Page 1

®

RFLN & RFMN

Freedom Line

Low or Medium Temperature

Compressor Ready

Narrow Footprint

Reach-in

Merchandisers

IMPORTANT

Keep in store for

future reference!

Manual - Installation & Operation Freedom RFLN & RFMN

Installation &

Operation Manual

Shipped With Case Data Sheets

P/N 0520677_J

July 2015

Spanish P/N 0532420

French P/N 0532421

Page 2

Page 3

P/N 0520677_J iii

®

TABLE OF CONTENTS

INSTALLATION

NSF Certication

Freedom Line Description

Location

........................... 1-1

Shipping Damage

Exterior Loading

Merchandisers Shipped with End Installed

Shipping Braces

Moving Merchandisers (Narrow Entrance)

................... 1-1

............ 1-1

.................... 1-2

.................... 1-2

1-2

..................... 1-2

1-3

Final Location ...................... 1-6

Leveling

Door Adjustment

Joining

............................ 1-7

.................... 1-7

............................ 1-8

REFRIGERATION / ELECTRICAL

/ SAFE-NET III

Refrigerant

Field Installation of Condensing Unit

About Quick Connect Couplings

Connect Lines

Insulate Refrigerant Lines

Field Wiring

Safe-NET III Display

Condensate Water and Pump

Safe-NET III User Instructions

Display

Start-Up

Temperature Adjustment

Alarms and Codes

Manual Defrost

Sensor Location

Controls and Adjustments

Merchandiser Electrical Data

Electrical Connections

Identication of Wiring

......................... 2-1

... 2-2

........ 2-3

...................... 2-3

............. 2-4

........................ 2-4

................ 2-4

.......... 2-4

......... 2-6

............................ 2-7

........................... 2-7

............. 2-9

................... 2-9

..................... 2-9

.................... 2-10

............ 2-11

......... 2-12

............... 2-12

.............. 2-12

FACADE AND SPLASHGUARDS

Install Facade ...................... 3-1

Installing Splashguard Brackets

Installing Splashguards

............... 3-4

Sealing Splashguard to Floor

Installing Bumpers

................... 3-6

........ 3-3

.......... 3-5

START UP / OPERATION

Expansion Valve Adjustment .......... 4-1

Prior to Start Up Checklist

Start Up Checklist

Defrost

............................ 4-3

................... 4-2

Checklist After 12 Hour Run Time

Load Limits

Stocking

........................ 4-4

........................... 4-4

............ 4-2

...... 4-3

Installing FDA/NSF

Required Thermometer .............. 4-4

MAINTENANCE

Care and Cleaning ................... 5-1

Cleaning Honeycomb Assemblies

Cleaning Stainless Steel Surfaces

Cleaning Coils

...................... 5-2

Top Mount Cleaning & Maintenance

Cleaning Under Merchandisers

Removing Scratches from Bumper

....... 5-2

....... 5-2

.... 5-3

........ 5-4

...... 5-4

SERVICE

Replacing Fan Motors and Blades ...... 6-1

Replacing Electric Defrost Heaters

Replacing Drain Pan Heater

Servicing Vertical Lighting

Servicing Doors and Frames

Repairing Aluminum Coil

............. 6-4

........... 6-4

............. 6-4

...... 6-2

........... 6-3

OPTIONAL DRIP PIPING

Waste Outlet and Water Seal ........... 7-1

Installing Drip Piping

................ 7-1

WARRANTY

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

®

®

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900

www.hussmann.com

© 2015 Hussmann Corporation

Page 4

iv Contents

REVISION HISTORY

REVISION J

Updated “Connect Lines,” Page 2-3

Insulate “Refrigerant Lines,” Page 2-4

“Run Time”, Page 4-3

* * * * * * * * * * * * * * * * * * * * * * * * * *

ANSI Z535.5 DEFINITIONS

• DANGER – Indicate[s] a hazardous

situation which, if not avoided, will

result in death or serious injury.

REVISION H

Excel Note 5.5 inch clearance, Page 1-1.

REVISION G – November 2014

Added California Warning label, Page 1-2

Added Optional Drip Piping, Page 7-1

REVISION F – May 2014

Updated Cover Page; Warning Page 2-1. Added Page 3-5

3-6. New Page 4-2

REVISION E – June 2013

Updated drawings and wording on Page 3-2 and 3-3 to

optional light channel and optional crown molding.

Set pressure contols on Page 4-1 added disconnect hoses

on Page 5-1

REVISION D – March 2013

Section 1: Revised caution box on page 1-2.

Section 2: Added leveling to condensate pan.

Section 5: Added Cleaning Coils.

REVISION C – November 2012

Section 2: Added Safe-NET startup code and optional

audible alarm

• WARNING – Indicate[s] a hazardous

situation which, if not avoided, could

result in death or serious injury.

• CAUTION – Indicate[s] a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

• NOTICE – Not related to personal injury –

Indicates[s] situations, which if not avoided,

could result in damage to equipment.

REVISION B – August 2012

Section 1: Added disassembly / reassembly procedure for

tting cases through smaller doors and

passage ways.

Section 7: Added Emerson Electonic Unit Control

Instructions

REVISION A – October 2011

Original Issue

PN 052677_J

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Page 5

P/N 0520677_J 1-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

INSTALLATION

NSF CERTIFICATION

These merchandisers are manufactured to

meet ANSI / National Sanitation Foundation

®

(NSF

) Standard #7 requirements. Proper installation is required to maintain certication.

Near the serial plate, each case carries a label

identifying the type of application for which

the case was certied.

ANSI/NSF-7 Type I – Display Refrigerator / Freezer

Intended for 75°F / 55%RH Ambient Application

ANSI/NSF-7 Type II – Display Refrigerator / Freezer

Intended for 80°F / 55%RH Ambient Application

ANSI/NSF-7 – Display Refrigerator

Intended for Bulk Produce

FREEDOM LINE DESCRIPTION

The Freedom Line RFLN and RFMN cases

are designed to be ready for remote installation

of a top-mounted air-cooled condensing unit,

such as Hussmann’s TCLA through TCMD

series of condensing units. They are controlled

by the Safe-NET III electronic control. The

case temperature is controlled by cycling the

compressor based on the discharge air

temperature input. The sensor for this input is

located above the interior top panel at the right

door. Another sensor, located on the bottom

center evaporator coil return bend, is used for

defrost termination. The Safe-NET III control

is pre-programmed for both ice cream and

frozen food operation, and is adjusted for the

required temperature by the control knob

located on the front of the controller, which is

on the top of the case.

RFLN cases running on individual condensing

units may be installed as stand-alone cases with

ends, or as a part of a lineup. When installed

in a lineup, Hussmann recommends that partitions be installed between individual cases

to prevent frost buildup and other issues that

might result from different defrost schedules

and operating temperatures.

LOCATION

These merchandisers are designed for displaying

products in air conditioned stores where temperature is maintained at or below the ANSI/

NSF-7 specied level and relative humidity is

maintained at or below 55%. Placing refrigerated merchandisers in direct sunlight, near hot

tables or near other heat sources could impair

their efciency. Like other merchandisers, these

are sensitive to air disturbances. Air currents

passing around merchandisers will seriously

impair their operation. Do NOT allow air conditioning, electric fans, open doors or windows,

etc. to create air currents around the merchandisers.

To prevent sweating on the exterior surfaces

of merchandisers, there must be

clearance of 4 inches (102 mm) between

a minimum

the merchandisers and other xtures or walls.

A 5.5 inch (140 mm) space is required between

facade top and the ceiling. A louvered Facade

Panel kit is available that will allow for a top

spacing minimum clearance of 3 inches (76

mm).

Product should always be maintained at proper

temperature. This means that from the time the

product is received, through storage, preparation

and display, the temperature of the product must

be controlled to maximize the life of the

product. Condensing units installed on top

of the merchandiser require air circulation to

operate properly. Blocking or restricting air

ow will adversely affect performance and may

damage the refrigeration system. If the ceiling

and/or walls are built up around the merchandiser, allow for a sufcient gap above or behind

the merchandiser to provide adequate air circulation. When merchandisers are installed in a

lineup, case must be taken to ensure that warm

condenser air is not blown from one unit into

the condenser of the adjacent unit.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Page 6

1-2 InstallatIon

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

1-2 InstallatIon

SHIPPING DAMAGE

All equipment should be thoroughly examined

for shipping damage before and during unloading.

This equipment has been carefully inspected at

our factory. Any claim for loss or damage must

be made to the carrier. The carrier will provide

any necessary inspection reports and/or claim

forms.

Do not store items or flammable

materials atop the unit.

Do not walk on case.

EXTERIOR LOADING

Apparent Loss Or Damage

If there is an obvious loss or damage, it must be

noted on the freight bill or express receipt and

signed by the carrier’s agent; otherwise, carrier

may refuse claim. The carrier will supply necessary forms.

Concealed Loss Or Damage

When loss or damage is not apparent until after

equipment is uncrated, a claim for concealed

damage is made. Upon discovering damage,

make request in writing to carrier for inspection

within 15 days and retain all packing. The carrier will supply inspection report and required

claim forms.

For California Businesses:

This product may contain chemicals known

to the State of California to cause cancer,

birth defects, or other reproductive harm.

This warning is the result of the California State

law known as the California Safe Drinking Water

and Toxic Enforcement Act of 1986, which is

commonly referred to as “Proposition 65.”

This warning does not mean that Hussmann

products will cause cancer or reproductive

harm, or is in violation of any product-safety

standards or requirements. As claried by the

California State government, Proposition 65

can be considered more of a ‘right to know’ law

than a pure product safety law. When used as

designed, Hussmann believes that our products

are not harmful. We provide the Proposition 65

warning to stay in compliance with California

State law. It is your responsibility to provide

accurate Proposition 65 warning labels to your

customers when necessary. For more information

on Proposition 65, please visit the California

State government website.

Do NOT walk on top of merchandisers or damage

to the merchandisers and serious personal injury could occur.

designed To supporT excessive exTernal

loading such as the weight of a person. Do

They are noT sTrucTurally

not store items or ammable materials atop the

case.

MERCHANDISERS SHIPPED WITH END

INSTALLED

If the case was shipped with the end installed,

two long bolts were used to hold the shipping

brace to the end. If the shipping bolts are

reinserted after removing the brace, they will

extend into the product area and may damage

the coil.

Th e s e bolTs w iTh Th e s horTer b o lTs

pr o v ided.

Th e r efore, b e sure T o replac e

Be careful not to damage the factory-installed

end while moving the merchandiser. Make sure

that tools are positioned past the end and beneath the merchandiser’s support bar.

Page 7

P/N 0520677_J 1-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

SHIPPING BRACES

Move the merchandiser as close as possible

to its permanent location and then remove all

packaging. Check for damage before discarding

packaging. Remove all separately packed

accessories such as kits and shelves.

