Hyd-Mech M-16A PLC 500 E600, M-20A PLC 100 E200, M-16A PLC 100 E200, M-20A PLC 500 E600 User Manual

M-16A & M-20A PLC 500 E600 & PLC 100 E200

2003 Revision C

393060 December 2003

Effective T0503338

THANK YOU,

On behalf of everyone at HYD.MECH, I would like to thank and congratulate you on your decision to purchase a

HYD.MECH band saw.

Your new machine is now ready to play a key role in increasing the efciency of your operation, helping you to reduce cutting costs while boosting quality and productivity.

To ensure you are maximizing the power and versatility of your new HYD.MECH band saw, please take the time to familiarize yourself and your employees with the correct operation and maintenance procedures as outlined in this manual.

We sincerely appreciate the condence you have demonstrated in purchasing our product and look forward to building a

long and mutually benecial relationship.

Thank-you.

HYD.MECH GROUP LIMITED

P.O. BOX 1030, 1079 Parkinson Road

Woodstock, Ontario Canada, N4S 8A4

Phone: (519) 539-6341

Service 1-877-237-0914

Sales 1-877-276-SAWS(7297)

Fax (519) 539-5126

e-mail, info@hydmech.com

01

Table of Contents

SECTION 0, SAFETY

M-16A & M-20A PLC 500 E600 & PLC 100 E200 ......................................................................................................01

SECTION 0 - SAFETY INSTRUCTIONS .................................................................................................................... 0.1

SUMMARY..................................................................................................................................................................0.1

OWNER IS RESPONSIBLE TO..................................................................................................................................0.1

OPERATOR AND MAINTENANCE PERSONNEL ARE RESPONSIBLE TO: .......................................................... 0.1

SECTION 0, SAFETY INSTRUCTIONS .....................................................................................................................0.2

BASIC RULES ............................................................................................................................................................ 0.3

RESPONSIBILITIES OF THE OWNER ...................................................................................................................... 0.5

RESPONSIBILITIES OF THE OPERATOR AND MAINTENANCE PERSONNEL .................................................... 0.6

SECTION 1, INSTALLATION

LIFTING INSTRUCTION.............................................................................................................................................1.1

FOUNDATION, LEVELLING AND ANCHORING.......................................................................................................1.2

BLADE TENSION CHECK ......................................................................................................................................... 1.3

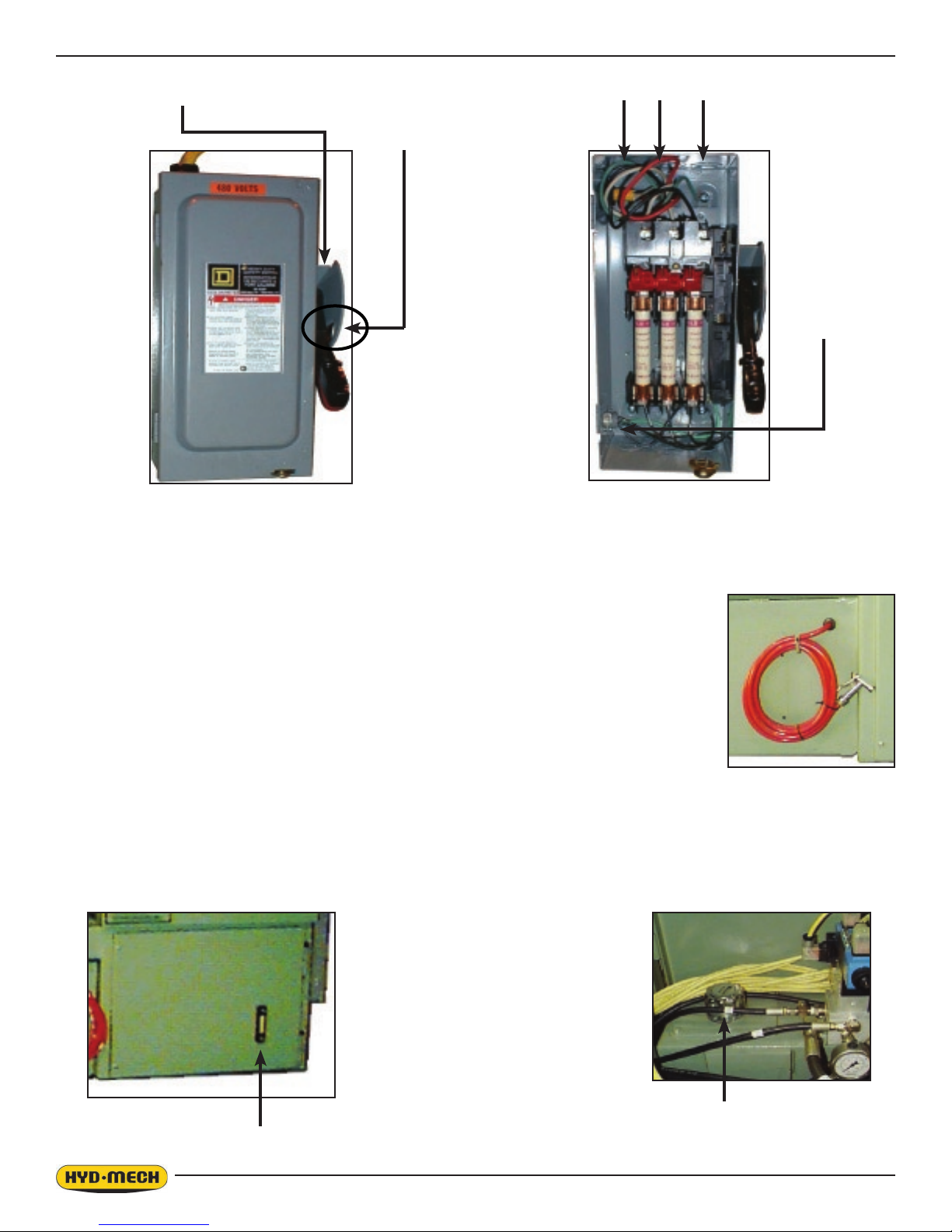

WIRING CONNECTIONS............................................................................................................................................1.3

CUTTING FLUID.........................................................................................................................................................1.4

HYDRAULIC OIL ........................................................................................................................................................ 1.4

HEAD HEIGHT CHECK..............................................................................................................................................1.5

SECTION 2, OPERATING INSTRUCTIONS

BLADE BASICS..........................................................................................................................................................2.1

VARIABLE SPEED CONTROL ..................................................................................................................................2.1

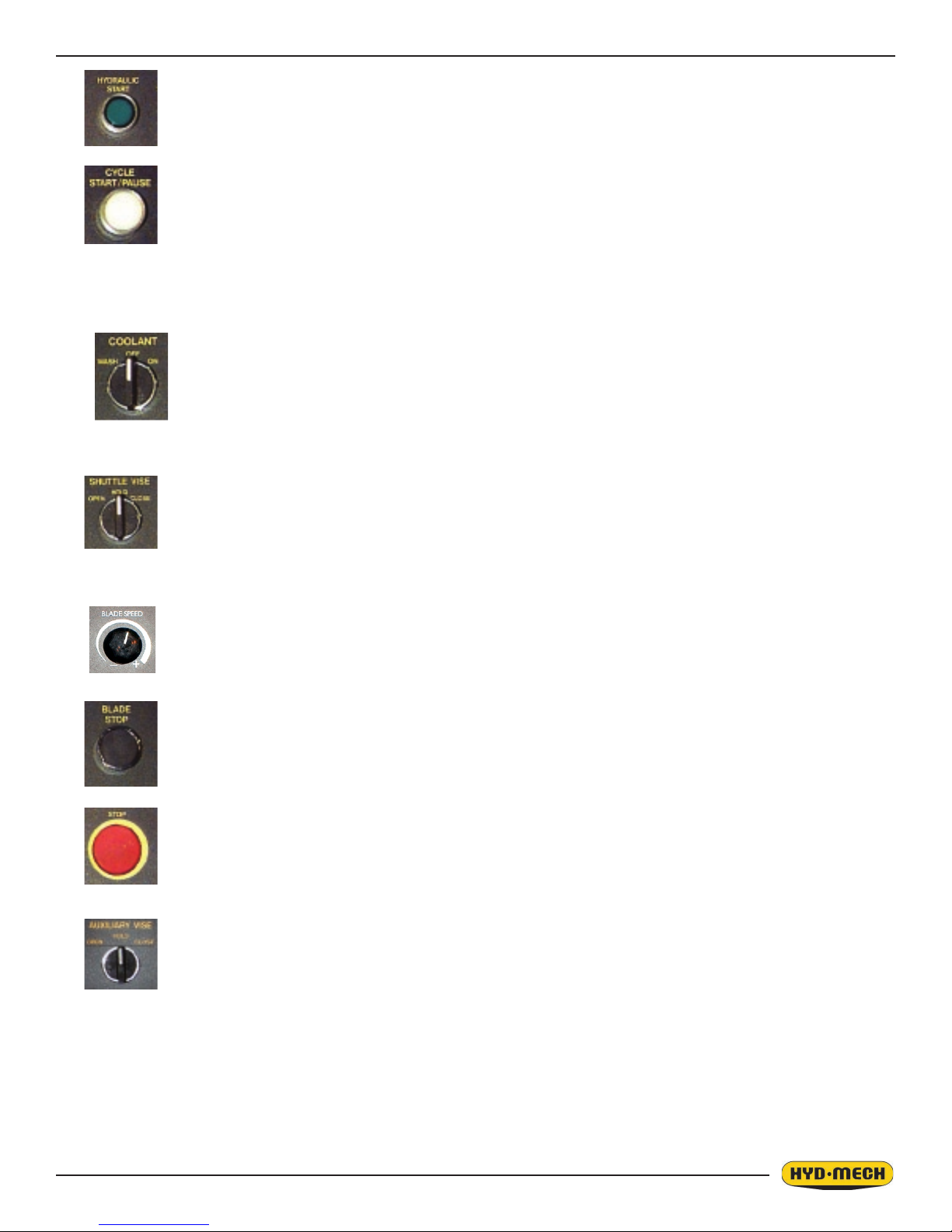

THE CONTROL CONSOLE........................................................................................................................................ 2.2

PANEL SWITCHES SPECIFIC TO PLC 100, E200 INTERFACE ..............................................................................2.4

CONTROL SYSTEM, MITSUBISHI PLC 500.............................................................................................................2.5

OPERATION OVERVIEW ........................................................................................................................................... 2.5

