Page 1

Electronic Pressure Switch

EDS 300

User manual

Stand 10.11.2000

Page 2

1. Functions of the EDS 300

points, switch-back points and

Depending on the model, the unit offers the following functions:

• Display of the actual pressure, maximum value or a switching point.

• Switching the switching outputs according to the pressure and the pre-set switching

parameters.

• Analogue output

• Menu for basic settings (adapting the EDS 300 to the particular application)

• Two different types of programming enable

Three different output models are available:

• EDS 300 with 1 switching output (1.2 A load capacity, no analogue output)

• EDS 300 with 2 switching outputs (1.2 A load capacity, no analogue output)

• EDS 300 with 1 switching output (1.2 A load capacity) and 1 analogue output (4...20 mA)

2. Mounting

The EDS 300 can be mounted directly onto a hydraulic block via the pressure connection

(7/16 SAE 4 female).

When used in critical applications (e.g. strong vibrations or knocks) the pressure connection

must be mechanically decoupled via a Minimess hose. Mounting clamps are available as an

accessory (see point 12.2 "Accessories - for mechanical connection").

The electrical connection should be carried out by a qualified electrician according to the

relevant regulations of the country concerned (VDE 0100 in Germany). The pressure switch

housing must be earthed properly at the same time. When fitted into a hydraulic block it is

sufficient if the block is earthed via the hydraulic system. In the case of Minimess hosemounting, the housing must be earthed separately.

Additional assembly notes which, from experience, reduce the effect of electromagnetic

interference:

• Make line connections as short as possible.

• Use screened lines (e.g. LIYCY 4 x 0.5 mm

2

)

• The cable screening must be fitted by qualified personnel subject to the ambient

conditions and with the aim of suppressing interference.

• Direct proximity to connecting lines of user units or electrical or electronic units causing

interference must be avoided as far as possible.

3. Operating keys on the membrane keypad

HYDAC EDS 300

4-digit

digital display

SP1 SP2

PSI

mode

keys for setting switching

additional functions

4. Digital display

Page 3

After switching on the supply voltage, the unit briefly displays “EdS” followed by the current

2 s

pressure.

In the basic settings the display can be altered. For example, the maximum value can be

permanently displayed. This is the largest measured value which has been recorded since

the unit was switched on or was last re-set. A switching point can likewise be permanently

displayed or the display can be set to be dark. Depending on the setting, "TOP", "S.P. 1",

"S.P. 2" or "OFF" appears briefly on the display following the switch-on message.

The actual pressure can be displayed briefly by pressing the

or the key. This causes

the maximum value to be re-set.

Notes:

• If the actual pressure exceeds the nominal pressure of the unit, it can no longer be

displayed and the display begins to flash.

• If the actual pressure is below 1 % of the nominal range, then 0 is displayed.

Page 4

5. Output function

t

Safety zone

Safety zone

Off

Switch-back valuet

5.1 Switching outputs

The EDS 300 has 1 or 2 switching outputs. The following settings can be made under the

basic setting:

5.1.1 Switching point setting (SP)

One switching point and one hysteresis can be set for each switching output. The respective

output switches when the pre-set switching point is reached and switches back when the

pressure falls below the switch-back point. The switch-back point is determined by the preset hysteresis (switch-back point = switching point minus hysteresis).

