Page 1

Aqua Sensor

AS 1000

User Manual

Part no.: 669705

Status: 09.04.2008

Page 2

User Manual AS 1000 09.04.2008

CONTENTS

1. General......................................................................................................................................... 3

2. Safety instructions......................................................................................................................... 3

3. Installation..................................................................................................................................... 3

4. Function........................................................................................................................................ 4

4.1 Switching output ...................................................................................................................... 4

4.2 Analogue output....................................................................................................................... 4

4.3 Ideal saturation level in hydraulic and lubrication systems...................................................... 5

5. Electrical connection..................................................................................................................... 5

6. Technical specification.................................................................................................................. 6

7. Order details .................................................................................................................................7

8. Dimensions................................................................................................................................... 7

9. Accessories................................................................................................................................... 8

9.1 Electrical..................................................................................................................................8

9.2 Mechanical............................................................................................................................... 8

10. Displays ......................................................................................................................................9

10.1 HDA 5500..............................................................................................................................9

10.2 HMG 510 ............................................................................................................................... 9

10.3 HMG 3000 ........................................................................................................................... 10

10.4 CMWIN................................................................................................................................10

11. Functions of the AS 1x08-P-000 (programmable) over and above the standard version......... 11

11.1 Main menu........................................................................................................................... 11

11.1.1 Output 1 and 2............................................................................................................... 12

11.1.2 System re-start..............................................................................................................12

12. Items supplied........................................................................................................................... 13

13. Important information - quick reference.................................................................................... 13

2

Page 3

User Manual AS 1000 09.04.2008

1. General

If you have any queries regarding technical details or the suitability of the unit for your application,

please contact our technical sales department. The AS 1000 is individually calibrated on

computer-controlled test rigs and subjected to a final test. In this way we can guarantee that the

unit is fault-free on despatch and conforms to the given specifications.

However, if there is a cause for complaint, please return the unit to HYDAC Service outlining the

fault. Interference by anybody other than HYDAC personnel will invalidate all warranty claims.

2. Safety instructions

The Aqua Sensor AS 1000 presents no safety concerns when installed and operated in

accordance with this user manual. However, in order to avoid any risk to the operator or any

damage due to incorrect handling of the unit, please adhere strictly to the following safety

instructions:

• Before commissioning, please read the operating instructions. Ensure that the unit is suitable for

your application.

• During transportation, extra care must be taken to protect the unit from vibration and shock.

• The AS 1000 must not be put into service if any known defects, either electrical or mechanical,

are apparent.

• The unit must be installed exactly according to the instructions.

• Read the information on the type code label.

• Fault investigation and repairs must only be carried out by HYDAC Service.

• All relevant and generally recognised safety requirements must be adhered to.

• If the unit is not handled correctly, or if the operating instructions and specifications are not

adhered to, damage to the product or to personal injury may result.

3. Installation

The sensor can be installed directly in the hydraulic system via the threaded connection. The

recommended mounting position for hydraulic applications is vertical with the mechanical threaded

connection pointing upwards. When fitting, ensure that the sensor is completely submerged in the

fluid and that the fluid can circulate freely around the sensor. It is important, therefore, when tankmounting, to install the sensor in a position where there is guaranteed turbulence.

The electrical connection must be carried out by a qualified electrician according to the relevant

regulations of the country concerned (VDE 0100 in Germany).

The sensors of the AS 1000 series carry the CE mark. A declaration of conformity is available on

request. The sensor conforms to EMC standards: EN 61000-6-1, EN 61000-6-2, EN 61000-6-3

and EN 61000-6-4. The requirements of the standards are fulfilled only if the sensor housing is

earthed correctly by qualified personnel. When installing into a hydraulic block it is sufficient if the

block is earthed via the hydraulic system.

Additional assembly notes which, from experience, reduce the effect of electromagnetic

interference:

Make inline connections as short as possible.

Use screened cables (e.g. LIYCY 5 x 0.5 mm²).

The cable-screening must be fitted by a qualified person subject to the ambient conditions

and with the aim of suppressing interference.

Direct proximity to connecting lines of user units or electrical or electronic units causing

interference must be avoided as far as possible.

