Hydra-Cell D-10, G-10 Installation & Service Manual

Installation & Service

W0215B

W0214B

D10-991-2400B

Models:

D-10 and G-10

WANNER ENGINEERING, INC.

1204 Chestnut Avenue, Minneapolis, MN 55403

TEL: (612) 332- 5 6 81 FA X: (612) 332- 693 7

TOLL-FREE FAX [US only]: (800) 332-6812

www.hydra-cell.com

email: sales@wannereng.com

D/G-10 Contents

Page

Specifications ..........................................................................2

Dimensions .............................................................................4

Installation ...............................................................................5

Maintenance ............................................................................9

Service (Fluid End) ...............................................................10

Service (Hydraulic End) ........................................................15

Troubleshooting ....................................................................18

D/G-10 Specifications

Max Pressure Metallic: 1000 psi (70 bar)

Non-Metallic: 250 psi (17 bar)

Slurry Duty (SD): 300 psi (21 bar)

Capacity @ Max Pressure

rpm gpm I/min

D/G-10-X 1450 7.8 29.0

D/G-10-E 1750 8.0 30.3

D/G-10-S 1750 6.0 22.7

D/G-10-I 1750 3.9 14.9

Delivery @ Max Pressure

revs/gal revs/liter

D/G-10-X 185 50

D/G-10-E 219 58

D/G-10-S 292 77

D/G-10-I 448 117

Max Inlet Pressure

Metallic: 250 psi (17 bar)

Non-Metallic: 50 psi (3.5 bar)

Slurry Duty (SD): 50 psi (3.5 bar)

Max Temperature

Metallic: 250°F (121°C) – consult factory for

temperatures above 160°F (71°C)

Non-Metallic: Polypropylene: 120°F (49°C);

Kynar, Celcon & Slurry Duty: 140°F

(60°C) – consult factory for tempera tures above 120°F (49°C)

Inlet Port D-10: 1 inch NPT

G-10: 1 inch BSPT

Discharge Port D-10: 3/4 inch NPT

G-10: 3/4 inch BSPT

Shaft Diameter 7/8 inch (22.22 mm)

Shaft Rotation Bidirectional

Bearings Tapered roller

Oil Capacity 1.1 US quarts (1.05 liters)

Weight Metallic Heads: 48 lbs (22 kg)

Non-Metallic Heads: 35 lbs (16 kg)

Calculating Required

Horsepower (kW)*

15 x rpm

63,000

15 x rpm

84,428

* rpm equals pump shaft rpm. HP/kW is required application

power. Use caution when sizing motors with variable speed

drives.

+

+

gpm x psi

1,4 60

lpm x bar

511

=

electric motor HP*

=

electric motor kW*

2

D10-991-2400B

RPM

0

NPSHr (feet of water)

NPSHr (meters of water)

1750

0 200 400 600 800 1000 1200 1400 1600 1800

4

8

12

16

20

24

0

1

2

3

4

5

6

7

1450

D/G-10-X

D/G-10-E

D/G-10-S

D/G-10-I

W0235

RPM

0 200 400 600 800 1000 1200 1400 1600 1800

10.0

0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

1750

Liters Per Minute

Gallons Per Minute

16.0

18.0

20.0

22.0

24.0

26.0

14.0

30.0

32.0

34.0

36.0

38.0

28.0

2.0

4.0

6.0

8.0

10.0

12.0

0

D/G-10-I

D/G-10S

D/G-10-E

1450

D/G-10-X

200 PSI (14 bar)

500 PSI (35 bar)

1000 PSI (70 bar)

W0236

1450

1750

RPM

0

Lift (feet of water)

0

1

2

3

4

5

6

7

8

200 400 600 800 1000 1200 1400 1600 1800

D/G-10-X

D/G-10-E

D/G-10-S

D/G-10-I

Lift (meters of water)