PLC CONTROL DESCRIPTION.................................................................................................................................2.6

FUNCTION BUTTON DESCRIPTION ........................................................................................................................2.7

ONE CUT MODE.........................................................................................................................................................2.9

AUTOMATIC OPERATION .........................................................................................................................................2.10

PROCEDURE FOR EDITING OR STARTING A NEW JOB IN AUTO MODE ...........................................................2.10

WORKING WITH A QUEUE .......................................................................................................................................2.12

PLC CONTROL SYSTEM E200 ................................................................................................................................. 2.13

OPERATION OVERVIEW ........................................................................................................................................... 2.13

ACTIVATING THE INTERFACE ................................................................................................................................. 2.14

FUNCTION KEY DESCRIPTIONS..............................................................................................................................2.14

SINGLE PART CYCLE OPERATION ......................................................................................................................... 2.15

AUTOMATIC OPERATION .........................................................................................................................................2.15

PROCEDURE FOR EDITING OR STARTING A NEW JOB IN AUTO MODE ...........................................................2.16

KERF CORRECTION FOR ANGLE CUTTING ..........................................................................................................2.18

HYDRAULIC FEED CONTROL..................................................................................................................................2.19

CUTTING PARAMETERS CHART ............................................................................................................................. 2.19

COOLANT FLOW ....................................................................................................................................................... 2.24

HEAD UP AND DOWN LIMIT SETTING .................................................................................................................... 2.24

SECTION 3, MAINTENANCE AND TROUBLESHOOTING

LOCK -OUT.................................................................................................................................................................3.1

LOCK OUT PROCEDURE.......................................................................................................................................... 3.1

BLADE CHANGING....................................................................................................................................................3.2

BLADE TRACKING .................................................................................................................................................... 3.3

DRIVE WHEEL ADJUSTMENT..................................................................................................................................3.3

IDLER WHEEL ADJUSTMENT .................................................................................................................................. 3.3

BLADE BRUSH ADJUSTMENT................................................................................................................................. 3.3

TOC.1

TOC.3

BLADE GUIDE ADJUSTMENT .................................................................................................................................. 3.4

BLADE HEIGHT ADJUSTMENT................................................................................................................................3.4

WORK LAMP ...........................................................................................................................................................3.4

LUBRICATION ............................................................................................................................................................ 3.5

HYDRAULIC MAINTENANCE.................................................................................................................................... 3.6

HEAD FEED RATE CALIBRATION...........................................................................................................................3.11

ANGLE CALIBRATION ..............................................................................................................................................3.11

PLC 500 E600 INPUT / OUTPUT TERMINAL............................................................................................................ 3.12

INFORMATION ...........................................................................................................................................................3.12

PLC 500 TROUBLESHOOTING EXAMPLES............................................................................................................3.15

PROGRAMMABLE LOGIC CONTROL, (E200, 2100 V1.0).......................................................................................3.17

PLC PARAMETERS (DESCRIPTIONS, E200 INTERFACE, 2100 SOFTWARE)...................................................... 3.17

PLC TROUBLESHOOTING........................................................................................................................................ 3.19

INCONSISTENT INACCURACY.................................................................................................................................3.21

CONSISTENT INACCURACY .................................................................................................................................... 3.21

LINEAR INACCURACY..............................................................................................................................................3.21

AUTO CYCLE NOT BEING COMPLETED.................................................................................................................3.22

AUTO CYCLE SEQUENCE:....................................................................................................................................... 3.22

FUSES E200 ............................................................................................................................................................... 3.23

MITSUBISHI FX2N 48MR INPUTS & OUTPUTS.......................................................................................................3.24

ENCODER AND PROXIMITY SENSOR CONNECTIONS ......................................................................................... 3.25

CALIBRATION PROCEDURE .................................................................................................................................... 3.26

SECTION 4, ELECTRICAL SYSTEM

GENERAL INFORMATION .........................................................................................................................................4.1

INITIAL START-UP ..................................................................................................................................................... 4.1

EARTH GROUNDING PROCEDURE......................................................................................................................... 4.1

M16A PLC500 COMPONENT LIST: NO OPTIONS ................................................................................................... 4.4

M16A PLC500 COMPONENT LIST: 208V .................................................................................................................4.8

M16A PLC500 COMPONENT LIST: 240V .................................................................................................................4.9

M16A PLC500 COMPONENT LIST: 480V .................................................................................................................4.10

M16A PLC500 COMPONENT LIST: 575V .................................................................................................................4.11

M20A PLC500 COMPONENT LIST: NO OPTIONS ................................................................................................... 4.12

M20A PLC500 COMPONENT LIST: 208V .................................................................................................................4.16

M20A PLC500 COMPONENT LIST: 240V .................................................................................................................4.17

M20A PLC500 COMPONENT LIST: 480V .................................................................................................................4.18

M20A PLC500 COMPONENT LIST: 575V .................................................................................................................4.19

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................ 4.20

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................ 4.22

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................ 4.24

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................ 4.26

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................ 4.28

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................ 4.30

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH OPTIONS ......................................................................4.32

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH OPTIONS ......................................................................4.34

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH OPTIONS ......................................................................4.36

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH OPTIONS ......................................................................4.38

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH OPTIONS ......................................................................4.40

M16/20 A 480V / 575V ELECTRICAL SCHEMATIC WITH OPTIONS ......................................................................4.42

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................. 4.44

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................. 4.46

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................. 4.48

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................. 4.50

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................. 4.52

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH NO OPTIONS................................................................. 4.54

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH OPTIONS .......................................................................4.56

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH OPTIONS .......................................................................4.58

TOC.2

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH OPTIONS .......................................................................4.60

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH OPTIONS .......................................................................4.62

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH OPTIONS .......................................................................4.64

M16/20 A 240V / 208V ELECTRICAL SCHEMATIC WITH OPTIONS .......................................................................4.66

M-16/20 A PLC 100, E200, 208/240V, WITH OPTIONS............................................................................................. 4.80

M-16/20 A PLC 100, E200, 208/240V, WITH OPTIONS............................................................................................. 4.82

M-16/20 A PLC 100, E200, 208/240V, WITH OPTIONS............................................................................................. 4.84

M-16/20 A PLC 100, E200, 208/240V, WITH OPTIONS............................................................................................. 4.86

M-16/20 A PLC 100, E200, 208/240V, WITH OPTIONS............................................................................................. 4.88

M-16/20 A PLC 100, E200, 208/240V, WITH OPTIONS............................................................................................. 4.90

M-16/20 A PLC 100, E200, 480/575V, WITH OPTIONS............................................................................................. 4.92

M-16/20 A PLC 100, E200, 480/575V, WITH OPTIONS............................................................................................. 4.94

M-16/20 A PLC 100, E200, 480/575V, WITH OPTIONS............................................................................................. 4.96

M-16/20 A PLC 100, E200, 480/575V, WITH OPTIONS............................................................................................. 4.98

M-16/20 A PLC 100, E200, 480/575V, WITH OPTIONS............................................................................................. 4.100

M-16/20 A PLC 100, E200, 480/575V, WITH OPTIONS............................................................................................. 4.102

SECTION 5, HYDRAULIC SYSTEM

M20 HYDRAULIC ASSEMBLY COMPONENT LIST.................................................................................................. 5.1

M16 HYDRAULIC ASSEMBLY COMPONENT LIST.................................................................................................. 5.2

M-16/20 HYDRAULIC PLUMBING DIAGRAM........................................................................................................... 5.4

M-16/20 HYDRAULIC SCHEMATIC ........................................................................................................................... 5.6

SECTION 6, MECHANICAL SYSTEM

BLADE BRUSH ASSEMBLY...................................................................................................................................... 6.1

GUIDE ARM ASSEMBLY............................................................................................................................................6.2

M-16 GUIDE ARM ASSEMBLY COMPONENT LIST .................................................................................................6.3

M-20 GUIDE ARM ASSEMBLY COMPONENT LIST .................................................................................................6.4

BLADE TENSION ASSEMBLY...................................................................................................................................6.5

BLADE TENSION ASSEMBLY COMPONENT LIST .................................................................................................6.6

PIVOT LINK ASSEMBLY............................................................................................................................................ 6.7

HYDRAULIC TANK ASSEMBLY ................................................................................................................................ 6.8

HYDRAULIC PUMP ASSEMBLY................................................................................................................................6.9

CONVEYOR ASSEMBLY ...........................................................................................................................................6.10

CONVEYOR ASSEMBLY COMPONENT LIST .......................................................................................................... 6.11

SHUTTLE VISE ASSEMBLY ...................................................................................................................................... 6.12

DATUM VISE JAW ASSEMBLY ................................................................................................................................. 6.13

ENCODER LENGTH CONTROL ASSEMBLY............................................................................................................6.14

ENCODER COVER ASSEMBLY ................................................................................................................................ 6.15

HYDRAULIC CHIP AUGER ASSEMBLY ................................................................................................................... 6.16

DOOR AND COVER ASSEMBLIES ........................................................................................................................... 6.17

DIRECT DRIVE ASSEMBLY.......................................................................................................................................6.18

GEARBOX ASSEMBLY.............................................................................................................................................. 6.20

SECTION 7, OPTIONAL EQUIPMENT

BUNDLING ASSEMBLY .............................................................................................................................................7.1

BUNDLING ASSEMBLY .............................................................................................................................................7.2

BUNDLING ASSEMBLY COMPONENT LIST............................................................................................................7.3

VERTICAL ROLLER ASSEMBLY .............................................................................................................................. 7.4

CUT LINE LASER SIGHT........................................................................................................................................... 7.6

OUTBOARD VISE ASSEMBLY OPTION ................................................................................................................... 7.7

MIST BLADE LUBRICATION SYSTEM .....................................................................................................................7.9

M16/20 A REMOTE CONSOLE .................................................................................................................................. 7.10

TOC.3

SECTION 8, SPECIFICATIONS

M-16 SPECIFICATIONS .............................................................................................................................................8.2

M20 LAYOUT .............................................................................................................................................................. 8.3

M16 LAYOUT .............................................................................................................................................................. 8.4

SECTION 9, WARRANTY

WARRANTY................................................................................................................................................................9.1

TOC.4

SECTION 0 - SAFETY INSTRUCTIONS

SUMMARY

All persons operating this machine must have read and understood all of the following sections of this Manual:

Section 0 SAFETY

Section 2 OPERATING INSTRUCTIONS

However, as a memory aid, the following is a summary of the Safety Section.

