HV Diagnostics TD30 User Manual

User Manual

TD30

E N G L I S H

Rev 1.4

HV Diagnostics, Inc

North and South America

271 Rope Mill Pkwy, Ste2

Woodstock, GA 30188

USA

Tel. +1 678-445-2555

Fax +1 678-445-2557

www.hvdiagnostics.com

sales@hvdiagnostics.com

HV Diagnostics S.à.r.l.

Africa, Asia, Australia,

Middle East

www.hvdsa.com

Portable Tan Delta Measurement System

User Manual

Rev 1.4

Page

2 HV Diagnostics

User Manual

HV Diagnostics

Page

3 Rev 1.4

Computer Notebook ID

TD System Ser No

COM Port #

Bluetooth Hardware

NOTE:

The information presented in this instruction manual is believed to be accurate and correct

for the intended use of this product. Should this instrument be used for other applications and

purposes not covered herein, please contact HV Diagnostics to validate its suitability. This

manual, all of its contents and the instruments specifications are subject to change without

notice.

Windows®, Windows 2000®, Windows XP®, Windows 7® are registered trademarks of Microsoft

Corporation.

Bluetooth® and the Bluetooth Label are owned by the Bluetooth SIG, Inc.

PDF and the Adobe Acrobat Family of Software are trademarks of Adobe Inc.

Space to note the used communication Parameters for your TD System:

User Manual

Rev 1.4

Page

4 HV Diagnostics

Table of Contents

1 Forward ................................................................................................... 5

Regarding this Document ........................................................................ 5

1.1

Documentation Conventions ................................................................... 6

1.2

Legal Considerations .............................................................................. 7

1.3

2 Safety ..................................................................................................... 8

General Safety ........................................................................................ 8

2.1

Work Safety ............................................................................................ 8

2.2

3 Introduction ............................................................................................. 9

4 Features .................................................................................................. 9

5 Applications ............................................................................................ 9

6 General Description ...............................................................................10

Technical Specifications* .......................................................................10

6.1

Materials ................................................................................................11

6.2

7 Hardware Description .............................................................................13

8 Connecting up the TD30 Instrument .......................................................16

9 Software TD ControlCenter ....................................................................17

10 Instrument Care .....................................................................................24

Appendix A: Software Installation Procedure ‘TD ControlCenter’...................25

Appendix B: Bluetooth® Setup and Config Procedure ...................................26

User Manual

HV Diagnostics

Page

5 Rev 1.4

User

Responsibilities

Focus

safety

1 Forward

Purpose

This operating manual serves to ensure the proper and safe use of the TD test instrument.

Regarding this Document

1.1

Target User

This operating manual is designed to inform various user groups. The scope and depth of the

information provided may not be appropriate for all users. However, it is important that all

users familiarize themselves with this document in full. The following is a guideline indicating

the most significant information as a function of the user’s responsibilities.

HVA Operator

Procurement,

Management

• To connect the equipment

• To carry out manual or pre-programmed test

sequence

• To verify validity of HVA application

• To verify validity of TD application

• To adjust instrument settings

• To program automatic test sequences in

ccordance with particular testing standards

a

• To assure that the workplace is safe and

has all required equipment

• To assure that HVA and TD operators are

qualified technicians

• To assure that operators fulfil their

responsibilities

All Sections

Particular focus on all

s

afety messages

Particular focus on

messages and information

regarding general product

description.

User Manual

Rev 1.4

Page

6 HV Diagnostics

Blue circle with white exclamation mark: Used to indicate recommended

Documentation Conventions

1.2

The following explain the symbols, and safety messages found in this document. The

employment of safety symbols and signal words are according to the American National

Standards Institute standard ANSI Z535.6 "Product Safety Signs and Labels".

Safety Messages

Danger

Indicates a hazardous situation which if not avoided will result in death or

serious injury

Warning

Indicates a hazardous situation which if not avoided could result in death

or serious injury.

Caution

Indicates a hazardous situation which if not avoided could result in minor

or moderate injury.

DANGER

WARNING

CAUTION

Notice

Symbols

NOTICE

Indicates suggested practices to protect equipment and property.

Yellow triangle, framed in black: Used to indicate a potential hazard.

Only used in conjunction with description of the possible hazard!

Detailed symbol may correspond to this specific hazard.

Red outlined circle with red diagonal line: Used to indicate forbidden

practices.

The described handling practice must not be carried out!

precautionary measures or a situation that can lead to property damage.

User Manual

HV Diagnostics

Page

7 Rev 1.4

Legal Considerations

1.3

Warranty

HV Diagnostics provides a one-year warranty from the original purchase date

of instrument for all necessary parts and labor. This warranty is void in the

event of abuse, incorrect operation or use, unauthorized modification or

repairs, or failure to perform the specified maintenance as indicated in this

operation manual. This warranty does not include normal consumable items

such as lamps, paper rolls, printer ribbons, batteries or other auxiliary items.

This warranty and our liability are limited to replacing or repairing defective

equipment, at our discretion. Equipment that is returned to HV Diagnostics

must be packed in original packaging. All shipped items must be prepaid and

insured. No other warranties are expressed or implied.

Contact Information

HV Diagnostics, Inc. H.V. Diagnostics S.à.r.l.

271 Rope Mill Pkwy. Africa, Asia, Australia,

Ste 2 Middle East

Woodstock, GA 30188 www.hvdsa.com

T. +1 678-445-2555

F. +1 678-445-2557

North and South America

www.hvdiagnostics.com

sales@hvdiagnostics.com

Copyright

©2006 HV Diagnostics. All rights reserved.

No part of this publication may be reproduced, transmitted, stored, or

translated in hardcopy or electronic form without the written consent of HV

Diagnostics.

Your opinion matters!

Your comments and suggestions are of value. We are dedicated to supporting

your needs. Offering you optimal documentation is part of our promise of

quality.

