HVAC Partners 801S, 80DSS, 801P, 80DSP Installation Instructions Manual

ISO 9001:2008

INSTALLATION INSTRUCTIONS

FOR DOWNFLOW SINGLE STAGE GAS FURNACES

(-)801S DOWNFLOW SERIES

(-)801P DOWNFLOW SERIES

(-)(-)80DSS DOWNFLOW SERIES

(-)(-)80DSP DOWNFLOW SERIES

U.L. and/or C.S.A. recognized fuel gas and CO (carbon monoxide) detectors are recommended in all applications, and their installation should be in accordance with the

manufacturer’s recommendations and/or local laws, rules, regulations, or customs.

Factory Use Only

92-24161-143-01

SUPERSEDES 92-24161-143-00

TABLE OF CONTENTS

1 TABLE OF CONTENTS. . . . . . . . . . . . . . . . . . . . . . . 2

2 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . 3

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Contents

California Proposition 65 Note . . . . . . . . . . . . . . . . . . 4

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 SAFETY INFORMATION. . . . . . . . . . . . . . . . . . . . . . 6

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Important Information About Efficiency and Quality. . 7

4 LOCATION REQUIREMENTS . . . . . . . . . . . . . . . . . 8

Site Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Clearance – Accessibility . . . . . . . . . . . . . . . . . . . . . . 8

Upflow Dimensions & Clearance Table . . . . . . . . . . . 9

5 DUCTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Downflow Installations . . . . . . . . . . . . . . . . . . . . . . . 10

6 COMBUSTION AND VENTILATION AIR . . . . . . . . 12

Combustion Air Requirements . . . . . . . . . . . . . . . . . 12

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

“B-1” Vertical Venting . . . . . . . . . . . . . . . . . . . . . . . . 16

Special Vent Systems (SVS) . . . . . . . . . . . . . . . . . . 17

Power Vent Systems . . . . . . . . . . . . . . . . . . . . . . . . 18

Existing Vent Systems . . . . . . . . . . . . . . . . . . . . . . . 18

7 GAS SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Gas Supply and Piping. . . . . . . . . . . . . . . . . . . . . . . 19

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . 22

9 ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . 23

Reversing the Electrical Connection . . . . . . . . . . . . 23

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 LP CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Field Installed Option Accessories. . . . . . . . . . . . . . 26

Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-Inch Flue Adapter . . . . . . . . . . . . . . . . . . . . . . . . . 26

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

RXGW-B01 Chimney Adapter . . . . . . . . . . . . . . . . . 26

11 TWINNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Furnace Twinning Installations. . . . . . . . . . . . . . . . . 27

Control Boards . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29

12 HIGH ALTITUDE . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Natural Gas at High Altitudes . . . . . . . . . . . . . . . . . . 30

LP Gas at High Altitudes. . . . . . . . . . . . . . . . . . . . . . 32

13 STARTUP PROCEDURES . . . . . . . . . . . . . . . . . . . 33

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . 33

14 DIAGNOSTICS & FAULT CODES . . . . . . . . . . . . . 34

15 LOCKOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

16 FIELD SELECTIONS & ADJUSTMENTS . . . . . . . 36

Field Selections – Dipswitches. . . . . . . . . . . . . . . . . 36

17 FAULT CLEAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

18 FAULT RECALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

19 FLAME STATUS L.E.D.. . . . . . . . . . . . . . . . . . . . . . 37

20 TIMING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . 37

21 ADJUSTING OR CHECKING FURNACE INPUT . 38

22 SETTING INPUT RATE . . . . . . . . . . . . . . . . . . . . . . 39

23 AIRFLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Blower Speed Selection . . . . . . . . . . . . . . . . . . . . . . 41

24 SAFETY FEATURES. . . . . . . . . . . . . . . . . . . . . . . . 42

25 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Gas Furnace (Direct Drive) Instructions. . . . . . . . . . 43

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

26 SYSTEM OPERATION INFORMATION . . . . . . . . . 44

27 ANNUAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . 45

28 REPLACEMENT PARTS. . . . . . . . . . . . . . . . . . . . . 45

24 DIAGNOSTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

30 WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . 47

IMPORTANT: TO INSURE PROPER INSTALLATION AND OPERATION OF THIS PRODUCT, COMPLETELY READ ALL INSTRUCTIONS PRIOR TO ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE, MAINTAIN OR REPAIR THIS PRODUCT. UPON UNPACKING

OF THE FURNACE, INSPECT ALL PARTS FOR DAMAGE PRIOR TO INSTALLATION AND START-UP.

2

GENERAL INFORMATION

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

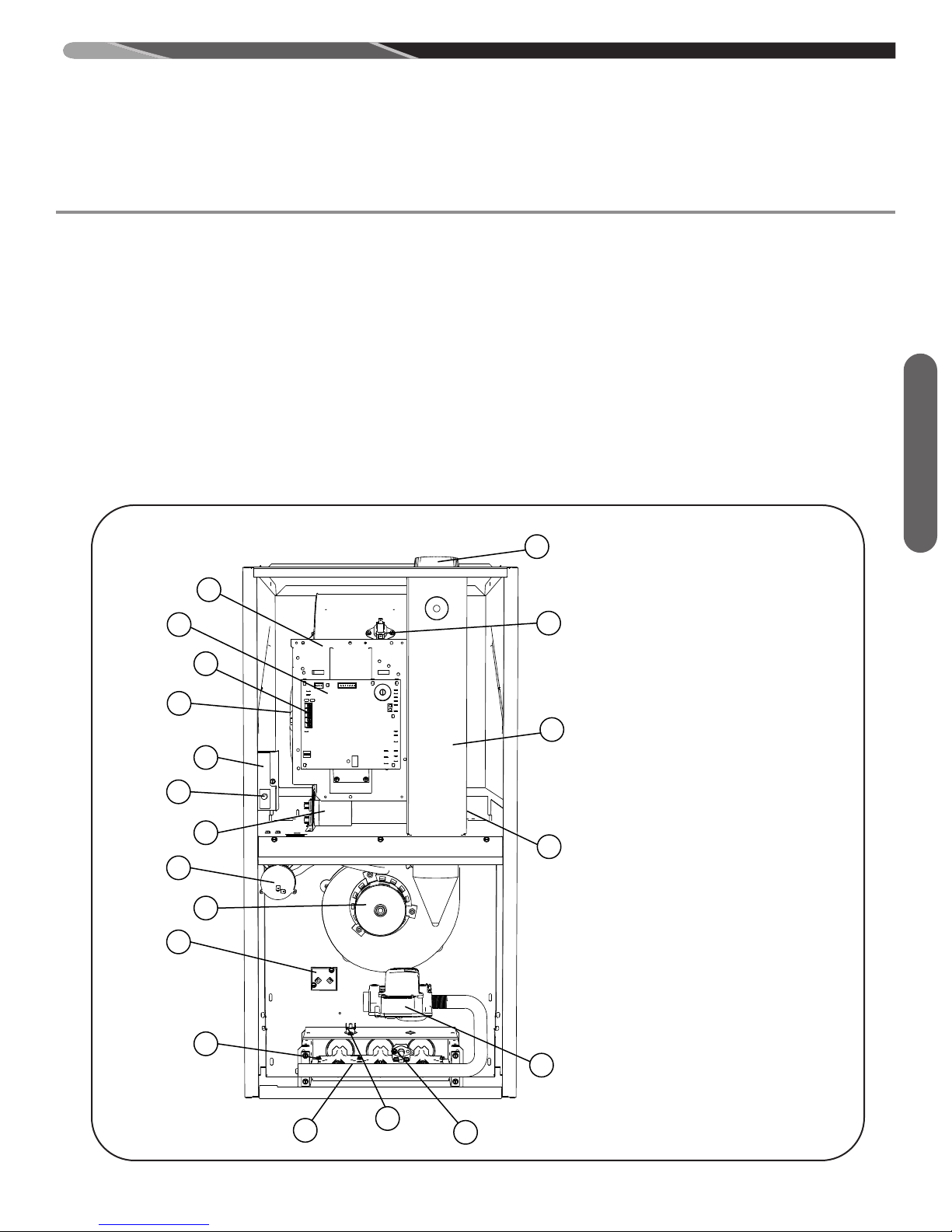

JUNCTION BOX

DOOR SWITCH

CAPACITOR

MAIN PRESSURE SWITCH

INDUCED DRAFT BLOWER (IDB)

MAIN LIMIT

BURNER

FLAME SENSOR

OVER T EMPERATURE SWI TCH

IGNITOR GAS VALVE

GAS VALVE

TRANSFORMER

FLUE PIPE ENCLOSURE

HEAT ASSISTED LIMIT CONTROL (HALC)

FLUE CONNECTION

CONTROL MOUNTING PLATE

FURNACE CONTROL

LOW V OLTAGE TERMINAL

BLOWER

16

17

18

19

1

2

3

4

5

6

7

8

11

9

10

12

13

14

15

ST-A1220-13-X0

NOTE: A heat loss calculation should be performed to properly

determine the required furnace BTU size for the structure. Also,

the duct must be properly designed and installed for proper airflow. Existing ductwork must be inspected for proper size and to

make sure that it is properly sealed. Proper airflow is necessary

for both user comfort and equipment performance.

Before opening the furnace carton, verify that the data tags on

the carton specify the furnace model number that was ordered

from the distributor and are correct for the installation. If not,

return the unit without opening the carton. If the model number

is correct, open the carton and verify that the furnace rating

label specifies the same furnace model number that is specified on the carton label. If the model numbers do not match, return the furnace to the distributor.

IMPORTANT: Proper application, installation and maintenance of

this furnace and system is a must if consumers are to receive the full

benefits for which they have paid.

