Page 1

9/20/2005

Installation Manual, Hussmann Part # 0385841

Page 2

Protocol™ Installation and

Service Manual

Table Of Contents

Installation ...................................................................................................... 1

Overview......................................................................................................................... 1

Shipping Damage............................................................................................................ 1

Apparent Loss or Damage .............................................................................................. 1

Concealed Loss or Damage ............................................................................................ 1

On Site Damage Control................................................................................................. 1

data plate for each unitDimensions and Weights.................................................................. 2

Dimensions and Weights ................................................................................................3

Field Supplied and Installed Water Components............................................................ 3

Accessibility.................................................................................................................... 3

Panel Removal................................................................................................................4

Horizontal Units – Top Removal.................................................................................... 5

Vibration Pads................................................................................................................. 6

TYPICAL PIPING & ELECTRICAL HOOKUP.......................................... 7

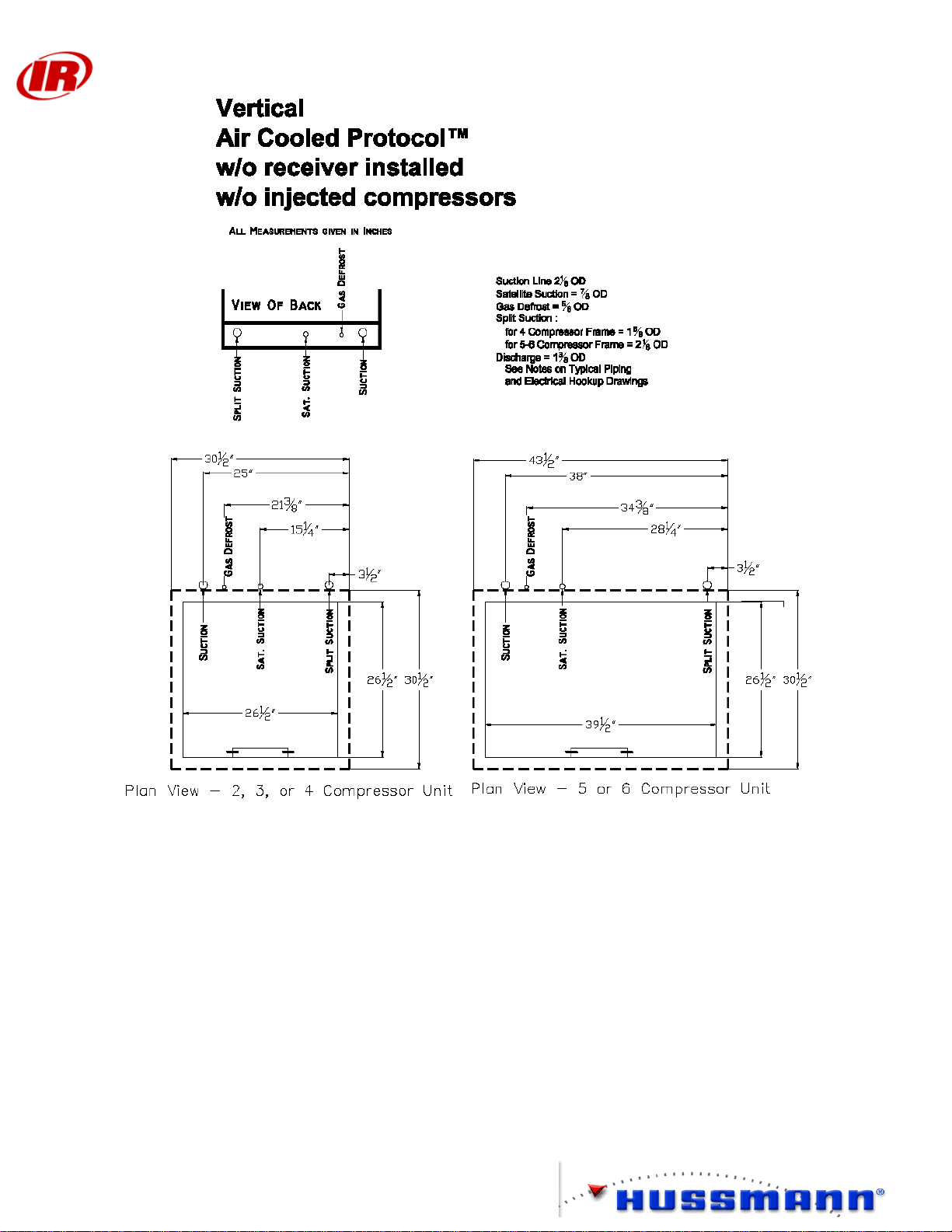

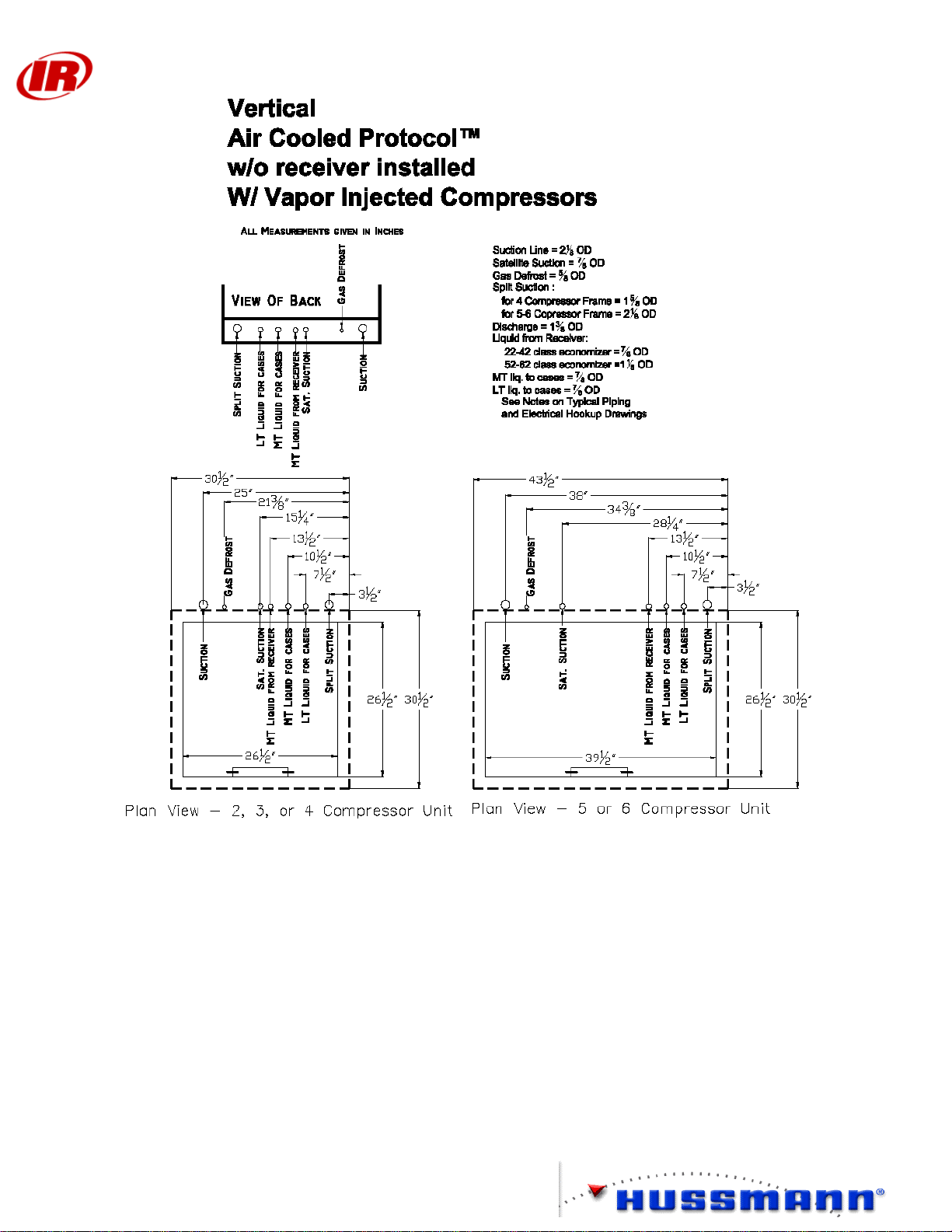

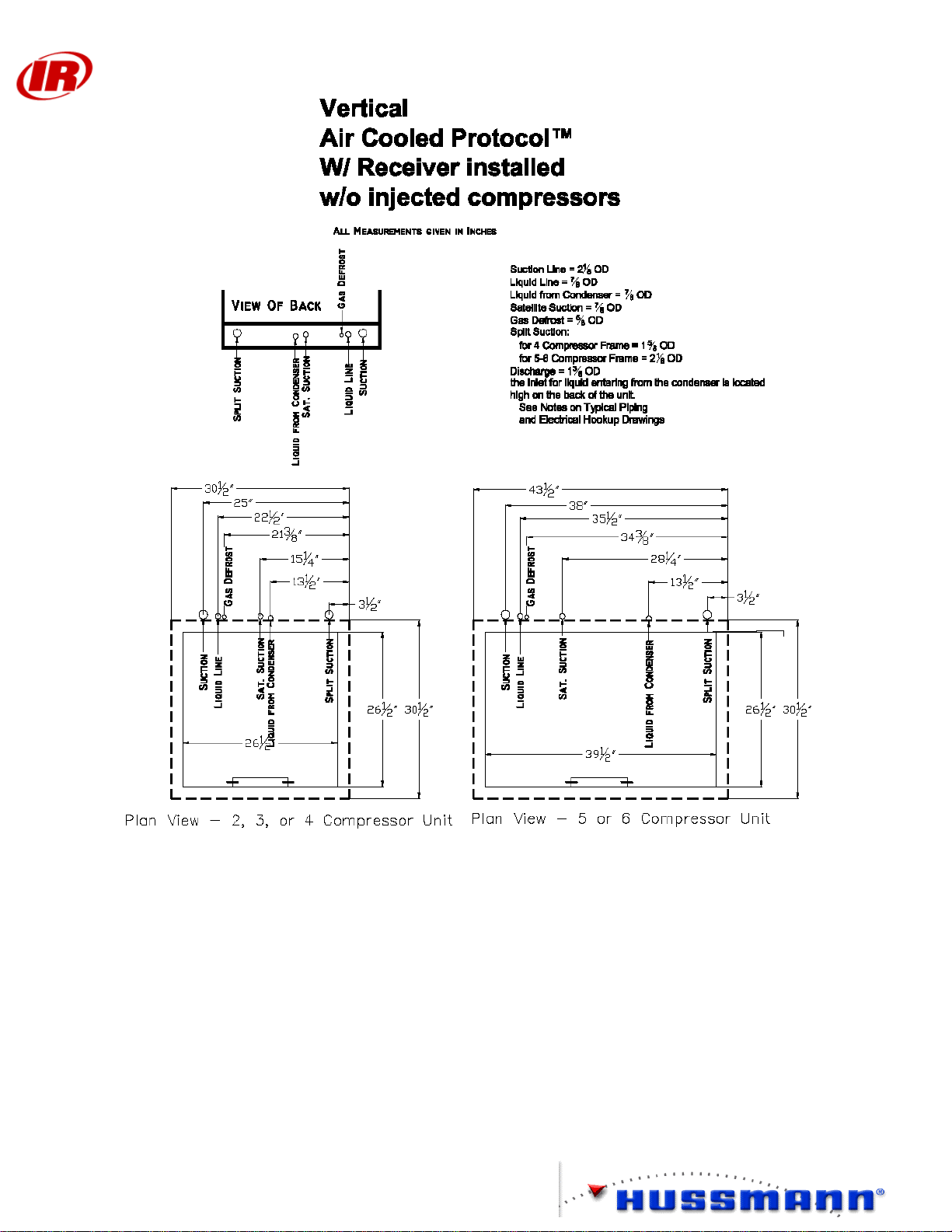

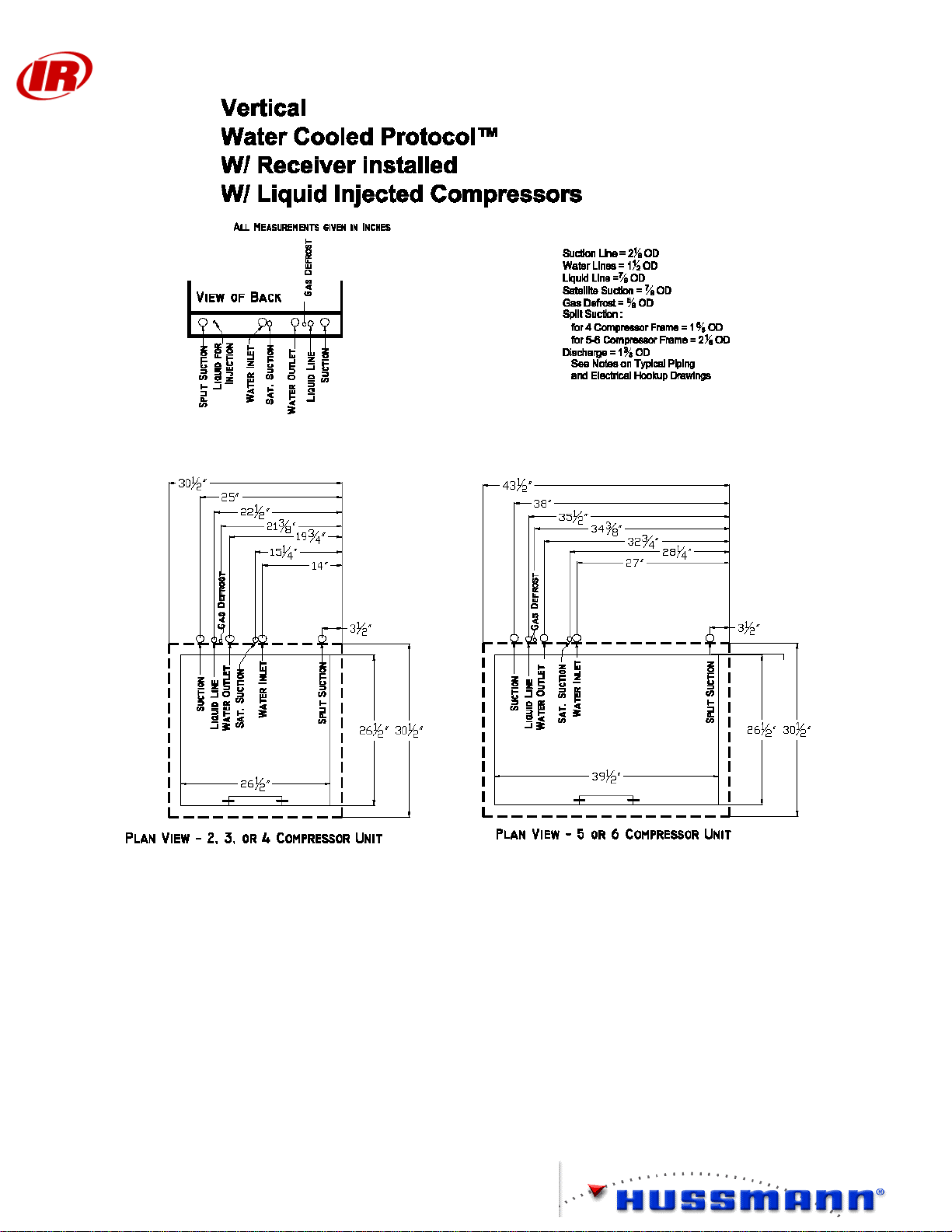

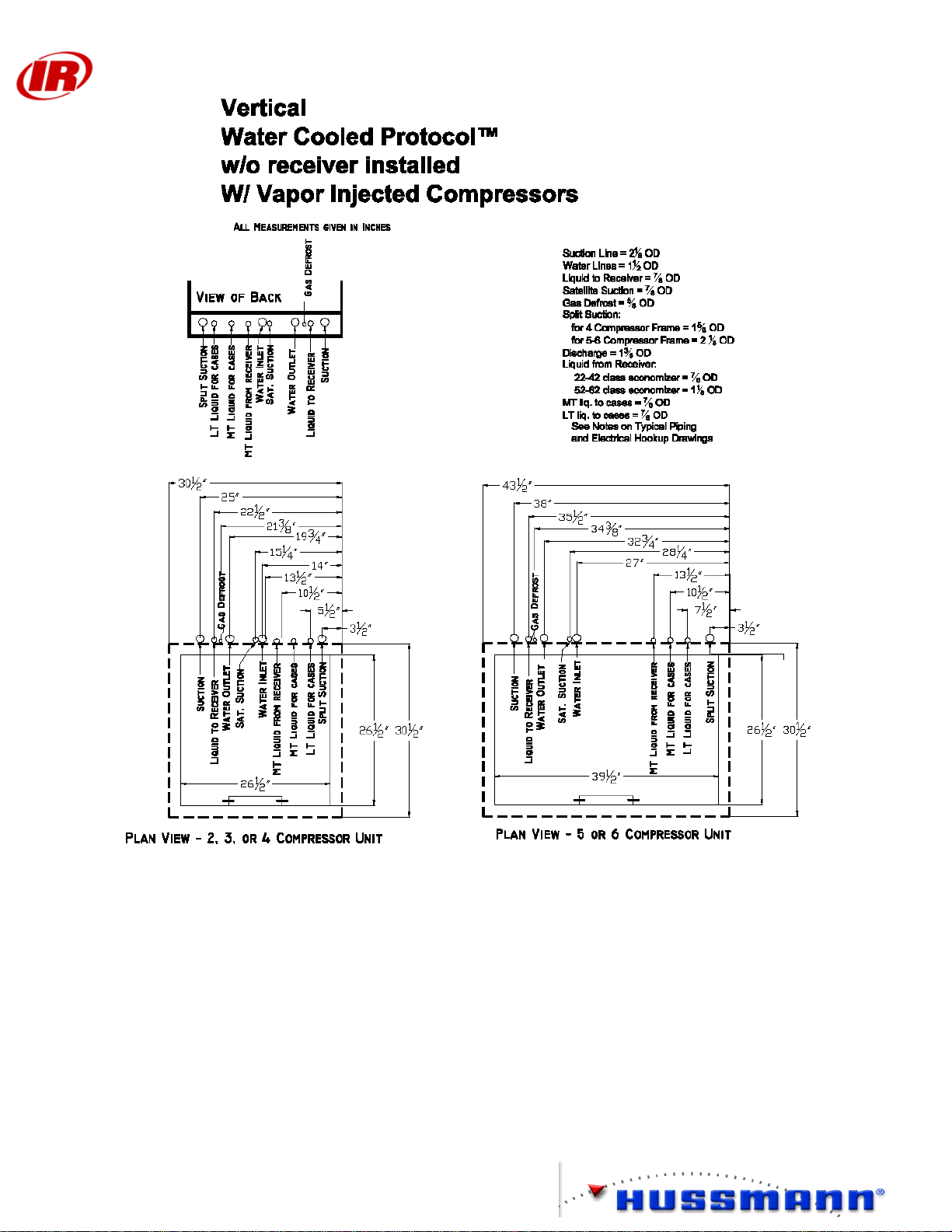

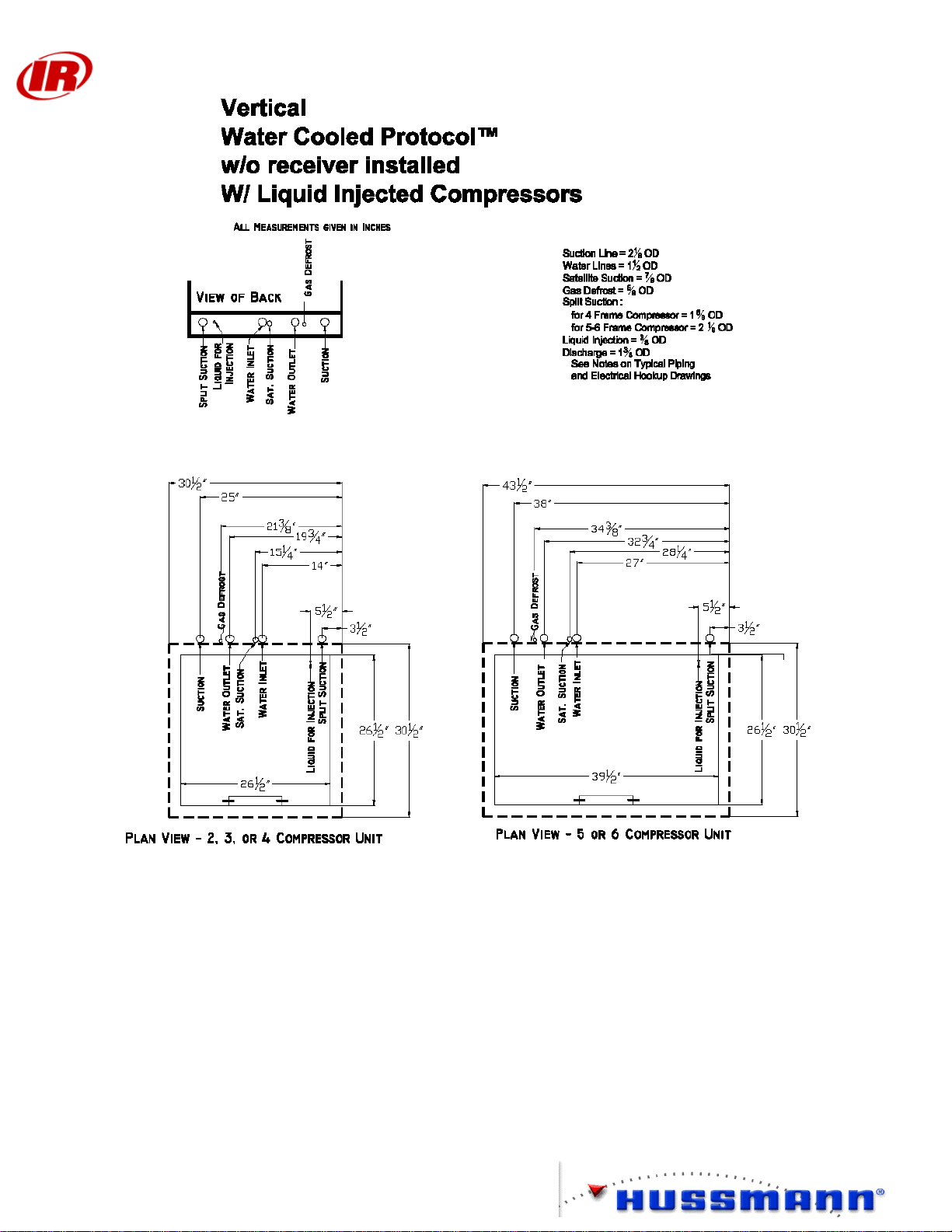

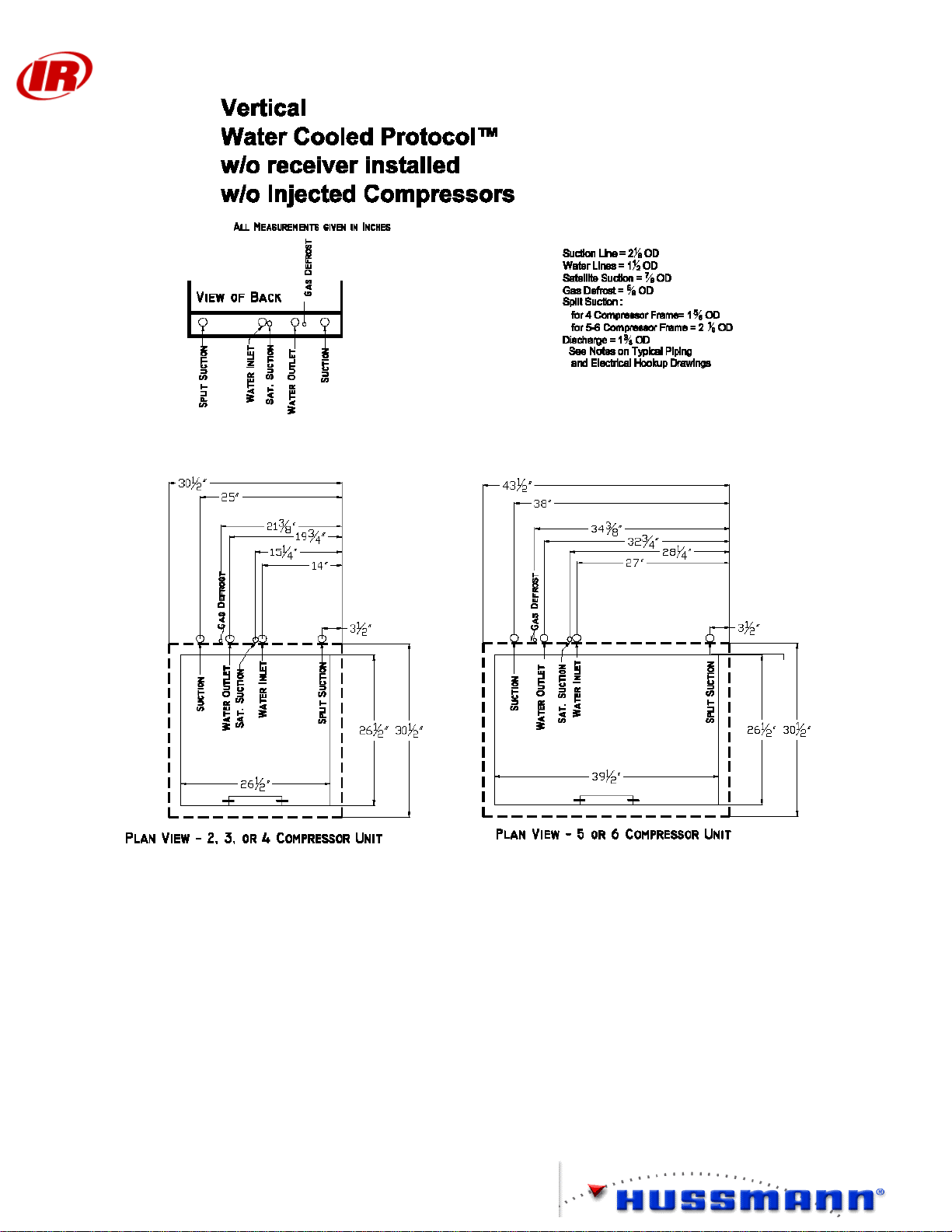

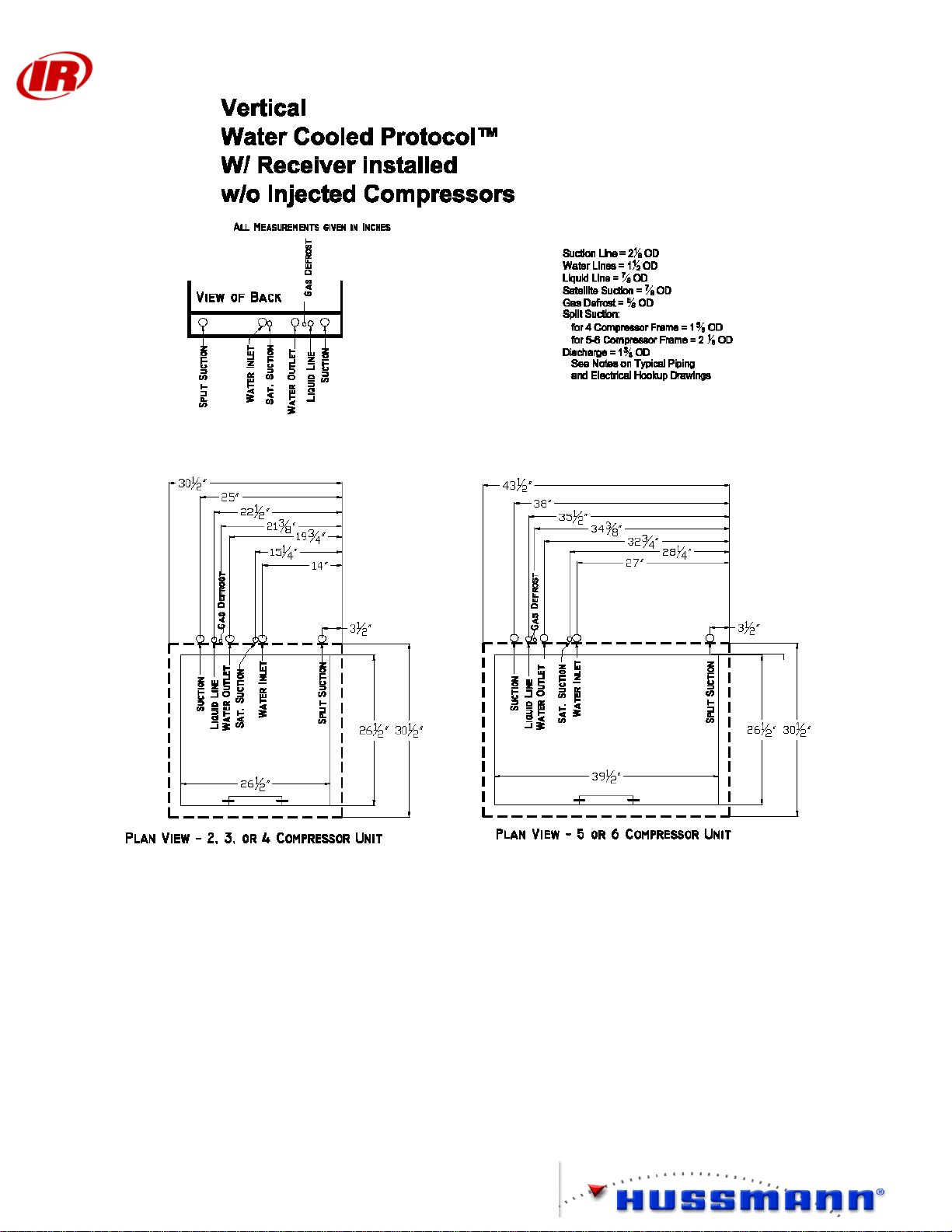

Vertical Units.................................................................................................................. 7