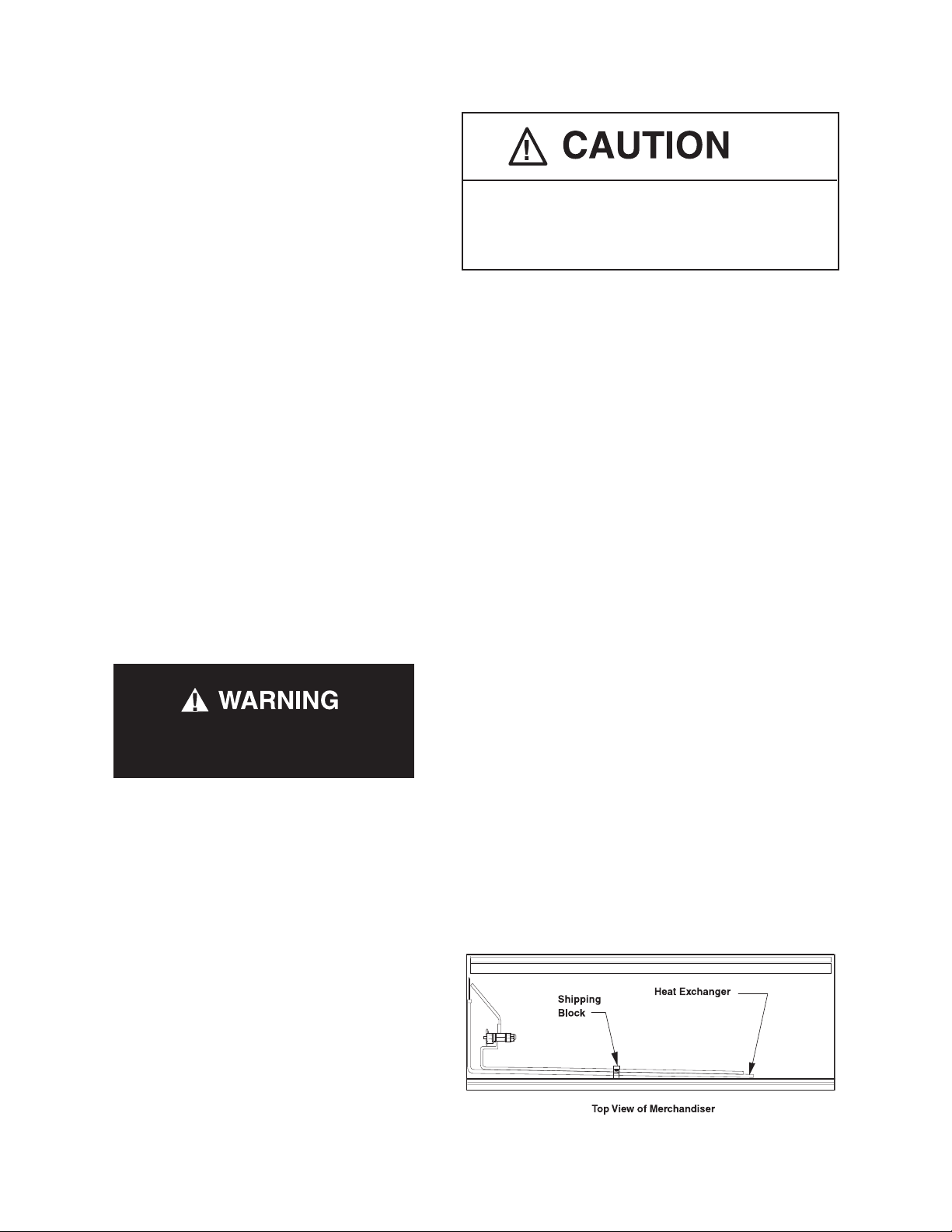

Locate the shipping block in the center of the

heat exchanger (see illustration), and remove it

before piping the merchandiser. This block was

installed to minimize shipping vibration.

MOVING MERCHANDISER THROUGH

NARROW STORE ENTRANCES

Some exterior merchandiser parts may be

disassembled for transit access through small

doors or passage ways. The minimum door

opening is 36 in. x 83 in. This procedure takes

approximately 30 minutes to disassemble and

reassemble one case. Contact your Hussmann

representative to see if store merchandisers

have this kit option.

2. Remove the front bumper. Pull from the

bottom and set aside.

3. Remove Lower Front Panel

Remove the front panel as follows: remove

screws from front panel tabs, then lift the front

panel. Refer to the illustration below.

Follow the steps below to decrease the

Freedom prole for narrow access:

1. Remove the door handles.

Remove

Screws from

Door Handle

Page 8

1-4 InstallatIon

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

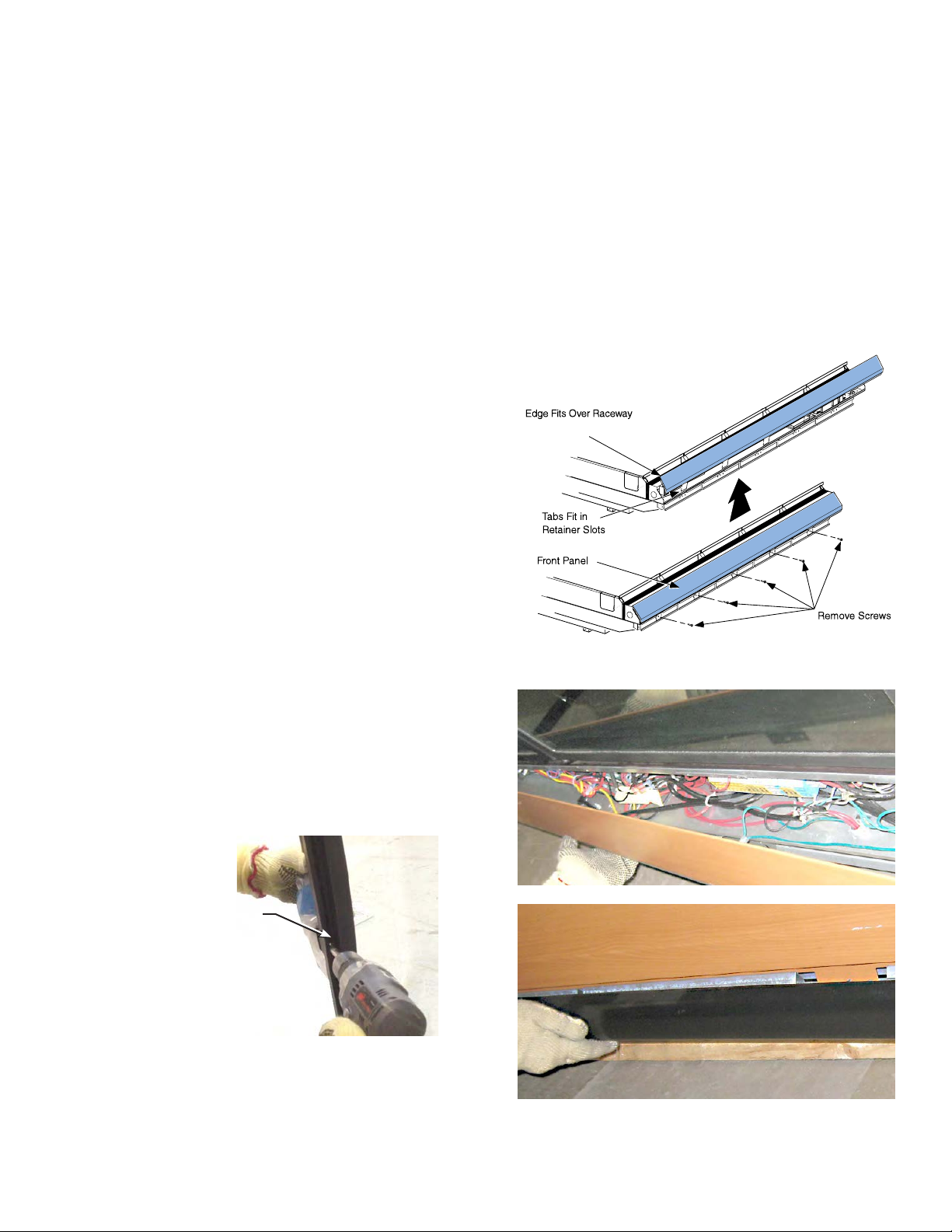

4. Remove the screws that attach the

wireway pan to the bottom assembly.

5. Detach the rubber and plastic gromets

from the wireway pan.

7. Slide the wireway pan out, and remove it

from the case. Bumper brackets and

supports are attached to wireway pan.

Removing the pan will remove the entire

assembly.

8. Remove the back, external braces from the

rear of the case as shown below. Braces will

slide straight back away from the case when

nuts and screws are removed.

6. Remove the screws that attach the

grounding lug to the wireway pan.

6 nuts and 1

bottom screw per

external brace

Bottom screw is located approximately 10

inches inboard from the rear of the case.

Bottom screw location on removed rear

brace.

Page 9

P/N 0520677_J 1-5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

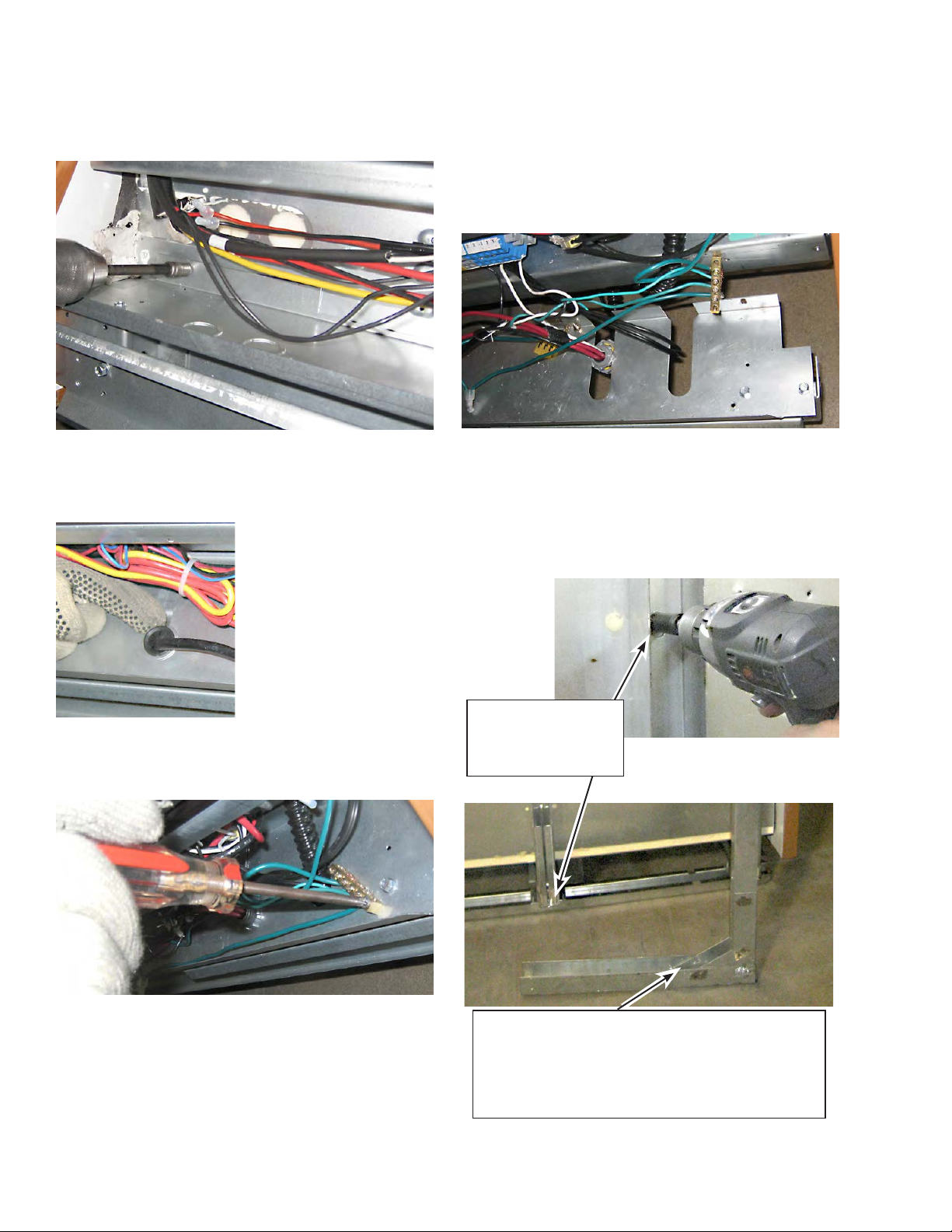

9. Remove the braces and exible insulation

from the hoses at the rear of the case.

NOTE: Care must be taken to ensure that

insulation is not damaged during removal or

replacement.

