Page 1

SMU 1000

SensorMonitoring Unit

Operating Manual

Valid from firmware versions 3.40 up

English (translation of original instructions)

Documentation no.: 3614430a

Page 2

SMU1000 Imprint

Imprint

Publisher and responsible for the content:

HYDAC FILTER SYSTEMS GMBH

Postfach 1251

66273 Sulzbach / Saarland

Germany

Telephone: +49 (0)6897 509 01

Telefax: +49 (0)6897 509 846

E-mail: filtersystems@hydac.com

Homepage: www.hydac.com

Court of Registration: Saarbrücken, HRB 17216

Executive director: Mathias Dieter,

Dipl.Kfm. Wolfgang Haering

Documentation Representative

Mr. Günter Harge

c/o HYDAC International GmbH, Industriegebiet, 66280 Sulzbach / Saar

Telephone: ++49 (0)6897 509 1511

Telefax: ++49 (0)6897 509 1394

E-mail: guenter.harge@hydac.com

© HYDAC FILTER SYSTEMS GMBH

All rights reserved. No part of this work may be reproduced in any form (print,

photocopy or by other means) or processed, duplicated or distributed using

electronic systems without the written consent of the publisher.

These documents have been created and inspected with the greatest care.

However, errors cannot be ruled out completely.

All details are subject to technical modifications. Technical specifications are subject

to change without notice.

The trademarks of other companies are exclusively used for the products of those

companies.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 2 / 48

Page 3

SMU1000 Content

Content

Imprint .......................................................................................................................2

Documentation Representative...............................................................................2

Content......................................................................................................................3

Preface ......................................................................................................................5

Technical Support...................................................................................................6

Modifications to the Product ...................................................................................6

Warranty .................................................................................................................6

Using the Documentation .......................................................................................7

General Safety Precautions..................................................................................... 8

Obligations and Liability..........................................................................................8

Explanation of Symbols and Warnings, etc. ........................................................... 9

Proper/Designated Use ..........................................................................................9

Improper Use ........................................................................................................ 10

Informal Safety Precautions.................................................................................. 10

Training and Instruction of Personnel ................................................................... 10

Packing, Storage .................................................................................................... 11

Transportation and Packing..................................................................................11

Storage .................................................................................................................11

Scope of Delivery ...................................................................................................11

SMU Features .........................................................................................................12

Installation ..............................................................................................................13

SMU Dimensions and Drilling Template............................................................... 14

Connecting the SMU ..............................................................................................15

Connecting cable SMU <-> sensor .......................................................................16

Power supply -> SMU ........................................................................................... 17

Connection cable AS2000 -> SMU ....................................................................... 17

Connection cable AS8000 -> SMU ....................................................................... 18

Connection cable CS2000 -> SMU.......................................................................18

Operating the SMU ................................................................................................. 19

Keypad.................................................................................................................. 19

Selecting menus and entering values...................................................................19

Selecting main and system menus....................................................................... 20

Status display .......................................................................................................20

Main menu without password protection ..............................................................21

Main menu with password protection ...................................................................21

System Menu........................................................................................................22

SMU setup...............................................................................................................24

Password protection .............................................................................................24

Password setup ....................................................................................................24

Select the scope of the password.........................................................................25

Activating the password........................................................................................25

Access with password protection.......................................................................... 26

Changing the password and range.......................................................................26

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 3 / 48

Page 4

SMU1000 Content

Password, delete ..................................................................................................27

Changing the menu language............................................................................... 28

Setting the date and time......................................................................................28

Startup behavior ...................................................................................................29

Setting the LCD contrast and backlighting............................................................ 30

Resetting ................................................................................................................. 31

Reset warm........................................................................................................... 31

Reset cold.............................................................................................................31

Reset original........................................................................................................31

Resetting to the factory settings (factoryset).........................................................31

Factory setting........................................................................................................ 32

Software Update ..................................................................................................... 32

Checking sensor settings (CS1000 / CS2000) .....................................................32

Functions / Menu guide .........................................................................................33

CS 1000 Menu......................................................................................................33

Sensor status CS1000 ......................................................................................34

CS 2000 Menu......................................................................................................34

AS1000 menu ....................................................................................................... 34

AS2000 menu ....................................................................................................... 34

AS8000 menu ....................................................................................................... 34

HLB1000 (HYDACLab).........................................................................................35

Sensor status HLB1000: ...................................................................................35

VLxGW (clogging indicator) .................................................................................. 35

Menus MCS1000 .................................................................................................. 35

Service menu........................................................................................................36

Data logging ...................................................................................................... 37

Data logging status........................................................................................37

Devices .............................................................................................................37

Status CS1000 / HLB.....................................................................................37

Status CS2000 / MCS1000............................................................................ 37

Status AS1000 / AS2000 / AS8000 / VLxGW................................................38

Display Information................................................................................................38

Changeover display mode automatic /manual...................................................... 38

Data format data logger+ ....................................................................................... 39

OPC Variables / OPC Server.................................................................................. 41

Setting up OPC server ...........................................................................................44

Setting - Server.....................................................................................................44

Setting - PLC ........................................................................................................44

Setting connection ................................................................................................44

Disposing of the SMU ............................................................................................45

Customer Service...................................................................................................45

Model Code ............................................................................................................. 46

Measurement sensors combination......................................................................46

Technical Data ........................................................................................................ 47

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 4 / 48

Page 5

SMU1000 Preface

Preface

For you, as the owner of a product manufactured by us, we have produced this

manual, comprising the most important instructions for its operation and

maintenance.

It will acquaint you with the product and assist you in using it as intended in an

optimal manner.

Keep it in the vicinity of the product so it is always available.

Note that the information on the unit's engineering contained in the documentation

was that available at the time of publication.There may be deviations in technical

details, figures, and dimensions as a result.

If you discover errors while reading the documentation or have additional comments

or suggestions, contact us at:

HYDAC FILTER SYSTEMS GMBH

Technische Dokumentation

Postfach 12 51

66273 Sulzbach / Saar

Germany

We look forward to receiving your input.

“Putting experience into practice”

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 5 / 48

Page 6

SMU1000 Preface

Technical Support

Contact our technical sales department if you have any questions on our product.

When contacting us, please always include the model/type designation, serial no.

and part-no. of the product:

Fax: ++49 (0) 6897 / 509 - 846

E-mail: filtersystems@hydac.com

Modifications to the Product

We would like to point out that changes to the product (e.g. purchasing additional

options, etc.) may mean that the information in the operating instructions is no

longer applicable or adequate.

After modification or repair work that affects the safety of the product has been

carried out on components, the product may not be returned to operation until it has

been checked and released by a HYDAC technician.

Please notify us immediately of any modifications made to the product whether by

you or a third party.

Warranty

For the warranty provided by us, please refer to the General Terms of Sale and

Delivery of HYDAC FILTER SYSTEMS GmbH.

Refer to these at www.hydac.com General terms and conditions.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 6 / 48

Page 7

SMU1000 Preface

Using the Documentation

Note that the method described for locating specific information does

not release you from your responsibility of carefully reading these

instructions prior to starting the unit up for the first time and at regular

intervals in the future.

What do I want to know?

I determine which topic I am looking for.

Where can I find the information I’m looking for?

The documentation has a table of contents at the beginning. There, I select

the chapter I'm looking for and the corresponding page number.

Product description /

l

t

e

i

p

a

K

t

/

k

d

u

o

P

r

Chapter heading

Page number

i

l

t

e

t

e

c

r

h

n

i

k

G

m

b

H

H

Y

D

C

A

F

B

2

a

1

4

e

a

d

3

6

W

5

de

e

200x-xx-xx

Seite x

Edition date

Documentation no.

