Dear Customer,

As a businessman you understand the necessity of keeping the cost of each step of production to an absolute

minimum without sacrificing quality. In the purchase of any new piece of equipment you are looking to increase your production and consequently reduce your cost, while maintaining or improving quality.

With these points clearly in mind we have designed the HYD-MECH S-25A. Our goal is to change stock cutoff from a "necessary evil" to a money making and time saving part of your operation.

Please use this manual to familiarize yourself and your employees on the proper operation and maintenance of

the S-25A.

We appreciate the confidence you have shown in our product and wish you every success in its use.

Sincerely,

HYD-MECH ENGINEERING LTD.

Stan Jasinski, P. Eng.,

President

HYD-MECH

P.O. BOX 1087 / WOODSTOCK, ONTARIO N4S 8P6 · PHONE (519) 539-6341 / FAX (519) 539-5126

PRINTED IN CANADA 1995

THIS PAGE INTENTIONALLY LEFT BLANK

TABLE OF CONTENTS

SECTION 1 - INSTALLATION

Safety......................................................................................................................................... 1.1

Lifting and Shipping.................................................................................................................... 1.1

Vise Cylinders............................................................................................................................. 1.2

Head Restraint Bar..................................................................................................................... 1.3

Leveling..................................................................................................................................... 1.3

Wiring Connections.................................................................................................................... 1.4

Hydraulic Oil and Cutting Fluid................................................................................................... 1.4

SECTION 2 - CONTROLS AND OPERATIONS

SUBSECTION 2A - The Control Console........................................................................................... 2.1

Start-up...................................................................................................................................... 2.1

S25 Manual Controls.................................................................................................................. 2.1

Shuttle Length Control................................................................................................................ 2.5

Conventional Length Control Set-up and Calibration................................................................... 2.5

S25 Automatic Controls (PLC 100)............................................................................................. 2.6

Blade Kerf......................................................................................................................... 2.6

PLC in Manual Mode ....................................................................................................... 2.7

PLC in Auto Mode - Single Job......................................................................................... 2.8

PLC in Auto Mode - Multi Job............................................................................................ 2.9

Important Notes With Respect To PLC Operation............................................................. 2.10

Interrupting the Auto Cycle...................................................................................... 2.10

Entering Blade Kerf................................................................................................. 2.11

Inch-Metric Input or Measuring................................................................................ 2.11

SUBSECTION 2B - Saw Cutting Controls........................................................................................... 2.12

Blade Basics............................................................................................................................... 2.12

Variable Speed Control............................................................................................................... 2.13

Hydraulic Feed Control............................................................................................................... 2.13

Using The Saw Cutting Parameters Door Chart........................................................................... 2.14

Step 1 Determine Effective MAterial Width....................................................................... 2.14

Step 2 Setting The Feed Force Limit................................................................................. 2.15

Step 3 Determine Optimum Blade Pitch............................................................................ 2.16

Step 4 Determine Optimum Blade Speed.......................................................................... 2.17

Step 5 Determine Feed Rate Setting................................................................................. 2.18

Cutting Control Set Up Examples................................................................................................ 2.20

SUBSECTION 2C - Mechanical Controls............................................................................................ 2.22

Head Up And Down Limit Setting................................................................................................ 2.22

Coolant Flow.............................................................................................................................. 2.23

Guide Arm Positioning................................................................................................................ 2.23

Blade Changing.......................................................................................................................... 2.24

SECTION 3 - MAINTENANCE AND TROUBLESHOOTING

Blade Brush................................................................................................................................ 3.1

Blade Guides.............................................................................................................................. 3.1

Lubrication............................................................................................................................... 3.2

Cleanliness................................................................................................................................. 3.3

Hydraulic Maintenance................................................................................................................ 3.3

Trouble Shooting......................................................................................................................... 3.4

SECTION 4 - ELECTRICAL SYSTEM

General Information.................................................................................................................... 4.1

Photos of Standard Electrical Components................................................................................. 4.1

Photos of Optional Electrical Components.................................................................................. 4.3

List of Electrical Components For An S-25A With the Optioanl PLC100.................................... 4.4

List of Electrical Components For A Standard S-25A.................................................................. 4.7

Standard Electrical Schematic S25-7-00-1.......................................................... 4.12

Standard Electrical Wiring Diagram S25-70-02 pg.1............................................... .... 4.13

Wiring Diagram S25-70-02 pg. 2 ................................................. 4.14

Wiring Diagram ( Contol Box) S25-70-02 pg.3.................................................... 4.15

Electrical Schematic (PLC Option) S25A-7-00-1A ..................................................... 4.16

Electrical Wiring Diagram PLC S25A-7-00-2A pg.1 ............................................. 4.17

Electical Wiring Diagram PLC (Control Box) S25A-7-00-2A2 pg.2 ........................................... 4.18

SECTION 5 - HYDRAULIC SYSTEM

General Information.................................................................................................................... 5.1

Parts List and Photos of Hydraulic Components.......................................................................... 5.1

Cylinder Components .................................................................................................................. 5.2

Positive Downfeed Valve Components ...................................................................................... 5.3

Hydraulic Schematic S25A-6-00-1 ...................................................... 5.4

Hydraulic Plumbing Diagram S25A-6-00-2 ....................................................... 5.5

Plumbing Diagram (VVP Option) S25A-6-00-2....................................................... 5.6

SECTION 6 - MECHANICAL ASSEMBLIES

Parts List and Photos:

Blade Guide Arm Assembly........................................................................................................ 6.1

Guide Arm Rack Assembly......................................................................................................... 6.2

Blade Brush Assembly................................................................................................................ 6.3

Drive Assembly.......................................................................................................................... 6.4

Idler Wheel Assembly................................................................................................................. 6.5

Vise Cylinder Mounting Assembly............................................................................................... 6.6

Front Table Assembly ................................................................................................................ 6.7

Gearbox Assembly.................................................................................................................... 6.8

Auxiliary Table Assembly............................................................................................................ 6.9

Shuttle Guide Assembly.............................................................................................................. 6.10

Infeed Conveyor assembly......................................................................................................... 6.11

Pivot Link Assembly.................................................................................................................. 6.12

Head Swing Assembly............................................................................................................... 6.13

Coolant System Assembly.......................................................................................................... 6.14

Outfeed Table Assembly............................................................................................................. 6.15

Length Control Assembly............................................................................................................ 6.16

SECTION 7 - OPTIONAL SAW EQUIPMENT

Overhead Bundling Attachment.................................................................................................. 7.1

Variable Vise Pressure................................................................................................................ 7.2

Blade Breakage Switch............................................................................................................... 7.3

Out of Stock Limit Switch............................................................................................................ 7.4

Remote Blade Speed Adjustment............................................................................................... 7.5

SECTION 8 - SPECIFICATIONS

Specification List........................................................................................................................ 8.1

Dimensional Drawings................................................................................................................ 8.2

SECTION 9 - WARRANTY

Warranty..................................................................................................................................... 9.1

SECTION 1 - INSTALLATION

SAFETY

All safety precautions must be observed during installation, operation, maintenance or repair work on the

S-25A bandsaw machine.

-Inspect the machine throughout before power hook-up. Special attention should be paid to electrical and

hydraulic systems keeping an eye out for any potential shipping damage.

-Power hook-up should be performed by qualified personnel.

-Machine should be used according to its specifications.

-Long hair, loose clothing, gloves, should not be worn while operating the machine.

-Stock must not be loaded while blade is running.

-Machine should not be operated unless all guards, covers and doors are in place and

closed.

1.1

-Long and heavy stock should be supported in where it extends off the saw table.

-Area around the machine should be kept clean and tidy.

-Operator should keep a safe distance from all moving parts especially the blade and vises.

-If not performing properly the machine should be stopped immediately and repaired by a qualified person.

-No modifications to the machine are allowed without Hyd-Mech’s prior approval. Any approved modifications

shall be performed by trained personnel.

LIFTING AND SHIPPING

To lift the S-25 bandsaw an overhead crane with a “T” shaped lifting harness should be used Fig. 1-1A and Fig.

1-2A. Hook the lifting harness to a chain shackle on the infeed base 'A' and to chain shackles on both sides of

the saw base 'B'. An experianced rigger should select the rigging based on the 7300 LB. weight of the saw.

WARNING: Under no circumstances should the lifting harness be pushing against any part of the saw.

B

B

A

Fig. 1-2AFig. 1-1A

1.2

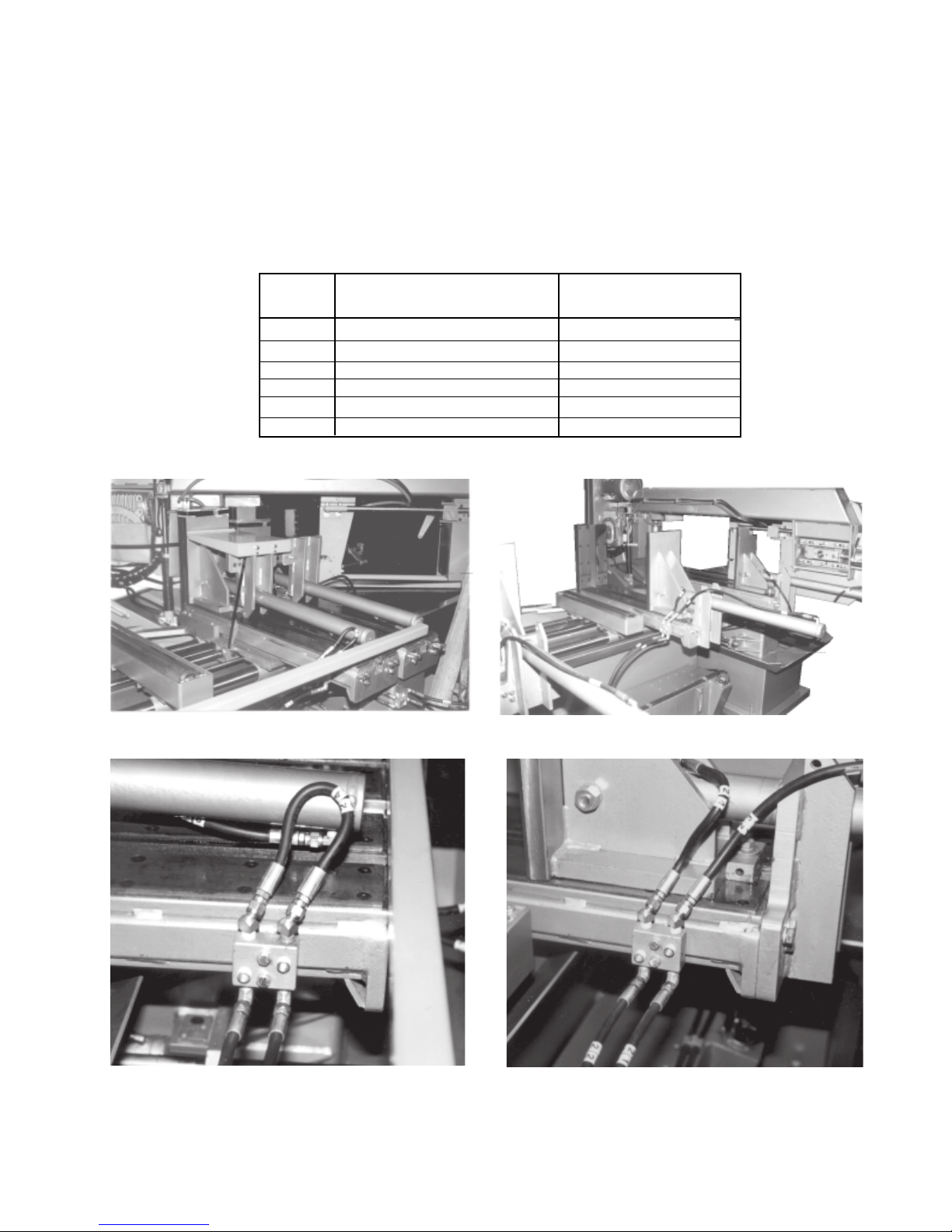

VISE CYLINDERS

To permit the S-25A to be shipped in a standard trailer, the three vise cylinders must be fully retracted, the

hydraulic hoses disconnected, and the mounting brackets unbolted from the infeed table Fig. 1-3. The cylinder

tube is then rotated around the cylinder rod so that the mounting bracket and tube are upside-down. This jaw

is now pushed completely toward the fixed jaw letting the bracket rest on the infeed table. Before the initial

start-up, reinstall the vise bracket and reconnect the vise cylinder hoses Fig. 1-4. TABLE 1 lists the hose

reconnections, Fig 1-5 shows one of the junction blocks as it appears when machine is shipped. Fig. 1-6

shows a junction block after the vise cylinder hoses have been reconnected.

