Hyd-Mech PH 211 Use And Maintenance Manual

EN

YEAR OF MANUFACTURE: ______________

PH 211

USE AND MAINTENANCE MANUAL

Introduction and technical specifications 1---1......................

Foreword 1---1..........................................................

Machine presentation 1--- 1...............................................

Machine specification 1--- 2...............................................

N am e p l a t e 1 --- 2........................................................

Dimensions 1 --- 4........................................................

F un c t i o n a l p a r t s 2 --- 1............................................

PH211 model 2 --- 1......................................................

Cutting head 2---1.......................................................

Vice 2 --- 2..............................................................

C on t r o l P an e l 2 --- 2......................................................

Safety and accident prevention 3---1................................

U se o f t he m a c hi n e 3 --- 1.................................................

General recommendatio ns 3---2...........................................

Recommendations to the operator 3--- 3....................................

Machine safety devices 3--- 5..............................................

Reference standards 3---5................................................

Protection against accidental contact with the blade 3--- 6......................

Electrical equipment 3--- 6................................................

Emergency devices 3--- 7..................................................

Noise level of the machine 3---8...........................................

Noise level measurement 3--- 8............................................

Noise level values 3--- 8...................................................

Vibration emission 3---9..................................................

Electromagnetic compatibility 3--- 9........................................

Machine installation 4---1........................................

Packaging and storage 4--- 1...............................................

Anchoring the machine 4--- 4..............................................

Minimum requirements 4--- 4..............................................

C he c k l is t 4 --- 5..........................................................

Balancing the cutting head 4--- 6...........................................

Connection to the power supply 4 --- 6.......................................

Description of machine operation 5---1.............................

Description of the control panel 5---1......................................

Basic instructions for carrying out a cutting operation cycle 5--- 3................

Manoeuvring the cutting head 5---3........................................

Clamping the work piece in the vice 5--- 3...................................

Wi d th o f c ut 5 --- 4.......................................................

Preliminary check list for cutting operation 5--- 5.............................

Manual operating cycle 5---5..............................................

A ng l e d c u t s 5 --- 7........................................................

Angled cuts 45˚ to the left 5--- 7...........................................

Angled cuts 60˚ to the left 5--- 8...........................................

Diagrams, exploded views and replacement parts 6---1................

Standardised Wiring Diagrams (single---phase) 6---1..........................

Standardised Wiring Diagrams HB (single--- phase) 6---2.......................

Standardised Wiring Diagrams (three--- phase) 6---3..........................

Exploded views 6--- 4.....................................................

Body frame assembly 6---4................................................

Motor assembly 6---6....................................................

Handle assembly 6--- 6....................................................

Bladeadjustableassembly(rear) 6---8......................................

Bladeadjustableassembly(front) 6---8.....................................

Idler wheel and Drive wheel assembly 6--- 10..................................

Blade back cover assembly 6--- 10...........................................

Control panel assembly 6--- 12..............................................

Base assembly 6--- 14......................................................

Vise assembly (A) 6--- 16...................................................

Vise assembly (B) 6 --- 16...................................................

Stand leg assembly 6--- 18..................................................

A d j u s t me n t s 7 --- 1...............................................

Vice 7 --- 1..............................................................

Vice play adjustment 7 --- 1................................................

Cutting head 7---2.......................................................

B la d e t e n s i on i ng un i t 7 --- 2................................................

Adjusting operating head travel 7---4.......................................

Blade guide part s 7---5...................................................

Blade guide heads 7--- 5..................................................

Blade guide plates 7--- 5..................................................

Blade 7 --- 8.............................................................

Tool change 7--- 8........................................................

Blade perpendicularity 7--- 10..............................................

Orthogonality of the blade 7---11...........................................

Maintenance and choice of consumables 8---1.......................

The role of the operator 8--- 1.............................................

Maintenance requirements 8---2...........................................

General maintenance 8---2...............................................

Daily 8 --- 2.............................................................

Weekly 8 --- 2............................................................

Monthly 8---3...........................................................

Maintenance of working parts 8 --- 3........................................

Consumable materials 8--- 3...............................................

Oil for transmission box 8---3.............................................

Oil for lubricant/coolant fluid 8--- 3.........................................

Cutting speed and choice of tools 9---1..............................

Cutting speed 9--- 1......................................................

Standard machine 9--- 1..................................................

Choice of blade 9--- 1....................................................

Saw tooth pitch 9 --- 1.....................................................

Cutting speed and downstroke speed 9---2..................................

Ty p e s o f s wa r f: 9 --- 2.....................................................

Lubricant/coolant fluid 9---3..............................................

Blade structure 9 --- 4.....................................................

B la d e t y p e s 9 --- 4........................................................

C on v e n t i o n a l r a k e 9 --- 5..................................................

Po s it i v e r ak e 9 --- 5.......................................................

Va r i a b le p i t c h 9 --- 5......................................................

Variable pitch blades with 0˚ cutting angle 9--- 6..............................

Variable pitch with positive rake (from 9 to 10 degrees) 9---6...................

Set: 9 --- 6...............................................................

Standard or splayed set 9---6..............................................

U nd u la t ed s e t 9 --- 7......................................................

Alternating grouped sets 9---7.............................................

A lt e rn a ti n g s et 9 --- 7.....................................................

Blade selection table relating to cutting speed and downstroke speed 9--- 8.......

Classification of steels 9 --- 9...............................................

Classification of steels 9---10...............................................

Troubleshooting 10---1............................................

Troubleshooting blade and cutting problems 10--- 1............................

Troubleshooting machine faults 10--- 8.......................................

1--1

Introduction and

technical

specifications

Foreword

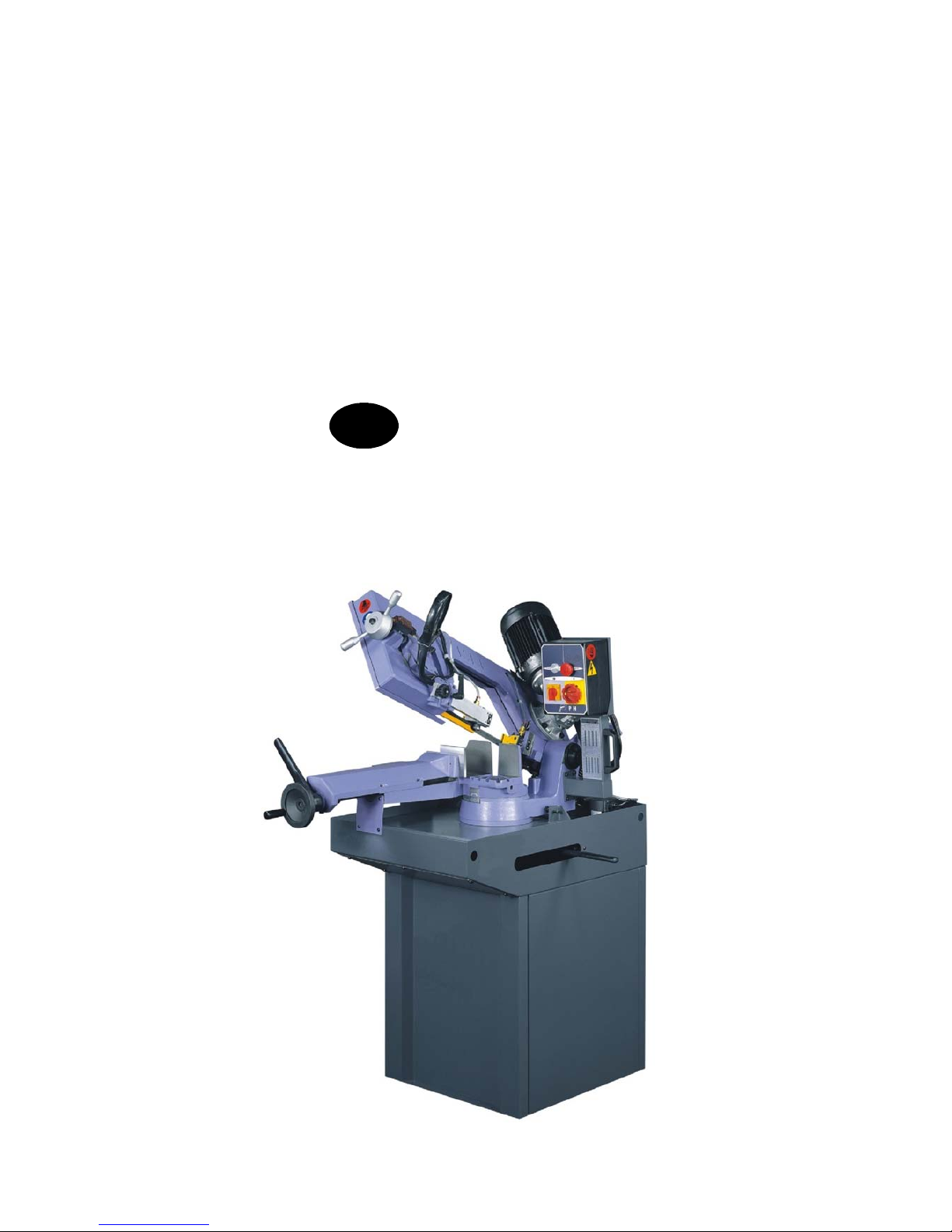

Hyd---Mech in response to modern production techniques, has developed the new

PH211.

This work tool has been designed to satisfy the wide range of cutting needs of a

modern workshop with simplicity and reliability, while at the same time complying with all EEC safety standards.

The PH211 is structurally rigid, silent and safe: it produces a minimum of waste

(1.2 mm) while its great versatility makes it suitable for cutting various materials

such as stainless steel light alloys, aluminium, copper and bronze at high speed

and with high precision.

Its high cutting capacity, which enables it to handle both single workpieces and

bundles, combined with the possibility of making inclined cuts from 0˚ to 60˚ left,

make this model the ideal solution for satisfying the wide strange of cutting needs

of machine shops, turneries, structural steel shops and engineering workshops.

We congratulate our clients on having chosen this product, which will give

effective and faithful service for many years, especially if the instructions

contained in this use and maintenance manual are carefully followed.

This cutting machine has been designed and made specifically for cutting metallic materials.

