Page 1

VRM

®

Medium Temperature Self Contained

Glass Door Merchandisers

WARNINGS:

If the information in these instructions are not followed

exactly, a fire or explosion may result, causing property

damage, personal injury or death.

Installation and service must be performed by a qualified

installer or service agency.

READ THE ENTIRE MANUAL BEFORE

INSTALLING OR USING THIS EQUIPMENT.

The unit uses R-290 (propane) gas as the refrigerant.

R-290 (propane) is flammable and heavier than air. It

collects first in low areas but can be circulated by the

fans. If propane gas is present or even suspected, do not

allow untrained personnel to attempt to find the cause.

The propane gas used in the unit has no odor. The lack

of smell does not indicate a lack of escaped gas. If a

leak is detected, immediately evacuate all persons from

the store, and contact the local fire department to advise

them that a propane leak has occurred. Do not let any

persons back into the store until the qualified service

technician has arrived and that technician advises that it

is safe to return to the store. No open flames, cigarettes

or other possible sources of ignition should be used

inside or in the vicinity of the units.

with R290 Refrigerant

Installation &

Operation Manual

FAILURE TO ABIDE BY THIS WARNING COULD

RESULT IN AN EXPLOSION, DEATH, INJURY AND

PROPERTY DAMAGE.

IMPORTANT

Keep in store for future reference!

MANUAL - SELF CONTAINED R290 VRM I/O

P/N 3034041_D

October 2018

Spanish 3034047

French 3034046

Page 2

2 InstallatIon

BEFORE YOU BEGIN

Read these instructions completely and carefully.

PERSONAL PROTECTION EQUIPMENT (PPE)

Personal Protection Equipment (PPE) is required whenever installing or servicing this

equipment. Always wear safety glasses, gloves, protective boots or shoes, long pants, and a

long-sleeve shirt.

1. If the information in these instructions are not followed exactly, a fire or explosion may result, causing property damage, personal

injury or death.

2. Installation and service must be performed by a qualified installer or service agency.

3. This unit is designed only for use with R-290 (propane) gas as the designated refrigerant.

THE REFRIGERANT LOOP IS SEALED. ONLY A QUALIFIED TECHNICIAN SHOULD ATTEMPT TO SERVICE!

• Propane is flammable and heavier than air.

• It collects first in the low areas but can be circulated by the fans.

• If R-290 (propane) is present or even suspected, do not allow untrained personnel to attempt to find the cause.

• The propane gas used in the unit has no odor.

• The lack of smell does not indicate a lack of escaped gas.

• If a leak is detected, immediately evacuate all persons from the store, and contact the local fire department to advise them that a pro

pane leak has occurred.

• Do not let any persons back into the store until the qualified service technician has arrived and that technician advises that it is safe to

return to the store.

• A hand-held propane leak detector (“sniffer”) shall be used before any repair and/or maintenance.

• No open flames, cigarettes or other possible sources of ignition should be used inside the building where the units are located until

the qualified service technician and/or local fire department determines that all propane has been cleared from the area and from the

refrigeration systems.

• Component parts are designed for propane and non-incendive and non-sparking. Component parts shall only be replaced with identical

repair parts.

FAILURE TO ABIDE BY THIS WARNING COULD RESULT IN AN EXPLOSION, DEATH, INJURY AND PROPERTY DAMAGE.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 3

P/N 3034041_D 3

AT TENTION

Merchandiser must operate for 24 hours

before loading product!

Regularly check merchandiser temperatures.

Do not break the cold chain. Keep products

in cooler before loading into merchandiser.

These merchandisers are designed

for only pre-chilled products.

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900

www.hussmann.com

© 2018 Hussmann Corporation

VRM Merchandisers

Page 4

4 InstallatIon

REVISION HISTORY

REVISION D

Removed Fan Key Page; Updated parts list and diagrams; added

California Warning.

REVISION C

Updated part numbers and wiring diagrams.

REVISION B

Added VRM 1-door cases

Changed info about door torque.

ORIGINAL ISSUE — JULY 2017

AT TENTION

Adjust closing torque by turning the bottom

hinge pin in the direction the door closes.

Use a 1/2 inch (13 mm) wrench, and turn

the hinge pin until the door closes on its own.

Usually it takes two clicks or a half turn.

* * * * * * * * * * * * * * * * * * * * * * * * * *

ANSI Z535.5 DEFINITIONS

• DANGER – Indicate[s] a hazardous

situation which, if not avoided, will

result in death or serious injury.

• WARNING – Indicate[s] a hazardous

situation which, if not avoided, could

result in death or serious injury.

• CAUTION – Indicate[s] a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

Do NOT remove shipping crate until

the merchandiser is positioned for

installation.

Excessive ambient conditions may

cause condensation and therefore

sweating of doors. Facility operators

should monitor doors and oor

conditions to ensure safety of persons.

• NOTICE – Not related to personal injury –

Indicates[s] situations, which if not avoided,

could result in damage to equipment.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 5

P/N 3034041_D 5

INSTALLATION

NSF LISTING

These merchandisers are manufactured to meet

ANSI / UL 471 standard requirements for

safety. Proper installation is required to maintain

this listing. Near the serial plate, each case

carries a label identifying the type of conditions

for which the merchandiser was tested.

ANSI/NSF-7 Type I – Display

Refrigerator / Freezer Intended for

75°F / 55% RH Ambient Application

ANSI/NSF-7 Type II – Display

Refrigerator / Freezer Intended for

80°F / 55% RH Ambient Application

ANSI/NSF-7 – Display Refrigerator

Intended for Bulk Produce

FEDERAL / STATE REGULATION

These merchandisers, at the time they are

manufactured, meet all federal and state /

provincial regulations.

Apparent Loss or Damage

If there is an obvious loss or damage, it must

be noted on the freight bill or express receipt

and signed by the carrier’s agent; otherwise,

carrier may refuse claim.

Concealed Loss or Damage

When loss or damage is not apparent until

after equipment is uncrated, retain all packing

materials and submit a written response to the

carrier for inspection within 15 days.

LOCATION

These merchandisers are designed for

displaying products in air conditioned stores

where temperature is maintained at or below

the ANSI / NSF-7 specified level and relative

humidity is maintained at or below 55%.

HUSSMANN PRODUCT CONTROL

The serial number and shipping date of all

equipment is recorded in Hussmann’s files

for warranty and replacement part purposes.

All correspondence pertaining to warranty or

parts ordering must include the serial number

of each piece of equipment involved. This is

to ensure the customer is provided with the

correct parts.

SHIPPING DAMAGE

All equipment should be thoroughly examined

for shipping damage before and during

unloading. This equipment has been carefully

inspected at our factory. Any claim for loss

or damage must be made to the carrier. The

carrier will provide any necessary inspection

reports and/or claim forms.

Recommended operating ambient

temperature is between

60°F (15.6°C) to 80°F (26.7°C).

Maximum relative humidity is 55%.

Placing refrigerated merchandisers in direct

sunlight, near hot tables or near other heat

sources could impair their efficiency. Like

other merchandisers, these merchandisers

are sensitive to air disturbances. Air currents

passing around merchandisers will seriously

impair their operation. Do NOT allow air

conditioning, electric fans, open doors or

windows, etc. to create air currents around

the merchandiser. VRM units in take air and

exhaust air through the front of the case, and

require no clearance space on top, at back or

either side.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 6

6 InstallatIon

36 in.

Front

Air Exhaust

Air Intake

SELF CONTAINED (LOCATION)

Product should always be maintained at proper

temperature. This means that from the time the

product is received, through storage, preparation

and display, the temperature of the product

must be controlled to maximize the life of the

product.

Be sure to position self contained

merchandisers properly.

VRM models have vented base panels to allow

air circulation through the condensing unit.

Allow for a minimum 36 in. clearance in the

front. Blocking or restricting air flow will

adversely affect performance and may damage

the refrigeration system.

36 in.

36 in.

36 in.

VRM1B

Air Intake

Air Intake

Front

Front

(Plan View)

(Plan View)

Air Exhaust

Air Exhaust

1 in. Clearance at

Zero Clearance

Sides and Rear

at Sides and Rear

36 in. Clearance at

36 in. Clearance

Front

at Front

VRM3B

Rear

Rear

36 in.

VRM2B

Air Intake

Front

(Plan View)

Air Exhaust

Zero Clearance

at Sides and Rear

36 in. Clearance

at Front

Rear

Air Exhaust

Air Intake

Front

(Plan View)

Air Exhaust

Zero Clearance

at Sides and Rear

36 in. Clearance

at Front

Rear

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 7

P/N 3034041_D 7

UNLOADING

Unloading from Trailer:

Lever Bar (also known as a Mule, Johnson

Bar, J-Bar, Lever Dolly, or Pry Lever)

Move the merchandiser as close as possible to

its permanent location and remove all packaging.

Check for damage before discarding packaging.

Remove all separately packed accessories such as

kits and shelves.

Improper handling may cause damage to the

merchandiser when unloading. To avoid damage:

1. Do not drag the merchandiser out of the

trailer. Use a Johnson bar (Mule).

2. Use a forklift or dolly to remove the

merchandiser from the trailer.

Remove the top of the crate and detach walls

from each other (if applicable). Lift crate from

the skid. Unscrew the case from the skid. The

merchandiser can now be lifted off the crate

skid. Lift only at base of skid! Remove any

braces and/or skids attached (blanket wrapped

merchandiser may have skids).

DO NOT TILT MERCHANDISER ON ITS

SIDE OR END WHEN REMOVING SKID.

