© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

1

IN1198 Edition A

Installation and planning Instructions For

Hwam

4410

3320

3310

This Manual Must Always be Available to the Stove Operator

Serial Number

Part No.

Model Name

This manual must be used in conjunction with document IN1173.

The Wood and Multifuel Chimney and Installation Guide.

Since April 2002 only Registered Competent Engineers may install solid fuel fired appliances without involving

the Local Authority Building Control Department. For more details contact HETAS.

Euroheat would suggest only Registered Competent Engineers such as HETAS approved engineers install

Euroheat appliances.

If a competent approved engineer is not employed to install your appliance building control must to contacted

and a building control number is issued.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

2

IMPORTANT

.

The installation of this appliance must comply with all local regulations, including those referring to

national and European Standards before it can be operated. The stove is not suitable for a shared flue.

However, for England and Wales, only, the coming into force on 1st April 2002 of SI 2002 No 440 exempts

the householder from this legal requirement for the installation of solid fuel fired appliance whose rated heat

output is 50kW or less in a building having no more than 3 storeys (excluding any basement) if a Competent

Engineer is employed who is registered under the Registration Scheme for Companies and Engineers involved

in the Installation and Maintenance of Domestic Solid Fuel Fired Equipment operated by HETAS Ltd. These

registered Competent Engineers may also carry out associated building work necessary to ensure that the

installed appliance complies with Building Regulations without involving the Local Authority Building Control

Department.

Improper adjustment, alteration, maintenance or the fitting of replacement parts not recommended by the

manufacturer can cause injury or property damage. Do not operate the stove with faulty seals or damaged

glass.

Due to the high operating temperatures of this appliance it should be located away from pedestrian traffic

and away from furniture and draperies. Do not store paper or wood near the appliance. Any mats and rugs put

in front of the stove should be fire proof and secured to prevent the possibility of tripping.

Advise all persons as to the stove’s high surface temperatures. If it is possible for children or infirm adults to

come into contact with the stove, fit a suitable fire guard.

It is imperative that all air passageways into, out of, and within the appliance are kept clean. All permanent

ventilation into the room provided for the stove must remain clear and unobstructed at all times. Consideration

must be given to the need for extra ventilation if another heating source needing air is to be operated

simultaneously. If an extraction fan is proposed to be fitted to a connecting area of the house, after the stove

has been installed, professional advice should be sought from a qualified engineer.

The user should be advised that the appliance should be inspected regularly and the chimney cleaned at

least annually.

More frequent cleaning may be required and the advice of a qualified chimney sweep should be sought.

Our range of stoves is capable of operating with outstanding efficiency if the flue system is correct. Because

so little heat is wasted to the flue it is possible that moisture within the products of combustion will condense

if the heat losses within the flue way are too great and allow the flue gasses to cool. For this reason we

recommend that the stove is fitted with a suitable flue liner, the same diameter as the flue spigot, to prevent

the possibility of acidic damage to the fabric of the chimney and damage to the stove which will reduce the

longevity of the stove.

When correctly installed, the stove is designed to produce heat, safely. It cannot do so if the installation is

less than absolutely stable, constructed of materials suitable for such an installation and consideration has not

been given to the possibility of people with less than ideal common sense operating it.

Has the existing chimney swept by a chimney sweep? Although you will be lining the chimney, any deposits

left in the chimney will cause problems and may become a fire hazard.

Your attention is drawn to the precautions and responsibilities under the Health and Safety at Work Acts,

and whatever new legislation being introduced during the life of this document.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

3

The Hwam 4410, 3320 and 3310 Range Explained

Hwam and Euroheat insist on progressive development to produce products which are market leading. Our

aims are to have stoves with the latest innovations, user friendly operation and highly efficient for lower cost

operation.

All three models can either be floor mounted on a stand or wall mounted with a hanging bracket. They have

swing up and drop down access door to the ash and control system area.

Important

Please ensure the warranty registration form is completed if you are the installer and confirm with the user

that it is there responsibility to return it to Euroheat. In this way the model and its history will be recorded for

reference in the future.

For the latest versions of manuals, technical information, accessories and spare parts visit the euroheat web

site. www.euroheat.co.uk

The part number and edition of this manual is listed on the front page and at the bottom of each page.

Stoves Supplied Through Euroheat Authorized Retailers.

For England, Wales, Scotland and Ireland

Euroheat Distributors (H.B.S). Ltd.

Unit 2,

Court Farm Business Park,

Bishops Frome,

Worcestershire. WR6 5AY.

www.euroheat.co.uk

info@euroheat.co.uk

Whilst Euroheat are always happy to assist, please ensure you have read this manual and the chimney and

installation guide IN1173.