Put Safety First

Mandatory Information – What operators and maintenance people must have read and understood.

Signatures – Everyone involved with this machine must sign to conrm they have read and understood mandatory infor-

mation.

Basic Rules – only use this machine when

• it is in good working order

• all safety equipment is in place and functional

• operations are in compliance with this manual

• materials are within designed specications and are non-hazardous

Owner is responsible to

• keep Manual accessible at the machine

• ensure only reliable, fully trained personnel work with the machine

• clearly dene responsibilities of all personnel working with the machine

• keep the machine in good working order

Operator and Maintenance Personnel are responsible to:

• keep all safety equipment in order, check its function at the beginning of each shift, and report any shortcomings

• shut-down machine and report any faults or malfunctions which could impair safety

• understand and obey safety hazard labels

• not to wear un-restrained long hair, loose clothing or jewellery

• wear all required personal protective equipment

• not to wear gloves within 24 inches of moving blade

• maintain a clean working area and machine

• always use Lock-out when performing maintenance or repairs.

0.1

0.3

SECTION 0, SAFETY INSTRUCTIONS

FOREWORD

Put Safety First!

This Safety Section contains important information to help you work safely with your machine and describes the dangers

inherent in our machines. Some of these dangers are obvious, while others are less evident.

It really is important to PUT SAFETY FIRST. Make it a habit to consider the hazards associated with any action BEFORE

you do it. If you feel any uncertainty, stop and nd a safer approach to the action. If you’re still uncertain, ask for advice

from your supervisor.

The SAFETY FIRST approach is particularly necessary when you do something new, or different, and most people instinctively recognize this, although impatience may still cause them to take unnecessary risks.

Danger also lurks in the routine task that we have done over and over. Here, familiarity, boredom, or tiredness may lull us

into unthinking, automatic repetition. Be alert for this, and when you feel it happening, stop and take stock of your situation. Review the safety hazards associated with what you are doing. That should get your brain working again.

Certainly production is important, but if you think you’re too busy to put safety rst, think how much production you’ll lose if

you get hurt.

You owe it to yourself, your family, and your co-workers to PUT SAFETY FIRST.

Mandatory Information

All persons operating this machine must have read and understood all of the following sections of this Manual:

Section 0 SAFETY

Section 2 OPERATING INSTRUCTIONS

Personnel involved in installation and maintenance of the machine must have read and understood all sections of the

manual

Persons who have difculty reading, or for whom English is not their rst language, must receive particularly thorough

instruction.

0.2

Signatures

Everyone involved in operation of this machine must sign below to conrm that:

I have read and understood all parts of Section 0 – Safety, and Section 2 – Operating Instructions.

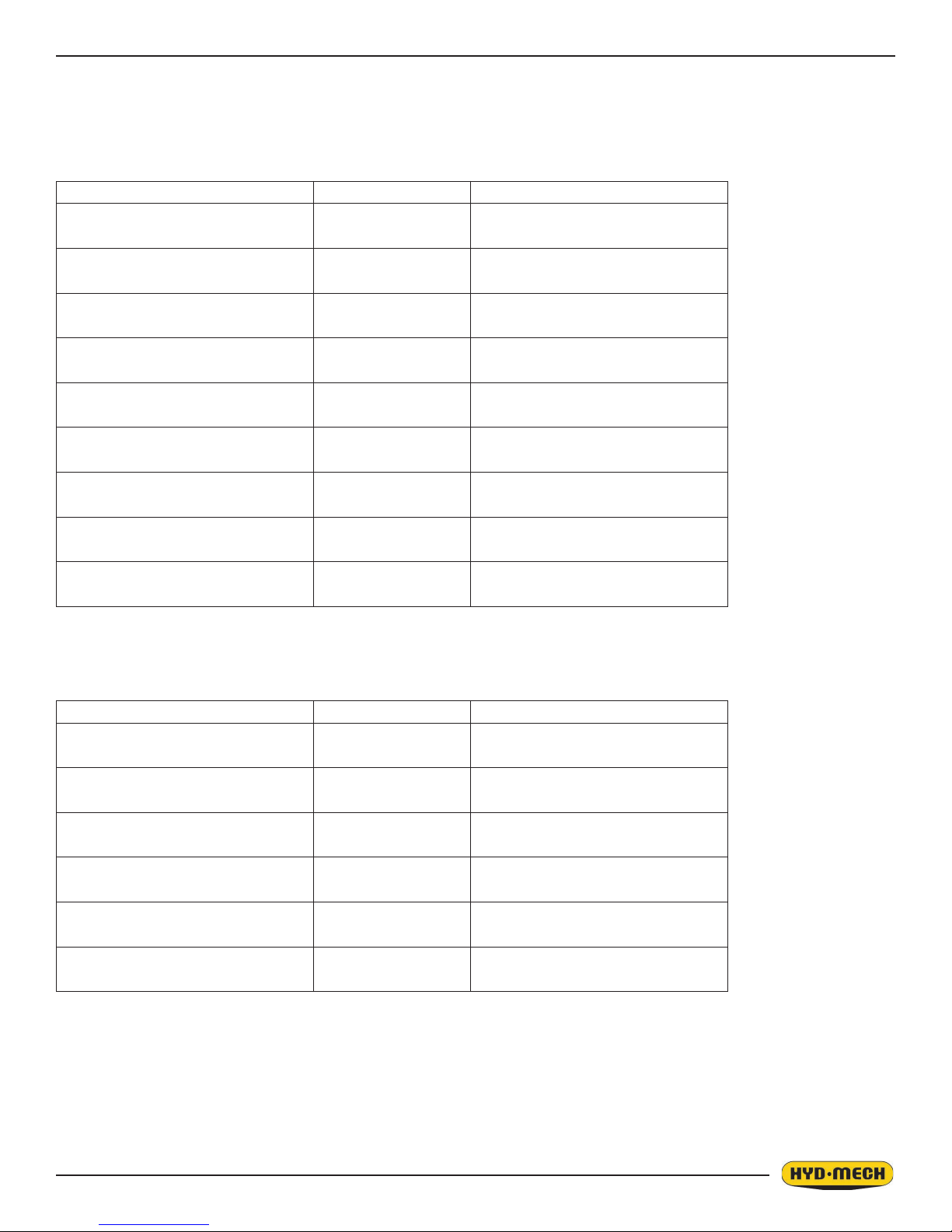

Name Date Signature

Everyone involved in the installation, inspection, maintenance, and repair of this machine must sign below to conrm that:

I have read and understood all parts of this Operation and Maintenance Manual.

Name Date Signature

BASIC RULES

Intended Use

Our machines are designed and built in line with the state of the art, and specically in accordance with

American National Standards Institute Standard B11.10 Safety Requirements for Metal Sawing Machines.

However, all machines may endanger the safety of their users and/or third parties, and be damaged,

or damage other property, if they are operated incorrectly, used beyond their specied capacity, or for

purposes other than those specied in this Manual.

0.3

0.5

Exclusion of Misuse

Misuse includes, for example:

Sawing hazardous materials such as magnesium or lead

Sawing work pieces which exceed the maximum workload appearing in the Specications

Operating the machine without all original safety equipment and guards

Liability

The machine may only be operated:

when it is in good working order, and

when the operator has read and understood the Safety and Operating Instructions Sections of the Manual, and

when all operations and procedures are in compliance with this Manual.

Hyd-Mech Group cannot accept any liability for personal injury or property damage due to operator errors

or non-compliance with the Safety and Operating Instructions contained in this Manual.

0.4

Responsibilities of the owner

Organization of work

This Operation and Maintenance Manual must always be kept near the machine so that it is accessible to

all concerned.

The general, statutory and other legal regulations on accident prevention and environmental protection

must also be observed, in addition to the Manual material. The operators and maintenance personnel

must be instructed accordingly. This obligation also includes the handling of dangerous substances and

the provision and use of personal protective equipment.

Choice and qualication of personnel

Ensure that work on the machine is only carried out by reliable persons who have been appropriately

trained for such work.

Training

Everyone working on or with the machine must be duly trained with regard to the correct use of the machine, the correct use of safety equipment, the foreseeable dangers that may arise during operation of the

machine, and the safety precautions to be taken.

In addition, the personnel must be instructed to check all safety devices at regular intervals.

Dene responsibilities

Clearly dene exactly who is responsible for operating, setting-up, servicing and repairing the machine.

Dene the responsibilities of the machine operator and authorize him to refuse any instructions by third

parties if they run contrary to the machine’s safety.

Persons being trained on the machine may only work on or with the machine under the constant supervision of an experienced operator. Observe the minimum age limits required by law.

0.5

0.7

Condition of Machine and Workplace

Ensure that the machine and its safety equipment is kept in good working order.

Ensure that the work area is well lit, and protected from the elements, such as rain, snow, abrasive dust,

and extremes of temperature.

Ensure that the machine is installed with sufcient clearance around it for the safe loading and unloading

of work pieces.

Responsibilities of the operator and maintenance personnel

Safety equipment

All machines are delivered with safety equipment that must not be removed or bypassed during operation.

The correction functioning of safety equipment on the machine must be checked:

• at the start of every shift.

• after maintenance and repair work

• when starting for the rst time, and after prolonged shutdowns

Emergency Stop Button ( E-Stops)

Always be aware of the location of the Emergency Stop Button(s). Do not allow material or objects to

block your access to an Emergency Stop.

Damage

If any changes capable of impairing safety are observed in the machine or its operation, such as damage,

malfunctions, or irregularities, then appropriate steps must be taken immediately, the machine switched

off, locked-out, and the fault reported to the responsible person.

Safe operation

The machine may only be operated when in good working order and when all protective equipment is in

place and operational.

Keep a safe distance from all moving parts – especially the blade and vises

Stock should not be loaded onto the saw if the blade is running

Long and heavy stock should always be properly supported in front of and behind the saw.

Never attempt to dislodge or move stock while the blade is moving. Take the time to stop the saw blade,

remove obstructions and restart the blade.

Faults

The machine must be switched off and locked-out before starting to remedy any faults.

Safety hazard labels

Safety hazard labels, and other instructional labels on the machine must be observed. They must be

clearly visible and legible at all times. If they become damaged they must be replaced.

0.6

Clothing, jewellery, protective equipment

Personnel operating or working on the machine must not wear un-restrained long hair, loosetting clothes and dangling jewellery.