Once the skid is removed, the merchandiser

must be lifted —NOT PUSHED— to

reposition. To remove the skid, remove screws

attaching skid to the merchandiser.

Check floor where merchandisers are to be set

to if it is a level area. Determine the highest

part of the floor.

Do NOT stand or walk on top of

merchandiser. Do not store items or

ammable materials atop the unit.

EXTERIOR LOADING

Do NOT walk on top of the merchandiser or

damage to the merchandisers and serious

personal injury could occur.

merchandisers are not structurally

designed to support excessive external

loading such as the weight of a person. Do

not place heavy objects on the merchandiser.

SHIPPING SKID

Each merchandiser is shipped on a skid to

protect the merchandiser’s base and to make

positioning the case easier.

August 31, 2018

This warning does not mean that Hussmann products

will cause cancer or reproductive harm, or is in

violation of any product-safety standards or

requirements. As clarified by the California State

government, Proposition 65 can be considered more of

a ‘right to know’ law than a pure product safety law.

When used as designed, Hussmann believes that our

products are not harmful. We provide the Proposition

65 warning to stay in compliance with California State

law. It is your responsibility to provide accurate

Proposition 65 warning labels to your customers when

necessary. For more information on Proposition 65,

please visit the California State government website.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 8

8 InstallatIon

MODEL DESCRIPTION

VRM merchandisers are medium temperature

self-contained cabinets, designed for the

display of dairy products, deli items and

beverages.

Design Features

- Contemporary styling places maximum

attention on merchandising

- All VRM merchandisers have the same

access panel design for commonality between

merchandisers

- Self-closing Innovator doors. Positive seal,

torsion type closure system

- Triple-pane thermal insulated glass door

assemblies

- Magnetic door gaskets of one-piece

construction, removable without tools for

ease of cleaning

- Merchandiser can be placed against wall no air gap is required behind the case

- Digital display in center of case air grill

Adjustable

Foot

CABINET LEVELING

This merchandiser must be installed level

(from back to front, and side to side) to allow

maximum draining of the condensate water as

well as proper door alignment and operation.

Choose a level area to install case.

VRM2B and VRM3B also have an adjustable

foot at center front and back. Turn the foot

levelers clockwise to add length to each foot

for leveling.

When optional casters are used, screw them

tight to the merchandiser base. Once in final

position, lock each caster.

Adjustable

Foot

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 9

P/N 3034041_D 9

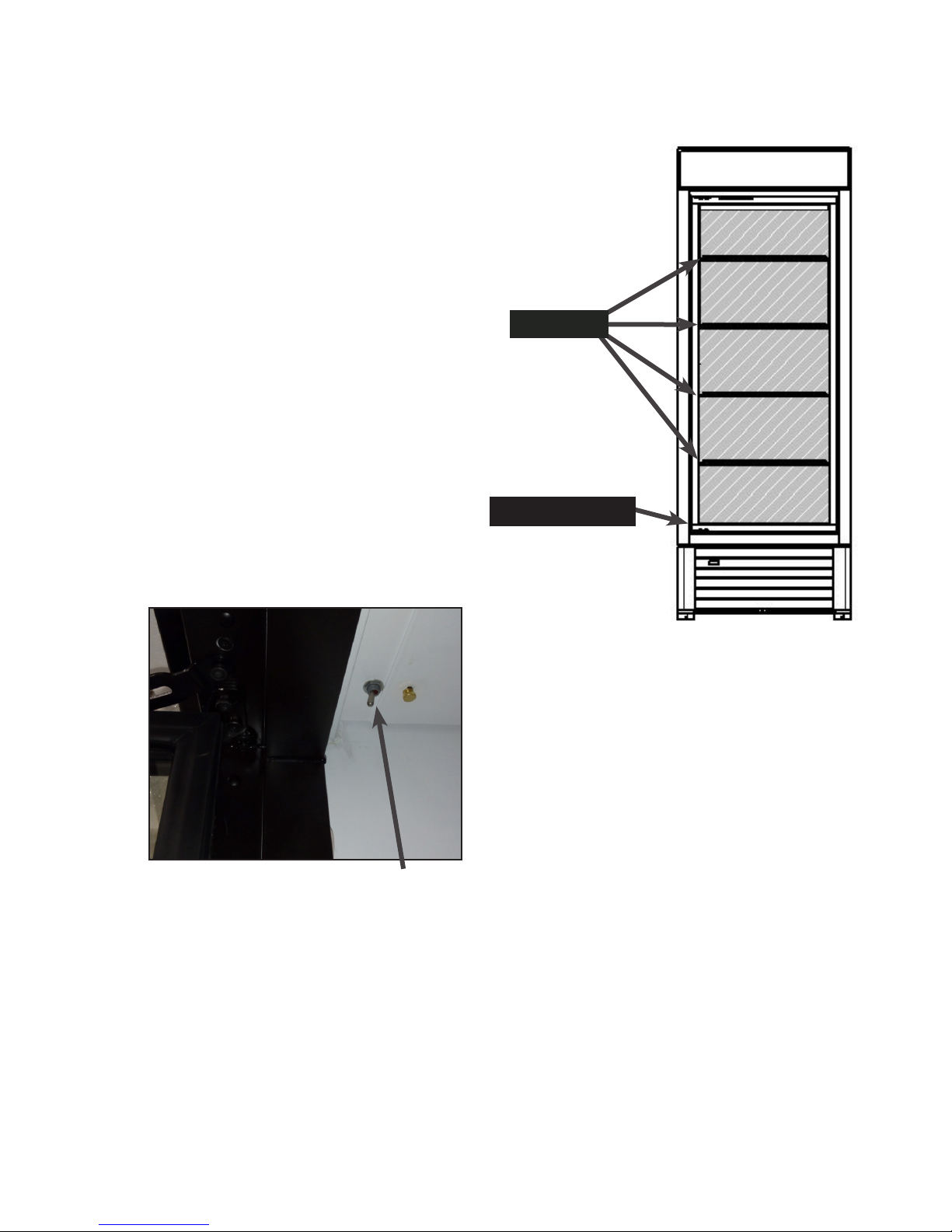

SHELF INSTALLATION

After the cabinet is leveled, the shelves may

be installed. Wire shelves are adjustable. Shelf

spacing can be adjusted by positioning the

shelf clips according to individual loading

requirements.

VRM merchandisers have four movable wire

shelves and one bottom wire shelf, per door.

Shelves

LAMPS

This merchandiser has a light switch inside of

the left door frame. The switch controls the

display lighting and interior lighting.

Bottom Shelf

Light Switch

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 10

10 InstallatIon

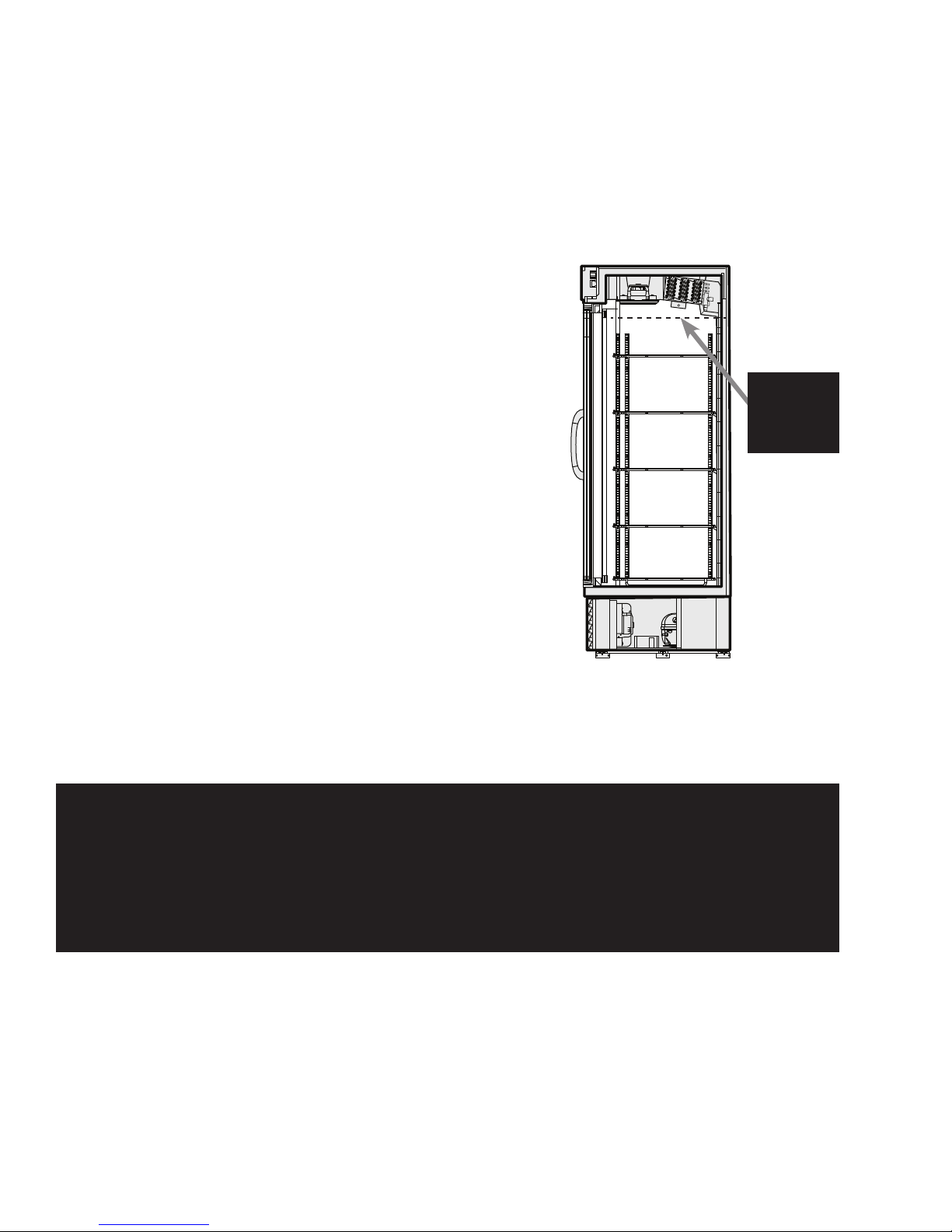

STOCKING

Product should NOT be placed in case

until merchandiser is at proper operating

temperature. VRM merchandisers must

remain in operation for at least 24 hours before

product may be loaded into case cabinet.