Abbreviations: "S.P.1", "S.P.2" = switching point 1 or 2

"h.Y.1", "h.Y.2" = hysteresis 1 or 2

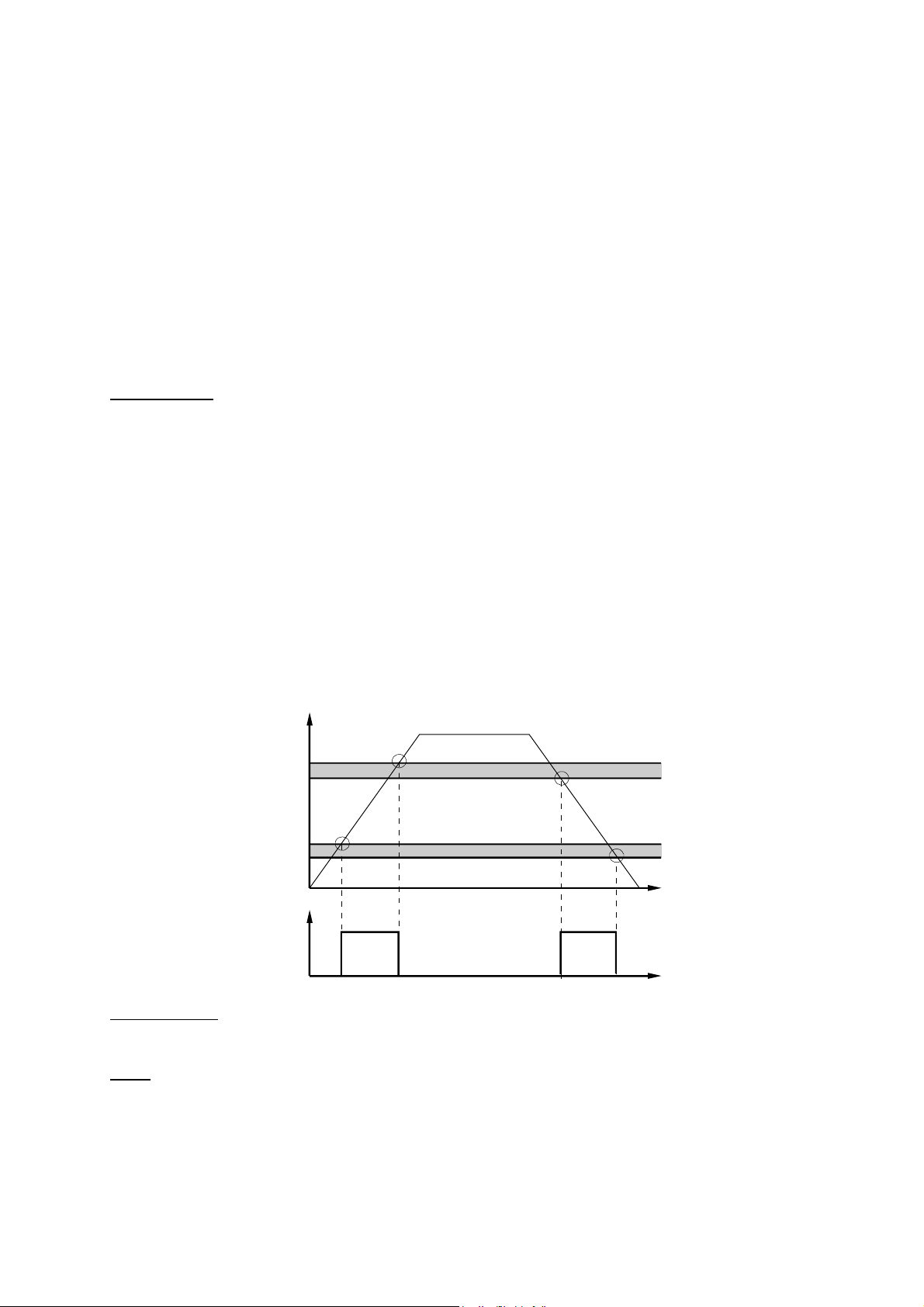

5.1.2 Window function setting (WIN)

The window function enables a range to be monitored. For each switching output, in each

case an upper and a lower switching value can be input which determine the range.

The respective output switches when the pressure enters this range. Upon leaving the

range, i.e. when the switch-back value has been reached, the output switches back. The

lower switch-back value is just below the lower switching value (lower switching value minus

three times the increment, see point 5.4). The upper switch-back value is just above the

upper switching value (upper switching value plus three times the increment, see point 5.4).