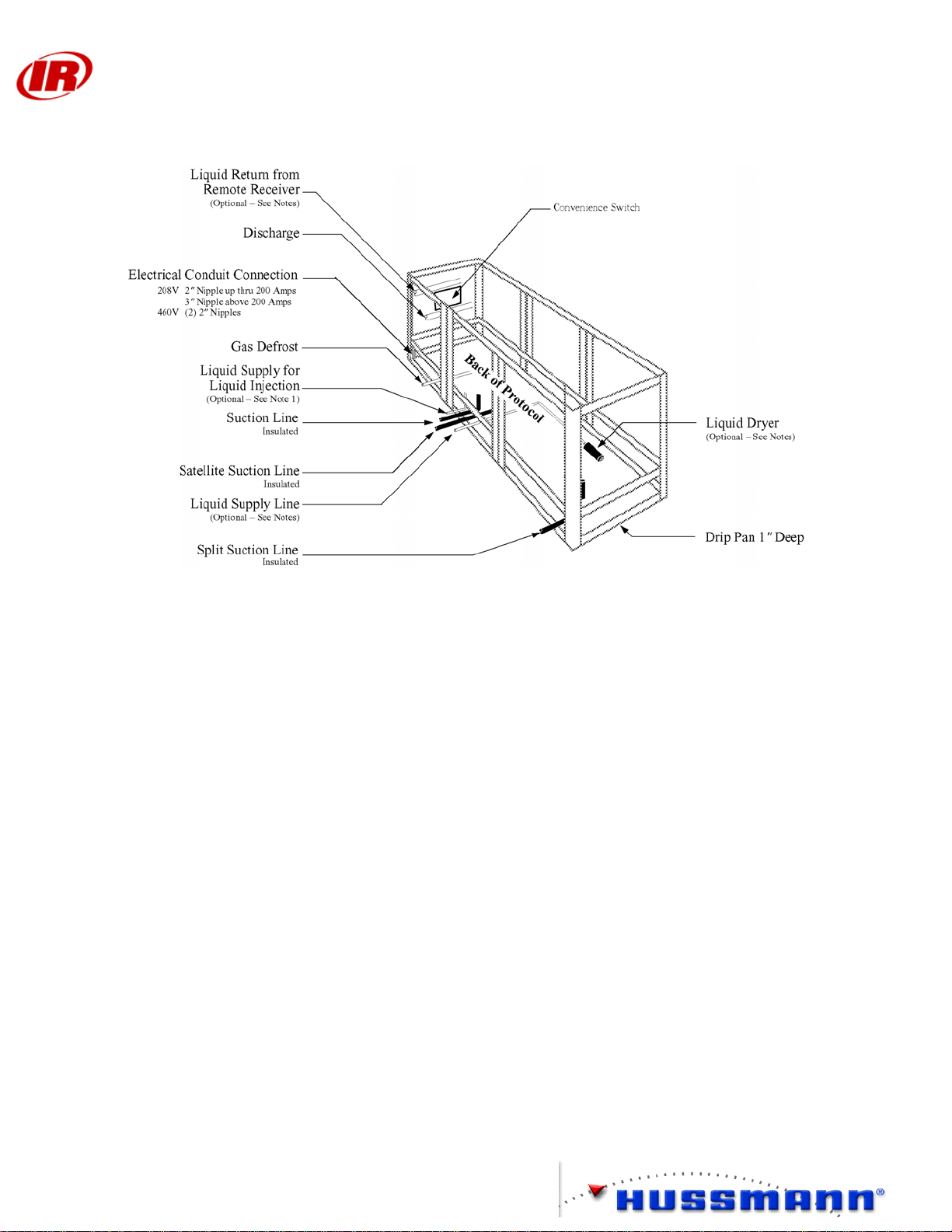

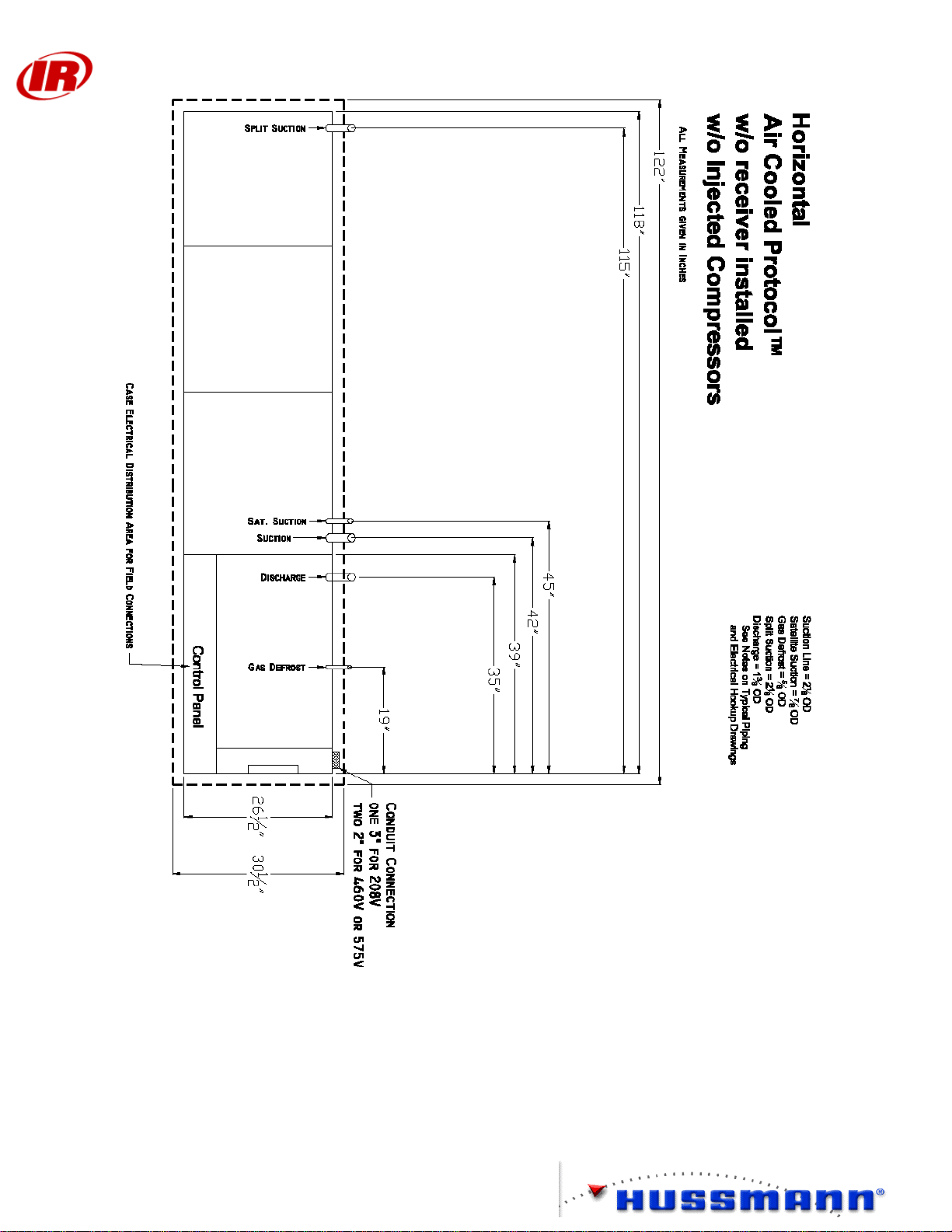

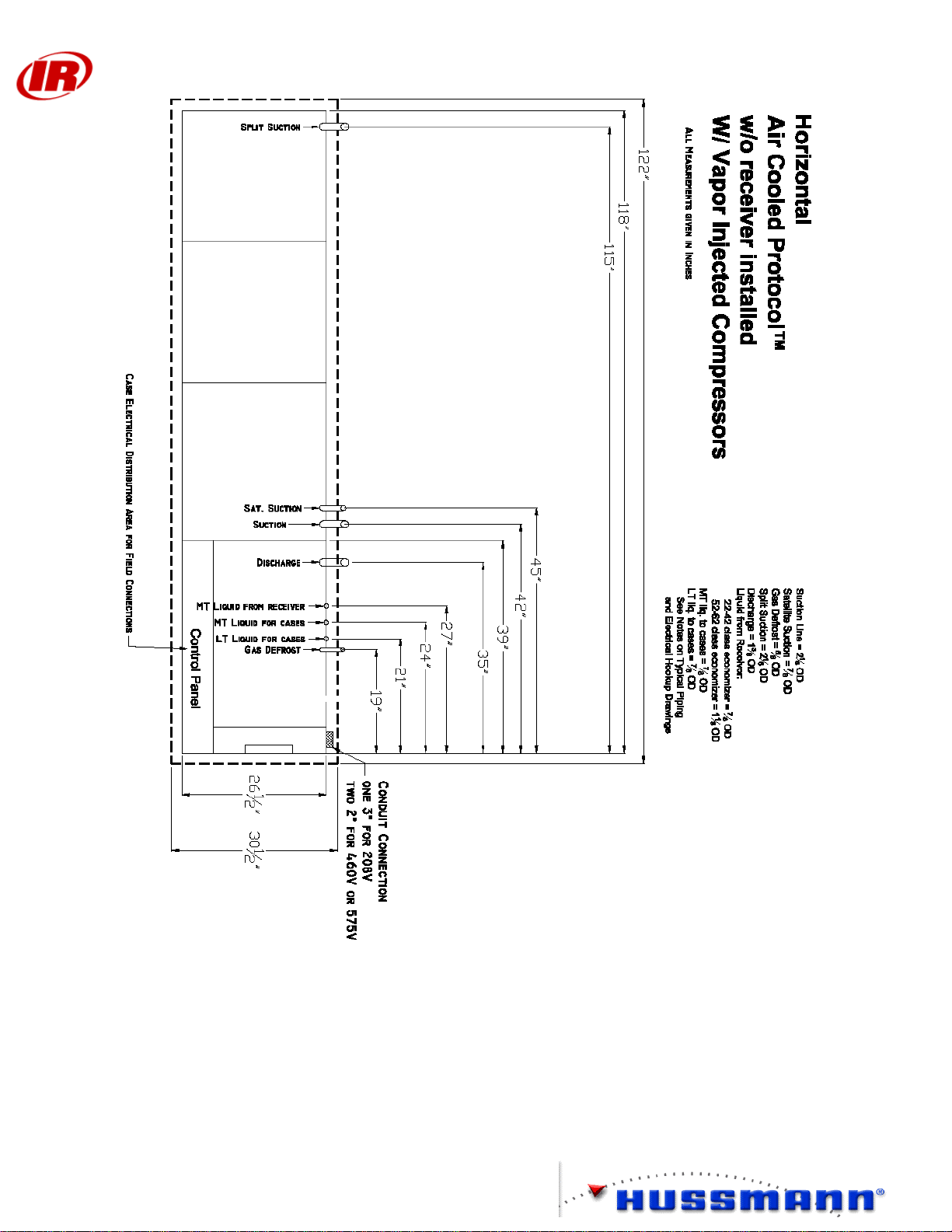

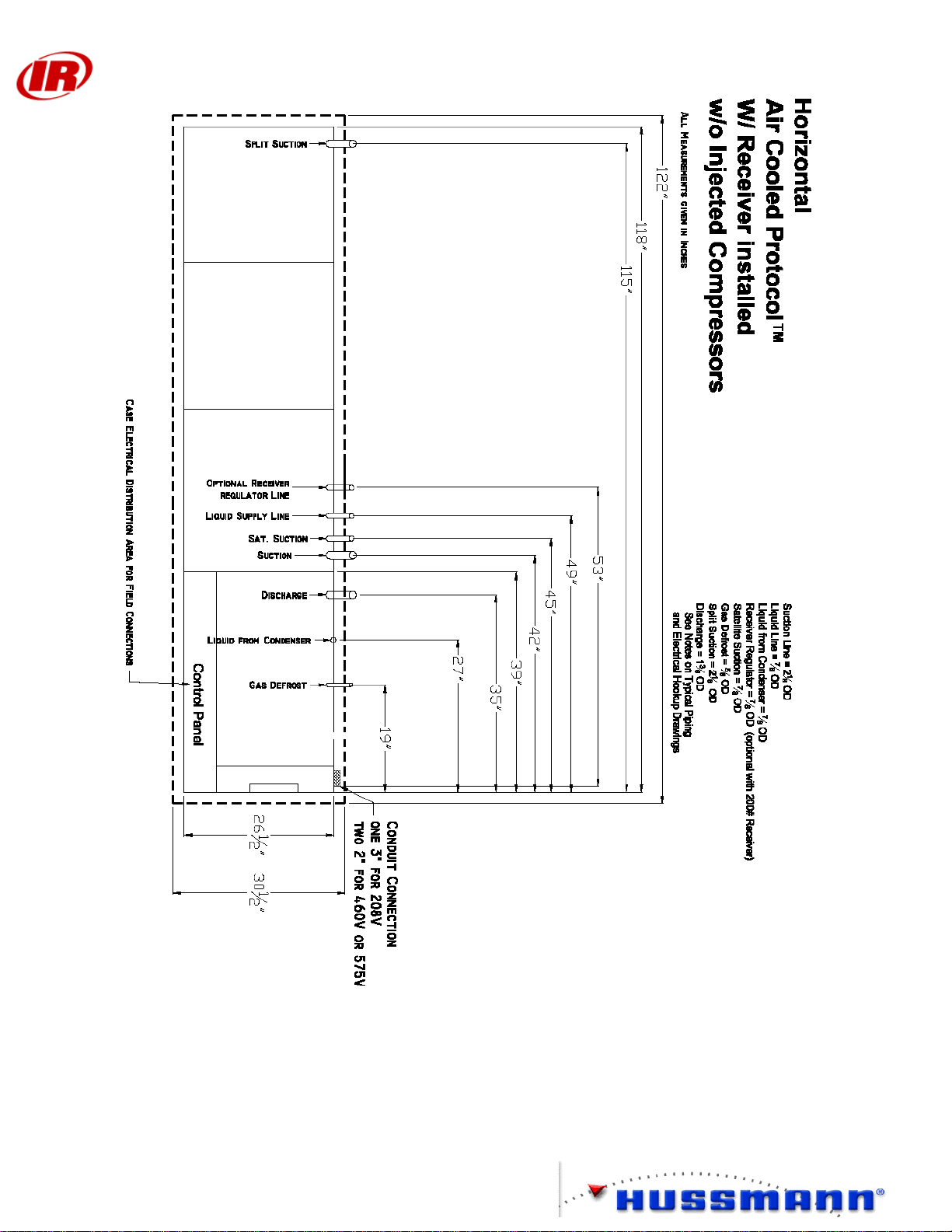

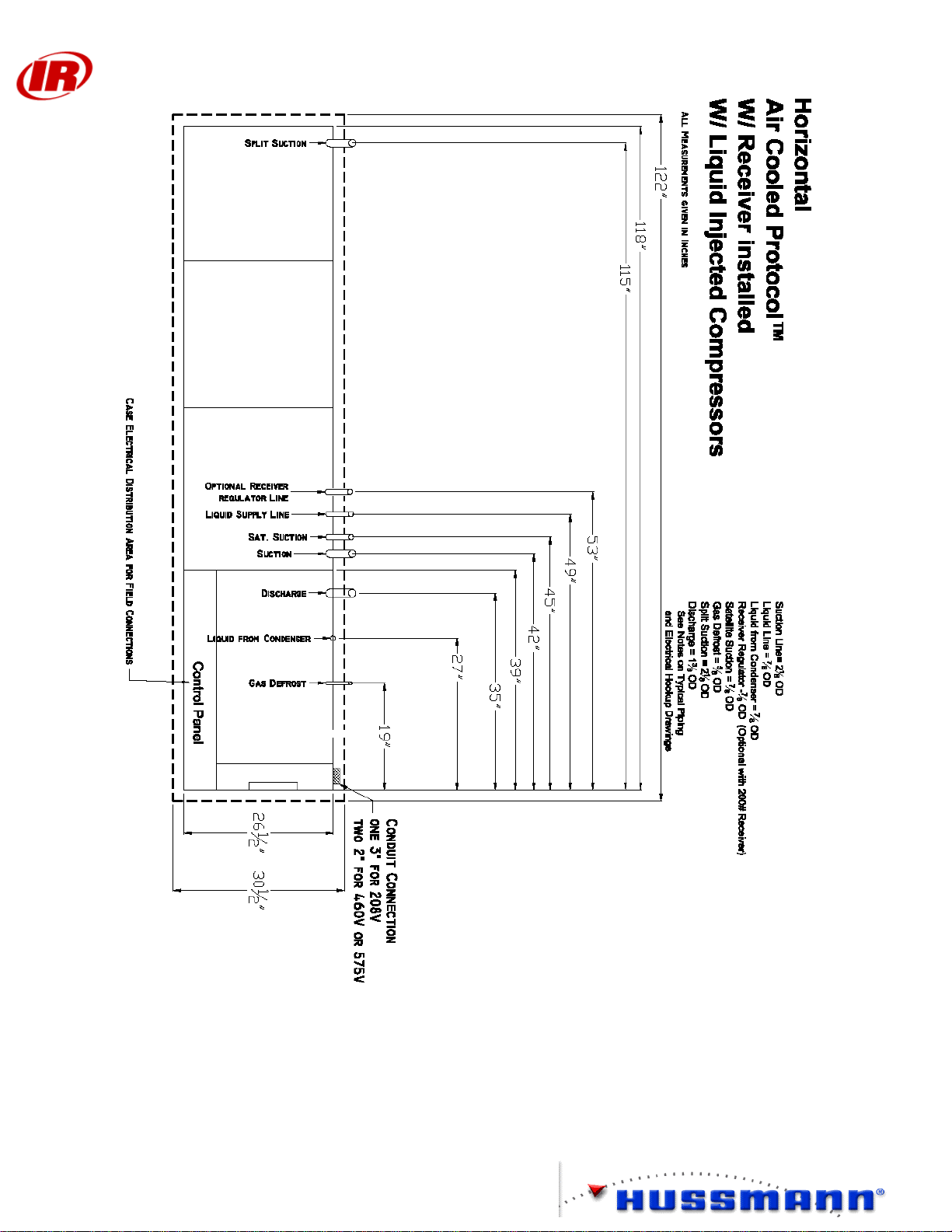

Horizontal Units............................................................................................................ 20

Proto_Aire Units........................................................................................................... 33

REFRIGERATION PIPING......................................................................... 40

Overview....................................................................................................................... 40

Refrigeration Line Piping ............................................................................................. 40

Refrigeration Cycle....................................................................................................... 41

Protocol™ with 3-Pipe Gas Defrost ............................................................................. 42

Protocol™ with Heat Reclaim...................................................................................... 43

Protocol™ with Split Suction....................................................................................... 44

Oil Cycle....................................................................................................................... 45

Liquid Injection............................................................................................................. 46

Vapor Injection ............................................................................................................. 47

Field Piping................................................................................................................... 48

Water Loop Piping........................................................................................ 49

Overview....................................................................................................................... 49

Water Loop Guidelines................................................................................................. 49

