Page 1

Condition Monitoring Unit

CMU 1000

User manual

(Translation of original manual)

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 2

Condition Monitoring Unit CMU 1000 Page 2

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 3

Condition Monitoring Unit CMU 1000 Page 3

Table of Contents

General...........................................................................................................................9

1

1.1 Previous Knowledge..............................................................................................9

1.2 Structure of the Manual.........................................................................................9

1.3 Copyright Protection ...........................................................................................10

1.4 Note on Warranty .................................................................................................10

1.5 Declaration of Conformity .........................................................................10

2 Safety ...........................................................................................................................11

2.1 General Safety Precautions ................................................................................11

2.2 Proper/Designated Use .......................................................................................12

2.3 System Configuration..........................................................................................12

3 Setup and Function.....................................................................................................13

3.1 Hardware Setup....................................................................................................13

3.2 Control Elements/Connections ..........................................................................13

3.3 Terminal Allocations............................................................................................14

3.4 Examples of Connections ...................................................................................16

3.4.1 SMART sensors .................................................................................................16

3.4.2 Standard HSI Sensors ....................................................................................17

3.4.3 Standard Analog Sensors ..................................................................................17

3.4.4 SMART Sensors and Standard Analog Sensors................................................17

3.4.5 GSM Module CSI-F-10......................................................................................18

4 Installation and Initial Operation ...............................................................................19

4.1 Installation Guidelines.........................................................................................19

4.2 Control Element on the Device...........................................................................20

4.3 Power Supply Connection ..................................................................................20

4.4 Behavior when Switching On/Restart ................................................................21

4.4.1 No CM Program Available in the Device ........................................................21

4.4.2 CM Program Available in the Device ..............................................................21

5 Basic Settings/Menu Structure..................................................................................23

5.1 Configuration on the Device ...............................................................................23

5.1.1 Menu Structure for Operation on the Device ..................................................23

5.1.2 Key Functions during Operation on the Device .............................................. 24

5.2 Configuration Using CMWIN PC Software.........................................................25

5.2.1 Direct Connection ........................................................................................... 25

5.2.2 Direct Connection via HSI Bus .......................................................................29

5.2.2.1 Device Connection via CSI-B-2 Interface Module....................................... 29

5.2.2.2 Connection Setup via CSI-B-2 Interface Module ........................................30

5.2.2.3 Device Connection without CSI-B-2 Interface Module................................ 32

5.2.2.4 Connection Setup without CSI-B-2 Interface Module..................................32

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 4

Condition Monitoring Unit CMU 1000 Page 4

5.2.3 Modem Connection.........................................................................................37

5.2.3.1 Device Connection/Pin Connections........................................................... 37

5.2.3.2 Establishing Connection with GSM Radio Module CSI-F-10 ......................38

5.2.3.3 Connection Setup with CMU 1000 using GSM Mobile Network..................42

5.2.4 TCP Connection .............................................................................................45

5.2.4.1 Device Connection......................................................................................45

5.2.4.2 Connection Setup........................................................................................45

5.2.5 Actions ............................................................................................................ 48

5.2.5.1 Display Device Status .................................................................................48

5.2.5.2 Display Device Information .........................................................................49

5.2.5.3 Sensor Values............................................................................................. 49

5.2.5.4 Managing Recordings .................................................................................50

5.2.5.5 Performing a Dialog ....................................................................................50

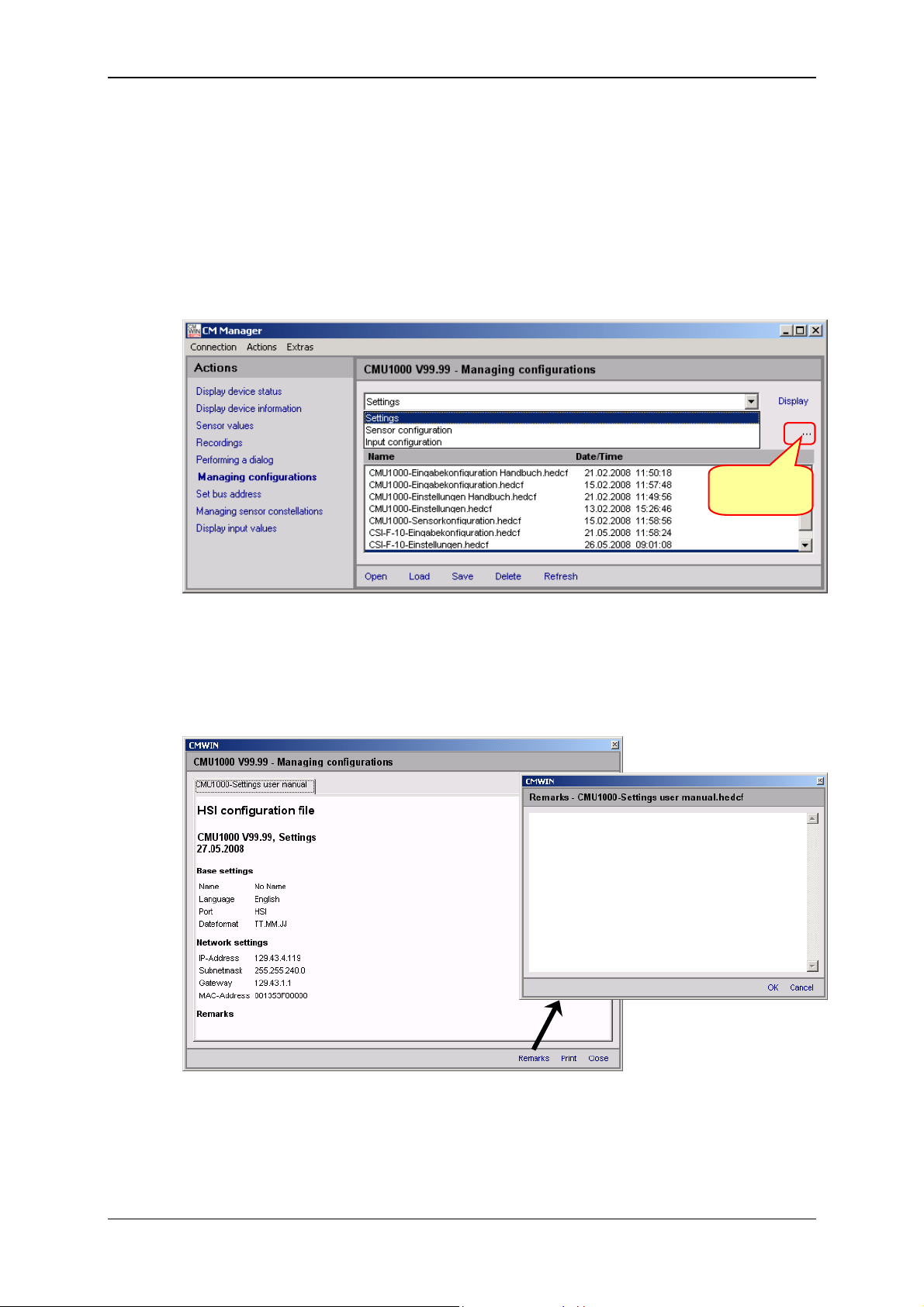

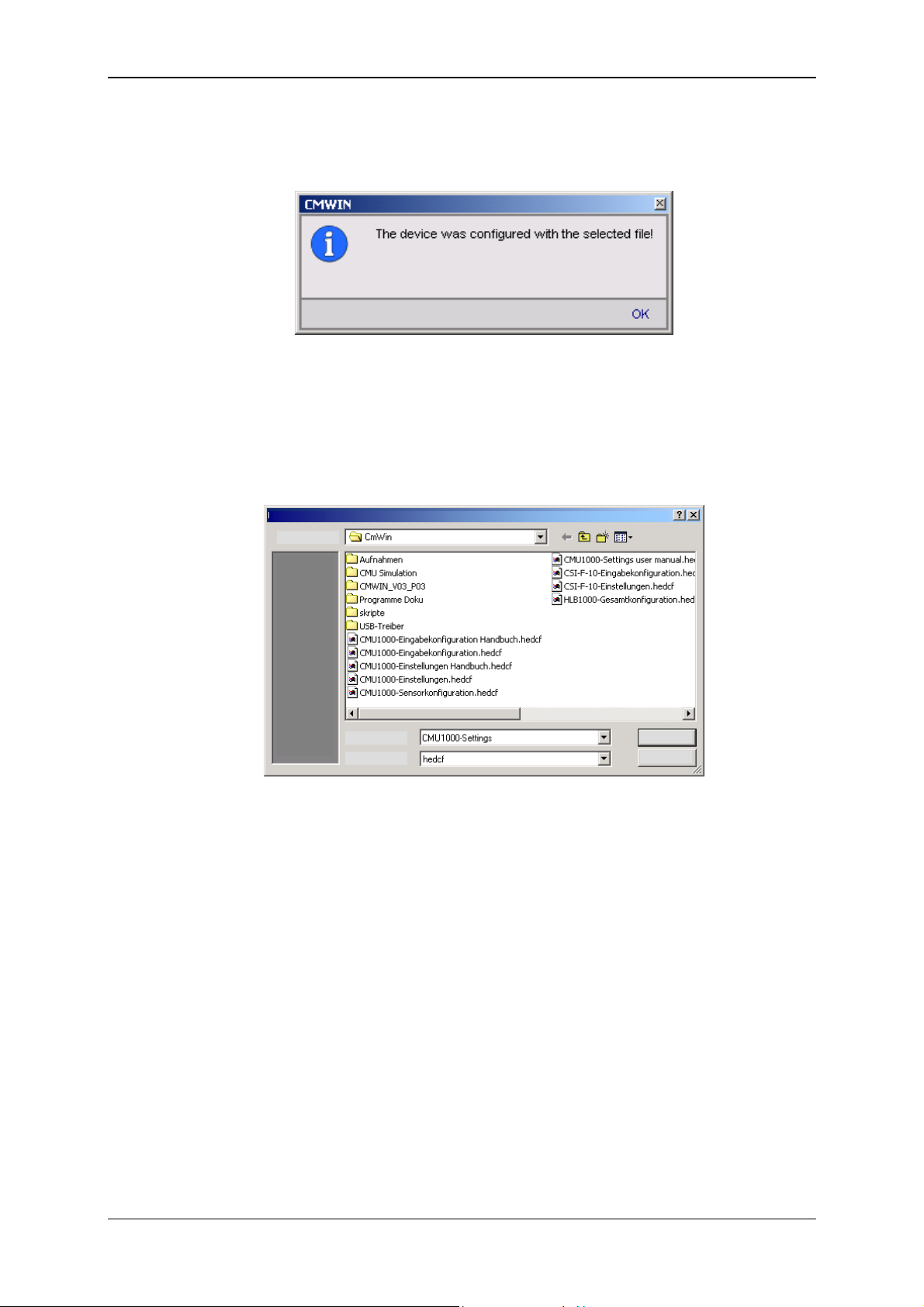

5.2.5.6 Managing Configurations ............................................................................55

5.2.5.7 Set bus address ..........................................................................................58

5.2.5.8 Managing Sensor Constellations ................................................................59

5.2.5.9 Display Input Values ...................................................................................60

5.2.6 Extras..............................................................................................................61

5.2.6.1 Update Firmware.........................................................................................61

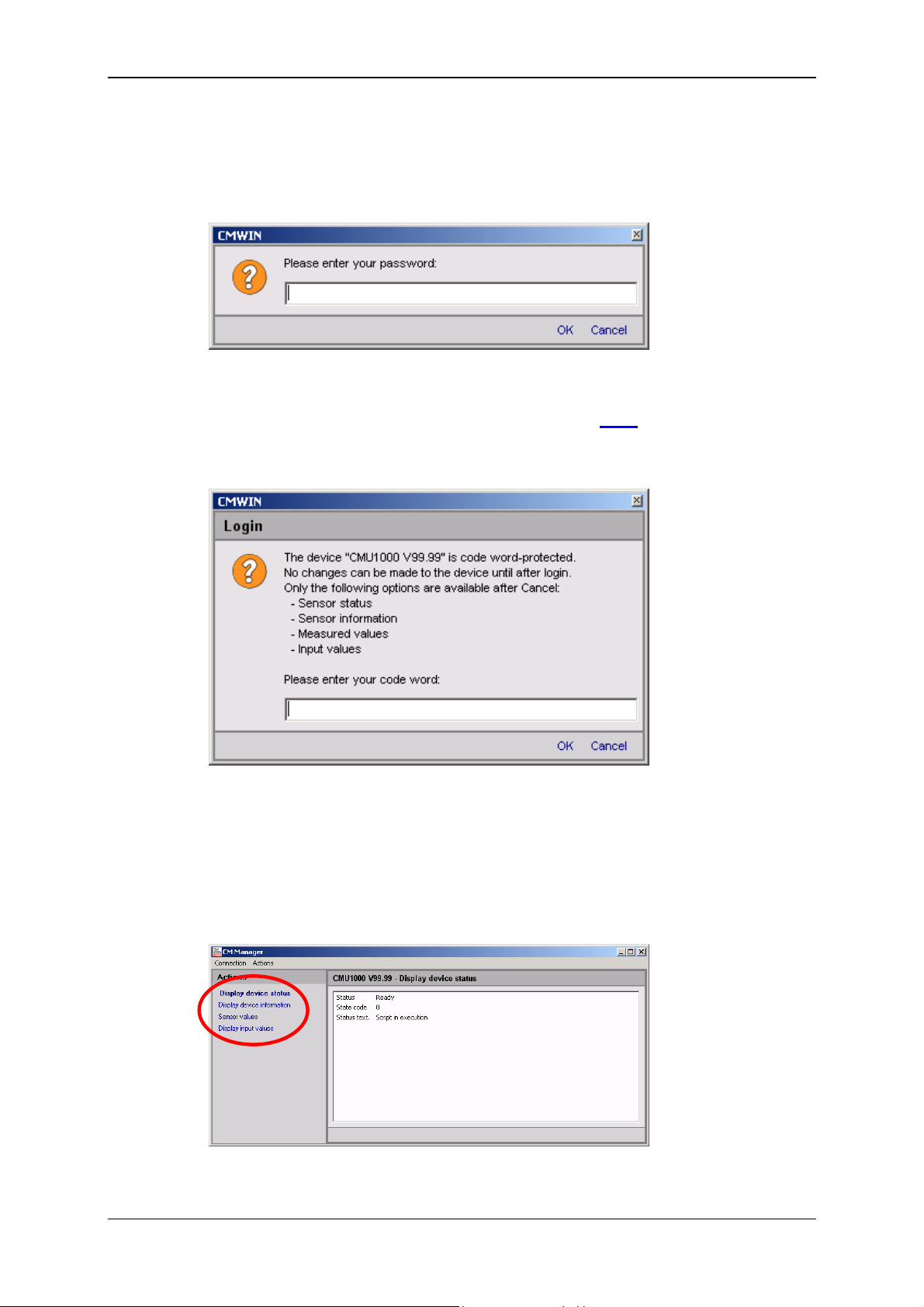

5.2.6.2 Set Password Protection............................................................................. 64

5.2.6.3 Change Password....................................................................................... 65

5.2.6.4 Removing Password Protection.................................................................. 65

5.2.6.5 Send Commands ........................................................................................65

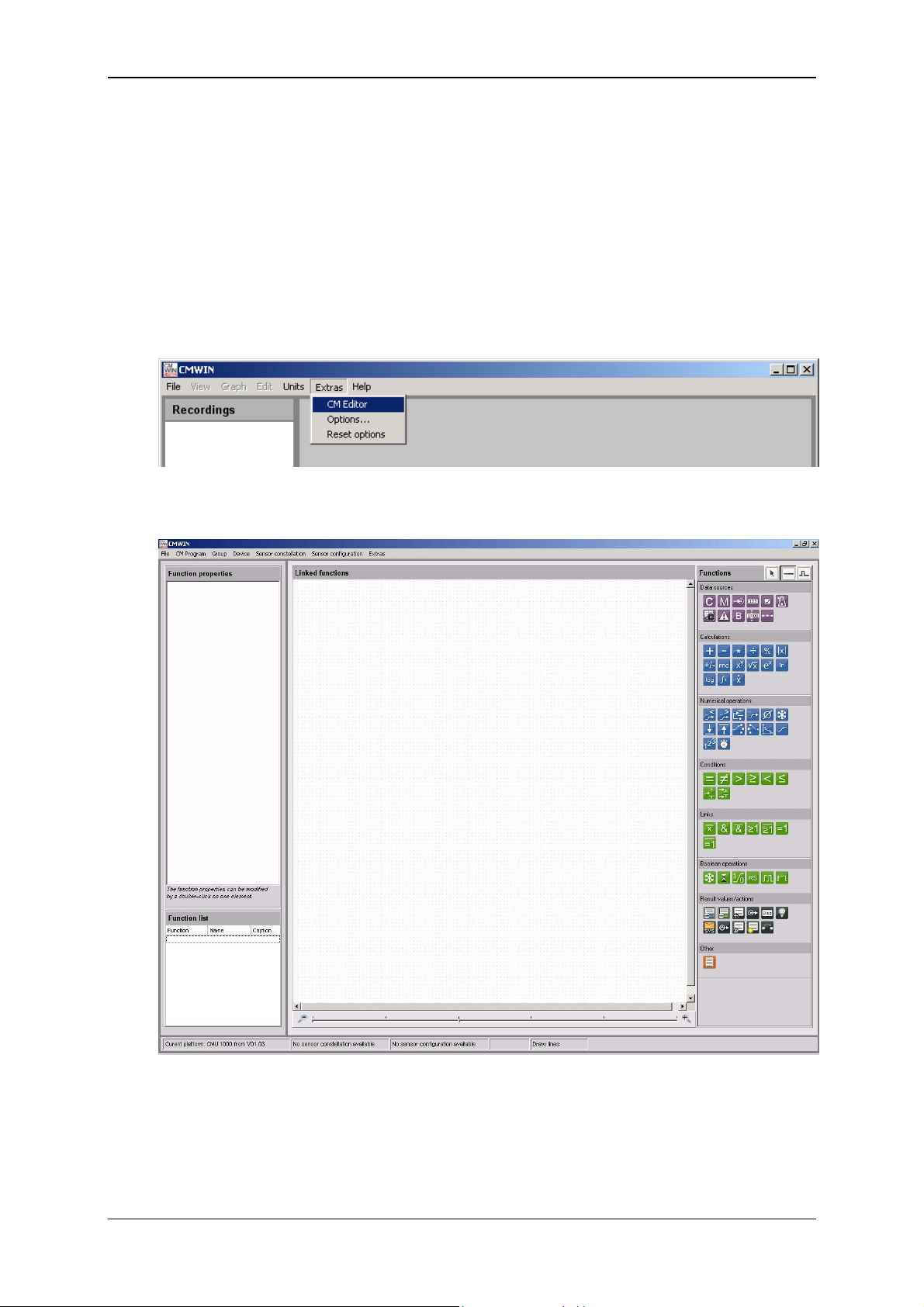

6 CM Editor.....................................................................................................................66

6.1 Menu Bar...............................................................................................................67

6.1.1 File .................................................................................................................. 67

6.1.2 CM Program ...................................................................................................68

6.1.3 Grouping ......................................................................................................... 72

6.1.4 Device.............................................................................................................72

6.1.5 Sensor Constellation.......................................................................................73

6.1.6 Sensor Configuration ...................................................................................... 75

6.1.7 Extras..............................................................................................................77

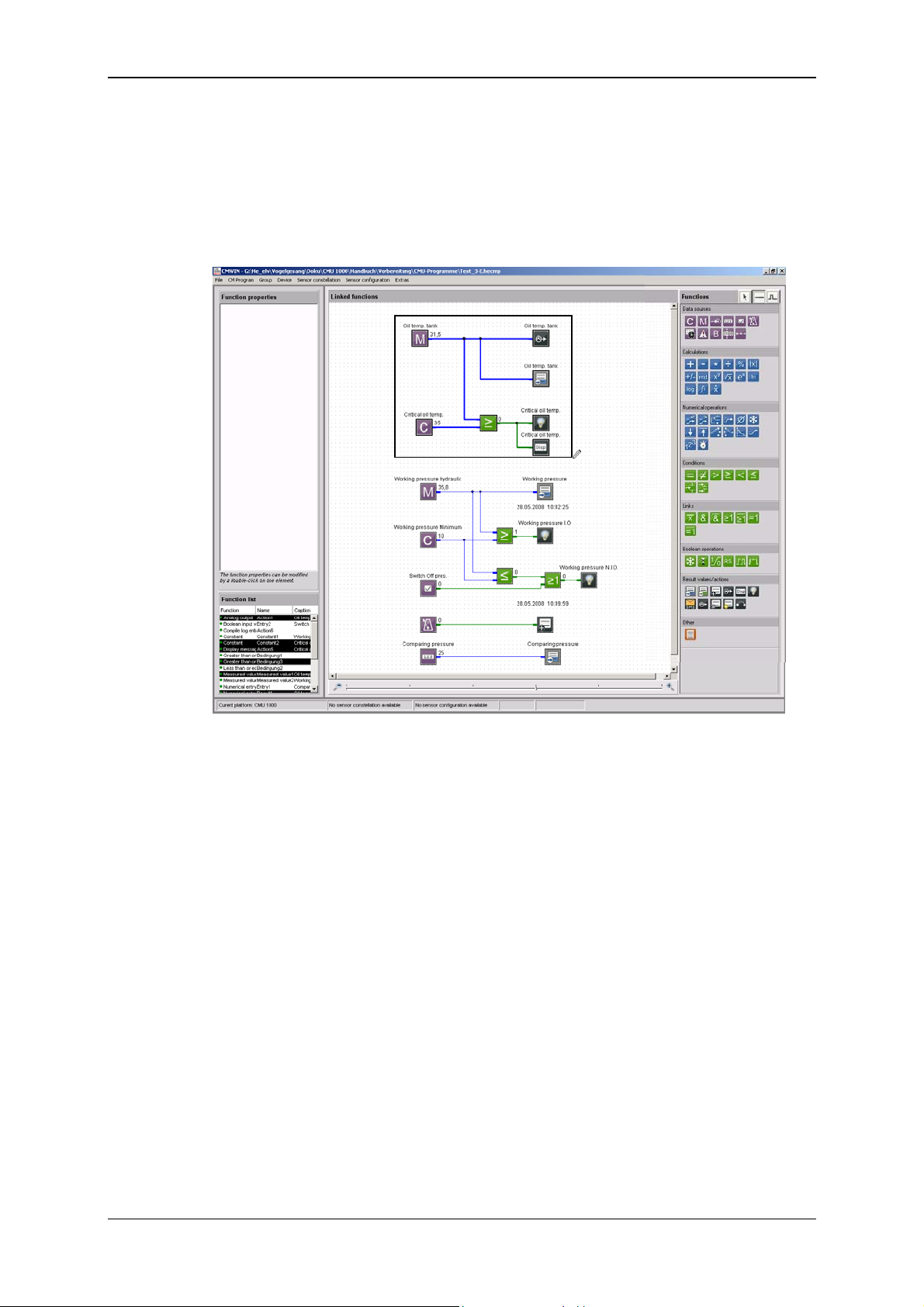

6.2 Window Divisions ................................................................................................ 78

6.2.1 "Function Properties" Window ........................................................................78

6.2.2 "Function List" Window ...................................................................................78

6.2.3 "Linked Functions" Window ............................................................................ 78

6.2.4 "Functions" Window........................................................................................78

7 CM Program Functions...............................................................................................79

7.1 General Information Concerning Functions...................................................... 79

7.1.1 Inputs / Outputs ..............................................................................................79

7.1.1.1 Numerical Values........................................................................................79

7.1.1.2 Boolean Values...........................................................................................79

7.1.2 Parameters ..................................................................................................... 80

7.1.2.1 Numerical Parameters ................................................................................80

7.1.2.2 Whole Number ............................................................................................80

7.1.2.3 Entry List .....................................................................................................80

7.1.2.4 Boolean Parameters ...................................................................................80

7.1.2.5 Character String..........................................................................................80

7.1.2.6 Values Table ...............................................................................................80

7.1.2.7 Time ............................................................................................................80

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 5

Condition Monitoring Unit CMU 1000 Page 5

7.2 Data Sources ........................................................................................................81

7.2.1 Numerical Constant ........................................................................................ 81

7.2.2 Measured Value..............................................................................................81

7.2.3 Digital Input.....................................................................................................81