0

1.0

0.5

1.5

2.0

2.5

W0234

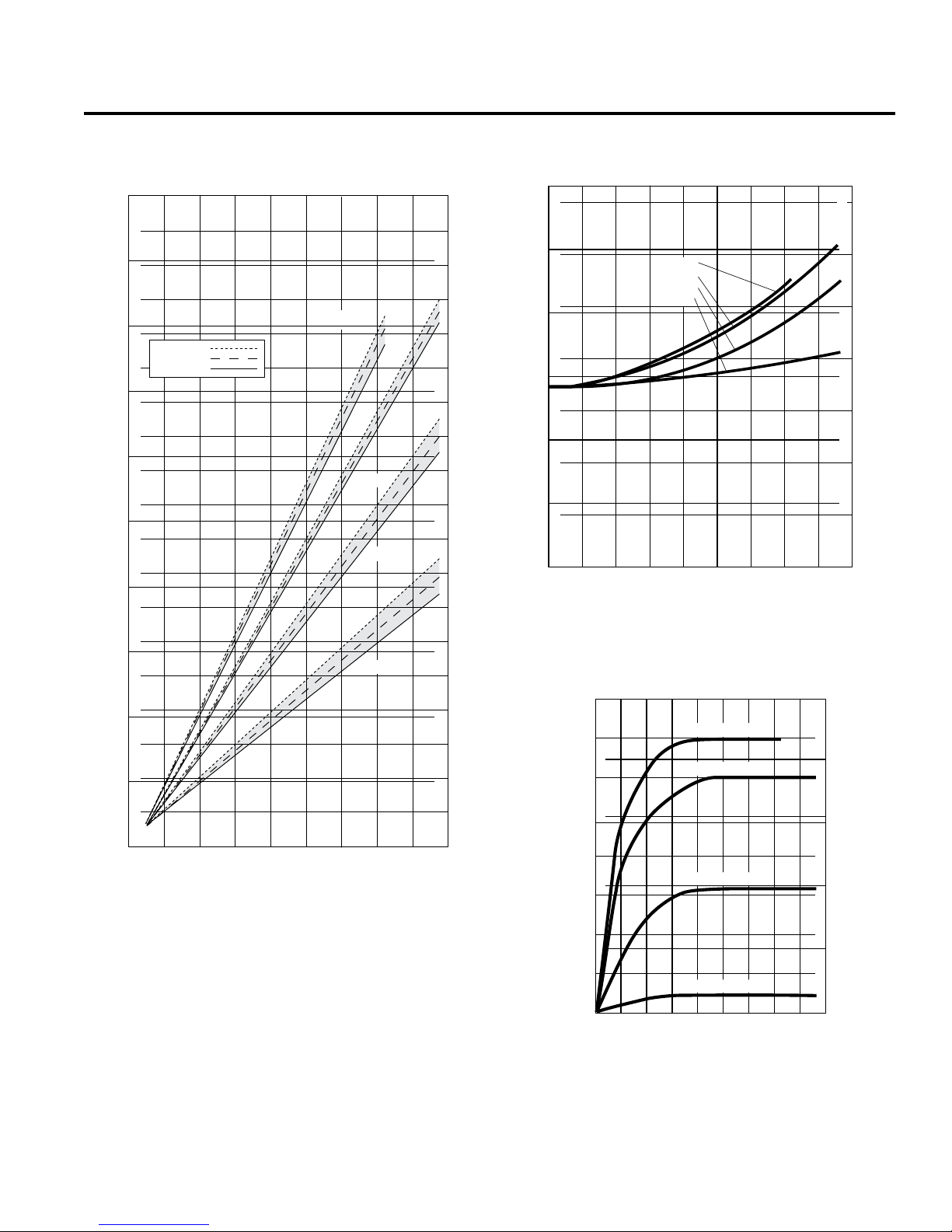

D/G-10 Specifications

Performance* Net Positive Suction Head –

NPSHr*

* Specifications depict D/G-10 metallic and non-metallic pump

head models only. Contact factory or visit our web site (www.

hydra-cell.com) for performance specifications on slurry duty

(SD) models.