Document language

with index/

file name

The documentation number with its index enables you to order another copy of the

operating and maintenance instructions. The index is incremented every time the

manual is revised or changed.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 7 / 48

Page 8

SMU1000 General Safety Precautions

General Safety Precautions

These operating instructions contain the key instructions for properly and safely

operating the SMU.

Obligations and Liability

The basic prerequisite for the safe and proper handling and operation of the

SMU is knowledge of the safety instructions and warnings.

These operating instructions in general, and the safety precautions in particular,

are to be adhered by all those who work with the SMU.

Adherence is to be maintained to pertinent accident prevention regulations

applicable at the site where the product is used.

The safety precautions listed herein are limited solely to using the SMU.

The SMU has been designed and constructed in accordance with the current

state of the art and recognized safety regulations. Nevertheless, hazards may be

posed to the life and limb of the individual using the product or to third parties.

Risk of damage may be posed to the product or other equipment and property.

The SMU is only to be used as follows:

solely for its designated use

only when in a safe, perfect condition

Any faults or malfunctions which might impair safety are to be properly repaired

or remedied immediately.

Our General Terms and Conditions (AGB) apply. They are made available to the

owner upon concluding purchase of the unit at the latest. Any and all warranty

and liability claims for personal injuries and damage to property shall be

excluded in the event they are attributable to one or more of the following

causes:

improper use of the SMU or use deviating from its designated use

improper assembly, installation, commissioning, operation and maintenance

of the SMU

Modifications to the SMU made by the user or purchaser

improperly performed repair work

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 8 / 48

Page 9

SMU1000 General Safety Precautions

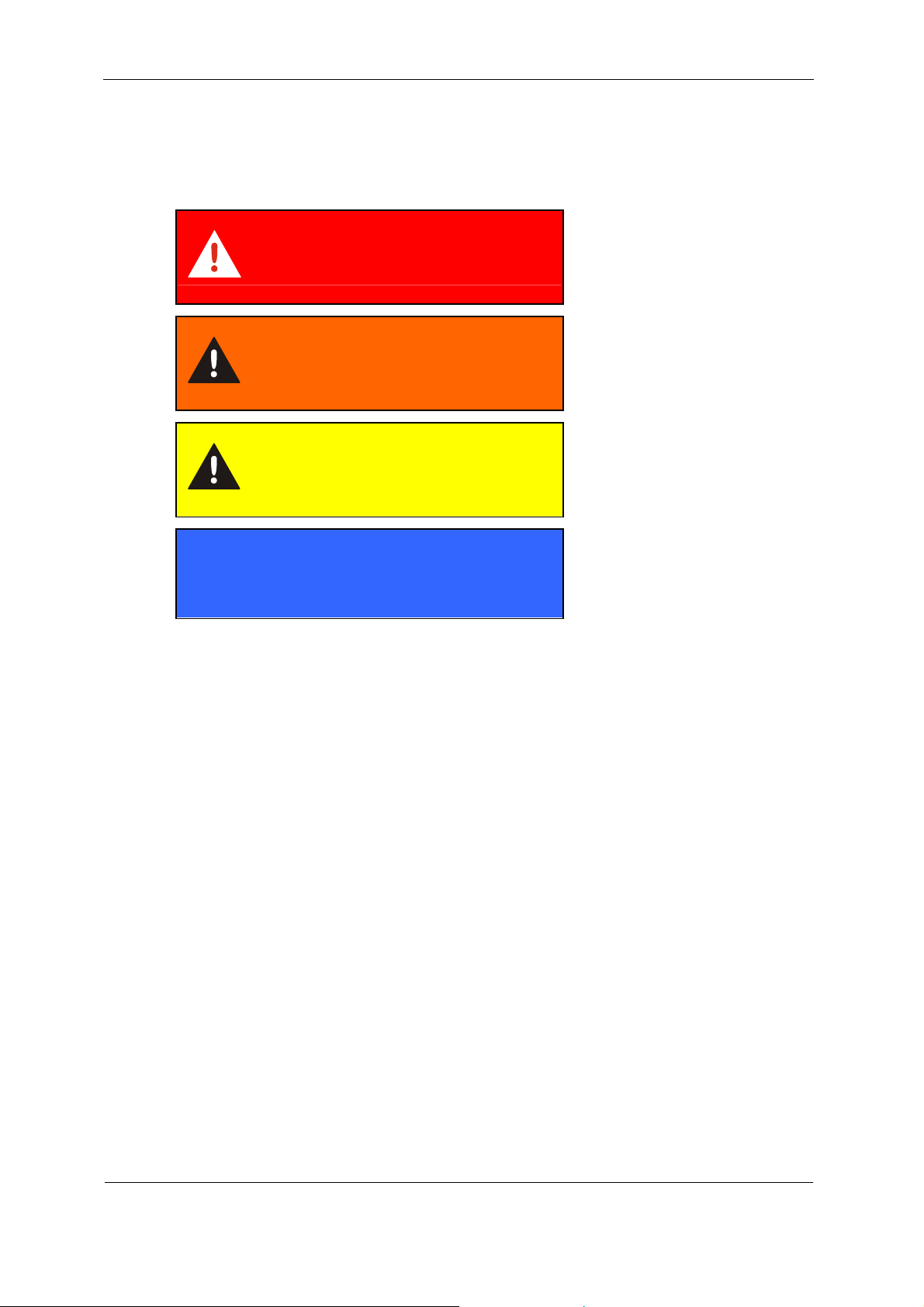

Explanation of Symbols and Warnings, etc.

The following designations and symbols are used in this manual to designate

hazards, etc.:

DANGER denotes situations

which can lead to death if

DANGER

WARNING

CAUTION

NOTICE

safety precautions are not

observed.

WARNING denotes situations

which can lead to death if

safety precautions are not

observed.

CAUTION denotes situations

which can lead to severe

injuries if safety precautions

are not observed.

NOTICE denotes situations

which can lead to property

damage if safety precautions

are not observed.

Proper/Designated Use

The SensorMonitoring Unit was developed to continuously record values measured

by HYDAC sensors.

Analyzing the type, size and quantity of contamination enables quality standards to

be verified and documented, and the requisite optimization measures to be

implemented.

Any other use shall be deemed to be improper and not in keeping with the product's

designated use; the manufacturer accepts no liability for any damage resulting from

such use.

Proper or designated use of the product extends to the following:

The continuous recording of values measured by HYDAC sensors

Maintaining adherence to all the instructions contained herein.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 9 / 48

Page 10

SMU1000 General Safety Precautions

Improper Use

Any use deviating from the proper/designated use described above is prohibited.

Improper use may result in hazard to life and limb.

Example of improper use:

- improper connection of the SMU voltage and sensor cables.

Informal Safety Precautions

Make sure to always keep the operating instructions in the vicinity of the SMU.

In addition to the manual, the general and local regulations concerning accident

prevention and protection of the environment should be available and observed.