7.2.4 Numerical Entry .............................................................................................. 82

7.2.5 Boolean Entry ................................................................................................. 82

7.2.6 Time Sensor ...................................................................................................83

7.2.7 Clock Timer.....................................................................................................83

7.2.8 Error Event......................................................................................................84

7.2.9 Boolean Constants .........................................................................................84

7.2.10 State-bit ..........................................................................................................84

7.2.11 Sequency................................................... Fehler! Textmarke nicht definiert.

7.2.12 Transition (in field „Result values / Actions“)Fehler! Textmarke nicht definiert.

7.3 Numerical Calculations ....................................................................................... 86

7.3.1 Addition...........................................................................................................86

7.3.2 Subtraction......................................................................................................86

7.3.3 Multiplication ................................................................................................... 86

7.3.4 Division ........................................................................................................... 86

7.3.5 Division Remainder.........................................................................................87

7.3.6 Absolute Value................................................................................................87

7.3.7 Change of Algebraic Sign ............................................................................... 87

7.3.8 Rounding ........................................................................................................87

7.3.9 Raising to a Higher Power ..............................................................................88

7.3.10 Square Root....................................................................................................88

7.3.11 Power at Base e .............................................................................................88

7.3.12 Natural Logarithm ........................................................................................... 88

7.3.13 Decade Logarithm ..........................................................................................89

7.3.14 Integral............................................................................................................89

7.3.15 Differential Quotient ........................................................................................ 90

7.4 Numerical Operations..........................................................................................91

7.4.1 Minimum ......................................................................................................... 91

7.4.2 Maximum ........................................................................................................ 91

7.4.3 Limit ................................................................................................................ 91

7.4.4 If - Then - Else ................................................................................................ 91

7.4.5 Median Value..................................................................................................92

7.4.6 Note Value ...................................................................................................... 92

7.4.7 Note Minimum.................................................................................................92

7.4.8 Note Maximum................................................................................................93

7.4.9 Tabular Value .................................................................................................93

7.4.10 Tabular Index..................................................................................................94

7.4.11 Characteristic Curve ....................................................................................... 94

7.4.12 Slope...............................................................................................................95

7.5 Counting Functions .............................................................................................96

7.5.1 Count Pulses ..................................................................................................96

7.5.2 Stop Clock ......................................................................................................96

7.6 Numerical Conditions..........................................................................................97

7.6.1 Equals.............................................................................................................97

7.6.2 Does not Equal ............................................................................................... 97

7.6.3 Greater than....................................................................................................98

7.6.4 Greater than or Equal to ................................................................................. 98

7.6.5 Less than ........................................................................................................ 98

7.6.6 Less than or Equal to......................................................................................99

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 6

Condition Monitoring Unit CMU 1000 Page 6

7.6.7 Within..............................................................................................................99

7.6.8 Outside ...........................................................................................................99

7.7 Boolean Links ....................................................................................................100

7.7.1 Not ................................................................................................................ 100

7.7.2 And ...............................................................................................................100

7.7.3 Not - And.......................................................................................................100

7.7.4 Or..................................................................................................................101

7.7.5 Not - Or .........................................................................................................101

7.7.6 Exclusive Or..................................................................................................102

7.7.7 Not Exclusive Or ...........................................................................................102

7.8 Other Boolean Operations ................................................................................103

7.8.1 Note Value .................................................................................................... 103

7.8.2 Switching Delay ............................................................................................ 103

7.8.3 T - Flipflop.....................................................................................................104

7.8.4 Mono Flop.....................................................................................................104

7.8.5 RS - Flipflop .................................................................................................. 105

7.8.6 Pulse Generation .......................................................................................... 105

7.9 Result Values .....................................................................................................106

7.9.1 Numerical Output Value................................................................................106

7.9.2 Boolean Output Value...................................................................................107

7.10 Actions................................................................................................................108

7.10.1 Setting Switching Output ..............................................................................108

7.10.2 Setting Analog Outputs.................................................................................108

7.10.3 Display Message ..........................................................................................109

7.10.4 Switch on LED .............................................................................................. 109

7.10.5 Compiling a Log Entry ..................................................................................110

7.10.6 Compiling Quick Log Entries ........................................................................110

7.10.7 Start new log.................................................................................................110

7.10.8 Transition (see Chap. 7.2.12) ....................................................................... 110

7.10.9 Send SMS.....................................................................................................111

7.11 Other ...................................................................................................................111

7.11.1 Comment ...................................................................................................... 111

8 Error Messages CM Program Compilation.............................................................112

8.1 Overriding Error Messages...............................................................................113

8.1.1 Function not Available in this Mode .............................................................. 113

8.2 Error Messages with Data Sources..................................................................113

8.2.1 Invalid Channel Setting.................................................................................113

8.2.2 Duplicate Channel Name..............................................................................113

8.2.3 Invalid Digital Input .......................................................................................113

8.2.4 Duplicate Digital Input...................................................................................113

8.2.5 Too many Boolean Input Fields ....................................................................113

8.2.6 No Inscription with Boolean Input ................................................................. 113

8.2.7 Duplicate Inscription with Boolean Inputs ..................................................... 113

8.2.8 Too Many Numerical Input Values................................................................113

8.2.9 No Inscription with Numerical Input .............................................................. 114

8.2.10 Duplicate Inscription with Numerical Input....................................................114

8.2.11 Duplicate Error Source .................................................................................114

8.3 Error Messages with Operations/Conditions ..................................................114

8.3.1 Upper and Lower Measured Value Limits too Close to one another ............114

8.3.2 Measured Value Limits Outside the Range of -30000 to 30000 ...................114

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 7

Condition Monitoring Unit CMU 1000 Page 7

8.3.3 Lower Measured Value Limit Greater than Upper Measurement Value Limit114

8.4 Error Messages with Result Values/Actions ...................................................114

8.4.1 Invalid Output LED Selected.........................................................................114

8.4.2 Duplicate Usage of Output LED....................................................................114

8.4.3 Invalid Digital Output.....................................................................................115

8.4.4 Duplicate Digital Ouput ................................................................................. 115

8.4.5 Invalid Analog Output ...................................................................................115

8.4.6 Duplicate Analog Output...............................................................................115

8.4.7 Too Many Boolean Output Fields ................................................................. 115

8.4.8 Duplicate Boolean Output Field .................................................................... 115

8.4.9 The Bit Number Must Be a Figure between 0 and 14................................... 115

8.4.10 Too Many Numerical Output Fields ..............................................................115

8.4.11 Duplicate Numerical Output Field .................................................................115

8.4.12 Message and Telephone Number too Long .................................................116

9 Technical Data...........................................................................................................117

9.1 Power Supply ..................................................................................................... 117

9.2 Connecting Sensors ..........................................................................................117

9.3 Analog Inputs .....................................................................................................117

9.4 Digital Inputs ...................................................................................................... 117

9.5 Measurement Channels.....................................................................................117

9.6 Analog Outputs ..................................................................................................118

9.7 Digital Outputs ................................................................................................... 118

9.8 Calculation Unit..................................................................................................118

9.9 Interfaces ............................................................................................................ 118

9.9.1 Keyboard ......................................................................................................118

9.9.2 View .............................................................................................................. 118

9.9.3 USB Mass Storage Device ...........................................................................118

9.9.4 Ethernet ........................................................................................................ 118

9.9.5 Serial Interface 0 (UART 0) ..........................................................................119

9.9.6 HSI Master....................................................................................................119

9.9.7 USB Device ..................................................................................................119

9.9.8 CAN Bus Interface ........................................................................................119

9.9.9 IO Link Interface ...........................................................................................119

9.10 Cycle Time ..........................................................................................................119

9.11 Operating and Ambient Conditions .................................................................119

9.12 Dimensions and Weight: ...................................................................................119

9.13 Technical Standards..........................................................................................119

9.14 Scope of Delivery...............................................................................................120

9.15 Maintenance and cleaning ................................................................................ 120

9.16 Recycling and Disposal.....................................................................................120

10 Ordering Details.....................................................................................................120

11 Accessories ...........................................................................................................121

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 8

Condition Monitoring Unit CMU 1000 Page 8

Preface

We have compiled the most important instructions for the operation and

maintenance of our product for you, its user, in this documentation.

It will acquaint you with the product and assist you in using it as intended in

an optimal manner.

Keep it in the vicinity of the product so it is always available.

Note that the information on the unit's engineering contained in the

documentation was that available at the time of publication. There may be

deviations in technical details, figures, and dimensions as a result.

If you discover errors while reading the documentation or have additional

suggestions or notes, contact us at:

HYDAC ELECTRONIC GMBH

Technical Documentation

Hauptstraße 27

66128 Saarbrücken

-GermanyTel: +49(0)6897 / 509-01

Fax: +49(0)6897 / 509-1726

Email: electronic@hydac.com

The editorial board would welcome your contributions.

„Putting experience into practice“

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 9

Condition Monitoring Unit CMU 1000 Page 9

1 General

This manual is a constituent part of the device. It contains texts and graphics

concerning the correct handling of the product and must be read before installation,

assembly and the operation of the device.

The manual offers information concerning the safe operation of as well as the

installation and programming of the Condition Monitoring Unit CMU 1000. It addresses

engineers, programmers, installers and maintenance personnel with general

knowledge of the automation technology involved.

Using this manual in the recommended manner will ensure that the goal of effective

and operationally safe utilisation of the CMU 1000 is achieved without delay. We are

providing you at this juncture with an overview of the following items:

What previous knowledge must one have in order to be able to progam the CMU

1000?

How is this manual structured?

How does one find one's way around in this manual?

What information is to be found in this manual?

1.1 Previous Knowledge

No special previous knowledge is required for programming the CMU 1000.

It is however to your advantage to have general knowledge in the area of automation

technology or memory-programmable controllers, knowledge of control technology or

SPS programming knowledge, and having them will shorten the familiarization period.

1.2 Structure of the Manual

We have integrated a variety of different Help functions for the purpose of making the

utilization of this manual somewhat easier. Please consult the Table of Contents to find

your way to a specific subject. A brief overview is provided at the beginning of each

Chapter listing the contents of that particular Chapter.

Selective Reading

You will find notes in the side margins that make it easier to find particular sections.

Pictograms and markings also appear, the significance of which will be explained

below.

Furthermore, this manual also contains instructions regarding personal safety and the

avoidance of property damage that must be observed. The instructions are highlighted

by a Warning symbol and displayed as follows, depending on the seriousness of the

hazard:

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 10

Condition Monitoring Unit CMU 1000 Page 10

Danger!

means that death, severe bodily injury or considerable property damage will occur if the

respective precautionary measures are not implemented.

Warning!

means that death, severe bodily injury or considerable property damage could occur if

the respective precautionary measures are not implemented.

Caution!

means that some non-severe bodily injury or property damage could occur if the

respective precautionary measures are not implemented.

Attention!

means that an unwanted event or condition could occur if the respective instruction is

not followed.

Note!

means an important piece of information about the product, its handling or a part of the

documentation to which particular attention should be paid.

In the event that several hazard levels occur simultaneously, it is always the warning

notice announcing with the respectively highest level present that will be used. If the

warning triangle appears in the warning notice to warn against possible personal injury,

then the same warning notice may also contain a warning against possible property

damage.

1.3 Copyright Protection

The dissemination and/or reproduction of this document, as well as the exploitation and

communication of its content, is not permitted until specifically authorized. Violations of

this stipulation will result in liability for damages. All rights reserved.

1.4 Note on Warranty

This manual was compiled with the greatest possible care. Nevertheless, errors or

deviations cannot be excluded, for which reason we assume no responsibility for the

complete accuracy of the content.

In view of the fact that, despite intensive endeavors, errors can never be completely

avoided, we are thankful at all times for tips and suggestions for improvement.

1.5 Declaration of Conformity

This product is labelled with the CE Marking and thus is in compliance with currently

valid German marketing authorization regulations and European standards.

This ensures that applicable guidelines for electromagnetic compatibility and the safety

provisions stipulated in the Low Voltage Directive are complied with.

This product is in compliance with the regulations contained in the following European

guidelines: EN 61000-6-1 / 2 / 3 / 4

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 11

Condition Monitoring Unit CMU 1000 Page 11

2 Safety

2.1 General Safety Precautions

Follow the specifications contained in this description. Non-observance of the

instructions, operation outside of the following intended utilization, incorrect

installation/assembly or erroneous handling of the product can lead to severe

impairments with respect to the safety of personnel and systems/machines and result

in the revocation of warranty and liability claims.

Immediately after unpacking, check the scope of delivery for completeness and the

device for proper condition.

The device may not be commissioned or operated except by qualified personnel who

can be regarded as being "competent" in the sense of the EMV and Low Voltage

Directives.

Qualified personnel are individuals who are authorized to operate, ground and label

devices, systems and electrical circuits in accordance with safety technology

standards.

All relevant and generally recognized safety technology directives are to be complied

with while doing so.

If the voltage supply to the device is not provided by an on-board electrical system V

(24 V battery operation), then care must be taken to ensure that the external voltage is

generated and routed in accordance with the criteria for secure low voltage (SELV

[Separated Extra Low Voltage] pursuant to EN 60950), in view of the fact that this is

provided for supplying the connected control system, sensor system and actuating

elements without any other additional measures being implemented.

The wiring of all of the signals connected with the SELV circuit in the device must also

meet the SELV criteria (safe protective low voltage, securely disconnected galvanically

from other electrical circuits).

If the fed-in SELV voltage is grounded externally (PELV pursuant to EN 50178), then

responsibility for this and for compliance with any national installation regulations that

apply to the site of installation rest with the operator.

All of the statements made in this manual refer to devices which are not grounded in

terms of the SELV voltage.

Generally speaking, DIN VDE 0100 Part 410 is to be observed for the supply voltage.

Only the signals which are respectively specified in the Technical Data and/or on the

device label may be fed in at the connection terminals; only authorized HYDAC

ELECTRONIC GMBH accessory components may be connected to them.

In accordance with the following technical specifications, the device can be operated in

a wide range of ambient temperatures. Due to the additional self-heating of the device,

high perceptible contact temperatures may develop on the housing in hot

environments.

In the event of malfunction or uncertainty, please contact your HYDAC representative.

Unauthorized interventions in the device could result in grave impairments to the safety

of persons and systems. These are not permitted and lead to the exclusion of all

liability and warranty claims.

Troubleshooting and repairs may only be performed by our HYDAC SERVICE GMBH

Customer Service Department.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 12

Condition Monitoring Unit CMU 1000 Page 12

2.2 Proper/Designated Use

The CMU1000 is an electronic evaluation unit designed for permanent machinery and

systems condition monitoring. The device must be supplied for this purpose with

machine data that is gathered through the connected sensors. The recorded data

(whether processed or unprocessed) can be forwarded by the CMU 1000 through

various interfaces to other units and/or monitoring levels. The device can also

intervene directly in the machine or system being monitored by means of the integrated

analog and digital outputs.

The units of the CMU 1000 family are designed for utilization under difficult conditions

(expanded temperature range). They are thus suitable for direct installation in

machines in not only stationary but also in mobile and robust utilization.

The specifications for these inputs and outputs mean that they are designed especially

for such utilization. Integrated hardware and software functions (operating system)

provide a greater level of protection for the machine.

Warning!

The device may be used only for the types of applications specified in the manual and

only in connection with accessory components authorized by HYDAC ELECTRONIC

GMBH. The trouble-free and safe operation of the product is contingent on proper

transport; on proper storage, setup and installation; and on careful operation and

maintenance.

The application software, the "CM Program", can be readily generated with the "CM

Editor" on a PC by the operator himself/herself. The "CM Editor" is a component part of

the HYDAC PC software "CMWIN", starting with Version 3.0.

Note!

All of the programming procedures and software functions subsequently described in

this documentation refer to the "CM Editor" in accordance with IEC 61131.

The operator is responsible himself/herself for the safe and application-appropriate

functioning of the CM Programs that he or she generates.

2.3 System Configuration

The CMU 1000 is a device concept that is intended for both single operation and

utilization in series. This means that the device can be configured in optimal fashion for

the respective application case. Special functions and special hardware solutions can

also be implemented if required.

Note!

Generally speaking, the following applies:

All of the performances, descriptions and explanations contained in this manual are

generally valid for the standard model of the CMU 1000.

A check must be made in each case before the control module is used to determine

whether particular functions, hardware options, inputs and outputs described in the

documentation are in fact available in the hardware.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 13

Condition Monitoring Unit CMU 1000 Page 13

3 Setup and Function

The CMU1000 is an electronic device for regular (permanent) status monitoring of

hydraulic systems or machinery.

This procedure is also referred to as "Condition Monitoring".

3.1 Hardware Setup

In order to fulfill the aforementioned task, the CMU 1000 must be supplied with relevant

machinery and/or systems data, which it receives through connected sensors. The

recorded data (whether processed or unprocessed) can be forwarded by the CMU

1000 through various interfaces to other units.

The CMU 1000 is equipped with a background-lit LCD display as well as three

different-colored LEDs for the status display and presentation of messages and values.

The entering of data and commands can proceed directly at the device by means of a

keypad,

within the specified menu structure, among other ways.

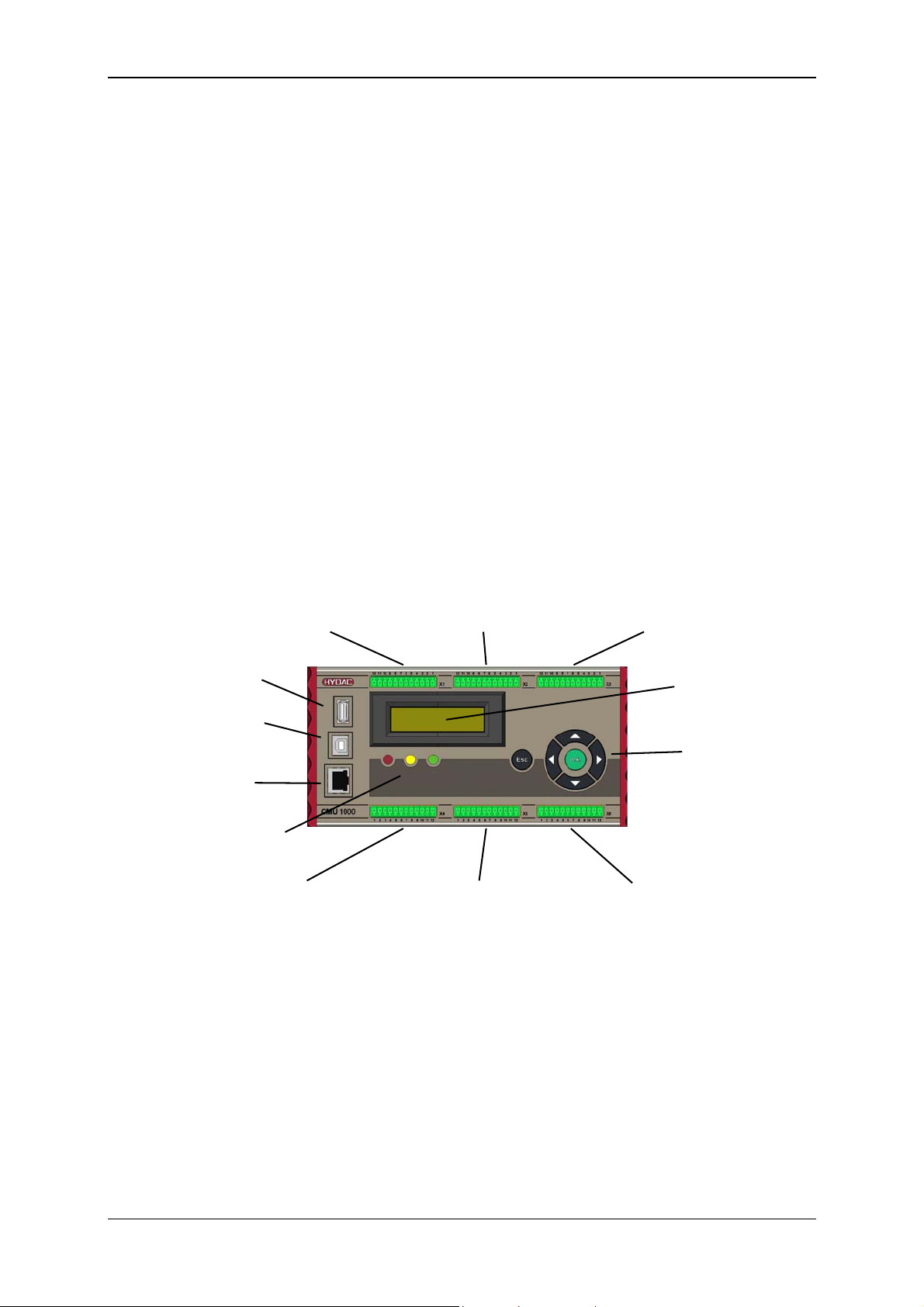

3.2 Control Elements/Connections

X1 X2 X3

HSI-channel A, B, C HSI-channel D, E, F HSI-channel G, H

Analog IN I, J, K Analog IN L, M, N Analog IN O, P and ± 10V L, P

with power supply with power supply with power supply

USB Master

(for MSD) LCD display

USB Slave

(PC connection)

Keypad

Ethernet

Status LEDs

X4 X5 X6

CAN, Frequency IN Q, R, Power supply. 24V 4x Relay OUT

Digital IN, Analog OUT RS232, HSI-Master, (changer)

