Page 1

OLFCM 15/30/45/60

English (translation of original instructions)

Document No.: 3595923a

OffLine Filter

Operating and Maintenance Instructions

Page 2

Imprint

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

HYDAC FILTER SYSTEMS GMBH

Postfach 1251

66273 Sulzbach / Saarland

Germany

Telephone:

+49 (0)6897 509 01

Fax:

+49 (0)6897 509 846

E-Mail:

filtersystems@hydac.com

Homepage:

www.hydac.com

Court of Registration:

Saarbrücken, HRB 17216

Executive director:

Mathias Dieter,

Mr. Günter Harge

c/o HYDAC International GmbH, Industriegebiet, 66280 Sulzbach / Saar

Telephone:

++49 (0)6897 509 1511

Fax:

++49 (0)6897 509 1394

E-Mail:

guenter.harge@hydac.com

Imprint

Publisher and responsible for the content:

Dipl.Kfm. Wolfgang Haering

Documentation Representative

© HYDAC FILTER SYSTEMS GMBH

All rights reserved. No part of this work may be reproduced in any form (print,

photocopy or by other means) or processed, duplicated or distributed using

electronic systems without the written consent of the publisher.

These documents have been created and inspected with the greatest care.

However, errors cannot be ruled out completely.

All details are subject to technical modifications. Technical specifications are

subject to change without noti ce .

OLFCM 15/30/45/60

en(us)

2 / 84

Page 3

Contents

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Contents

Imprint ............................................................................................................ 2

Documentation Representative ................................................................... 2

Contents ........................................................................................................ 3

Preface ........................................................................................................... 6

Technical Support ........................................................................................ 7

Product modification .................................................................................... 7

Warranty ...................................................................................................... 7

Using the documentation ............................................................................. 8

Safety information ........................................................................................ 9

Hazard symbols ........................................................................................... 9

Signal words and their meaning in the safety information and

instructions ................................................................................................ 10

Structure of the safety information and instructions ................................... 11

Observe regulatory information ................................................................. 11

Proper/Designated Use ............................................................................. 12

Improper Use or Use Deviating from Intended Use ................................... 13

Qualifications of personnel / target group .................................................. 14

Wear suitable clothing ............................................................................... 16

Stoppage in an emergency (EMERGENCY STOP) ................................... 16

Transporting the OLF ................................................................................. 17

Storing the OLF ........................................................................................... 18

Checking the scope of delivery ................................................................. 19

OLF Features ............................................................................................... 20

Pressure drop over DIMICRON® filter element(s) ...................................... 20

OLFCM components ................................................................................... 21

Dimensions ................................................................................................. 23

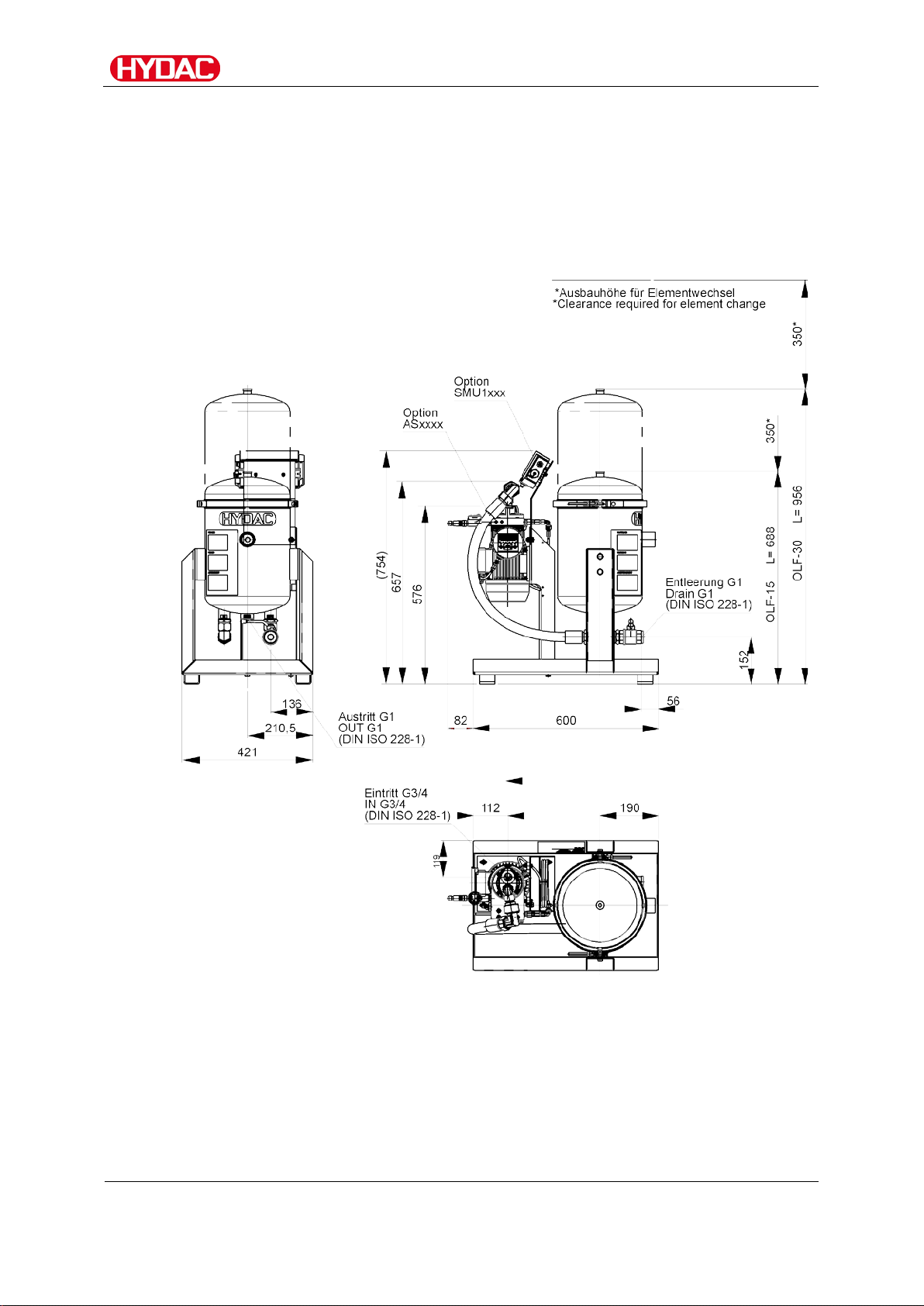

Version OLF 15/15, 30/15 .......................................................................... 23

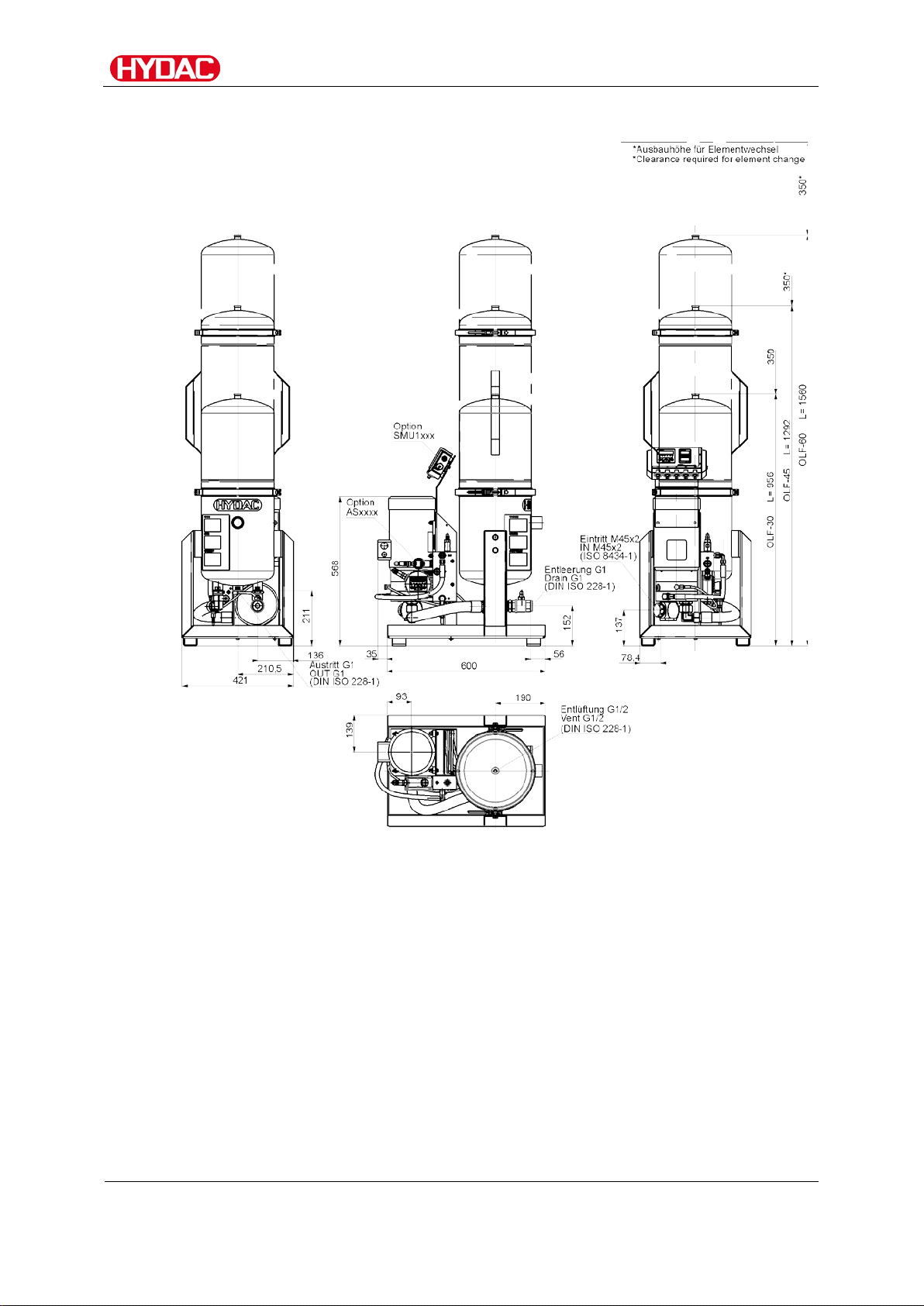

Version – OLF 30-60 ................................................................................. 24