Dry Lift*

3

D10-991-2400B

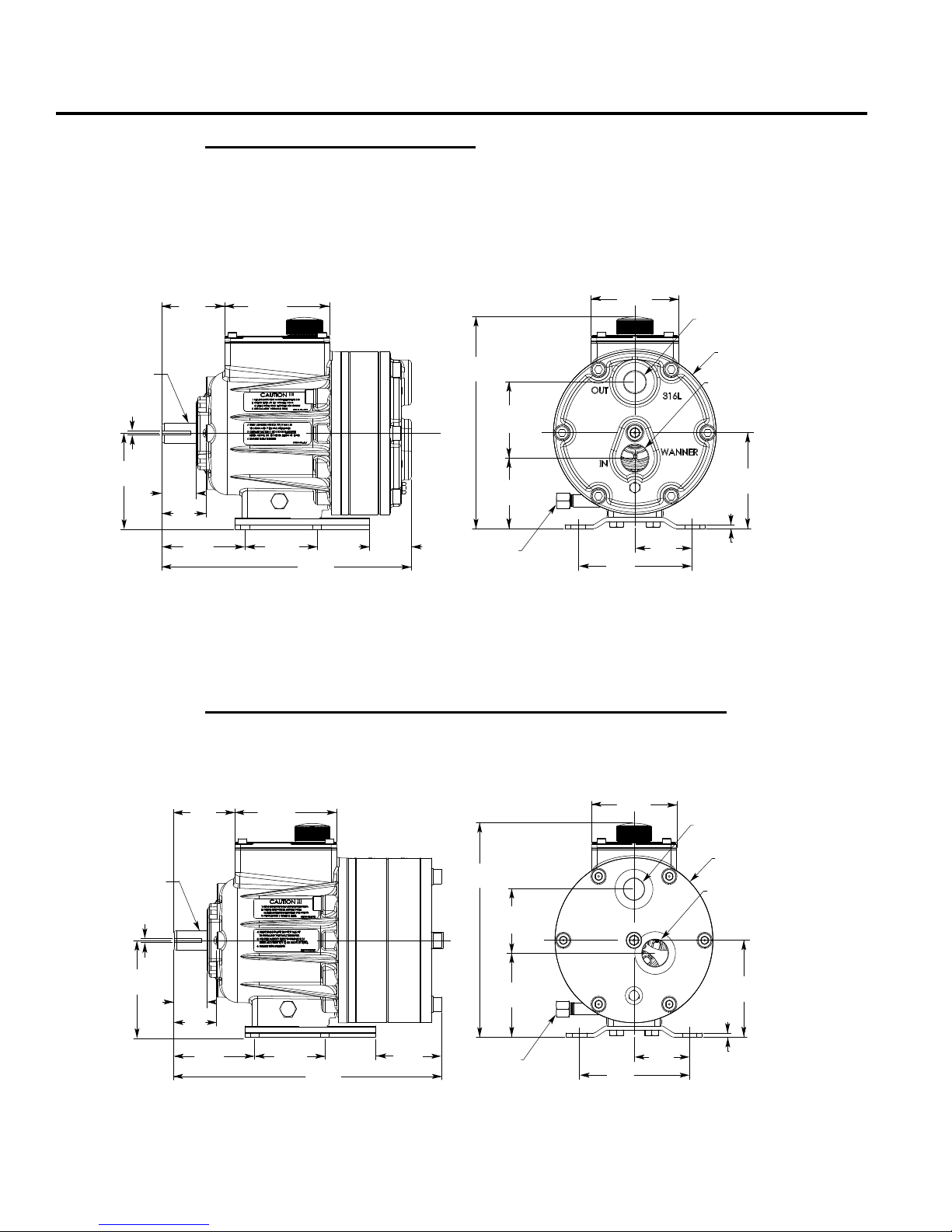

D/G-10 Dimensions

W0527

4.27

(108.3)

Outlet

D-10: 3/4" NPT

G-10: 3/4" BSPT

4.97

(126.2)

2.48

(63.1)

2.82

(71.5)

1.52

(38.6)

1.97

(50.0)

4.67

(118.7)

3.78

(96.0)

3.00

(76.2)

11.14

(283.0)

1.86

(47.3)

Oil Drain

(either side)

3.14

(79.8)

3.38

(85.7)

9.42

(239.2)

3.91

(99.2)