3

Page 4

User Manual AS 1000 09.04.2008

4. Function

The Aqua Sensors in the series AS 1000 are water and temperature sensors for the continuous

and accurate online monitoring of hydraulic and lubrication fluids.

They measure the water content relative to the saturation concentration (saturation point) and read

out the degree of saturation in the range 0..100% as a 4..20mA analogue signal. A reading of 0%

would indicate a fluid free of water, whilst 100% would indicate a fluid that is saturated with water.

The capacitance sensor used in the AS 1000 absorbs water molecules from the fluid which results

in a change in capacitance of the sensor element. The measured value obtained represents the

level of saturation of the fluid in percent.

A thermal element on the sensor measures the temperature in the range

-25 ... +100°C. This is read out as a 4...20mA analogue signal, like the saturation level.

Outputs 1 and 2 can be configured independently of each other as switch or analogue outputs.

4.1 Switching output

With switching output 1 or switching output 2 the following variables can be monitored within

their limits:

Saturation level: 0 % ... 100 %

Temperature: -25 °C ... +100 °C

"Switch on point" is used to indicate the value at which the output switches when the pre-set

value is exceeded.

"Switch off point" is used to indicate the value at which the output switches back when the

value falls below its pre-set level.

"Switching direction" is used to determine whether the output, when exceeding the pre-set

value, switches:

a) from GND to U

b) from U

to GND (N/C function)

b

4.2 Analogue output

With analogue output 1 or analogue output 2 the following variables can be displayed within

their limits:

Saturation level: 0 % ... 100 %

Temperature: -25 °C ... +100 °C

The outputs are always configured as current outputs (4 ... 20 mA).

(N/O function)