The area between switching and switch-back value forms a safety zone which prevents

unwanted switching operations from occurring (e.g. triggered by pulsations from a pump).

Example for switching output 1 (normally open function):

P

hi.1 plus 3xincrement

hi.1

On

Lo.1

Lo.1 minus 3xincrement

ON

Off

On

Off

Switching value

Switching value

Switch-back value

Abbreviations: "hi.1", "hi.2"= High level 1 or 2 = upper switching value 1 or 2

"Lo.1", "Lo.2"= Low level 1 or 2 = lower switching value 1 or 2

Note: The window function only operates correctly (switching on and off), when all switching

values (including the safety zone) are greater than 0 bar and lower than the nominal

pressure range.

5.2 Analogue output

On specified models, the EDS 300 provides one analogue output with a 4...20 mA signal.

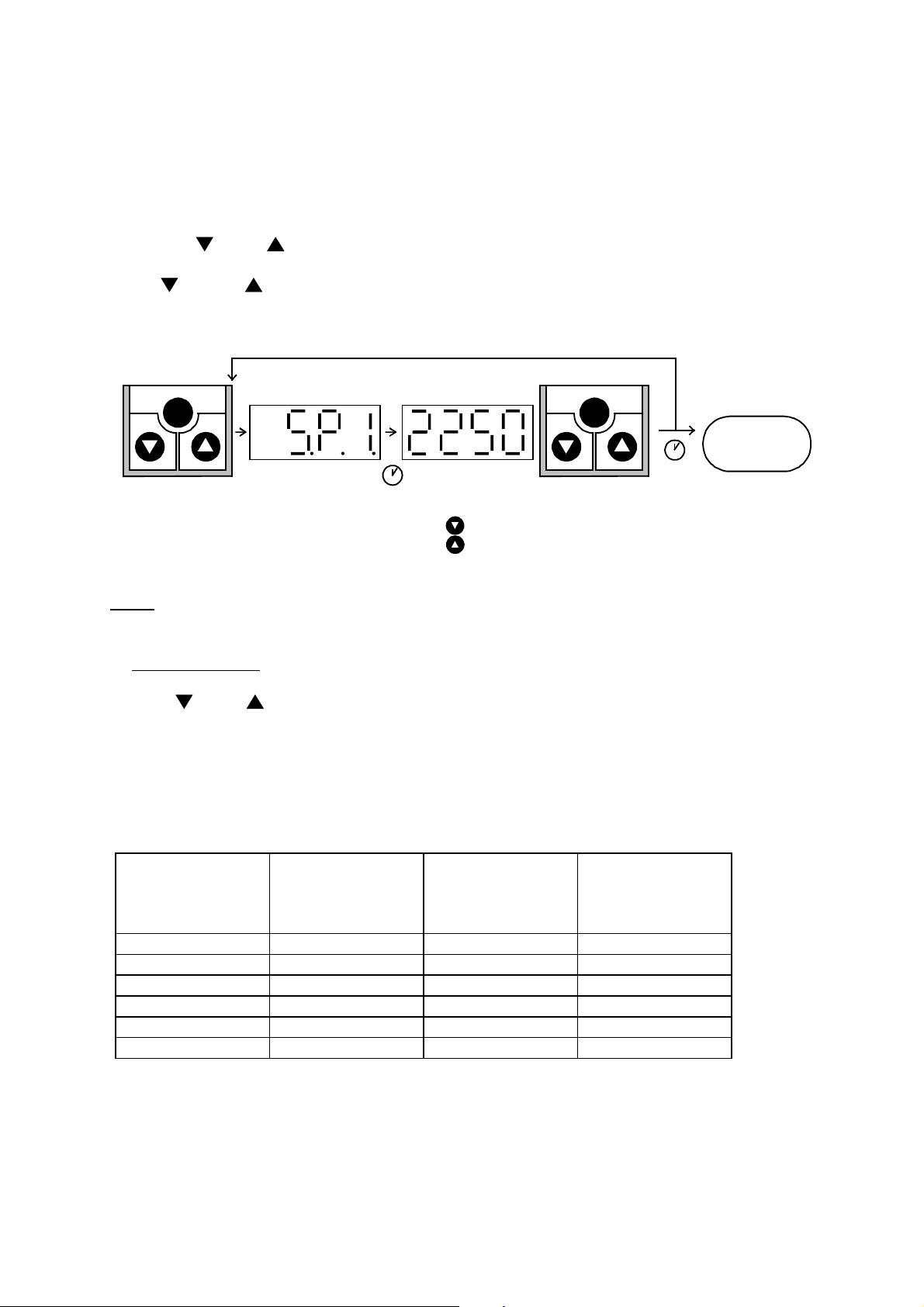

5.3. Setting the Switching Points and Hystereses

Page 5

• Press "mode" key

2 s

3 s

pressure

set switching point

reached.

• "S.P.1" or "hi.1" is displayed

• Keep pressing the "mode" key until the required parameter is displayed (depending on

he basic setting: "S.P.1", "h.Y.1", "S.P.2", "h.Y.2", "hi.1", "Lo.1", "hi.2" or "Lo.2").

t

• After 2 seconds the actual setting flashes.

• Use the

• Use the "mode" key to call up other parameters, if required, and alter the setting using

the

• If no keys are pressed for 3 seconds, the display changes back and the settings are

saved.

or the keys to alter the setting.

and the keys.

mode

press “mode” key display

until the required

parameter is

Notes:

• If "LOC" appears in the display when trying to alter the settings, programming is disabled.

Corrective action: set programming enable to "ON"

(see point 7 "Programming enable")

• If the

• If a setting has been altered, "PRG" appears briefly in the display when the display is

switched over. The new setting is then saved in the unit.