Ø7.27

(184.6)

Inlet

D-10: 1" NPT

G-10: 1" BSPT

4.27

(108.3)

.187

(4.75)

0.187

(4.74)

Ø0.875

(22.23)

1.52

(38.6)

1.97

(50.0)

2.82

(71.5)

4.67

(118.7)

4.27

(108.3)

3.78

(96.0)

3.00

(76.2)

12.31

(312.7)

3.03

(77.1)

0.187

(4.74)

Ø0.875

(22.23)

W0528

4.97

(126.2)

2.48

(63.1)

3.91

(99.2)

Outlet

D-10: 3/4" NPT

G-10: 3/4" BSPT

Oil Drain

(either side)

3.70

(94.0)

2.81

(71.4)

9.42

(239.2)

Ø7.25

(184.2)

Inlet

D-10: 1" NPT

G-10: 1" BSPT

4.27

(108.3)

.19

(4.7)

Models with Metallic Pumping Head

Brass

Cast Iron

316 Stainless Steel

Nickel Alloy (C Series)

Models with Non-Metallic or Slurry Duty (SD) Pump Head

®

Kynar

Polypropylene

Celcon

4

D10-991-2400B

D/G-10 Installation

W0219

Location

Locate the pump as close to the supply source as possible.

Install it in a lighted clean space where it will be easy to inspect

and maintain. Allow room for checking the oil level, changing

the oil, and removing the pump head (manifold, valve plate and

related items).

Mounting

The pump shaft can rotate in either direction.

To prevent vibration, mount the pump and motor securely on

a level rigid base.

On a belt-drive system, align the sheaves accurately; poor

alignment wastes horsepower and shortens the belt and bearing

life. Make sure the belts are properly tightened, as specified by

the belt manufacturer.

On a direct-drive system, align the shafts accurately. Unless

otherwise specified by the coupling manufacturer, maximum

parallel misalignment should not exceed 0.015 in. (0.4 mm)

and angular misalignment should be held to 1° maximum.

Careful alignment extends life of the coupling, pump, shafts,

and support bearings. Consult coupling manufacturer for exact

alignment tolerances.

Important Precautions

Adequate Fluid Supply. To avoid cavi tatio n and

premature pump failure, be sure that the pump will have

an adequate fluid supply and that the inlet line will not be

obstructed. See “Inlet Piping”.

Positive Displacement. This is a positive-displacement

pump. To avoid severe system damage if the discharge line

ever becomes blocked, install a relief valve downstream

from the pump. See “Discharge Piping”.

Safety Guards. Install adequate safet y guards over

all pulleys, belts, and couplings. Follow all codes and

regulations regarding installation and operation of the

pumping system.

Shut-Off Valves. Never install shut-off valves between

the pump and discharge pressure regulator, or in the

regulator bypass line.

Freezing Conditions. Protect the pump from freezing.

See also the Maintenance Section.

Consult the Factory for the following situations:

• Extreme temperature applications – above 160° F. (71°

C) or below 40° F. (4.4° C)

• Pressure feeding of pumps

• Viscous or abrasive fluid applications

• Chemical compatibility problems

• Hot ambient temperatures – above 110° F. (43° C)

• Conditions where pump oil may exceed 200° F. (93° C)

because of a combination of hot ambient temperatures,

hot fluid temperature, and full horsepower load — an

oil cooler may be required

5

D10-991-2400B

D/G-10 Installation

Inlet Piping (Suction Feed)

CAUTION: When pumping at temperatures above 160° F

(71° C), use a pressure-feed system.

Install draincocks at any low points of the suction line, to permit

draining in freezing conditions.

Provide for permanent or temporary installation of a vacuum

gauge to monitor the inlet suction. To maintain maximum flow,

vacuum at the pump inlet should not exceed 7 in. Hg at 70° F

(180 mm Hg at 21° C). Do not supply more than one pump

from the same inlet line.