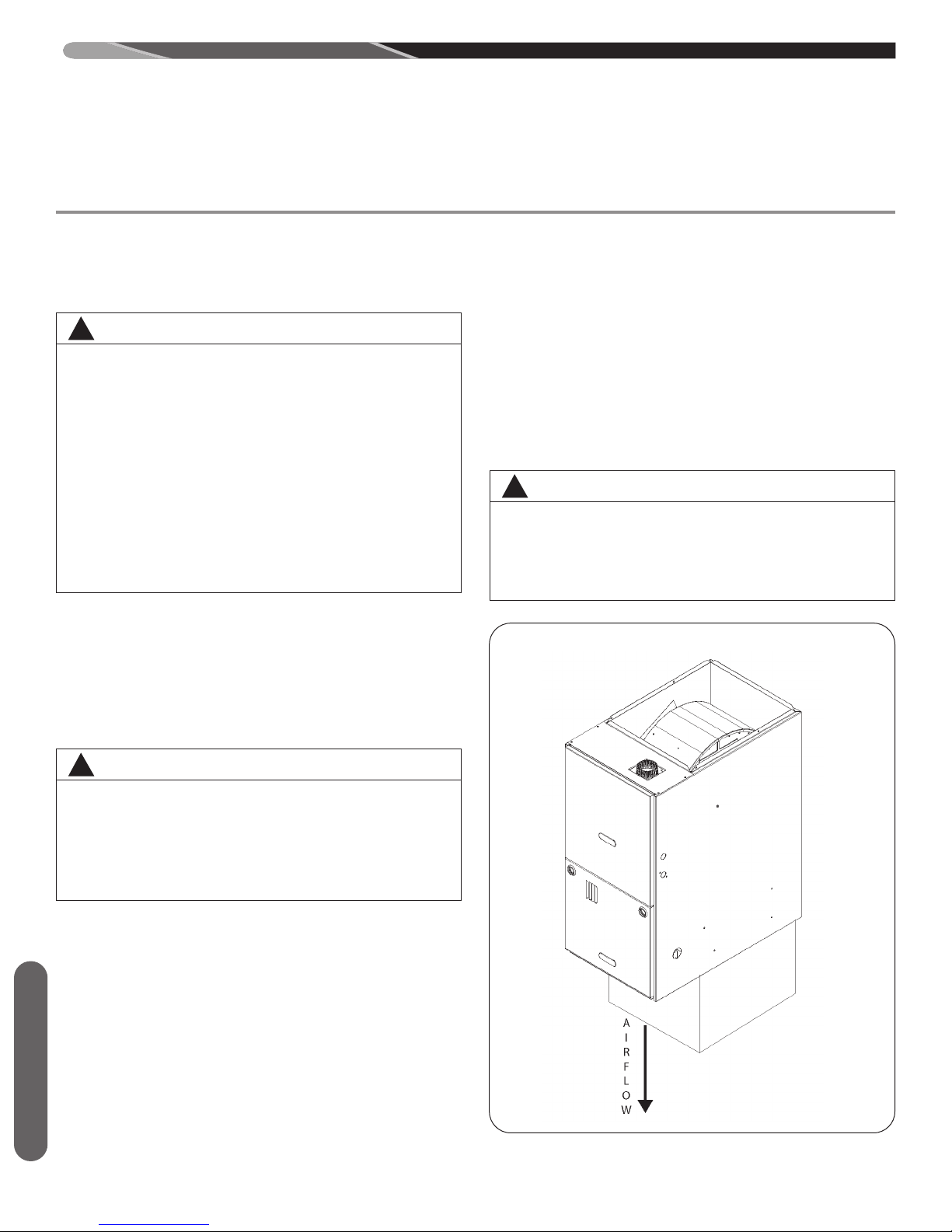

FIGURE 1

FURNACE COMPONENTS

The (-)801S/(-)801P series furnaces are design certified by CSA

for use with natural and propane gases as follows:

As a Category I furnace, it may be vented vertically with type B1 vent pipe and also may be common vented as described in

these instructions.

This furnace should be installed in accordance with the American

National Standard Z223.1 - latest edition booklet entitled “National

Fuel Gas Code” (NFPA 54), and the requirements or codes of the

local utility or other authority having jurisdiction including local

plumbing or waste water codes.

With the introduction of higher efficiency furnaces, special attention

must be paid to the venting system. Only listed venting systems

may be used as stated in the installation instructions and the Na-

tional Fuel Gas Code, ANSI Z223.1 (NFPA 54),. Since furnace

technology and venting requirements are changing, awareness of

local, state, and federal codes and industry changes is imperative.

General Information

ST-A1220-13-X0

3

GENERAL INFORMATION (cont.)

Install this furnace in accordance with the American National Standard Z223.1 – latest edition entitled “National Fuel Gas Code”

NFPA54) and requirements or codes of the local utilities or other

(

authorities having jurisdiction. This is available from the following:

National Fire Protection Association, Inc.

Batterymarch Park

General Information

Quincy, MA 02269

RECEIVING

Immediately upon receipt, all cartons and contents should be inspected for transit damage. Units with damaged cartons should

be opened immediately. If damage is found, it should be noted on

the delivery papers, and a damage claim filed with the last carrier.

• After unit has been delivered to job site, remove carton taking

care not to damage unit.

• Check the unit rating plate for unit size, electric heat, coil, voltage, phase, etc. to be sure equipment matches what is required for the job specification.

• Read the entire instructions before starting the installation.

• Some building codes require extra cabinet insulation and gasketing when unit is installed in attic applications.

• If installed in an unconditioned space, apply caulking around

the power wires, control wires, refrigerant tubing and condensate line where they enter the cabinet. Seal the power wires on

the inside where they exit conduit opening. Caulking is required to prevent air leakage into and condensate from forming

inside the unit, control box, and on electrical controls.

• Install the unit in such a way as to allow necessary access to

the coil/filter rack and blower/control compartment.

• Install the unit in accordance with any local code which may

apply and the national codes. Latest editions are available

from: “National Fire Protection Association, Inc., Batterymarch

Park, Quincy, MA 02269.” These publications are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning

systems.

• The equipment has been evaluated in accordance with the

Code of Federal Regulations, Chapter XX, Part 3280.

CALIFORNIA RESIDENTS ONLY

IMPORTANT: All manufacturer products meet current Federal

OSHA Guidelines for safety. California Proposition 65 warnings

are required for certain products, which are not covered by the

OSHA standards.

California's Proposition 65 requires warnings for products sold in

California that contain, or produce, any of over 600 listed chemicals known to the State of California to cause cancer or birth defects such as fiberglass insulation, lead in brass, and combustion

products from natural gas.

All “new equipment” shipped for sale in California will have labels

stating that the product contains and/or produces Proposition 65

chemicals. Although we have not changed our processes, having

the same label on all our products facilitates manufacturing and

shipping. We cannot always know “when, or if” products will be

sold in the California market.

You may receive inquiries from customers about chemicals found

in, or produced by, some of our heating and air-conditioning equipment, or found in natural gas used with some of our products.

Listed below are those chemicals and substances commonly associated with similar equipment in our industry and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO)

• Formaldehyde

• Benzene

More details are available at the Websites for OSHA (Occupational Safety and Health Administration), at www.osha.gov

State of California's OEHHA (Office of Environmental Health Hazard Assessment), at www.oehha.org.

portant since the chemicals and substances on the list are found

in our daily lives. Most consumers are aware that products present safety and health risks, when improperly used, handled and

maintained.

Consumer education is im-

and the

4

Installation Instructions remain with the furnace as a reference guide to the servicing contractor. We recommend

that performance and installation data be recorded for future reference on this sheet to meet service and warranty

bligations so that job site information is available when required.

o

Installation Checklist

REFER TO INSTALLATION INSTRUCTIONS

GAS SUPPLY

______ Correct pipe size (record size)

______ Correct supply pressure (during furnace operation) (record pressure)

______ Manifold pressure (record upstream pressure)

______ No gas leaks

______ L.P. Kit Number (if applicable) (record kit number)

ELECTRICAL

______ 115 V.A.C. supply (Dedicated Circuit) (record voltage)

______ Polarity observed

______ Furnace properly grounded

Checklist

______ Correct wire size (record type and gauge)

FURNACE INSTALLATION

______ Correct clearance to combustibles (record clearance)

______ Correct clearance for service (at front) (record clearance)

DUCT STATIC PRESSURE

______ in. w.c. on heating speed (record static pressure)

______ in. w.c. on cooling speed (record static pressure)

______ Air temperature rise in heat (record air temperature rise)

______ Air temperature rise in cool (record air temperature rise)

VENTING

______ Correct vent pipe diameter and length (according to NFGC tables) _________________ Vent connection size

______ Correct venting material (according to NFGC tables)

______ Correct lining for masonry chimneys

______ Adequate clearance from combustibles

______ Proper negative pressure reading in the vent

______ Vent pipe secured to induced draft blower housing

COMBUSTION AIR

______ Proper source of combustion air

______ Correct combustion air opening size

______ Optional attic combustion air pull

______ Non-attic combustion air pull

5

SAFETY INFORMATION

WARNING

!

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME!!

THIS FURNACE IS NOT APPROVED FOR INSTALLATION

IN A MOBILE HOME. DOING SO COULD CAUSE FIRE,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

INSTALL THIS FURNACE ONLY IN A LOCATION AND POSITION AS SPECIFIED IN THE LOCATION REQUIREMENTS AND CONSIDERATIONS SECTION OF THESE

INSTRUCTIONS.

WARNING

!

IMPROPER INSTALLATION CAN RESULT IN UNSATISFACTORY OPERATION AND/OR DANGEROUS CONDITIONS

AND ARE NOT COVERED BY THE MANUFACTURER’S

WARRANTY.

WARNING

!

DO NOT BYPASS, JUMPER, OR REMOVE ANY SAFETY

SWITCH FROM THE FURNACE CONTROL CIRCUIT. IF A

SAFETY SWITCH CAUSES THE FURNACE TO SHUT

DOWN OR OPERATE INTERMITTENTLY, IT IS AN INDICATION OF A POTENTIAL SAFETY HAZARD THAT MUST BE

ADDRESSED BY A QUALIFIED TECHNICIAN, SERVICE

AGENCY OR THE GAS SUPPLIER. DO NOT RESET

SAFETY CONTROLS WITHOUT CORRECTIVE ACTION

Safety Information

AND/OR VERIFICATION OF PROPER SAFE OPERATION

BY A QUALIFIED INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER.

REPLACE ANY SAFETY CONTROL COMPONENT ONLY

WITH IDENTICAL OEM REPLACEMENT PARTS. WHEN A

NEW SAFETY SWITCH IS INSTALLED, IT MUST BE

TESTED FOR A MINIMUM OF 15 MINUTES WITH THE

FURNACE OPERATING AT MAXIMUM INPUT RATE AND

WITH BOTH BLOWER AND BURNER DOOR INSTALLED.

