Hyd-Mech S-20H Operations & Maintenance Manua

IN BANDSAW TECHNOLOGY

OPERATIONS &

MAINTENANCE

MANUAL

THANK YOU,

S-20H

2002, rev b, 393320

On behalf of everyone at

HYD.MECH

Y our new machine is now ready to play a key role in increasing the efficiency of your operation, helping you to

reduce cutting costs while boosting quality and productivity .

T o ensure you are maximizing the power and versatility of your new

to familiarize yourself and your employees with the correct operation and maintenance procedures as outlined in this

manual.

We sincerely appreciate the confidence you have demonstrated in purchasing our product and look forward to

building a long and mutually beneficial relationship.

Thank-you.

HYD.MECH GROUP LIMITED

P .O. BOX 1030, 1079 Parkinson Road

Woodstock, Ontario Canada, N4S 8A4

Phone: (519) 539-6341

Service 1-877-237-0914

Sales 1-800-276-SAWS(7297)

Fax (519) 539-5126

e-mail, info@hydmech.com

band saw.

HYD.MECH

, I would like to thank and congratulate you on your decision to purchase a

HYD.MECH

band saw, please take the time

THIS PAGE INTENTIONALLY LEFT BLANK

S20H Series II Table of Contents

INSTALLATION and SPECIFICATIONS

SAFETY PRECAUT IONS ........................................................................................................................................ 1

SPECI FICA TI ONS ................................................................................................................................................... 2

LA YO UT DR AW INGS............................................................................................................................................... 3

LIFTING THE S-20 SERIES I I ................................................................................................................................. 5

WRAPPED FOR SHIP PING .................................................................................................................................... 5

REMOVING THE SA W FROM SHIPP ING SKID ...................................................................................................... 5

CUTT ING FL UID...................................................................................................................................................... 6

HYD RAUL IC OI L ...................................................................................................................................................... 6

LEVELLIN G THE SAW............................................................................................................................................. 6

POWE R WIRI NG CON NECTI ONS........................................................................................................................... 7

OPERATING INSTRUCTIONS

OPER A TOR CONT ROL P ANE L................................................................................................................................ 9

ELEC TRICA L CON TROLS.................................................................................................................................. 9

VISE CON TROLS............................................................................................................................................... 9

HEAD CONT ROLS ............................................................................................................................................. 9

BLADE BASICS ................................................................................................................................................... 10

DETERMINE OPTIMUM B LADE PITCH........................................................................................................... 1 1

BLADE SPEED SELECTION................................................................................................................................. 12

CHANGING BELT POSITION ................................................................................................................................ 12

V ARIABLE SPE ED CONTROL .............................................................................................................................. 12

HEAD SWING and BREAK................................................................................................................................... 12

GUIDE ARM POSITI ONING .................................................................................................................................. 13

COOL ANT F LOW................................................................................................................................................... 13

OPTI ONAL C ONTRO LS ........................................................................................................................................ 14

WORK S TOP......................................................................................................................................................... 1 4

HYD RAU LIC B UNDL ING........................................................................................................................................ 14

VARIABLE VISE PRESSURE ............................................................................................................................... 14

MAINTENANCE and TROUBLESHOOTING

SAFETY LOCKO UT and P ROCEDU RE ................................................................................................................. 15

BLADE CHANG ING PR OCEDU RE ........................................................................................................................ 16

BLADE TRACK ING ADJUS TMENT ....................................................................................................................... 17

IDLER WHEELADJUSTMENT ......................................................................................................................... 17

DRIVE WHEELADJUSTMENT......................................................................................................................... 1 7

BLADE BRUS H A DJUSTMENT............................................................................................................................. 1 8

ANGLE BRAKE ADJUSTMENT a nd PROCEDUR E............................................................................................... 1 8

BLADE GUIDE AD JUSTMENT.............................................................................................................................. 18

HEAD DOWN LI MIT SWITCH................................................................................................................................ 19

BEL T TENSION ADJUSTMENT............................................................................................................................ 19

LUB RIC AT ION ....................................................................................................................................................... 1 9

TROUB LE SHO OTING GUIDE .............................................................................................................................. 21

SERVIC E RECORD & NOTES............................................................................................................................... 22

ELECTRICAL SYSTEM

CONTROL P ANE L & COM PONENTS.................................................................................................................... 23

ELECTRIC AL COMPON ENTS LISTS.................................................................................................................... 2 4

ELECT RICAL SCHE MA TIC an d WIRIN G DRA WINGS ........................................................................................... 27

---- Continued ----

i S22H ce 2002a

HYDRAULIC SYSTEM

HYD RAUL IC CO MPON ENTS................................................................................................................................. 29

HYDRAUL IC CYLIND ER AS SEMBLIES ................................................................................................................ 30

HYDRAUL IC SER VICE KI TS ................................................................................................................................. 30

S22H HYDR AULIC SCHE MA TIC............................................................................................................................ 31

S22H PLUM BING DIAG RAM................................................................................................................................. 3 2

MECHANICAL ASSEMBLIES

GUIDE ARM & CARBIDE ASSEMBL IES .............................................................................................................. 33

BLADE DRIVE AS SEMBLY ................................................................................................................................... 34

3 HORSE POWER DRIVE OPTION ...................................................................................................................... 3 6

IDLER WHEELASSEMBLY.................................................................................................................................. 38

BLADE BRUSH ASSE MBL Y .................................................................................................................................. 39

COUNTER BALAN CE SPRING ASSEMB L Y.......................................................................................................... 4 0

PIVOT LINK ASSEMBL Y ....................................................................................................................................... 41

FRONT VISE ASSEMBLY .................................................................................................................................... 42

WORK STOP ASSEMBLY ..................................................................................................................................... 43

COOLAN T GROUP............................................................................................................................................... 4 4

DOOR S and C OVERS ........................................................................................................................................... 45

BLADE BREAKAGE.............................................................................................................................................. 4 5

ii S22H ce 2002a

SECTION 1 - INSTALLATION

SECTION 1

INSTALLATION

SECTION 1 - INSTALLATION

SPECIFICATIONS and INSTALLATION

Upon delivery of your new S-20 Series II saw, it is imperative that a thorough inspection be undertaken to

check for any damage that could have been sustained during shipping. Special attention should be paid to the

electrical and hydraulic systems to check for damaged cords, hoses and fluid leaks. In the event of damage

caused during shipping, contact your carrier to file a damage claim. At the begining and through out this manual

there are precuationary indicators, these will inform you of areas which require special attention.

