REV.

Manual

Installation

& Operation

/Chino

RID

ROLL IN DELI/DAIRY DISPLAY

9610(9911)

RID

ROLL IN DELI/DAIRY DISPLAY

P/N IGUP-RID-9610(9911)

INSTALLATION & OPERATION GUIDE

Ta b l e of Contents

IGUP-RID-9610(9911)

General Instructions

THIS BOOKLET CONTAINS INFORMATION ON:

General Instructions ................................................. 2

Cut & Plan Views ....................................................... 3

Installation ................................................................. 4

LEVELING.............................................................................................................. 4

JOINING ................................................................................................................ 4

Plumbing .................................................................... 5

WASTE OUTLET AND P-TRAP .............................................................................. 5

Refrigeration ............................................................. 6

Electrical .................................................................... 7

WIRING COLOR CODE ......................................................................................... 7

User Information ...................................................... 8

STOCKING.............................................................................................................. 8

CASE CLEANING.................................................................................................... 8

Maintenance .............................................................. 9

ELECTRICAL PRECAUTIONS ................................................................................... 9

REPLACING FLUORESCENT LAMPS ....................................................................... 9

TIPS & TROUBLESHOOTING ................................................................................. 9

Electrical and Refrigeration Specifications ............ 10

Electrical Schematics ............................................... 10

Appendices ................................................................ 11

APPENDIX A. – Temperature Guidelines ............................................................ 11

APPENDIX B. – Application Recommendations.................................................. 11

APPENDIX C. – Field Recommendations -......................................................... 11

APPENDIX D. – Recommendations to user - .................................................... 12

RIDStraight-glass refrigerated service meat/fish merchandiser

SHIPPING DAMAGE

All equipment should be thoroughly examined for shipping damage before and during unloading.

This equipment has been carefully inspected at our factory and the carrier has assumed responsibility for safe

arrival. If damaged, either apparent or concealed, claim must

be made to the carrier.

APPARENT LOSS OR DAMAGE

If there is an obvious loss or damage, it must be noted on

the freight bill or express receipt and signed by the carrier’s

agent; otherwise, carrier may refuse claim. The carrier will

supply necessary claim forms.

CONCEALED LOSS OR DAMAGE

When loss or damage is not apparent until after equipment

is uncrated, a claim for concealed damage is made. Make

request in writing to carrier for inspection within 15 days,

and retain all packaging. The carrier will supply inspection

report and required claim forms.

SHORTAGES

Check your shipment for any possible shortages of material. If a shortage should exist and is found to be the responsibility of Hussmann Chino, notify Hussmann Chino. If

such a shortage involves the carrier, notify the carrier imme-

diately, and request an inspection. Hussmann Chino will

acknowledge shortages within ten days from receipt of

equipment.

HUSSMANN CHINO PRODUCT CONTROL

The serial number and shipping date of all equipment has

been recorded in Hussmann’s files for warranty and replacement part purposes. All correspondence pertaining

to warranty or parts ordering must include the serial number of each piece of equipment involved, in order to provide the customer with the correct parts.

Keep this booklet with the case at all times for future reference.

/Chino

A publication of

Hussmann® Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

The Hussmann warranty is printed on the back

of this guide.

2

Rev. 9610(9911)