IO-Link

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 14

Condition Monitoring Unit CMU 1000 Page 14

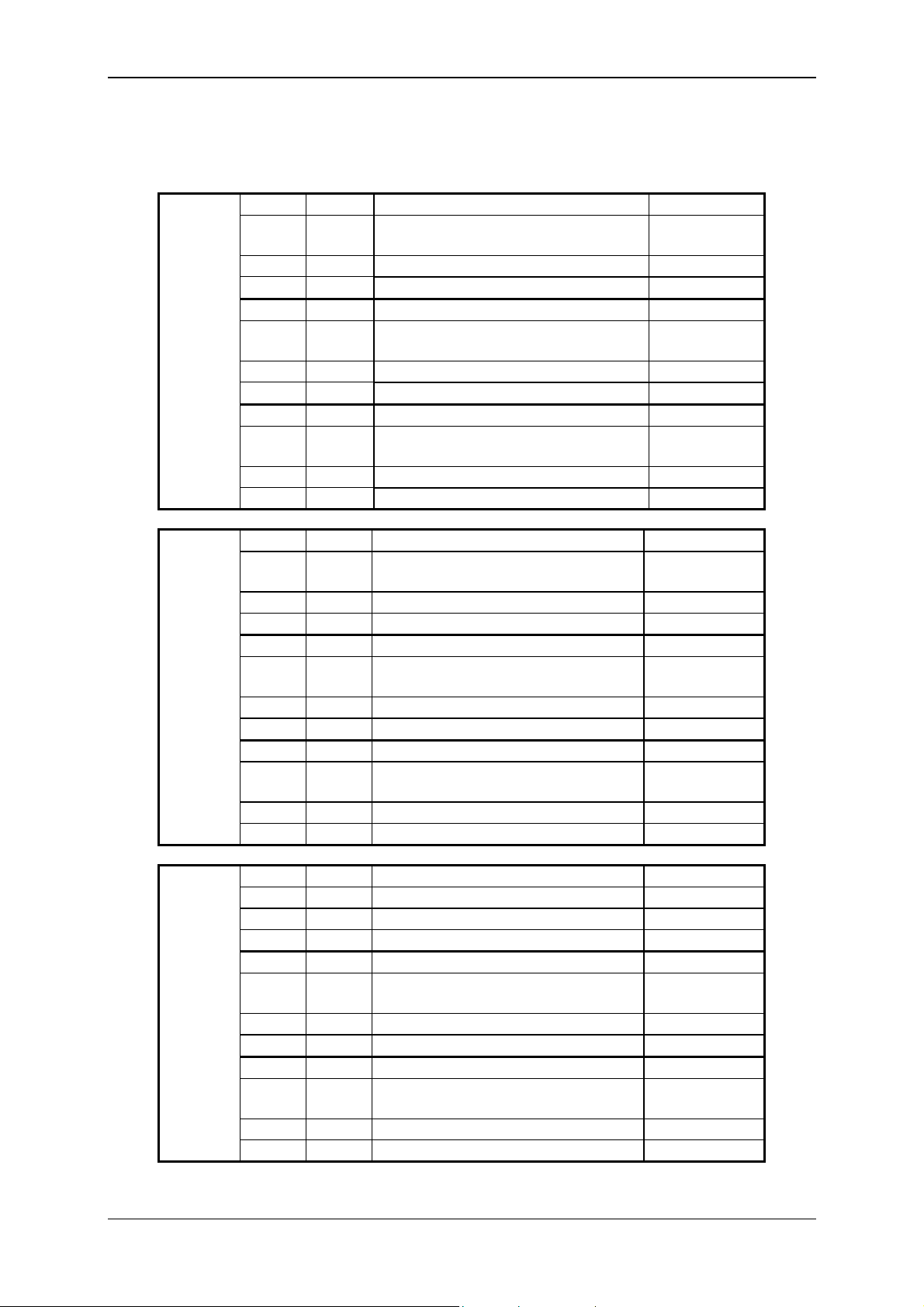

3.3 Terminal Allocations

Plugs Pin Channel Function I/O

1

2

3

4

5

6

K

C

J

B

X1

7

8

9

10

11

12

1

2

I

A

Analog input N IN

N

HSI Channel F /

F

Sensor recognition input N

3

4

5

6

X2

7

8

9

10

GND

Power supply

Analog input M IN

M

HSI Channel E /

E

Sensor recognition input M

GND

Power supply

Analog input L IN

L

HSI Channel D /

D

Sensor recognition input L

11

12

1

2

3

4

5

6

X3

7

8

9

10

GND

Power supply

+/-10V, Channel L IN

L

GND +/-10V

+/-10V, Channel P IN

P

GND +/-10V

Analog input P IN

P

HSI Channel H /

H

Sensor recognition input P

GND

Power supply

Analog input O IN

O

HSI Channel G /

G

Sensor recognition input O

11

12

GND

Power supply

Analog input K IN

HSI Channel C /

Sensor recognition input K

GND

Power supply

Analog input J IN

HSI Channel B /

Sensor recognition input J

GND

Power supply

Analog input I IN

HSI Channel A /

Sensor recognition input I

GND

Power supply

IN / OUT

IN / OUT

IN / OUT

IN / OUT

IN / OUT

IN / OUT

IN / OUT

IN / OUT

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 15

Condition Monitoring Unit CMU 1000 Page 15

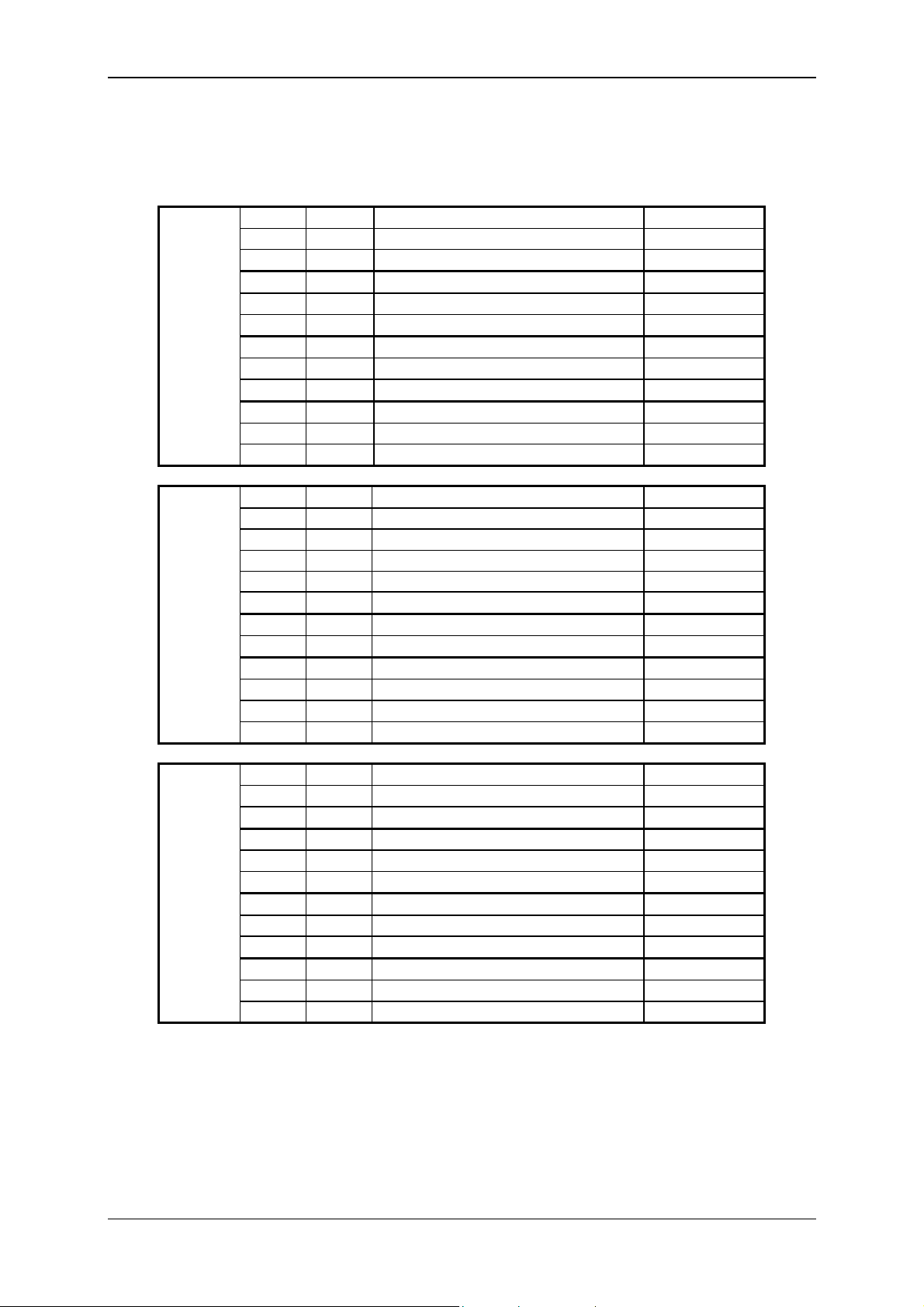

Plugs Pin Channel Function I/O

1

2

3

CAN

CAN

GND

4

5

X4

6

7

8

9

10

11

12

1

2

3

4

5

X5

6

7

8

9

10

11

12

GND

DI 1

DI 2

GND

AO 1

AO 2

GND

HSI

RS232

RS232

IO-Link

IO-Link

GND

+U

+U

0 V DC

0 V DC

0 V DC

0 V DC

1

2

DO 1

3

4

X6

5

6

7

8

DO 2

DO 3

9

10

11

DO 4

12

CAN Bus Low IN / OUT

CAN Bus High IN / OUT

CAN GND

Frequency input Q IN

Q

Frequency input R IN

R

GND

Digital In 1 IN

Digital In 2 IN

GND

Analoge out 1 OUT

Analoge out 2 OUT

GND Analoge out

HSI Master IN / OUT

RS232 OUT

RS232 IN

Power supply IO-Link IN

IO-Link communication IN / OUT

GND HSI / RS232 / IO-Link

Power supply +U

B

Power supply +U

B

B

B

Power supply 0 V DC

Power supply 0 V DC

Power supply 0 V DC

Power supply 0 V DC

Relay 1 NC

Relay 1 COM

Relay 1 NO

Relay 2 NC

Relay 2 COM

Relay 2 NO

Relay 3 NC

Relay 3 COM

Relay 3 NO

Relay 4 NC

Relay 4 COM

Relay 4 NO

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 16

Condition Monitoring Unit CMU 1000 Page 16

A

A

A

A

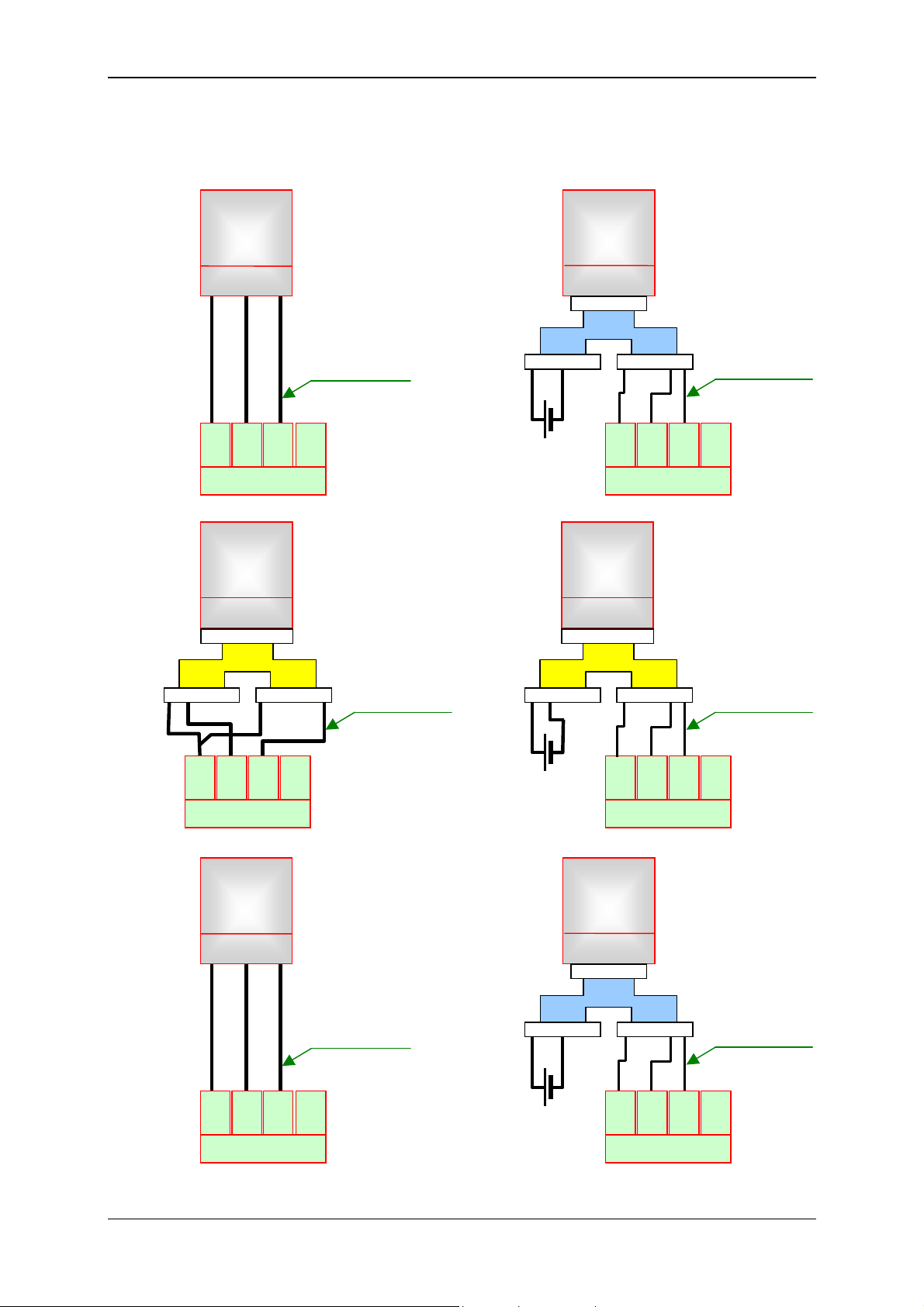

3.4 Examples of Connections

3.4.1 SMART sensors

HLB 1000

+UB GND HSI

1 2 3 4 5

12

11

10

+U

GND

B

HSI

A

- X 1

Sensor recognition

+ Signal

9

Ana.

I

1 2 3 4 5 1 2 3 4 5

External power

supply:

10..36 V DC

HLB 1000

+UB GND HSI

1 2 3 4 5

1 2 3 4 5

ZBE 26

B

12

11

+U

GND

B

10

HSI

- X 1

Sensor recognition

+ signal

9

Ana.

A

I

CS 1000

+UB GND HSI

1 2 3 4 5 6 7

1 2 3 4 5 6 7

ZBE 41

B

1 2 3 4 5 1 2 3 4 5 6 7 8

Sensor recognition

+ signal

CS 1000

+UB GND HSI

1 2 3 4 5 6 7

1 2 3 4 5 6 7

ZBE 41

B

1 2 3 4 5 1 2 3 4 5 6 7 8

Sensor recognition

+ signal

8

+U

7

GND 6 HSI

B

- X 1

5

Ana.

B

J

External power

supply:

10..36 V DC

8

+U

7

GND 6 HSI

B

- X 1

5

Ana.

B

J

AS 1000

+UB GND HSI

1 2 3 4 5

4

3

+U

GND 2 HSI

B

C

- X 1

Sensor recognition

+ Signal

1

Ana.

K

1 2 3 4 5 1 2 3 4 5

External power

supply:

10..36 V DC

AS 1000

+UB GND HSI

1 2 3 4 5

1 2 3 4 5

ZBE 26

B

4

3

+U

GND 2 HSI

B

- X 1

Sensor recognition

+ signal

1

Ana.

C

K

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 17

Condition Monitoring Unit CMU 1000 Page 17

A

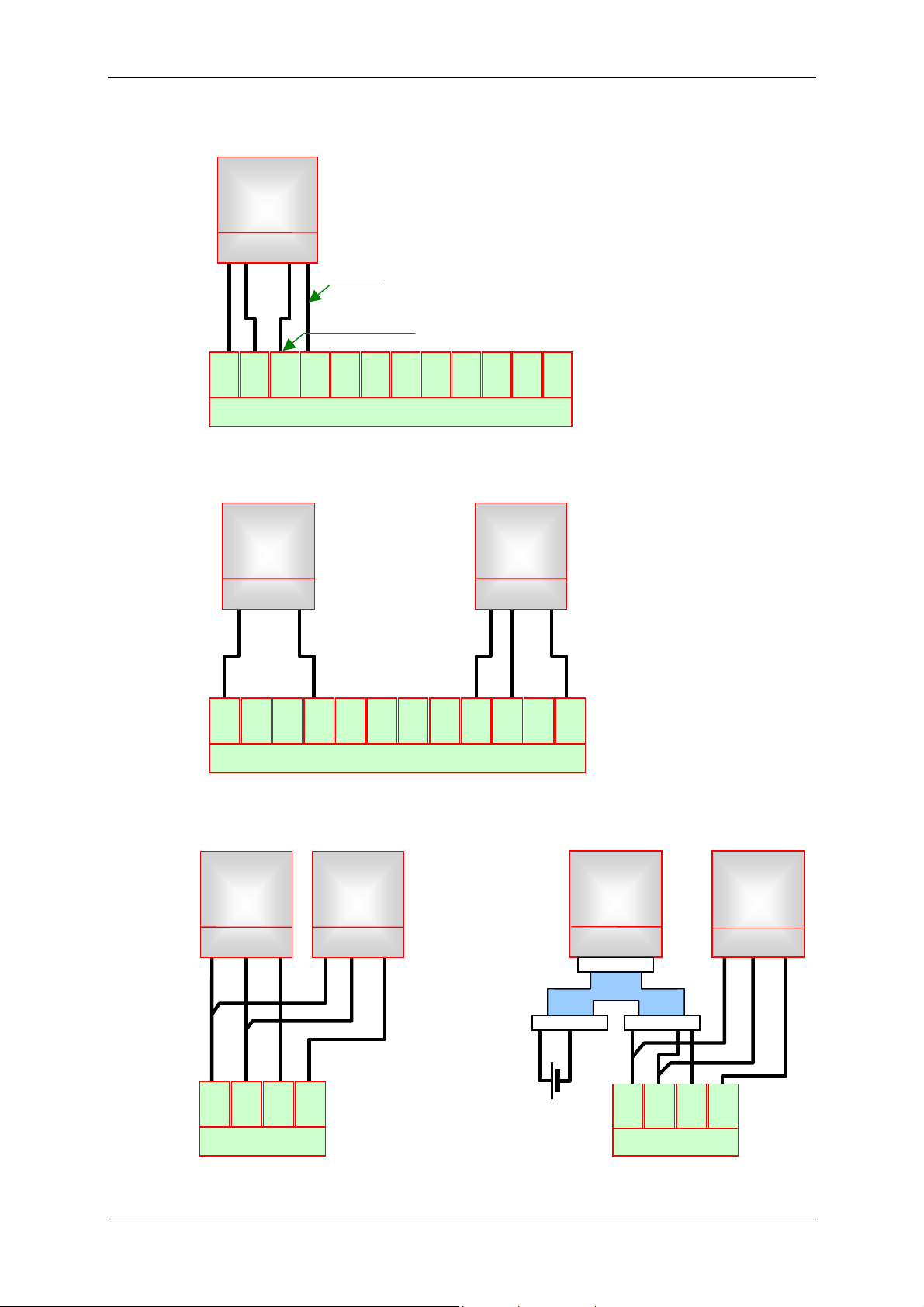

3.4.2 Standard HSI Sensors

HDA xxxx-H

ETS xxxx-H

EVS xxxx-H

+UB Gnd Adr HSI Sig

12

+U

1 4 2 5 3

11

10

GND

HSI

B

A

Signal

Sensor recognition

9

8

7

Ana.

+U

GND6 HSI

B

I

5

4

+U

3

GND2 HSI

B

Ana.

B

J

1

Ana.

C

K

- X 1

3.4.3 Standard Analog Sensors

5

J

HDA xxxx

ETS xxxx

EVS xxxx

ENS xxxx

Three-wire line

GND Signal

+U

B

4

3

+U

GND2 HSI

B

1

Ana.

C

K

HDA xxxx

ETS xxxx

EVS xxxx

ENS xxxx

Two-wire line

Signal + Signal -

12

11

10

+U

GND

B

HSI

9

8

7

Ana.

A

+U

GND6 HSI

B

I

Ana.

B

-X 1

3.4.4 SMART Sensors and Standard Analog Sensors

HLB 1000

CS 1000

AS 1000

+UB GND HSI

1 2 3 4 5

HDA xxxx

ETS xxxx

EVS xxxx

ENS xxxx

Three-wire line

GND Signal

+U

B

HLB 1000

+UB GND HSI

1 2 3 4 5

1 2 3 4 5

ZBE 26

B

1 2 3 4 5 1 2 3 4 5

HDA xxxx

ETS xxxx

EVS xxxx

ENS xxxx

Three-wire line

GND Signal

+U

B

12

11

10

+U

B

GND

- X 1

HSI

A

9

Ana.

I

External power

supply:

10..36 V DC

+U

12

B

11

GND

- X 1

10

HSI

A

9

Ana.

I

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 18

Condition Monitoring Unit CMU 1000 Page 18

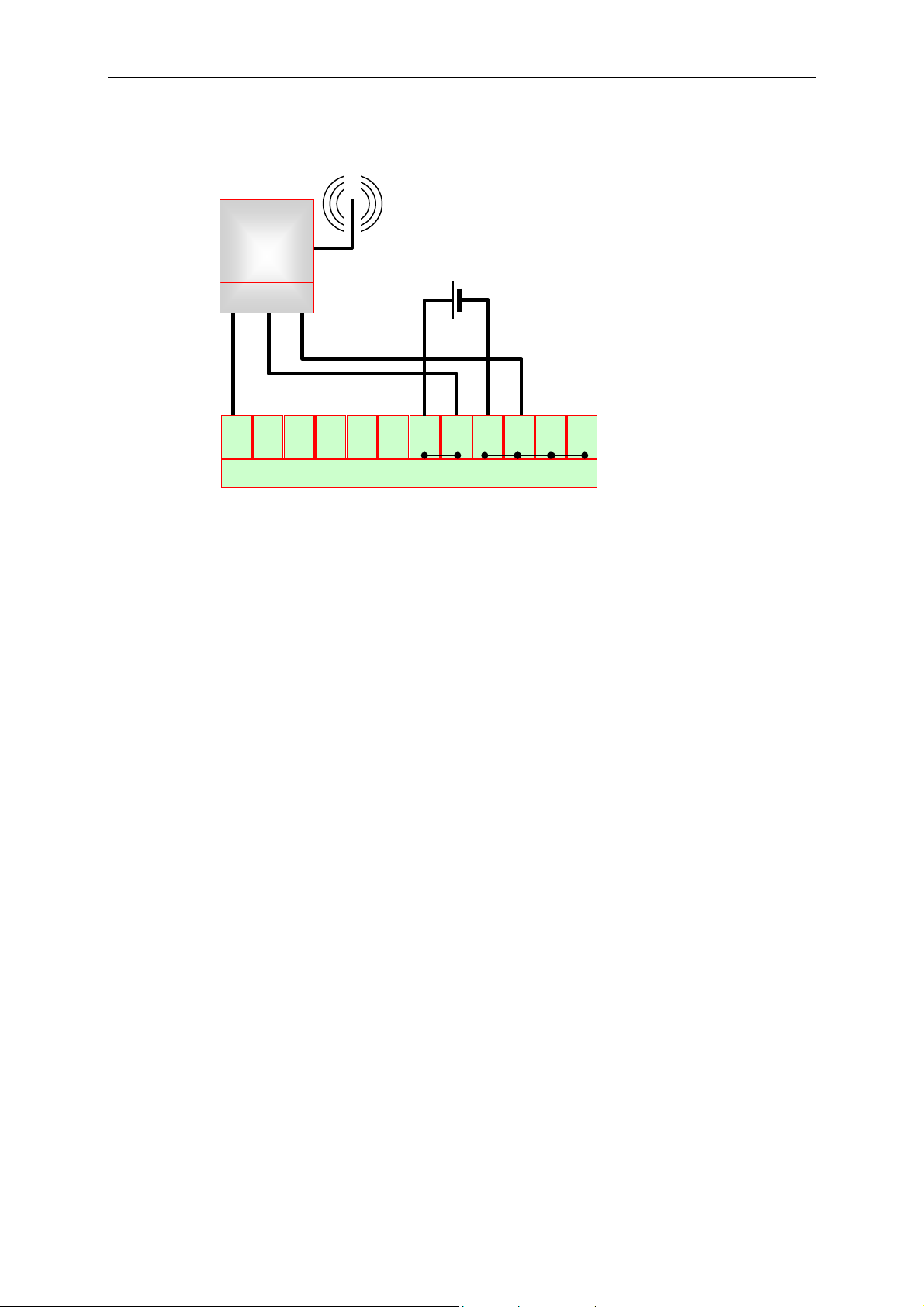

3.4.5 GSM Module CSI-F-10

CSI-F-10

HSI +UB GND

5 4 1 2 3

1

2

3

HSI

RS232

Master

TxD

RS232

RxD

4

IOLink

L+

IOLink

C/Q

18..35 V DC / 3,5 A

5

6

IOLink

GND

-X 5

7

VDC

IN

8

VDC

IN

9

VDC

GND

10

VDC

GND

11

VDC

GND

12

VDC

GND

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 19

Condition Monitoring Unit CMU 1000 Page 19

4 Installation and Initial Operation

4.1 Installation Guidelines

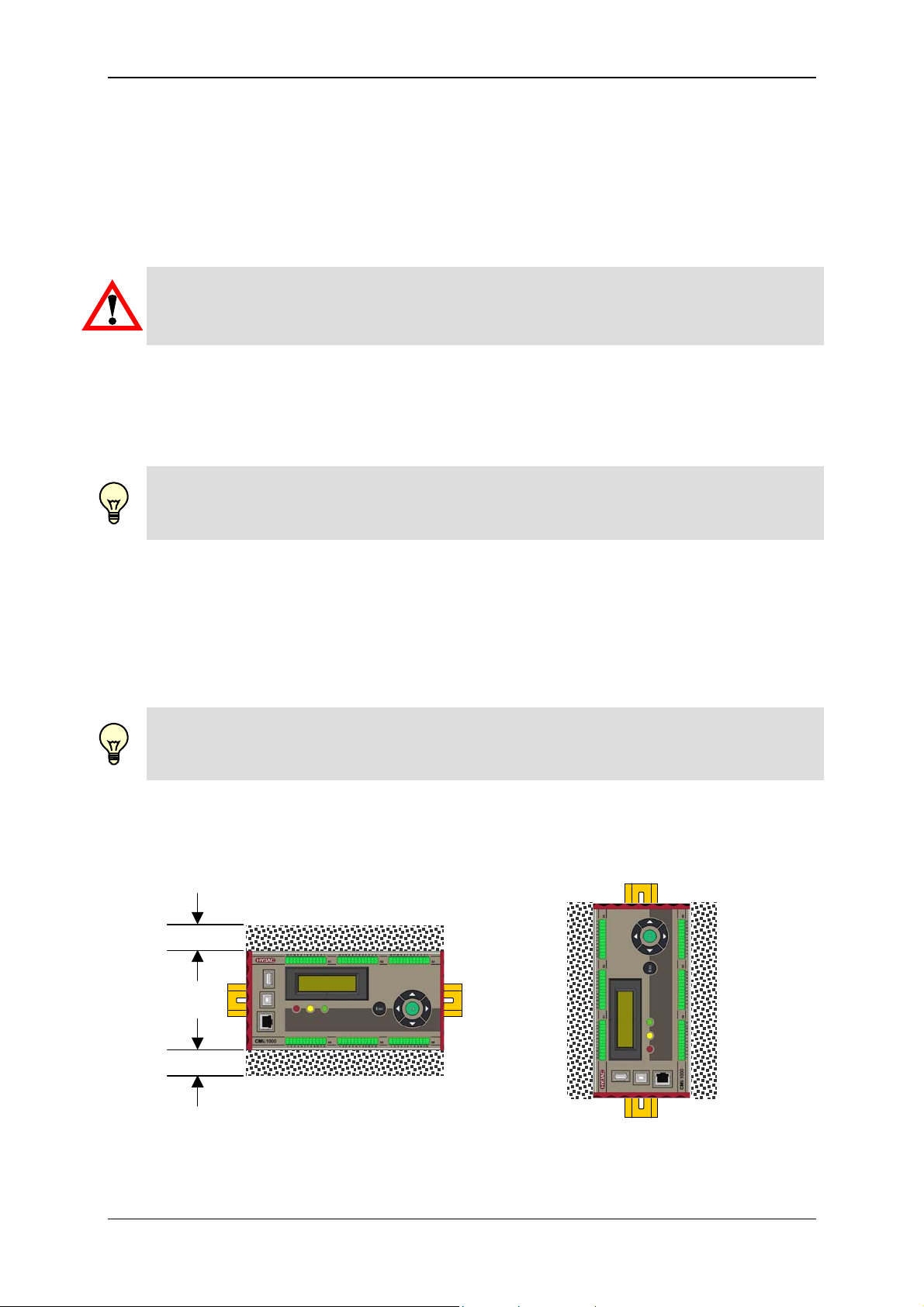

We recommend the installation of the CMU 1000 in a control cabinet or switchbox. It

can be mounted on a standard top hat rail either horizontally or vertically.

