Page 1

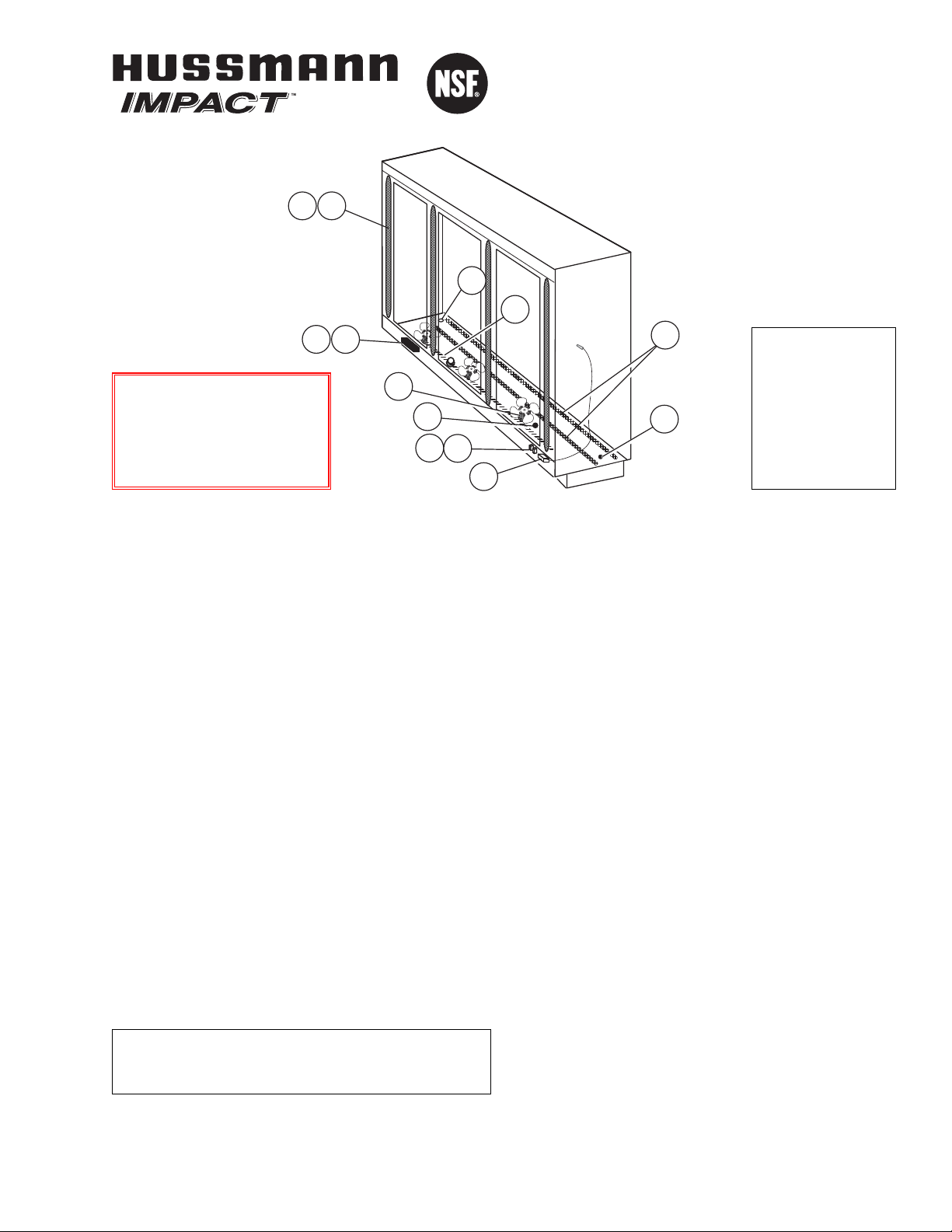

E

F

C

G

B

I

A

J

K

D

H

M

L

Merchandisers

®

RL

with INNOVATOR II

No Heat Doors

Technical Data Sheet

P/N 0440999_J

NSF

®

Certified

November 2009

Item Part # Description Wiring Item #

FAN ASSEMBLIES, AND THERMOSTATS

A. 12W Standard Fan Assembly (1)

0047000 Fan Motor, Evaporator

(MO.4410103)