SAFETY PRECAUTIONS

The S-20 Series IIhas been designed to give years of reliable service. It is essential that operators be alerted to

the safe operation of this saw, and the practices to avoid that could lead to injury. The following safety rules are at

the minimum necessary for the safe installation, operation, and maintenance of the saw. T ake every precaution for

the protection of operators and maintenance personnel.

Ø POWER HOOK-UPS AND RE PAIRS SHOULD BE A TTEMPTED ONL Y BY QUALIFIED TRADESMEN.

Ø THE SAW SHOULD BE LOCA TED IN AN AREA WITH SUFFICIENT ROOM TO SAFEL Y LOAD STOCK

INTO THE SAW . SECURE THE SAW TO THE FLOOR.

Ø THE AR EA AROUND THE SA W SHOULD BE MAINT AINED IN A CLEAN AND TIDY CONDITION TO A VOID

OBST ACLES OPERAT ORS COULD TRIP OVER.

Ø THE S-20 SERIES II SHOULD ONL Y BE OPERA TED ACCORDING TO THE SPECIFICA TIONS OF THE

SAW . AVOID UNSAFE USAGE PRACTICES.

Ø IF AT ANY TIME THE SA W DOES NOT AP PEAR TO BE OPERATING PROPERL Y IT SHOULD BE

STOPPED IMMEDIA TEL Y AND REP AIRED.

Ø OPERATOR : THE SAW SHOULD NEVER BE OPERA TED UNLESS ALL G UARDS AND DOORS

ARE IN PLACE AND CLOSED.

Ø OPERATOR : KEEP A SAFE DISTANCE FROM ALL MOVING PARTS - ESPECIALLY THE BLADE

AND VISES.

Ø OPERA T OR : LOOSE CLOTHING AND GLOVES SHOULD NEVER BE WORN WHILE OPERA TING

THE SAW . COVER LONG HAIR.

Ø OPERATOR : STOCK SHOULD NOT BE LOADED ONTO THE SAW IF THE BLADE IS RUNNING.

Ø OPERATOR : LONG AND HEA VY STOCK SHOULD AL WA YS BE PROPERLY SUPPORTED IN

FRONT OF AND BEHIND THE SAW .

Ø OPERATOR : NEVER A TTEMPT TO DISLODGE OR MOVE ST OCK WHILE THE BLADE IS MOVING.

T AKE THE TIME T O STOP THE SA W BLADE, REMOVE OBSTRUCTIONS, AND

RESTAR T BLADE.

Ø OPE RA T OR : MUST WEAR EYE PROTECTION

Ø OPE R ATO R: MAINTAIN PROPER ADJUS TMENT OF BLADE TENSION, BLADE GUIDES AND

BEARING SURFACES.

Ø OPE RATOR: HOLD WORK PIECE FIRMLY AG AINST T ABLE.

Ø OPE RATOR: DO NOT REMOVE JAMMED CUTOFF PIECES UNTIL BLADE HAS STOPPED.

NO MODIFICATIONS T O THE MACHINE ARE PERMITTED WITHOUT PRIOR APPROV AL FROM HYD.MECH.

ANYAPPROVED MODIFICATIONS SHOULD ONL Y BE UNDERT AKEN BY TRAINED PERSONNEL.

Pg 1 S22Hce 2002a

SPECIFICA TIONS

IMPERIAL DIMENSIONS METRIC DIMENSIONS

Cutting Capacity

rect an g ul ar 13" High x 18" Wide 325mm x 450mm

ro u n d 12" dia @ 45 deg 300mm dia @ 45 deg

Blade length 13' 6" 4115mm

widt h 1 " (1.075" including teeth) 25mm (27.3mm including teeth)

thickness .032 " 0.8mm

Blade speed (with 50Hz, 1450 RPM motor)

