Hydra-Cell P100 Installation, Operation & Maintenance Instructions Manual

TM

P100 Metering Pump

Installation, Operation & Maintenance

P100-991-2400C

1204 Che stnut Avenue, Minneapo lis, MN 55403

Tel: (612) 332-5681 Fax: (612) 332-6937

Toll-fre e fax [US only]: (800) 332-6812

www.hydra-cell.com/metering

email: sales@wannereng.com

W0032B

Metallic pump shown

P100 Contents

W0032B

Page

Operation ................................................................................2

Specications ..........................................................................2

Dimensions .............................................................................4

Installation ...............................................................................5

Calibration ...............................................................................7

Maintenance ............................................................................7

Fluid End

Service .................................................................................8

Parts List .............................................................................10

Hydraulic End Parts List ........................................................12

Reducer Parts List.................................................................13

Troubleshooting .....................................................................14

Replacement Parts Kits ........................................................15

Warranty ................................................................................16

Hydra-Cell Metering Solutions Pumps are hydraulicallyactuated, hydraulically-balanced diaphragm metering pumps

that exceed API 675 performance standards of ±1% steady state

accuracy, ±3% linearity and ±3% repeatability.

Due to their multiple diaphragm design, the P Series

metering pumps, with the exception of the P100, provide virtually

“pulse-free” linear ow. Unlike conventional single diaphragm

metering pumps, this linear ow reduces the need for pulsation

dampeners and increases the reliability, performance, and

safety of the metering pump system.

Pump operation and plunger activation are accomplished

through a crankshaft (P100, P200 and P300) or wobble plate

(P400, P500 and P600). Horizontal disk check valves allow for

the pumping of particulates that ordinarily collect on vertical

ball check valves common to conventional metering pumps.

P Series pumps utilize speed to adjust ow rate through a

motor and variable-frequency drive (VFD), eliminating the need

for mechanical adjustment.