5.4 Setting ranges of the switching points and/or hystereses

or the key is held down during alteration, the value automatically advances.

=smaller value

=larger value

mode

display

Measuring range

* All ranges given in the table are adjustable by the increments shown.

6. Basic settings

Switching point

in psi

-14 .. 75 -12.5 .. 75.0 -0.5 .. 74.0 0.5

0 .. 150 3 .. 150 1 .. 148 1

0 .. 1000 15 .. 1000 5 .. 990 5

0 .. 3000 45 .. 3000 15 .. 2970 20

0 .. 6000 90 .. 6000 30 .. 5940 30

0 .. 9000 150 .. 9000 50 .. 8900 50

and/or upper

critical value

in bar

Hysteresis and/or

lower critical value

in bar

Increment *

in psi

Page 6

In order to adapt the unit to a particular application, the function of the EDS 300 can be

altered via several basic settings. These are combined in a menu.

6.1 Altering the basic settings

Important note: when the menu is activated no switching operations are carried out.

Switch off supply voltage or disconnect the unit from the supply voltage.

mode

mode

mode

3 s

press “mode” key and

hold down. Switch

on supply voltage

(hold key down for 3s)

To close the basic setting menu

Call up the menu point "END", set to "YES", the EDS 300 returns to the normal display

mode after 2 seconds.

Note:

If after about 50 seconds no keys have been pressed, the menu automatically closes down.

Any changes which may have been made will not be saved.

6.2 Summary of the basic settings

Setting Display Setting

Switching mode switching output 1 (Sm 1)

display

(release

“mode” key)

press “mode” key until th e

required menu point appears

in the display

(for summary, see 6.2)

.

2 s

Use or to alter

setting, then s elect next

menu point

range

SP/ Win SP

.

Presetting

Switching output 1 operates in switching

point / hysteresis function

Switching output 1 operates in window

function

Switching direction switching output 1 (S 1)

“ON”: normally open function.

“OFF”: normally closed function.

