3)

9.60

(243.8)

9.64

(244.9)

9.87

(250.7)

8.63

(219.2)

9.63

(244.6)

14.50

(368.3)

12.50

(317.5)

Ø0.41

(10.4)

4X

11.99

(304.5)

Ø6.50

(165.1)

NEMA 56C Flange

Pilot

Ø4.500

(114.3)

Bolt Circle

Ø5.875

(149.2)

NEMA

56C

Ø0.625

(15.88)

Square

Key

0.187

(4.75)

W0003

P300 Models with Metallic Pumping Head

304 Stainless Steel

316 Stainless Steel

Hastelloy® C

3

P300-991-2400B

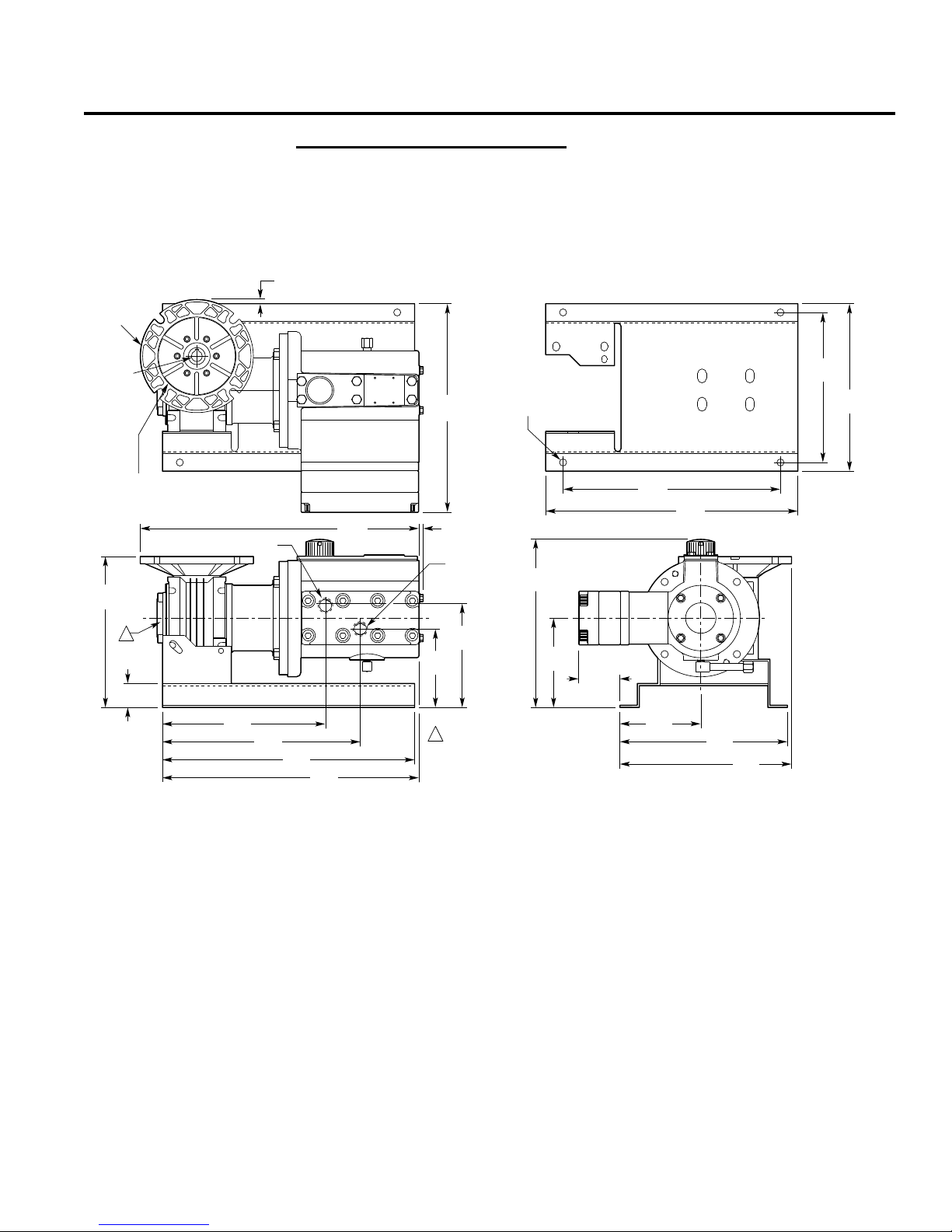

P300 Dimensions

OUT

IN

13.15

(334)

8.68

(220.5)

16.51

(419.4)

0.24

(6.1)

1.37

(34.8)

Ø7.00

(177.8)

11.99

(304.5)

8.63

(219.2)

9.63

(244.6)

13.14

(333.8)

9.60

(243.8)

5.13

(130.3)

2.36

(59.9)

4.65

(118.1)

9.64

(244.9)

0.48

(12.2)

12.50

(317.5)

Ø0.41

(10.4)

4X

14.50

(368.3)

NEMA 143/5TC Flange

Ø4.500 (114.3) Pilot

Ø5.875 (149.2) B.C.