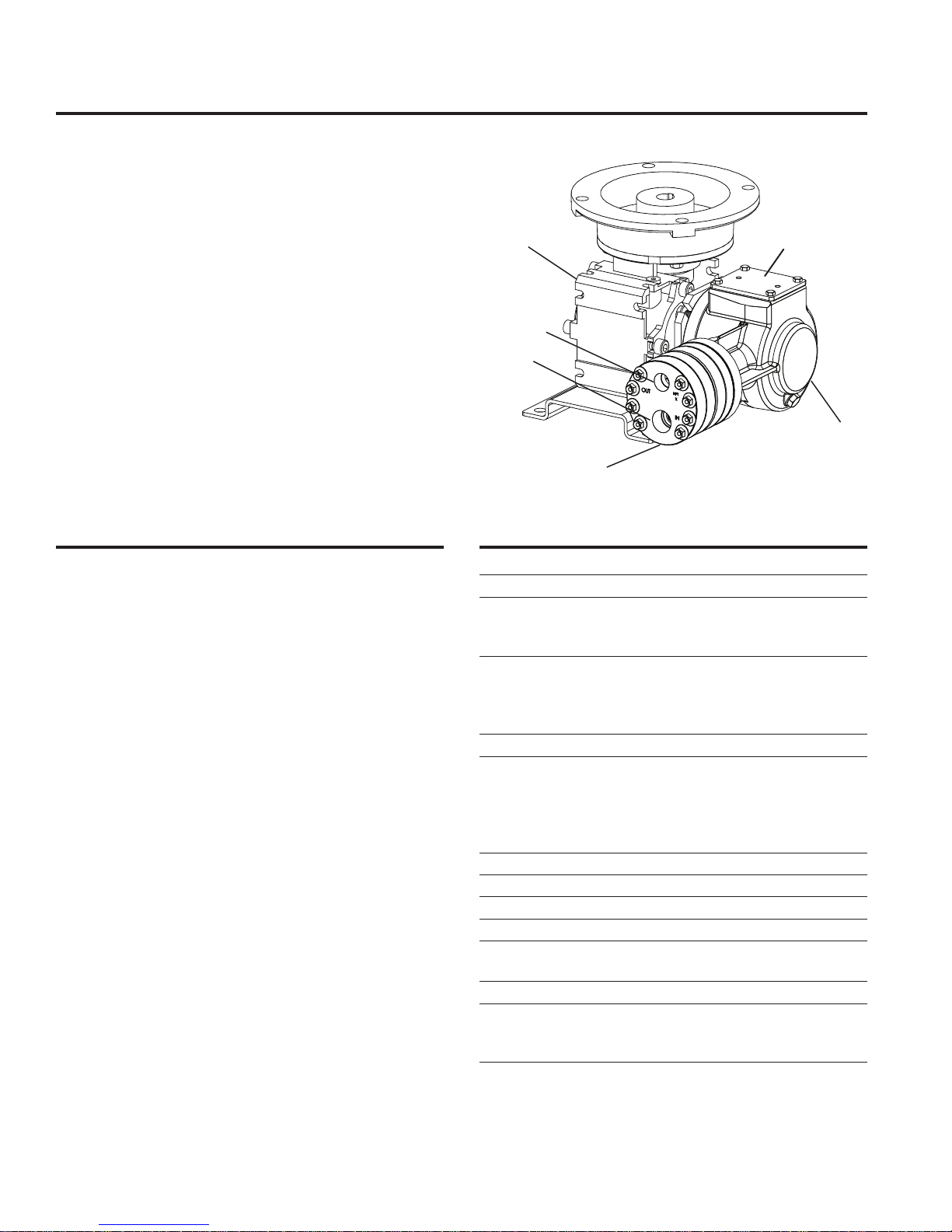

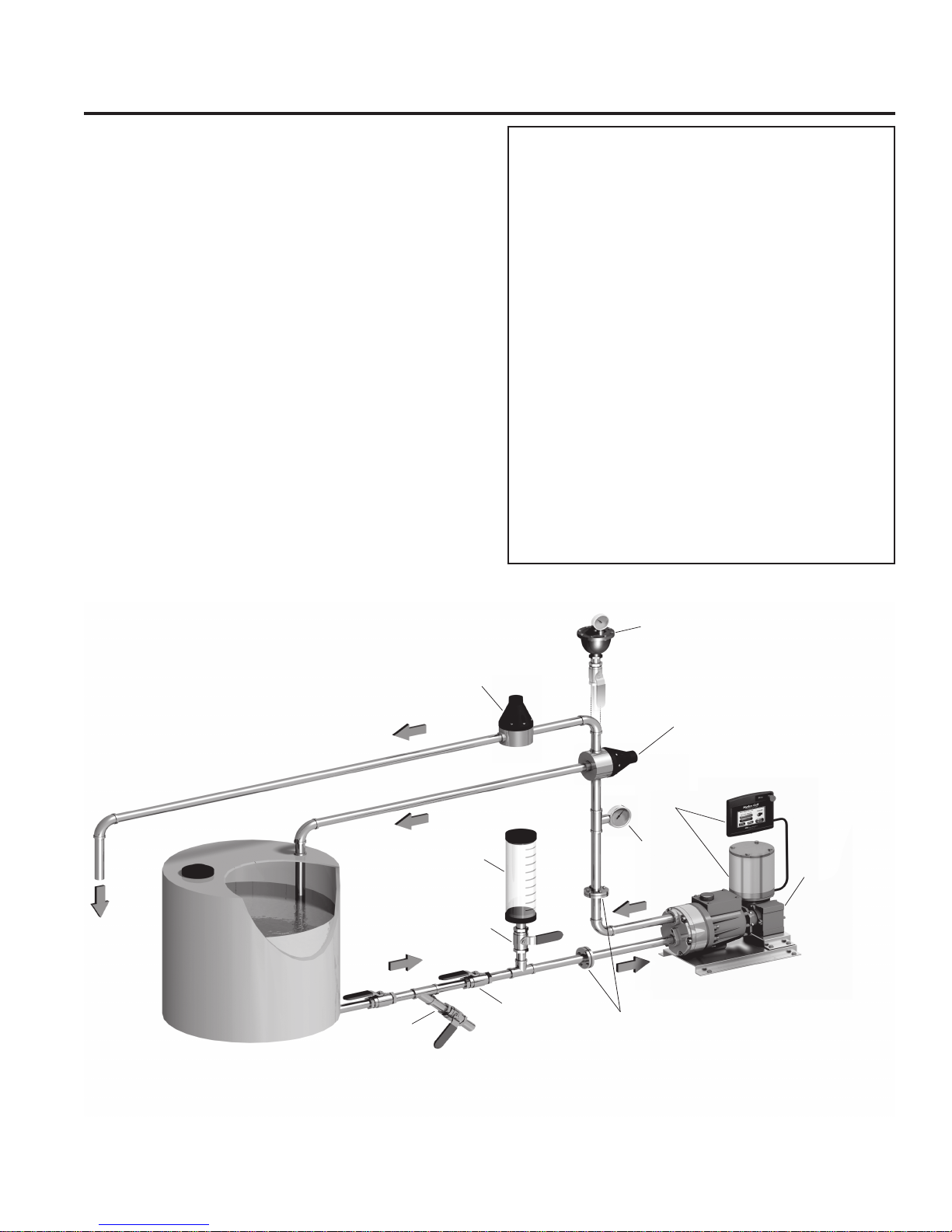

Component Identication

Reducer

Outlet

Inlet

Pump Assembly

Fluid End

Oil Cover/ID Plate

Pump Assembly

Hydraulic End

P100 SpecicationsP100 Operation

Diaphragms per Liquid End 1 (non Kel-Cell pistons)

Flow Control Electronic variable speed drive

Steady State Accuracy ±1%

Linearity ±3%

Repeatability ±3%

Maximum Pressure

Metallic Heads: 1500 psi (103 bar)

Non-Metallic Heads: PVDF: 350 psi (24 bar)

Polypropylene: 250 psi (17 bar)

Maximum Inlet Pressure 250 psi (17 bar)

Fluid Operating Temperatures*

Metallic Head: 250°F (121°C)

Non-Metallic Head: 140°F (60°C)

* Consult factory for correct component selection for

temperatures from 160˚F (71˚C) to 250˚F (121˚C).

Inlet Port 1/2 inch NPT or BSPT

Discharge Port 3/8 inch NPT or BSPT

Maximum Solids 200 microns

Shaft Rotation Bi-directional

Materials Used See Replacement Parts Kits Section

for individual pump materials.

Oil Capacity 1/8 US quart (0.12 liters)

Weight (less motor)

Metallic Heads: 21.2 lbs (9.6 kg)

Non-Metallic Heads: 19.1 lbs (8.7 kg)