Standard step pulley 90/140/2 20/310 S FM 22/34/58/90 m/min

V ariable speed option 65 to 330 SFM - V ariable 22 to 122 m/min - V ariable

Blade guides Carbide Inserts

Blade wheel diameter 16" 400 mm

Motors Standard 2 HP 1.5 kW

V ariable Speed Option 3 HP 2.2 kW

Hydraulic Drive 1/4 HP 0.2 kW

Hydrau lic Optional - Micro Powerpack gear pump

Coola nt pum p 2.4 US Gal/min 9 L/min

Coolant reservoir 6 Gallons 23 Litre

Table height 30 " High 762 mm

Machine weight 1800 pounds 810 kg

Overall Dimension s 80" W x 80.5" L x 55.5" H 2037mm W x 2046mm L x 1408mm H

Pg 2 S22Hna 2002a

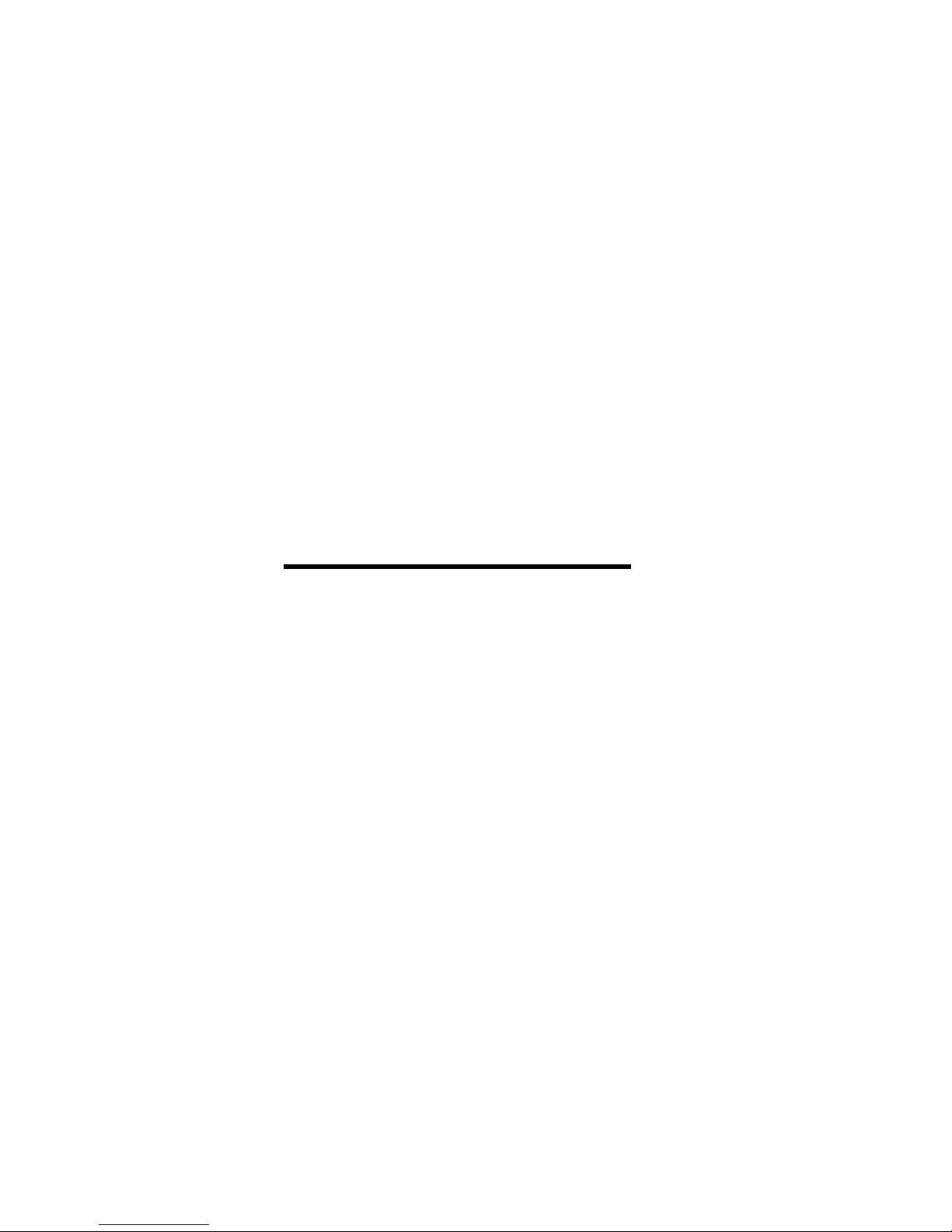

LAYOUT DRAWINGS

Pg 3 S22Hce 2002a

Pg 4 S22Hna 2002a

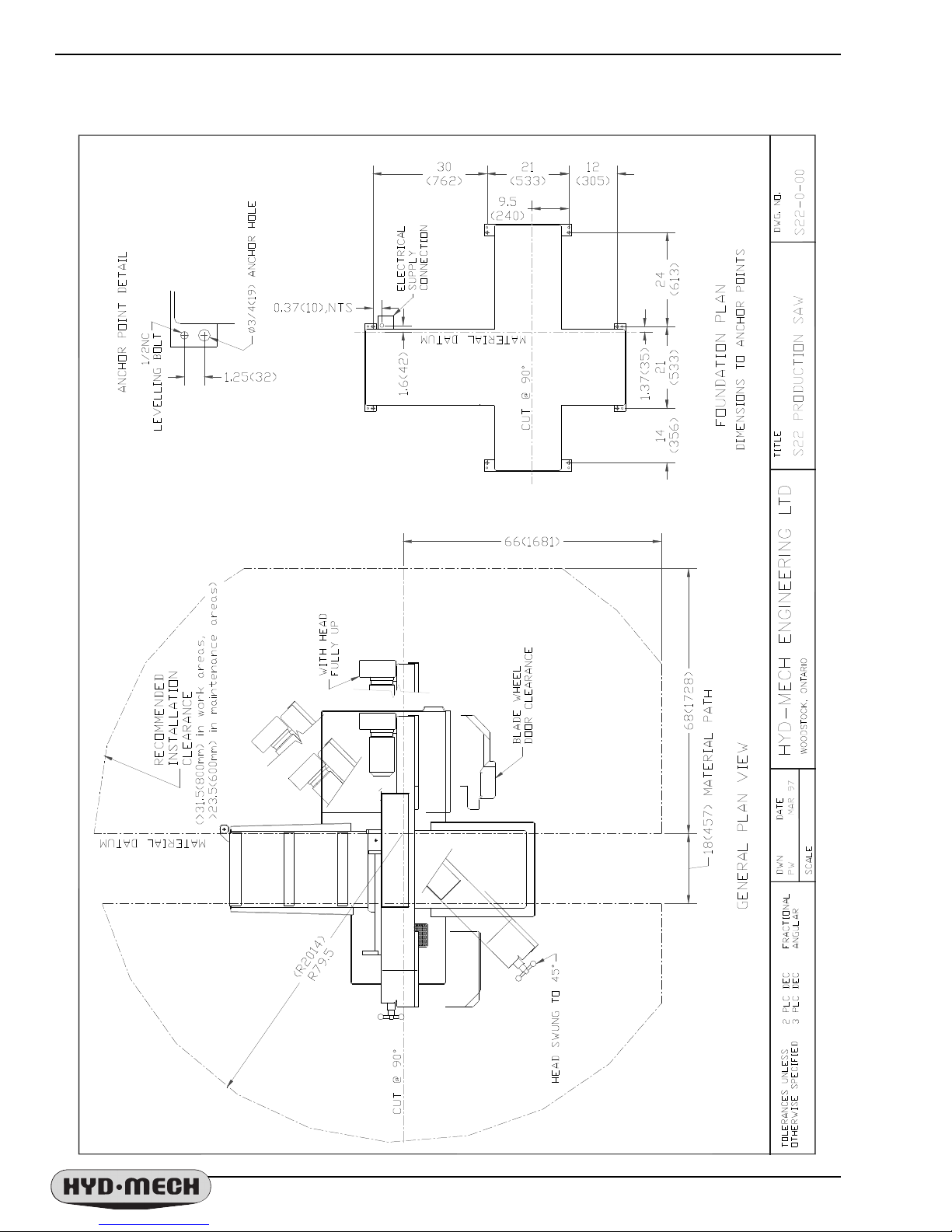

LIFTING THE S-20 SERIES II

The S-20 is shipped with a shipping pallet attached

to the saw. When lifting the pallet with a forklift truck

make sure that the load is firmly balanced. The

following photo shows a lift truck lifting the saw and

pallet from the correct side. The pallet length dimension

is 87” (213cm). Minimum fork length of 72” (182cm) is

recommended to safely lift the pallet.

