RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

CNC-H6DL-B3

CNCH6DLB3, CNCH6DL B3, CNCH6DL-B3, CNC H6DLB3, CNC H6DL B3, CNC H6DL-B3, CNC-H6DLB3,

CNC-H6DL B3, CNC-H6DL-B3

HUST

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

BENDING MACHINE

OPERATION MANUAL

H6D-B 3-AXIS

2012-12

HUST Automation Inc.

No. 80 Industry Rd., Toufen, Miaoli, Taiwan

Tel: 886 37 623242 Fax: 886 37 623241

Contents

i

Contents:

1. Non Mode Page 1

2. AUTO mode (main page)

3

3. File setting page

6

4. MCM(Vice)setting page

8

5. Editing mode

10

6. The main page of program number selection

11

7. Bending-selection for fold setting page

13

8. JOG mode

16

9. HOME mode

18

10. Error and Absolve

19

11. Graph for reference(Graph)

21

12. Bending Machine I/O List

22

13. Machine Connection Diagram

25

Appendix 1、 Emergent Stop Connection Diagram

28

Appendix 2、 Servo Driver Servo-On Connection Diagram

29

Appendix 3、 H6D-B Controller size

30

Appendix 4、 Bending Angle Conception

32

Appendix 5、 H6D-B Control Structure of Bending Machine

33

Appendix 6、 MCM (Parameter)

34

Appendix 7、 Sanyo Servo Machinery Connection

66

Appendix 8、 Mitsubishi Servo Machinery Connection

67

Appendix 9、 Servo Motor And MPG Connection

68

Appendix 10、 Install Manual

69

H6D-B LCD flow-process diagram

74

Appendix 11、 ERROR MESSAGES

75

Appendix 12、 USB Operation instructions

79

Appendix 13、 BL-Compensation Operation instructions

81

HUST CNC H6D-B3 MANUAL

ii

HUST CNC H6D-B3 MANUAL

1

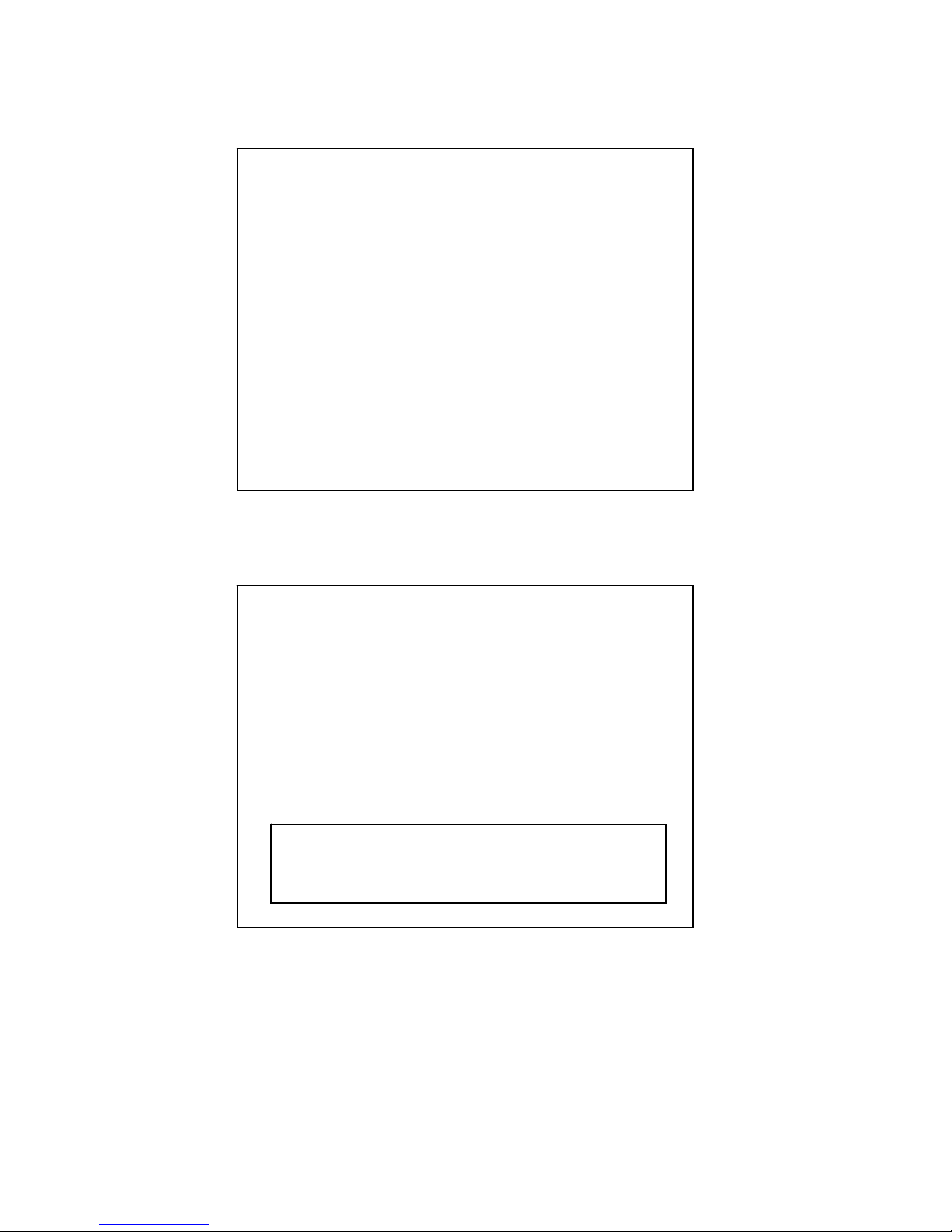

When the controller is power on it will download some data. So do not operate

the controller till the download operation finished.

Fig 1

1. Non Mode Page (Freedom editor)

Fig 2

開機資料處理中

Data Loading

請稍候……..

Please Wait……

億圖實業股份有限公司

H

H

U

U

S

S

T

T

C

C

N

N

C

C

TEL:886-37-623242

FAX:886-37-623241

e-mail:hust@ms14.hinet.net

HUST CNC H6D-B3 MANUAL

2

Fig 3

Caution !!! When the power is reopened, plz execute 3 Axes to

home

To main page : Press “AUTO” on the key board

HUST CNC H6D-B3 MANUAL

3

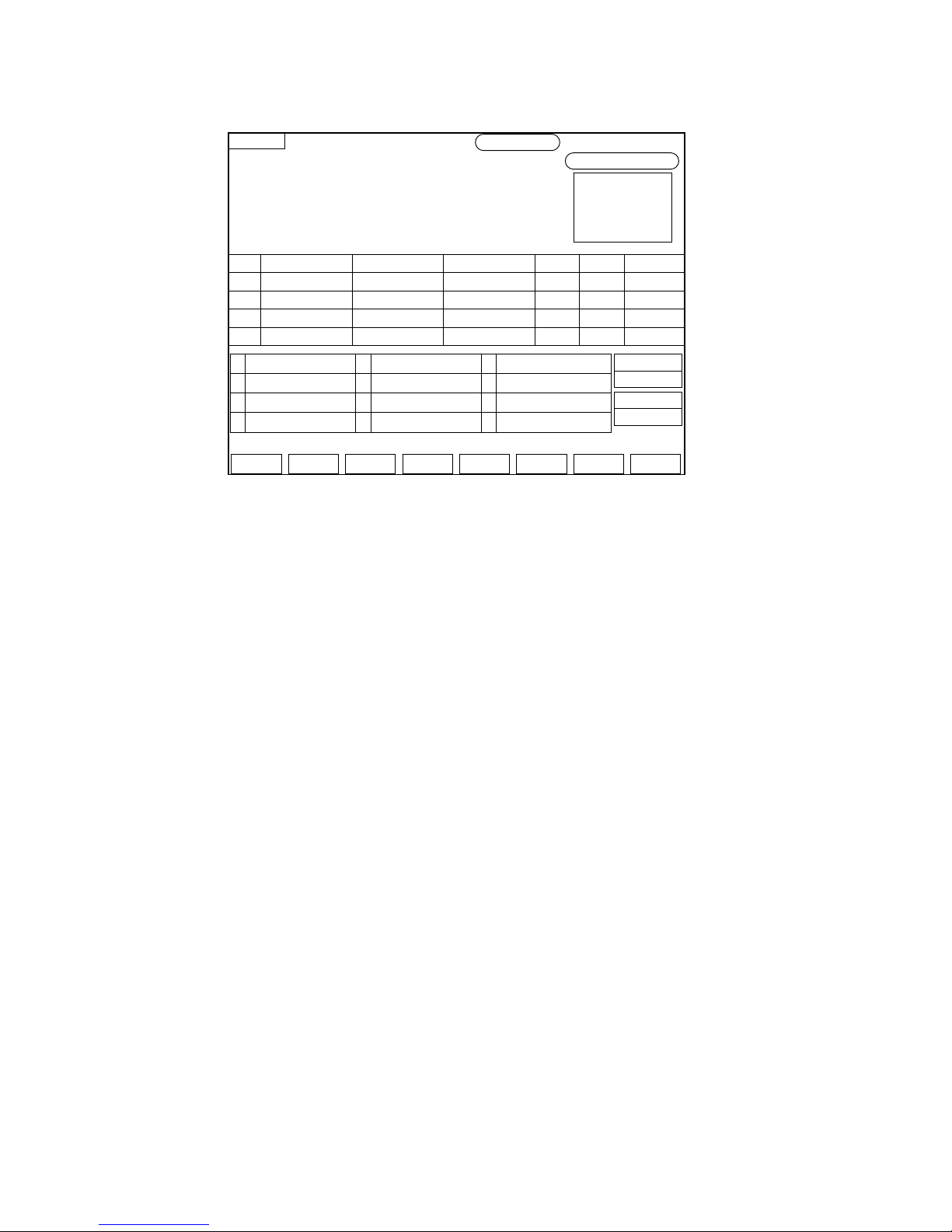

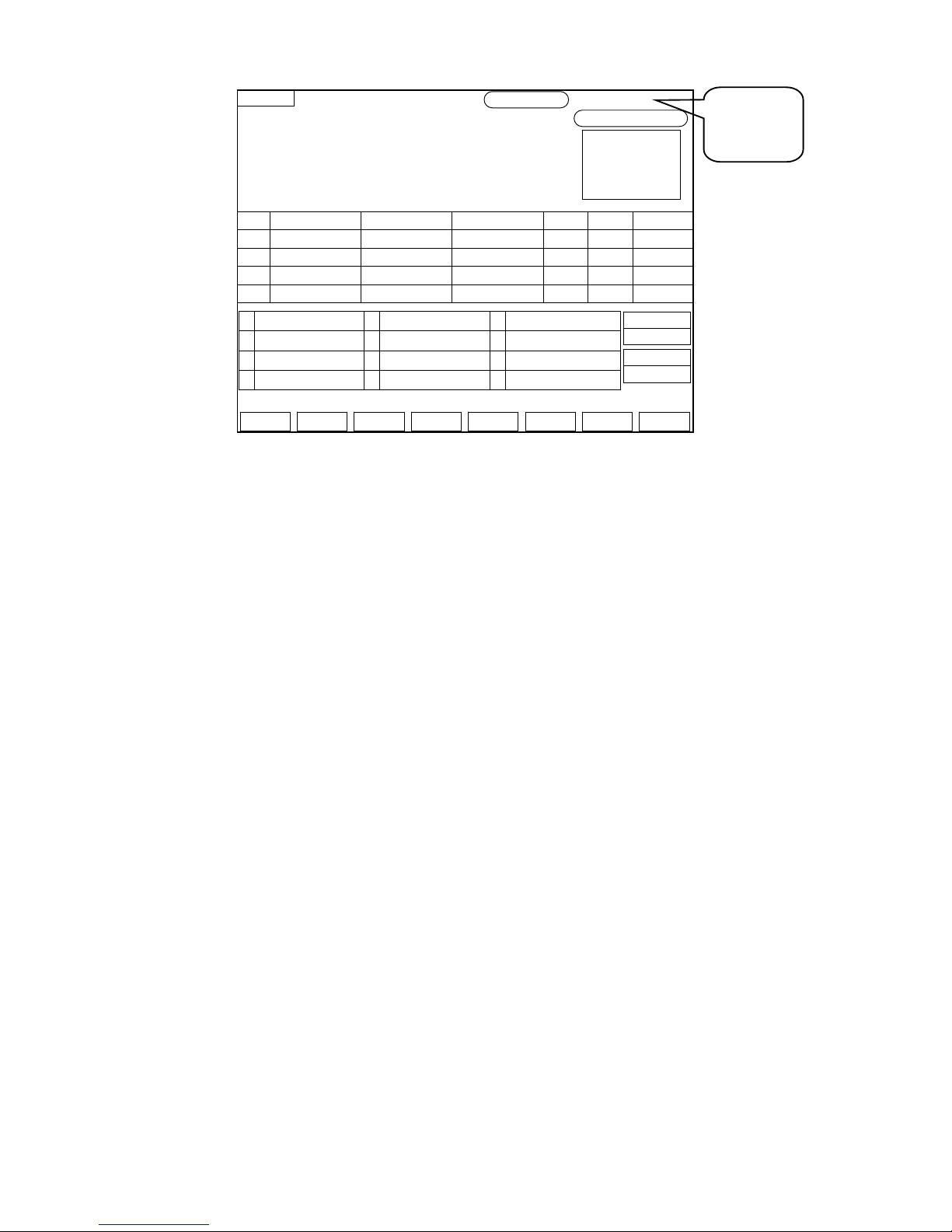

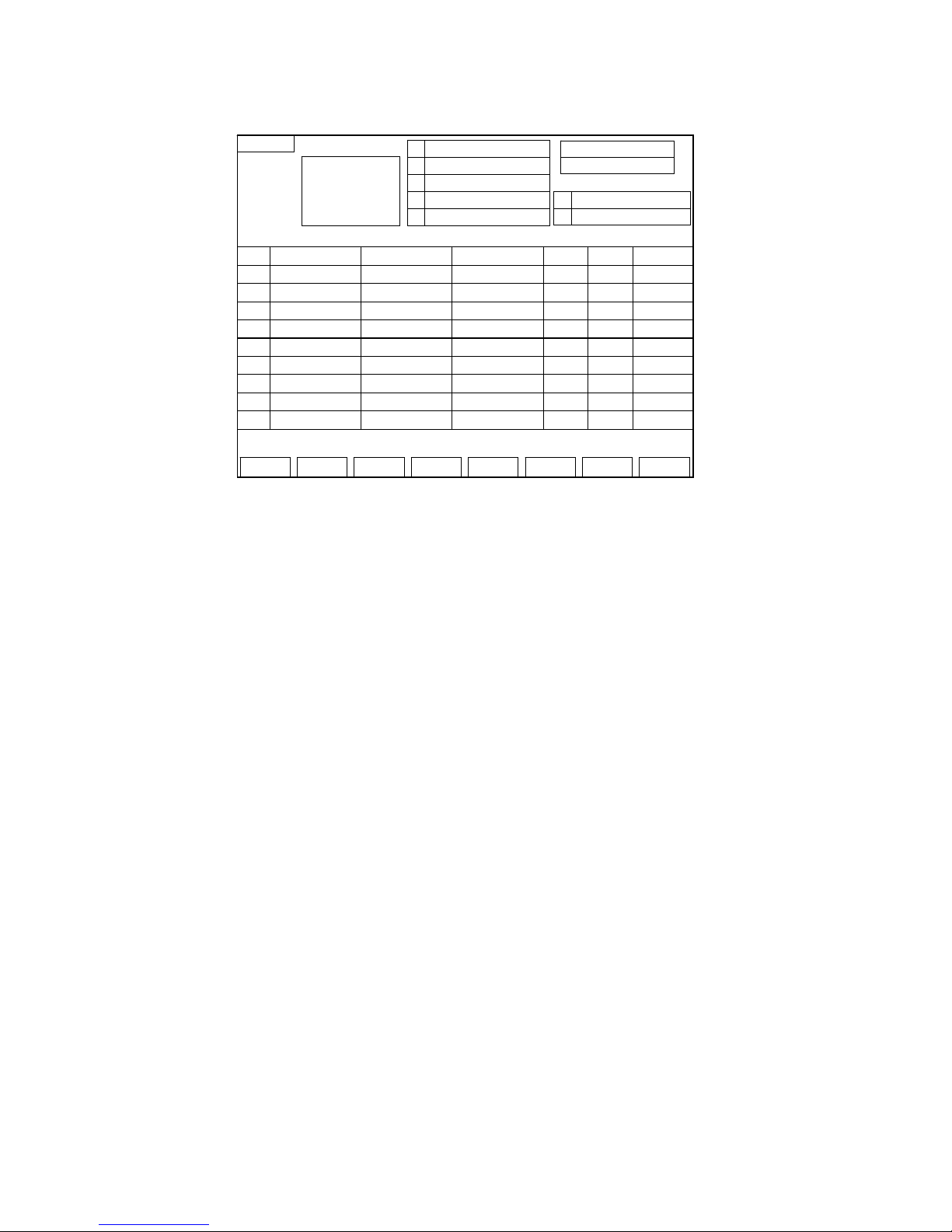

2. AUTO mode : (main page)

Fig 4

(1) Function key:

a. CYCST:Cycle start

(a) Press this key to run the program.