2

P100-991-2400C

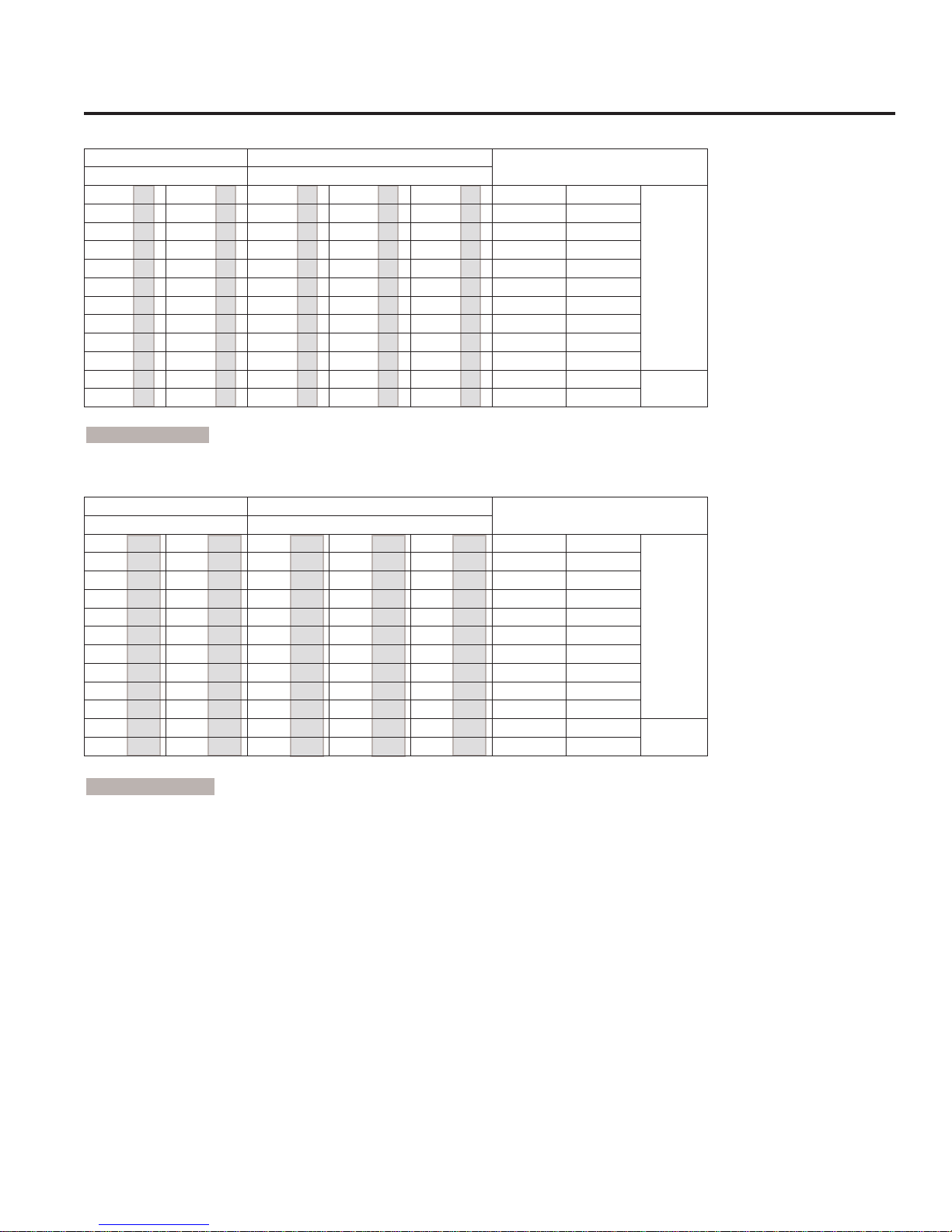

P100 Specications (Cont’d)

Performance Maximum Flow at Designated Pressure - Imperial *

All Pumps (gph) Metallic Pump Heads Only (gph)

100 psi 250 psi 500 psi 1000 psi 1500 psi

1.086 (½) 1.077 (¾) 1.058 (¾) 1.015 (¾) 0.981 (¾) 30 60:1

1.316 (½) 1.300 (¾) 1.273 (¾) 1.220 (¾) 1.184 (¾) 36 50:1

1.630 (½) 1.628 (½) 1.607 (¾) 1.535 (¾) 1.492 (¾) 45 40:1

2.192 (½) 2.182 (½) 2.148 (½) 2.056 (½) 2.000 (¾) 60 30:1

2.643 (½) 2.626 (½) 2.582 (½) 2.473 (½) 2.405 (½) 72 25:1

3.318 (½) 3.291 (½) 3.232 (½) 3.099 (½) 3.014 (½) 90 20:1

4.444 (½) 4.400 (½) 4.316 (½) 4.141 (½) 4.028 (½) 120 15:1

6.695 (½) 6.618 (½) 6.483 (½) 6.226 (½) 6.057 (½) 180 10:1

8.947 (½) 8.836 (½) 8.651 (½) 8.311 (½) 8.085 (½) 240 7.5:1

13.45 (½) 13.27 (½) 12.99 (½) 12.48 (½) 12.14 (¾) 360 5:1

17.95 (½) 17.71 (½) 17.32 (½) 16.65 (¾) 16.20 (¾) 480 7.5:1

26.96 (½) 26.58 (½) 25.99 (¾) 24.99 (¾) 24.31 (1) 720 5:1

*Capacity data shown is for pumps with elastomeric diaphragms. Consult factor y for performance characteristics of pumps with PTFE diaphragms.

( ) Required Motor hp

Performance Maximum Flow at Designated Pressure - Metric *

All Pumps (lpm) Metallic Pump Heads Only (lpm)