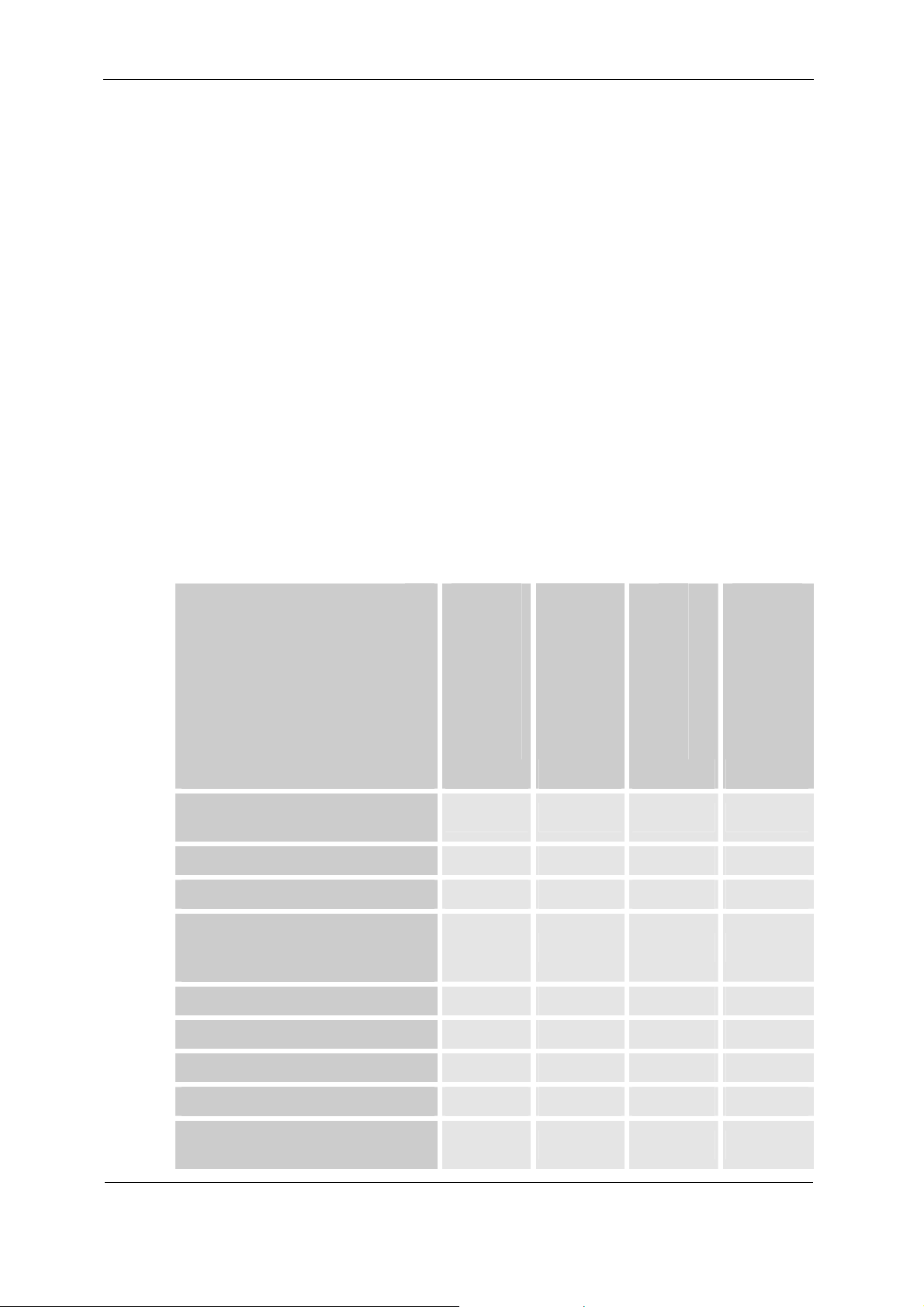

Training and Instruction of Personnel

The SMU may only be operated by properly trained and instructed personnel.

The areas of responsibility of your staff must be established in a clear-cut manner.

Staff undergoing training may not use the SMU unless supervised by an

experienced staff member.

Individuals

Individuals

undergoing

training

Individuals with

technical training/

engineering

background

Electrician

Supervisor with the

appropriate

Activity

Packing

Transportation

Commissioning

Operation

X X

X X X

X X X X

X

Troubleshooting/

locating the source of

X X X

malfunction

authority

Remedying of mechanical faults

X

Remedying of electrical faults

Maintenance

X X X X

Servicing

Decommissioning /

Storage

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

X X X X

X

X X

X

Page 10 / 48

Page 11

SMU1000 Packing, Storage

Packing, Storage

Transportation and Packing

The SMU comes packed in a cardboard box.

Unpack the unit and check it for damage in transit. Report any damage to the

forwarding agent immediately.

Storage

Make sure to store the SMU in a clean, dry place, in the original packing, if possible.

Do not remove the packing until you are ready to install the unit.

Scope of Delivery

The SMU comes packed and factory-assembled. Before commissioning the SMU,

check the content of the package to make sure everything is present.

The following items are supplied:

Qty. Designation

1 SensorMonitoring Unit - SMU 1000

1 MMC card 128 MB including card holder

1 Power supply cable, length = 5m, (ZBE 08-05)

3 Connection cable in accordance with the model code or the sensors

to be read off

1 Operation and Maintenance Instructions (this document)

1 SMU Support CD

1 FluMoS Light CD

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 11 / 48

Page 12

SMU1000 SMU Features

SMU Features

The SensorMonitoring Unit SMU is a small control unit for saving measured values

on an MMC memory card.

The following fluid sensors can be connected directly, depending on model code:

- ContaminationSensor CS1000, CS2000

- AquaSensor AS 1000, AS 2000, AS 8000

- HYDACLab

- GW display

- MCS1000

The display shows the fluctuating measured values of the connected sensors.

The measured values are saved in a file on the card in data exchange format *.csv

every 60 seconds (a 128 MB memory card records ~ 3 years' worth of data).

For further processing and evaluation, the data can simply be transferred to Office

applications, e.g. FluMoS or MS Excel.

Uses for the SMU include:

- Storage of data from fluid monitoring in the field.

- Test installation to validate sensors

Advantages offered by the SMU unit:

- Cost-effective, easy-to-install solution

- Simple data processing and evaluation with FluMoS or MS Excel

- Ethernet interface for OPC servers (optional)

- Program restarts independently after a voltage loss

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 12 / 48

Page 13

SMU1000 Installation

Installation

In the availability status, the project is located on the control unit. The application

starts automatically when the power supply is switched on.

During the initial installation or in the case of a longer service life without power, the

system clock should be checked and reset if necessary.

The system clock is checked when the program starts. If this times out, the following

message appears on the display: „SET CLOCK -> Reboot system“. To set the

system clock, first press the ESC to switch to the main menu. Set the hour and date

by pressing the ALT button several times (see Setting the system clock on page 28).

The installat

ion phase lasts ~ 105 seconds and appears on the start page as a %

specification.

The sensors are connected to the M12-unit plug on the underside of the SMU.

The analog output signal of the sensors must be checked or set before

commissioning. For details, see page 32.

For all sensors, the SMU requires a 4-20 mA signal for analog input (no

CS 1000

with a 0-10 V voltage signal!).

When using the SMU as a data logger, the memory card must be correctly inserted.

This will show up on the display as "MC". To check this when the program is

running, press the "ESC" button to switch to the main menu.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 13 / 48