When operating or working on the machine, always wear suitable, ofcially tested personal protective equipment such as safety glasses and safety boots and any other equipment required by

plant regulations.

Gloves

Experience has shown that careless use of gloves around machinery is a major factor in serious

hand injuries.

Gloves should not be worn when operating or adjusting the machine, except:

Wear protective gloves when handling bandsaw blades at blade changes.

Gloves may be worn when handling work pieces, only if the machine is in Manual Mode

and the bandsaw blade is not running.

If the machine is running in Auto Mode, and only if the cut parts are greater than 24

inches long, it may be possible to safely wear gloves for handling the cut parts, but the

wearer of the gloves must never put his hands near the blade for any reason. If the cut

parts are less than 24 inches long, it is required to arrange their automatic ow into a

parts bucket or other suitable arrangement to avoid the necessity to pick them off the

machine by hand.

Hearing protection

Workplace

A clear working area without any obstructions is essential for safe operation of the machine. The oor

must be level and clean, without any build-up of chips, off-cuts, coolant, or hydraulic oil.

The workplace must be well lit, and protected from the elements, such as rain, snow, abrasive dust, and

extremes of temperature

Nothing may ever be placed on, or leaned against the machine, with the obvious exception of the work

piece on the table and conveyor of the machine.

Ear protection must be worn whenever necessary.

The level and duration of noise emission requiring hearing protection depends upon the national

regulations in the country in which the machine is being used.

The actual level of noise emission by band sawing machines depends upon work piece size,

shape and material, blade type, blade speed and feed rate.

The only practical course of action is to measure the actual noise emission levels for the type of

work that typically done, and with reference to national standards, decide upon the necessary

hearing protection required.

In the absence of such measurements, it is advisable for anyone exposed to long periods of

moderate to loud noise to wear hearing protection. It is important to understand that hearing loss

is gradual and easily goes un-noticed until it is serious and irreversible.

Master Disconnect

Lock-out the machine before undertaking any maintenance or repair work on it. ‘Lock-out’ refers switching

off the master electrical disconnect switch, and locking it out so that it cannot be switched on again

without authorization.

0.7

On Hyd-Mech machines the Master Disconnect Switch will be of one of three types:

• Rotary switch mounted in electrical control cabinet door and inter-locked with door

• Lever switch mounted in separate box mounted on the machine

• Supply disconnect switch supplied by user at installation and usually wall-mounted within sight of

the machine, depending upon local regulations.

In almost all jurisdictions, it is required that owners of industrial equipment establish and post lock-out procedures. Know and use the lock-out procedures of your company or organization.

Residual Risks

The machine is still not completely de-energized if an electrical cabinet door type switch is

locked-out.

The line side of the disconnect switch itself remains energized.

Variable speed blade drives store dangerous voltage in their capacitors, and this requires time to

dissipate. After locking out power, wait 3 minutes before beginning to work on machine electrical

circuits.

If compressed air is supplied to the machine to power a mist lubrication system or other devices,

it should be disconnected, and any stored air pressure released before working on the machine.

The weight of individual machine components represents stored potential energy that can be

released if they fall when disconnected. Secure these components with adequate hoisting gear

before disassembly.

0.8

SECTION 1 INSTALLATION

Upon delivery of your new M-16/20 bandsaw, it is imperative that a thorough inspection be undertaken to check for any

damage that could have been sustained during shipping. Special attention should be paid to the electrical and hydraulic

systems to check for damaged cords, hoses and uid leaks. In the event of damage caused during shipping, contact your

carrier to le a damage claim.

• POWER HOOK-UPS AND REPAIRS SHOULD BE ATTEMPTED ONLY BY QUALIFIED TRADESPEOPLE.

• THE SAW SHOULD BE LOCATED IN AN AREA WITH SUFFICIENT ROOM TO SAFELY LOAD STOCK INTO

THE SAW. SECURE THE SAW TO THE FLOOR.

NO MODIFICATIONS TO THE MACHINE ARE PERMITTED WITHOUT PRIOR APPROVAL FROM HYD·MECH. ANY

APPROVED MODIFICATIONS SHOULD ONLY BE UNDERTAKEN BY TRAINED PERSONNEL.

LIFTING INSTRUCTION

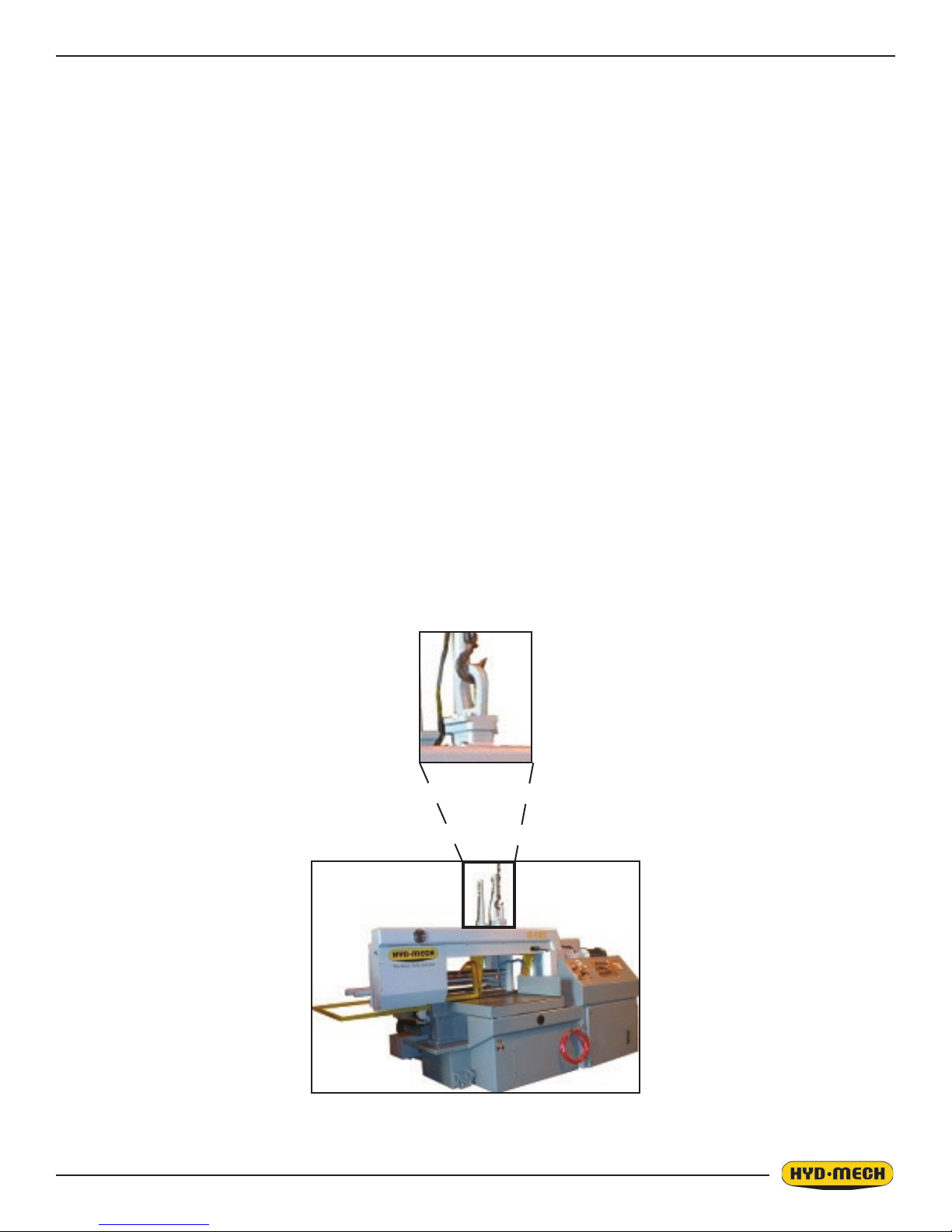

This machine is designed to be lifted in one, fully assembled piece. In order to lift the machine it needs to be in following

condition.

- Saw head in its bottom position at 90O.

- Shuttle vise fully forward.

- Coolant tank emptied.

There is a large lifting eye (shown below) at the top of the machine. The machine may be lifted with an overhead hoist and

chain, both being rated for 7400 lbs (3356 kg) for M-16A or 7700lbs (3465kg) for M-20A. For “P” models the weight is less,

6400lbs (2880kg) for M-16P and 6800lbs (3060kg) for M-20P.

Lifting hook

M-16A being lifted.

