Hussmann VSG, VTB Installation And Operation Manual

Manual

Installation

& Operation

Rev. 0309

/Chino

Rev. 0309

VTB, VSG

Upright Bakery Merchandisers

VTB, VSG

Upright Bakery Merchandisers

VTB

VSG with DSS

Bagel Bin Option

p/n IGSV-VTB, VSG-0309

INST ALLA TION & OPERA TION GUIDE

1

IGSV-VTB, VSG-0309

General Instructions

Contents

General Instructions................................................. 2

APPLICATION ..................................................................................................... 2

Cut & Plan Views....................................................... 3

Installation ................................................................. 5

LOCATION............................................................................................................. 5

UNCRATING THE STAND....................................................................................... 5

LEVELING.............................................................................................................. 5

HEADER............................................................................................................. 6

INSTALLING PEDESTAL BASE CLOSE OFF......................................................... 6

Plumbing.................................................................... 7

WASTE OUTLET AND P-TRAP .............................................................................. 7

INSTALLING CONDENSATE DRAIN........................................................................ 7

Refrigeration ............................................................. 8

REFRIGERANT TYPE ............................................................................................. 8

MEASURING THE OPERATING SUPERHEAT.......................................................... 8

T-STAT LOCATION.................................................................................................. 8

WIRING COLOR CODE ......................................................................................... 9

Case Specifications ................................................... 9

ELECTRICAL ............................................................ 9

Electrical Schematics ............................................... 10

User Information ...................................................... 12

STOCKING.............................................................................................................. 12

IMPORTANT STEPS................................................................................................ 12

CASE CLEANING.................................................................................................... 12

Light Fixtures....................................................................................................... 13

CLEANING GLASS & MIRRORS.............................................................................. 13

PLEXIGLASS & ACRYLIC CARE.............................................................................. 13

Maintenance .............................................................. 14

ELECTRICAL PRECAUTIONS................................................................................... 14

REPLACING FLUORESCENT LAMPS ....................................................................... 14

TIPS & TROUBLESHOOTING ................................................................................. 14

REPOSITIONING SHELF LIGHT FIXTURE ..............................................................14

Appendices ................................................................ 16

APPENDIX A. – Temperature Guidelines............................................................ 16

APPENDIX B. – Application Recommendations.................................................. 16

APPENDIX C. – Field Recommendations............................................................ 16

APPENDIX D. – Recommendations to user -.................................................... 17

THIS BOOKLET CONTAINS INFORMATION ON:

VTB-Vista Tower Bakery. Self service bakery case with

5 rows of shelves, and self closing doors.

VSG –Vista Sweet Goods Display. Self service bakery

case with 4 rows of shelves, and self closing

doors.

APPLICATION

These service-type merchandisers have been specifically

designed for bakery departments. The full length, glass

front provides complete product visibility.

The VSG, VCB, VTB, and VBW ar e non-refrigerated

models designed to display fresh bakery products that

have a fast turnover and require no refrigeration.

SHIPPING DAMAGE

All equipment should be thoroughly examined for

shipping damage before and during unloading.

This equipment has been carefully inspected at our

factory and the carrier has assumed responsibility for

safe arrival. If damaged, either apparent or concealed,

claim must be made to the carrier.

APPARENT LOSS OR DAMAGE

If there is an obvious loss or damage, it must be noted on

the freight bill or express receipt and signed by the

carrier’s agent; otherwise, carrier may refuse claim. The

carrier will supply necessary claim forms.

CONCEALED LOSS OR DAMAGE

When loss or damage is not apparent until after equipment

is un-crated, a claim for concealed damage is made. Make

request in writing to carrier for inspection within 15

days, and retain all packaging. The carrier will supply

inspection report and required claim forms.

SHORTAGES

Check your shipment for any possible shortages of

material. If a shortage should exist and is found to be the

responsibility of Hussmann Chino, notify Hussmann Chino.

If such a shortage involves the carrier, notify the carrier

immediately, and r equest an inspection. Hussmann Chino

will acknowledge shortages within ten days from receipt

of equipment.

HUSSMANN CHINO PRODUCT CONTROL

The serial number and shipping date of all equipment has

been recorded in Hussmann’s files for warranty and

replacement part purposes. All correspondence pertaining to warranty or parts ordering must include the serial

number of each piece of equipment involved in order to

provide the customer with the corr ect parts.