Switch-on delay switching output 1 (T

Time in seconds which must elapse, once the

particular switching point has been reached or

exceeded, before switching will occur.

on

1)

ON/ OFF ON

0.00..75s 0

Page 7

Switch-off delay switching output 1 (T

Time in seconds which must elapse, once the pressure

has fallen below the particular switch-back point,

before switching will occur.

Switching output 2, as above

off

1)

0.00..75s 0

Primary display (Primary)

Display value which should remain permanently in the

display:

“ACT.”: base pressure

“Top”: pressure peak value

“S.P.1” or “S.P.2”:switching point 1 or 2

“OFF”: display dark

(for function, see point 4 “Digital display”)

Calibration of sensor zero point (Calibrate)

“YES”: The base pressure is saved as the new zero

point. This is possible in the range +/- 3 % of

the unit’s nominal pressure range.

“new” appears in the display when a

calibration is carried out in the permissible

range, otherwise “Err” is displayed.

This function is useful for example if there is always a

residual pressure in the system which should

however be displayed as 0 bar.

Please note:

Following a zero point adjustment, for example, on a

600 bar unit, a pressure of up to 18 bar is displayed

as 0 bar. Before any work is carried out on the

hydraulic system, ensure that the system is depressurised.

ACT/

Top/

S.P.1/

S.P.2/

OFF

YES/ NO NO

ACT

Version number (Version)

Display of the current software version (for reference

only)

To close basic settings (End)

YES/ NO NO

Page 8

7. Programming enable

3 s

pressure

for 3 s

useorto alter setting,

3 s

pressure

useorto alter setting,

= programming disabled

= programming possible

"main program state"

The unit has 2 types of programming enable which must both be set to "ON" to change the

settings. The operating programming enable can be set or removed during operation. It

provides protection from unintentional alteration. A programming disable via the main

programming enable has the effect that no change to the settings can be carried out during

operation. This serves, for example, as a safety function or as protection against

unauthorised alterations.

7.1 Altering the operating programming enable

mode mode

display

press both

arrow keys

simultaneously

and hold down

7.2 Altering the main programming enable

Switch off supply voltage or disconnect the unit from the supply voltage.

mode mode

arrow keys

simultaneously

and hold down.

Switch on supply

voltage (hold keys

down for 3 s)

3 s

3 s

display

(release

arrow keys)

displaypress both arrow

(release

arrow keys)

= programming possible

ON

= programming disabled

OFF

ON

OFF

display

Note:

• If a setting has been changed "PRG" is displayed briefly when the display is switched

over. The new setting is then saved in the unit.

Page 9

8. Error messages

If an error is detected, then a corresponding error message appears which must be

acknowledged by pressing any key. Possible error messages are as follows:

E 01 The switching points and hystereses have been set in such a way that the

resulting switch-back point is no longer within the permissible setting range.

Corrective action: Correct the settings

E 10 A data error has been detected in the saved settings. Possible causes are strong

electromagnetic interference or a component fault.

Corrective action: Check all the settings (programming enable, switching points,

switch-back points and basic settings) and correct these if

necessary. If the errors occur frequently, please contact Hydac

Service.

E 12 An error has been detected in the stored calibration data. Possible causes are

strong electromagnetic interference or a component fault.

Corrective action: Switch the unit off and on again. If the error message is still

displayed, the unit must be returned to the manufacturer for recalibration or repair.

E 20 A short-circuit has been detected on a switching output.

Corrective action: Eliminate the short circuit.

Page 10

9. Technical specifications

Input data::

Measuring ranges: -14 .. 75 / 0..150, 1000, 3000, 6000, 9000 psi

Overload pressures: 150 % FS, max. 13000 psi

Burst pressure: 300 % FS

Output data:

Accuracy (display, analogue output)

Repeatability:

Temperature drift: zero point max.

range max.