b

4

Page 5

User Manual AS 1000 09.04.2008

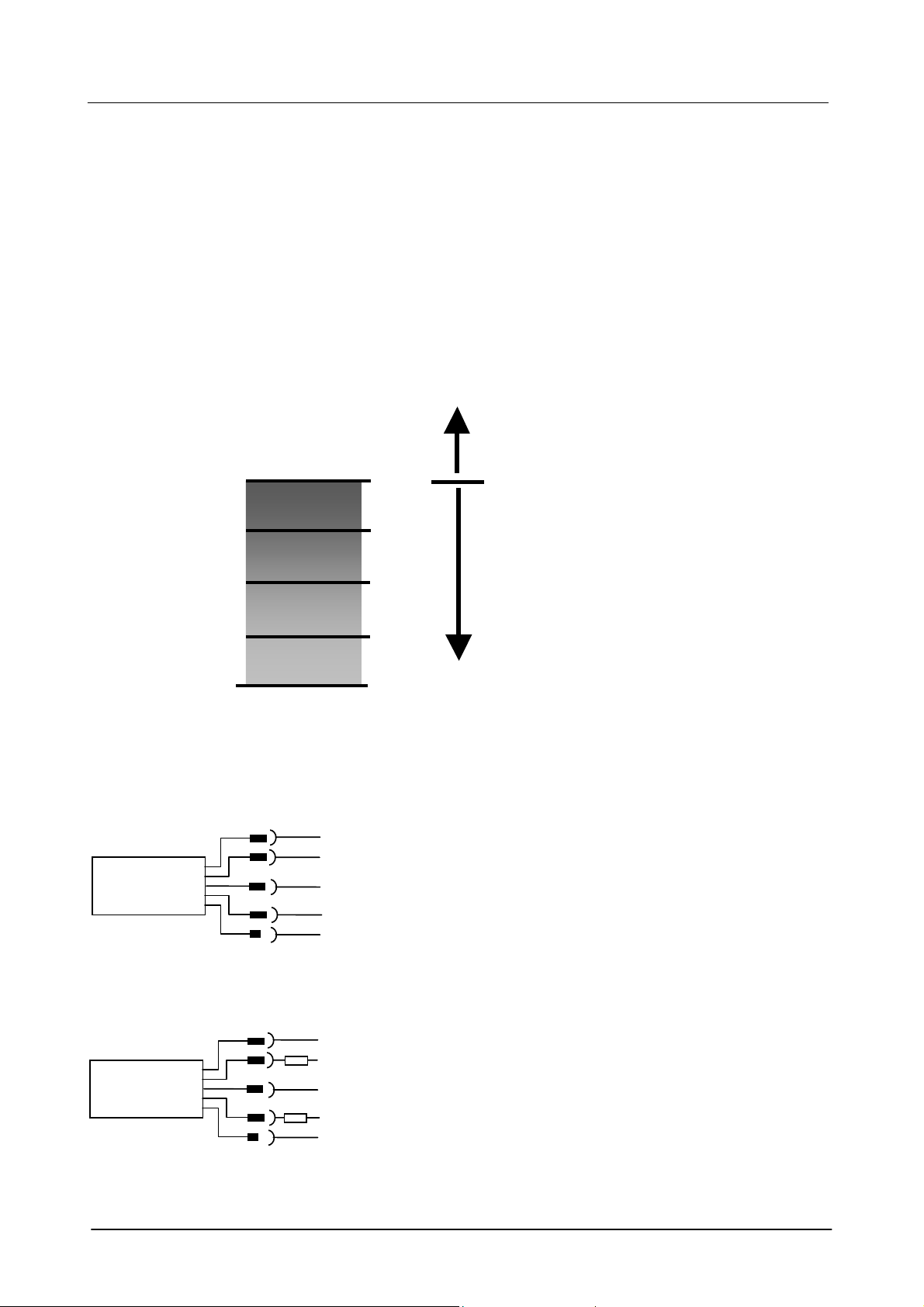

4.3 Ideal saturation level in hydraulic and lubrication systems

Since the effects of free (or emulsified) water are considerably more damaging than

dissolved water, the water content should always be significantly lower than the

saturation point. However, even dissolved water can cause damage,. All reasonable

measures should be taken therefore to keep the level of saturation as low as

possible. Hydraulic and lubrication fluids cannot be "too dry"!

As a guide, we recommend a saturation level of 45% for all systems.

5. Electrical connection

Saturation level

100%

50 %

25 %

75 %

0 %

Free water

Dissolved water

Saturation

point

1

2

3

AS 1000-P

4

5

+U

b

Progr. output 1

GND

Progr. output 2

(do not connect during normal operation!)

HSI

*

R

= (UB-10V) / 20mA [kΩ]

Lmax

1

2

3

AS 1000-C

4

5

+U

b

RL

Signal saturation level

GND

RL

Signal temp.

(do not connect during normal operation!)

HSI

*

* HSI = HYDAC Sensor Interface (HYDAC internal communication interface)

5

Page 6

User Manual AS 1000 09.04.2008

6. Technical specification

Input data

Measuring range (saturation level) 0 .. 100 %

Measuring range (temperature) -25 .. +100 °C

Operating pressure max. 50 bar

Overload pressure max. 630 bar

Parts in contact with the fluid Stainless steel, Viton / or EPDM seal,

Output data

Saturation level

Output signal 4 .. 20 mA

Calibration accuracy

Accuracy when measuring in fluids

Pressure dependence + 0.025 % FS/bar

Output data

Temperature

Output signal 4 .. 20 mA

Accuracy

Switch output 1 and 2

Output signal PNP switch output 1 A max

Switch level

Ambient conditions

Nominal temperature range (measurement of

saturation level)

Ambient temperature range -40 .. +100 °C

Temperature range of fluid -40 .. +125 °C

Viscosity range 1 .. 5000 cSt

Flow velocity < 5 m/s

Fluid compatibility Mineral oil based fluids,

- mark

Protection class to DIN 40050 IP 67

Other data

Supply voltage 12 .. 32 V DC

Residual ripple supply voltage

Mechanical connection G3/8A DIN 3852

Torque value approx. 25 Nm

Electrical connection

Pin 1: +U

b

Pin 2: analogue output 1 / switch output 1

Pin 3: 0V / GND

Pin 4: analogue output 2 / switch output 2

Pin 5: HSI

Reverse polarity protection of the supply voltage,

excess voltage, override and short circuit protection

Weight approx. 145 g

Note: FS (Full Scale) = relative to the full measuring range

ceramic with vapour-deposited metal

≤ ± 2 % FS max.

≤ ± 3 % FS typ.

≤ ± 2% FS max.