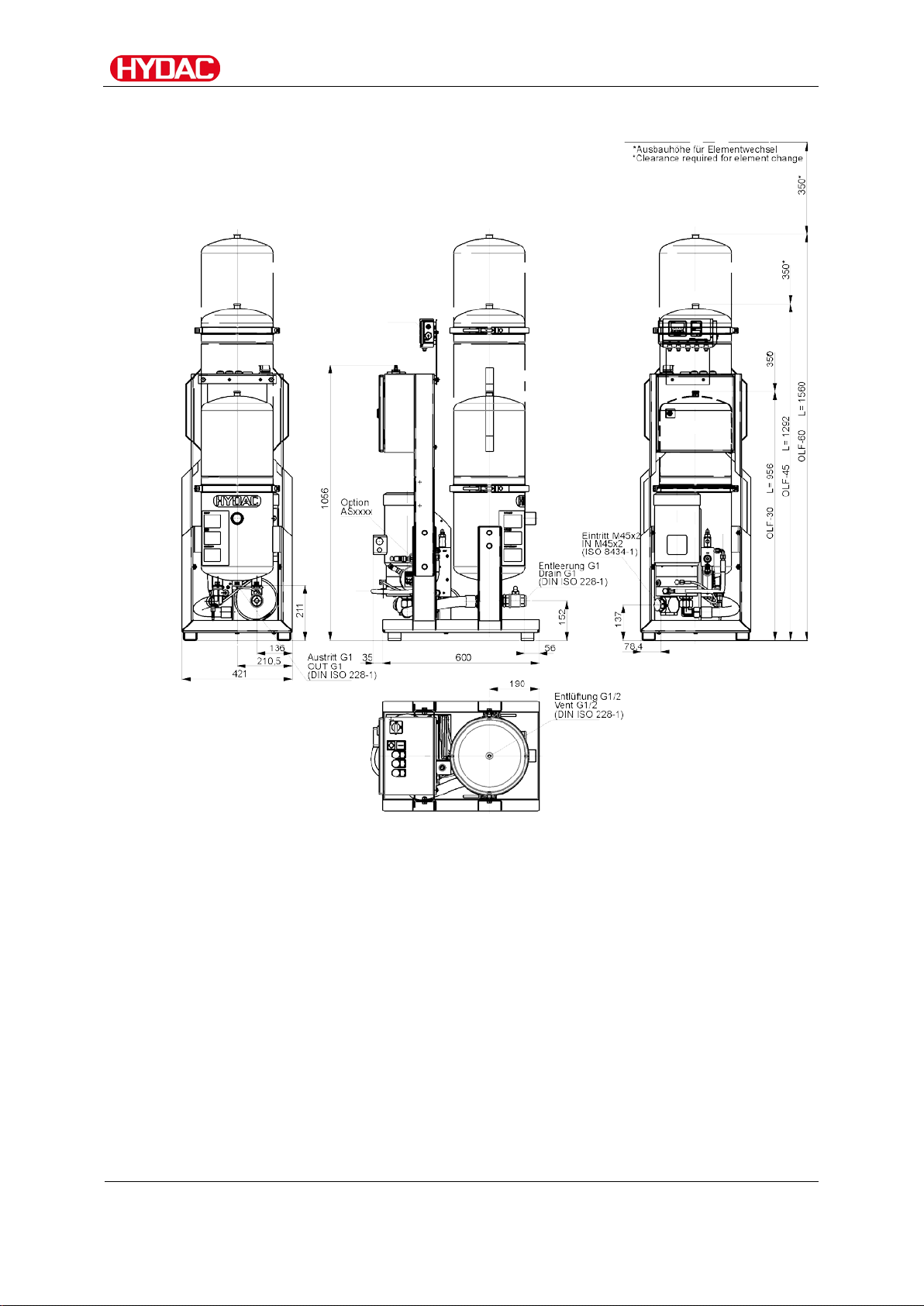

Version – OLF30-60 - FA ........................................................................... 25

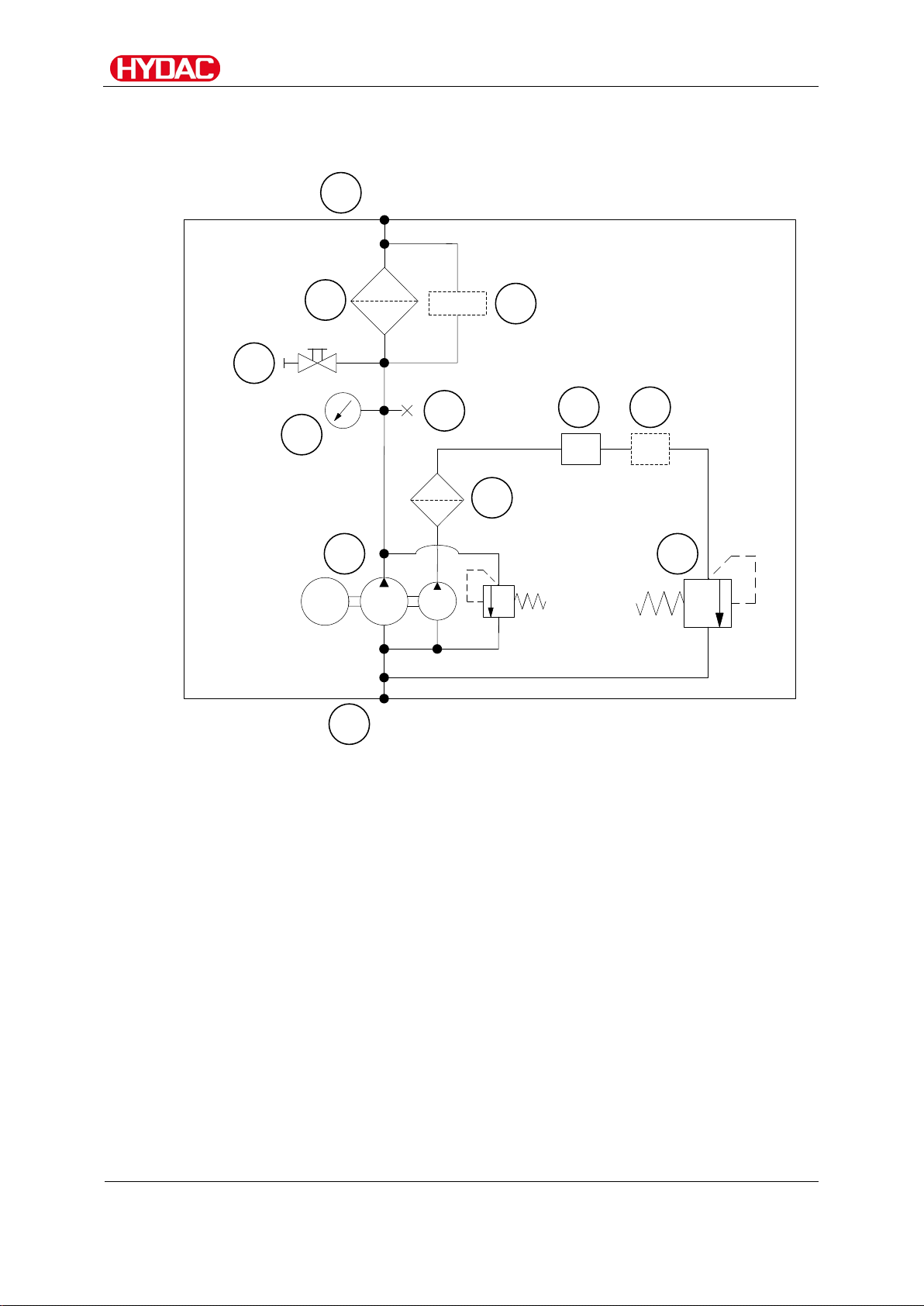

Hydraulic diagram ....................................................................................... 26

Setting up / installing the unit .................................................................... 28

Drilling template for flo or anch ors .............................................................. 28

Notes on pipes and hoses ......................................................................... 29

Connecting the suction port ....................................................................... 30

Connecting the pressure port .................................................................... 30

Electrical connection of the unit ................................................................. 31

Check direction of rotation ...................................................................... 32

OLFCM 15/30/45/60

en(us)

3 / 84

Page 4

Contents

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Identifying electrical equipment ................................................................. 33

Without electrical equipment .................................................................. 34

PKZ – On/off switch with connection cable ............................................ 34

FA0 – Filter switch-off 0 .......................................................................... 34

FA1 – Filter switch-off 1 .......................................................................... 34

FA2 – Filter switch-off 2 .......................................................................... 34

FA3 – Filter switch-off 3 .......................................................................... 35

Starting up the OLF .................................................................................... 36

Operating elements - PKZ version ............................................................. 36

Operating elements – version FA1 / FA2 ................................................... 37

Operating elements – version FA3 ............................................................ 38

Setting operating mode "Operation until target purity reached" on

the CS .................................................................................................... 39

Setting operating mode "Operation until target purity reached" on

the SMU. ................................................................................................ 40

Operational mode "Cont inuous operation" ............................................. 40

Operating the ContaminationSensor (display is optional) ...................... 41

Function of the Keys .................................................................................. 42

Measured variables on the display ............................................................ 43

ISO (Cleanliness class) .......................................................................... 43

SAE (Cleanliness class) ......................................................................... 43

NAS (Cleanliness Class - only CS 13xx) ................................................ 43

Service variables on the display ................................................................ 44

Flow (flow rate) ....................................................................................... 44

Out (Analog output) ................................................................................ 44

Drive (performance of the LED).............................................................. 44

Temp (Temperature) .............................................................................. 44

Activate / deactivate keypad lock. .............................................................. 45

Operating the SensorMonitoring Unit SMU (optional) ............................. 46

Display (CS1000 and AS1000) .................................................................. 46

Keyboard elements .................................................................................... 46

Activating/deactivating key lock ................................................................. 47

Switching the display on and off ................................................................ 48

Measured variables CS1000 ..................................................................... 49

Measured variable "ISO" ........................................................................ 49

Measured variable "SAE" ....................................................................... 49

Measured variable "NAS" ....................................................................... 49

Service variables ....................................................................................... 50

Service variable "Flow" ........................................................................... 50

Service category "Out" ........................................................................... 50

Service variable "Drive" .......................................................................... 50

Service category "Temp" ........................................................................ 50

OLFCM 15/30/45/60

en(us)

4 / 84

Page 5

Contents

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

AquaSensor AS1000 measured variables .............................................. 51

Measured variable "Water saturation" .................................................... 51

Measured variable "Temperature" .......................................................... 51

Performing Maintenance ............................................................................ 51

Changing the filter element(s) .................................................................... 52

Exchanging the prefilter to the ContaminationSensor ................................ 57

Status messages – SMU1200 (optional) ................................................... 58

Status messages – CS1000 (optionally with display) .............................. 62

Status LED / Display .................................................................................. 62

Error........................................................................................................... 65

Exceptions Errors ...................................................................................... 66

Errors and troubleshooting........................................................................ 68

Disposal of OLF .......................................................................................... 70

Disposing of the OLF .................................................................................. 70

Spare Parts List ........................................................................................... 71

Prefilter to the ContaminationSensor ......................................................... 74

Technical Data............................................................................................. 75

Model Code ................................................................................................. 76

Nominal flow rate ....................................................................................... 77

Index ............................................................................................................ 78

OLFCM 15/30/45/60

en(us)

5 / 84

Page 6

Preface

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

HYDAC FILTER SYSTEMS GMBH

Technische Dokum ent ati on

Pos tfach 12 51

66273 S ulzbach / Saar

Preface

We have compiled the most important instructions for the operation and

maintenance of our product for you, its user, in this docu me nt ation.

It will acquaint you with the product and assist you in using it as intended in

an optimal manner.

Keep this documentation in the v i ci ni ty of the produc t for i mm ediate

reference.

Sometimes the information contained in the documentation cannot always

keep up with changes made to the product as we attach considerable

importance to keeping our products cutting-edge.Consequently, there might

be deviations in technical details, illustrations and dimensions.

If you discover errors while reading the documentation or have suggestions

or other useful information, please don’t hesitate to contact us:

Germany

OLFCM 15/30/45/60

en(us)

6 / 84

Page 7

Preface

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Fax:

+49 (0) 6897 509 - 846

E-Mail:

filtersystems@hydac.com

Technical Support

Contact our technical sales department if you have any questions on our

product. When contacting us, always include the model/type designation,

serial no. and part-no. of the product:

Product modification

We would like to point out that changes to the product (e.g. purchasing

additional options, etc.) may mean that the information in the operating

instructions is no longer applicable or adequate.

After modification or repair work that affects the safety of the product has

been carried out on components, the product may not be returned to

operation until it has been checked and released by a HYDAC technician.

Report any modifications carried out on the product by you or a third party

immediately.

Warranty

For the warranty provided by us, please refer to the General Terms of Sale

and Delivery of HYDAC FILTER SYST EMS GMBH.

You will find these under www.hydac.com -> General terms and con di ti ons .

OLFCM 15/30/45/60

en(us)

7 / 84

Page 8

Preface

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Note that the method described for locating specific information

these instructions prior to starting the unit up for the first time and

Chapter description

Page number

Document language

Documentation no.

Using the documentation

does not release you from your responsibility of carefully reading

at regular intervals in the future.

What do I want to know?

I determine which topic I am looking for.

WHERE can I find the information I’m looking for?

The documentation has a table of contents at the beginning. There, I select

the chapter I'm looking for and the corresponding page number.

Edition date

with index/

file name

The documentation number with its index enables you to order another copy

of the operating and maintenance instructions.