HOSE # HOSE TO CYLINDER CONNECTING HOSE

CON NECTI ON AT JUNCTION BLOCK

34 ROD END (FRONT VISE) 32

33 PISTON END 31

24 ROD END (SHUTTLE VISE) 22

23 PISTON END 21

34C ROD END (AUX. VISE) 32 C

33C PISTON 31C

TABLE 1

Fig. 1-3 Vises disassembled for shipping.

Fig. 1-5 Junction block plumed for shipping.

Fig. 1-4 Reassembled vises.

Fig. 1-6 Vise cylinder plumed to junction block.

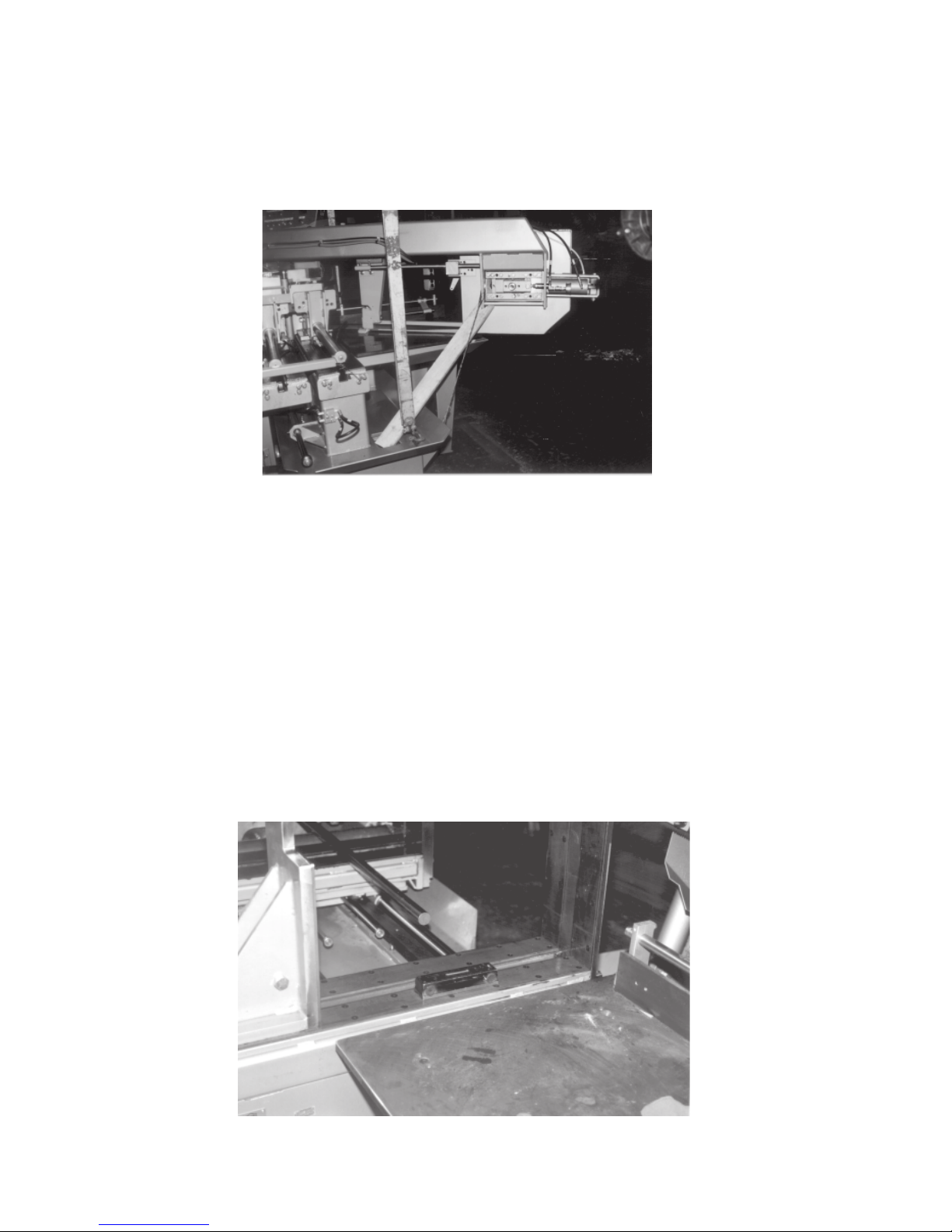

HEAD RESTRAINT BAR

The S-25A bandsaw is shipped with the head secured at the 45° position by a restraint bar and is wired down

to the base to ensure that the head can not move in any direction during shipping. After the saw has been lifted

into position, the head restraint bar must be removed along with the wire.

Fig. 1-7 Head restraint member and tie down wire.

1.3

LEVELLING

Machine location should be carefully selected. A flat concrete floor area should be chosen. It should have

enough free space surrounding the machine to enable free access for safe operation and maintenance.

Machine should be levelled in both directions ie. across its table and along its infeed conveyor especially when

machine is to be inserted into a large conveyor system.

Nine levelling screws are provided. Steel plates are to be placed under each screw to prevent their sinking into

the concrete floor. In cases when machine is to be anchored permanently, anchoring holes are provided. They

are located next to the levelling screws.

NOTE: In some cases levelling the saw infeed and auxiliary conveyors with a slight slope towards the blade is

recommended. This will prevent coolant from running down the raw stock. (This is especially true when cutting

tubing or bundles).

Fig. 1-8 Level the saw using a precision level.

1.4

WIRING CONNECTIONS

After the machine is levelled and anchored the necessary power hook-up needs to be performed. In order to

provide safe operation as well as to prevent potential damage to the machine, only qualified personnel should

make the connections.

BEFORE START-UP THE FOLLOWING TWO POINTS SHOULD BE CHECKED FOR

-signs of damage that may have occurred during shipping to the electrical cables and the hydraulic hoses.

-the hydraulic oil level is between the upper and lower lines on the level gauge (see SECTION 3 pg. 3.4).

As supplied, the machine is set to run on three phase voltage as indicated on the serial plate and voltage

label.

Power connection to the machine is made to L1, L2, L3 terminals at the junction block inside the control box

Fig.1-9. During the initial hook-up it is very important to check that the phase order is correct. This is indicated

by the hydraulic pressure gauge registering a pressure rise Fig. 1-10 and the blade running in a counter

clockwise direction. If the hydraulics do not register an immediate pressure rise, shut the hydraulics off and

change the phase order.

ATTENTION: Running the hydraulics "backwards" can damage the hydraulic pump.

L1, L2, L3

Terminals

Ground Clamp

Fig. 1-10 System pressure gauge.

Fig. 1-9 Electrical junction block.

HYDRAULIC OIL AND CUTTING FLUID

The S-25A bandsaw is supplied with Valvoline 150-46 hydraulic oil. If it is necessary to change the oil to a

different brand see the HYDRAULIC SECTION for an equivalent grade oil.

No cutting fluid is supplied with the machine. There are two types of coolant available:

- oil based; dilute 1:10 ratio

(one part concentrated coolant to 10 parts water)

- synthetic; dilute as recommended by the manufacturer.

SUB SECTION 2A - CONTROLS AND OPERATIONS

THE CONTROL CONSOLE

START-UP

The S-25A control console has been designed to simplify the operation of the saw, to give the operator the

ability to stop any function at any time, and to be able to control all the functions remotely. (See Fig. 2A-1)

We can not overstress the importance of familiarizing yourself with the controls of the S-25A prior to starting

the machine.

2.1

NOTE: WHEN STARTING THE S-25A FOR THE FIRST TIME

SWITCH IS IN IT'S

NEUTRAL

POSITION, THE BLADE IS RUNNING IN A

DIRECTION, AND THAT THE HYDRAULIC PRESSURE IS

pg. 3.4).

MAKE SURE

900 PSI

THAT THE MODE SELECTOR

COUNTER CLOCKWISE

± 25 PSI (see SECTION 3

Fig. 2A-1 Standard S-25A operation control panel.

S-25A MANUAL CONTROLS

HYDR AULI C STAR T B UTTO N: Starts hydraulic pump motor and energizes the BLADE START BUTTON

BLADE MO TOR This button is only operative when the hydraulic system has been

STA RT BUTTO N: started. Momentarily depressing this button will start the blade

BLADE MOTOR Momentarily depressing this button will stop the blade motor.

STOP BUTTON:

and the MODE SWITCH.

The fixed vise will open or close according to its selector switch position.

The actions of all other functions are dependent upon the MODE SWITCH

position. (see MODE SWITCH)

motor.

2.2

EMERGENCY STOP

This button will stop both the hydraulic and blade motors and

BU TTO N: de-energizes the MODE SWITCH.

The head and shuttle motion will cease.

The vises will remain as they are, but if closed, they will gradually

lose gripping force. For this reason all long stock should be

supported so that in this eventuality, it will not fall.

HYDRAULIC AND B LADE Both of the drive motors are protected by individual overload relays.

MOTOR RES ET B UTTONS : If a motor draws excessive amperage, the corresponding relay will

open and the entire machine will shut down as if the EMERGENCY

STOP button had been pressed.

Depressing the corresponding RESET button will close the opened

contactor overload and allow the machine to be restarted.

MODE SWITCH: Has three positions, MANUAL, NEUTRAL, and AUTO

MANUAL: in manual all the following functions except the HEAD

SWING CONTROLS and the AUTO CYCLE DIAL,

are operative.

NEUTRAL:only the FIXED VISE SWITCH, the COOLANT SWITCH

and the HEAD SWING CONTROLS are operative.

AUTO: all of the functions are under the control of the AUTO

CYCLE DIAL, and the MANUAL CONTROL switches

are inoperative.

HEAD CONTR OL S WITCH: Inoperative unless MODE SWITCH is in MANUAL.

UP: the head will rise until it reaches the HEAD UP LIMIT SWITCH

SETTING.

HOLD: the head will remain stationary.

DOWN: the head will descend until it reaches the bottom. Descent

is controlled by the FEED RATE and FEED FORCE

controls.

INDE X F ORWA RD BUTTON : Button is inoperative except when MODE SWITCH is in MANUAL.

Depressing this button fully will cause the shuttle table to quickly

advance toward the saw table until the button is released or the

shuttle reaches the forward limit of travel.

Depressing this button partially will cause the shuttle table to

advance toward the saw table at a very slow rate until the button is

released or the shuttle reaches the forward limit of travel. This

control is intended to assist in the accurate positioning of heavy

pieces of stock.

INDEX REV ERSE BUT TON: Button is inoperative except when MODE SWITCH is in MANUAL.

Depressing this button fully will cause the shuttle table to quickly

retract away from the saw table until the button is released or the

shuttle reaches the rearward limit of travel.

Depressing this button partially will cause the shuttle table to retract

away from the saw table at a very slow rate until the button is

released or the shuttle reaches the rearward limit of travel. This

control is intended to assist in the accurate positioning of heavy

pieces of stock.

INDEX VISE SWIT CH: This switch is only operative when the MODE SWITCH is in

MANUAL. It operates in the same manner as the FIXED VISE

SWITCH but controls the vise mounted on the shuttle table.

2.3

FIXED VISE SWITCH:

This switch is operative as long as the machine is supplied with

power. Unlike the other function switches it is active when the

MODE SWITCH is in NEUTRAL. The FIXED VISE SWITCH

is wired this way to insure that the fixed vise will not release the

work piece when switching between AUTO and MANUAL, or if the

saw should shut down during a cut due to a motor overload. This

security is provided only if the FIXED VISE SWITCH is left in the

CLOSE position during automatic operation; the AUTO CYCLE

DIAL will open the front vise as required. The FIXED VISE

SWITCH should be turned to OPEN when shutting the saw down

for a prolonged period of time (i.e. overnight). When this switch

is in the CLOSE position, the fixed vise will stay closed even when

shutting the saw down with the EMERGENCY STOP button, but the

vise pressure will quickly drop off and it should not be relied upon

to hold unbalanced work pieces after shutdown.

FAST SWING SWITCH: This switch is only operative when the MODE SWITCH is in the

NEUTRAL position.

Positioning this selector switch to 90° will swing the head fast towards the 90°

position. Likewise positioning this selector switch to 30° will swing the head

toward the 30° position. Leaving the switch on the lock position will restrain

the head from further angular motion. The angle change can be observed on

the angle scale located on the head swing drum Fig. 2A-2.