≤ U

B

0 .. + 90 °C

synthetic and natural esters

EN 61000-6-1, EN 61000-6-2

EN 61000-6-3, EN 61000-6-4

≤ 5 %

M12x1, 5 pole

Provided

6

Page 7

User Manual AS 1000 09.04.2008

7. Order details

AS 1 X 0 8 - X - 000

Series

1 = Series 1000

Medium

0 = Mineral oils

1 = Phosphate ester

Type of connection, mechanical

0 = G 3/8A DIN 3852

Type of connection, electrical

8 = M12x1, 5-pole (without connector)

Signal technology

C = output 1 (Pin 2) saturation level ( 4 .. 20 mA)

output 2 (Pin 4) temperature (4 .. 20 mA)

P = output 1 programmable

output 2 programmable

Modification number

000 =

8. Dimensions

standard

hex. AF27

M12x1 –5 pole connection

7

Page 8

User Manual AS 1000 09.04.2008

9. Accessories

9.1 Electrical

ZBE 08 (5-pole)

Connector M12x1, right-angle

Order no.: 6006786

ZBE 08-02 (5-pole) with 2m cable

Order no.: 6006792

ZBE 08-05 (5-pole) with 5m cable

Order no.: 6006791

ZBE 08S-02 (5-pole)

with 2m screened cable

Order no.: 6019455

ZBE 08S-05 (5-pole)

with 5m screened cable

Order no.: 6019456

ZBE 08S-10 (5-pole)

with 10m screened cable

Order no.: 6023102

ZBE 36

Adaptor AS / HLB - HMG 3000

Order no.: 909737

ZBE 30-02

Sensor cable M12x1, 2m

Order no.: 6040851

ZBE 30-05

Sensor cable M12x1, 5m

Order no.: 6040852

9.2 Mechanical

ZBM 22

Adapter for connecting to a G1/2“ line

Order no.: 3248511

Colour code:

Pin 1: brown

Pin 2: white

Pin 3: blue

Pin 4: black

Pin 5: grey

8

Page 9

User Manual AS 1000 09.04.2008

10. Displays

10.1 HDA 5500

The HDA 5500, version HDA 5500-1-1-AC-000 or HDA 5500-1-1DC-000, is a display unit with 4 programmable switch outputs,

specially designed for use with the AS 1000.

In conjunction with the HDA 5500 it is possible to display the

actual measured values.

Order no.: 908869 HDA 5500-1-1-AC-000

Order no.: 908870 HDA 5500-1-1-DC-000

Connection to a HDA 5500

X1: Pin 1: + supply HDA 5500

X1: Pin 2: - supply HDA 5500

X2: Pin 5: GND AS 1000 (blue)

X2: Pin 6: +12V supply AS 1000 (brown)

X2: Pin 4: temperature (black)

X2: Pin 2: saturation point (white)

10.2 HMG 510

Portable 2-channel data recorder, specially designed to display measured values from HSIand SMART sensors.

In conjunction with the HMG 510 it is possible to display the actual measured values on the

display of the HMG 510.

Order no.: 909889 HMG 510-000

Connection to a HMG 510

Remove the supply cable from the electrical connection of the AS 1000 and screw the

connection adaptor AS / HLB "ZBE 36" into the sensor. Connect one of the inputs A or B of

the HMG 510 to the output of the "ZBE 36" using a sensor cable "ZBE 30-0x"

9

Page 10

User Manual AS 1000 09.04.2008

10.3 HMG 3000

Portable data recorder with a full graphical colour display for displaying or recording measured

values of the AS 1000. In addition changes can be made to the parameters of the AS 1000

using the HMG 3000.

In conjunction with the HMG 3000 the actual measured values can be shown on the HMG

3000 display. The recordings can also be saved on the HMG 3000 and edited (for a more

detailed description, see HMG 3000 Operating Manual).

Order no.: 909437

Connection to a HMG 3000

Remove the supply cable from the electrical connection of the AS 1000 and screw the

connection adaptor AS / HLB "ZBE 36" into the sensor.

Connect one of the inputs A to D of the HMG 3000 to the output "ZBE 36" using a sensor

cable "ZBE 30-0x".

When connecting to an HMG 3000 the voltage supply for the sensor is via the measuring unit.

10.4 CMWIN

Specially developed PC software which communicates via a communication bridge (HMG 510

or

HMG 3000) with the AS 1000. Using the software, measurement curves can be transferred

to your PC, saved, displayed and edited or the actual measured values can be displayed. With

the AS 1000 "P" version, it is also possible to configure the sensor according to individual

requirements.

CMWIN is supplied with the HMG 510 and HMG 3000.

HMG 3000-000-E (without accessories)

10

Page 11

A

A

User Manual AS 1000 09.04.2008

11. Functions of the AS 1x08-P-000 (programmable)

over and above the standard version

In addition to the standard functions, it is possible to configure the AS 1000 "P" version using the

HMG 3000 and the PC software CMWIN under the menu point "Sensor dialogue".

The following menu navigation applies in this case and is identical in both the HMG 3000 and in the

PC software CMWIN:

11.1 Main menu

The AS 1000 supports German, English and French. Use the main menu to access the

following setup options of the sensor:

Output 1:

Configuration of output 1 as analogue or switching output

Output 2:

Configuration of output 2 as analogue or switching output

System re-start:

Re-start of the sensor

Main menu

nalogue output 1

Output 1

Switching output 1

nalogue output 2

Output 2

Switching output 2

System re-start

11

Page 12

User Manual AS 1000 09.04.2008

11.1.1 Output 1 and 2

Each of the two menu points subdivides into a menu in which outputs 1 and 2 can be

configured independently of the other as either analogue or switching output.

• Analogue output

Here you can set the display parameters. The outputs are always configured as current

outputs (4 .. 20 mA).

Possible display parameters:

• Saturation level: Display range: 0 .. 100 %

• Temperature: Display range: -25 .. +100°C

"Ok" is used to write back the changed data into the sensor. "Cancel" is used to discard the

data and to return to the previous menu.

• Switching output

This is used to set the parameters which are to be monitored, as well as the values of the

switch-on and switch-off points and the switch direction (N/C, N/O).

In the display area, you can select which of the following parameters are to be monitored

within their limits using the switch output:

• Saturation level: Display range: 0 ... 100 %

• Temperature: Display range: -25 .. +100°C

In the "Switch on point“ box, the value is displayed at which the output switches when the

pre-set parameter is exceeded.

In the "Switch off point" box the value is displayed at which the output switches back

once the value falls below the pre-set parameter.

"Switch direction" is used to determine whether the output switches from GND to the

value of the supply voltage Vs (N/O function) or switches from the value of the supply

voltage Vs to GND (N/C function).

"Ok" is used to write back the changed data to the sensor. "Cancel" is used to discard the

data and to display the previous menu.

11.1.2 System re-start

Use this menu point to force the sensor to re-start. Afterwards all the settings previously

made become active. Use the "Ok" button to re-start. Use "Cancel" to return to the main

menu.

This should avoid making changes to the output configuration during operation which can

cause damage to the sensor. The error message which appears can be ignored. Use

"Cancel" to return to the main menu after the re-start.

12

Page 13

User Manual AS 1000 09.04.2008

12. Items supplied

1 AS 1000 sensor

1 Operating Manual

13. Important information - quick reference

• We recommend that for hydraulic applications, the sensor is fitted vertically with the

electrical plug pointing downwards.

• When installing, please ensure that the sensor is completely submerged in the fluid and

that the fluid can circulate freely through the sensor.

• Please ensure a constant flow and prevent the formation of air bubbles as much as

possible. If the oil is not flowing, the possibility of deviations in measurement is

increased.

13

Page 14

User Manual AS 1000 09.04.2008

HYDAC ELECTRONIC GMBH

Hauptstr. 27

D-66128 Saarbrücken

Germany

Web: www.hydac.com

E-Mail: electronic@hydac.com

Tel.: +49 (0)6897 509-01

Fax.: +49 (0)6897 509-1726

HYDAC Service

For enquiries about repairs or alterations, please contact HYDAC Service.

HYDAC SERVICE GMBH

Hauptstr. 27

D-66128 Saarbrücken

Germany

Tel.: +49 (0)6897 509-1936

Fax.: +49 (0)6897 509-1933

Note

The information in this manual relates to the operating conditions and applications described. For

applications and operating conditions not described, please contact the relevant technical

department.

If you have any questions, suggestions, or encounter any problems of a technical nature, please

contact your Hydac representative.

All technical details are subject to change without notice.

14

Loading...

Loading...