Improvement suggestions regarding this manual may be sent to:

sales@hvdiagnostics.com

Thank you for your feedback!

User Manual

Rev 1.4

Page

8 HV Diagnostics

2 Safety

General Safety

2.1

Work Safety

2.2

Safety is priority! Respect all safety information; only use the TD for

appropriate applications and ensure that operators possess the required

operator qualifications.

NOTICE

Operation Manual

Before carrying out any high voltage test with this instrument, read this

Operating Manual in its entirety.

DANGER

Electric Shock Hazard

Never assume that equipment is safe to handle without using the

necessary safety equipment and grounding procedures.

• All procedures must comply with local safety regulations

• Always treat exposed connectors and conductors as potential electric

shock hazards. All cables and connectors must be inspected for

damage before use. Damaged equipment must not be used.

• All equipment to be high potential tested must be de-energized and

properly isolated from all power sources. All equipment grounds must

remain in place.

• DUT must be grounded, de-energized and isolated from

sources. DUT must be discharged and grounded before disconnecting

the test lead.

• All auxiliary electrical apparatus such as switchgear, surge arresters

etc. must be isolated from the test power source and the DUT.

• Ground connections must be made first and removed last!

• Avoid testing alone. In the event of an emergency another person’s

presence may be essential.

• The visual signals of the TD30 are designed to be easily distinguished

even under bright sunlight to avoid incorrect readings. Always keep at

least 6 feet / 2 meters distance when looking directly at the LED

signals. Avoid long direct exposure of eyes to the signals especially

under dark conditions.

The LED signal colors on the TD system indicate a TD value / range or equipment

status condition. These LED lights signals in no way indicate the presence or absence

of high voltage and the TD30 should be considered energized at all times when

connected to a potential voltage source like a HVA test system.

all power

User Manual

HV Diagnostics

Page

9 Rev 1.4

3 Introduction

The TD30 model is an easy to use, single piece, Digital Signal Processor based, field

portable, fully automatic VLF (Very Low Frequency) high voltage measurement instrument

developed for the high potential measuring of the insulation dielectrics of various types of

electrical apparatus.

4 Features

• Lightweight, portable, battery powered unit

• Solid state air insulated design

• Suitable for use with the HVA30 VLF test systems.

• Test results are easily stored via Notebook Computer or PocketPC via wireless

Bluetooth® connection.

• Supplied complete with TD communication and analysis software – TD Control

Center.

• Real-time display of actual output waveform.

• Power Save (Sleep) function (1 hour of inactivity), automatic wakeup on reapplication

of high voltage. One-Click reconnect in ControlCenter after Sleep

5 Applications

The TD30 provides the testing and commissioning engineer/technician with a versatile

high voltage tan delta measuring system suitable for testing medium voltage electrical

insulation systems such as cables (including: XLPE, PE, EPR, PILC, etc.), capacitors,

switchgear, transformers, rotating machines, insulators and bushings.

Tan Delta testing enables the cable test engineer to detect insulation defects before the

cable fails in service. The TD30 is a versatile tan delta measuring system that is directly

connected to the HVA series of VLF test systems from HV Diagnostics. The tan delta test

results of the test object can now be easily measured and recorded and the results stored

on a standard PC or Laptop for analysis, trending or quality control. This enables the

cable engineer to now make tan delta testing a routine maintenance test.

The TD30 is a battery powered system that is directly connected to the HVA30 series of

VLF test systems. Standard “C” size alkaline or rechargeable battery cells that are

commonly available will last up to 10 hours of continuous operation.

The TD30 is supplied with 30 feet /10 meters of terminated output cable to plug directly

into the HVA30 test system and is supplied complete with operating software which gives

a complete picture of the tan delta measurement together with a real time display of the

output voltage and current. The data transmission to standard notebook PC or PDA that

is Bluetooth® enabled, thus eliminating a direct connection between the TD30 and the

data collection device.