Caution!

Keep the CMU 1000 devices well away from heat, high voltage and electrical

interference from other consumers!

When planning the installation space of the CMU 1000 in your control cabinet, take into

account any heat-generating devices present there and reserve cooler areas of the

control cabinet for the CMU 1000.

If an electronic device is operated in a high ambient temperature, then this reduces the

time interval between breakdowns.

Note!

Allow sufficient clearance between the CMU 1000 and other devices for cooling and

wire placement!

The CMU 1000 devices are designed for natural heat dissipation by means of

convection. For that reason, allow at least 25 mm of open space both above and below

the devices in order to ensure heat dissipation. Also ensure a minimum installation

depth of 75 mm.

If the ambient temperature nonetheless still exceeds the maximum authorized

operating temperature of the device, then a system providing sufficient cooling (e.g.

control cabinet air-conditioning) must be provided for.

Note!

If the CMU 1000 is installed in vertical position, then the maximum permissible ambient

temperature is reduced by 10°C!

When planning the layout for your system, leave sufficient clearance around the device

both above and below between it and all other devices to allow for the wiring the

peripherals and connecting of the communications cable.

min. 25 mm

min. 25 mm

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 20

Condition Monitoring Unit CMU 1000 Page 20

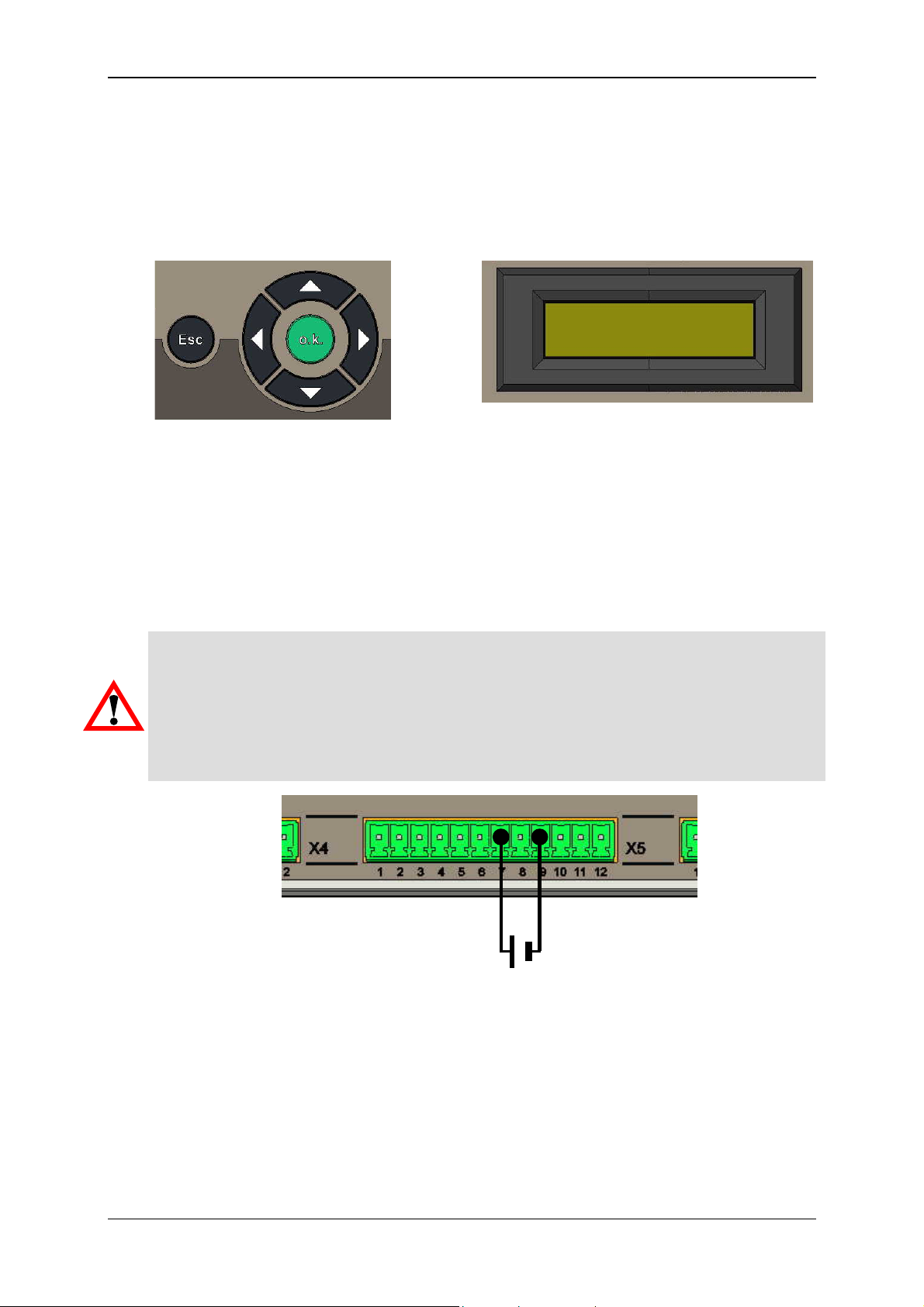

4.2 Control Element on the Device

The following control element is available on the device for operating the CMU 1000

and performing the basic settings:

Keypad LCD display

4.3 Power Supply Connection

Before installing or removing an electrical device, you must make sure that the voltage

supply to the devices is switched off. Implement all of the necessary safety precautions

and make sure that the voltage supply to the CMU 1000 is switched off before

installation/removal.

Warning!

If you attempt to install or to wire the CMU 1000 and/or connected accessory

components while it or they are switched on, this could lead to an electrical shock

and/or to device malfunction. Implement all of the necessary safety precautions and

make sure that the voltage supply to the CMU 1000 and/or to connected accessory

components is switched off prior to installation/removal.

+ -

18 .. 35 V DC

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 21

Condition Monitoring Unit CMU 1000 Page 21

4.4 Behavior when Switching On/Restart

The CMU 1000 is not equipped with a power switch. The behavior of the device

following switch-on depends on whether or not a CM Program has been stored in the

device memory.

4.4.1 No CM Program Available in the Device

If the CMU 1000 is still in the condition it was at the time of delivery, and if no

application program has yet been loaded into the CMU, then the following displays will

appear in sequence in the LCD display:

HHyyddaacc EElleeccttrroonniicc

CCMMUU11000000 VVxxxx..yyyy

NNoo

RReessuulltt VVaalluueess

SSeennssoorr CChheecckk

........

4.4.2 CM Program Available in the Device

If an application program is stored in the CMU, then this will restart. The sensor

configuration and the sensor constellation will also be checked at this time.

The following displays appear in sequence:

HHyyddaacc EElleeccttrroonniicc

CCMMUU11000000 VVxxxx..yyyy

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

>>PPrrooggrraamm nnaamme

LLooaaddeedd

SSeennssoorr CChheecckk

........

e

<<

Page 22

Condition Monitoring Unit CMU 1000 Page 22

If one or more output values are programmed in the CM Program that is loaded, (see

Chap. 7.9.1 and 7.9.2), then the display will jump to the first output value after startup.

When several output values have been programmed, you can switch between the

individual program values with the ▲ and ▼ key.

Example:

OOiill tteemmpp.. ttaannk

3311..22°°CC

▲ ▼

k

WWoorrkkiinngg pprreessssuurre

2277 bbaarrss

Note!

No conditions are registered or saved in the device after switch-off. Exceptions to this

are the input parameters (settings), which the user has defined and saved in the menu.

e

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 23

Condition Monitoring Unit CMU 1000 Page 23

5 Basic Settings/Menu Structure

The CMU 1000 configuration and settings can be carried out in two different modes:

5.1 Configuration on the Device

5.1.1 Menu Structure for Operation on the Device

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6

Input values

Settings

Sensor A

Sensor B

:

:

Sensor R

Basic settings

CM Program

settings

Peripherals

[Display of current

measured value]

[Display of current

measured value]

[Display of current

measured value]

Name [Enter name]

Language

Port RS 232 / HSI

Dateformat

Recording settings

HLB reset

Time settings

Network settings

Numerical input

values

Boolean input

values

Channel settings

German

English

French

TT.MM.JJ

MM/TT/JJ

JJ-MM-TT

Delete record

Continue record

HLB reset

Sensor

Date

Time

IP-Address

Subnetmask

Gateway

MAC-Address

[Enter value]

Yes / No

Channel A

:

Channel H

Channel I

:

Channel P

Yes /

No

Yes /

No

Yes /

No

Sensor A …

Sensor H

[Enter

current date]

[Enter

current time]

[enter

IP address]

[enter

subnetmask]

[enter

Gateway address]

[MAC address

is permanently

set at the factory]

The menu option appears only if one

or more input functions are used in

the CM Program!

Name

Name

Mode

Input signal

Low

range

[Enter

name]

[Enter

name]

Automatic

Off

Manual

HSI

0 .. 20 mA

4 .. 20 mA

0 .. 5 V

0 .. 10 V

0,5 .. 4,5 V

0,5 .. 5,5 V

1 .. 5 V

1 .. 6 V

[Enter

value]

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 24

Condition Monitoring Unit CMU 1000 Page 24

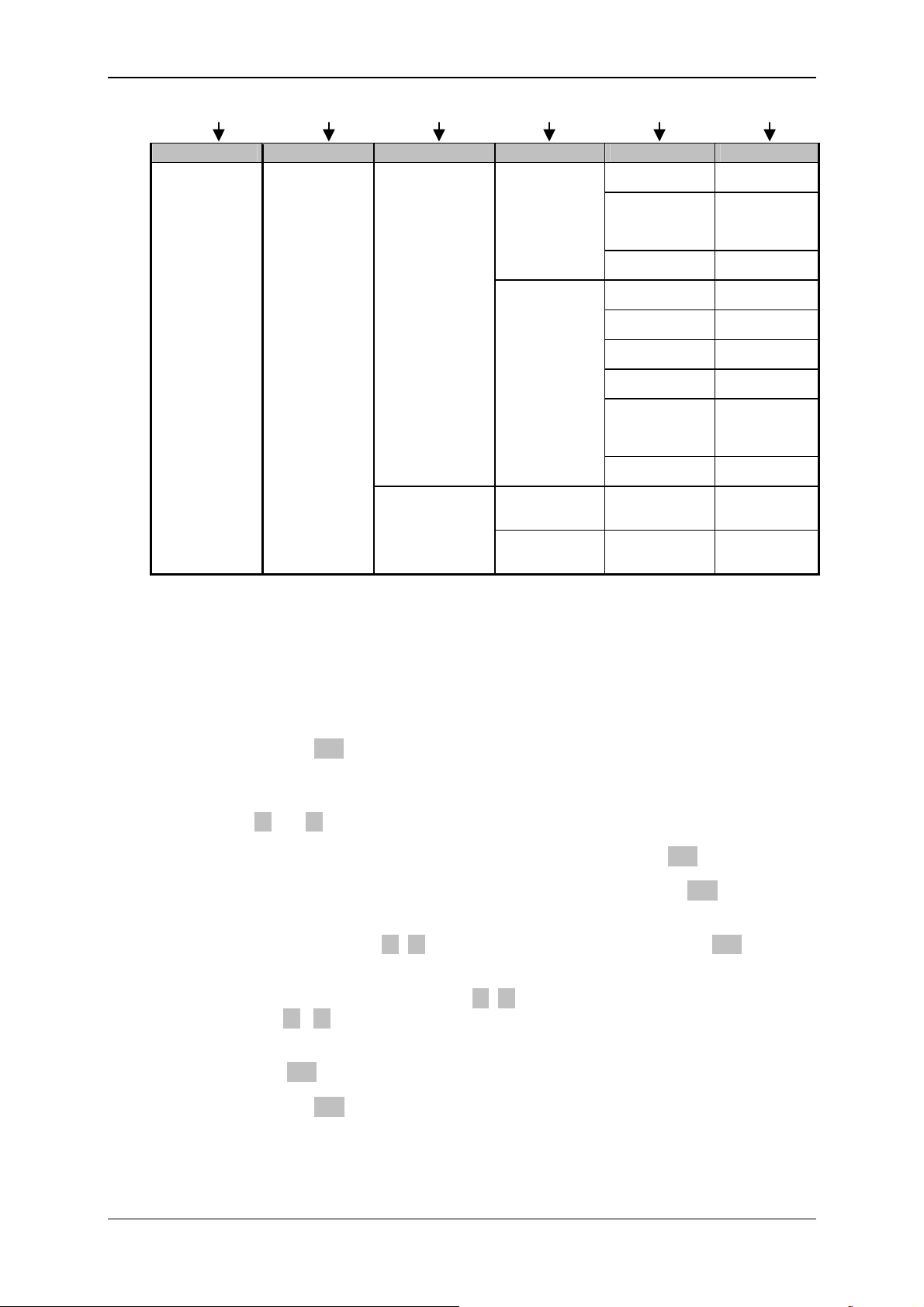

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6

Settings

Peripherals

Channel settings

PWM settings

(analog outputs)

Channel I

:

Channel P

Channel Q

:

Channel R

PWM 1

(analog output 1)

PWM 2

(analog output 2)

High

range

Decimal

format

Unit (of

measurement)

Name

Mode

High

range

Factor

Decimal

format

Unit (of

measurement)

0 to 20 mA

4 to 20 mA

0 to 10 V

0 to 20 mA

4 to 20 mA

0 to 10 V

[Enter

value]

0

0.0

0.00

0.00

[Enter

unit]

[Enter

name]

Off

Active

[Enter

value]

[Enter

value]

0

0.0

0.00

0.00

[Enter

unit]

5.1.2 Key Functions during Operation on the Device

The setting parameters and displays listed in the previously shown menu structure can

be called up and the corresponding settings and selections can be made with the key

pad.

Pressing the o.k. key once takes you out of the measured value display and

into the CMU 1000 menu. .

You can switch between the individual menu options of a level by pressing the

keys ▲ or ▼ .

The next-lower menu level can be accessed by pressing the o.k. key once.

You can go back to the next-higher menu level by pressing the Esc key once.

The selection of the specific setting values (e.g. interface, date format, mode,...)

can be made with the ▲ ▼ keys and confirmed by pressing the o.k. key.

To enter name, date and time values, addresses measurement ranges, etc.,

select the cursor position with the ◄ ► keys.

Use the ▲ ▼ keys to select the required uppercase and lowercase letters,

numbers and special characters.

Press the o.k. key to confirm the completed entry.

Pressing the Esc key aborts the entry without applying the changes.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 25

Condition Monitoring Unit CMU 1000 Page 25

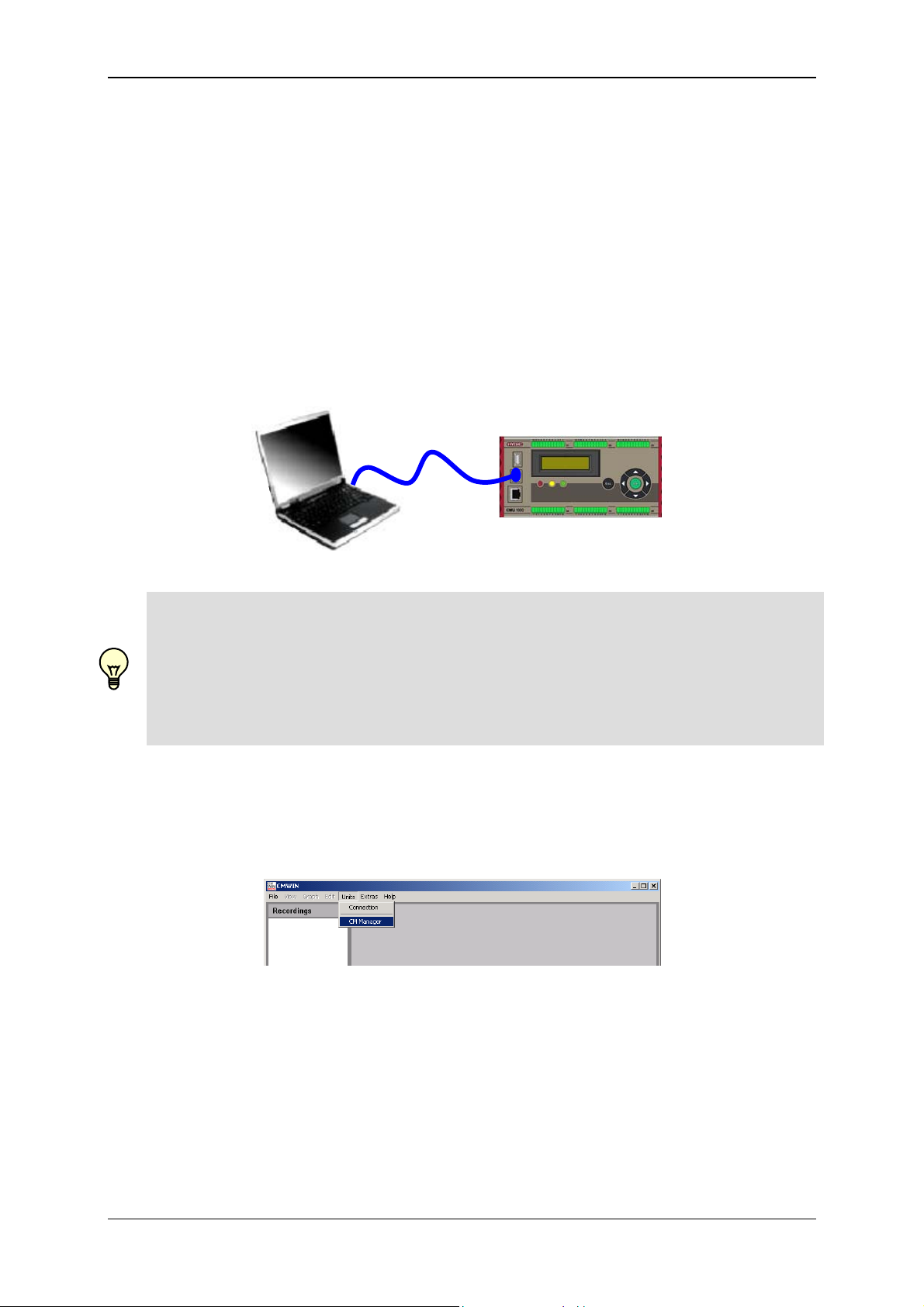

5.2 Configuration Using CMWIN PC Software

The configuration of the CMU 1000 and the carrying out of the basic settings can also

be performed from a PC with the "CM Manager".

The "CM Manager" is a component part of the CMWIN HYDAC PC software, starting

with Version 3, and provides you with various tools and functions for the connecting,

configuring, parameterizing and reading-out of CM devices.

The following options are available for setting up the connection with the CMU 1000:

5.2.1 Direct Connection

• First connect your PC with the USB slave port on the CMU 1000

USB

Note!

If the CMU 1000 is being connected for the first time with the PC via USB, then you

must first install the HYDAC USB driver „HE-Virtual-Comport-Driver“.

The driver are included on the CD-ROM contained in the scope of delivery.

• Call up the file “HE-V

OMPORT-DRIVER” folder and follow the instructions of the “Setup Wizard”.

C

IRTUAL-COMPORT-INSTALLER.EXE” in the “HE-VIRTUAL-

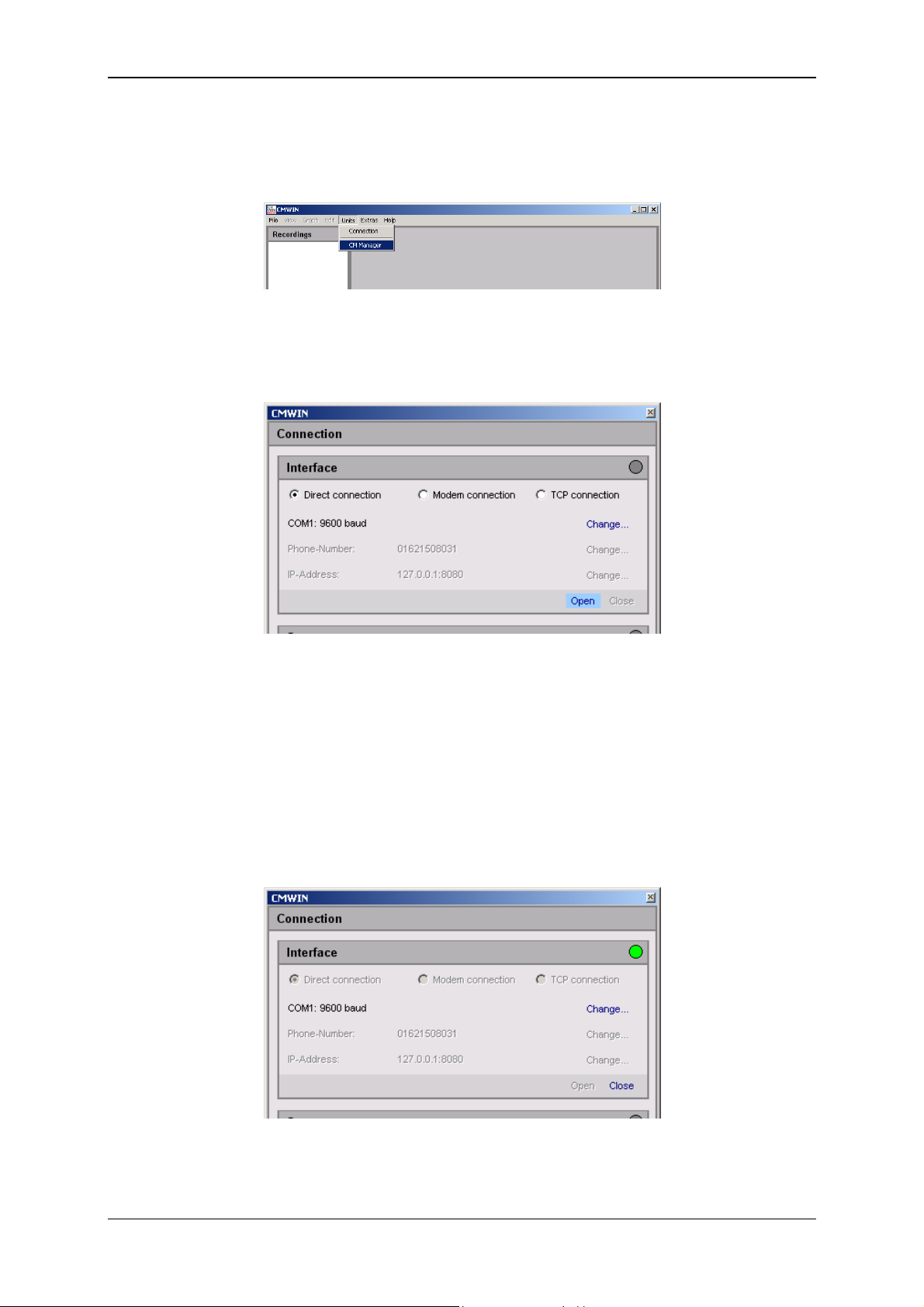

• Start the HYDAC PC software CMWIN

• In the Units Menu, select the "CM Manager" option.