Page 14

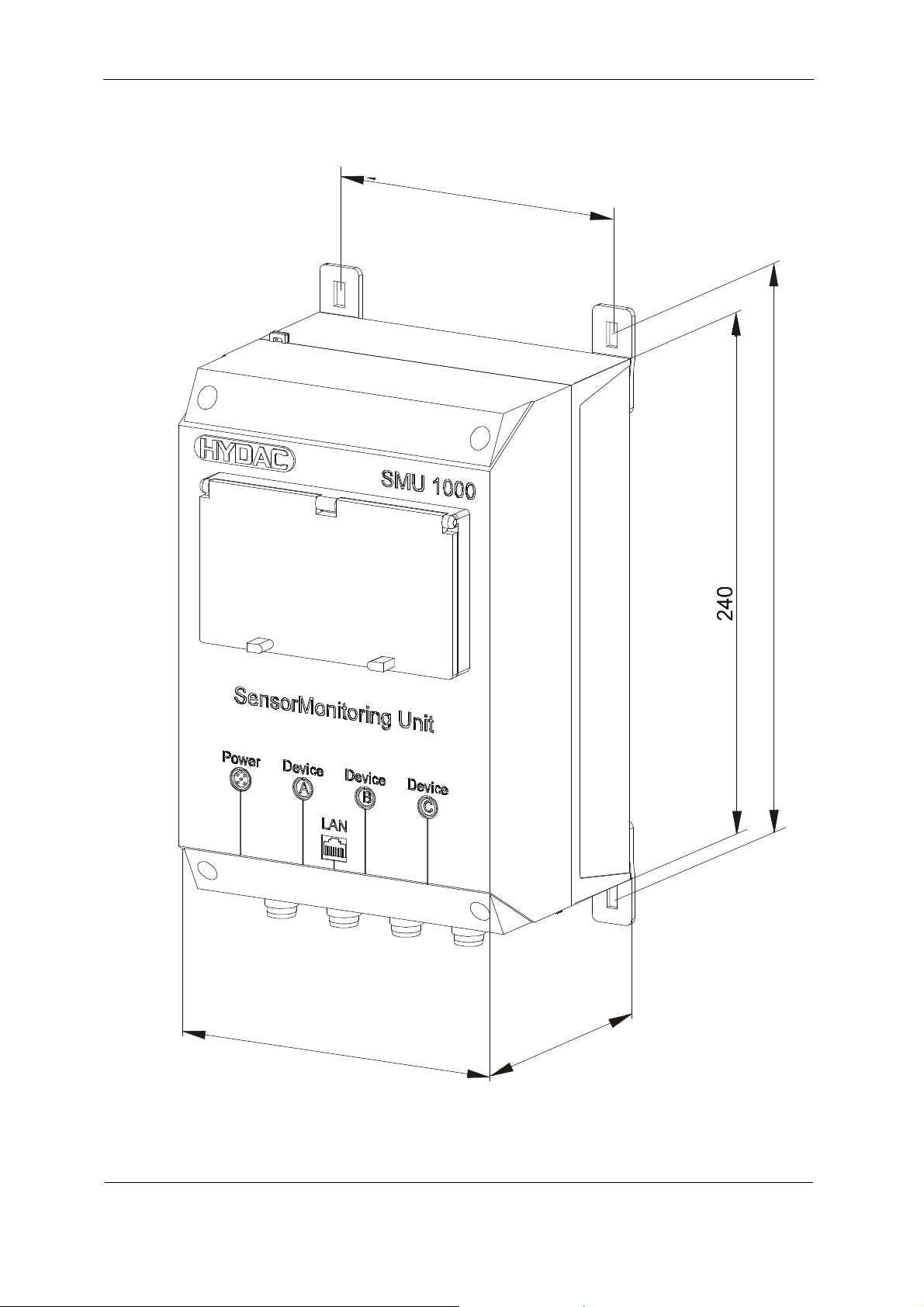

SMU1000 SMU Dimensions and Drilling Template

SMU Dimensions and Drilling Template

1

40

5

5

2

1

6

0

5

2

1

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 14 / 48

Page 15

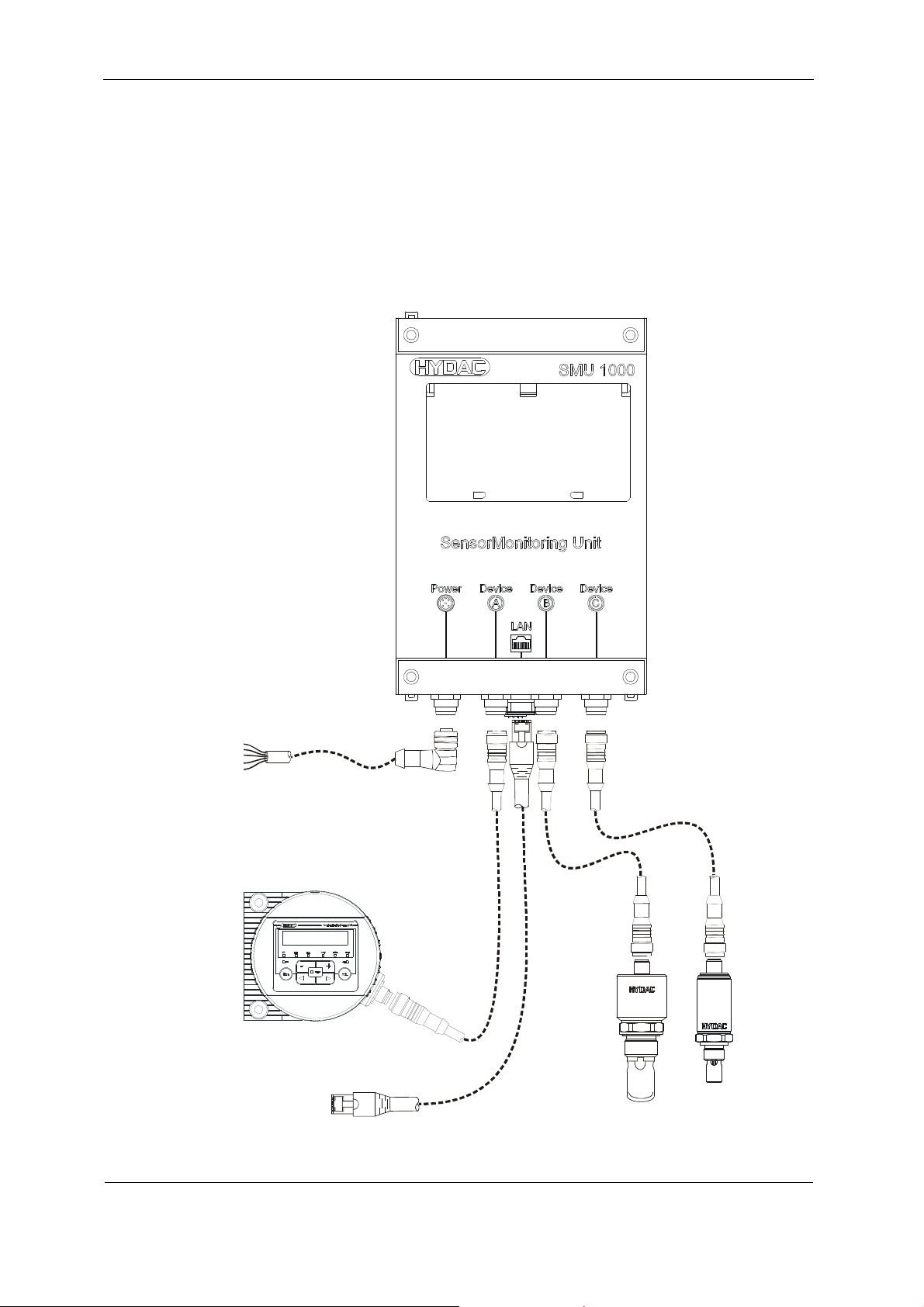

SMU1000 Connecting the SMU

Connecting the SMU

The connections (DEVICE A / B / C) are each assigned to a specific sensor and

cannot be assigned at will.

For the assignment of the sensors, observe the sensor index on the rating plate of

the SMU. You can find a table for the identification of the SMU <-> measurement

sensor combination on page 46.

Connection

5

example with: CS1000 / HYDACLab (HLB) / AS1000

24 V DC

Power

CS 1000

RJ45

Ethernet

HYDACLab

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

AS 1000

Page 15 / 48

Page 16

SMU1000 Connecting cable SMU <-> sensor

Connecting cable SMU <-> sensor

Ready-made cables are available for the vast majority of sensors to be connected.

For connection to the SMU, these cables must be merely plugged in and tightened.

However, some sensors have a clamp gib which the open cable ends have to be

connected to.