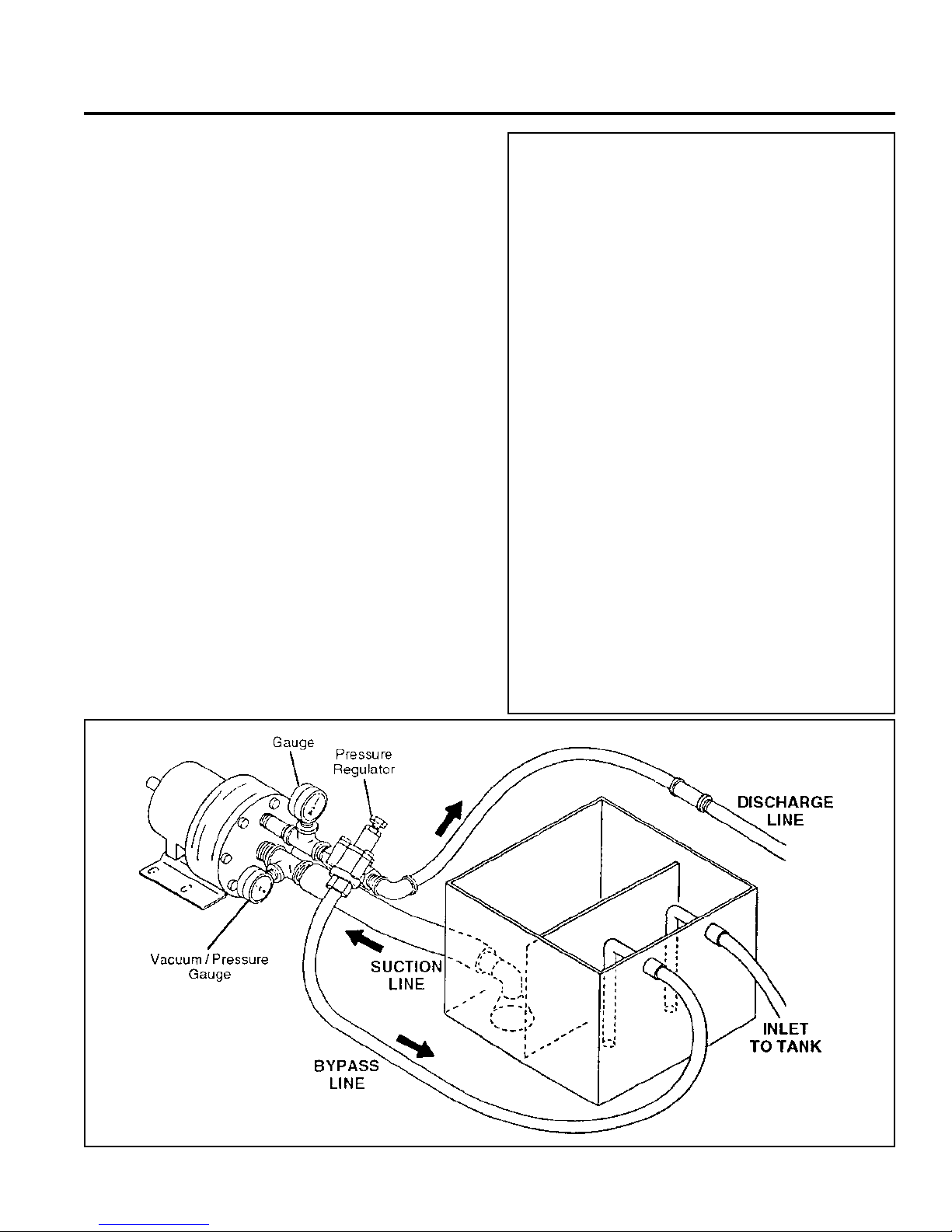

Supply Tank

Use a supply tank that is large enough to provide time for any

trapped air in the fluid to escape. The tank size should be at

least twice the maximum pump flow rate.

Isolate the pump and motor stand from the supply tank, and

support them separately.

Install a separate inlet line from the supply tank to each pump.

Install the inlet and bypass lines so they empty into the supply

tank below the lowest water level, on the opposite side of the

baffle from the pump suction line.

If a line strainer is used in the system install it in the inlet line

to the supply tank.

To reduce aerat ion and turbulence, install a completely

submerged baffle plate to separate the incoming and outgoing

liquids.