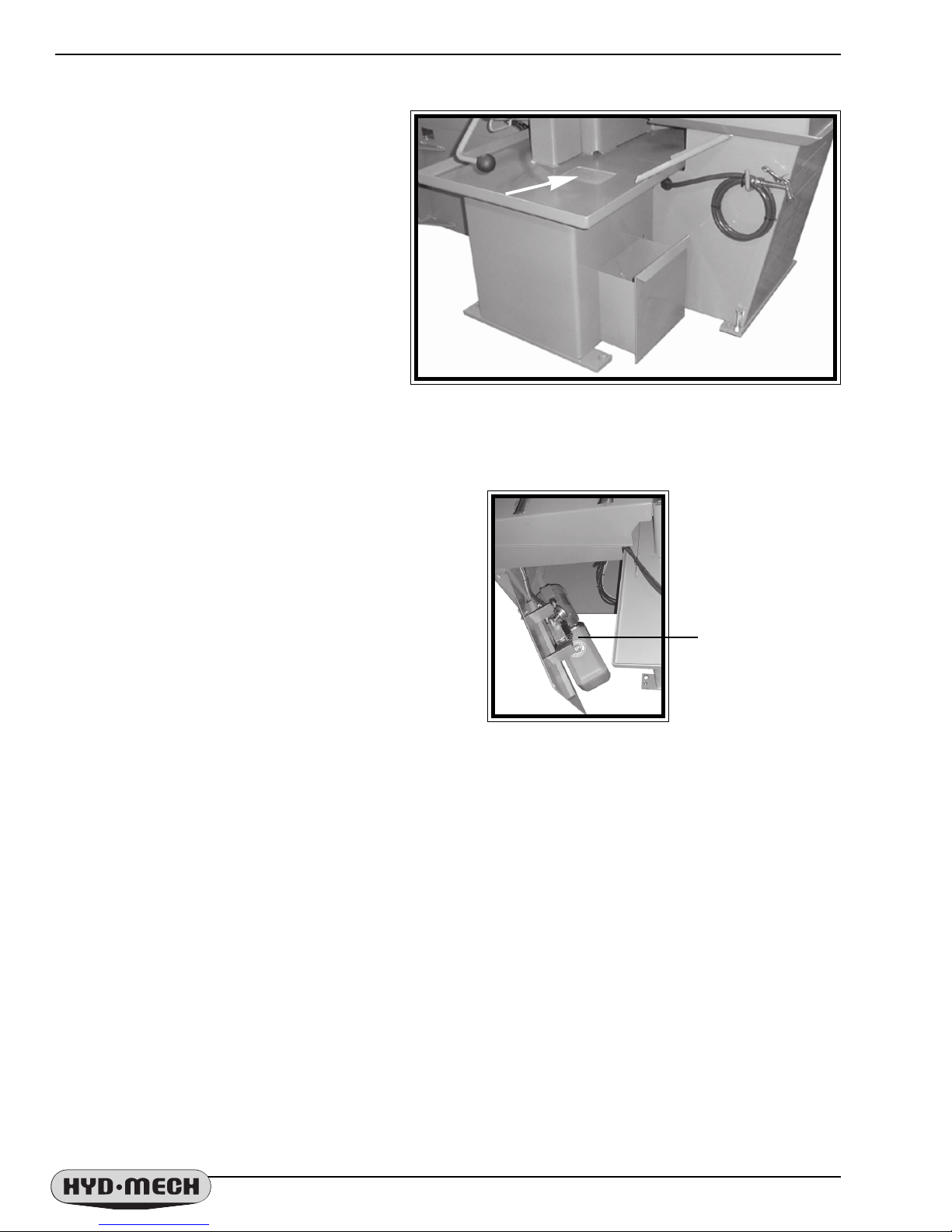

WRAPPED FOR SHIPPING

The S-20 Series II is shrink-wrapped for shipping

from our plant. Remove the wrapping from around the

saw. Complete the inspection for signs of damage. The

photo shows the floor mounting plates located at the

corners of the saw. Undo the bolts that hold the saw to the pallet. Retain

these bolts to use for levelling. The larger diameter hole is used for

retaining during shipping and for use with concrete floor anchors. The

smaller diameter, threaded holes at each corner are used for levelling the

saw properly .

Lifting the packaged S-20 Series II with a lift truck.