/Chino

A publication of

Hussmann® Chino

13770 Ramona A ven ue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

Keep this booklet with the case at all times for future reference.

The Hussmann warranty is printed in the back

of this guide.

2

1

Rear

Load

Option

26

(661)

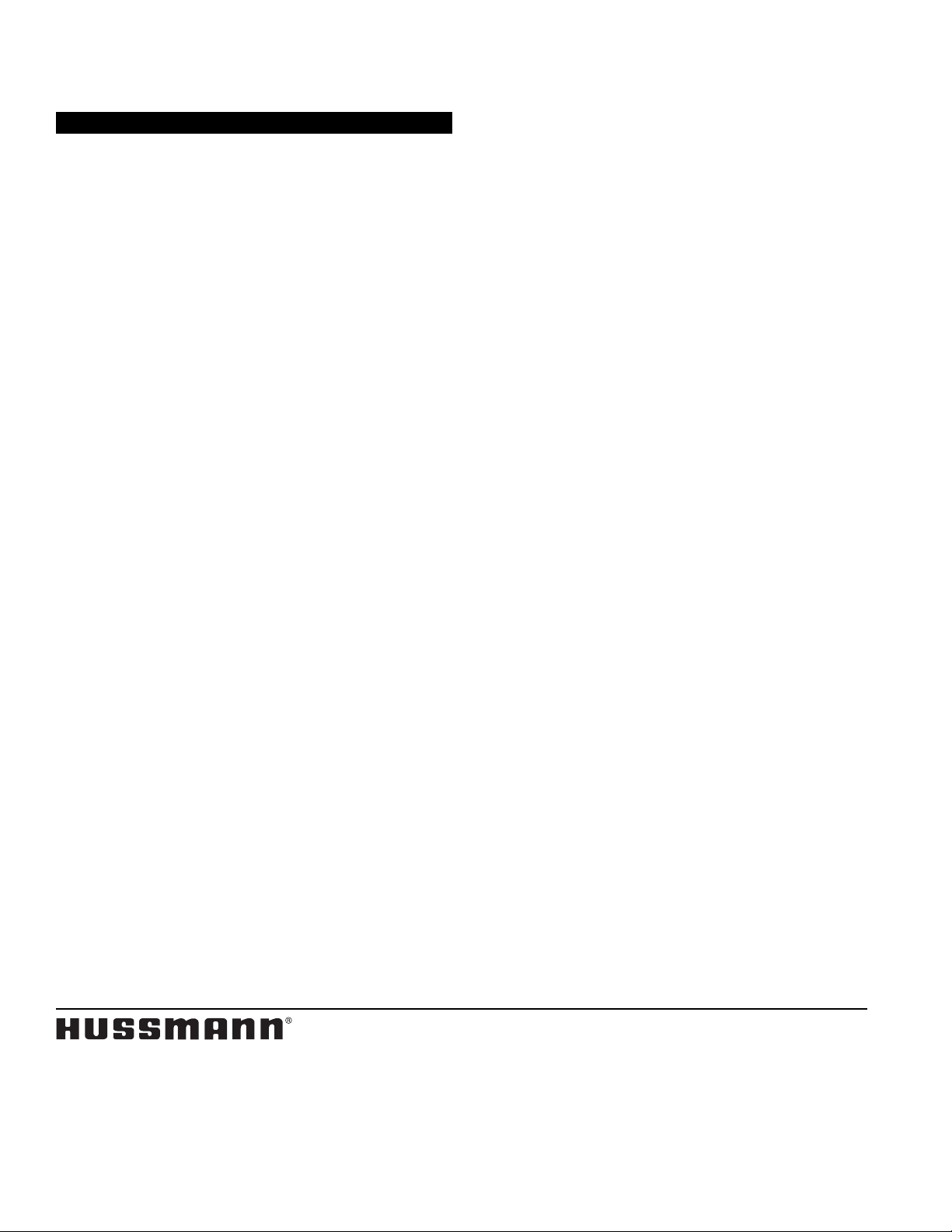

VTB

Vista Tower Merchandiser Bakery Case

Scale = 1/2"

8

7

1

/

2

"

(

M

a

t

c

h

e

s

S

e

l

f

C

o

n

t

a

i

n

e

d

H

e

i

g

h

t

)

4

5

3

/4"

3

8

"