(b) When the program is running, the LED-light located left-up of the

CYCST will be on. Then the number of piece bended will begin to be

counted.

b. RESET:

CNC gives an order to controller that let it stay on the non-mode, and the

frame jumps to the non-mode page.

c. Edit :

When pressing this key on any mode, the controller will execute RESET first.

Let the controller stay on non-mode status and then jump to the file-set page.

d. Set:

When pressing this key on any mode, this key will highlight. It means that the

controller is not running any program. And use CURSOR key to set the value

of Total-Cor.(Gα), SD-Pos., Total-number(T-Time) 【Material】、【Depth】、

【Pre.-BL】and Count number(C-Time).

e. FORWARD : Execute last program

Do not press the NEXT key again when the white light is not canceled.

Because the program is not running over.

f. NEXT : Execute next program

Do not press the FORWARD key again when the white light is not canceled.

Because the program is not running over

g. Lock:

AUTO

Next For Edit Set Lock Pre. GRAPH

PRO-RUN

FILE000

Bendin

g

-Force:000.00 Ton.

Calculate the bending-force

must settin

g

the item of 5.6.7

L-POS :-0000.000

D-POS :-0000.000

R-POS :-0000.000

Assign the graph

Adtion

None Graph

01 UP:00 000.000

05

M: 0 Aluminum 09C: -0000.000

02 UN:00 000.000 06 TH: 00.000 10Sd-Pos: 0000.000

03

K-out B:-0000.000

07

Pre.-BL: 00000 11UN-V、TH:00

04 K-out S:-0000.000 08 UN-V: -000.000 12

0000000

T-Time

0000000

C-Time

N X

R

Vic e BL C

00 0000.00 -000.00 000.00 00 0000 -00.00

HUST CNC H6D-B3 MANUAL

4

When pressing this key, the running program will stop at this step.

※ Press again to cancel.

h. Pre.-BL

Calculate the Bending-Force must be setting the item of 5,6,8.

i. Graph for reference(Graph)

Push this key and enter Graph for reference and establish pages.

(2) Additional description : When the setting key is highlight:

a. Total correction(Gα):

Programs in the file are all corrected When trying to bending 90 degree, the

angle is not enough : Set value positive too deep : Set negative value

EX 1 :

(a) The Y-axis(D-axis)movement of one unit is set as 0.01 ( P-αD = 0.01 ).

Set in the mode of Edit-FOLD-UN-SET.

(b) Gα= 5.000 ( total correction )

(c) The unit of the total correction is

P-αD × Gα÷ 1000 = 0.010 × 5000 ÷ 1000 = 0.05 mm

EX 2 :

(a) The Y-axis(D-axis)movement of one unit is set as 0.04 ( P-αD = 0.04 ).

Set in the mode of Edit-FOLD-UN-SET.

(b) Gα= 5.000 ( total correction )

(c) The unit of the total correction is

(d) d. P-αD × Gα÷ 1000 = 0.040 × 5000 ÷ 1000 = 0.2 mm

b. SD-position :

Input the location of angle-axis directly. Then press 【CYCST】key to execute

it. When the position is arrived, the number of D-axis will be canceled

automatically. At this time we can press【CYCST】key to run the program

directly.

c. T-Time :

Set total number of pieces

d. C-Time :

When it has run all the programs, the number will be added by 1 (Number of

piece)

e. Material:(Establish the range 0-2)

Establishment:0,Stainless steel 、1,Iron 、2,Aluminium

f. Pre.-BL

g. Calculate the Bending-Force condition needed

h. Thickness:

Input the Bending Machine of project

HUST CNC H6D-B3 MANUAL

5

Fig 5

Display :

(1) Press RESET to the frame of non-mode.

(2) Status display

When the number of work pieces is up to the setting:

The MARK【Reaching-End】will highlight if the setting value is not equal to 0

OR current number is > or = the setting number.

a. K-OUT ≦

b. UP-H ≦ 0

c. UN-H ≦ 0

d. UN-V ≦ 0

e. TH ≦ 0

※When status is shown, it can not be operated by controller.

(3) L-axis :(X-coordinate)

Show the position of L-axis right now.

(4) D-axis :(Y-coordinate)

Show the position of D-axis right now

(5) R-axis :(Z-coordinate)

Show the position of R-axis right now

a. Show the bend song pressure number value of this project.

b. In the project lasts:When projects are carried out , will show the white.

(6) Graph for reference(Graph)

Show this procedure chooses at present Graph for reference.

The situation

shows the

position

AUTO

Next For Edit Set Lock Pre. GRAPH

PRO-RUN

FILE000

Bendin

g

-Force:000.00 Ton.

Calculate the bending-force

must settin

g

the item of 5.6.7

L-POS :-0000.000

D-POS :-0000.000

R-POS :-0000.000

Assign the graph

Adtion

None Graph

01 UP:00 000.000

05

M: 0 Aluminum 09C: -0000.000

02 UN:00 000.000 06 TH: 00.000 10Sd-Pos: 0000.000

03

K-out B:-0000.000

07

Pre.-BL: 00000 11UN-V、TH:00

04 K-out S:-0000.000 08 UN-V: -000.000 12

0000000

T-Time

0000000

C-Time

N X

R

Vic e BL C

00 0000.00 -000.00 000.00 00 0000 -00.00

HUST CNC H6D-B3 MANUAL

6

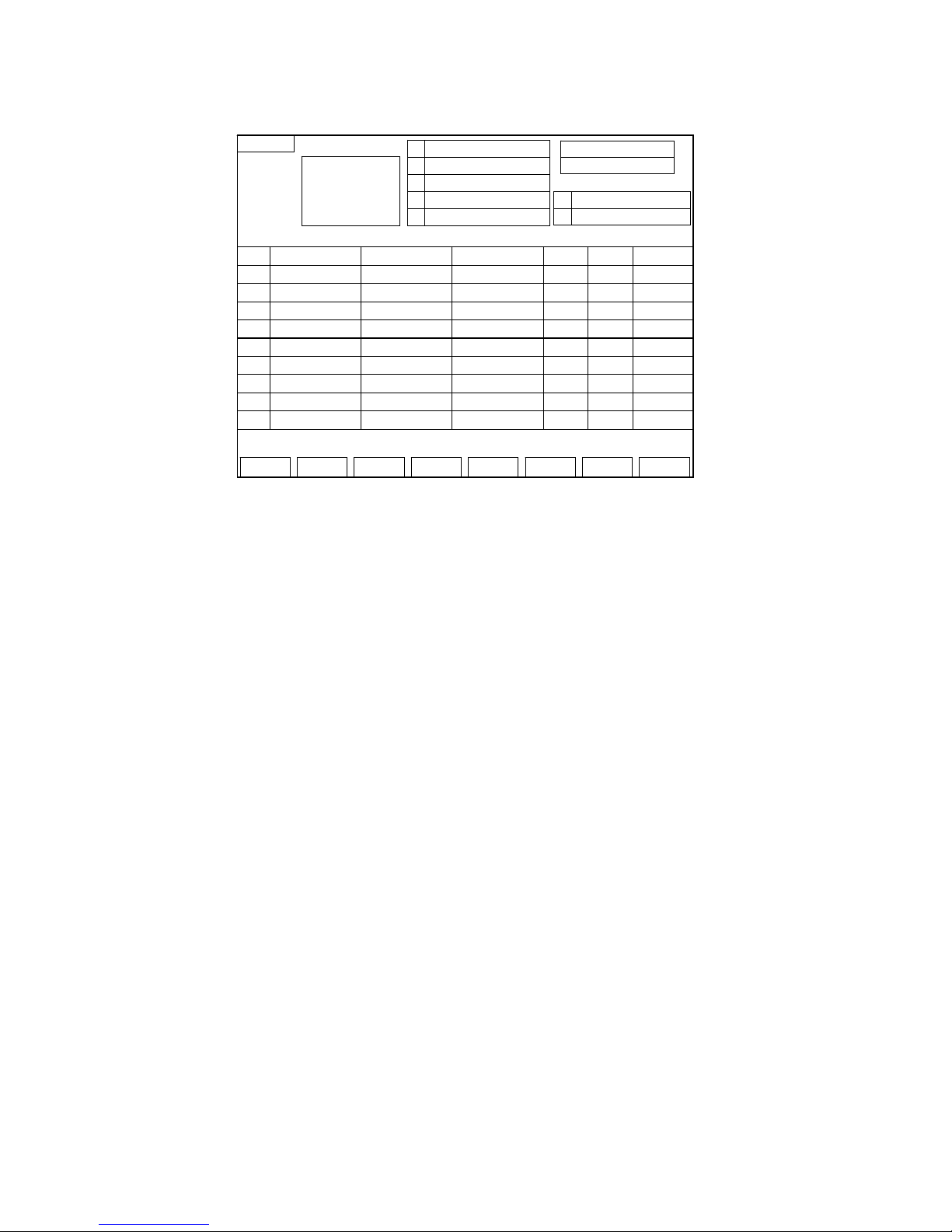

3. File setting page :

Fig 6

(1) 【Show】the maximum number of file can be set.

(2) After pushing the fast procedure options button, Press the number keys on the

keyboard directly. Input the number of file( Number will show up the INSERT

key.) When input the number of file and then press INPUT key, “data loading

please wait…” will show below. When it disappears , we can choose other

function key.

(3) After the number of file is set, please go to the page of BENDING-SELECTION

and TYPE-SET to enter correct data. Then we go to the EDIT page input

bending

(4) INSERT key:(Ins.)

Insert one line of blank program below current cursor.

(5) DELETE key:(Del.)

Delete the setting value of one line.

(6) Fold-Selection

Push this key and enter Fold-Selection and establish pages.

(7) MCM key:

Go to the PARAMETER setting page.

(8) BTO key:(Back To One)

Move the cursor back to the first node.

(9) Fast procedure options KEY:

After pushing this function key,Can do movements that the fast procedure

chooses.

(10) Graph for reference(Graph)

Push this key and enter Graph for reference and establish pages.

EDIT

Fold V.MCM BTO F.P ro -S GRAPH Del Graph Ret

None Graph

N X

R

Vic e BL C

00 0000.00 -000.00 000.00 00 0000 -00.00

Set-File:0500

File:000

K-Out B:-0000.000

K-Out S:-0000.000

06

07

M : Aluminum

TH: 00.000

01

02

UP :00 0000.000

UN:00 0000.000

03

04

V : -000.00005

HUST CNC H6D-B3 MANUAL

7

(11) Graph delete(Del.-Graph)

After pushing this function key, can delete the figure of all Graph for reference

of procedure.

(12) RET:BACK TO AUTO MODE

PS:

When the MCM setting value is 0, the program has no recycle and no DX. It ranges

from 0 to 10.

Ex : Function setting(Vice)

Value 1: The program will execute first motion by the MCM-setting page.

Value 2: The program will execute second motion by the MCM-setting page.

ETC…

HUST CNC H6D-B3 MANUAL

8

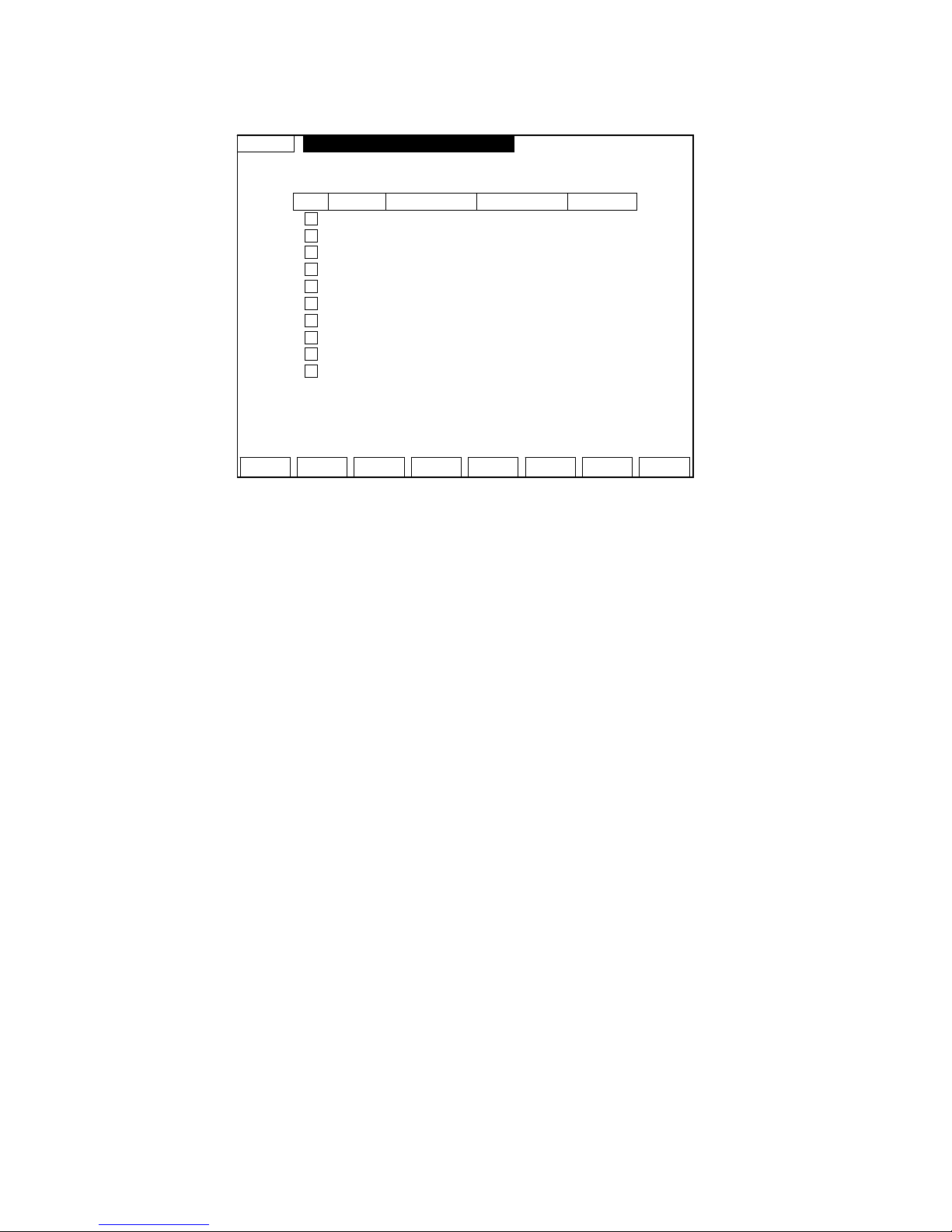

4. MCM(Vice)setting page:

Fig 7

(1) Cycle:(Cyc)

Square input-area number chosen

value 1 Successful recycle.【bending arc】

value 0 Failed recycle. Only run the distance of DX

※ By using this function you must set counter value as not zero. Or this

function will be useless.

(2) Delay Time:(Time) Range from 0 to 9.9s

Cycle setting value【1】: The pausing time is set as when executing cycle motion

for bending arc, there is a pausing time between each time bending.

(3) DX:

Set the distance of X-axis move out or cycle when bending.

(4) Count :

If the cycle setting value is 1, the program motion will proceed orderly by【Ran】

setting value.

Ex : If the【Ran】 value is 3mm,【count】value is 10 , X-axis will proceed 3mm

and repeat 10 times. And each time will proceed after I007 signal changes on to

off.

Attention :

When the cycle setting value is 1 , we must notice that if the total distance of cycle

will be over X initial coordinate.【between X difference and keep-out setting】If it

dose, system will adjust cycle value automatically.

EX:

Vice Cyc Time Ran Count

01

0 00.0 -000.000 0000

02

0 00.0 -000.000 0000

03

0 00.0 -000.000 0000

04

0 00.0 -000.000 0000

05

0 00.0 -000.000 0000

06

0 00.0 -000.000 0000

07

0 00.0 -000.000 0000

08

0 00.0 -000.000 0000

09

0 00.0 -000.000 0000

10

0 00.0 -000.000 0000

VMCM

Ret

Prarmeter Setting 1~10

HUST CNC H6D-B3 MANUAL

9

Set value of cycle to 1,【Ran】to 3, 【count】 to 10, X initial coordinate to 20.000,

keep-out area to 7.9, System will adjust it to 4 times automatically.

3×10=30

20-7.9=12.1

30>12.1,【count】value will turn to 4 automatically.