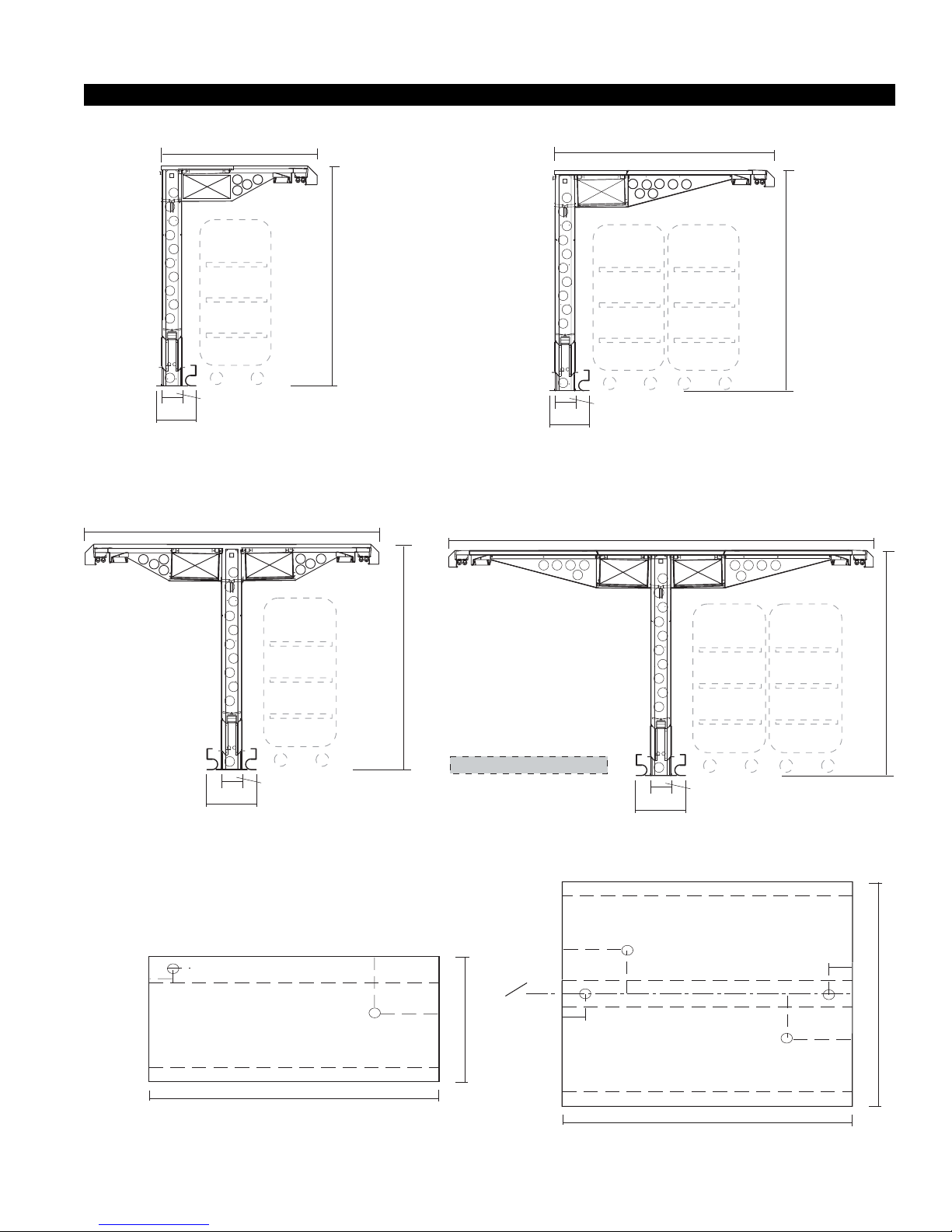

RID01, SINGLE DEPTH

4'-55/16"

Cut & Plan Views

RID03, DOUBLE DEPTH

6'-65/16"

ROLL-IN

CARTS

1

/2"

7

1'1/4"

RID012 SINGLE DEPTH

RID-01

8'-105/8"

ROLL-IN

CARTS

"

4

/

1

6'-11

1'1/4"

ROLL-IN

CARTS

ROLL-IN

CARTS

"

4

/

1

6'-11

1

7

/2"

RID-03

RID04, DOUBLE DEPTH

13'-05/8"

"

4

/

1

ROLL-IN

CARTS

ROLL-IN

CARTS

6'-11

"

4

/

1

6'-11

SINGLE DEPTH

3"

6"

Drain

Elec.

4"

1

7

/2"

1

1'-6

/4"

ELEC. FLEXED ASSEMBLED IN FIELD

DRAIN IS 1" PLASTIC TUBE

REFRIG. STUBBED UP THROUGH TOP

VARIABLE LENGTHS

PLAN VIEW

Single Sided

RID-02

Ref.

FRONT

18"

PALLET

1

/2"

7

1'-61/4"

RID-04

DOUBLE DEPTH

FRONT

Ref.

18"

C

18"

L

Drain

6"

"

4

/

1

14

"

4

/

1

14

Ref.

ELEC. FLEXED ASSEMBLED IN FIELD

SINGLE OR DOUBLE DEPTH

Elec.

4"

DRAIN IS 1" PLASTIC TUBE

REFRIG. STUBBED UP THROUGH TOP

FRONT

VARIABLE LENGTHS

PLAN VIEW

18"

Drain

4"

Elec.

6"

1

SINGLE DEPTH)

DOUBLE DEPTH)

" (

" (

2

8

/

/

5

8'-10

13'-0

3

Installation

LOCATION

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature and

humidity are maintained at or below 75°F and 55% relative humidity. DO NOT allow air conditioning, electric fans,

ovens, open doors or windows (etc.) to create air currents around the merchandiser, as this will impair its correct operation.