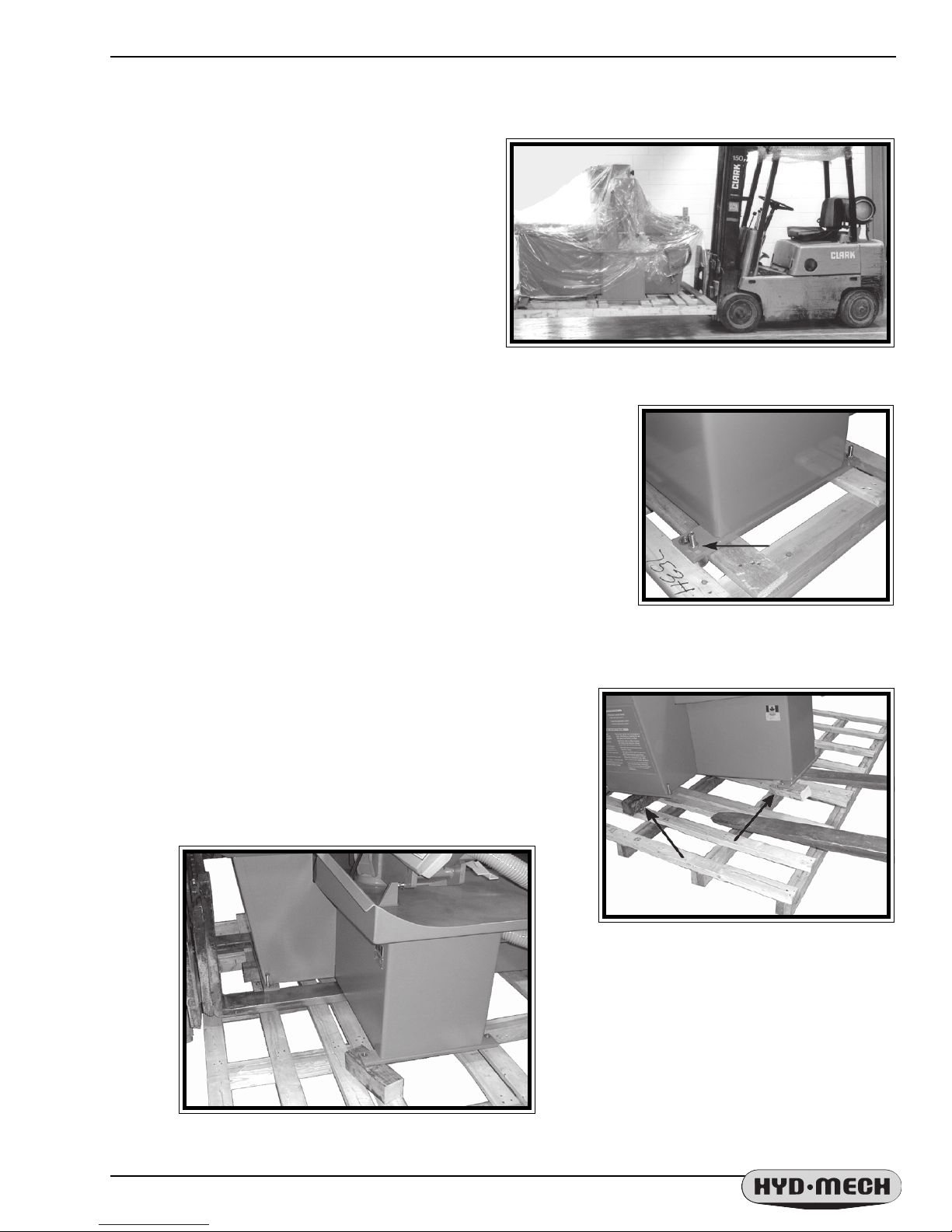

REMOVING THE SAW FROM SHIPPING SKID

Lift the right (drive) side of the saw as shown with a lift truck and

place two blocks under the saw as shown. With a lift truck (fork

length 60” (150cm) and rated for 1800lb (810kg) minimum), lift the

saw from the skid at the FRONT of the machine as shown and place

it where required.

Bolt holding the saw to the skid (4

places).

Blocks placed under the saw.

Lifting the machine with a lift truck from the front

of machine.

Pg 5 S22Hce 2002a

LEVELLING THE SAW

Use a machinist's level across the vise table

to level the saw. Adjust the level with the

levelling bolts supplied. Consideration should be

given to the flow of the coolant as it returns to

the coolant trough at the vise end of the saw.

Levelling to give a small incline towards this

area helps to ensure the coolant supply returns

to the container.

Coolant filter

S25-1-03 &

screen, S22-1-11

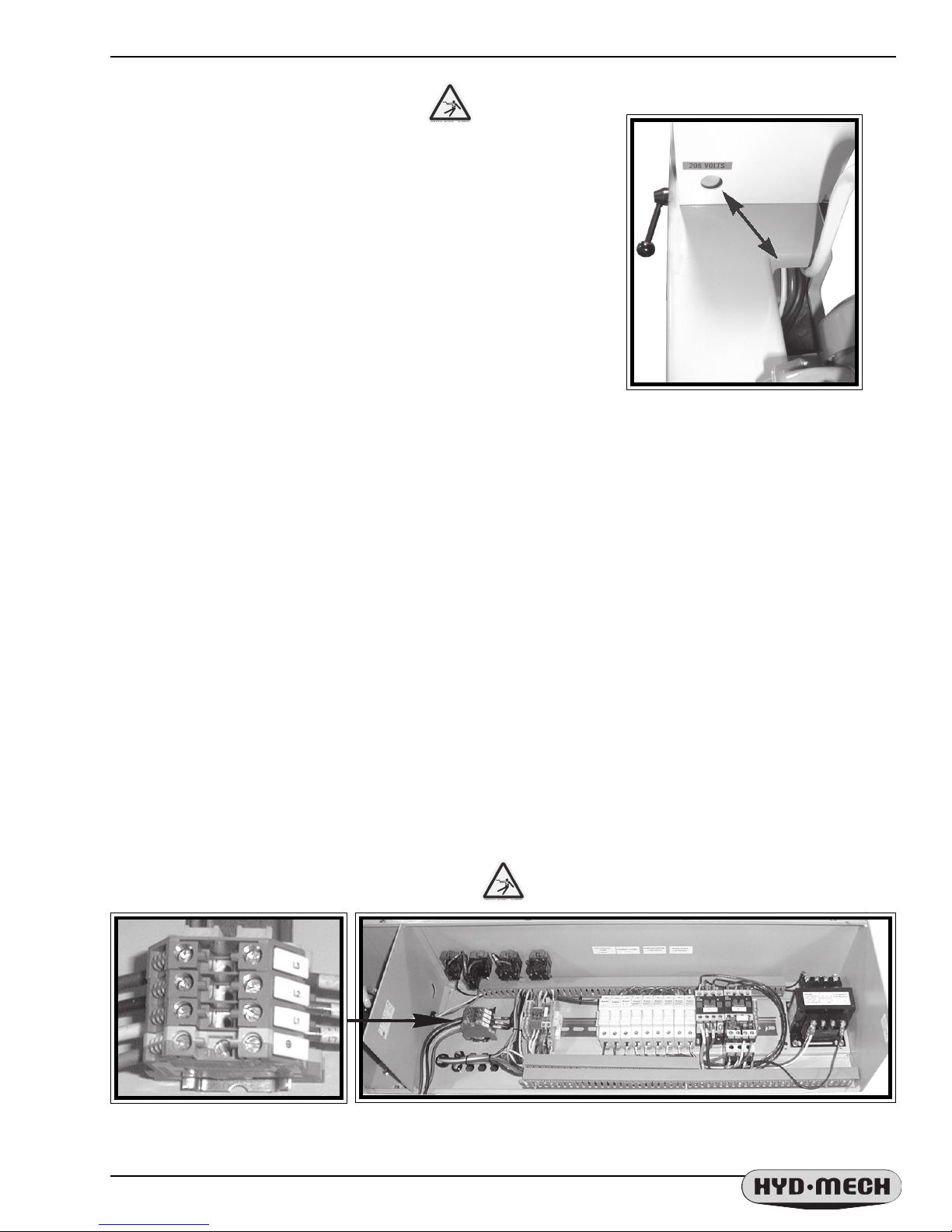

HYDRAULIC OIL

The S-20H option is supplied with T exaco Rando HD46

hydraulic oil. Substitutes should be a #46 hydraulic oil. The

power pack and tank is mounted on the inside of the door

found at the idler side of the infeed table. The tank should

be at least 3/4 full at all times.