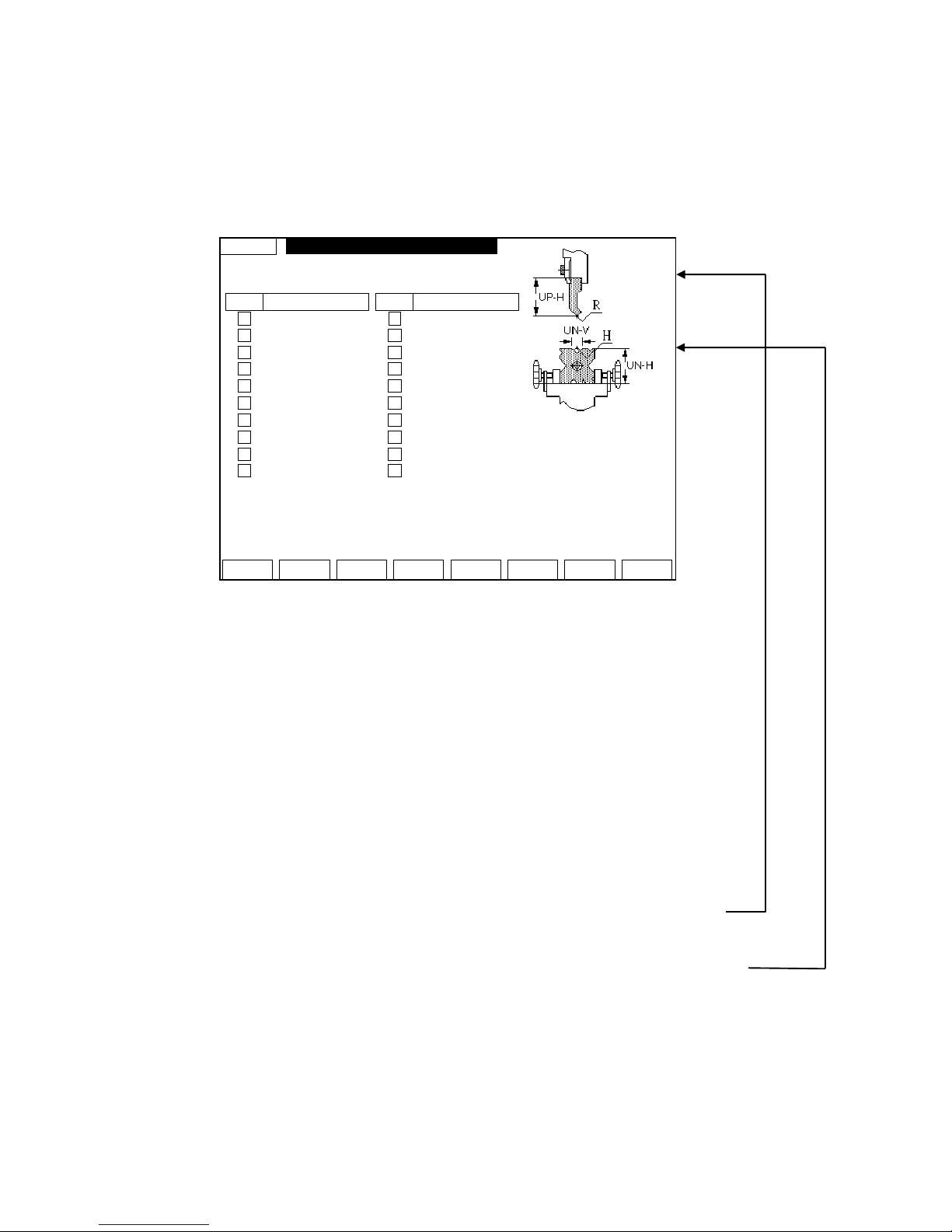

Fig 8

X initial coordinate is 20.000

keep-out area is

【count】value will turn to 4

automaticall

y

HUST CNC H6D-B3 MANUAL

10

5. Editing mode

Fig 9

(1) Press the CURSOR key to move to the column to be input. Then input the value.

(2) When the cursor is located on the last line of program, by pressing the

cursor-down key the controller will insert one blank program line automatically.

If you are not going to use this blank program line, please press the DELETE

key to delete this blank program.

(3) If you want to set the value as “BLANK”, you can press the CLEAR key first

and then press the INPUT key. The setting column will be on the blank status.

EDIT

Fold V.MCM BTO F.P ro -S GRAPH Del Graph Ret

None Graph

N X

R

Vic e BL C

00 0000.00 -000.00 000.00 00 0000 -00.00

Set-File:0400

File:000

K-Out B:-0000.000

K-Out S:-0000.000

06

07

M : Aluminum

TH: 00.000

01

02

UP :00 0000.000

UN:00 0000.000

03

04

V : -000.00005

HUST CNC H6D-B3 MANUAL

11

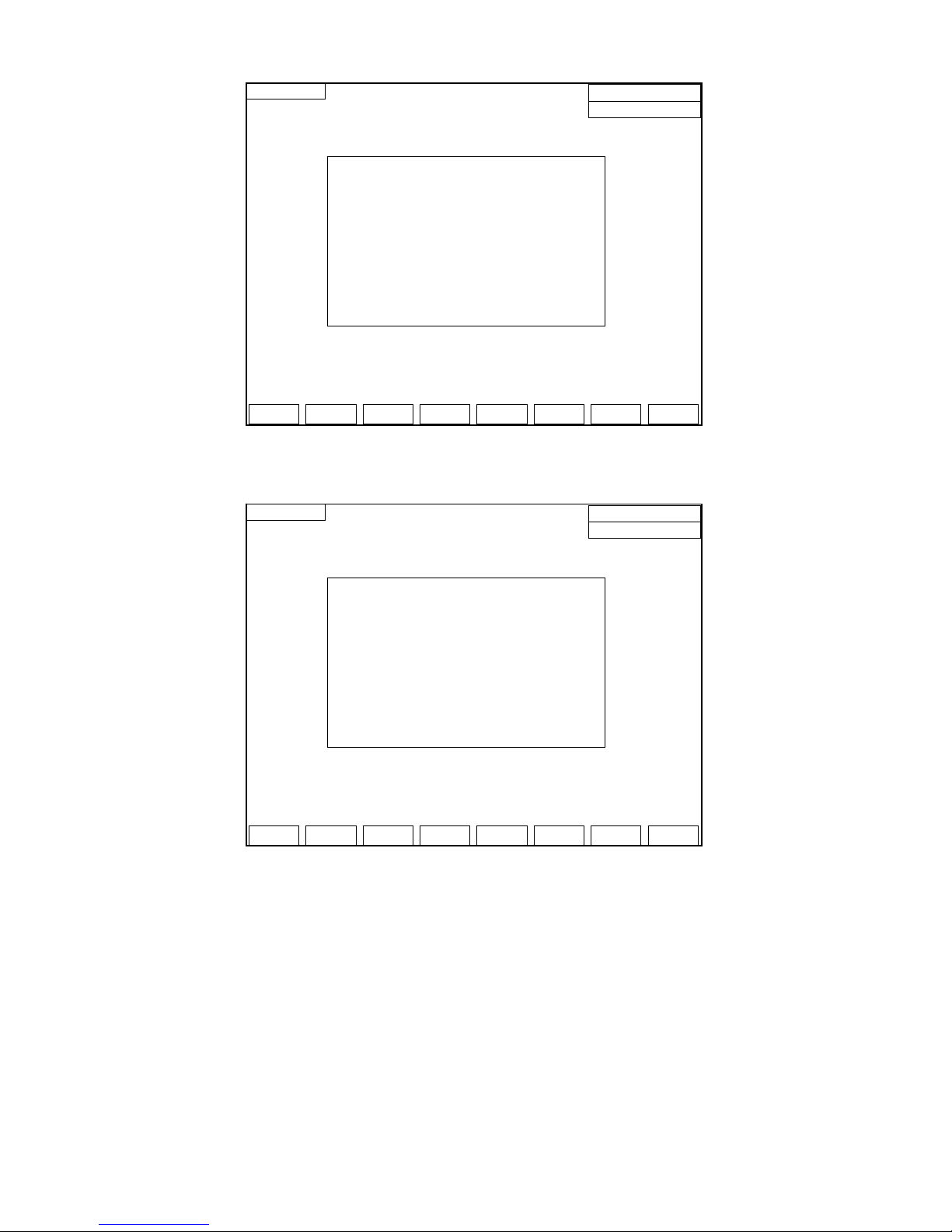

6. The main page of program number selection

Fig 10

(1) Press【PAG E】or【CURSOR】key to move the cursor.

(2) 【Ret】key:back to the File setting page.

(3) 【COPY】key:go to the PRO-COPY page.

(4) Move to the set number then press the SELECT【SEL】key.

(5) Editor key:After choosing the procedure,to editor's page editor's procedure.

(6) Group number after altering,Show above right of the screen.

The cursor stays on the position of O000 ,The group shows it is 0, If the cursor

is moved to O004, The group shows it is 4 after pushing the options button.

(7) 【DELETE【Del】key: When you are trying to delete the program number the

cursor pointing at, the confirming line will be shown as the picture below

Press【Y】:Delete the content of the program.

Press【N】:Back to the former page.

※ After finishing carrying out movements , get back to the procedure and choose the

page。

Annotation

SEL-FILE

DEL Copy Select

Ret

Set-File:0400

000

SOURCE 000 TARGET 000

> O000 EMPTY

O001 EMPTY

O002 EMPTY

O003 EMPTY

O004 EMPTY

O006 EMPTY

O007 EMPTY

O008 EMPTY

O009 EMPTY

CURSOR

EMPTY The

representative is an

empty procedure.

HUST CNC H6D-B3 MANUAL

12

Fig 11

※ The program-copy page

Fig 12

(1) Move the cursor to the program number to be copied and press the【SOURCE】

key.

(2) Then move the cursor to the program number to be placed and press the

【TARGE T】key.

(3) Press the【COPY】key. The operation of copying program will be executed.

EX:A group and 0 (O000) copy 5 to the group (O005)

a. The cursor is moved to “Source” Group (O000) Press down the Source

key。

b. The cursor is moved to “Purpose” Group (O005) Press down the

Purpose key。

SEL-FILE

DEL Copy Select

Ret

Set-File:0500

000

SOURCE 000 TARGET 000

> O000 EMPTY

O001 EMPTY

O002 EMPTY

O003 EMPTY

O004 EMPTY

O006 EMPTY

O007 EMPTY

O008 EMPTY

O009 EMPTY

SEL-FILE

YES

N

O

Set-File:0400

000

SOURCE 000 TARGET 000

> O000 EMPTY

O001 EMPTY

O002 EMPTY

O003 EMPTY

O004 EMPTY

O006 EMPTY

O007 EMPTY

O008 EMPTY

O009 EMPTY

HUST CNC H6D-B3 MANUAL

13

c. Will show at this moment【0 groups copy to 5】。

d. Push and copy the key, Can finish copying movements.

(4) Press the enter key and get back to the automatic way page.

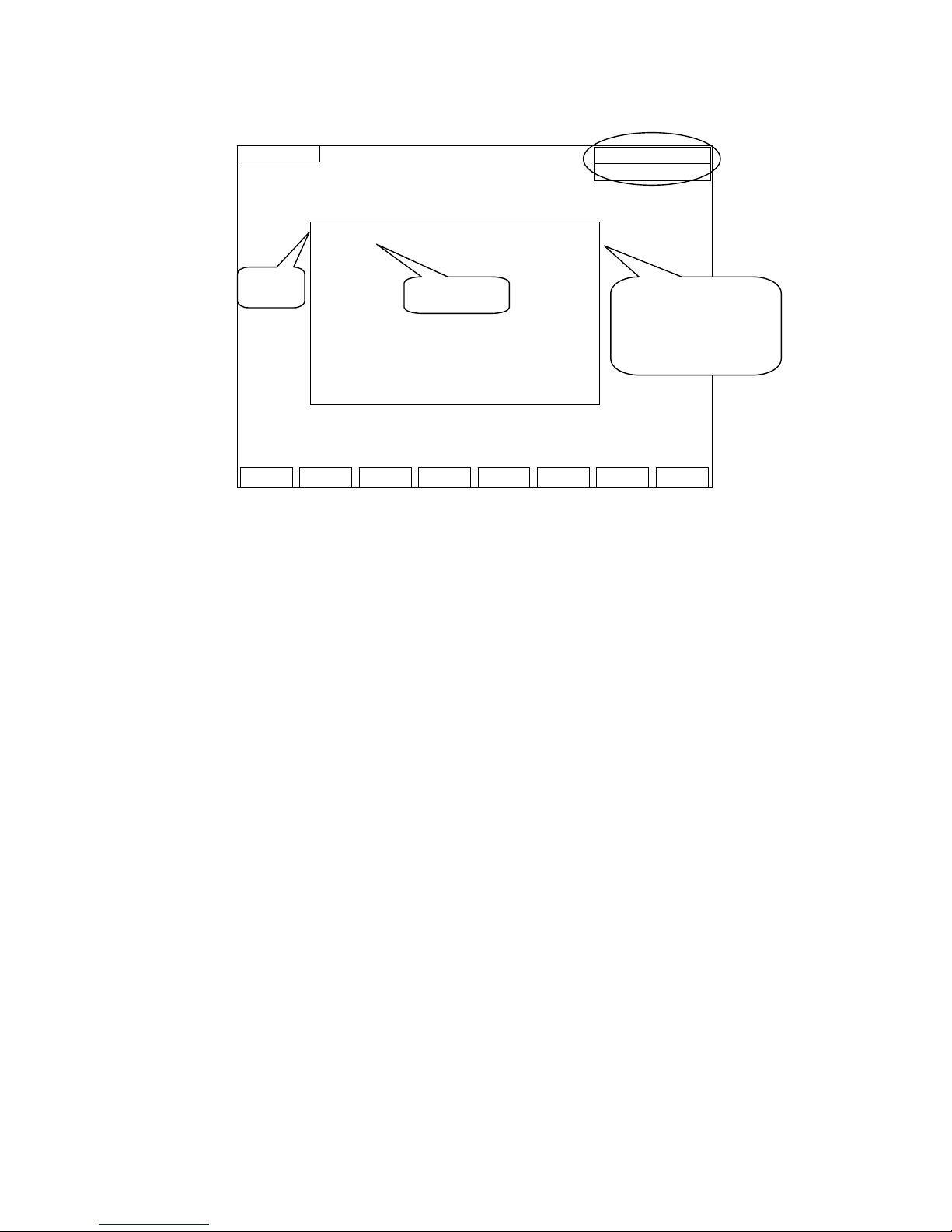

7. Bending-selection for fold setting page :(FOLD)

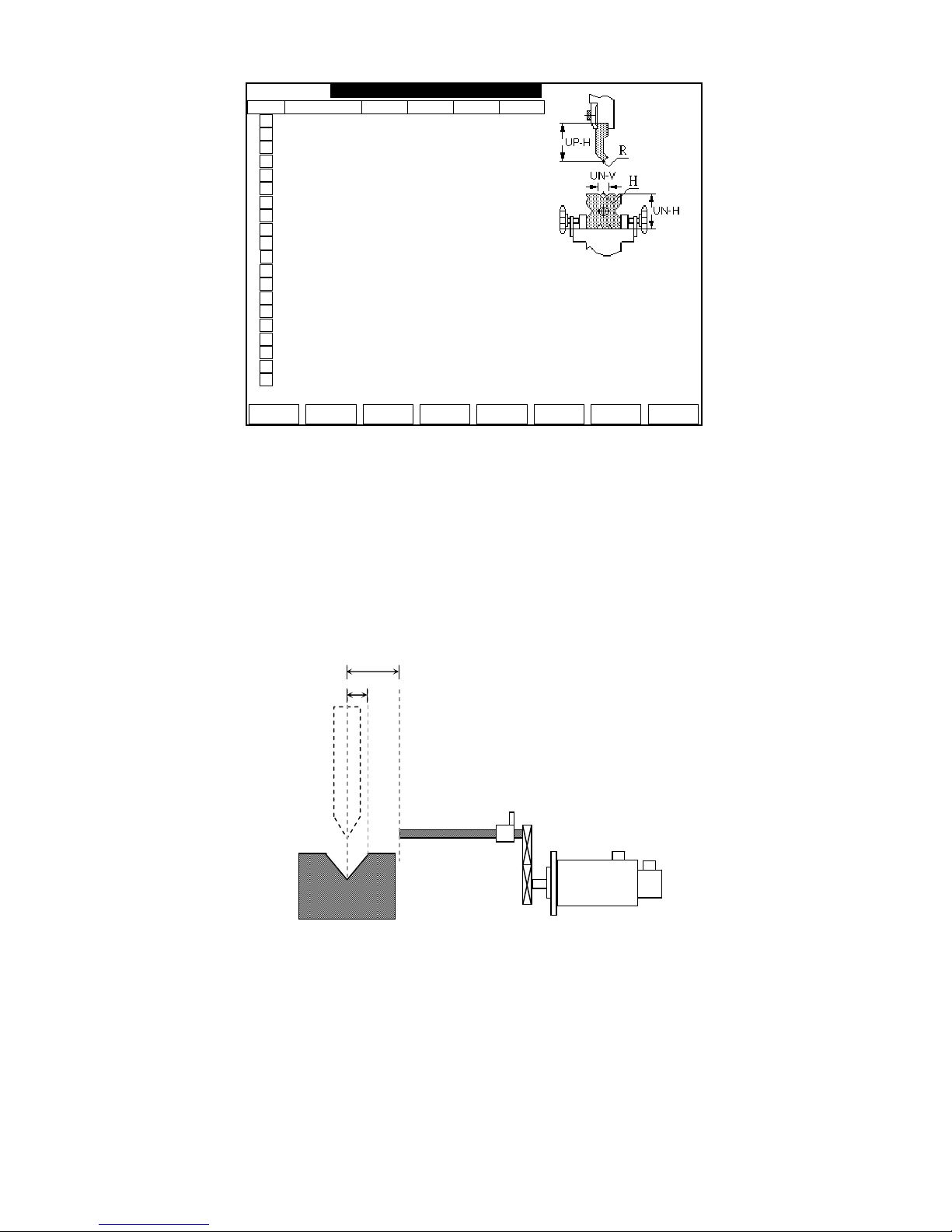

Fig 13

(1) Upper-CHICE number :(UP)

Input the serial number of upper- CHICE

(2) UNIT- CHICE number :(UN)

Input the serial number of unit- CHICE

(3) UP-SET :

Total file setting of UP-SET is 20.