SLOW SWING SWITCH: Operates in the same manner as the FAST SWING SWITCH except it

swings the head at a slower rate making fine adjustment easier.

COOL AN T SWITC H: Has three positions ON, WASH, and OFF

MUL TI I NDE X CO UNT ER:The counter is operative only in the AUTO MODE. The number on

Fig. 2A-2 Angle scale.

ON: the coolant flows only when the head descends

WASH: coolant flows any time the machine is under power, permitting

wash-down with the hand line without running the machine

OFF: no coolant flow

the manually set thumb wheel display, controls the number of

shuttles made by the shuttle table between each saw cut Fig 2A-3. If the

setting is changed during the shuttling portion of the AUTO CYCLE,

the new setting will not be accepted until after the current cutting

cycle.

2.4

AUTO CYCLE DIAL:

This knob rotates in a clockwise direction when the saw is running and the

MODE SWITCH is in AUTO Fig. 2A-4.

As it rotates it sends out control commands indicated on the dial. Whenever

the head or shuttle motion is initiated, the dial will stop and wait for the

motion to reach the end of its travel, and then it will resume its rotation.

It is recommended that the AUTO MODE always be initiated with the AUTO

CYCLE DIAL in the START position. This will result in the fixed vise closing,

the index vise opening, the head lowering (unless it is already down), and

the shuttle table retracting (unless it is already retracted). The head will then

rise to the limit set by the HEAD UP LIMIT SWITCH and the cycle will

proceed in order, as on the dial. When manually positioning the AUTO

CYCLE DIAL, it should always be turned in the clockwise direction.

NEVER TURN THE AUTO CYCLE DIAL COUNTER CLOCKWISE.

PIECE COUNTER: The counter is operative in both AUTO and MANUAL Fig. 2A-5. It is manually

set to the number of cuts desired and counts down to zero at which point it

turns the saw off. If the counter is set at zero it will not permit the saw to be

started. If in the MANUAL MODE it is desired to have the saw shut down at

the end of the cut, the PIECE COUNTER must be set to 1 (one) before the

cut. The counter counts one half count when the head down signal begins and

the other half count when the head down signal ends. Thus, if the AUTO

CYCLE is interrupted during cutting, a false count will be recorded. In this

event simply push the PIECE COUNTER back up one count.

Fig. 2A-3 Multi index

counter.

BLADE SPEED SWITCH: This optional switch controls the blade speed which can be infinitely adjusted

(OPTIONAL)

between 75 and 400 SFPM. The blade speed change can be observed on the

blade speed digital display, located on the front control panel (Fig. 2A-6). On

machines quipped with the optional PLC 100 controller the blade speed is

displayed in the blade speed window located on the PLC controller (Fig. 2A-

7). Switch is active only when blade is running.

Fig. 2A-6 Blase speed digital readout.

Fig 2A-4 Auto cycle dial. Fig. 2A-5 Piece counter.

Fig. 2A-7 Blade speed display

window on the PLC 100.

SHUTTLE LENGTH CONTROL

To adjust for desired stock for a production run,as shown in Fig. 2A-8, move the Adjusting block 'A' to the

desired position along the scale. Fine adjustments can be made using the micrometer 'B'. The zero point on

the micrometer is .250 inch. This gives you 1/4" in and 1/4" out for fine adjustment.

A

B

Fig. 2A-8 Length control block.

CONVENTIONAL LENGTH CONTROL SET-UP AND CALIBRATION

2.5

The calibration makes no allowance for kerf loss and this must be added by the operator. Although blade

thickness is standard with relation to blade size, blade kerf may vary due to different pitch or manufacturer. We

recommend that you measure the kerf of the blade which you are using by making a cut into a solid piece of

steel and measuring the width of the cut. In the following examples we will use a blade kerf of .080". The

procedure for setting and calibrating the conventional length control is as follows:

To obtain a desired piece length add the kerf allowance. If the resulting length is less then 40", fully advance

the shuttle and set the adjusting block pointer to the resulting length. Set the Multi-Index Counter to "1".

If the resulting length is greater than 40", divide it by the smallest number which will result in a dividend less

than 40". Fully advance the shuttle and set the adjusting block pointer to the resulting dividend. Set the MULTI

INDEX COUNTER to the divisor.

Example 1

Desired piece length 9 3/4"

+ Kerf aprox. 1/16"

= Total shuttle required 9 13/16"

The result is less than 40". Set the adjusting block pointer to 9 13/16" and the MULTI INDEX COUNTER to "1".

Example 2

Desired piece length 73 3/8"

+ Kerf 1/16"

= Total shuttle required 73 7/16"

The result is greater than 40". We must divide by 2 in order to get a dividend less than 40 inches.

Set the adjusting block to 36 23/32" and the MULTI INDEX COUNTER to "2".

73.4375

= 36.719

2

2.6

It is wise to make a trial cut in order to check the accuracy of the length setting. Start by being certain that the

head up limit switch is correctly set up for the work piece. Using the manual mode raise the head fully and

advance the stock about 1/16" - 1/8" beyond the blade for a trim cut. Make the required trim cut.

Set the PIECE COUNTER to "2" and the AUTO CYCLE KNOB to "START". Start the blade and switch the

MODE SWITCH to "AUTO". The stock will advance and a cut will be made resulting in a trial piece.

Check the length of this piece. If it is not accurate enough, use the micrometer head to zero in on exactly the

length you require. The general procedure for using the micrometer length adjustment is as follows:

NEW MICRO SETTING = OLD MICRO SETTING + (DESIRED LENGTH - ACTUAL LENGTH)

NUMBER OF INDEXES

If in example 1, the resulting piece was 9.775 inches rather than the disired 9.750" then:

NEW MICRO SETTING = .250 + 9.750 - 9.775

1

= .250 + (-.025)

= .225

If in example 2, the resulting piece was 83.313" rather than the required 83.275" then:

NEW MICRO SETTING = .250 + 83.375 - 83.313

3

= .250 + .062

3

= .271

Increasing the micrometer setting increases the part length, while decreasing the micrometer setting decreases the part length.

NOTE: Remember to reset the micrometer to exactly midscale at the end of each run.

S-25A AUTOMATIC CONTROLS

BLADE KERF

Although blade thickness is standard with respect to blade size, blade

kerf may vary due to different pitch

or manufacturer. We recommend

that you measure the kerf of the

blade which you are using by making a cut into a solid piece of steel

and measuring the width of the cut.

In the following examples we will

use a blade kerf of .080".

Fig 2A-9 Optional PLC 100 programmable controler.

2.12

SUBSECTION 2B - SAW CUTTING CONTROLS

This section has been prepared to give the operator the ability to set up the saw for most cutting situations.

The saw is equipped with variable speed control and hydraulic feed control, as well as an extensive door chart

to guide the operator in the correct setting of these controls.

BLADE BASICS

Technology is rapidly changing all aspects of production machining. Metal cut-off is no exception. The

advances made in the bandsaw blade industry have definitely brought down the cost per cut, despite the three

fold higher price of high technology blades.

Variable pitch, bi-metal blades (like the 2/3 or 4/6 bi-metal blade supplied with the S-25A series saws) last

much longer, cut faster, and more accurately than conventional carbon steel blades.

In order to take advantage of the superiority of bi-metal blades, it is critical to properly “break-in” a new blade.

This is accomplished by taking two or three cuts through solid four or five inch diameter mild steel at an

extremely slow feed rate. (utilizing a very slow blade speed is recommended)

These two or three slow cuts sufficiently lap (polish) the new blade so that it does not snag the material being

cut. Proper break-in will alleviate blade vibration, improve surface finish, accuracy, and blade life.

After “break-in” the following six points must be closely monitored to ensure long blade life:

1. Proper blade tension should be maintained. (see SECTION 3 pg. 3.4 BLADE TENSION)

2. Generous coolant application is essential with almost all materials. A high quality and well mixed

coolant will many times extend blade life, and also increase cutting rate quality. On those materials

where c oolant is undes irable forcutting, a slight coolant flow or periodic oiling of the blade is necessary

to prevent the blade from being scored by the carbide guides.

3. The stock being cut must be securely clamped in the vises.

4. The proper feed force must be chosen.

5. The proper blade speed must be selected.

6. The proper feed rate must be applied.

2.13

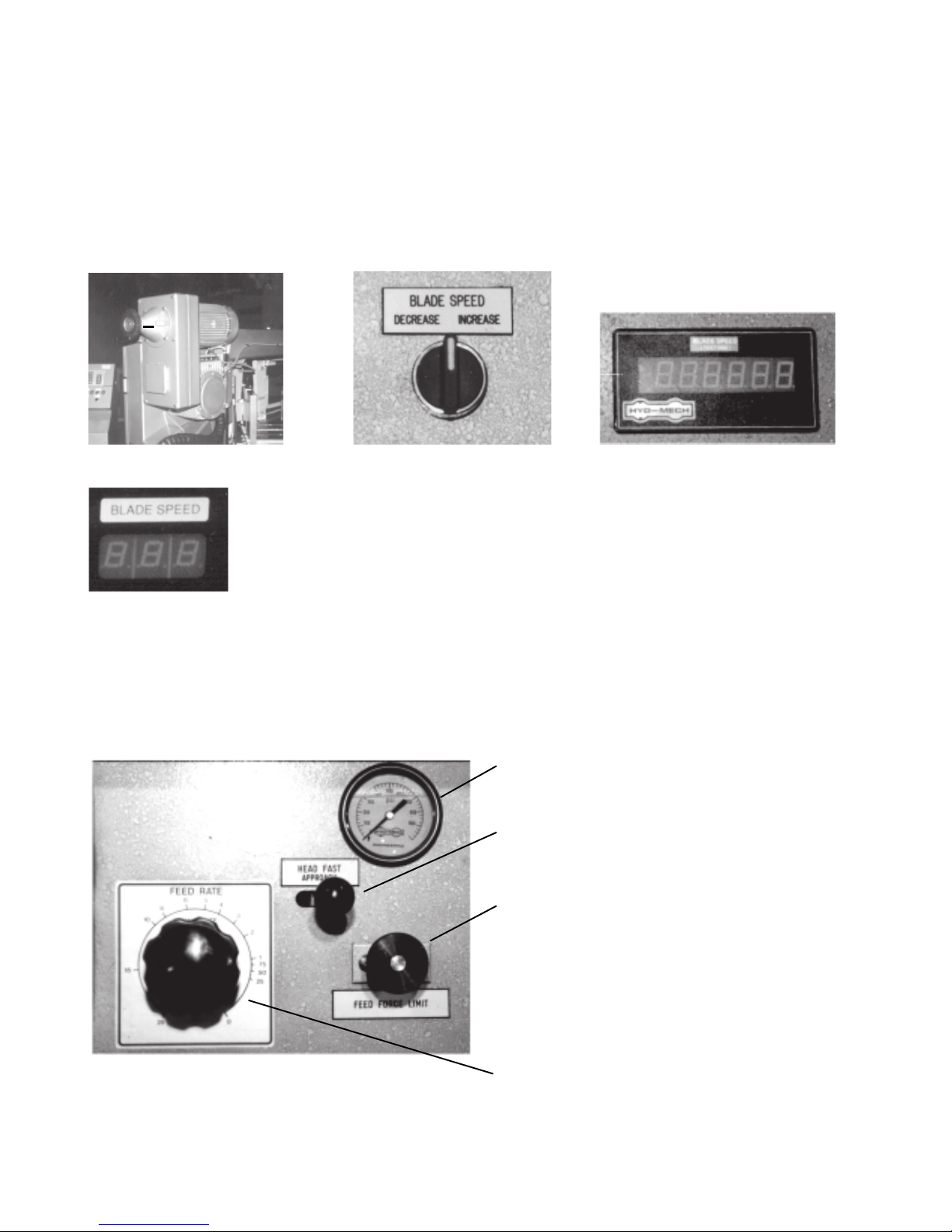

VARIABLE SPEED CONTROL

Blade speed can be adjusted infinitely between 75 and 400 SFPM (Surface Feet/Minute). Adjustment should

be made only when the blade is running. Clockwise rotation of handwheel “A” (Fig. 2B-1) increases the blade

speed while counter clockwise rotation decreases the blade speed. Blade speed is displayed on an indicator

located in the adjustment hand wheel. On machines equipped with the optional remote blade speed adjustment, adjustment is made using the BLADE SPEED selector switch Fig 2B-2 located on the control panel.