1.1

1.3

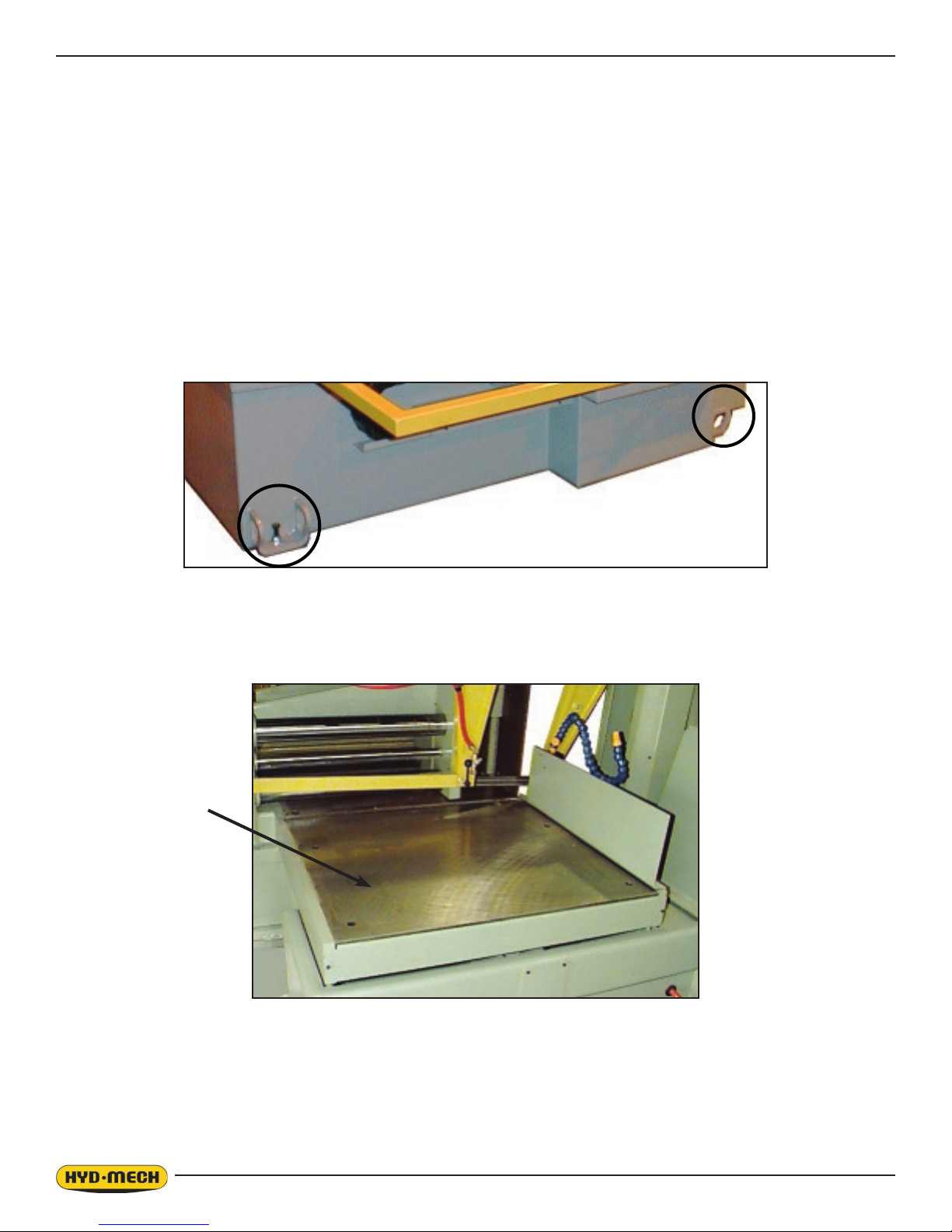

FOUNDATION, LEVELLING AND ANCHORING

Machine location should be carefully selected. A at concrete oor area should be chosen. It should have enough free

space surrounding the machine to enable free access for safe operation and maintenance.

The machine should be leveled in both directions, i.e. along and across its in-feed conveyor especially when machine is

to be inserted into a larger conveyor system. Four leveling screws are provided, one in each corner of the machine base.

Steel plates are to be placed under each screw to prevent their sinking into the concrete oor. In cases when the machine

is to be anchored permanently, anchoring holes are provided. They are located next to the leveling screws.

NOTE:

In some cases leveling the saw in-feed and auxiliary conveyors with a slight slope towards the blade is recommended.

This will prevent coolant from running down the raw stock. (This is especially true when cutting tubing or bundles).

Use Precision Level

on Outfeed Table in

both directions

2 leveling bolts at the idler side of the machine are shown.

Level saw from front to rear and from side to side

1.2

BLADE TENSION CHECK

When the machine is rst started, the head must be swung to the 45O position so the blade position

can be checked. Open the door at the idler end of the head and see that the blade has not moved off

of the wheel. Correct tracking of the blade would see the teeth overhang the rim of the wheel by .260”

to .300”. If it has stayed in its correct position, then turn the blade tension switch to the “+” and close

the door, if not, please refer to section 3 of the manual to correct this.

Blade tension

switch, behind

WIRING CONNECTIONS

After the machine is leveled and anchored the necessary power hook-up needs to be performed.

In order to provide a safe operation as well as to prevent potential damage to the machine, only qualied personnel

should be allowed to do the work.

The rst two areas that need to be checked are:

• There are no signs of shipping damage to electrical conduits, cords or hydraulic hoses.

• Hydraulic oil level is between the upper and lower lines on the level gauge.

During the initial hook-up it is very important to check that the phase order is correct. This is indicated by the hydraulic

pressure gauge registering a pressure rise and the blade running in a counterclockwise direction. If the hydraulics do not

register an immediate pressure rise,

the idler door.

- SHUT THE HYDRAULICS OFF -

and change the phase order. As supplied, the machine is set to run on the three phase voltage as indicated on the serial

plate and voltage label. Power connection to the machine is made to the main disconnect switch and the Ll, L2, L3 and

Ground terminals. The disconnect switch box is located on right side of the Operator Control Panel.

The Power Terminal Block is shown below. We also recommend that an earth ground be attached to the machine.

To gain access to the disconnect box, follow these steps:

1. Ensure the switch is in the OFF position and power is disconnected.

2. Push the lockout tab to the right and pull the door open.

To close the door properly, reverse the above steps.

1.3

1.5

ON/OFF SWITCH SHOW

IN “OFF” POSITION

L1 L2 L3

SAFETY LOCKOUT HOLE

GROUND

Disconnect Box

Main Power Connections

CUTTING FLUID

The M16/20 uses a pump and reservoir to circulate the necessary cutting uid to the blade for

maximum blade life. Your saw blade supplier will be able to provide information on the cutting

uid products that are available for your needs. No cutting uid (coolant) is supplied with the

machine. There are two types of coolant available:

- Oil based; dilute 1:10 ratio (one part concentrated coolant to 10 parts water)

- Synthetic; dilute as recommended by manufacturer.

Coolant wash down gun

on the front of the saw

HYDRAULIC OIL

As shipped, the saw oil tank is lled with Texaco Rando HD 46 hydraulic oil. If you want to change the hydraulic oil or the

brand of oil, see HYDRAULIC MAINTENANCE in Section 3.

Oil Level Gauge on the power pack door

1.4

Oil Filler Cap found inside power pack door.

HEAD HEIGHT CHECK

The head height is carefully checked at the factory prior to shipping and should not change, however there may be a possibility that either through lifting or when the machine is in transit, the position changes slightly. This should be checked at

the time of installation.

If adjustment is required, the blade should be 1/8” below the top surface of the infeed table.

Blade teeth 1/8” below the top

surface of the Infeed Table

Blade

Outfeed Table

Head Height Adjustment

1.5

SECTION 2, OPERATION INSTRUCTIONS

This section has been prepared to give the operator the ability to set up the saw for most cutting situations. The saw is

equipped with variable blade speed control and hydraulic feed control, as well as an extensive door chart to guide the

operator to the correct setting of these controls.

BLADE BASICS

Technology is rapidly changing all aspects of production machining. Metal cutoff is no exception. The advances made

in the bandsaw blade industry have denitely brought down the cost per cut, despite the three fold higher price of high

technology blades. Variable pitch, bi-metal blades (like the 4/6 or 3/4 bi-metal blade supplied with the M-16/20) last much

longer, cut faster, and more accurately than conventional carbon steel blades. In order to take advantage of the superiority

of bi-metal blades, it is critical to properly “break-in” a new blade. This is accomplished by taking two or three cuts through

solid four or ve inch diameter mild steel at an extremely slow feed rate. (It is also advisable to utilize a slow blade speed.)

These two or three slow cuts sufciently lap (polish) the new blade so that it does not snag the material being cut. Proper

break-in will alleviate blade vibration; improve surface nish, accuracy, and blade life.

After “break-in”, the following six points must be closely monitored to ensure long blade life:

1. Proper blade tension should be maintained. (See Section 3, Blade Changing)

2. Generous coolant application is essential with most materials. A high quality and well mixed coolant will extend

blade life, and also increase cutting rate and quality. On those materials where coolant is undesirable for cutting,

a slight coolant ow or periodic oiling of the blade is necessary to prevent the blade from being scored by the

carbide guides.

3. The stock being cut must be securely clamped in the vises.

4. The proper feed force should be chosen.

5. The proper blade speed must be selected.

6. The proper feed rate must be applied.

VARIABLE SPEED CONTROL

Blade speed can be adjusted innitely between 60 to 350 SFM (Surface Feet/Minute) (18 to 105 meters/min). The blade

speed is controlled with dial on the control panel.

Blade speed adjuster.

2.1

2.3

THE CONTROL CONSOLE

START-UP

The M-16A and M-20A control console has been designed to simplify the operation of the saw, to give the operator the

ability to stop any function at any time, and to be able to control all the functions remotely. We cannot overstress the importance of familiarizing yourself with the controls of the M-16A and M-20A prior to starting the machine.

NOTES:

1. ALL SWITCHES MUST BE IN THE CENTER NEUTRAL POSITION TO START THE MACHINE!

2. WHEN STARTING THE MACHINE FOR THE FIRST TIME MAKE SURE THAT BLADE IS MOVING IN A

COUNTERCLOCKWISE DIRECTION, AND THAT THE HYDRAULIC PRESSURE IS 900 PSI (6200kP). IF

THERE IS NO IMMEDIATE PRESSURE, SHUT THE SAW DOWN AND CHANGE THE PHASE ORDER AS

STATED IN SECTION 1 .

Operator Control Console TOP ROW

FRONT VISE - This switch has three positions, OPEN, HOLD and CLOSE. With the switch held in the

OPEN position the vise will open all the way or until the switch is released. With the switch

in the HOLD position, the vise will stay where it is and will not move freely although it will

not resist a large force indenitely without creeping. In CLOSE, the vise will close all the

way, or until it encounters enough resistance to stop it.

HEAD CONTROL - This switch has three positions: UP, HOLD and DOWN. The switch is inactive unless

the PLC is in manual mode. In the UP position, the head will rise until it trips the head

up limit switch. In the HOLD position the head will stay still. In the DOWN position the

head will descend until it reaches the head down limit switch. The speed of descent is

controlled by the Head Feed and Head Force Limit controls.

BLADE START - The blade can be started only when the hydraulics are running in either manual or auto

mode.

NOTE: In automatic Mode the head will not descend until the blade has been started, which the PLC will

prompt the operator to do so.

2.2

CENTER ROW

HYDRAULIC START - To start the hydraulic system, the switches for the head and both vises

must be in the “NEUTRAL” position. The “HYDRAULIC START” button

must be depressed and held in momentarily until the PLC display becomes active.

CYCLE START / PAUSE - This button starts the cutting cycles and will stay illuminated white until

the cycles are completed. The PLC control system will prompt you

to start the blade if it is not running. The machine will then begin the

automatic cycle until completed when it will shut itself off. The current

cycle can be PAUSED by pressing this button at any time during a

cycle and restarted by pressing it again.

COOLANT - This switch has three positions, ON, OFF, and AUTO. In the ON position, the coolant

system will operate when there is power to the machine, this allows using the wash

gun to clean the machine. In the OFF position, the coolant system is inactive. In the

AUTO position the coolant system will only run when the head is descending. This

minimizes coolant carry over on the stock.

