Product Instruction Manual

Speedflow

SF05K, SF10K & SF15K

SF05KSS, SF10KSS & SF15KSS

Undersink unvented water heater

Version 3.2 Jan 2015

V16.5/7

Thank you for purchasing a Hyco Speedflow unvented water heater. The

Speedflow is ideal for use in cloakrooms and kitchens in offices, shops,

student accommodation and domestic premises which have been extended

and there is no central hot water system nearby. One unit located under the

kitchen sink is often used to supply hot water for light dishwashing in the

kitchen sink and hand washing in the cloakroom basin. Please read and

understand these instructions before commencing installation and leave

them with the user when installation is complete.

1. Important safety points

•

The unit must be installed and maintained by a competent person in accordance

with current electrical and plumbing regulations.

•

Only connect the heater to a single phase supply with a mains voltage as specified

on the rating plate.

•

Do not connect to power unless unit is full of water – open tap and allow water

to flow freely to clear airlocks.

•

Do not switch power on if water in heater or pipes could be frozen.

•

Always fit the heater the correct way up (pipes should be at the top).

•

It is essential that the supplied pressure-relief device is fitted, make plumbing

connections with flexible stainless steel hoses to facilitate future maintenance.

•

Water may drip from the discharge pipe of the pressure-relief device and this

pipe must be left open to the atmosphere.

•

The pressure-relief device is to be operated regularly to remove lime deposits and

to verify that it is not blocked.

•

Use lowest acceptable temperature setting to save energy and reduce lime scale.

•

This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of

the appliance in a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

2

2. Installation

Wall Mounting

The Speedflow is normally fitted immediately below the outlet to be supplied, but it

can be mounted above or to the side of the outlet provided it is vertical with the

pipe outlets at the top.The unit can either be placed directly on the floor or fixed to

a wall using the mounting bracket supplied.

Ensure the mounting surface is strong enough to support the speedflow

including the weight of the water.

The 5 litre models (SF05K/SS) can typically serve 1 sink, the 10 litre models

(SF10K/SS) can typically serve 1 or 2 sinks and the 15 litre models (SF15K/SS)

can typically serve 2 or 3 depending on simultaneous usage.

3

Plumbing

A service valve should be fitted to allow / facilitate future maintenance.

The supplied 6 bar pressure relief valve must always be fitted. There must be

no obstructions in the pipwork between the heater and the relief valve. The

relief valve must discharge to a safe and visible place.

The hot and cold fittings are 1⁄2” BSP and are at the top of the unit. These

connections are colour coded (blue = cold, red = hot).They are not interchangeable.

The final connection of the Speedflow to pipework should be implemented with

flexible stainless steel hoses.

Open hot water tap and allow water to run through fpr at lease 5 seconds

to clear airlocks.

Depending on the installation circumstances, other accessories may be required.

If required, these must be ordered separately and are installed as shown on the

diagrams below and on the next page.Water pressure can increase considerably

at night when demand is low, so a pressure reducing valve may be required even

if there is no obvious problem at installation.