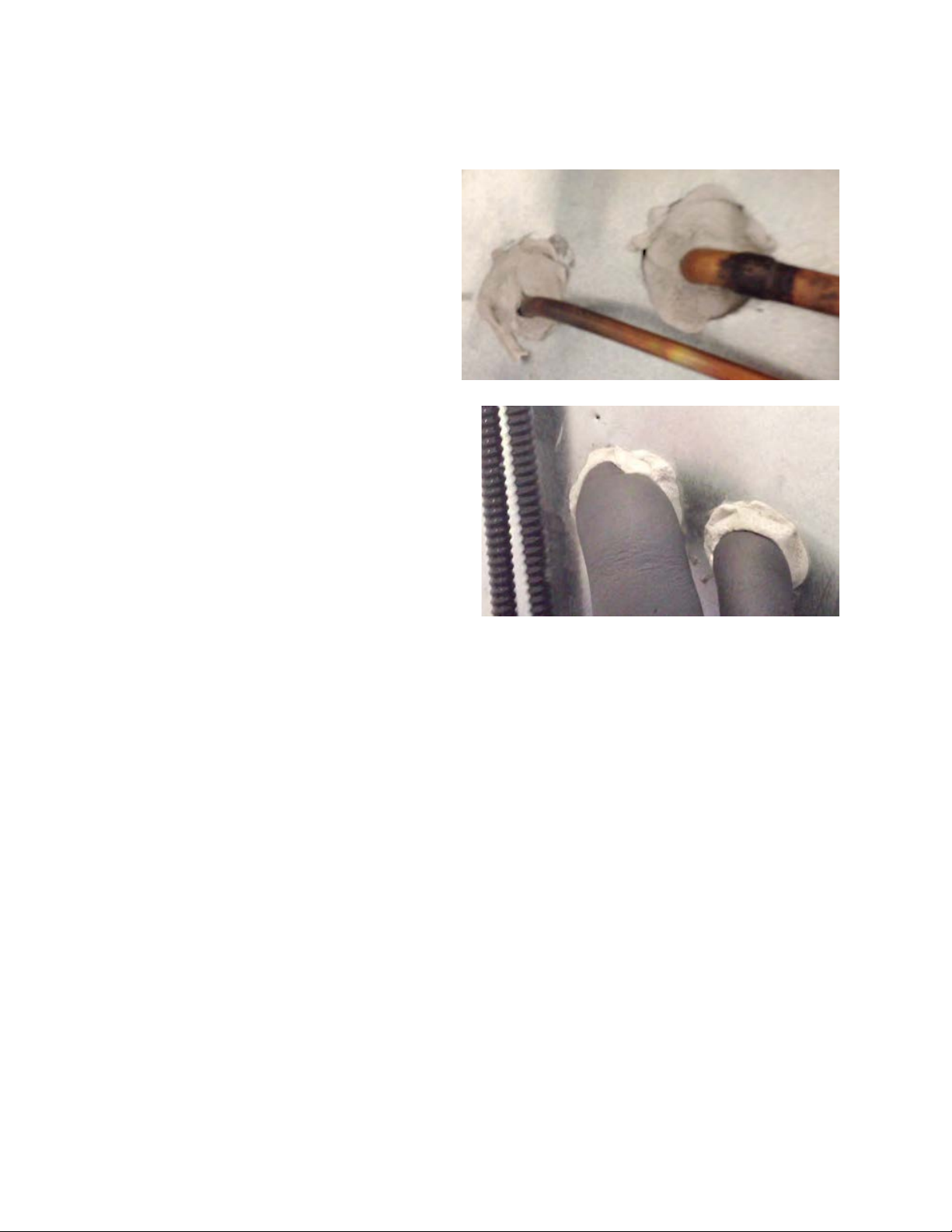

10. Remove the sealing gum from around the

refrigeration tubing.

11. Pull the hoses to the inside of the case.

Do not suspend these components by their wire

conduits. The case height without these

components installed on top is 82.75 in.

(2102 mm). Case depth is 35.5 in. with handles,

raceway pan and external frames removed.

Be sure to replace all screws and to secure all

components. The condensing unit produces

vibration that can cause screws to loosen.

Check the following before the rear of the

case is positioned at its final location

according to the store plan:

Avoid bending tubing sharply to prevent

damaging the tubes.

A. Check that all wiring is secured inside of

the case and wireway.

B. Check that all hoses are tucked away.

C. Use tie-wraps to secure any loose wires

or hoses.

The electrical box, GFCI receptacle and

evaporation pan are mounted on top of the

case. They can be temporarily detached and

suspended if required to provide clearance for

door openings during shipment and installation.

1. Make sure all electrical and refrigeration is

installed and secured on the back and top

of the case.

2. Ensure refrigeration tubing is attached

sealed and insulated at the rear of the

case as shown.

Secure Flex Hoses When

Detached

Page 10

1-6 InstallatIon

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

3. The external braces must be reinstalled with

(6) nuts per brace, torqued to 24 foot

pounds.

4. Replace and secure condensate tubing.

FINAL LOCATION

Once the case reaches its nal location,

reassemble the wireway and door handles as

follows:

1. Reinstall wireway pan in reverse order of

removal.

2. The ground lug must be reinstalled using the

two screws provided.

3. Replace the conduit connectors and plastic

gromets to the wireway pan.

4. Replace wireway cover, bumper and door

handles.

5. Use Sealing gum around refrigeration to

seal each side of the merchandiser.

At completion of all electrical work,

installation contractor shall re-install the

front panels using care to ensure all panels

are centered and properly fastened.

Use sealing gum around refrigeration

lines both inside and outside

of the merchandiser.

Page 11

P/N 0520677_J 1-7

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

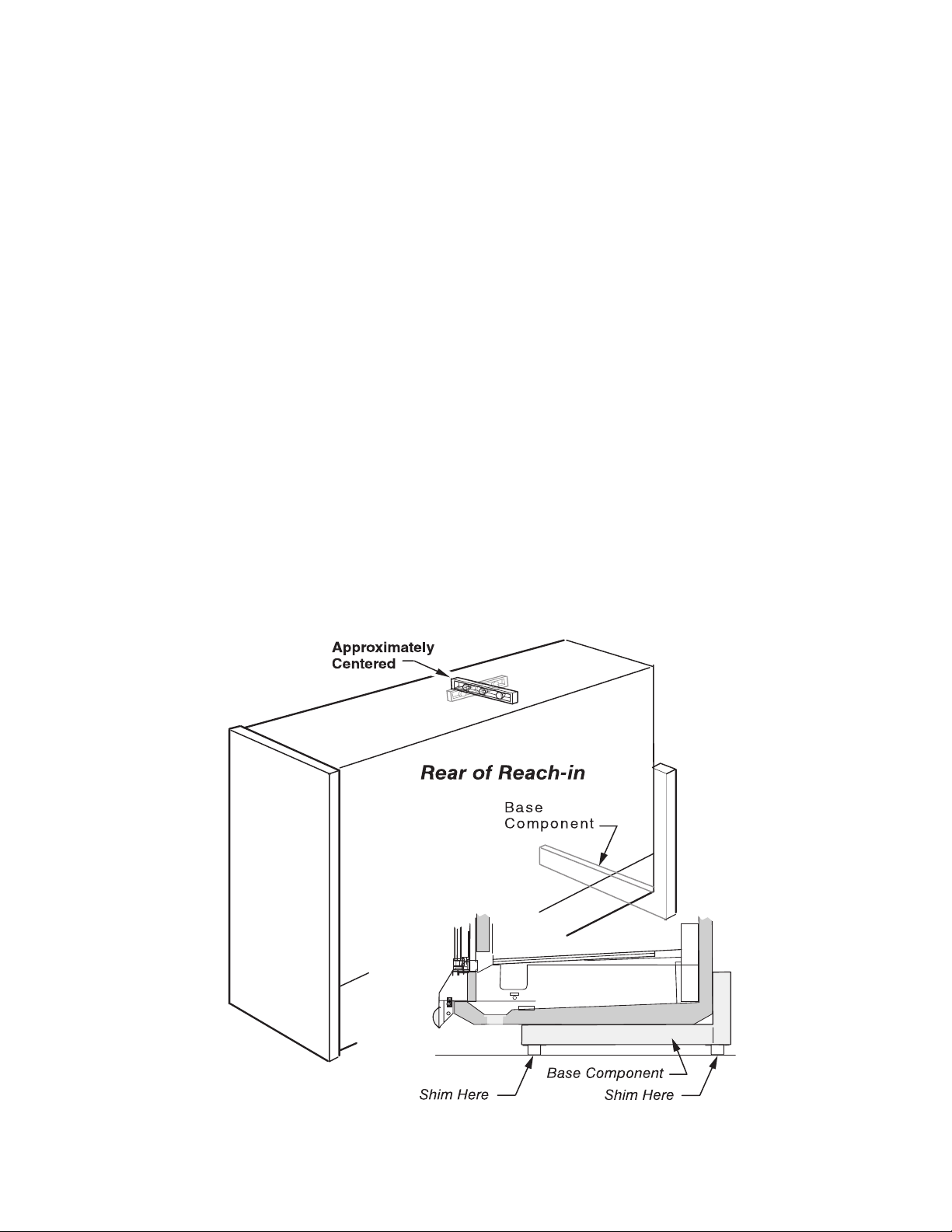

LEVELING

Merchandisers must be installed level to ensure

proper operation of the refrigeration system

and to ensure proper drainage of defrost water.

When leveling merchandisers, use a carpenter’s

level as shown.

Metal leveling shims or wedges are provided

with each merchandiser for use if needed.

NOTE:

po I n t of th e store f l o or.

Be g I n lIneu p levelI n g from t h e hIghes t

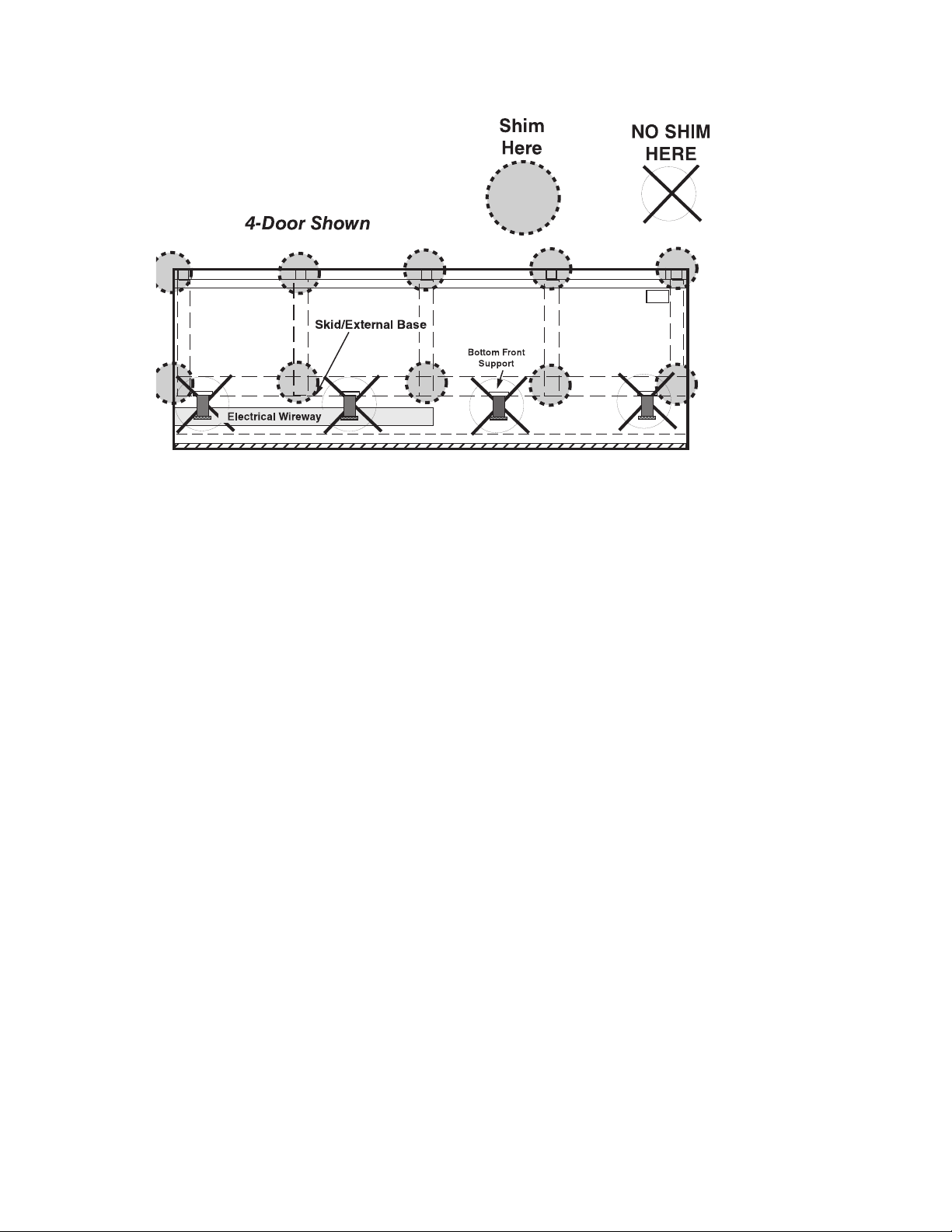

Place shims under the rail and make sure that

they are positioned at a base component (crossbar). This transfers the weight directly from the

loaded case through to the oor.