4

7

1

/

2

"

3

0

"

(

M

a

t

c

h

e

s

S

e

l

f

C

o

n

t

a

i

n

e

d

H

e

i

g

h

t

)

2

4

1

/

2

"

(

M

a

t

c

h

e

s

S

e

l

f

C

o

n

t

a

i

n

e

d

H

e

i

g

h

t

)

1

0

"

1

10''

''

2

/

47

''

2

/

30

Rev. 0309

Cut & Plan Views

38''

'

'

8

1

88''

6 1/8''

Cookie Bin

1

7

''

''

8

/

3

13

30 3/8''7 5/8''

VSG

Optional Cookie Bin and 3 Shelves

1

10''

/2''30

47

/2''

1

3

Optional Cookie Bin and 3 Shelves

Cookie

Bin

6 1/8''

/8''

13

5

7

Scale = 1/2"

38''

1

7

'

'

/8''

30 3/8''

VSG

Scale = 1/4"

"

4

/

3

'

'

8

1

88''

8

"

2

/

1

48

Refrigerated

Lower Storage

25"

Optional

"

4

/

3

13

"

2

/

1

10

Bakery Tower with Optional

Refrigerated Lower Storage

36"

"

8

1

3

26

/4"

VSG-DSS

Scale = 1/4"

10''

'

'

6

2

/2''

"

4

/

1

82

1

47

88''

1

7

/8''

13

''

5

7

/8''

30 3/8''

/2''

1

30

3

VSG

Optional 4 Deep Shelf

Scale = 1/4"

3

38''