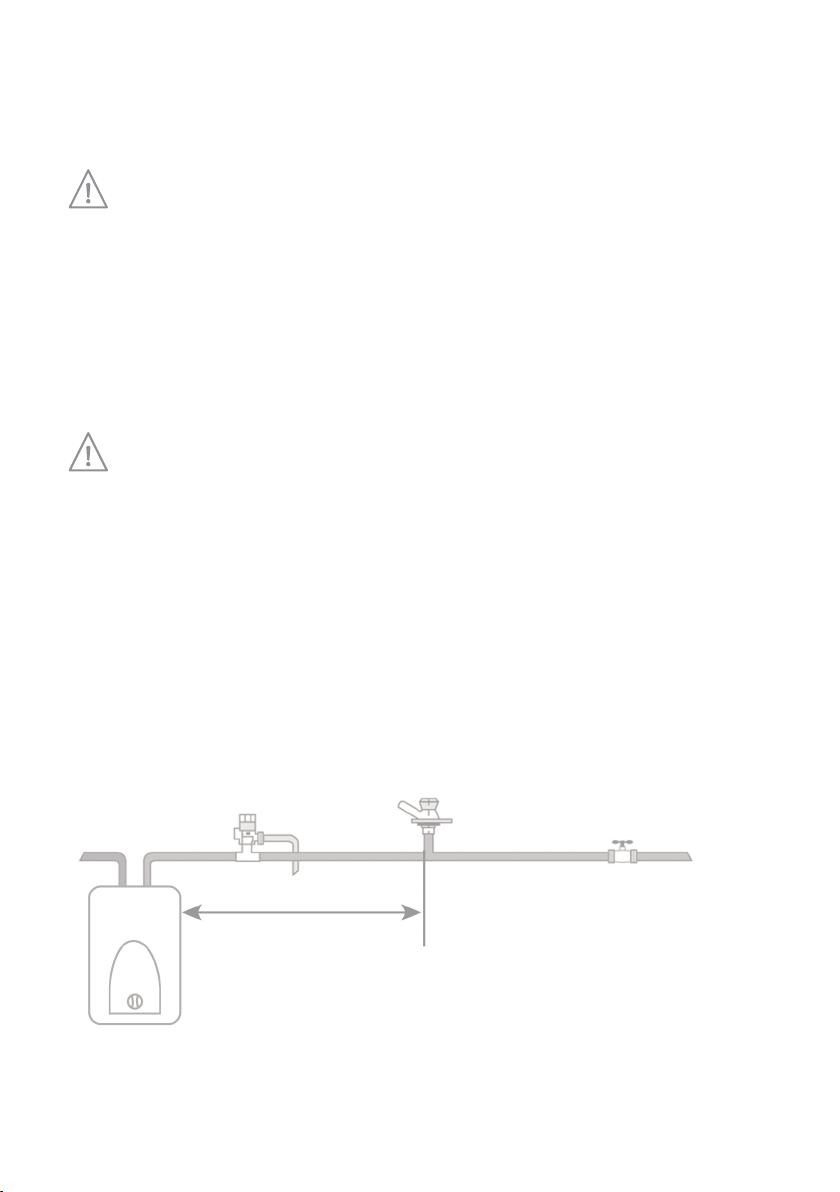

DIAGRAM A - Pressure below 4.2 bar

Pressure

relief valve

Hot

Cold

T piece

Speedflow

Length of pipework

required for expansion

5 litres - 1.4m

10 litres - 2.8m

15 litres - 4.2m

4

To drain

Nearest cold

draw off

Service valve

Cold water mains

No accessories needed.

DIAGRAM B - Pressure above 4.2 bar

Nearest cold

draw off

Pressure

reducing

valve

Service valve

Cold water mains

Hot

Cold

Speedflow

Pressure

relief valve

T piece

To drain

Accessory SF5 needed.

DIAGRAM C - Pressure below 4.2 bar and cold water draw off nearby

Hot

Cold

Pressure

relief valve

Expansion

vessel

Nearest cold

Check

valve

draw off

Service valve

Speedflow

T piece

To drain

Cold water mains

Accessory SF3 needed.

DIAGRAM D - Pressure above 4.2 bar and cold water draw off nearby

Cold

Hot

Speedflow

Expansion

Pressure

relief valve

T piece

Length of pipework

required for expansion

vessel

To drain

5 litres - 1.4m

10 litres - 2.8m

15 litres - 4.2m

Nearest cold

draw off

Check

valve

Pressure

reducing

valve

Service valve

Cold water mains

Accessory SF4 needed (ie SF3 + SF5).

5

Electrical

•

Installation must comply with the latest IEE regulations.

•

Connection should be to a fused switched 13A spur. If the cable length is insufficient,

it is recommended that the entire cable is replaced and no joins made to the original.

This product must be earthed.

Important: do not switch the heater on unless you are certain that it is

completely full of water. failure to do so will void the warranty.

3. Operation

Switch on the mains supply. The external neon lamp indicates when the element

is heating.

Use the lowest acceptable temperature setting to save energy.

Hot water may present a scalding hazard, especially to children or the infirm.

Athermostatic blending valve is recommended in high risk situations.