0461805 Fan Blade (FB.4780446)

12W Optional Energy Efficient Fan Assembly (1)

0477655 Fan Motor, Evaporator

(MO.4410546)

0461805 Fan Blade (FB.4780446)

B. 0474033 Standard Non-adjustable (2)

Defrost Thermostat (CT.4440726)

C. Optional Adjustable

Refrigeration Thermostat (3)

D. 0344662 Defrost Limit Thermostat (4)

(CT.4440261)

E. 0461814 Relay Control Thermostat or (5)

Fan and Anti-sweat Heater

Thermostat (CT.4481296)

RELAYS

F. 0342598 Anti-Sweat Control Relay (6)

(120V) (RL.4480238)

G. 0342599 Fan Control Relay (208V) (7)

(RL.4480237)

Item Part # (Qty) Description Wiring Item #

HEATERS

H. Electric Defrost Heaters – Front (208V) (8)

0441755 (1) 2 Door Models (HE.4850346)

0441756 (1) 3 Door Models (HE.4850337)

0441757 (1) 4 Door Models (HE.4850347)

0441758 (1) 5 Door Models (HE.4850323)

Electric Defrost Heaters — Rear (208V) (8)

0463891 (1) 2 Door Models (HE.4850358)

0463892 (1) 3 Door Models (HE.4850359)

0463893 (1) 4 Door Models (HE.4850360)

0463894 (1) 5 Door Models (HE.4850361)

I. Drain Pan Heater (Electric & Kool Gas) (9)

(120V)

0387036 (1) 2 Door Models (HE.4850239)

0387037 (1) 3 Door Models (HE.4850240)

0387038 (1) 4 Door Models (HE.4850241)

0387039 (1) 5 Door Models (HE.4850242)

LAMPS, BALLASTS, LED FIXTURES AND POWER SUPPLY

J. 0430330 2 Lamp Ballast (BA.4480342)

0454319 3 Lamp Ballast (BA.4480601)

0424649 Export Ballast (BA.0424649)

K. Standard Fluorescent Lamp

Replace with like fixtures

L. 0499399 LED Power Supply (EP.4481668)

M. LED Fixture

Replace with like fixtures

NOTE: For LED lighting parts contact your Hussmann

service representative at 1-800-922-1919. Please have

your model and serial number available.

We reserve the right to change

or revise specifications and

product design in connection

with any feature of our

products. Such changes

do not entitle the buyer to

corresponding changes,

improvements, additions or

replacements for equipment

previously sold or shipped.

Warning:

Terminal block NOT for

case-to-case

wire connection!

©2009 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

U.S. & CANADA 1-800-922-1919 • MEXICO 1-800-522-1900 • WWW.HUSSMANN.COM

Refer to INNOVATOR REACH-IN GLASS DOOR

INSTALLATION AND SERVICE manual, P/N 0425683,

for Innovator II door and frame replacement parts.

P/N0440999J

NOTE: Revision J updates electrical data, Page 4.

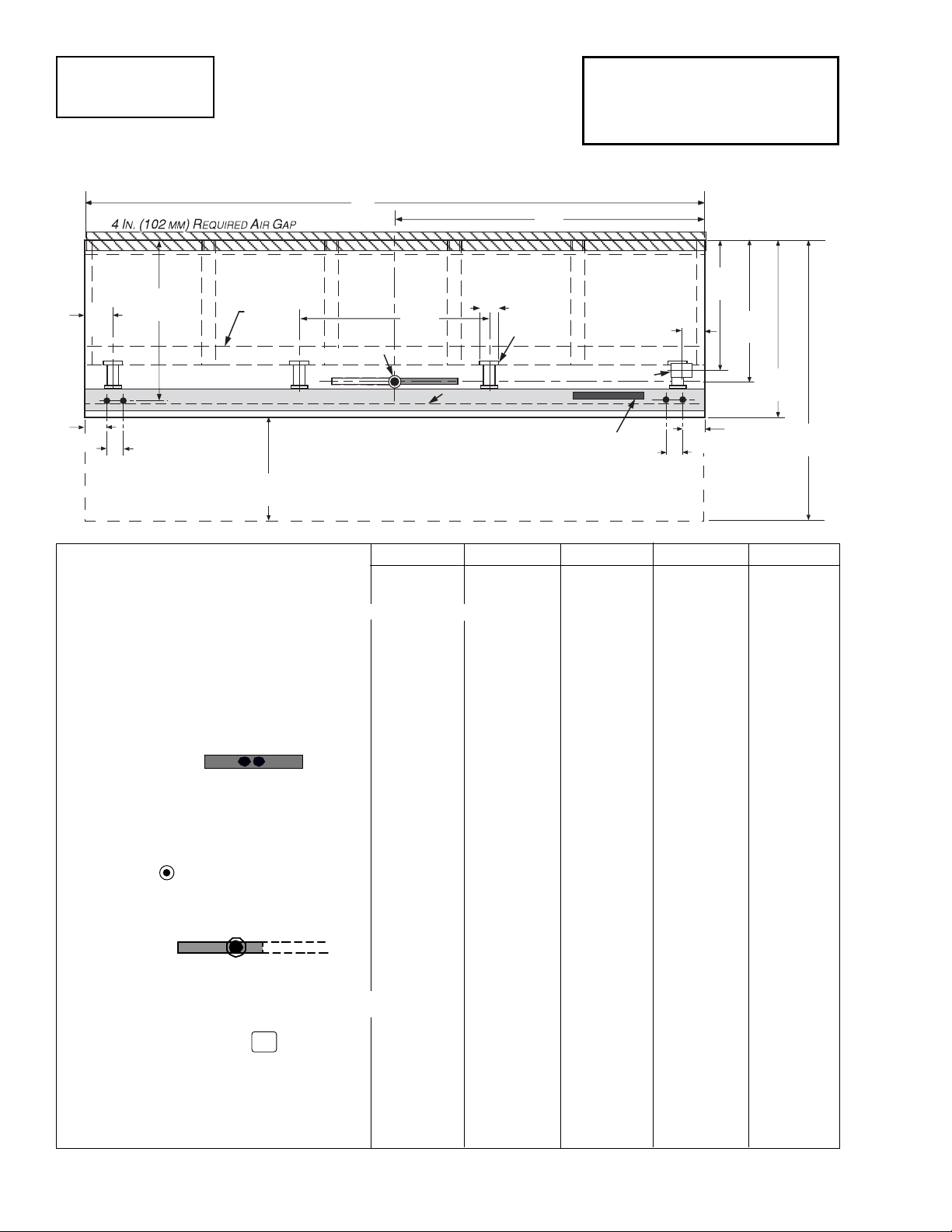

Page 2

RL with Innovator II Doors Technical Data Sheet

2 of 7

HUSSMANN • U.S. & CANADA 1-800-922-1919 • MEXICO 1-800-522-1900

1 Dr 2 Dr 3 Dr 4 Dr 5 Dr

General

(A) Case Length

(without ends or partitions) 31

1

/

2 (800) 62 (1575) 92

1

/

2 (2350) 122

7

/

8 (3121) 153

3

/

8 (3896)

(Each end adds 2 in. (51 mm) to length of lineup; each insulated partition adds 1 1/

2 in. (38 mm).

Maximum O/S dimension of case back to front 43 3/

4 (1111) 43

3

/

4 (1111) 43

3

/

4 (1111) 43

3

/

4 (1111) 43

3

/

4 (1111)

(Includes bumper. Add 26 1/

2 in. (673 mm) for door swing.)

Back of case to rear of splashguard 39 7/

8 (1013) 39

7

/

8 (1013) 39

7

/

8 (1013) 39

7

/

8 (1013) 39

7

/

8 (1013)

Width of Skidrail 3

3

/

4 (95) 3

3

/

4 (95) 3

3

/

4 (95) 3

3

/

4 (95) 3

3

/

4 (95)

Width of Bottom Front Support 6 (152) 6 (152) 6 (152) 6 (152) 6 (152)

Stub-up area between front support and splashguard 3

1

/8 (79) 3 1/8 (79) 3 1/8 (79) 3 1/8 (79) 3 1/8 (79)

Electrical Service

RH end of case to the center of nearest knockout 4 (102) 4 (102) 4 (102) 4 (102) 4 (102)

RH end of case to the center of LH knockout 27 1/

2 (698) 58 (1473) 88

1

/

2 (2248) 118

7

/

8 (3019) 149

3

/

8 (3794)

Back O/S of case to center of knockout 41

5

/

8 (1058) 41

5

/

8 (1058) 41

5

/

8 (1058) 41

5

/

8 (1058) 41

5

/

8 (1058)

* NOTE: Electrical Field Wiring Connection Point is at terminal.

Waste Outlet

(B) Right end of case to center of waste outlet 15 3/

4 (400) 23

7

/

8 (606) 54

1

/

4 (1378) 46

1

/

4 (1175) 76

5

/

8 (1946)

Back O/S of case to center of waste outlet 34

5

/

8 (879) 34

5

/

8 (879) 34

5

/

8 (879) 34

5

/

8 (879) 34

5

/

8 (879)

Water Seal

Edge of water seal to center of waste outlet 13 (330) 13 (330) 13 (330) 13(330) 13 (330)

Schedule 40 PVC drip pipe 1

1

/

4 (32) 1

1

/

4 (32) 1

1

/

4 (32) 1

1

/

4 (32) 1

1

/

4 (32)

** NOTE: Field installed water seal outlets, tees, and connectors are shipped with case

Refrigeration Outlet

RH end of case to center of RH refrigeration outlet 5 3/

8 (137) 5

3

/

8 (137) 5

3

/

8 (137) 5

3

/

8 (137) 5

3

/

8 (137)

Back O/S of case to center of refrigeration outlet 32 (813) 32 (813) 32 (813) 32(813) 32 (813)

Outside bottom front supports from end of case 6

3

/

4 (170) 6

3

/

4 (170) 6

3

/

4 (170) 6

3

/

4 (170) 6

3

/

4 (170)

Center bottom front support from Centerline NA 24 (610) 24 (610) 24 (610) 24 (610)

Distance between Center and Outside supports will vary

4

(102)

43

3

/4

(1111)

Front

5-Door Shown

6

(152)

34

5

/8

(879)

32

(813)

5

5

/8

(143)

41

5

/8

(1057)

Refrig. Outlet

A

B

Electrical Wireway

Bottom

Front

Support

48

(1219)

Waste Outlet

Relay & Terminal

Block Location

Skid/

External

Base

13/4

(44)

13/4

(44)

7

(178)

4

(102)

Splashguard

Clearance for Door Swing

26

1

/2

(673)

70

1

/4

(1784)

Dimensions shown as in. & (mm).

Reach-In

2, 3, 4 & 5 Door

Engineering

Plan Views

PHYSICAL DATA

Merchandiser Drip Pipe (in.) 1 1/4

Merchandiser Liquid Line (in.)

3

/8

Merchandiser Suction Line (in.)

7

/8

RL - RM - RMF

Plan View

06-2009

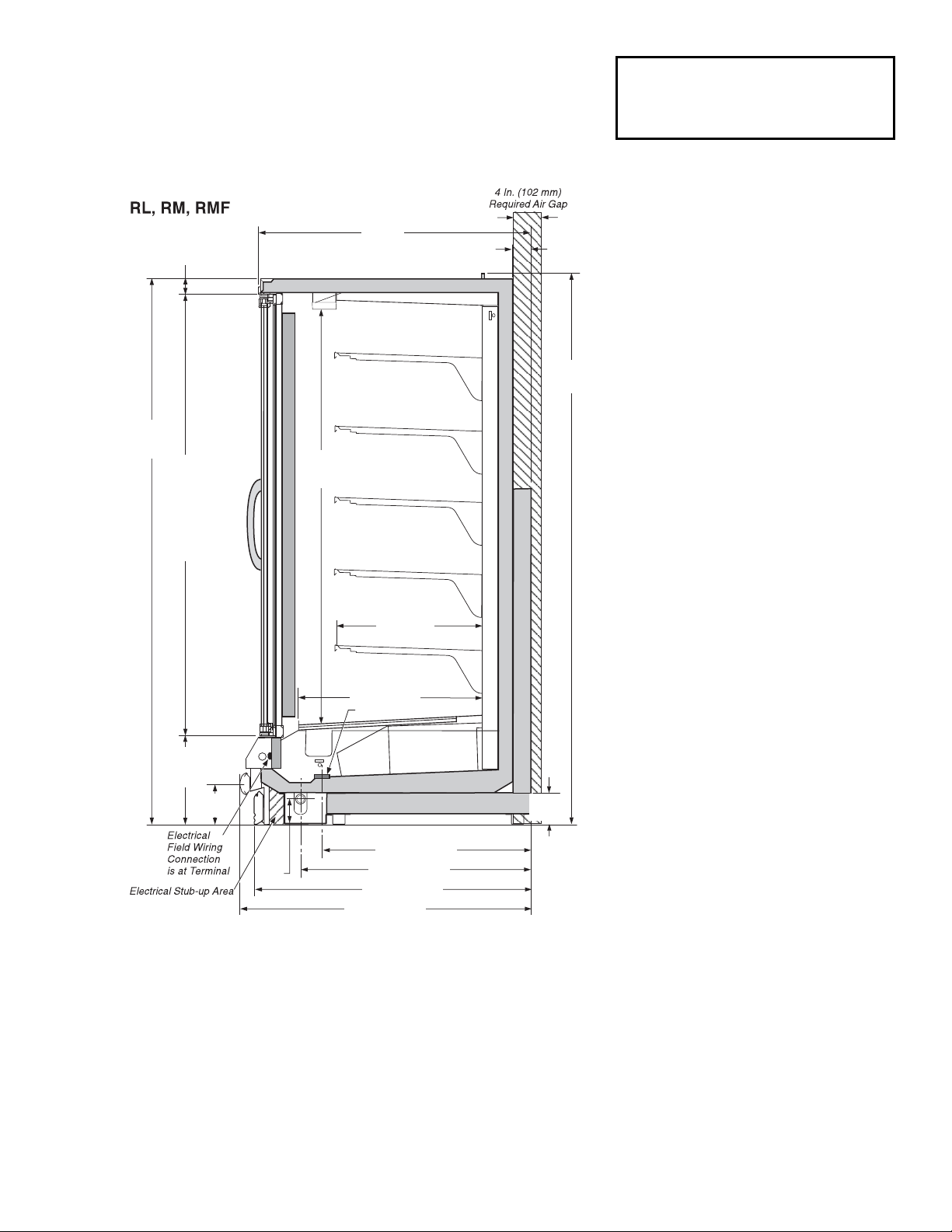

Page 3

Impact RL

With INNOVATOR II Doors

Frozen Food & Ice Cream

REFRIGERATION DATA

Note: This data is based on store temperature and

humidity that does not exceed 75°F and 55% R.H.

FF IC

Discharge Air (°F) –5 –12

Evaporator (°F) –9 –17

Unit Sizing (°F) –12 –20

Btu/hr/Door

†

FF IC

Parallel

1195 1258

Conventional

1220 1310

†Optional LED lighting reduces refrigeration

load by 100 Btu/hr/Door.

Optional Energy Efficient Fan motors reduce

refrigeration load by 109 Btu/hr/Door.

DEFROST DATA

FF IC

Frequency (hr) 24 24

Defrost Water (lb/Dr/day) 1.2 1.2

(± 15% based on case configuration and

product loading.)

ELECTRIC FF IC

Temp Term (°F) 48° 48°

Failsafe (minutes) 45 45

GAS

Duration (minutes) 20 20

O

FFTIME Not Recommended

CONVENTIONAL CONTROLS

Low Pressure Backup Control

FF IC

CI/CO (Temp °F)** -18°/ -34° - 26°/-45°

Indoor Unit Only, Pressure Defrost

Termination (Temp °F)**

Not Recommended

**Use a Temperature Pressure Chart to

determine PSIG conversions.

Estimated Charge (lb)***

2Dr 1.8

3Dr 2.7

4Dr 3.6

5Dr 4.6

***This is an average for all refrigerant types.

Actual refrigerant charge may vary by approximately half a pound.

Length Added to Lineup by each

Standard End (in.) 2

Optional End with Window (in.) 1

1

/

2

Optional Partition (in.) 1 1/

2

Reach-in 2, 3, 4 and 5 Door Models

3 of 7P/N 0440999_J

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

4 3/4

(121)

32 (813)

34 5/8 (879)

2 5/8

(67)

2

1

/8

(54)

Fan

Coil

62 1/2

(1588)

22 Shelf

(559)

41

(1041)

27 7/8 (708)

Refrigeration Outlet

67

(1702)

Frame

65 1/2

(1664)

Door

83

(2108)

82 1/4

(2089)

6

1

/4

(159)

13 1/8

(333)

Frame

41 7/8 (1064)

43 3/4 (1111 )

3 1/2

(89)

Dimensions shown as in. & (mm).

NSF Certification

This merchandiser model is manufactured to meet ANSI/NSF

(National Sanitation Foundation) Standard #7 requirements for

construction, materials & cleanability.

Page 4

HUSSMANN • U.S. & CANADA 1-800-922-1919 • MEXICO 1-800-522-1900

Electrical Data

2Dr 3Dr 4Dr 5Dr

Number of Fans—12W 2 3 4 5

Amperes Watts

Merchandiser 2Dr 3Dr 4Dr 5Dr 2Dr 3Dr 4Dr 5Dr

Evaporator Fan

120V 60Hz Standard 1.30 1.95 2.60 3.25 100 150 200 250

120V 50Hz Standard 1.50 2.25 3.00 3.75 114 171 228 285

220V 60Hz Export 0.66 0.99 1.32 1.65 100 150 200 250

220V 50Hz Export 0.76 1.14 1.52 1.90 114 171 228 285

120V 60Hz Energy Efficient 0.60 0.90 1.20 1.50 36 54 72 90

220V 60Hz Energy Efficient 0.30 0.45 0.60 0.75 36 54 72 90

Door Anti-sweat Heaters (on fan circuit) NA

Frame Anti-sweat Heaters (on fan circuit)

120V 50/60Hz Standard 0.89 1.34 1.79 2.24 107 161 215 269

220V 50/60Hz Export 0.49 0.73 0.98 1.22 107 161 215 269

Minimum Circuit Ampacity

120V 60Hz Standard 2.39 3.49 4.59 5.69

120V 50Hz Standard 2.59 3.79 4.99 6.19

220V 60Hz Export 1.35 1.92 2.50 3.07

220V 50Hz Export 1.45 2.07 2.70 3.32

120V 60Hz Energy Efficient 1.69 2.44 3.19 3.94

220V 60Hz Energy Efficient 0.99 1.38 1.78 2.17

Maximum Over Current Protection 120V 20 20 20 20

Maximum Over Current Protection 220V 15 15 15 15

Defrost

Drain Heaters (120V) 0.63 1.25 2.00 2.57 75 150 240 300

(Export: 220V 50 Hz) 0.34 0.76 1.22 1.53 84 168 269 336

208V Electric Defrost 6.72 10.08 13.46 16.82 1400 2100 2800 3500

(Export: 220V 50 Hz) 7.11 10.66 14.24 17.79 1564 2345 3133 3914

Standard Vertical Lighting 2Dr 3Dr 4Dr 5Dr 2Dr 3Dr 4Dr 5Dr

Innovator* Doors (120V) 1.50 2.00 2.50 3.00 180 240 300 360

(Export: 220V 50 Hz) 0.84 1.12 1.40 1.68 185 246 308 370

Optional LED Lighting

Hussmann EcoShine™ [27 W] (120V) 0.45 0.68 0.90 1.13 54 81 108 135

Hussmann EcoShine™

[27 W] [220V (Export)] 0.25 0.37 0.49 0.61 54 81 108 135

Hussmann EcoShine™ EP [16 W] (120V) 0.27 0.40 0.53 0.67 32 48 64 80

Hussmann EcoShine™

EP [16 W] [220V (Export)] 0.15 0.22 0.29 0.36 32 48 64 80

Hussmann EcoShine™ [20 W] (120V) 0.33 0.50 0.67 0.83 40 60 80 100

Hussmann EcoShine™

[20 W] [220V (Export)]

0.17 0.25 0.33 0.42 40 60 80 100

Gelcore (120V) 0.48 0.73 0.97 1.21 58 87 116 145

Gelcore (120V)

[220V (Export)]

0.26 0.40 0.53 0.66 58 87 116 145

* Innovator or Innovator II

RL with Innovator II Doors Technical Data Sheet

4 of 7

Impact RL

With INNOVATOR II Doors

Frozen Food & Ice Cream

Hussmann recommends against frame heater cycling with

Innovator

doors to prevent door seals from freezing to the

frames and tearing.

Page 5

5 of 7P/N 0440999_J

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

ESTIMATED SHIPPING WEIGHT

5

Case Solid End

1 Dr 2 Dr 3 Dr 4 Dr 5 Dr (each)

lb (kg) NA (NA) 997 (453) 1295 (589) 1595 (725) 1874 (852) 55 (25)

5

Actual weights will vary according to optional kits included.

Product Data

Recommended Usable Cube

1

(Cu Ft/Dr) 23.46 ft3 /Dr (0.66 m3 /Dr)

ARI Total Display Area

2

(Sq Ft/Dr) 13.31 ft2/Dr (1.24 m2 /Dr)

Shelf Area 3(Sq Ft/Dr) 29.32 ft2/Dr (2.72 m2 /Dr)

1

ARI Refrigerated Volume less shelving and other unusable space: Refrigerated Volume/Unit of Length, ft3/ft [m3/m]

2

Computed using ARI 1200 standard methodology: Total Display Area, ft2[m2]/Unit of Length, ft [m]

3

Shelf surface area is composed of bottom deck plus standard shelf complement, as shown in the Hussmann

Product Reference Guide. The standard shelf complement for this model is (5) rows of 22-inch shelves.

Impact RL

With INNOVATOR II Doors

Frozen Food & Ice Cream

Page 6

RL with Innovator II Doors Technical Data Sheet

6 of 7

OR

120V POWER

OR

Switch

NEUTRAL

17

20

Defrost Termination

Thermostat

Refrigeration

Thermostat

(Optional)

Pink

2

3

}

To

Condensing

Unit

A.S. Relay

Coil

BR

Evaporator Fans

1

Fan Relay

F

COM

N.O.

Rod Heater (Drain)

9

Y

Y

N.C.

7

7

1

3

W

Relay Control

c

25

Fan Relay

F

5

6

BK

COM

N.C.

6

A.S. Relay

A.S.

24

Door A.S. Heaters

Frame A.S. Heaters

21

22

2P

P

2P

P

12

11

10

120V POWER

16

13

Evaporator Fan

Relay Coil

1

3

Rear Defrost Heater

R

R

C

8

R

R

Front Defrost Heater

R

5

4

7

R

N.C.

7

8

8

Defrost Limit

208V

208V

Terminal Blocks in Raceway

Low Temperature with

Electric Defrost

20

21

22

26

17

1234

56 7

81011 1413 16

LIGHTS

(120V)

DEFROST HEATERS

(208V)

CIRCLED NUMBERS = PARTS LIST ITEM NUMBERS

THESE ARE MARKER COLORS (WIRE MAY VARY.)

CAUTION: When multiplexing

merchandisers equipped with defrost

heaters, if branch circuit overcurrent

protection is larger than the

circuit load, then additional

supplemental overcurrent protection

may be required per NEC Articles

210 and 240.

R = Red P = Purple 2P = Purple (2 Bands) DB = Dark Blue BL = Black

LB = Light Blue BR =Brown Y =Yellow OR = Orange W = White

Low Temperature

24 2512

FANS & A.S.

(120V)

LIGHTS

(Neutral)

FANS & A.S. (Neutral)

Permanent Internal

Jumpers

R P

W

BRORRRRBKBKRRBKP

2P

BK BK ORBK 2P Y

14

26

C.O.R.