IF THE FURNACE IS INSTALLED IN A CLOSET, THE

CLOSET DOOR MUST ALSO BE CLOSED FOR THIS

TEST. REPEAT THE TEST AT THE MINIMUM INPUT RATE

IF THE FURNACE IS A MULTI-STAGE FURNACE.

WARNING

!

USE ONLY WITH THE TYPE OF GAS APPROVED FOR THIS

FURNACE. REFER TO THE FURNACE RATING PLATE.

WARNING

!

COMBUSTION AND VENTILATION AIR MUST BE PROVIDED TO THE FURNACE AS REQUIRED BY THE NATIONAL FUEL-GAS CODE (U.S.) AND THE COMBUSTION

AND VENTILATION AIR SECTION OF THESE INSTRUCTIONS.

W

AR

N

IN

N

N

N

M O

N S

PR

E

C

NLY, AS

ECTIO

O

G

T

D

U

TH

C

I

TS

S

SP

N O

FU

MU

F

S

R

N

E

CIFIE

THE

T

A

B

C

E

S

E INS

E

D

T

O

D IN

I

S

C

H

A

A

N

A

P

THE

V

TRUCTIO

R

G

E

PR

OV

ENT P

NS

D

O

U

T

E

D

IPE

.

!

C

O

MB

U

STI

D

O

O

VE

NT S

INST

!

WHEN A FURNACE IS INSTALLED SO THAT SUPPLY

DUCTS CARRY AIR CIRCULATED BY THE FURNACE TO

AREAS OUTSIDE THE SPACE CONTAINING THE FURNACE,

THE RETURN AIR SHALL ALSO BE HANDLED BY DUCT(S)

SEALED TO THE FURNACE CASING AND TERMINATING

OUTSIDE THE SPACE CONTAINING THE FURNACE.

!

DO NOT OPERATE THE SYSTEM WITHOUT FILTERS. A

PORTION OF THE DUST ENTRAINED IN THE AIR MAY

TEMPORARILY LODGE IN THE AIR DUCT RUNS AND AT

THE SUPPLY REGISTERS. ANY CIRCULATED DUST PARTICLES WILL BE HEATED AND CHARRED BY CONTACT

WITH THE FURNACE HEAT EXCHANGER. THIS SOOTY

RESIDUE WILL SOIL CEILINGS, WALLS, DRAPES, CARPETS AND OTHER HOUSEHOLD ARTICLES. SOOT DAMAGE MAY ALSO RESULT WITH, OR WITHOUT, FILTERS IN

PLACE, WHEN CERTAIN TYPES OF CANDLES ARE

BURNED, OR CANDLEWICKS ARE LEFT UNTRIMMED.

!

IN COMPLIANCE WITH RECOGNIZED CODES, IT IS RECOMMENDED THAT AN AUXILIARY DRAIN PAN BE INSTALLED UNDER THIS FURNACE AND ANY INSTALLED

EVAPORATOR COIL THAT IS LOCATED IN ANY AREA OF

A STRUCTURE WHERE DAMAGE TO THE BUILDING OR

BUILDING CONTENTS MAY OCCUR AS A RESULT OF AN

OVERFLOW OF THE A/C COIL DRAIN PAN.

O

R

S

.

C

O

YSTE

ALLA

TIO

WARNING

WARNING

WARNING

-

WARNING

!

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

USE A COMMERCIALLY AVAILABLE SOAP SOLUTION

MADE SPECIFICALLY FOR THE DETECTION OF LEAKS

TO CHECK ALL CONNECTIONS, AS SPECIFIED IN GAS

SUPPLY AND PIPING SECTION OF THESE INSTRUCTIONS.

6

SAFETY

WARNING

!

BLOWER AND BURNERS MUST NEVER BE OPERATED

WITHOUT THE BLOWER DOOR IN PLACE. THIS IS TO PREVENT DRAWING GAS FUMES (WHICH COULD CONTAIN

HAZARDOUS CARBON MONOXIDE) INTO THE HOME THAT

COULD RESULT IN PERSONAL INJURY OR DEATH.

WARNING

!

ALWAYS INSTALL THE FURNACE TO OPERATE WITHIN

THE FURNACE’S INTENDED TEMPERATURE-RISE

RANGE WITH A DUCT SYSTEM WHICH HAS AN EXTERNAL STATIC PRESSURE WITHIN THE ALLOWABLE

RANGE, AS SPECIFIED IN THE DUCTING SECTION OF

THESE INSTRUCTIONS. SEE ALSO FURNACE RATING

PLATE.

THE FURNACE MAY BE USED FOR HEATING OF BUILDINGS OR STRUCTURES UNDER CONSTRUCTION.

INSTALLATION MUST COMPLY WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

PROPER VENT INSTALLATION;

-

FURNACE OPERATING UNDER THERMOSTATCONTROL;

RETURN AIR DUCT SEALED TO THE FURNACE;

-

AIR FILTERS IN PLACE;SET FURNACE INPUT RATE AND TEMPERATURERISE PER RATING PLATE MARKINGS;

MEANS FOR PROVIDING OUTDOOR AIR RE-

-

QUIRED FOR COMBUSTION;

RETURN AIR TEMPERATURE MAINTAINED BE-

-

TWEEN 55°F (13°C) AND 80°F (27°C); AND

CLEAN FURNACE, DUCT WORK AND COMPO-

-

NENTS UPON SUBSTANTIAL COMPLETION OF

THE CONSTRUCTION PROCESS, AND VERIFY

THAT THE FURNACE OPERATING CONDITIONS

INCLUDING IGNITION, INPUT RATE, TEMPERATURE RISE AND VENTING, ACCORDING TO THE

INSTRUCTIONS AND CODES.

WARNING

!

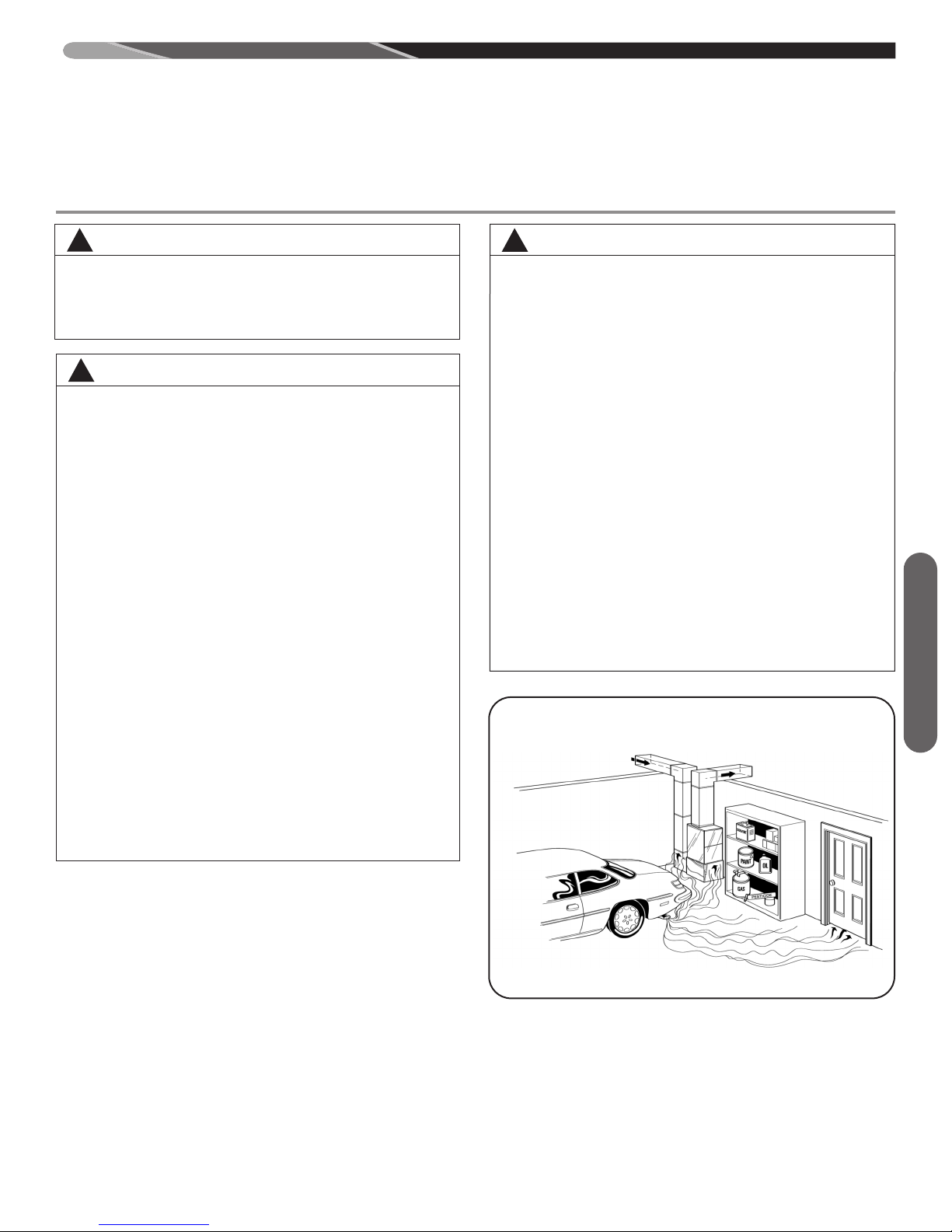

DUCT LEAKS CAN CREATE AN UNBALANCED SYSTEM

AND DRAW POLLUTANTS SUCH AS DIRT, DUST, FUMES

AND ODORS INTO THE HOME CAUSING PROPERTY

AMAGE. FUMES AND ODORS FROM TOXIC, VOLATILE

D

OR FLAMMABLE CHEMICALS, AS WELL AS AUTOMOBILE EXHAUST AND CARBON MONOXIDE (CO), CAN BE

DRAWN INTO THE LIVING SPACE THROUGH LEAKING

DUCTS AND UNBALANCED DUCT SYSTEMS CAUSING

PERSONAL INJURY OR DEATH (SEE FIGURE 2).