The index is incremented every time the manual is revised or changed.

OLFCM 15/30/45/60

en(us)

8 / 84

Page 9

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Safety informati on

The unit was built according to the statutory provisions valid at the time of

delivery and satisfies current safety requirements.

Any residual hazards are indicated by safety information and instructions and

are described in the operating instructions.

Observe all safety and warning instructions attached to the unit. They must

always be complete and legible.

Do not operate the unit unless all the safety devices are present.

Secure the hazardous areas which may arise between the unit and other

equipment.

Maintain the unit inspection intervals prescribed by law.

Document the results in an inspection certificate and keep it until the next

inspection.

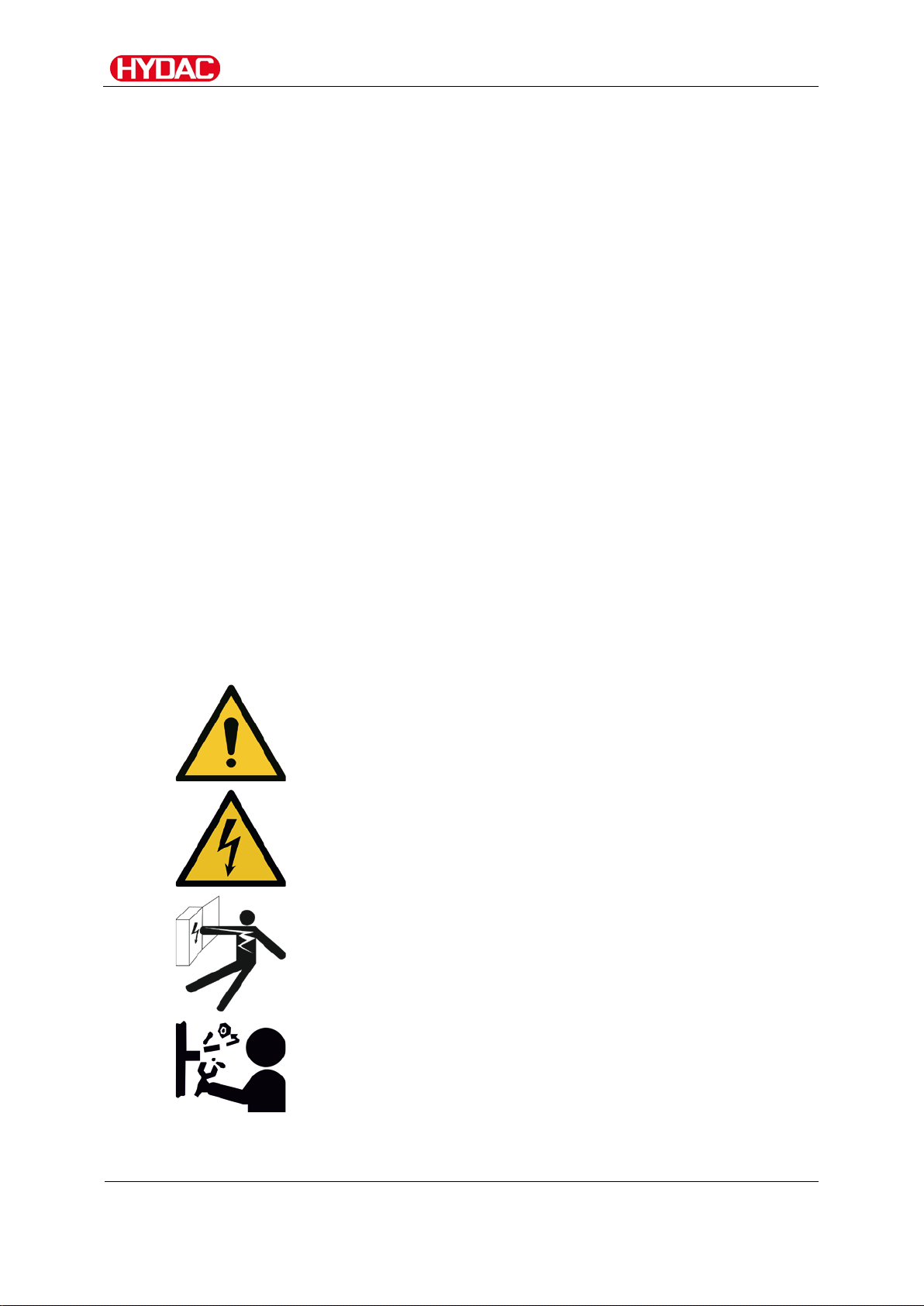

Hazard symbols

These symbols are listed for all safety information and instructions in these

operating instructions which indicate particular hazards to persons, property

or the environment.

Observe these instructions and act with particular caution in such cases.

Pass all safety information and instructions on to other users.

General hazard

Danger due to electrical voltage / current

Exposed electrical co mp on en ts

Danger of electrical shock

OLFCM 15/30/45/60

Danger due to operating pressure

en(us)

9 / 84

Page 10

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

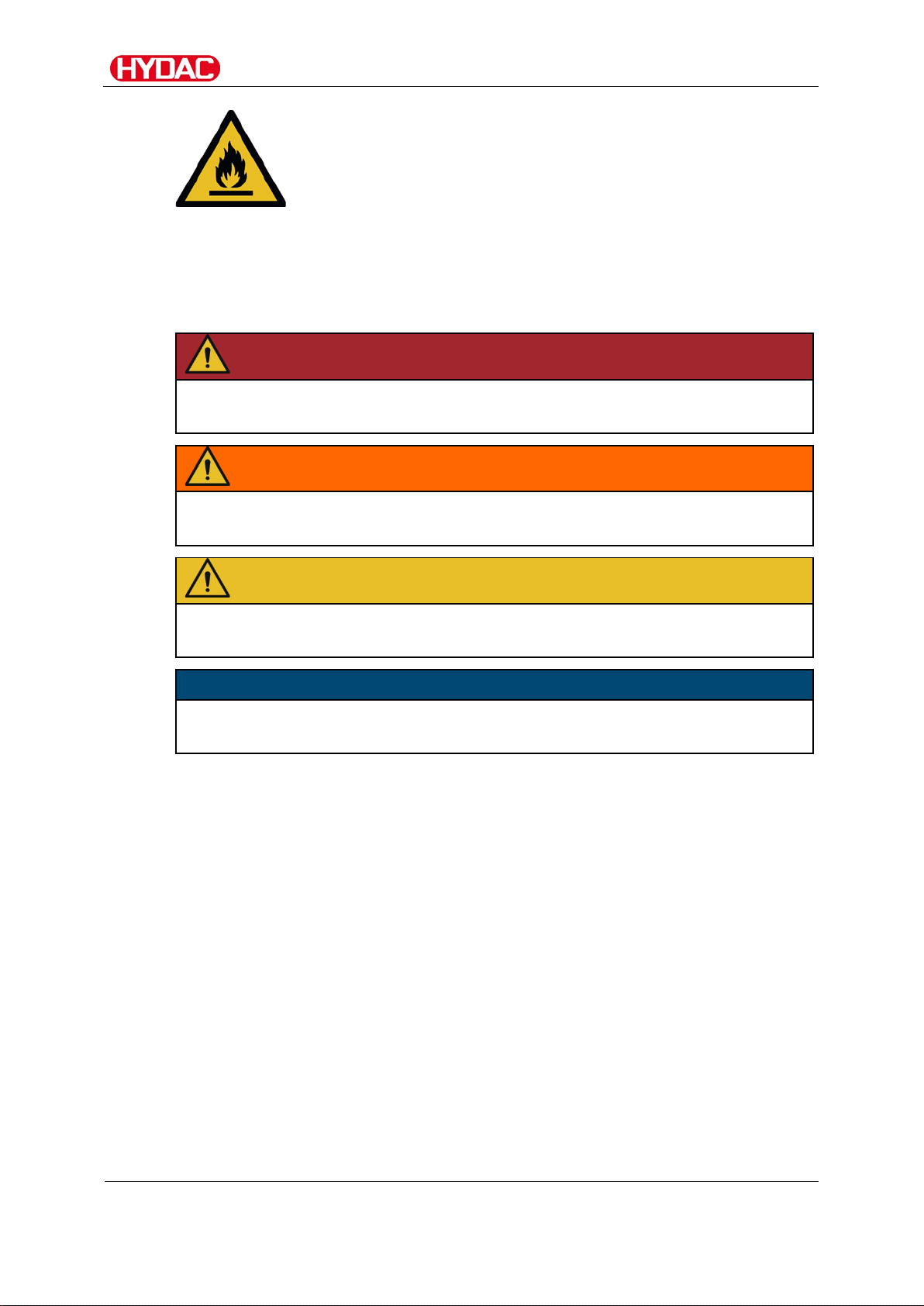

DANGER

DANGER – The signal word indicates a hazardous situation with a high level

WARNING

WARNING – The signal word indicates a hazardous situation with a medium

CAUTION

CAUTION – The signal word indicates a hazardous situation with a low level

NOTICE

NOTICE – The signal word indicates a hazardous situation with a high level

Warning of flammable substances

Signal words and their meaning in the safety information and instructions

In these instructions you will find the following signal words:

of risk, which, if not avoided, will result lethal or serious injury.

level of risk, which, if not avoided, can result lethal or serious injury.

of risk, which, if not avoided, can result in minor or moderate injury.

of risk, which, if not avoided, will result in damage to property.

OLFCM 15/30/45/60

en(us)

10 / 84

Page 11

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

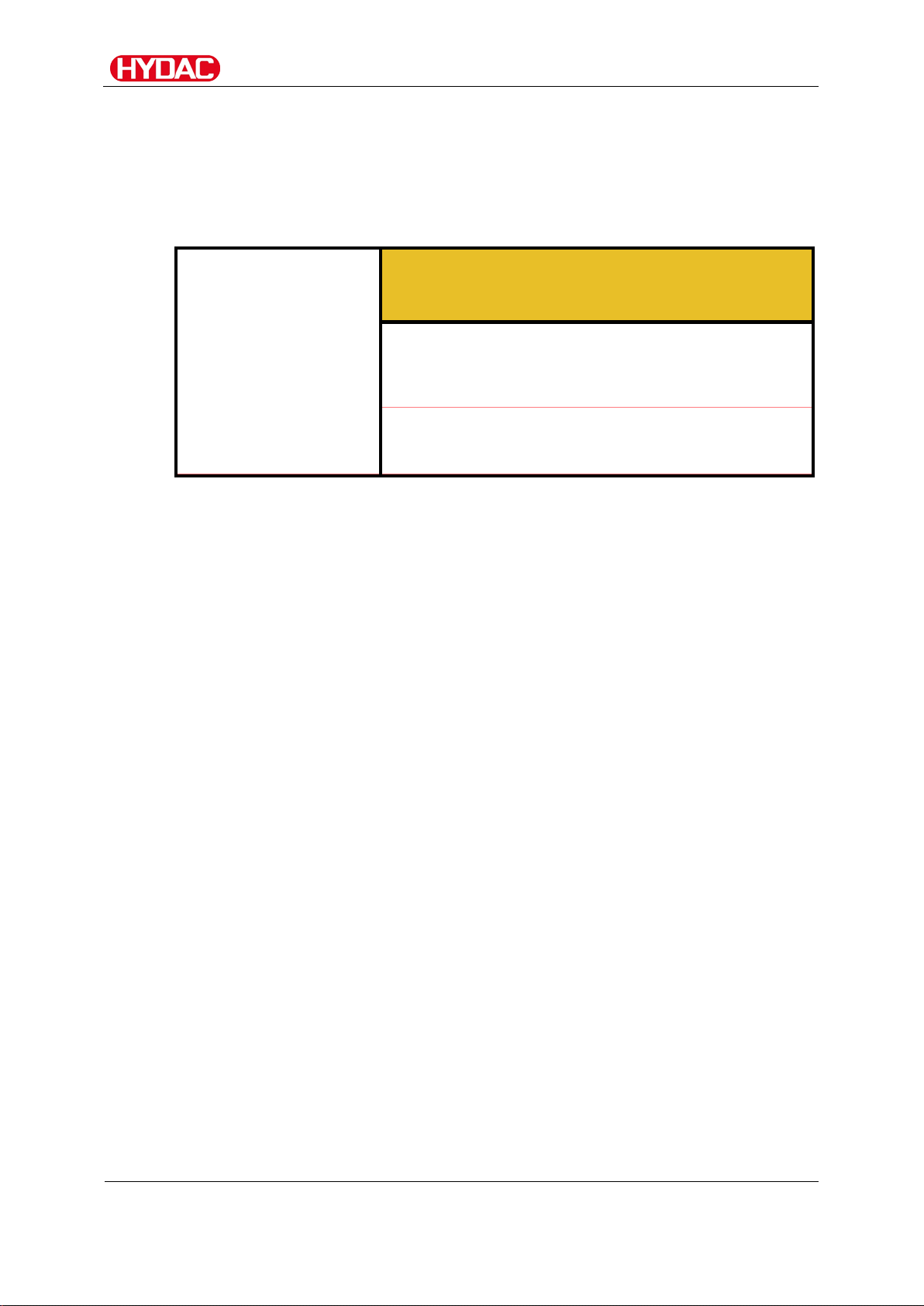

Structure of the safety information and instructions

All warning instructions in this manual are highlighted with pictograms and

signal words. The pictogram and the signal word indicate the severity of the

danger.

Warning instructions listed before an activity are laid out as follows :

HAZARD SYMBOL

SIGNAL WORD

Observe regulatory information

Observe the following regulatory information and guidelines:

• Legal and local regulations for accident prevention

• Legal and local regulat ions for environmental protectio n

• Country-specific regul a t ions , or g ani zation-specific regulations

Type and source of danger

Consequence of the danger

► Measures to avert danger

OLFCM 15/30/45/60

en(us)

11 / 84

Page 12

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Proper/Designated Use

Use the unit only for the application described in the following.

The OLF Compact is a stationary filter unit used for filtering hydraulic or

lubricating oils in bypass flow.

Proper or designated us e of the prod uc t extends to the following :

• observing all instructions contained in the instruction manual.

• performing inspectio n and maintenance work.

Depending on the version (see model code), you may use the OLF only in

connection with the following media:

WARNING

Fire hazard

Danger of bodily injury

► With the OLF, you may filter/pump only

media/fluids with a flash point ≥ 56°C/133°F

NOTICE

Unpermitted operating media

The filtration unit will be destroyed.

► The OLF is to be used only with mineral oils or mineral oil-based

raffinates.

► Do not filter any caustic or explosive media.

OLFCM 15/30/45/60

en(us)

12 / 84

Page 13

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Never operate the unit in potentially explosive

Improper Use or Use Deviating from Intended Use

DANGER

Danger due to unanticipated use of the unit

Bodily injury and damage to property will result

when operated improperly.

►

atmospheres.

► The unit is only to be used with permissible

media.

Any use extending beyond or deviating therefrom shall not be considered

intended use. HYDAC Filter Systems GmbH will assume no liability for any

damage resulting from such use. The user alone, shall assume any and all

associated risk

Improper use may result in hazards and/or will damage the unit. Examples of

improper use:

• Operation in potentially explosive atmospheres.

• Operation with a non-approved medium.

• Operation under non-approved operational conditions.

• Operation when the safety devices are defective.

• Modifications to the power unit made by the user or purchaser.

• Inadequate monitoring of parts that are subject to wear and tear

• Improperly performed repair work.

OLFCM 15/30/45/60

en(us)

13 / 84

Page 14

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Qualifications of personnel / target group

Persons who work on the power unit must be aware of the associated

hazards when using the power unit.

Auxiliary and specialist personnel must have read and understood the

operating instructions, in particular the safety information and instructions,

and applicable regulations before beginning work.

The operating instructions and applicable regulations are to kept so they are

accessible for operating and specialist personnel.

These operating instructions is intended for:

Auxiliary personnel: such persons have been instructed in power unit

operation and are aware of pote nti al haz ar ds due to i mproper use.

Specialist personnel : such persons with corresponding specialist training and

several years work experience. They are able to assess and perfor m the

work assigned to them, they are also able to recognize potential hazards.

OLFCM 15/30/45/60

en(us)

14 / 84

Page 15

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

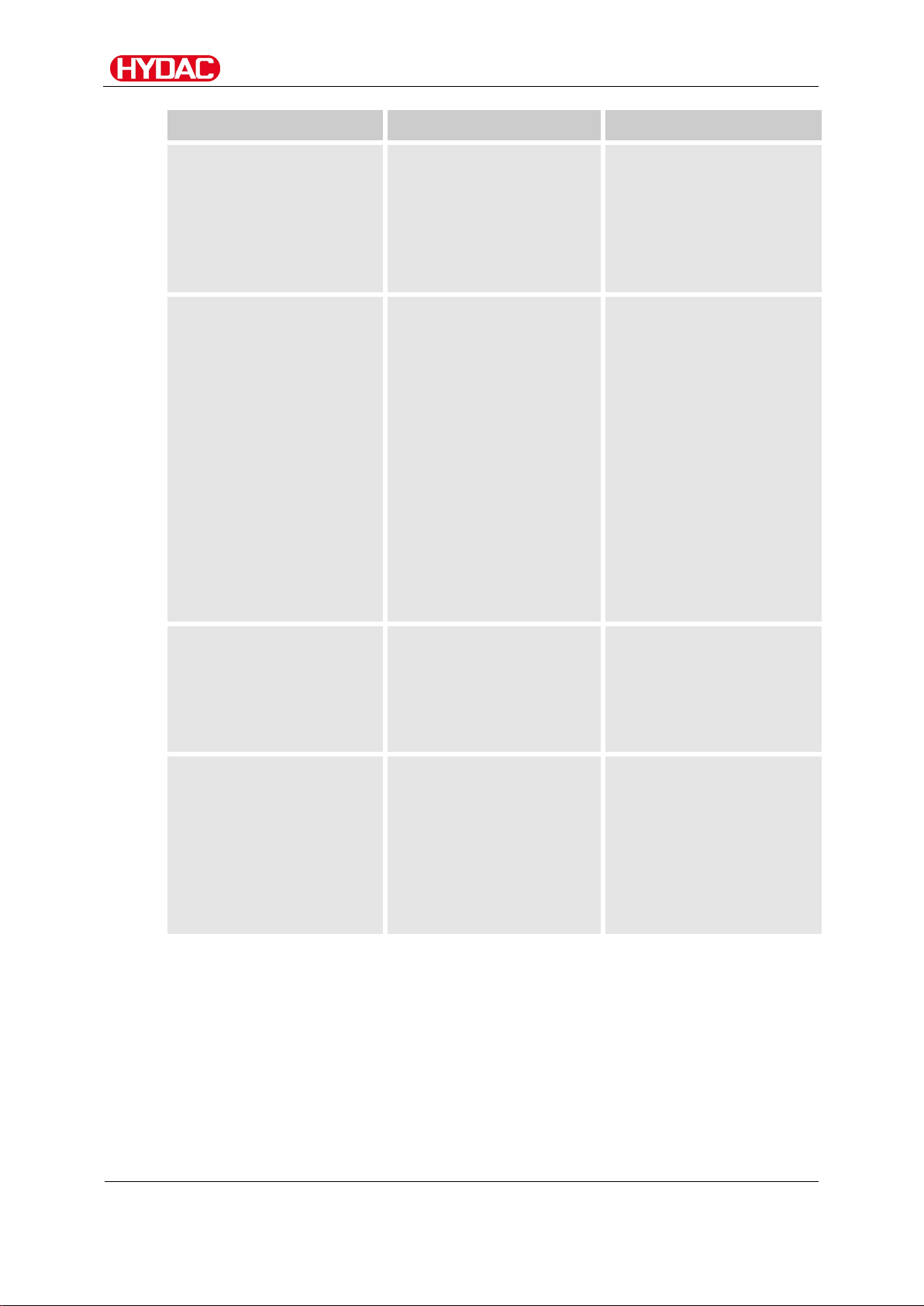

Activity

Personnel

Knowledge

Transport / storage

Forwarding agent

Proof of knowledge of

Hydraulic / electrical

Specialist personnel

Safe handling/use of

Operation,

Auxiliary personnel

Product-specific

Disposal

Specialist personnel

Proper and

installation,

first commissioning,

operation/settings

maintenance,

troubleshooting,

repair,

decommissioning,

disassembly

Specialist personnel

cargo securing

instructions

Safe handling/operat ion

of hoisting and lifting

equipment

tools

Fitting and connection

of hydraulic lines and

connections

Fitting and connection

of electrical lines,

electrical machinery,

sockets, etc.

Checking the phase

sequence

Product-specific

knowledge

Operations control

knowledge

Knowledge about how

to handle operating

media

environmentally-friendly

disposal of materials

and substances

Decontamination of

contaminants

Knowledge about reuse

OLFCM 15/30/45/60

en(us)

15 / 84

Page 16

Safety information

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Wear suitable clothing

Loose-fitting clothing increases the risk of being caught or being drawn in on

rotating parts, and the risk of getting caught on protruding parts. You can be

severely injured or killed.

• Wear close-fitting clothing.

• Do not wear any rings, chains or any other jewelry.

• Wear work safety shoes.

Stoppage in an emergency (EMERGENCY STOP)

In case of emergency, switch off the power unit at the main switch.

OLFCM 15/30/45/60

en(us)

16 / 84

Page 17

Transporting the OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

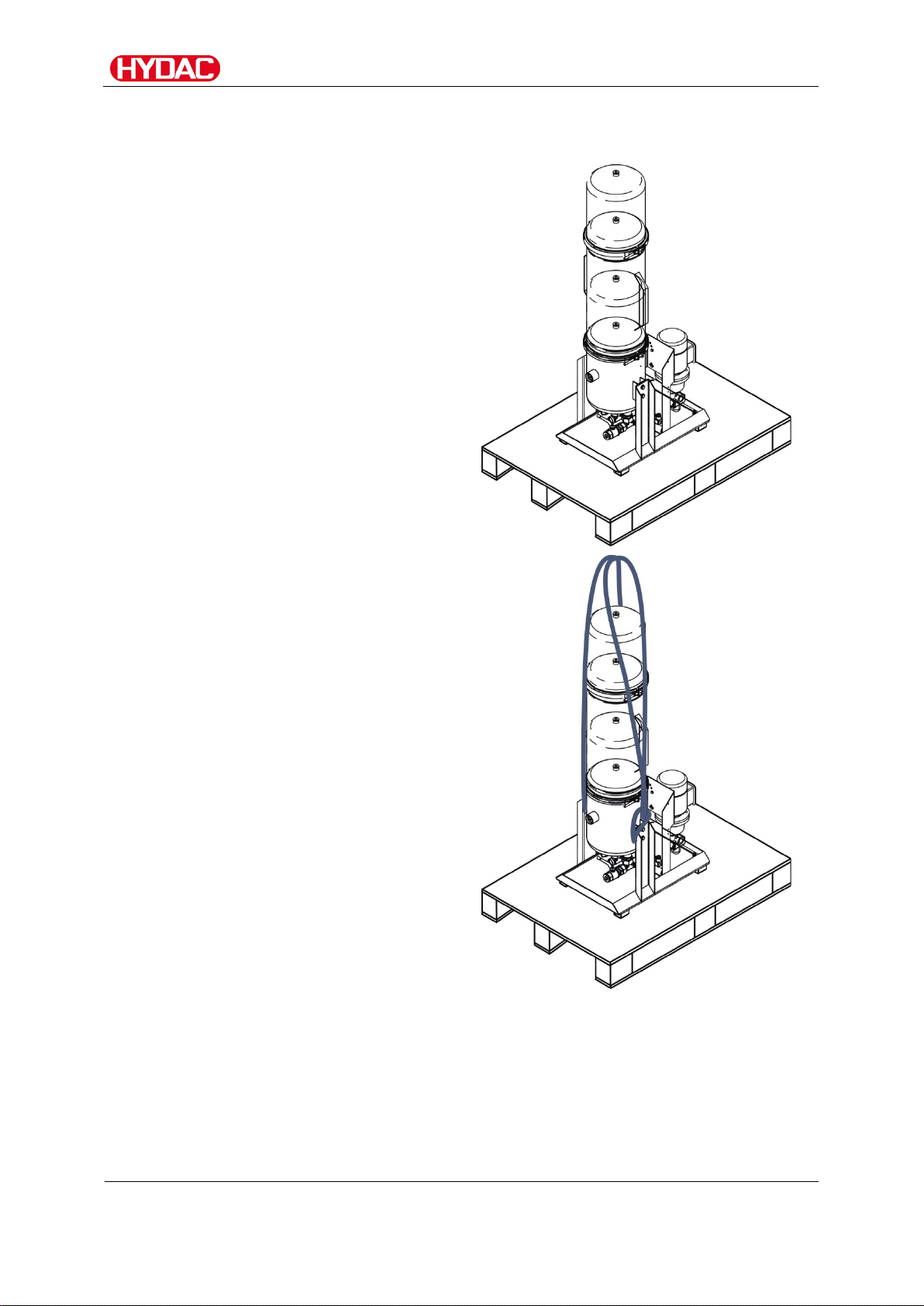

Transport the OLF in an upright

For transportation using a crane or

Transporting the OLF

position only.

forklift, use two slings at the

specified anchor points between

the filter housing and the base.