Blade speed is displayed on the digital blade speed display Fig. 2B-3 or on the blade speed display window

located on the optional PLC 100 controller Fig. 2B-4.

A

Fig. 2B-1 Blade speed adjustment.

Fig. 2B-2 Blade speed selector

switch.

Fig. 2B-3 Digital blade speed

display.

Fig. 2B-4 Blade speed display window.

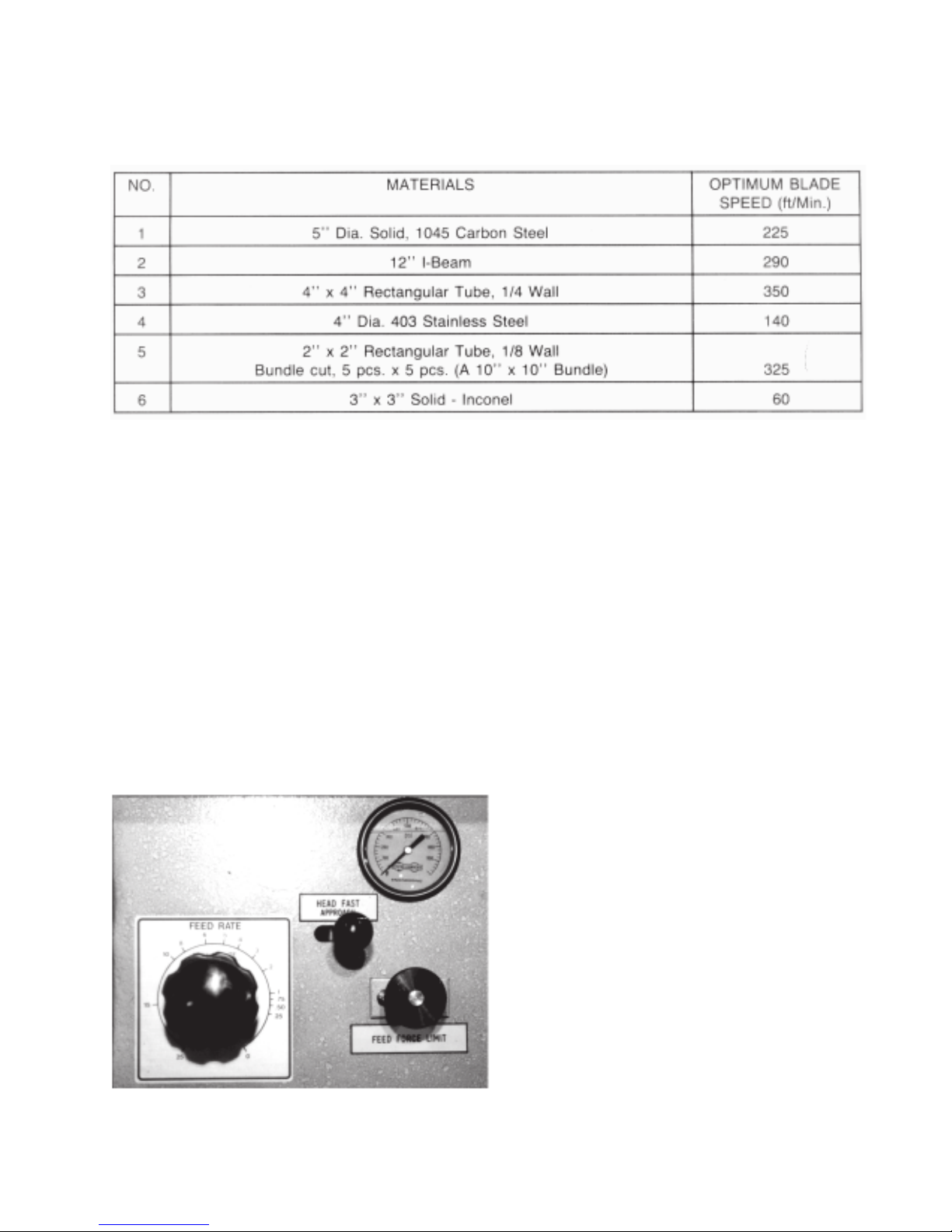

HYDRAULIC FEED CONTROL

The hydraulic feed control is located on the control panel below the electrical control console. These controls

allow independent control of Feed Force and Feed Rate. See Fig. 2B-5.

Feed Force Gauge

Fast Approach Lever

Depress for fast head descent

Feed Force Knob

Used to set Feed Force Limit

(clockwise rotation to increse

and counter clockwise rotation

to decrease).

Fig 2B-5 Hydraulic feed control.

Feed Rate Knob with feed rate scale

(calibrated in inches/minute)

Used to set Feed Rate (counter clockwise

rotation to increase and clockwise

rotation to decrease

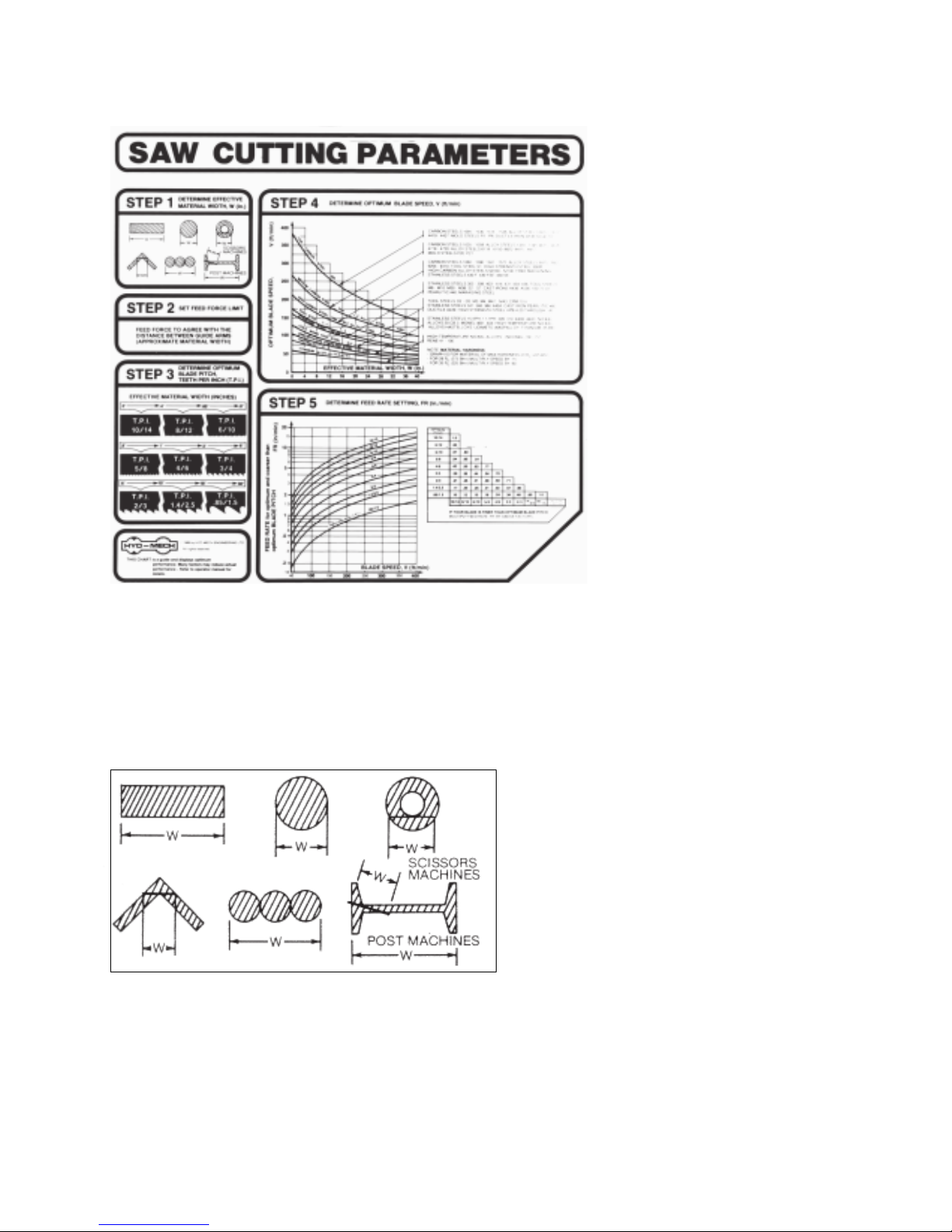

USING THE SAW CUTTING PARAMETERS ON CHART

2.14

A full size chart is mounted on the

panel. The chart contains five steps for

the operator to follow in order to achieve

optimum performance of the saw.

Fig. 2B-6 Saw cutting parameter door chart.

As Example #1 we will use the CHART to set up the saw, for cutting 8" Diameter, 1045 Carbon Steel.

STEP 1

DETERMINE EFFECTIVE MATERIAL WIDTH, W (in.)

Effective material width, W (in.) for most

common shapes of materials, is the widest

solid part of the material to be in contact with

blade during cutting. For simple shapes, as

illustrated on the chart, this can be diractly

measured. For bundles of tubes and

structuals, measuring the effective width is

difficult. For those cases effective width is

60% to 75% of the actual material width.

Fig. 2B-4

NOTE:

2.15

Both effective material width and guide arm width are used in setting the saw. Guide arm width is the distance

between the guide arms and is used in STEP 2. Effective material width, as determined here in STEP 1, can be

thought of as the average width of material “seen” by each tooth, and it is used in STEP 3 and 4.

In Example #1, for an 8" diameter solid, effective material width is 8".

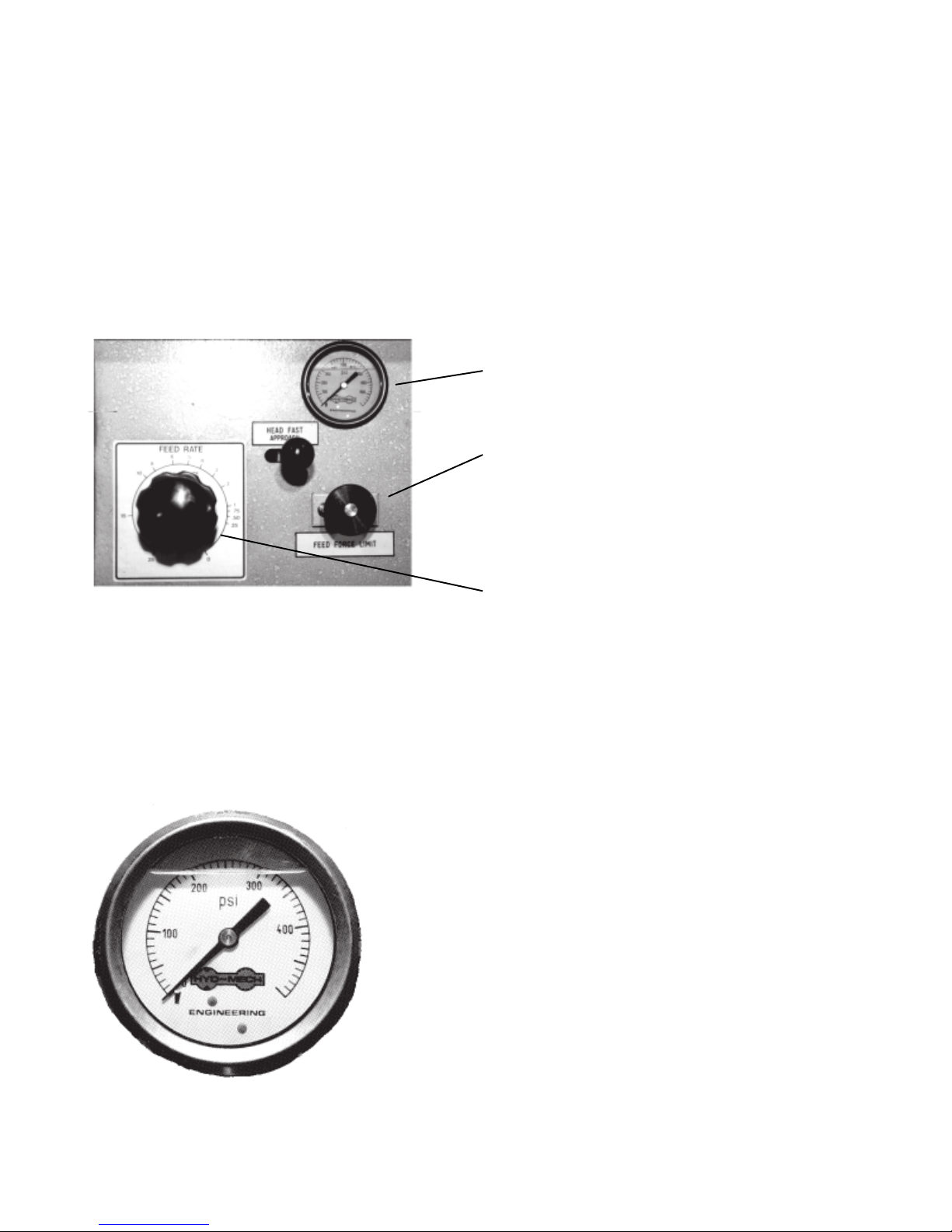

STEP 2

SET FEED FORCE LIMIT

The Feed Force Limit is the maximum amount of force with which the head is allowed to push the blade into the

workpiece. The controls for setting the Feed Force Limit consist of:

Feed Force Gauge

Feed Force Knob

Feed Rate Knob

To set FEED

Fig. 2B-5 Hydraulic feed control.