Function key:

(UN)Lower:Establish pages to make the(UN) Lower.

Editor:To editor's page.

Turn back:Get back to the automatic way.

Display:

Ones that show and choose at present specification of the cutter。

(UP) Upper and(UN)Lower Choice the structure chart,Can establish the

specifications of a knife of tools according to the sign of the figure .

(UP) Upper-Choice page:(Can establish the height , width of cannelure ,

SMALL K-OUT setting、BIG K-OUT setting.)

(4) UN-SET :

Total file setting of UN-SET is40

UP UP-H

01

0000.000

02

0000.000

03

0000.000

04

0000.000

05

0000.000

06

0000.000

07

0000.000

08

0000.000

09

0000.000

10

0000.000

Fold

UN-Set Edit Ret

Upper-Choice 1~20/Lower-Choice 1~40

Tool Use

d

UP-H : 000.000

UN-H : 000.000

UN-V : 00.000

K-Out B : 000.000

K-Out S : 000.000

Instruction

UP UP-H

11

0000.000

12

0000.000

13

0000.000

14

0000.000

15

0000.000

16

0000.000

17

0000.000

18

0000.000

19

0000.000

20

0000.000

UP-SET:00

HUST CNC H6D-B3 MANUAL

14

Fig 14

The upper-highness(UP-H)、unit- highness(UN-H)and unit-vice(UN-V)will show

up after the value of upper and unit setting.

PS1:The upper file and UNIT file can match each other freely

PS2:1:SMALL K-OUT setting.

2:BIG K-OUT setting

※ It must be careful to setting the K-OUT value.

Fig 15

Function key:

(UN) Lower:Establish pages to make the (UN) Lower.

Editor:To editor's page.

Turn back:Get back to the automatic way.

UP (DOWN) page:Switch over the UP(DOWN) page of establishing.

Display:

UN UN-H UN-V K-Out SK-Out B P-D

01

0000.000 00.000 00.000 00.000 00.000

02

0000.000 00.000 00.000 00.000 00.000

03

0000.000 00.000 00.000 00.000 00.000

04

0000.000 00.000 00.000 00.000 00.000

05

0000.000 00.000 00.000 00.000 00.000

06

0000.000 00.000 00.000 00.000 00.000

07

0000.000 00.000 00.000 00.000 00.000

08

0000.000 00.000 00.000 00.000 00.000

09

0000.000 00.000 00.000 00.000 00.000

10

0000.000 00.000 00.000 00.000 00.000

11

0000.000 00.000 00.000 00.000 00.000

12

0000.000 00.000 00.000 00.000 00.000

13

0000.000 00.000 00.000 00.000 00.000

14

0000.000 00.000 00.000 00.000 00.000

15

0000.000 00.000 00.000 00.000 00.000

16

0000.000 00.000 00.000 00.000 00.000

17

0000.000 00.000 00.000 00.000 00.000

18

0000.000 00.000 00.000 00.000 00.000

19

0000.000 00.000 00.000 00.000 00.000

20

0000.000 00.000 00.000 00.000 00.000

UN-SET:00

UP-Set PAGE Edit Ret

Upper-Choice 1~20/Lower-Choice 1~40

Tool Use

d

UP-H : 000.000

UN-H : 000.000

UN-V : 00.000

K-Out B : 000.000

K-Out S : 000.000

Instruction

X(L)-axis

SEVRO

1

2

HUST CNC H6D-B3 MANUAL

15

Ones that show and choose at present specification of the cutter。

(UP) Upper and (UN) Lower Choice the structure chart,Can establish the

specifications of a knife of tools according to the sign of the figure .

HUST CNC H6D-B3 MANUAL

16

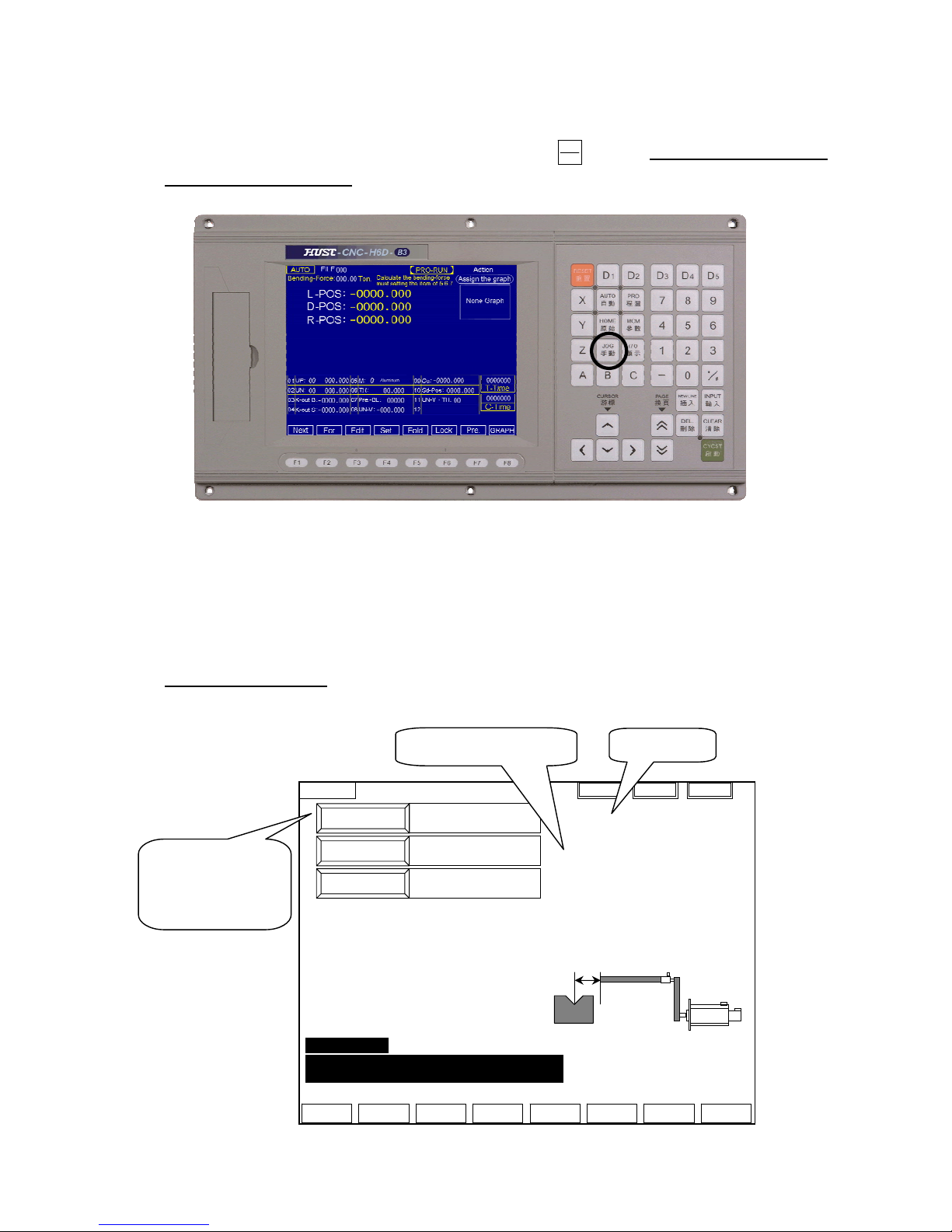

8. JOG mode:

(1) The page will move to JOG mode by pressing key. ( this key will fail when

the program is running)

Fig 16

(2) Choose axis value of JOG by MPG or choose it on the keyboard. When the

MPG is off, then the function on the keyboard is on.

L-axis(X)、D-axis(Y)

Parameter 22 = 0 :The function is on by MPG hand wheel.

Parameter 22 = 1 :JOG operation on the keyboard.

Setting by engineer

(3) Turn the “MPG” or press “PAGE” key Manual control

Fig 17

JOG

手動

JOG

Correct Enter Ret

L-POS

-0000.000

-0000

-0000.000

D-POS

-0000.000

-0000

-0000.000

Correct Step:

1. MPG or JOG mode, move the

L(X)-axis to suitable position.

2. Measure the actually value.

3. Input the Value.

4. Quickly press the ENTER key twice.

Then renew the coordinate.

5. After renew the coordinate then turn

to the JOG mode automatically.

R-POS

-0000.000

-0000

-0000.000

Setting coordinate

L:-0000.000

D:-0000.000

R:-0000.000

X1 X10 X100

Error Message:

Err56 The Z-axis(R-axis) negative way assign value

is smaller than the setting value.

Measuring value:-0000.000

Servo Error

Machinery coordinate

+ limit signal

HOME limit signal

- limit signal

HUST CNC H6D-B3 MANUAL

17

(4) After inputting assign point of each axis, by pressing the “M.T.C” key, the axis

will move to the assign coordinate.

When executing this operation, some error maybe occur:

Err 51:The X -axis(L-axis)positive way assign value is bigger than the setting

value.

Err 52:The X -axis(L-axis)negative way assign value is smaller than the

“Keep-Out” area value.

Err 53:The Y -axis(D-axis)positive way assign value is bigger than the setting

value.

Err 54:The Y -axis(D-axis)negative way assign value is smaller than the setting

value.

Err 55:The Z -axis(R-axis)positive way assign value is bigger than the setting

value.

Err 56:The Z -axis(R-axis)negative way assign value is smaller than the setting

value.

(5) DX:(add pressure limit)

When this function is on, it will highlight. When the DX signal(I007 = 1)is

coming in, the X-axis will do the operation of DX. The distance is based on the

VICE of the 10th group of EDIT MODE.

(6) Correct:【Just only L-axis(X)】

a. move the L-axis and measuring.

b. Enter the L-axis of measuring value。

c. Quickly press the ENTER key twice , then renew the coordinate.

d. After renew the coordinate then turn to the JOG mode automatically.

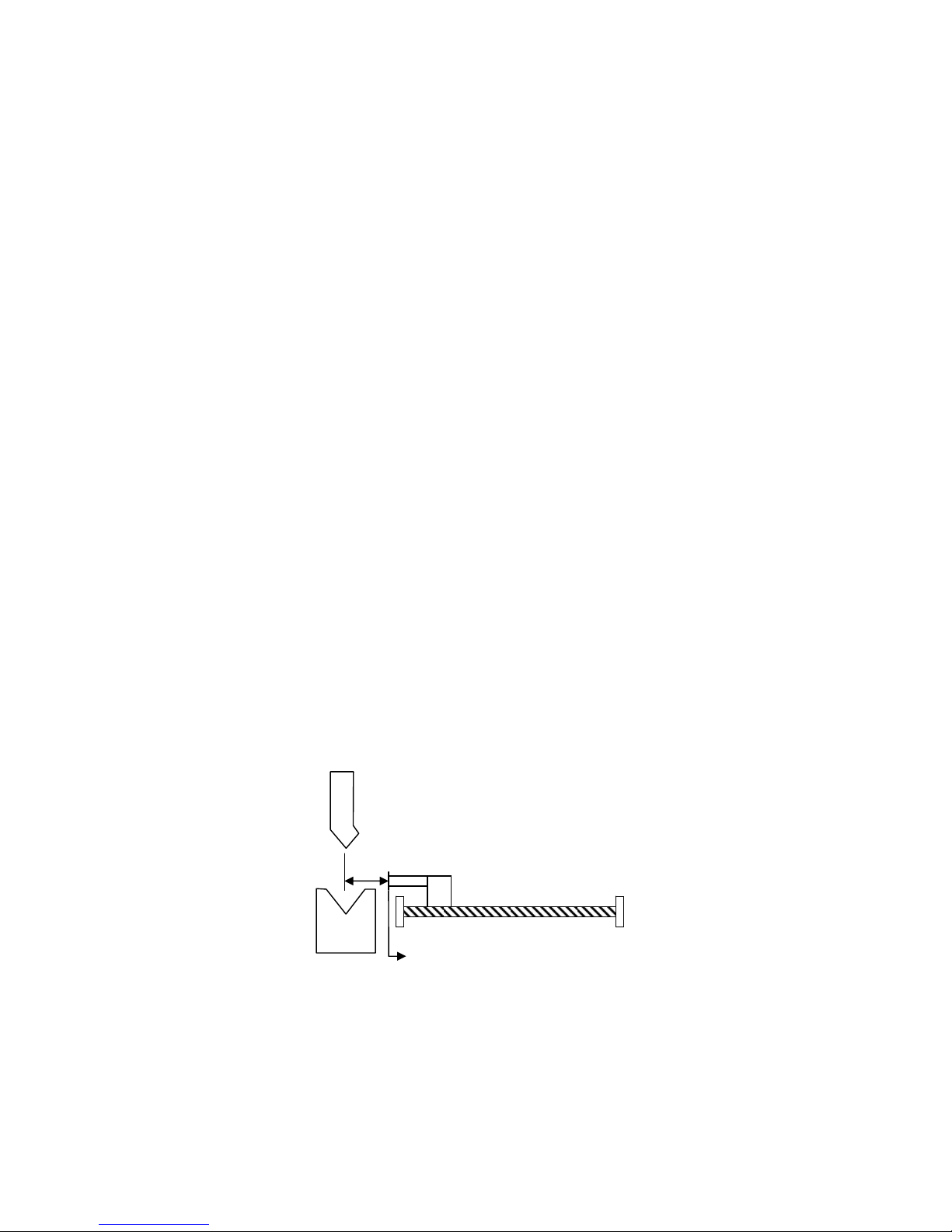

Fig 18

measuring

The actually range is 20.000 mm

HUST CNC H6D-B3 MANUAL

18

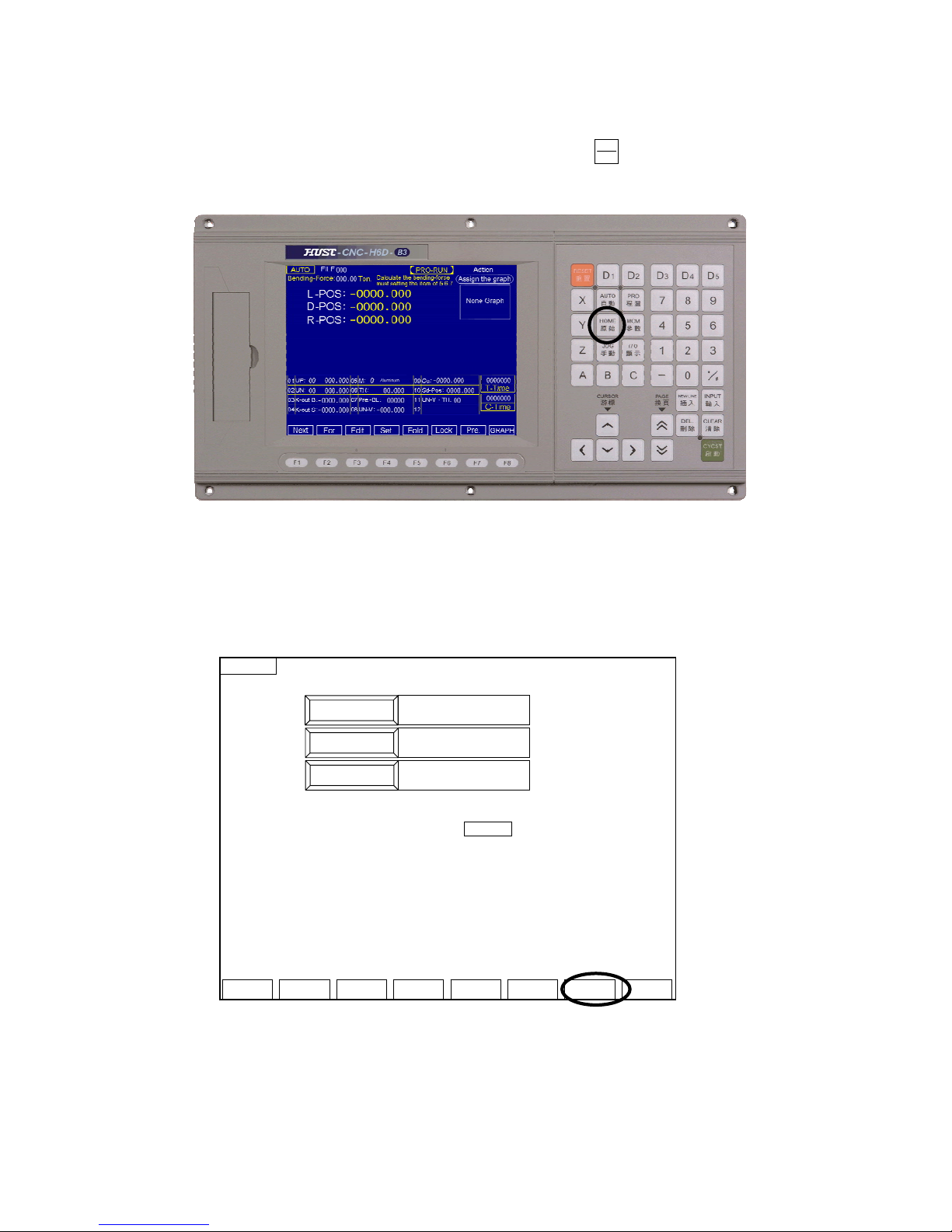

9. HOME mode

(1) It will move to the HOME-mode page by pressing key ( This key will fail

when the program is running.)