User Manual

Rev 1.4

Page

10 HV Diagnostics

6 General Description

Technical Specifications*

6.1

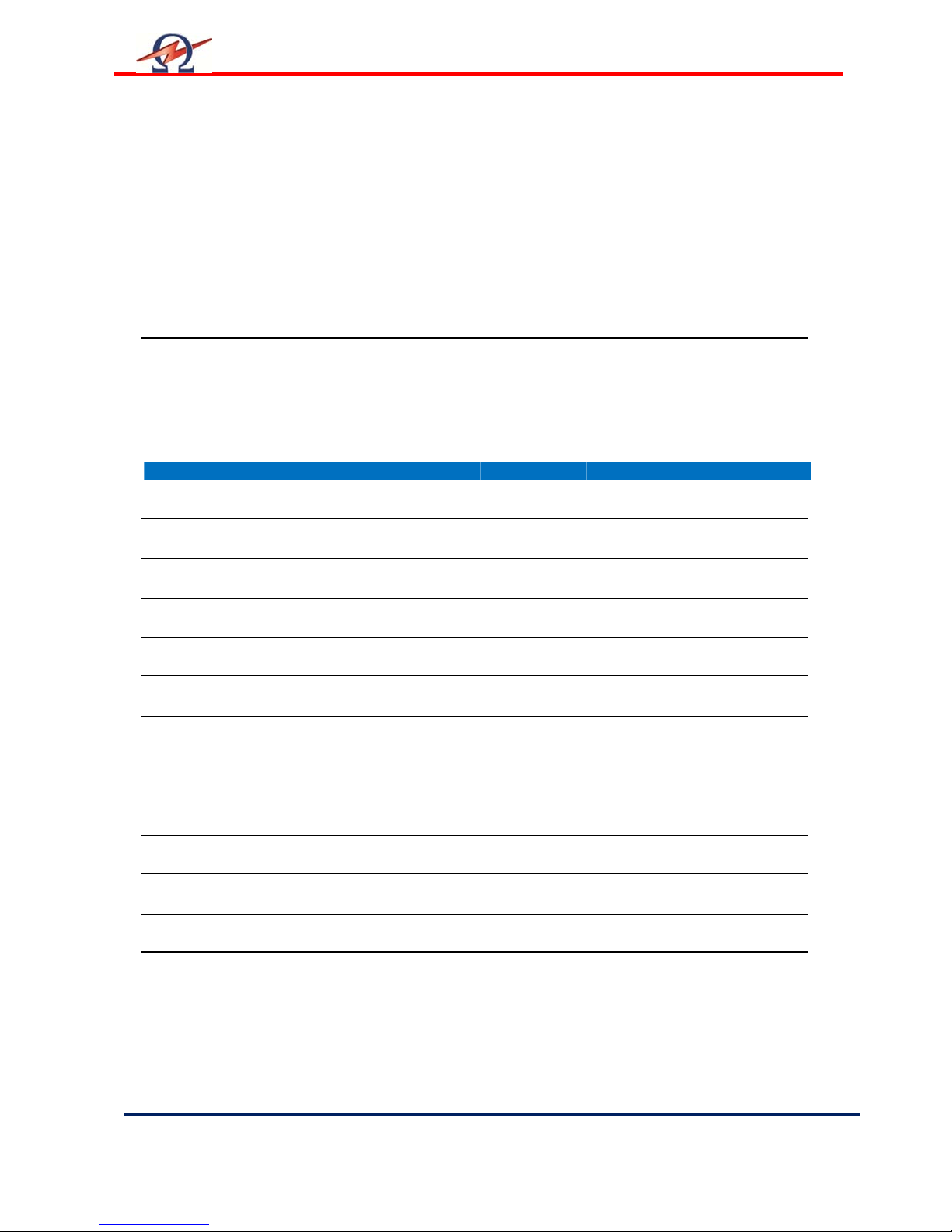

Characteristic TD30

Supply Power 2 C-Size Alkaline or NiMH Rechargeable Batteries

Operating Time Alkaline Batteries: min. 10 hours

Operating Time Rechargeable Battery: min 5 hours

Operating Time means uninterrupted use under full load. The

TD system incorporates an automatic power shutdown mode

during extended periods of inactivity which will further extend

the battery life.

Operating Voltage

Voltage Measurement

Operating Current

Current Measurement

Operating Frequency 0.1 Hz

Tan Delta Measurement 0.1 E-3 to 1000 E-3

Load Capability Limit Minimum Load: 5nF

Computer Interface Bluetooth® Class 1

HV Cable Test Lead Standard is 30 ft (10 m) with direct plug interface to HVA30

Operating Temperature 20 to 113°F / -5 to 45°C

Storage Temperature -13 to 155°F / -25 to 70°C

Relative Humidity 0-80% non-condensing.

Weight 11 lbs / 5 kg

Dimensions Length x Diameter: 11” x 3” / 28 cm x 8 cm

*Technical Specifications are subject to change. HV Diagnostics reserves the right to modify values in accordance with

future HVA development.

1 – 24 kVrms

Resolution 100 Vrms

Accuracy 0.5% of reading

0.001mA - 14 mA rms

Resolution 1 µArms

Accuracy 1% of reading

Resolution 0.1 E-3

Accuracy: Load > 15nF and < 500nF: +/-0.2 E-3

Accuracy: Load < 15nF and > 500nF: +/-0.5 E-3

max. Transmission Power 12dB @ range 45 ft (15 meters)

indoor fully Bluetooth® SIG™ certified communication

Series of HV Test Generators – other lengths are available.

User Manual

HV Diagnostics

Page

11 Rev 1.4

Materials

6.2

Shipment Content

Items included upon delivery of the HVA are listed below. The * marking

specifies items that are country specific. For inquiries, please contact HV

Diagnostics. For inquiries, please contact HV Diagnostics.

