Product Instruction Manual

Rho

IN44T & IN60T

Instantaneous inline water heater

Version 3.2 Jan 2015

V15.6/3

2

Thank you for purchasing a Hyco instantaneous water heater. Instantaneous

water heaters are very energy efficient since they only consume energy

when they are used and so have no standing losses. The IN44T & IN60T

models are mains pressure instantaneous water heaters with external

electronic temperature control. Bare wire heating systems offer rapid heat

up times and a near instant supply of hot water. The heaters are intended

for handwashing applications and should be used in conjunction with spray

head taps. Please read and understand these instructions before commencing

installation, and leave them with the user when installation is complete.

1. Important safety points

•

The appliance must only be connected to a single phase supply.

•

Isolate electrical and water supply before installation.

•

Electrical installation must be carried out by a qualified electrician in accordance

with the latest edition of the IEE wiring regulations.

•

Only connect the appliance to a power supply that conforms to the specification

stated on rating plate.

•

The appliance must be earthed at all times.

•

The appliance must be permanently connected to the electrical supply through

an isolating switch with a contact separation of no less than 3mm in all poles.

•

Do not use the appliance if there is any possibility of the water supply being frozen.

•

Never remove the cover of the appliance without first isolating it from the electrical

power supply.

•

This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved. Children shall not play

with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

•

Do not use a supply with incoming water temperatures greater than 600C.

3

2. Installation

Wall Mounting

Do not install if there is a risk of water freezing in the heater.

Do not install the heater where the consequences of a leak could be

unusually severe. (e.g. above computer equipment).

•

When choosing a location for the heater, consider the visibility of any leak that

might arise. This is particularly important when locating in a concealed area such

as a cupboard.

•

The heater must be mounted horizontally with the inlet and outlet connections

at the top of the heater.

•

Before attaching the heater to the wall, consider the wiring route to the heater.

It is advised that the heater be located as close as practical to the hot water outlet in

order to avoid unnecessary heat losses through the pipework.

4

There are two options available for the mounting of the product, select either the

L

N

E

P

CB

RELAY

THERMAL

CUT OUT

TANK

TRIAC

TRIAC

TRIAC

key hole slots at the rear of the product or use the supplied bracket.

Using the bracket

1

Using the supplied bracket and ensuring a level, mark the two screw holes onto

the desired mounting surface.

Using the key hole slots

2

The back plate of the heater is detachable by the four screws located in each

corner. Once removed use the backplate as a template and, ensuring a level,

mark the two required screw holes.

Ensure there are no hidden cables or pipes before commencement of drilling.

Drill the holes, insert the wall plugs and screw the bracket/heater to the wall.

(see diagram below).

1

2

5

Plumbing connections

The heater is designed for use with spray head type taps.

Ensure the following criteria are met for the water supply:

•

Minimum flow = 2.0L/min

•

Pressure Min/Max = 0.1Mpa/0.75Mpa

•

Water resistivity = ≥1300 Ωcm

Suitable for use with pre-heated water e.g. solar heating systems to a maximum

0

of 60

C.

Flush supply pipes to remove any debris before connecting the heater

to the water supply.

Make the plumbing connections as indicated on the front cover of the heater:

•

Blue/Inlet (cold mains)

•

Red/Outlet (hot tap/outlet)

It is strongly recommended that a service valve be fitted close to the product on

the cold feed, this will aide future maintenance.

The inlet is the left hand pipe and the outlet the right, when viewed from the

front. The supplied gauze should be fitted into the inlet side of the heater.

The enclosed spray head/flow limiter attachment should be installed into the

outlet of the hot tap to ensure best performance of the heater.

Turn on the colds main feed and draw water through the heater for several

minutes by opening the hot outlet. Ensure a smooth flow of water from the outlet

to confirm all air is purged from the system and check for leaks on all connections.

This step is required every time the heater has been drained for any reason, such

as routine maintenance.