• IF AIR-MOVING EQUIPMENT OR DUCTWORK IS LOCATED IN GARAGES OR OFF-GARAGE STORAGE

AREAS - ALL JOINTS, SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST BE SEALED TO LIMIT

THE MIGRATION OF TOXIC FUMES AND ODORS INCLUDING CARBON MONOXIDE FROM MIGRATING

INTO THE LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR DUCTWORK IS LOCATED IN SPACES CONTAINING FUEL BURNING APPLIANCES SUCH AS WATER HEATERS OR BOILERS ALL JOINTS, SEAMS, AND OPENINGS IN THE EQUIPMENT AND DUCT MUST ALSO BE SEALED TO PREVENT DEPRESSURIZATION OF THE SPACE AND

POSSIBLE MIGRATION OF COMBUSTION BYPRODUCTS INCLUDING CARBON MONOXIDE INTO THE LIVING SPACE.

FIGURE 2

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO

LIVING SPACES

Safety Information

IMPORTANT INFORMATION ABOUT

EFFICIENCY AND INDOOR AIR

QUALITY

Central cooling and heating equipment is only as efficient as the

duct system that carries the cooled or heated air. To maintain efficiency, comfort and good indoor air quality, it is important to have

the proper balance between the air being supplied to each room

and the air returning to the cooling and heating equipment.

Proper balance and sealing of the duct system improves the efficiency of the heating and air conditioning system and improves

the indoor air quality of the home by reducing the amount of airborne pollutants that enter homes from spaces where the ductwork and / or equipment is located. The manufacturer and the

U.S. Environmental Protection Agency’s Energy Star Program

recommend that central duct systems be checked by a qualified

contractor for proper balance and sealing.

Adapted from Residential Duct Diagnostics and Repair, with permission of Air Conditioning

Contractors of America (ACCA).

7

LOCATION REQUIREMENTS

GENERAL INFORMATION

WARNING

!

WHEN THIS FURNACE IS INSTALLED IN A RESIDENTIAL

GARAGE, IT MUST BE INSTALLED SO THE BURNERS

AND IGNITION SOURCE ARE LOCATED NO LESS THAN

18 INCHES [450MM] ABOVE THE FLOOR. THIS IS TO PREVENT THE RISK OF IGNITING FLAMMABLE VAPORS

WHICH MAY BE PRESENT IN A GARAGE. ALSO, THE FURNACE MUST BE LOCATED OR PROTECTED TO AVOID

PHYSICAL DAMAGE BY VEHICLES. FAILURE TO FOLLOW

THESE WARNINGS CAN CAUSE A FIRE OR EXPLOSION,

RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

1. IMPORTANT: If using a cooling evaporator coil with this fur-

nace, be sure the air passes over the heat exchanger before

passing over the cooling coil. The cooled air passing over the

warm ambient air inside the heat exchanger tubes can cause

condensation inside the tubes resulting in corrosion and eventual failure. An auxiliary drain pan should extend under any

evaporator coil installed with the furnace.

If there are manual dampers, they must be equipped to prevent

heating or cooling operation unless the damper is in the full heat

or cool position.

2. NOTE: This furnace is shipped with heat exchanger support

brackets installed under the back of the heat exchanger. These

may be removed before installation, but it is not required.

3. IMPORTANT: This furnace is not approved or recommended

for installation on its back, with access doors facing upwards.

4. This furnace is suitable for installation in buildings constructed

on-site. This heating unit should be centralized with respect to

the heat distribution system as much as practicable.

5. NOTE: These furnaces are approved for installation in attics,

as well as alcoves, utility rooms, closets and crawlspaces.

6. IMPORTANT: Support this unit when installed. Unit may be rein-

stalled on combustible wood floorin if using a supply air plenum.

If not using supply air plenum, a combustible floor base is required. See ducting section of this manual.

7. IMPORTANT: If installing in a utility room, be sure the door is

wide enough to:

Location

a. allow the largest part of the furnace to pass; or

b. allow any other appliance (such as a water heater) to pass.

WARNING

!

THIS FURNACE IS NOT APPROVED OR RECOMMENDED

FOR INSTALLATION ON ITS BACK, WITH ACCESS DOORS

FACING UPWARDS.

SITE SELECTION

1. Select a site in the building near the center of the proposed, or existing, duct system.

2. Give consideration to the vent system piping when selecting the furnace location. Be sure the venting system

can get from the furnace to the termination with minimal

length and elbows.

3. Locate the furnace near the existing gas piping. Or, if

running a new gas line, locate the furnace to minimize

the length and elbows in the gas piping.

4. Locate the furnace to maintain proper clearance to

combustibles as shown in following Figure 3.

WARNING

!

DO NOT LIFT THE UNIT BY THE HEAT EXCHANGER

TUBES. DOING SO CAN DAMAGE THE HEAT EXCHANGER ASSEMBLY.

CLEARANCE – ACCESSIBILITY

The design of forced air furnaces with input ratings as

listed in the tables under Figure 3 are clearances to combustible materials shown in inches.

See name/rating plate and clearance label for specific

model number and clearance information.

Service clearance of at least 24 inches (30 cm) is recommended in front of all furnaces.

NOTE: Use recommended 24” (30 cm) clearance if accessibility clearances are greater than fire protection clearances.

ACCESSIBILITY CLEARANCES, WHERE GREATER, MUST

TAKE PRECEDENCE OVER FIRE PROTECTION CLEARANCES.

WARNING

!

COMBUSTIBLE MATERIAL MUST NOT BE PLACED ON

OR AGAINST THE FURNACE JACKET. THE AREA

AROUND THE FURNACE MUST BE KEPT CLEAR AND

FREE OF ALL COMBUSTIBLE MATERIALS INCLUDING

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS. PLACEMENT OF COMBUSTIBLE MATERIALS ON,

AGAINST OR AROUND THE FURNACE JACKET CAN

CAUSE AN EXPLOSION OR FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH. THE

HOMEOWNER SHOULD BE CAUTIONED THAT THE FURNACE AREA MUST NOT BE USED AS A BROOM CLOSET

OR FOR ANY OTHER STORAGE PURPOSES.