FORCE LIMIT:

- With the Mode Switch in “manual” position, move the head fully down.

- After the head is down, open the feed rate valve, depress the yellow FEED

FORCE SETTING button and adjust the FEED FORCE.

Example #1

Set the feed force at 250-300 psi. This will protect

the blade from buckling. This amount of feed force

will also prevent the blade from cutting out of square.

If the cuts obtained are not square and the blade is

not at fault, reduce the feed force pressure. Generally a higher feed force can be used when cutting

solids. When cutting structuals or bundles a lower

feed force should be used.

Fig. 2B-6 Feed Force pressure.

2.16

SIGNIFICANCE OF GAUGE READING:

With the head down and yellow button depressed the (FEED FORCE “set” on manual control panel) FEED

FORCE gauge indicates the setting of the FEED FORCE LIMIT. During cutting the gauge shows the actual

force being applied by the blade to the workpiece.

In typical cutting situations, the needle on the gauge will rise toward the preset FEED FORCE LIMIT and

stabilize, usually at a lower level. If the material being cut is very hard or wide, the needle may rise all the way

to the preset FEED FORCE LIMIT, which it will not exceed.

When cutting soft materials and or narrow cross sections, the gauge reaging may be low, but the FEED RATE

will be maintained. Any changes during cutting, such as, material hardness or material cross section will

influence the gauge readings. Therefore, in some cutting situations the gauge reading may rise and fall. A very

low gauge reading is uaully observed when the blade is approaching the material to be cut, but not yeyt cutting.

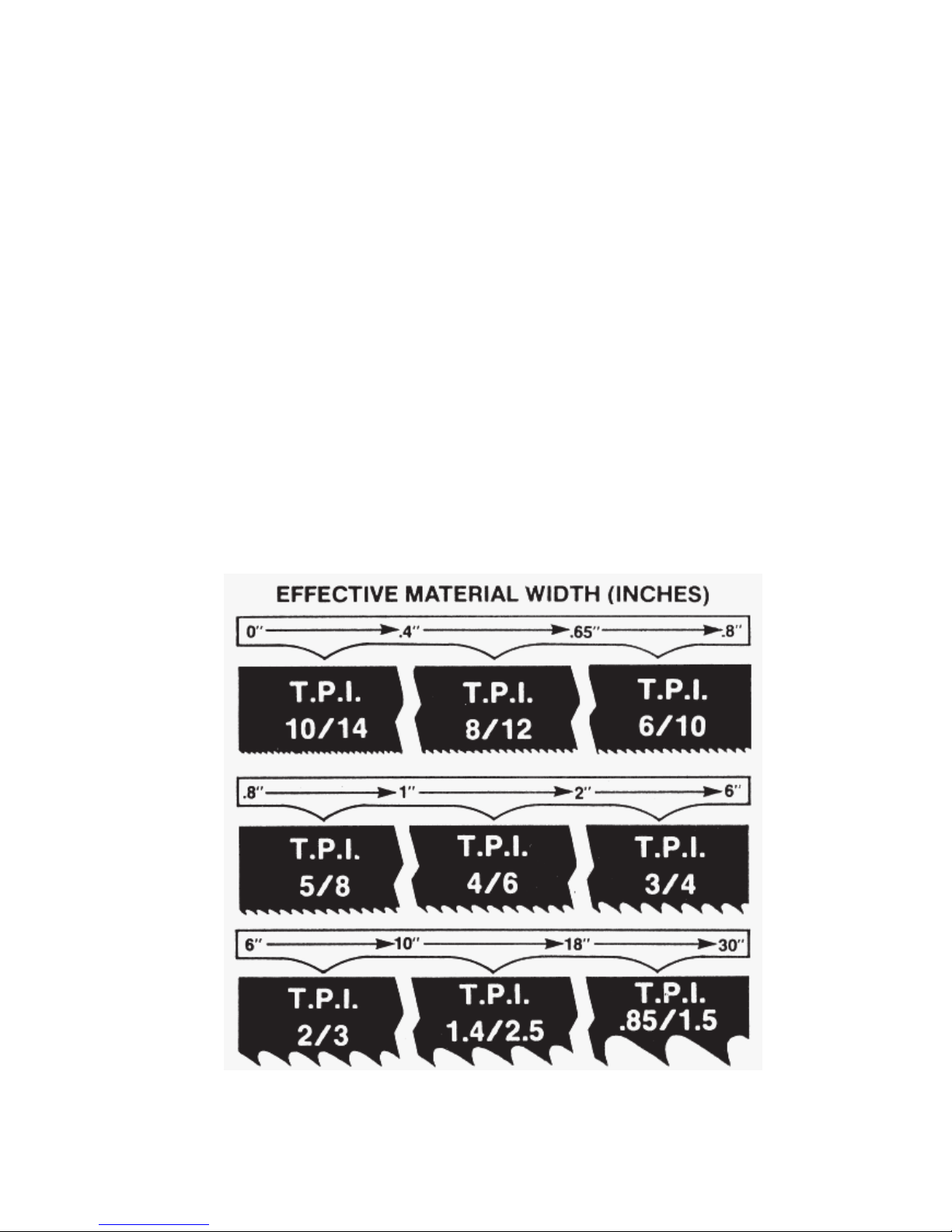

STEP 3

DETERMINE OPTIMUM BLADE PITCH, TEETH PER INCH (T.P.I)

Selecting a blade with proper tooth pitch is important in order to acheive optimal cutting rates and good blade

life.

For cutting narrow or thin wall structual materials a fine blade with many teeth per inch (T.P.I) is recommended.

For wide materials a blade with a coarse pitch should be used (see Fig 2B-7 below).

It is impractical to change the blade to the proper pitch every time a different width of material is cut and it is not

Fig. 2B-7 Optimum blabe pitch, teeth per inch (T.P.I.) for effective material

width, W (in.).

2.17

necessary, but remember that the optimum blade will cut most efficiently. Too fine a blade must be fed slower

on wide material because the small gullets between the teeth will get packed with chips before they get across

and out of the cut. Too coarse a blade must be fed slower because it has fewer teeth cutting and there is a limit

to the depth of a cut taken by each tooth. Allowance for the use of a non-optimum blade is made in STEP 5.

In our Example #1, for an effective material width of 8" the optimum blade has 2/3 teeth per inch.

STEP 4

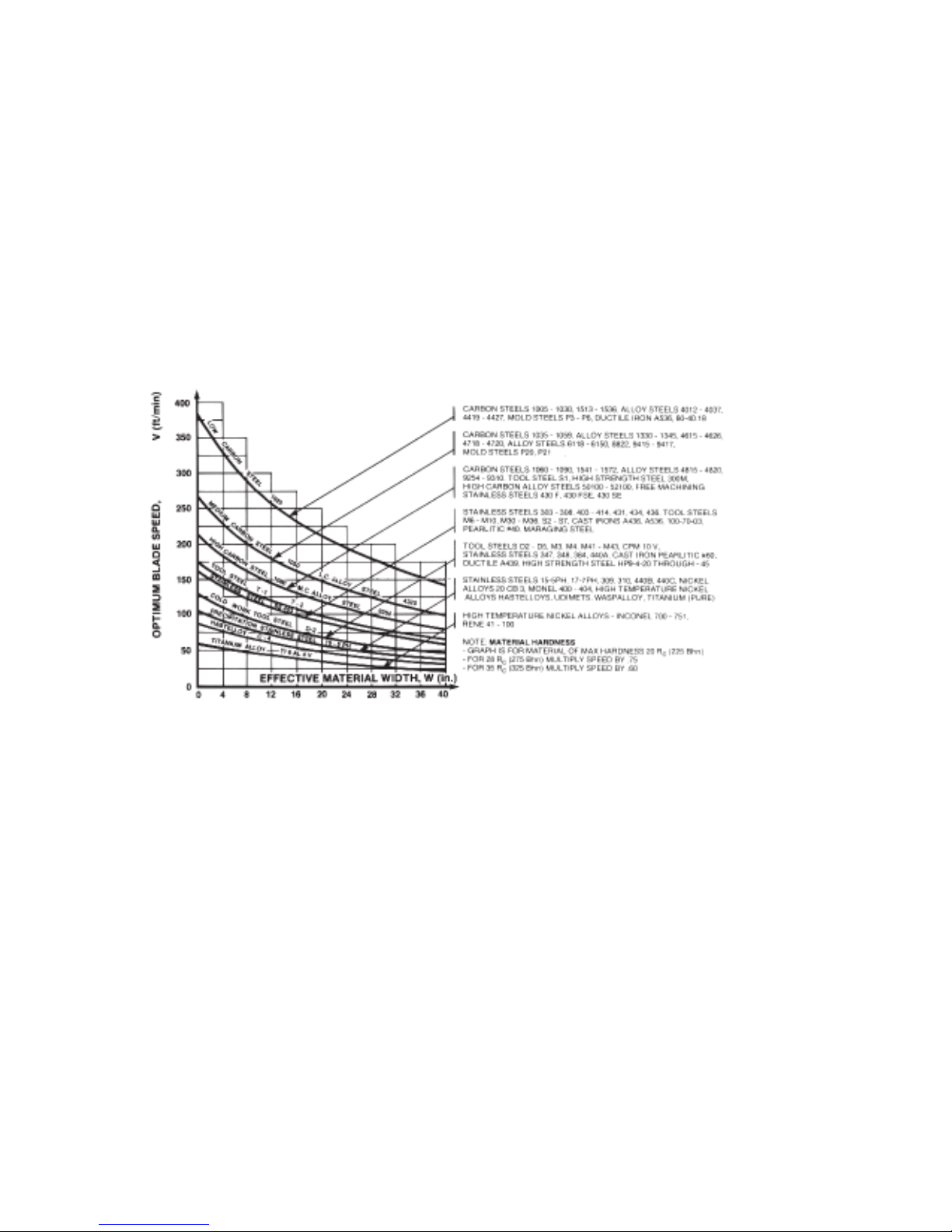

DETERMINE OPTIMUM BLADE SPEED, V (ft/min)

The relationship between optimum blade speed and effective material width for various materials is represented

on the graph Fig. 2B-8.

The graph shows that as effective material width gets wider or as material gets harder, lower blade speeds are

recomended. If material is narrower or soft, higher blades speeds should be selected.

Fig. 2B-8 Optimum blade speed curves.

In Example #1 8" Dia, 1045 Medium Carbon Steel solid bar is to be cut.

- On the graph above find the Medium Carbon Steel Curve which represents the optimum blade speeds for

1045 Carbon Steel.

- On the horizontal axis (effective material width axis) find number 8 which represent effective material width

of an 8" diameter solid.

- Find the point where a vertical line from 8" intersects the Medium Carbon Steel Curve.

- From this intersection point run horizontally left to the vertical axis (optimum blade speed axis) and find the

point marked “200”.

- Thus, for 8"diameter, 1045 Carbon Steel solid bar 200 ft/min is the optimum blade speed.

NOTE: Higher than optimum blade speed will cause rapid blade dulling. Lower than optimum blade speeds

reduce cutting rates proportionately and do not result in significantly longer blade life except where there is a

vibration problem. If the blade vibrates appreciably at optimum speed as most often occurs with structuals and

bundles, a lower blade speed may reduce vibration and prevent premature blade failure.

The table below shows a few examples of optimum blade speed for different materials.

TABLE 2B-1

NOTE: About Material Hardness

The Graph - Step 4, Fig 2B-8, illustrates blade speed curves for material hardness 20 Rc (225 Bhn) or lower.

If the material is harder , use multipliers from the NOTE (near the bottom) of the Graph.