7 bar 17 bar 34 bar 69 bar 103 bar

3.425 (0.18) 3.396 (0.18) 3.337 (0.18) 3.203 (0.18) 3.095 (0.55) 25 60:1

4.150 (0.18) 4.102 (0.18) 4.016 (0.18) 3.850 (0.18) 3.735 (0.55) 30 50:1

5.140 (0.18) 5.135 (0.18) 5.068 (0.18) 4.841 (0.25) 4.708 (0.55) 37.5 40:1

6.916 (0.18) 6.884 (0.18) 6.777 (0.18) 6.486 (0.25) 6.307 (0.25) 50 30:1

8.336 (0.18) 8.283 (0.18) 8.145 (0.18) 7.801 (0.25) 7.587 (0.25) 60 25:1

10.47 (0.18) 10.38 (0.18) 10.20 (0.18) 9.774 (0.25) 9.507 (0.25) 75 20:1

14.02 (0.18) 13.88 (0.18) 13.61 (0.18) 13.06 (0.37) 12.71 (0.37) 100 15:1

21.12 (0.18) 20.88 (0.18) 20.45 (0.18) 19.64 (0.37) 19.11 (0.37) 150 10:1

28.22 (0.18) 27.87 (0.18) 27.29 (0.18) 26.22 (0.37) 25.50 (0.37) 200 7.5:1

42.43 (0.18) 41.87 (0.18) 40.96 (0.18) 39.37 (0.37) 38.30 (0.55) 300 5:1

56.63 (0.37) 55.86 (0.37) 54.64 (0.37) 52.53 (0.55) 51.10 (0.55) 400 7.5:1

85.04 (0.37) 83.85 (0.37) 81.98 (0.55) 78.84 (0.55) 76.70 (0.55) 600 5:1

*Capacity data shown is for pumps with elastomeric diaphragms. Consult factor y for performance characteristics of pumps with PTFE diaphragms.