Product temperature should always be maintained at a

constant and proper temperature. This means that from

the time the product is received, through storage, preparation and display, the temperature of the product must

be controlled to maximize life of the product.

UNCRATING THE STAND

Place the fixture as close to its permanent position as

possible. Remove the top of the crate. Detach the walls

from each other and remove from the skid. Unbolt the

case from the skid. The fixture can now be lifted off the

crate skid. Lift only at base of stand!

EXTERIOR LOADING

These models have not been structurally designed to sup-

port excessive external loading. Do not walk on their

tops; This could cause serious personal injury and damage to the fixture.

SETTING AND JOINING

The sectional construction of these models enable them

to be joined in line to give the effect of one continuous

display. A joint trim kit is supplied with each joint.

LEVELING

Leveling is necessary to insure proper operation, water

drainage and alignment. When joining, use a carpenters

level and shim legs accordingly. Case must be raised

correctly, under legs where support is best, to prevent

damage to case.

The RID case is tall and narrow and can be tipped over if

it is raised too high on one side.

JOINING

IGUP-RID-9610(9911)

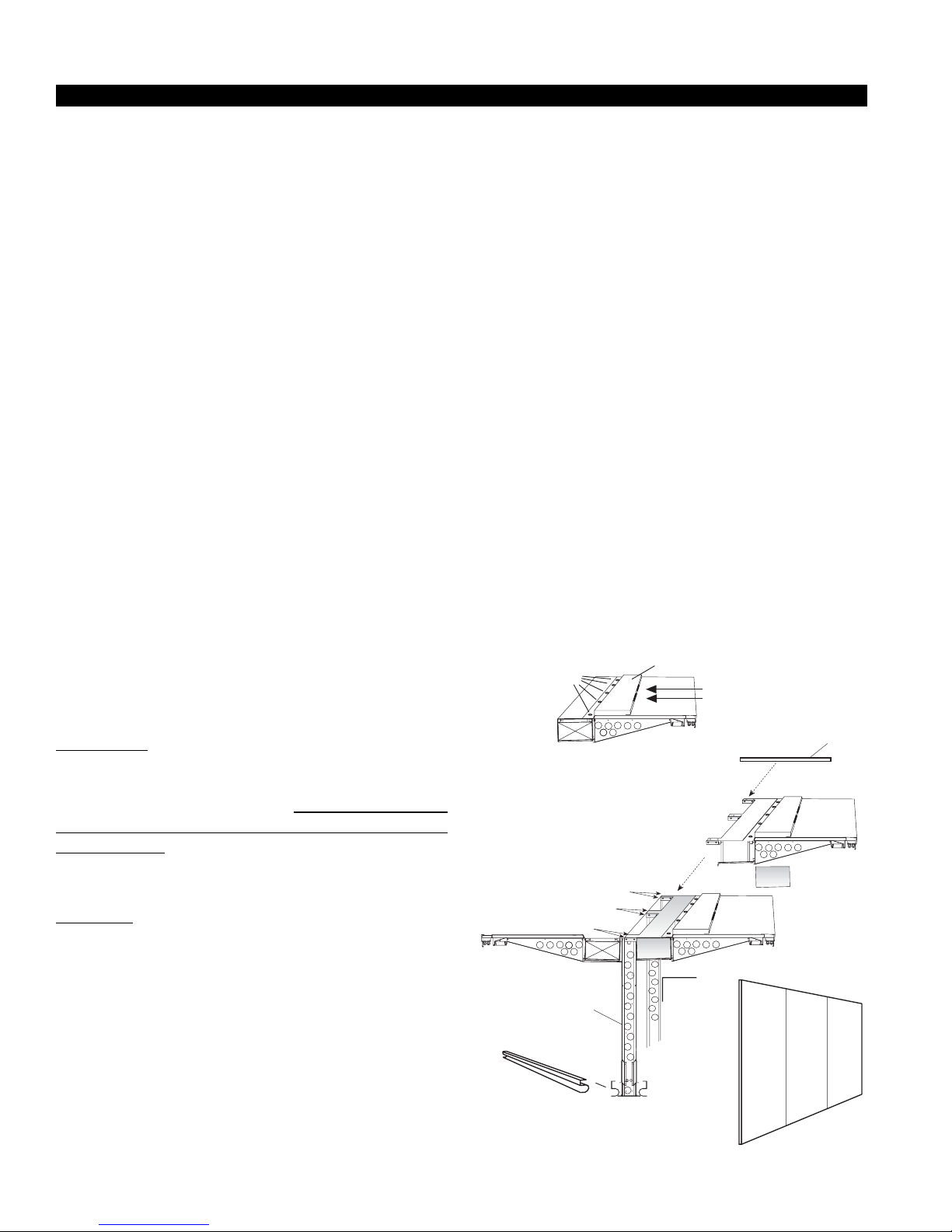

(B) 2 Canopies

(C) 2 End Panels - each consisting of 3 pieces plus trim

(D) Top Panel

(E) Floor Track

A special floor Track for the Center Wall and End

Panels has been provided to anchor the case to the floor.

Also enclosed is a special Beam to allow the canopies to

be positioned on the Center Wall with a forklift.

CASE ASSEMBLY

1. Lay out the supplied floor Track in the required

location, and check for level floor in all directions.

2. (a ) If the highest and lowest points are within

1/4" of each other, the Track can be pinned to the

floor, and the case leveled by adding shims between

the case and the Track.

(b) If the Track is out of level by more than 1/

4", the track must be brought back to within 1/4" of

level, by shimming to the floor under the Track. Final

case leveling can now be done as noted before.

3. Position the Center Wall centrally in the wide Track

and level. Fasten to Track using the screws provided.

Add a temporary 2" x 4" wood brace to the end of

the Center Wall to prevent toppling.

4. Attach the supplied Beam to the top of the first

section of the Canopy using the supplied 5/8"bolts.

CANOPY

BEAM

5 BOLTS

Secure 4 bolts on each

C-channel to wall

supports - every 2' along

case

HOLES FOR

FORKLIFT BLADES

CANOPY

TOP PANEL

NOTE: FOR EASE OF INSTALLATION, IT IS

RECOMMENDED THAT THE UNIT IS ASSEMBLED

BY A CREW OF THREE TO FOUR (3-4) PEOPLE

AND ONE (1) FORKLIFT.

During the development of this product, a simulated field

installation was carried out, to identify the simplest method

of assembly. To reduce installation time and to avoid any

confusion, the case has been pre-assembled into six (6)

main pieces:

(A) Center Wall

END PANEL

CENTER WALL

FLOOR BUMPER

4

Rev. 9610(9911)

WARNING: DO NOT LET ANY WEIGHT BEAR

DOWN ON THE COIL ASSEMBLY. USE 5

GALLON BUCKETS OR SIMILAR UNDER THE

CANOPY TO HOLD THE WEIGHT WHILE THE

BEAM IS BEING ATTACHED. THE FORK HOLES

ON THE BEAM SHOULD FACE TOWARD THE

OUTSIDE EDGE OF THE CANOPY.

5. Carefully raise and position Canopy on Center Wall

"C" channels. Fasten with screws provided - two on

each side of the C channel. "C" channels are located

every two feet along the length of the case.

6. Screw first panel of both End Panels to the Canopy to

stabilize the case. Shim to level

Plumbing

ACCESS PANELS

The drain line is accessable through a panel on the interior

back wall if the case on the left hand side..

DRAIN AND P-TRAP

The drain line is located on the left hand side of the case.

There are two drain lines for back to back (double sided)

cases.

WASTE OUTLET AND P-TRAP

The waste outlet is located off the center of the case on

one side allowing drip piping to be run lengthwise under

the fixture.

A 1-1/2" P-trap and threaded adapter are supplied with

each fixture. The P-trap must be installed to prevent air

leakage and insect entrance into the fixture.

NOTE: PVC-DWV solvent cement is recommended.

Follow the manufacturer’s instructions.

INSTALLING CONDENSATE DRAIN

Poorly or improperly installed condensate drains can seriously interfere with the operation of this refrigerator,

and result in costly maintenance and product losses. Please

follow the recommendations listed below when installing

condensate drains to insure a proper installation:

1. Never use pipe for condensate drains smaller than

the nominal diameter of the pipe or P-trap supplied

with the case.

2. When connecting condensate drains, the P-trap

must be used as part of the condensate drain to

prevent air leakage or insect entrance. Store

plumbing system floor drains should be at least 14"

off the center of the case to allow use of the P-trap

pipe section. Never use two water seals in series in

any one line. Double P-traps in series will cause a

lock and prevent draining.

After cases have been leveled and joined, and refrigeration, electrical, and wasted piping work completed, install

the splashguards. Fasten along the top edge, or center, with

#10 X 3/3" sheet metal screws.

DO NOT SEAL JOINT T RIM T O FLOOR!

3. Always provide as much down hill slope (“fall”) as

possible; 1/8" per foot is the preferred minimum.

PVC pipe, when used, must be supported to maintain

the 1/8" pitch and to prevent warping.

4. Avoid long runs of condensate drains. Long runs

make it impossible to provide the “fall” necessary for

good drainage.

5. Provide a suitable air break between the flood rim

of the floor drain and outlet of condensate drain. 1"

is ideal.

6. Prevent condensate drains from freezing:

a. Do not install condensate drains in contact with

non-insulated suction lines. Suction lines should

be insulated with a nonabsorbent insulation

material such as Armstrong’s Armaflex.

b. Where condensate drains are located in dead air

spaces (between refrigerators or between a

refrigerator and a wall), provide means to

prevent freezing. The water seal should be

insulated to prevent condensation.

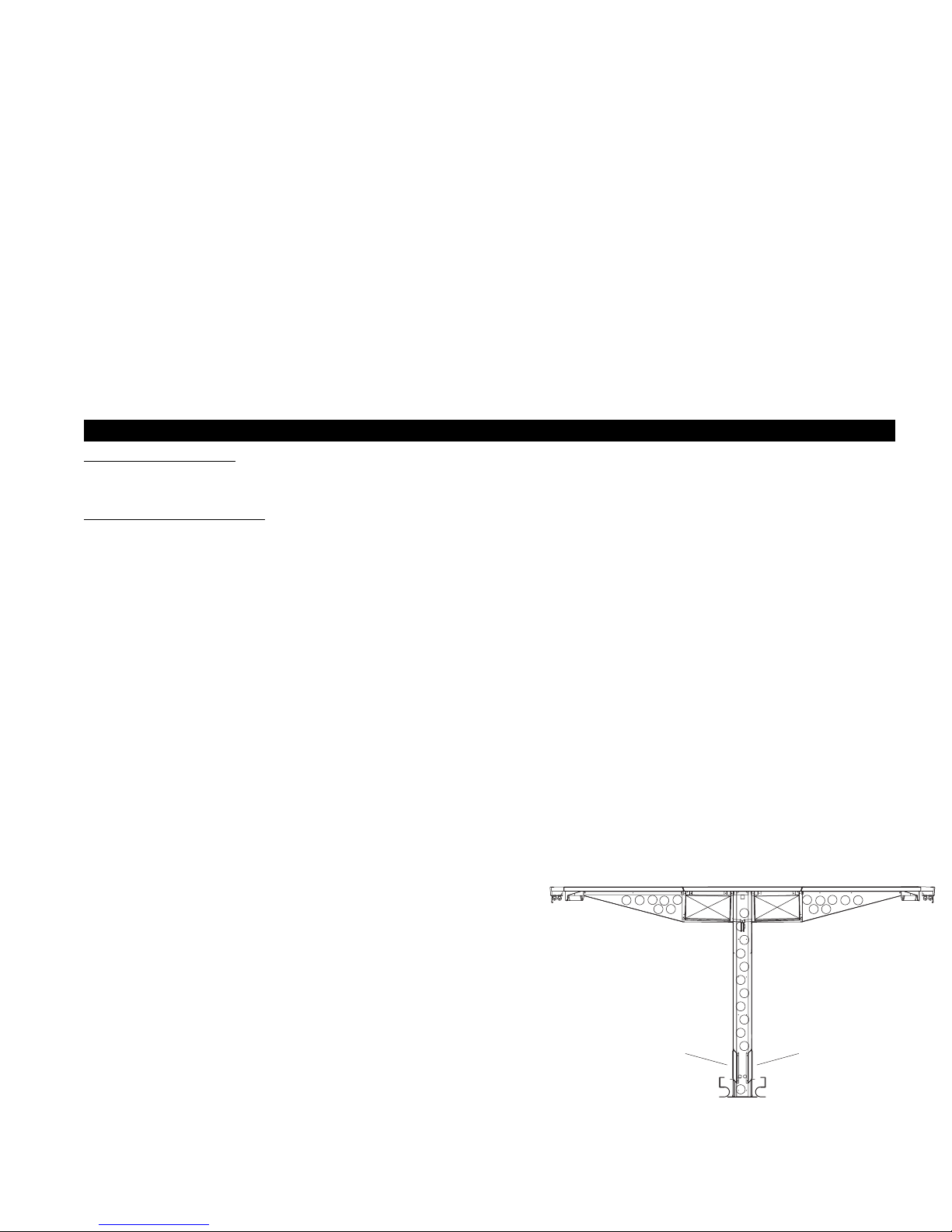

DRAIN ACCESS

LEFT SIDE

DRAIN ACCESS

LEFT SIDE

5

Loading...

Loading...