6

Thermal cutout reset, element replacement and anode replacement

Discount electricity supply before maintenance.

A re-settable safety thermal cut-out switches off the element in the event of the

unit over-heating.

The thermal cut-out may trip occasionally in normal use. If this happens the heater will

not heat water and the element light will not come on.

The thermal cut-out is located underneath the unit behind the grey access plate.

Depending on the mounting position of the unit, you may need to uninstall the unit for

ease of access to the cutout.

In these cases, disconnect electricity supply and unscrew flexible hose connectors. Drain

water from heater and locate grey access plate.

Remove the cover retaining screws and gently prise cover off. The thermal cut-out will

be visible, as shown below.

To reset the cutout, depress the button in the centre of the device. If the device has

tripped reduce the thermostat setting if possible.

If the device trips repeatedly with a low thermostat setting, contact Hyco Technical

Department on 01924 225200.

To access the element or anode, unscrew the bolts holding the flange in position.

The element and anode can then be removed. Reverse to re-fit.

Thermal cutout

- Press to reset.

Element securing bolt

Element flange - remove to access anode.

(x4) 6mm Allen key

required to remove.

7

4. Maintenance

A grey cylindrical magnesium sacrificial anode is fitted to the element to aid tank

corrosion resistance.The anode condition should be inspected annually and replaced

if the there are signs of significant corrosion.

The pressure relief valve should be checked annually by twisting the cap and verifying

water is discharged.

8

5. Specifications

W

H

D

Supply 230V ~ 50Hz

Power 2kW

Tank Capacity SF05K/SS - 5 Litres

SF10K/SS - 10 Litres

SF15K/SS - 15 Litres

Tank Material K Models - Vitreous enamel lined steel

SS Models - Stainless steel SUS 304 1.2mm

Dimensions (h x w x d) SF05K/SS 320 x 280 x 245mm

SF10K/SS 410 x 310 x 280mm

SF15K/SS 530 x 310 x 280mm

Pressure relief valve setting 6 bar

Thermal cutout Manual reset 85°C

9

6. Troubleshooting

Sympton Possible cause Solution

Water constantly flows Water pressure is too Fit Pressure Reducing

from pressure relief valve. high (above 4 bar). Valve Kit (Hyco Kit SF4).

Water flows from Heated water cannot Fit Expansion Vessel Kit

pressure relief valve expand back up inlet (Hyco kit SF3).

pipe

Water is not heated 1. Thermal cut-out has 1. See section 6. Check

tripped. heater is correct way

2. Element has failed. up (pipes at top).

3. Thermostat has failed. 2. Replace element.

See section 6 for access

to element.

3. Replace thermostat.

Small volume of 1. Unit upside down. 1. Re-install correct way up.

hot water 2. Thermostat set 2. Increase thermostat setting.

too low. 3. Replace thermostat.

3. Thermostat fault.

Water appears to leak 1. Poor connections 1. Check plumbing

from heater to pipework. connections, especially

2. Element gasket leak. those to inlet and outlet.

2. Refit gasket, tighten flange

bolts evenly. Do not over

tighten. See section 6 for

access to element.

If problems persist contact Hyco Technical Dept on 01924 225200.

10

7. Guarantee and service policy

This product is guaranteed against faulty materials and manufacture for a period of one

year from the date of purchase. Hyco will in its sole discretion replace, repair or refund

any faulty unit. Incorrect installation and failure to follow correct operating instructions

are excluded. Consequential costs such as labour charges or damage to surroundings

are expressly excluded.

11

INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH THE

EUROPEAN DIRECTIVE 2002/96/E.

At the end of its working life this equipment must not be disposed of as household

waste. It must be taken to a local authority waste collection centre or to a dealer

providing this service. Disposing of electrical and electronic equipment separately

enables its components to be recovered and recycled to obtain significant savings in

energy and resources. In order to underline the duty to dispose of this equipment

separately, the product is marked with a crossed out dustbin.

Hyco Manufacturing Ltd

Normandy Court

Express Way

Castleford, WF10 5NR

T 01924 225 200

F 01924 225 210

E sales@hyco.co.uk

hyco.co.uk

Loading...

Loading...