YEAR OF MANUFACTURE: ______________

USE AND MAINTENANCE MANUAL

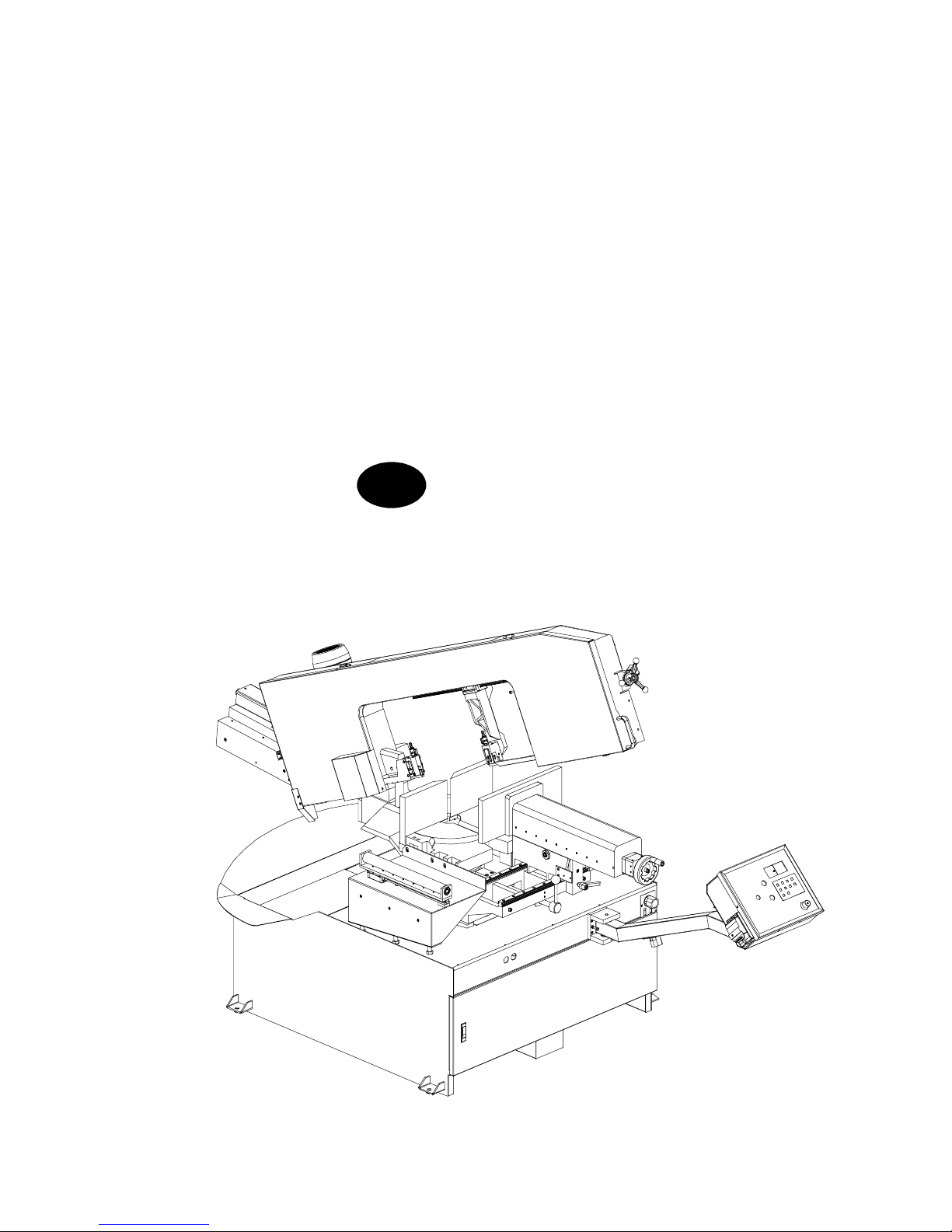

S20DSP

EN

Introduction and technical specifications 1---1......................

Foreword 1---1..........................................................

Machine presentation 1---1...............................................

Machine specification 1--- 2...............................................

Dimensions 1 --- 4........................................................

F un c t io n a l p a r t s 2 --- 1............................................

S20DSP model 2 --- 1.....................................................

Cutting head 2---2.......................................................

Vice 2 --- 3..............................................................

C o n t r o l P a n e l 2 --- 3......................................................

Tu r nt a b l e 2 --- 4..........................................................

F i x e d p l at f or m 2 --- 4.....................................................

M o t i o n --- v a ri a t o r --- r e d u c e r u n i t 2 --- 5.......................................

Base 2 --- 6..............................................................

Safety and accident prevention 3---1................................

U se o f t h e m a ch i ne 3 --- 1.................................................

General recommendatio ns 3---2...........................................

Recommendations to the operator 3--- 3....................................

Machine safety devices 3--- 5..............................................

Reference standards 3---5................................................

Protection against accidental contact with the blade 3--- 6......................

Electrical equipment 3--- 6................................................

Emergency devices 3---7..................................................

Noise level of the machine 3---8...........................................

Noise level measurement 3--- 8............................................

Noise level values 3--- 8...................................................

Vibration emission 3 --- 9..................................................

Electromagnetic compatibility 3--- 9........................................

Machine installation 4--- 1........................................

Packaging and storage 4---1...............................................

Anchoring the machine 4--- 4..............................................

Minimum requirements 4--- 4..............................................

C h e c k l i s t 4 --- 5..........................................................

Connection to t he power supply 4 --- 6.......................................

Description of machine operation 5---1.............................

Control panel description 5---1............................................

Basic instructions for carrying out a cutting operation cycle 5--- 3................

Manoeuvring the cutting head 5---3........................................

Clamping the work piece in the vice 5--- 3...................................

Rapid vice positioning 5---4...............................................

R a p i d v i c e t r a n s l a t i on 5 --- 6...............................................

Wi d t h o f c u t 5 --- 6.......................................................

Preliminary check list for cutting operation 5---7.............................

Semi---automatic operating cycle 5--- 7......................................

Execution of inclined cuts 5---10............................................

Loading side rollerway position 5---10.......................................

Angled cuts 45˚ to the left 5--- 11...........................................

Angled cuts 60˚ to the left 5--- 12...........................................

Angled cuts 45˚ to the right 5--- 14..........................................

Angled cuts 60˚ to the right 5--- 15..........................................

Diagrams, exploded views and replacement parts 6---1................

Hydraulic diagram 6---2..................................................

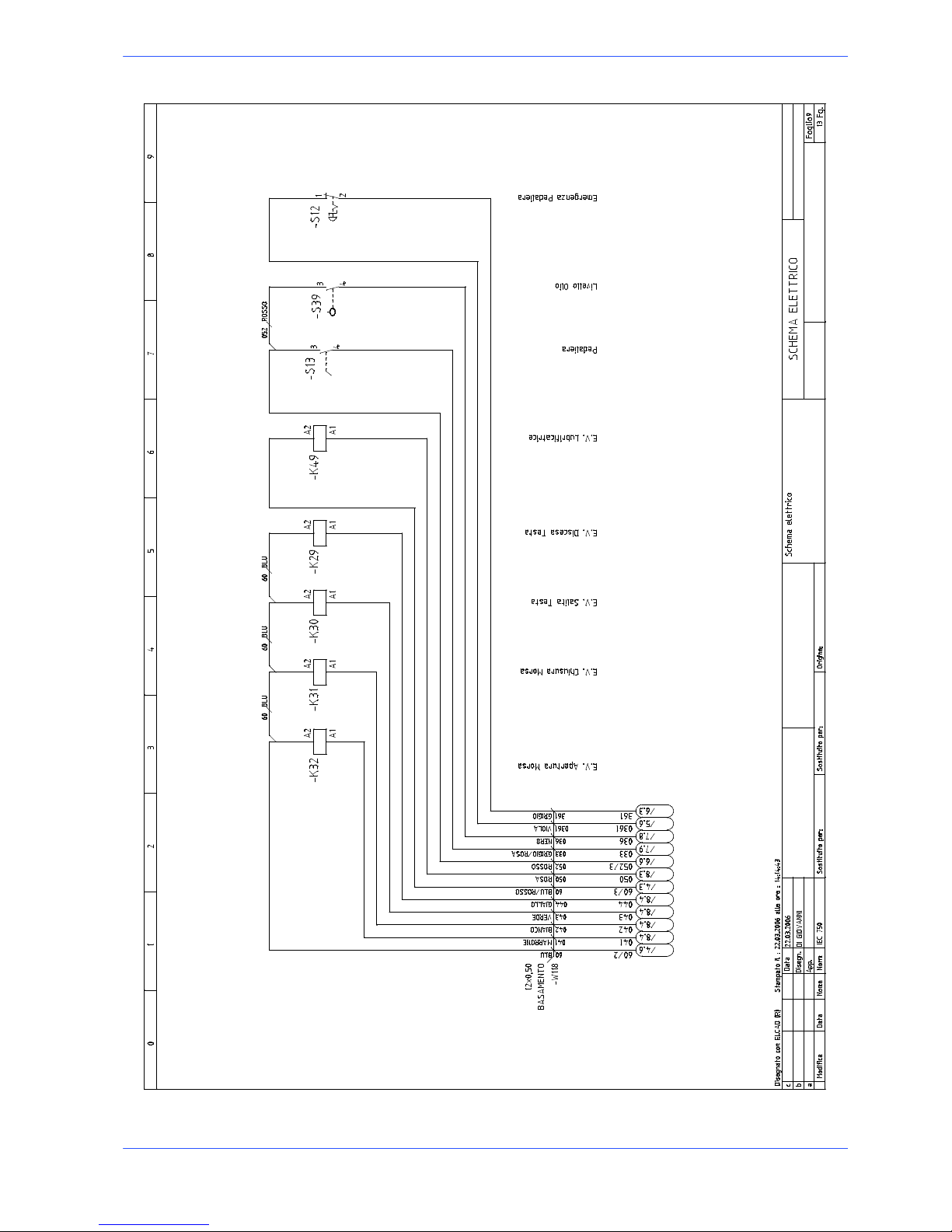

How to read the wiring diagrams 6---3......................................

D2 --- Letter codes used to designate the type of component 6--- 5...............

Standardised Wiring Diagrams S20DSP (CENELEC Standard) 6---8............

IUD/IUV card 6 --- 21.....................................................

Exploded views 6--- 22.....................................................

M o t o r u n i t 6 --- 2 2.........................................................

Driving pulley unit 6---24..................................................

Front flywheel assembly 6--- 26..............................................

F i x e d w o rk t ab l e 6 --- 2 8....................................................

Cutting head cover 6---30..................................................

C y l i n d e r s 6 --- 3 2.........................................................

Base assembly 6---34......................................................

C o n t r o l p a n e l 6 --- 3 6......................................................

Vice assembly 6---38......................................................

A d j u s t me n t s 7 --- 1...............................................

Displaying and editing the set---up parameters 7--- 1..........................

Set language parameter 7---2..............................................

Set parameter for machine type 7--- 2.......................................

Semiautomatic---Dynamic and Manual operation setting (optional) 7 --- 2.........

Pedal control setting (optional) 7--- 3.......................................

Optional inverter presence settings 7--- 3....................................

Blade speed proximity settings 7--- 3........................................

Minimal lubrication system settings 7---3....................................

FCTI / FCTA digital output enabling setting 7--- 3............................

Blade stop setting 7---3...................................................

Cutting vice opening setting 7--- 4..........................................

Cutting vice opening/closing time setting 7---4...............................

Machine maximum power input setting 7---4................................

Measurement unit setting 7---4............................................

Setting minimum blade tensioning 7---5.....................................

Display backlighting time setting 7---5......................................

Cutting head stroke 7 --- 5.................................................

Software version and total use time of the machine 7--- 8......................

Adjusting the display brightness 7--- 8.......................................

Machine working pressures 7---9...........................................

Hydraulic pressure 7 --- 9..................................................

Cutting head 7---10.......................................................

Blade tensioner slide play adjustment 7--- 10..................................

B la d e g ui d e c o m p o n e n t s 7 --- 1 1.............................................

Blade guide heads 7--- 11..................................................

Blade steady buttons 7 --- 11................................................

Blade guide plates 7--- 11..................................................

Blade 7 --- 1 4.............................................................

Tool changeover 7--- 14....................................................

Blade perpendicularity 7--- 16..............................................

Blade orthogonality 7---17.................................................

Front flywheel 7--- 18......................................................

Rear flywheel 7---18......................................................

Maintenance and choice of consumables 8---1.......................

The role of the operator 8--- 1.............................................

Maintenance requirements 8--- 2...........................................

General maintenance 8--- 2...............................................

Daily 8 --- 2.............................................................

Weekly 8 --- 2............................................................

Monthly 8---3...........................................................

Maintenance of working parts 8 --- 3........................................

Consumable materials 8 --- 3...............................................

Oils for oleopneumatic circuit 8--- 3........................................

Oil for lubricant/coolant fluid 8--- 4.........................................

Cutting speed and choice of tools 9---1..............................

Cutting speed 9--- 1......................................................

Standard machine 9---1..................................................

Choice of blade 9---2....................................................

Saw tooth pitch 9---2.....................................................

Cutting speed and downstroke speed 9--- 2..................................

Ty p e s o f s w ar f : 9 --- 3.....................................................

Lubricant/coolant fluid 9---4..............................................

Blade structure 9---4.....................................................

B la d e t y pe s 9 --- 5........................................................

C o n v e n t i on a l r ak e 9 --- 5..................................................

Po s it i v e r a ke 9 --- 5.......................................................

Va r i a b le p i tc h 9 --- 5......................................................

Variable pitch blades with 0˚ cutting angle 9--- 6..............................

Variable pitch with positive rake (from 9 to 10 degrees) 9---6...................

Set: 9 --- 6...............................................................

Standard or splayed set 9---6..............................................

U nd u la t ed s e t 9 --- 7......................................................

Alternating grouped sets 9---7.............................................

A lt e rn a t i n g s e t 9 --- 7.....................................................

Blade selection table relating to cutting speed and downstroke speed 9--- 8.......

Classification of steels 9---9...............................................

Classification of steels 9 --- 10...............................................

Troubleshooting 10---1............................................

Troubleshooting blade and cutting problems 10--- 1............................

Troubleshooting 10---7....................................................

D i a g n o s t i c s s y st e m 1 0 --- 8..................................................

Machine alarms and emergencies 10---10.....................................

1--1

Introduction and

technical

specifications

Foreword

Hyd---Mech in response to modern production techniques, has developed the new

S20DSP.

This work tool has been designed to satisfy the wide range of cutting needs of a

modern workshop with simplicity and reliability, while at the same time complying with all EEC safety standards.

The S20DSP is structurally rigid, silent and safe: it produces a minimum of waste

while its great versatility makes it suitable for cutting various materials such as

stainless steel light alloys, aluminium, copper and bronze at high speed and with

high precision.

Its high cutting capacity, combined with the possibility of making inclined cuts

from 60˚ left to 60˚ right, make this model the ideal solution for satisfying the

wide strange of cutting needs of machine shops, turneries, structural steel shops

and engineering workshops.

We congratulate our clients on having chosen this product, which will give

effective and faithful service for many years, especially if the instructions

contained in this use and maintenance manual are carefully followed.

This band saw has been exclusively designed to cut metals.

Machine presentation

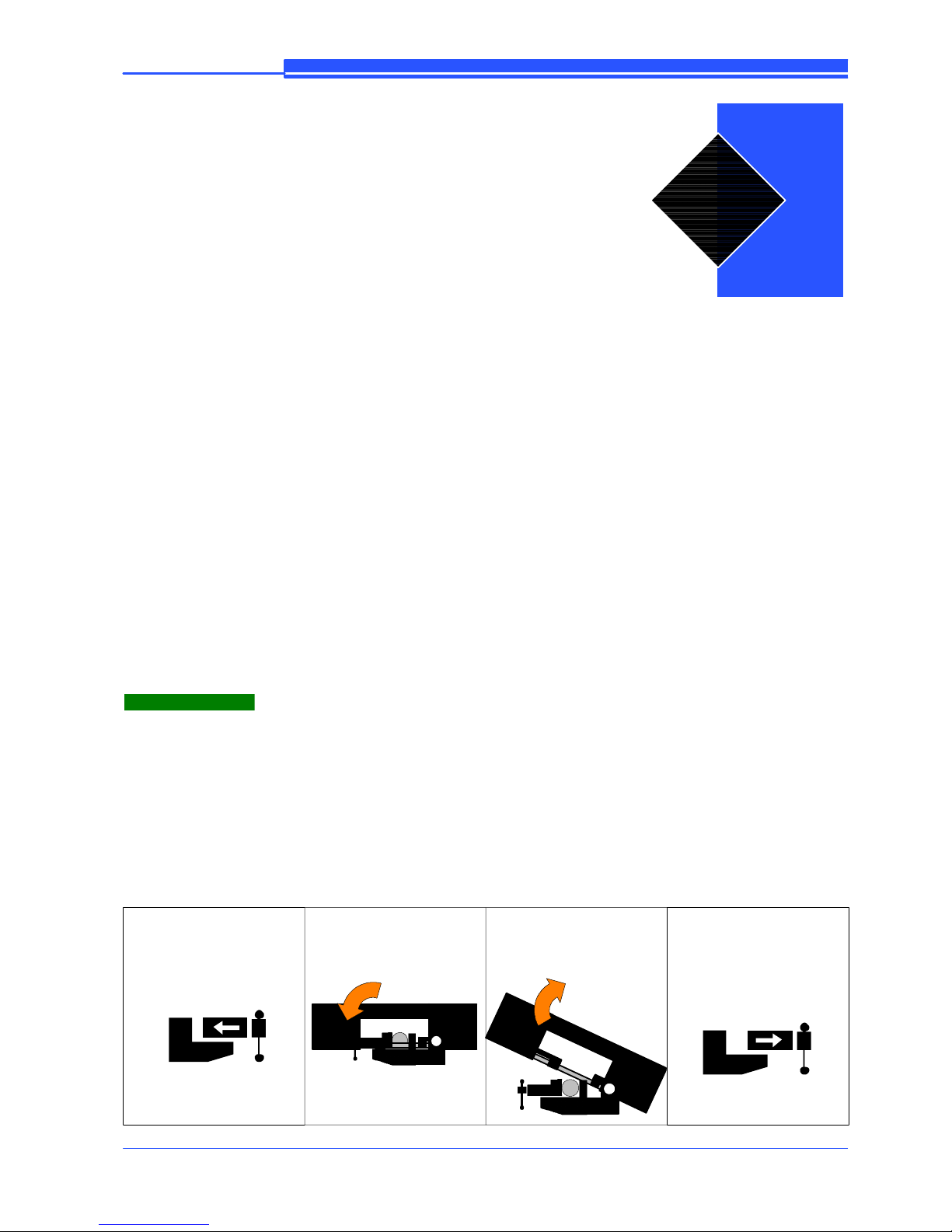

Functioning is SEMI ---AUTOMATIC.

In Semi ---automatic mode, after setting the head cutting stroke on the control

panel and the head downstroke speed, the operator positions the vice 2÷3 mm

from the workpiece and presses the start button (or optional foot pedal if fitted)

on the control panel to start up the band saw. The vice then clamps the material,

the head lowers, cuts the piece and returns to its start position and the vice opens

again.

1.Thecuttervicecloses

2. The head lowers until the cut is made

(FCTA)

3. The head returns to

start position (FCTI)

4. The cutter vice

opens

Warning

1

1--2

2

Use and maintenance manual S20DSP

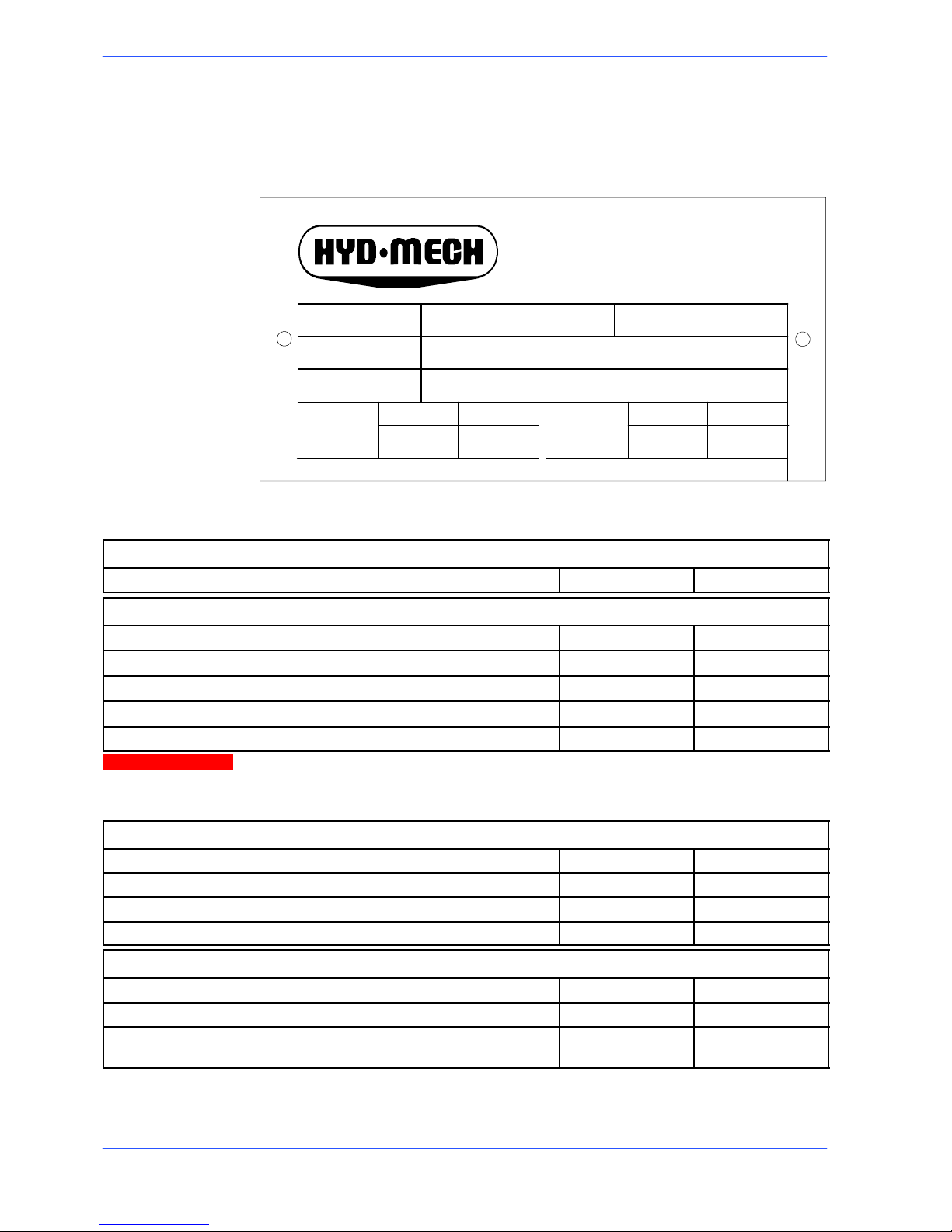

Machine specification

Theanodisedaluminiumnameplateisrivetedonthesideofthemachine;the

same data are reproduced on the declaration of conformity included with this use

and maintenance manual.

bar bar

------ --

V

1PH

AVA

3PH

model

air pressure

data code

oil pressure

HYD--MECH

The Rock Solid Solution

When communicating with the Technical Service department, the model, serial

number and year of manufacture of the machine must be quoted.

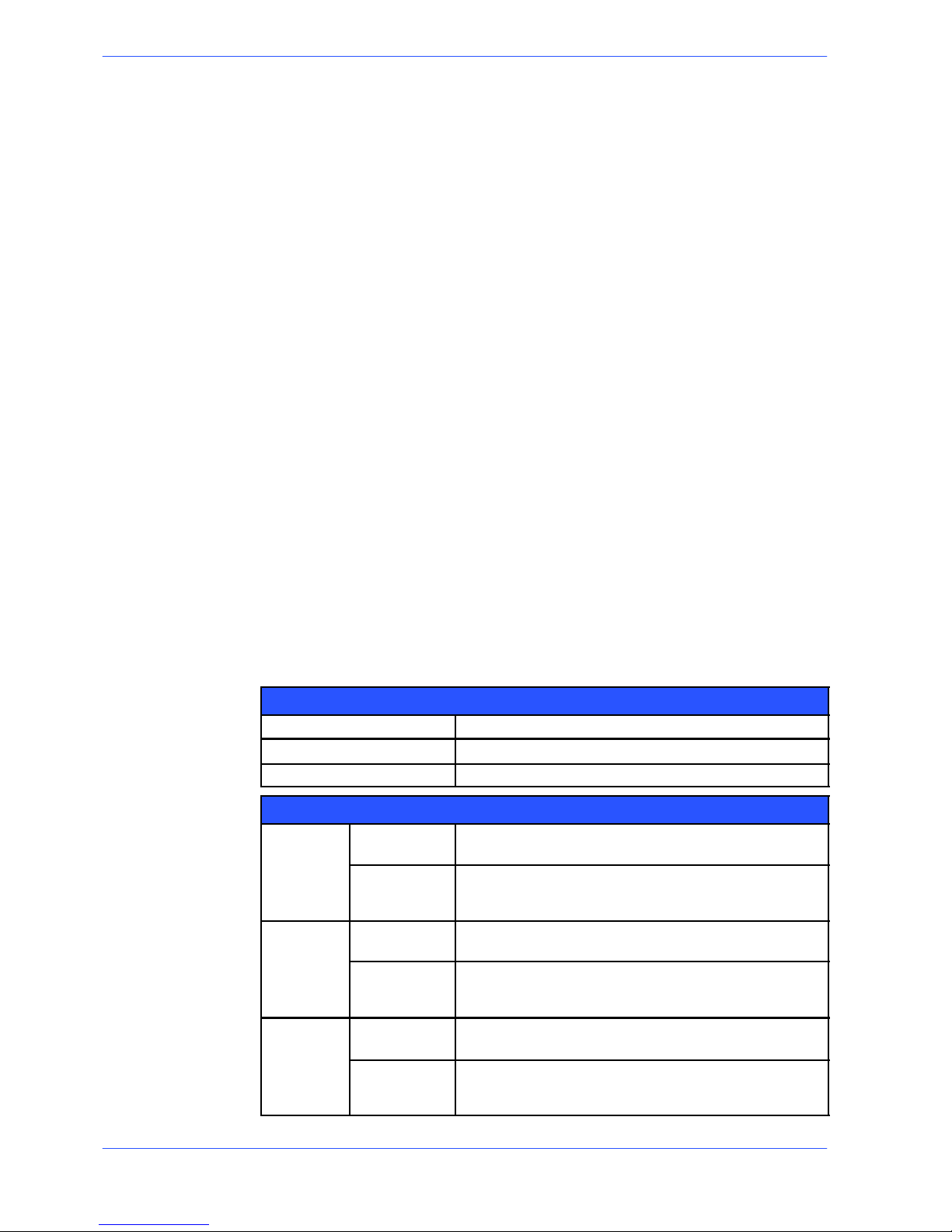

CUTTING SPEEDS

Blade rotation speed mt/min

15 100

BAND SAW

Rated size mm

4500 x 27 x 0,9

Max/min blade length mm

4500 ± 40

Blade height mm

27

Blade width mm

0,9

Band saw tension Kg

1250

When choosing the cutting tool, if its dimensions do not correspond to those

included in the ”Rated size” section, check that the dimensions at least fall

within the admissible max/min specifications.

RATED ELECTRICAL POWER

Head spindle motor KW 1.,5

Electric coolant pump motor KW 0,1

M1 power pack motor (optional) KW

0,37

Max installed power KW 1,97

WORKING PRESSURE

Working pressure blade tensioning/detensioning

Kg

1250/900

Head working pressure in the ascent phase (optional) Bar 20

Vice working pressure during opening/closure phase (AV ver-

sion)

Bar 6

N.B.

Attention

1--3

3

Introduction and technical specifications

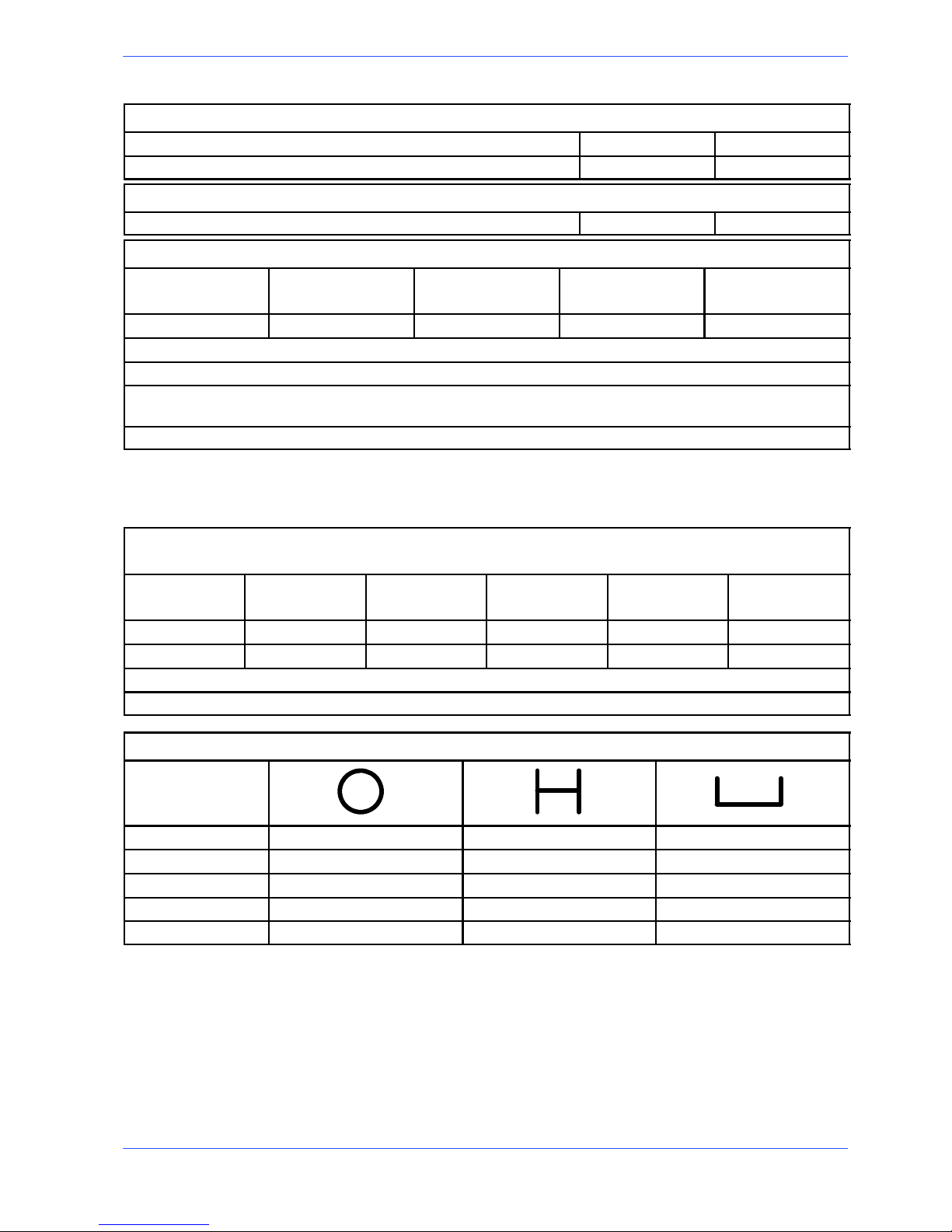

LUBRICANT/COOLANT FLUID AND OIL

Oil for blade t ensioner unit (optional) capacità Lt 8,5

Lubricant/coolant fluid (oil concentration 5---6%) capacità Lt 200

VICE

Vice max. opening mm 455

SPINDLE MOTOR

No.of poles Current (Volts) Absorption

(Amps)

Power (Kw) rpm

4 400 3,7 1,5 1410

Stator wound with enamelled copper wire, class H 200˚C.

Class F insulation (limit temperature TL 155˚C).

IP 55 protection rating (total against contact with live parts, water sprayed from all directions, with shaft oil

seal).

Conforming to CEI norms, publication: IEC 34 of 01/07/1985.

Example of class F insulation: in air--cooled machines at an ambient temperature of 40˚ C (according to CEI 2--3 and IEC 85), the allowable overtemperature is 100˚ C (where 100

ٛ

C represents the allowable DT).

ELECTROPUMP MOTOR

Single phase; Frequency 50 Hz.

Voltage ( Vo l ts) Absorption

(Amps)

Power (Kw) rpm Delivery rate

lt/min

Head (mt. )

230 0,30 0,09 2800 24 1,5

400 0,18 0,09 2800 24 1,5

Protection rating IP 55.

Conforming to CEI norms, publication: IEC 34 of 01/07/1985.

CUTTING CAPACITY

Section

0˚ 330 330 450x330

45˚ a 320 300 300x300

60˚ a 210 200 200x200

45˚ ' 320 300 300x300

60˚ ' 210 200 200x200

N.B.

1--4

4

Use and maintenance manual S20DSP

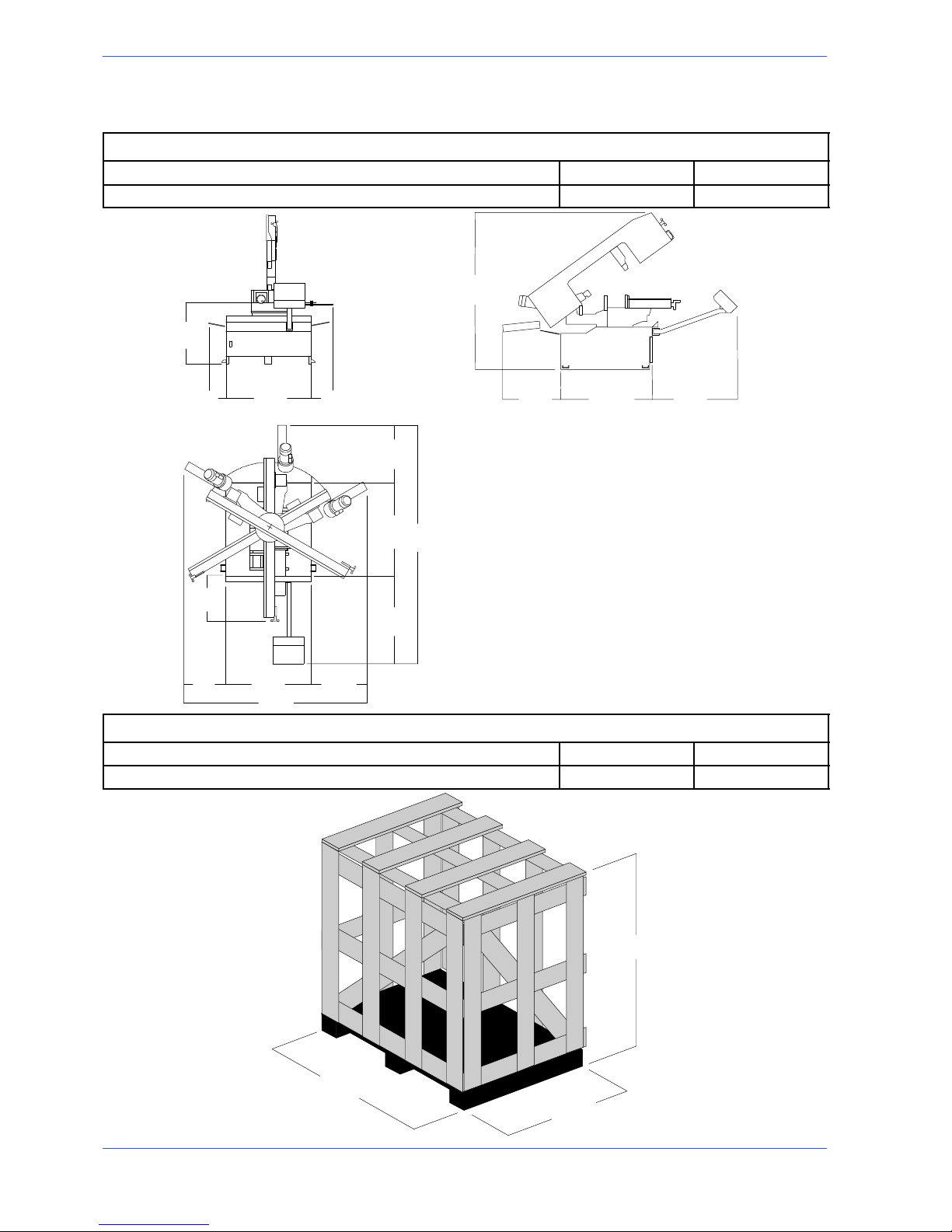

Dimensions

MACHINE INSTALLED

Work table he ight mm 880

Weight Kg 1110

12001300800

2260

1200 310230

880

2580

1200

3300

1300 800

1200 780600

650

PAC KED WEIGHT

Wooden cage and pallet Kg 130

Wooden pallet Kg 70

2900

1800

1800

2--1

Functional parts

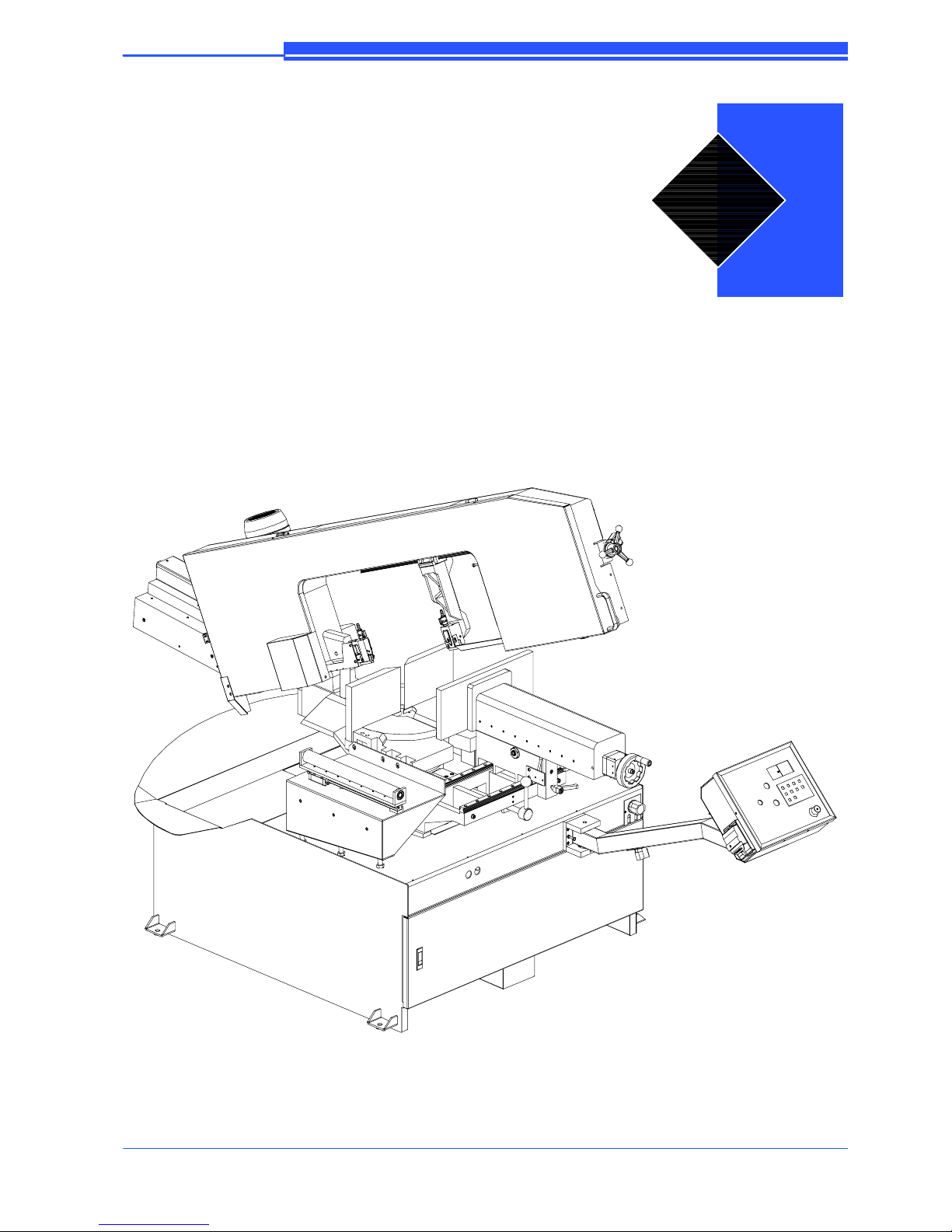

S20DSP model

In order for the user to move towards a full understanding of how the machine

works, which is described in detail in the chapter 5, this chapter deals with the

main units and their locations.

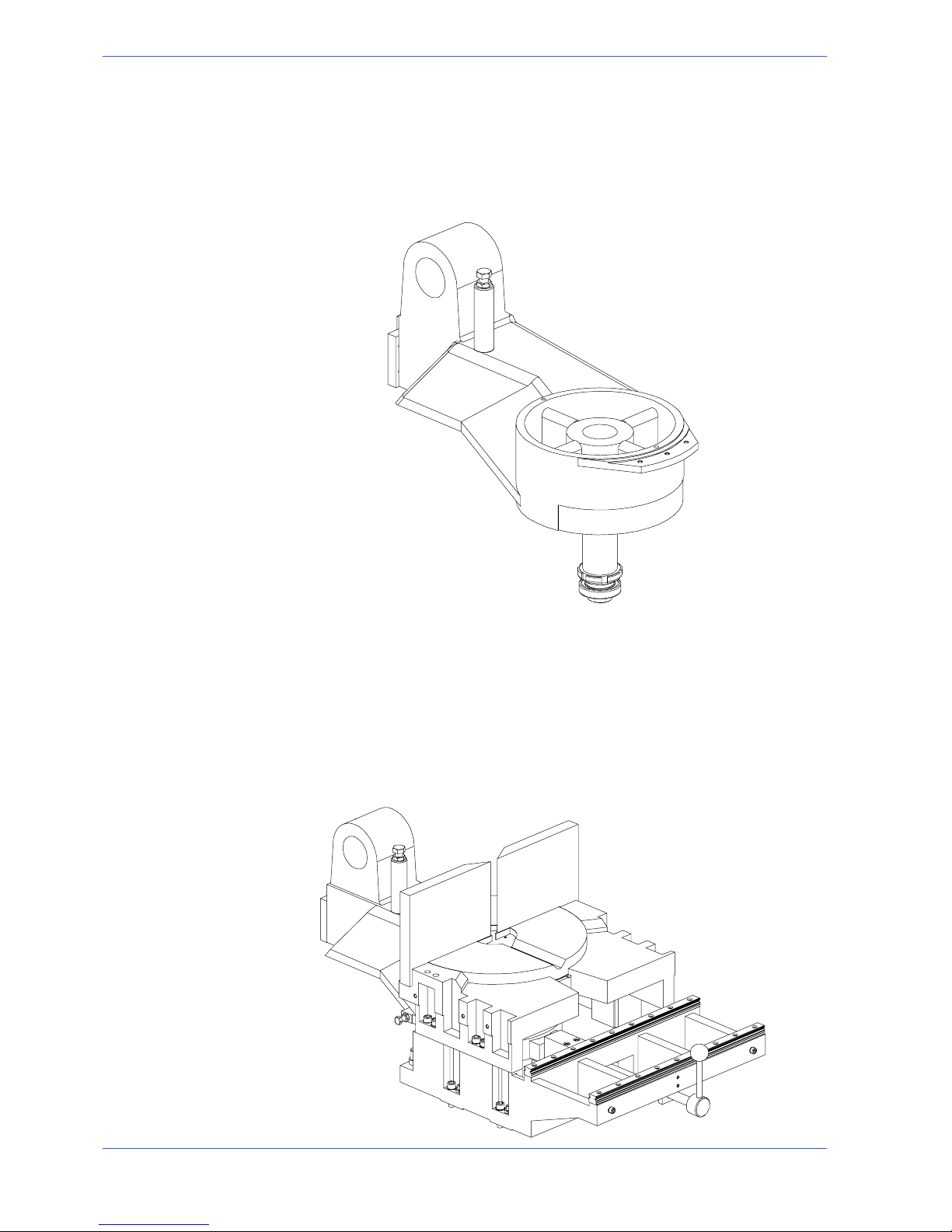

CUTTING HEAD

CONTROL

PANEL

VICE

TURNTABLE

BASE

2

2--2

6

Use and maintenance manual S20DSP

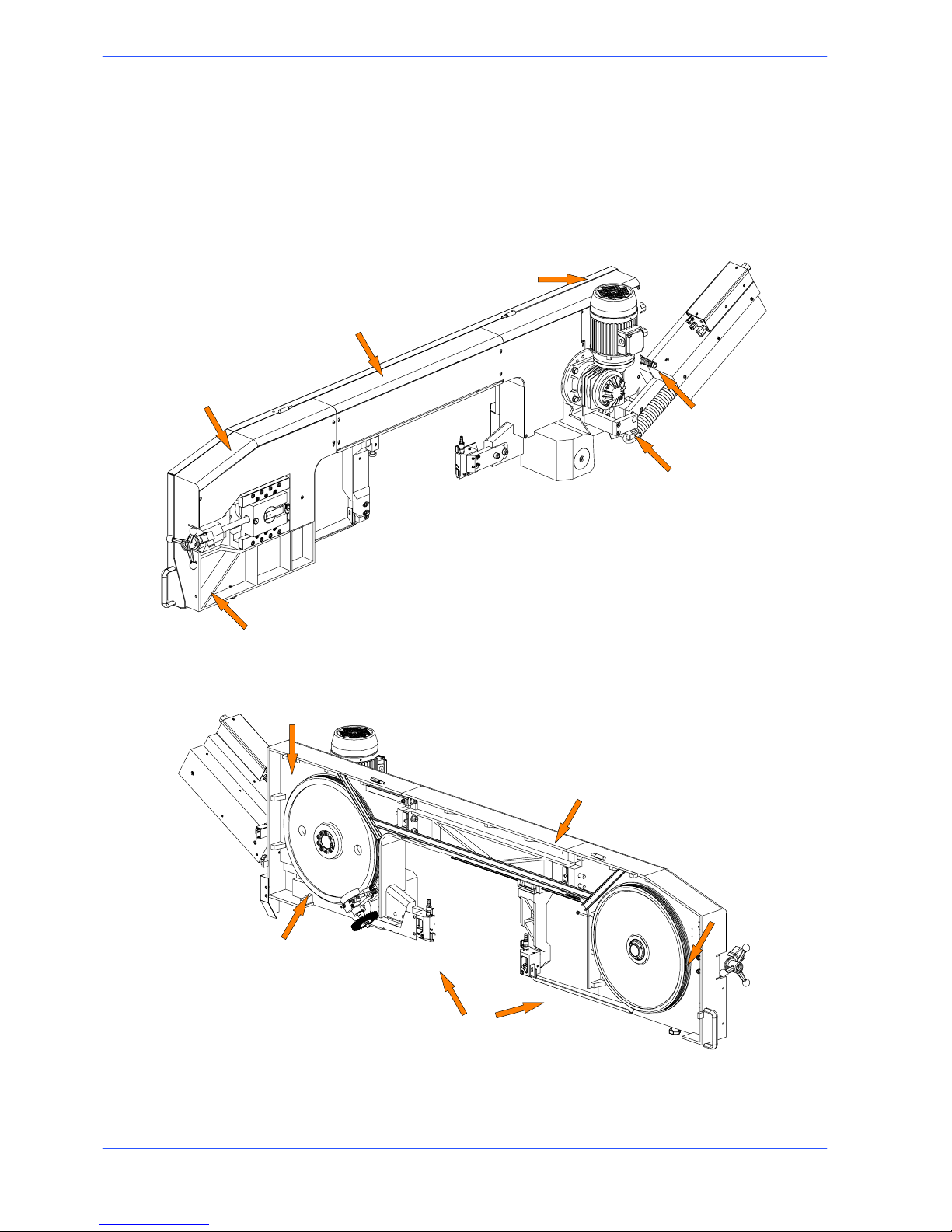

Cutting head

The oerating head is the element that performs the cut and is made up of a bow

made from a fusion of cast iron onto which the band, the band guide elements,

the band tensioning unit and the mechanical speed variator are mounted. The

operating head is restricted in its movements by the articulated joint on the

rotatng platform.

Motor

Blade guide heads

Belt tensioning wheel

Transmission box

Drive pulley

Idle pulley

Rear flywheel

Speed variator

Cutting head beam

Front flywheel

Blade casing

2--3

7

Functional parts

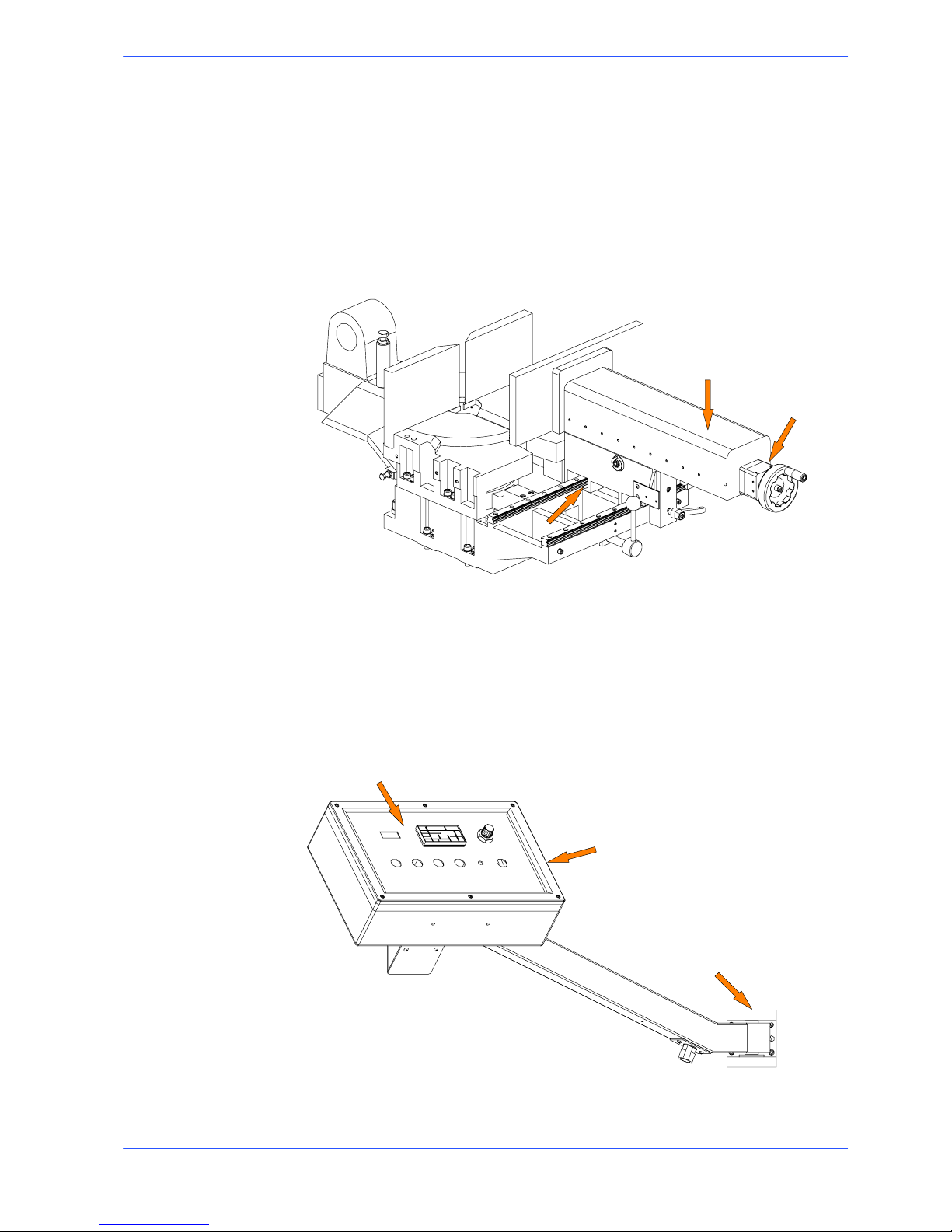

Vice

The vice is the unit that clamps the workpiece during cutting. It consists of a vice

support, commonly known as a “lead nut”, fixed to the work table, and a lead

screw with a sliding support on which the mobile jaw is mounted. It can run

transversely with respect to the cutting surface, or lengthways, for opening and

closing, on the linear guides and slides with recirculation of pre---loaded spheres.

Theviceismanuallynearedtothematerialtobecutusingahand---wheeland

blocking is performed using a hydraulic cylinder (in the AV version).

Slideway

Handwheel

Vice support (lead nut)

Control Panel

The control panel has a protection rating of IP 54 and contains the electronic

equipment. Access to the control panel is protected by a safety panel mounted on

hinges and fastened with screws, specially designed to prevent tampering. The

control panel swivels on two articulated joints so that it can be positioned by the

operator for greater ease---of---use and safety.

Control panel

Articulated joints

Control console

2--4

8

Use and maintenance manual S20DSP

Turntable

Made from a fusion of cast iron it makes up the fulcrum of the cutting band. By

releasing the blocking lever on the fixed platform right and left rotation of the

bow is consented.

Fixed platform

It is made up of two parts, upper and lower, which close the rotating and platform

and support the cutting surface in interchangeable steel.

The lower part is the resting base of the rotating platform, cutting surface and

vice. It is free to run transversely on linear guides and slides with re---circulation

of pre ---loaded spheres. It is integral to the base and the rear part has the

reference strokes for 60˚ left and 60˚ right cuts.

2--5

9

Functional parts

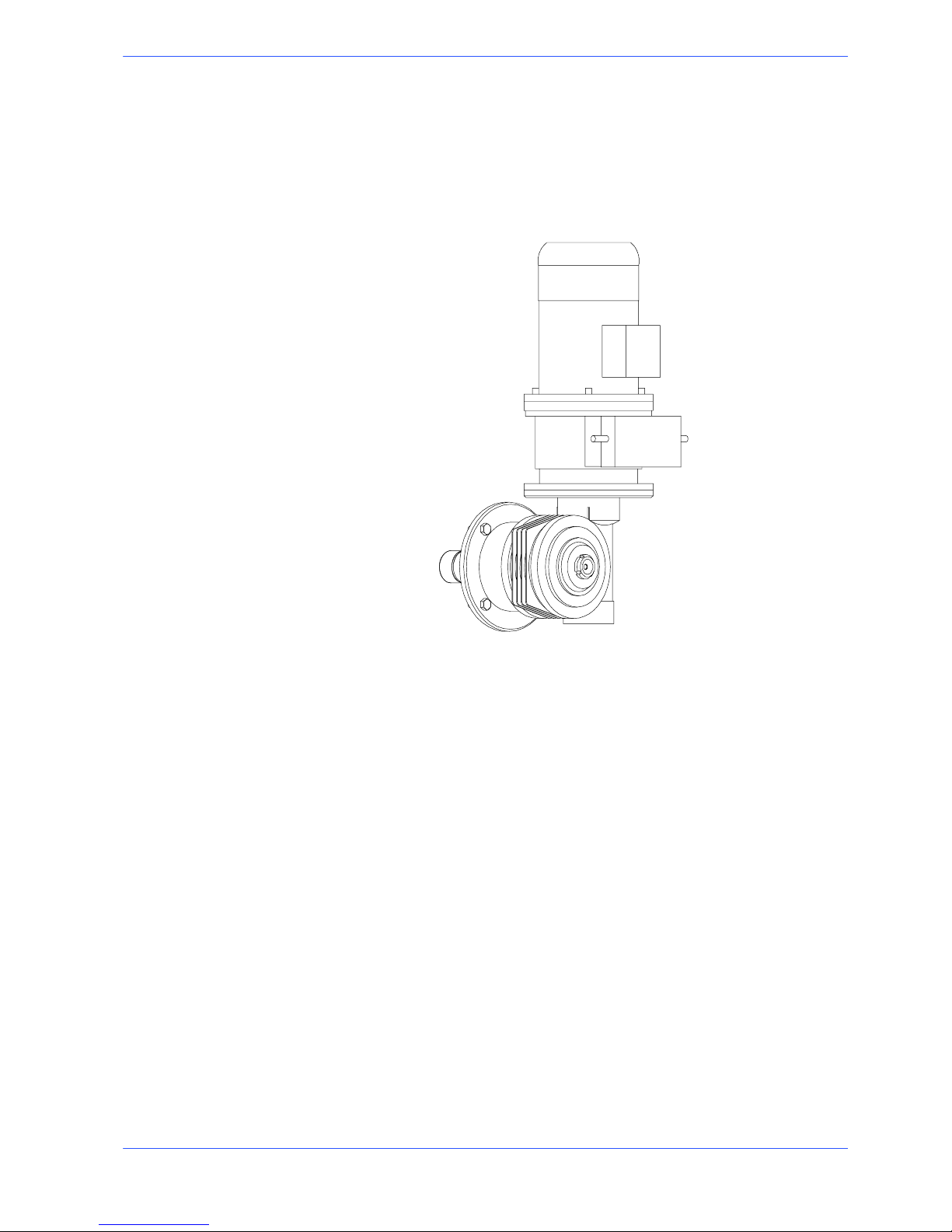

Motion--variator--reducer unit

Rotation of the band is performed by a system made up of a motor connected to a

variator and a mechanical speed reducer.

This unit allows rotation of the band in a continuous adjustment range that goes

from 20 to 100m/min.

2--6

10

Use and maintenance manual S20DSP

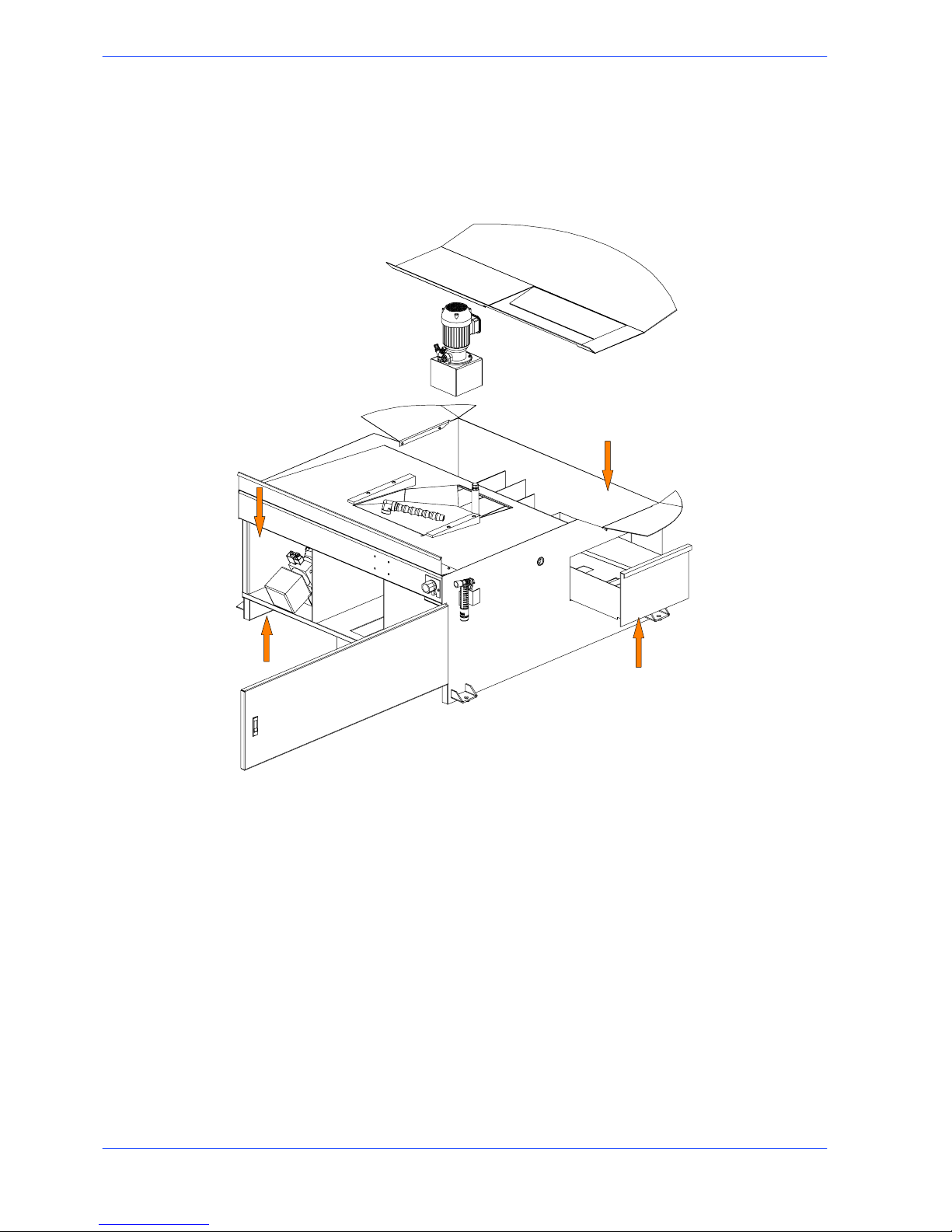

Base

This unit features a large coolant collection surface which conveys the coolant to

the rear tank via the tank cover, and a swarf collection drawer. An electric pump

is housed inside the tank which draws the clean fluid from the filter system.

Lubricant/coolant tank

Electric pump housing

Swarf collection drawer

Hydraulic single box housing

3--1

Safety and accident

prevention

The S20DSP has been designed and produced in accordance with European

standards. Forthecorrectuseofthemachinewerecommendthattheinstructions contained in this chapter are carefully followed.

Use of the machine

The S20DSP band saw cutting machine is intended exclusively for cutting metallic

materials, ferrous or non ---ferrous, in section or solid.

Other types of material and machining are not compatible with the s pecific

characteristics of the saw.

The employer is responsible for instructing the personnel who, in turn, are

obliged to inform the operator of any accident risks, safety devices, noise

emission and accident prevention regulations provided for by international

standards and national laws regarding the use of the machine. The operator must

be perfectly aware of the position and function of all the machine’s controls.The

instructions, warnings and accident prevention standards in this manual must be

respected without question by all those concerned.The following definitions are

those provided for by EEC MACHINES DIRECTIVE 98/37/CE :

H “Danger zone”: any zone in and/or around a machine in which the presence of a

person constitutes a risk for the safety and health of that person.

H “Person exposed”: any person finding himself either completely or partly in a

danger zone.

H “Operator”: the person or persons given the responsibility of installing, operating,

adjusting, maintaining, cleaning, repairing or transporting the machine.

The manufacturer declines any responsibility whatsoever, either civil or criminal, should there be unauthorised interference or replacement of one or more

parts or assemblies on the machine, or if accessories, tools and consumable

materials are used that are different from those recommended by the manufacturer itself or if the machine is employed in a plant system and its proper

function is thereby altered.

Attention

3

3--2

12

Use and maintenance manual S20DSP

General recommendations

LIGHTING

Insufficient lighting for the types of operation envisaged could constitute a safety

hazard for the persons concerned. For this reason, the machine user must provide

lighting in the working area sufficient to eliminate all shadowy areas while also

avoiding any blinding light concentrations. (Reference standard ISO 8995---89

“Lighting in work environments”).

CONNECTIONS

Check that the power supply cables and pneumatic feed systems comply with the

maximum machine absorption values listed in the “Machine Specification” tables;

replace if necessary.

EARTHING

The installation of the earthing system must comply with the requirements set out

in IEC STANDARD 204.

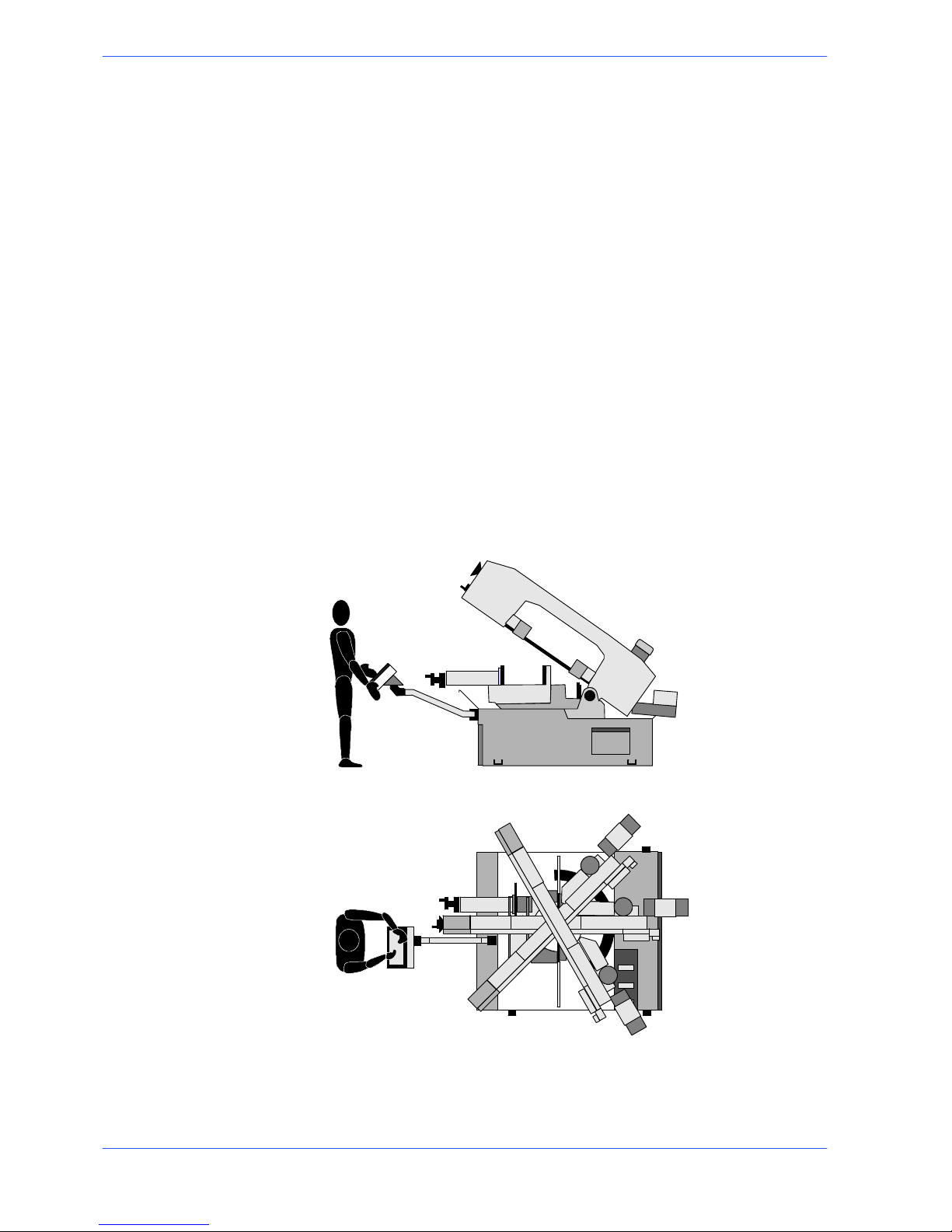

OPERATOR POSITION

The position of the operator controlling machine operations must be as shown in

the diagram below.

3--3

13

Safety and accident prevention

Recommendations to the operator

Always wear proper goggles or protective glasses.

Do not use the machine wit hout the guards in position. Replace the polycarbonate windows , if subject to corrosion.

Do not allow ha nds or arms to encroach on the cutting zone while the

machine is in operation.

Do not wear oversize clothing with long sleeves, oversize gloves, bracelets, necklaces or any other object that may become entangled in the machine duri ng working; long hair must be tied back and bunched.

Alwaysdisconnectthepowersupplytothemachinebeforecarryingout

any maintenance work whatsoever, including in the case of abnormal

operation of the machine.

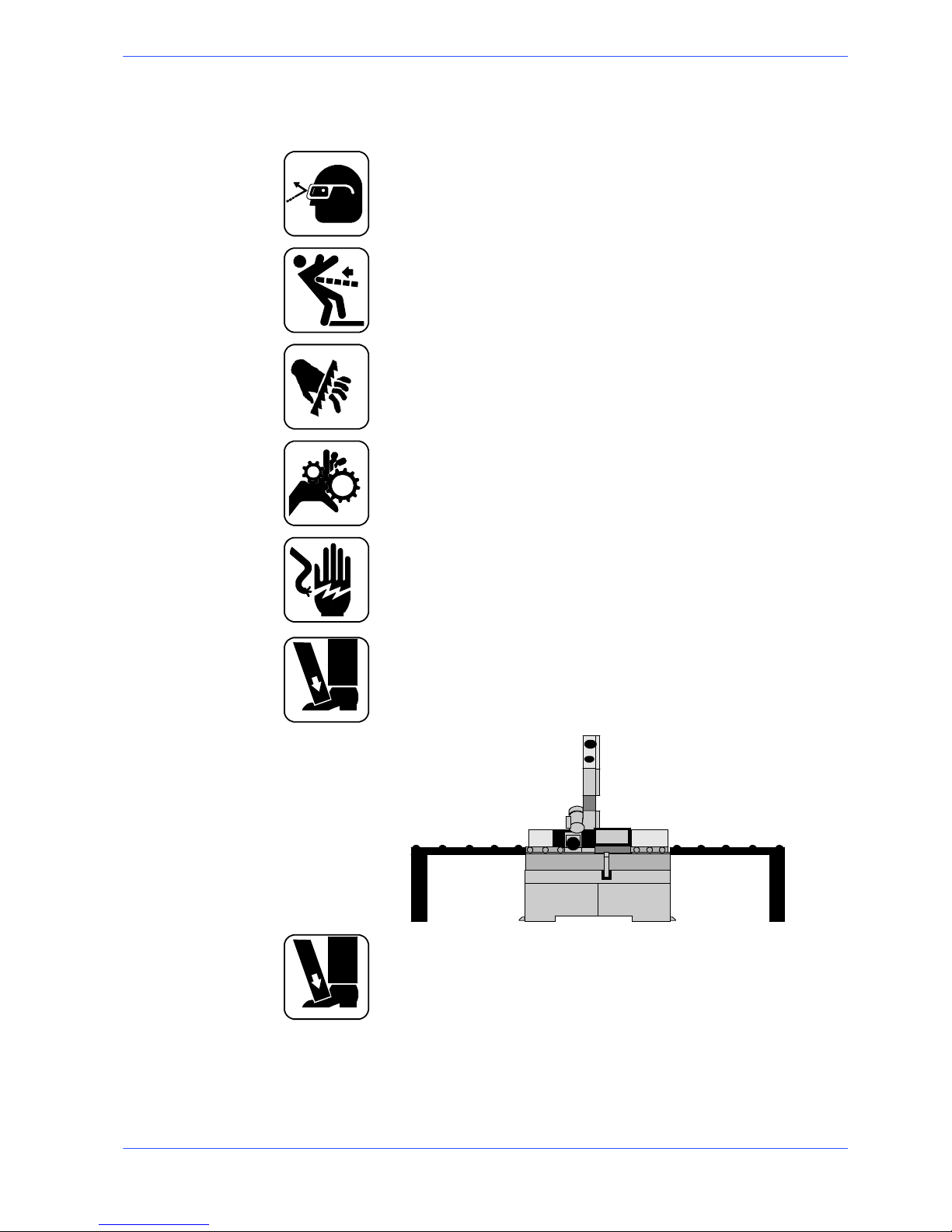

Before starting cutting operations, support the material at both ends of

the machine using the support arm --- standard, or OPTIONAL accessories such as the feed and discharge roller tables shown in the diagram

below. Before removing the devices supporting and moving the material,

fasten the latter in place using the machine’s clamping devices or other

suitable equipment.

mm. 1500

mm. 1500

FEED ROLLER TABLE DISCHARGE ROLLER TABLE

Arrange recovery/collection systems for the cut pieces, such as metal

baskets, for example.

3--4

14

Use and maintenance manual S20DSP

mm. 1500

FEED ROLLER TABLE

COLLECTION BASKET

Any maintenance work on the hydraulic or pneumatic systems must be

carried out only after the pressure in the system has been released.

The o perator must not perform any risky operations or operations not

required for the machining operati on under way (e.g. remove swarf or

metal shavings from the machine while cutting).

Remove equipment, tools or any other objects from the cutting zone;

always keep the working area as clean as possible.

Before starting any cutting operations, ensure that the workpiece is

securely held in the vice and the machine has been set correctly. A

number of examples of how to clamp different profiles correctly in our

machines are shown below.

Do not use the machine to cut pieces that exceed the capacity of the

machine as listed in the machine specifications.

Never move the machine while it is cutting.

Do not use blades of dif ferent sizes to those recommended in the

machine specifications.

When cutting very short pieces, make sure that they are not dragged

behind the support shoulder, where they could jam in the blade.

3--5

15

Safety and accident prevention

When the hydraulic vice is used automatically, check it actually locks the

piece, as its stroke is 8 mm only, and that the tightening pressure is correct.

When working on the band saw, wear gloves only when handling

materials and for tool changing or adjustment operations. Only perform

one operation at a time and do not hold more than one item or operate

more than one device simultaneously. Keep hands as clean as possible.

Warning: if the blade jams in the cut, press the emergency stop push--button immediately. If this does not free the blade, slowly loosen the

vice, remove the piece and check the blade or blade teeth for breakage.

Replace the blade if necessary.

Before carrying out any repair work on the machine, consult the

Hyd--- Mech Technical Assistance Service: this can be done through a

representative in the country of use of the machine.

Adjustmentoftheblade---guideheadmustonlybecarriedoutwiththe

machine at a standstill.

Machine safety devices

This use and maintenance manual is not intended as purely a guide for the use of

the machine in a strictly productive environment, it is instead an instrument

providing information on how to use the machine correctly and safely. The

following standards are those specified by the EEC Committee in the directives

regarding safety of machinery, health and safety at work, personal protection and

safeguarding of the environment. These standards have been applied to the

S20DSP band saw.

Reference standards

MACHINE SAFETY

H EEC MACHINES DIRECTIVE 98/37/CE ;

H EEC directive no. 89/336 ”EMC -- Electromagnetic Compatibility”;

H EEC Directive No. 73/23 known as ”Low voltage directive”.

HEALTH AND SAFETY AT WORK

H EEC Directive No. 80/1107; 83/477;86/188;88/188; 88/642 for the protection of

workers against risks caused by exposure to physical, chemical and biological agents during working;

H EEC Directive No. 89/391 and Special EEC Directives No. 89/654 and No. 89/655

for improvements in health and safety at work;

H EEC Directive No. 90/394 for the protection of workers against risks deriving from

exposure at work to carcinogenic substances;

3--6

16

Use and maintenance manual S20DSP

H EEC Directive No. 77/576 and No. 79/640 on safety signs at work.

PERSONAL PROTECTION

H EEC Directive No. 89/656 and No. 89/686 on the use of personal protection de-

vices.

ENVIRONMENTAL PROTECTION

H EEC Directive No. 75/442 on waste disposal;

H EEC Directive No. 75/439 on the disposal of used oil.

H Directive 2002/95/EC on the restriction of the use of certain hazardous substances

in electrical and electronic equipment (RoHS).

Protection against accidental contact with the blade

1. Metal guard screwed to the rear blade guide head (machine side);

2. metal guard screwed to the front blade guide head (operator side);

3. front head sliding support: when the head is at maximum aperture, the

support ensures that the blade is covered, leaving free only the part of the

blade engaged in the actual cutting, in accordance with Presidential Decree

no. 547/55, art. 108;

4. hinged protective cover over blade, fitted with removable closing devices;

5. blade guide plates completely covering the blade teeth;

6. the cutting vice is operated by hydraulic devices, with a max. stroke of 8 mm;

the jaws locking the piece must be moved at a distance of 2P3 mm from the

piecetobemachined.

7. programming and control panel mounted on an articulated, adjustable arm,

so that the operator is always at a safe distance from moving components.

5

2

1

6

4

3

7

Electrical equipment

In accordance with Italian standard CEI 60204---1, April 1998, derived from

European Standard EN 60204---1 publication IEC 204---1, 1997:

H Access to electrical control panel limited by screws and panel ---lock device,

allowing panel to be opened only after the electricity supply has been turned

off;

H 24 Vac Control voltage for actuators, in accordance with chapter 6 or

European Standard ”Control and indication circuits”, paragraph 2 ”Control

Circuits” sub---section 1 ”Preferential voltage values for control circuits”;

3--7

17

Safety and accident prevention

H plant short---circuit protection by means of rapid fuses, earthing of all plant

parts connected with work as well as all foreseeable accidental contact; a

thermal ---magnetic overload cutout switch shuts down the motor;

H protection from accidental start---up by a minimum voltage relay in case of

power failure.

Emergency devices

In accordance with Standard CEI 204 ---1:

H Chapter 5 Section 6 Sub--section 1 ”Emergency stop device”: «the emergency

stop device immediately stops all the dangerous and other functions of the machine»;

H chapter 6 Section 2 Sub--section 4 Point 7 ”Protective guards”: «the removal of

protective guards designed to prevent access to dangerous parts or zones causes the

machine to stop immediately; replacing the guards does not restart the functions,

which must be reset».

...Emergency devices applicable to the S20DSP:

1. Emergency stop: a non---return mushroom---head pushbutton, colour red on

yellow background, is located on the control panel of the machine. To release

the pushbutton, the actuator must be rotated 45˚. After the emergency situation has been resolved, the machine must be reset.

2. Automatic thermal ---magnetic cutout switch with thermal--- magnetic relay:

The machine’s automatic switch, positioned on the left---hand side of the

base, has two protective systems against the lack of voltage. In fact, if there is

a lack of voltage, it disconnects all electrical devices, blocking the machine

immediately and impedes the automatic restore of the voltage. The other

function is that of re---arming the circuit breaker relay, positioned to protect

from the overloads of current.

3. Pressure transducer for monitoring the blade tension: the machine stops immediately if the blade breaks or the tensioner cylinder pressure drops.

4. Protective guard for blade: a coded key microswitch is operated if the blade

cover is accidentally or intentionally opened during the machine operating

cycle, immediately shutting down all functions.

1

2

3

4

3--8

18

Use and maintenance manual S20DSP

Noise level of the machine

Noise can cause hearing damage and represents one the problems faced by many

countries who adopt their own standards. In accordance with the EEC

MACHINES DIRECTIVE 98/37/CE , we are listing the standards that specify

noise levels for machine tools. This chapter also reports the noise levels produced

by the S20DSP during its various operating phases and the methods used for

measuring these levels. The Italian standard governing this aspect is

D.M.n.277/91 drawn from EEC Directives 80/1107, 82/605, 83/477, 86/188, 88/642,

UNI EN ISO 4871 (1998).

Noise level measurement

Noise levels are measured using an instrument known as an Integrator noise--meter which registers the equivalent continuous acoustic pressure level at the

work station.The damage caused by noise depends on three parameters: level,

frequency and duration. The equivalent level concept Leq combines the three

parameters and supplies just one indication. The Leq is based on the principle of

equal energy, and represents the continuous stationary level containing the same

amount of energy, expressed in dBA, as that actually fluctuating over the same

period of time.This calculation is made automatically by the integrator noise --meter. The measurements are taken every 60 seconds, in order to obtain a

stabilised value. The reading stays on the display for a sufficient time to enable a

reading to be taken by the operator.Measurements are taken by holding the

instrument at approximately 1 metre from the machine at a height of 1.60 metres

above the platform at the operator’s work station.

Two measurements are taken: the first while the machine operates without cutting

anything, the second while cutting in manual mode.

Noise level values

Identification

Machine type Band saw for metal applications

Model

S20DSP

Reference standard ISO 3746

Results

Description

C53 ste el cut --- pipe 356 x 286 mm

Bimetal band 4500 x 27 x 0, 9

Tes t 1st 0

Results

Mean sound level (Leq) 71,00 dB (A)

Environmental correction (K) 3,76 dB(A)

Peak sound power (Lw) 81,93 dB(A)

Descriprion

C 40 steel cut --- HPE 400 x 300 mm

Bimetal band 4500 x 27 x 0, 9

Test 2nd

Results

Mean sound level (Leq) 68,92 dB(A)

Environmental correction (K) 3,76 dB(A)

Peak sound power (Lw) 81,90 dB(A)

Description

34CND6 material cut ---pipe Ø 150 mm

Bimetal band 4500 x 27 x 0, 9

Test 3rd

Results

Mean sound level (Leq) 69,07 dB(A)

Environmental correction (K) 3,76 dB(A)

Peak sound power (Lw) 79,78 dB(A)

3--9

19

Safety and accident prevention

Vibration emission

This sawing machine complies with the norms EN1299 and EN1033, as the

machine vibration emission on the devices controlled by the operator does not

exceed the threshold of 2.5 m/s

2

Electromagnetic compatibility

As from 1 January 1996 all electrical and electronic appliances bearing the CE

marking that are sold on the European market must conform to Directive

89/336/EEC and 70/23/CEE and 98/37/CEE. The prescriptions regard two specific

aspects in particular:

1. “EMISSIONS: during its operation, the appliance or system must not emit spurious

electromagnetic signals of such magnitude as to contaminate the surrounding

electromagnetic environment beyond clearly prescribed limits”;

2. “IMMUNITY: the appliance or system m ust be able to operate correctly even when

it is placed in an electromagnetic environment that is contaminated by disturbances

of defined magnitude”.

The following text contains a list of the applied standards and the results of the

electromagnetic compatibility testing of machine model S20DSP; Test report no.

140201.

Product family standards

H CEI EN 55011 (1999) Industrial, scientific, and medical radio frequency appliances

(ISM). C haracteristics of radio frequency disturbance -- Limits and methods of

measurement.

H CEI EN 50370--2 (2004): Electromagnetic Compatibility (EMC) -- Product family

for machine tools -- Part 2: Immunity.

Basic standards

H EN 61000--4--2 + A1 + A2 (1996--1999--2001) Electromagnetic Compatibility

(EMC) -- Part 4: Test and measurement techniques -- Section 2: Electrostatic discharge immunity tests -- Basic publication.

H EN 61000--4--3 + A1 + A2 (2003 -- 1999 -- 2001): Electromagnetic Compatibility

(EMC) Part 4: Test and measurement techniques -- Section 3: Radiated, radio-- frequency, electromagnetic field immunity test.

H EN 61000--4--4 + A1 + A2 (1996 -- 2001 -- 2002) Electromagnetic Compatibility

(EMC) -- Part 4: Test and measurement techniques -- Section 4: Fast transients/

bursts immunity tests -- Basic publication.

H EN 61000--4--5 + A1 (1995 -- 2001): Electromagnetic Compatibility (EMC) -- Part

4: Test and measurement techniques -- Section 5: Surge immunity test.

H EN 61000--4--6 + A1 (1997 -- 2001) Electromagnetic Compatibility (EMC) -- Part

4: Test and measurement techniques -- Section 6: Immunity to conducted interference, induced by radio frequency fields.

H EN 61000--4--11 + A1 (1995 -- 2001): Compatibilità Elettromagnetica (EMC) Part

4: Test and m easurement techniques -- S ection 11: Voltage dips, short interruptions

and voltage variations immunity tests.

3--1020Use and maintenance manual S20DSP

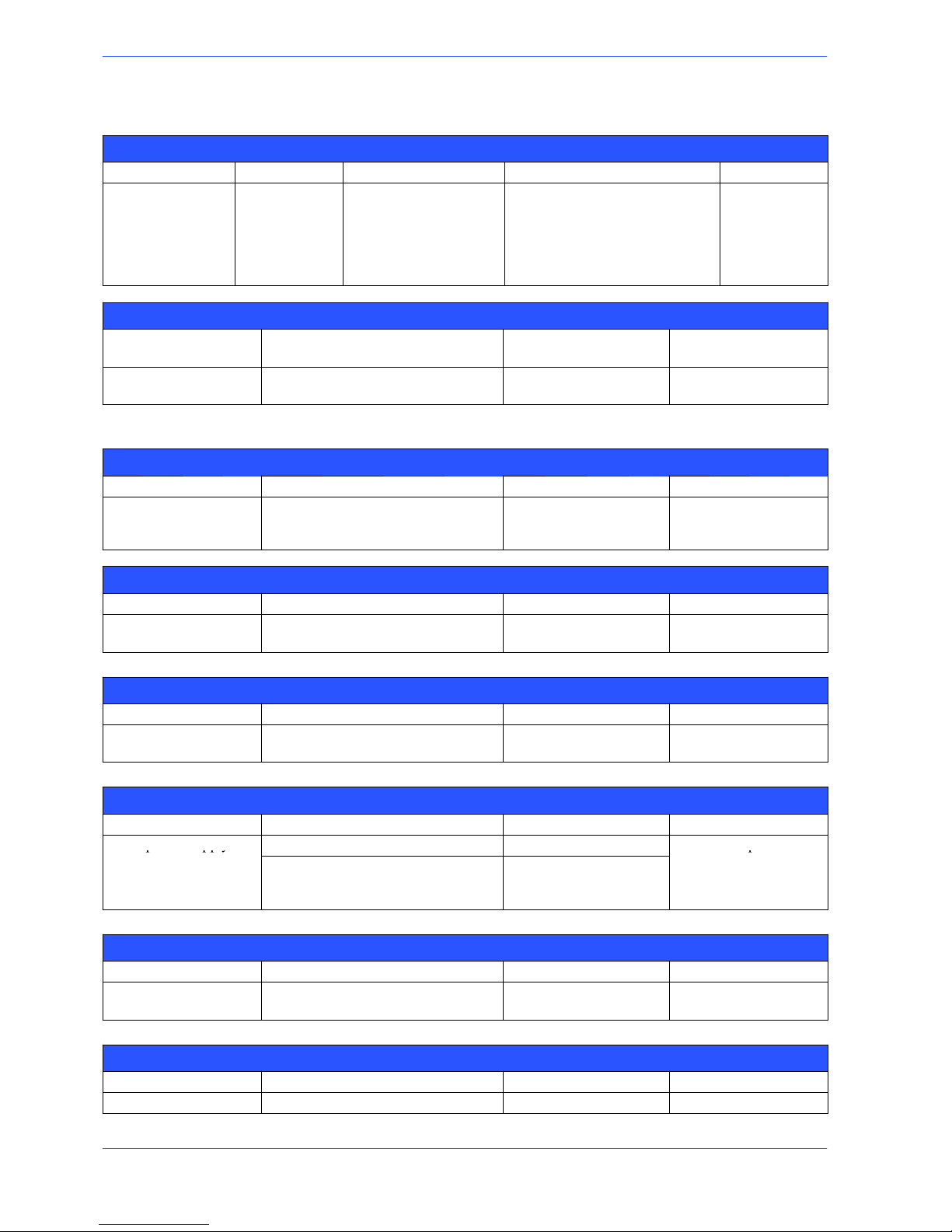

Emissions

CONDUCTED EMISSIONS

Gate A Freq. (MHz) Q --- p e a k l i m i t ( d B u V) Mean value limit (dBuV) Result

A.C. power supply

input

0.15 --- 0.5

0 . 5 --- 5

5 --- 3 0

79 --- 73

(linear reduction with

log of frequency)

73

73

66 --- 60

(linear reduction with log of fre-

quency)

60

60

Complies

IRRADIATED EMISSIONS

Gate Freq. (MHz) Q--- peak limit (10 m)

(dBuV/m)

Result

Enclosure 30 --- 230

230 --- 1000

40

47

Complies

Immunity

IMMUNITY TO ELECTROSTATIC DISCHARGES

Gate Test levels Evaluation criterion Result

Enclosure contact 4 kV

steel plate 4 kV

in air 8 kV

B Complies

IMMUNITY TO VOLTAGE (BURSTS)

Gate Test levels Evaluation criterion Result

A.C. power supply in-

put

2kV B Complies

IMMUNITY TO HIGH VOLTAGE PULSES (Surge)

Gate Test levels Evaluation criterion Result

A.C. power supply in-

put

1 kV (Phase --- phase)

2 k V ( P ha s e --- e a r th )

B Complies

IMMUNITY TO DIPS AND SHORT VOLTAGE INTERRUPTIONS (PQT)

Gate Test levels Evaluation criterion Result

A.C. power supply in- 70% per 0.5 periods B Complies

ppp

y

put

0% per 0.5 periods

40% per 5 periods

40% per 50 periods

B

p

IMMUNITY TO CONDUCTED ELECTROMAGNETIC FIELDS

Gate Test levels Evaluation criterion Result

A.C. power supply in-

put

10V A Complies

IMMUNITY TO IRRADIATED ELECTROMAGNETIC FIELDS

Gate Test levels Evaluation criterion Result

Enclosure 10 V/m A Complies

4--1

Machine installation

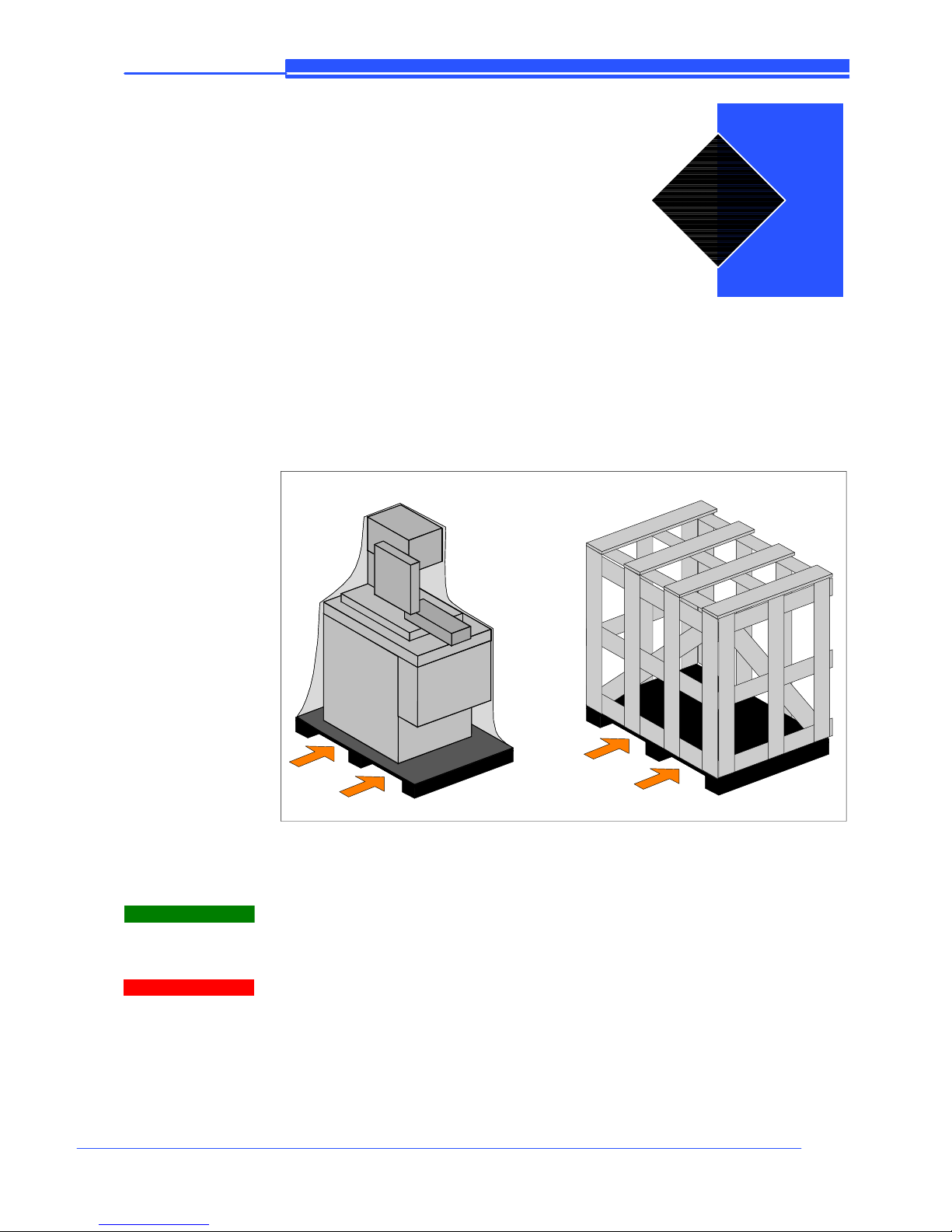

Packaging and storage

Hyd---Mech use packing materials that guarantee the integrity and protection of

the machine during its transport to the customer.

The type of packing differs according to the size, weight and destination.

Therefore the customer will receive the machine in one of two following ways:

1. on a pallet with straps and heat--- shrink plastic;

2. on a pallet with straps, heat---shrink plastic and a wooden crate.

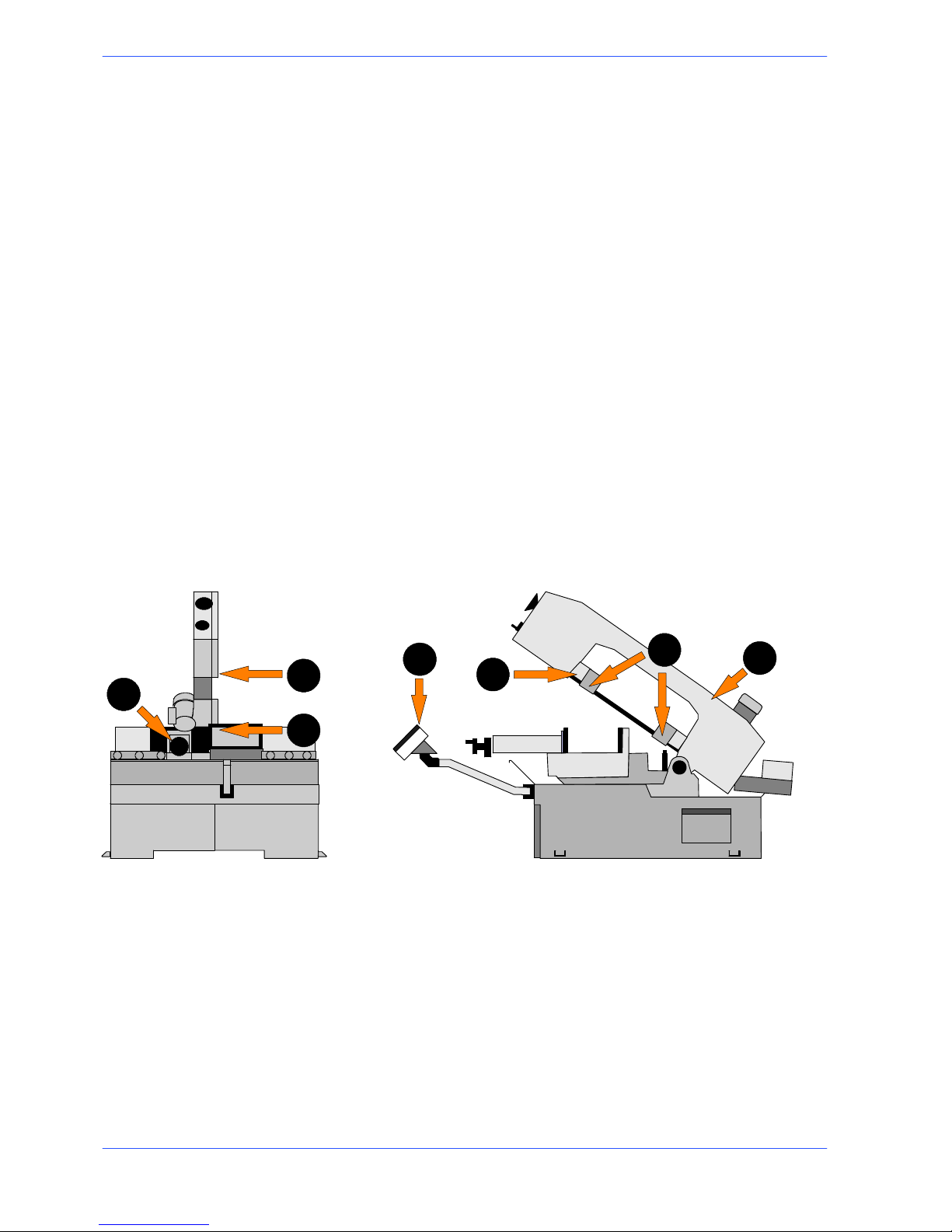

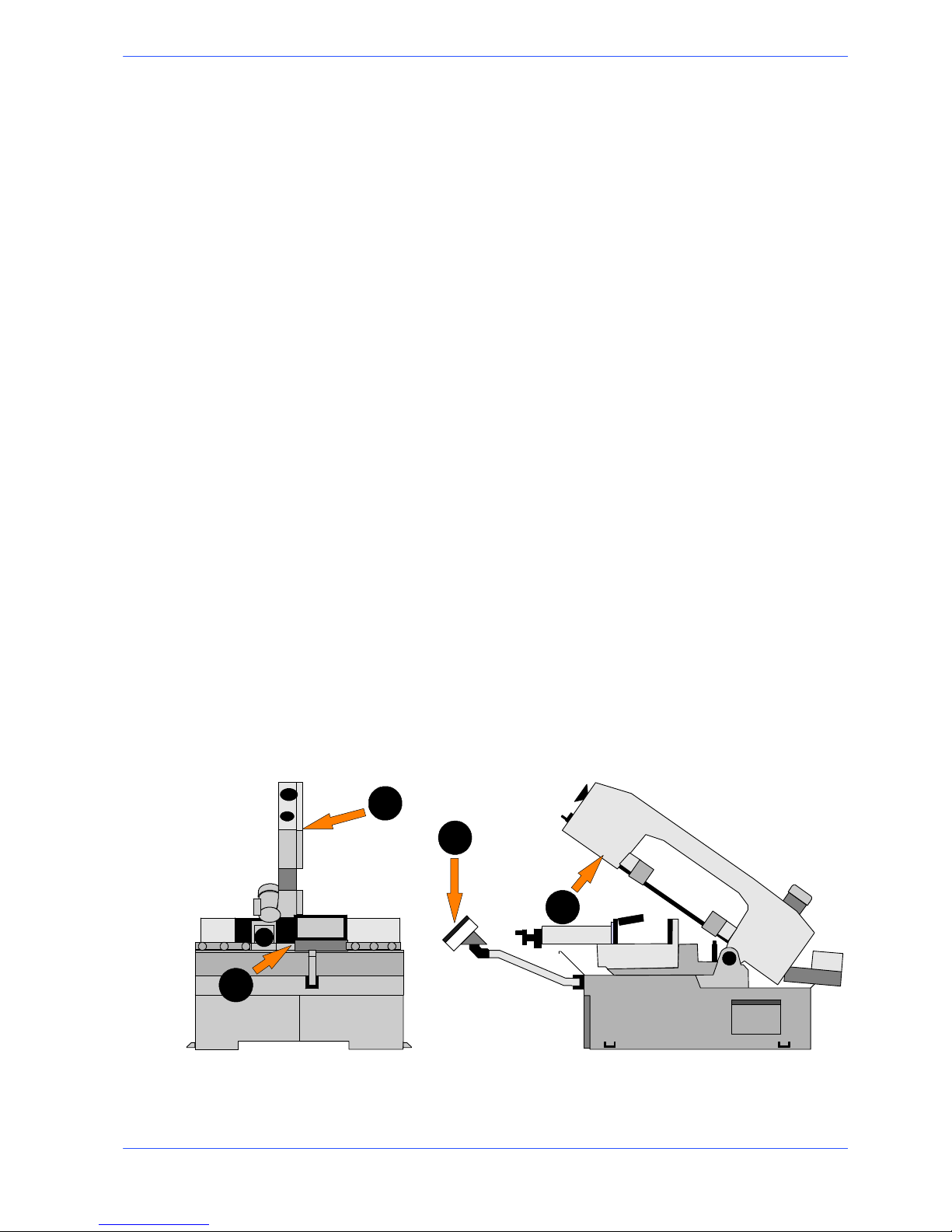

In both cases, for correct balancing the machine must be handled using a

fork--lift truck, inserting the tines at the points indicated by the arrows, using

the reference marks on the crate itself.

Before carrying out lifting operations, make sure that the weight of the machine, as indicated on the crating or other packaging, is within the forklift truck

load limit.

Warning

Attention

4

4--2

22

Use and maintenance manual S20DSP

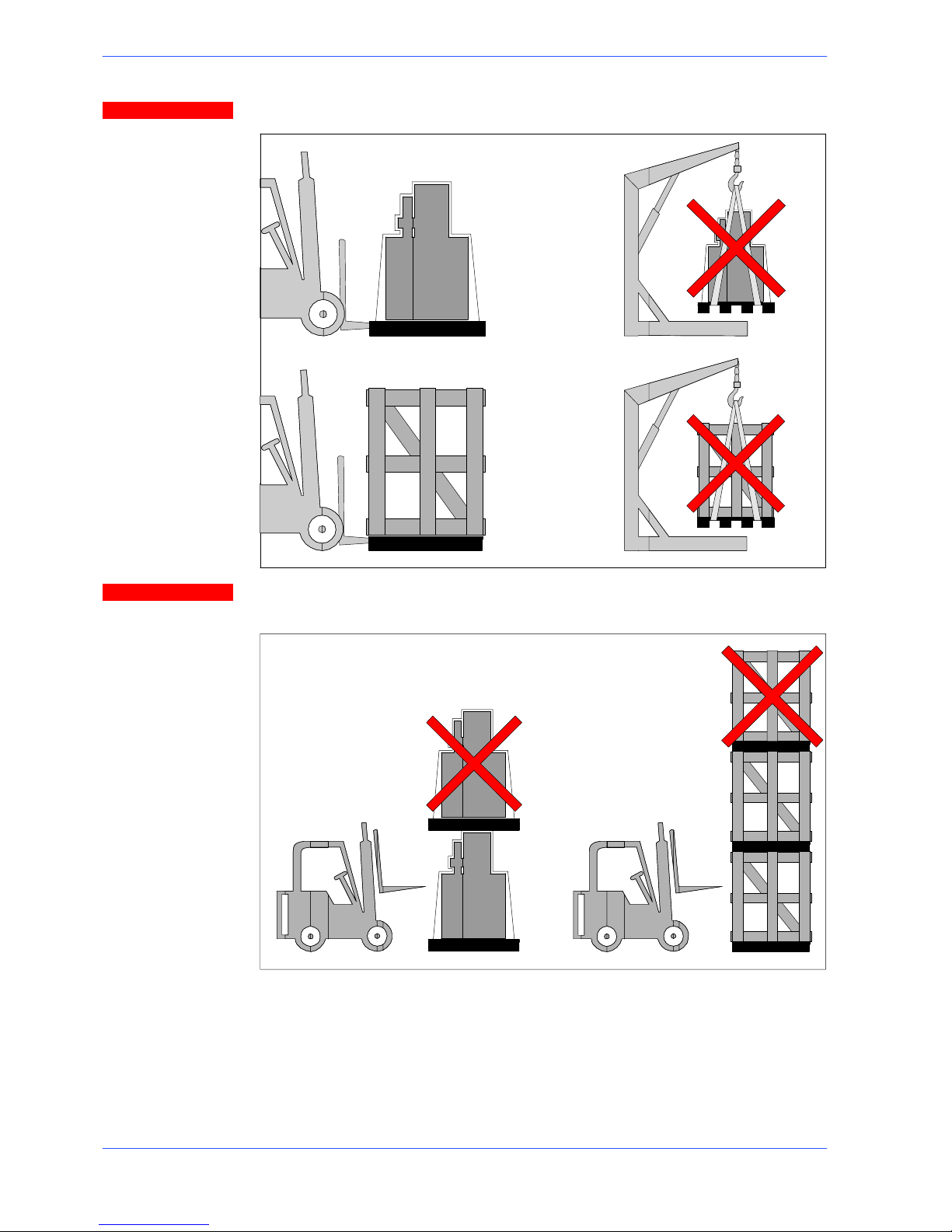

Do not handle the packed machine using slings.

When storing, machines palletized and shrink--wrapped must not be stacked

two high, and machines pallettized and crated must not be stacked three high.

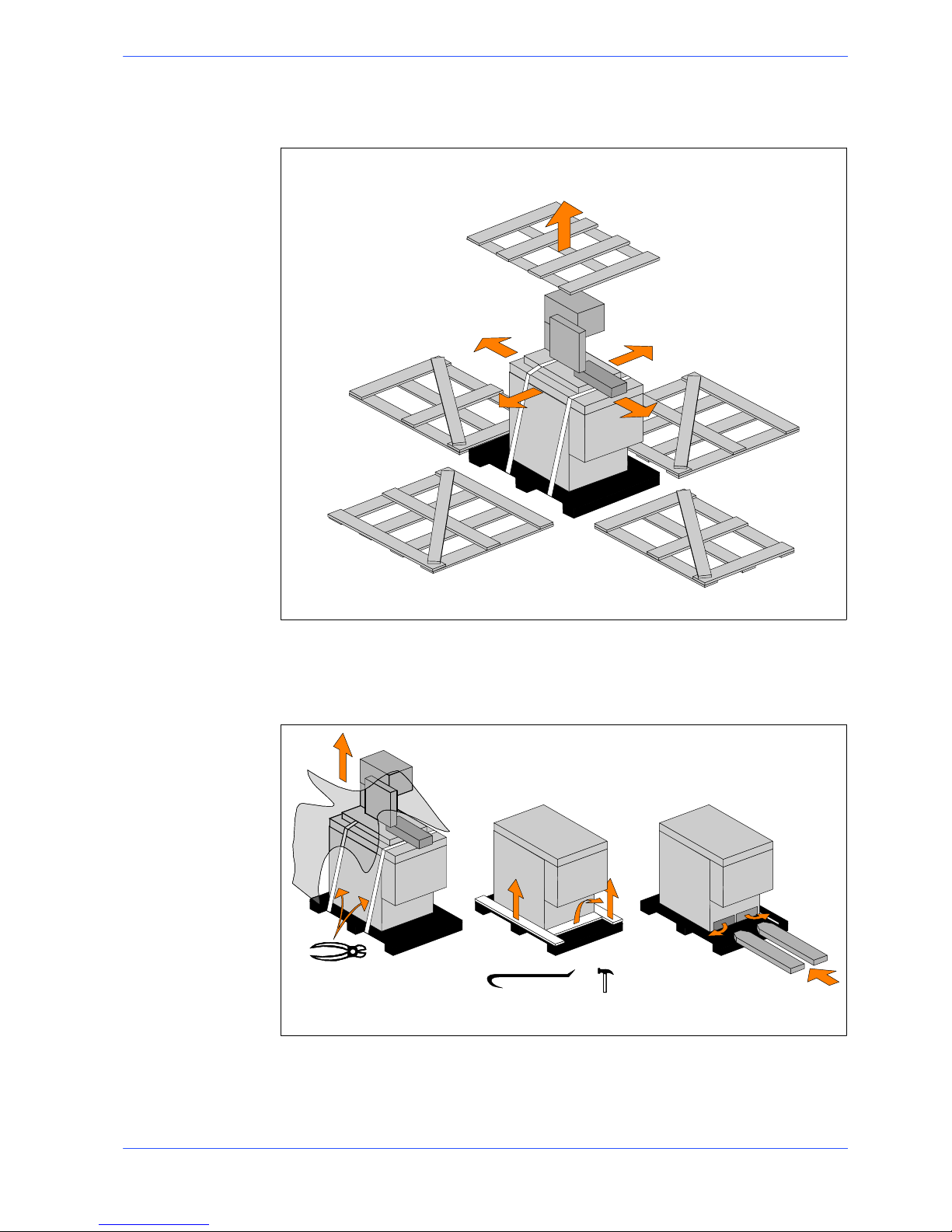

To install the machine, first remove the packing, paying particular attention not to

cut any electric wires or hydraulic hoses; if necessary use pliers, a hammer and a

cutter.

Open crate in the illustrated order:

Attention

Attention

4--3

23

Machine installation

1. remove nails and lift the top of the cage;

2. remove nails and lower walls;

2

2

2

2

1

3. remove heat---shrink covering;

4. remove the straps;

5. remove nails from pallet securing planks and remove planks;

6. remove the front panel and insert fork tines.

3

4

5

6

To locate the machine in the workplace, the machine dimensions and necessary

operator working space, including the spaces laid down in safety standards, must

be taken i nto account.

4--4

24

Use and maintenance manual S20DSP

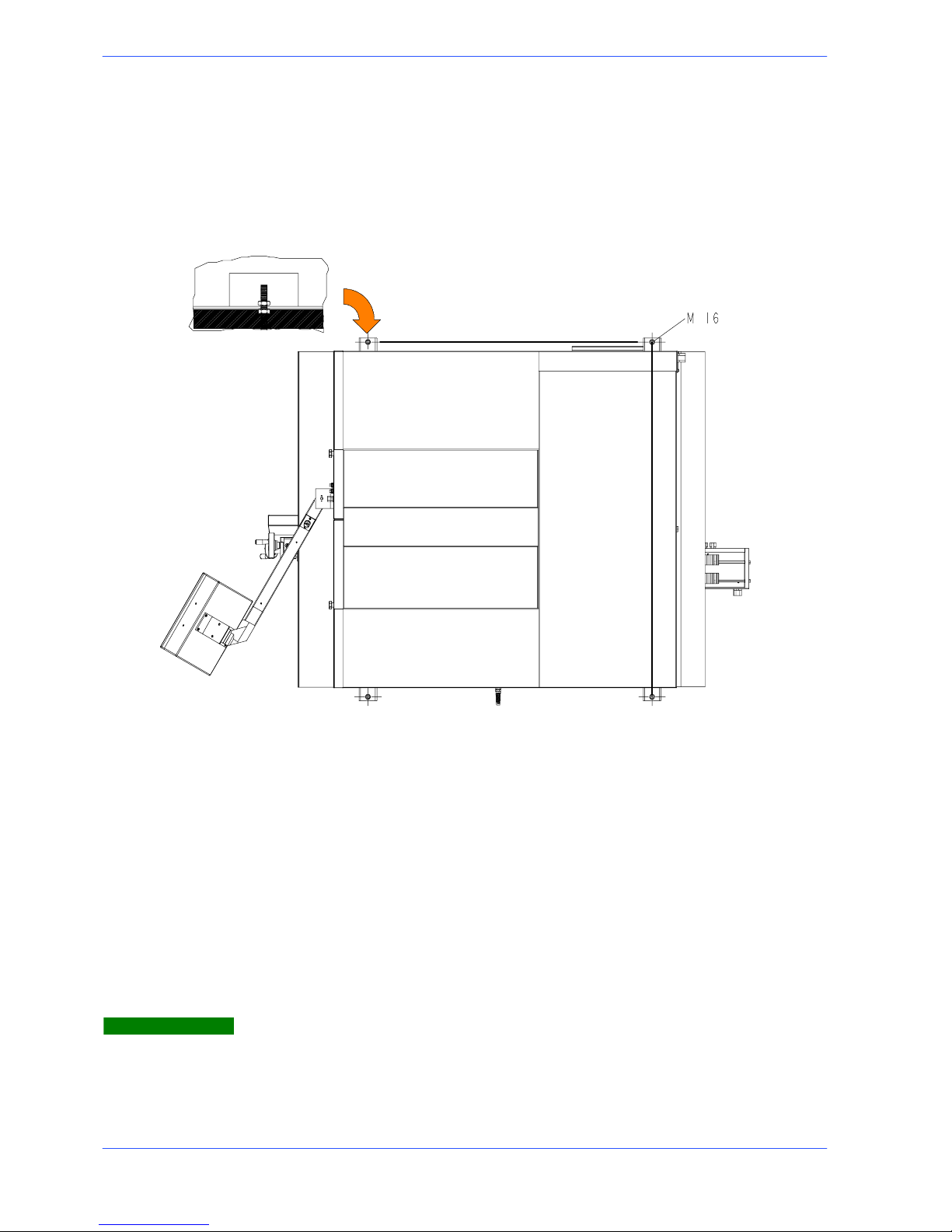

Anchoring the machine

The base of the machine is anchored to the floor by two permanent studs located

on the sides of the base. The studs are screwed into nuts previously sunk into the

concrete, and tightened from above with lock nuts. The schematic specifications

set out in Chapter 1 should be taken into account when positioning the machine.

BASE

1138

1296

Minimum requirements

For the machine to function correctly, the room in which it is to be installed must

satisfy the following requirements:

H power supply voltage/frequency: refer to the values on the rating plate;

H pneumatic operating pressure: not less than 6 Bar and not more than 8 Bar;

H temperature of machine location: from -- 10 to + 50ٛC;

H relative humidity: not more than 90%

H lighting: not less than 500 Lux.

The machine is already protected against voltage variations, but will only run

trouble--free if the variations do not exceed ± 10%.

Warning

4--5

25

Machine installation

Check list

Before starting installation, check that all the accessories, whether standard or

optional, supplied with the machine are present.

CHARACTERISTICS

STANDARD OPTIONAL

Base with large swarf collection drawer, removable coolant tank and electropump for band saw lubrication/cooling

n

Bar support sliding on straight ball guides, located to the left of the cutting

table

n

Mechanical variator of blade rotation from 20 to 100m/min n

Small head mobile blade--- guide running on the linear guides and slides with

re---circulation of pre---loaded spheres

n

Blade 4500 x 27 x 0,9 mm n

Recordable stroke to perform cuts of the same size n

Rotating head on a rotating surface with ball bearings and recordable strokes

allow the stopping and the blocking in correspondence of the 0˚,45˚,60˚

right and 45˚,60˚ left angles

n

Electronic transducer of the stretching of the band with display on the console

n

Blade cleaning device with rotating brushes with movement transmitted from

the pulley engine

n

Designed for transpallet handling systems n

Mobile console to operate while maintaining visual control n

Manual vice with screws with rapid nearing and transfer on the linear guides

a n d s li d e s w i th r e --- c i rc u l a t io n o f p r e --- l o a d e d s p he r es

n

Motorchipdischargerunit n

Steel blade guide head with adjustable hard metal blocks which open to facilitate blade replacement

n

Work table sp ray gun n

Accessory kit n

Vertical roller table pair n

Feed roller table K250 (1500 x N) n

Discharge roller table K250 (1500 x N) n

Cutting oil 5 lt n

*ACCESSORIES AVAILABLE ON REQUEST

The bag of accessories is enclosed in the machine before being packed and

contains:

H hex wrenches 3/4/5/6/10 mm;

H pipe wrench 10 mm;

H 36mm wrench;

H use and Maintenance manual, including order form for parts in relevant user lan-

guage.

4--6

26

Use and maintenance manual S20DSP

Connection to the power supply

Before connecting the machine to the power supply, check that the socket is not

connected in series with other machines. This requirement is fundamental for the

good operation of the machine.

To connect the machine to the power supply, proceed as follows:

" connect the power supply cable of the machine to a plug which matches the

socket to be used. (EN 60204 ---1; par. 5.3.2)

CONNECTION FOR ”5-CORE” WIRE SYSTEMS WITH NEUTRAL

R=L1

S=L2

T=L3

PE = GND

N = NEUTRAL

CONNECTION FOR ”4-CO

R

E” WIRE SYSTEMS WITH NEUTRAL

S=L2

T=L3

PE = GND

R=L1

When using systems with a neutral wire, special care must be taken when connecting the blue neutral wire, in that if it is connected to a phase wire it will discharge the phase voltage to the equipment connected for voltage: phase--

neutral.

" Insert the plug in the socket, ensuring that the mains voltage is the same as

that for which the machine has been setup.

VOLT ?VOLT ?

Attention

4--7

27

Machine installation

" Power up the machine by turning the main switch on the left hand side of the

base (the control console should illuminate);

Check that the motor is rotating in the correct direction. For this check the

following operations must be carried out:

" set the blade tension to 1200 BAR;

" make sure the cover is properly closed: at the back of the cutting head there is

a bayonet limiter for correct cover closure;

" make sure that the machine is not in an emergency condition (red mush-

room ---head pushbutton released);

" after having applied voltage to the machine, set the selector for permission of

motor start up to 1;

4--8

28

Use and maintenance manual S20DSP

" Ensure that the head lowering control is at zero (fully closed);

" start the belt turning by pressing “CYCLE START”;

" if all the above operations have been carried out correctly, the blade motor

will start up and the blade will start rotating.

Ensure that the blade moves in the correct direction as shown in the

above figure. If it does not, simply reverse two of the phase wires on the

machine power supply input.

The sawing machine is now ready to start the work for which it was designed.

Chapter 5 provides a detailed description of the various functions of the machine

and its operating cycles.

Attention

5--1

Description of

machine operation

This chapter analyses all the machine functions. We begin with a description of

the pushbuttons and other components on the control panel.

Control panel description

The figure below shows the control panel of the S20DSP.

Key of control console keyboard

Initialisation key: enables machine operation

Zeroing key for cuts made

5

5--2

30

Use and maintenance manual S20DSP

Blade motor selector: enables or disables

the cutting cicle start button

Gun for washing the work tops

Selection for min. lubrication (optional) No lubricant/coolant key

RESET key: resets the machine after an

emergency condition or conflicting command

Lubricant/coolant spray cock key (only

available during cycle)

Manual cycle key Vice opening

Vice closing

FCTI (Head Upstroke Limit) memory key for Head Positioning System

Semi--- automatic cycle key

FCTA (Head Downstroke Limit) memory key for Head Positioning System

Head “up” key Diagnostics key

Head “down” key Programmed cycle start key

Machine parameters input/edit key

Key for displaying the machine parameters for performing a machining cycle:

TL blade t ension, PT head position, VL

blade speed, T cutting time, PZ cut piece

number, I motor absorption

Electronic speed control (inverter).

Blade cutting speed potentiometer: 20 to

45 m/min. at low speed and 35 to

90 m/min. at high speed

Mushroom head emergency stop button:

when pressed, this button immediately

shuts down the machine. To reset the

emergency stop button, simply rotate

through 45˚

5--3

31

Description of machine operation

Hydraulic adjuster for choosing the head

lowering speed

THERMAL- MAGNETIC CIRCUIT- BREAKER WITH UNDERVOLTAGE

COIL AND DOOR LOCKING DEVICE

On the left side of the control board, the machine is equipped with a main switch

that, when set ON (1), powers the machine. When set to ON (1), this switch

powers up the machine. The main switch is fitted with three power failure

protection systems. In fact, in the event of a power failure, this switch disconnects

all the electrical devices, causing the machine to immediately shut down, and

prevents it from automatically starting up again when power is restored. This

device also resets the thermal relay fitted to protect against current overloads.

Basic instructions for carrying out a cutting operation cycle

Manoeuvring the cutting head

The cutting head may be operated by the head “up” and “down” buttons of the

Head Positioning System (previously illustrated in the key for the control console

keyboard), which are enabled in SEMI ---AUTOMATIC mode.

Head “down” key Head “up” key

During any processing cycle it is possible to control the machine operating

parameters TL (blade tensioning) and PT (head position), pressing the key

below it is also possible to display the values VL (blade speed), T (cutting

time), PZ (cut piece counting) and I (motor current absorption).

SEMIAUT.:PRONTO

TL=0880 PT=0968

SEMIAUT.:PRONTO

VL=0 T=00:00:00

SEMIAUT.:PRONTO

PZ=0001 I=00.0A

Clamping the work piece in the vice

Vice opening and closure is controlled by the corresponding buttons on the

control console. However, to ensure that the workpiece is securely clamped in the

vice, proceed as follows:

N.B.

5--4

32

Use and maintenance manual S20DSP

" make sure the workpiece dimensions do not exceed the machine’s cutting ca-

pacity;

" make sure the piece is correctly supported on both sides of the machine;

" move the vice to within 2÷3 mm of the workpiece using the handwheel.

2/3 mm

" Turn the selector for the closure of the vice;

" make sure the workpiece is securely clamped in the vice by trying to move it

manually.

Rapid vice positioning

By means of a simple device the vice can be slid back and forth to accelerate vice

opening and closing operations.

5--5

33

Description of machine operation

" Grip the lever illustrated in the figure below and rotate in a clockwise direc-

tion: the vice is now free to slide back and forth to the required position.

Once positioned, release the lever to lock the vice in place.

" Finally, position the vice to within 2÷3 mm of the workpiece using the han-

dwheel.

5--6

34

Use and maintenance manual S20DSP

Rapid vice translation

Thevicecanbemovedtotheleftortotherightinordertocarryoutangledcuts,

by sliding it along the straight guides.

" Release the blocking ball grip indicated in the figure;

" Position the vice on the left or on the right and tighten the blocking ball grip;

Width of cut

The machine is fitted with protections which protect the entire blade stroke,

leaving exposed only the part of the blade required to make the cut itself as

specified by current standards. The width of the cut is determined by the

longitudinal section of the workpiece, so that only the part of the blade required

to make the cut is actually exposed.

" Position the workpiece on the work table in proximity to the blade down-

stroke trajectory and clamp it in the vice;

" release the lever to allow the blade guide small head rod to run inside the

bow;

" positionthemobilefrontguideheadneartheworkpiecesothatthedownstro-

ke trajectory exceeds the mobile vice jaw;

5--7

35

Description of machine operation

Preliminary check list for cutting operation

To guarantee complete safety during cutting cycles, the operator should work

through a check list of the entire apparatus, checking:

" blade tension;

" that the blade guide head bracket is locked in the correct position;

" that the cutting angle is correct and the cutting head is locked;

" that the work piece is properly clamped in place;

" that the blade teeth are correct for the job to be begun;

" that the speed selected is right for the kind of piece to be cut;

" that all protections are in place and correctly locked;

" the level of lubricant/coolant and that the electropump is activated;

" That the blade descent speed is correct.

Semi--automatic operating cycle

Semi---automatic cutting sequence:

" power up the machine by turning the main switch;

" position the workpiece in the vice.

During this programming phase of the cycle, do not position the workpiece perpendicular to the blade so that the head may be moved up and down without

colliding with the workpiece.

" Select semi---automatic mode by pressing the corresponding button on the

control console.

Warning

5--8

36

Use and maintenance manual S20DSP

" Select the required cutting speed in accordance with the type of material

being cut (tortoise = low speed; hare = high speed).

If the machine is equipped with the optional inverter, set the speed for the type

of material being cut using the potentiometer on the control console.

" Program the lubricant/coolant spray using the corresponding button on the

control console and adjust the delivery rate using the cocks on the blade guide

heads. It is also possible to set the lubricant/coolant delivery mode.

OPTIONAL

" Position the cutting head about 10 mm from the workpiece using the up (Y+)

a n d d o w n ( Y --- ) a r r ow k e y s.

" Press the FCTI (Head Upstroke Limit) memory button to save the head start

position at the beginning of the cycle.

" L o we r t h e h e a d t o t h e e nd --- o f --- c u t p o si t i on b y p re s s i ng t h e d o wn ( Y --- )

arrow key.

" Press the FCTA (Head Downstroke Limit) memory key to determine the fi-

nal position of the head at the end of the cut. As soon as you have pressed the

FCTA memory key the vice will close and the head will return up to the FCTI

position ready for cycle start.

N.B.

5--9

37

Description of machine operation

" Fully close the head lowering adjuster, on the right side of the control con-

sole.

" Correctly position the workpiece in the vice and calculate the length of cuts

( u s i n g t h e c u t --- t o --- s i z e r o d ) .

" Opentheviceusingtherelativebuttonandmanuallymovethevicetowards

the material, leaving a minimum distance of 2÷3 mm. (as illustrated in the

Manual cycle).

23mm

" Start the cutting cycle pressing the cycle start key.

" After you have given the START command, the blade starts to rotate, the vice

clamps the workpiece and the coolant spray is activated. The cutting head will

remain in the start position until the head descent regulator located on the

front right of the base is opened.

Adjust the head downstroke speed in accordance with the type of material

being cut, the blade rotation speed and the quality of finish required.

" Once the piece has been cut (FCTA position), the blade stops rotating, the

cutting head returns to the FCTI position and the vice opens. The machine is

now ready to start a new cycle.

Warning

5--1038Use and maintenance manual S20DSP

Execution of inclined cuts

It is possible to perform inclined cuts with angles from 60˚ left and 60˚ right. The

rotating platform has pre---set reference strokes for the fast execution of cuts at

0˚,45˚,60˚ right, and 45˚,60˚ left.

Inanycaseitmustbepointedoutthatthebarsupportrollerway,locatedonthe

loading side of the machine (to the left of the cutting table) has two pre ---set

positions, one for straight cuts or cuts with an inclination of up to 30° (left or

right), the other for cuts with an inclination of 60° right.

Loading side rollerway position

For 0° or 30° left/right cuts check that the rollerway is positioned as shown in the

drawing below:

For 30˚ to 60° right cuts check that the rollerway is positioned as shown in the

drawing below:

5--11

39

Description of machine operation

Angled cuts 45˚ to the left

" Make sure the vice is positioned to the left of the 0˚ cutting slot;

" slacken the turntable lock/release lever.

The 0, 45 and reference stops for cuts to the right and the 45˚ reference stop

for cuts to the left facilitate rapid head positioning during turntable rotation.

However, the eccentric pin is only correctly positioned if the initial rotation of

the turntable when released is corrected.

Warning

5--1240Use and maintenance manual S20DSP

" Swing the head from left to right until it is positioned at the required angle, as

indicated by the graduated scale on the turntable.

Always rotate the head when it is in the upper position to avoid blade collision

with the moving jaw on the clamp.