Wash Down

Hose

,

Coolant

T ank & Pump

Coolant components (Shown with tank removed).

Hydraulic tank

filler cap is

found

near the pump

& motor

assembly .

The power pack with the

door opened.

CUTTING FLUID

The S20 uses a pump and reservoir to circulate the necessary cutting fluid to the blade for maximum blade life.

Y our saw blade supplier will be able to provide information to the cutting fluid products that are available for your

needs.

No cutting fluid (coolant) is supplied with the machine. There are two types of coolant available:

- oil based; dilute 1:10 ratio (one part concentrated coolant to 10 parts water)

- synthetic; dilute as recommended by manufacturer.

Pg 6 S22Hna 2002a

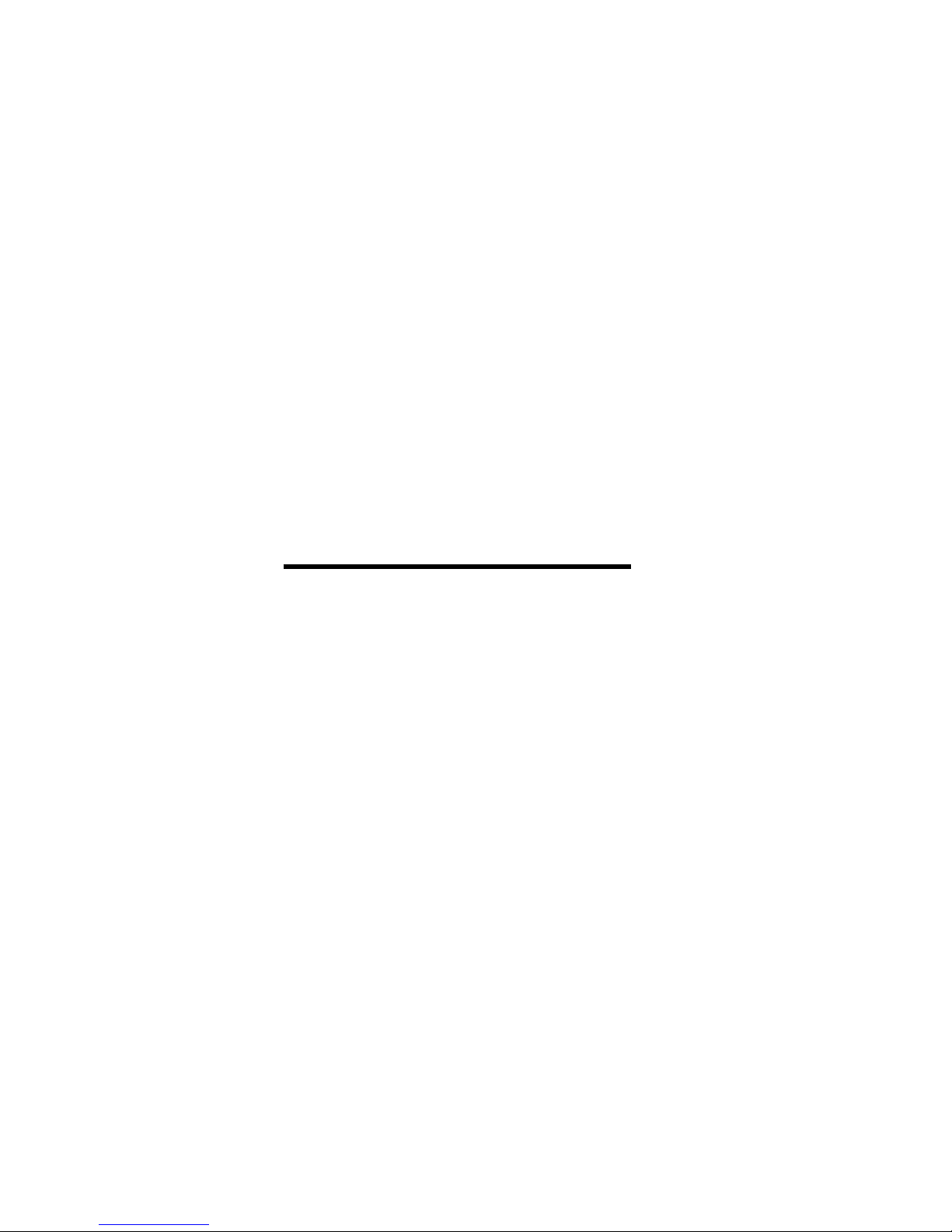

POWER CABLE ROUTING

The main power cable can be routed up through the bottom of the

head frame to the access holes in the end of the control panel. Cable

liquide tight reliefs should be used to secure the cable into the control

panel to ensure there is no movement of the cable when the machine is

operated.

POWER WIRING CONNECTIONS

When the machine has been anchored and levelled the power hook-up is the last installation step. In order to

provide safe operation and to prevent potential damage to the machine, only qualified personnel should make the

electrical connections.

As supplied your new S-20 Series II is set to run on three phase voltage or single phase. The supply voltage of

the machine is displayed on the Serial # Plate and the Voltage Label.

Connection from the Main supply is made to L1, L2, L3, (or L1 & L2 for single phase) and Ground terminals

between the contactor & transformer.

Supply conductors should be rated for the current supplied and should be protected by time delay fusing rated for

the amperage stated on the machine serial plate

CHECK FOR:

- Signs of damage to the electrical cables from shipping or installation.

- Correct phase order. The blade should be running counter clockwise.