See illustration on next page

Placing shims at other locations will cause

uneven distribution of weight leading to piping

leaks, as well as sagging or wracked doors.

DOOR ADJUSTMENT

After leveling and joining the merchandisers,

adjust and level doors according to manufacturer’s

instructions shipped with each product. Factory

settings may be lost due to vibration during

shipment.

Page 12

1-8 InstallatIon

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Correct Shim Location is Critical

JOINING

Sectional construction means that two or more

merchandisers may be joined in line yielding

one long continuous display requiring only one

pair of ends. Joining kits and instructions are

shipped with each merchandiser.

To join like xtures, a joining kit is required.

To join unlike xtures, or like xtures operating

at different temperatures, a 1

1

/2inch (38mm)

partition kit is required. To join same temperature merchandisers on different defrost cycles,

a plexiglass partition kit is required.

all joinTs musT be air-TighT To prevenT

formaTion of ice or condensaTion.

Page 13

P/N 0520677_J 2-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

REFRIGERANT

The correct type of refrigerant will be stamped

on each merchandiser’s serial plate. The serial

plage is located on the left-hand end of the

interior top liner.

When brazing pipes be sure to use the

insulation blanket shipped with the

merchandiser to prevent damage to

the plastic case bottom.

Refrigeration lines are under pressure.

Depressurize and recover refrigerant before

attempting any connection or repair.

Refrigerant vapor is hazardous to your health

and can cause death. Avoid breathing refrigerant and lubrication vapor or mist. Exposure

may irritate eyes, nose and throat. If accidental system discharge occurs,ventilate work

area before resuming service.

Always wear safety goggles and protective

gloves when working with refrigerants. Contact

with refrigerant may cause injury. Disconnect

hoses with extreme caution! All hoses may

contain liquid refrigerant under pressure.

Be sure that any room where you are working

is thoroughly ventilated, especially if a leak is

suspected.

Read all safety information regarding the safe

handling of refrigerant and refrigerant oil, including the Material Safety Data Sheet. MSDS

sheets can be obtained from your

refrigerant supplier.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Page 14

2-2 RefRigeRation/electRical/Safe-net iii

P/N 0520677_J

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

REFRIGERATION / ELECTRICAL / SAFE-NET III

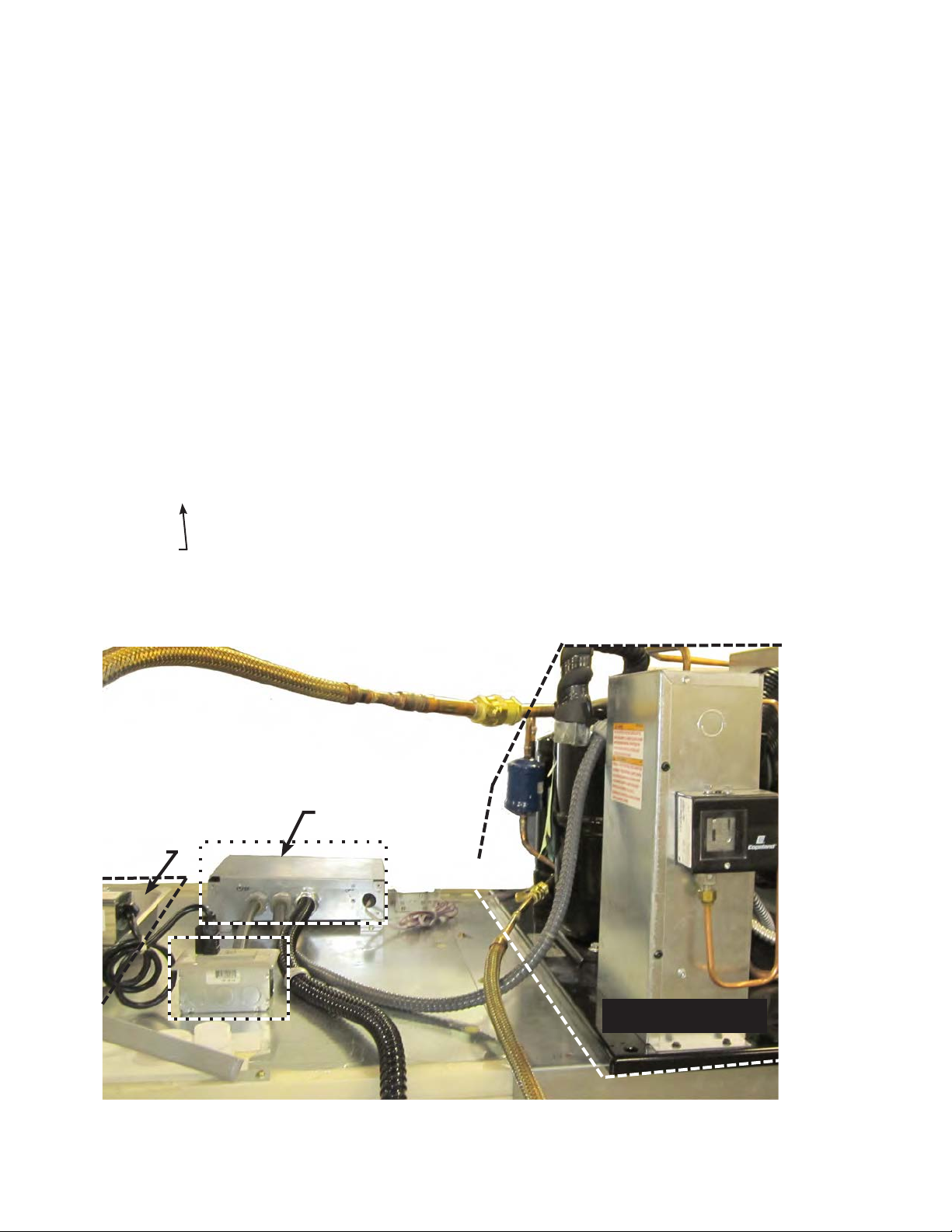

FIELD INSTALLATION OF CONDENSING UNIT

A mounting plate is provided on top of the

case with pilot holes that provide specic

attachment points for the condensing unit

base. The mounting plate is located above the

next to last door on the right.

Front of Case

Mounting Plate

After mounting the condensing unit, the

electrical box and GFCI receptacle must be

re-attached to the top. The condensate pan, if

provided, is packed inside the case and must

also be installed and leveled on top of the

case, then plugged into the 120V GFCI outlet

provided. The TCMA, TCMB, and TCLA

units have integral condensate pans, so an

external pan is not required.

Exact component location is not critical;

however, the components should be mounted

in the general locations shown to ensure that

electrical connections reach, and the condensate pan has adequate air ow from the

condenser, and the Safe-NET adjustment

knob is accessible.

Evaporator

Pan

Electrical Box

GFCI Receptacle

Safe-NET

control knob on

this side of electrical box

Front of Case

Condensing Unit

Recommended Component Locations

Page 15

P/N 0520677_J 2-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

ABOUT QUICK CONNECT COUPLINGS

Quick Connect ttings are provided on

both the case inlet and outlet lines, and on

Hussmann’s TCL and TCM series of condensing units. The case and condensing unit

are pre-charged with the correct amount of

R404A refrigerant, and the lines are sealed.

Connecting the Quick Connects together

breaks the seals to connect the refrigeration lines of the unit to the case. The Quick

Connects must be properly torqued to avoid

refrigerant leaks.

CONNECT LINES

Mount the suction line and liquid line to the

condensing unit. When ready to connect, remove protector caps and plugs from the Quick

Connect couplings.

Tighten a ¼ turn after the coupling bottoms

out to ensure a leak proof seal (equivalent to

the foot pounds shown below).

Coupling Foot Pounds

Size (Ft. Lbs.)

3

/8 in. 10-12

5

/8 in. 35-45

If necessary, carefully wipe coupling seats and

threaded surfaces with a clean cloth to prevent

the inclusion of dirt or any foreign material in

the system.

Lubricate male half of diaphragm and

synthetic rubber seal with refrigerant oil.

Thread the coupling halves together by hand

to ensure proper mating of threads. Use

proper size wrenches (on coupling body hex

and on union nut) and tighten until coupling

bodies “bottom” or a denite resistance is felt.

Hex Wrench

Coupling Size

3

/8 in. Male

3

/8 in. Female

5

/8 in. Male 1 1/16 in.

5

/8 in. Female 1 5/16 in.

3

/4 in.

13

/16 in.

Inlet Quick Connect

Outlet Quick Connect

Inlet Quick Connect

Page 16

2-4 RefRigeRation/electRical/Safe-net iii

P/N 0520677_J

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

INSULATE REFRIGERANT LINES

Suction lines are insulated to prevent condensation; extra insulation is provided to

cover the eld connected tubing sections.

These exposed sections must be covered with

insulation. Check that all suction lines are

adequately covered with insulation from case

penetration to compressor; including suction

service valves as some insulation may have

been dislodged during shipping and installation. Do not locate the tubing above the

electrical box in order to prevent condensation

from dripping onto electrical components.

Insulation

The disconnect switch to switch off power

to all case components and the condensing

unit is on top of the case, on the front of the

electrical box. When this switch is off, some

electrical terminals in the case wireway may

be energized. The wiring connection for the

condensing unit is provided with 5-ft leads and

1

⁄4-inch terminals. The conduit must be con-

nected to the condensing unit electrical box,

and the leads are connected to the condensing

unit input terminals. The heated condensate

pan, if provided, is plugged into the 120V

GFCI receptacle at the top of the case.

Safe-NET III DISPLAY

Insert the Safe-NET III display from the front

into the opening provided in the facade.

Compressor

FIELD WIRING

All wiring must be in compliance with NEC

and local codes. Field wiring must be sized for

component amperes stamped on the serial plate.

Actual ampere draw may be less than specied.

Terminal blocks are used for eld connection

of the 120V single phase and 208/230V single

phase power supply. The terminal blocks are

located inside the electrical box on top of the

case. The wiring diagram and circuit requirements are provided on the Technical Data

Sheets provided with the case and condensing

unit.