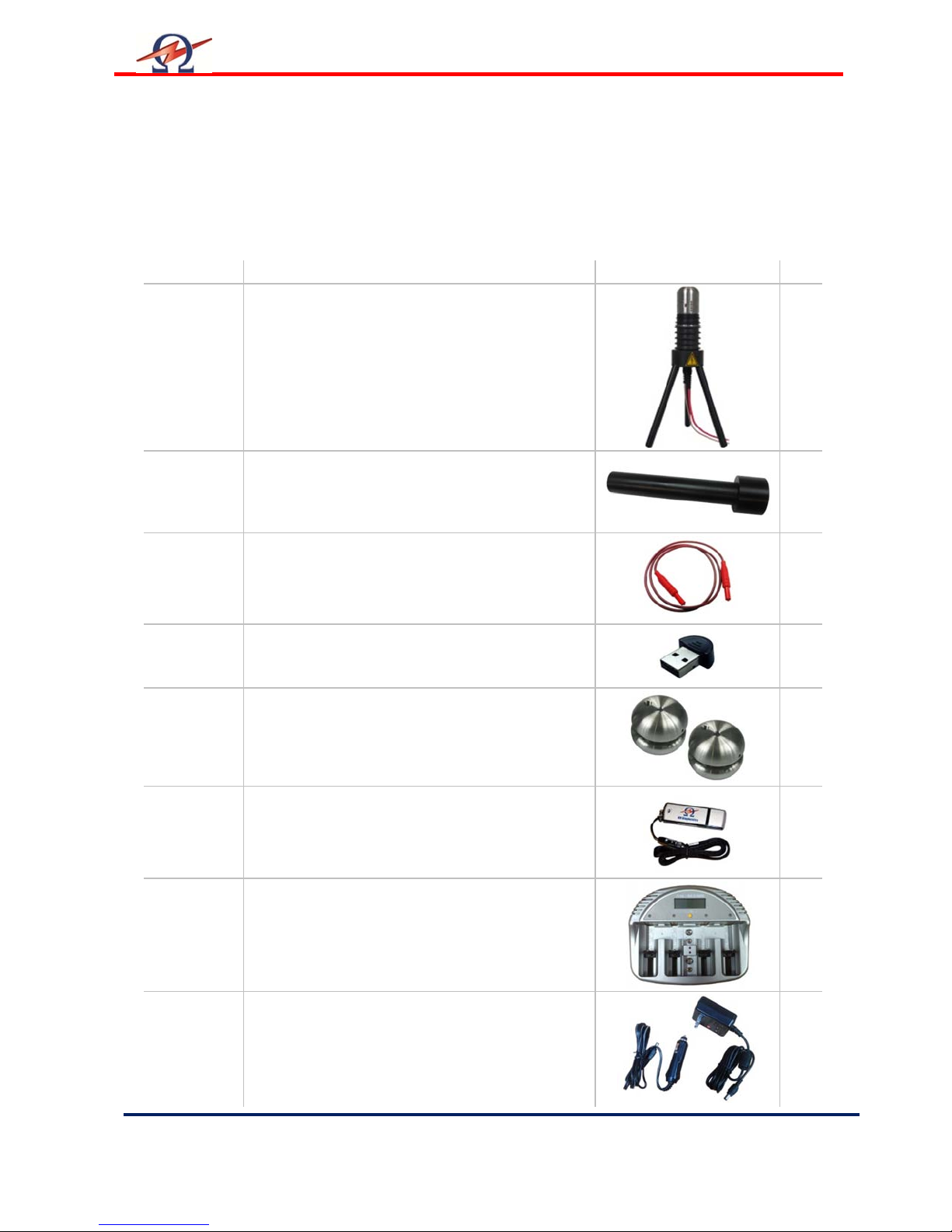

Part No. Item Description Qty

700 003 TD30 Tan-Delta System 24 kVrms

With TD stand

1

700 086 HV Protective Cap

700 062 Red Jumper Cable 36“/100cm

700 053 BlueTooth Adapter

700 050 Corona Protection Shield; 2 parts

USB Stick Flash Drive HV Diagnostics

Battery Charger

1

1

1

1

1

1

AC Power Adapter for Battery Charger*

DC Power Adapter for Battery Charger

1*

1

User Manual

Rev 1.4

Page

12 HV Diagnostics

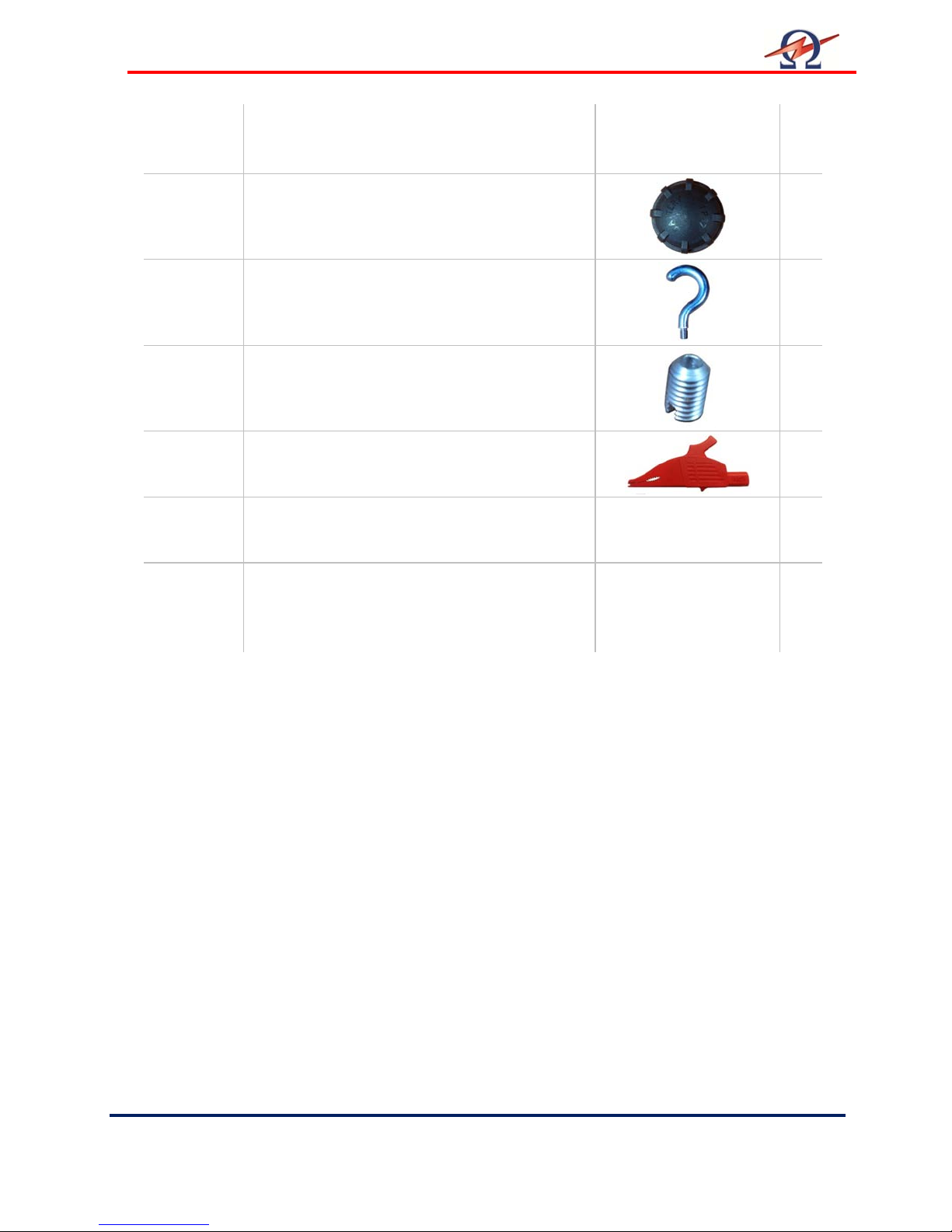

C Batteries

1.5 V

Battery Cap

Hooks

TD head inserts

Alligator Clip

TD30 Manual

4

2

1

3

1

1

TD Software: TD Control Center

(On USB Flash Drive)

1

User Manual

HV Diagnostics

Page

13 Rev 1.4

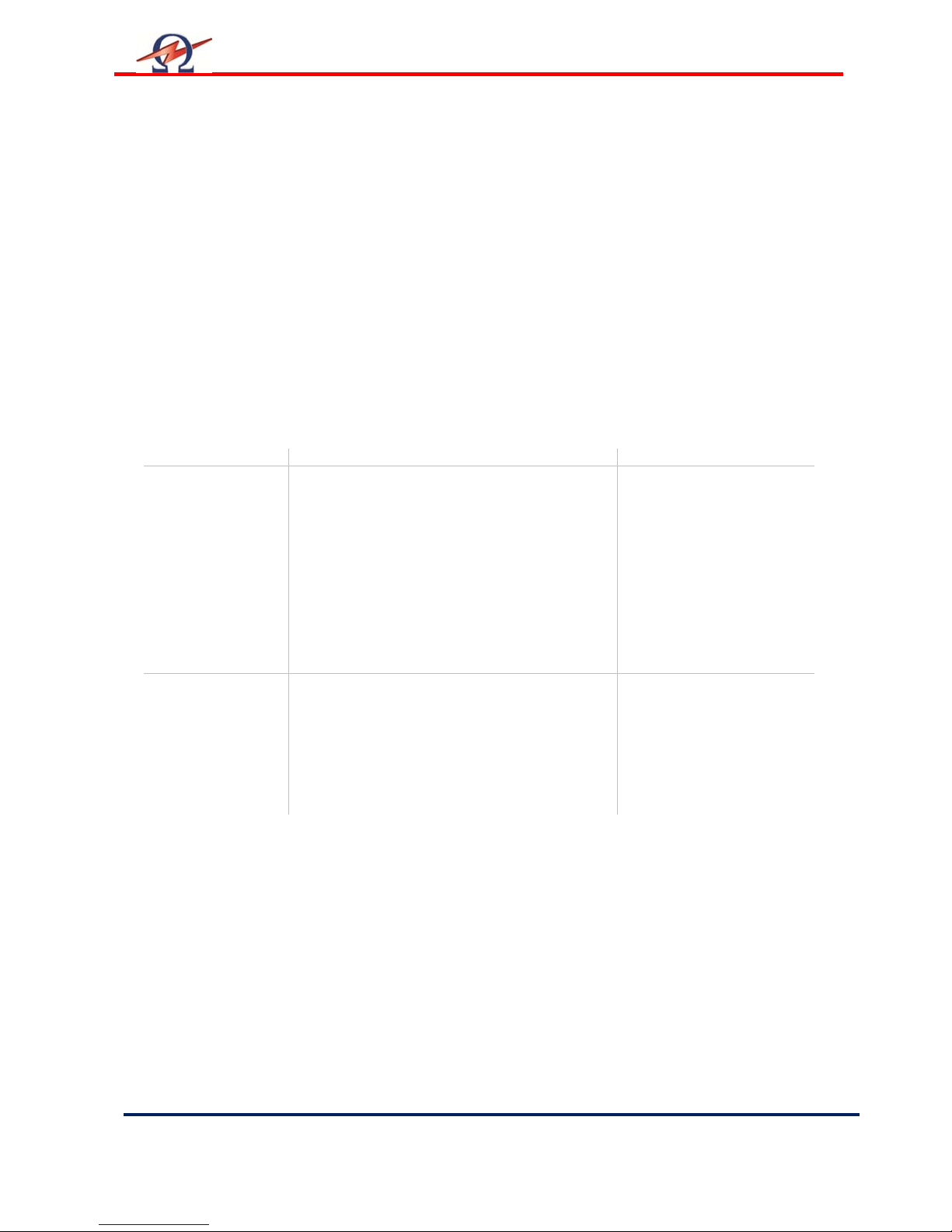

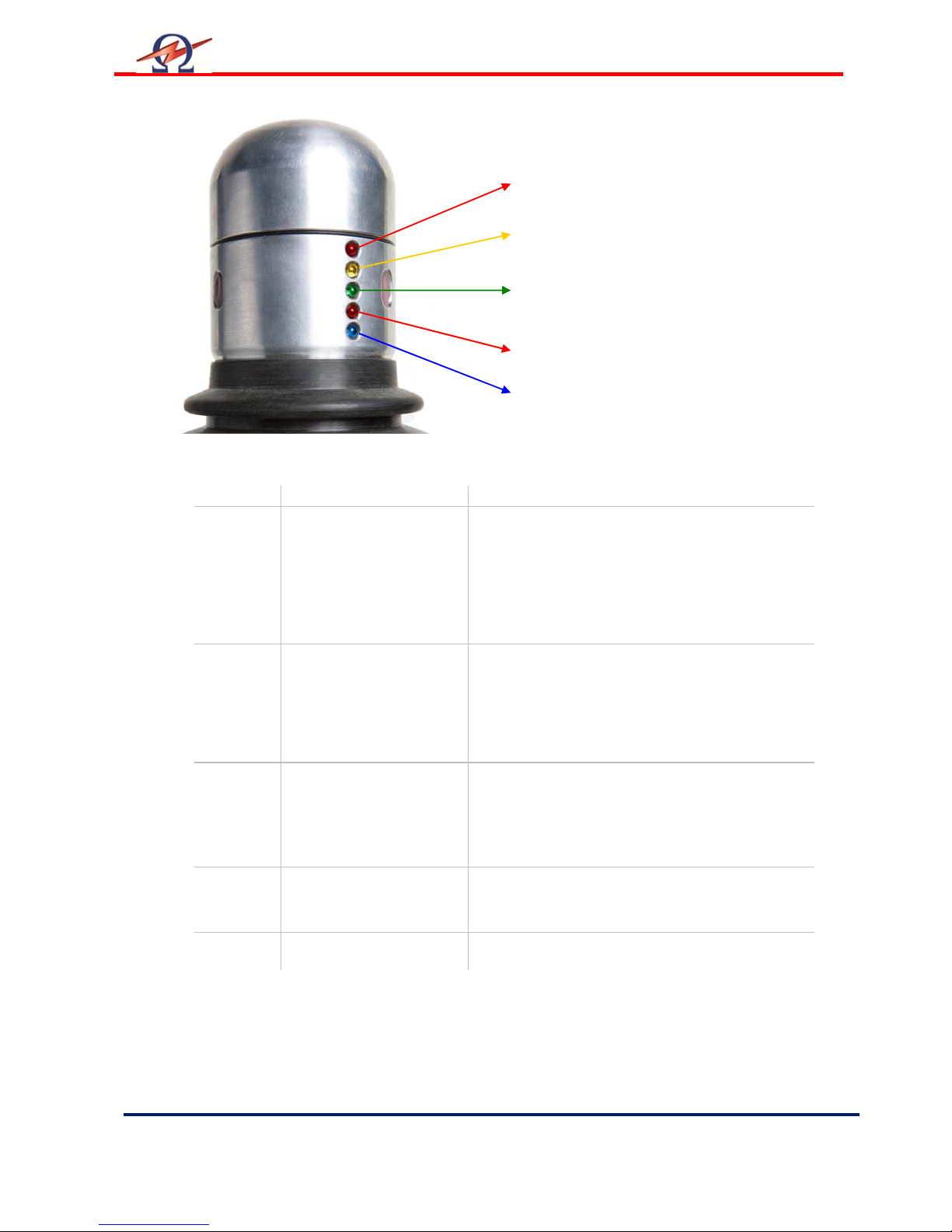

Pos. Item Descrip

tion

4

3

1

5

6

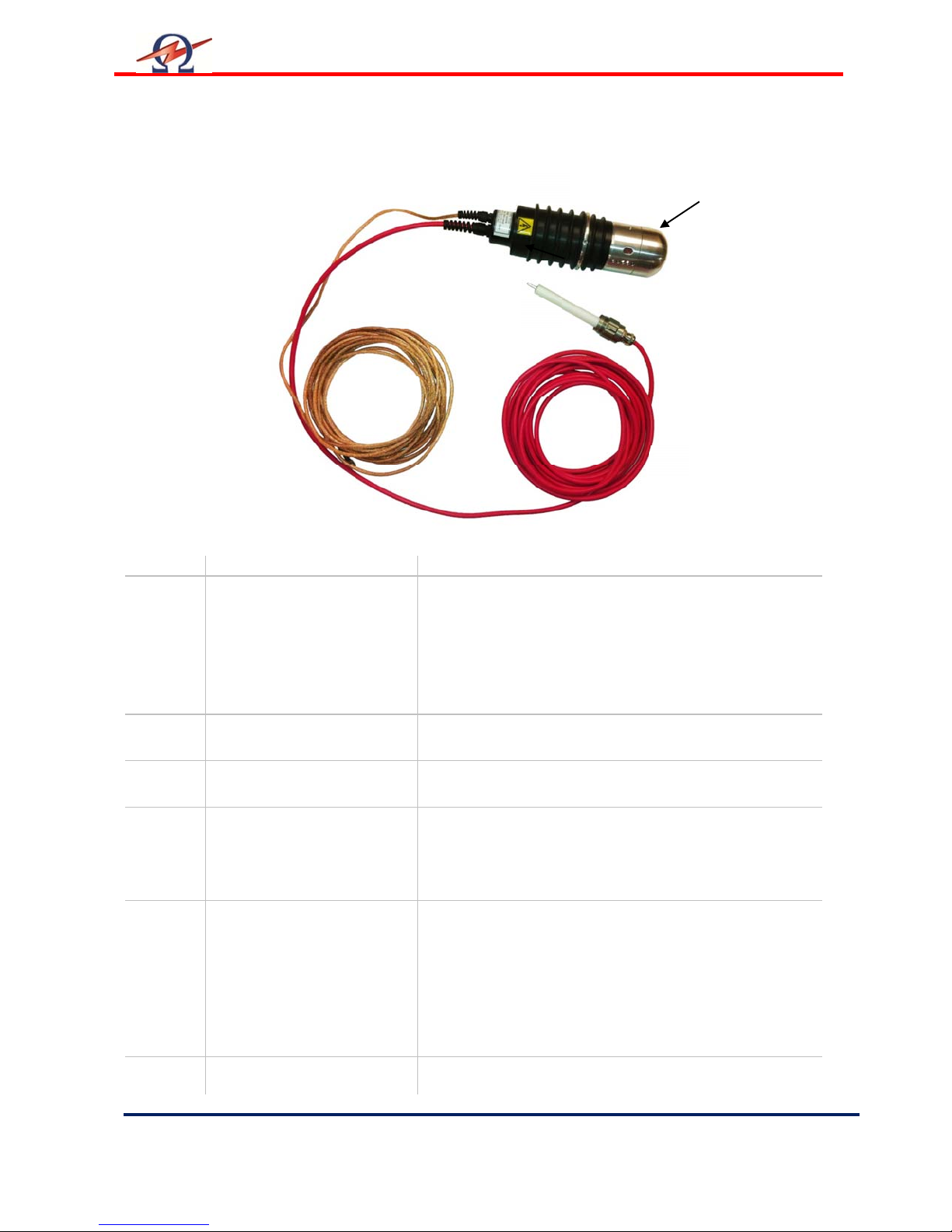

7 Hardware Description

2

1 TD System Housing The TD System housing/enclosure. Note the TD30 will

assume a potentially dangerous high potential /

voltage during testing and measurement. Always keep

the housing isolated and clear of any ground during

testing. Depending on the application, the 3-Pod

“Sputnik” Stand which is supplied can be used to

ensure proper isolation.

2 High Voltage Cable High Voltage connection cable that links the TD30 to the

HVA generator.

3 High Voltage Plug TD30 Plug directly into HVA30 HV output plug socket.

4 Ground/Earth Cable Ground connection for load / station ground.

Always connect this cable to a station ground. Do not

use this cable to “ground” the Device Under Test

without a suitable connection to a safe station / earth

ground.

5 Tan Delta Head

Tan Delta Head covers the main ON/OFF switch and

the battery housing. This head also incorporates an

8mm metric thread, which assists in providing a number

of different connection options to the DUT. Unscrew

head cap section to remove from the rest of the housing

to turn ON/OFF the system or to replace the batteries.

To re-install the head cap section, carefully screw on the

cap, taking care not to cross thread the connection.

6 LED and Bluetooth® RF 5 LEDs showing operation status information. Do not

cover this area.

User Manual

Rev 1.4

Page

14 HV Diagnostics

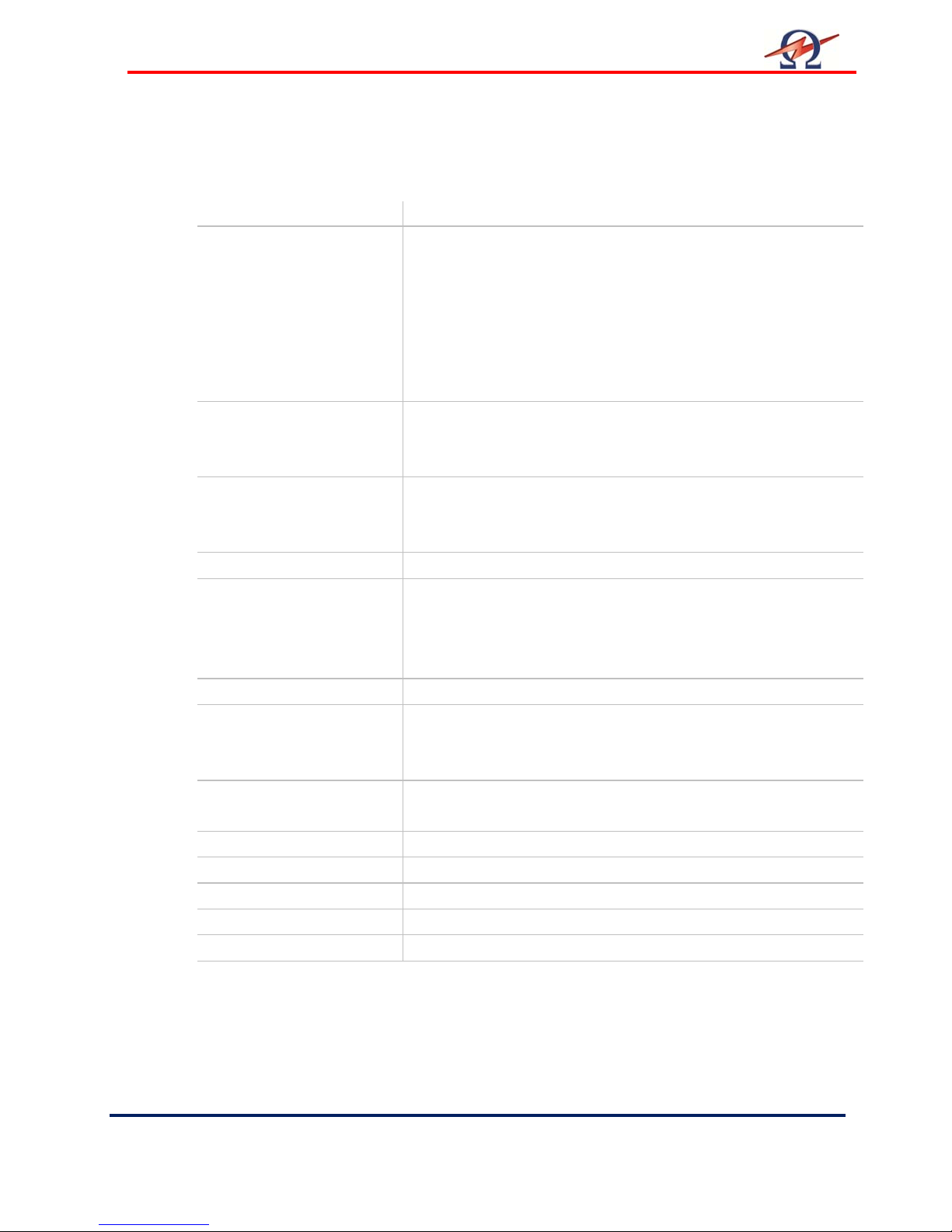

Pos. Item Description

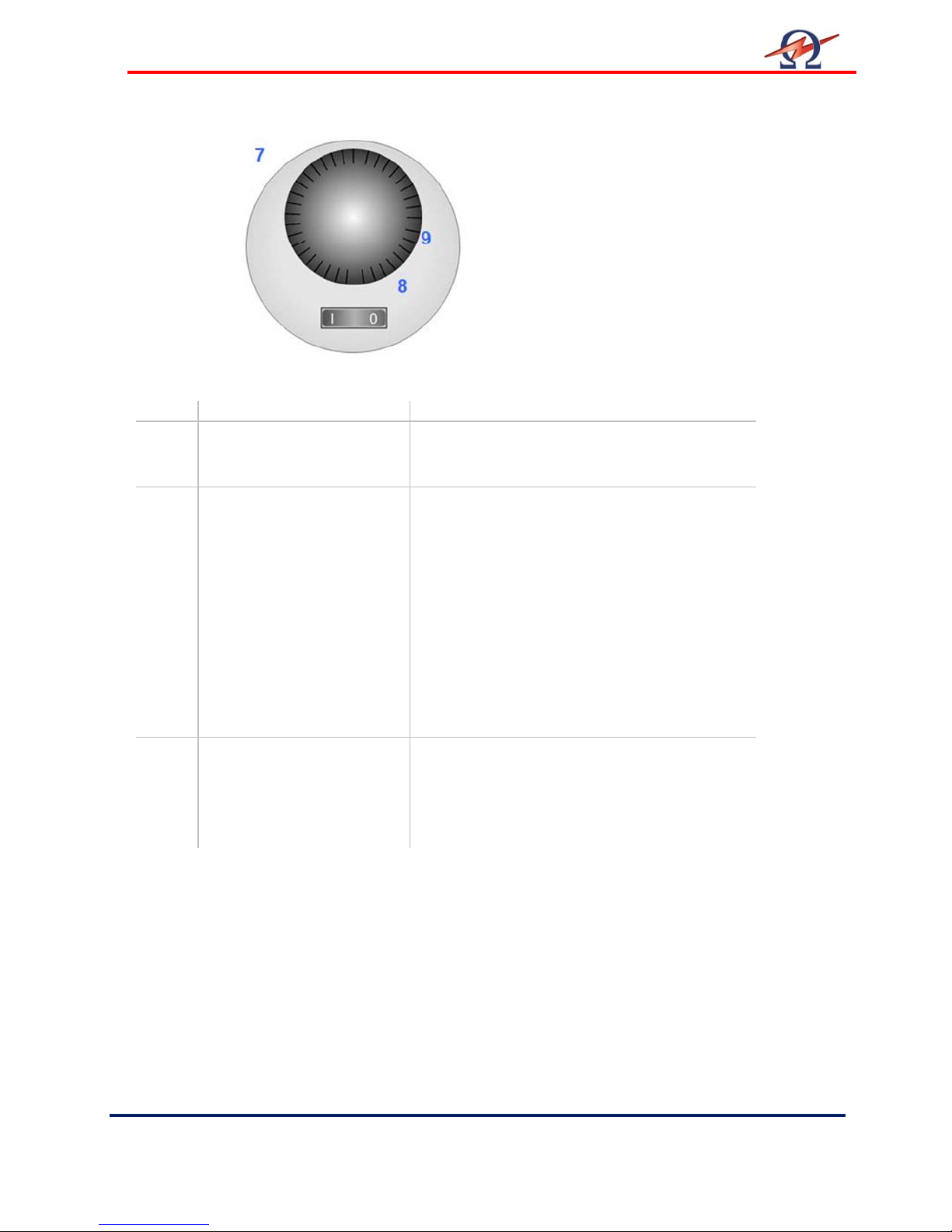

The Head of the TD30 system

with the Cap removed showing

the Battery compartment and

the ON / OFF switch.

7 TD system control By removing the Tan Delta head cap the main

switch and the battery housing can be

accessed.

8 Main Switch Switch for powering up or shutting down the TD

system. It is advisable to turn off the system to

conserve battery life if the system is not

planned to be used for an extended period of

time.

The TD system incorporates an automatic

power save sleep mode, which shuts down the

system after no voltage (<1kV) has being

sensed for 60 minutes or more. In this mode

the main switch has to be set to 0 (off) for about

2 minutes and then on again to wake up the

system manually, or you can reapply voltage

with the HVA which will also wake up the unit.

9 Battery Compartment Unscrew the cover of the battery compartment

to replace or install batteries. 2 of C-Size 1.5V

batteries are required. Insert the batteries with

the + positive upwards (towards the operator)

See Battery Cover for polarity marking if in

doubt.

User Manual

HV Diagnostics

Page

15 Rev 1.4

Pos.

Item Description

of the system.

LED 1

– High Limit TD

LED 2 – Medium Limit TD

ED 3 – Low Limit TD

L

LED 4 – Battery Low

LED 5 – TD30 Status

LED Test during Startup

After Power On and during system startup/wake mode the TD unit performs a LED test to make

sure that all of the LED signals work and performs a quick self check

LED 1 Signal High TD

(RED)

LED 2 Signal Medium TD

(YELLOW)

LED 3 Signal Low TD

(GREEN)

LED 4 Signal Battery Low

(RED)

LED 5 Signal Status (BLUE) Flashing status signal showing active operation

A flashing signal here indicates a TD level that

is higher than the HIGH TD setting. If setup

correctly, this will normally indicate a poor TD

result. Flashing will occur simultaneously with

the status LED signal. The TD HIGH limit can

be set using the TD ControlCenter PC

Software.

A flashing signal here indicates a TD level that

is lower than the HIGH limit and higher than the

LOW limit. If setup correctly, this will normally

indicate a mediocre (medium) condition. The

limits of the TD value can be set using the TD

ControlCenter PC Software.

A flashing signal here indicates a TD level that

is lower than the LOW limit. If setup correctly,

this will normally indicate a good TD result. The

limit of the TD value can be set using the TD

ControlCenter PC Software.

Battery Low signal. Permanently ON if battery

voltage drops below critical limit. In battery

condition is OK then this light will not be ON.

Loading...

Loading...