Proper rotation of product during stocking

is necessary to prevent product loss. Always

bring the oldest product to the front and set

the newest to the back.

Air exhAust And return grille must remAin

open And free of obstruction At All times.

Do not allow product, packages, signs, etc. to

block air exhaust or return grille. Do not use

non-approved shelving, baskets, display racks,

or any accessory that could hamper air curtain

performance.

LOAD LIMITS

Product must be within designated load limit

to ensure proper refrigeration and air curtain

performance.

no product

within

4 inches

of top

do not stock product in the top four

inches of Vrm cAses becAuse product will

block the cold Air flow.

Load Limit for VRM Merchandisers

At no time should product be stocked:

• Beyond the front and rear of the shelves

• Near the air supply duct located at the top rear of case

• Near or covering the evaporation fan grilles

• Within four inches of the top of the cabinet (This space must be free of product and other materials.)

DO NOT LOAD CASE WITH WARM PRODUCT.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 11

P/N 3034041_D 11

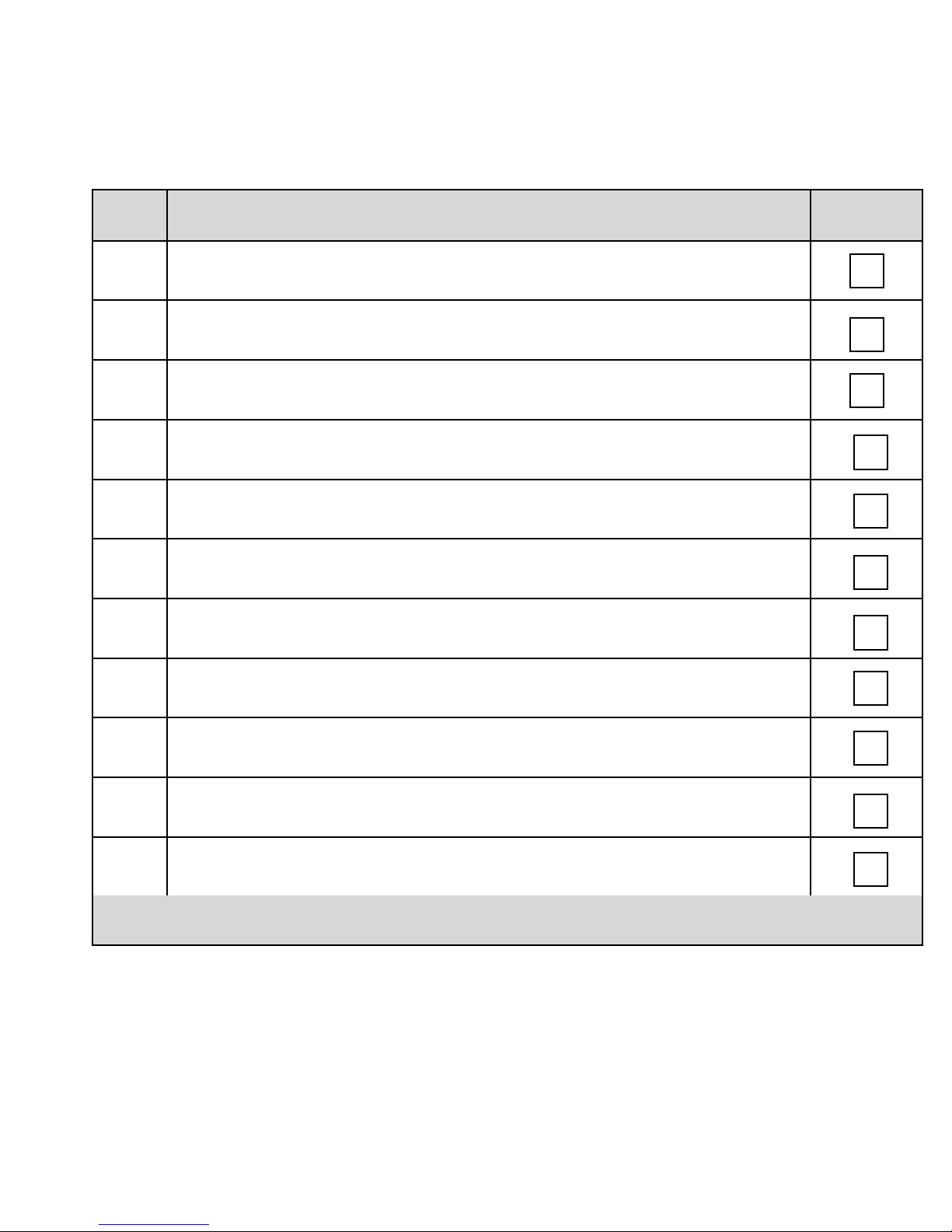

Hussmann Self-Contained Refrigeration Equipment Start Up Check List

***Please note that failure to follow this start-up document may void your factory warranty***

Step Startup Activity Check

1

Locate, read and maintain install/operation manual in a safe place for

future reference.

2 Examine unit. Conrm there is NO damage or concealed damage.

3 Level the unit, side to side and front to rear.

4 Remove all shipping brackets/compressor straps/bolts etc.

5

6

Unit must be run on a dedicated electrical circuit without the use of an

extension cord.

Ensure that the proper electrical requirements for the equipment are

supplied.

7 Verify eld electrical connections are tight.

8

Verify all electrical wiring is secured and clear of any sharp edges or

hot lines.

9 Verify the condensate drain line is properly trapped and pitched.

10 Verify all required clearances on the sides and back of unit.

11

Verify there are no air disturbances external to the unit. Heat and air

registers, fans, and doors etc.

Advise owner/operator that merchandiser must operate at temperature for 24 hrs prior to

loading with product.

Form HSCW01 Rev. 30MAY12 P/N 0525209_B

LEGAL DISCLAIMER:

Hussmann shall not be liable for any repair or replacements made without the written consent of Hussmann, or when the product is installed or operated in a

manner contrary to the printed instructions covering installation and service which accompanied such product.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 12

12 InstallatIon

NOTES:

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 13

P/N 3034041_D 13

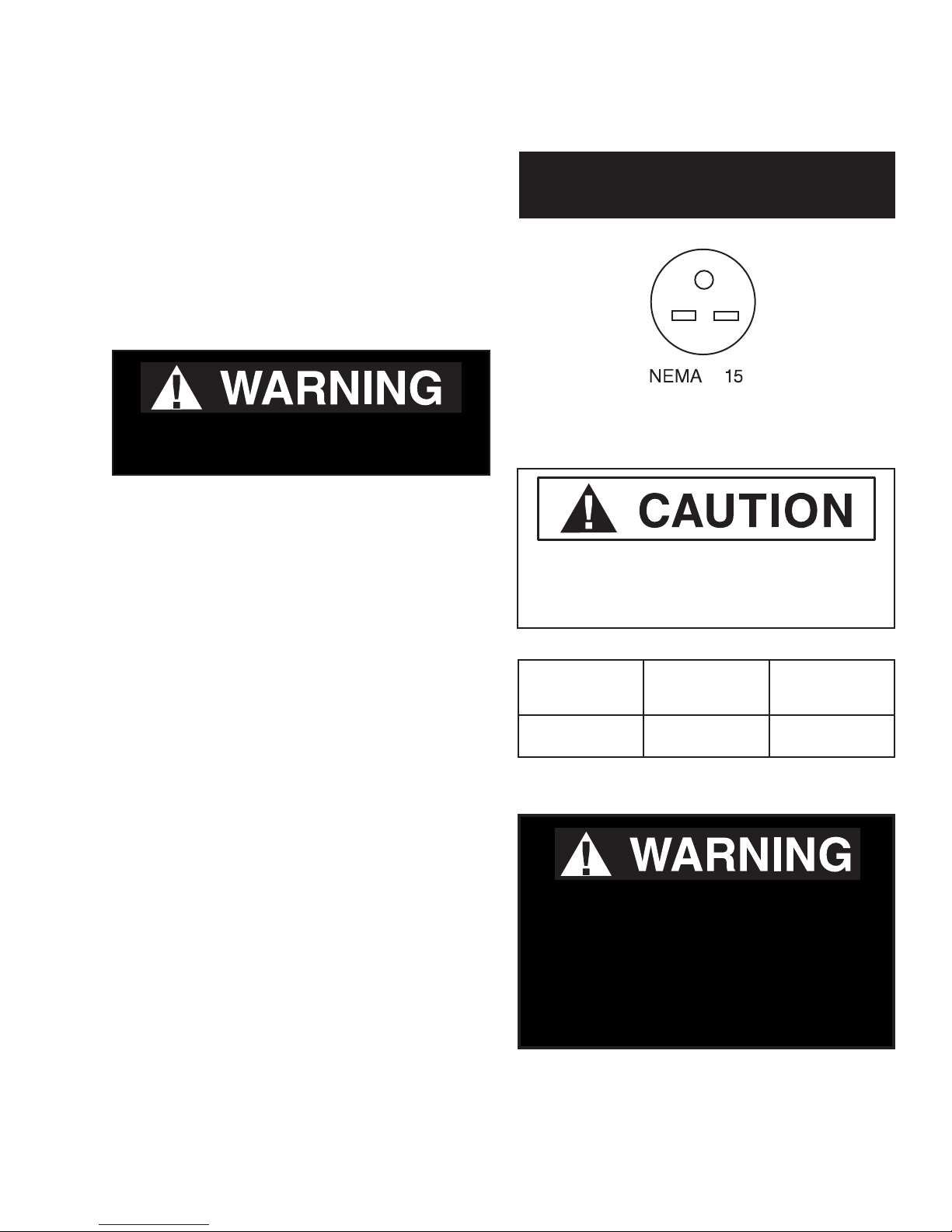

5-15P

ELECTRICAL / REFRIGERATION

PLUG

ALWAYS CHECK THE SERIAL PLATE FOR

The plug cord is 9 ft long and is located on

the right hand rear of the merchandiser.