SHUTTLE VISE - This switch has three positions, OPEN, HOLD and CLOSE. With the switch

held in the OPEN position the vise will open all the way or until the switch

is released. With the switch in the HOLD position, the vise will stay where it

is and will not move freely although it will not resist a large force indenitely

without creeping. In CLOSE, the vise will close all the way, or until it encounters

enough resistance to stop it.

EMERGENCY

BOTTOM ROW

BLADE SPEED - This dial will increase or decrease the speed at any time while the blade is run-

ning.

BLADE STOP BUTTON - Stops the blade. If the blade is stopped during a cycle, the cycle will

continue but will not let the head descend until the blade is started.

STOP - This mushroom button stops the blade and hydraulic motors. Both vises will hold their po-

sition but, pressure will begin to fall off. Long pieces of work should always be supported

so they will not become loose over time and fall while the machine is shut down.

AUXILLARY VISE - This switch has three positions, OPEN, HOLD and CLOSE. With the switch

held in the OPEN position the vise will open all the way or until the switch

is released. With the switch in the HOLD position, the vise will stay where it

is and will not move freely although it will not resist a large force indenitely

without creeping. In CLOSE, the vise will close all the way, or until it encounters enough resistance to stop it.

2.3

2.5

GUIDE ARM - This switch controls the position of the idler (left) guide arm.

WORK LAMP - This switch has two positions, OFF and ON.

LASER GUIDE - This option switch has two positions, OFF and ON.

PANEL SWITCHES SPECIFIC TO PLC 100, E200 INTERFACE

HEAD SWING 90°

This is a two position push button. By pressing the button in partially, the head will slowly swing

towards the 90° position until it reaches 90° or the button is released. This allows for a ne adjustment in the cut angle, If pressed fully in, the head will swing at a fast rate

Note:

The head control switch must be in the “HOLD” position for this button to operate.

HEAD SWING 30°

This is a two position push button. By pressing the button in partially, the head will slowly swing

towards the 30° position until it reaches 30° or the button is released. This allows for a nd adjustment in the cut angle. If pressed fully in, the head will swing at a fast rate.

Note:

The head control switch must be in the “HOLD” position for this button to operate.

2.4

CONTROL SYSTEM, MITSUBISHI PLC 500

OPERATION OVERVIEW

The PLC is a programmable logic controller which allows the operator to run the machine in both manual and automatic

modes.

In manual mode, all functions can be operated by using a combination of selector switches on the control console and

the PLC function buttons. Also the operator has the ability to execute a single cut utilizing a preprogrammed “ONE CUT

MODE”.

In automatic mode, the PLC has the capacity to program and store 99 jobs. Designated job numbers can be programmed

for quantity required (maximum of 999 pieces). Piece lengths from 0.1” to 220” (5588mm) and cut angles from 900 through

to 300. Jobs can be run individually or in a QUEUE which allows a maximum of 5 jobs to run consecutively.

NOTE: If an emergency situation arises during any operation, use the large red mushroom “emergency stop” button

located on the control panel to shut down the machine.

2.5

2.7

PLC CONTROL DESCRIPTION

ACTIVATING THE PLC

The PLC control will become active when all selector switches are in the neutral position and the HYDRAULIC START

button is depressed and “held in” momentarily. If the head is not in the 900 position, the display will prompt you to “SWING

THE HEAD TO 90 DEGREES”, press and hold the 900 key until the display returns to “MANUAL MODE”. When the head

is at 900, the AUTO/MAN indicator light will be green, all MANUAL controls as described previously are enabled, and the

“MANUAL MODE STATUS” screen will appear as shown below. The PLC controls are described on the following pages.

The length value (shuttle vise position) will display the previous positions. To reset or clear the length value, press the F8

key.

PLC 500 CONTROL PANEL

All key functions are explained in detail on the following pages.

2.6

FUNCTION BUTTON DESCRIPTION

On the dual function buttons, if a green indicator light is illuminated, it means that the function printed in green on the top

of the button is enabled. A red light indicates the function printed in red at the bottom of that button is enabled.

•

•

•

•

AUTO

MAN

FWD

REV

90

MANUAL MODE (Green light)

Enables all control switches and PLC function buttons. Also stops an automatic job in

progress by switching to MANUAL.

AUTO MODE (Red light)

Puts the machine in AUTO MODE and disables all manual functions. The front vise selector switch must be in the closed position.

MANUAL MODE

This key will advance the shuttle toward the head (home position).

AUTO MODE

Key is disabled.

MANUAL MODE

This key will retract the shuttle away from the head.

AUTO MODE

Key is disabled.

MANUAL MODE

This key will swing the head toward 90 degrees.

•

•

•

30

SLOW

FAST

INCH

METRIC

AUTO MODE

Key is disabled.

MANUAL MODE

This key will swing the head toward 30 degrees.

AUTO MODE

Key is disabled.

MANUAL MODE

Green light indicates that the shuttle movement and head swing will move at a slow

speed.

Red light indicates that the same movements will be at a fast speed.

AUTO MODE

Key is disabled.

MANUAL MODE/AUTO MODE

Green light indicates Imperial values.

Red light indicates Metric values.

2.7

2.9

F5

•

AUTO MODE

Energizes CYCLE START button.

MANUAL MODE

No function

F6

•

F16

•

F7

•

F8

•

MANUAL MODE

After entering an angle value, pressing F2 will cause the screen to read “TO INTIATE

MOVEMENT TO XX.X DEGREES PRESS CYCLE START”. Upon pressing “CYCLE

START” the head will swing to the programmed angle.

AUTO MODE

Used to scroll up through job information.

MANUAL MODE

Used for accessing the PARAMETERS screen which will then require a pass word before

entering the parameters.

MANUAL MODE

Used for accessing the KERF screen. The KERF screen cannot be accessed while in

METRIC mode and any change made to the KERF value will not be accepted by the controller until it has been shut down and restarted. (The standard kerf values are .066 for 1

1/4” blade & .074 for 1 1/2” blade at 90O.)

AUTO MODE

Used to scroll down through job information.

MANUAL MODE

Used to clear the length display (shuttle vise position) value.

AUTO MODE

Used to CLEAR the jobs from the queue or job values for whichever job the cursor is at.

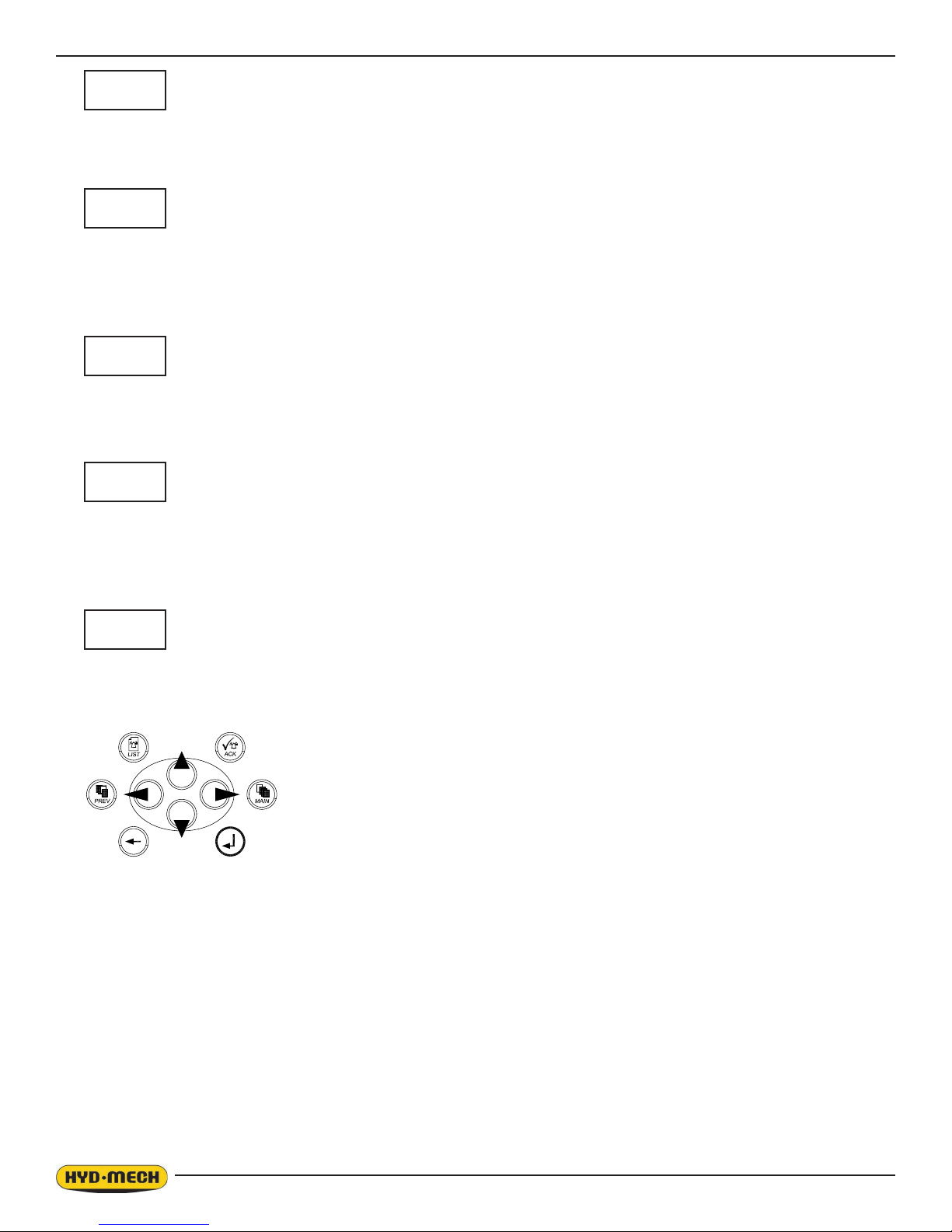

CURSOR KEY PAD

The cursor keys are used to navigate the cursor box on the screen. If the display

has columns, only the UP and DOWN keys are activated. If the display has both

rows and columns, then all four cursor keys are activated.

2.8

ONE CUT MODE

In MAN mode, switching the front vise to closed position changes the PLC to “One Cut Mode “ to cut one piece at a desired length. To accomplish this, follow the procedure below.

1. In “MAN MODE” position the head for the required angle by using the 900 or 300 function keys. You can also

accomplish this by moving the cursor to the “Angle Go” feature, input desired angle, press ENTER. Then press

F6. The screen will display “ TO INITIATE ANGLE MOVEMENT TO __.__ DEGREES PRESS CYCLE START”.

Press CYCLE START and the head will travel to the displayed angle.