Machine presentation

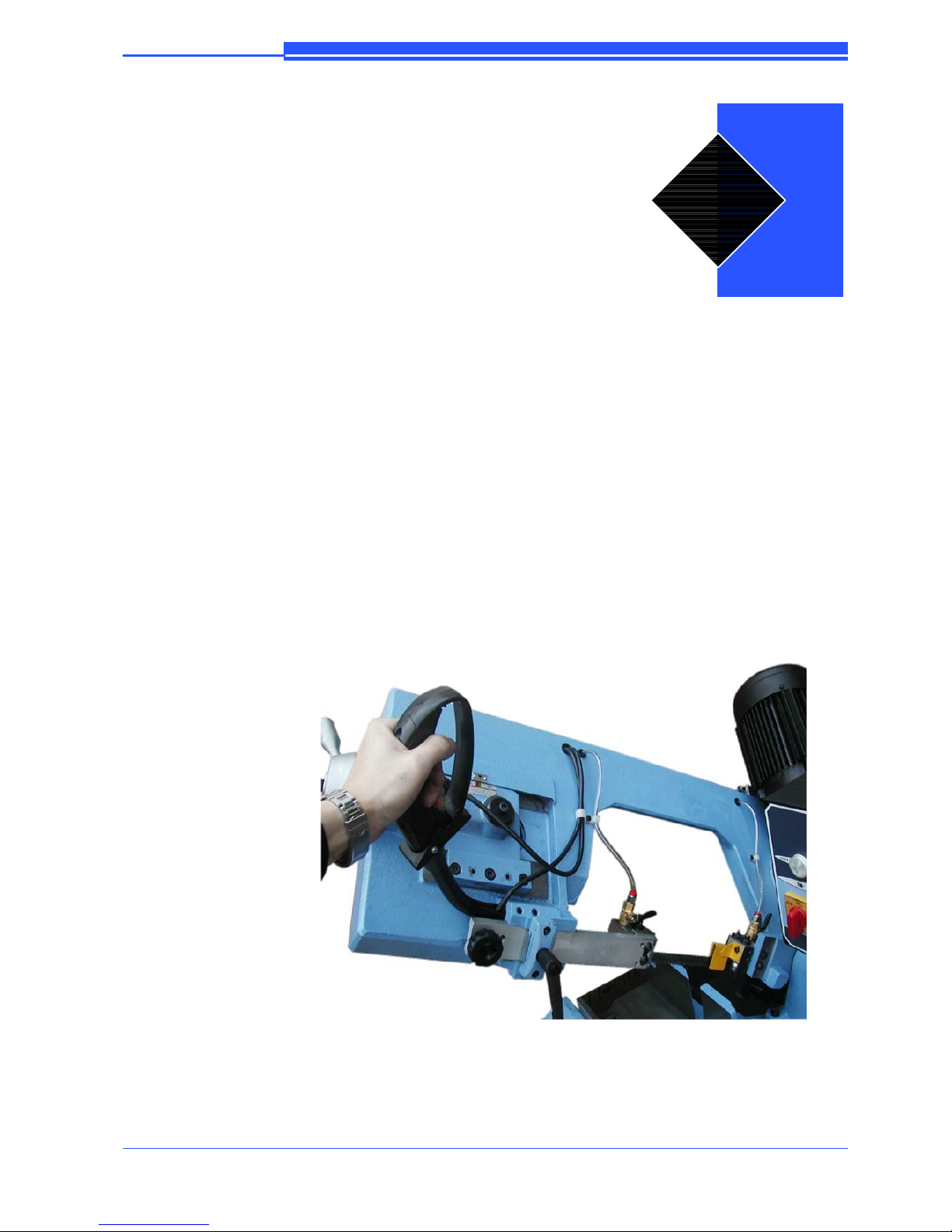

Functioning is completely manual: the operator, after having checked the

workpiece in the vice, grips the control lever and presses the bandsaw start

microswitch; with a downwards movement, the material is cut to the preset

length; the cutting head returns up at the end of the cutting operation, ready to

start a new work cycle.

Warning

1

1--2

2

Use and maintenance manual PH211

Machine specification

Name plate

Theanodisedaluminiumnameplateisrivetedonthesideofthemachine;the

same data are reproduced on the declaration of conformity included with this use

and maintenance manual.

bar bar

------ --

V

1PH

AVA

3PH

model

air pressure

data code

oil p ressure

PH101

The Roc k Solid Solution

When communicating with the Technical Service department, the model, serial

number and year of manufacture of the machine must be quoted.

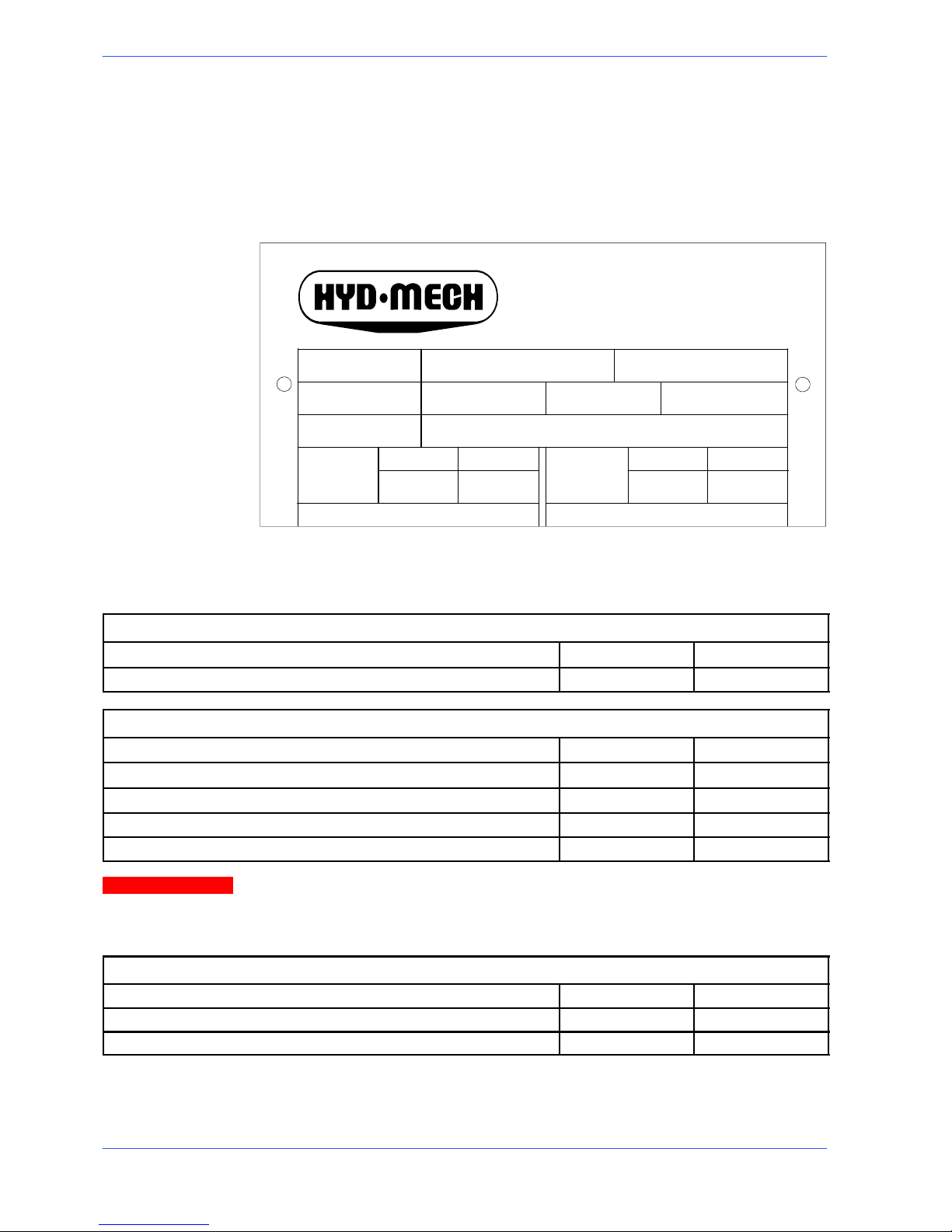

CUTTING SPEEDS

1st Slow Speed mt/min

40

2nd Fast Speed mt/min

80

BAND SAW

Rated size mm

2085 x 20 x 0,9

Max/min blade length mm

2075÷2095

Blade height mm

20

Blade width mm 0,9

Band saw tension Kgs/cm2--- L b s / i n

2

2250 --- 32000

When choosing the cutting tool, if its dimensions do not correspond to those

included in the “Rated size” section, check that the dimensions at least fall

within the admissible max/min specifications.

RATED ELECTRICAL POWER

Head spindle motor KW 1/1,3

Electric coolant pump motor KW 0,1

Max installed power KW 1,4

N.B.

Attention

1--3

3

Introduction and technical specifications

LUBRICANT/COOLANT FLUID AND OIL

Oil for transmission box capacità Kg 0,32

Lubricant/coolant fluid (oil concentration 5---6%) capacità Lt 10

VICE

Vice max. opening mm 200

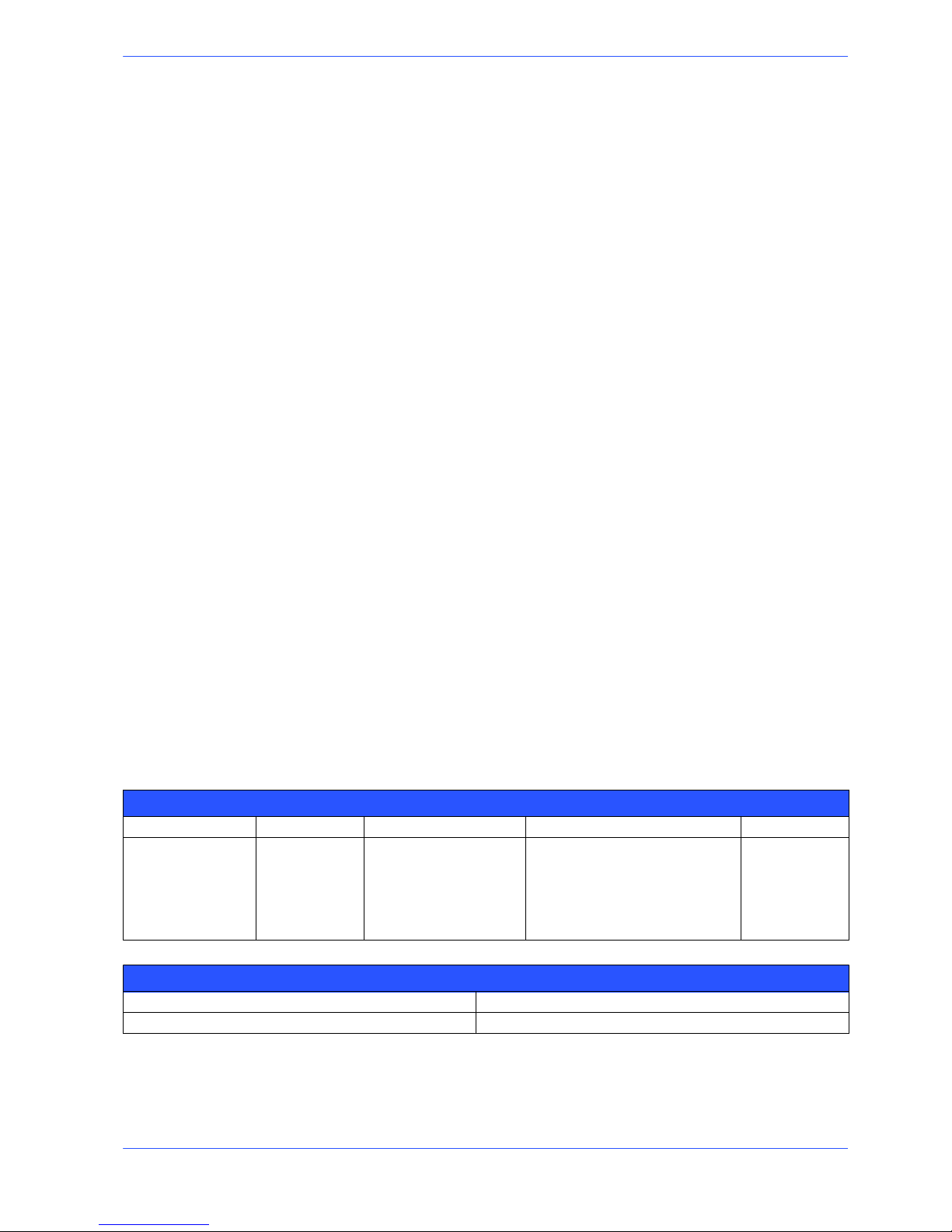

SPINDLE MOTOR

No.of poles Current (Volts) Absorption

(Amps)

Power (Kw) rpm Band saw spe-

ed

2 230/400 4,1/3,0 1,3 2950 80 mt/min

4 230/400 2,4/1,7 1 1430 40 mt/min

Stator wound with enamelled copper wire, class H 200˚C.