Disconnect power before servicing. VRM

merchandisers require a dedicated electrical

circuit with ground. 12AWG is the minimum

sized acceptable wire.

Merchandiser must be grounded.

Do not remove the power supply cord ground.

COMPONENT AMPERES

5- P

All Models

• The VRM models require a dedicated

15AMP/115V circuit with a grounded wall

receptacle (NEMA 5-15R).

• Always use a dedicated circuit with the

amperage stated on the unit.

• Plug into an outlet designed for the plug.

• Do not overload the circuit.

• Do not use long or thin extension cords.

Never use adapters.

• If in doubt, call an electrician.

Risk of Electric Shock. If cord or plug

becomes damaged, replace only with a

cord and plug of the same type.

Nominal

Voltage

Minimum

Voltage

Maximum

Voltage

120 108 132

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical

shock, always disconnect the electrical power

at the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 14

14 ElEctrIcal / rEfrIgEratIon

Before Beginning Any Service or Repair:

Use a hand-held propane leak detector (“sniffer”)

to ensure no propane is present in the immediate

area, the inside of the display case and the inside

of the refrigeration system. R-290 is an odorless

refrigerant. Keep the area clear of all customers

and non- essential or unauthorized personnel.

Only Hussmann or factory

trained technicians should

Verify that all repair parts are identical models

to the ones they are replacing. Do not substitute

parts such as motors, switches, relays, heaters,

compressors, power supplies or solenoids. Failure

to do so can result in an explosion, death, injury

and property damage. Parts used on hydrocarbon

cases must meet specic UL certication for nonincendive or non-sparking components. Use only

Hussmann approved parts approved through the

Hussmann Performance Parts Website.

https://parts.hussmann.com/

Brazing must not begin before all propane has

been cleared from the immediate area — the

inside of the displays case and the inside of the

refrigeration system.

If a leak is detected, follow store safety

procedures. It is the store’s responsibility to have

a written safety procedure in place. The safety

procedure must comply with all applicable codes

such as local re department’s codes.

At minimum, the following actions are required:

• Immediately evacuate all persons from the

store, and contact the local re department to

advise them that a propane leak has occurred.

• Call Hussmann and/or a qualied service

agent and inform them that a propane sensor has

detected the presence of propane.

• Do not let any persons back into the store

until the qualied service technician has arrived

and that technician advises that it is safe to

return to the store.

service or repair this R-290

(propane) equipment.

Failure to follow

instructions can result in

an explosion, death, injury

and property damage.

• The propane gas used in the unit has no odor.

The lack of smell does not indicate a lack of

escaped gas.

• A hand-held propane leak detector

(“sniffer”) should be used before any repair and/

or maintenance is attempted. All repair parts

must be identical models to the ones they are

replacing.

• No open flames, cigarettes or other possible

sources of ignition should be used inside the

building where the units are located until the

qualied service technician and/or local re

department determines that all propane has been

cleared from the area and from the refrigeration

systems.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 15

P/N 3034041_D 15

REPLACING REFRIGERATION SYSTEM

COMPONENTS

Component parts shall be replaced with like

Only Hussmann service technicians or

technicians qualified to handle R-290

(propane) refrigerant should service or repair

this R-290 (propane) equipment Failure to

components, and servicing shall be done by

factory authorized service personnel only, so

as to minimize the risk of possible ignition

due to incorrect parts or improper service.

follow instructions can result in an explosion,

death, injury and property damage.

Extreme care must be taken not to overll the

refrigeration system. After charging, carefully

disconnect the hoses, attempting to minimize

CHARGING

the quantity of refrigerant released. Further

leak check the service ports, hoses, refrigerant

A calibrated scale with +/-2 gram accuracy

must be used to charge the system. The charge

amount is shown on the serial plate. Only R-290

grade refrigerant can be used. Standard propane

tanks. The service ports shall be checked for

leaks using a hydrocarbon leak detector with a

sensitivity of 3 grams/year (0.106 Oz/year) leak

rate.

does not meet the purity/moisture content of

R-290, and therefore cannot be used to charge

cases.

Thoroughly leak check the service ports. If no

leak is present, use a pinch-off tool to close

the ends of the service tubes before brazing

No gas charge adjustments are allowed. When

connecting hoses between the refrigeration

system, manifold gauges, and refrigerant

cylinder, ensure that the connections are secure

them shut. If a Schrader valve is used on the

compressor service tube, it must be removed and

the previous steps followed in order to braze the

service tube shut.

and there are no potential sources of ignition

nearby. Ensure that contamination of different

refrigerants does not occur when using charging

equipment.

Use dedicated hoses to service R-290 (propane)

refrigeration systems. Hoses or lines should be

as short as possible to minimize the amount of

refrigerant contained in them.

Ensure that the refrigeration system is properly

grounded prior to charging the system with

refrigerant, to avoid the potential for static

build-up.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 16

16 ElEctrIcal / rEfrIgEratIon

VRM3B

B

VRM3B

Typical Sensor to Control Conguration

B

B

3.08

ROOF TO BOT

EDGE OF EVAP BASE

EVAP BASE EDGE

B

P/N 3033936

SENSOR

DEFROST

FIX IN THE

SUCTION TUBE

SENSOR

AIR DISCHARGE

DETAIL B

SCALE 1:4

FIX IN THE WALL

15.00

3032520

ROOF LINE

B

.30

GAP BTW EDGE

OF BASE AND SENSOR

3.38

ROOF TO

SENSOR

B

B

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 17

P/N 3034041_D 17

VRM2B

C

D

VRL2B/

VRM2B

Typical Sensor to Control Conguration

C

ROOF TO BOT

EDGE OF EVAP BASE

B

EVAP BASE EDGE

B

P/N 3033490

ROOF TO BOT

EDGE OF EVAP BASE

3.08

3.08

SENSOR

DEFROST

FIX IN THE

SUCTION TUBE

SENSOR

DEFROST

ROOF LINE

VRM2B

DETAIL C

SCALE 1:2.67

SENSOR

AIR DISCHARGE

15.00

FIX IN THE WALL

3032520_B

B

3.38

ROOF TO

B

SENSOR

.30

GAP BTW EDGE

OF BASE AND SENSOR

B

VRM1B

SENSOR

AIR DISCHARGE

12.72

ROOF LINE

3.38

ROOF TO

SENSOR

EVAP BASE

EDGE LINE

P/N 3041402

FIX IN THE

SUCTION LINE

3032520_B

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

SCALE 1:2.29

FIX IN THE WALL

.30

GAP BTW EDGE

OF BASE AND SENSOR

VRM Merchandisers

Page 18

18 ElEctrIcal / rEfrIgEratIon

CONTROLLER

Hussmann Controller Operation RTN

1. Plug the merchandiser plug into its receptacle.

a. The controller display will illuminate.

b. The interior light will illuminate.

2. After the control preprogrammed time

delay of up to 6 minutes, the compressor and

evaporator fan(s) will start if the control is

calling for cooling.

3. The control will cycle the compressor but

may also cycle evaporator fan(s) on and off

determined by the Set-Point and Differential

temperatures.

a. The Set-Point is the adjustable

preprogrammed temperature.

b. The Differential is the non-adjustable pre

programmed temperature.

c. The Control is designed to read and display

a cabinet temperature not a product

temperature.

Taking as an example a VRL case, freezer, If the

Set-Point is -12°F and the Differential is 9°F.

(Set-Point) -12°F + 9 (Differential) = -3°F. The

compressor and evaporator fan(s) will cycle off

-12°F and back on at -3°F.

Main Features:

• Panel-mounted

• Energy saving algorithms and optimised

defrost control

• 8 preloaded applications

• Defrost at single / double evaporator

• Frame Heater

• Local network auto-conguration

• Direct load connection (up to 2 HP)

• Supply voltage control LVD

• Presence of an open collector output

This cabinet temperature may reflect the

refrigeration cycle of the Set-Point and it’s

Differential. The most accurate temperature

on a cabinets operation is to verify the product

temperature.