2. A trim cut should be made in “MAN MODE” before initiating the “ONE CUT MODE” operation. This will ensure a

clean inital cut and that the head is above the material height so no damage is caused when the shuttle moves

the material forward.

As the head up limit switch must be tripped in order for the cycle to continue, set the head height using this procedure;

a) Raise the head up limit switch (located behind the console).

b) Move the head with the HEAD switch so the blade is just above the material.

c) Loosen the grip knob on the limit switch block, move the block so the trip plate is almost touching the

limit switch roller and tighten the grip knob.

d) Turn the head switch to “UP”. When the head trips the limit switch, the head will stop.

3. To enable the “ONE CUT MODE”, turn the front vise switch to the CLOSED position.

4. To the left of the F5 button, the display will be ashing. Move the cursor to the rectangular box

and key in the desired length using the numeric key pad and press “ENTER”.

5. If the blade is not running, “BLADE” will be ashing beside the length value, press the “BLADE START” button.

Adjust the blade speed as required, then press the “CYCLE START / PAUSE” button to continue the cycle. When

the “CYCLE START” button is pressed, the shuttle vise will move to the forward home position before executing

the length movement.

6. When the cut is completed, the head will retract, the blade will stop and the display will reset for the next cut.

7. To make another cut, repeat steps 5 through step 6.

NOTE: To cut multiple pieces, load and position the material and head up limit for a trim cut and follow the automatic

procedures on the following pages.

2.9

2.11

AUTOMATIC OPERATION

To enter AUTO MODE, the front vise switch must be in the closed position. When the AUTO/MAN button is pressed, the

red indicator above it will come on, the screen will change to the PICK LIST display as shown on the following page and

be ready for editing or starting a new job. The VISE and HEAD switches on the control panel will be disabled.

PROCEDURE FOR EDITING OR STARTING A NEW JOB IN AUTO MODE

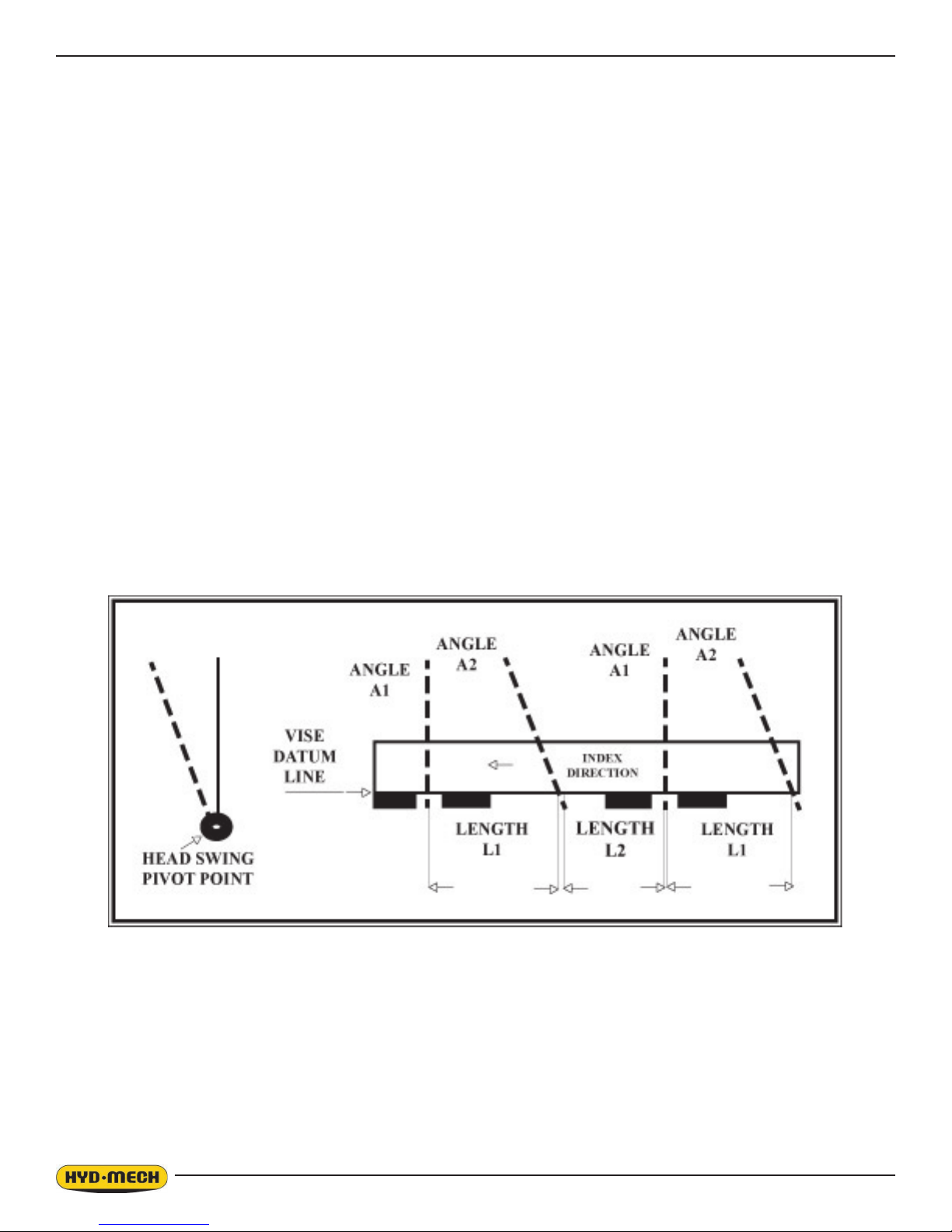

Each job is dened by two angles and two lengths. Angle 1 (A1) is the rst angle to be cut (this will be the trim cut). Length

1 (L1) is the length of the material to be cut as measured between the two intersection points of the blade axis and the

saw table datum line. Angle 2 (A2) is the second angle to be cut and length 2 (L2) again is the length of material as measured between the two intersection points of the blade axis and the vise datum line.

2.10

PICK LIST SCREEN

Before switching to AUTO MODE, position both the material for a trim cut as well as the head up limit switch so that no

damage is caused by the shuttle moving the material into the blade (see “ONE CUT MODE”).

1. Immediately after entering the AUTO mode, the PICK LIST screen will be displayed with the cursor located at “A1

of JOB #1”. Both the ENTER button or the cursor key can be used to move through this screen.

2. Enter proper “A1” value (compensate if 90.50 stops are used), press ENTER and the cursor will move to “L1”

3. Enter correct value, press ENTER and the cursor will move to “A2”.

4. Enter proper “A2” (compensate if 90.50 stops are used)value, press ENTER and the cursor will move to “L2”

5. Enter correct value, press ENTER and the cursor will move to “QTY REQ’D”.

6. Enter required quantity. The cursor will move to “QTY CUT”

7. When starting a NEW JOB or PIECE COUNT, zero out “QTY CUT” by entering “0”.

Assuming that the material is positioned for a trim cut, the job is now ready to start (up to ve jobs can be in the queue) or

jobs can be programmed at this time. A job or queue can be deleted by pressing F8. The desired job or queue must be

selected using the cursor key in order for the item to be deleted. Move the cursor to the 1st JOB and key in the desired

JOB # and ENTER then press F5 “INIT (initiate) CYCLE”. You will then be prompted to enter “MATERIAL WIDTH” and

press ENTER. The display will then read “PRESS CYCLE START TO INITIATE JOB QUEUE”.

If the blade is not running, the cycle will not continue. Press the BLADE START button and the cycle will begin.

When the last cut has been made, the machine will shut down.

When the AUTO cycle commences, the screen will change to the “AUTO MODE STATUS” screen and the following

events will take place:

1. If the head has not tripped the head up limit switch, the cycle will stop when the head should descend. In this

case, the machine should be switched to MAN MODE and the head height should be set as described on pg. 2.9

or by raising the head until the limt switch is tripped.

2. The head will swing to “A1” to perform the rst cut (trim cut).

3. After the trim cut, the shuttle will advance the material to the “L1” value.

4. The head will swing to the “A2” value to make the second cut and complete the rst part.

5. The shuttle vise will advance to the “L2” value after the “A2” cut is done.

At completion of the “JOB”, the machine will shut off.

2.11

2.13

NOTES:

1. The CYCLE START button is used to PAUSE a job in progress. When a job is PAUSED the PICK LIST will appear

and the operator can make eventual alterations to the job values which will take place on the next piece to be cut

or to edit a new job. To resume a job, press the CYCLE START key and the screen will change back to the AUTO

MODE STATUS screen and the AUTO CYCLE will resume.

2. If “QTY RQ’D” equals or exceeds “QTY CUT”, the AUTO CYCLE will not start.

WORKING WITH A QUEUE

The purpose of a QUEUE is to allow the operator to run several jobs (max of 5) in series if they are of like material. To

run a QUEUE, it is necessary to program in all job values as is done with programming a single job. After the jobs are

programmed in, scroll the cursor to the QUEUE, press F8 to clear the QUEUE and enter the desired JOB #’s in desired

sequence. To run the QUEUE, press F4, CYCLE START and start the blade.

The AUTO MODE STATUS screen will appear and display each individual JOB as it is being run. The STOP and PAUSE

functions are as above and at completion of the last JOB in the QUEUE, the machine will shut off. The machine will automatically advance the stock between jobs for trim cuts as needed.

2.12

PLC CONTROL SYSTEM E200

NOTE: This instruction manual is applicable to the M-16A and M-20A equipped with a MITSUBISHI PLC manufactured

after and including the following serial numbers:

Machine Model Serial #

M-16A S0801197

M-20A T0801245 + T0801250, T0801252

OPERATION OVERVIEW

The PLC is a programmable logic controller, which allows the operator to run the

machine in both manual and automatic modes.

In manual mode, all functions can be operated by using a combination of selector switches on the control console and the PLC function buttons. Also the operator has the ability to execute a single cut utilizing a pre programmed “Single

Part Cycle”.

In automatic mode, the PLC has the capacity to program and store 99 jobs. Designated job numbers can be programmed for quantity required (maximum of 999

pieces) and lengths from 0” to 220” (5588mm).

Jobs can be run individually or in a QUEUE which allows a maximum of 5 jobs

E200 operator interface.

to run consecutively and the queue can be repeated automatically as well.

All machine operators should be familiar with the entire operation instructions prior to operating the machine.

NOTE: If an emergency situation arises during any operation, use the large red mushroom “STOP” button located on the

control panel to shut down the machine. To operate the machine, the “STOP” button must be pulled out.