" Relock the turntable lock/release lever.

" Perform the cut keeping in mind the preliminary safety instructions noted in

this chapter.

Angled cuts 60˚ to the left

" Ensure that the vice is positioned on the left of the cutting slit at 05, see the

previous paragraph;

" Release the the block/unblock head rotating surface lever.

" remove the pre--- set stroke to 45˚ left;

Attention

5--13

41

Description of machine operation

" Turn the head from left to right until the desired inclination is obtained. This

is displayed on the graduation noted on the rotating surface.

Always rotate the head when it is in the upper position to avoid blade collision

with the moving jaw on the clamp.

" Tighten the block/unblock rotating surface lever;

" Perform the cut keeping in mind the preliminary safety instructions noted in

this chapter.

Attention

5--1442Use and maintenance manual S20DSP

Angled cuts 45˚ to the right

Carry out the same operations described in the previous paragraph, remembering

that before you start machining you must first:

" move the vice to the right of the cutting slot;

When positioning the vice to the left or right, make sure the moving jaw is beyond the 0˚cutting slot to avoid any risk of collision with the blade downstroke.

" slacken the turntable lock/release lever;

" remove the 0˚ stop;

" swing the head from left to right until it is positioned at the required angle, as

indicated by the graduated scale on the turntable;

" relock the turntable lock/release lever;

" Perform the cut keeping in mind the preliminary safety instructions noted in

this chapter.

Attention

5--15

43

Description of machine operation

Angled cuts 60˚ to the right

" Move the vice to the right of the cutting slit;

" Remove the pre ---set stroke to 45˚ right

When positioning the vice on the left or on the right, pay attention that the mobile jaw does not exceed the cutting slit at 05. In this way it will not interfere

with the band during descent.

Attention

5--1644Use and maintenance manual S20DSP

" Slacken the turntable lock/release lever;

" swing the head from left to right until it is positioned at the required angle, as

indicated by the graduated scale on the turntable;

" relock the turntable lock/release lever;

" Perform the cut keeping in mind the preliminary safety instructions noted in

this chapter.

6--1

Diagrams, exploded

views and replace-ment parts

This chapter contains functional diagrams and exploded views of the S20DSP.

This document is intended to help in identifying the location of the various

components making up the machine, giving information useful in carrying out

repair and maintenance operations; This chapter will also enable the user to

order replacement parts with no risk of misunderstanding, as all parts are given

codes.

Hydraulic components legend

M1 C P T M on o ---

control unit

CMT Cutting clamp

cylinder

RDTM Motorised

flow adjuster

(cutting head

descent speed)

M2 C M T M on o ---

control unit

RDT Flow adjuster

(cutting head

descent speed)

RPP Cutting head

pressure adjuster

RPM Vice pressure

adjuster

EV.RIG Regenerator

electrovalve

CPT Cutting head

holder cylinder

6

6--2

46

Use and maintenance manual S20DSP

Hydraulic diagram

Automation Studio

ABCDE

ABCDE

1

2

3

1

2

3

LEGENDA:

CPT= CILI NDRO PORTA TESTA

CMT= CILI NDRO MORSA DI TAGLIO

RDT= REG. DISCESA TESTA

EV BY--PASS= ACCOSTAMENTO RAPIDO

EV RIG= ELETTROVALVOL ARIGENERATRICE

POMPA= 2,2 cmq/giro

PRESSIONE DI ESERCIZIO= 30Bar MAX.

MOTORE= 71-- B14/0,37KW /1400RPM/230/400--50HZ--240/480--60HZ

CMT

CENTRALINA IDRAULICA

0

R.D.T.

CPT

EVB BY --PASS

EVB RIG

EVM

EVT

6--3

47

Diagrams, exploded views and replace--

How to read the wiring diagrams

With the introduction of the new standardised wiring diagrams, the following

gives an illustration of the way in which they have been drawn up.

Each sheet of the project contains a box which gives the following information:

The numbers indicate the columns into

which the entire drawing is divided

Indications of the date production

started

Identification of the designer

Identification of the Reference Standard

Indications of the

model of machine

Indication of the

page number

MARIO ROSSI

6--4

48

Use and maintenance manual S20DSP

Each component in the wiring diagram is identified by a unique alphanumeric

identification code, in compliance with regulations:

The motor is identified by the code ---M1

The wire is identified by the

c od e --- W 4

These symbols, known as potentials, are used to

provide page references: the first number indicates the page to be referred to, the second

number, after the dot, identifies the column on

that page; example /11.8 indicates that the wire

continues on page no. 11 in column 8

This symbol identifies the wire

with its relative number and colour

The pages following the wiring diagrams contain the following lists:

1. components list (list of all components) and terminals list (list of all the terminals) with the following information:

n in ---house article code;

n identification code;

n reference, no. of the page and column on which it can be found;

n description;

n manufacturer.

ART. COD.

ID PRES. REF DESCRIPTION MANUFACTURER

022.2151 -- B 1 /5.2 STRAIN GAUGE DELTATEC

6--5

49

Diagrams, exploded views and replace--

2. wires list (list of all wires) with the following information:

n in ---house article code;

n identification code;

n description;

n section of wire (mm2);

n colour of wire;

n start: indicates the component (identification code and contact number)

at which the wire starts;

n end: indicates the component (identification code and contact number) at

which the wire ends; e.g.

CODE CABLE DESCRIPTION SECTION NO. COLOUR START END

022.0141 -- W 7 RESET+EMERGENZA

0.50 317 BIANCO -- S 3 4 -- K 1 0 14

In this example, wire no. 317 white, identified as ---W7, starts from contact no. 4

on component ---S3, and ends at contact no. 14 on component ---K10.

Enclosed below is Appendix D2 to European Standard EN 60204 ---1

D2 -- Letter codes used to designate the type of component

LETTER TYPE OF COMPONENT EXAMPLES IDENTIFICATION OF

THE APPLIANCE

A

Complex units Laser

Maser

Regulator

A

B

Tra ns du ce rs co nv ert in g a n on

electrical signal to an electrical

signal and vice versa

Transist or amplifier

IC amplifier

Magnetic amplifier

Valve amplifier

Printed circuit board

Drawer

Rack

AD

AJ

AM

AV

AP

AT

AR

C

Capacitors

C

D

Binary operators, timing devices,

storage devices

Digital integrated circuits and

devices:

Delay line

Bistable element

Monostable element

Record er

Magnetic memory

Tape or disk recorder

D

E

Va r io us ma te ri a ls Devices not specified in this

table

E

F

Protective Devices Lightning protectors

Arrestors

F

Instant action current threshold protector

Delayed action current threshold protector

Instant and delay ed action

current threshold protector

Fuse

Voltage threshold prot ector

FA

FR

FS

FU

FV

6--6

50

Use and maintenance manual S20DSP

LETTER IDENTIFICATION OF

THE APPLIANCE

EXAMPLESTYPE OF COMPONENT

G

Generators, feeders Rotating generators

Crystal oscillators

G

Accumulator battery

Rotating or static frequency

converter

Power feeder

GB

GF

GS

H

Signaling Devices Buzzer

Optical signal, indicator light

device

HA

HL

J

K

Relays, Contactors Instant all or nothing relays or

instant contactors

Bistable relays or interdependent contactors

(All or nothing contactors with

mechanical contact or permanent magnet etc.)

Contactors

Polarised relays

Reed relays

All or nothing timed relays

(timers)

KA

KL

KM

KP

KR

KT

L

Inductors, reactors Inductor

Stop coil

Reactor

L

M

Motors

M

N

Analogue intgrated circuits Operational amplifiers

Hybrid analog/digital appliances

N

P

Measurement equipment, test devices

Indicator, recorder and integrator measurement devices

Signal generators

P

Q

Power circuit switching appliances Automatic switch

Engine saver switch

Knife switch

QF

QM

QS

R

Resistors Fixed or variable resistor

(rheostat)

R

S

Command or control devices Selector or swit ch

Button (including electronic

proximity switch)

Numerical all or nothing sensors (single step) of mechanical and electronic type:

--- L i q ui d l e ve l s e n s o r

---Pressure sensor

Position sensor (including

proximity)

--- Rotation sensor

--- Te mp e r a t u r e p ro b e

SA

SB

SL

SP

SQ

SR

ST

6--7

51

Diagrams, exploded views and replace--

LETTER IDENTIFICATION OF

THE APPLIANCE

EXAMPLESTYPE OF COMPONENT

T

Tra ns for me rs Current transformer

Control circuit supply transformer

Power transformer

Magnetic stabiliser

Voltage transformer

TA

TC

TM

TS

TV

U

Modulators, converters Discriminator

Demodulator

Frequency converter

Coder

Converter

Inverter

Telegraphic repeater

U

V

Electronic pipes, semiconductors Electronic pipe

Gas di scharge pipe

Diode

Transist or

Thyristor

V

W

Transmission lines, wave guides,

antennas

Conductor

Cable

Bar

Wa v e gu id e

Wave guide directional

coupler

Dipole

Parabolic antenna

W

X

Terminals, sockets, plugs Connector bar

Te s t p lu g

Plug

Socket

Terminal connector band

XB

XJ

XP

XS

XT

Y

Electrically operated mechanical

appliances

Electromagnet

Electromagnetic brake

Electromagnetic clutch

Magnetic table spindle

Electromagnetic valve

YA

YB

YC

YH

YV

Z

Transformers, impedence

adapters, equalizers, band limiters

Line equalizer

Compresser

Crystal filter

Z

6--8

52

Use and maintenance manual S20DSP

Standardised Wiring Diagrams S20DSP (CENELEC Standard)

S20DSP

6--9

53

Diagrams, exploded views and replace--

S20DSP

6--1054Use and maintenance manual S20DSP

S20DSP

6--11

55

Diagrams, exploded views and replace--

S20DSP

6--1256Use and maintenance manual S20DSP

S20DSP

6--13

57

Diagrams, exploded views and replace--

S20DSP

6--1458Use and maintenance manual S20DSP

S20DSP

6--15

59

Diagrams, exploded views and replace--

S20DSP

6--1660Use and maintenance manual S20DSP

S20DSP

6--17

61

Diagrams, exploded views and replace--

S20DSP

6--1862Use and maintenance manual S20DSP

S20DSP

6--19

63

Diagrams, exploded views and replace--

S20DSP

6--2064Use and maintenance manual S20DSP

S20DSP

6--21

65

Diagrams, exploded views and replace--

IUD/IUV card

Blade guard lim switch

Amperometer trans-

former

Oil level

Speed switch

Blade guard lim. sw.

Vice opening SV

Regenerator solenoid

valve

Vice closing SV

Head lowering SV

Blade motor

Electric pump

Head lifting SV

Bypass solenoid v.

Hydraulic control unit

Handgrip start

Head position

Proximity

M

R

HS

V

N

R

M

031

032

033

034

NC

036

037

038

041

042

043

044

045

046

047

048

049

050

NC

M

B

V

G

Z

RRR

R

S

Blade tension

NC

Wire colour--coding

A -- light blue M -- brown

B--white N--black

C -- orange R -- red

G -- yellowe S -- pink

H -- grey V -- green

L -- blue Z -- purple

114

027

052

025

024

023

022

021

G

S

R

B

G

H

R

R

LR051

052

0Vdc

24 Vdc

LR60

561

0Vdc

24 Vdc

NC

Emergency

01

02

R

R

01

02

R

R

Reset

Min. lubrication

060

061

H

L

R

L

059

58

0Vdc

24 Vdc

GV PE

Inverter start

Inverter start

0 Vdc (inv)

+24Vdc

-- 1 2 V d c

+12Vdc

6--2266Use and maintenance manual S20DSP

Exploded views

This part of the manual contains detailed exploded views of the machine which

can help to gain a deeper knowledge of how it is made.

Motor unit

S20DSP

6--23

67

Code

Description U. of M. Quantity

001.5010 MOTOR WHEEL NR 1,000

010.0355 SELF--LOCKING RING NUT 25X1,5 T NR 1,000

010.0356 SELF--LOCKING RING NUT 45X1,5 S NR 1,000

010.0373 BEARING FIX. RING NUT SH400 --42 NR 1,000

010.2139 GEARBOX SHAFT NR 1,000

010.7111 8X7X32KEY NR 1,000

010.7112 8X7X35KEY NR 1,000

010.7604 0 8 WASHER NR 4,000

010.7605 0 10 WASHER NR 4,000

010.7645 M8 SPRING WASHER NR 4,000

010.7891 TCEI 8 X 16 SCREW NR 4,000

010.7893 TCEI 8 X 20 SCREW NR 4,000

010.7895 TCEI 8 X 30 SCREW NR 9,000

010.7963 TE 8 X 25 SCREW NR 4,000

010.7976 TE 10 X 30 SCREW NR 4,000

019.3621 NR 1,000

022.0212 RAPID JOINT SEM PG 16 NR 1,000

025.0121 REDUCER MVF 63 FCO 1A38 90 B14 NR 1,000

025.0625 MOTOR GASKET SH 310--320--330 NR 1,000

025.0863 CONNECTOR TLK 130 50X80 SH 400 NR 1,000

025.0923 BEARING 3210E--2RS NR 1,000

034.0418 REDUCTOR COVER SH 260 NR 1,000

6--2468Use and maintenance manual S20DSP

Driving pu lley unit

S20DSP

6--25

69

Code

Description U. of M. Quantity

001.4023 REAR BAND GUIDE HEAD SHARK NR 1,000

001.5016 MOTOR WHEEK BOW HEAD SH 452 NR 1,000

007.4828 BOW PIVOTING PIN FEMALE FITTIN NR 1,000

007.4829 BOW PIVOTING PIN MALE FITTING NR 1,000

007.6611 SWIVELING POINT SPACER NR 1,000

007.6631 COUNTERBALANCING PLATE SHARK 4 NR 2,000

007.6635 BRUSH REGULATING PLATE NR 1,000

007.6644 FRONT BLADE HEAD GUIDE BRACKET NR 1,000

007.6645 BRUSH SHAFT FIXING BRACKET NR 1,000

007.6672 BRUSH SHAFT SUPPORT NR 1,000

007.6681 BRUSH SHAFT SHARK 452 NR 1,000

010.0315 SCREW 8.8 10X140 SH 320 NR 1,000

010.0827 RUBBER WHEEL F. CHIP BRUSH NR 1,000

010.0896 HEAD RETURN SPRING SH 400 NR 1,000

010.0902 HEAD FIXED POINT SPRING NR 4,000

010.1201 SCREWS AND BOLTS NR 3,000

010.1580 HEAD RETURN SPRING COVER SH 45 NR 1,000

010.1582 HEAD CYLINDER BRACKET SH 452 NR 1,000

010.1583 EXTERNAL BRACKET CYLINDER SH 4 NR 1,000

010.1704 1 INSERT REAR BAND GUIDE SH N NR 1,000

010.1706 2 INSERTS RAER BAND GUIDE SH N NR 1,000

010.1721 BAND PUSHER SH NR 1,000

010.7230 M10 SELF--LOCKING SCREW NUT NR 1,000

010.7402 6 X 12 CYLIND.POINT VCE GRUB S NR 5,000

010.7470 6 X 35 FLAT POINT VCE GRUB SCR NR 1,000

010.7831 5 X 12 BUTON SCREW NR 5,000

010.7859 TCEI 5 X 12 SCREW NR 3,000

010.7873 TCEI 6 X 30 SCREW NR 2,000

010.7890 TCEI 8 X 12 SCREW NR 2,000

010.7893 TCEI 8 X 20 SCREW NR 4,000

010.7899 TCEI 8 X 60 SCREW NR 4,000

010.7911 TCEI 10 X 20 SCREW NR 1,000

010.7925 TCEI 10 X 40 SCREW NR 4,000

010.7926 TCEI 10 X 45 SCREW NR 2,000

010.7927 TCEI 10 X 60 SCREW NR 1,000

010.7932 TCEI 10 X 110 SCREW NR 2,000

010.7934 TCEI 12 X 50 SCREW NR 2,000

010.8152 M16 NUT NR 1,000

016.0118 REAR BOW HEAD COVER SH 452 NR 1,000

016.0438 REAR BAND GUARD SH 330 HH NR 1,000

016.1196 PNEUMATIC EQUIPMENT CABLING PA NR 1,000

022.0211 RAPID JOINT SEM PG 13,5 NR 1,000

022.0212 RAPID JOINT SEM PG 16 NR 2,000

022.0215 REDUCTION NR 1,000

022.0234 CORD PRESSER NR 1,000

022.0238 CABLE PRESSER PG 7 BS01 NR 2,000

022.0244 LOCK NUT 3217B GREY PG 13,5 NR 1,000

022.0249 POLYAMIDE HUMMEL NUT 1.262.160 NR 1,000

022.2702 NUT PG 7 BL01 NR 2,000

025.0075 BEARING 32009X NR 2,000

025.0088 BEARING 6001 2Z PH 100 NR 2,000

025.0275 NILOS GUARD RING 32009X NR 2,000

025.0555 BAND BRUSH 3103 0 100 SH 400 NR 1,000

025.0802 GRAPHITIZED BUSHING L. 15 DIA NR 1,000

025.0930 BEARING 51100 NR 1,000

028.0130 JOINT 1/4--9 CL 2601 NR 1,000

043.0229 MF 1/4 -- CL 2520 REDUCTION NR 1,000

043.0652 1/4F.M.TAP NR 1,000

6--2670Use and maintenance manual S20DSP

Front flywheel assembly

S20DSP

6--27

71

Code

Description U. of M. Quantity

001.4030 SUPPORT SH 330 CNC FE MOD.1403 NR 1,000

001.4404 BAND TENSION SLIDE SH 452 NR 1,000

001.5009 IDLER WHEEL NR 1,000

001.5015 IDLER WHEEL BOW HEAD SH 452 NR 1,000

007.4822 IDLER WHEEL PIN SH 400 NR 1,000

007.4824 LOCKING PIN SH 400 NR 1,000

007.4891 SLIDE GIB SH 400 NR 2,000

007.5321 BAND TENSION PIN NR 1,000

010.0356 SELF--LOCKING RING NUT 45X1,5 S NR 1,000