(If the blade direction is wrong, two lines should be reversed to correct)

The S-20, with "H" option control panel, opened.L3, L2, L1 and Ground

Pg 7 S22Hce 2002a

THIS PAGE INTENTIONALLY LEFT BLANK

SECTION 2 - OPERATING INSTRUCTIONS

SECTION 2

OPERATING INSTRUCTIONS

SECTION 2 - OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

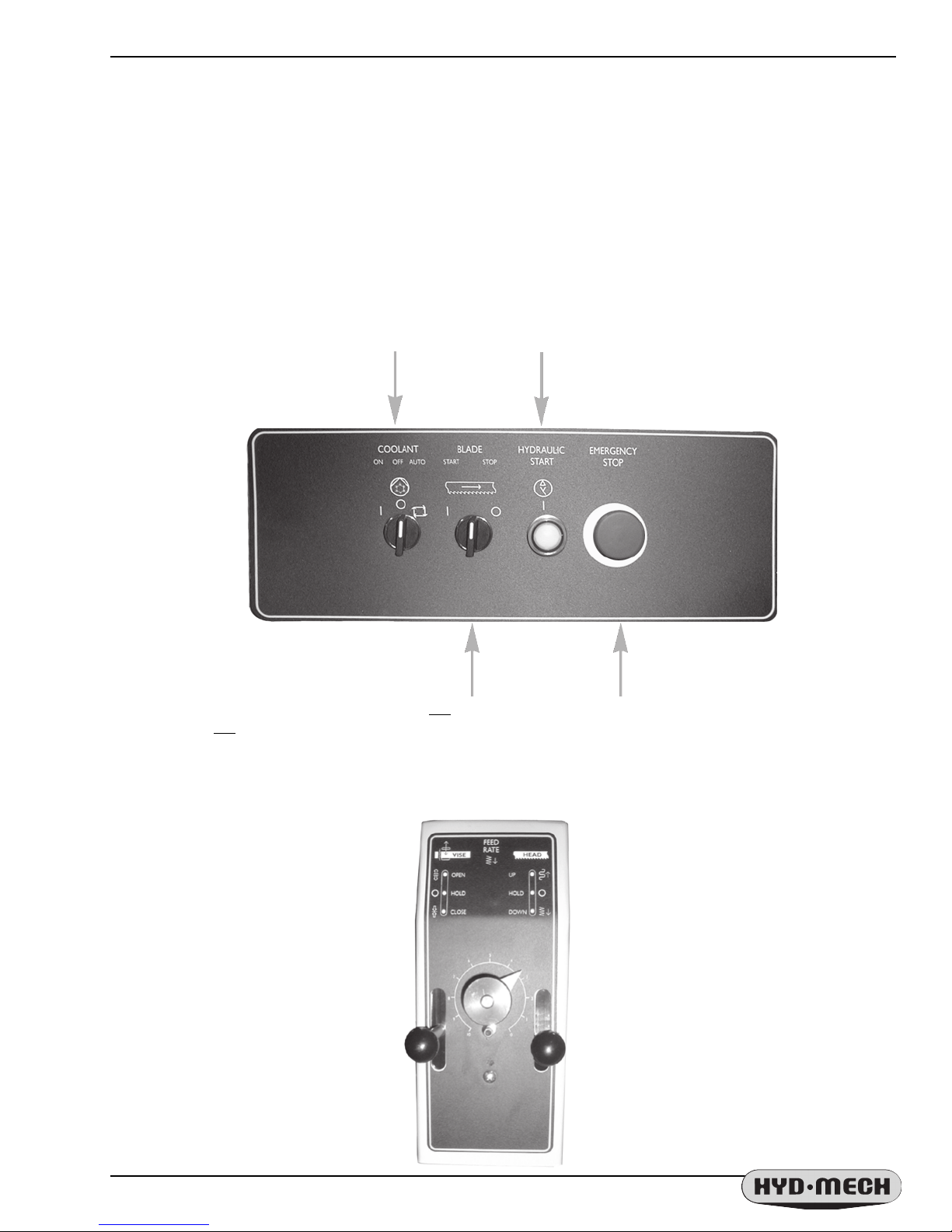

OPERA TOR CONTROL PANEL

The operator control panel provides the operator with all the controls necessary to operate the saw after the

cutting angle has been set and the stock has been loaded and secured. All of the electrical functions are operated

from the control panel. The Vise and Feed Rate setting are both controled with the hydraulic controls shown on the

next page.

ELECTRICAL CONTROLS

COOLANT SWITCH

ON :

OFF :

WASH :

Coolant flow when

blade is running.

No coolant flow.

Constant flow.

BLADE SWITCH

This selector switch starts and

stops the saw blade. The blade will

not start with the Head in the down

position.

HYDRAULIC BUTTON

This button will start the hydraulic

ST AR T Button, system. It will

illuminate when pressed and held

momentarily .

EMERGENCY STOP BUTTON

Pressing the red EMERGENCY STOP

Button STOP Button will turn OFF all

machine functions with the exception of

the coolant if the selector switch is in

the WASH position.

VISE CONTROL

OPEN

the lever is pushed up.

HOLD

position when the lever is in the

center position.

CLOSE

the lever is pushed down.

NOTE:

option is present.

The vise will open when

The vise will hold it's

The vise will close when

See page 14 if the bundling

Pg 9 S22Hna 2002a

HEAD CONTROLS

UP

The head will rise as long as the

lever is pushed up.

HOLD

current position when the lever is in this

position.

DOWN

Feed Rate.

FEED RA TE DIAL

the head will descend can be set on the

scale of 1 to 10. As the number

increases so does feed rate.