Class F insulation (limit temperature TL 155˚C).

IP 55 protection rati ng (total against contact with live parts, water sprayed from all directions, with shaft oil

seal).

Conforming to CEI norms, publication: IEC 34 of 01/07/1985.

Example of class F insulation: in air--cooled machines at an ambient temperature of 40˚ C (according to CEI 2--3 and IEC 85), the allowable overtemperature is 100˚ C (where 100

ٛ

C represents the allowable DT).

The machine is supplied with a 2/4 pole three phase motor giving 2 band saw

speeds:

-- 1ª speed (4 poles) = 40 mt/min

--- 2ª speed (2 poles)= 80 mt/min;

ELECTROPUMP MOTOR

Single phase; Frequency 50 Hz.

Voltage

(Volts)

Absorption

(Amps)

Power (Kw) rpm Delivery rate lt/min Head (mt. )

230 0,3 0,1 2840 11 1,5

400 0,17 0,1 2840 11 1,5

Protection rating IP 55.

Conforming to CEI norms, publication: IEC 34 of 01/07/1985.

CUTTING CAPACITY

Section

0˚ 180 180 200 x 150

45˚ a 115 110 125 x 110

60˚ a 70 70 70 x 70

N.B.

Warning

1--4

4

Use and maintenance manual PH211

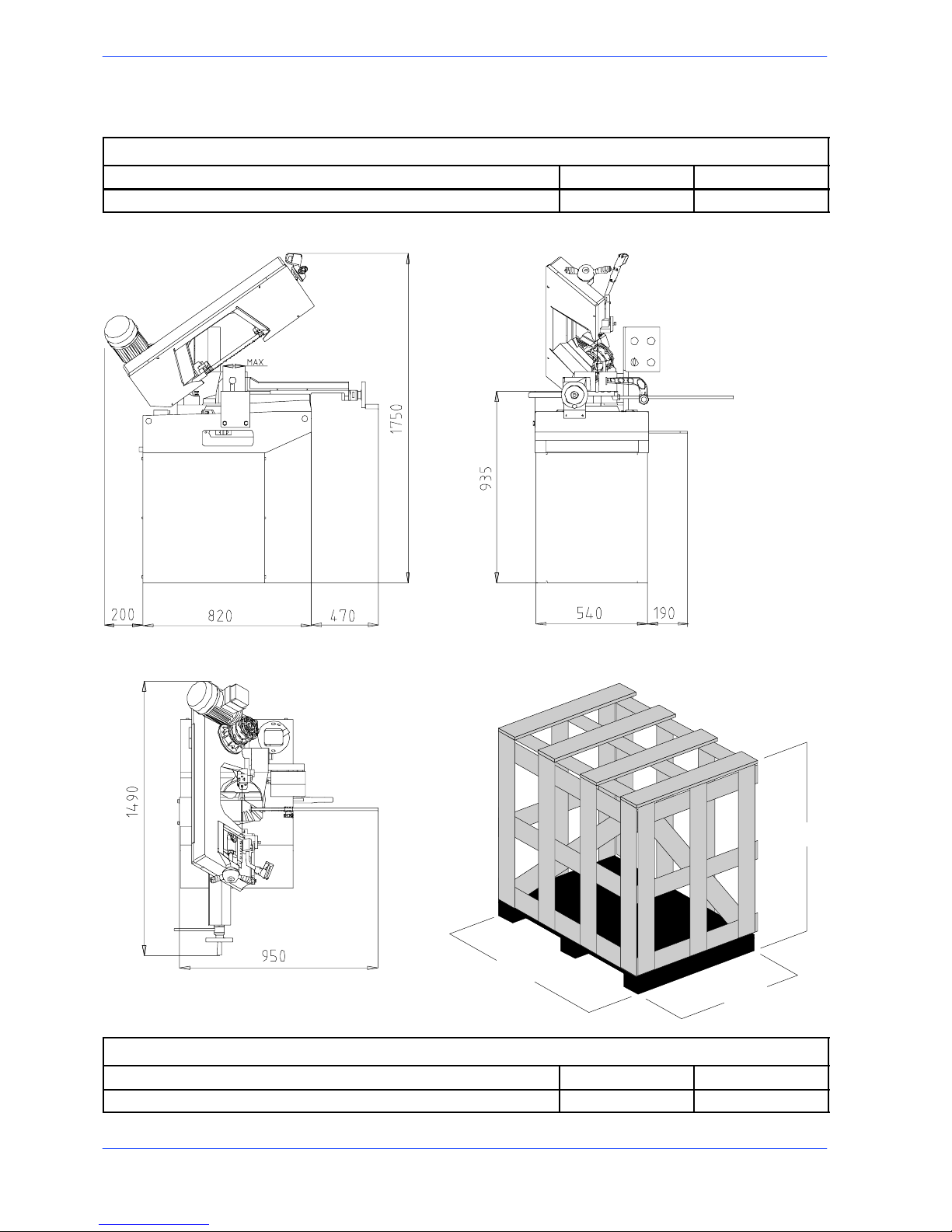

Dimensions

MACHINE INSTALLED

Work ta ble he i ght mm 935

Weight Kg 180

1280

840

1600

PAC KED WEIGHT

Wooden cage and pallet Kg 70

Wooden pallet Kg 20

2--1

Functional parts

PH211 model

In order for the user to move towards a full understanding of how the machine

works, which is described in detail in the chapter 5, this chapter deals with the

main units and their locations.

Cutting head

The cutting head is the unit that cuts the material. It consists of a cast iron head

on which the following are mounted: the band saw, the blade guide components,

the blade tensioner components, the transmission box and the spindle motor. The

cutting head is limited in its movements by the joint on the work table, and its

cutting stroke is manually guided by the operator.

2

2--2

6

Use and maintenance manual PH211

Vice

The vice is the unit that clamps the workpiece in place during cutting; it consists

ofavicesupport,commonlyknownasaleadnut,fixedtotheworktable,anda

lead screw with a slideway on which the mobile jaw is mounted. The vice is

operated manually by a handwheel, or by a pneumatic cylinder in the MA version

(optional).

Control Panel

The control panel has a protection rating of IP 54 and contains the electrical

equipment. Access is gained by removing the screws fastening a safety panel,

while the operator’s safety is guaranteed by a key---operated safety switch,

designed to prevent any intentional interference with the unit. In order to remove

the panel from its mounting, the main switch has to be shifted to 0 (OFF), which

automatically cuts off the electrical supply.

stand by

STOP

3--1

Safety and accident

prevention

The PH211 has been designed and produced in accordance with European

standards. Forthecorrectuseofthemachinewerecommendthattheinstructions contained in this chapter are carefully followed.

Use of the machine

The PH211 band saw cutting machine is intended exclusively for cutting metallic

materials, ferrous or non---ferrous, in section or solid.

Other types of material and machining are not compatible with the specific

characteristics of the saw.

The employer is responsible for instructing the personnel who, in turn, are

obliged to inform the operator of any accident risks, safety devices, noise

emission and accident prevention regulations provided for by international

standards and national laws regarding the use of the machine. The operator must

be perfectly aware of the position and function of all the machine’s controls.The

instructions, warnings and accident prevention standards in this manual must be

respected without question by all those concerned.The following definitions are

those provided for by EEC MACHINES DIRECTIVE 98/37/CE :

H “Danger zone”: any zone in and/or around a machine in which the presence of a

person constitutes a risk for the safety and health of that person.

H “Person exposed”: any person finding himself either completely or partly in a

danger zone.

H “Operator”: the person or persons given the responsibility of installing, operating,

adjusting, maintaining, cleaning, repairing or transporting the machine.

The manufacturer declines any responsibility whatsoever, either civil or criminal, should there be unauthorised interference or replacement of one or more

parts or assemblies on the machine, or if accessories, tools and consumable

materials are used that are different from those recommended by the manufacturer itself or if the machine is employed in a plant system and its proper

function is thereby altered.

Attention

3

3--2

8

Use and maintenance manual PH211

General recommendations

LIGHTING

Insufficient lighting for the types of operation envisaged could constitute a safety

hazard for the persons concerned. For this reason, the machine user must provide

lighting in the working area sufficient to eliminate all shadowy areas while also

avoiding any blinding light concentrations. (Reference standard ISO 8995 ---89

“Lighting in work environments”).

CONNECTIONS

Check that the power supply cables and pneumatic feed systems comply with the

maximum machine absorption values listed in the “Machine Specification” tables;

replace if necessary.

EARTHING

The installation of the earthing system must comply with the requirements set out

in IEC STANDARD 204.