KDEPLUS BUTTONS

The KDEPlus keyboard has 4 keys, as shown in the illustration:

UP

1

DOWN SET

2

STANDBY or ESC

3

4

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 19

P/N 3034041_D 19

2 - SPECIFICATIONS

Key Functions:

• 2 ON/OFF regulators for HOT/COLD

• Single defrost and double evaporator

(heatings, modulated heaters, reverse cycle, hot gas)

• Evaporator fans and condenser fans

• Frame Heater

• AUX

• Light

• Door switch

• ON /OFF

• Deep cooling cycle

• Day / Night

• Diagnostics

• “Easy Map” programming

• Programmable inputs/outputs

• LINK2 local area network

• RS485 communication protocol: Modbus

• Compatible with Device Manager (DM)

• Compatible with Unicard and Multi-function key

TECHNICAL DATA

Classification: electronic automatic control (not safety) device for incorporation

Mounting: panel mounting

Type of action: 1.B

Pollution class: 2

Material class: IIIa

Overvoltage category: II

Nominal pulse voltage: 2500V

Temperature: Use: –5 … +55°C - Storage: -30 … +85°C

Power supply: SMPS 100-240Va ±10% 50/60 Hz

Power consumption: 5.5W max

Fire resistance category: D

Software class: A

RTC battery life: In absence of external power, the clock battery will last 3 years.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 20

20 ElEctrIcal / rEfrIgEratIon

2 - SPECIFICATIONS

TECHNICAL DATA

Classification: electronic automatic control (not safety) device for incorporation

Mounting: panel mounting

Type of action: 1.B

Pollution class: 2

Material class: IIIa

Overvoltage category: II

Nominal pulse voltage: 2500V

Temperature: Use: –5 … +55°C - Storage: -30 … +85°C

Power supply: SMPS 100-240Va ±10% 50/60 Hz

Power consumption: 5.5W max

Fire resistance category: D

Software class: A

RTC battery life: In absence of external power, the clock battery will last 3 years.

: The technical specifications stated in this document regarding measurement (range, accuracy, resolution, etc.) refer to

FURTHER INFORMATION

INPUT CHARACTERISTICS

Measurement range: NTC: -50.0°C ... +110°C; PTC: -55.0°C ... +150°C; PT1000: -60.0°C ... +150°C

(on 3-digit display with +/- sign)

Accuracy: ±1.0° for temperatures below -30°C

±0.5° for temperatures between -30°C and +25°C

±1.0° for temperatures above +25°C

Resolution: 1 or 0.1°C

Buzzer: NO

Analogue/Digital Inputs: 5 configurable NTC/PTC/PT1000/DI inputs

1 multi-function, voltage-free digital input (D.I.)

OUTPUT CHARACTERISTICS

Digital Outputs: OUT1: 1 SPST relay: 2HP

OUT2: 1 SPDT relay: 1HP

OUT3: 1 SPDT relay: 8(4)A

OUT4: 1 SPST relay: 8(4)A

OC (Open Collector) Output: OC: 1 multifunctional output:

max 240V

max 250V

max 250V

max 250V

12V

a

a

a

a

c 20mA

MECHANICAL CHARACTERISTICS

Dimensions: 121x92 mm

Terminals: faston and screw for wires with cross-section of 2.5mm

Connectors:

Humidity:

TTL for Unicard / Device Manager connection (via DMI)

Usage / Storage: 10...90% RH (non-condensing)

REGULATIONS

Electromagnetic compatibility: The device complies with Directive 2004/108/EC

Safety: The device complies with Directive 2006/95/EC

Food Safety: The device complies with standard EN13485 as follows:

• Suitable for storage.

• Application: air.

• Climate range A

• measurement class 1 in the range from -25°C to 15°C (*)

(* with Eliwell probes only)

2

NOTE

the instrument alone and not to any accessories provided, such as the probes.

This means, for example, that the error introduced by the probe must be added to the error of the instrument.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 21

P/N 3034041_D 21

CONNECTIONS

TERMINALS

1

2

3

4

5

6

7

8

9

OUT3 (8A)

10

11

OUT1 (2HP)

12

13

14

OUT4 (8A)

OUT2 (1HP)

A

15 16 17

RS485

OPTIONAL

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

12V

OC

D

GND

D

GND

LINK

{

2

GND D

12V

{

KEYB

* N.B.: analogue inputs PB1...PB5 can also be configured as Digital Inputs DI.

TERMINALS

1-2 NEUTRAL.

3 LINE. These are power supply terminals. 19-18 PB1 probe connection.

4 OUT2 Shared Terminal 21-20 PB2 probe connection.

5 N.O. OUT2 23-22 PB3 probe connection.

6 N.C. OUT2 23-24 PB4 probe connection.

7 OUT3 Shared Terminal 23-25 PB5 probe connection.

8 N.C. OUT3 27-26 Digital input (DI).

9 N.O. OUT3 28-29 LINK

10 OUT1 Shared Terminal 30-31 LINK

11 N.O. OUT1 32-33 Open Collector Output (OC).

12 Not Used A TTL Unicard/DMI/Multi Function Key connection

13 OUT4 Shared Terminal 34-35-36 RS485. Connection 1 - Supervision Gateway.

14 N.O. OUT4 37-38-39 RS485. Connection 2 - Supervision Gateway.

These are power supply terminals. 15-16-17

34 35 36 37 38 39

Connection to KDEPlus or KDWPlus external

keyboard or ECPlus echo module.

2

. Connection 1 - local area network.

2

. Connection 2 - local area network.

ELIWELL

ELIWELL

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 22

22 ElEctrIcal / rEfrIgEratIon

LED

RTN400 family controllers will also function even if a keyboard has not been connected.

With KDEPlus or KDWPlus keyboards (which are the same and guarantee the same functions), the display will be as follows:

Meaning of LEDs:

1

2

3

4

No Icon LED Operation Meaning

Permanently on compressor on

1

2

3

Compressor

Defrost

Fans

Blinking Delay, protection or start-up blocked

OFF otherwise

Permanently on Defrost active

Blinking Activated manually or from Digital Input

OFF otherwise

Permanently on Fans active

OFF otherwise

5

6

7

8

Permanently on Energy Saving active

4

5

6

7

8

N.B.: When the instrument is powered on it performs a lamp test, during which time the display and LEDs will

Reduced SET / Economy

Alarm

°F readout

AUX

°C readout

flash for several seconds to check that they all function correctly.

Blinking Reduced setpoint active

OFF otherwise

Permanently on alarm active

Blinking Alarm acknowledged

OFF otherwise

Permanently on °F setting (dro =1)

OFF otherwise

Permanently on Aux output active and/or light on

Blinking Deep cooling on

OFF otherwise

Permanently on °C setting (dro = 0)

OFF otherwise

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 23

P/N 3034041_D 23

KDEPLUS BUTTONS

The KDEPlus keyboard has 4 keys, as shown in the illustration:

UP

1

DOWN SET

Each key has a different function depending on whether it is:

• Pressed and released

• Pressed for at least 5 seconds

• Pressed and held at start-up

• Pressed in combination with another key.

KEYS

The following table summarizes the function of each key:

No Key

1

2

• Scrolls through menu items

• Decreases values

• Scrolls through menu items

• Decreases values

2

Pressed and released Press for at least 5 secs Start-up

Activates the Manual Defrost function

(from outside menus).

Function can be configured by the user

(from outside menus).

(see parameter H32)

Action

STANDBY or ESC

3

4

---

---

• Returns to the previous menu

3

4

set

level

• Confirms parameter value

• Displays any alarms

(if active)

• Opens Machine Status menu

• Confirms commands

Activates the Stand-by function

(from outside menus).

Opens the Programming Menu

(User and Installer parameters)

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

---

When pressed during

start-up it enables

the user to select the

application to be loaded.

VRM Merchandisers

Page 24

24 ElEctrIcal / rEfrIgEratIon

SETPOINT: SETTING AND EDIT LOCK

To display the Setpoint value, press the

set

key to enter the “Machine Status” menu, then press the

set

key again when the “SEt”

label is displayed.

The Setpoint value appears on the display. To change the Setpoint value, press the and keys within 15 seconds.

Press

set

to confirm the modification.

set

set

set

It is possible to disable the keypad on this device.

The keypad can be locked by programming the “LOC” parameter appropriately.

With the keypad locked, you can still access the “Machine Status” menu by pressing

set

to display the Setpoint, but you cannot edit

it. To disable the keypad lock, repeat the locking procedure.

DISPLAY PROBES VALUE

To display the value read by probes connected to the device, press the

set

key and enter the “Machine Status” menu, then press

the key again when one of the probe-related labels “Pb1...Pb5” press the

set

key again. The value measured by the associated

probe will appear on the display.

NOTE: The displayed value is read-only and cannot be modified.

SETPOINT: SETTING AND EDIT LOCK

To display the Setpoint value, press the

label is displayed.

The Setpoint value appears on the display. To change the Setpoint value, press the and keys within 15 seconds.

Press

to confirm the modification.

set

set

set

key to enter the “Machine Status” menu, then press the

set

set

key again when the “SEt”

set

It is possible to disable the keypad on this device.

The keypad can be locked by programming the “LOC” parameter appropriately.

With the keypad locked, you can still access the “Machine Status” menu by pressing

it. To disable the keypad lock, repeat the locking procedure.

set

to display the Setpoint, but you cannot edit

DISPLAY PROBES VALUE

To display the value read by probes connected to the device, press the

the key again when one of the probe-related labels “Pb1...Pb5” press the

probe will appear on the display.

NOTE: The displayed value is read-only and cannot be modified.

KDEPLUS BUTTONS

The KDEPlus keyboard has 4 keys, as shown in the illustration:

set

key and enter the “Machine Status” menu, then press

set

key again. The value measured by the associated

UP

1

DOWN SET

2

KEY-ACTIVATED FUNCTIONS

All models have the UP key set to enable the “Manual Defrost” function.

The DOWN and ESC keys can also be set to activate any other function required by the user.