First contact your supplying retailer for assistance. If you find this unsuccessful contact the Euroheat Technical

support team. Technical support telephone Number +44 01885 491117. E-mail tech@euroheat.co.uk.

Before telephoning ensure you have the stoves serial number to hand and that you are a Registered Competent

Engineer. If you are not a registered engineer seek one for assistance. A list of engineers can be obtained from

HETAS. www.hetas.co.uk

Euroheat unfortunately are unable to offer support for appliances which were not supplied by Euroheat.

Hwam

Nydamsvej 53 Dk -8362 Horning Denmark

www.hwam.com

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

4

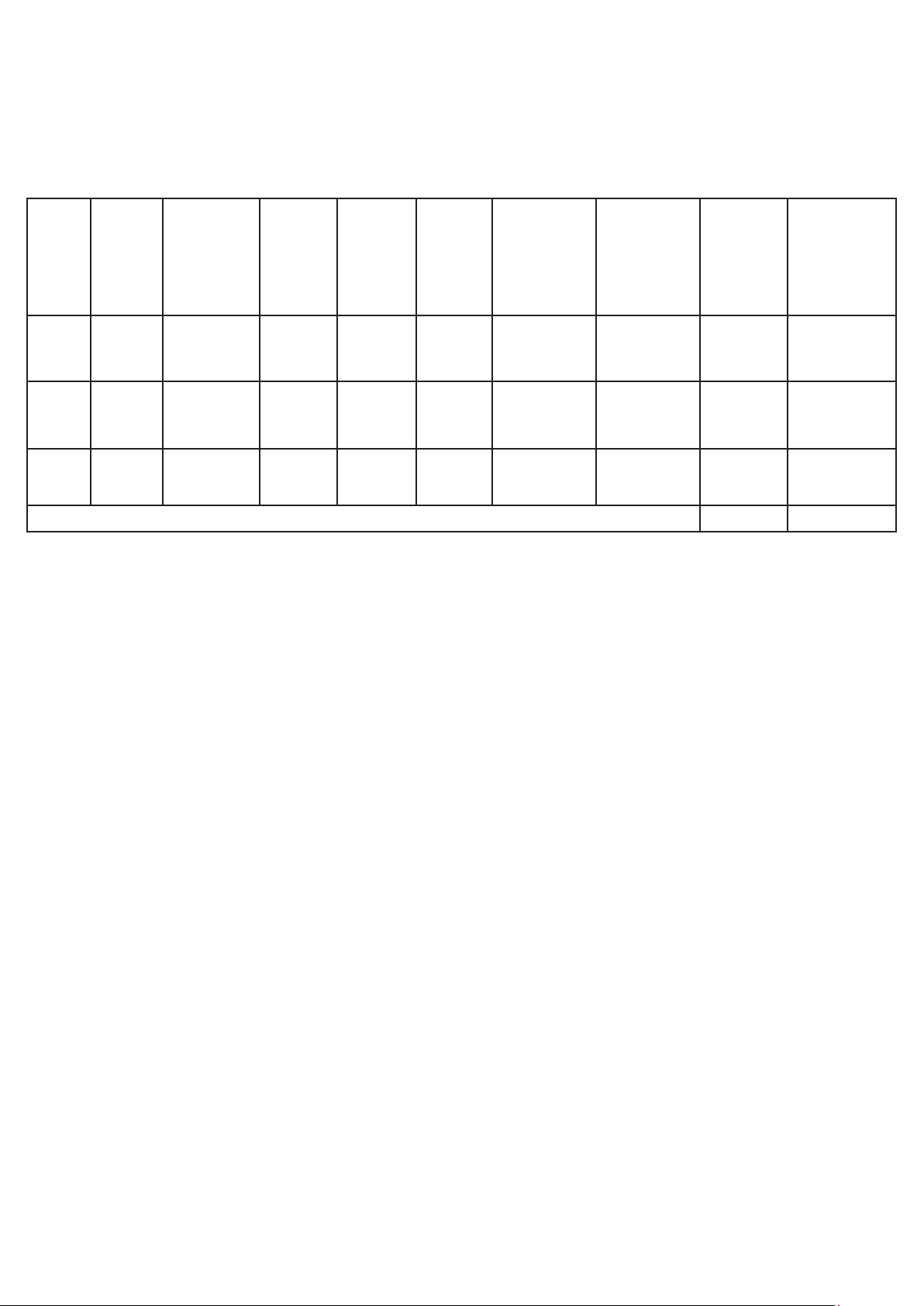

Technical Details Intermittent Operation

Intermittent operation is when the appliance is used for short firing periods for example 45 minutes to 2 hours.