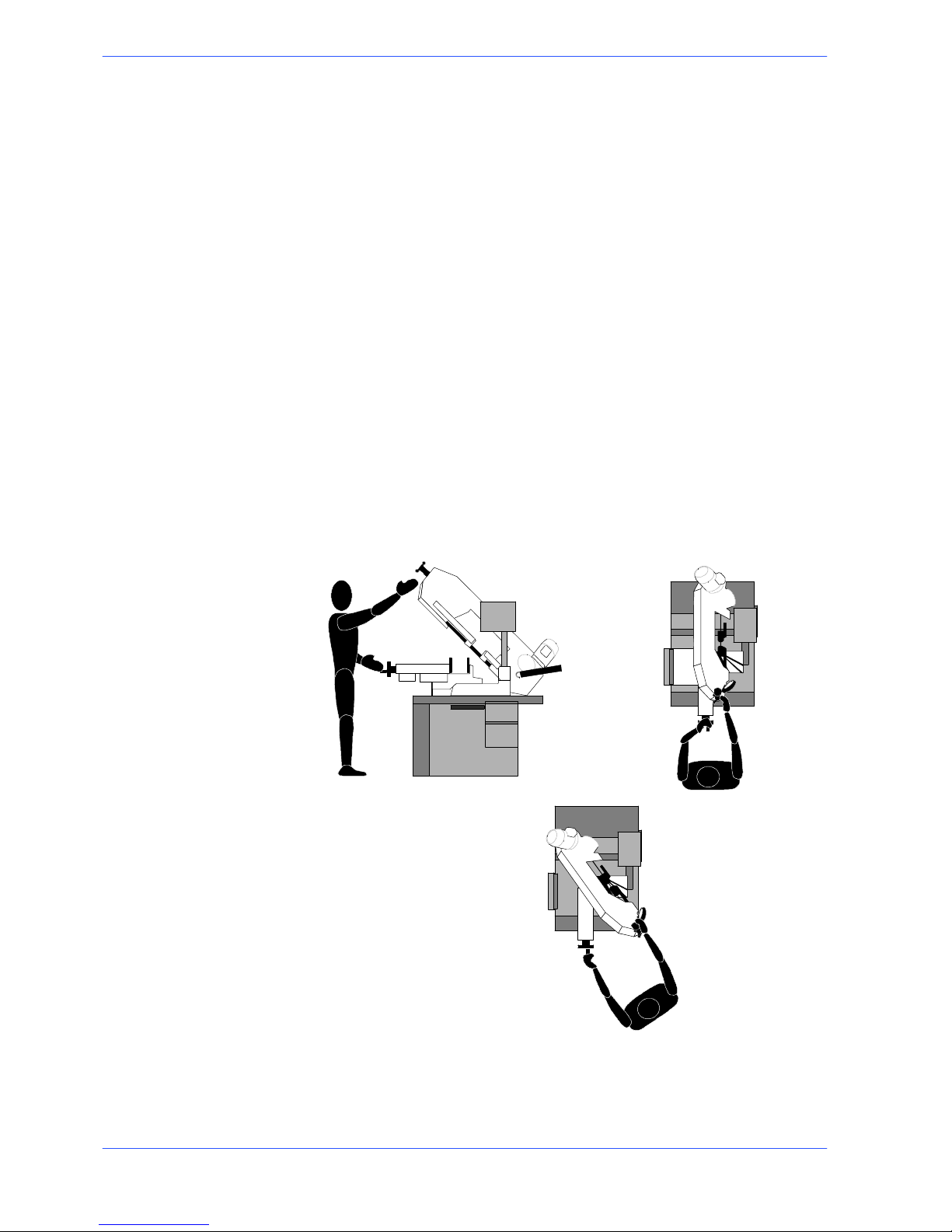

OPERATOR POSITION

The position of the operator controlling machine operations must be as shown in

the diagram below.

3--3

9

Safety and accident prevention

Recommendations to the operator

Always wear proper goggles or protective glasses.

Do not use the machine without the guards in position.

Do not allow hands or arms to encroach on the cutt ing zone while the

machine is in operation.

Do not wear oversize clothing with long sleeves, oversize gloves, bracelets, necklaces or any other object that may become entangled in the machine duri ng working; long hair must be tied back and bunched.

Alwaysdisconnectthepowersupplytothemachinebeforecarryingout

any maintenance work whatsoever, including in the case of abnormal

operation of the machine.

Before starting cutting operations, support the material at both ends of

the machine using the support arm --- standard, or OPTIONAL accessories such as the feed and discharge roller tables shown in the diagram

below. Before removing the devices supporting and moving the material,

fasten the latter in place using the machine’s clamping devices or other

suitable equipment.

mm. 1500

mm. 1500

FEED ROLLER TABLE DISCHARGE ROLLER TABLE

Any maintenance work on the hydraulic or pneumatic systems must be

carried out only after the pressure in the system has been released.

3--4

10

Use and maintenance manual PH211

The o perator must not perform any risky operations or operations not

required for the machining operation under way (e.g. remove swarf or

metal shavings from the machine while cutting).

Remove equipment, tools or any other objects from the cutting zone; always keep the working area as clean as possible.

Before starting any cutting operations, ensure that the workpiece is securely held in the vice and the machine has been set correctly. A number of

examples of how to clamp different profiles correctly in our machines are

shown below.

Do not use the machine to cut pieces that exceed the capacity of the machine as listed in the machine specifications.

Never move the machine while it is cutting.

Do not use blades of different sizes to those recommended in the machine specifications.

When cutting very short pieces, make sure that they are not dragged behind the support shoulder, where they could jam in the blade.

When working on the band saw, wear gloves only when handling materials and for tool changing or adjustment operations. Only perform one

operation at a time and do not hold more than one item or operate more

than one device simultaneously. Keep hands as clean as possible.

Warning: if the blade jams in the cut, press the emergency stop push--button immediately. If this does not free the blade, slowly loosen the

vice, remove the piece and check the blade or blade teeth for breakage.

Replace the blade if necessary.

Before carrying out any repair work on the machine, consult the Technical Assistance Service: this can be done through a re presentative in the

country of use of the machine.

3--5

11

Safety and accident prevention

Machine safety devices

This use and maintenance manual is not intended as purely a guide for the use of

the machine in a strictly productive environment, it is instead an instrument

providing information on how to use the machine correctly and safely. The

following standards are those specified by the EEC Committee in the directives

regarding safety of machinery, health and safety at work, personal protection and

safeguarding of the environment. These standards have been applied to the

PH211 band saw.

Reference standards

MACHINE SAFETY

H EEC MACHINES DIRECTIVE 98/37/CE ;

H EEC directive no. 89/336 “EMC -- Electromagnetic Compatibility”;

H EEC Directive No. 73/23 known as “Low voltage directive”.

HEALTH AND SAFETY AT WORK

H EEC Directive No. 80/1107; 83/477;86/188;88/188; 88/642 for the protection of

workers against risks caused by exposure to physical, chemical and biological agents during working;

H EEC Directive No. 89/391 and Special EEC Directives No. 89/654 and No. 89/655

for improvements in health and safety at work;

H EEC Directive No. 90/394 for the protection of workers against risks deriving from

exposure at work to carcinogenic substances;

H EEC Directive No. 77/576 and No. 79/640 on safety signs at work.

PERSONAL PROTECTION

H EEC Directive No. 89/656 and No. 89/686 on the use of personal protection de-

vices.

ENVIRONMENTAL PROTECTION

H EEC Directive No. 75/442 on waste disposal;

H EEC Directive No. 75/439 on the disposal of used oil.

3--6

12

Use and maintenance manual PH211

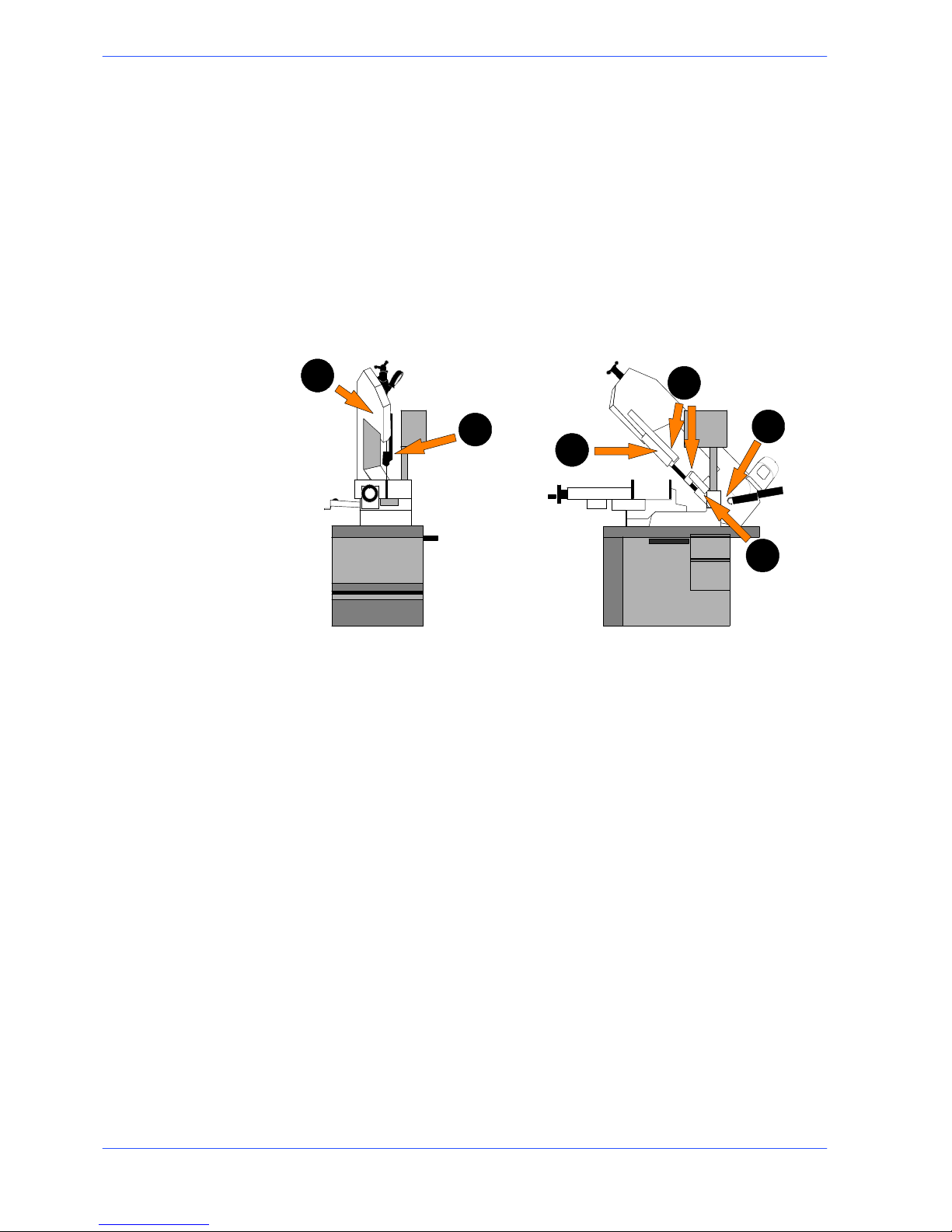

Protection against accidental contact with the blade

1. Metal guard screwed to the rear blade guide head (machine side);

2. metal guard screwed to the front blade guide head (operator side);

3. front head sliding support: when the head is at maximum aperture, the support ensures that the blade is covered, leaving free only the part of the blade

engaged in the actual cutting, in accordance with Presidential Decree no.

547/55, art. 108;

4. hinged protective cover over blade, fitted with “removable” closing devices;

5. blade guide plates completely covering the blade teeth;

6. Electric limit switch for stopping the band at the cutting head stroke end (HB

models only).

5

1

4

3

2

6

Electrical equipment

In accordance with Italian standard CEI 60204---1, April 1998, derived from

European Standard EN 60204 ---1 publication IEC 204---1, 1997:

H Access to electrical control panel limited by screws and panel---lock device,

allowing panel to be opened only after the electricity supply has been turned

off;

H 24 Vac Control voltage for actuators, in accordance with chapter 6 or Euro-

pean Standard “Control and indication circuits”, paragraph 2 “Control Circuits” sub---section 1 “Preferential voltage values for control circuits”;

H plant short---circuit protection by means of rapid fuses, earthing of all plant

parts connected with work as well as all foreseeable accidental contact; a thermal---magnetic overload cutout switch shuts down the motor;

H protection from accidental start---up by a minimum voltage relay in case of

power failure.

3--7

13

Safety and accident prevention

Emergency devices

In accordance with Standard CEI 204 ---1:

H Chapter 5 Section 6 Sub--section 1 “Emergency stop device”: «the emergency

stop device immediately stops all the dangerous and other functions of the machine»;

H Chapter 6 Section 2 Sub--section 4 Point 7 “Protective guards”: «the removal

of protective guards designed to prevent access to dangerous parts or zones causes

the machine to stop immediately; replacing the guards does not restart the functions, which must be reset».