NOTICE

Electrical short circuit

The SMU will be destroyed

► Insulate all unnecessary wires to prevent them from accidentally touching

each other.

The color coding of the connection cable is valid only for cables from

the SMU scope of delivery and original replacement cables.

5-pin connection cable, open cable end:

5

1

4

2

3

8-pin connection cable, open cable end:

Schirm

8

1

7

6

5

2

Shield

Blindage

3

4

Schirm

Shield

Blindage

1

braun

weiss

2

blau

/ blue / bleu

3

schwarz

4

grau

/ grey / gris

5

weiss

1

braun

2

grün

3

gelb

4

grau

5

rosa / pink / rose

6

7

blau

/ brown / brun

/ white / blanc

/ black / noir

/ white / blanc

/ brown / brun

/ green / vert

/ yellow / jaune

/ grey / gris

/ blue / bleu

8

rot

/ red / rouge

Schirm

/ Shield / Blindage

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 16 / 48

Page 17

SMU1000 Connecting cable SMU <-> sensor

Power supply -> SMU

To connect the power supply, you need a 5-pin connection cable. The connection

assignment must be made in accordance with the following table.

Schirm

5

1

4

Pin Color code Designation Connection

1 Brown Voltage + 24 V DC

2 White

3 Blue Voltage GND 0 V DC

4 Black

5 Gray

2

Shield

Blindage

3

1

braun

weiss

2

blau

3

schwarz

4

grau

5

/ brown / brun

/ white / blanc

/ blue / bleu

/ black / noir

/ grey / gris

Connection cable AS2000 -> SMU

To connect the AS2000, you need a 5-pin connection cable. The connection

assignment must be made in accordance with the following table.

1

4

Pin Color code Designation Terminal on the

1 Brown Voltage + 24 V DC

2 White "Saturation" analog output 4 ... 20 mA Saturation(-)

3 Blue

4 Black "Temperature" analog output 4 ... 20 mA Temperature(-)

5 Gray

Schirm

5

Shield

2

Blindage

1

braun

/ brown / brun

weiss

/ white / blanc

2

3

blau

/ blue / bleu

3

schwarz

4

grau

5

/ black / noir

/ grey / gris

AS2000

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 17 / 48

Page 18

SMU1000 Connecting cable SMU <-> sensor

Connection cable AS8000 -> SMU

To connect the AS8000, you need an 8-pin connection cable. The connection

assignment must be made in accordance with the following table.

Pin Color code Designation Terminal on the

AS8000

1 White Voltage + 24 V DC 24 V

2 Brown Analog output S1+ S1+

3 Green Voltage 0 V DC 0 V

4 Yellow Analog output S2+ S2+

5 Gray

6 Pink Analog output S1- GND S17 Blue

8 Red Analog output S2- GND S2-

Connection cable CS2000 -> SMU

To connect the CS2000, you need an 8-pin connection cable. The connection

assignment must be made in accordance with the following table.

Schirm

8

1

7

6

5

2

Shield

Blindage

3

4

1

2

3

4

weiss

braun

grün

gelb

/ white / blanc

/ brown / brun

/ green / vert

/ yellow / jaune

grau

/ grey / gris

5

rosa / pink / rose

6

7

blau

/ blue / bleu

rot

/ red / rouge

8

Schirm

/ Shield / Blindage

Pin Color code Designation Terminal on the

CS2000

1 White Voltage + 24 V DC

2 Brown

3 Green Voltage GND GND

4 Yellow

5 Gray PNP output to PLC 3

6 Pink

7 Blue PLC GND 1

8 Red 24 V from PLC 2

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 18 / 48

Page 19

SMU1000 Operating the SMU

Operating the SMU

The following chapter describes the operation of the buttons and the display on the

front plate.

Keypad

DEL

Delete or return to applications program from

main menu

A

L

T

Special function, status display

Cursor buttons ▲ ▼ ◄ ►:

Move cursor

Select menu items

Set numbers and values

OK

Next menu level, save entry

E

S

C

Previous menu level, cancel

Selecting menus and entering values

DEL

and

Call up system functions

A

L

T

Move to next menu level

OK

Call menu item

Activate, change, save entry

Move to previous menu level

E

S

C

Cancel entries since last OK

▲ Change menu item

♣▼ Change value, change place

◄► P-button function

▲ Input P1 ► Input P2

▼ Input P3 ◄ Input P4

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 19 / 48

Page 20

SMU1000 Selecting main and system menus

Selecting main and system menus

Status display

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 20 / 48

Page 21

SMU1000 Selecting main and system menus

Main menu without password protection

Main menu with password protection

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 21 / 48

Page 22

SMU1000 Selecting main and system menus

System Menu

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 22 / 48

Page 23

SMU1000 Selecting main and system menus

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 23 / 48

Page 24

SMU1000 SMU setup

SMU setup

Settings are all changed using the operating elements on the control unit.

Password protection

You can protect access to the main menu and system menu, the clock setting and

the operating mode (RUN/STOP) with a password. Choose <Security l Range> for

the individual setting options.

The system menu is always protected when a password is activated.

The password consists of a value between 000001 and 999999.

Clear a password with the number combination of 000000.

Password setup

A password can be set in the system menu in either the RUN or STOP mode. You

cannot change to the system menu if a password is already activated.

Press DEL and ALT to call up the system menu.

Select the menu option SECURITY to enter the password.

Press the OK button and move to the password menu.

Press OK again for the password entry mode.

Six dashes will appear if no password is entered:

No password present.

Press OK, and six zeroes will appear

Set the password using the cursor button:

◄ ►:Select position in the password,

▲ ▼ Set a value between 0 and 9.

Save the new password by pressing OK.

Press OK to exit the password menu and press

ESC and ▼ to the RANGE menu...

The scope of the password has not yet been

defined. The password is now valid but not yet

activated.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 24 / 48

Page 25

SMU1000 SMU setup

Select the scope of the password

Confirm with the OK button.

Select the function or menu to be protected.

Press OK to protect the function or menu

(checked box = protected).

The password protects the program by default.

At least one function or one menu must be protected.

PROGRAM: The PROGRAM menu is protected.

CLOCK: Date and time are password-protected.

OPERATING MODE: The toggling of the RUN or STOP operating mode is

protected.

Activating the password

You can activate an existing password in four different ways:

- Automatically when the control unit restarts.

- Automatically after the program is loaded.

- Automatically if no telegram was sent to the computer interface 30 minutes after

the password was entered.

- Via the password menu.

► Press DEL and ALT to call up the system

menu.

► Open the password menu via the SECURITY

menu item...

The password menu is displayed only if a

password is present.

The password protects the program by default.

Make note of the password before activating it. If you forget the

password, you will not be able to access the system menu.

► Select CHANGE PW and press OK.

The password is now activated. The status display is activated.

You must enter the password before you can access a protected function, a

protected menu or the system menu.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 25 / 48

Page 26

SMU1000 SMU setup

Access with password protection

Password protection is deactivated after the password is entered. You can

reactivate the password later using the password menu or by switching the power

supply off and the on again.

► Press OK to switch to the main menu.

The PASSWORD... entry will flash.

► Press OK to call up the password entry

screen.

If the main menu shows PROGRAM instead of PASSWORD...,

this means that password protection is not activated.

The password entry field is shown.

► Set the password using the cursor button.

► Confirm with OK.

If the password entry is correct, the status display is reactivated.

The menu item PROGRAM... is enabled.

The system menu is also accessible.

Changing the password and range

► Enter your password.

► Press DEL and ALT to call up the system menu.

► Open the password menu via the SECURITY and PASSWORD... menu item.

The entry CHANGE PW will flash.

This menu is only displayed if a password is

present.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 26 / 48

Page 27

SMU1000 SMU setup

► Press OK for the password entry field.