6

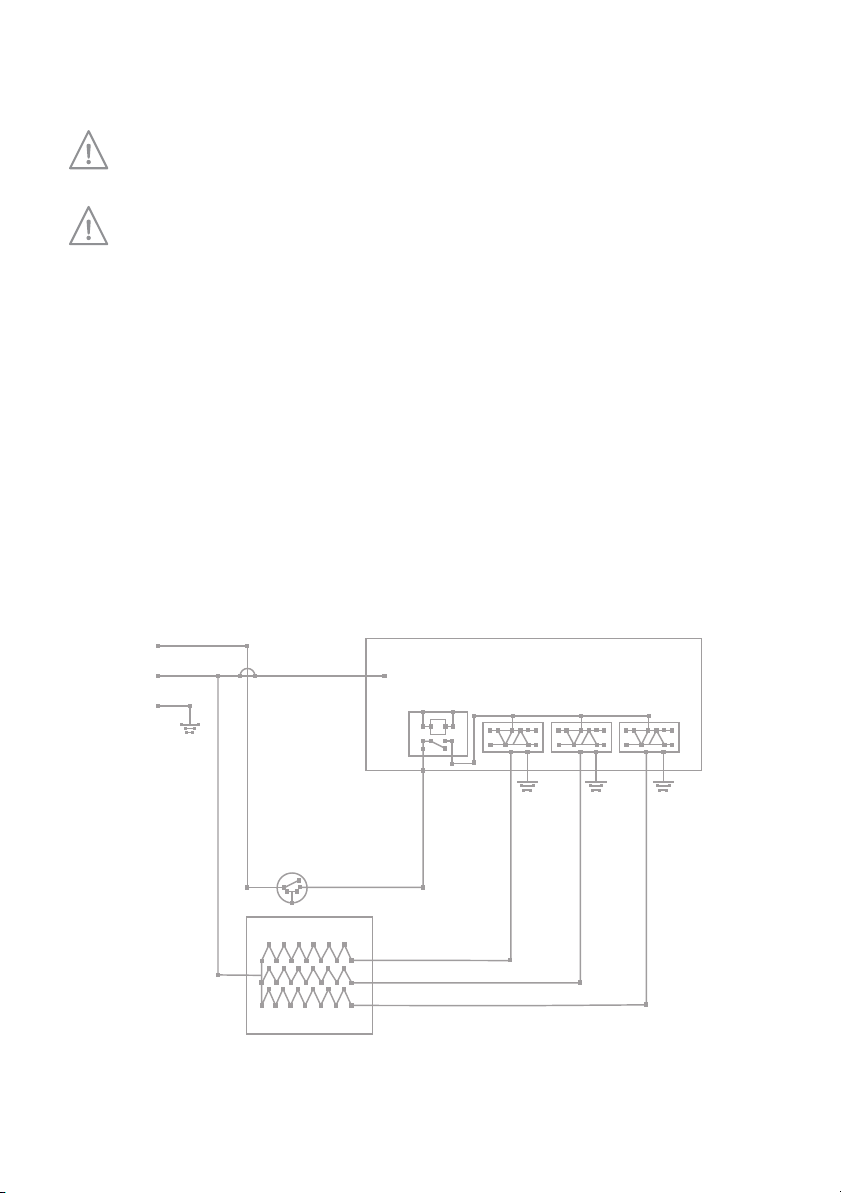

Electrical connection

L

N

E

PCB

RELAY

THERMAL

CUT OUT

TANK

TRIAC

TRIAC

TRIAC

Do not commence electrical installation before connecting the heater

to the water supply and verifying there are no leaks or air gaps.

Electrical installation must be carried out by a qualified electrician in

accordance with the latest edition of the IEE wiring regulations.

•

Electrical supply should be capable of isolation via a double poled switch.

•

The heater must be earthed.

•

Isolate electric and water supply before electrical installation.

•

Refer to the rating label on the heater to ensure correct specification of

installation.

The heaters are supplied pre-wired.

(see diagram below).

7

3. Operation

Once installed and connected to the electrical supply the heater is ready for use.

Turn on the heater using the power On/Off button. On first installation the

temperature setting will default to 38

the desired maximum target temperature is displayed. The heater will automatically

begin heating when it detects a flow of water through it (min 2.0L/m).

Open the outlet valve and check the display, the temperature display will flash if the

set temperature cannot be reached. It may be possible to reduce the flow rate in

order to achieve the set temperature, but it must have a minimum flow of 2.0L/min

in order to operate.

Due to the nature of instantaneous heaters, water is only heated as it passes

through the tank. Because the maximum power of the heater is fixed there is

a limit to the rate at which hot water can be delivered.

The heater incorporates intelligent control and will ensure the maximum

temperature setting is not exceeded regardless of drop in flow or increase in

incoming water temperature.

0

C. To adjust this press the +/- buttons until

4. Maintenance

•

Always disconnect the power before commencing any cleaning or maintenance.

•

Never open the cover of the heater without first isolating the mains power supply.

To clean the heater cover only use a clean damp cloth, do not use abrasive compounds.

Electrical and plumbing components should be inspected on a regular basis by a

suitably qualified/competent person.

5. Specifications

80mm

190mm

140mm

IN44T IN60T

Power supply 230V~ 50Hz 230V~ 50Hz

Dimensions H140 x W190 x D80mm H140 x W190 x D80mm

Power 4400W 6000W

Protection class IPX4 IPX4

Rated current 19A 27A

Over heat protection 80

temperature

Minimum operating 2.0L/Min 2.0L/Min

flow rate

Minimum operating 0.1MPa 0.1MPa

pressure

Maximum rated pressure 0.75MPa 0.75MPa

Required water resistivity ≥1300 Ωcm ≥1300 Ωcm

Maximum incoming water 60

supply temperature

0

C 800C

0

C 600C

Water fittings 1/2” BSP 1/2” BSP

6. Trouble Shooting

Defect Possible cause Action

Water is too hot Temperature set too Turn down the temperature

high on the heater on the heater (see section 6).

Water is too cold Water flow rate is Ensure flow restrictor and

too high spray attachment are fitted.

(see section 4).

Temperature setting Turn up temperature

is too low setting (see section 6).

No display on Unit in standby Turn On the heater

the heater (see section 6).

Power supply problem Check that power is supplied

to heater and is correct

specification as per the rating

label.

Minimum flow not met Ensure a flow of at least

2L/min.

For technical faults that cannot be resolved using the trouble shooting table contact

the technical department on 01924 225200 for further assistance and advice.

7. Guarantee and service policy

This product is guaranteed against faulty materials and manufacture for a period of one

year from the date of purchase. Hyco will in its sole discretion replace, repair or refund

any faulty unit. Incorrect installation and failure to follow correct operating instructions

are excluded. Consequential costs such as labour charges or damage to surroundings

are expressly excluded.

INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH THE

EUROPEAN DIRECTIVE 2002/96/E.

At the end of its working life this equipment must not be disposed of as household

waste. It must be taken to a local authority waste collection centre or to a dealer

providing this service. Disposing of electrical and electronic equipment separately

enables its components to be recovered and recycled to obtain significant savings in

energy and resources. In order to underline the duty to dispose of this equipment

separately, the product is marked with a crossed out dustbin.

Hyco Manufacturing Ltd

Normandy Court

Express Way

Castleford, WF10 5NR

T 01924 225 200

F 01924 225 210

E sales@hyco.co.uk

hyco.co.uk

Loading...

Loading...