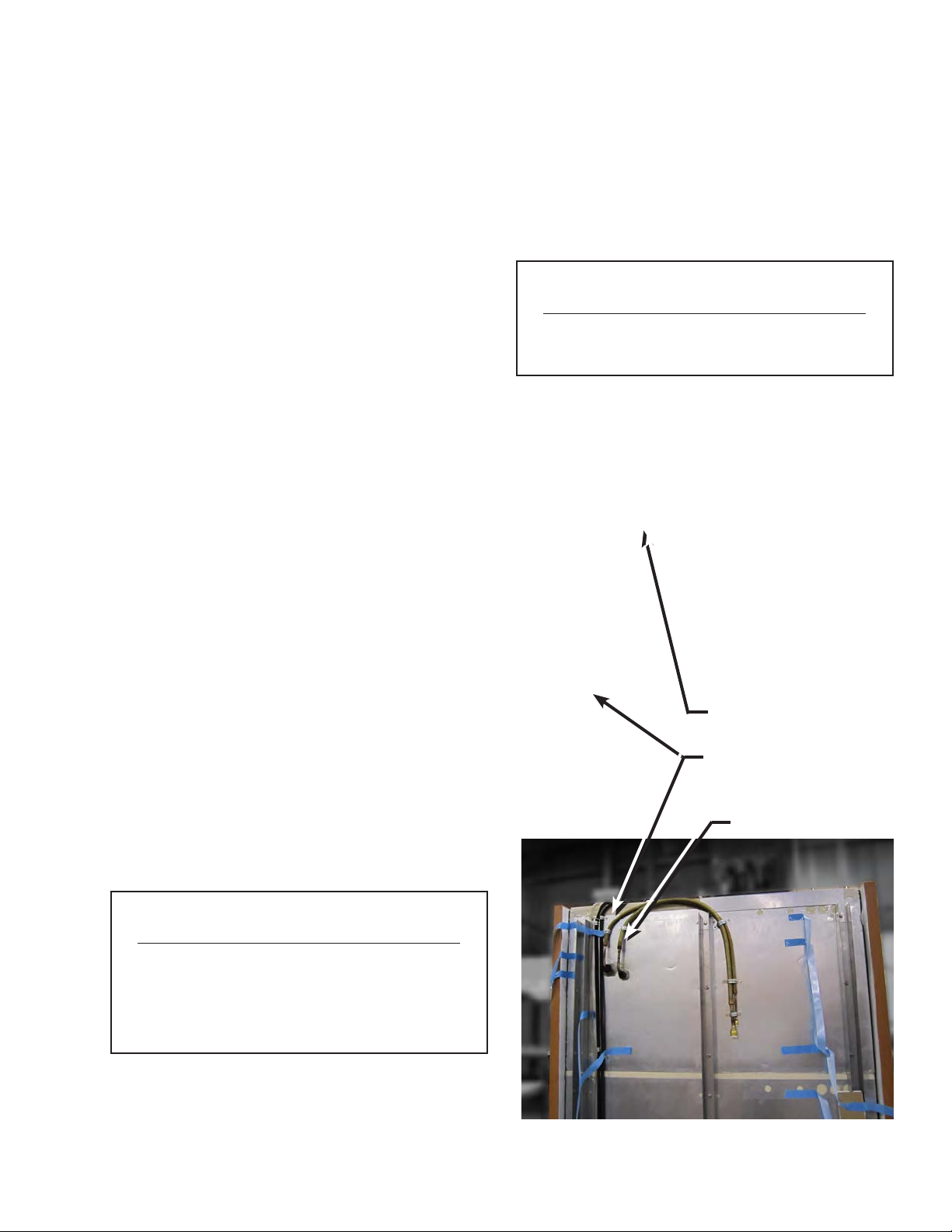

CONDENSATE WATER AND PUMP

The bottom drain for defrost water from the

evaporator coil of the RLN case is connected

to an evacuation pump which uses

3

/8-inch

plastic drain tubing to pump the water to the

condensate pan on top of the case. The tubing

should be inspected through its entire length

to ensure that it has not been cut, kinked,

obstructed, or damaged during shipping and

installation.

The illustration on the next page shows the

location of the condensate pump and drain.

Blocked drain lines will cause water to back up

in the case and spill onto the floor, causing a

slip hazard.

Page 17

P/N 0520677_J 2-5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Safe-NET III

Control

GFCI Outlet

Condensate

Evaporator Pan

Condensate Drain

Hose

Electrical Box

Page 18

2-6 RefRigeRation/electRical/Safe-net iii

P/N 0520677_J

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Safe-NET III™

TEMPERATURE AND DEFROST CONTROLLER

SAFE-NET III™ USER INSTRUCTIONS

Your refrigerated case uses a Hussmann

Safe-NET™ III temperature and defrost

controller to precisely maintain the temperature and prevent frost buildup on the cooling

coil. LEDs indicate when the compressor or

• Controller LEDs:

refrigeration is on, when the case is in a defrost

cycle, if the temperature is outside the desired

range, or if there is a sensor failure.

An adjustment knob allows the temperature

to be set within the congured range and can

power off the controller and compressor. Your

controller has been custom-congured to provide the best temperature and defrost control

for your chilled or frozen food.

Compressor Powered On LED (green):

Lights while the compressor is running or

the refrigeration valve is open.

Defrost Cycle LED (yellow):

Lights while the refrigeration coil is defrosting.

Temperature or Sensor Alarm (red):

Lights if the temperature is too warm or

too cold. Flashes if a sensor fails.

The front of the controller has an adjustment

knob and status LEDs. The back of the

controller has connections for sensors and

switched equipment.

The Safe-NET III controller includes the

following features and connections.

• Adjustment knob:

Adjusts the temperature setpoint.

Turn adjustment knob to OFF to turn off

refrigeration system. Unplug merchandiser

from power before servicing the unit.

• Audible Temperature Alarm (optional)

See page 2-8 for alarm settings.

• Rear connections:

– Case temperature sensor:

• Typically senses the temperature

of the air in the case.

Used by the controller to determine when

to power on or power off the compressor

or refrigeration.

– Evaporator temperature sensor:

• Senses the temperature of the

refrigeration coil.

Terminates a defrost cycle when

refrigeration coil ice melts.

– Compressor or refrigeration relay:

• Switches on the compressor or

refrigeration valve for cooling.

The evaporator fans remain ON when the

adjustment knob is in the OFF position.

Page 19

P/N 0520677_J 2-7

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

DISPLAY

The display includes three red LEDs and two

digits for temperature, defrost status, and error

codes.

The three display LEDs are red; their behavior

matches the LEDs on the controller.

START-UP

1. After the toggle switch is turned on, fans and

lights will energize immediately.

The OFF Position does not disconnect line

voltage to the input terminal blocks.

2. After turning on the disconnect switch, wait

for the self check to complete. During the

self check, each LED ashes for one second,

then all LEDs turn on for two seconds. If

the LEDs do not ash, make sure the adjustment knob is not in the Off position.

• After the self check, all LEDs turn off

until the compressor starts. There may be a

delay before the compressor starts. If the red

Temperature or Sensor Alarm LED stays

on after the self check.

• The green Compressor Powered On LED

turns on when the compressor starts.

3. The compressor will continue to run until it

reaches its cut-out temperature (pulldown).

Door and frame anti-sweat heaters will

energize after the evaporator temperature

reaches a stable operating temperature, this

may take 30 minutes or longer.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

NOTE: Do NOT load product until AFTER

merchandiser operates for 24 hours and reaches

desired operating temperature.

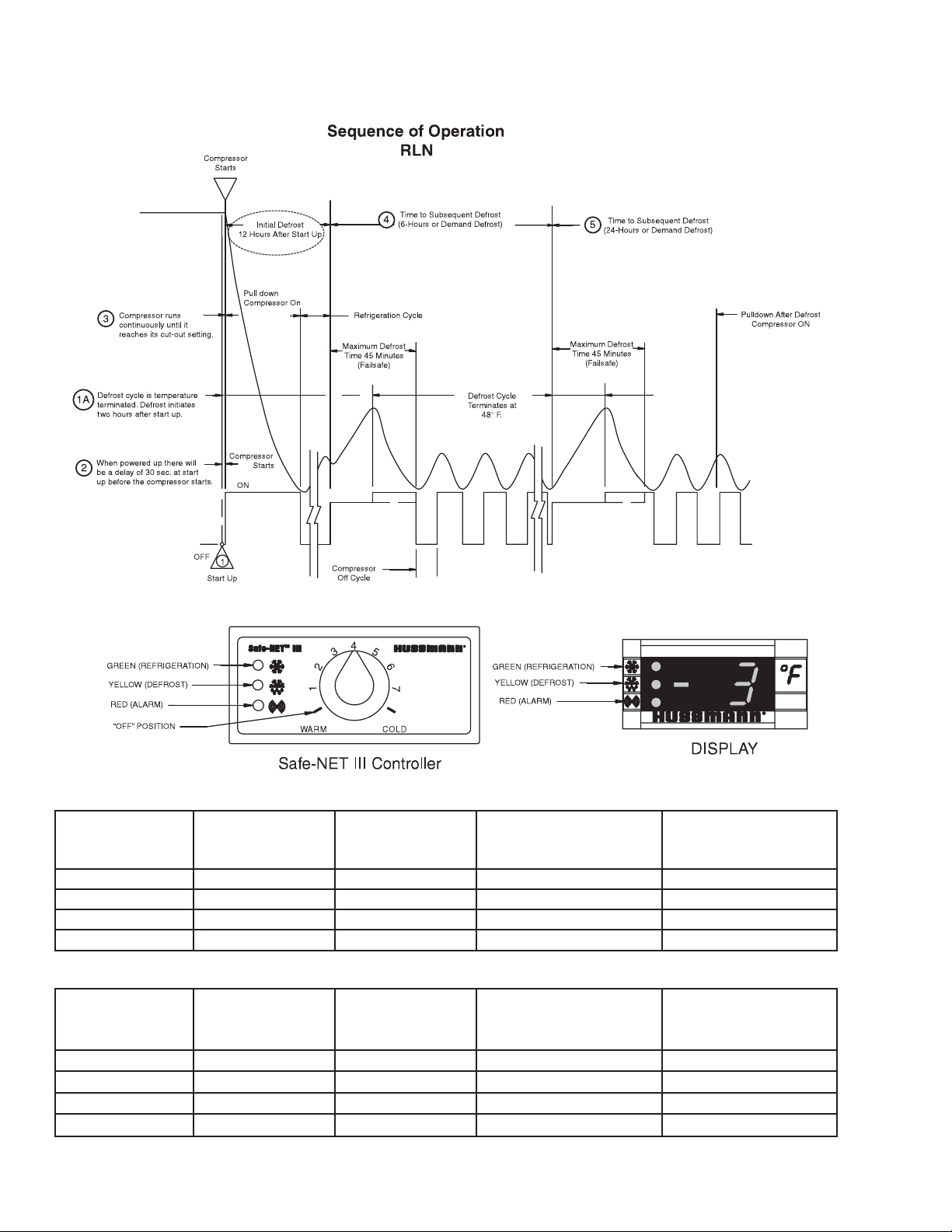

1. The merchandiser temperature displays at

startup. The initial defrost starts twelve hours

later. During defrost, the display shows “df.”

This reading will remain displayed during defrost

and until it times out, even though the refrigeration mode has been initiated. (The green LED

will be lit.)

2. The compressor will start after a 30 second delay

once power is applied.

3. The compressor will continue to run until it

reaches its cut-out temperature (Pulldown).

4. The refrigeration cycle will continue for the next

subsequent scheduled (24-hours) or demand

defrost.

5. The above process will repeat (steps3 and 4)

until the power is interrupted.

6. If power stops, the process will start over at step

1, and the time to subsequent defrost will reset.

7. Medium temperature is the same except for a

60-minute time terminated defrost

Page 20

2-8 RefRigeRation/electRical/Safe-net iii

P/N 0520677_J

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Safe-NET

Safe-NET

Low Temperature Freedom Safe-NET III Settings

Dial

Discharge

air Cut-In

Discharge

air Cut-Out

Avg Discharge Air

Temperature

Product Temperature

Range

0 Off

1 0 -6 -2 -5 to 10

4 -8 -14 -6 -11 to 5

7 -17 -23 -14 -18 to 0

Medium Temperature Freedom Safe-NET III Settings

Dial

Discharge

air Cut-In

Discharge

air Cut-Out

Avg Discharge

air Temperature

Product Temperature

Range

0 Off

1 38 32 36 32 to 42

4 35 29 33 29 to 39

7 33 27 31 27 to 37

Page 21

P/N 0520677_J 2-9

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

TEMPERATURE ADJUSTMENT

Rotate the adjustment knob counter clockwise

for a warmer setpoint or clockwise for a colder

setpoint.

• While the temperature is being adjusted, the

optional display shows the setpoint (cut out

value). A few seconds after the temperature

is set, the display reverts to showing the

sensed temperature in the merchandiser.

ALARMS AND CODES

Flashing TemperaTure or sensor alarm

leD, e1 or e2

Alarm Settings

Low Temperature –7°F to 10°F

Medium Temperature 43°F to 48°F

Alarm settings vary depending on temperature

control setting. The Safe-NET control features

an alarm delay to allow for stocking, pulldown

after defrost, and startup.

MANUAL DEFROST

4

5

3

2

1

Warm

6

7

I

I

Cold

Note:

This procedure initiates

a manual or forced

defrost.