► Press OK to move to the 6-digit entry field.

► The current password will be displayed.

► Change the six password digits with the

cursor buttons.

► Confirm with OK.

Press ESC to exit the security menu.

Password, delete

Use the number combination of 000000 to clear a

password.

Six dashes will appear if no password is entered.

Password incorrect or no longer known

Have you entered an incorrect password?

Re-enter the password.

This can be repeated as many times as require!

Pressing ESC returns you to the start menu.

If you forget the password, you can only call up the browser command

"factoryset." The password, user program, and boot project will be

deleted and the command unit will be reinitialized with the default

parameters; see section "Reset".

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 27 / 48

Page 28

SMU1000 SMU setup

Changing the menu language

You can set the menu languages German and English using the system menu.

The language option is only available if the control unit is not protected

by a password.

Press DEL and ALT to call up the system menu.

To change the menu language, select MENU LANGUAGE .

The option ENGLISH is displayed.

Select the new menu language with ▲ or ▼.

Confirm with OK. Enter a check mark next to

"language".

Exit the menu with ESC.

The new menu language is activated.

Press ESC to return to the status display.

Setting the date and time

The units are provided with a real-time clock with date and time. During the first

commissioning, set the hour, minute, day, month, and year.

► Select SET CLOCK... in the main menu.

The clock setting menu will flash.

► Select SET CLOCK:

► Enter the values for hour, day, month, and

year.

► Press OK to access the entry mode.

– ◄► Select location.

– ▲▼ Change the value.

– OK Save date and time.

– ESC Keep previous setting.

Press ESC to leave the clock setting display.

:

:

:

:

:

:

:

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 28 / 48

Page 29

SMU1000 SMU setup

Startup behavior

Setting the startup behavior

The following startup options can be set using the menu.

STOP

WARM START

COLD START

► Switch to the system menu.

If the control unit is protected by a password, the system menu can only

be accessed after entering the password (see section "Access with

password protection," page 26).

►

Set the startup behavior.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 29 / 48

Page 30

SMU1000 SMU setup

Setting the LCD contrast and backlighting

The background lighting of the LCD display can be switched off. The display

contrast can be set to one of 5 levels. The display is not needed during operation.

Backlighting is only required during maintenance and when texts are being

displayed.

► Switch to the system menu.

If the control unit is protected by a password, the system menu can only

be accessed after entering the password; see "Access with password

protection," page 26.

►

Select the SYSTEM menu.

► Confirm with the OK button.

► Select the DISPLAY menu with the cursor

keys ▲ and ▼ and confirm with OK.

The menus for setting the contrast and backlighting are displayed.

► Press OK to access contrast entry mode.

Using the cursor buttons ▲ and ▼, change the

contrast to a value between -2 and +2.

► Select your setting.

► Confirm the setting with the OK button.

The contrast setting remains the same until you change it.

► Switch to the LIGHTING menu using the

cursor buttons ▲ and ▼.

► Confirm with the OK button.

► The background lighting is deactivated.

► If you want to reactivate the background

lighting, press the OK button.

► The check mark ✔ shows that the background

lighting is activated.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 30 / 48

Page 31

SMU1000 Resetting

Resetting

You can reset the system using the PC in the online mode or via the menu of the

controller. To do so, select the menu item in the control configurator or in the menu

of the controller.

Reset commands are described in detail below

Reset warm

The program is stopped.

The non-remanent variables are initialized; the "retain" variables are retained.

The program can be restarted.

Reset cold

The program is stopped.

All variables are initialized.

The program can be restarted.

Reset original

The program in the working memory and the boot project in the system memory of

the controller are deleted.

With a memory card plugged in:

- All project-specific files on the memory card, the operating system, and

the boot project are deleted.

- All user-specific files and the startup.ini file remain unchanged

The controller is set to the NOT READY condition.

Resetting to the factory settings (factoryset)

Using the browser command "factoryset" or the controller's menu item <SYSTEM l

WERKSEINSTELLUNG>, a "Reset original" is performed (see section "Reset

original").

In addition, the Startup.ini file on the memory card and the system parameters in the

controller are deleted. After a start the controller works with the STARTUP data

again. The interfaces are initialized with their default values.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 31 / 48

Page 32

SMU1000 Factory setting

Factory setting

The basic settings when the SMU is delivered are:

- The contrast is at the setting 0.

- The background lighting is constantly activated.

- Menu setting: LIGHTING ✔

Software Update

If the existing program was deleted (see controller main menu), the program is

available on the SMU support CD.

To do this, copy the files under "SMU1000Bootprojekt_Vxxx" onto the memory card.

Then disable the write-protection of the files on the MMC card. Select the files and

open the properties by right-clicking. Remove the checkmark next to "Writeprotected".

When the memory card is inserted, the program is automatically loaded again with a

system restart.

If the program has been deleted (see main menu "Control unit"), the program is still

saved on the memory card and can be loaded automatically by restarting the

system. You can also carry out a software update in this way.

Checking sensor settings (CS1000 / CS2000)

The connected sensors CS1000 and CS2000 must be set up or adjusted for

operation with the SMU in accordance with the following table.

You can find details in the corresponding sensor documentation.

The sensors AS1000 / AS2000 / AS8000 / HYDACLab and VLxGW do not need

further adjustment for operation on the SMU.

Sensor Settings

CS1000 ANA.OUT = HDA.ISO

Measurement time = 60 sec.

CS2000 The PLC output must give a signal based on the ISO code.

MCS1000 Evaluation is only possible from switching output 1.

Configure the MCS accordingly.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 32 / 48

Page 33

SMU1000 Functions / Menu guide

Functions / Menu guide

A maximum of three sensors can be connected to the SMU. The combination of sensors to

be connected depends on the sensor index in the model code (for details see page ).

The program of the SMU is divided into the following submenus:

- Start page

- CS 1000 (ContaminationSensor)

- CS 2000 (ContaminationSensor)

- AS1000 (AquaSensor)

- AS2000 (AquaSensor)

- AS8000 (AquaSensor)

- HLB1000 (HYDACLab)

- VLxGW (clogging indicator)

- MCS1000 (Metallic ContaminationSensor)

- Service menu

- Datalogging

- Units

- Information

The sensor data is automatically displayed in ~ 5 second intervals.

The OK button can also be used to switch between manual (using cursors ◄►) and

automatic display.

You can find more detailed information on the individual menu pages in the

corresponding chapters.

CS 1000 Menu

Display of the current measured values and of the sensor status

State: = Sensor status CS1000

CISO: = ISO-Code for 0 -> 4 µm Channel

C1 -> 6 µm Channel

C2 -> 14 µm Channel

C3 -> 21 µm Channel

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 33 / 48

Page 34

SMU1000 Functions / Menu guide

Sensor status CS1000

0 = "Undefined": error in the evaluation of the status signal

1 = "OK..." : CS is functioning without errors

2 = "Error..." : Unit error / CS not ready

3 = "Flow 2 Low": Flow too low

4 = „ISO <9<8<7“: Flow too high

5 = "No value": no measured value (flow undefined)

CS 2000 Menu

Display of the current measured values and of the unit status

ISO: = ISO code

AS1000 menu

Display of the current measured values

AS2000 menu

Display of the current measured values

AS8000 menu

Display of the current measured values

Sat: = Water saturation in %

T: = Temperature in °C

Sat: = Water saturation in %

T: = Temperature in °C

Sensor1: = Water saturation in %

Sensor2: = Water saturation in %

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 34 / 48

Page 35

SMU1000 Functions / Menu guide

HLB1000 (HYDACLab)

Display of the current measured values and of the sensor status

V = relative change of viscosity in %

DK = relative change in dielectric constant value in %

Sat = Water saturation degree in %

T = Temperature in °C

State = Sensor status

Sensor status HLB1000:

0 = "Undefined": error in the evaluation of the status signal

1 = „Reference“: Reference phase

2 = „Operating“: Operating phase

3 = „OutOfRange“: oil status not plausible

4 = „Error“: Internal error

VLxGW (clogging indicator)

Display of the current measured values and of the sensor status

Pin = Inlet pressure

DeltaP = Pressure differential

Menus MCS1000

Display of the current measured values and of the sensor status

Sum = Number of particles, output on switching output

xxx = Valu

1

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 35 / 48

Page 36

SMU1000 Functions / Menu guide

Service menu

The selected menu item flashes in the service menu. Select the next menu item with

the cursor buttons ▲▼ and press OK.