Fig 19

(2) Choose axis to home operation on the keyboard.

L-axis(X)、D-axis(Y)、R-axis(Z)

(3) Press CYCST key. Motor begins to execute the motion to HOME.

(4) After the motion done, press AUTO key to the main page.

Fig 20

HOME

L.D.R Ret

L-POS

-0000.000

-0000

-0000.000

D-POS

-0000.000

-0000

-0000.000

R-POS

-0000.000

-0000

-0000.000

INSTRUCTION:

1.When 3-Axis Move, Select L.D.R Key.

(They Must Not ON 0 Position.) or Select The

Axis on Key-Board.

2.Press Cycst Key.

HOME

原點

HUST CNC H6D-B3 MANUAL

19

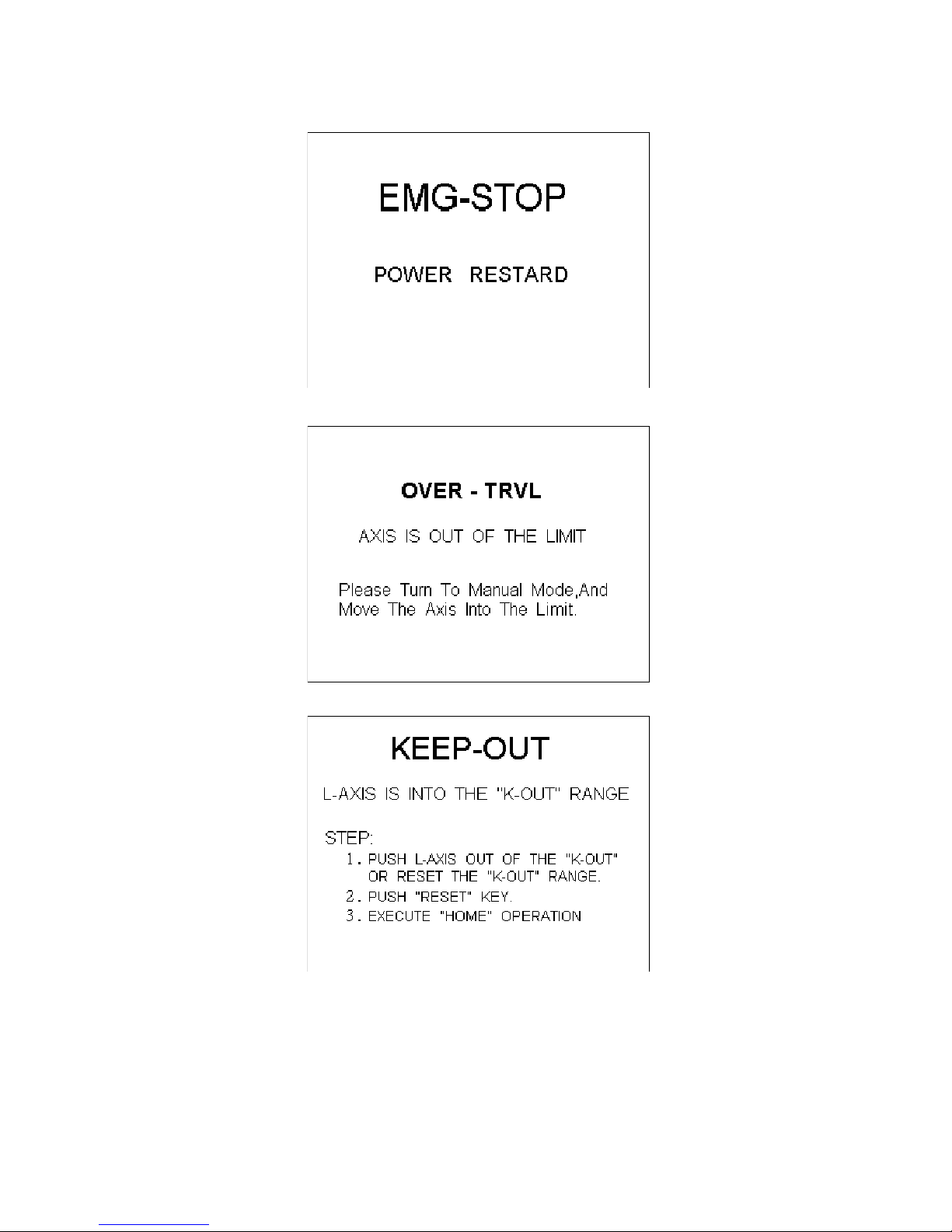

10. Error and Absolve (total Error page)

Fig 22

Fig 23

Fig 24

HUST CNC H6D-B3 MANUAL

20

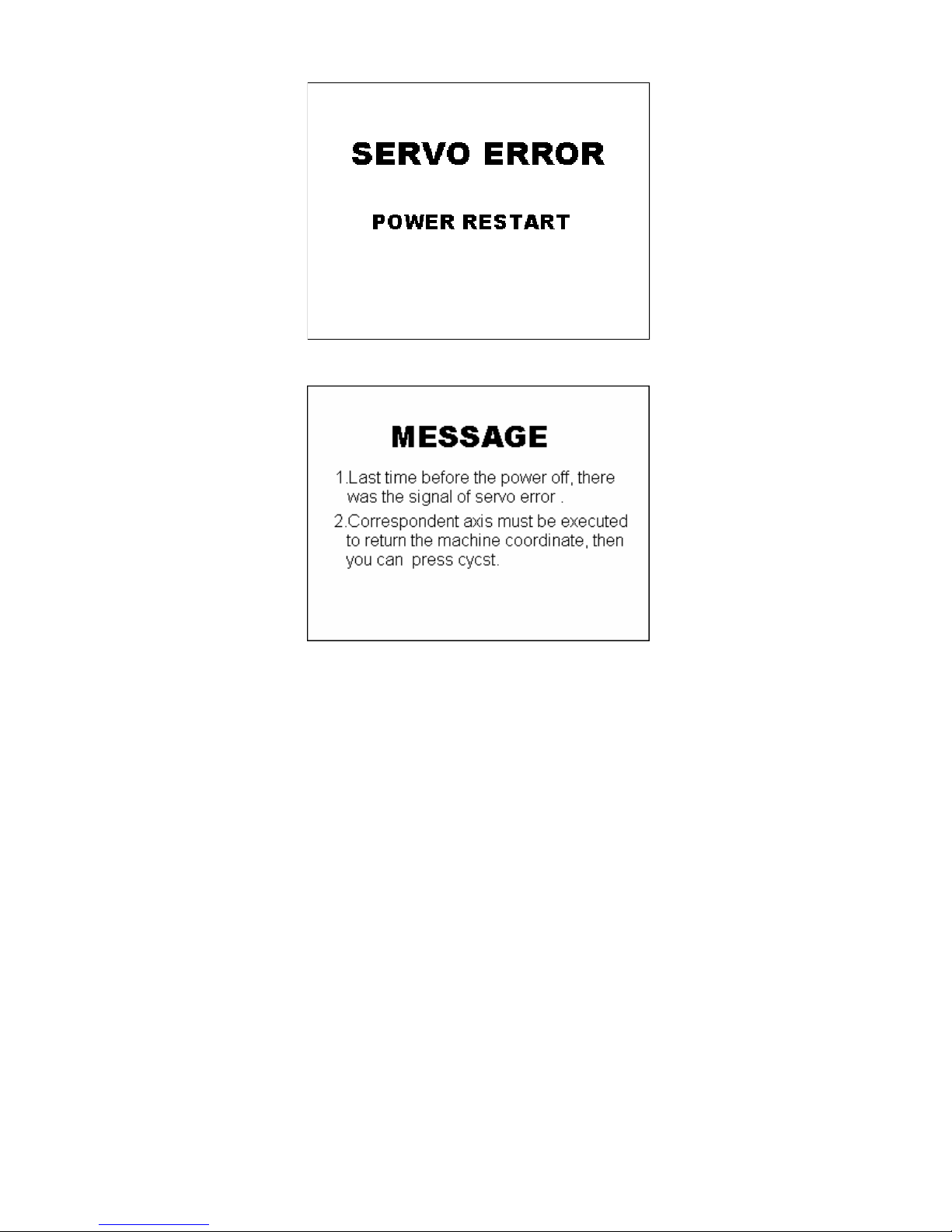

Fig 25

Fig 26

HUST CNC H6D-B3 MANUAL

21

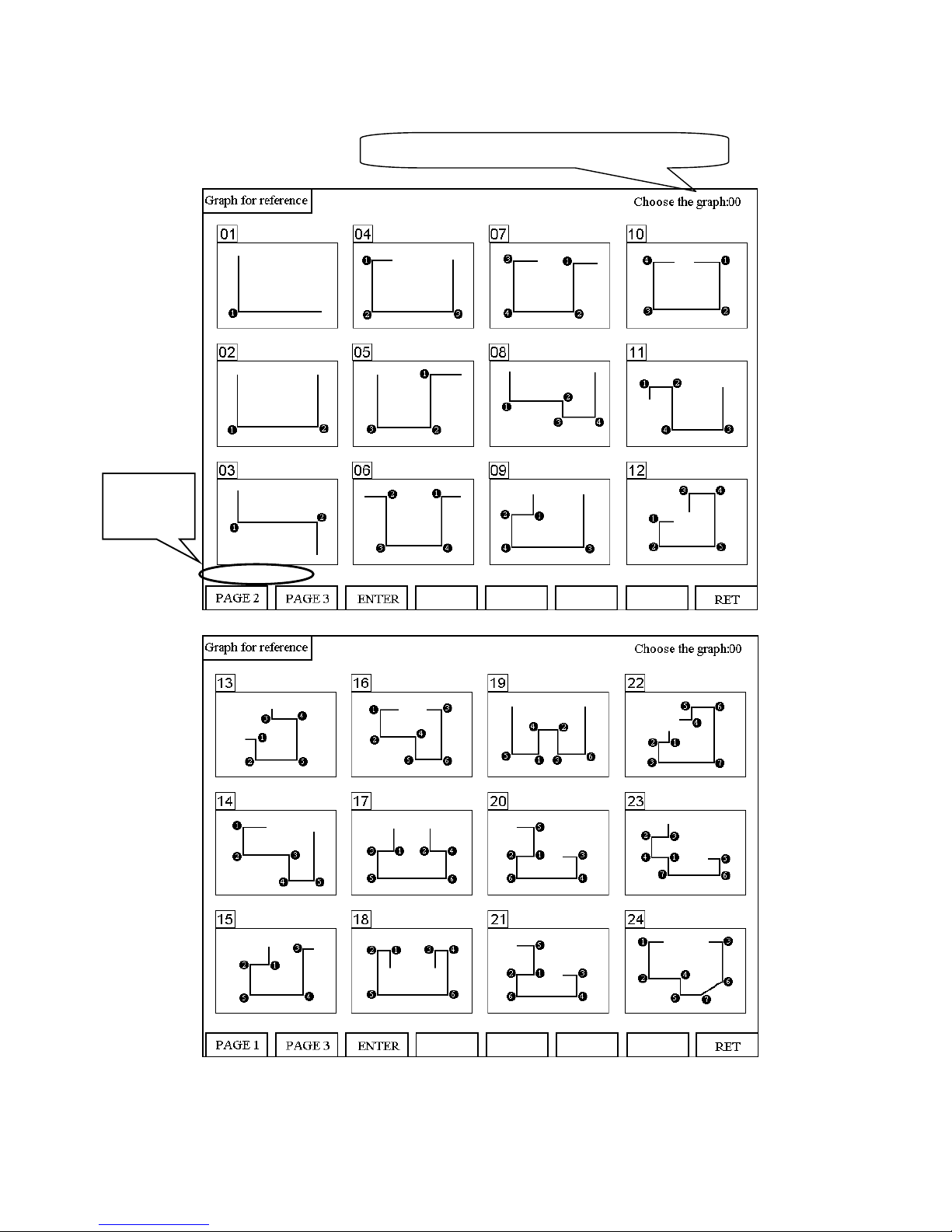

11. Graph for reference ( Graph )

Fig 27

Fig 28

Show that chooses the serial number of the figure

Input the

position

HUST CNC H6D-B3 MANUAL

22

Fig 29

Display:

36 kinds of crooked pictures, and label crooked orders, as reference.

Function:

Page 1:Consult page 1 to the figure。

Page2:Consult page 2 to the figure。

Page 3:Consult page 3 to the figure。

Affirmation key:While choosing to consult the figure, push and confirm the key,

can enter the editor and establish pages and memory procedure the graph for

reference.

Press the enter key and get back to the automatic way page.

Operating sequence

1. Controlled the page or the editor mainly and established pages, choose to consult

and pursue buttons, enter and consult page 1 of figure .

2. Use and change the function key of pages, switch over and look for necessary

reference to pursue .

3. While seeing Graph for reference needed, input the serial numbers of the figure

upper left corner, then push INPUT button.

4. After finishing choosing , press editor's button, reach editor set for pages , or push

the carriage return button, the carriage return mainly controls pages.

HUST CNC H6D-B3 MANUAL

23

12. Bending Machine I/O List

INPUT INFORMATION OUT INFORMATION

0 NC L-axis Limit (hardware +) 0 Oil - Stop

1 NC L-axis Limit (hardware -) 1 L-AXIS SERVO-ON

2 NC D-axis Limit (hardware +) 2 D-AXIS SERVO-ON

3 NC D-axis Limit (hardware -) 3 R-AXIS SERVO-ON

4 NC Emergent Stop (EM-STOP) 4 NC ALARM

5 5 EM-STOP

6 NO Re-CYCST(Oil Upper Limit) 6

7 NO DX signal(add pressure limit) 7

8 NC L-axis Home Limit 8

9 NC D-axis Home Limit 9

10 NC R-axis Home Limit 10

11 NO MPG –X-axis 11

12 NO MPG –Y-axis 12

13 NO MPG –Z-axis 13

14 NO MPG × 1 14

15 NO MPG × 10 15

16 NO MPG × 100

17 NC R-axis Limit (hardware +)

18 NC R-axis Limit (hardware -)

19

20 NO “CYCST” key unused

21

22

23

NO:Normally-Open NC:Normally-Close

OT limit and HOME limit can be found in the parameter page 2. They are set as

Normally-Open or Normally-Close. And the default is Normally-Close.

HUST CNC H6D-B3 MANUAL

24

Press this key, the I/O signal will be shown:

Fig 31

I/O

I00

INPUT

I01

I02

I04

I03

I06

I05

I07

I08

I10

I09

I12

I11

I13

I14

I15

L axis OT+

Explain

L axis OT-

D axis OT+

EM-STOP

D axis OT-

RE-START

DX-SIGNAL

L axis Home Limit

R axis Home Limit

D axis Home Limit

MPG - Y

MPG - X

MPG - Z

MPG X 1

MPG X 10

O00

OUTPUT

O01

O02

O04

O03

O06

O05

O07

O08

O10

O09

O12

O11

O13

O14

O15

Oil system stop

Explain

L axis Servo ON

D axis Servo ON

NC ALARM

R axis Servo ON

EM-STOP

I16

INPUT

I17

I18

I20

I19

I22

I21

I23

MPG X 10

Explain

R axis OT+

R axis OT-

Cycst signal fail

I / O

顯示

HUST CNC H6D-B3 MANUAL

25

13. Machine Connection Diagram

Input Signal

(Input Board) Connect signal line to input board of HUST, and then connect to input

connector on the H3BN through DB25LF of the input board. Using HUST input

board has an advantage that it will protect the controller lines of H3BN series. This

connecting way is only suit for the input connector of NPN type

Fig 32

MPG connection:Plz check the MPG diagram.

EM-STOP:Plz check the Appendix 1

L-axis Limit(hardware+)

+24V

GND

I000

L-axis Limit(hardware-)

+24V

GND

I001

D-axis Limit(hardware+)

+24V

GND

I002

D-axis Limit(hardware-)

+24V

GND

I003

L-axis Home Limit

+24V

GND

I008

D-axis Home Limit

+24V

GND

I009

HUST CNC H6D-B3 MANUAL

26

Output Signal Type

(1) If we use output relay-board, each joint can sustain up to 250V(alternate) and 1A.

(2) If we don’t use output relay-board, each joint can only sustain up to 24V and

100mA.

Fig 33

Oil System Interruption

24V

O000 interruption signal

RELAY

Oil-System control cycle

Connect normally

close signal

L-axis、D-axis、R-axis SERVO-ON

RELAY

24V

O001-L-axis SERVO-ON

Servo Driver

Servo-On

Signal

Servo Driver

Servo-On

Signal

24V

O002-D-axis SERVO-ON

Servo Driver

Servo-On

Signal

24V

O003-D-axis SERVO-ON

HUST CNC H6D-B3 MANUAL

27

Machine Illustration

Fig 34

Bending switch

Oil - System

Oil-Stop(output)

D-axis(Y)

SEVRO

L-axis(X)

SEVRO

-I001 I008 +I000

I006

I007

material

I009

+I002

-I003

I009

-I003

+I002

D-TYPE

O-TYPE

SEVRO

+I017

-I018

I010

R-axis(Z)

HUST CNC H6D-B3 MANUAL

28

Appendix 1:Emergent Stop Connection Diagram

Fig 35 Emergent Stop Connection

PS :

1. Relay A、B are protective lines for starting. They prevent the controller starting

failure. Output will destroy machinery construction.

2. Relay C is servo-on relay.

3. Relay A、B are two outputs in PLC.

4. Relay C commonly is multi-joint. Each driver needs an unique joint. And some

drivers can’t.

5. The PLC edition of servo-on is mentioned in appendix-3.

Spark Killer

Relay B

PLC

Output

24V

Spark Killer

Relay A

PLC

Output

24V

SERVO-DRIVER

Servo-On

Si

g

nal

Spark Killer

SERVO ON Relay C

24V

+24VGND

Limit switch

(EM-Stop)

INPUT

HUST CNC H6D-B3 MANUAL

29

Appendix 2:Servo Driver Servo-On Connection Diagram

Fig 36 Right and Wrong way of driver connection

Fig 37

Right way:

24V

Servo moving signal

RELAY C

Servo Driver

Servo-On

Si

g

nal

Servo Driver

Servo-On

Signal

Wrong way:

Servo

moving

signal

RELAY C

24V

Servo Driver

Servo-On

Signal

Servo Driver

Servo-On

Signal

TMR T 000

50

msec #30

A 0127

O 001

O 001

HUST CNC H6D-B3 MANUAL

30

Appendix 3:H6D-B Controller size

Fig 38 H6D-B CPU Main Board Connectors

H6D-B The Size of Box (Back)

Fig 39

HUST CNC H6D-B3 MANUAL

31

H6D-B The Size of Box (Upper)

Fig 40

H6D-B CUT OUT Size

Fig 41

HUST CNC H6D-B3 MANUAL

32

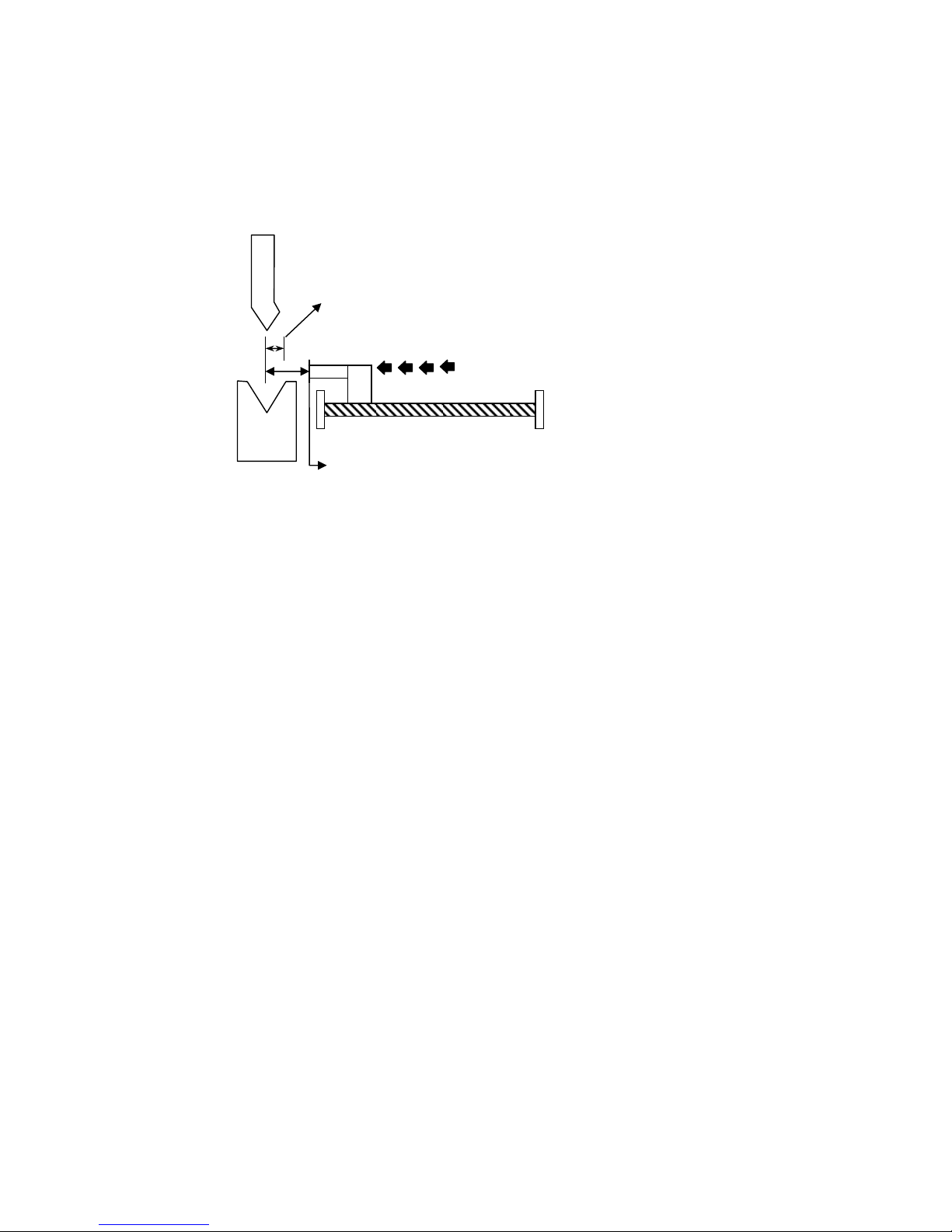

Appendix 4:Bending Angle Conception

D-axis gear wheel 10:1

(Motor runs 10 circles

Fig 42

sinθ= S/L ; cosθ = H/L ; tanθ = sinθ/cosθ = S/H ; H = S/tanθ

Ex1:

UNIT-CHICE model is 30mm width (S = 15mm);angle 90 degree;the piece 2mm

thickness (actual calculation usesμas unit)

Calculation :

(1) 90 ÷2 = 45

(2) sin45 = 0.707;cos45 = 0.707;tan45 = 1

(3) H = 15000(μ)÷1 =15000(μ)

(4) 15000(μ)- 2000(μ)= 13000(μ)

(5) 13 mm Pressing Down Depth∴

EX2:

UNIT-CHICE model is 30mm width ( S = 15mm Actual calculation usesμas unit);

angle 150 degree;what is the pressing down depth H?

Calculation :

(1) 150 ÷2 = 75

(2) sin75 = 0.9659;cos75 = 0.2588;tan75 = 0.9659÷0.2588 = 3.7322

(3) H = 15000(μ)÷3.7322 = 4019.077

(4) 4019.077(μ)- 2000(μ)= 2019.077(μ)

(5) ∴2.019 mm Pressing Down Depth

T:Thickness

S

H

θ

L

UNIT model

HUST CNC H6D-B3 MANUAL

33

Appendix 5:H4CL-B Control Structure of Bending Machine

Fig 43

Control Box

X

DriverY Driver

Slip and Stop

for Y-axis

SEVRO

X-axis stop material ledge

SEVRO

Oil - System

R

Driver

R-axis stop material ledge

SEVRO

Bending switch

Oil-Stop(output)

HUST CNC H6D-B3 MANUAL

34

Appendix 6:MCM (Parameter)。

Fig 44

Fig 45

Then press “MCM” key twice quickly to go to the page below

Parameter cipher

≠0, if you first into

the parameter page,

it will ask you input

the cipher code.

Edition date

The function key

shown is set by

parameter, don’t

operation except

engineer !

HUST CNC H6D-B3 MANUAL

35

Fig 47

Fig 48

The function key shown is set by parameter,

don’t operation except engineer !

HUST CNC H6D-B3 MANUAL

36

1. Resolution – DEN Format:□□□□□□□ (Default = 100)

2. Resolution – NUM Format:□□□□□□□ (Default = 100)

3. Encoder Factor Format:□ (Default = 4)

Denominator (D) = pulses/rev for the encoder on motor.

Numerator (N) = pitch length (mm/rev) of the ball-screw.

Gear Ratio (GR) = Tooth No. on ball-screw / Tooth No. on motor.

Pulse Multiplication Factor (MF) = Encoder Factor

Ex1: X-axis as linear axis, pitch = 5 mm = 5000 m

Encoder = 2500 pulses

Encoder Factor = 4

GR = 5 (motor rotates 5 times while ball-screw rotates once)

Machine resolution = 5000/(2500 x 4)/5 = 5000/50000 = 1/10 = 0.1

m/pulse

Therefore, the setting value for Resolution – DEN and Resolution – NUM

can be one of the three combinations. They are all correct.

(1) D=10000, N=1000 (2) D=10, N=1 (3) D=100, N=10

Setting by engineer.※

4. Traverse Speed Format:□□□□□

Unit: mm/min (Default=10000)

Note : The format is only for integer.

The traverse speed limit can be calculated from the following equation:

Fmax = 0.95 * RPM * Pitch * GR

RPM : The max. rpm of servo motor

Pitch : The pitch of the ball-screw

GR : Gear ratio of ball-screw/motor

Ex: Max. rpm = 3000 rpm for X-axis, Pitch = 5 mm/rev, Gear Ratio = 5/1

Fmax = 0.95 * 3000 * 5 / 5 = 2850 mm/min

Therefore, it is recommended to set Traverse Speed =2850.

Machine Resolution =

(Pitch of Ball - screw)

(Encoder Pulse) * (MF)

*

1

GR

HUST CNC H6D-B3 MANUAL

37

Setting by engineer.※

5. Rotate Direction Format:□ (Default = 0)

Setting = 0, Motor rotates in the positive direction. (CW)

Setting = 1, Motor rotates in the negative direction. (CCW)

This MCM can be used to reverse the direction of motor rotation if desired. So

you don’t have to worry about the direction of rotation when installing motor.

These parameters will affect the direction of HOME position

6. HOME Direction Format:□ (Default = 0)

Setting = 0, Tool returning to HOME in the positive

direction.

Setting = 1, Tool returning to HOME in the negative

direction

7. HOME Speed 1 Format:□□□□ (Default = 2500)

Setting by engineer.※

8. HOME Speed 2 Format:□□□□ (Default = 40)

Unit: mm/min

Set the moving speed when the tool, after having touched the HOME limit switch,

is searching for the encoder grid signal during HOME execution. H4B CNC has

three (3) different speeds when you execute HOME function as shown by Fig A

~D.

Speed 1: The motor accelerates to Speed 1 and its maximum speed is determined

by the settings of MCM #136, #137, #138, #139 (X, Y, Z, A-axis) and

the direction by MCM #130, #131, #132, #133. When tool touches the

home limit switch, it starts deceleration to a stop.

Speed 2: The motor accelerates again to speed 2 and its maximum speed is equal

to 1/4 of Speed 1 and the direction is by MCM #231~#234. When tool

starts leaving the home limit switch, it starts deceleration to a stop.

Speed 3: The motor accelerates to speed 3 and its maximum speed is determined

by the settings of MCM #142~#145 and the direction by MCM

#231~#234. Once the encoder grid index is found, motor decelerates to

a stop. This is the HOME position.

Note that the length of the Home limit switch should be longer than the distance

for the deceleration of Speed 1. Otherwise, serious error may result. The equation

to calculate the length of the Home limit switch is

HUST CNC H6D-B3 MANUAL

38

Length of Home Limit Switch (mm)

FDCOM *ACC

60000

FDCOM = Speed 1, in mm/min. (MCM #136~ #139)

ACC = Time for acceleration/deceleration, in ms. (MCM #167)

60000 = 60 seconds = 60 * 1000 milliseconds

When the C-bit C063=1 in PLC program, it commands the controller to do

homing operation. Do homing operation for X-axis if R232=1, do Y-axis if

R232=2, do Z –axis if R232=4 , do A–axis if R232=8 and do four axes

simultaneously if R232=15.

Ex: FDCOM = 3000.00 mm/min, and ACC = 100 ms

Length of Home Limit Switch = 3000 * 100 / 60000 = 5 mm

Fig 49 A Homing Speed and Direction of finding(GRID)

Fig 50 B Homing Speed and Direction of finding(GRID)

Speed:MCM #136~ #139

Direction:MCM#130~ #133

3

rd

2nd

Tool Position

Speed

Touch the LIMIT SWITCH

C064=1、C065=1、C066=1

Leave the LIMIT SWITCH

C064=0、C065=0、C066=0

Speed:MCM#136~ #139 × 1/4

Direction:MCM#231~ #234= 256

INDEX of finding Encoder

Speed:MCM#142~ #145

Direction:MCM#231~ #234= 256

1st Section Spee

d

Speed

3

r

d

2

nd

Tool Position

1st Section Speed

Speed:MCM #136~ #139

Direction:MCM#130~ #133

Touch the LIMIT SWITCH

C064=1、C065=1、C066=1

Leave the LIMIT SWITCH

C064=0、C065=0、C066=0

Speed:MCM#136~ #139 × 1/4

Direction:MCM#231~ #234= 0

INDEX of finding Encoder

Speed:MCM#142~ #145

Direction:MCM#231~ #234= 0

HUST CNC H6D-B3 MANUAL

39

Fig 51 C Homing Speed and Direction of finding(GRID)

Fig 52 D Homing Speed and Direction of finding(GRID)

Setting by engineer.※

9. Software OT +1 Format:□□□□□□□ (Default = 9999.999)

Unit: mm/min

Set the software over-travel (OT) limit in the positive (+) direction, the setting

value is equal to the distance from positive OT location to the machine origin

(HOME).

10. Software OT -1 Format:-□□□□□□□ (Default = -9999.999)

Unit: mm/min

Set the software over-travel (OT) limit in the negative (-) direction, the setting

3

r

d

2

n

d

Tool Position

1st Section Spee

d

Touch the LIMIT SWITCH

C064=1、C065=1、C066=1

Leave the LIMIT SWITCH

C064=0、C065=0、C066=0

Speed:MCM#136~ #139 × 1/4

Direction:MCM#231~ #234= 1

INDEX of finding Encoder

Speed:MCM#142~ #145

Direction:MCM#231~ #234= 1

Speed

Speed:MCM #136~ #139

Direction:MCM#130~ #133

rd

2

nd

Tool Position

1st Section Speed

Touch the LIMIT SWITCH

C064=1、C065=1、C066=1

Leave the LIMIT SWITCH

C064=0、C065=0、C066=0

Speed:MCM#136~ #139 × 1/4

Direction:MCM#231~ #234= 128

INDEX of finding Encoder

Speed:MCM#142~ #145

Direction:MCM#231~ #234= 0

Speed

Speed:MCM #136~ #139

Direction:MCM#130~ #133

HUST CNC H6D-B3 MANUAL

40

value is equal to the distance from negative OT location to the machine origin

(HOME). Figure below shows the relationship among the software OT limit, the

emergency stop, and the actual hardware limit.

Fig 53

11. Backlash Comp Format:□.□□□ (Default = 0.000)

Unit: mm

12. MPG-NUM Format:□□□□□□□ (Default = 100)

13. MPG-DEN Format:□□□□□□□ (Default = 100)

Ex1: For X-axis, MPG-DEN = 100 pulses, MPG-NUM = 100 m.

The resolution for X-axis = 100/100 = 1 m/pulse.

If MPG hand-wheel moves 1 notch (=100 pulses), the feed length in X-axis

= 100 × (100/100) = 100 m = 0.1 mm.

Ex2: For Y-axis, MPG-DEN = 200 pulses, MPG-NUM = 500 m.

The resolution for Y-axis = 500/200 = 2.5 m/pulse.

If MPG hand-wheel moves 1 notch (=100 pulses), the feed length in Y-axis

= 100 × (500/200) = 250 m = 0.25 mm.

※ Setting by engineer.

14. Software Program-Pos. OT +

Format:□□□□□□□ (Default = 9999.999)

15. Software Program-Pos. OT -

Format:-□□□□□□□ (Default = -9999.999)

16. JOG Feed-Rate Format:□□□□ (Default = 1000)

JOG mode, setting the speed of the Feed-Rate.

17. Setting the range of Grid Format:□□□□.□□□ (Default = 1000.000)

Machine Origin

(Home)

Software OT Limit

(MCM#171~ #182)

Emergency Stop

Actual Hardware Limit

5~10 mm each

HUST CNC H6D-B3 MANUAL

41

The distance’s maximum when servo motor searching the Grid signal:

EX:

The servo motor of X-axis turns 3/4 round = 5.000 mm MCM216 = 5.200

The servo motor of Y-axis turns 3/4 round = 5.000 mm MCM217 = 5.200

※ If it exceeds the range and the motor can not find the Grid still. ERR15 will be

shown up.

Setting by engineer.※

18. HOME Limit Format:□ (Default = 0)

Val u e = 0 ; The signal type is 『Normally Close』.

Val u e = 1 ; The signal type is 『Normally Open』.

19. OT Limit Format:□ (Default = 0)

Val u e = 0 ; The signal type is 『Normally Close』.

Val u e = 1 ; The signal type is 『Normally Open』.

20. D-axis adjust value Format:□□□□.□□□ (Default = 0.000)

EX 1.

MOPM = 326.00

Measure the distance of machine opening = 327.319

『D-axis adjust value』= 1.319

EX 2.

MOPM = 326.00

Measure the distance of machine opening = 325.117

『D-axis adjust value』= -0.883

21. Y-Opening default setting Format:□□□□.□□□ (Default = 0.000)

Fig 54

HUST CNC H6D-B3 MANUAL

42

22. D-axis HOME Limit setting Format:□□□□.□□□ (Default = 0.000)

Show the coordinate when finish the HOME operation

23. R-axis HOME Limit setting Format:□□□□.□□□ (Default = 0.000)

Measure the distance when finish the HOME operation

Fig 55

24. G00 Linear accel / decel Format:□□□ (Default = 100)

Unit: millisecond

Setting Range: 4 ~ 512 millisecond.

25. MPG direction Format:□ (Default = 0)

Adjust the MPG direction (Positive or Negative to the Axis)

According to the bit, bit 0 represents X-axis, bit 1= Y-axis, and bit 2=Z-axis.

EX1: When tending to change the MPG direction of Y-axis, its setting is 2

EX2: When tending to change the MPG direction of X-axis and Y-axis, it’s

setting is 3.

26. MPG Accel / Decel time Format:□□□ (Default = 64)

Unit: milliseconds

Setting Range: 4~512 ms.

The motor acceleration / deceleration time is equal to MCM #236 when MPG

hand-wheel is used in JOG mode.

27. 0 = Metric mode, 1 = Inch mode Format:□ (Default = 0)

Setting = 0, Measurement in METRIC unit.

Setting = 1, Measurement in INCH unit.

Setting by engineer.※

28. Language 0 = Chinese, 1 = English Format:□ (Default = 0)

29. Basic parameter cipher code 1 Format:□□□□ (Default = 0)

+ I017

I010

- I018

The value setting

HUST CNC H6D-B3 MANUAL

43

30. Basic parameter cipher code 2 Format:□□□□ (Default = 0)

If the password setting of MCM is zero, user can get in the displaying page

directly.

If it is not zero, user must enter the correct password to get in the MCM page.

Until the password has been solved, the『Correct』function under JOG mode will

not be set-up.

31. Parameter list 0 = NO, 1 = YES Format:□

※ Setting by engineer.

32. Lock the function key on the MCM page Format:□

The value = 0, Lock

The value = 1, Unlock

value = 1, illustration is below:

Fig 56

Y SET 0: Clean the machine coordinate when press this key 6 sec.

CLR_ALL: Press this key 6 sec

Clean the memory of the FLASH ROM and set the default to

original value.

B_MCM: Burn MCM parameters into FLASH-ROM when press this key 2

sec.

B_VAR: Burn variables into FLASH-ROM when press this key 2 sec.

(#9000-#9999)

CLR_P: Delete all programs.

LD VAR: Read variables burned into FLASH-ROM when press this key 2

sec. (#9000-#9999)

LD MCM: MCM parameters reset when press this key 2 sec.

HUST CNC H6D-B3 MANUAL

44

Setting by engineer.※

33. The basic point of Y-axis HOME direction Format:□□□.□□□ (Default = 0.000)

The setting means that after executing HOME, the distance of moving alone the

direction to HOME. Then the HOME signal input in the controller.

Setting by engineer.※

34. The calculation of Y-opening default Format:□

Setting=0 The bigger Y-axis’ coordinate is set, the more bending angle is

executed.

Setting=1 The smaller Y-axis’ coordinate is set, the more bending angle is

executed.

This setting factor is set by engineer before selling. So, any change of this

setting will effect the location of Y-axis very critically.

Setting by engineer.※

35. The mode after Power-On Format:□

Show the page when Power-On

The value = 0 AUTO MODE

The value = 1 JOG MODE

The value = 2 HOME MODE

HUST CNC H6D-B3 MANUAL

45

HUST H6D MCM Parameter

H6D / H6DL : X, Y, Z, A, B, C-AXES

H9D / H9DL : X, Y, Z, A, B, C , U, V, W-AXES

MCM

No.

Factory

Default

Setting

Unit Description

Setting

1 0

mm

G54 X-axis 1st Work coordinate (origin)

2 0

mm

G54 Y-axis 1st Work coordinate (origin)

3 0

mm

G54 Z-axis 1st Work coordinate (origin)

4 0

mm

G54 A-axis 1st Work coordinate (origin)

5 0

mm

G54 B-axis 1st Work coordinate (origin)

6 0

mm

G54 C-axis 1st Work coordinate (origin)

7 0

mm

G54 U-axis 1st Work coordinate (origin)

8 0

mm

G54 V-axis 1st Work coordinate (origin)

9 0

mm

G54 W-axis 1st Work coordinate (origin)

10-20

System Reserved!

21 0

mm

G55 X-axis 2nd Work coordinate (origin)

22 0

mm

G55 Y-axis 2nd Work coordinate (origin)

23 0

mm

G55 Z-axis 2nd Work coordinate (origin)

24 0

mm

G55 A-axis 2nd Work coordinate (origin)

25 0

mm

G55 B-axis 2nd Work coordinate (origin)

26 0

mm

G55 C-axis 2nd Work coordinate (origin)

27 0

mm

G55 U-axis 2nd Work coordinate (origin)

28 0

mm

G55 V-axis 2nd Work coordinate (origin)

29 0

mm

G55 W-axis 2nd Work coordinate (origin)

30-40

System Reserved!

41 0

mm

G56 X-axis 3rd Work coordinate (origin)

42 0

mm

G56 Y-axis 3rd Work coordinate (origin)

43 0

mm

G56 Z-axis 3rd Work coordinate (origin)

44 0

mm

G56 A-axis 3rd Work coordinate (origin)

45 0

mm

G56 B-axis 3rd Work coordinate (origin)

46 0

mm

G56 C-axis 3rd Work coordinate (origin)

47 0

mm

G56 U-axis 3rd Work coordinate (origin)

48 0

mm

G56 V-axis 3rd Work coordinate (origin)

49 0

mm

G56 W-axis 3rd Work coordinate (origin)

50-60

System Reserved!

61 0

mm

G57 X-axis 4th Work coordinate (origin)

62 0

mm

G57 Y-axis 4th Work coordinate (origin)

63 0

mm

G57 Z-axis 4th Work coordinate (origin)

64 0

mm

G57 A-axis 4th Work coordinate (origin)

65 0

mm

G57 B-axis 4th Work coordinate (origin)

66 0

mm

G57 C-axis 4th Work coordinate (origin)

67 0

mm

G57 U-axis 4th Work coordinate (origin)

68 0

mm

G57 V-axis 4th Work coordinate (origin)

69 0

mm

G57 W-axis 4th Work coordinate (origin)

70-80

System Reserved!

81 0

mm

G58 X-axis 5th Work coordinate (origin)

82 0

mm

G58 Y-axis 5th Work coordinate (origin)

83 0

mm

G58 Z-axis 5th Work coordinate (origin)

84 0

mm

G58 A-axis 5th Work coordinate (origin)

85 0

mm

G58 B-axis 5th Work coordinate (origin)

86 0

mm

G58 C-axis 5th Work coordinate (origin)

87 0

mm

G58 U-axis 5th Work coordinate (origin)

HUST CNC H6D-B3 MANUAL

46

MCM

No.

Factory

Default

Setting

Unit Description

Setting

88 0

mm

G58 V-axis 5th Work coordinate (origin)

89 0

mm

G58 W-axis 5th Work coordinate (origin)

90-100

System Reserved!

101 0

mm

G59 X-axis 6th Work coordinate (origin)

102 0

mm

G59 Y-axis 6th Work coordinate (origin)

103 0

mm

G59 Z-axis 6th Work coordinate (origin)

104 0

mm

G59 A-axis 6th Work coordinate (origin)

105 0

mm

G59 B-axis 6th Work coordinate (origin)

106 0

mm

G59 C-axis 6th Work coordinate (origin)

107 0

mm

G59 U-axis 6th Work coordinate (origin)

108 0

mm

G59 V-axis 6th Work coordinate (origin)

109 0

mm

G59 W-axis 6th Work coordinate (origin)

110-120

System Reserved!

121 0

mm

X-axis, G28 reference point coordinate

122 0

mm

Y-axis, G28 reference point coordinate

123 0

mm

Z-axis, G28 reference point coordinate

124 0

mm

A-axis, G28 reference point coordinate

125 0

mm

B-axis, G28 reference point coordinate

126 0

mm

C-axis, G28 reference point coordinate

127 0

mm

U-axis, G28 reference point coordinate

128 0

mm

V-axis, G28 reference point coordinate

129 0

mm

W-axis, G28 reference point coordinate

130-140

System Reserved!

141 0

mm

X-axis, G30 reference point coordinate

142 0

mm

Y-axis, G30 reference point coordinate

143 0

mm

Z-axis, G30 reference point coordinate

144 0

mm

A-axis, G30 reference point coordinate

145 0

mm

B-axis, G30 reference point coordinate

146 0

mm

C-axis, G30 reference point coordinate

147 0

mm

U-axis, G30 reference point coordinate

148 0

mm

V-axis, G30 reference point coordinate

149 0

mm

W-axis, G30 reference point coordinate

150-160

System Reserved!

161 0

mm

X-axis, Backlash compensation (G01), 0~9.999

162 0

mm

Y-axis, Backlash compensation (G01), 0~9.999

163 0

mm

Z-axis, Backlash compensation (G01), 0~9.999

164 0

mm

A-axis, Backlash compensation (G01), 0~9.999

165 0

mm

B-axis, Backlash compensation (G01), 0~9.999

166 0

mm

C-axis, Backlash compensation (G01), 0~9.999

167 0

mm

U-axis, Backlash compensation (G01), 0~9.999

168 0

mm

V-axis, Backlash compensation (G01), 0~9.999

169 0

mm

W-axis, Backlash compensation (G01), 0~9.999

170-180

System Reserved!

181 0

mm

X-axis, Backlash compensation (G00), 0~9.999

182 0

mm

Y-axis, Backlash compensation (G00), 0~9.999

183 0

mm

Z-axis, Backlash compensation (G00), 0~9.999

184 0

mm

A-axis, Backlash compensation (G00), 0~9.999

185 0

mm

B-axis, Backlash compensation (G00), 0~9.999

186 0

mm

C-axis, Backlash compensation (G00), 0~9.999

187 0

mm

U-axis, Backlash compensation (G00), 0~9.999

188 0

mm

V-axis, Backlash compensation (G00), 0~9.999

189 0

mm

W-axis, Backlash compensation (G00), 0~9.999

190-200

System Reserved!

201

1000 mm/min

X-axis, JOG Feed-rate

HUST CNC H6D-B3 MANUAL

47

MCM

No.

Factory

Default

Setting

Unit Description

Setting

202

1000 mm/min

Y-axis, JOG Feed-rate

203

1000 mm/min

Z-axis, JOG Feed-rate

204

1000 mm/min

A-axis, JOG Feed-rate

205

1000 mm/min

B-axis, JOG Feed-rate

206

1000 mm/min

C-axis, JOG Feed-rate

207

1000 mm/min

U-axis, JOG Feed-rate

208

1000 mm/min

V-axis, JOG Feed-rate

209

1000 mm/min

W-axis, JOG Feed-rate

210-220

System Reserved!

221

10000 mm/min

X-axis, G00 Traverse speed limit

222

10000 mm/min

Y-axis, G00 Traverse speed limit

223

10000 mm/min

Z-axis, G00 Traverse speed limit

224

10000 mm/min

A-axis, G00 Traverse speed limit

225

10000 mm/min

B-axis, G00 Traverse speed limit

226

10000 mm/min

C-axis, G00 Traverse speed limit

227

10000 mm/min

U-axis, G00 Traverse speed limit

228

10000 mm/min

V-axis, G00 Traverse speed limit

229

10000 mm/min

W-axis, G00 Traverse speed limit

230-240

System Reserved!

241

100 pulse

X-axis,Denominator,resolution calc.(Encoder pulse)

242

100 μm

X-axis,Numerator,resolution calculation.(Ball-screwpitch)

243

100 pulse

Y-axis,Denominator,resolutioncalc.(Encoder pulse)

244

100 μm

Y-axis,Numerator,resolutioncalc.(Ball-screwpitch)

245

100 pulse

Z-axis,Denominator,resolutioncalc.(Encoder pulse)

246

100 μm

Z-axis,Numerator,resolutioncalc.(Ball-screwpitch)

247

100 pulse

A-axis,Denominator,resolutioncalc.(Encoder pulse)

248

100 μm

A-axis,Numerator,resolutioncalc.(Ball-screwpitch)

249

100 pulse

B-axis,Denominator,resolutioncalc.(Encoder pulse)

250

100 μm

B-axis,Numerator,resolutioncalc.(Ball-screwpitch)

251

100 pulse

C-axis,Denominator,resolutioncalc.(Encoder pulse)

252

100 μm

C-axis,Numerator,resolutioncalc.(Ball-screwpitch)

253

100 pulse

U-axis,Denominator,resolutioncalc.(Encoder pulse)

254

100 μm

U-axis,Numerator,resolutioncalc.(Ball-screwpitch)

255

100 pulse

V-axis,Denominator,resolutioncalc.(Encoder pulse)

256

100 μm

V-axis,Numerator,resolutioncalc.(Ball-screwpitch)

257

100 pulse

W-axis,Denominator,resolutioncalc.(Encoder pulse)

258

100 μm

W-axis,Numerator,resolutioncalc.(Ball-screwpitch)

259-280

System Reserved!

281

0

X-axis, HOME direction, 0=+ dir.1=-dir

282

0

Y-axis, HOME direction, 0=+ dir.1=-dir

283

0

Z-axis, HOME direction, 0=+ dir.1=-dir

284

0

A-axis, HOME direction, 0=+ dir.1=-dir

285

0

B-axis, HOME direction, 0=+ dir.1=-dir

286

0

C-axis, HOME direction, 0=+ dir.1=-dir

287

0

U-axis, HOME direction, 0=+ dir.1=-dir

288

0

V-axis, HOME direction, 0=+ dir.1=-dir

289

0

W-axis, HOME direction, 0=+ dir.1=-dir

287-300

System Reserved!

301

2500 mm/min

X-axis, HOME speed 1

302

2500 mm/min

Y-axis, HOME speed 1

303

2500 mm/min

Z-axis, HOME speed 1

304

2500 mm/min

A-axis, HOME speed 1

305

2500 mm/min

B-axis, HOME speed 1

306

2500 mm/min

C-axis, HOME speed 1

HUST CNC H6D-B3 MANUAL

48

MCM

No.

Factory

Default

Setting

Unit Description

Setting

207

2500 mm/min

U-axis, HOME speed 1

308

2500 mm/min

V-axis, HOME speed 1

309

2500 mm/min

W-axis, HOME speed 1

310-320

System Reserved!

321

40 mm/min

X-axis, Home grid speed during HOME execution

322

40 mm/min

Y-axis, Home grid speed during HOME execution

323

40 mm/min

Z-axis, Home grid speed during HOME execution

324

40 mm/min

A-axis, Home grid speed during HOME execution

325

40 mm/min

B-axis, Home grid speed during HOME execution

326

40 mm/min

C-axis, Home grid speed during HOME execution

327

40 mm/min

U-axis, Home grid speed during HOME execution

328

40 mm/min

V-axis, Home grid speed during HOME execution

329

40 mm/min

W-axis, Home grid speed during HOME execution

330-340

System Reserved!

341

0 0/1

X-axis,Home grid direction during HOME execution

342

0 0/1

Y-axis,Home grid direction during HOME execution

343

0 0/1

Z-axis,Home grid direction during HOME execution

344

0 0/1

A-axis,Home grid direction during HOME execution

345

0 0/1

B-axis,Home grid direction during HOME execution

346

0 0/1

C-axis,Home grid direction during HOME execution

347

0 0/1

U-axis,Home grid direction during HOME execution

348

0 0/1

V-axis,Home grid direction during HOME execution

349

0 0/1

W-axis,Home grid direction during HOME execution

350-360

System Reserved!

361 0 mm X –axis Home grid setting

362 0 mm Y-axis Home grid setting

363 0 mm Z-axis Home grid setting

364 0 mm A-axis Home grid setting

365 0 mm B-axis Home grid setting

366 0 mm C-axis Home grid setting

367 0 mm U-axis Home grid setting

368 0 mm V-axis Home grid setting

369 0 mm W-axis Home grid setting

370-380

System Reserved!

381 0 mm X-axis, HOME shift data

382 0 mm Y-axis, HOME shift data

383 0 mm Z-axis, HOME shift data

384 0 mm A-axis, HOME shift data

385 0 mm B-axis, HOME shift data

386 0 mm C-axis, HOME shift data

387 0 mm U-axis, HOME shift data

388 0 mm V-axis, HOME shift data

389 0 mm W-axis, HOME shift data

390-400

System Reserved!

401

10.000 mm

X-axis,Setting the value of search servo grid

402

10.000 mm

Y-axis,Setting the value of search servo grid

403

10.000 mm

Z-axis,Setting the value of search servo grid

404

10.000 mm

A-axis,Setting the value of search servo grid

405

10.000 mm

B-axis,Setting the value of search servo grid

406

10.000 mm

C-axis,Setting the value of search servo grid

407

10.000 mm

U-axis,Setting the value of search servo grid

408

10.000 mm

V-axis,Setting the value of search servo grid

409

10.000 mm

W-axis,Setting the value of search servo grid

410-420 0

System Reserved!

HUST CNC H6D-B3 MANUAL

49

MCM

No.

Factory

Default

Setting

Unit Description

Setting

421 0

X-axis Origin switch (+ :N.O (normallyopen) node; -:N.C

(normally closed) node)

422 0 Y-axis Origin switch (+ :N.O node; -:N.C node)

423 0 Z-axis Origin switch (+ :N.O node; - :N.C node)

424 0 A-axis Origin switch (+ :N.O node; - :N.C node)

425 0 B-axis Origin switch (+ :N.O node; - :N.C node)

426 0 C-axis Origin switch (+ :N.O node; - :N.C node)

427 0 U-axis Origin switch (+ :N.O node; - :N.C node)

428 0 V-axis Origin switch (+ :N.O node; - :N.C node)

429 0 W-axis Origin switch (+ :N.O node; - :N.C node)

430-440

System Reserved!

441

0

X-axis, Direction of motor rotation, 0=CW, 1=CCW

442

0

Y-axis, Direction of motor rotation, 0=CW, 1=CCW

443

0

Z-axis, Direction of motor rotation, 0=CW, 1=CCW

444

0

A-axis, Direction of motor rotation, 0=CW, 1=CCW

445

0

B-axis, Direction of motor rotation, 0=CW, 1=CCW

446

0

C-axis, Direction of motor rotation, 0=CW, 1=CCW

447

0

U-axis, Direction of motor rotation, 0=CW, 1=CCW

448

0

V-axis, Direction of motor rotation, 0=CW, 1=CCW

449

0

W-axis, Direction of motor rotation, 0=CW, 1=CCW

450-460

System Reserved!

461

4

X-axis,Encoder pulse multiplicationfactor,1,2,or 4

462

4

Y-axis,Encoder pulse multiplicationfactor,1,2,or 4

463

4

Z-axis,Encoder pulse multiplicationfactor,1,2,or 4

464

4

A-axis,Encoder pulse multiplicationfactor,1,2,or 4

465

4

B-axis,Encoder pulse multiplicationfactor,1,2,or 4

466

4

C-axis,Encoder pulse multiplicationfactor,1,2,or 4

467

4

U-axis,Encoder pulse multiplicationfactor,1,2,or 4

468

4

V-axis,Encoder pulse multiplicationfactor,1,2,or 4

469

4

W-axis,Encoder pulse multiplicationfactor,1,2,or 4

470-480

System Reserved!

481 5 X-axis impulse command width adjustment (4=625KPPS)

482 5 Y-axis impulse command width adjustment (4=625KPPS)

483 5 Z-axis impulse command width adjustment (4=625KPPS)

484 5 A-axis impulse command width adjustment (4=625KPPS)

485 5 B-axis impulse command width adjustment (4=625KPPS)

486 5 C-axis impulse command width adjustment (4=625KPPS)

487 5 U-axis impulse command width adjustment (4=625KPPS)

488 5 V-axis impulse command width adjustment (4=625KPPS)

489 5 W-axis impulse command width adjustment (4=625KPPS)

490-500 6

System Reserved!

501 0

Master/Slave mode, 0=CNC, 1=X-axis, 2=Y-axis

3=Z-axis,4=A-axis,5=B-axis,6=C-axis,7=U-axis,

8=V-axis, 9=w-axis, 256= non-stop mode in a single block

502

0

Accel/Decel mode,0=exponential,1=linear,2=”S” curve

0

Home command mode setting.

BIT0 = 0 , X axis find Home grid available,

= 1 , no need to find.

BIT1 = 0 , Y axis find Home grid available,

= 1 , no need to find.

BIT2 = 0 , Z axis find Home grid available,

= 1 , no need to find.

503

BIT3 = 0 , A axis find Home grid available,

= 1 , no need to find.

HUST CNC H6D-B3 MANUAL

50

MCM

No.

Factory

Default

Setting

Unit Description

Setting

BIT4 = 0 , B axis find Home grid available,

= 1 , no need to find.

BIT5 = 0 , C axis find Home grid available,

= 1 , no need to find.

BIT6 = 0 , U axis find Home grid available,

= 1 , no need to find.

BIT7 = 0 , V axis find Home grid available,

= 1 , no need to find.

BIT8 = 0 , W axis find Home grid available,

= 1 , no need to find.

504

100 msec

G00 Linear accel./decel. Time, 4~512 ms

505

100 msec

G01 Linear accel./decel. Time, 10~1024 ms

506

100 msec

Accel/Decel time when in G99 mode (mm/rev)

507

100 msec

Time Setting for spindle acceleration

508

0

System Reserved!

509

4096 pulse

Spindle encoder resolution (pulse/rev)

510

3000 rpm

Max. spindle rpm at 10 volts

511 0 v Spindle voltage command zero drift correction (open circuit)

512 0

Spindle voltage command acce/dece slope correction (open

circuit)

513 0 rpm Spindle RPM correction (based on feedback from the encoder)

514

0

Start number for program block number generation

515

0

Increment for program block number generation

516

1

Denominator of feed-rate when in MPG test mode

517

1

Numerator of feed-rate when in MPG test mode

518 0

MPG direction

519

64 ms

Set Acceleration/Deceleration Time for MPG (4~512)

520

38400

RS232 Baud rate, 38400, 19200 / EVEN /2 Bit

521 0

Setting whether R000~R99 data in PLC are stored when power

is cut off. 0=NO, 256=YES

522

0 pulse

Servo Error Counter

523 0

Radius/Diameter Programming mode

524

0

0=Metric mode, 25400=inch mode mcm541=0,1

525

3

Error in Circular Cutting, ideal value=1

526 0

Pulse settings

0: pulse + direction 1: +/- pulse 2: A/B phase

527 1000 Setting G01 speed value at booting

528 0 Setting tool compensation direction =1 FAUNC, =0 HUST

529 0

It is used for adjusting the G01’s acceleration/deceleration time

when the acceleration/deceleration type is set to an “S” curve.

When MCM 502=2, the function can then be sustained.

530 0

G31 input motion stop at hardware

531 0

Format setting

=0 standard,

=1 the system will automatically add a decimal point to even

numbers,

=2 line editing,

=4 automatically added with a decimal point in programming

532

2.000 mm

Mill mode;Setting the backlash of G83

533 4096 pulse Setting the following error count for testing

534

Testing the function of axial setting of the servo following

error(bit0-X..)

535 Controller ID number

536

Minimum slope setting of the Auto Teach function (with use of

C040)

HUST CNC H6D-B3 MANUAL

51

MCM

No.

Factory

Default

Setting

Unit Description

Setting

537

First distance setting of the Auto Teach function ( with use of

C040)

538 0 G41 and G42 processing types

539 System reserved

540 0 Adjustment of the axis feedback direction.

541 0 Arc type

541-560

System Reserved!

561 0

"S" curve accel./decel. profile setting for the X-axis

562 0

"S" curve accel./decel. profile setting for the Y-axis

563 0

"S" curve accel./decel. profile setting for the Z-axis

564 0

"S" curve accel./decel. profile setting for the A-axis

565 0

"S" curve accel./decel. profile setting for the B-axis

566 0

"S" curve accel./decel. profile setting for the C-axis

567 0

"S" curve accel./decel. profile setting for the U-axis

568 0

"S" curve accel./decel. profile setting for the V-axis

569 0

"S" curve accel./decel. profile setting for the W-axis

570~580

System Reserved!

581

9999999 mm

X-axis, Software OT limit, (+) direction (Group 1)

582

9999999 mm

Y-axis, Software OT limit, (+) direction (Group 1)

583

9999999 mm

Z-axis, Software OT limit, (+) direction (Group 1)

584

9999999 mm

A-axis, Software OT limit, (+) direction (Group 1)

585

9999999 mm

B-axis, Software OT limit, (+) direction (Group 1)

586

9999999 mm

C-axis, Software OT limit, (+) direction (Group 1)

587

9999999 mm

U-axis, Software OT limit, (+) direction (Group 1)

588

9999999 mm

V-axis, Software OT limit, (+) direction (Group 1)

589

9999999 mm

W-axis, Software OT limit, (+) direction (Group 1)

590-600

System Reserved!

601

-9999999 mm

X-axis, Software OT limit, (-) direction (Group 1)

602

-9999999 mm

Y-axis, Software OT limit, (-) direction (Group 1)

603

-9999999 mm

Z-axis, Software OT limit, (-) direction (Group 1)

604

-9999999 mm

A-axis, Software OT limit, (-) direction (Group 1)

605

-9999999 mm

B-axis, Software OT limit, (-) direction (Group 1)

606

-9999999 mm

C-axis, Software OT limit, (-) direction (Group 1)

607

-9999999 mm

U-axis, Software OT limit, (-) direction (Group 1)

608

-9999999 mm

V-axis, Software OT limit, (-) direction (Group 1)

609

-9999999 mm

W-axis, Software OT limit, (-) direction (Group 1)

610-620

System Reserved!

621

9999999 mm

X-axis, Software OT limit, (+) direction (Group 2)

622

9999999 mm

Y-axis, Software OT limit, (+) direction (Group 2)

623

9999999 mm

Z-axis, Software OT limit, (+) direction (Group 2)

624

9999999 mm

A-axis, Software OT limit, (+) direction (Group 2)

625

9999999 mm

B-axis, Software OT limit, (+) direction (Group 2)

626

9999999 mm

C-axis, Software OT limit, (+) direction (Group 2)

627

9999999 mm

U-axis, Software OT limit, (+) direction (Group 2)

628

9999999 mm

V-axis, Software OT limit, (+) direction (Group 2)

629

9999999 mm

W-axis, Software OT limit, (+) direction (Group 2)

630-640

System Reserved!

641

-9999999 mm

X-axis, Software OT limit, (-) direction (Group 2)

642

-9999999 mm

Y-axis, Software OT limit, (-) direction (Group 2)

643

-9999999 mm

Z-axis, Software OT limit, (-) direction (Group 2)

644

-9999999 mm

A-axis, Software OT limit, (-) direction (Group 2)

645

-9999999 mm

B-axis, Software OT limit, (-) direction (Group 2)

646

-9999999 mm

C-axis, Software OT limit, (-) direction (Group 2)

647

-9999999 mm

U-axis, Software OT limit, (-) direction (Group 2)

HUST CNC H6D-B3 MANUAL

52

MCM

No.

Factory

Default

Setting

Unit Description

Setting

648

-9999999 mm

V-axis, Software OT limit, (-) direction (Group 2)

649

-9999999 mm

W-axis, Software OT limit, (-) direction (Group 2)

650-660

System Reserved!

661

0

X-axis, Cycle clearing w/ M02, M30, M99

662

0

Y-axis, Cycle clearing w/ M02, M30, M99

663

0

Z-axis, Cycle clearing w/ M02, M30, M99

664

0

A-axis, Cycle clearing w/ M02, M30, M99

665

0

B-axis, Cycle clearing w/ M02, M30, M99

666

0

C-axis, Cycle clearing w/ M02, M30, M99

667

0

U-axis, Cycle clearing w/ M02, M30, M99

668

0

V-axis, Cycle clearing w/ M02, M30, M99

669

0

W-axis, Cycle clearing w/ M02, M30, M99

670-680

0

System Reserved!

681

1

X-axis,0=incrementalcoord.,1=absolute coordinate

682

1

Y-axis,0=incrementalcoord.,1=absolute coordinate

683

1

Z-axis,0=incrementalcoord.,1=absolute coordinate

684

1

A-axis,0=incrementalcoord.,1=absolute coordinate

685

1

B-axis,0=incrementalcoord.,1=absolute coordinate

686

1

C-axis,0=incrementalcoord.,1=absolute coordinate

687

1

U-axis,0=incrementalcoord.,1=absolute coordinate

688

1

V-axis,0=incrementalcoord.,1=absolute coordinate

689

1

W-axis,0=incrementalcoord.,1=absolute coordinate

690-700

1

System Reserved!

701

64 pulse

X-axis, Position gain, standard=64

702

64 pulse

Y-axis, Position gain, standard=64

703

64 pulse

Z-axis, Position gain, standard=64

704

64 pulse

A-axis, Position gain, standard=64

705

64 pulse

B-axis, Position gain, standard=64

706

64 pulse

C-axis, Position gain, standard=64

707

64 pulse

U-axis, Position gain, standard=64

708

64 pulse

V-axis, Position gain, standard=64

709

64 pulse

W-axis, Position gain, standard=64

710-720

64 pulse

System Reserved!

721

10 pulse

X-axis,Break-over point for position gain, std=10

722

10 pulse

Y-axis,Break-over point for position gain, std=10

723

10 pulse

Z-axis,Break-over point for position gain, std=10

724

10 pulse

A-axis,Break-over point for position gain, std=10

725

10 pulse

B-axis,Break-over point for position gain, std=10

726

10 pulse

C-axis,Break-over point for position gain, std=10

727

10 pulse

U-axis,Break-over point for position gain, std=10

728

10 pulse

V-axis,Break-over point for position gain, std=10

729

10 pulse

W-axis,Break-over point for position gain, std=10

727-740

10 pulse

System Reserved!

741

100

X-axis, Denominator, MPG resolution calc.

742

100

X-axis, Numerator, MPG resolution calc.

743

100

Y-axis, Denominator, MPG resolution calc.

744

100

Y-axis, Numerator, MPG resolution calc.

745

100

Z-axis, Denominator, MPG resolution calc.

746

100

Z-axis, Numerator, MPG resolution calc.

747

100

A-axis, Denominator, MPG resolution calc.

748

100

A-axis, Numerator, MPG resolution calc.

749

100

B-axis, Denominator, MPG resolution calc.

750

100

B-axis, Numerator, MPG resolution calc.

751

100

C-axis, Denominator, MPG resolution calc.

HUST CNC H6D-B3 MANUAL

53

MCM

No.

Factory

Default

Setting

Unit Description

Setting

752

100

C-axis, Numerator, MPG resolution calc.

753

100

U-axis, Denominator, MPG resolution calc.

754

100

U-axis, Numerator, MPG resolution calc.

755

100

V-axis, Denominator, MPG resolution calc.

756

100

V-axis, Numerator, MPG resolution calc.

757

100

W-axis, Denominator, MPG resolution calc.

758

100

W-axis, Numerator, MPG resolution calc.

760-780

System Reserved!

781

0

Set X-axis as Rotating (1) / Linear axis (0)

782

0

Set Y-axis as Rotating (1) / Linear axis (0)

783

0

Set Z-axis as Rotating (1) / Linear axis (0)

784

0

Set A-axis as Rotating (1) / Linear axis (0)

785

0

Set B-axis as Rotating (1) / Linear axis (0)

786

0

Set C-axis as Rotating (1) / Linear axis (0)

787

0

Set U-axis as Rotating (1) / Linear axis (0)

788

0

Set V-axis as Rotating (1) / Linear axis (0)

789

0

Set W-axis as Rotating (1) / Linear axis (0)

790-800

System Reserved!

801

0.000

mm Distance of S bit sent before the X-axis reaches in position. (S176)

802

0.000

mm Distance of S bit sent before the Y-axis reaches in position. (S177)

803

0.000

mm Distance of S bit sent before the Z-axis reaches in position. (S178)

804

0.000

mm Distance of S bit sent before the A-axis reaches in position. (S179)

805

0.000

mm Distance of S bit sent before the B-axis reaches in position. (S180)

806

0.000

mm Distance of S bit sent before the C-axis reaches in position. (S181)

807

0.000

mm Distance of S bit sent before the U-axis reaches in position. (S182)

808

0.000

mm Distance of S bit sent before the V-axis reaches in position. (S183)

809

0.000

mm Distance of S bit sent before the W-axis reaches in position. (S184)

810-820

System Reserved!

821

0 msec

Set Acceleration/Deceleration Time for X-axis

822

0 msec

Set Acceleration/Deceleration Time for Y-axis

823

0 msec

Set Acceleration/Deceleration Time for Z-axis

824

0 msec

Set Acceleration/Deceleration Time for A-axis

825

0 msec

Set Acceleration/Deceleration Time for B-axis

826

0 msec

Set Acceleration/Deceleration Time for C-axis

827

0 msec

Set Acceleration/Deceleration Time for U-axis

828

0 msec

Set Acceleration/Deceleration Time for V-axis

829

0 msec

Set Acceleration/Deceleration Time for W-axis

830-840

System Reserved!

841

0

X-axis allowable compensation of back screw pitch

842

0

Y-axis allowable compensation of back screw pitch

843

0