The parameters for configuring the two keys are:

• H11 = DOWN key configuration

• H33 = ESC key configuration

The values that can be set apply to both keys and the functions that can be activated are:

H32/H33 value Function to enable

0 disabled

1 defrost

2 reduced set

3 Light

4 Energy saving

5 AUX

6 Stand-by

7 Deep cooling cycle

8 Start/end defrost

STANDBY or ESC

3

4

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 25

P/N 3034041_D 25

MAINTENANCE

Interior Surfaces

do not use AmmoniA-bAsed products to

cleAn light shields. neVer use AbrAsiVe

To reduce the risk of fire, electrical shock or

injury when cleaning this merchandiser:

• Unplug the merchandiser before cleaning;

• Keep all liquids away from electrical and

electronic components;

• Do not use any mechanical device or other

means to speed the defrost process, except

as recommended by the manufacturer.

CARE AND CLEANING

Long life and satisfactory performance of

any equipment is dependent upon the care it

receives. To ensure long life, proper sanitation

and minimum maintenance costs, this unit

should be thoroughly cleaned, all debris

removed and the interiors washed down.

Cleaning often will control or eliminate odor

buildup. Frequency of cleaning is dependent

on usage and local health requirements.

cleAnsers or scouring pAds.

The interior surfaces may be cleaned with most

domestic detergents and sanitizing solutions

with no harm to the surface. Always read and

follow the manufacturer’s instructions when

using any cleaning product.

Inspect all LED connections and plug/

receptacles for signs of arcing. Replace any

component that shows signs of arcing. Make

sure all unused receptacles have close-off covers

securely attached.

CLEANING UNDERNEATH THE CASE

The case can be moved to facilitate cleaning.

Unplug the merchandiser, and move it out if

the way in order to sweep and mop the area

underneath the case. Brush away all dirt and

liter from the area. Ensure there is no dirt

build up around the bottom of the case or near

the intake or exhaust.

Do not use HOT water on COLD glass surfaces.

This can cause the glass to shatter and could

result in personal injury. Allow glass fronts,

ends and service doors to warm before applying

hot water.

Exterior Surfaces

The exterior surfaces must be cleaned with a

mild detergent and warm water to protect and

maintain their attractive finish.

neVer use AbrAsiVe cleAners or scouring

pAds. neVer use cAustic sodA, kerosene,

gAsoline, thinner, solVents, detergents,

Acids, chemicAls or AbrAsiVes. do not use

AmmoniA-bAsed cleAners on Acrylic pArts.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 26

26 MaIntEnancE

Do NOT Use:

• Abrasive cleansers and scouring pads, as

these will mar the finish.

• Coarse paper towels on coated glass.

• Ammonia-based cleaners on acrylic parts.

• A hose on lighted shelves or submerge the

shelves in water.

• Solvent, oil or acidic based cleaners on any

interior surfaces.

• A hose on rail lights, canopy lights or any

other electrical connection.

Do:

• Rinse with hot water, but do NOT flood.

• Allow merchandiser to dry before resuming

operation.

• Wipe down lighted shelves with a damp

sponge or cloth so that water does not enter

the light channel. do not use A hose or

submerge shelVes in wAter.

• After cleaning is completed, restore power

and turn on the merchandiser.

• First turn off refrigeration, then disconnect

electrical power.

• Remove product and loose debris.

• Thoroughly clean all surfaces with soap

and hot water. do not use steAm or

high wAter pressure hoses to wAsh the

interior. these destroy merchandiser’s

sealing causing leaks and poor

performance.

• Take care to minimize direct contact between

fan motors and cleaning or rinse water.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 27

P/N 3034041_D 27

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

Cleaning Shelves

Shelves and shelf clips are easily removed for

cleaning the interior as well as the shelves

themselves.

Cleaning Condenser Coils

To maintain peak operating efficiency, the coil

should be cleaned at least once each month. A

dirty coil slows product cooling significantly

and increases energy consumption by as

much as 20%. Dirt buildup on coils can also

cause the compressor to lock up damaging

the condenser unit. All VRM models have

the same access panel design for commonality

between merchandisers.

1. Loosen screws at each side of the front

bottom grille, then lift up and pull off the

grille.

Loosen screws from each side of the bottom grille.

2. Next, detach the merchandiser’s electrical

wire harness.

3. Unscrew the stop bracket that holds the

condensing unit to the rail base.

4. Grab the condensing unit from condensing

unit handle.

use only the unit hAndle to pull out

the refrigerAtion system. pulling on

refrigerAtion lines or other pArts will

cAuse dAmAge to the refrigerAtion unit.

Front Grille

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Refrigeration Unit

VRM Merchandisers

Page 28

28 MaIntEnancE

5. Use a soft hand brush attachment on a

vacuum to remove accumulated dust and

debris.

Consult an authorized service technician

if more extensive cleaning is needed. If the

refrigeration unit is damaged, it can be

replaced with a new unit.

TIPS AND TROUBLESHOOTING

There are a few simple things to check before

calling for service:

1. Product not cold? Refrigeration unit

requires 24 hours at initial startup to cool

down to operating temperature with no

product loAded in merchandiser. Ask

when merchandiser was stocked, and what

the usage has been. It may take 30 minutes

or more for product to chill following

stocking.

2. Check the door and door seal for air leaks.

3. Power Supply:

Is the unit plugged in?

Is there power to the unit?

4. Location

What are the ambient conditions—

temperature and humidity, direct sun,

nearby source of heat, such as oven or

grill? Is the unit level? Has the unit been

moved recently?

IMPORTANT

INFORMATION

For prompt service when contacting the

factory, be sure to have the case model and

serial number from the case serial plate.

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical

shock, always disconnect the electrical power

at the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

ADJUSTING CLOSING TORQUE

Adjust closing torque by turning the bottom

hinge pin in the direction the door closes. Use

a 1/2 in. (13 mm) wrench. Turn the hinge pin

until the door closes on its own, usually to

2clicks or 1/2 turn.

DO NOT over-torque the hinge spring

assembly. Excessive torque (over 1 full turn)

will result in damage to the spring assembly

and/or door. If door does not close on its

own after one full turn (5 clicks), look for

obstructions causing the door to hang up.

5. Shelves and Stocking

Are the standard shelves in the correct places?

Is the product stocked properly?

Is the bottom shelf at the proper location?

6. Confirm that the defrost schedule is

properly set.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Adjusting Closing Torque

Page 29

P/N 3034041_D 29

ADJUSTING DOOR SAG

To adjust door sag (saw-tooth effect from door

to door), loosen the two hinge plate mounting

screws using a Torx Plus no. 27 bit. Adjust

hinge plate as needed, then tighten the screws.

CONDITIONING GASKETS

The manufacturer cannot control the

environment surrounding cases during shipment.

Temperature and humidity fluctuations during

shipment, as well as excessive vibration, may

promote gaps between gasket and frame. These

gaps prevent gaskets from sealing even when

correctly fitted at the factory.

This is not a warranty issue or defect.

4. Monitor all gaps. If gaps remain at the end of

four hours, follow the procedure for Restoring

Gasket Seal, beginning on page 6 of this

manual.

5. Initiate cooling sequence once gaps disappear.

Do not exceed 8 hours of energized circuits

without refrigeration. Doing so may cause

damage to the case and will void the warranty.

ATTENTION

TO ENSURE PROPER DOOR GASKET SEAL - REMOVE ALL SHIPPING

RETAINERS AND ENERGIZE ALL ANTI-SWEAT, FAN & LIGHT CIRCUITS

2 TO 4 HOURS PRIOR TO INITIATING REFRIGERATION CYCLE.

DO NOT EXCEED 8 HOURS OF ENERGIZED CIRCUITS

WITHOUT REFRIGERATION. DAMAGE OR PRODUCT FAILURE MAY

OCCUR AND VOID THE WARRANTY.

DO NOT REMOVE THIS LABEL UNTIL REFRIGERATION IS INITIATED.

Loosen both

hinge plate

mounting

screws.

Adjusting Door Sag

Follow this procedure to ensure gaps close and

gaskets seal properly:

1. Remove all shipping retainers and all packing

material.

2. Close each door. Use a flashlight to identify

any gaps between frame and gasket.

3. Energize all anti-sweat, fan and light circuits

for at least two hours, but not more than four

hours, prior to initiating the refrigeration cycle.

Gap

Before and After Gasket Conditioning

Gap Closed

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 30

30 MaIntEnancE

INNOVATOR DOOR MAINTENANCE

As part of an ongoing maintenance program

for Innovator Doors, Hussmann recommends

that the items below be checked annually.

a) Proper door closing torque

b) Gasket performance (check for tearing and

proper sealing)

c) Check the top hinge pin to ensure the pin is

properly seated and not bent

d) Check the bottom hinge plate for excessive

wear (worn cam teeth)

e) Proper operation of hold open brackets

1. Check the doors for proper closing torque:

Test 1: Open door 90 degrees and close it

manually. Make sure the door opens and closes

without binding

Test 2: Open door 90 degrees and release it.

The door should close on its own

Test 3: Open door more than 3” but less than

6” and release it. The door should close on its

own.

Torque adjustment, if needed, should be

performed “one click” at a time. A “zero”

torque door should not require more than

4 clicks. If the torque cam and hinge socket

are severely rusted, both components should

be replaced. A severely rusted cam / socket

assembly will not hold torque. Rust on the cam

socket assembly is usually caused by one of the

following:

• High humidity conditions > ASHRAE Type I

• Cycling of the frame heaters

If the door is seated too far down the torque

rod assembly, it most likely damaged the top

hinge pin sleeve bearing. If the pin is not bent,

replacing the pin’s nylon sleeve bearing will be

sufficient. Although the torque rod assembly’s

sleeve bearing and spacer are replaceable, we

recommend that a severely rusted torque rod

assembly be replaced.