• If the Connection window does not open automatically, select

"Connection" in the menu bar of the CM Manager.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 26

Condition Monitoring Unit CMU 1000 Page 26

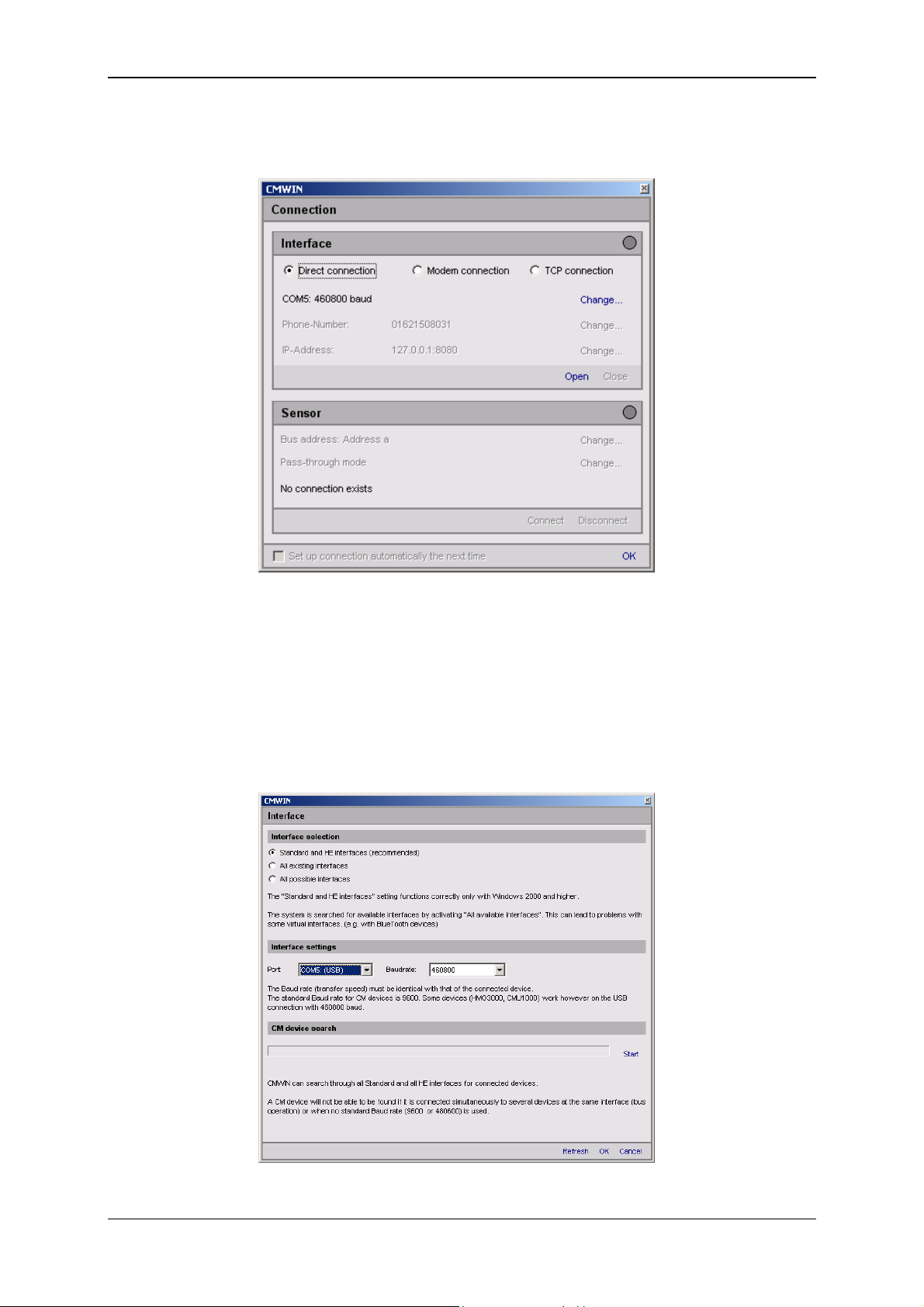

• Mark the option "Direct Connection" option in the window that opens.

• Click on "Change" to open the window for the interface settings.

• Make the corresponding preselection for the port settings in the window that

opens under Interface selection.

• Select the respective port address and Baud rate under Interface settings.

• As an alternative, you can also search automatically under CM device search

for CM devices connected to the PC by pressing "Start".

• Pressing "Refresh" causes the interfaces marked under Interface selection to

be refreshed in terms of availability.

• Click on “OK“ to apply the modified settings or “Cancel“ to discard these

changes. In either case you will then return to the Connection window.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 27

Condition Monitoring Unit CMU 1000 Page 27

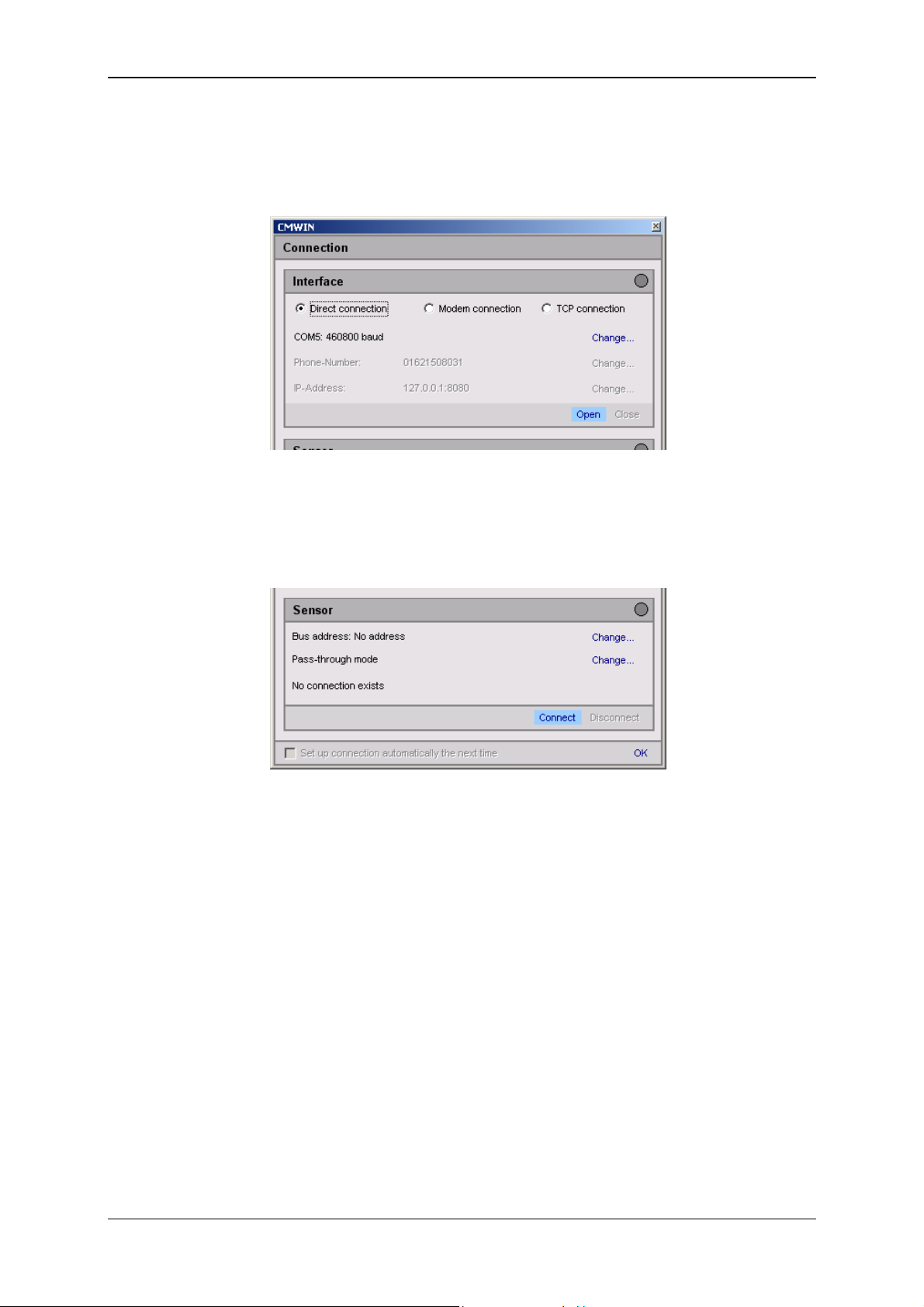

• In the Interface field, select the option "Open" in order to open the selected

interface (COM port).

The opened interface will be symbolized by a green dot on the right-hand edge

of the window.

• Afterwards click on "Connect" in the Sensor field to connect the CMU 1000 to

the PC.

The successful connection will be symbolized by a green dot on the right-hand

edge of the window.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 28

Condition Monitoring Unit CMU 1000 Page 28

• Pressing "Disconnect" in the Device field allows you to interrupt the existing

connection between the CMU 1000 and the PC.

• The interface (COM port) used can be closed again on the PC by pressing

"Close" in the Interface field.

• At the end you also have the option of selecting an automatic connection setup.

Placing a checkmark in the box for "Set up connection automatically next

time " causes the CMWIN software to set up a connection automatically with

the CMU 1000 that is linked via USB during startup. To ensure that this

happens, no changes should be made to the interface parameter settings after

the currently existing connection is disconnected.

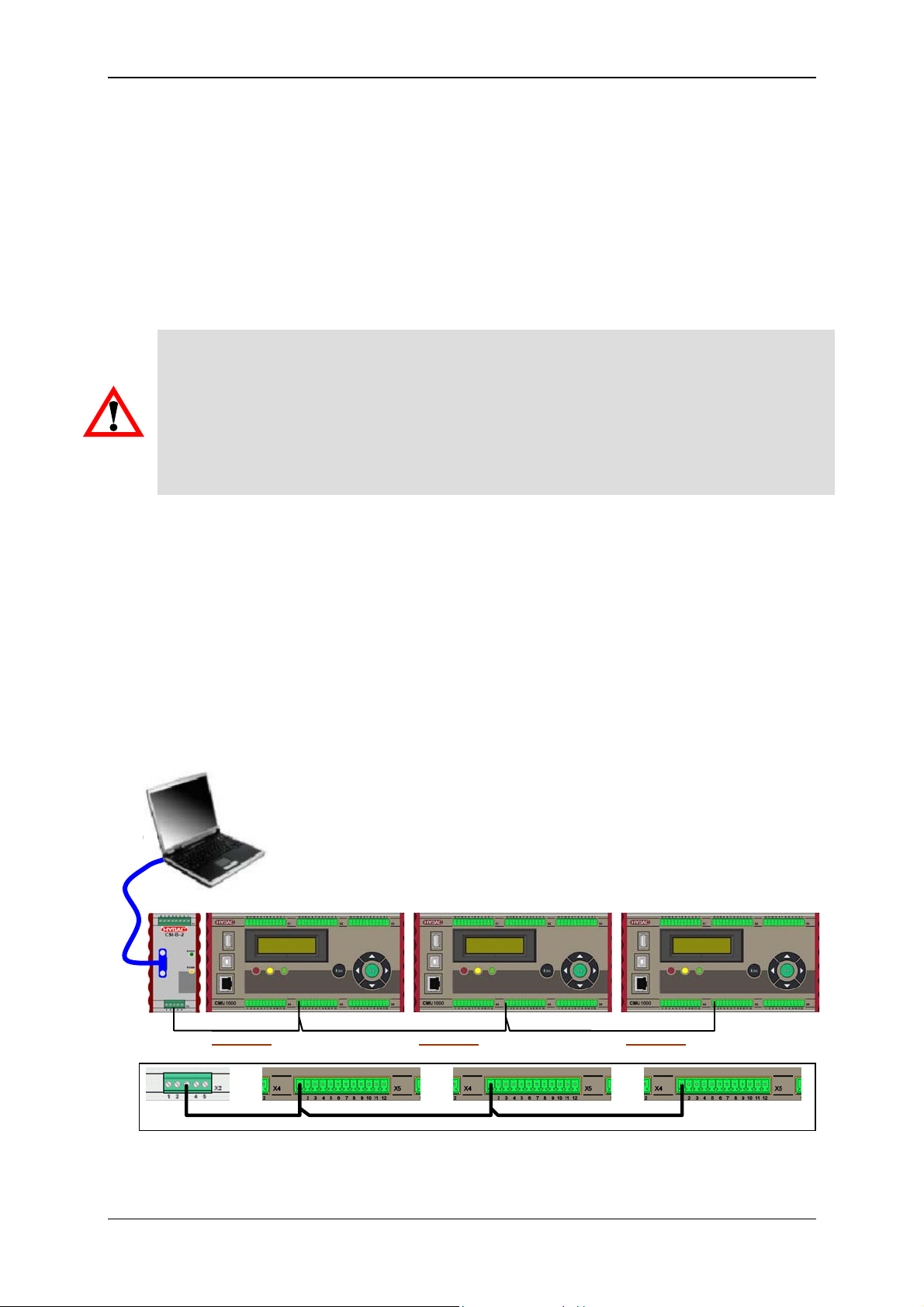

• Click on "OK" to complete the connection setup and to

return to the CM Manager.