2.18

For example, if the 5 diameter, 1045 Carbon Steel material, from the table above, had been hardened to 35 Rc

(325 Bhn) then we must multiply the blade speed of 225 ft/min by .60.

Thus 225 ft/min x .60 = 135 ft/min. (This is the optimum blade speed for 5" diameter, 1045 Carbon Steel, 35 Rc

hard).

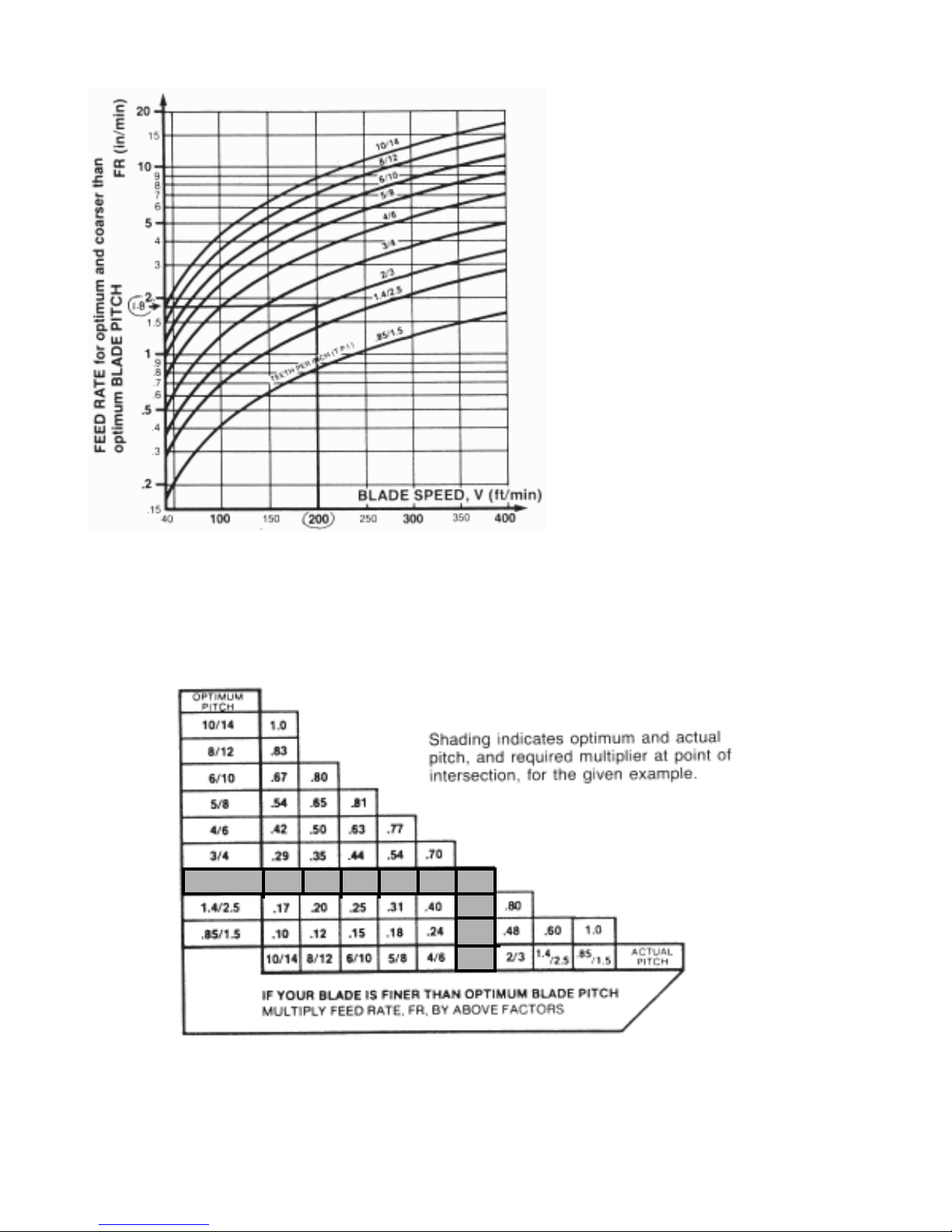

STEP 5

DETERMINE FEED RATE SETTING, FR (in/min)

FEED RATE is the vertical speed at which the blade descends through the workpiece.

FEED RATE Knob controls FEED RATE of the

blade in the range 0 to 25 in/min.

The FEED RATE should be adjusted only in one

direction (from “0” to required value). If you go too

far, go back to “0” and come back up.

To set FEED RATE for particular cutting situations

use the Graph, Fig 2B-10, which represents the

relationship between FEED RATE, blade speed

and blade pitch.

Fig. 2B-9 Hydraulic feed control.

2.19

` For Example #1, it is known from Step

3 that otimum blade pitch is 2/3, and

from Step 4 that blade speed ,200 ft/

min. From the graph, Fig. 2B-10 the

FEED RATE is determined in the

following way:

- On the horizontal axis (blade speed

axis), find 200 ft/min.

- Find the point where a vertical line

from 200 ft/min would intersect the

2/3 blade pitch curve.

- From this intersection point run

horizontally left to the vertical (FEED

RATE) axis, to arrive at 1.8 in/min

FEED RATE. Thus 1.8 in/min is the

FEED RATE for cutting 8" diameter,

1045 Carbon Steel when the optimum

2/3 pitch blade is used.

Fig. 2B-10

If the machine is fitted with a blade coarser than optimum (eg. 1.4/2.5 TPI) we can still use the graph, but we go

to the 1.4/2.5 curve. As a result we find that the FEED RATE is decresed to 1.3 in/min for this blade.

If however, the machine is fitted with a finer than optimum blade (eg. 3/4 TPI) we use the graph for the optimum

blade as before, and then use a multiplier given by the table 2B-2.

2/3 .21 .25 .31 .50.38 .71

.57

.34

3/4

TABLE 2B-2

As a result we find that we must decrease our FEED RATE of 1.8 in/min by a factor of .71. In this case we

should use FEED RATE of 1.8 in/min x .71 = 1.3 in/min.

CUTTING CONTROL SET UP EXAMPLES

FOR EXAMPLES #2 AND #3 PLEASE GO TO THE SAW AND FOLLOW STEPS 1-5 ON THE CHART:

Example #2

Material to be cut

-Round Steel Tube

SAE 4320

6" OD x 4" ID

-Hardened to 35 Rc (325 Bhn)

STEP 1

Effective Material Width: 4 1/2" (.75 x6)

STEP 2

Feed Force limit setting for 6" Diameter material 180 P.S.I.

STEP 3

Optimum blade pitch (TPI): 3/4 T.P.I.

Actual blade pitch on the saw: 4/6 T.P.I.

2.20

STEP 4

Optimum blade speed for 4 1/2" effective 225 ft/min

material width

Blade speed reduced by hardness factor: 225 ft/minx.60=135ft/min

STEP 5

Feed Rate for 3/4 TPI blade: 1.8 in/min

Feed Rate for 4/6 TPI blade: 1.8 in/minx.70=1.3in/min

(reduced by finer than optimum blade pitch factor,

Table 2B-2 - STEP 5)

2.21

Example #3

Material to be cut

-low carbon steel

-2" x 2" tube x 1/4" wall

-clamped in vises 12 pcs in a bundle (6" x 6")

STEP 1

Effective material width: 5" (6" x 8")

STEP 2

Feed Force limit for 8" wide material: 180 P.S.I.

STEP 3

Optimum blade pitch for 5" effective material width: 3/4 T.P.I.

STEP 4

Optimum blade speed for 5" effective material width: 320 ft/min

STEP 5

Feed Rate: 4.0 in/min

SUBSECTION 2C - MECHANICAL CONTROLS

HEAD UP AND HEAD DOWN LIMIT SETTING

Head Up Limit: In order to maximize production in the automatic cycle the HEAD UP LIMIT should be set

to match the height of the material. By adjusting the HEAD UP LIMIT SETTING KNOB

the head can be set to rise just above the material eliminating unnecessary head travel in

the cycle and therefore shortening the cycle time.

To Set Limit: As in Fig. 2C-1,for coarse adjustment depress button 'A' and slide knob 'B' up or down to

approximately the desired height. To finely adjust the height turn knob 'B'. Counter clock

wise rotation of the knob raises the upper limit of head travel and clockwise to lower the limit

of head travel. The head up limit should be set by starting with the head below the required

height and the knob screwed in to the limit switch. MANUAL mode must then be selected

and the HEAD CONTROL SWITCH rotated counter clockwise until the blade has at leas 1/

2" clearance above the material and slightly more when cutting bundles.

A

2.22

B

Fig. 2C-1 Head limit adustment.

Head Down The coolant pumpshuts off when the cut has been completed.

Limit Switch: The exact instant it shuts off the power supply can be set by the adjustment bolt 'A' as

shown in Fig. 2C-2

NOTE: This limit is factory set and under ordinary cutting requirements should not be

changed. If changed it may cause the machine to malfunction in the auto cycle.

A

Fig 2C-2 Head down limit switch

2.23

GUIDE ARM POSITIONING

It is desirable, in order to maintain maximum beam strength in the blade, to keep the guides as close together

as possible. This span is obviously determined by stock size. As shown in Fig. 2C-3 ,in order to increase or

decrease the span between the guide arms, simply undo the guide arm lock handle A and move the guide arm

closer to or further away from the other guide via the rack-and-pinion crank B. We cannot overstress the

importance to performance of keeping blade span to a minimum.

A

B

Fig. 2C-3

COOLANT FLOW

A generous flow of coolant should be applied in order to increase production and blade life.

Machine is provided with two independently controlled coolant spouts.

- One from the adjustable guide arm nozzle. This one should always flood the blade with coolant. Slight

readjustment may be required when changing the blade speed. A properly adjusted flow of coolant should cover

the blade which in turn will carry it into the cutting area. Flow adjusting tap is shown in Fig. 2C-4.

- The coolant hose on the fixed guide arm should be used in cases when cutting solid bars, bundles or wide

structurals. The flow of coolant should be directed into the opening created by the blade. Flow adjusting tap is

shown Fig. 2C-4.

NOTE: When cutting materials that do not need coolant (cast iron) some coolant flow is required to provide

blade lubrication to prevent blade scoring by carbides.

Coolant Flow

Adjusting Taps

Fig. 2C-4

BLADE CHANGING

1. Select manual mode and raise the head slightly (about two inches at the drive side guide arm).

2. Open the idler and drive doors.

3. Remove the blade guard Fig. 2C-5.

4. Release the carbide guides Fig. 2C-6.

5. Release the blade tension by positioning the blade tension selector switch to '-' Fig. 2C-7.

TURN THE HYDRAULICS OFF.

6. Push the blade out from between the carbide guides.

7. Remove the blade.

8. Install a new blade. The teeth should be facing away from the head of the saw. The teeth on the part of

the blade between the two guide blocks should point towards the drive side of the head.

9. Turn the hydraulics on and tension the blade by positioning the blade tension selector switch to '+'.

2.24

10. Start the blade for a few rotations in order for the blade to seat in the carbide guides and to track itself on

the wheels.

11. Replace the blade guard.

12. Close the carbide guides Fig. 2C-8.

13. Close the idler and drive doors.

Fig. 2C-5 Blade guard.

Fig 2C-6 Carbide handles (released).

Fig. 2C-7 Blade tension switch.

Fig. 2C-8 Carbide handles (locked).

THIS PAGE INTENTIONALLY LEFT BLANK

3.1

SECTION 3 - MAINTENANCE AND TROUBLESHOOTING

BLADE BRUSH

The blade brush is properly set when machine leaves the factory but it wears out during operation and needs to

be readjusted periodically. The blade brush assembly is shown in Fig. 3-1. In order to readjust it, the nut on the

adjusting screw needs to be loosened and the screw turned counter clockwise until wires from the brush touch

the bottom of the blade gullets Fig. 3-2.

NOTE: Proper adjustment and operation of the blade brush is essential to the correct operation of the bandsaw

and the longegivity of the blade. Therefore periodic maintenance and inspection of the machine should not be

neglected.

If the brush gets worn to approximately 70% of its original diameter 3 " OD it should be replaced. A brush may

be purchased through a HYD-MECH dealer in your area.

Adjusting screw

Fig. 3-1 Blade brush assembly

Fig. 3-2 Properly adjusted blade brush

BLADE GUIDES

Each guide arm is provided with a set of blade guides. Both sets are identical, except for the top carbides. Each

set consists of: top carbide, fixed carbide and adjustable carbide pad. Guide blocks fitted with blade guides are

shown in Fig. 3-3.