You can exit the service menu or return to the sensor data display by pressing the

DEL button.

You cannot switch from the service menu to the control unit menu. The ESC button

is blocked.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 36 / 48

Page 37

SMU1000 Functions / Menu guide

Data logging

Display status, time, and data size

State = Status at last storage

Time [s] = Remaining time until next storage (storing

interval fixed at 60 seconds)

Size = Size = Specification of data size in kB

or MB

Data logging status

„OK…“: Memory card present

-

- „No disc“: No memory card present

- „Disc FULL“: Memory card full

- „Error“: Other data writing errors.

The MMC card can be removed and reinserted during operation. If no card is

inserted during data storage, this data is lost. When the card is reinserted, the data

that follows is added on to the existing data. If a memory card was not present

during a measurement, this can be recognized by a time gap in the data.

Devices

Automatic scanning of the input and display of the connected sensors or the current

scan phase for each individual sensor.

Special function:

Pressing the button sequence OK – DEL – OK within 2 seconds requests a restart in

order to change the variant with VLxGW.

Status CS1000 / HLB

„No sensor“: Sensor is not attached, broken cable

-

- „Sync…“: Synchronizing, recognition of waiting time between transfer of

measured values (HDA.ISO Signal)

- „Sync…OK“: Start impulse recognized, begin transfer of measured values

(HDA.ISO Signal)

The status of device A / B / C depends on the sensors

connected.

- „Read…“: Reading measured values (HDA.ISO Signal)

Status CS2000 / MCS1000

The status at the CS2000 is always "Read..." since it is read in via the counter

entry.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 37 / 48

Page 38

SMU1000 Display Information

Status AS1000 / AS2000 / AS8000 / VLxGW

- „No sensor“: Sensor is not attached, broken cable

- „Read…“: Reading measured values

Display Information

This information appears after switching on the SMU or in the service menu under

the menu item "Information".

Product name

Software:

Software: Version number

Version

number

Sensor index: For sensor information see page 46.

Homepage (WWW)

Changeover display mode automatic /manual

While the program is running, you can switch between the

manual and automatic display of pages by pressing the "OK"

button.

During the changeover, the set mode appears briefly on the

display.

In automatic mode, the individual windows are displayed for ~

5 seconds. The sensor menus are skipped when a sensor

and measured values are no longer present.

If the SMU finds no sensor, or if no sensor has been

attached, this message will appear on the display.

Setting the VL x GW clogging indicator:

Editing with ALT -> input field blinks, then OK and use the

arrow keys to switch between the values 2, 3, or 5.

If a specification is invalid, the value 5 or the last valid value

is applied automatically.

Add the corresponding selection with the OK and ALT keys.

Factory setting: VL5 GW

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 38 / 48

Page 39

SMU1000 Data format data logger+

Data format data logger+

The measured values are deposited on a memory card in a text folder in CSV format

(separated with a comma). This data format can be opened and edited further in

different user programs, e.g. FluMoS or MS Excel.

The name of the measurement file is always

"HYDAC_SMU1000_xx_Data_JJJJMM.csv" and is found on the memory card in the

following directory:

Every month, a new file is created.

In the file name the following placeholders are defined as follows:

Xx = Sensor index 00 - 13

JJJJMM = Year (4-digit) + month (2-digit)

Example of a file view in MS Excel:

The LOG file always consists of two parts. In the first part, general information about

the recording and units / sensors is saved.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 39 / 48

Page 40

SMU1000 Data format data logger+

This includes:

SMU - version:

Time when the recording was started, number of measurement data entries,

recording interval

Number of units, unit IDs

Channel number for each unit

Upper and lower limit of the measurement category and measurement units

After the word *Data,* the actual measurement data is saved. Each measurement

value is placed in a column. The channel name is found in the header.

The CSV file has the following structure:

(Example with CS1000, HLB1000, AS1000)

Records Column Description

a Date

B Time

C CS1000 sensor connected

0 = False / 1=True

D ISO channel 0

E ISO channel 1

F ISO channel 2

G ISO channel 3

H CS1000 sensor status, for details see page 34.

I AS 1000 sensor connected

0 = False / 1=True

J Degree of saturation in %

K Temperature in °C

L HLB sensor connected

0 = False / 1=True

M Relative change of viscosity in %

N Relative change in dielectric constant value in %

O Degree of saturation in %

P Temperature in °C

Q HLB sensor status, for details see page 35.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 40 / 48

Page 41

SMU1000 OPC Variables / OPC Server

OPC Variables / OPC Server

The OPC server is a software product from either the Moeller or the 3S company.

For details on its installation and configuration, see the the included instructions

from these companies.

In addition to the OPC server, the IP address of the SMU must be customized for

the client. For this purpose, there is a file on the support CD called "STARTUP.ini".

With this file and with the help of an editor, you can change the IP address as well

as the subnet mask (default setting: IP address 192.168.119.60, subnet mask:

255.255.255.0).

The INI file is located in the same file as the CSV files.

Structure of INI files:

After making changes to the address, you must save all entries, insert the memory

card in the controller and reboot the system.

See the Moeller company's operating manual for how to test if the address has been

correctly set, as well as for connecting the network cable.

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 41 / 48

Page 42

SMU1000 OPC Variables / OPC Server

The following variables have been defined or enabled for communication using the

OPC.

Variable Data

Description

type

.g_AS1000_Enable BOOL AS1000 per model code

.g_AS2000_Enable BOOL AS2000 per model code

.g_AS8000_Enable BOOL AS8000 per model code

.g_AS8_Connected BOOL AS8000 connected Yes/No

AS1000/AS2000 connected

.g_AS_Connected BOOL

Yes/No

.g_CS1000_DevA_Enable BOOL CS1000 at connection A

.g_CS1000_DevB_Enable BOOL CS1000 at connection B

.g_CS1000_DevC_Enable BOOL CS1000 at connection C

.g_CS2000_Enable BOOL CS2000 per model code

.g_CS2_Connected BOOL CS2000 connected Yes/No

CS1000 connected at

.g_CS_DevA_Connected BOOL

connection A Yes/No

CS1000 connected at

.g_CS_DevB_Connected BOOL

connection B Yes/No

CS1000 connected at

.g_CS_DevC_Connected BOOL

connection C Yes/No

.g_GW_Connected BOOL GW display connected Yes/No

.g_GW_Enable BOOL GW display per model code

.g_GW_VL2_Enable BOOL VL2GW configured Yes/No

.g_GW_VL3_Enable BOOL VL3GW configured Yes/No

.g_GW_VL5_Enable BOOL VL5GW configured Yes/No

.g_MCS_Connected BOOL MCS connected Yes/No

.g_HLB_Connected BOOL HLB connected Yes/No

.g_MCS_Enable BOOL MCS per model code

.g_HLB_Enable BOOL HLB per model code

PLC_PRG.AS8_Sensor1Value DINT AS8000 value sensor1 [%]

PLC_PRG.AS8_Sensor2Value DINT AS8000 value sensor2 [%]