...Emergency devices applicable to the PH211:

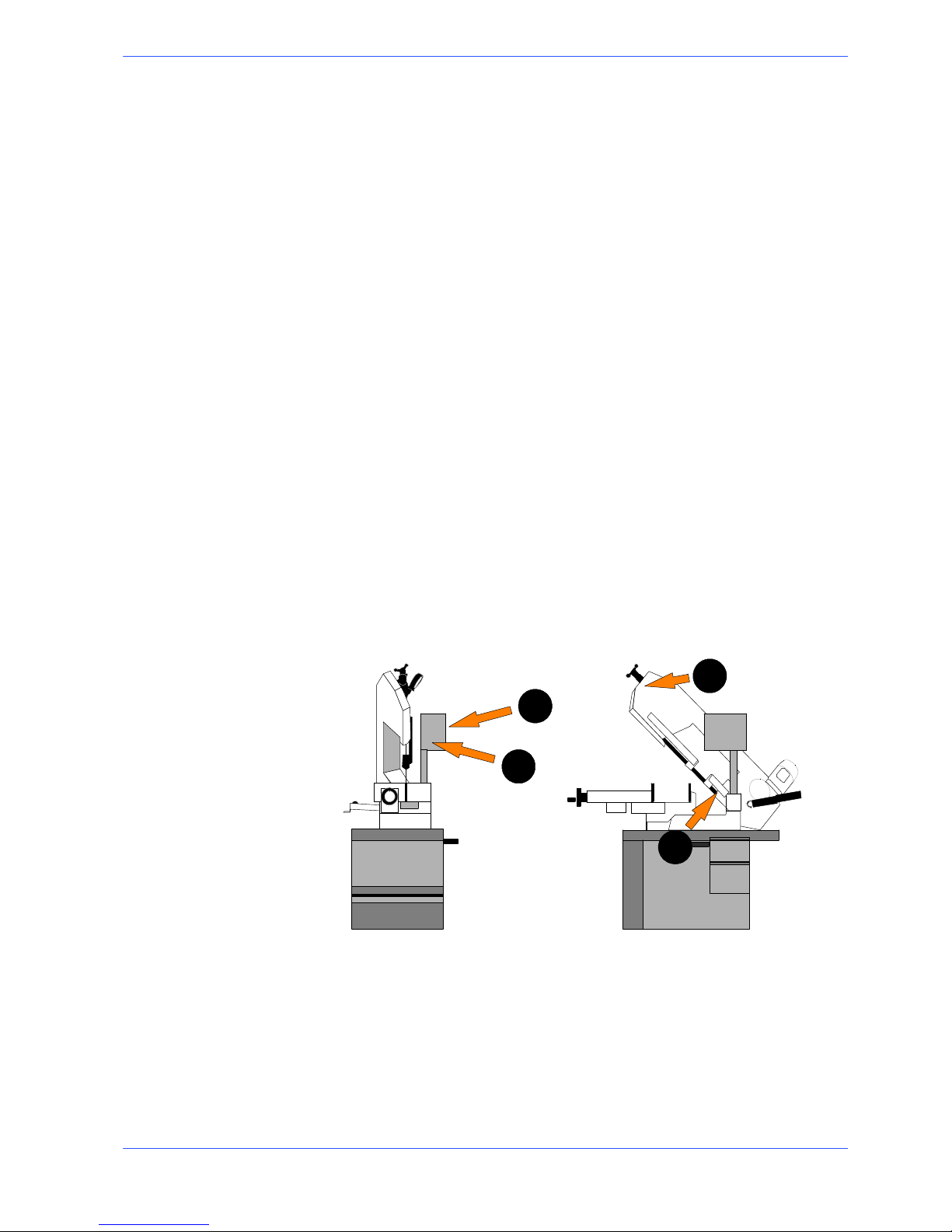

1. Emergency stop: a non---return mushroom---head pushbutton, colour red on

yellow background, is located on the control panel of the machine. To release

the pushbutton, the actuator must be rotated 45˚. After the emergency situation has been resolved, the machine must be reset.

2. Automatic thermal---magnetic cutout switch with thermal--- magnetic relay:

the machine auto switch, located on the control panel, has two protection systems against voltage drops. In the case of a voltage drop, all electrical components are disengaged, the machine stops immediately, and automatic restart

when the power supply returns is inhibited. Another function is that of resetting the thermal relay provided to protect against overcurrents.

3. Pressure contact for monitoring blade tension: the machine stops immediately if the blade breaks or if the tensioner cylinder pressure drops.

4. Protective guard for blade: a coded key microswitch is operated if the blade

cover is accidentally or intentionally opened during the machine operating

cycle, immediately shutting down all functions.

1

2

3

4

3--8

14

Use and maintenance manual PH211

Noise level of the machine

Noise can cause hearing damage and represents one the problems faced by many

countries who adopt their own standards. In accordance with the EEC MA-

CHINES DIRECTIVE 98/37/CE , we are listing the standards that specify noise

levels for machine tools. This chapter also reports the noise levels produced by

the PH211 during its various operating phases and the methods used for measuring these levels. The Italian standard governing this aspect is D.M.n.277/91 drawn

from EEC Directives 80/1107, 82/605, 83/477, 86/188, 88/642, UNI EN ISO 4871

(1998).

Noise level measurement

Noise levels are measured using an i nstrument known as an Integrator noise--meter which registers the equivalent continuous acoustic pressure level at the

work station.The damage caused by noise depends on three parameters: level,

frequency and duration. The equivalent level concept Leq combines the three

parameters and supplies just one indication. The Leq is based on the principle of

equal energy, and represents the continuous stationary level containing the same

amount of energy, expressed in dBA, as that actually fluctuating over the same

period of time.This calculation is made automatically by the integrator noise --meter. The measurements are taken every 60 seconds, in order to obtain a

stabilised value. The reading stays on the display for a sufficient time to enable a

reading to be taken by the operator.Measurements are taken by holding the

instrument at approximately 1 metre from the machine at a height of 1.60 metres

above the platform at the operator’s work station.

Two measurements are taken: the first while the machine operates without cutting

anything, the second while cutting in manual mode.

Noise level values

Identification

Machine type Band saw for metal applications

Model

PH211

Reference standard ISO 3746

Results

Description

C 40 steel cut --- pi pe 50x82 mm

Bimetal band 2085x20x09 S.VGLB Z 5/8

Test 1st

Results

Mean sound level (Leq) 76,42 dB (A)

Environmental correction (K) 3,54 dB(A)

Peak sound power (Lw) 87,34 dB(A)

Descriprion

C 40 steel cut --- solid rod 150 mm dia. Ø

Bimetal band 2085x20x09 S.VGLB Z 5/8

Test 2nd

Results

Mean sound level (Leq) 76,50 dB(A)

Environmental correction (K) 3,54 dB(A)

Peak sound power (Lw) 87,42 dB(A)

Description

34CND6 material cut ---pipe 140x130 mm

Bimetal band 2085x20x09 S.VGLB Z 5/8

Test 3rd

Results

Mean sound level (Leq) 76,19 dB(A)

Environmental correction (K) 3,54 dB(A)

Peak sound power (Lw) 87,12 dB(A)

3--9

15

Safety and accident prevention

Vibration emission

This sawing machine complies with the norms EN1299 and EN1033, as the

machine vibration emission on the devices controlled by the operator does not

exceed the threshold of 2.5 m/s

2

Electromagnetic compatibility

As from 1 January 1996 all electrical and electronic appliances bearing the CE

marking that are sold on the European market must conform to Directive

89/336/EEC and 70/23/CEE and 98/37/CEE. The prescriptions regard two specific

aspects in particular:

1. “EMISSIONS: during its operation, the appliance or system must not emit spurious

electromagnetic signals of such magnitude as to contaminate the surrounding

electromagnetic environment beyond clearly prescribed limits”;

2. “IMMUNITY: the appliance or system must be able to operate correctly even when

it is placed in an electromagnetic environment that is contaminated by disturbances

of defined magnitude”.

The following text contains a list of the applied standards and the results of the

electromagnetic compatibility testing of machine model PH211; Test report no.

170201.

Emissions

H CEI EN 61000--6 --4 (2002) Electromagnetic Compatibility (EMC) -- Generic stan-

dard regarding emissions. Part 6--4: Industrial Environment.

H EN 55011 (1999) Industrial, scientific, and medical radio frequency appliances

(ISM). C haracteristics of radio frequency disturbance -- Limits and methods of

measurement.

H EN 55014--1 (2002) Electromagnetic Compatibility -- Prescriptions for domestic

appliances, electric power tools, and similar equipment. Part 1: Standard Emission

in relation to product family.

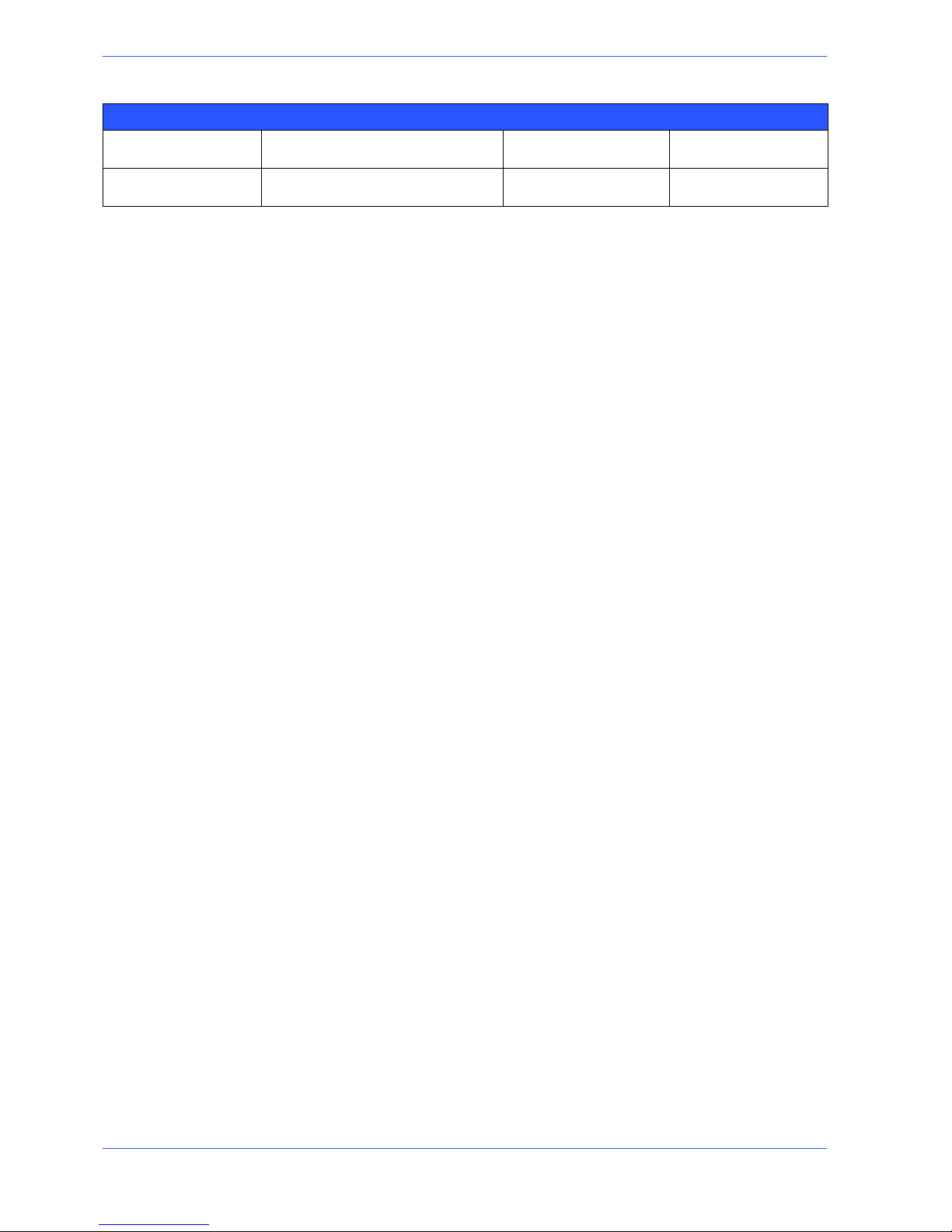

CONDUCTED EMISSIONS

Gate A Freq. ( MHz) Q --- p e a k l i mi t ( d B u V) Mean value limit (dBuV) Result

A.C. power supply

input

0.15 --- 0.5

0 . 5 --- 5

5 --- 3 0

79 --- 73

(linear reduction with

log of frequency)

73

73

66 --- 60

(linear reduction with log of fre-

quency)

60

60

Complies

CONDUCTED EMISSIONS --- ANALYSIS OF INTERMITTENT DISTURBANCES

Gate Result

A.C. power supply input Not applicable

3--1016Use and maintenance manual PH211

IRRADIATED EMISSIONS

Gate Freq. ( MHz) Q---peak limit (10 m)

(dBuV/m)

Result

Enclosure 30 --- 230

230 --- 1000

40

47

Complies

Immunity

H CEI EN 61000--6 --2 (2000) Electromagnetic Compatibility (EMC) -- Generic stan-

dard on immunity. Part 6--2: Industrial Environment.

The EUT is deemed to fulfil the immunity requirements without testing, because

it contains no electonic control circuitry.

4--1

Machine installation

Packaging and storage

Hyd---Mech use packing materials that guarantee the integrity and protection of

the machine during its transport to the customer.

The type of packing differs according to the size, weight and destination.

Therefore the customer will receive the machine in one of two following ways:

1. on a pallet with straps and heat ---shrink plastic;

2. on a pallet with straps, heat---shrink plastic and a wooden crate.

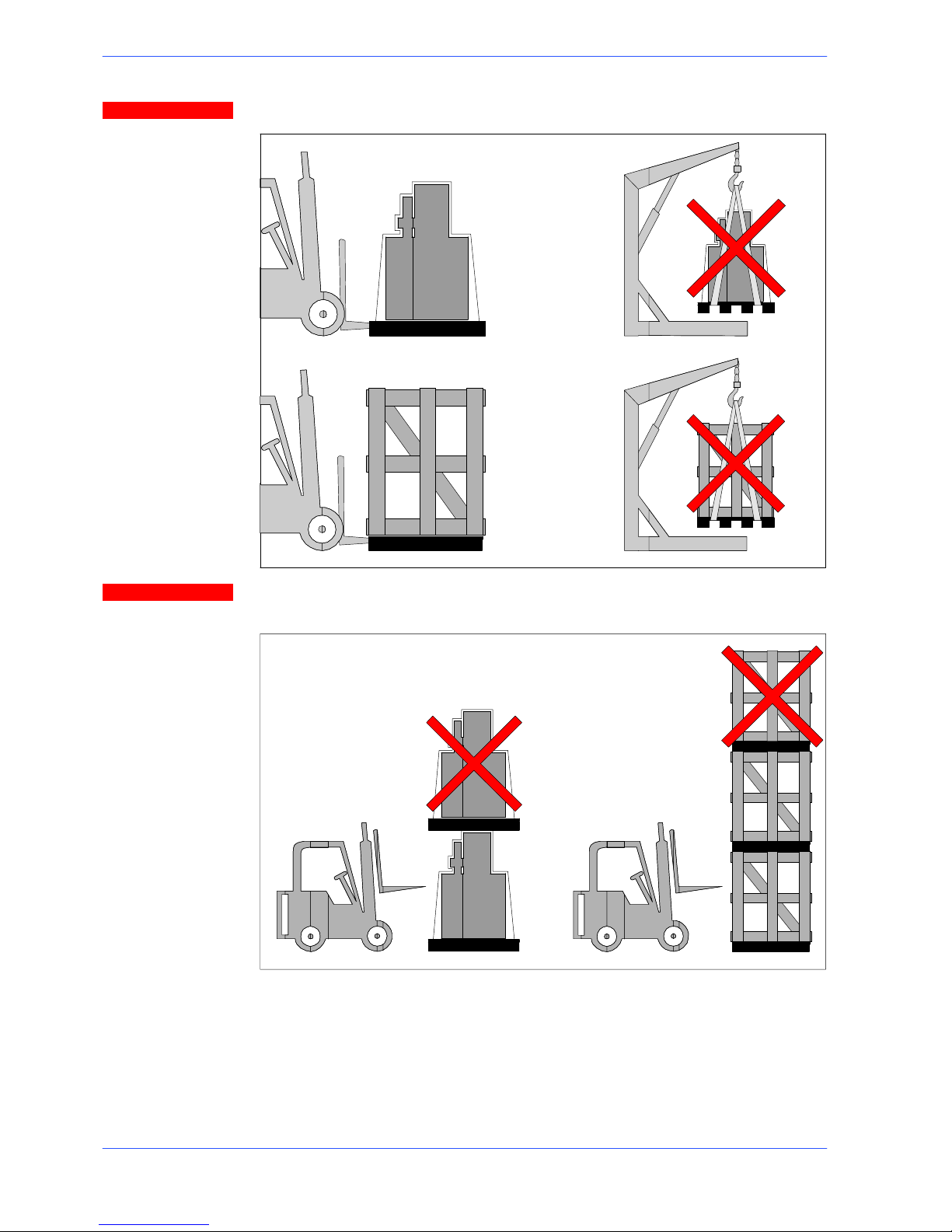

In both cases, for correct balancing the machine must be handled using a

fork--lift truck, inserting the tines at the points indicated by the arrows, using

the reference marks on the crate itself.

Before carrying out lifting operations, make sure that the weight of the machine, as indicated on the crating or other packaging, is within the forklift truck

load limit.

Warning

Attention

4

4--2

18

Use and maintenance manual PH211

Do not handle the packed machine using slings.

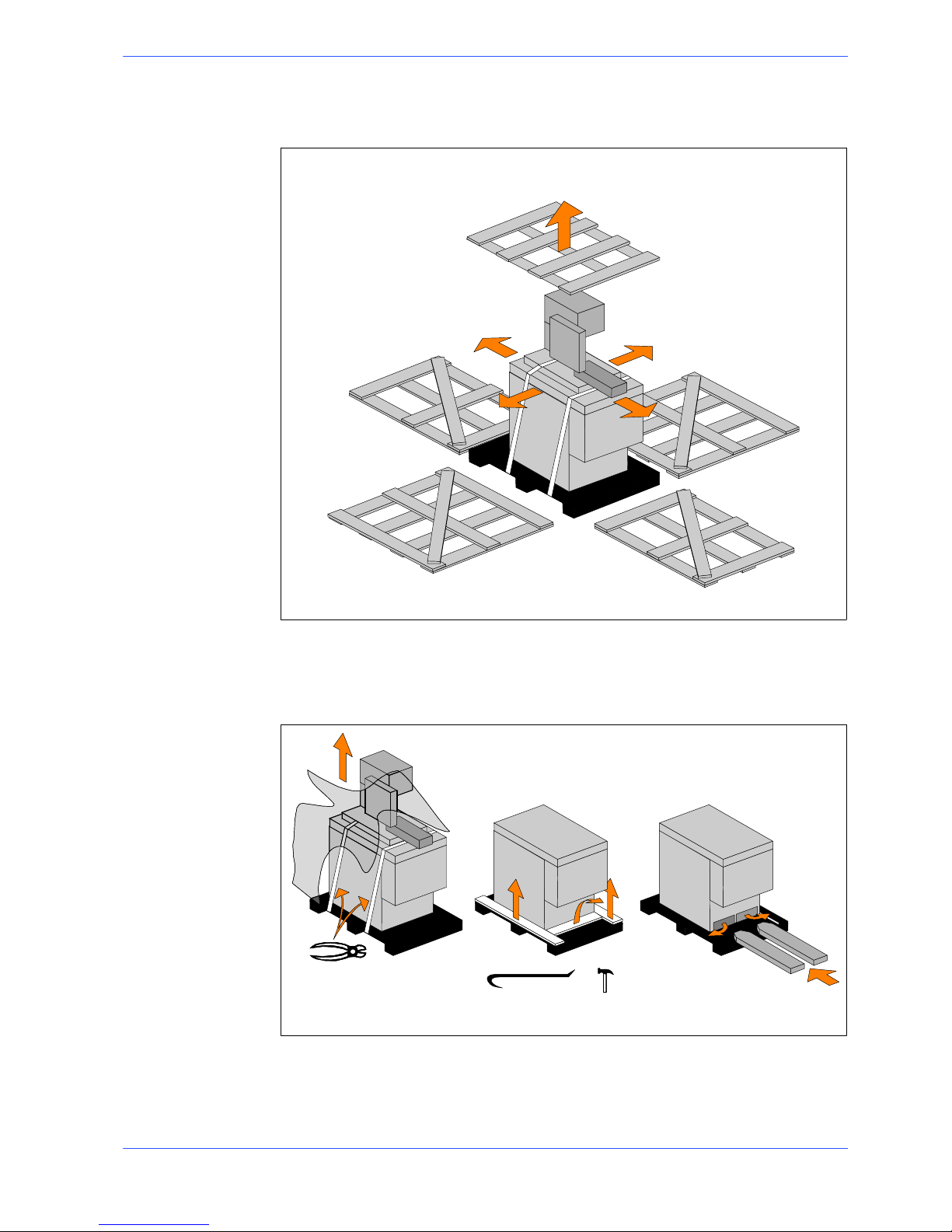

When storing, machines palletized and shrink--wrapped must not be stacked

two high, and machines pallettized and crated must not be stacked three high.