OLFCM 15/30/45/60

en(us)

17 / 84

Page 18

Storing the OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Storage temperature:

5 … 30°C / 41 … 86°F

Humidity:

up to 80% relative humidity, non-condensing

Air condition:

Clean, salt-free air, not near oxidizing substances

Storage duration:

Indefinite.

Store the OLF in an upright

Storing the OLF

Completely drain the OLF and remove all filter elements before putting into

storage.

position only.

(rust film).

Before the unit is started up again after being

stored for more than two years, all seals must be

replaced.

OLFCM 15/30/45/60

en(us)

18 / 84

Page 19

Checking the scope of delivery

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Item

Qty.

Description

1 1 OffLine Filter 15/30/45/60

Operation and Maintenance Instructions OLFCM 15-60

- 1 Operating and maintenance instructions CS1000

- 1 Operating and maintenance instructions AS 1000 (optional)

- 1 Operating and maintenance instructions SMU1200 (optional)

Checking the scope of delivery

Upon receiving the OLF, check it for any damage in transit. Do not put the

OLF into operation unless it is in perfect condition. Any damage in transit is to

be reported to the forwarding agent or the department in charge immediately;

the unit may not be commissioned until this damage is properly remedied.

The following items are suppl ied:

- 1

(this document)

OLFCM 15/30/45/60

en(us)

19 / 84

Page 20

OLF Features

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Differential pressur e at 15l/min.

Viscosity [mm²/s]

OLF Features

The filters of the OLF 15/30/45/60 series are sturdy filters for stationary

applications in hydraulic and lubrication systems with large volumes of fluid.

Features of the DIMICRON® filter elements used in thes e filter s ar e thei r

particularly high contamination retention capacity and an environmentally

safe method of disposal (incinerable).

The OLFCM has a vane pump and is suitable for operating fluids with a

viscosity of 15–200 mm²/s.

Pressure drop over DIMICRON® filter element(s)

Differential pressur e [bar]

The pressure loss through the filter housing is negligible.

OLFCM 15/30/45/60

en(us)

20 / 84

Page 21

OLFCM components

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

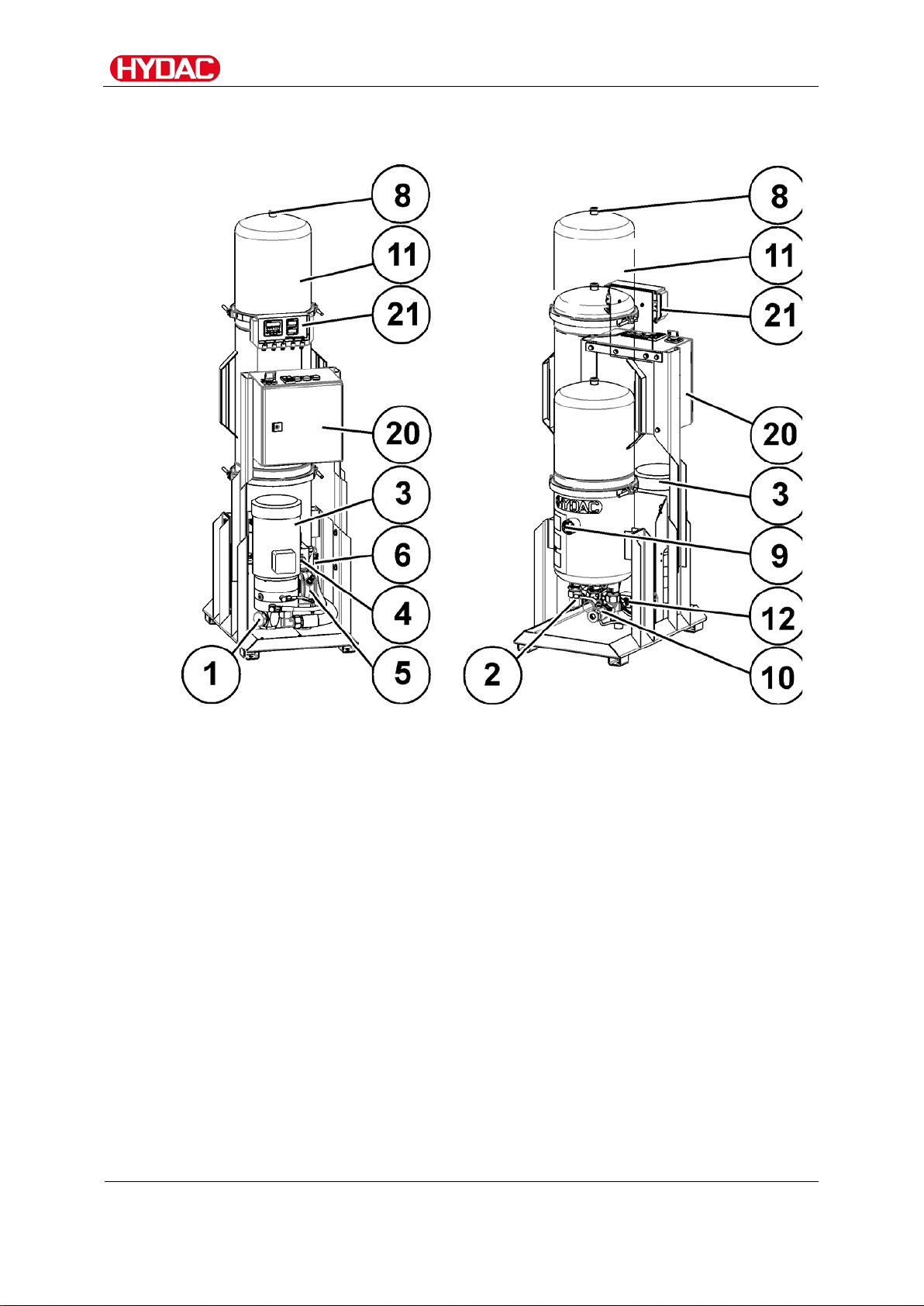

OLFCM components

OLFCM 15/30/45/60

en(us)

21 / 84

Page 22

OLFCM components

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Item

Description

1

Inlet (IN)

2

Outlet (OUT)

3

Motor pump assembly

4

Protective screen

5

ContaminationSensor CS1000

6

AquaSensor AS1000 (optional)

8

Air bleed

9

Back-pressure indicator

10

Draining

11

Filter housing

12

Differential pressur e indicator (optional)

20

Switch cabinet (optional)

21

SensorMonitoring Unit (opt ional)

OLFCM 15/30/45/60

en(us)

22 / 84

Page 23

Dimensions

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Dimensions

The filtration unit is available in different versions; below you will find an

overview with the corresponding dimensions.

Version OLF 15/15, 30/15

(All dimensions in mm)

OLFCM 15/30/45/60

en(us)

23 / 84

Page 24

Dimensions

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Version – OLF 30-60

(All dimensions in mm)

OLFCM 15/30/45/60

en(us)

24 / 84

Page 25

Dimensions

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Version – OLF30-60 - FA

(All dimensions in mm)

OLFCM 15/30/45/60

en(us)

25 / 84

Page 26

Hydraulic diagram

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

M

CS

OUT

IN

AS

3

4

5

6

7

8

12

11

10

9

1

2

Hydraulic diagram

OLFCM 15/30/45/60

en(us)

26 / 84

Page 27

Hydraulic diagram

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Item

Description

1

Inlet (IN)

2

Outlet (OUT)

3

Motor pump assembly

4

Protective screen

5

ContaminationSensor CS1000

6

AquaSensor AS1000 (optional)

7

Pressure control valve

8

Air bleed

9

Back-pressure indicator

10

Draining

11

Filter housing

12

Differential pressur e indicator (optional)

OLFCM 15/30/45/60

en(us)

27 / 84

Page 28

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

1.

Set up the unit horizontally on a level surface.

2.

Fasten the unit with suitable floor anchors.

3.

Make sure that there is sufficient space above the filter housing to

4.

Observe the maximum permissible ambient temperature and constant

5.

In the case of installation below the fluid level, install shut-off valves in

6.

We recommend installing a dirt trap or suction strainer with ~250 µm in

Setting up / installing the unit

Observe the following points when setting up the unit:

replace the filter elements.

supply of cooling air to avoid overheating the motor/pump assembly.

the feed and return lines.

the supply line of the filtration unit.

Drilling template for floor anchors

(All dimensions in mm)

OLFCM 15/30/45/60

en(us)

28 / 84

Page 29

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Δp ~ 6,8 * L / d4 * Q * V * D

Δ

=

Pressure differential in [bar]

L = Pipe length [m]

d = Internal pipe diameter [mm]

Q = Flow rate [l/min]

V = Kinematic viscosity [mm²/s]

D = Density [kg/dm³]

Mineral oil-based hy dr aul ic fluid has a

Notes on pipes and hoses

Make sure that no vibrations or stress/loading from other machinery and

equipment are carried over to the filter housing. If necessary, use expansion

joints.

The pressure loss in a hydraulic line depends upon:

• Flow rate

• Kinematic viscosity

• Pipe dimensions

• fluid density

The pressure loss can be estimated for hydraulic oils as follows:

p

density of ~ 0.9 kg/dm³.

This applies to straight pipelines and hydraulic oils. Additional threaded

connections and pipe bends increase the pressure differential. Additional

threaded connections and pipe bends increase the pressure differential.

Keep the height difference between the pump and the oil level in the tank as

low as possible.

Constrictions in the connections and lines should be avoided. This could

compromise suction output and cause cavitation .

Take note that the nominal size of the connected hoses/piping must be at

least as large as the inlet port sizes.

Make sure that no vibrations or stresses are carried over to filtration unit

when connecting the piping. Make sure that no vibrations or stress/loading

from other machinery and equipment are carried over to filter unit. Use hoses

or expansion joints if necessary.

OLFCM 15/30/45/60

en(us)

29 / 84

Page 30

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Connecting the suction port

For the suction port connection, use a flexible hose that is resistant to

negative pressure. Avoid constrictions in the connecting lines, as they

compromise suction performance and increase the risk of cavitation.

In case of coarse contamination (> 100 µm) such as weld splatter, an

appropriate suction strainer must be installed in the suction line in order to

protect the pump.

Overpressure at the suction port connection

The filter unit will be damaged

► The maximum pressure on the suction port connection IN must not be

more than -0.4 to 0.6 bar.

NOTICE

Connecting the pressure port

Make sure that the nominal width of the pressure line corresponds to the

threaded connection of the filter housing.