( ) Required Motor kW

Pump

rpm

Pump

rpm

Gear

Ratio

Gear

Ratio

Motor

rpm

1800

3600

Motor

rpm

1500

3000

3

P100-991-2400C

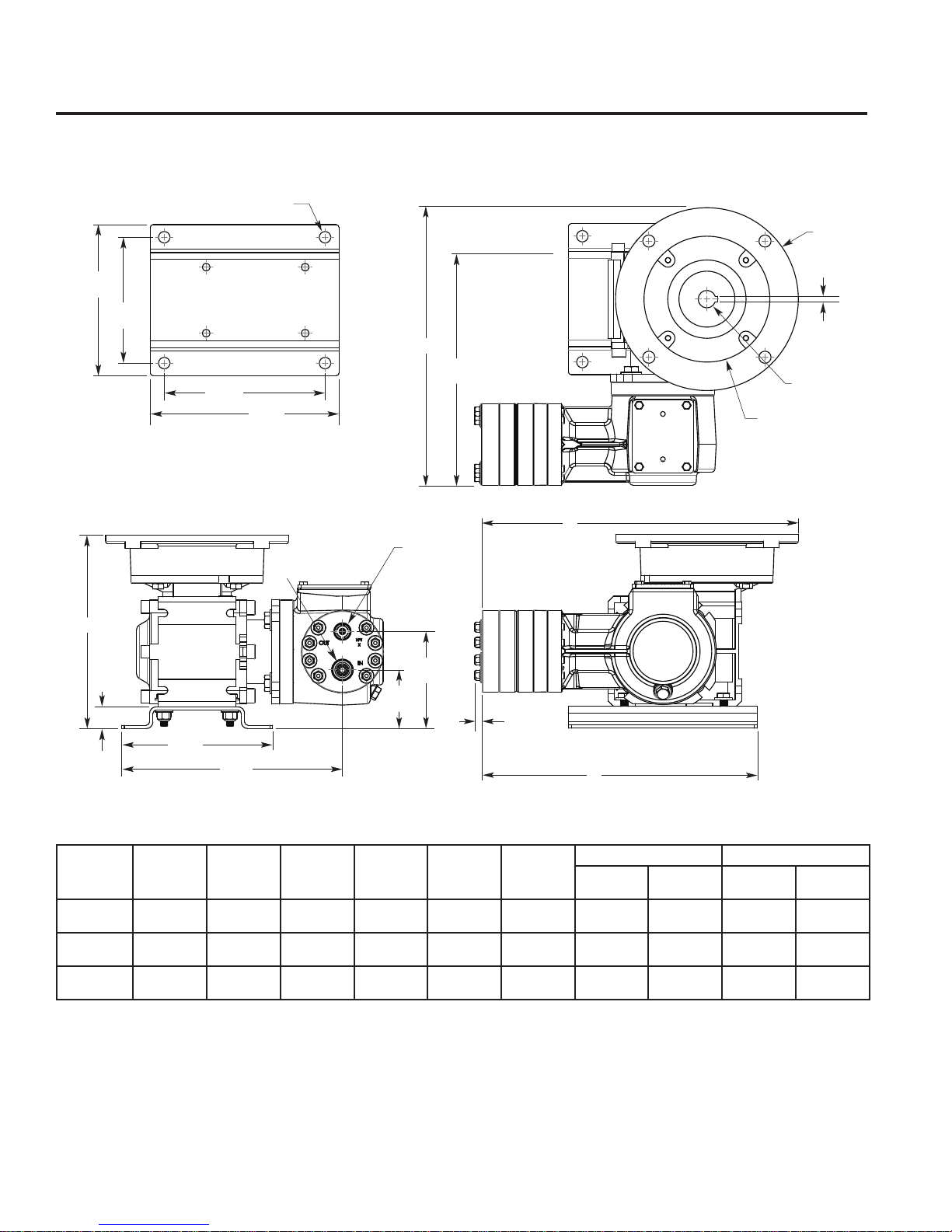

5.75

(146.1)

7.27

(184.7)

5.40

(137.2)

4.50

(114.3)

Ø0.41

(10.4)

(4X)

0.78

(19.8)

5.40

(137.2)

7.90

(200.6)

2.10

(53.3)

3.47

(88.1)

1/2" NPT or

1/2" BSPT

3/8" NPT or

3/8" BSPT

E

9.36

(237.8)

A

B

C

F

D

H

0.26

(6.7)

G

W0035A

P100 Dimensions

P100 Models: Metallic and Non-Metallic

Input

Frame Size

NEMA 56C

IEC 63 B5

IEC 71 B5

A B C D E

9.93 (252.2)

9.42 (239)

9.81 (249.2)

Ø 6.54

(Ø 166)

Ø 5.51

(Ø 140)

Ø 6.30

(Ø 160)

Dimensions in Inches (Millimeters)

Ø 4.50

(Ø 114.3)

Ø 3.74

(Ø 95)

Ø 4.33

(Ø 110)

(Ø 15.7)

(Ø 11)

(Ø 14)

Ø .62

Ø .43

Ø .55

Ø 6.92

(Ø 175.8)

Ø 6.74

(Ø 171.3)

Ø 6.74

(Ø 171.3)

(Square

Key)

0.187 (4.75)

0.157 (4)

0.196 (5)

F

Metallic

Pump Head

(2 87. 4)

(275. 3)

(285.5)

G H

11. 36

10.84

11. 24

Plastic

Pump Head

11. 61

(294.9)

11. 09

(281.7)

11. 49

(291. 8)

Metallic

Pump Head

9.84 (250)

9.84 (250)

9.84 (250)

Plastic

Pump Head

10.09

(256 .3)

10.09

(256 .3)

10.09

(256 .3)

4

P100-991-2400C

P100 Installation

W0323A

(To process)

Pulsation

Dampener

(Optional)

Relief

Valve

Flanges & Manifolds

Ball Valve

Y-Strainer

Isolating

Valve

Calibration

Cylinder

Pressure

Gauge

Back Pressure

Valve

P-Series

Metering Pump

Typical Metering Installation

Controllers

& Motors

Location

Locate the pump as close to the supply source as possible.

Install the pump system in a lighted clean space where it will be

easy to inspect and maintain.

Motor and Controller

The P Series pump shaft can rotate in either direction,

therefore direction of motor shaft rotation is not critical.

Flow rate is determined by motor speed, which is controlled

using an inverter duty constant torque motor and VFD. Flow

rate functions can also be easily controlled using the Hydra-Cell

Control Freak and appropriate motor.

Accessories

Consult installation drawing below for typical metering uid

system components. Contact Wanner Engineering or the

distributor in your area for more details.

Important Precautions

Adequate Fluid Supply. To avoid cavitation and

premature pump failure, be sure that the pump will have

an adequate uid supply and that the inlet line will not be

obstructed. See Inlet Piping.

Positive Displacement. This is a positive-displacement

pump. To avoid severe system damage if the discharge line

ever becomes blocked, install a relief valve downstream

from the pump. See Discharge Piping.

Safety Guards. Follow all codes and regulations regarding

installation and operation of the pumping system.

Shut-O Valves. Never install shut-o valves between

the pump and relief valve, or in the regulator bypass line.

Consult the Factory for the following situations:

• Extreme temperature applications (above 160°F or

below 40°F)

• Pressure feeding of pumps

• Viscous or abrasive uid applications

• Chemical compatibility problems

• Hot ambient temperatures (above 110°F)

5

P100-991-2400C

Loading...

Loading...