DISPLAY WINDOW

BLADE SPEED

(SFM) IN SURFACE

FEET (METERS)

PER MINUTE and

SHUTTLE VISE (LTH)

POSITION

PLC FUNCTION

KEYS

NUMERIC KEY PAD

CURSOR KEYS

ENTER KEY

2.13

2.15

ACTIVATING THE INTERFACE

Position the head, xed vise, and shuttle vise switches to the NEUTRAL (center) positions. If any of these switches are

not in the NEUTRAL position, the hydraulics will not start. The PLC control will become active when the HYDRAULIC

START button is depressed and “held in” momentarily. First, the HMI and PLC’s current revision number, 2100 1.0, will

be shown on the display window and nally the MANUAL MODE display window will appear as shown below. The AUTO/

MAN green indicator light will be on and all MANUAL controls are enabled. The “LTH” value (shuttle vise position) will

always display zero at start up. The “LTH” value can be reset or cleared at any time in MANUAL mode by pressing the

CLEAR function button.

FUNCTION KEY DESCRIPTIONS

If a red indicator light above a function button is illuminated, it means that the function printed in red at the top of the button is enabled. No light indicates the function printed in black at the bottom of the function button is enabled.

The following are the function keys for AUTO and MAN modes:

AUTO / MAN MODE

- This key will toggle between MAN and AUTO modes. Auto mode cannot be accessed unless the front vise is

closed.

- Also used to stop an automatic job in progress by switching to MANUAL mode.

UNLABELED

- The function of theses keys is displayed directly above them. The function will change as the PLC is

switched from one mode to another and as the action of each mode changes.

INCH/MM / CLEAR

- While depressed momentarily, it resets the displayed length value to zero. If held depressed for a few seconds, the displayed length will toggle between millimeters and inches and the blade speed in either surface

feet per minute or meters per minute. It becomes disabled once any cycle is initiated.

MANUAL MODE FUNCTION KEY DESCRIPTIONS

While in manual mode, the display will show the current function of the unlabeled key. They are shown below.

FWD : FORWARD - This key will advance

the shuttle vise toward the head (home

position). If pressed simultaneously with

the REV key, (the front vise must be

closed and a password is required) the

parameters will be displayed.

S/F : SLOW / FAST - This key will toggle

between slow and fast shuttle speed.

REV : REVERSE - This key will retract

the shuttle vise away from the head

(home position). If pressed simultaneously with the FWD key, (the front vise

must be closed and a password is required) the parameters will be displayed.

2.14

SINGLE PART CYCLE OPERATION

In MAN mode, the PLC allows the operator to initiate a “Single Part Cycle “ to cut one piece at a desired length. To accomplish this, follow the procedure below.

1. A trim cut should be made before initiating the “Single Part Cycle “ operation.

2. Make sure the front vise switch is in the closed position and set the head up limit switch. The AUTO/MAN indicator

light will ash alternately green and red.

3. Make sure the head is set so that the blade is above the material and the head selector switch is in the HOLD

position.

4. The cursor will be ashing at the LENGTH position. Key in the desired value from 0” to 220” and press. If the

value is incorrect, re-enter the value and press again.

BLADE SPEED

LENGTH

5. If the blade is not running, you will be prompted by the word “BLADE” ashing on the display window. Start the

FLASHING

blade and adjust the blade speed as required.

6. When the blade is started, the word “BLADE” will change to the word “CYCLE” ashing on the display window to

begin the cut. Press CYCLE START and the cycle will begin.

7. When the start button is pressed, the shuttle vise will move to the forward home position before executing the

length movement. The head will descend and make the cut.

8. When the cut is completed, the head will rise to the head up limit switch, the blade will stop and the display window will reset for the next cut.

9. To cut another piece, repeat steps 2 through 6.

NOTES:

1. To “PAUSE” the “SINGLE CUT CYCLE”, press the “CYCLE START” button. The “CYCLE START” button will begin to ash and the screen will indicate a paused condition. All movements will immediately cease. To continue the

cycle, press “CYCLE START” button again.

2. To cut multiple pieces, switch to AUTO MODE and follow the automatic procedures.

AUTOMATIC OPERATION

When the AUTO/MAN button is pressed, the red indicator light above it will come on, and the blade will stop if it has been

running. The screen will change to the JOB display window as shown below and be ready for editing or starting a new job.

All manual functions will be disabled.

2.15

2.17

JOB DISPLAY WINDOW

Job Number

Length

Required Quantity

Cut Quantity

PROCEDURE FOR EDITING OR STARTING A NEW JOB IN AUTO MODE

1. In AUTO mode, key in a job number from 0 to 99 and press If the job number has previously been programmed, the REQUIRED QUANTITY (RQ), LENGTH (LTH) and QUANTITY (CT) will be displayed. The values

displayed can be edited by pressing ENTER after each new value, and the job will be stored in memory with the

new values. To navigate through the values, use the CURSOR keys.

2. After the values are entered, press the CYCLE START button, the switch will illuminate, the display window will

prompt you to start the blade for a trim cut (if the “Trim Cut” parameter has been selected).

3. CAUTION; if the head is in it’s full down position it will rise to the head up limit so that no damage to the blade will

occur.

4. After starting the blade, the head will descend for the cut and the machine will complete the required job.

JOB IN PROGRESS

5. At the completion of the job, the machine will shut down if “0” has been entered in the “POWER DWN TIMER”

parameter or continue running for the specied time up to a maximum of 180 minutes.

NOTES:

1. The “CT” value is the accumulated total number of parts that have been cut from the JOB number since it was last

reset. The machine will only cut the quantity, which is the difference between REQUIRED QUANTITY and CUT

QUANTITY. When REQUIRED QUANTITY equals CUT QUANTITY, the machine AUTO CYCLE will stop and you

will be unable to restart the same job until the “CUT QUANTITY” value has been reset.

2. The AUTO cycle may exit and stopped at any time by pressing the key.

2.16

NOTE: Before entering “AUTO MODE” and working with a “QUEUE”, follow the same procedures outlined on the previous

page for “AUTOMATIC OPERATION” with regards to setting up for an initial trim cut.

WORKING WITH A QUEUE

The purpose of a QUEUE is to allow the operator to run several jobs (max of 5) in series if

they are of the same material and shape.

In AUTO mode, press the key below the word “QUE” on the display and the dis-

First Job

Programmed

Job Number

Quantity

To Cut

Length

To Cut

play window will appear as shown.

If you choose to VIEW the QUEUE, press the key below the words “VIEW QUE” on

the display. The display window will show the jobs in the current QUEUE. Four jobs at a

time are shown.

Use the CURSOR buttons to view all the jobs. To run the QUEUE as it is displayed (jobs may be edited in this mode),

press the CYCLE START button on the control panel. The screen will now prompt you to start the blade for a trim cut.

If you choose to edit the QUEUE, press the key below the words “CLEAR QUE” on the display. This will clear any

jobs that are in the QUEUE and the display window will show an empty Queue. Jobs may be entered and edited in this

mode.

To ll the QUEUE, follow these two steps.

1. Key in a job number and press ENTER. If that job number has previously been programmed, its values will be

displayed. The cursor will move to the next position in the QUEUE. Up to ve jobs may be in the QUEUE at any

time. The job values can be edited in this mode.

2. When the desired jobs have been entered, you may press the CYCLE START button on the control panel to execute the jobs in the QUEUE. (Follow the same procedures to initiate a cycle as in “AUTOMATIC OPERATION”)

The QUEUE may be exited to the previous screen at any time by pressing the key under JOB.

At completion of the “QUEUE”, the machine will shut down if “0” has been entered in the “POWER DWN TIMER” parameter or continue running for the specied time up to a maximum of 180 minutes.

NOTE: For angled cuts, see “Kerf Correction” on the following page.

2.17

2.19

KERF CORRECTION for ANGLE CUTTING

When making mitered cuts and depending on the accuracy of the part length required, the part length must be set longer than the desired length by an amount called the “KERF CORRECTION”. This is due to the fact that the PLC will not

account for a difference in the kerf value (width of material removed by the blade) at various angles other than 90O. If the

kerf value is to be adjusted it’s value can be accessed while in Auto Mode. Press and hold the key below the word

“KERF” on the display until the display appears as shown. Enter the desired kerf value and press When the cuts

are to be at 90O, the Kerf value must be returned to the appropriate value for accurate cuts.

Returns

to Auto

Mode.

Returns

to the

Queue.

IMPERIAL

STANDARD KERF @ XX DEGREES

BLADE SIZE 90 75 60 55 50 45 40 35 30

1 1/4” 0.066 0.068 0.076 0.081 0.086 0.093 0.103 0.115 0.132

1 1/2” 0.074 0.077 0.085 0.09 0.097 0.105 0.115 0.139 0.148

METRIC

STANDARD KERF @ XX DEGREES

BLADE SIZE 90 75 60 55 50 45 40 35 30

31.7MM 1.67 1.72 1.93 2.05 2.18 2.36 2.61 2.91 3.35

38.1MM 1.87 1.95 2.16 2.28 2.46 2.66 2.92 3.53 3.76

2.18

HYDRAULIC FEED CONTROL

The Hydraulic Feed Control is located to the left of the control panel. These controls allow control of Feed Force Limit and

Feed Rate.

Feed Force Knob

Used to set Feed Force Limit (counterclockwise rotation to

increase and clockwise rotation to decrease).

Fast Approach Lever

Depress for fast head descent.

Feed Rate Knob

Used to set Feed Rate (counterclockwise rotation to increase

and clockwise rotation to decrease).

Hydraulic Feed Control

CUTTING PARAMETERS CHART

A full size CUTTING PARAMETERS CHART is mounted on the front of the saw. The chart contains ve steps for the

operator to follow in order to achieve optimum performance of the saw.

Saw Cutting Parameters Chart

2.19

2.21

CHART EXAMPLE #1

We will use the parameters chart to set up the saw for cutting 8” (200mm) Diameter #1045 Carbon Steel.

STEP 1, DETERMINE EFFECTIVE MATERIAL WIDTH - W (inches) or (mm)

Effective material width, W (in.) for most common shapes of materials, is the widest solid part of the material to be in contact with blade during cutting. For simple

shapes, as illustrated on the chart, this can be directly measured. For bundles of

tubes and structurals, measuring the effective width is difcult. Effective width is 60%

to 75% of the actual material width.

NOTES: