Hycontrol Microflex LR Integral Installation/operation Instruction Manual

Elec. Iss. 04

Hycontrol Limited, Larchwood House, Orchard Street,

Redditch, Worcestershire, UK. B98 7DP

Tel: + 00 44 (0)1527 406800 Fax: +00 44(0)1527 406810

Email: sales@hycontrol.com Web: www.hycontrol.com

May 2013 Rev 04

Microflex LR – Integral

(Ultrasonic Level Measurement)

Installation & Operation

Instruction Manual

INDEX

PAGE

1. GENERAL DESCRIPTION 3

1.1. Microflex LR Integral 4

2. INSTALLATION GUIDE 5

2.1. Installation Position 5

2.2. Installation Dimensions 6

2.3. Installation Wiring 7

2.3.1. MI2 – 2 wire loop powered transmitter 7

2.3.2. MI3 – transmitter with 2 relays and 4-20mA outputs 7

2.3.2.1. MI3 - Terminal Connections for AC supply 7

a. Modulating from User’s External DC Supply (RL to Pos) 7

b. Modulating from User’s External DC Supply (RL to Neg) 8

c. 4 Wire DC – Driving from Internal Isolated Supply (Is) 8

2.3.2.2. MI3 – Terminal Connections for DC Supply 8

a. 4 Wire DC – Driving from Internal Isolated Supply (Is) 8

b. 3 Wire DC – Modulating from Common User Supply (RL to +DC) 8

c. 3 Wire DC – Modulating from Common User Supply (RL to GND) 9

2.4. Hycontrol Link Wiring for Remote diagnostics via GSM 9

3. PROGRAMMING 10

3.1. Entering Data 10

3.2. Access to Main Menu 10

3.3. Entering Basic Data – QUICKSET 11

3.3.1. Flow – Programming 12

3.3.2. Volume 13

3.4. Entering Output Adjustments 13

3.5. Tx Set-up for Gain and Threshold 14

3.6. Diagnostic Display 15

4. GENERAL SPECIFICATION 16

5. PART NUMBER SELECTION 17

6. LABELLING INFORMATION 18

7. MODBUS REGISTER LIST 19 - 22

8. ASSEMBLY OF FLANGE AND CONES 23

APPENDIX A. CROSS TALK PREVENTION 24 - 25

APPENDIX B. APPLICATION TYPES 26 - 27

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 2

USER MANUAL

1.

GENERAL DESCRIPTION

The Microflex LR – Integral Transmitter is capable of non-contact level

measurement over distances of up to 60 metres, depending on the

application. The Integral is an intelligent, system approach to measurement

of solids and liquids with maximum performance combined with a display and

keypad.

The Integral is available with four different transducers for ranges of 10, 20,

40 and 60 metre operation. Each configuration is available as a 2-wire, DC

powered 4-20mA loop (MI2) or 2, 3 and 4 wire DC and AC powered (MI3)

with a combination of Modbus, 2 relays, 4-20mA and PC comms outputs.

The transmitter must be mounted directly above the surface of the material to

be monitored.

Ultrasonic pulses are transmitted to the surface of the material to be

monitored and reflected back to the transmitter. The time period between

transmission and reception of the pulses is directly proportional to the

distance between the transmitter and the material.

Since the speed of sound through air is affected by temperature, a

temperature sensor is integrated into the face of the transmitter to improve

accuracy.

The Integral transmitter is suitable for measuring the following on solids and

liquids:

a) Ullage space or distance to material

b) Material level

c) Volume measurement

d) Material percentage

e) Flow of liquids in open channels

MICROFLEX LR LONG RANGE LEVEL TRANSMITTERS

WARNING

Do not open the transmitter terminal cover or remove

any connection whilst the power is ON.

REFER TO ‘ATEX Safety & Operating Instructions Manual’

IF INSTALLING IN A HAZARDOUS AREA

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 3

1.1 Microflex LR Integral

The Integral Transmitter is an easy-to-use level

transmitter available with four (4) different high

power, low frequency front ends, capable of reliably

tracking the level of solids and liquids under difficult

conditions, programmed via a 4 button keypad and

an integral menu driven display.

The transmitter is available with a choice of 2 relay

switches, 4-20mA or Modbus outputs; up to 32

instruments can be networked together.

If specified, the instruments are available approved

for ATEX EEx ia Zone 0 gases & Zone 20 dusts

(24Vdc only) or ATEX Dust Protection only, Zone

20.

Remote programming of the product is available via

Hycontrol’s Vision System II software and all the

instruments can be connected via the Hycontrol

Link to a Service Engineer in the Redditch office to

analyse and overcome any problems which may be

experienced in the field, without incurring any

expensive call-out charges.

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 4

2.

INSTALLATION GUIDE

The Integral transmitters are designed to be screwed directly into a flange on a

tank. For long range and dusty applications, the use of a focaliser on the

underside of the flange improves the concentration of the signal and ensures

that spurious signals are eliminated.

2.1 Installation Position

Ensure that the mounting surface is not subject to vibration and is not in close

proximity to high voltage power cables, contactors or drive controls. The unit

should not be mounted in a confined space where temperature might exceed

the safe working temperature –20°C to + 60°C*. If the unit is mounted outside

it should be protected from direct sunlight or severe weather conditions.

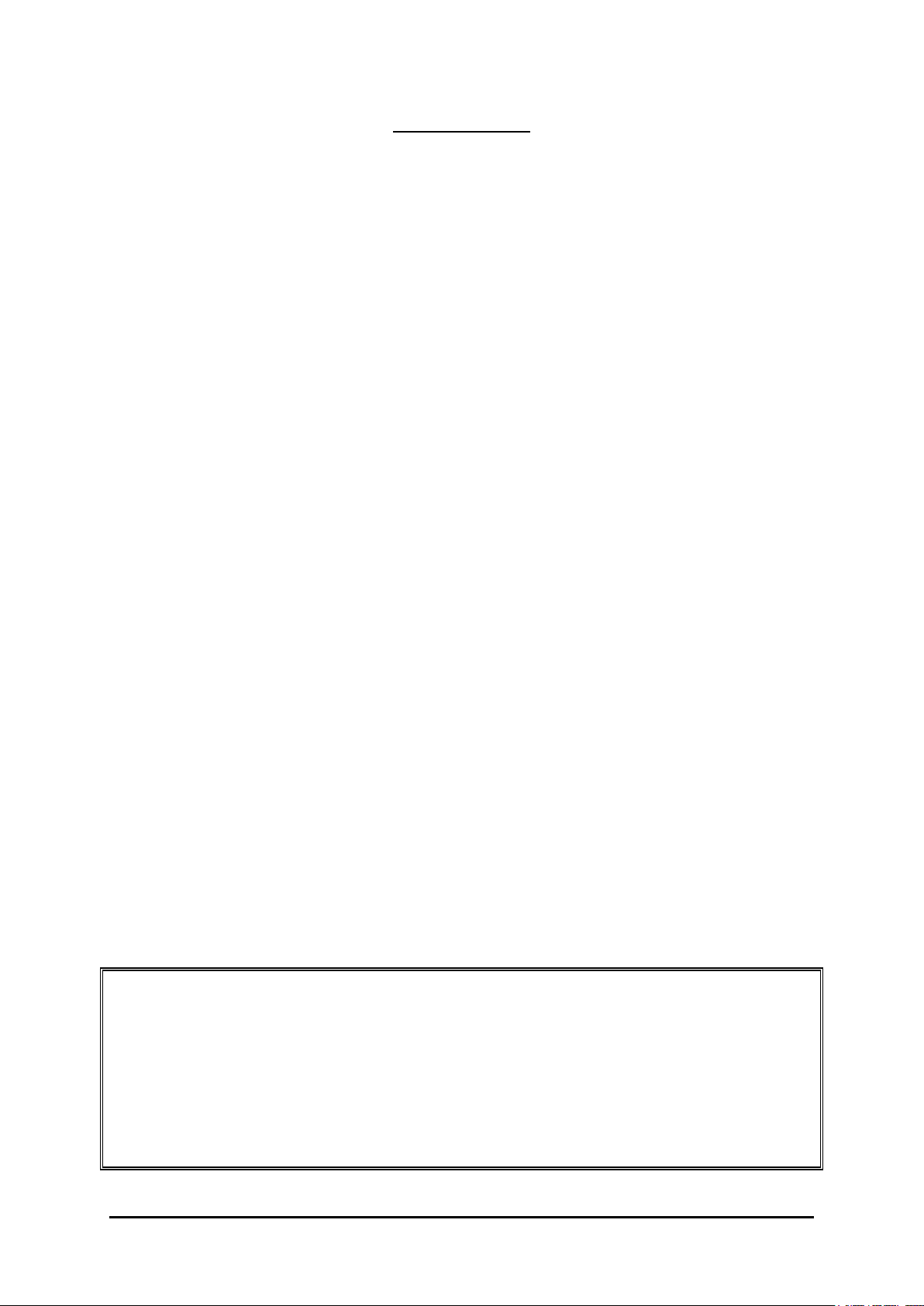

When using a focaliser cone, ensure that it protrudes at least 50mm into the

vessel.

The transmitter must be installed to ensure a clear line of sight from the

radiating face to the product being monitored. Refer to diagrams on Page 6.

Avoid mounting near fill points, ladders, baffles, agitators etc.

Minimum

50mm (2")

NOZZLE

MOUNT

FLUSH

MOUNT

STAND PIPE

MOUNT

Minimum

50mm (2")

‘B’

TOP LEVEL

For ‘B’ blanking – refer to table on page 6.

30KHz 2"

BSP / NPT

MOUNT

*For ATEX temperature classifications see ATEX Safety & Operating Instructions Manual.

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 5

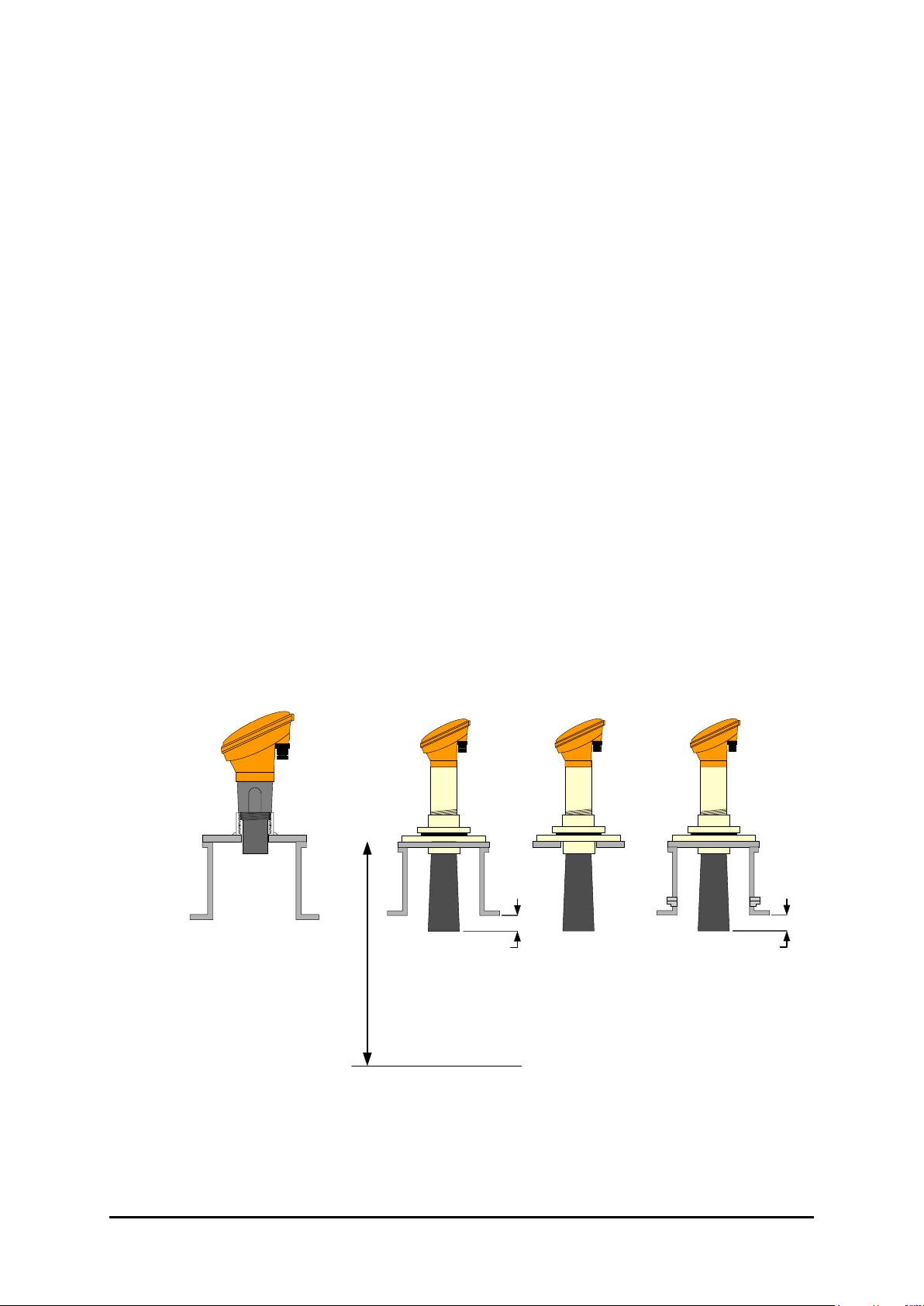

Transmitter Mounting

SOLID (Granular)

LIQUID

DUAL OUTFEED

POWDER

Aim transmitter at

point of outfeed.

Transmitter should be

as perpendicular to

product as practicable.

Use two transmitters and

wire and program as

shown in Appendix A to

avoid cross-talk.

Mount away from

infeed

2.2 Installation Dimensions

MI2 Two wire loop powered transmitter with display and 4-20mA output.

MI3 2, 3 or 4 wire transmitter with display and can have PC Comms,

Modbus and Relay output.

Thread

size

Flange

optional

D

L1

120LC

DC

Optional

160

3 x M16

Conduit

entries

MI2 Two wire transmitter with display

MI3 2, 3 or 4 wire transmitter with display and 2 relays

Range

Metres

L1

LC

Optional

D

DC

Optional

Thread

Size

Flange

Optional

10

177 - 50 - 2”

-

20

255

275

75

98

3”

4”

40

410

413

89

236

3.5”

10”

60

687

460

89

236 - 10”

Flange Options: ANSI, DIN or JIS

Dimensions for 10, 20, 40 & 60 metre range

Ensure that the transmitter face always has the minimum Blanking Distance

above the highest product level in the tank. See table below.

TRANSMITTER

MINIMUM DISTANCE

Minimum

Nominal

MI__10

0.35m (1.2ft)

0.5m (1.6ft)

MI__20

0.5m (1.6ft)

0.8m (2.6 ft)

MI__40

1.0m (3.3ft)

1.3m (4.2 ft)

MI__60

1.2m (4ft)

1.5m (5 ft)

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 6

2.3 Installation Wiring

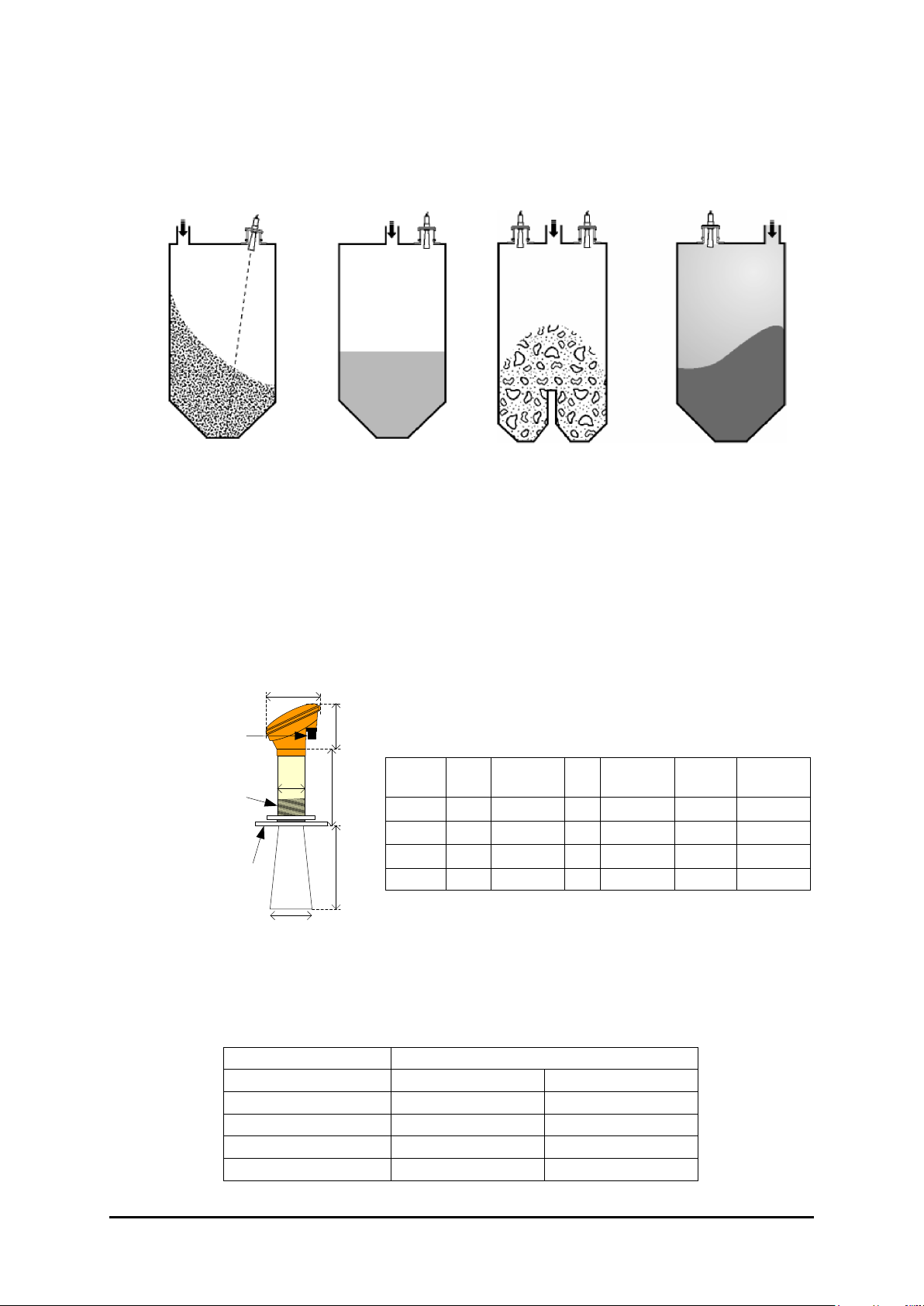

2.3.1 Wiring Diagram – MI2 – 2 wire Loop Powered Transmitter

Terminals

Terminal Connection

+

-

Use

Shielded cable

+

-

User 24V

DC Supply

PLC

DCS

IND

+

-

RL Max 750Ω

4-20mA

TEST

4-20mA

MI2

Terminal

Connection

2.3.2 Wiring Diagram – MI3 – Transmitter with 2 relays & 4-20mA Outputs

Terminals

RL2 COMMS RL1

See Appendix A for ‘Test’ function.

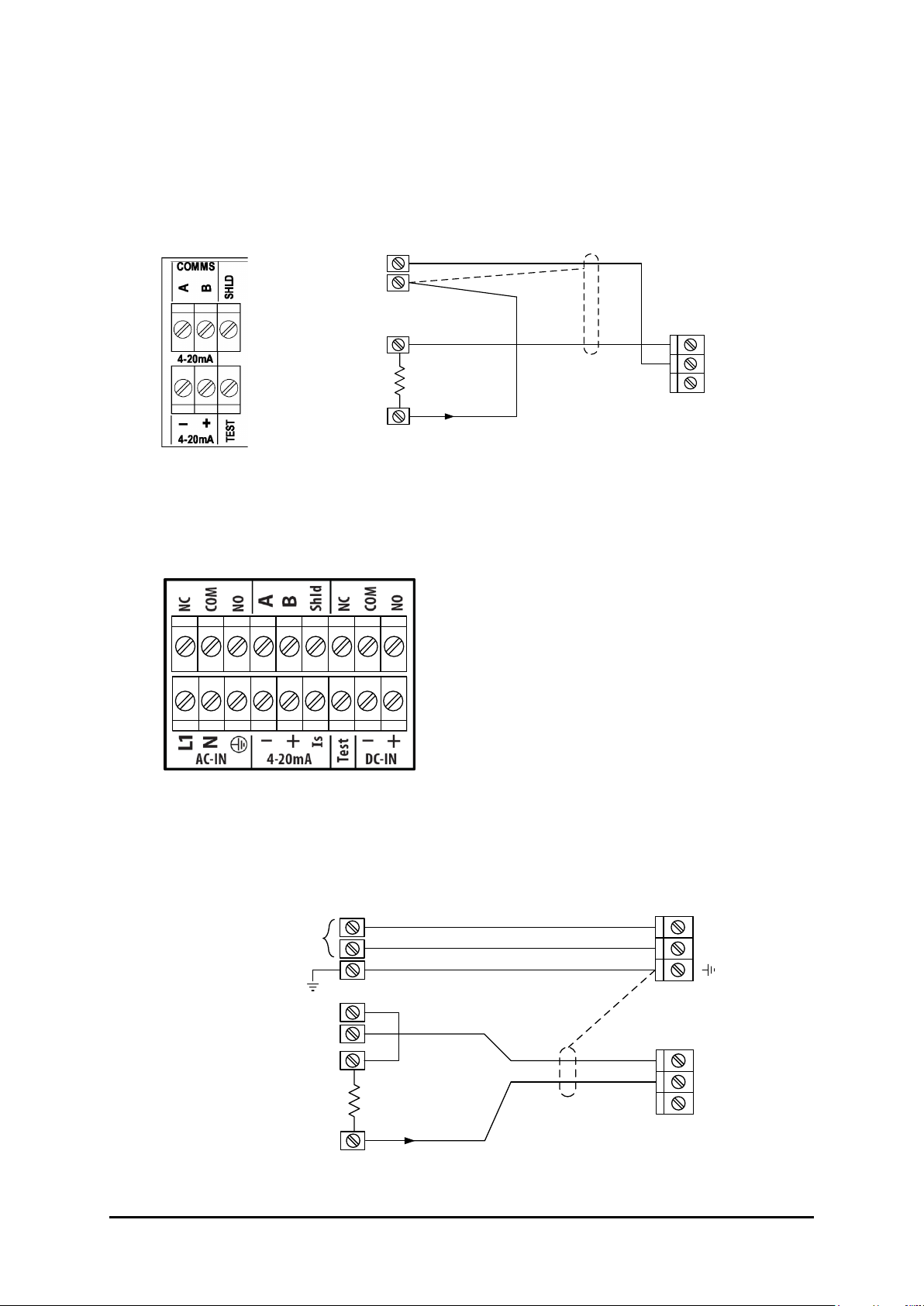

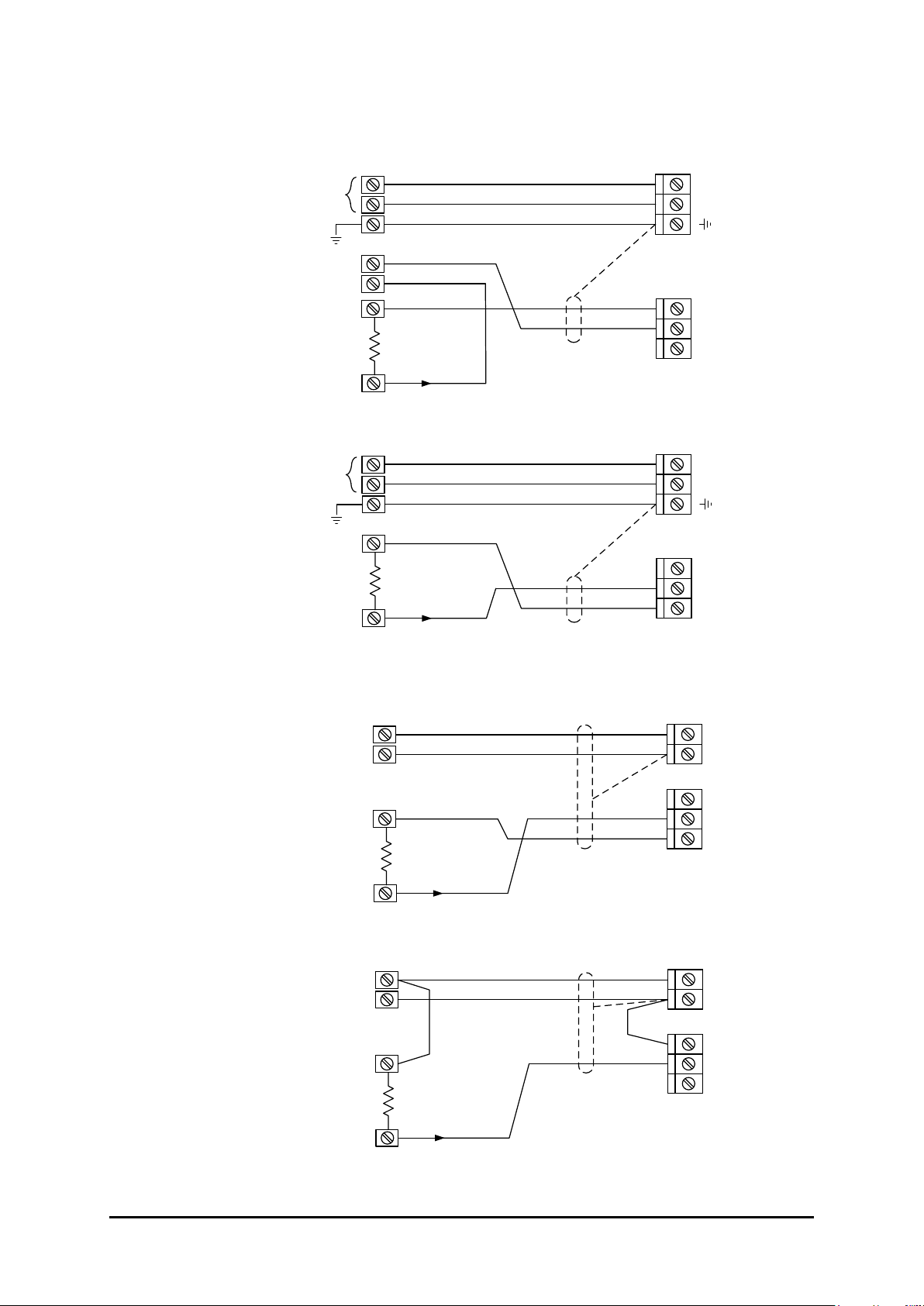

2.3.2.1 MI3 – Terminal Connections for AC Supply

a) Modulating from User’s External DC Supply (RL to Pos.)

4-20mA

+

-

Use

Shielded cable

PLC

DCS

IND

+

-

RL Max 750Ω

Is

4-20mA

MI3

Terminal

Connection

N

L1

AC-IN

User

90 – 260V

AC Supply

+

-

User 24V

DC Supply

NOTE:

RL Max = 750Ω

If user DC Supply 24V

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 7

b) Modulating from User’s External DC Supply (RL to Neg.)

+

-

Use

Shielded cable

PLC

DCS

IND

+

-

RL Max 750Ω

4-20mA

Is

4-20mA

MI3

Terminal

Connection

N

L1

AC-IN

User

90 – 260V

AC Supply

+

-

User 24V

DC Supply

NOTE:

RL Max = 750Ω

If user DC Supply 24V

c) 4 Wire DC – Driving from Internal Isolated Supply (Is)

+

-

Use

Shielded cable

PLC

DCS

IND

+

-

RL Max 400Ω

4-20mA

Is

4-20mA

MI3

Terminal

Connection

N

L1

AC-IN

User

90 – 260V

AC Supply

NOTE:

Isolated current output can be

made common with external

DC Supply Positive or

Negative if required

(e.g. RL – connected to GND)

2.3.2.2 MI3 – Terminal Connection for DC Supply

a) 4 Wire DC – Driving from Internal Isolated Supply (Is)

+

-

Use

Shielded cable

+

-

User 24V

DC Supply

PLC

DCS

IND

+

-

RL Max 400Ω

4-20mA

Is

4-20mA

MI3

Terminal

Connection

GND

+DC

DC-IN

NOTE:

Isolated current output can be

made common with +DC or

GND if required

(e.g. RL – connected to GND)

b) 3 Wire DC – Modulating from Common User Supply (RL to +DC)

+

-

Use

Shielded cable

+

-

User 24V

DC Supply

PLC

DCS

IND

+

-

RL Max 750Ω

4-20mA

Is

4-20mA

MI3

Terminal

Connection

GND

+DC

DC-IN

NOTE:

RL Max = 750Ω

If user DC Supply 24V

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 8

c) 3 Wire DC – Modulating from Common User Supply (RL to GND)

+

-

Use

Shielded cable

+

-

User 24V

DC Supply

PLC

DCS

IND

+

-

RL Max 750Ω

4-20mA

Is

4-20mA

MI3

Terminal

Connection

GND

+DC

DC-IN

NOTE:

RL Max = 750Ω

If user DC Supply 24V

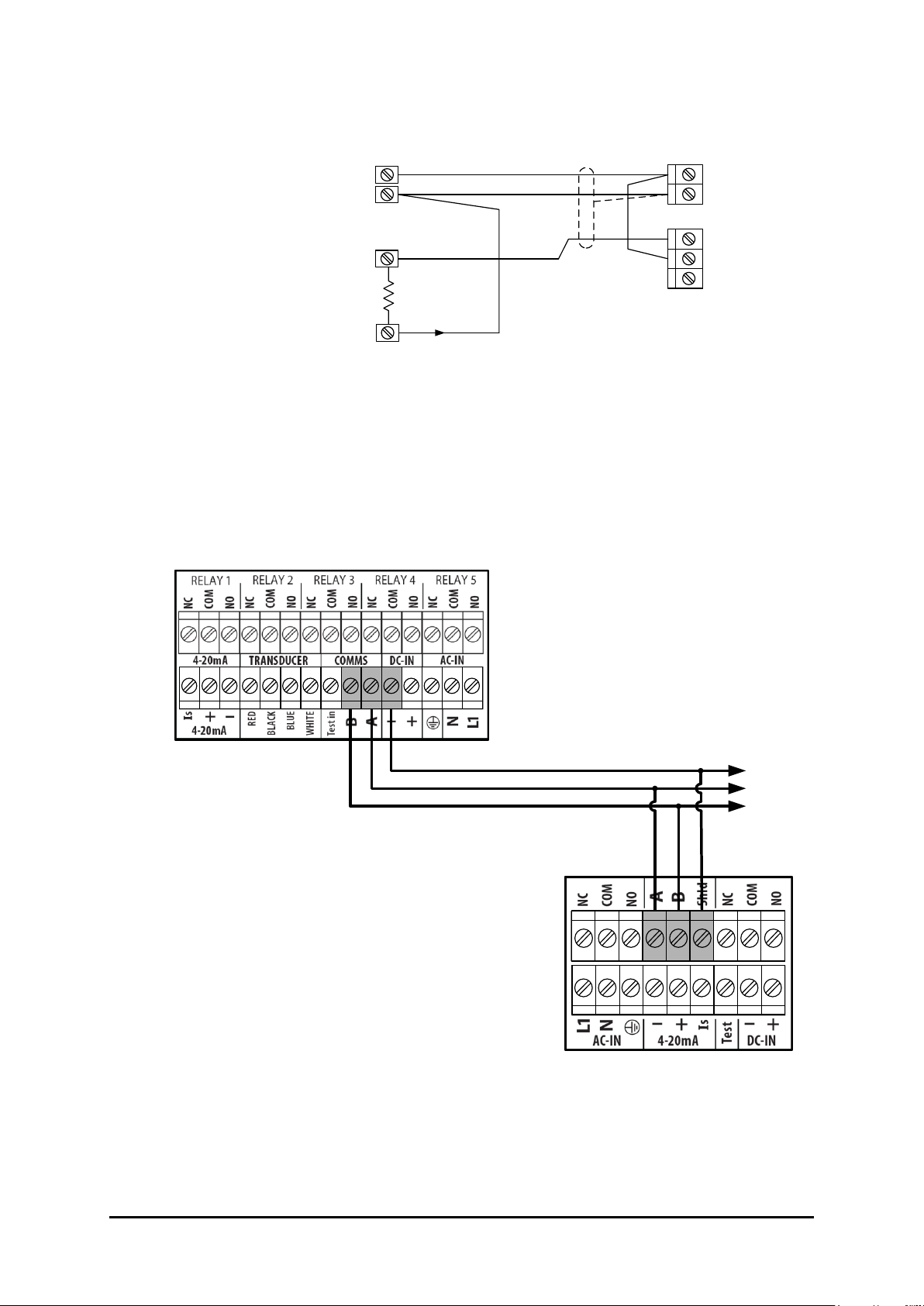

2.4 Hycontrol Link GSM Connection

The Hycontrol Link is a separately powered GSM module which enables

Hycontrol Service Engineers to interrogate and programme any MI3

transmitter.

The following diagram shows how to wire it to the MI3.

Hycontrol Link Terminal

MI3 Series Transmitter

(2 Relays)

To other Microflex LR

and Reflex LR units

Microflex LR Integral Transmitter Operating & Installation Manual May 2013 Rev 4

Page 9

Loading...

Loading...