IGSV-VTB, VSG-0309

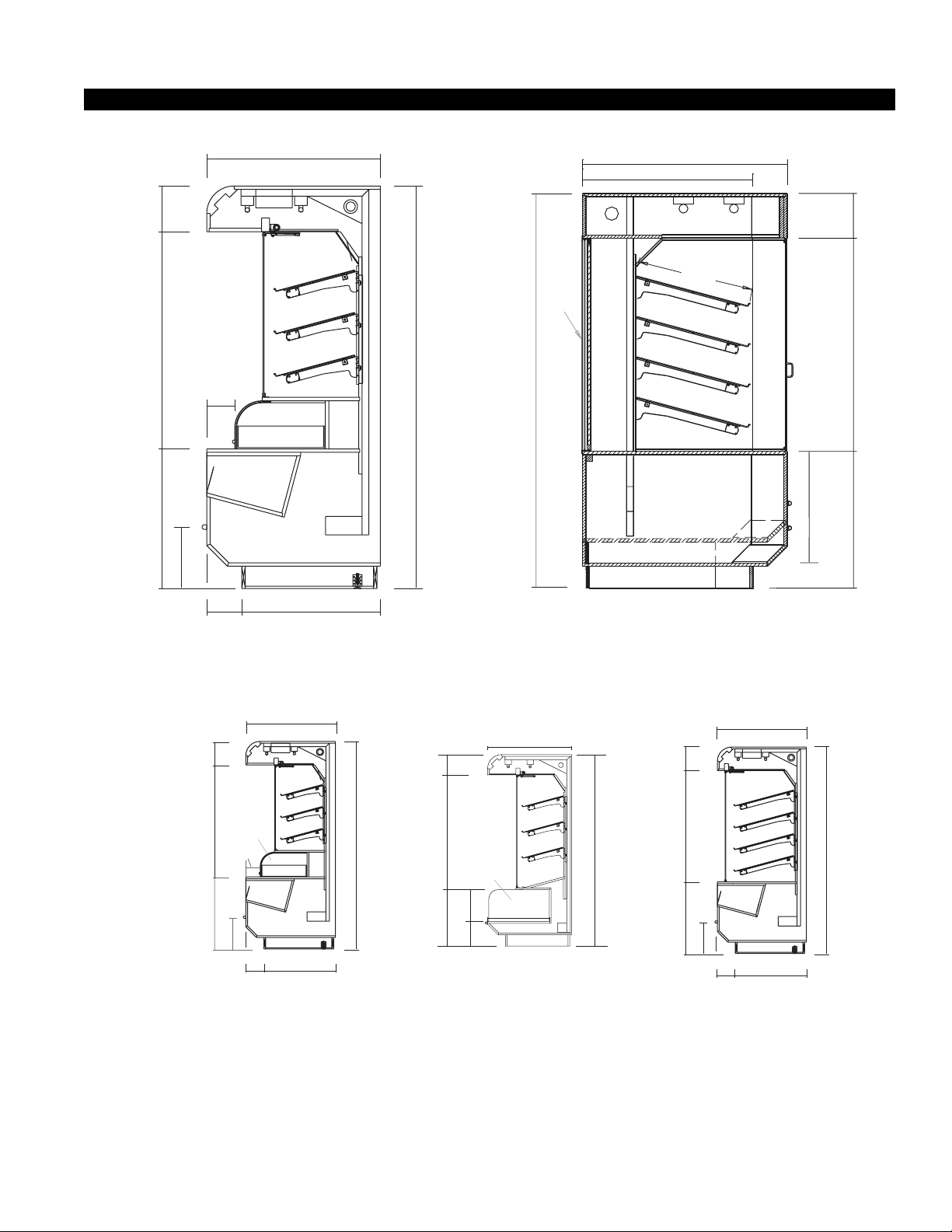

1” Bumper

38''

48" 2-Door Case

56" 2-Door Case • 78" 3-Door Case

56" (78")

VSG

Plan

Scale = 1/2"

88''

56''

8

VTB

Scale = 1/4"

''

Bakery Vista Tower Merchandiser

3

VSG

Overhead view

Scale = 1/4"

4

Installation

LOCATION

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature

and humidity are maintained at or below 75°F and 55%

relative humidity. DO NOT allow air conditioning,

electric fans, ovens, open doors or windows (etc.) to

create air currents around the merchandiser, as this will

impair its correct operation.

Product temperature should always be maintained at a

constant and proper temperature. This means that from

the time the product is receiv ed, through storage,

preparation and display, the temperature of the product

must be controlled to maximize life of the product.

UNCRATING THE STAND

Place the fixture as close to its permanent position as

possible. Remove the top of the crate. Detach the walls

from each other and remove from the skid. Unbolt the

case from the skid. The fixture can now be lifted off the

crate skid. Lift only at base of stand!

EXTERIOR LOADING

These models have not been structurally designed to

support excessive external loading. Do not walk on

their tops; This could cause serious personal injury and

damage to the fixture.

DANGER!

SETTING AND JOINING

The sectional construction of these models enable them

to be joined in line to give the effect of one continuous

display. A joint trim kit is supplied with each joint.

LEVELING

IMPORTANT! It is imperative that cases be leveled

from front to back and side to side prior to joining. A

level case is necessary to insure proper operation,

water drainage, glass alignment, and operation of the

hinges supporting the glass. Leveling the case correctly will solve most hinge operation problems.

NOTE: A. To avoid removing concrete flooring, begin lineup

leveling from the highest point of the store floor.

B.When wedges are involved in a lineup, set them first.

All cases were leveled and joined prior to shipment to

insure the closest possible fit when cases are joined in

the field. When joining, use a carpenter’s level and shim

legs accordingly. Case must be raised correctly, under

legs where support is best, to prevent damage to case.

Merchandisers must be installed level to ensure proper

operation of self closing doors. Place prybar under base

Rev. 0309

and lift. DO NOT LIFT END PANEL. Turn leveler,

with 5mm allen wrench, clockwise to raise, counter

clockwise to lower. Repeat process with other levelers

until case is level.

NOTE: To avoid removing concrete flooring, begin

lineup leveling from the highest point of the store.

1. Check level of floor where cases ar e to be set.

Determine the highest point of the floor; cases will

be set off this point.

2. Set first case, and adjust legs over the highest part

of the floor so that case is level. Prev ent damage –

case must be raised under leg or by use of 2x6 or

2x4 leg brace. Remove side and back leg braces

after case is set.

3. Set second case as close as possible to the first case,

and level case to the first using the instructions in

step one.

4. Apply masking tape 1/8" in from end of case on

inside and outside rear wall on both cases to be

joined.

5. Apply liberal bead of case joint sealant (butyl) to

rear adjoining wall of first case.

DO NOT USE PERMA GUM!

It is the contractor's

responsibility to install

case(s) according to local

construction and health

codes.

6. Slide second case up to first case snugly . Then lev el

second case to the first case so deck, bumper and

top are flush.

7. To compress silicone at joint, use two J urgenson

wood clamps. Mak e sure case is lev el from front to

back and side to side on inside bulkheads at joint.