4

5

3

2

1

I

Warm

6

7

I

Cold

If the Temperature or Sensor Alarm LED (red)

on the controller and display is ashing, a

temperature sensor has failed. The display

shows E1 if the case sensor has failed or E2 if

the evaporator sensor has failed.

If the merchandiser sensor fails, refrigeration

will run continuously. Turn off, or repeat a duty

cycle of a few minutes on and a few minutes off.

When the Safe-NET control is powered up, a

two-digit code will be displayed indicating that

the current settings are installed.

Safe-NET Status Code

Low Temperature 68

Medium Temperature 69

4

5

3

2

1

Warm

6

7

I

I

Cold

IMPORTANT: Return the control knob to its

original setting (Step1) once the manual defrost has been initiated.

Page 22

2-10 RefRigeRation/electRical/Safe-net iii

P/N 0520677_J

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

8

9

10

11

Page 23

P/N 0520677_J 2-11

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

1. The Safe-NET III Controller controls refrig-

eration temperature. This is factory installed in

the control panel. Adjust this control knob to

maintain the discharge air temperature shown.

Measure discharge air temperatures at the

center of the honeycomb.

For low temperature models, defrosts are time

initiated and temperature terminated. The defrost setting is factory set as shown.

To ensure a thorough defrost, the defrost must

be terminated by the temperature termination

setting — not by time.

For medium temperature models, defrost is

time initiated and time terminated.

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical

shock, always disconnect the electrical power

at the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

Page 24

2-12 RefRigeRation/electRical/Safe-net iii

P/N 0520677_J

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

ELECTRICAL CONNECTIONS

ALWAYS CHECK THE SERIAL PLATE FOR

COMPONENT AMPERES

.

All wiring must be in compliance with NEC

and local codes.

Electric Defrost is standard for low temperature merchandisers and requires temperature

termination. Off Time Defrost is standard for

medium temperature merchandisers and is time

terminated.

When two or more merchandisers with full

length wireways are installed in line, remove the

splashguards, end caps and wireway covers, and

install the nipple and nuts (supplied) providing

electrical passage from one merchandiser to the

next. Following NEC and local codes is the

responsi bility of the electrical contractor.

IDENTIFICATION OF WIRING

Leads for all electrical circuits are identied by

MERCHANDISER ELECTRICAL DATA

colored plastic bands. These bands correspond

to the color code sticker (shown below) located

Merchandiser data sheets for specic models

inside the merchandiser wireway.

are shipped with this manual. The data sheets

provide merchandiser electrical data, standard

electrical schematics, parts lists and performance

data. Refer to the merchandiser data sheets and

merchandiser serial plate for electrical information. Refer to the separate wiring diagrams

shipped with the case for specic information

about the merchandiser and any optional wiring

kits that may have been applied.

Terminal block NOT for case-to-case wire

connection.

IN STA LLER

It is the contractor’s responsibility to install

merchandiser(s) in accordance with all local

building and health codes.

Leads for all electrical circuits are identified by a colored plastic band: neutral wire for each circuit has either

White insulation or a White plastic sleeve in addition to the color band.

Pink ...........RefRig. theRmoStat low temP. oRange oR

light Blue ...RefRig. theRmoStat noRm temP. tan ......... lightS

DaRk Blue .... DefRoSt teRm. theRmoStat maRoon .... RecePtacleS

PuRPle ........anti-Sweat heateRS Yellow* ... DefRoSt heateRS, 120V

BRown ........fan motoRS ReD* ....... DefRoSt heateRS, 208V

gReen* .......gRounD

WIRING COLOR CODE

*eitheR coloReD SleeVe oR coloReD inSulation

ELECTRICIAN NOTE: Use copper conductor wire only.

CASE MUST BE GROUNDED

theSe aRe maRkeR coloRS wiReS maY VaRY.

Page 25

P/N 0520677_J 3-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

FACADE AND SPLASHGUARD

INSTALL FACADE

Refer to the Hinge Location illustration to

determine where hinges will be positioned on

the top of the merchandiser.

A

Notice that hinge position will vary with the

number of doors, or length, of the merchandiser.

A

A

Facade Hinge Locations

Page 26

3-2 Facade and SplaShguard

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COMP/N 0520677_J

Identify the corresponding positions on the

facade panel, then fasten the hinges to the

facade panel with provided screws.

Fasten Hinges to Facade

Attach reinforcement straps to the Facade

condensing unit and the electrical box. If

necessary, the electrical box can be relocated.

Fasten Reinforcement Straps to Facade

Panel with provided screws.

Position the facade centered on case length

and ush with the fascia as shown in the side

view. below. One hinge will be between the

Fasten Facade and Baffle to Merchandiser

Fasten the hinge. Fasten the reinforcement

straps after hinges are attached using provided

screws.

Position Facade (Optional Light Channel)

Facade is centered on case length and recessed

if optional light channel is provided as shown

in side view below.

Position Facade

Page 27

P/N 0520677_J 3-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Position the facade light channel (if provided)

as shown below. Fasten to merchandiser using

provided screws.

Position Facade

The end view below shows the correct placement of the light channel, facade, hinges and

supports.

INSTALLING SPLASHGUARD BRACKETS

1. Attach splashguard retainer and splashguard

retainer support to splashguard support

bracket using two screws per bracket.

2. Install splashguard support brackets

before pIpIng case. The leveling brackets

have a maximum extension of one(1) inch

(25mm) for uneven oors.

DO NOT

br a c kets.

place shims under splashguard

End View of Facade

Page 28

3-4 Facade and SplaShguard

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COMP/N 0520677_J

INSTALLING SPLASHGUARDS

The splashguard is shipped inside each

merchandiser. after merchandisers have

been leveled and joined, and all drip piping,

electrical and refrigeration work has been

completed, re-install the front color panel,

then install the splashguards.

First, position top of splashguard over the top

edge of the bracket; second, push the lower

edge of the splashguard toward the bottom of

the bracket until it snaps into place.

Splashguard

Joint

Splashguards are joined with a

galvanized metal splice connector that

comes with the joint kit. Join the

splashguards before installing on case.

Splashguard

Retaining

Bracket

Splashguard

Splice Connector

Side

Detail

Page 29

P/N 0520677_J 3-5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

SEALING SPLASHGUARD TO FLOOR

if required by local sanitation codes, or if

desired by the customer, plastic splashguards

may be sealed to the floor using silicone type

sealer. The amount needed will depend on how

much the floor is out of level.

• Remove all dirt, wax and grease from the area

of the splashguard where adhesion will be

necessary. This is to ensure a good, secure

installation.

• Apply a good silicone type sealer along the

bottom of the splashguard. Sealant must be

removed and replaced when servicing.

Splashguard

Silicone-type

Sealer

OptiOnal stainless steel splashguards may be

sealed to the floor using a vinyl cove base trim.

The size of trim needed will depend on how

much the floor is out of level.

To install the trim to the splashguard:

• Remove all dirt, wax and grease from the

area of the splashguard where adhesion will be

necessary. This is to ensure a good and secure

installation.

• Apply a good contact cement to the cove

trim and allow proper drying time according

to the directions supplied with the cement.

• Install the trim to the splashguard so that it

is lying flush with the floor. Do not seal the

trim to the floor.

• If required by local health codes Cove Trim

may be sealed to the floor using a silicone type

sealer. Sealant must be removed and replaced

when servicing.

Splashguard

Cement

Cove Trim

Page 30

3-6 Facade and SplaShguard

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COMP/N 0520677_J

INSTALLING BUMPERS

Offsetting the bumpers and top rails helps to

disguise the joint locations, giving the lineup

a smoother look.

Begin at the left end of the line-up. A starter

bumper is factory-installed with end kits. Insert

the internal joint trim, then add the full-length

bumper.

Align each bumper section with its retainer and

push into place, working from the end of the

lineup. Install full length bumpers and internal

joint trims offset across joints. Make sure that

no gaps exist between sections. Continue installing bumpers the length of the line up.

Do NOT install the last bumper sections at this

time. These sections will be installed in the last

step.

Once all except the last section of bumper have

been installed, refrigerate the case line-up for at

least six (6) hours. The last sections of bumper

should be kept inside a refrigerated case or

cooler during this time to allow the bumpers to

contract.

Before installing the last full-length section,

measure the remaining space. Use a miter box

and ne-tooth saw to cut last bumper to length.

Install the last section.

Remove protective lm from

bumpers once installation is

complete.

Optional end bumpers are

factory-installed.

Page 31

P/N 0520677_J 4-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

START UP / OPERATION

EXPANSION VALVE ADJUSTMENT

Expansion valves must be adjusted to fully feed

the evaporator. Before attempting to adjust

valves, make sure the evaporator is either clear

or only lightly covered with frost, and that the

merchandiser is within 10 deg F (6.5 deg C)

of its expected operating temperature. Adjust

valves as follows:

Attach two sensing probes (either

thermocouple or thermistor) to the

evaporator. Position one under the

clamp holding the expansion valve

bulb; securely tape the other to the

coil inlet line.

”

Some “hunting

of the

expansion valve is normal. The

valve should be adjusted so that

during the hunting the greatest

difference between the two

probes is 3–5degf (1.7–2.8degc).

With this adjustment, during a portion of the hunting the temperature

difference between the probes will

be less than 3degF (1.7degC) and

at times 0.

Make adjustments of no more than

1

/4 turn for Balanced Port TEV

and 1/2turn at a time for other

valve models. Wait at least 15 minutes before re checking the probe

temperature or making further adjustments.

Component Location in

RL / RM / RLN /

RLNI Models

Page 32

4-2 Start up

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

START UP CHECKLIST

Start up should be performed

only by a qualified technician.

PRIOR TO START UP CHECKLIST

• Is the case connected to a power supply as

specied on the nameplate?

• Is the power on at the breaker panel?

• Are the doors properly torqued? Are they

self closing? Check each door from a fully

open position and from about a 1-inch open

positions.

• Are the evaporator fans plugged in? Do they

rotate freely? (The fans can be inspected by

lifting the deck pans in the bottom of the

cases. Manually rotate each fan to conrm

it is free and visually inspect to conrm that

each fan is plugged into its receptacle.)

• Verify that refrigeration line shutoff valves

are in the back-seated (open) position.

• Check that the Safe-NET control knob is in

the correct position:

Low temperature:

7 for ice cream and 1 for frozen food

Medium temperature:

7 for colder, 1 for warmer

The unit will shut off when the knob is set to 0.

• Once the case is considered ready for start up,

move the main switch on the electrical box to

the “on” position.

This switch is located on the front of the

electrical box, on the top of the case. This

toggle switch turns on the power to the

condensing unit, and all case electrical

components, including anti-sweat heaters,

lights and fans.

• Check the reading on the Safe-NET III

display; it should be displaying the case

temperature. The display is located in the

center of the front of the facade above the

doors. The displayed temperature will show

the merchandiser’s discharge air temperature.

• Set high and low pressure controls according

to the merchandiser’s data sheet.

• Check the reading on the Safe-NET III

display; it should be displaying the case

temperature. The display is located in the

center of the front of the facade above the

doors. The displayed temperature will show

the merchandiser’s discharge air temperature.

• Listen for any unusual sounds or events. For

example: evaporator fan blade interference,

compressor trip on overload, or high head

due to excessive ambient temperature, circuit

breaker trip, etc.

• Check the fan at each door to ensure all

fans are running. The discharge air output

at the top inside front of the case should be

relatively even across the length of the case

(honeycomb area).

Page 33

P/N 0520677_J 4-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

DEFROST

Defrost will occur 12 hours after switching the

disconnect switch to the ON position. Defrost

can be set to any time desired by switching the

unit off, then back on again, 12 hours before

the desired defrost time. “Df” is displayed on

the Safe-NET display during defrost. It will

show the discharge air temperature when the

evaporator coil has returned back to stabilized

operating temperature.

During defrost, the condensate pump will

pump defrost water to the condensate pan

located at the top of the merchandiser. On low

temperature cases, the fans shut off during

defrost, and electric defrost heaters energize to

melt the frost off the evaporator coil. Defrost

terminates when the evaporator coil reaches

approximately 48°F. On medium temperature

cases, the fans runs continuously, there are no

defrost heaters, and defrost is time-terminated

after 60 minutes.