Install the return line below the oil level to prevent air from entering the fluid

in the tank

If the clogging indicator pressure displayed for the a clean

filter element is > 1 bar, use a differential pressure clogging

indicator.

OLFCM 15/30/45/60

en(us)

30 / 84

Page 31

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Electrical connection of the unit

Exposed electrical co mponents in the switch

cabinet

Danger of fatal injury due to electric shock

► Any work involving the electrical system may

The electrical connection of units without connection plugs to the power

supply module may only be performed by a technician with corresponding

knowledge and skills.

DANGER

only be done by a properly trained, certified

electrician.

Compare the voltage and frequency specifications on the motor type label

with the existing network specifications.

Depending on the voltage supply, connect the electri c mot or of the pum p wi th

a Y or delta connection (see nameplate on the corresponding motor).

Star (Y-) connection Delta connection

OLFCM 15/30/45/60

en(us)

31 / 84

Page 32

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Check direction of rotation

Check the direction of rotation of the motor by switching it on briefly (jog

mode).

The unit requires a clockwise rotating field at the connecting socket.

Incorrect phase sequence / rotation direction of the motor

The pump will be destroyed.

► In jog mode, check the direction of rotation of the motors.

► A rotation direction arrow on the fan cover of the motor identifies the

correct direction of rotation.

If rotation is in the opposite direction, change the phases in the terminal box

or rotate the phases in the connection plug using the phase inverter in the

connection plug.

NOTICE

OLFCM 15/30/45/60

en(us)

32 / 84

Page 33

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

- PKZ

FA0

FA1

FA2

FA3

The motor protection switch switches

Power supply for the installed

The differential pressure switch

The differential pressure switch

The differential pressure switch

Identifying electrical equipment

The unit is supplied with a variety of electrical equipment. Below you will find

the explanations of the abbreviations.

You can identify the electrical equipment using the type label.

off in case of electrical ov er l oad of

the filtration unit.

sensors

switches the filtration unit off when

the message "Filter clogged"

appears.

Neutral wire required.

switches the filtratio n unit off when

the message "Filter clogged"

appears.

No neutral wire required.

switches the filtratio n unit off when

the message "Filter clogged" or

"Target purity reached" appears.

No neutral wire required.

OLFCM 15/30/45/60

en(us)

33 / 84

Page 34

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Without electrical equipment

Install a suitable motor protection switch and connect the power supply to the

electric motor terminal box.

Connect the differential pressure sensor and forward the desired signals to

the control.

Supply the contamination sensors with the appropriate voltage and forward

the desired signals to the control.

PKZ – On/off switch with connection cable

Connect the power supply from the on/off switch to your network. If the builtin motor protection switch trips, the fault indicator lamp lights up.

Connect the differential pressure sensor and forward the desired signals to

the control.

Supply the contamination sensors with the appropriate voltage and forward

the desired signals to the control.

FA0 – Filter switch-off 0

Connect the power supply from the control cabinet to your network. If the

built-in motor protection switch trips, the fault indicator lamp lights up.

Connect the differential pressure sensor and forward the desired signals to

the control.

The contamination sensors are supplied with the appropriate voltage.

FA1 – Filter switch-off 1

Connect the power supply from the control cabinet to your network. If the

built-in motor protection switch trips, the fault indicator lamp lights up.

The differential pressure sensor switches the filtration unit off when the

message "Filter clogged" appears. The fault indicator lamp "Change oil filter"

lights up.

No neutral wire is required in the connecting line.

FA2 – Filter switch-off 2

Connect the power supply from the control cabinet to your network. If the

built-in motor protection switch trips, the fault indicator lamp lights up.

The differential pressure sensor switches the filtration unit off when the

message "Filter clogged" appears. The fault indicator lamp "Change oil filter"

lights up.

No neutral wire required.

OLFCM 15/30/45/60

en(us)

34 / 84

Page 35

Setting up / installing the unit

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

FA3 – Filter switch-off 3

Connect the power supply from the control cabinet to your network. If the

built-in motor protection switch trips, the fault indicator lamp lights up.

The differential pressure sensor switches the filtration unit off when the

message "Filter clogged" appears. The fault indicator lamp "Change oil filter"

lights up.

The ContaminationSensor monitors the contamination of the fluid and

switches the filtratio n u nit off at the set target purity .

OLFCM 15/30/45/60

en(us)

35 / 84

Page 36

Starting up the OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

In the "PKZ" version , the unit has an

Starting up the OLF

WARNING

Hydraulic system is under pressure

6 bar maximum

87 psi max.

Danger of bodily injury

► Note the maximum operating pressure

► The hydraulic system must be depress ur ized

► Vent the filter housing

Before commissioning, open the filter housing and check that the filter

elements are firmly in place and that the locking cap is installed, or insert the

filter elements if necessary. You can find details about changing the filter

elements on page 52.

Put the OLF into operation only after all preparations for commissioning are

complete.

Operating elements - PKZ version

on/off switch with a motor protection

switch. Switch the pump on or off at

the on/off switch.

before performing any work on the hydraulic

system.

OLFCM 15/30/45/60

en(us)

36 / 84

Page 37

Starting up the OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Item

Description

Q1

Main switch

S1

On switch

S2

Stop switch

H1

Fault indicator lamp

H2

Fault indicator lamp "Replace filter eleme nts"

Operating elements – version FA1 / FA2

This version has the following operating elements on the switch box:

OLFCM 15/30/45/60

en(us)

37 / 84

Page 38

Starting up the OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Item

Description

Q1

Main switch

S1

On switch

S2

Stop switch

H1

Fault indicator lamp

H2

Fault indicator lamp "Replace filter eleme nts"

S3

Operating mode selector switch

Operating elements – version FA3

This version has the following operating elements on the switch box:

OLFCM 15/30/45/60

en(us)

38 / 84

Page 39

Starting up the OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

1.

o.k.

2.

SWtOUT

o.k.

3.

o.k.

4.

TARGET

o.k.

5.

o.k.

6.

RSTART

o.k.

7.

Setting the target purity on the CS is complete.

Setting operating mode "Operation until target purity reached" on the CS

Turn the operating mode selector switch S3 to position "Operation until target

purity reached" and turn the unit on at on-switch S1.

To adjust the target purity of the CS, proceed as follows:

Press the

Scroll with the buttons until the display shows

confirm with the

Confirm the M4 display with the

Scroll with the buttons until the display shows

press the

button.

and

button.

button.

and

button.

Set the desired target puri ty with the buttons + and

confirm with the

Scroll with the buttons until the display shows

press the

button.

button.

and

OLFCM 15/30/45/60

en(us)

39 / 84

Page 40

Starting up the OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

1.

o.k.

2.

SENS A

o.k.

2.

SWtOUT

o.k.

3.

o.k.

4.

TARGET

o.k.

5.

o.k.

6.

Esc

SAVE

o.k.

7.

Unplug the power supply / plug for the CS or SMU for 20 seconds

8.

Setting the target purity on the SMU is complete.

Setting operating mode "Operation until target purity reached" on the SMU.

Turn the operating mode selector switch S3 to position "Operation until target

purity reached" and turn the unit on at on-switch S1.

To adjust the target purity of the SMU, proceed as follows:

Press the

button.

Scroll with the buttons until the display shows

confirm with the

button.

Scroll with the buttons until the display shows

confirm with the

Confirm the M4 display with the

button.

button.

Scroll with the buttons until the display shows

press the

button.

Set the desired target puri ty with the buttons + and

confirm with the

Press the

with the

button.

button.

button three times until

appears and confirm

and then plug them in again.

and

and

and

Operational mode "Continuous operation"

Turn the operating mode selector switch S3 to position "Continuous

operation" and turn the unit on at on-switch S1.

OLFCM 15/30/45/60

en(us)

40 / 84

Page 41

Operating the ContaminationSensor (display is optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

WAIT99

WAIT0

Item

LED

Designation

A

Status

B

Display

C

Measured

D

Service variable

E

Switch point 1

F

Switch point 2

Operating the ContaminationSensor (di splay is optional)

If the sensor is switched on or supplied with power, the display shows

HYDAC CS1000 in moving letters, then the firmware version is displayed for

2 seconds.

This is followed by a countdown:

…

.

The durat ion of the countdown corresponds to the set measurement time

MTIME. This means that the countdown runs from 99 ... 0 within the set

measurement time (factory setting = 60 sec).

OLFCM 15/30/45/60

variable

Status display

6-figure display with 17 segments each

Display of respective measured variable,

e.g: ISO / SAE / NAS

Display of respective service variable,

e.g.: Flow / Out / Drive / Temp

Indicates the status of the switching output. When

the LED is lit, the switching output is activated, i.e.

the switch is closed.

Reserved

en(us)

41 / 84

Page 42

Operating the ContaminationSensor (display is optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Key

Function

o.k.

You jump one menu level down.

Esc

You jump up one menu level.

o.k.

+

You scroll throug h the di spl ay

Function of the Keys

The following keys are available to you for operating and setting the C S1x2x.

You confirm a changed value at the lowest menu level.

You confirm at the top menu level to save or reject a

change in value.

In order to leave the menu without changing the values,

press the ESC key until SAVE appears in the display.

With the keys switch to CANCEL and confirm

with the

key or wait 30 seconds without pressing a

key.

You exit the menu without changing the values.

You change values / settings on the lowest menu level.

ISO / SAE/NAS / Flow / Out / Drive / Temp.

You move through the menu.

You select numbers.

Once the lowest menu level has been reached, the values in the display will

start to flash.

OLFCM 15/30/45/60

en(us)

42 / 84

Page 43

Operating the ContaminationSensor (display is optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Display

Designation

Display

Designation

Display

Designation

2=1(1%

A &1

15 1§2

Measured variables on the display

The measured variables give you information on the oil cleanliness in the

system.

You will gain a measured value with an accuracy of ± 1/2 ISO code wi thi n the

calibrated range.

ISO (Cleanliness class)

SAE (Cleanliness class)

Measured value ISO code

NAS (Cleanliness Class - only CS 13xx)

SAE class measurement cat eg or y

NAS class measurement categ or y

OLFCM 15/30/45/60

en(us)

43 / 84

Page 44

Operating the ContaminationSensor (display is optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Display

Designation

Display

Designation

Display

Designation

Display

Designation

1§8

60

2)5C

Service variables on the display

The service variables inform you about the current status in the

ContaminationSensor.

The service variables are not calibrated. They represent an approximate

value for installing the sensor in the hydraulic system.

Flow (flow rate)

Out (Analog output)

Flow rate in permissible range

Drive (performance of the LED)

Temp (Temperature)

Current or voltage output at the analog

output.

(example: 13.8 mA)

Performance (1-100%) of the LED in the

sensor.(example: 60%)

Fluid temperature in the sensor.

(example: 29.5 °C or 84.2 °F)

OLFCM 15/30/45/60

en(us)

44 / 84

Page 45

Operating the ContaminationSensor (display is optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Keys

The following appears in the

+

+

LOCK

UNLOCK

Activate / deactivate keypad lock.

Activate or deactivate the keypad lock by pressing both keys simultaneously

to prevent further input.

display (1 sec)

The display switches to the preset display after 1 second.

When the supply voltage to the CS is disconnected, the activated keypad

lock "LOCK" is unlocked and reset to "UNLOCK".

Designation

Activating key lock

Deactivating key lock

OLFCM 15/30/45/60

en(us)

45 / 84

Page 46

Operating the SensorMonitoring Unit SMU (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

2=1(1%

C

A

D

B

3/8

1)3

E

Item

LED

Description

A

Status

Status display

B

Display

Consists of a 6-digit display and shows the

C

Measured

This indicates which measurement is currently

D

Service variable

Indicates which service variable is shown in the

E

Unit (of

The units of the fluid temperature display can be

Operating the SensorMonitoring Unit SMU (optional)

If the SMU is powered up, then it can be used and parameters can be set,

even without any sensors being connected.

The saving of measurement data is accomplished after a minimum of one

sensor has been connected.

The individual controls and their operation are described in the following.

Display (CS1000 and AS1000)

variable

measurement)

Keyboard elements

The keyboard consists of six buttons. These buttons are used to operate the

SMU and to navigate through the menus (hierarchically structured).

selected measured values.

being shown in the display e.g. ISO / SAE/NAS.

display e.g. Flow / Drive.

set to °C or °F.

OLFCM 15/30/45/60

en(us)

46 / 84

Page 47

Operating the SensorMonitoring Unit SMU (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Keyboard

Designation

o.k.

One level lower

Esc

One level higher

Scroll through display

Keys

The following appears in the

+

LOCK

+

UNLOCK

Confirmation of changed value (lowest level)

confirm when changes are to be saved or cancelled (top

level)

No value change

Change values at the lowest levels

(if you are at the lowest menu level, the display will flash)

Scroll through menu

Select numbers

Activating/deactivating key lock

Lock the keyboard to prevent unwanted / accidental entries or operation. To

activate or deactivate keypad locking, press both keys simultaneously.

display (1 sec)

Designation

Key Lock is activated

The display switches to the preset display after 1 second.

Key Lock is deactivated

OLFCM 15/30/45/60

en(us)

47 / 84

Page 48

Operating the SensorMonitoring Unit SMU (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Keys

Display

Designation

o.k.

2=1(1%

3/8

1)3

Switching the display on and off

You can switch off the display. Only the status LED stays active on switched

off displays.

To switch off the display, press the two keys simultaneously.

Switching back on is accomplished by pressing any key.

Switches displays off

Esc

Switches displays on

OLFCM 15/30/45/60

en(us)

48 / 84

Page 49

Operating the SensorMonitoring Unit SMU (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Display

Designation

2=1(1%

Display

Designation

&6A

ISO

Flow Out

TempDriveSAE/NAS

Display

Designation

15 1§2

Measured variables CS1000

The measurements provide you with information about the purity of the oil in

the system concerned. The measurement variables are calibrated. They

indicate a measured value with an accuracy of +/- 1/2 codes/class.

Measured variable "ISO"

Measured variable "SAE"

The measured value is updated

depending on the set measuring time.

Display of the 3-digit ISO code.

Measured variable "NAS"

The measured value is updated

depending on the set measuring time.

Display of a channel in the SAE class.

The measured value is updated

depending on the set measuring time.

Display of a channel in the NAS class.

OLFCM 15/30/45/60

en(us)

49 / 84

Page 50

Operating the SensorMonitoring Unit SMU (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Display

Designation

108

Display

Designation

1§8

Display

Designation

42

Display

Designation

2)5C

Display of the media temperature

Service variables

These values give you information about the current flow and the LED

brightness within the CS1000 Sensor. The service variables are not

calibrated.

Service variable "Flow"

Service category "Out"

Here, you can see the averaged flow

through the ContaminationSensor unit

(e.g. 108 ml/min)

Service variable "Drive"

Service category "Temp"

Here you can see the value emitted as

analog output signal (example: 13.8 mA)

Display of the current LED brightness (1100%) in the ContaminationSensor

(example: 42%).

indirectly measured in the

ContaminationSensor. The display takes

place dependent on setting in °C or °F

(example: 29.5°C)

OLFCM 15/30/45/60

en(us)

50 / 84

Page 51

Performing Maintenance

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Display

Designation

1)3

Display

Designation

3/8

AquaSensor AS1000 measured vari ables

Measured variable "Water saturation"

When using the AS, the measurement is

shown on the display as the relative

humidity of the operating fluid, expressed

as percentage saturation.

Measured variable "Temperature"

The AS continuously measures the fluid

temperature. Depending on the setting

under TP.UNIT, the measurement is

either shown in Celsius °C, or as

Fahrenheit °F.

Performing Mai ntenance

The OLF is standard-equipped with a dynamic pressure gauge. This displays

the pressure ahead of the filter ele men t.

Replace the filter elements immediately when the back pressure is > 2.5 bar

or when the indicator is in the red range.

Optionally, the OLF can also be supplied with electrical differential pressure

gauges.

WARNING

Hydraulic systems are under pressure

Danger of bodily injury

► The hydraulic system must be depress ur ized

before performing any work on the hydraulic

system.

OLFCM 15/30/45/60

en(us)

51 / 84

Page 52

Performing Maintenance

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

1.

Switch off the unit and make sure it cannot

2.

Close all shut-off valves at the inlet and

3.

Unscrew the air bleed screw (x) completely

4.

(1) Have a suitable drip tray on hand to

3.

Screw in the air bleed screw (x) by hand in a

Changing the filter element(s)

To change the filter elements, proceed as follows:

be inadvertently switched back on.

outlet.

using a 10 mm Allen wr ench.

catch the operating fluid.

(2) Open the drain fitting, and collect the

escaping fluid in the tray.

Once the housing has been completely

drained, close the drain fitting.

clockwise direction and tighten it firmly using

a 10 mm Allen wrench.

OLFCM 15/30/45/60

en(us)

52 / 84

Page 53

Performing Maintenance

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

4.

Release the housing tensioning clamps (1)

5.

Turn the element locking cap on the top filter

and remove them.

Remove the cover (a).

Remove the intermediate piece (b).

element by 90° in counterclockwise direction

(1) and lift off the locking cap (2).

OLFCM 15/30/45/60

en(us)

53 / 84

Page 54

Performing Maintenance

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

6.

Turn all filter elements 90° in a

7.

8.

Clean the inside of the filter housing of

counterclockwise direction, and remove

them.

in an environmentally friendly manner.

coarse dirt.

Check the O-rings on the filter housing for

damage. If necessary, replace them.

Dispose of the used filter eleme nt s

OLFCM 15/30/45/60

en(us)

54 / 84

Page 55

Performing Maintenance

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

9.

Insert the filter element into the bayonet

fitting (1), and lock it in place by turning each

10.

Place the element locking cap on the upper

individual filter element 90° in the clockwise

direction (2).

filter element (1).

Turn the locking cap 90° in the clockwise

direction to lock it in place.

No element locking cap = no

filtration.

OLFCM 15/30/45/60

en(us)

55 / 84

Page 56

Performing Maintenance

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

11.

Put the intermediate piece (b) on the lower

12.

Open all shut-off valves at the inlet and

13.

Fill the filter housing slowly.

14.

The filter element change is now complete.

section (c).

Mount the lower housing tensioning clamp

(1) and tighten it with a torque of 20 Nm.

Secure it using the lock nut.

Put the cover (a) on the intermediate piece

(b).

Mount the upper housing tensioning clamp

(2) and tighten it with a torque of 20 Nm.

Secure using the lock nut.

We recommend applying lubricant

containing a slip additive to the threads of

the housing tensioning clamp each time filter

elements are changed so that it remains

easy to remove.

Lubricant containing a slip additive - HYDAC

p/no..: 3066287

outlet.

Switch the unit on.

Slightly undo the air bleed screw (x). The air

in the filter housing can escape via the slot

on the air bleed screw.

Bleed the filter housing through the air bleed

screw (x) until operating fluid comes out.

Tighten the air bleed screw.

OLFCM 15/30/45/60

en(us)

56 / 84

Page 57

Performing Maintenance

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

10

20

20

30

40

Item

Description

10

Protective screen, 100 µm

20

O-ring

30

Screw connection

40

Screw connection

Exchanging the prefilter to the ContaminationSensor

NOTICE

Missing prefilter / operation without prefilter

The ContaminationSensor is blocked

► Never operate the unit without a prefilter

► Clean the prefilter regularly

A prefilter is installed to stop the ContaminationSensor from blockin g up.

Exchange the prefilter regularly depending on the contamination level of the

fluid.

OLFCM 15/30/45/60

en(us)

57 / 84

Page 58

Status messages – SMU1200 (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Display

Status

To do

Status

SMU

Check the power

SMU ready for

You can make further

0

NoSENS

A sensor is

Check sensor

NoSENS

No sensor is

Connect a sensor to

Status messages – SMU1200 (optional)

The SMU can take on the following status:

flashing code

-

Green

Red

no digits displayed

no function

operation

connected to sensor

interface A.

This is not

recognized.

supply to the SMU.

Contact the HYDAC

service department.

measurements.

interface A – is an

MCS1000 or a

CS1000 connected?

Check the connection

cables between the

sensor and the SMU.

Check the sensor bus

address. The bus

address must be

different to SENS B.

Switch the SMU off

and then on again.

-

3

OLFCM 15/30/45/60

Green

connected.

This display will go

out after 10

seconds.

en(us)

If the fault recurs,

contact HYDAC

service department.

sensor interface A.

Switch the SMU off

and then on again.

0

58 / 84

Page 59

Status messages – SMU1200 (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

ERROR

Sensor A is causing

Switch the SMU off.

ERROR

Sensor A is causing

Check sensor A (use

OUT

RNGE

AS1000 ≤ firmware

Wait for a few more

AS1000 ≥ firmware

Wait for a few more

Red

Red

Red

a moderate fault.

a major fault.

V2.04:

The senso r at

sensor interface B is

outside of the

measurement range.

V2.10:

If the error occurs

again, check sensor A

(use HNG 3000 as an

aid)

HMG3000 as an aid)

measurement cycles.

measurement cycles.

3

4

2

Green

The senso r at

sensor interface B is

outside of the

measurement range

or has a short circuit

at the sensor.

Dewater the fluid in

the saturated range.

Check the sensor

outside the fluid or

with the calibration

and adjustment set

(part no. 3122629)

2

OLFCM 15/30/45/60

en(us)

59 / 84

Page 60

Status messages – SMU1200 (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

No

SENS

A sensor is

Check sensor

No

SENS

No sensor is

Connect a sensor to

EROR

EROR

AS1000 ≥ firmware

Switch the SMU off

Red

Green

connected to sensor

interface B.

This is not

recognized.

connected.

This display will go

out after 10

seconds.

interface B – is an

AS1000 connected?

Check the connection

cables between the

sensor and the SMU.

Check the sensor bus

address. The bus

address must be

different to SENS A.

If the fault recurs,

contact HYDAC

service department.

sensor interface B.

Switch the SMU off

and then on again.

3

0

Red

V2.10:

The senso r at

sensor interface B is

causing a major

error.

and then on again.

If the fault recurs,

contact HYDAC

service department.

4

OLFCM 15/30/45/60

en(us)

60 / 84

Page 61

Status messages – SMU1200 (optional)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Display

Status /

Status

NoLOG

No log files are stored in the

ERROR

SMU

The SMU has a moderate

ERROR

SMU

The SMU has a major fault.

Red

flashing code

To do

memory.

Possible cause:

Other or new sensors have

been connected

The parameters for

REC.MOD have been

changed

3

Delete the memory in the

PowerUp menu.

Back up the data in advance

using the USB memory stick.

When adju sting the

REC.MOD, one must take

into account the fact that this

will need to be reset before

saving.

Red

Red

fault.

Switch the SMU off and then

on again.

If the fault recurs, contact

HYDAC service department.

Contact HYDAC.

3

4

OLFCM 15/30/45/60

en(us)

61 / 84

Page 62

Status messages – CS1000 (optionally with display)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Flash code /

Status

Remedy

Error

Analogue output

Switching output

Flow status on the

Status messages – CS1000 (optionally with display)

Status LED / Display

Gree

n

Gree

n

display

digital output

-

current value

mA / V*

Conductive

-

current value

mA / V*

Conductive

CS o.k. ---

The flow rate has

reached the upper

limit.

Reduce the flow

rate to prevent the

sensor from going

into the CHECK

error state.

no.

-

-

OLFCM 15/30/45/60

Gree

n

55

current value

mA / V*

Conductive

44

The flow rate has

reached the upper

permissible range.

en(us)

Check the flow rate

in short cycles.

The sensor is in

the upper

permissible flow

rate range.

-

62 / 84

Page 63

Status messages – CS1000 (optionally with display)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Flash code /

Status

Remedy

Analogue output

Switching output

Flow status on the

Error

no.

display

digital output

Gree

n

Gree

n

current value

mA / V*

Conductive

33

current value

mA / V*

Conductive

22

The flow rate is in

the middle

permissible range.