Fig. 3-3 Assembled blade guides.

Adjustable

carbide pad

Fixed carbide pad

Fig. 3-4 Disassembled blade guides.

Top servo carbide

Top carbide

3.2

LUBRICATION

The design of the S-25A was intended to minimize maintenance, although periodically certain moving parts

need lubrication. We recommend that this periodic lubrication be done once a month using any general purpose

grease at the points indicated G.

Fig. 3-5 Vertical Pivot.

G

G

Fig. 3-6 Horizontal Pivot.

G

G

Fig. 3-7 90 Degree Shaft.

G

G

Fig. 3-9 Idler Wheel Slider.

Fig. 3-8 Vise Ways.

G

Fig. 3-10 Guide Arm Positioning Shaft.

3.3

G

G

Fig. 3-11 Counterbal-

Fig. 3-12 Shuttle Bearing Housing.

ance Shaft.

CLEANLINESS

The S-25A series design should endure heavy operating conditions and provide the customer with flawless

machine performance. To extend good performance some care is required, especially cleanliness.

The following areas should be kept clean of dirt, grease and chips:

-CONTROL CONSOLE -OUT FEED TABLE

-DOOR CHARTS -LARGE BUILD UP OF CHIPS IN THE SAW BASE

-WHEEL BOXES -VISE WAYS

-BLADE GUIDES

NOTE: All parts should be cleaned before any repair or service is performed on them.

A wash gun is supplied for washing chips off the table and vise ways Fig. 3-14.

Oil filter

Level gauge Oil fill cap

Fig. 3-13 Oil tank.

HYDRAULIC MAINTENANCE

There are only four items of routine maintenance associated with the hydraulic system.

1. OIL FILTER - Ten micron filtration of the hydraulic oil is provided by a spin on type filter mounted on the

tank return line. The element should be changed every 1000 working hours or once per year. Suitable

replacement elements are:

Fig. 3-14 Wash down hose.

CANFLO RSE-30-10

GRESEN K-23018

LHA SPE-15-10

ZINGA AE-10

3.4

2. OIL LEVEL - Oil level should be maintained in the upper half of the level gauge. Normally the rate of oil

consumption will be very low and it should be unnecessary to add oil more often than at filter changes. Add oil

only to the top line on level gauge.

The S-25A is shipped from the factory with Valvoline 150-46 hydraulic oil. Generally any brand of recognized

mineral hydraulic oil with the same properties should be compatible with Valvoline 150-46, but to avoid any risk

we suggest staying with Valvoline 150-46. If it is desired to change brands, it is necessary to drain the tank and

1/3 refill it with the new oil, operate through several automatic cycles with the index set to full stroke and head

to full rise, drain the tank again, and finally fill the tank with the new brand.

Hydraulic tank capacity is approximately 17 US gallons.

Recommended replacement oils: Chevron AW Hydraulic Oil 46

Esso - NUTO H46

Mobil - Mobil DEC 25

Petro Canada - Harmony AW 46

Texaco - Rando HD 46

Shell Tellus 46

3. OIL TEMPERATURE - Oil temperature is indicated by a thermometer contained in the level gauge Fig 3-13.

Oil temperature during steady operation should stabilize at about 50 - 55 F° above room temperature. Thus in a

70 F° shop one might expect an oil temperature of about 120 F°. Oil temperature should never exceed 160 F°.

4. SYSTEM PRESSURE - System pressure is factory set to 900 ± 25 psi and should not require further

attention except precautionary observation at start-up and occassionally thereafter.

5. BLADE TENSION - Is controlled by system pressure.

6. VISE PRESSURE - Is controlled by system pressure. If machine is equipped with the optional variable vise

pressure; vise pressure is operator adjustable.

TROUBLE SHOOTING

Most problems which may occur have relatively simple solutions which appear in this section. If the solution is

not found here, contact the Hyd-Mech Distributor from whom you purchased your bandsaw. They have trained

field service people who will be able to rectify the problem.

PROBLEM

1. Saw is cutting out of square

vertically.

2. Saw is cutting out of square

horizontally.

PROBABLE CAUSE

1a. Blade worn.

1b. Carbide guides loose.

2a. Angle not set correctly.

2b. Angle pointer has moved.

2c. Stock not square in vise.

SOLUTION

1a. Change blade.

1b. Adjust

2a. Adjust accordingly.

2b. The scale is accurate. Adjust

and tighten the pointer.

2c. Adjust accordingly.

3. Blade comes off wheels.

3a. Not enough blade tension.

3b. Improper tracking.

3a. Blade tension is determined

by system pressure. Check

that system pressure is as

specified earlier in this

section.

3b. Adjust accordingly

3.5

PROBLEM

4. Blade stalls in cut.

5. Blade vibrating excessively.

6. Excessive blade breakage.

PROBABLE CAUSE

4a. Not enough blade tension.

4b. Excessive feed force.

5a. Blade speed too fast.

5b. Guide arms too far apart.

5c. Not enough blade tension.

6a. Excessive blade tension.

6b. Excessive feed rate.

SOLUTION

4a. Blade tension is determined

by system pressure. Check

that system pressure is as

specified earlier in this

section..

4b. Reduce.

5a. Reduce.

5b. Adjust accordingly.

5c. Blade tension is determined

by system pressure. Check

that system pressure is as

specified earlier in this

section.

NOTE: New blades tend to vibrate

until they are "broken in".

6a. Blade tension is determined

by system pressure. Check

that system pressure is as

specified in this section.

6b. Reduce.

7. No coolant flow.

8. Saw will not start.

9. Saw starts but will not run after

Start Button has been released.

10. Saw starts but no hydraulic

functions.

7a. No coolant.

7b. Coolant line blockage.

7c. Coolant pump inoperable.

8a. Piece counter set at "0".

8b. Motor overload has tripped.

8c. Control circuit fuse has

blown.

9a. On machines so equipped,

the out-of-stock or blade

breakage limit switch has

been tripped.

10a.If blade wheels run clock

wise, wrong phase order in

power connection to saw.

10b.If pump is noisy, low hydrau-

lic oil.

7a. Add coolant.

7b. Blow out coolant lines.

7c. Check and replace if it is

necessary.

8a. Reset Piece Counter.

8b. Depress each of the reset

buttons on the main control

box. Depressing one reset at

a time and trying to start the

saw will indicate which motor

was overloaded.

8c. Replace the fuse with a 5

Amp 250 Volt AG1 type fuse.

Random blowouts may occur

but a quickly repeated blow

out indicates an internal

wiring fault.

9a. Reload with stock or remount

blade.

10a. Stop immediately; reverse

any two of the three line

phase connections.

10b. Stop immediately; add

hydraulic oil (see hydraulic

maintenance earlier in this

section).

3.6

11. Saw starts but only front vise

functions.

IN MANUAL MODE

12. Head will not rise.

13. Head will not descend.

14. Head still will not rise or fall,

or any individual function will

PROBABLE CAUSE

11a.Mode Selector Switch is in

"Neutral".

Head up limit switch is set

12a.

fully down.

13a. Feed Rate valve is fully

closed (pointer is set on "0"

or close to "0" in/min).

13b.Feed Force Limit is set too

low.

13c. Pointer is adjusted incor-

rectly.

14a.Observe pilot light(s) on

relevant valve, visible by

removing the side panel on

infeed base. If pilot light

related to inoperable function

fails to light, problem is

electrical.

14b.If pilot light related to inoper

able function does light,

problem may still be the coil

(see 14a. SOLUTION). If

problem remains it probably

results from dirt in the valve

spool. If the problem is

related to index forward or

retract, or head swing it may

also be dirt in the cushion

valve mounted near the

manifold.

SOLUTION PROBLEM

11a. Select "manual" mode.

Readjust head up limit

12a.

switch.

13a. Turn Feed Rate Knob count-

er clockwise to open valve.

13b. Increase Feed Force limit to

at least 150 psi.

13c. Loosen pointer, turn knob

clockwise until it bottoms;

tighten pointer at "0".

14a.In case of head and index

functions check operation of

related limit switches. Limit

switch buttons should operate freely and emit an audible click on both depress and

release. If not replace the

switch. Look for cause of

switch damage. To check

the switch unit itself, remove

the switch lid and wire

together the two terminals

closest to the wiring port. If

function now responds to

manual switch replace the

switch. If function still

does not respond then...

Remove the side

panel on the infeed to gain

access to the valves. Re

move coil retaining nut and

withdraw problem related

coil, replace it with any other

coil from the group. If the

problem remain it requires

the attention of a qualified

service person.

14b.Disassembly of hydraulic

valves should be undertaken

only by qualified service

personnel or those knowledg

able with hydraulic components.

PROBLEM PROBABLE CAUSE SOLUTION

not respond to its manual

control switch.

15a. Pointer of Feed Rate valve is

15a.Readjust pointer as in 13c.

stopped by stop bolt but not

15. Head descends when Feed

fully closing the valve.

Rate valve pointer is set to

"0" on the scale and Feed

Force limit gauge is more

than 150 psi.

16a Cushion limit switch is

stuck or damaged.

16a.As in 14a check and repair or

replace.

16. Index retracts but only very

slowly.

3.7

IN AUTOMATIC MODE

17. Auto cycle stops.

17a.If cycle seems to stop be

cause of a particular function

is inactive, switch to manual

and see it that function is still

inactive. If so see previous

section "IN MANUAL

MODE".

17b.If the function is active in

"manual" mode.

17c. If the cycle does not respond

to limit switch prodding.

check for a damaged limit

switch as outlined in 14a.

SOLUTION, above. In this

case wire together the two

switch terminals furthest from

the wiring port.

17a.Readjust limit switch actua-

tor.

17b. Begin auto cycle over again

from start position on Auto

Cycle Dial. Note last function

motion before the cycle stops

and check related limit switch

function. For example, if the

head comes down and then

the cycle stops, check that

the head down limit switch is

being actuated by prodding it

with a screwdriver. If the

auto cycle resumes, the limit

switch actuating bolt must be

readjusted. Similarly if the

shuttle advances and then

the cycle stops, check that

the shuttle forward limit

switch is being actuated.

17c. Check for cause of damage

and replace limit switch

as needed.

18. Piece length gradually in

18a.Length adjustment block not

tight.

18b.Micrometer adjustment is

creeping.

18a. Tighten the knob.

18b.Very slightly tighten the set

screw which retains the

micrometer in the adjusting

block. This will increase the

stiffness of the micrometer

threads.

3.8

PROBLEM PROBABLE CAUSE

creases during production

run.

19a.Stock is slipping in rear vise

during advance or in front

19. Piece length shows large

vise during retraction.

erratic decreases from set

value.

IN AUTO MODE (Optional) PLC

20a.No job or job que pro

grammed to run.

20. Auto cycle will not start.

21a. Headup, head down, or

shuttle home limit switch not

21. Auto cycle stops before

being contacted.

completion.

SOLUTION

19a. Apply oil to front and rear

vise jaws.

20a.Enter job number(s) and job

data as in SECTION 2A

CONTROL CONSOLE.

21a.Run saw in auto cycle. Note

last function motion before

the cycle stops and check

related limit switch function.

For example, if the head

comes down and then the

cycle stops, check that the

head down limit switch is

being actuated by prodding it

with a screwdriver. If the auto

cycle resumes, the limit

switch actuating bolt must be

readjusted. Similarly if the

shuttle advances and then

the cycle stops, check that

the shuttle forward limit

switch is being actuated.

SECTION 4 - ELECTRICAL SYSTEM

GENERAL INFORMATION

The power connection to the machine is made to the L1, L2 and L3 terminals of the contactor located in the

main control box. As supplied, the machine is set to run on three phase voltage as indicated on the serial plate

and the voltage label.

In order to use the machine on a different supply voltage the following changes must be made:

1. Change the blade motor (or if equipped with a dual voltage motor, rewire it)

2. Change the hydraulic pump motor (or if equipped with a dual voltage motor, rewire it)

3. Change the control transformer (or if equipped with a dual voltage unit, rewire it)

4. Change the blade and pump motor overloads, located adjacent to the contactor, to suit the full load

current of the new or rewired motor.

All other components are supplied from the control transformer and operate on 115V, single phase. They do not

need altering.

4.1

The machine is supplied for use on a 60HZ supply. For use on a 50HZ supply consult the factory.

WHEN CHANGING THE SUPPLY VOLTAGE, CAREFULLY OBSERVE THE ABOVE STEPS. THESE STEPS

ARE ESSENTIAL TO AVOID SEVERE DAMAGE TO THE MOTOR AND CONTROLS.