Degree of saturation [%]

PLC_PRG.AS_SatValue DINT

(AS1000/2000)

Temperature [°C]

PLC_PRG.AS_TempValue DINT

(AS1000/2000)

PLC_PRG.CS2_isoCh0_Value WORD ISO channel 0 (CS2000)

PLC_PRG.CS2_isoCh1_Value WORD ISO channel 1 (CS2000)

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 42 / 48

Page 43

SMU1000 OPC Variables / OPC Server

PLC_PRG.CS2_isoCh2_Value WORD ISO channel 2 (CS2000)

PLC_PRG.CS_DevA_isoCh0_Value WORD ISO channel 0 (CS1000)

PLC_PRG.CS_DevA_isoCh1_Value WORD ISO channel 1 (CS1000)

PLC_PRG.CS_DevA_isoCh2_Value WORD ISO channel 2 (CS1000)

PLC_PRG.CS_DevA_isoCh3_Value WORD ISO channel 3 (CS1000)

PLC_PRG.CS_DevB_isoCh0_Value WORD ISO channel 0 (CS1000)

PLC_PRG.CS_DevB_isoCh1_Value WORD ISO channel 1 (CS1000)

PLC_PRG.CS_DevB_isoCh2_Value WORD ISO channel 2 (CS1000)

PLC_PRG.CS_DevB_isoCh3_Value WORD ISO channel 3 (CS1000)

PLC_PRG.CS_DevC_isoCh0_Value WORD ISO channel 0 (CS1000)

PLC_PRG.CS_DevC_isoCh1_Value WORD ISO channel 1 (CS1000)

PLC_PRG.CS_DevC_isoCh2_Value WORD ISO channel 2 (CS1000)

PLC_PRG.CS_DevC_isoCh3_Value WORD ISO channel 3 (CS1000)

PLC_PRG.CS_DevA_stateValue WORD Sensor status CS 1000 - A

PLC_PRG.CS_DevB_stateValue WORD Sensor status CS 1000 - B

PLC_PRG.CS_DevC_stateValue WORD Sensor status CS 1000 - C

PLC_PRG.GW_deltaPValue DINT Delta P [mbar] (GW)

PLC_PRG.GW_PinValue DINT Inlet pressure [mbar] (GW)

relative change dielectric

PLC_PRG.HLB_DKValue DINT

constant value [%] (HLB)

Water saturation degree [%]

PLC_PRG.HLB_SatValue DINT

(HLB)

PLC_PRG.HLB_stateValue WORD HLB Sensor status:

PLC_PRG.HLB_TempValue DINT Temperature [°C] (HLB)

relative change in viscosity [%]

PLC_PRG.HLB_ViscValue DINT

(HLB)

Number of particles -

PLC_PRG.MCS_CounterValue DWORD

Switching output 1 (MCS)

These variables always give the current measured value/status and are not

positioned according to the storage interval.

The associated symbol file is located on the support CD in the folder

"…\SMU1000_Option_Ethernet\Symbolfiles_SMU1000_Vxxx\ …" and must be

copied into the directory* C:\WINxx\GatewayFiles on the PC.

*) WINxx = Directory depends on operating system

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 43 / 48

Page 44

SMU1000 Setting up OPC server

Setting up OPC server

The OPC server can be set up via the OPC configurator. Start the OPC configurator

on the PC at Start -> Programs -> 3S Software.

The settings of the following parameters are to be checked and adjusted as

necessary.

You can find detailed information in the file in the 3S installation directory:

OPC_20_how_to_use_x.pdf

Setting - Server

Update rate (ms) : 1000

Public Groups : Disable

Sync Init : Enable

Log Events : Disable

Setting - PLC

Project name : HYDAC_SMU1000

Timeout (ms) : 10 000

Number of attempts : 3

Buffer size (bytes) : 0

Waiting time (s) : 20

Reconnect time (s) : 5

You will need the following settings only if you are going to connect several SMUs to

one OPC server.

Active : Enable (only in multi-PLC)

Motorole byte folder : Disable (only in multi-PLC)

No login service : Disable (only in multi-PLC)

Setting connection

Gateway : Local

Device : TCP/IO (level 2 route)

Address : Set up IP address from setup.ini

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 44 / 48

Page 45

SMU1000 Disposing of the SMU

Disposing of the SMU

Please dispose of the packaging material in an environmentally friendly manner.

After dismantling the unit and separating the various materials, dispose of the unit in

an environmentally friendly manner.

Customer Service

HYDAC Service GmbH

Friedrichsthaler Straße 15A, Werk 13

66540 Neunkirchen - Heinitz

Germany

Telephone:

Telefax:

++49 (0)681 509 883

++49 (0)681 509 324

E-Mail: service@hydac.com

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 45 / 48

Page 46

SMU1000 Model Code

Model Code

SMU - 1- 1- 1- 0- U - 00 / 000

Type

SMU = SensorMonitoring Unit

Series

1 = 1000 Series

Data input

1 = Analog

Interface

0 = serial RS232

1 = serial RS232 + Ethernet

Application

0 = Standard

Supply voltage

U = 24 V DC

Sensor index for the "Measurement sensors combination"

00 = See table "Measurement sensors combination"

Modification ID

000 = Standard

Measurement sensors combination

Sensor index a b C

00 CS1000 HYDACLab AS1000

01 CS1000 HYDACLab AS2000

02 CS1000 HYDACLab AS8000

03 CS1000 HYDACLab GW

04 CS2000 HYDACLab AS1000

05 CS2000 HYDACLab AS2000

06 CS2000 HYDACLab AS8000

07 CS2000 HYDACLab GW

08 CS2000 GW AS1000

09 CS2000 GW AS2000

10 CS2000 GW AS8000

11 CS2000 AS8000 AS1000

12 CS2000 AS8000 AS2000

13 CS1000 CS1000 CS1000

14 CS2000 MCS1000 AS1000

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 46 / 48

Page 47

SMU1000 Technical Data

Technical Data

General data

Mounting position Arbitrary

Self-diagnosis Continuously with error indication on

display

Display LCD, 4-lined, 17 segmented

Drop (IEC/EN 60068-2-31)

Ambient temperature range

Storage temperature range

relative humidity

Electrical safety class

IP class

Weight

Fall height 50 mm

-25° … 55° C

-40° … 70° C

maximal 95%, non-condensing

III (low voltage protection)

IP65

~ 1.3 kg

Electrical data

Voltage supply 24 V DC (-15%/+20%)

Residual ripple ≤ 5 %

Power consumption ~ 15 Watt

Accuracy of the real-time clock ± 5 s/day / ± 0.5 h/year

Clock back-up

Vibrations (IEC/EN 60028-2-6)

- constant amplitude 0.15 mm

- constant acceleration 2g

at least 72 h

5 … 9 Hz

8 … 150 Hz

CPU

Microprocessor Infineon XC161

Memory specifications

Program code 256 kByte

Program data 14 segments of 16 KB each

Marker/Input/Output/Retain data 16/4/4/8 kByte

Cycle time for 1 k instructions < 0.3

HYDAC FILTER SYSTEMS GMBH

BeWa SMU1000 34x 3614430a en-us 2012-03-13.doc 2012-03-13

en(us)

Page 47 / 48

Page 48

HYDAC FILTER SYSTEMS GMBH

Industriegebiet Postfach 12 51

66280 Sulzbach/Saar 66273 Sulzbach/Saar

Germany Germany

Phone: +49 (0) 6897 509 01 Central

Fax: +49 (0) 6897 509 846 (Technical Department)

Fax: +49 (0) 6897 509 577 (Sales Department)

Internet: www.hydac.com

E-Mail: filtersystems@hydac.com

Loading...

Loading...