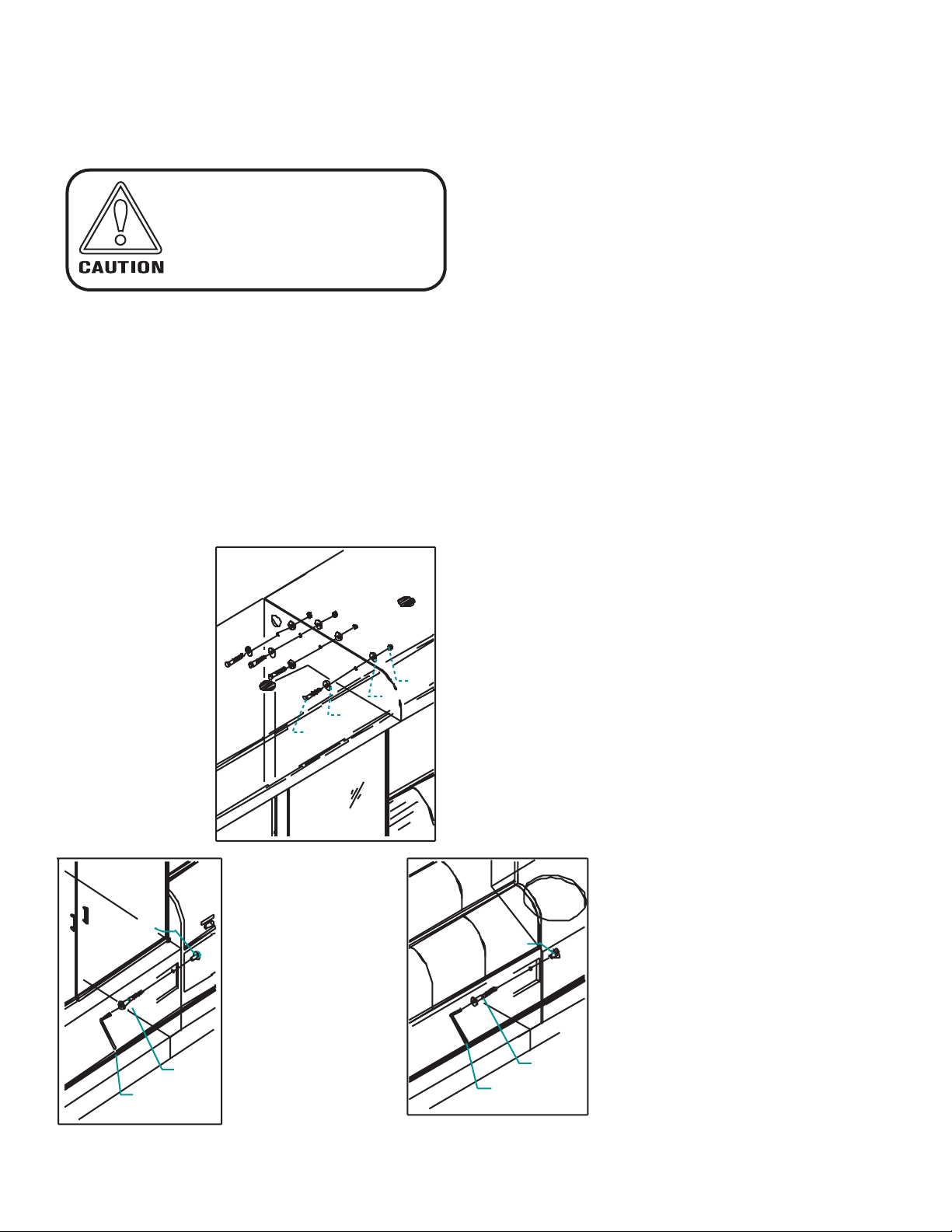

8. Attach sections together via a 3 bolts located in the

5

IGSV-VTB, VSG-0309

base of the case. Secure the ov erhead structure by

bolting the rear mullions tegether.

Do not use bolts

9. Apply bead of silicone aling rear wall.

10. Use finger to smooth silicone as thin as possible at

masking tape

HEADER

Remove light diffuser of adjoining cases and attach

nut, bolt and washers as shown.

to pull cases together!

1.