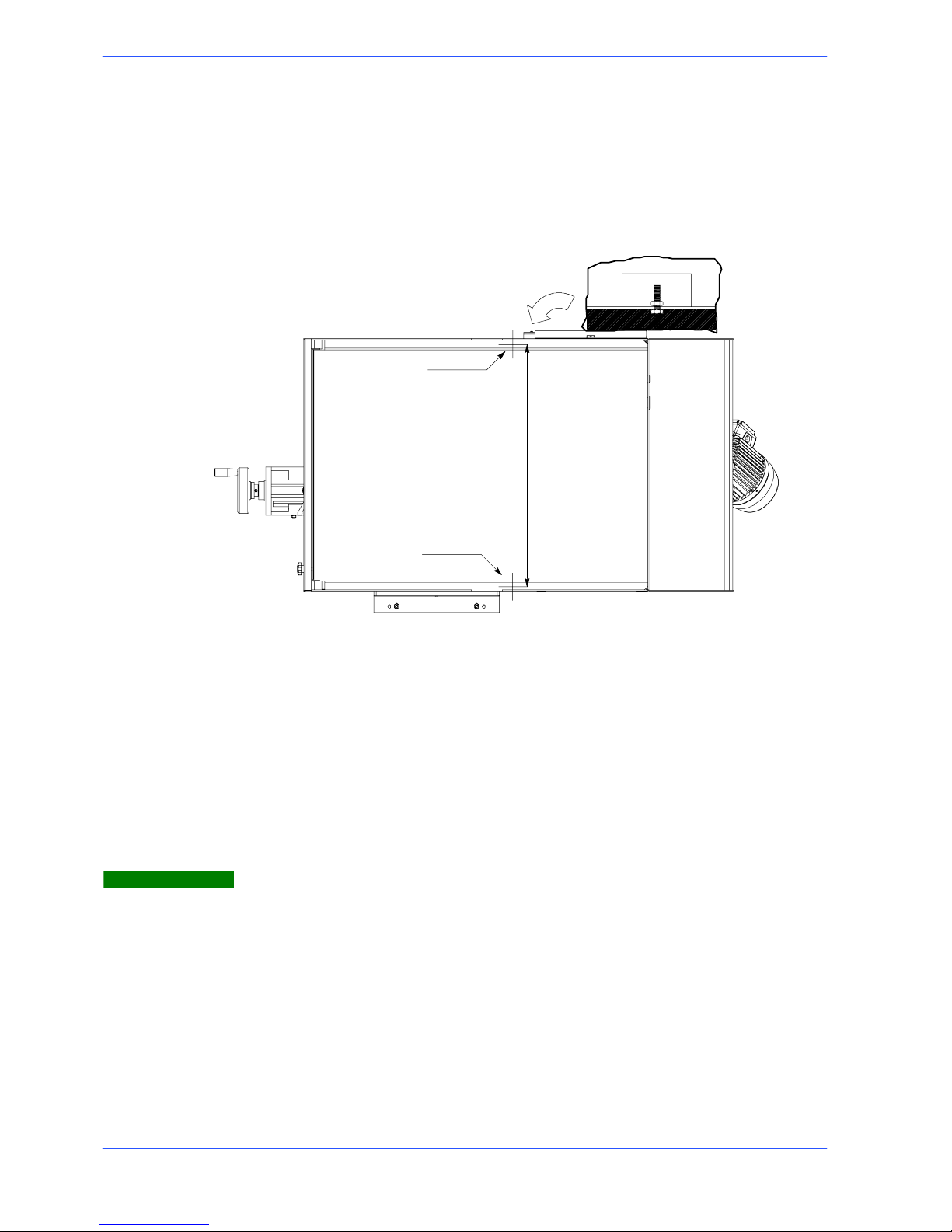

To install the machine, first remove the packing, paying particular attention not to

cut any electric wires or hydraulic hoses; if necessary use pliers, a hammer and a

cutter.

Open crate in the illustrated order:

Attention

Attention

4--3

19

Machine installation

1. remove nails and lift the top of the cage;

2. remove nails and lower walls;

2

2

2

2

1

3. remove heat---shrink covering;

4. remove the straps;

5. remove nails from pallet securing planks and remove planks;

6. remove the front panel and insert fork tines.

3

4

5

6

To locate the machine in the workplace, the machine dimensions and necessary

operator working space, including the spaces laid down in safety standards, must

be taken into account.

4--4

20

Use and maintenance manual PH211

Anchoring the machine

The base of the machine is anchored to the floor by two permanent studs located

on the sides of the base. The studs are screwed into nuts previously sunk into the

concrete, and tightened from above with lock nuts. The schematic specifications

set out in Chapter 1 should be taken into account when positioning the machine.

BASE

Ø12mm

Ø12mm

667,5 mm

Minimum requirements

For the machine to function correctly, the room in which it is to be installed must

satisfy the following requirements:

H power supply voltage/frequency: refer to the values on the rating plate;

H temperature of machine location: from -- 10 to + 50˚ C;

H relative humidity: not more than 90%;

H lighting: not less than 500 Lux.

The machine is already protected against voltage variations, but will only run

trouble--free if the variations do not exceed ± 10%.

Warning

4--5

21

Machine installation

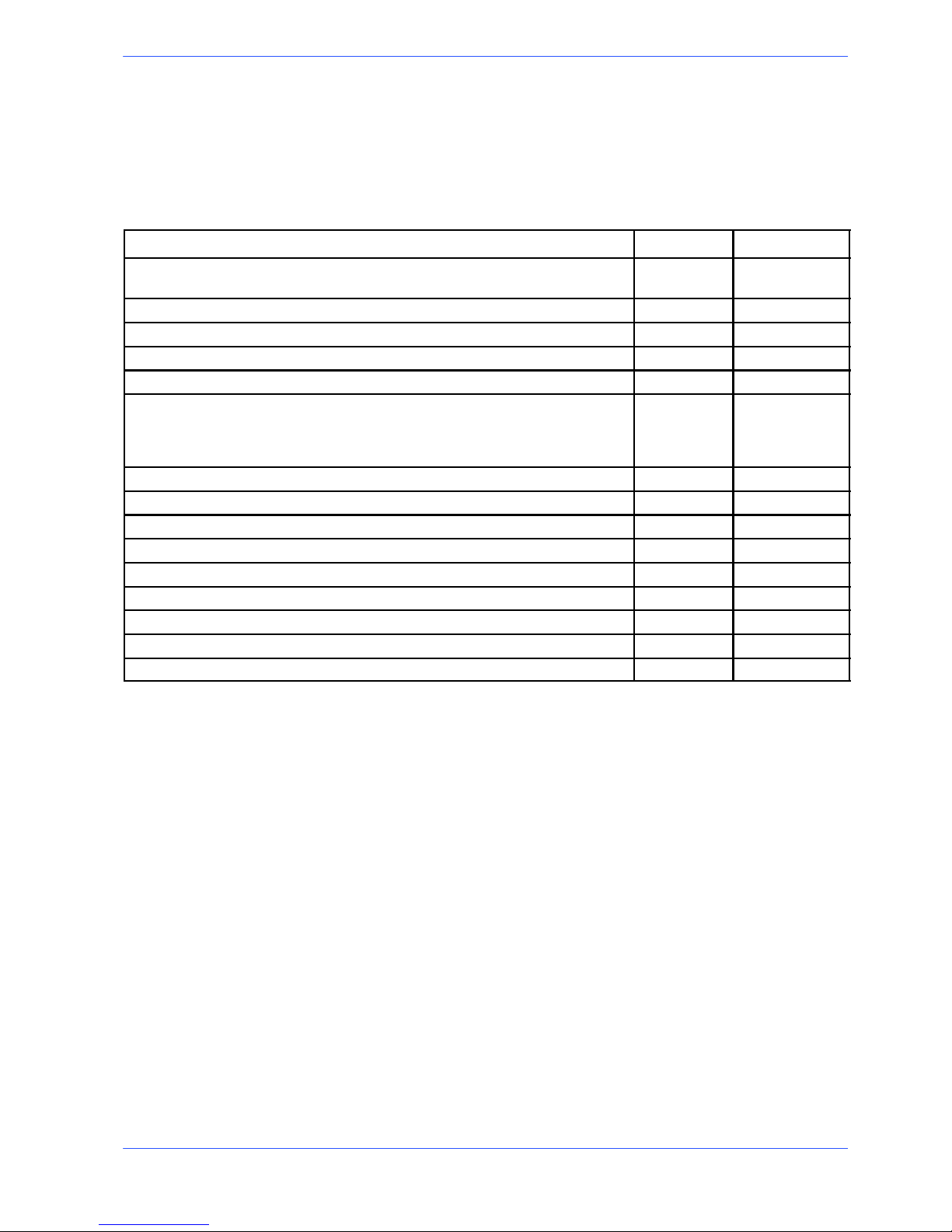

Check list

Before starting installation, check that all the accessories, whether standard or

optional, supplied with the machine are present. The basic version of the PH211

2---SPEED machine is supplied complete with:

CHARACTERISTICS

STANDARD OPTIONAL

Steel base with coolant tank and electric pump for band lubricating and cooling

n

Double return spring for head upstroke n

Bimetal blade for solid and section materials n

Vice with quick clamping lever n

Blade cleaning brush n

Electric control panel (totally identifiable cabling, stand---by, main switch with

lockable panel--- closing device, speed switch, emergency device, thermal---magnetic o verload cutout, minimum voltage relay, voltage drop protection, 24 V

low--- voltage plant)

n

IP 55 handgrip n

Adjustable stops at 0˚ and 60˚ left with clamping lever for in between angles n

Head pivoting with pre--- loaded taper bearings n

Adjustable stop to make cuts of the same length n

Accessory kit n

5 l can of emulsible oil n

2085x20x0.9 M42 bimetal band saw n

Discharge side roller table adaptor n

Adapter for laoding table K110 n

The bag of accessories is enclosed in the machine before being packed.