Analogue output:

Switching outputs:

Type: PNP transistor output

Switching current: max. 1.2 A

Switching cycles:

Reaction time: approx. 10 ms

Ambient conditions:

Temperature range of medium: -13 .. 176 °F (-25 .. + 80 °C)

Ambient temperature range: -13 .. 176 °F (-25 .. + 80 °C)

Storage temperature range: -40 .. 176 °F (-40 .. + 80 °C)

Nominal temperature range: 14 .. 158 °F (-10 .. + 70 °C)

- mark: EN 50081-1 and -2, EN 50082-1 and -2

Vibration resistance: approx. 10 g / 0..500 Hz

Shock resistance: approx. 50 g / 1ms

Other data:

Supply voltage: 20 .. 32 VDC

Electrical connection: plug M12x1

Current consumption: approx. 100 mA (without switching output)

Safety type: IP 65

Hydraulic connection: 7/16 SAE 4 female

Parts in contact with medium: stainless steel

Material of housing: tube: stainless steel, keypad housing: PA6.6 Gf30

Display: 4-digit, 7-segment LED, red

Weight: approx. 300 g

±1.0 % FS max.

±0.5 % FS max.

±0.016 %/°F ( ±0.03 %/°C)

±0.016 %/°F ( ±0.03 %/°C)

4 .. 20 mA, ohmic resistance 400

100 million

Note: FS (Full Scale) = relative to the full measuring range

Page 11

10. Circuit diagram

Model with 1 switching output

+

20..32 V

-

Model with 2 switching outputs

+

20..32 V

-

1

EDS 356-1

3

1

EDS 356-2

3

4

4

2

Imax. 1.2 A

SP 1

Imax. 1.2 A

SP 1

Imax. 1.2 A

SP 2

Model with 1 switching output and

1 analogue output

Imax. 1.2 A

+

1

EDS 356-3

4

SP 1

20..32 V

I = 4..20 mA

-

3

2

analogue

RL

Page 12

11. Model code

401 = vacuum version -14..75 psi (determined by manufacturer)

EDS 3 5 6 - X -XX 4XX- 00

Series no.

Determined by manufacturer

Type of connection, mechanical

5 = 7/16 SAE4 female

Type of connection, electrical

4 = 4-pole plug M12X1

Output

1 = 1 switching output

2 = 2 switching outputs

3 = 1 switching output and 1 analogue output

Pressure ranges in psi

0150; 1000; 3000; 6000; 9000

vacuum version = 0089 (range -14..75; see also modification number)

Modification number

400 = standard (determined by manufacturer)

Page 13

12. Accessories

1.528 (38.8)

Ø

0.433 (11.0)

12.1 For electrical connection

4-pole connector with flying leads, Female interface

M12x1, 90° angled

1.24 (31.5)

34

2

1

1.043 (26.5)

0.807 (20.5)

All dimensions

are in inches and

M12 x1

(millimeters)

Ø 0 .571 (14.5)

Wire colors: Pin 1: brown, Pin 2: white, Pin 3: blue, Pin 4: black

Available types: ZBE 06-02: Female Screw-Lock Type 90° Connector (2 meter cord)

ZBE 06-05: Female Screw-Lock Type 90° Connector (5 meter cord)

12.2 For mechanical connection

ZBM 300 clamp for wall-mounting the EDS 300 (material: polypropylene)

Mounting:

• Glue damping strips into the recesses of

the base plate.

• Mount base plate, the top is indicated by

"OBEN", "TOP" and 2 arrows.

• Insert EDS 300.

• Fit clip (only one possible position) and

press hard on the cross-pieces until they

engage.

ZBM 310 clamp for wall-mounting the EDS 300 (material: polypropylene, aluminium

AlSi12, steel)

Mounting:

• Weld the steel base plate

• Mount EDS 300 in accordance with the

drawing

13. Dimensions

Page 14

HYDAC Technology Corporation

Electronic Division

2260 City Line Road

USA-Bethlehem, PA 18017

Phone.: (610) 266-0100

Fax: (610) 266-3540

E-mail: powerup@hydacusa.com

Loading...

Loading...