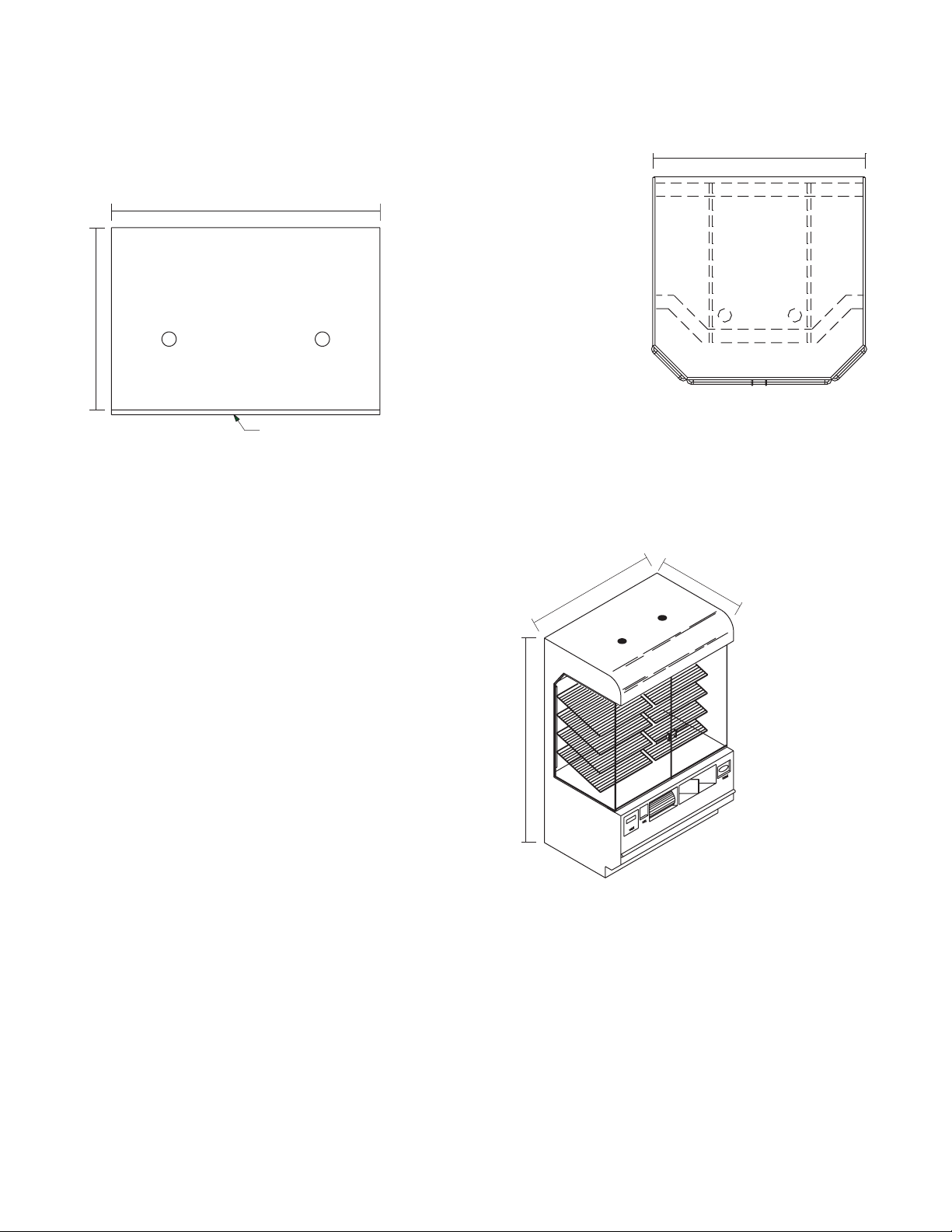

INSTALLING PEDESTAL BASE CLOSE OFF

1. Bolt (1/4-16 x 1) front angle to base gusset. Do not

tighten.

2. Align front angle to floor .

3. Tighten front angle to base gusset.

4. Align the threaded rod in the fr ont close-off with

the 1/4" hole located in front angle, then bolt

together.

5. Slide rear close-off around case r ear frame and slide

between front angle and fr ont close-off. After a

secure fit bolt on rear close-off to r ear gusset.

2. BASE (case access two

sides) Bolt cases together

as shown.

3. BASE ((case access

one side) Bolt cases

together as shown.

6

Loading...

Loading...