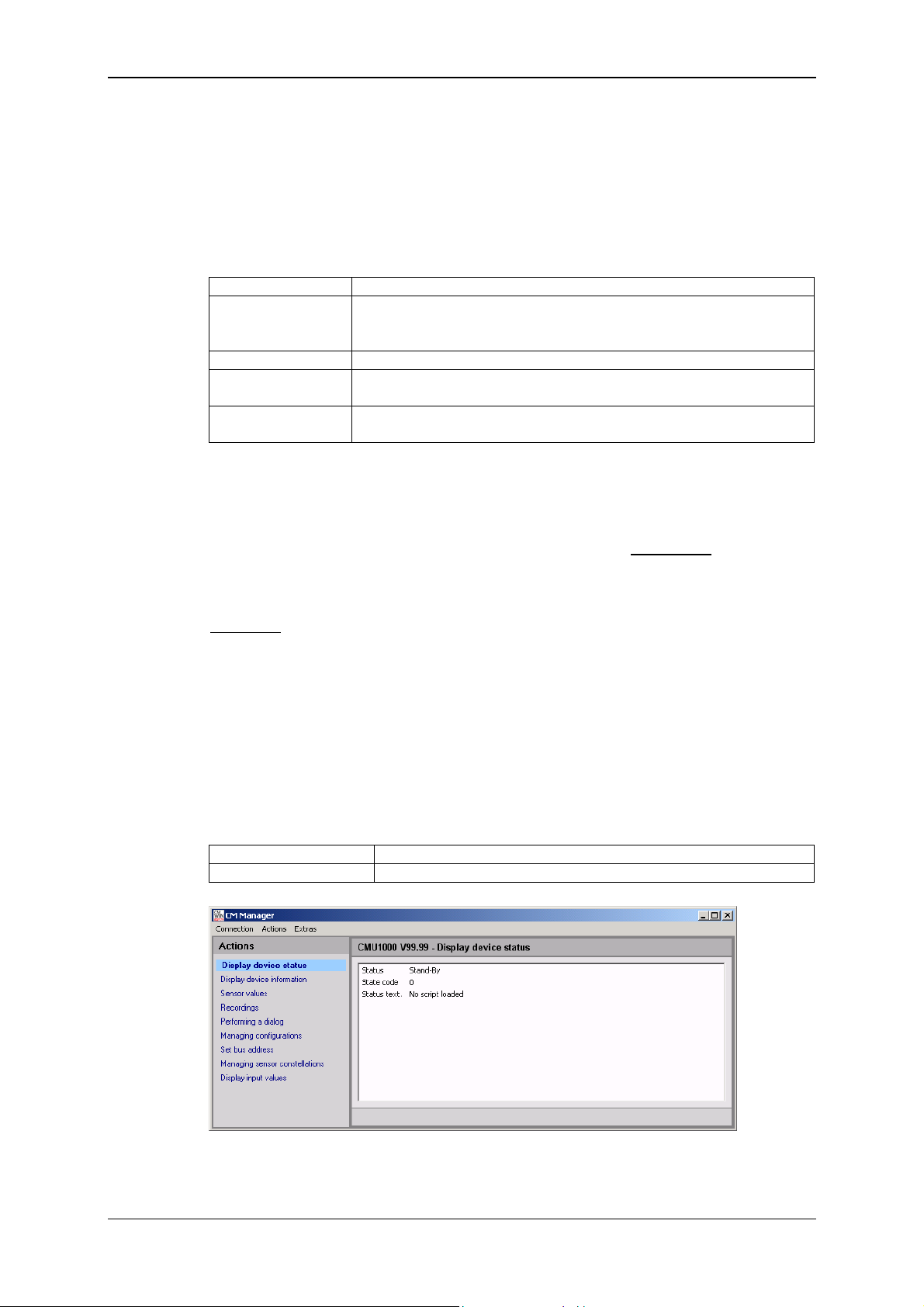

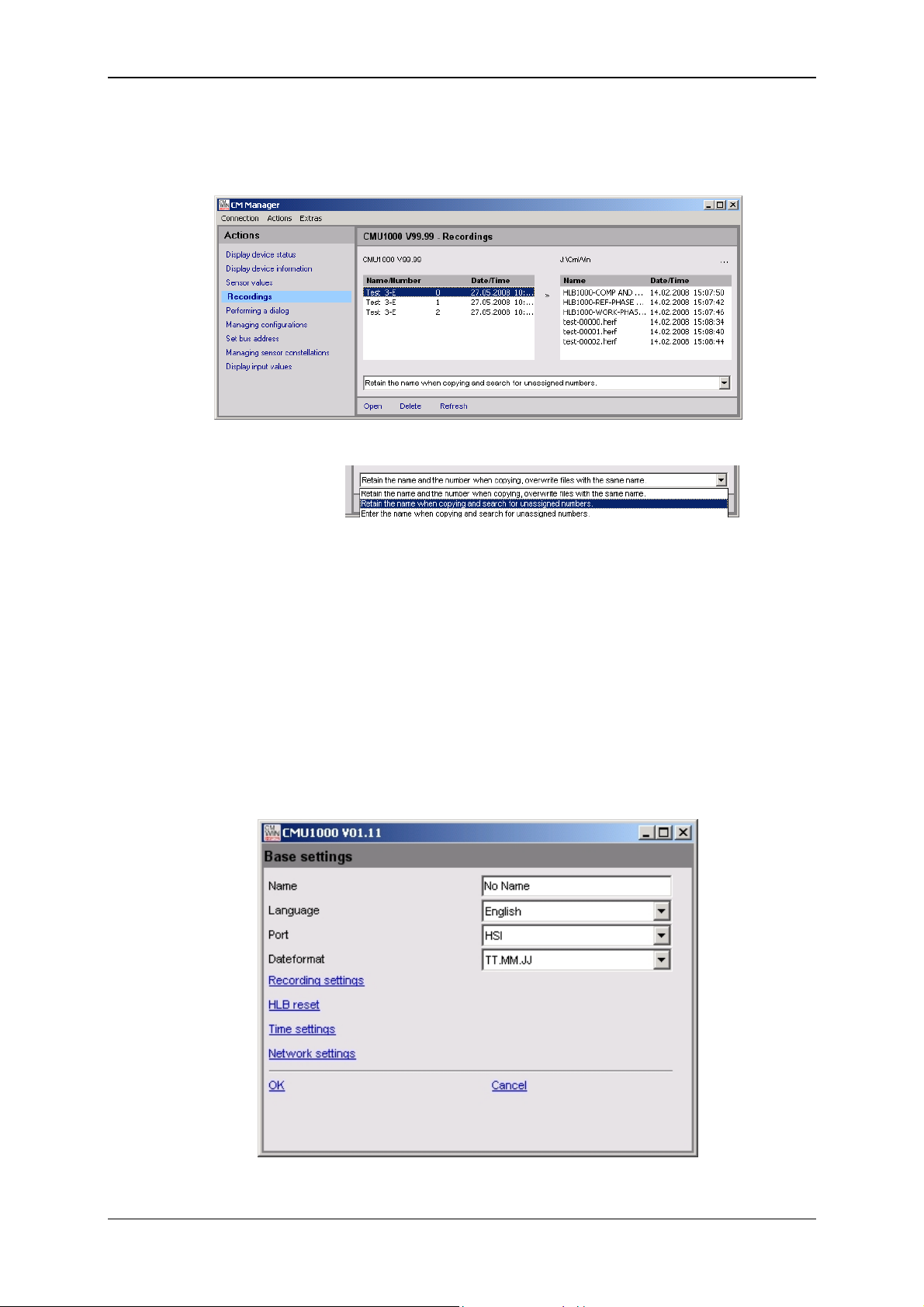

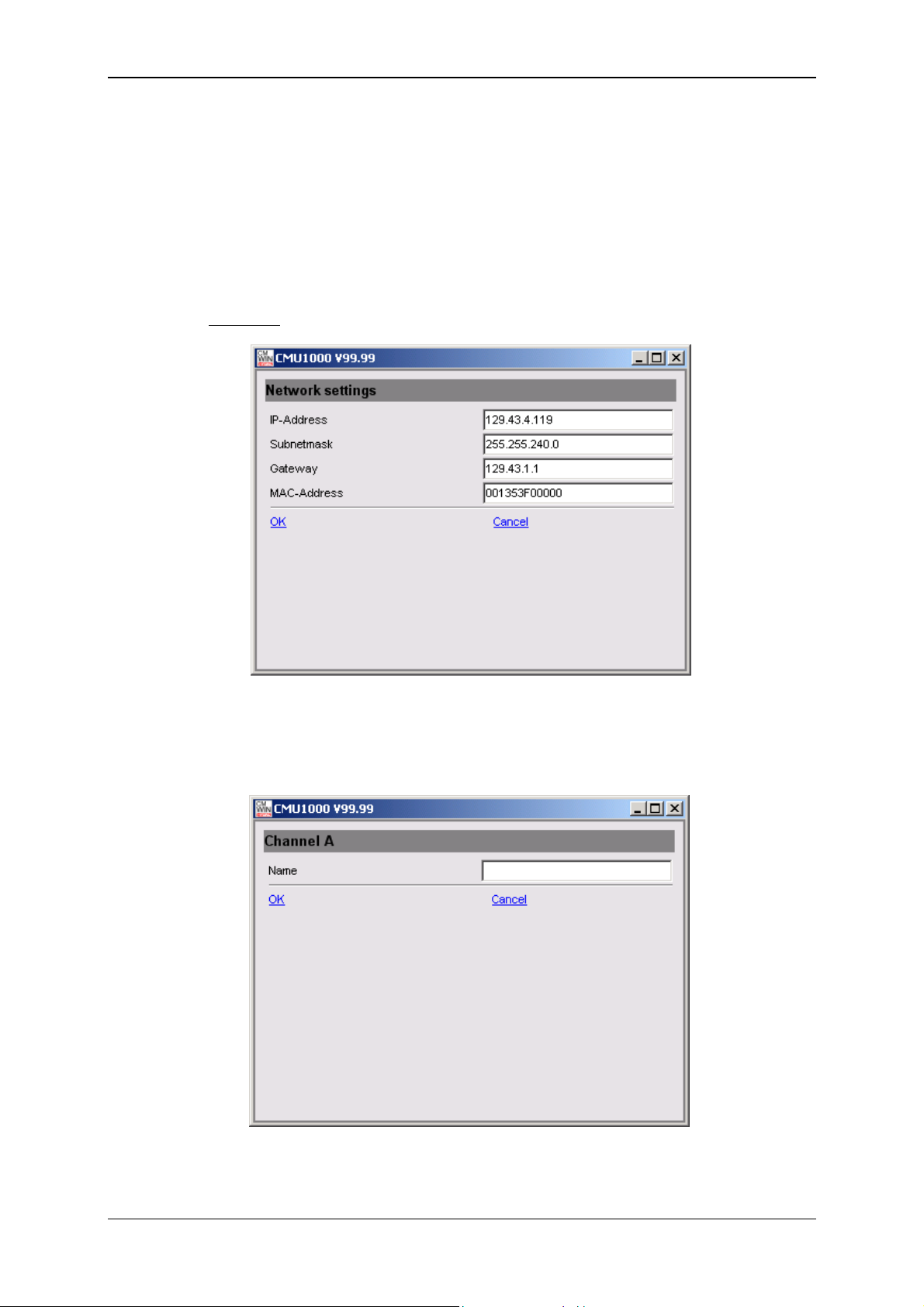

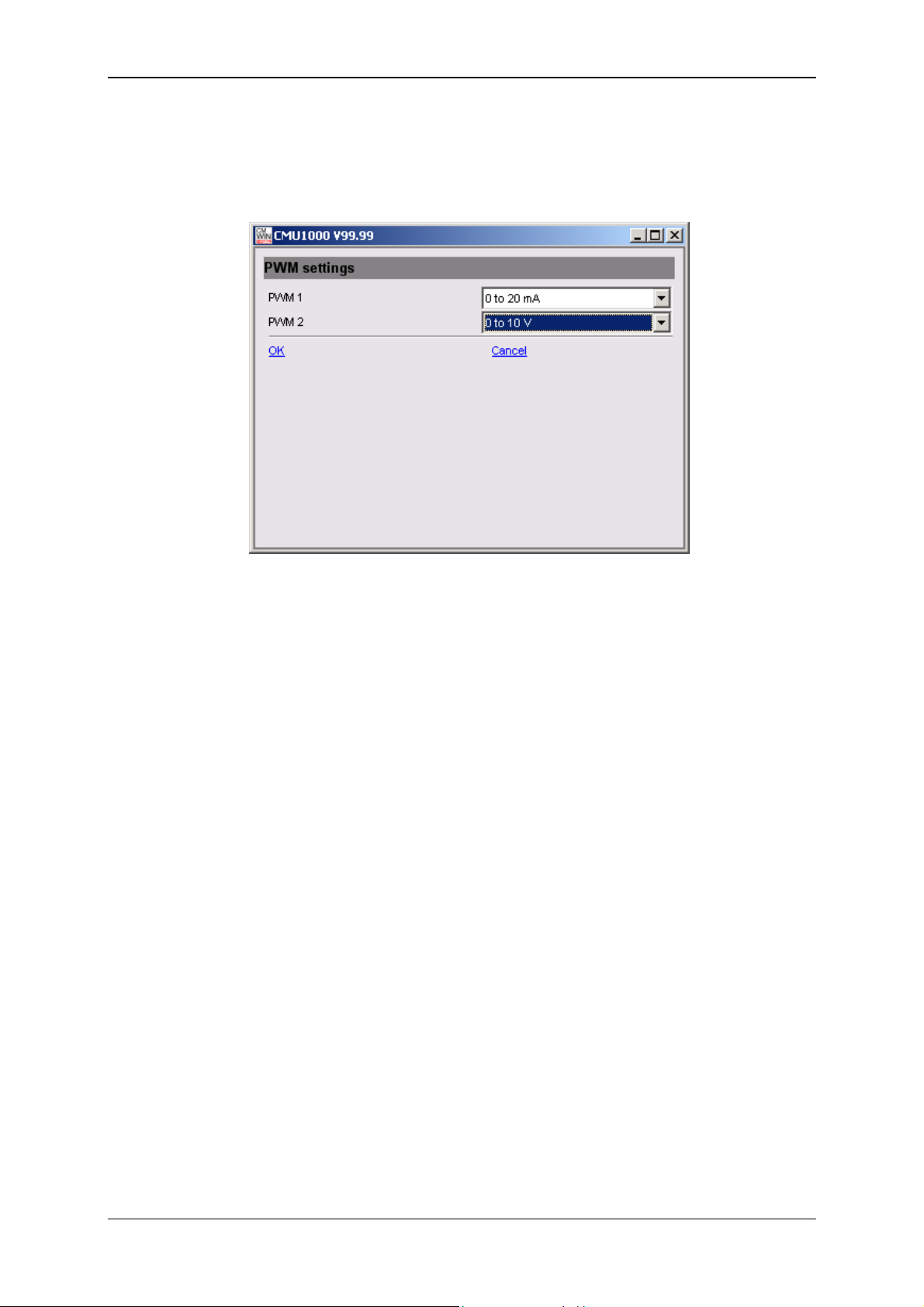

• The following window opens after the connection has been successfully

established:

The menu structure and window properties of the CM Manager are explained below in

greater detail in Chapter 5.2.5 ff.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 29

Condition Monitoring Unit CMU 1000 Page 29

A

A

c

A

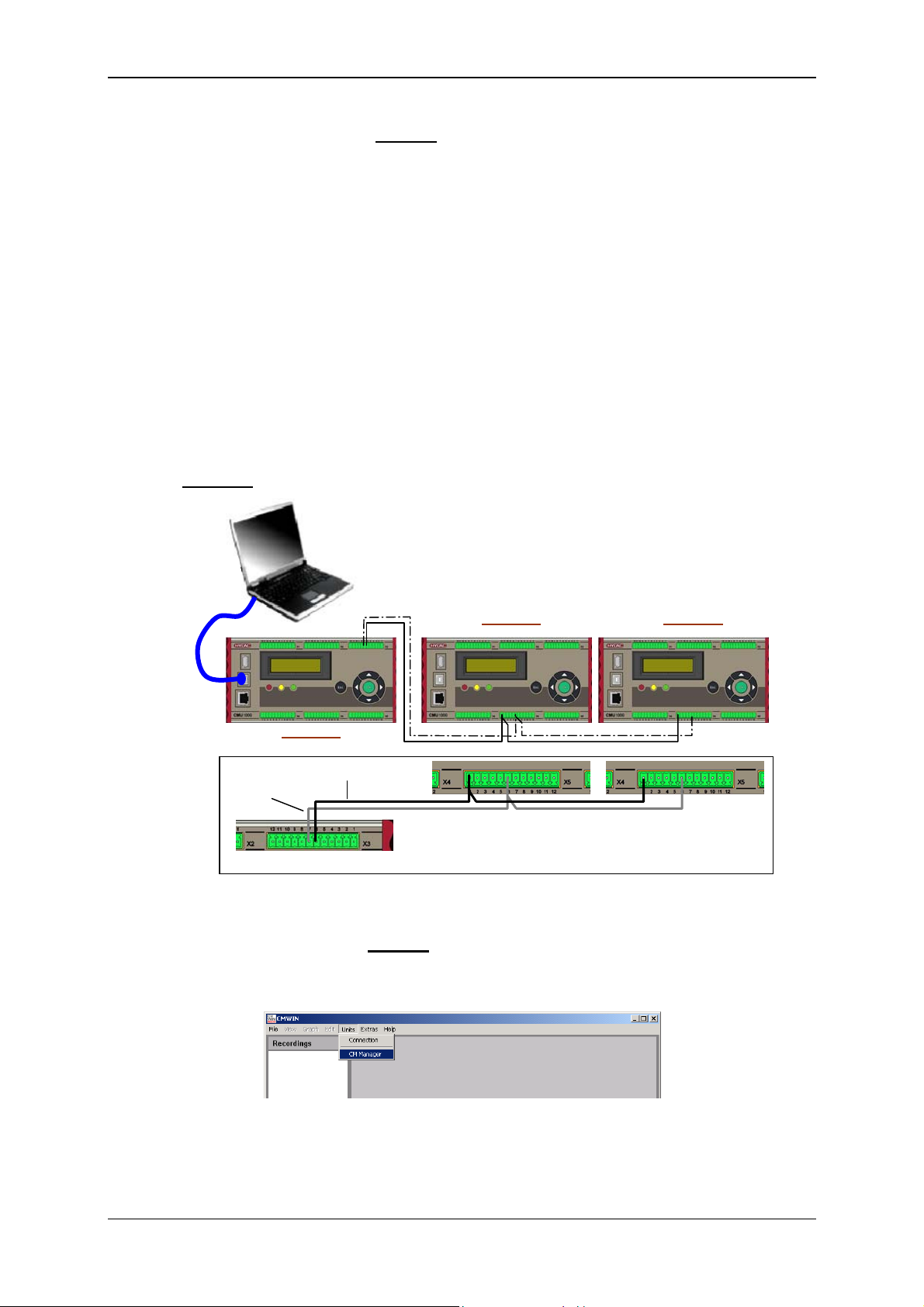

5.2.2 Direct Connection via HSI Bus

You can connect several HYDAC CM devices with one another (maximum of 26

devices) via the so-called "HSI Bus". Each CM device must be assigned an HSI

Bus address for this purpose (see Chap. 5.2.5.7).

This kind of bus setup is presented below, using as an example three CMU 1000

devices. Other HYDAC CM devices such as SMART sensors (e.g. HYDACLab

CS 1000) or CSI modules can however also be linked in random sequence and

configuration in one HSI Bus.

Caution!

If you connect devices with one another that do not have the same reference

voltage, this can cause unwanted currents in the HSI connection cable.

These unwanted currents can lead to communication errors or property damage in

the devices.

Make sure that all of the devices that you connect with one another via HSI Bus

either have the same reference wire in the electricity circuit or are electrically

disconnected, so that no unwanted currents can arise.

5.2.2.1 Device Connection via CSI-B-2 Interface Module

®

,

RS232 /

RS485

• Connect the serial interface of your PC (RS232 or RS485) with the 9-pin SUB-D

socket of the HYDAC interface module CSI-B-2 via a corresponding data cable

(interface module and data cable are not included in the scope of delivery for

the CMU 1000).

• Connect all of the devices via the "HSI Master" connection.

(-X2/Pin 3 on the CSI-B-2 and -X5/Pin 1 on the CMU 1000)

• Switch on the voltage supplies for all of the connected devices.

dresse a

dresse

dresse d

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 30

Condition Monitoring Unit CMU 1000 Page 30

5.2.2.2 Connection Setup via CSI-B-2 Interface Module

• Start the HYDAC PC software CMWIN

• In the Units Menu, select the "CM Manager" option.

• If the Connection window does not open automatically, select

"Connection" in the menu bar of the CM Manager.

• Mark the option "Direct Connection" option in the window that opens.

• Click on "Change" to open the window for the interface settings.

• Make the corresponding preselection for the port settings in the window that

opens under Interface selection.

• Select the respective port address and Baud rate under Interface settings

(RS232 or RS485 with 9600 Baud).

• Pressing "Refresh" causes the interfaces marked under Interface selection to

be refreshed in terms of availability.

• Click on “OK“ to apply the modified settings or “Cancel“ to discard these

changes. In either case you will then return to the Connection window.

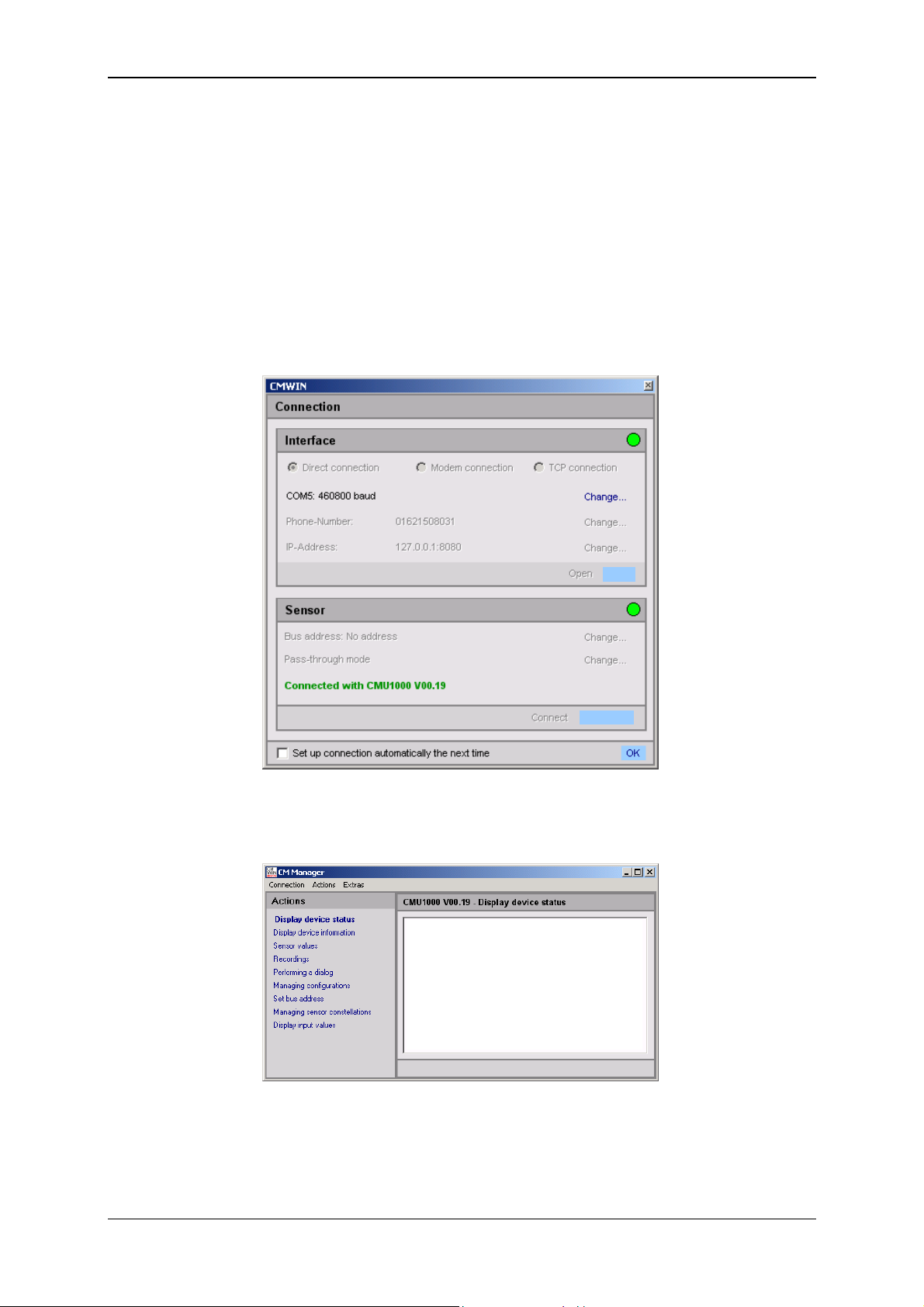

• Click on Open to open the selected interface. The opened interface is indicated

by a green dot on the upper right.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 31

Condition Monitoring Unit CMU 1000 Page 31

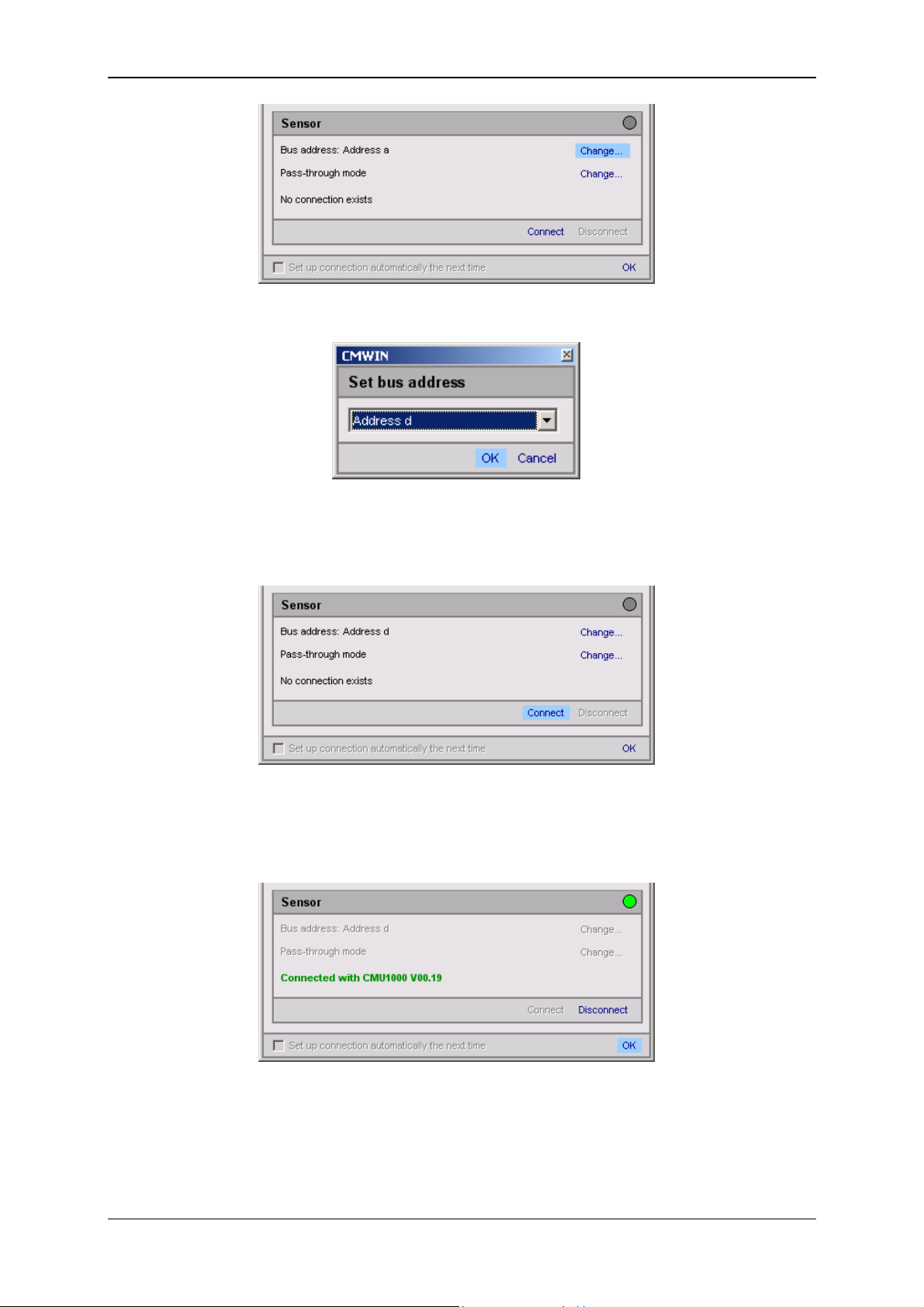

• Select Change in the Bus address line. The following window opens:

• Select the respective device address in the selection window (Address d in our

example).

• Confirm this with OK.

• Afterwards click on Connect to connect the PC to the CMU 1000 (Address d).

• The successful establishment of the connection will be signalled as shown

below:

• End the connection setup by confirming with OK.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 32

Condition Monitoring Unit CMU 1000 Page 32

A

A

c

A

5.2.2.3 Device Connection without CSI-B-2 Interface Module

As an alternative, you can also set up an HSI Bus without a CSI-B-2 interface

module and access the individual devices from the PC. For this you will need a

CMU 1000 for communications with the PC, which in such cases functions as an

"HSI Master".

• First establish which CMU 1000 is the "Master" for the HSI Bus, i.e. at which

CMU 1000 the PC will be connected.

The other CMU devices are connected to this device as "Slaves". Because of

the fact that the "Master" treats all of the other devices on the HSI Bus as

SMART sensors, the first "Slave" must be connected to one of the eight HSI

channels of the CMU 1000 (Channels A ... H) (see Chap. 3.3).

• Connect your PC via USB with the "Master" CMU 1000

• All "Slave devices" are connected via the "HSI Master" connection (-X5/Pin 1

and Pin 6) to the HSI Bus and linked with one another.

Example:

dresse a

HSI Master

HSI GND

Channel

dresse

5.2.2.4 Connection Setup without

CSI-B-2 Interface Module

• Start the HYDAC PC software CMWIN

• In the Units Menu, select the "CM Manager" option.

dresse d

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 33

Condition Monitoring Unit CMU 1000 Page 33

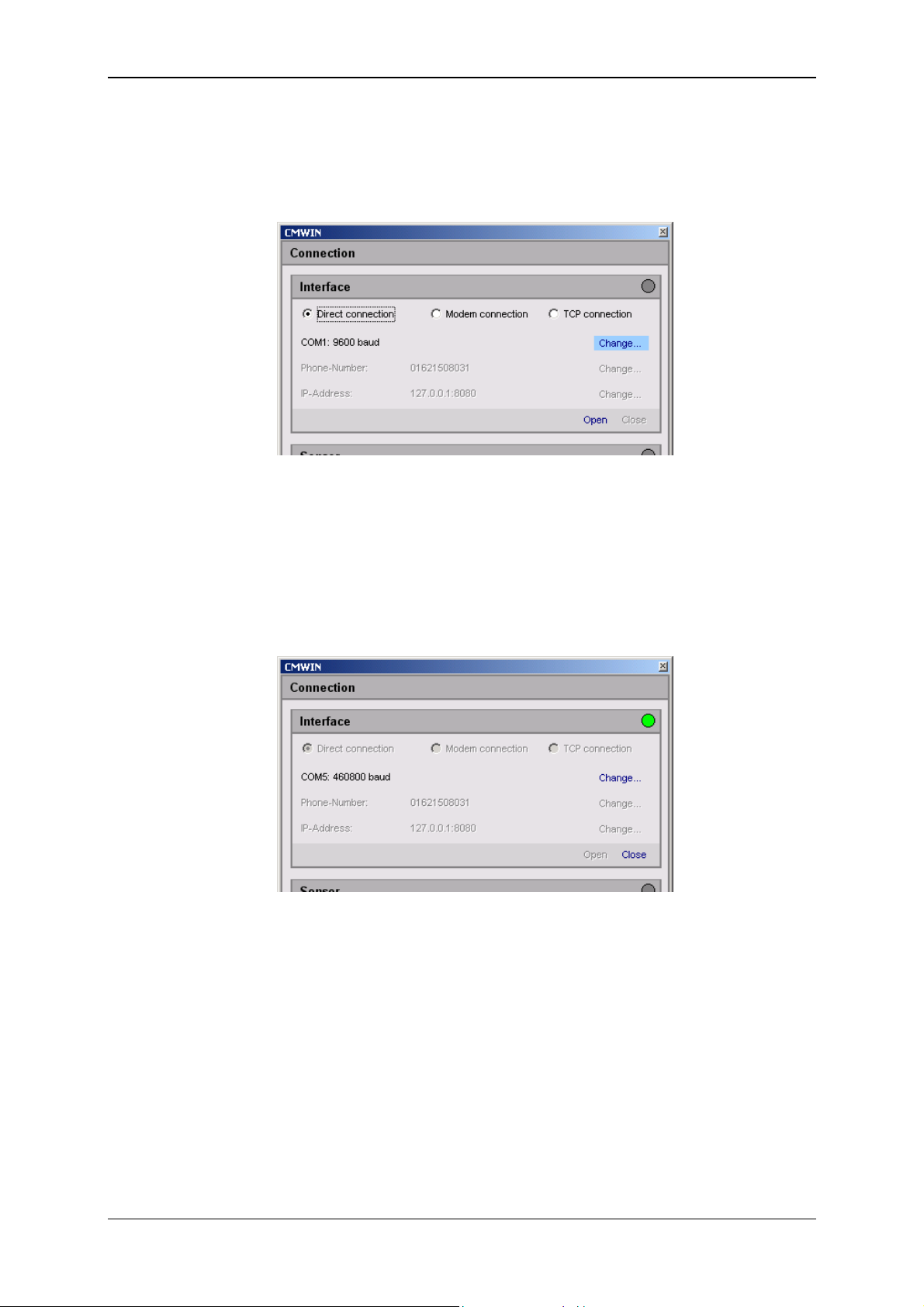

• If the Connection window does not open automatically, select

"Connection" in the menu bar of the CM Manager.

• Mark the option "Direct Connection" option in the window that opens.

• Click on "Change" to open the window for the interface settings.

• Make the corresponding preselection for the port settings in the window that

opens under Interface selection.