The head will stay at it's

The Head will descend at set

The speed at which

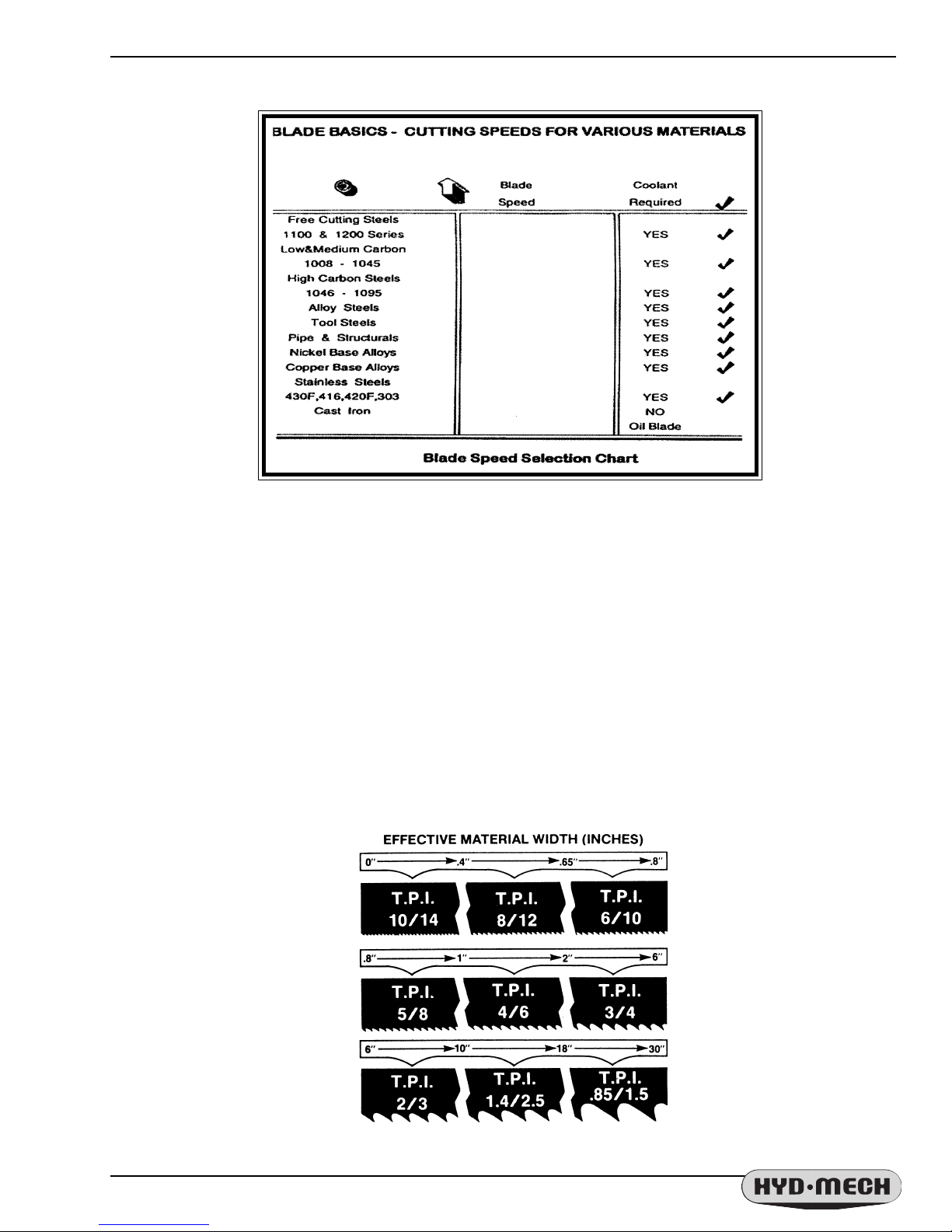

BLADE BASICS

Technology is rapidly changing all aspects of production machining. Metal cutoff is no exception. The

advances made in the bandsaw blade industry have definitely brought down the cost per cut, despite the three fold

higher price of the newer technology blades. V ariable pitch (following page), bi-metal blades (like the 3/4 or 4/6 bimetal blade supplied with the machine) last much longer, cut faster , and more accurately than the conventional

carbon steel blades. In order to take advantage of the superiority of bi-metal blades, it is critical to property “breakin” a new blade. This is accomplished by taking two or three cuts through solid four or five inch diameter mild steel

at an extremely slow feed rate. These two or three slow cuts sufficiently lap (polish) the new blade so that it does

not snag the material being cut. Proper break-in will alleviate blade vibration, improve surface finish and accuracy ,

and improve expected blade life.

1. A new blade must be properly "broken-in". Proper break-in will alleviate blade vibration, improve surface

finish and accuracy , and extend blade life. The most convenient way to do this is to cut the intended work-piece,

at the standard recommended blade speed for that material, but with the feed rate reduced to about 25% of

normal. Near the end of the first cut, increase the feed rate again, and once again when the blade approaches

the end of the second cut. Keep increasing feed rate in this fashion, so that normal feed rate is reached after

300 to 500 sq. cm of cutting.

2. Generous coolant application is essential with almost all materials. A high quality and well mixed

coolant will dramatically extend blade life, and will increase cutting rate and surface finish. On those few

materials where coolant is undesirable, a slight coolant flow or periodic oiling of the blade is necessary to

prevent the blade from being scored by the carbide guides.

3. The stock being cut must be securely clamped in the vises. Stock movement during cutting will strip

blade teeth. Noticeable stock vibration reduces cutting performance and blade life - consideration should be

given to reorientation of the stock, or additional clamping measures (e.g. wood between vise jaws and work-

piece).

4. The proper blade speed for the work-piece material must be selected.

Use the following chart as a starting point.

- Blade speeds higher than recommended will quickly dull the blade. Blue chips are evidence of excessive

blade speed.

- Lower than recommended speeds will not prolong blade life, and will require reduced feed rate - but

reduced speeds may be helpful in reducing vibration, and will increase blade life in that case.

5. The proper feed rate must be applied. Feed Rate is the speed which the head "free-falls", and is set with

the feed rate control knob. The head will descend more slowly when the blade encounters the work-piece but

the force of the blade on the work will not be changed unless the setting is changed. Verification of proper feed

rate is provided by the appearance of the cut chips which ideally form nicely curled "clock springs". (Note that

cast irons, and interrupted cuts result in short, broken chips even at ideal feed rates).

- Excessive feed rate will result in short blade life and/or crooked cuts.

Pg 10 S22Hna 2002a

( in SFM )( in SFM )

( in SFM )

( in SFM )( in SFM )

(

310310

310

310310

220220

220

220220

140, 220140, 220

140, 220

140, 220140, 220

140, 220140, 220

140, 220

140, 220140, 220

90, 14090, 140

90, 140

90, 14090, 140

140, 220140, 220

140, 220

140, 220140, 220

90, 14090, 140

90, 140

90, 14090, 140

140, 220140, 220

140, 220

140, 220140, 220

140, 220140, 220

140, 220

140, 220140, 220

140, 220140, 220

140, 220

140, 220140, 220

DETERMINE OPTIMUM BLADE PITCH - TEETH PER INCH (T.P.I.)

Selecting a blade with proper tooth pitch is important in order to achieve optimal cutting rates and good blade

life.

For cutting narrow or thin wall structural materials a fine, blade with many teeth per inch (T.P.I.)is recommended.

For wide materials a blade with a coarse pitch should be used. See the sketch below for the blade pitch changes

fordiffering effective material widths.

It is impractical to change the blade to the proper pitch every time a different width of material is cut and it is not

necessary , but remember that the optimum blade will cut most effic iently. T oo fine a blade must be fed slower on

wide material because the small gullets between the teeth will get packed with chips before they get across and out

of the cut. Too coarse a blade must be fed slower because it has fewer teeth cutting and there is a limit to the depth

of a cut taken by each tooth.

Optimum Blade Pitch ( T.P.I. ) for Material Width ( Inches )

Pg 11 S22Hna 2002a

Loading...

Loading...