2) Inspect door gaskets:

• Check for tearing gaskets

• Make sure the gasket’s dart is properly

seated into the door’s gasket groove.

3) Inspect the top hinge assembly for excessive

movement at the top hinge socket.

• By design, the door will have a small, but

discernible amount of movement at the top

hinge pin / hinge plate socket joint. If excessive

movement is detected, the hinge pin assembly

should be inspected to ensure that the hinge pin

is not bent (refer to note #1)

4) Inspect hold open bracket:

• Open the door to the “hold open”

engagement position. The “hold open”

bracket should retain the door.

• If the bracket fails to retain the door, replace

the bracket and the shoulder screw.

5) If a door passes the three “open / close”

tests, and there is no excessive movement at the

top hinge pin, then it is highly unlikely that any

components require replacement.

Note 1: A rusted torque cam / socket assembly

can cause excessive wear on the torque rod’s

spacer and sleeve bearing. The result is a door

that can “seat” farther down the rod assembly

to the point that it causes binding at the hold

open bracket. It can also cause the top hinge

pin’s sleeve bearing to deform.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 31

P/N 3034041_D 31

Record starting date

Store Name and Num ber

Store Addres s

Unit Model Number

Unit Serial Number

Contractor/Technician

Check in with sto re manager, record any compl aints or issue s

x

Look unit over forany damage, vibrationsor abnormalnois e.

x

x

Confi rm refrigerant lines properly are secured and n ot touching

or rubbing other lines, wires or fram e work.

x

x

Confi rm fan blade/s are t ight and not rubbing or hitting.

x

x

x

x

any sharp edges or hot lines.

x

Check for ai r disturbances ex ternal l to the unit. Heat and air

register s, fans, and doors etc.

x

x

base cleaner. Rinse off any cleaner residue.

x

Clean discharge air honeycom bs or grilles. Do not use anaci d

base cleaner. Rins eoff any cleaner residue.

x

Clean c ondenser coil/s and f an blade/s. Do not u se an aci d base

Cleaner. Rin seoff any cleaner residue.

x

Clean condensate drain pan and dr ain line.

x

x

x

Verify cond enser and evaporator fans are working.

x

Record condenser air inl et temperature

x

x

x

x

Self-Contained Refrigeration Equipment Maintenance Check List

* * * * * Warranty does not cover issues caused by improper installation or lack of basic preventative maintenance. * * * * *

Technici an

PM date

PM activity-For visualinsp ectionitems, denote "ok or

complete" in the column to righ t when PM has been

performed. For measured data requested, recor d data

requested in the appropriate column to the rig ht)

they have with unit.

Verify uni t is lev el side to side and front to rear.

Verify fan motors and mot or mounts are ti ght.

Make sure all el ectrical c onnections, factory and fi eld, are tight.

Verify ele ctricalc onnections at lam ps are they secure and dry.

Check for and replace any fray ed or chaffed wiring.

Check all electrical wiring m ake sure it is secured an d not on

Check for water leaks.

Clean evaporator coil/s and fan blade/s. Do not use an acid

Verify conde nsate dr ain lines are clear and functioning.

Record voltage reading at unit wi th unit off?

Record condenser air outlet temperature

Is condenser ai r inlet or air exhaust restricted or recirculating?

Use a handheld propane leak detector ("sniffer") to check

for refrigerant leaks.

Record voltage reading with unit runni ng.

Record compressor amp draw.

Record defrost heater voltage and amp dra w.

Record anti-sweat heater voltage an d amp dra w.

Record case product temperature.

Record unit discharge ai r temperature.

Record unit return air t emperature.

Record ambient conditions around unit (wet Bul bt emperature

and dry bulb t emperature).

Check product loading, do not load beyon dthe units load limit s.

Verify clear ances on sides/back of uni t.

Check u nit controller for proper oper ation. See controller or 1/ 0

Manual for proper cont roller operation.

Confi rm door switches functi on.

Verify unit doors and lids work and are seal ed correctly.

Verify t hat all the panels, shields an d covers are in place.

Quarterly

x

x

x

x

x

x

x

x

x

Semi-

Annually

x

x

x

x

x

Ql

Q2

Q3 Q4

Ql

Q2

Q3 Q4

Technici an Notes:

Form HSCW03 Rev-29 OCTOBER13

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 32

32 MaIntEnancE

NOTES:

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 33

P/N 3034041_D 33

SERVICE

REPLACING DISPLAY LAMP

1. Disconnect power to the merchandiser.

Remove the screws at the top of the unit

display.

2. Remove the top panel.

Display Slides out to access Wireway

3. Remove the merchandiser’s plexiglass panel.

REPLACING SHELF LAMPS

1. Disconnect power to the merchandiser. The

LED fixtures are located behind the top of the

door frame.

LED Location

2. Remove the screws and disconnect the LED

fixture from the merchandiser.

4. Remove the cover display in order to access

the LED fixture and LED power supply.

LED and Power Supply Shown

with Display Panel Removed

5. Replace the LED with like fixture, and

re-attach connection.

6. Replace the display panel cover.

7. Return power to the merchandiser.

3. Replace the LED with like fixture.

4. Return power to the merchandiser.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 34

34 InstallatIon

34 sErvIcE

FRAME HEATER REPLACEMENT

Always turn off power to the case before working

on any electrical components. The old wireway

covers must be removed to access the door

frame heaters. Begin by inserting a putty knife

into the groove between the wireway cover and

fiberglass frame, about an inch (25 mm) away

from joints in the frame as shown. Carefully

begin to pry off the cover.

Use a second putty knife or flat head

screwdriver to hold up the cover as shown in

A. Pry the remainder of the section up, using

putty knife only, until the entire cover is off

and the frame heater inside the door frame is

exposed as shown in B.

A

Door frame heaters may now be replaced.

During installation, the white portion of the

heater should not come in contact with itself.

The heater should be installed so that only one

white portion of the wire enters the raceway.

The other portion entering the raceway will be

the black lead wire.

Once the heater wire is connected, check

resistance (ohm reading) before replacing

wireway covers. This will ensure that heater

wire was not broken during installation. Wiring

diagrams are shown on the last pages of this

manual.

After covers are reinstalled, turn power on and

verify that heaters are working properly.

B

C

D

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

E

Page 35

P/N 3034041_D 35

Technical Data

Visual Description of R290 Replacement Parts

Main Switch

Light Switch

Control RTN400

Control Display KDE

Component parts are specifically chosen

for propane exposure and therefore non-

incendive and non-sparkling. Component

parts shall be replaced with identical

components, and servicing shall be done by

factory authorized service personnel only, so

as to minimize the risk of possible ignition

due to incorrect parts or improper service.

Solid State Relay 25 Amp

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 36

36 tEchnIcal data

VRM Replacement Parts List

Models

StandardParts

Description PartNumber VRM1B VRM2B VRM3B

PowerCord(NEMA5‐15P) 0521094 XX X

LightSwitch 3038707 XX X

SensorNTC4mtsGreen 3023554 XX X

SensorNTC4mtsOrange 3031571 XX X

ControlEliwellRTN400 3023537 XX X

ControlDisplayKDE 3023552 XX X

MainSwitch 3038707 XX X

SolidStateRelay10Amp 3025471 XX X

Rail‐Shelf(50") 3015493 XX X

ShelfClips(insertintoRail‐Shelf) 3009285 XX X

WireShelf(White)21X24.312 3015794 XX

WireShelfBottom(White)21X24.312 3015795 XX

WireShelf(White)21X24.812 3041925 X

WireShelfBottom(White)21X24.812 3041926 X

LedLightCTR4000K 3024564 XX

LedLightRH4000K 3024573 XX

DoorBlackMedTempLH 3025860 XX X

DoorTorsionDoorAssy 3017256 XX X

DoorGasket 3017271 XX X

DoorHandle 051007300 XX X

UpperLightedDisplay

WhitePlexiglassDisplay1Doors 3041296 X

WhitePlexiglassDisplay2Doors 3020063 X

WhitePlexiglassDisplay3Doors 3016789 X

PowerSupply100W24VDC 3013744 XX X

LedLight24"Display 3004888 X

LedLight36"Display 3004891 X

LedLight48"Display 3004897 X

MagneticClipforLedLight 0523762 XX X

PartNumber VRM1B VRM2B VRM3B

Component parts are specifically chosen for

propane exposure and therefore non-incendive

and non-sparkling. Component parts shall

be replaced with identical components, and

servicing shall be done by factory authorized

service personnel only, so as to minimize the

risk of possible ignition due to incorrect

parts or improper service.