• Select the respective port address and Baud rate under Interface settings

(USB with 460,800 Baud).

• Pressing "Refresh" causes the interfaces marked under Interface selection to

be refreshed in terms of availability.

• Click on “OK“ to apply the modified settings or “Cancel“ to discard these

changes. In either case you will then return to the Connection window.

• Click on Open to open the selected interface. The opened interface is indicated

by a green dot on the upper right.

• To set up a connection with the "Master" CMU, simply click on Connect and

then OK.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 34

Condition Monitoring Unit CMU 1000 Page 34

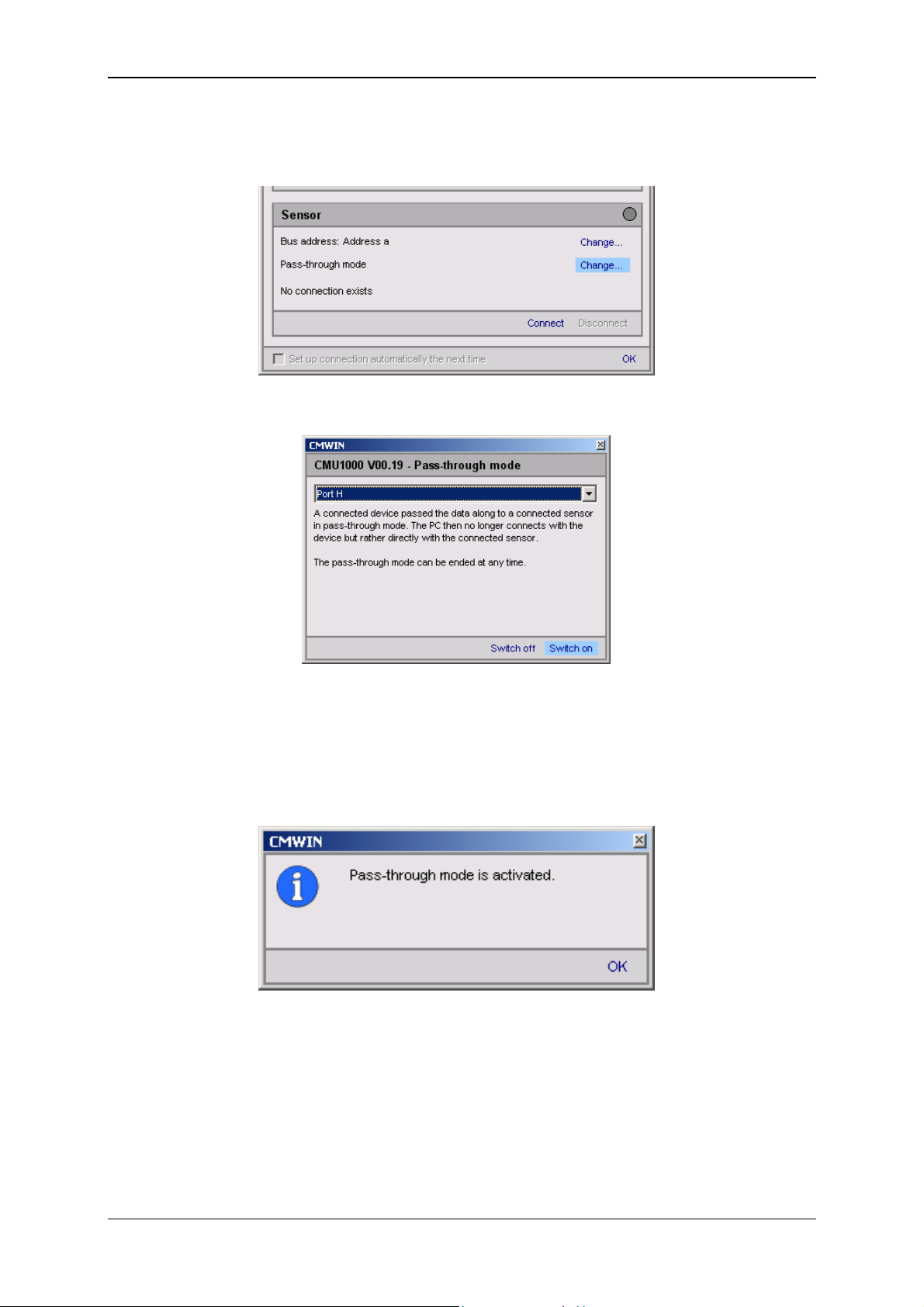

• To set up a connection with one "Slave" CMU (e.g. Address d), proceed as

follows:

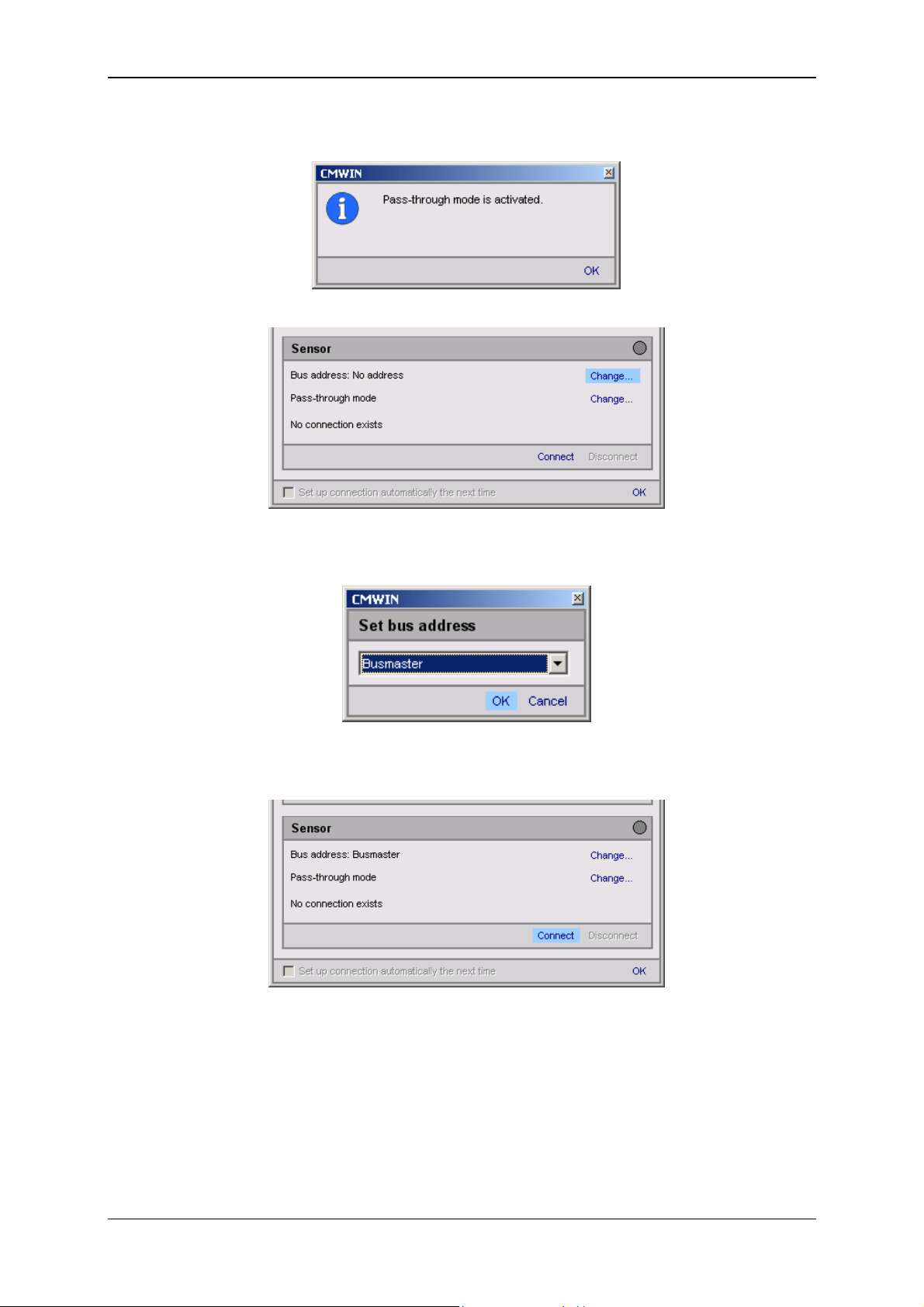

• Select Change in the Pass-through mode line. The following window opens:

• Select the HSI channel in the selection window to which the slave devices are

connected (in our example, Port H at the "Master" CMU).

• Afterwards, click on Switch on in order to switch on the pass-through mode for

the selected channel.

• The following message appears:

• Confirm this with OK.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 35

Condition Monitoring Unit CMU 1000 Page 35

• Select Change in the Bus address line. The following window opens:

• Select the respective device address in the selection window

(Address d in our example).

• Confirm this with OK.

• Afterwards click on Connect to connect the PC to the Slave CMU (Address d).

• The successful establishment of the connection will be signalled as shown

below:

• End the connection setup by confirming with OK.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 36

Condition Monitoring Unit CMU 1000 Page 36

• The following message now appears in the Master CMU display:

PPaassss--tthhrroouugghh MMoodde

EESSCC ttoo FFiinniisshh

The message will remain in the display for as long as the "Master" CMU

continues to be operated in pass-through mode.

The pass-through mode can also be switched off on the CMU itself (instead of

by means of the Connection Menu in the CM Manager) by pressing the Esc key

on the device.

Note!

Error messages can occur if the pass-through mode is switched off at the "Master"

CMU (either via software or directly on the device), because the signals to the channel

to which the "Slave" devices are connected can no longer be evaluated under certain

circumstances.

e

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 37

Condition Monitoring Unit CMU 1000 Page 37

5.2.3 Modem Connection

You also have the option of setting up a connection by means of the Standard GSM

mobile radio network.

In the following we present an example of this kind of communication link.

5.2.3.1 Device Connection/Pin Connections

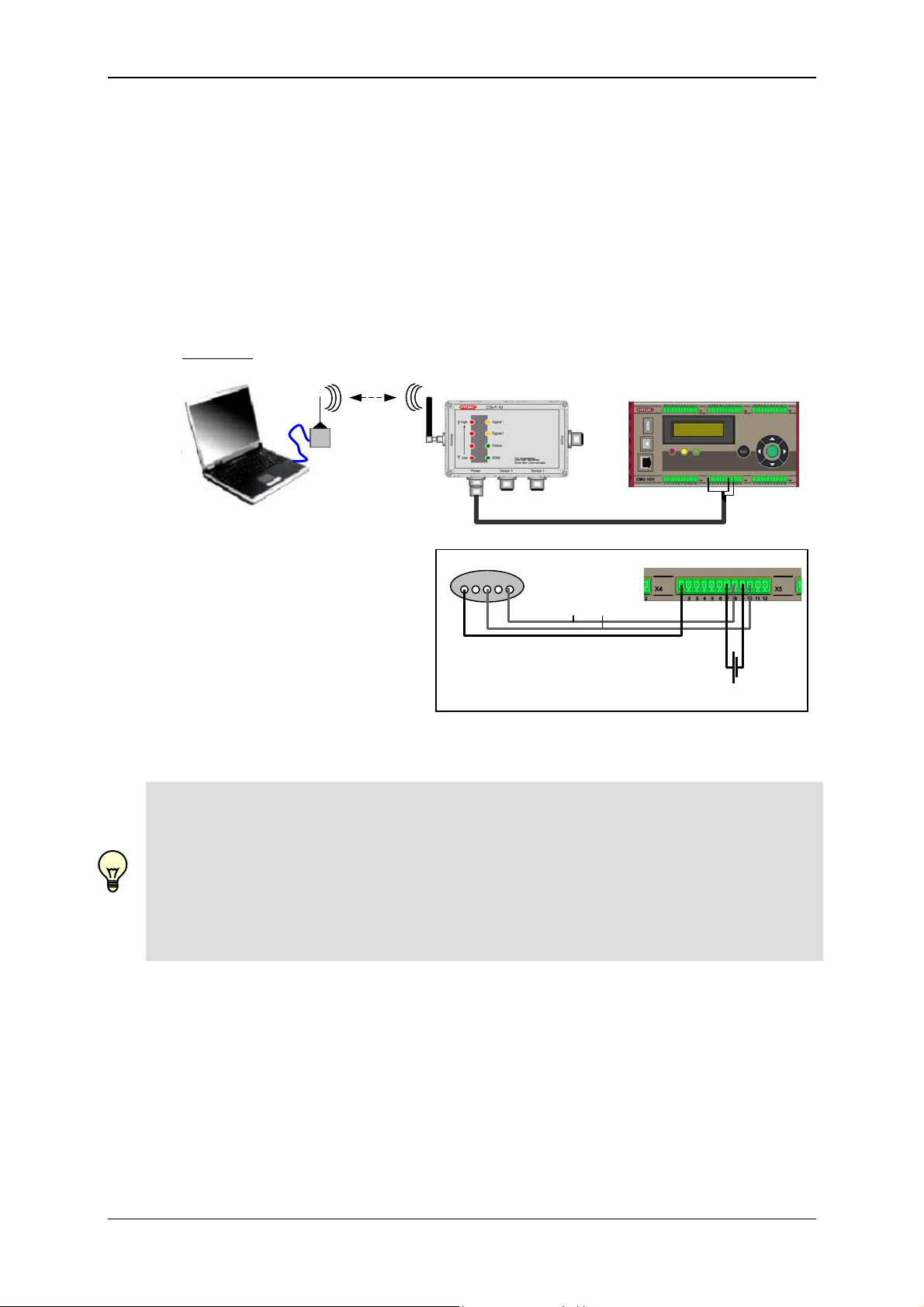

Connect a Standard GSM modem to your PC and connect the CMU 1000 to the

HYDAC GSM radio module CSI-F-10 in accordance with the diagram.

Example:

GSM

5 4 3 2 15

+U

GND

B

HSI

18..35 V DC / 5 A

Note!

In order to be able to communicate with the CMU 1000 via the connected CSI-F-10

GSM radio module, this must first be configured. This means that the mobile phone

numbers which are authorized for access must be stored in the CSI-F-10 and

appropriate permissions assigned.

To configure the GSM radio module CSI-F-10, or to make changes in a configured

device, first connect directly with the GSM radio module CSI-F-10 as described below.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 38

Condition Monitoring Unit CMU 1000 Page 38

5.2.3.2 Establishing Connection with GSM Radio Module CSI-F-10

• Connect the CMU 1000 for configuring the CSI-F-10 GSM radio module to your

PC as also described in Chapter 5.2.1 Direct Connection, Chapter 5.2.2 Direct

Connection via HSI Bus or Chapter 5.2.4 TCP Connection.

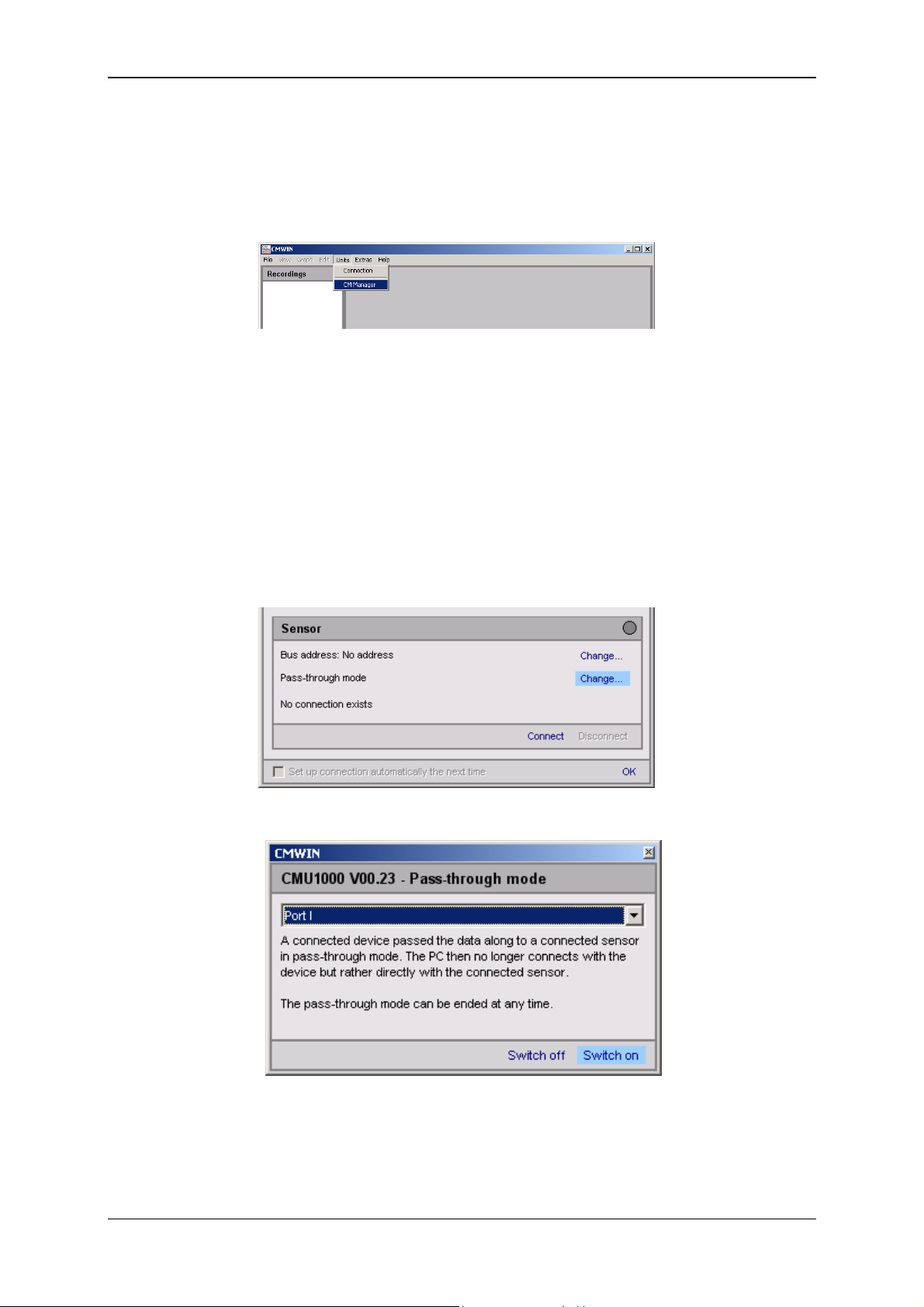

• Start the HYDAC PC software CMWIN

• In the Units Menu, select the "CM Manager" option.

• If the Connection window does not open automatically, select

"Connection" in the menu bar of the CM Manager.

• Under Interface Settings make the settings necessary for the available

connection type (for configuring the CSI-F-10).

• Click on “OK“ to apply the settings or “Cancel“ to discard these changes. In

either case you will then return to the Connection window.

• Click on Open to open the selected interface. The opened interface is indicated

by a green dot at the top right.

• Select "Change" in the Pass-through mode line. The following window opens:

• In the drop-down menu, select "Port I" and then click on Switch on in order to

switch on the pass-through mode.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 39

Condition Monitoring Unit CMU 1000 Page 39

• The following message appears:

• Select "Change" in the Bus address line. The following window opens:

• In the selection window, select "Busmaster" and then click on OK to apply the

address.

• Then click on "Connect" to connect the PC to the CSI-F-10 GSM radio module

(address busmaster).

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 40

Condition Monitoring Unit CMU 1000 Page 40

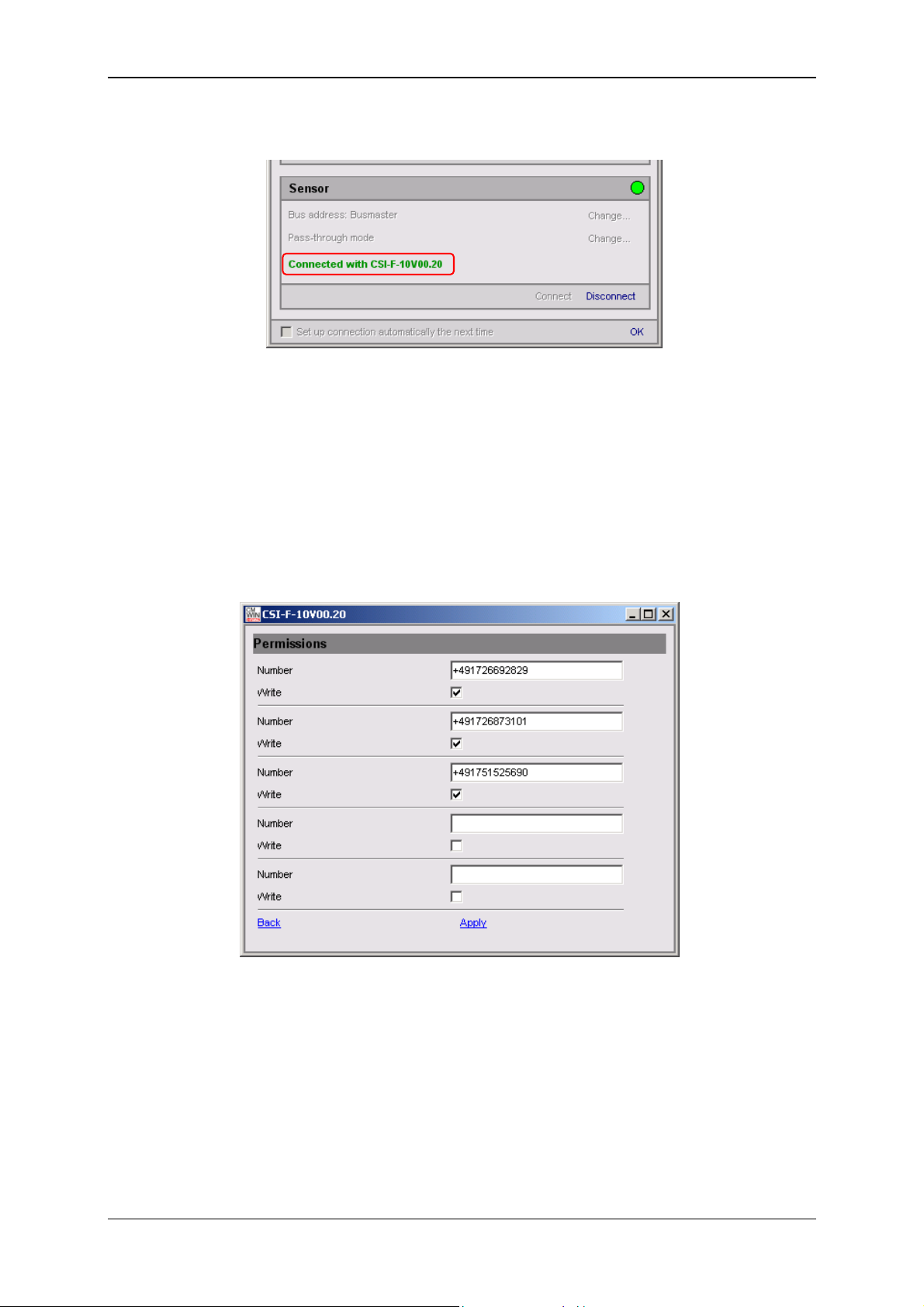

• Successful establishment of the connection will be signaled as shown below:

• End the connection setup by confirming with OK.

• In the CM Manager under Actions / Performing a Dialog / Permissions, open

the following input window and input the mobile phone number authorized for

accessing the CMU 1000.

• Permissions

Number [input telephone number with country code]

Write [allow written access]

You can input up to five telephone numbers to which the CSI-F-10 may send

messages and from which the device may receive enquiry text messages.

By placing a checkmark in the "Text" box, you are also allowing access by text

to the CSI-F-10 from this telephone number (change settings, transfer CM

program, update firmware, ...)