This is a common operation in warmer weather such as cold spring evenings. The information provided below

where indicated as HETAS approved is from the current CE standards EN 13240:2001 and EN 13240 A2:2004.

The test fuel is wood.

Model

Name

Hwam

4410

Hwam

3320

Hwam

3310

Model

Number

4410* 6kW

3320* 5kW

3310* 5kW

Heat Output

Nominal

Wood

Weight KGFlue

Draught

Nominal

109kg

125kg

with plinth

95kg

110 kg

with plinth

92kg

107kg

with plinth

12pa 7.49 291

12pa 7.4 280

12pa 7.4 280

Flue Gas

Mass

Flow g/s

Flue Gas

Temperature

Efficiency

with

Top Flue

Connection

81.6% Net

74.6% Gross

81.6% Net

74.6% Gross

81.6% Net

74.6% Gross

Flue

Size

6” (152mm) 550mm2

6” (152mm) 0mm2

6” (152mm) 0mm2

Air

Requirement

Equivalent

Area as

Approved

Document J

* HETAS Approved

* Air requirement equivalent area. Building regulations Document J, advises that an air supply should be

installed for appliances with a heating output over 5kW. Document J indicates that there should be sufficient

advantageous air for heating outputs below this amount. With modern properties this may not always be the

case and/or more free air may be required. Continuous or intermittent operation will result in different heating

outputs due to the nature of the fuel and the appliance. If in doubt increase the suggested area listed or contact

your HETAS approved engineer for assistance.

Useful Organizations UK

Solid Fuel Association 0845 601 4406 www.solidfuel.co.uk

The National Association of Chimney Sweeps 01785 811732 www.chimneyworks.co.uk

HETAS Ltd. 0845 634 5626 www.hetas.co.uk

Models indicated above as HETAS approved to a certain flue position are indicated by **

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

5

Load Bearing Surface

5

7

4

2

1

6

5

4

7

3

3

Before installing the stove, make sure that the surface it will stand on can carry the weight of the stove and

any flue connecting pipe.

Installation Clearances

Diagram Number Description 3310 3320 4410

1 To inflammable surface at rear 0mm 0mm 0mm

1 To flammable wall at rear 150mm 150mm 150mm

2 To inflammable surface at side 100mm 100mm 100mm

2 To flammable surface at side 250mm 250mm 250mm

3 To inflammable surface at the side/corner 100mm 100mm 100mm

3 To flammable surface at the side/corner 150mm 150mm 100mm

4 Hearth in front of stove 300mm 300mm 300mm

5 Fire proof area in front width 800mm 800mm 950mm

6 From opening edge of door to edge of hearth 150mm 150mm 150mm

7 Distance to furniture or draperies in front of stove 800mm 800mm 900mm

* When installed as a free standing appliance or in a pre-fabricated fireplace. All other applications must

conform to current constructional fireplace requirements per Building regulations with a constructional hearth.

All installations surrounding flammable materials must not exceed 65°C.

Curtains and furnishings should be a minimum of 1m from the stove or the surface temperature and must not

exceed 65°C.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

6

Hearths

The stove should stand wholly above a hearth constructed of suitably robust materials and should be able to

accommodate the weight of the appliance and its unsupported flue components. The materials should conform

to local Building Regulations and British Standards.

If the stove is not to stand in an appliance recess, a hearth made of non-combustible board/sheet material or

tiles of at least 12mm thick may be used as long as the floor can accommodate the weight of the appliance

and its unsupported flue components. If it is installed on a wooden floor or similar, the floor must be covered

with a non-combustible material, a minimum of 12mm thick, to a distance of 300mm in front of the stove and

150mm to each side measuring from the closed door of the combustion chamber.

The Hwam range of wood and multifuel stoves have been tested and conform to standards DIN18891 and DIN

18891-A1 where the hearth temperature does not exceed 100°C

For further information on hearths of either glass, granite or slate visit our web site

www.euroheat.co.uk

Appliance independently tested to verify that the hearth temperature does not exceed 100°C

Non-combustable board

sheet material or tile

Combustible

material

300mm

12mm

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

7

Fireplace Design

1

2/3

2/3

1/3 2/3

Do not be tempted to fit the stove into an unsuitable fireplace. Beyond the requirements of Building

Regulations and access to facilitate servicing the stove, providing a setting which will compliment a stove is

not a luxury, it is the practicality of making the most of an investment. A good builder or fireplace specialist

will be able to transform even the most utilitarian of fireplaces. Whether altering its proportions to those of the

“Golden Mean” ideal, see below, or exposing a wooden or stone lintel or simply removing superfluous detailing

for a comparatively small cost, and the result will be a pleasure for many years.

“Golden Mean”

1. The stove must always stand perfectly level. Adjustment screws and/or triangular plastic levelling spacers

may be provided with the stove. The provision of a suitable level hearth within the recess is an important

consideration when planning a fireplace.

2. Sufficient space should be allowed for service work.

3. At least the minimum clearance from inflammable materials and conforming to the current Building

Regulations.

4. Sufficient space around the stove so that the controls may be operated without the risk of injury to the

operator.

5. Mounting brackets should be installed to facilitate the secure fitting of a fire guard, if one is to be fitted to

protect the young, elderly or infirm.

6. Curtains and soft furnishings should be a minimum of 1m from the stoves body or the surface temperature of

these furnishings must not exceed 65°C.

7. The mounting of expensive paintings, mirrors and plasma screen televisions above a fireplace is not

recommended.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

8

Fresh Air System

5

Instead of letting the air from the room into the stove for combustion, it is possible to take in fresh air from

outside and introduce this directly via a duct into the back of the stove.

Today, many modern dwellings are so airtight to conform with building regulations that it is an advantage to

attach a fresh air intake to the stove. This continually supplies the air for combustion while the stove is in use

but as the air is ducted directly into the back of the stove it stops cold fresh air mixing with the warm air in the

room chilling the room or causing draughts.

This ensures that the air extracter fan outlets in the kitchen and bathroom function optimally without affecting

the air required for combustion. The advantage of this is that a multifuel stove may now be fitted into a room

where an air extracter fan is fitted, however a flue draught test must be carried out with the extracter fan

running at its maximum setting to ensure that the fan is not drawing air from the stove.

The 3310 and 3320 can be equipped with an optional fresh air system. Further information can be found in

the fresh air system’s instruction manual. If you wish to install a fresh air system on your stove, you have the

following options:

1) Stove mounted on the wall: connect the fresh air system on the lower back of the stove.

2) Stove mounted on a plinth: connect the fresh air system either on the lower back of the stove or on the back

of the plinth.

The HWAM 4410 can be equipped with an optional fresh air system. Further information can be found in the

fresh air system’s instruction manual. The following connection options are available:

1) Stove mounted on the wall: connect the fresh air system on the lower back of the stove.

2) Stove mounted on the wall: connect the fresh air system on the lower bottom of the stove.

3) Stove mounted on a plinth: connect the fresh air system either on the lower back of the stove or on the back

of the plinth.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

9

Mounting Stove onto a Plinth

2

2

1

3

1

Note: HWAM 3310 HWAM 3320 and HWAM 4410 must always be mounted on the wall or on a plinth.

When mounting your wood-burning stove on the wall or on a plinth, it must be placed a minimum of 100mm

above the ground, as measured from the lower edge of the stove.

3310/3320 4410

Mount the plinth with the open side facing forwards at the location where the stove is to be placed. Place the

stove on top of the plinth so that the two guide pins (1) on top of the plinth fit into the two holes (2) in the

bottom of the stove, and the guide block (3) (3310 & 3320) fits into the hole (4) at the bottom rear edge of the

stove.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

10

Wall Mounting

The Hwam 4410, 3320 and 3310 can be wall mounted with an optional wall hanging bracket. Full fitting

instructions are included with the hanging bracket.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. April 2008 E & OE Instructions Part number IN1198 Edition A

11

Door Lifting Mechanism

2

1

2

1

4

3

The door lift mechanism consists of a chain pull placed on either side of the stove and a spring placed beneath

the stove. Note: always let a professional grease and repair these parts.

Hwam 3310 and 3320

If the door opens with difficulty, you may correct

this by greasing the chain wheel boxes (1) and door

hinges (2) with copper grease. You should do this

once every year. Tighten the spring with a special

tool, which can be bought separately. Ask your local

HWAM dealer for assistance.

Hwam 4410

If the door opens with difficulty, you may correct

this by greasing the chain wheel boxes (1) and door

hinges (2) with copper grease. You should do this

once every year. If the door slides too easily, the

spring has loosened. Tighten the spring with a special

tool, which can be bought separately. Ask your local

HWAM dealer for assistance.

Surface

Normally, additional surface treatment will not be required. However, damage to the coating may be repaired

with approved Hwam spray paint.

Loading...

Loading...