At initial hook-up it is important to check that the phase order is correct. This is indicated by the blade drive

wheel revolving in a counterclockwise direction and the hydraulic pressure gauge registering a pressure rise.On

the following pages are the electrical schematics and physical wiring diagrams along with a list of electrical

components.

PHOTOS OF STANDARD ELECTRICAL COMPONENTS

L 1

L 2

L 3

GND

TR 1CR 2C R 1M

2M

Fig. 4-1 Inside of the standard electrical control box.

4.2

9SS 1PB8SS4SS7SS 4PB

6SS 3SS 5SS 5PB 2PB 4PB

TM

MI

2SS

FU

Fig. 4-2 Back of the control panel.

1SS

1CNT

Fig. 4-3 Blade Tension selector switch 6SS,

10SS.

Fig. 4-5 Head Down limit switch 2LS.

Fig. 4-4 Head Up limit switch 1LS.

4LS

6LS

Fig. 4-6 Shuttle control limit switches.

3LS

5LS

4.3

Fig. 4-7 Blade motor 2MTR.

Fig. 4-8 Hydraulic pump motor 1MTR.

Fig. 4-9 Coolant pump motor 3MTR.

PHOTOS OF OPTIONAL ELECTRICAL COMPONENTS

Fig. 4-10 Hirschman connectors and directional

valve solenoids.

1PB

3PB

FE

Fig. 4-11 Back of the control panel with the optional PLC 100 controler.

5PB 7PB 5SS 8SS 7SS

2SS

6PB

3SS

4SS

1SS

9SS

2PB

4PB

PLC100

4.4

Fig. 4-12 Encoder.

Fig. 4-13 Shuttle hohe limit switch 3LS.

Fig. 4-14 Blade speed pickup PROX.

LIST OF ELECTRICAL COMPONENTS FOR AN S-25A WITH THE OPTIONAL PLC100

Item Cose Function Description Component Component

as on Manufacturer Number

S-25A Sch.

1PB Emergency Stop Operating head (red mushroom) Telemecanique ZB2BC4

push button 1 NC contact block Telemecanique ZB2BE102

2PB Hydraulic Start Operating head (green illuminated, Telemecanique ZB2BW33

push button flush style)

Light block Telemecanique ZB2BW061

130 V Lamp Telemecanique SP106

1 NO contact block Telemecanique ZB2BE101

3PB Blase Stop Operating head (black flush style) Telemecanique ZB2BA2

push button 1 NC contact block Telemecanique ZB2BE102

4PB Blade Start Operating head (green illuminated, Telemecanique ZB2BW33

push button flush style)

Lamp block Telemecanique ZB2BW061

130V Lam p Telemecanique SP105

1 NO contact block Telemecanique ZB2BE101

Item Cose Function Description Component Component

as on Manufacturer Number

S-25A Sch.

5PB Feed Force Limit Operating heaf (yellow flush Telemecanique ZB2BA5

setting push style)

button 1 NO contact block Telemecanique ZB2BE101

6PB Index Forward Booted push button operator Telemecanique XACB9212

push button 2 speed 2 contact block assembly

1 NO, 1 NO early close Telemecanique XENB1181

7PB Index Reverse Booted push button operator Telemecanique XACB9212

push button 2 speed 2 contact block assembly

1 NO, 1NO early close Telemecanique XENB1181

1SS Mode Operation head (3position Telemecanique ZB2BJ3

Man/Off/Auto maintained, long)

selector switch 1 NO early close Telemecanique ZB2BE201

1 NC late open Telemecanique ZB2BE202

1 NO Telemecanique ZB2BE101

2 NC Telemecanique ZB2BE102

4.5

2SS Head Operating head (3 position Telemecanique ZB2BJ3

Up/Hold/Down maintained, long)

selector switch 2 NO contact blocks Telemecanique ZB2BE101

3SS Coolant Operating head (3 position Telemecanique ZB2BD3

selector switch maintained)

2 NO contact blocks Telemecanique ZB2BE101

4SS Fixed Vise Operating head (3 position, one Telemecanique ZB2BJ7

selector switch maintained, one spring return to

center, long)

2 NO contact blocks Telemecanique ZB2BE101

5SS Shuttle Vise Operating head (3 position, one Telemecanique ZB2BJ7

selector switch maintained, one spring return to

center, long)

2 NO contact blocks Telemecanique ZB2BE101

6SS Blade Tension Selector switch and housing Telemecanique XALJ133

selector switch assembly (3 position maintained)

2 NO contact blocks Telemecanique ZB2BE101

7SS Slow Head Operating Head (3 position with Telemecanique ZB2BD5

Swing selector spring return to center)

switch 2 NO contact blocks Telemecanique AB2BE101

8SS Fast Head Operating Head (3 position with Telemecanique ZB2BD5

Swing selector spring return to center)

switch 2 NO contact blocks Telemecanique AB2BE101

9SS PLC on/off Operating head (standard 2 position Telemecanique ZB2BJ2

selector switch maintained)

1 NO contact blocks Telemecanique ZB2BE101

4.6

Item Cose Function Description Component Component

as on Manufacturer Number

S-25A Sch.

1LS Head Up R od Plung er Telemecanique XCKL110H7

limit switch

2LS Head Dow n Rod Plun ger Telemecanique XCKL110H7

limit switch

3LS Shuttle Home Rod Plunger Telemecanique XCKL110H7

limit switch

TR Transformer Open Style 500VA

60Hz single phase

Prim. V. - Sec. V.

240V-120V Hammond HT97838

480V-120V Hammond HT97818

600V-120V Hammond HT96808

1M Motor Contactor Open Style

(hydr aulics) 240V Telemecanique LC1D5811G6

480/600V Telemecanique LC1D1810G6

2M Motor Contactor OPen Style

(blade) 240V Telemecanique LC1D5811G6

480/600V Telemecanique LC1D1810G6

1AC Auxiliary Contact 2 NO contacts Telemecanique LA1DN20

Block

1CR Auto-Manual 4 NO contacts Telemecanique CA2DN40G6

relay

2CR Head Down 2 NO, 2 NC contacts Telemecanique CA2DN22G6

relay

1OL Motor Overload Triple Pole Thermal

(hydr aulics) 3HP 208/24 0V Telemecanique LR2D1314

3HP 480V Telemecanique LR2D1310

3HP 600V Telemecanique LR2D1308

2OL Motor Overload Triple Pole Thermal

(blade) 10HP 208/240V Telemecanique LR2D3353

10H P 480V Telemecanique LR2D1316

10H P 600V Telemecanique LR2D1316

1MTR El. Motor 182TC/3PH/3HP US Motors 2HP182TC

(hydraulics) 208/240V

480V

600V

2MTR El. Motor 215TC/3PH/10HP US Motors 5HP215TC

(blade) 208/240V

480V

600V

Item Cose Function Description Component Component

as on Manufacturer Number

S-25A Sch.

3MTR El. Motor 1PHZ 120VAC Little Giant 2E-NT502186

(coolant pump)

(with pump assembly)

PLC Length Programable logic control Hyd-Mech PLC100

Controller

FH Fuse holder Standard for 1 1/4" x 1/4" Little Fuse H342-858

Fuse 5A 250V BUSS MDL-5

PROX Blade speed Inductive proximity switch Omron TL-X2C1-E

pickup

Hirschman Female connector with light GDM 927811-011

connectors indicator GDM 2011

Encoder Incremental shaft encoder Deem MBE-3122-1000-QWCY

Directional Vickers Y(120 VAC)

valve

solenoid

4.7

LIST OF ELECTRICAL COMONENTS FOR A STANDARD S-25A

Item Cose Function Description Component Component

as on Manufacturer Number

S-25A Sch.

1SS Mode selector Operating head (3 position Telemecanique ZB2BJ3

switch maintained, long)

1 NO contact block Telemecanique ZB2BE101

1 NC contact block Telemecanique ZB2BE102

2SS Coolant selector Operating head (3 position Telemecanique ZB2BD3

swi tch maintained)

2 NO contact blocks Telemecanique ZB2BE101

3SS Fixed Vise Operating head (3 position, Telemecanique ZB2BJ7

selector switch one maintained, one spring return

to center, long)

2 NO contact blocks Telemecanique ZB2BE101

4SS Shuttle Vise Operating head (3 position, Telemecanique ZB2BJ7

selector switch one maintained, one spring return

to center, long)

2 NO contact blocks Telemecanique ZB2BE101

5SS Head Up/Hold/ Operating head (3 position Telemecanique ZB2BJ3

Down selector maintained, long)

switch 2 NO contact blocks Telemecanique ZB2BE101

6SS Fast shuttle Operating Head (spring return Telemecanique ZB2BD5

selector switch to center, short)

4 NO contact block Telemecanique ZB2BE101

4.8

Item Cose Function Description Component Component

as on Manufacturer Number

S-25A Sch.

7SS Slow shuttle Operating head (spring return Telemecanique ZB2BD5

selector switch to center, short)

2 NO contact block Telemecanique ZB2BE101

8SS Fast head swing Operating head (3 position with Telemecanique ZB2BD5

selector switch spring return to center)

4 NO contact blocks Telemecanique ZB2BE101

9SS Slow head swing Operating head (3 position with Telemecanique ZB2BD5

selector switch spring return to center)

2 NO contact blocks Telemecanique ZB2BE101

10SS Blade Tension Selector switch and housing ass'y Telemecanique XALJ133

selector switch (3 position maintained)

2 NO contact blocks Telemecanique ZB2BE101

1PB Emergency Stop Operating head (red mushroom) Telemecanique ZB2BC4

push button 1 NC contact block Telemecanique ZB2BE102

2PB Hydraulic Start Operating head (green illuminated, Telemecanique ZB2BW33

push button flush style)

Light block Telemecanique ZB2BW061

130 V Lamp Telemecanique SP105

1 NO contact block Telemecanique ZB2BE101

3PB Blade Start Operating head (green illuminated, Telemecanique ZB2BW33

push button flush style)

Lamp block Telemecanique ZB2BW061

130V Lam p Telemecanique SP105

1 NO contact block Telemecanique ZB2BE101

4PB Blade Stop Operating head (black flush style) Telemecanique ZB2BA2

push button 1 NC contact block Telemecanique ZB2BE102

5PB Feed Force Limit Operating heaf (yellow flush Telemecanique ZB2BA5

setting push style)

button 1 NO contact block Telemecanique ZB2BE101

1LS Head Up R od Plung er Telemecanique XCKL110H7

limit switch

2LS Head Dow n Rod Plun ger Telemecanique XCKL110H7

limit switch

3LS Shuttle forward Rod Plunger Telemecanique XCKL110H7

limit switch

4LS Shuttle back Rod Plunger Telemecanique XCKL110H7

limit switch

5LS Shuttle forward Roller Arm Telemecanique XCKL115H7

cushion L.S.

Item Cose Function Description Component Component

as on Manufacturer Number

S-25A Sch.

6LS Shuttle back Roller Arm Telemecanique XCKL115H7

cushionlimit

switch

FU Fuse holder Standard for 1 1/4" x 1/4" Little Fuse H342-858

Fuse 5A 250V BUSS MDL-5

TR Transformer Open Style 500VA

60Hz single phase

Prim. V. - Sec. V.

240V-120V Hammond HT97838

480V-120V Hammond HT97818

600V-120V Hammond HT96808

1M Motor Contactor Open Style

(hydr aulics) 240V Telemecanique LC1D5811G6

480/600V Telemecanique LC1D1810G6

4.9

2M Motor Contactor OPen Style

(blade) 2 40V Telemecanique LC1D5811G6

480/600V Telemecanique LC1D1810G6

1M5,6 Auxiliary Contact 2 NO contacts Telemecanique LA1DN20

Block

1CR Auto-Manual 4 NO contacts Telemecanique CA2DN40G6

relay

1CR5-8 Auxiliary Contact Telemecanique LA1DN13

on 1CR

2CR Head Down 2 NO, 2 NC contacts Telemecanique CA2DN22G6

relay

1OL Motor Overload Triple Pole Thermal

(hydr aulics) 3HP 208/24 0V Telemecanique LR2D1314

3HP 480V Telemecanique LR2D1310

3HP 600V Telemecanique LR2D1308

2OL Motor Overload Triple Pole Thermal

(blade) 1 0HP 208/240 V Telemecanique LR2D3353

10H P 480V Telemecanique LR2D1316

10H P 600V Telemecanique LR2D1316