4--6

22

Use and maintenance manual PH211

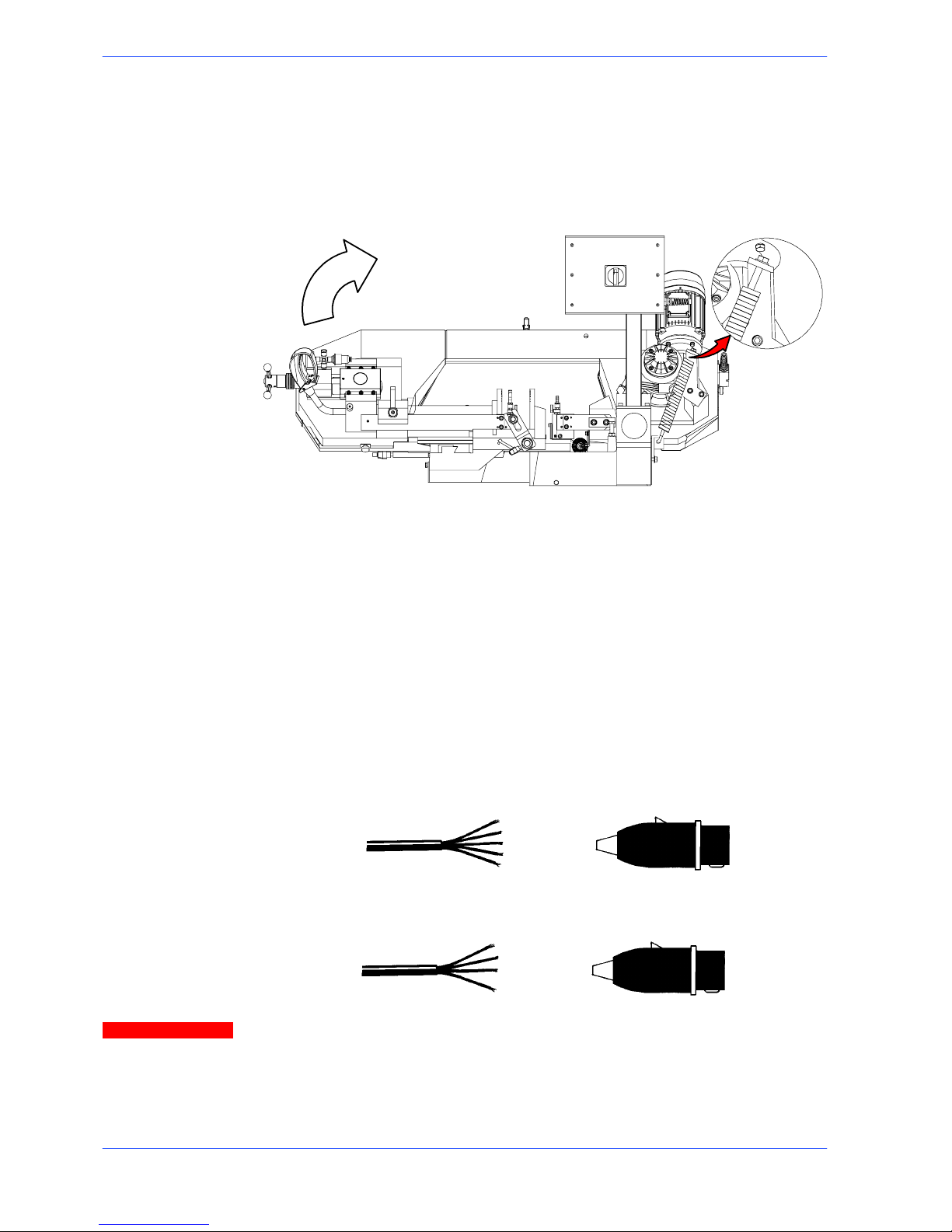

Balancing the cutting head

Before making the electrical connections, the head return springs must be

tensioned to balance the cutting head weight. Using a 10 mm. wrench, tighten the

screws until the distance between the first coil of the spring and the bracket is 8

mm.

Connection to the power supply

Before connecting the machine to the power supply, check that the socket is not

connected in series with other machines. This requirement is fundamental for the

good operation of the machine.

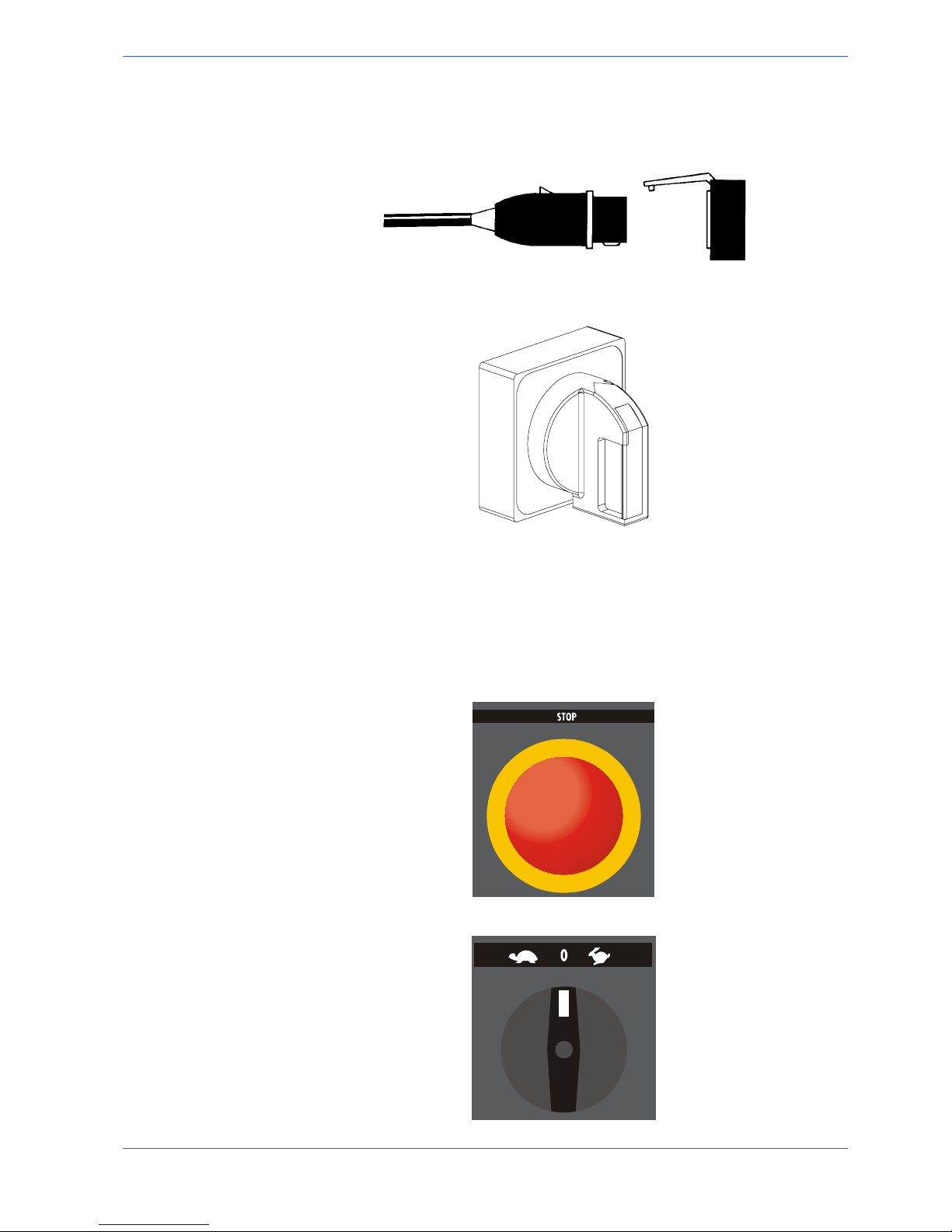

To connect the machine to the power supply, proceed as follows:

" connect the power supply cable of the machine to a plug which matches the

socket to be used. (EN 60204 ---1; par. 5.3.2)

CONNECTION FOR ”5-CORE” WIRE SYSTEMS WITH NEUTRAL

R=L1

S=L2

T=L3

PE = GND

N = NEUTRAL

CONNECTION FOR ”4-CO

R

E” WIRE SYSTEMS WITH NEUTRAL

S=L2

T=L3

PE = GND

R=L1

When using systems with a neutral wire, special care must be taken when connecting the blue neutral wire, in that if it is connected to a phase wire it will discharge the phase voltage to the equipment connected for voltage: phase--

neutral.

Attention

4--7

23

Machine installation

" Insert the plug in the socket, ensuring that the mains voltage is the same as

that for which the machine has been setup.

VOLT ?VOLT ?

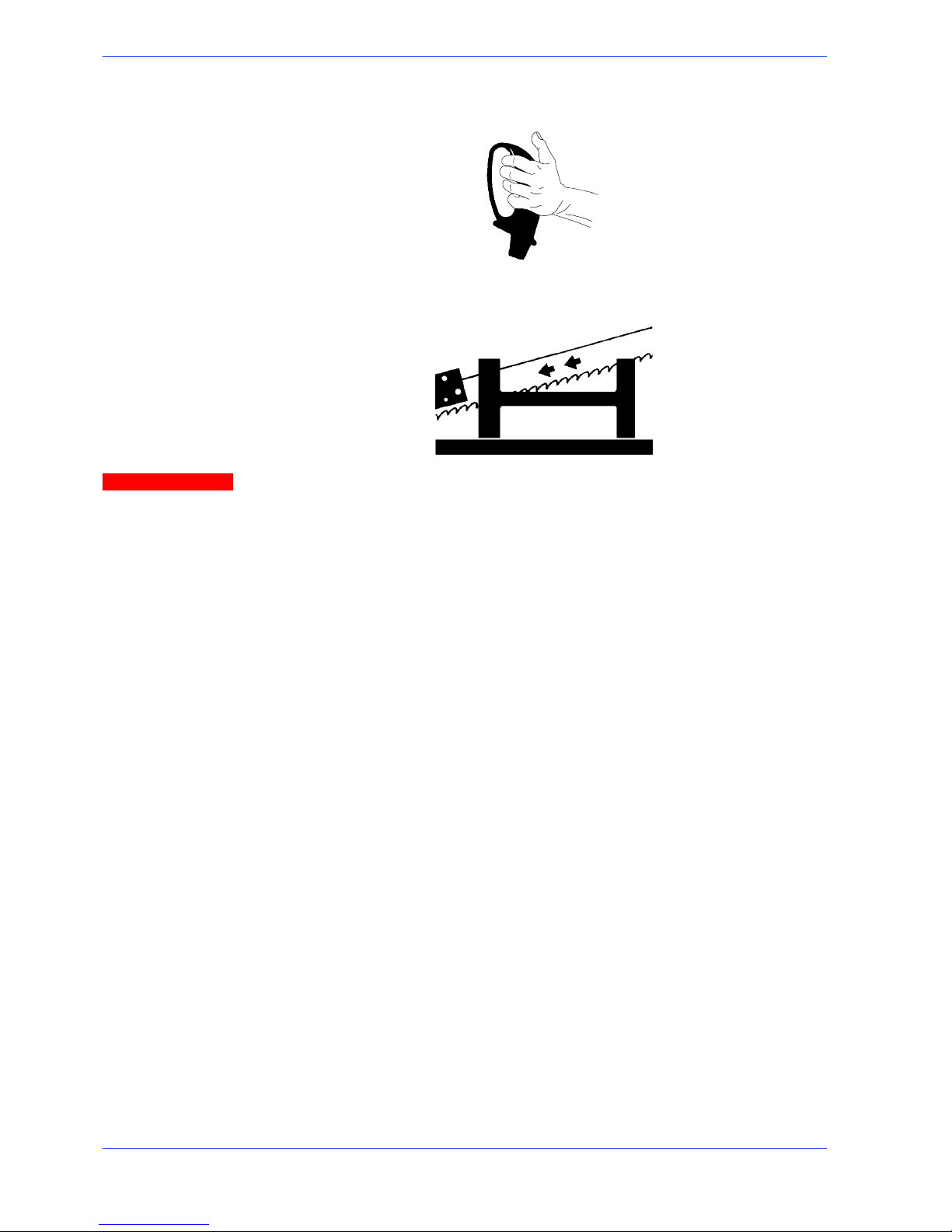

" Power up machine by rotating the main switch located on the right side of the

control panel (The STAND BY LED lights up).

Check that the motor is rotating in the correct direction. For this check the

following operations must be carried out:

" set the blade tension to 70 BAR;

" make sure the cover is properly closed: at the back of the cutting head there is

a bayonet limiter for correct cover closure;

" make sure that the machine is not in an emergency condition (red mush-

room ---head pushbutton released);

" select a cutting speed using the polarity change switch;

4--8

24

Use and maintenance manual PH211

" operate the jog button on the manual head control lever;

" if all the above operations have been carried out correctly, the blade motor

will start up and the blade will start rotating.

Ensure that the blade moves in the correct direction as shown in the above figure. If it does not, simply reverse two of the phase wires on the machine

power supply input.

The sawing machine is now ready to start the work for which it was designed.

Chapter 5 provides a detailed description of the various functions of the machine

and its operating cycles.

Attention

Loading...

Loading...