Install a vortex breaker in the supply tank, over the outlet port

to the pump.

Place a cover over the supply tank, to prevent foreign objects

from falling into it.

Hose and Routing

Size the suction line at least one size larger than the pump

inlet, and so that the velocity will not exceed 1-3 ft/sec (0.3 to

0.9 m/s):

For pipe in inches: Velocity (ft/sec) = 0.408 x GPM/Pipe ID2

For pipe in mm: Velocity (m/sec) = 21.2 x LPM/Pipe ID2

Keep the suction line as short and direct as possible. A

maximum of 3 feet (1 m) is recommended.

Use flexible hose and/or expansion joints to absorb vibration,

expansion, or contraction.

If possible, keep the suction line level. Do not have any high

points to collect vapor unless these high points are vented.

To reduce turbulence and resistance, do not use 90° elbows.

If turns are necessary in the suction line, use 45° elbows or

arrange sweeping curves in the flexible inlet hose.

If a block valve is used, be sure it is fully opened so that the flow

to the pump is not restricted. The opening should be at least

the same diameter as the inlet plumbing ID.

Do not use a line strainer or filter in the suction line unless

regular maintenance is assured. If used, it should have a freeflow area of at least three times the free-flow area of the inlet.

Install piping supports where necessary to relieve strain on the

inlet line and to minimize vibration.

Loctite is a registered trademark of Loctite Corporation.

Scotchbrite is a registered trademark of 3M Company.

Inlet Piping (Pressure Feed)

Provide for permanent or temporary installation of a vacuum/

pressure gauge to monitor the inlet vacuum or pressure.

Pressure at the pump inlet should not exceed 250 psi (17 bar);

if it could get higher, install an inlet pressure reducing regulator.

Do not supply more than one pump from the same inlet line.

Inlet Calculations

Acceleration Head

Calculating the Acceleration Head

Use the fol low ing f orm ula to c al cul ate acce lera tion head los ses.

Subtract this figure from the NPSHa, and compare the result to

the NPSHr of the Hydra-Cell pump.

Ha = (L x V x N x C) ÷ (K x G)

where:

Ha = Acceleration head (ft of liquid)

L = Actual length of suction line (ft) — not equivalent length

V = Velocity of liquid in suction line (ft/sec) [V = GPM x (0.408

÷ pipe ID

N = RPM of crank shaft

C = Constant determined by type of pump — use 0.066 for

the D-10 and G-10 Hydra-Cell pumps

K = Constant to compensate for compressibility of the fluid —

use: 1.4 for de-aerated or hot water; 1.5 for most liquids;

2.5 for hydrocarbons with high compressibility

G = Gravitational constant (32.2 ft/sec

Friction Losses

Calculating Friction Losses in Suction Piping

When following the above recommendations (under “Inlet

Piping”) for minimum hose/pipe I.D. and maximum length,

frictional losses in the suction piping are negligible (i.e., Hf =

0) if you are pumping a water-like fluid.

When pumping more-viscous fluids such as lubricating oils,

sealants, adhesives, syrups, varnishes, etc., frictional losses

in the suction piping may become significant. As Hf increases,

the available NPSH (NPSHa) will decrease, and cavitation will

oc cur.

In general, frictional losses increase with increasing viscosity,

increasing suction-line length, increasing pump flow rate, and

decreasing suction-line diameter. Changes in suction-line

diameter have the greatest impact on frictional losses: a 25%

increase in suction-line diameter cuts losses by more than

two times, and a 50% increase cuts losses by a factor of five

times.

Consult the factory before pumping viscous fluids.

Minimizing Acceleration Head and Frictional Losses

To minimize the acceleration head and frictional losses:

• Keep inlet lines less than 3 ft (1 m) long

• Use at least 1-1/2 in. (38 mm) I.D. inlet hose

• Use soft hose (low-pressure hose, non collapsing) for the

inlet lines

• Minimize fittings (elbows, valves, tees, etc.)

• Use a suction stabilizer on the inlet.

6

2

)]

2

)

D10-991-2400B

Loading...

Loading...