8

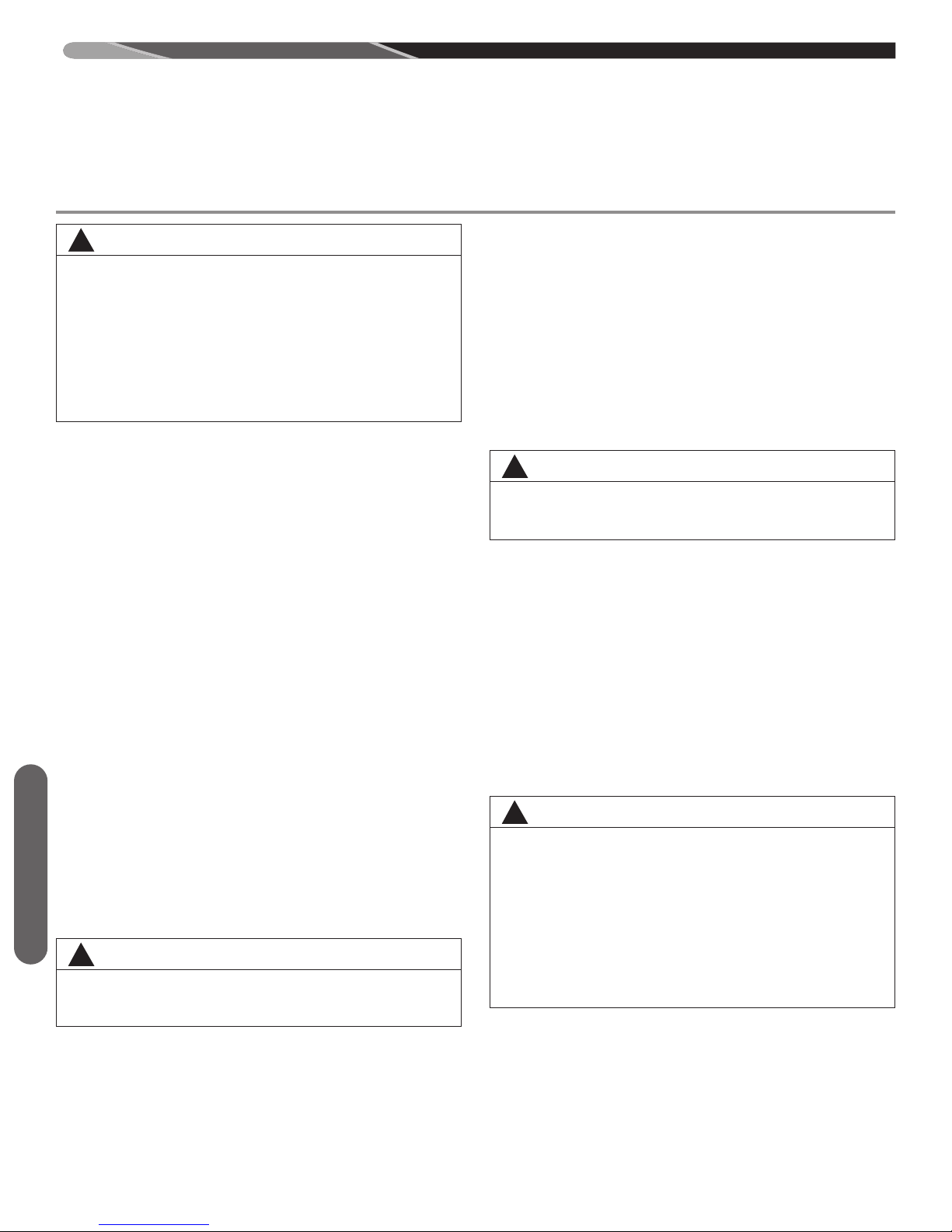

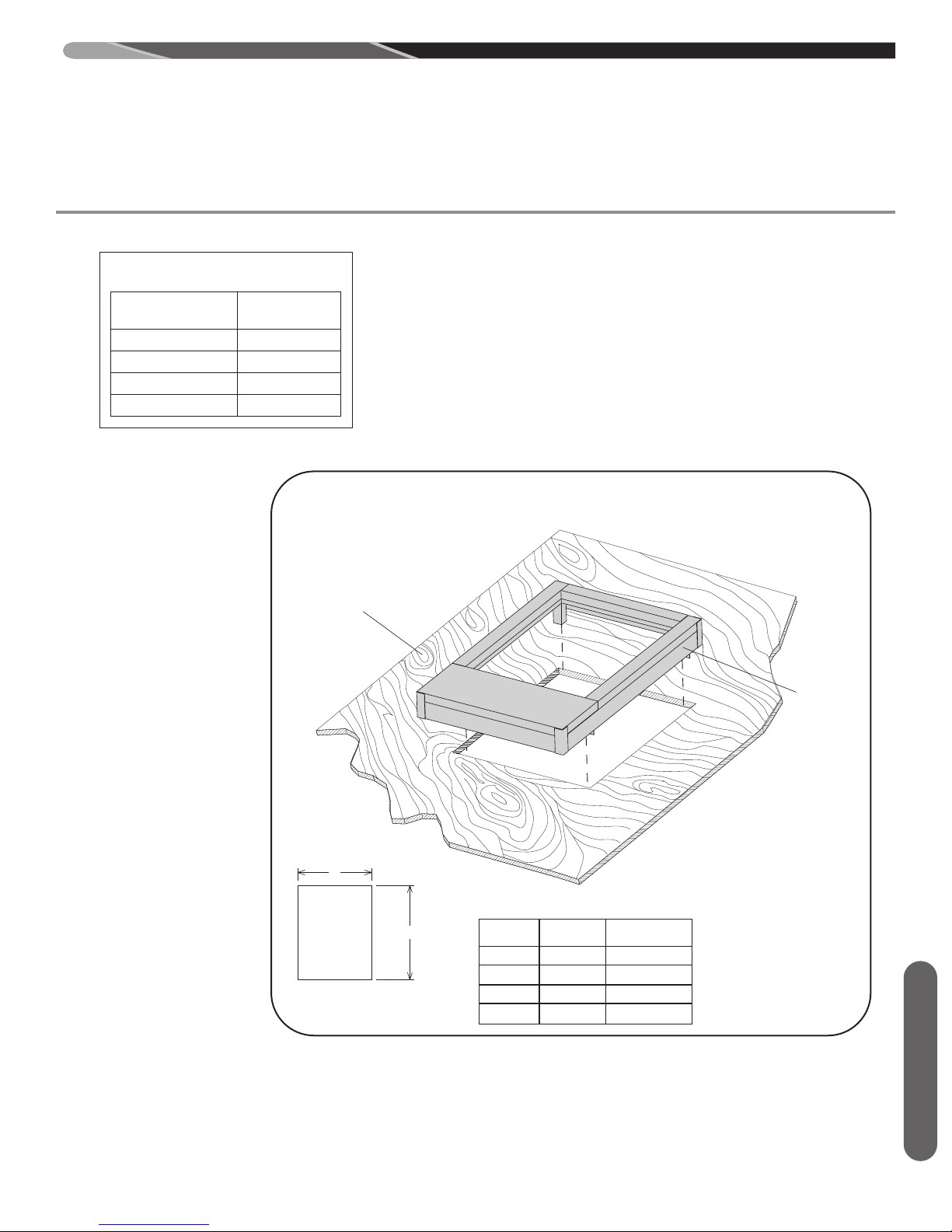

FIGURE 3

DOWNFLOW DIMENSIONS

Ship.

Back Top Front Vent

REDUCED CLEARANCE (IN.)

Left Right

/8

5

/8

1

20

/16

1

28

➀ May require 3” to 4” or 3” to 5” adapter.

➁ May be 0” with type B vent.

➂ May be 1” with type B vent.

/8

5

26

/8 DIA.

/8 DIA.

7

7

/16

7

24

/8 DIA.

5

1

D

/16

3

/8

/8 0 4➁ 0 1 3 6➂ 85 lbs.

/8 0 3➁ 0 1 3 6➂ 105 lbs.

/8 0 3➁ 0 1 3 6➂ 115 lbs.

/8 0 0 0 1 3 6➂ 120 lbs.

/8 0 0 0 1 3 6➂ 140 lbs.

1

5

5

/8 0 0 0 1 3 6➂ 150 lbs.

1

5

5

3

20

/8

3

6

23

/8 ➀ 13

/8 ➀ 16

/8 ➀ 16

/8 ➀ 20

/8 ➀ 23

3

1

1

/32 10

/32 12

/32 12

27

11

11

/2 16

/2 16

1

1

Model A B C D E

05 14 12

CLEARANCE TO COMBUSTIBLE MATERIAL (INCHES)

DOWNFLOW MODELS

Side Side Wgts.

10(A) 17

07 17

/8 ➀ 23

7

5

5

/32 13

/32 15

/32 15

27

11

11

/2 23

/2 23

1

1

10(B) 21 19

12 24

15 24

/4

3

19

/8

5

R.A.

B

A

/8

5

/4

3

SIGHT

34

GLASS

AIRFLOW

S.A.

E

/8

3

23

/8

3

Location

20

/16

3

6

TOP BOTTOM

/2

1

24

/8

5

26

C

LOW VOLTAGE

/16

13

26

GAS CONNECTION

ELECTRIC CONNECTION

NOTE: IN DOWNFLOW CONFIGURATION, OPTIONAL AIR CUTOUT IS NOT PERMITTED.

9

DUCTING

roper air flow is required for the correct operation of this

P

furnace. Restricted air flow can cause erratic operation and

can damage the heat exchanger. The duct system must

carry the correct amount of air for heating and cooling if

summer air conditioning is used.

WARNING

!

SOME HEATING AIRFLOW VALUES MAY BE

HIGHER THAN THOSE REQUIRED FOR COOLING.

BE SURE TO SIZE DUCT FOR THE MAXIMUM POSSIBLE AIRFLOW VALUE.

SIZE AIRFLOW DISTRIBUTION SYSTEM TO ACCEPTABLE INDUSTRY STANDARDS AND METHODS. TOTAL STATIC PRESSURE DROP OF THE AIR

DISTRIBUTION SYSTEM SHOULD NOT EXCEED .8

INCHES W.C. THIS WILL INCLUDE ANY AIR CONDITIONER COIL, AIR FILTRATION SYSTEM, ZONING

SYSTEM, DUCTWORK, ETC. REFER TO ADDED

EQUIPMENT TECHNICAL INFORMATION TO OBTAIN

PRESSURE DROP INFORMATION WHEN EQUIPMENT IS OPERATING AT RECOMMENDED HEATING OR COOLING CFMS.

IMPORTANT: When using outside air, design and adjust

the system to maintain a return air temperature ABOVE

55° F during the heating season.

NOTE: Return air grilles and warm air registers must not

be obstructed or closed.

5. Connect the return air ducting to the return air opening

at the top of the unit. Make the connection air tight to

prevent the migration of toxic fumes and odors including carbon monoxide from migrating into the living

space from an adjacent fuel-burning appliance.

NOTE: In downflow configuration, side return air cut

out is not permitted. Do not take return air from the

back of the unit.

6. If a filter is installed near the furnace, be sure to

have adequate space for installation and removal

of the unit filter.

NOTE: DO NOT take return air from furnace rooms,

garages or cold areas. Avoid return air from utility

rooms, kitchens, laundry rooms and bathrooms.

WARNING

!

BLOWER AND BURNERS MUST NEVER BE OPERATED

WITHOUT THE BLOWER DOOR IN PLACE. THIS IS TO

PREVENT DRAWING GAS FUMES (WHICH COULD CONTAIN HAZARDOUS CARBON MONOXIDE) INTO THE

HOME THAT COULD RESULT IN PERSONAL INJURY OR

DEATH.

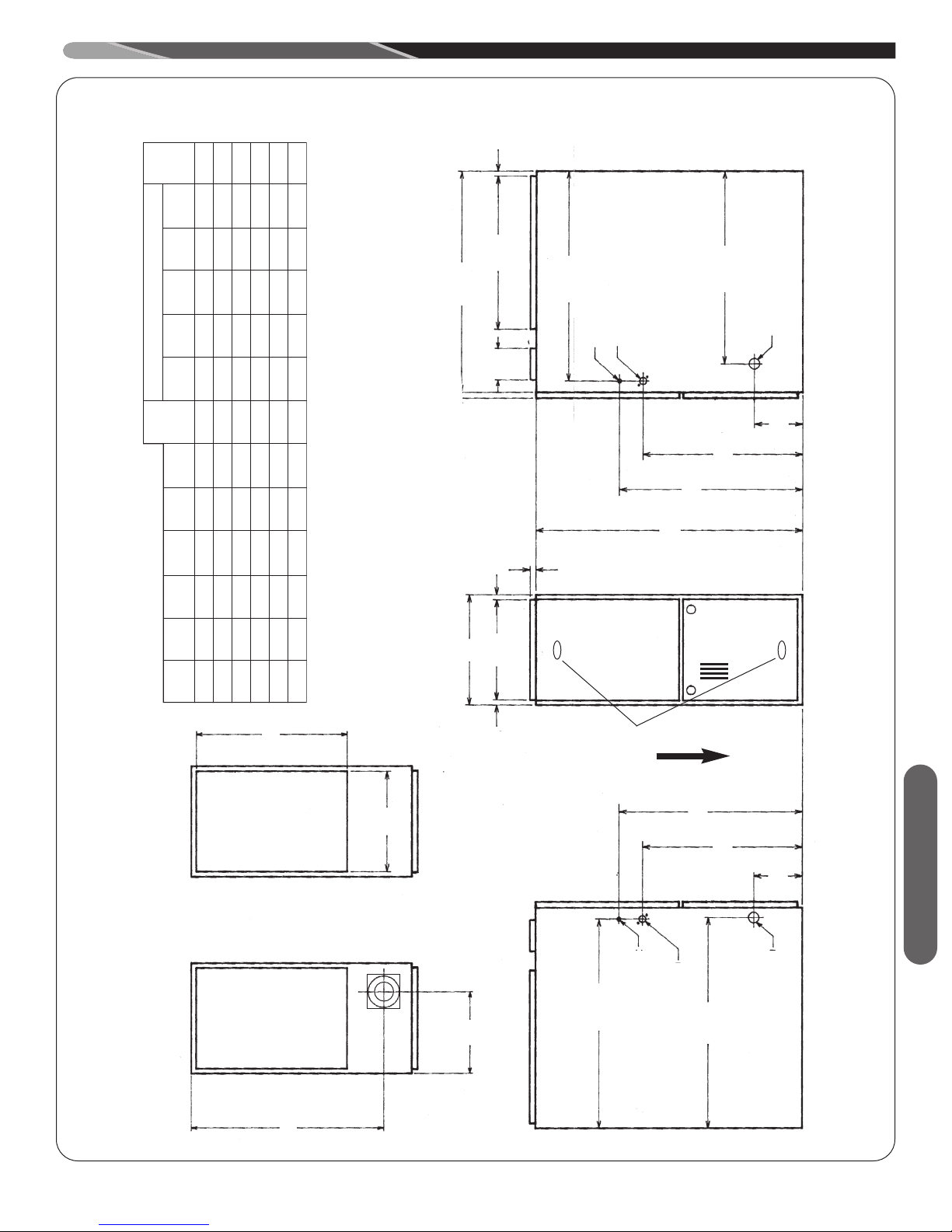

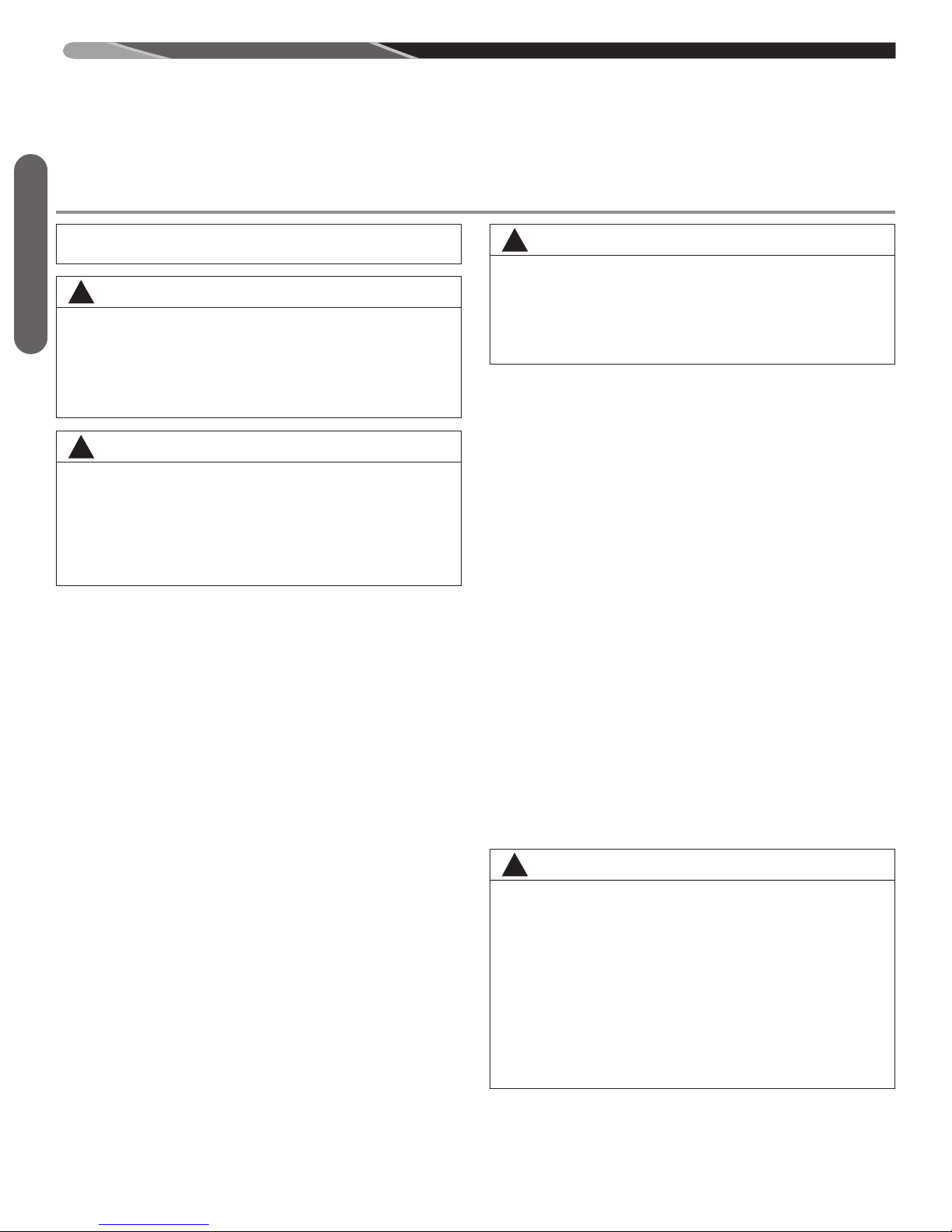

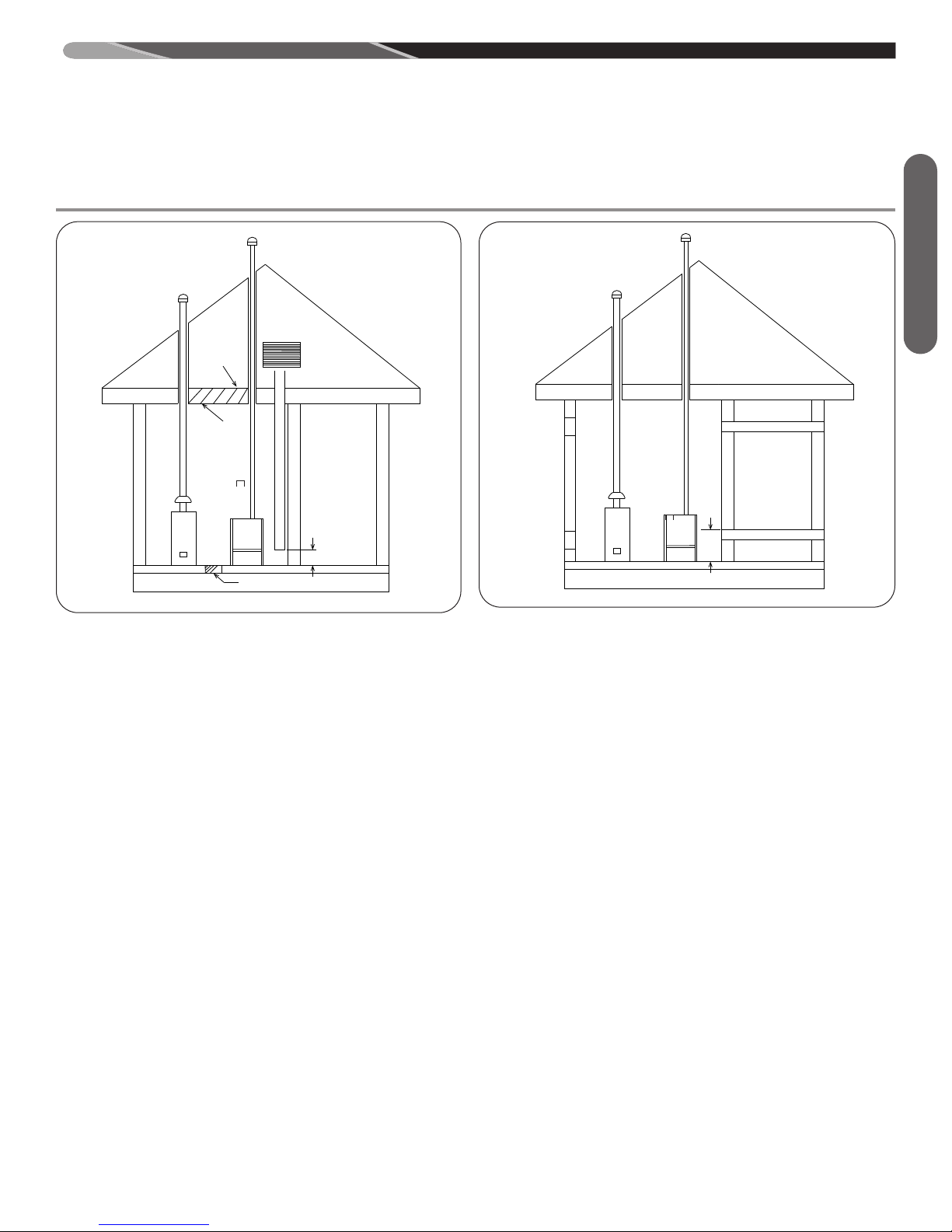

FIGURE 4

DOWNFLOW INSTALLATIONS

WARNING

!

A DOWNFLOW INSTALLATION IS CERTIFIED FOR

INSTALLATION ON A NON-COMBUSTIBLE FLOOR.

USE THE SPECIAL BASE SPECIFIED ON THE FURNACE CLEARANCE LABEL. FAILURE TO INSTALL

THE SPECIAL BASE MAY RESULT IN FIRE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

THIS BASE IS AVAILABLE AS AN ACCESSORY.

1. Position the unit to minimize long runs of duct or runs

of duct with many turns and elbows.

2. If summer air conditioning is desired, position the indoor coil on the supply-air side of the unit. Ensure that

no air can bypass this coil.

3. If installing on a combustible floor and not using an

air conditioning plenum, install the special non-combustible floor base. See Table 1 and Figure 5.

4. Connect the furnace to the supply air plenum. See Figure 4.

Ducting

10

21 5/8"

F

LOOR

M

ATE RIA L

NON-COM

FLOOR BASE

FLOOR CUTOUT

DIMENSIONS

FLOOR

BASE NO.

CABINET

WIDTH

FLOOR CUTOUT

DIMENSION “A”

RXGC-B14

RXGC-B17

RXGC-B21

14.0”

17.5”

21.0”

13.4”

17.0”

20.0”

RXGC-B24

24.5”

23.5”

A

21 5/8"

TABLE 1

ON-COMBUSTIBLE FLOOR BASES

N

Floor Base Size

No. Cabinet

RXGC-B14 14

RXGC-B17 17

RXGC-B21 21

RXGC-B24 24

DUCTING

FIGURE 5

NON-COMBUSTIBLE FLOOR BASE INSTALLATION INSTRUCTIONS

COMBUSTIBLE

FLOOR

MATERIAL

NON-COM-

BUSTIBLE

FLOOR

BASE

FLOOR CUTOUT

DIMENSIONS

ST-A1194-43-00

Ducting

11

COMBUSTION AND VENTILATION AIR

COMBUSTION AIR REQUIREMENTS

IMPORTANT: This is not a direct vent furnace. Review venting

instructions before installing.

WARNING

!

Combustion Air

HIS FURNACE AND ANY OTHER FUEL-BURNING APPLI-

T

ANCE MUST BE PROVIDED WITH ENOUGH FRESH AIR

FOR PROPER COMBUSTION AND VENTILATION OF THE

FLUE GASES. MOST HOMES WILL REQUIRE THAT OUTSIDE AIR BE SUPPLIED INTO THE FURNACE AREA. FAILURE TO DO SO CAN CAUSE DEATH FROM CARBON

MONOXIDE POISONING.

WARNING

!

ADEQUATE FACILITIES FOR PROVIDING AIR FOR COMBUSTION AND VENTILATION MUST BE PROVIDED IN ACCORDANCE WITH SECTION 5.3, AIR FOR COMBUSTION

AND VENTILATION, OF THE NATIONAL FUEL GAS CODE,

ANSI, Z223.1 LATEST EDITION OR APPLICABLE PROVISIONS FOR THE LOCAL BUILDING CODES, AND NOT

OBSTRUCTED SO AS TO PREVENT THE FLOW OF AIR TO

THE FURNACE.

1. IMPORTANT: Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to corrosive elements in the atmosphere is excluded from warranty

coverage.

2. Combustion air must be free of acid forming chemicals; such

as sulphur, fluorine and chlorine. These elements are found in

aerosol sprays, detergents, bleaches, cleaning solvents, air

fresheners, paint and varnish removers, refrigerants and many

other commercial and household products. Vapors from these

products when burned in a gas flame form acid compounds.

The acid compounds increase the dew point temperature of

the flue products and are highly corrosive after they condense.

3. The following types of installation may require OUTDOOR AIR

for combustion, due to chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces in hobby or craft rooms

• Furnaces installed near chemical storage areas.

4. If combustion air is exposed to the following substances (but

not limited to the following), it should not be used and the furnace may require outdoor air for combustion.

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine-based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry curing and acid washing materials

WARNING

!

ALL FURNACE INSTALLATIONS MUST COMPLY WITH

THE NATIONAL FUEL GAS CODE AND LOCAL CODES TO

PROVIDE ADEQUATE COMBUSTION AND VENTILATION

AIR FOR THE FURNACE. FAILURE TO DO SO CAN CREATE HAZARDOUS CONDITIONS RESULTING IN PROPERTY DAMAGE, BODILY INJURY OR DEATH FROM

SMOKE, FIRE OR CARBON MONOXIDE.

Combustion air requirements are determined by whether

the furnace is in an open (unconfined) area or in a confined space such as a closet or small room.

When the furnace is installed in the same space with other

gas appliances, such as a water heater, be sure there is an

adequate supply of combustion and ventilation air for the

furnace and the other appliances. Do not delete or reduce

the combustion air supply required by the other gas appliances in this space. See Z223.1, National Fuel Gas Code

(NFPA 54). An unconfined space must have at least 50

cubic feet (volume) for each 1,000 BTUH of the total input of

all appliances in the space. If the open space containing the

appliances is in a building with tight construction (contemporary construction), outside air may still be required for the

appliances to burn and vent properly. Outside air openings

should be sized the same as for a confined space.

IMPORTANT: ONLY THE CURRENT VENT INSTRUCTIONS APPLY. All gas furnaces cannot be common-

vented.

OVERTEMPERATURE SAFETY

SWITCHES

Furnaces are equipped with safety switches in the burner

compartment to protect against over-temperature conditions caused by inadequate combustion air supply. The

switches are located in the burner compartment. If a switch

is tripped it must be manually reset after clearing the fault

condition which caused it to open.

WARNING

!

Y

T

E

F

A

S

Y

N

A

E

V

O

M

E

R

R

O

,

R

E

P

M

U

J

,

S

S

A

P

Y

B

T

O

N

O

D

C

T

I

W

S

T

E

F

A

S

N

W

O

D

O

N

O

I

T

E

R

D

D

A

C

N

E

G

A

T

E

F

A

S

O

/

D

N

A

Q

A

Y

B

S

S

A

G

A

L

P

E

R

T

N

E

D

I

M

O

R

F

H

Y

Y

R

U

C

C

I

C

T

I

W

S

E

P

O

R

O

T

O

P

A

F

B

D

E

S

S

H

T

R

O

Y

T

N

O

C

F

I

R

E

V

E

I

F

I

L

A

U

R

E

I

L

P

P

Y

N

A

E

E

O

L

A

U

F

E

H

T

U

A

C

H

I

E

T

A

R

L

A

I

T

N

E

U

Q

A

Y

S

A

G

E

W

S

L

O

R

N

O

I

T

A

C

I

T

S

N

I

D

.

T

E

F

A

S

L

P

E

R

M

E

C

A

N

R

E

H

T

S

E

S

N

A

A

Y

I

M

R

E

T

T

E

F

A

S

D

E

I

F

I

L

I

L

P

P

U

S

T

U

O

H

T

I

R

P

F

O

,

R

E

L

L

T

N

O

C

E

M

E

C

A

R

T

N

O

C

T

O

S

R

N

A

N

R

U

F

Y

L

T

N

E

T

R

A

Z

A

H

Y

T

E

I

N

H

C

E

O

D

.

R

E

R

R

O

C

A

S

R

E

P

E

C

I

V

R

E

O

C

L

O

T

R

A

P

T

C

R

I

C

L

O

M

S

O

T

E

C

,

C

N

C

S

N

A

S

I

T

I

T

A

H

T

D

E

S

,

N

A

I

S

E

R

T

O

A

E

V

I

T

E

P

O

E

F

C

N

E

G

A

N

E

N

O

P

.

Y

L

N

O

A

F

I

.

T

I

U

T

U

H

I

M

R

E

T

C

A

R

Y

T

-

A

C

I

D

N

E

B

T

S

U

E

C

I

V

T

N

O

I

N

O

I

T

E

H

T

R

O

H

T

I

W

12

COMBUSTION AND VENTILATION AIR (cont.)

TABLE 7: MINIMUM SPACE REQUIREMENTS

FOR UNCONFINED SPACE, NON-DIRECT VENT*

Input

(BTUH)

Minimum

Space

(Cubic Ft)

Minimum Area

with 8

Ceilings (sq )

Typical Room

Size w/ 8'

Ceilings ( x )

50,000

2,500

313

16 x 20

75,000

3,750

470

24 x 20

100,000

5,000

625

32 x 20

125,000

6,300

790

36 x 30

150,000 7,500 940 32 x 30

TABLE 8: MINIMUM FREE AREA

OPENING REQUIRED FOR A

FURNACE LOCATED IN A

CONFINED SPACE USING

INDOOR AIR FOR COMBUSTION.

Input (BTUH)

Free Area for Each

Opening (sq inches)

50,000

100

75,000

100

100,000

100

125,000

130

150,000 150

COMBUSTION AIR REQUIREMENTS: CONFINED AND

UNCONFINED SPACES

ARNI

W

!

ALL FURNACE INSTALLATIONS MUST COMPLY WITH

THE NATIONAL FUEL GAS CODE, NFPA 54 AND LOCAL

CODES TO PROVIDE ADEQUATE COMBUSTION AND

VENTILATION AIR FOR THE FURNACE. FAILURE TO DO

SO CAN RESULT IN EXPLOSION, FIRE, PROPERTY DAMAGE, CARBON MONOXIDE POISONING, PERSONAL INJURY OR DEATH.

For improved indoor air quality, added safety and product performance we recommend direct vent type installations. If non-direct type vent system is used, the requirements for combustion

air must be provided as identified in the National Fuel Gas Code.

Combustion air requirements are determined by whether the furnace is in an open (unconfined) area or in a confined space such

as a closet or small room.

WARNING

!

N

A

D

A

E

R

M

T

F

N

S

M

D

A

S

T

N

E

V

L

A

N

O

I

U

O

T

E

A

E

C

A

N

R

E

R

I

D

-

N

I

T

C

U

R

A

F

T

N

E

G

A

M

FURNACE LOCATED IN AN UNCONFINED SPACE

USING INDOOR AIR FOR COMBUSTION:

An unconfined space must have at least 50 cubic feet for each

1,000 BTUH of total input for all appliances in the space. Table 1

below specifies minimum space requirements and a few examples of the room sizes required for different inputs. The sizes are

based on 8-foot ceilings.

If the open space containing the furnace is in a building with tight

construction, outside air may still be required for the furnace to

operate and vent properly. Outside air openings should be sized

the same as for a confined space.

NG

-

E

R

I

U

Q

E

R

G

N

I

T

N

E

V

L

A

R

E

N

E

G

E

H

T

W

O

L

L

O

F

D

N

O

I

,

D

I

U

G

D

G

N

I

T

N

E

L

L

A

T

S

N

I

N

E

V

T

C

T

N

I

S

N

E

,

E

R

U

O

S

R

E

P

S

E

N

I

L

E

R

I

U

Q

E

R

N

O

I

T

A

L

T

H

Q

N

F

.

)

G

N

I

N

A

M

S

I

E

M

P

I

U

J

N

I

L

A

I

H

T

F

O

T

N

E

M

E

L

C

N

I

(

S

E

R

U

L

I

A

C

L

A

U

M

A

D

T

N

R

O

Y

R

U

U

N

A

M

S

T

R

E

P

S

G

N

I

D

U

O

F

O

T

S

E

R

N

A

P

,

E

G

A

H

T

A

E

D

R

O

F

L

A

G

N

I

N

I

A

T

C

E

R

I

D

W

O

L

L

N

I

T

L

U

R

E

P

O

R

.

-

I

D

D

A

L

L

A

O

T

D

N

A

-

N

I

L

L

A

-

P

I

U

Q

E

Y

T

FURNACE LOCATED IN A CONFINED

SPACE

A confined space is defined as any space for a given furnace input

rating which is smaller than that which is specified in Table 1 as

minimum for an “unconfined” space. If the space is less than that

specified in this table, the space is defined as “confined”.

If the space is small enough to be designated as “confined”, it

must have openings into the space which are located in accordance with the requirements set forth in the following subsections

A and B. Size connected to the heated area or to the outside, and

by the input of ALL

If the confined space is within a building with tight construction,

combustion air must be taken from outdoors or from an area

freely communicating with the outdoors.

A. USING INDOOR AIR FOR COMBUSTION:

IMPORTANT: Air should not be taken from a heated space

with a fireplace, exhaust fan or other device that may produce negative pressure.

If combustion air is taken from the heated area, the openings

must each have at least 100 square inches of free area.

Each opening must have at least one square inch of free

area for each 1,000 BTUH of total input in the space. Table 2

shows some typical examples of openings required for combustion air openings required for a confined space.

TABLE 2: MINIMUM FREE AREA

OPENING REQUIRED FOR A

FURNACE LOCATED IN A

CONFINED SPACE USING

INDOOR AIR FOR COMBUSTION.

appliances in the space.

Combustion Air

TABLE 1: MINIMUM SPACE REQUIREMENTS

FOR UNCONFINED SPACE, NON-DIRECT VENT

B. USING OUTDOOR AIR FOR COMBUSTION:

IMPORTANT: Do not take air from an attic space that is

equipped with power ventilation.

The confined space must communicate with the outdoors in

accordance with Methods 1 or 2 below. The minimum dimension of air openings shall not be less than 3 inches. Where

ducts are used, they shall be of the same cross-sectional

area as the free area of the openings to which they connect.

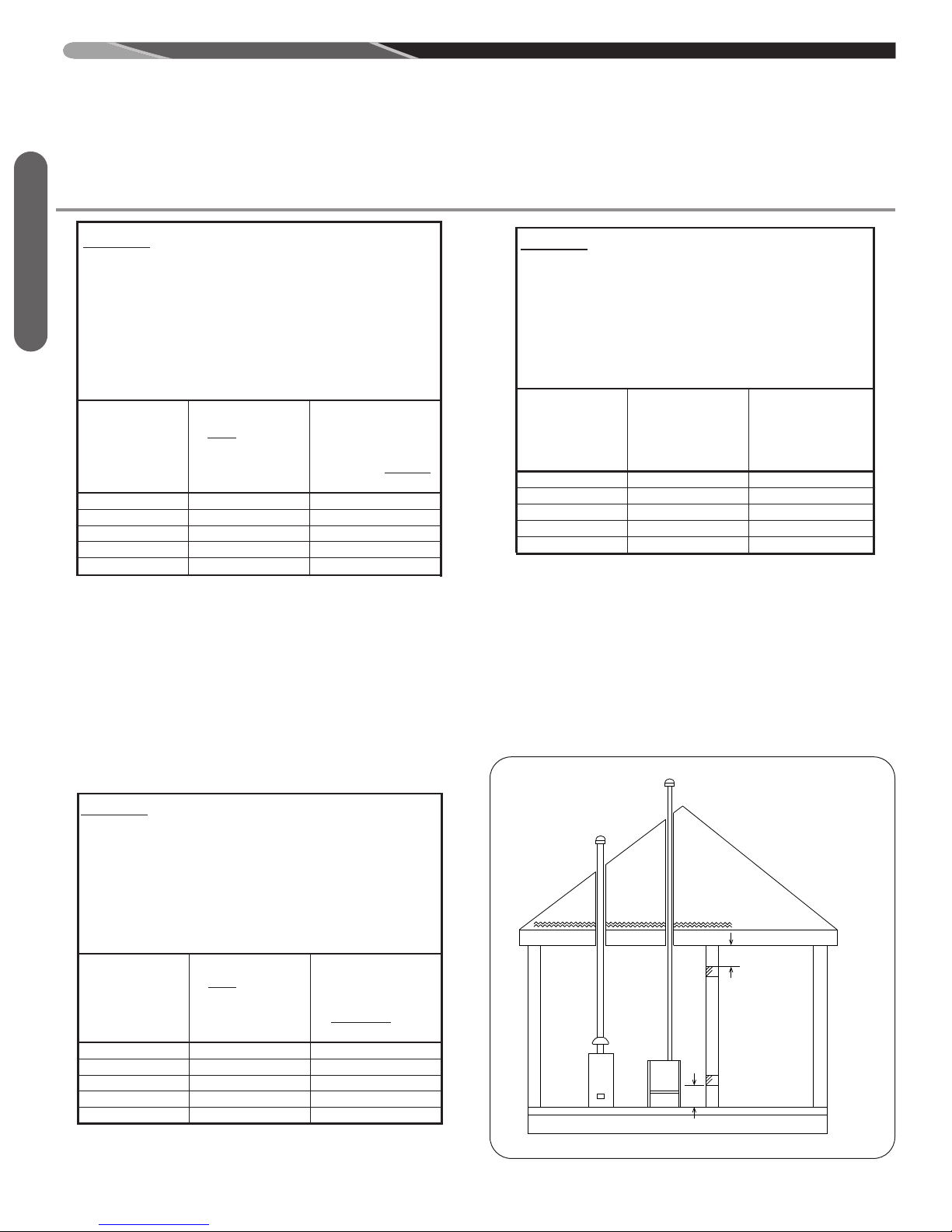

METHOD 1:

Two permanent openings, one located within 12 inches of the

top and one located within 12 inches of the bottom of the enclosure, shall be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces (crawl or

attic) that freely communicate with the outdoors.

13

COMBUSTION AND VENTILATION AIR (cont.)

TABLE 9 : MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

OUTSIDE THROUGH AN OPENING OR

THROUGH A VERTICAL VENT DUCT.*

Total Input for

ALL Gas

Appliances

(BTUH)

Free Area for

Each Opening

when 2 Separate

Openings are

used (sq inches)

Round Pipe Duct

Diameter (Vercal

Duct Only) (inches)

50,000

13

5

75,000

19

5

100,000

25

6

125,000

32

8

150,000 38 8

TABLE 1 0: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

OUTSIDE THROUGH A H ORIZONTAL DUCT.

Total Input for

ALL Gas

Appliances

(BTUH)

Free Area for

Each Opening

when 2 Separate

Openings are

used (sq inches)

Round Pipe Duct

Diameter

(Horizontal Duct

Only) (inches)

50,000

25

6

75,000

38

8

100,000

50

8

125,000

63

10

150,000 75 10

TABLE 1 1: MINIMUM FREE AREA REQUIRED

FOR AN O P E N I NG ( W H E N O N E OPENING I S

USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

*

Total Input for

ALL Gas

Appliances

(BTUH)

Free Area for an

Opening when 1

Opening is used

(sq inches)

Round Pipe Duct

Diameter (inches)

50,000 25 6

75,000

38

8

100,000

50

8

125,000

63

10

150,000 75 10

OUTSIDE.

GAS

WATER

HEATER

FURNACE

12”

MAX

12”

MAX

NOTE:

EACH OPENING SHALL

HAVE A FREE AREA OF

NOT LESS THAN ONE

SQUARE INCH PER

1,000 BTU PER HOUR OF

THE TOTAL INPUT

RATING OF ALL

EQUIPMENT IN THE

ENCLOSURE, BUT NOT

LESS THAN 100

SQUARE INCHES.

AIR FROM HEATED SPACE

COMBUSTION AIR REQUIREMENTS: CONFINED AND

UNCONFINED SPACES

TABLE 3: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

Combustion Air

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

3. OUTSIDE THROUGH AN OPENING OR

3. THROUGH A VERTICAL DUCT.

A. Where directly communicating with the outdoors through an

opening or where communicating to the outdoors through

vertical ducts as shown in Figure 7, each opening shall have

a minimum free area of 1 square inch for each 4,000 BTUH

of total appliance input rating of all equipment in the enclosure. Table 3 specifies the minimum area for each of the 2

combustion air openings and minimum round duct diameter

for direct openings and vertical ducting only.

B. Where communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1

square inch for each 2,000 BTUH of total appliance input rating of all equipment in the enclosure (see Figure 8). Table 4

TABLE 4: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

3. OUTSIDE THROUGH A HORIZONTAL DUCT.

TABLE 5: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

3. OUTSIDE THROUGH A HORIZONTAL DUCT.

specifies the minimum area for each of the 2 combustion air

openings and minimum round duct diameter for horizontal

ducting only.

METHOD 2:

One permanent opening located within 12 inches of the top of

the enclosure, shall be permitted where the equipment has

clearances of at least 1 inch from the sides and back and 6

inches from the front of the appliance. The opening shall directly communicate with the outdoors or communicate

through a vertical or horizontal duct to the outdoors or spaces

(crawl or attic) that freely communicate with the outdoors,

and shall have a minimum of:

FIGURE 6

AIR FROM HEATED SPACE

14

ST-A1227-01-00

COMBUSTION AND VENTILATION AIR (cont.)

GAS

W

ATER

HEATER

FURNACE

OPTIONAL 1 SQ. INCH PER 4000 BTUH INLET AIR

GABLE

VENT

V

ENTILATED

ATTIC GABLE OR

SOFFIT VENTS

OUT LET A IR

I

N ATT IC

MUST BE

ABOVE

I

NSULATION

1 SQ. INCH PER

4000 BTUH INLET AIR

12” MAX

1 SQ. INCH PER

4

000 BTUH

OUT LET A IR

G

AS

WATER

HEATER

FURNACE

12”

MAX

INLET AIR 1 SQ. INCH

PER 2000 BTUH

OUTLET AIR 1 SQ. INCH

PER 2000 BTUH

OUTLET AIR

1 SQ. INCH PER

4

000 BTUH

I

NLET AIR

1 SQ. INCH PER

4000 BTUH

COMBUSTION AIR REQUIREMENTS: CONFINED AND

UNCONFINED SPACES

FIGURE 7

IR FROM ATTIC/CRAWL SPACE

A

A. 1 Square inch for each 3,000 BTUH of the total input rat-

ing of all equipment located in the enclosure

and

B. Not less than the sum of the areas of all vent connectors

in the confined space.

If the unit is installed where there is an exhaust fan, sufficient

ventilation must be provided to prevent the exhaust fan from creating negative pressure.

It is also acceptable to run the condensate drain (or refrigerant) line access over the air intake hole as long as a 1" minimum clearance is maintained.

Combustion air openings must not be restricted in any manner.

IMPORTANT: When indoor combustion air is used, the inlet air

opening at the furnace must be protected from accidental blockage.

ST-A1227-02-00

FIGURE 8

OUTSIDE AIR USING A

ORIZONTAL INLET & OUTLET

H

ST-A1227-03

IMPORTANT: If the furnace is in a location with an exhaust fan,

there must be sufficient ventilation to prevent the exhaust fan

from creating a negative pressure in the room.

Combustion air openings must NOT BE RESTRICTED in any

manner.

CONSULT LOCAL CODES FOR SPECIAL REQUIREMENTS.

B: Method 3

For the optimum in quiet operation, attic air may be brought directly to the furnace.

IMPORTANT: In applications using Method 3 for combustion air,

the attic must be ventilated by gable or soffit vents.

Combustion Air

15

Loading...

Loading...