Click on "Apply", to apply the settings. "Back" takes you back to the main

menu.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 41

Condition Monitoring Unit CMU 1000 Page 41

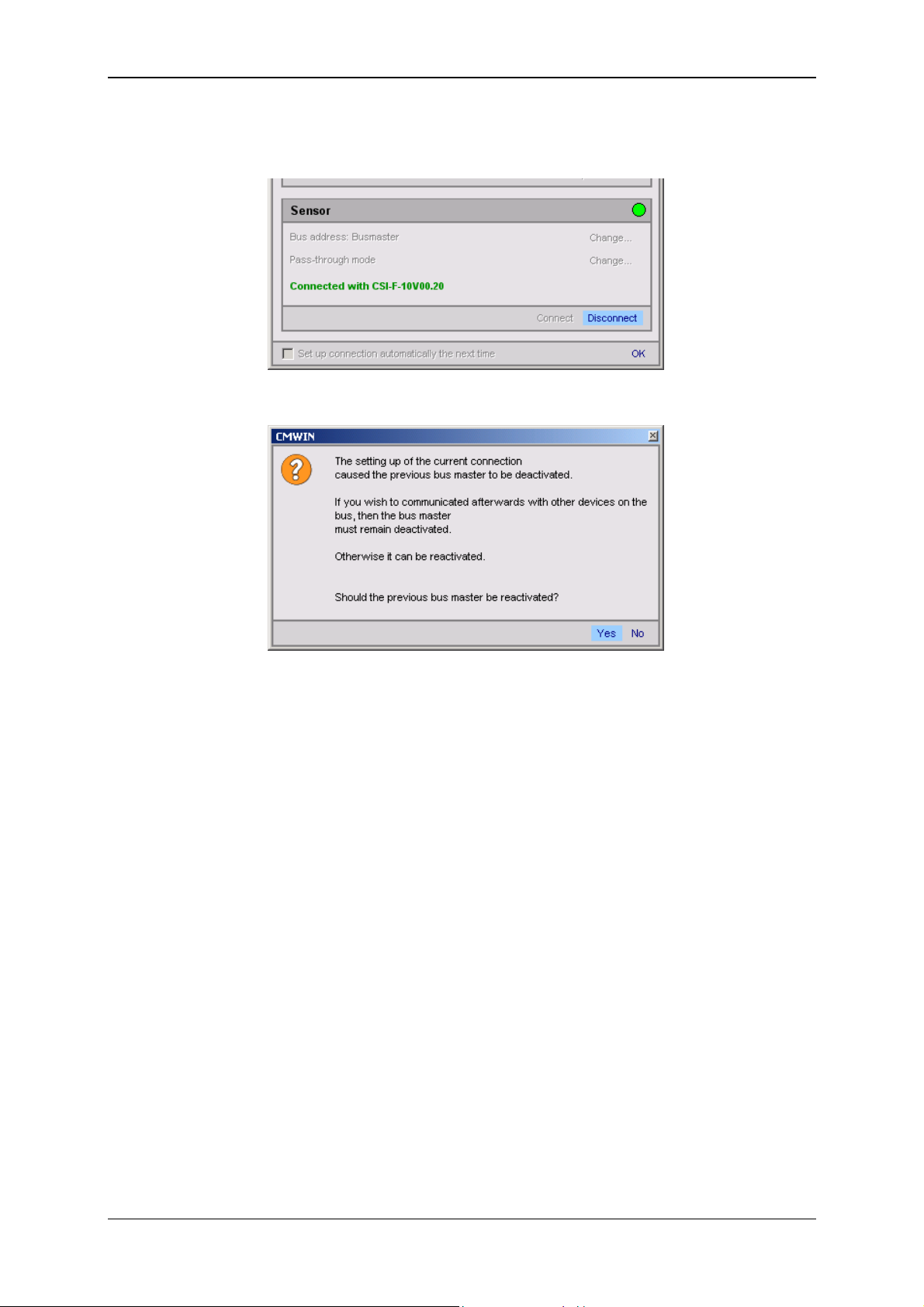

• Click on "Disconnect" under Connection in the Device box to break the

existing connection with the CSI-F-10.

• The following window opens:

• Then click on "Yes" to reactivate the busmaster again.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 42

Condition Monitoring Unit CMU 1000 Page 42

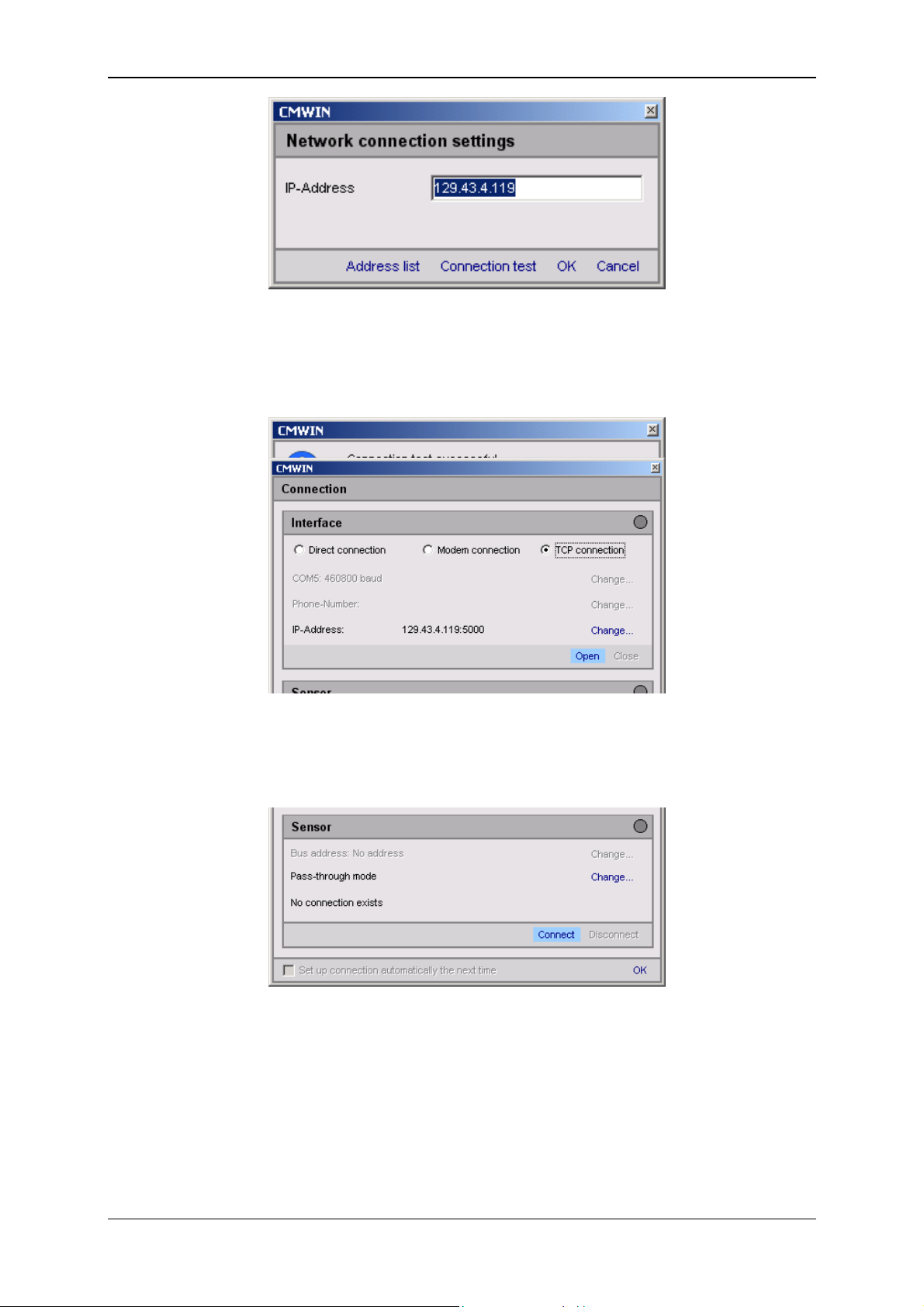

5.2.3.3 Connection Setup with CMU 1000 using GSM Mobile Network

• Start the HYDAC PC software CMWIN

• In the Units Menu, select the "CM Manager" option.

• If the Connection window does not open automatically, select

"Connection" in the menu bar of the CM Manager.

• Mark the "Modem Connection" option in the window that opens.

• Click on "Change" to open the window for the interface settings.

• Make the corresponding preselection for the port settings in the window that

opens under Interface selection.

• Select the respective port address and Baud rate under Interface settings.

• Pressing "Refresh" causes the interfaces marked under Interface selection to

be refreshed in terms of availability.

• Click on “OK“ to apply the modified settings or “Cancel“ to discard these

changes. In either case you will then return to the Connection window.

• Click on "Change" to open the window for entering the telephone numbers.

• Enter the telephone number of the SIM card mounted in the GSM module

CSI-F-10.

• In the Pin box, input the pin code given for the SIM card which is operated in

the GSM modem in the PC (not for the SIM card in the CSI-F-10!). If no PIN

code has been assigned, then leave this box empty.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 43

Condition Monitoring Unit CMU 1000 Page 43

• You can set up a list of telephone numbers (address book) with Telephone list.

• Click on “OK“ to apply the entries or “Cancel“ to discard these changes. In

either case you will then return to the Connection window.

• Click on Open to open the selected interface. The opened interface is indicated

by a green dot on the upper right.

• Click on "Change" to open the window for the pass-through mode.

• Select the HSI address of the CMU 1000 connected to the CSI-F-10 in the

selection window (Address a in our example).

• Afterwards, click on Switch on in order to switch on the pass-through mode for

the selected channel.

Revised 17.12.2009 HYDAC ELECTRONIC GMBH Mat.-No.: 669749

Page 44

Condition Monitoring Unit CMU 1000 Page 44

• The following message appears:

• Confirm this with OK.

• Afterwards click on Connect to connect the PC to the CMU 1000 that is

connected with the CSI-F-10

• The successful establishment of the connection will be signalled as shown

below:

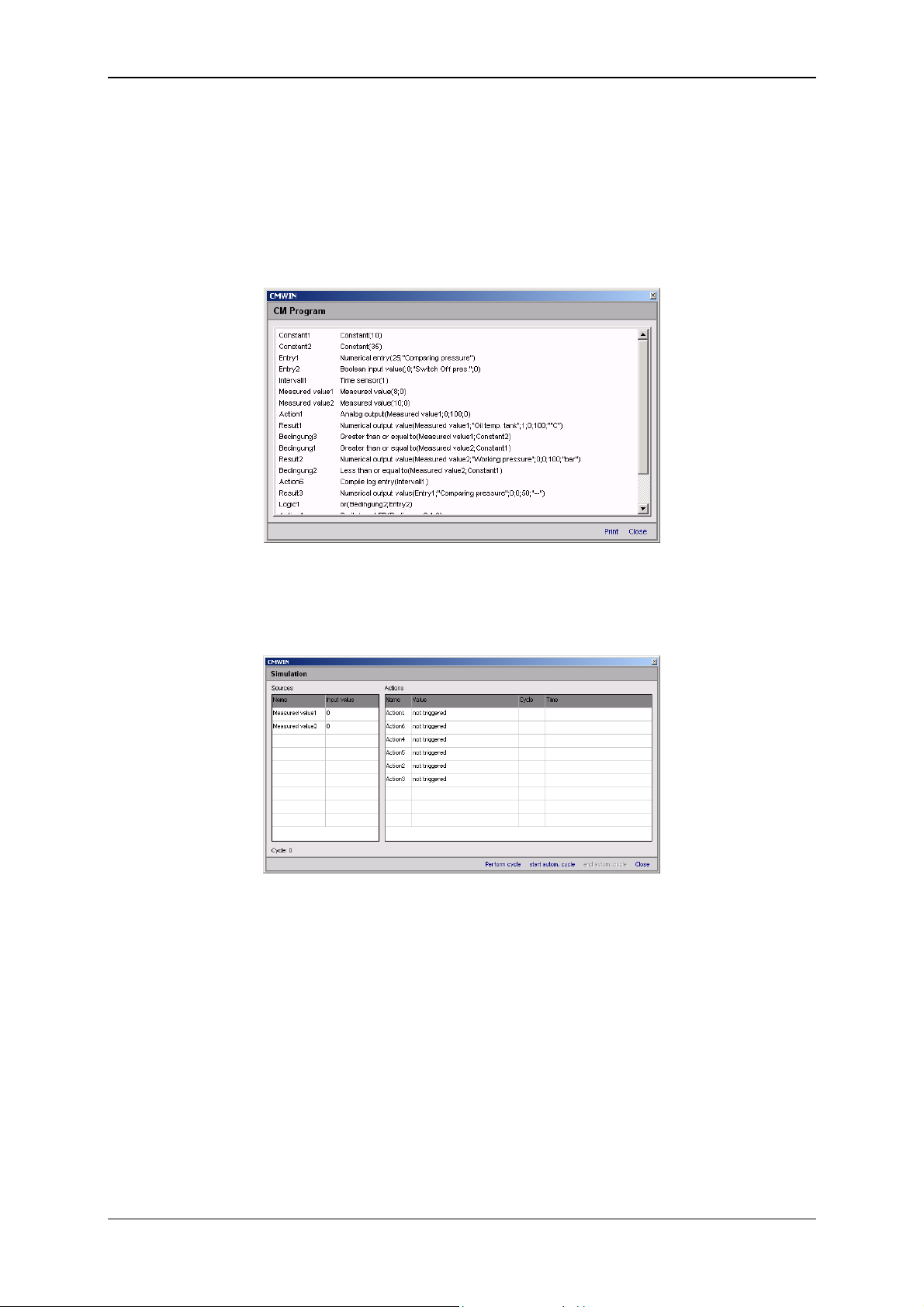

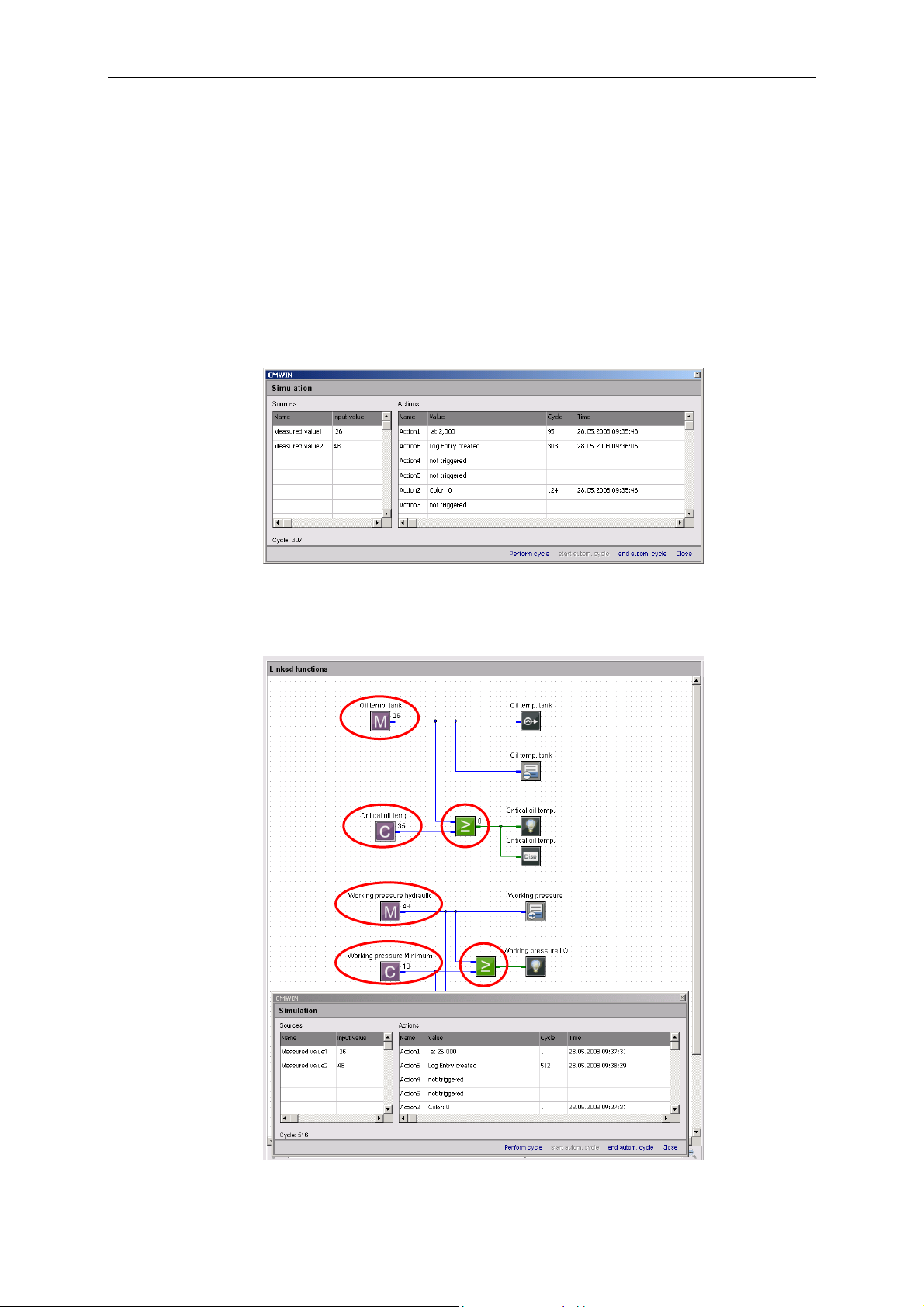

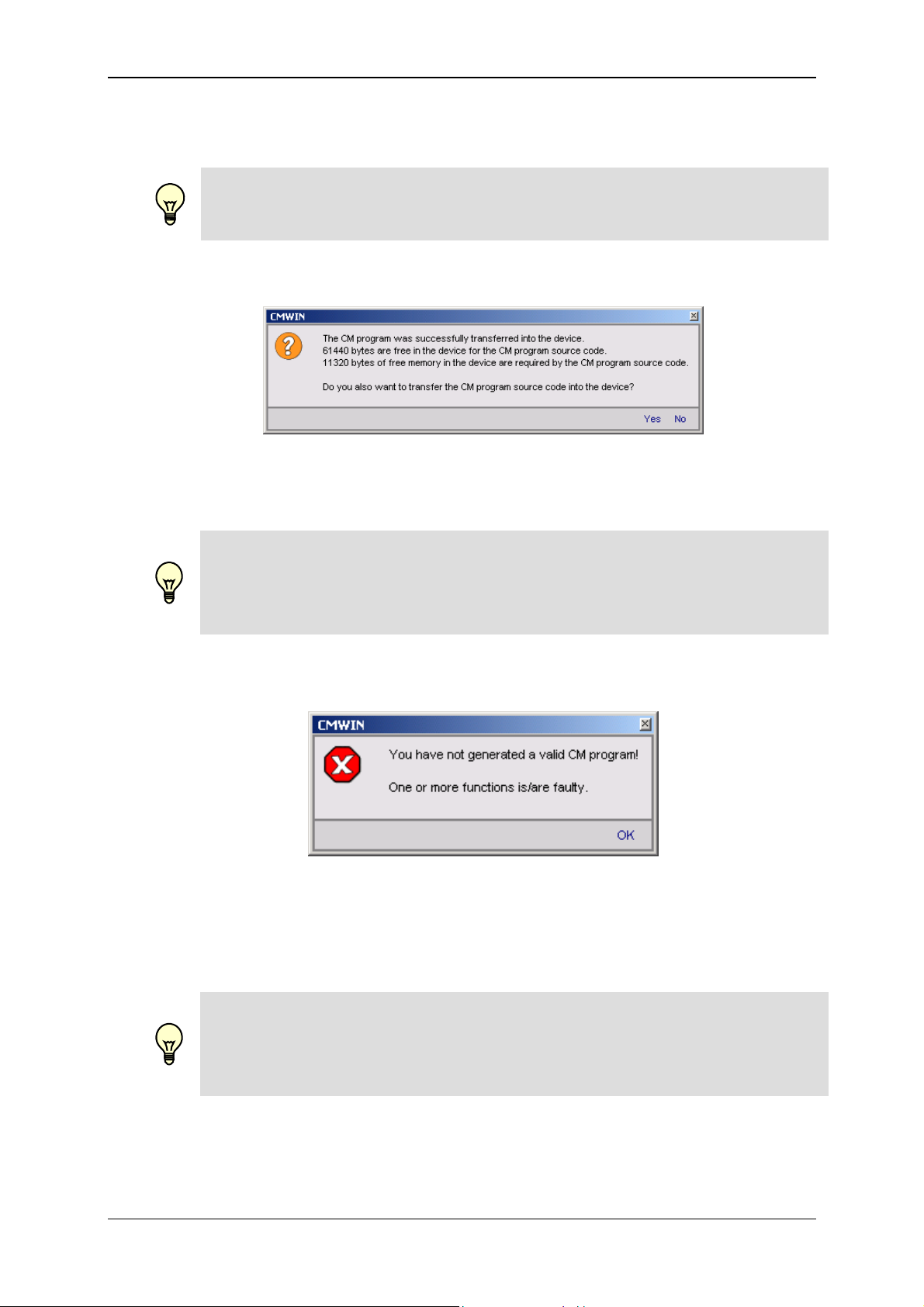

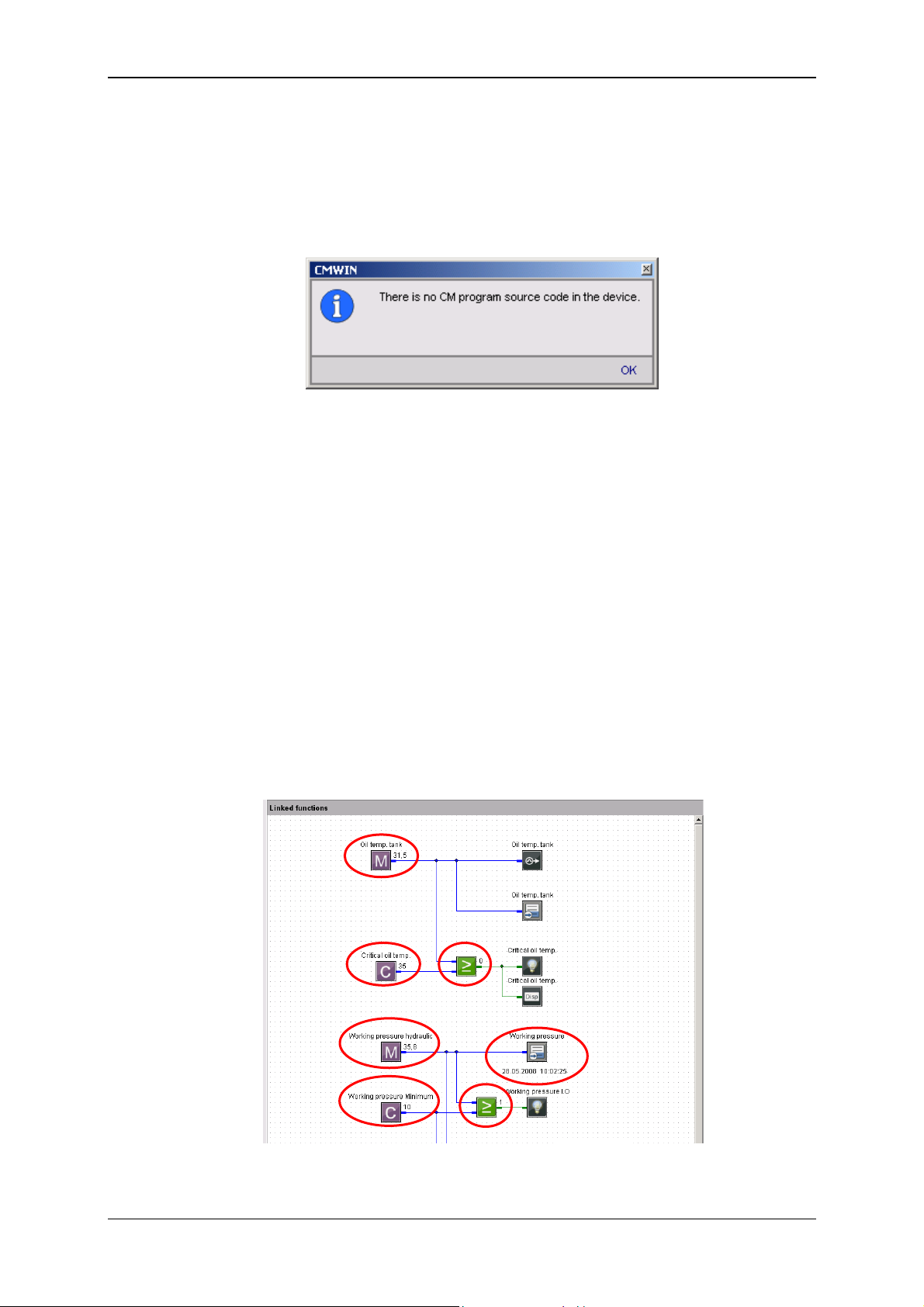

• End the connection setup by confirming with OK.