1

2

3

4

6

O.O.R.

Removable External

Jumpers

DB

C.O.R.

2

Defrost Termination

Thermostat

FIELD WIRED

DB

NEUTRAL

Dark Blue

Refer to Innovator Reach-In

Glass Door, Installation and

Service manual, P/N 0425683,

for Innovator door and frame

replacement parts.

BK

BK

BK

BK

BK

Electric Defrost Sequence - Low Temperature

1. Power from the defrost contactor energizes Defrost Heaters and 208V Evaporator Fan Relay Coil (7). Relay Contacts open the fan

circuit and energizes the Drain Pan Heater.

2. If the Defrost Heater raises internal air temperature above 90°F, the Defrost Limit Thermostat (4) will open.

3. Temperature rise of the evaporator closes the Relay Control Thermostat (5) at about 35°F, energizing 120V A.S. Relay Coil (6).

This relay’s contacts open the Frame and Door Heater Circuits.

4. When Defrost Termination Thermostat ends defrost period, the defrost contactor opens the Defrost Heater and Evaporator Fan

Relay Coil Circuits. The Drain Pan Heater goes off and fans are on.

5. Temperature fall of the evaporator opens the Relay Control Thermostat (5) at about 20°F, de-energizing 120V A.S. Relay Coil (6).

A.S. Relay Contacts close the Frame and Door Heater Circuits.

HUSSMANN • U.S. & CANADA 1-800-922-1919 • MEXICO 1-800-522-1900

Page 7

7 of 7P/N 0440999_J

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

CIRCLED NUMBERS = PARTS LIST ITEM NUMBERS

THESE ARE MARKER COLORS (WIRE MAY VARY.)

R = Red P = Purple 2P = Purple (2 Bands) DB = Dark Blue BL = Black

LB = Light Blue BR =Brown Y =Yellow OR = Orange W = White

Permanent Internal

Jumpers

A.S. Relay

Coil

BR

Evaporator Fans

1

Fan Relay

F

COM

N.O.

Rod Heater (Drain)

9

Y

Y

N.C.

7

7

1

3

W

Relay Control

c

25

Fan Relay

F

BK

5

6

COM

N.C.

6

A.S. Relay

A.S.

24

Door A.S. Heaters

Frame A.S. Heaters

22

2P

2P

P

12

10

120V POWER

13

26

C.O.R.

P

OR

120V POWER

OR

Switch

NEUTRAL

17

20

Terminal Blocks in Raceway

Low Temperature with

Gas Defrost

20

21

22

26

17

10 11 1413 16

LIGHTS

(120V)

Refrigeration

Thermostat

(Optional)

Pink

3

}

To

Condensing

Unit

24 2512

FANS & A.S.

(120V)

LIGHTS

(Neutral)

FANS & A.S. (Neutral)

P

W

BRORBK P

2P

BK BK ORBK 2P Y

Removable External

Jumpers

Low Temperature

16

7

Fan Relay

Coil

11

c

Defrost Limit

4

O.O.R.

14

21

NEUTRAL

Refer to Innovator Reach-In

Glass Door, Installation and

Service manual, P/N 0425683,

for Innovator door and frame

replacement parts.

BK

BK

BK

Gas Defrost Sequence - Low Temperature

1. Defrost vapor enters evaporator causing a rise in temperature. At about 35°F the Control Relay Thermostat

(5) closes

the Fan Relay Coil (7) and Control Relay Coil (6) circuit. The Coil opens the Fan, Door Heater, and Frame Heater cir-

cuits, while energizing the Drain Pan Heater

(9).

2. If the Drain Pan Heater (9) raises internal air temperature above 90°F, the Heater Limit Thermostat (4) will open.

3.

When the defrost timer ends a defrost period, the evaporator temperature will start to fall. At about 20°F, the Control

Relay Thermostat will open, de-energizing the Control Relay Coil and Fan Relay Coil (7). Control and Fan Relay’s will

open the Drain Pan Heater circuits, and will close the Fan, Door Heater, and Frame Heater circuits.

Loading...

Loading...