NEMA 143/5TC

Ø0.875 (22.2)

0.187 (4.75) Square Key

1

1/2" NPT or

1/2" BSPT

1/2" NPT or

1/2" BSPT

9.38

(238.3)

11.38

(289.1)

14.50

(368.3)

5.86

(148.8)

4.52

(114.8)

15.07

(382.8)

1

Worm Gear Reducer

available in the following

ratios - 5:1, 7.5:1

Note:

2. Weight = 57 lbs (25.9 kg)

(no motor)

W0305

P300 Models with Metallic Pumping Head and Motor Adapter

304 Stainless Steel

316 Stainless Steel

Hastelloy® C

Inches (mm)

4

P300-991-2400B

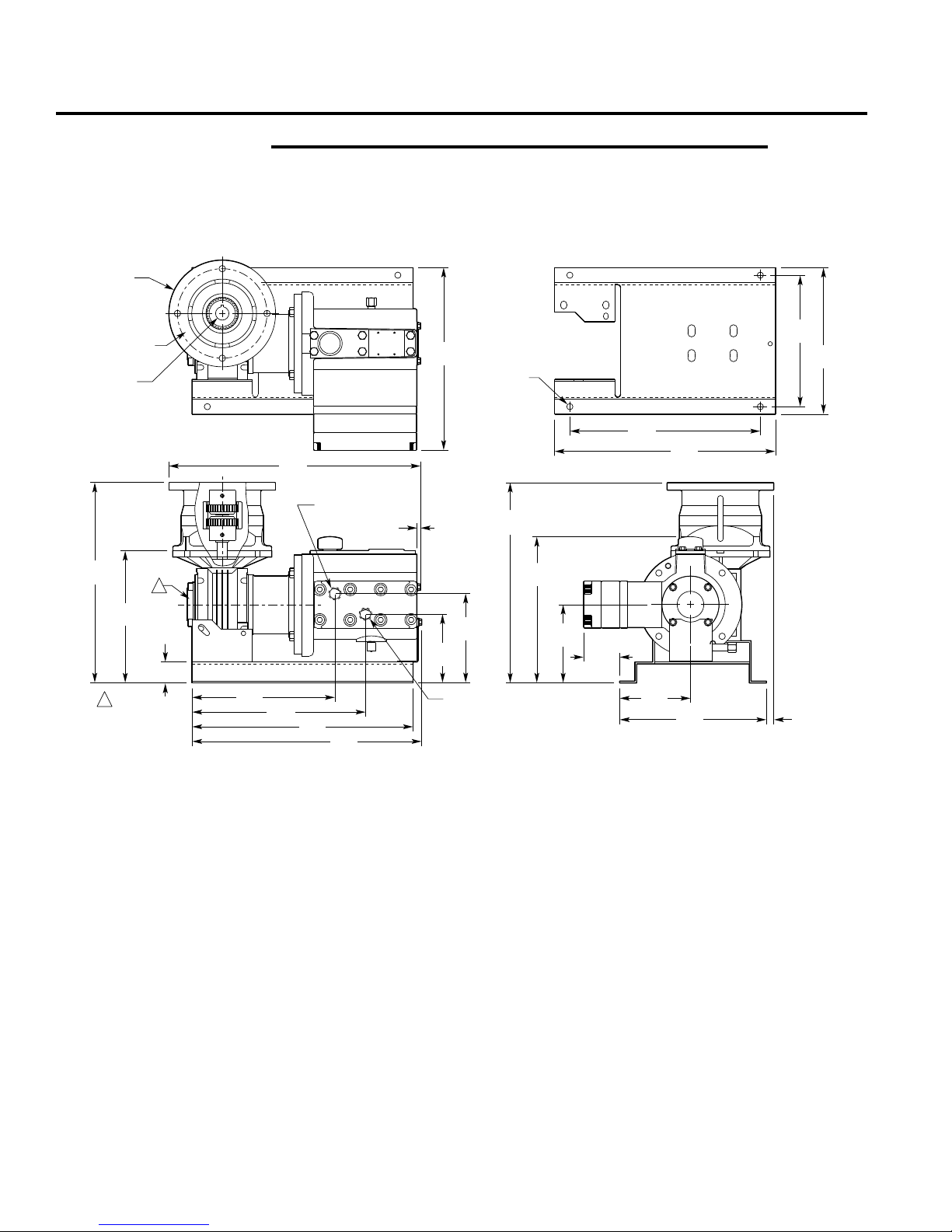

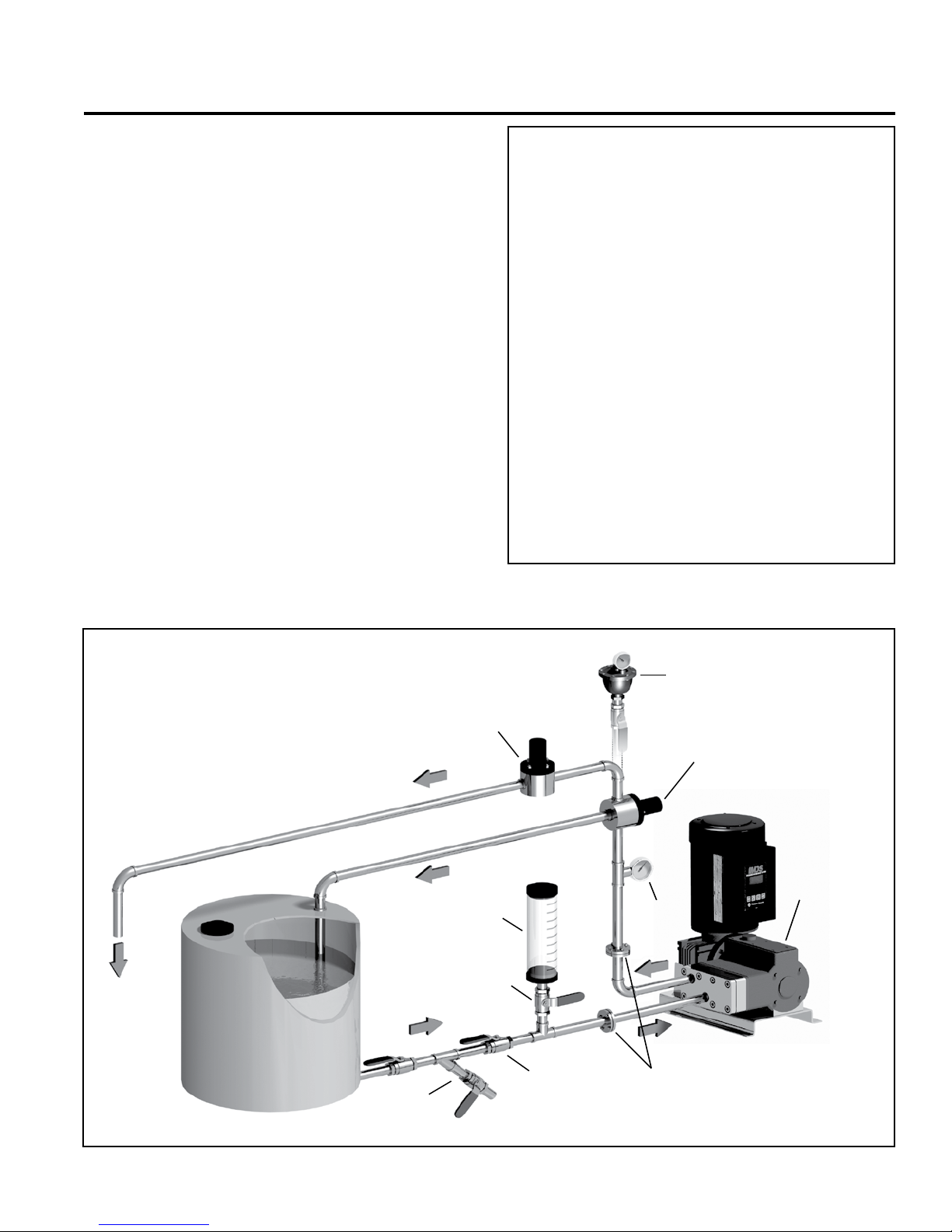

P300 Installation

P300

METERING PUMP

W0325

PULSATION

DAMPENER

(OPTIONAL)

CALIBRATION

CYLINDER

Y-STRAINER

ISOLATING VALVE

BALL VALVE

RELIEF

VALVE

FLANGES & MANIFOLDS

BACK PRESSURE

VALVE

(To process)

PRESSURE

GAUGE

Location

NOTE: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

Locate the pump as close to the supply source as possible.

Install it in a lighted clean space where it will be easy to inspect

and maintain.

Motor and Controller

The P Series pump shaft can rotate in either direction, therefore

direction of motor shaft rotation is not critical.

Accessories

Consult installation drawing below for typical precision metering

fluid system components. Contact Wanner Engineering or the

distributor in your area for more details.

Important Precautions

Ad equate Fluid Suppl y. To avoid c avitati on and

premature pump failure, be sure that the pump will have

an adequate fluid supply and that the inlet line will not be

obstructed. See Inlet Piping on page 6.

Positive Displacement. This is a positive-displacement

pump. To avoid severe system damage if the discharge line

ever becomes blocked, install a relief valve downstream

from the pump. See Discharge Piping on page 6.

Safety Guards. Follow all codes and regulations regarding

installation and operation of the pumping system.

Shut-Off Valves. Never install shut-off valves between

the pump and discharge pressure regulator, or in the

regulator bypass line.

Consult the Factory for the following situations:

• Extreme temperature applications (above 160°F or

below 40°F)

• Pressure feeding of pumps

• Viscous or abrasive fluid applications

• Chemical compatibility problems

• Hot ambient temperatures (above 110°F)

5

P300-991-2400B

Loading...

Loading...