The flow rate has

reached the lower

permissible range.

Do nothing. The

sensor is in the

middle flow rate

range.

Check the flow rate

in short cycles.

The sensor is in

the lower

permissible flow

rate range.

-

-

Gree

n

current value

mA / V*

Conductive

OLFCM 15/30/45/60

11

The flow rate has

reached the lower

limit.

en(us)

Increase the flow

rate to prevent the

sensor from going

into the CHECK

error state.

-

63 / 84

Page 64

Status messages – CS1000 (optionally with display)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Flash code /

Status

Remedy

Analogue output

Switching output

Flow status on the

<)<(</

2CLEAN

Error

no.

display

digital output

The sensor is

Red

below its

measurement

---

-

range ISO 9/8/7

current value

mA / V*

Conductive

-1

OLFCM 15/30/45/60

en(us)

64 / 84

Page 65

Status messages – CS1000 (optionally with display)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Flash code /

Status

To do

Error

Analogue output

Switching output

Flow status on the

below

CHECK

2%2$2§

2DIRTY

Error

Red

display

digital output

- mA / - V

open

-1

It is not possible to

determine the flow

rate.

The sensor status

is undefined.

Check that the flow

is between 30 …

500 ml/min.

If the fluid

cleanliness is

the measurement

limit (ISO 9/8/7), it

may take several

measurement

cycles until

measured values

are displayed.

no.

3

Red

19.9 mA / 9.95 V*

open

-1

The sensor is

above its

measurement

range

ISO 25/24/23.

It is not possible to

determine the flow

rate.

Filter the fluid.

3

OLFCM 15/30/45/60

en(us)

65 / 84

Page 66

Status messages – CS1000 (optionally with display)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Flash code /

CS1000 Status

To do

Error

Analogue output

Switching output

Flow status on the

Exceptions Errors

OFF

Red

display

digital output

0 mA / 0 V*

open

-

-

4.1 mA / 2.05 V*

CS

no display

no function.

Firmware error

Check the supply

voltage for the CS.

Contact HYDAC.

Reset the unit. (To

do this, disconnect

the CS from the

voltage supply) or

contact HYDAC.

no.

-

-1…-19

Red

open

-

-

4.1 mA / 2.05 V*

open

-

Communication

error

Check the wiring.

-20…-39

OLFCM 15/30/45/60

en(us)

66 / 84

Page 67

Status messages – CS1000 (optionally with display)

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

LED

Flash code /

CS1000 Status

To do

Analogue output

Switching output

Flow status on the

Error

no.

display

digital output

Red

Red

Red

-

4.1 mA / 2.05 V*

open

-

-

4.1 mA / 2.05 V*

open

-

-

4.1 mA / 2.05 V*

open

-

System error

Error during

automatic

adjustment

Error measuring

cell LED

Reset the unit. (To

do this, disconnect

the CS from the

voltage supply) or

contact HYDAC.

Reset the unit. (To

do this, disconnect

the CS from the

voltage supply)

/ check the flow

rate or contact

HYDAC.

Reset the unit. (To

do this, disconnect

the CS from the

voltage supply)

/ check the flow

rate or contact

HYDAC.

-40…-69

-70

-100

* Is not valid for HDA 5500 output signal

OLFCM 15/30/45/60

en(us)

67 / 84

Page 68

Errors and troubleshooting

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Error

Cause(s)

Remedy

No oil flow

Pump transf ers in

Make sure that the pump is

Screw connection

Retighten the screw

Strainer in the

Check or clean the suction

Suction hose bent /

Check the suction hose for

Air in suction area

Fill the pump via the suction

The viscosity of the

Check the viscosity of the

Motor without

Check the supply line to the

Motor / pump

Contact HYDAC.

Change oil filter

Medium heavily

Replace the filter element s.

The viscosity of the

Check the viscosity of the

No supply voltage

Check the supply voltage.

Errors and troubleshooting

the wrong direction

of suction pipe

untight

suction pipe dirty

defective

and pump

fluid is too high

functioning in the direction

shown by the arrows on the

housing. If necessary, switch

two phases in the motor

control box.

connection on the hose

coupling.

strainer.

freedom of passage. Replace

it if necessary.

hose / hose coupling.

medium.

Heat the medium to reach the

permissible viscosity.

(Clogging indicator

appears)

OLFCM 15/30/45/60

voltage

defective

contaminated

Filter element

lifetime is exceeded

fluid is too high

available

en(us)

filtration unit. Replace it if

necessary.

medium.

Heat the medium to reach the

permissible viscosity.

68 / 84

Page 69

Errors and troubleshooting

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Error

Cause(s)

Remedy

Running noise of

cavitation due to

Clean the suction strainer.

2=2=19

The pump is

Push the suction hose deeper

The pump is

Check the screwed fitting for

Air is drawn into the

The pressure hose or the

The viscosity of the

Check the viscosity.

The volumetric flow

Remove the CS and blow it

The CS does not

Check the pump for proper

The CS is blocked.

Remove the CS and blow it

The pump is not

There is no oil in

Fill the pump via the suction

CHECK

CHECK

motor-pump assembly

becomes substantially

louder.

blocked strainer in

the suction pipe.

sucking in air. The

suction hose is

positioned above

the oil level.

sucking in air.

tank.

fluid to be

conveyed is too

high.

into the tank, beneath the oil

level.

leaks.

pressure lance is positioned

about the level of the oil. Dip

the pressure lance into the oil.

sucking or sucking

badly.

over the CS is too

low.

The CS or the

prefilter is blocked.

recognize flow.

the pump.

out using compresse d air

against the direction of flow.

Check the prefilter to the CS.

Clean or replace the prefilter.

functioning.

Switch the unit on.

out using compressed air

against the direction of flow.

hose.

OLFCM 15/30/45/60

en(us)

69 / 84

Page 70

Disposal of OLF

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

1.

Switch the unit off.

2.

Close all shut-off valves on the unit.

3.

Drain the unit completely.

4.

Remove all the filter elements.

5.

Clean the inside of the filter housing.

6.

Remove all the hydraulic and electrical connections to the unit.

Disposal of OLF

To take the OLF out of operation, proceed as follows:

Disposing of the OLF

Dispose of the packaging material in an environmentally-friendly manner.

After dismantling the unit and separating the various materials, dispose of the

unit in an environmentally friendly manner.

OLFCM 15/30/45/60

en(us)

70 / 84

Page 71

Spare Parts List

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

Spare Parts List

Use only original spare parts. Make sure to always indicate the exact unit

designation (see nameplate) and the serial number when ordering spare

parts.

OLFCM 15/30/45/60

en(us)

71 / 84

Page 72

Spare Parts List

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

OLFCM 15/30/45/60

en(us)

72 / 84

Page 73

Spare Parts List

BeWa OLFCM 15-60 3595923a en-us 2018-06-28 .docx

2018-06-28

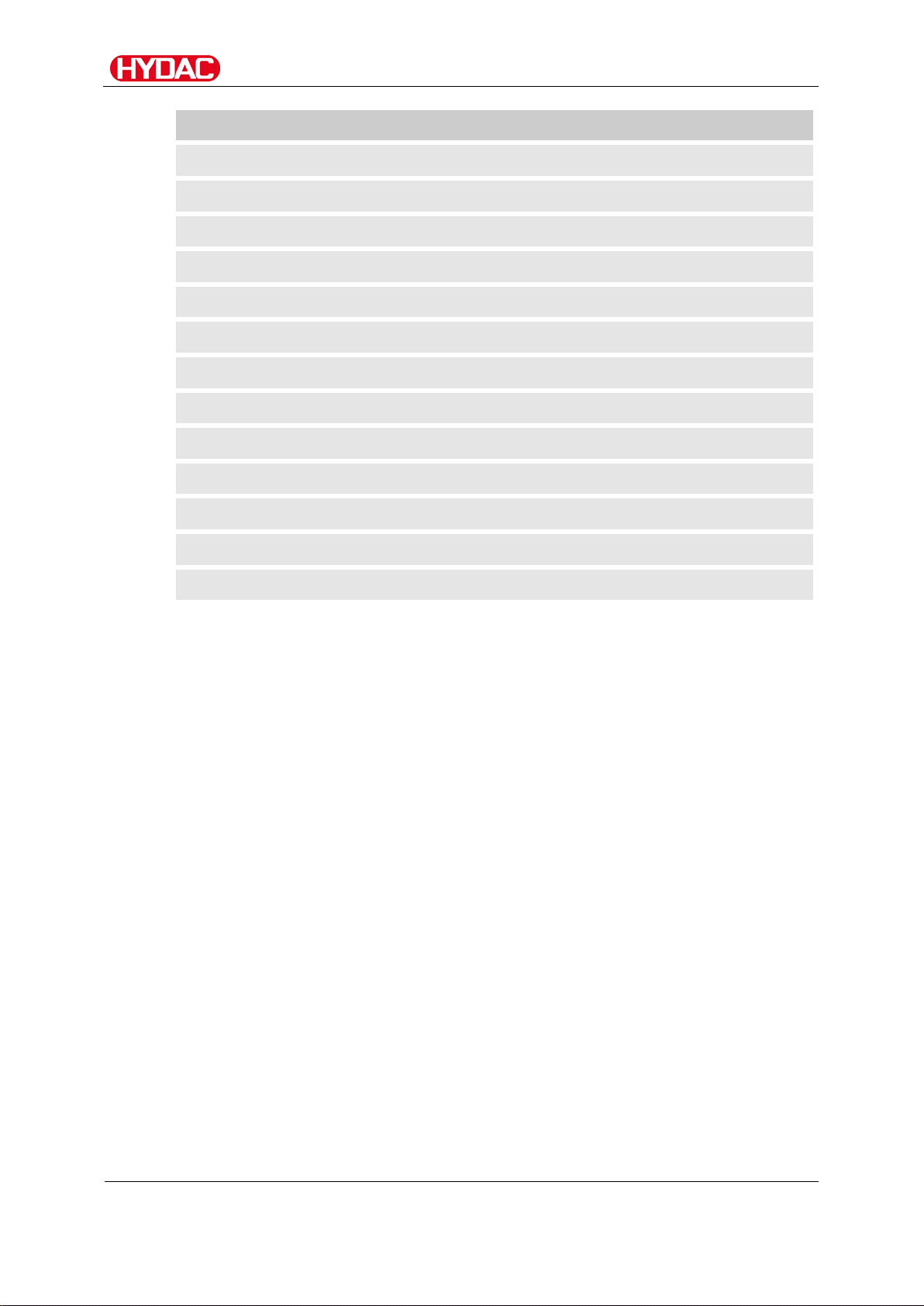

Item

Description

Part no.

Qty.

15

30

45

60 1 Foot

3030479

1 1 1 1 2

Lower section

3076290

1 1 1 1 3

Intermediate piece

3030463

- - 1 1 4

Cover, tall

3030461

- 1 - 1 5

Cover, flat

3030462

1 - 1 - 6

Filter element locking cap

0349235

1 1 1

1

7

Tensioning clamp for the

6 bar / 87 psi

6005235

1 1 2

2

8

O-ring for housing

NBR

6005449

1 1 2 2 8

O-ring for housing

FKM

6012630

1 1 2 2 9

Air bleed plug [Air bleed]

0403302

1 1 1 1 10

Filter element 2 µm

N15DM002

1251590

1 2 3 4 10

Filter element 5 µm

N15DM005

3252552

1 2 3 4 10

Filter element 10 µm

N15DM010

3115180

1 2 3 4 10

Filter element 20 µm

N15DM020

0349576

1 2 3 4 10

Filter element 30 µm

N15DM030

3048790

1 2 3 4 11

Dynamic pressure gauge

0036198

1 1 1

1

12

Clogging indicator /

* - - -

13

Vane pump with motor

* - - - - -

SMU1200

*

-

CS1000

*

-