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 37

ControlEliwellRTN400 3023537 XX X

ControlDisplayKDE 3023552 XX X

MainSwitch 3038707 XX X

SolidStateRelay10Amp 3025471 XX X

Rail‐Shelf(50") 3015493 XX X

ShelfClips(insertintoRail‐Shelf) 3009285 XX X

WireShelf(White)21X24.312 3015794 XX

WireShelfBottom(White)21X24.312 3015795 XX

WireShelf(White)21X24.812 3041925 X

WireShelfBottom(White)21X24.812 3041926 X

LedLightCTR4000K 3024564 XX

LedLightRH4000K 3024573 XX

DoorBlackMedTempLH 3025860 XX X

DoorTorsionDoorAssy 3017256 XX X

DoorGasket 3017271 XX X

DoorHandle 051007300 XX X

UpperLightedDisplay

PartNumber VRM1B VRM2B VRM3B

WhitePlexiglassDisplay1Doors 3041296 X

WhitePlexiglassDisplay2Doors 3020063 X

WhitePlexiglassDisplay3Doors 3016789 X

PowerSupply100W24VDC 3013744 XX X

LedLight24"Display 3004888 X

LedLight36"Display 3004891 X

LedLight48"Display 3004897 X

MagneticClipforLedLight 0523762 XX X

P/N 3034041_D 37

VRM Replacement Parts List

(Continued)

Refrigeration

CondenserUnitAssyVRM1B 3042225 X

CondenserUnitAssyVRM2B 3019958 X

CondenserUnitAssyVRM3B 3022938 X

CompressorR290115V/60Hz1/4HP 3024061 XX X

CondenserMedTemp 3020001 XX X

CondenserFanMotorAssy8.25"(Motor,Blade&Brkt) 3054705 XX X

EvaporatorCoilVRM1B 0534325 X

EvaporatorCoilVRM2B 0547180 X

EvaporatorCoilVRM3B 3025973 X

EvaporatorFanMotor1200RPM 3055126 XX X

EvaporatorFanBlade8.25" 3055130 X

EvaporatorFanBlade7.00" 3055131 XX

EvaporatorFanMotorBracket 3058806 XX X

DistributorOrifice0.11in 3020662 XX

DistributorOrifice0.16in 3025975 X

CapillaryTube.049"x195" 3020535 XX X

FilterDrier704‐200 0530462 XX X

PartNumber VRM1B VRM2B VRM3B

Heaters

HeaterFrame115VVRM1B 3037337 X

HeaterFrame115VVRM2B 3022285 X

HeaterFrame115VVRM3B 3022286 X

SheelMetalReplacementPartsPainted

SupportPostRearPanel 3023820 X

SupportPostRearPanel 3015489 X

SupportPostShelf 3015492 XX

PanAssy‐Evap1Doors 3042234 X

PanAssy‐Evap2Doors 3020069 X

PanAssy‐Evap3Doors 3022670 X

FrontGrillAssy1Doors 3041170 X

FrontGrillAssy2Doors 3018400 X

FrontGrillAssy3Doors 3016857 X

ExtRearBottomPanel1Doors 3041401 X

ExtRearBottomPanel2Doors 3020018 X

ExtRearBottomPanel3Doors 3015027 X

PartNumber VRM1B VRM2B VRM3B

PartNumber VRM1B VRM2B VRM3B

propane exposure and therefore non-incendive

service personnel only, so as to minimize the

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Component parts are specifically chosen for

and non-sparkling. Component parts shall

be replaced with identical components, and

servicing shall be done by factory authorized

risk of possible ignition due to incorrect

parts or improper service.

VRM Merchandisers

Page 38

38 tEchnIcal data

Dimensions

VRM Cross Section Dimensions

shown as inches and (mm).

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 39

P/N 3034041_D 39

Dimensions

VRM Plan View Dimensions

shown as inches and (mm).

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRM Merchandisers

Page 40

40 tEchnIcal data

Evaporator Fans

VRM1B VRM2B

Number of Motors

2

Amperes

0.26

Watts

32

Compressor LRA 14.9 14.9

Compressor RLA 2.85 2.85

Electrical Data

DEFROST DATA

Frequency (hr) 12

OFF-TIME DEFROST

PHYSICAL DATA

Refrigerant Charge (R290)

(0.150 kg each system)

VRM1B 5.3 oz 0.150 kg (1 system)

VRM2B 5.3 oz 0.150 kg (1 system)

VRM3B 5.3 oz 0.150 kg (1 system)

Note: This data is based on store temperature

and humidity that does not exceed 80°F and

55% R.H. unless otherwise stated. Schedule

defrost at night while lights are off.

1

0.13

16

VRM3B

2

0.26

32

14.9

2.85

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 41

P/N 3034041_D 41

1 FAN

COND.

S

12

C

R

BK

BK

123

BW

W

RELAY

COMPRESSOR

NO

1

W

BK

4

LED

INPUT

OUTPUT

3

2

1

2

BK

BK

BK

W

BK

W

4

BK

W

W W

W

BK

W

COMPRESSOR LH

3

RELAY

CURRENT

W

BK

BK

W

WW

BK

KEYB

WARNING

15 cm.

AIR

GREEN

SENSOR TEMP

PB1

1819202122

PB2

23

24

ORANGE

DEFROST

SENSOR TEMP

25

2627

GND

28

D

29

GND

30

D

3132

OC

12V

33

ELECTRICAL SPECS

MODEL VRM

VOLTAGE 115 V

FRECUENCY 60 HZ

BK= BLACK

MAX.

OUT4

D

12V

GND

OPTIONAL

TTL

MODULE

RS-485

OUT2

RTN400 SM

W= WHITE

BL= BLUE

R= RED

BW=BROWN

WARNING

UNPLUG THE UNIT BEFORE SERVICING.

OUT1

OUT3

ADVERTENCIA:

14

OUT4

12 13

11

OUT1

10

BK

BK

56 789

OUT2 OUT3

4

LINE

NEUTRO

BK

NEUTRO

123

W

BK

BK

W

BK

DESCONECTE EL EQUIPO ANTES DE REALIZAR

CUALQUIER SERVICIO O MANTENIMIENTO.

2b

1b

21

BK

W W

BK

ELEC-TRON

25 26

W

23 24

BK

11 12

9 10

BK

7 8

5 6

W

3 4

1 2

W

3-S-226

W

BK

W

BK

W

W

BK

LIGHT

SWITCH

BK

W

BK

All components must have mechanical ground, and the merchandiser must be grounded.

R = Red Y = Yellow G = Green BL = Blue BK = Black W = White B = Brown O = Orange GR = Grey

POWER SUPPLY

LED DISPLAY

LED DISPLAY

BL

R

LIGTHS

BK

FRAME

HEATER

ENDLE

D

EVAP. FANS

DOOR AND FRAME HEATERS

E

B KW

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GRN

115 V

60HZ

1HP

G

5-15P

NEMA

W

VRM Merchandisers

Page 42

42 tEchnIcal data

LINE

NEUTRO (LINE2)

W

POWER SUPPLY

BK

VRM1B

BL (-)

R (+)

FUSE

0.6 A

E

END LED

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 43

P/N 3034041_D 43

R = Red Y = Yellow G = Green BL = Blue BK = Black W = White B = Brown O = Orange GR = Grey

33

12V

SENSOR TEMP

DEFROST

303132

26272829

D

D

OC

GND

GND

RTN400 SM

ELECTRICAL SPECS

MODEL: VRM

VOLTAGE: 115 V

FRECUENCY: 60 HZ

W=WHITE

BK= BLACK

R=RED

BL=BLUE

BW=BROWN

NOTE:

3 DOOR CASE: 2X LED AT THE CENTER

2 DOOR CASE: 1X LED AT THE END, 1X LED AT THE CENTER

H

W

OUT2

OUT3

LINE

NEUTRO

NEUTRO

OUT2

OUT3

123456 7891011 121314

BK

SENSOR TEMP

AIR

PB2

PB1

232425

1819202122

RS-485

MODULE

OPTIONAL

12V

TTL

D

GND

OUT1

OUT1

OUT4

15 cm.

OUT4

KEYB

MAX.

WARNING

UNPLUG THE UNIT BEFORE SERVICING.

ADVERTENCIA:

DESCONECTE EL EQUIPO ANTES DE REALIZAR

CUALQUIER SERVICIO O MANTENIMIENTO.

BK

BK

BK

1

C

R

S

1

2

COMPRESSOR LH

FAN

COND.

2

3

CURRENT

RELAY

NEMA

5-15P

GRN

G

W

BK

BW

W

3

RELAY LH

COMPRESSOR

2

BK

BK

BK

LED

INPUT

OUTPUT

MAIN

SWITCH

1b

1

2

W

2b

W

RELAY 2

4

NO

1

BK

30 A.

BK

1

W

2

GRN

BK

3

W

4

W

5

BK

6

7

GRN

W

BK

W

BK

W

BK

W

BK

W

3-S-226

W

1 2

3 4

W

R

POWER SUPPLY

W

BL

W

BK

BK

LED DISPLAY

FRAME

WW

W

HEATER

LIGTHS

C

E

N

T

E

R

L

E

D

C

E

N

T

E

R

L

E

D

EVAP. FANS

W

BK

BK

7 8

5 6

BK

11 12

9 10

DOOR

SWITCH

ELEC-TRON

25 26

23 24

BK

All components must have mechanical ground, and the merchandiser must be grounded.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

WARNING

DOORS AND FRAME HEATERS

VRM Merchandisers

Page 44

44 tEchnIcal data

LINE 1 NEUTRO (LINE2)

W

POWER SUPPLY

BK

BL (-)

R (+)

VRM3B

FUSE

1.0 A

H

FUSE

1.0 A

LINE 1 NEUTRO (LINE2)

W

BK

POWER SUPPLY

BL (-)

R (+)

VRM2B

FUSE

1.0 A

CENTER LED

H

CENTER LED

FUSE

0.6 A

CENTER LED

END LED

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 45

To obtain warranty information

or other support, contact your

Hussmann representative.

Please include the model and

serial number of the product.

Hussmann Corporation, Corporate Headquarters: Bridgeton, Missouri, U.S.A. 63044-2483 01 October 2012

Page 46

46 tEchnIcal data

Hussmann Corporation

12999 St. Charles Rock Road

Bridgeton, MO 63044-2483

www.hussmann.com

P/N 3034041_D U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Loading...

Loading...