CHECKLIST AFTER 12 HOUR RUN TIME

• Are all inspection plates and covers properly

replaced?

• Inspect for any water accumulation resulting from incorrect or unsealed penetrations

where electrical or other lines pass through

the case insulated walls.

• Check that the lights come on when the light

switch is in the on position.

• Check that the condensate pump and condensate fan turns on. Condensate pump pumps

water to the condensate pan during defrost

Check to ensure there are no leaks. The pump

will be on for only a few seconds. If condensate pan does not energize, GFCI may need

to be reset.

• See the merchandiser’s Data Sheet Set for

refrigerant settings and defrost requirements.

Bring merchandisers down to the operating

temperatures listed on the data sheet.

• Check case temperature.

• Verify that the fans are running. (The fans

will be off if the case is in a defrost cycle.

They will come back on after the completion

of this cycle.)

• Initiate a defrost cycle and ensure the heaters

are working properly. See the Safe-NET III

instructions for how to force a defrost cycle.

Check the amp draw at the terminal block,

located in the front electrical raceway, just

below the right most door of the case.)

• Check the door operation again, to ensure

they close properly once the case is down to

operating temperature.

Do not store items or flammable

materials atop the unit.

Do not walk on case.

Page 34

4-4 Start up

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

LOAD LIMITS

Shelf life of perishables will be short if load limit

is violated. at no time should merchandisers

be stocked beyond the load limits indicated.

Proper rotation of product during stocking is

necessary to prevent product loss. Always bring

the oldest product to the front and set the newest to the back.

Air disChArge And return flues must re-

mAin open And free of obstruCtion At All

times to provide proper refrigeration and air

curtain performance. Do not allow product,

packages, signs, etc. to block these grilles. Do

not use non-approved shelving, baskets, display

racks, or any accessory that could hamper air

curtain performance.

Do not prop doors open while stocking. And

keep the doors closed as much as possible to

prevent coil frosting and high merchandiser

temperature.

STOCKING

Product should NOT be placed in merchandisers until all refrigeration controls have been

adjusted and merchandisers are at proper operating temperature.

All shelves and the lower deck are intended to

display product. Shelf height is adjustable in

one inch increments. Spacing of 12inches is

recommended for most applications. Maximum

load per shelf is 170pounds. Merchandisers

may be ordered with optional “L” shaped wire

shelves.

INSTALLING FDA/NSF REQUIRED

THERMOMETER

The following pages provide the same information that ships with the thermometer.

This requirement does not apply to display

refrigerators intended for bulk produce (refer

to Page 1-1).

Please note that the tape cannot be exposed

after installation.

Page 35

P/N 0520677_J 4-5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Sugge sted Mount ing Locati on s

This is an NSF-7 &

US FDA Food Code

Required

Thermometer

Thermometer — Hussmann Part TM.4911251

Hussmann Corporation • 12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900 • www.hussmann.com

© 2007 Hussmann Corporation

in Single De ck G lass Front

Impact Me rcha ndis ers

Package Guard,

Facin g Out

Doub le Stic k Tape

Flexible Plastic

Fits in Price Tag

Moldings

Hussmann P/N 0429971_C 10/2007

End Pane l

Price Ta g

Moldin g

Suggested Mount ing Locati ons

in Multi-deck Mercha ndis ers

Page 36

4-6 Start up

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Important – Please read!

Food and Drug Administration (US FDA) Food Code [ http://www.fda.gov/ ]

National Sanitation Foundation (NSF / ANSI) Standard 7 [ http://www.nsf.org/ ]

This thermometer is provided in response to United States

and

Each installation will be different

depending on how the unit is

stocked, shopping patterns in the

department and ambient conditions

of the store. The suggested loca-

tions provided herein are possible

locations. It is the responsibility of

the purchaser / user to determine

the location within the food storage

area of the unit that best meets the

code requirements above.

The thermometer may need to be

moved several times to find the

warmest location. Mounting options

include flexible plastic for price tag

molding application, magnet

applied to back of flexible plastic for

steel end wall, and double stick

tape. Tape must not be exposed

after installation.

Questions about either code should

be addressed to local agencies or

other appropriate officials.

Keep with merchandiser

or give to store manager.

DO NOT DESTROY.

Page 37

P/N 0520677_J 5-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

MAINTENANCE

CARE AND CLEANING

Long life and satisfactory performance of any

equipment is dependent upon the care it receives. To ensure long life, proper sanitation and

minimum maintenance costs, these merchandisers

should be thoroughly cleaned, all debris removed and

the interiors washed down, weekly.

Always*Clear™ Glass

Wipe inside of glass with isopropyl alcohol and

a soft cloth. Allow surface to dry before closing

door. Use of other cleaners or abrasives may

damage the Always*Clear surface, and/or void

the warranty. Refer to manual that ships with

doors..

Exterior Surfaces

The exterior surfaces should be cleaned with a mild

detergent and warm water to protect and maintain

their attractive nish.

ers or scouriNg pads.

Never use abrasive cleaNs-

Interior Surfaces

The interior surfaces may be cleaned with most

domestic detergents, ammonia based cleaners

and sanitizing solutions with no harm to the

surface.

Do No t Use:

• Abrasive cleansers and scouring pads, as

these will mar the nish.

• Solvent, oil or acidic based cleaners on any

interior surfaces.

• Ammonia based cleaners on acrylic

surfaces.

Do :

• Remove the product and all loose debris to

avoid clogging the waste outlet.

• Store product in a refrigerated area such as

a freezer. Remove only as much product as

can be taken to the freezer in a timely

manner.

• First turn off refrigeration, then disconnect

electrical power.

• Before washing, disconnect hose from condensate pan on top of case, and discharge

water into a drain.

• Thoroughly clean all surfaces with soap

and hot water. do Not use steam or high

water pressure hoses to wash the

iNterior. These will desTroy The

merchandisers’ sealing causing leaks

and poor performance.

• Remove screws and lift hinged fan plenum

for cleaning.

plenum afTer cleaning merchandiser.

Be sure To reposiTion The fan

• Take care to minimize direct contact between fan motors and cleaning or rinse

water.

• Rinse with hot water, but do NOT ood.

Never iNtroduce water faster thaN the

waste outlet caN remove it.

• Allow merchandisers to dry before

resuming operation.

• After cleaning is completed, turn on power

and refrigerant to the merchandiser.

• Verify that merchandiser is working

properly.

SHUT FANS OFF

Do NOT allow cleaning agent or cloth to

contact food product.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

DURING CLEANING PROCESS.

Page 38

5-2 Maintenance

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0520677_J

Fan Plenum

To facilitate cleaning, the fan plenum is hinged

and also fastened with screws at each end.

After cleaning be sure the plenum is properly

lowered into position and that screws are reinstalled

or producT loss will resulT due to

improper refrigeration.

CLEANING HONEYCOMB ASSEMBLIES

Honeycombs should be cleaned every six

months. Dirty honeycombs will cause merchandisers to perform poorly. The honeycombs

may be cleaned with a vacuum cleaner. Soap

and water may be used if all water is removed

from the honeycomb cells before reassembling.

Be careful not to damage the honeycombs.

1. Remove the sheet metal screws located in

the front metal retainer which holds the

honey comb assembly in place.

CLEANING STAINLESS STEEL

SURFACES

Use non-abrasive cleaning materials, and always polish with grain of the steel. Use warm

water or add a mild detergent to the water and

apply with a cloth. Always wipe rails dry after

wetting.

Use alkaline chlorinated or non-chlorine

containing cleaners such as window cleaners

and mild detergents. Do not use cleaners

containing salts as this may cause pitting and

rusting of the stainless steel nish. Do not use

bleach.

Clean frequently to avoid build-up of hard,

stubborn stains. A stainless steel cleaning

solution may be used periodically to minimize

scratching and remove stains. Rinse and wipe

dry immediately after cleaning. Never use hydrochloric acid (muratic acid) on stainless steel.

2. Lift the honeycomb assembly out of the

L-bracket to remove it.

3. Clean and dry the honeycomb.

4. After cleaning, reassemble in reverse order

of removal.

Inte rnal

Frame

SIDE VIE W

Hone ycomb

Top Pane l

Screw

Adhe sive

Inte rior

Top Pane l

Hone ycomb

Reta iner

CLEANING COILS

NEVER USE SHARP OBJECTS AROUND

COILS. Use a soft brush or vacuum brush to

clean debris from coils. Do not puncture coils!

Do not bend ns. Contact an authorized

service technician if a coil is punctured,

cracked, or otherwise damaged.

ICE in or on the coil indicates the refrigeration

and defrost cycle is not operating properly.

Contact an authorized service technician to

determine the cause of icing, and to make adjustments as necessary. To maintain product

integrity, move all product to a cooler until

the unit has returned to normal operating

temperatures.

Page 39

P/N 0520677_J 5-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Mimimum Suggested Cleaning and Maintenance Frequency

with Separate TOP-MOUNTED Condensing Unit*

Average Total

Type of Maintenance Maintenance Estimated

Case Scheduled Frequency Duration Maintenance

Component Maintenance (Times / Year)* (hours)* Time/Year (hours)

Evaporator Coil / Case Interior

Honeycomb

Return Air Grille

Drip Piping

Condenser Coil

Condensate Evaporation

Pan

Condensate Evaporation

Pan Heater

Condensate Pump

Compressor

Electromechanical

Thermostats

Compressor Power Relays

Cleaning

Cleaning

Cleaning

Cleaning

Cleaning

Cleaning

None

Cleaning

None

Replacement

Replacement

1

1

12

6

4

4

N/A

6

N/A

0.2

0.2

2

0.05

0.1

0.1

0.1

0.2

N/A

0.05

N/A

1

1

2

0.05

1.2

0.6

0.4

0.8

N/A

0.03

N/A

0.2

0.2

*This table is provided for reference only. The suggested maintenance frequency is

the minimum required to reduce unexpected equipment failure. Performance and

efciency may be enhanced with more frequent cleaning. Individual cleaning

schedules must take into account local environment and usage, as well as all

applicable health codes.

Page 40

5-4 Maintenance

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0520677_J

CLEANING UNDER MERCHANDISERS

Remove splashguards not sealed to oor. Use

a vacuum with a long wand attachment to remove accumulated dust and debris from under

the merchandiser.

Do NOT use HOT water on COLD glass surfaces.

This can cause the glass to shatter and could

result in personal injury. Allow glass doors to

warm before applying hot water.

REMOVING SCRATCHES FROM BUMPER

Most scratches and dings can be removed

using the following procedure.

1. Use steel wool to smooth out the surface

area of the bumper or top rail.

2. Clean area.

3. Apply vinyl or car wax and polish surface

for a smooth glossy nish.

Page 41

P/N 0520677_J 6-1

SERVICE

REPLACING FAN MOTORS AND BLADES

See cross section for location of evaporator

fans. Should it ever be necessary to service

or replace the fan motors or blades be certain

that the fan blades are re-installed correctly.

For access to RLN / RMN fans:

1. Turn off power.

2. Remove bottom display pans.

3. Disconnect fan from wiring harness.

4. Remove fan blade.

Always disconnect the electrical power

at the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items

as fans, heaters, thermostats and lights.

5. Remove screws holding fan motor/bracket

assembly to plenum and remove assembly.

6. Replace fan motor/bracket assembly and

reinstall screws.

7. Reinstall fan blade.

8. Reconnect fan to wiring harness.

9. Turn on power.

10. Verify that motor is working and blade is

turning in the correct direction.

11. Close air gaps under fan plenum. Warmer

air moving into refrigerated air reduces

effective cooling. If the plenum does not

rest against the case bottom without gaps,

apply foam tape to the bottom of the fan

plenum to reduce improper air movement.

Use silicone sealant to close other gaps.

12. Replace display pans. Bring merchandiser

to operating temperature before restocking.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Hussmann recommends against frame heater

cycling with Innovator doors to prevent door

seals from freezing to the frames and tearing.

Page 42

6-2 Service

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Product will be degraded and may spoil if al-

lowed to sit in a non-refrigerated area.

5. Position new heater in bracket.

6. Bend tabs back to vertical to hold heater in

bracket.

7. Replace the coil cover and lower fan plenum.

REPLACING ELECTRIC DEFROST

HEATERS

Electric defrost requires a heater on the front

and rear of the coil as shown. The heaters are

held in place by tabs in the coil brackets.

Front Defrost Heater

1. Disconnect power.

2. Lift fan plenum up and back to access the

heater.

3. Bend tabs holding heater to horizontal.

4. Remove heater from coil bracket.

Electric Defrost

8. Turn on power.

9. Verify that heater is working correctly.

10. Close air gaps under fan plenum. Warmer

air moving into refrigerated air reduces

effective cooling. If the plenum does not

rest against the case bottom without gaps,

apply foam tape to the bottom of the fan

plenum to reduce improper air movement.

Use silicone sealant to close other gaps.

11. Replace display pans. Bring merchandiser

to operating temperature before

restocking.

Rear Defrost Heater

1. Disconnect Power.

2. Remove coil cover.

Back Heater

3. Remove clips holding heater to coil tube.

4. Remove heater from slots in coil bracket.

5. Position new heater in slots.

Front Heater

Page 43

P/N 0520677_J 6-3

6. Replace clips.

7. Replace the coil cover.

Always disconnect the electrical power

8. Turn on power.

at the main disconnect when servicing or

replacing any electrical component. This

9. Verify that heater is working correctly.

includes, but is not limited to, such items

as fans, heaters, thermostats and lights.

10. Replace display pans. Bring merchandiser

to operating temperature before

restocking.

REPLACING DRAIN PAN HEATER —

ELECTRIC AND GAS DEFROST

(Low Temperature Only )

The drain pan heater is located as shown below.

Remove Drain Pan Heater

1. Disconnect power.

2. Pull heater out from

under jiffy clips.

3. Position new heater

under jiffy clips. Be

sure offset is properly

positioned around

the drain. If jiffy clips

are removed, make cer-

tain sealer is replaced.

4. Reconnect power.

5. Verify that heater is

working correctly.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Page 44

6-4 Service

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

SERVICING VERTICAL LIGHTING

Refer to door manufacturer’s manual for

servicing of vertical lamps.

SERVICING DOORS AND FRAMES

See door manufacturer’s service manual for

servicing information. One manual is shipped

with each merchandiser.

REPLACING DOOR OR DOOR FRAME PARTS

Parts for Reach-in doors and door frame

assemblies must be ordered direct from the

door manufacturer This includes the glass

doors, door frame assemblies, lamps, ballasts,

door handles, hold open slides, and power

cords. Refer to specic warranty supplied with

the door. The manufacturers have a warranty

against moisture penetration, a warranty

against tempered glass breakage, and a

warranty on ballasts. Lamps are not covered by

Hussmann or the door manufacturer.

X-Ergon

1570 E. Northgate

P.O. Box 2102

Irving, TX 75062

Phone: 1-800-527-9916

NOTE:

Hussmann Aluminum melts at 1125°F (607°C)

Aladdin 3-in-1 rod at 732°F (389°C)

X-Ergon Acid core at 455°F (235°C)

Technique:

1. Locate Leak.

2. REMOVE ALL PRESSURE.

3. Brush area UNDER HEAT.

4. Use PRESTOLITE TORCH ONLY.

Number6 tip.

5. Maintain separate set of stainless steel

brushes and USE ONLY ON

ALUMINUM.

REPAIRING ALUMINUM COIL

The aluminum coils used in Hussmann

merchandisers may be easily repaired in the

eld. Materials are available from local

refrigeration wholesalers.

Hussmann recommends the following solders

and technique:

Solders

Aladdin Welding Products Inc.

P.O. Box 7188

1300 Burton St.

Grand Rapids, MI 49507

Phone: 1-800-645-3413

6. Tin surface around area.

7. Brush tinned surface UNDER HEAT,

thoroughly lling the open pores around

leak.

8. Repair leak. Let aluminum melt solder,

NOT the torch.

9. Don’t repair for looks. Go for thickness.

10. Perform a leak check.

11. Wash with water.

12. Cover with a good exible sealant.

Page 45

P/N 0520677_J 7-1

OPTIONAL DRIP PIPING

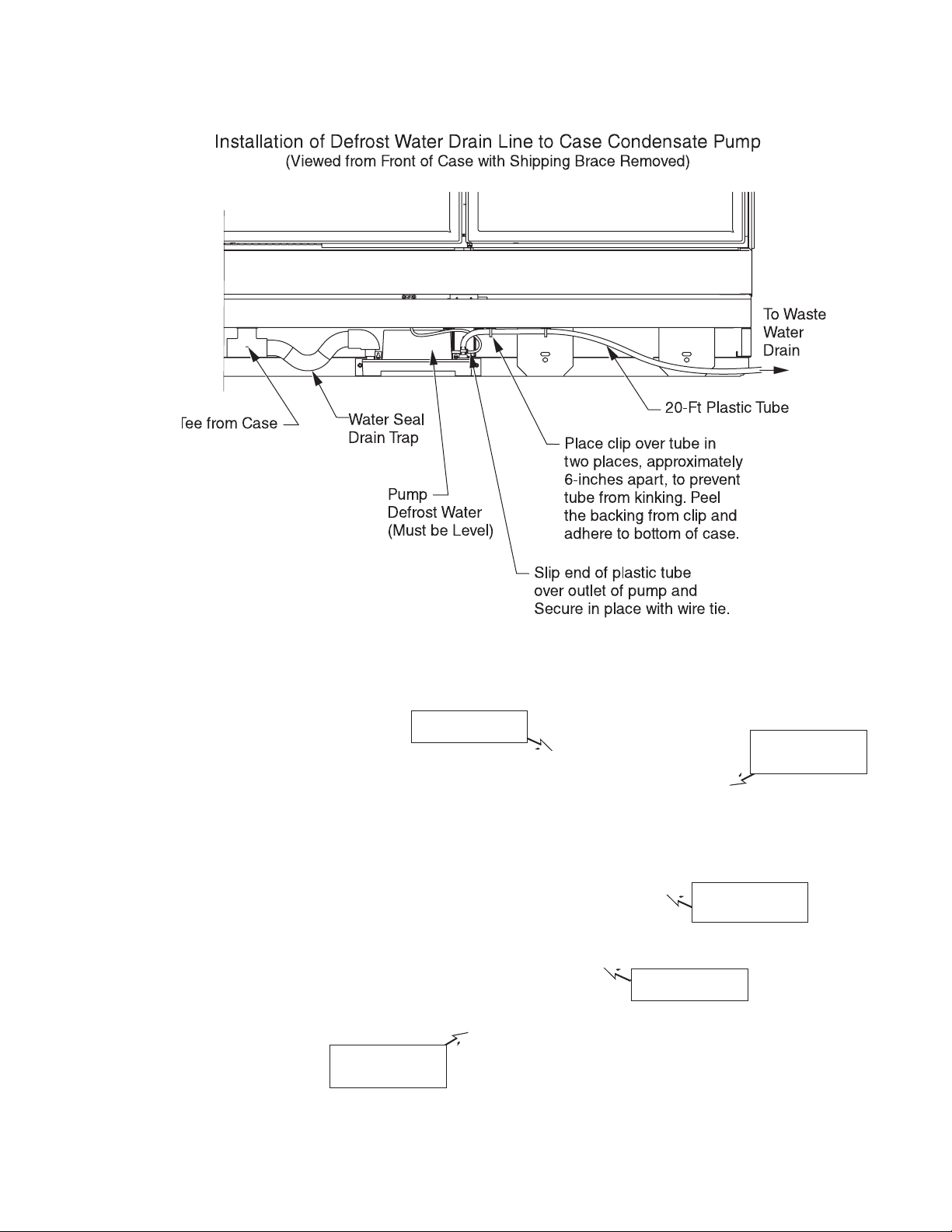

WASTE OUTLET AND WATER SEAL

Drip piping must be installed for cases without evaporation pans. Drip piping is located

between the front merchandiser base and the

splashguard xture and runs parallel to the merchandiser (see Data Sheet for exact locations).

INSTALLING DRIP PIPING

Poorly or improperly installed drip pipes can

seriously interfere with the merchandiser’s operation and result in costly maintenance and

product losses. Please follow the recommendations listed below when installing drip pipes to

ensure proper installation.

• Never use drip piping smaller than the

nominal diameter of the pipe or water seal

supplied with the merchandiser.

Splashguard brackets MUST be installed

before piping merchandiser.

• Provide a suitable air break

between ood rim of the

oor drain and outlet of

drip pipe. To meet code on

low base merchandisers, it

may be necessary to install

a eld-supplied drip pipe

reducer. An alternative is

to cut the last section of

drip pipe at an angle.

• When connecting drip piping, the water

seal must be used as part of the drip piping

to prevent air leakage or insect entrance.

Never use two water seals in series in any

one drip pipe.

ries will cause an air lock anD

prevent Draining.

Double water seals in se-

• Pitch the drip piping in the direction of

ow. There should be a minimum pitch of

1

/4in. perft (20mm per 1m).

• Avoid long runs of drip piping. Long runs

make it impossible to provide the pitch

necessary for good drainage.

• Prevent drip pipes from freezing sweating

or freezing:

A. Do NOT install drip pipes in contact

with uninsulated suction lines. Suction lines

should be insulated with a non-absorbent

insulation material.

B. Where drip pipes are located in dead air

spaces, such as between merchandisers or

between a merchandiser and a store wall,

provide means to prevent drip pipe from

sweating. External ventilation fans may be

required to prevent sweating.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Page 46

7-2 Service

Do NOT use Thread Sealer on Drain Fitting!

(Drain Fitting)

Factory Installed (four turns)

Approx.

1

/

2

in. Clearance to Floor

1. Tee is factory-installed. If adjustment is necessary,

tighten factory-installed tee no more than ¼

turn. Do not overtighten threads, or the drain

tting or tee may become damaged.

2. Do NOT use thread sealer on ABS drain tting.

If sealer is used the ABS drain tting may crack

or leak! (If a tee needs to be installed it should be

hand tightened) Do not overtighten threads.

2. Dry t the supplied

water seal / trap to ensure approximately

1

/2

in. of clearance from the

bottom of the trap to the

oor as shown.

Merchandiser

Bottom

Factory-Installed

Tee Fitting

NOTE: It may be necessary to rotate water

seal (trap) inside the tee a few degrees to ensure clearance at two locations. There must be

clearance 1) between the bottom of the water

seal and the oor, and 2) between the top of

the water seal outlet and the bottom of the

merchandiser. Do not over-rotate or gravity seal

may be compromised. Always rotate trap bottom toward merchandiser support rail.

Front of

Merchandiser

Waste

Outlet

Maintain Clearance

to Bottom of Case

Field-Installed

Water Seal

Floor

Rotate Water Seal

towards back of

Merchandiser if required

1/2-in.

Clearance to Floor

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Page 47

P/N 0520677_J 7-3

3. Install remaining PVC drain parts using

recommended PVC cleaner, primer and

cement per manufacturer’s recommendations.

4. Thread plug into the adapter until snug but

not to exceed four full rotations.

It is the installing contractor’s responsibility

to consult local agencies for

local code requirements.

5. Installed drip piping may require additional

support depending on the number and location of the hub oor drains. The installer

should always provide adequate support to

all drip piping arrangements to prevent excess stress on all drip piping

components. The installer must provide

additional support when “evac” type waste

water systems are applied.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. Freedom Line Reach-in

Page 48

7-4 Service

The instructions on the following pages detail the

installation and operation of the Electronic

Unit Controller. These instructions are reprinted with permission from: Emerson

Climate Technologies, Inc.

Notes:

P/N 0520677_J U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Page 49

Application Engineering

BULLETIN

Application Engineering

BULLETIN

AE8-1376 R2

AE8-1376 R2

September 2013

Electronic Unit Controller

TABLE OF CONTENTS

Section Page Section Page

Safety