Pipe Connections ...................................................................................................... 49

Isolation Valves ........................................................................................................ 49

Strainers .................................................................................................................... 49

Air Vent Valves ........................................................................................................ 50

Tie-Ins to Supply Headers ........................................................................................ 50

Pipe Supports............................................................................................................ 50

Exposure to Direct Sunlight...................................................................................... 50

Leak Check ............................................................................................................... 50

Cleaning and Flushing .............................................................................................. 50

Filling........................................................................................................................ 50

Balance Valve Adjustment ....................................................................................... 51

Presetting The Flow Control (Balancing) Valve .......................................................... 51

Balancing the Water Loop........................................................................................ 52

Balancing the Water Loop for Direct Return Piping................................................ 52

Page 3

Protocol™ Installation and

Service Manual

Balancing the Water Flow for Each Protocol™....................................................... 53

Balancing the System for Piping Head Loss............................................................. 55

Presetting the Degree of Closure .............................................................................. 57

Electrical....................................................................................................... 59

Field Wiring.................................................................................................................. 59

Main Power Wiring....................................................................................................... 65

208V Two Wide Protocol™..................................................................................... 65

208V 5 or 6 Compressor Protocol™ ........................................................................ 66

460V Two Wide Protocol™..................................................................................... 67

460V 5 or 6 Compressor Protocol™ ........................................................................ 68

460V Two Wide Protocol with Factory installed transformer.................................. 69

460V Two Wide Protocol™ with Field supplied transformer.................................. 70

460V 5 or 6 Compressor Protocol™ with Field supplied transformer..................... 71

600V Two Wide Protocol™..................................................................................... 72

600V 5 or 6 Compressor Protocol™ ........................................................................ 73

600V Two Wide Protocol™ with Field supplied transformer.................................. 74

Terminal Connections................................................................................................... 75

120V Circuit Logic....................................................................................................... 75

24V Circuits.................................................................................................................. 75

Electronic Oil Level Control......................................................................................... 75

Satellite Short Cycle Control Relay.............................................................................. 76

Control and Compressor Wiring................................................................................... 77

PCS without Vapor Wiring....................................................................................... 77

PCS with Vapor Wiring............................................................................................ 78

CPC, Danfoss, Comtrol without Vapor Wiring........................................................ 79

CPC, Danfoss, Comtrol with Vapor Wiring............................................................. 80

Controller Wiring.......................................................................................................... 81

PCS ........................................................................................................................... 81

CPC........................................................................................................................... 82

CPC Einstein............................................................................................................. 83

Danfoss ..................................................................................................................... 84

Comtrol..................................................................................................................... 85

Liquid Injection............................................................................................................. 86

Vapor Injection ............................................................................................................. 86

Refrigeration Circuit Control.................................................................................... 88

Off time Sequence of Operation............................................................................... 88

Hot Gas ..................................................................................................................... 89

Electric Defrost......................................................................................................... 89

Special Case of Heat Reclaim with Hot Gas Defrost ............................................... 90

Lighting Control............................................................................................................ 91

Unit Cooler Fan Wiring................................................................................................ 92

Protocol™ Remote Condenser Fan Wiring.................................................................. 93

POWERLINK™ Operation.......................................................................................... 97

Wiring Optional Auto Dialer and In-Store Alarm........................................................ 98

Startup........................................................................................................... 99

Startup........................................................................................................................... 99

Electronic Oil Level Control....................................................................................... 103

Page 4

Protocol™ Installation and

Service Manual

Auxiliary Systems....................................................................................................... 104

3-Pipe Gas Defrost...................................................................................................... 105

Electric Defrost........................................................................................................... 105

Offtime Defrost........................................................................................................... 106

Sensor Applications.................................................................................................... 106

Suction Pressure Sensor.......................................................................................... 106

Suction Pressure Input ............................................................................................ 106

Temperature Input................................................................................................... 107

All Additional Pressure/Temperature Inputs.......................................................... 107

Programming the Optional In-store Alarm and Auto Dialer...................................... 107

Troubleshooting Guide............................................................................... 108

Electrical Questions.................................................................................................... 109

Trouble Shooting Alarms............................................................................................ 113

Service......................................................................................................................... 115

Recommended Maintenance....................................................................................... 116

Sample Protocol™ Checklist.................................................................................. 118

Page 5

Protocol™ Installation and

Service Manual

Installation

Overview

This section is limited to the information needed to set the Protocol™ Unit. Auxiliary

equipment information is found in the sections devoted to them or in the manuals

accompanying them.

Related information is contained in Protocol™ Planning Data and the Pumping Station

Planning Data.

Shipping Damage

All equipment should be thoroughly examined for shipping damage before and while

unloading.

This equipment has been carefully inspected at our factory, and the carrier has assumed

responsibility for safe arrival. If damaged, either apparent or concealed, the claim must be

made to the carrier.

Apparent Loss or Damage

If there is an obvious loss or damage, it must be noted on the freight bill or express receipt

and signed by the carrier’s agent; otherwise, carrier may refuse claim. The carrier will

supply the necessary claim forms.

Concealed Loss or Damage

When loss or damage is not apparent until after equipment is uncrated, a claim for

concealed damage is made. Upon discovering damage, make request in writing to carrier

for inspection within 15 days and retain all packing. The carrier will supply inspection

report and required claim forms.

On Site Damage Control

The Protocol™ is shipped on skids with panels installed. Remove panels to access lifting

points on frame. Do not attempt to move the unit from the skids without first removing the

panels.

1

Page 6

Protocol™ Installation and

Service Manual

PROTOCOL UNIT NOMENCLATURE

The model numbers of PROTOCOL units are shown on the legend in modular form. The nomenclature is

interpreted as follows:

O P A V 1 3 P K - XX XX XX XX

COMPRESSOR CODES

VOLTAGE K=208/230;

M= 460/3/60; P= 575/3/60;

U= 380/3/50

REFRIGERANT J=134a;

P=R507; V=R22; S=404a

# OF PARALLEL

COMPRESSORS

# OF SATELLITE

COMPRESSORS

FRAME TYPE

V=Vertical

H=Horizontal

A= AIR COOLED

W= WATER COOLED

P=PROTOCOL

L=LOW PROFILE

H=HIGH EFFICIENCY

PROTOCOL

PROTO-AIRE DESIGNATION

The unit nomenclature is part of the UL code requirements and must be included on the legend as well as the

data plate for each unit

2

Page 7

Protocol™ Installation and

Service Manual

Dimensions and Weights

Vertical L H D Weight

Nomenclature (in.) (in.) (in.) (lb)

17FR 30.5 80 30.5 1200

18FR 43.5 80 30.5 1500

Horizontal L H D Weight

Nomenclature (in.) (in.) (in.) (lb)

20FR, 13FR, 29ZX 122 32 30.5 1700

32FX, 33FX, 34FX 122 32 30.5 1900

Proto-Aire™ L H D Weight

Nomenclature (in.) (in.) (in.) (lb)

3 & 4 fan 128 56.5 42 2800

6 fan (super) 185 56.5 42 3700

Note: Maximum weight includes sound coating and refrigerant.

Receiver Capacities are based on 80% liquid fill at 105 °F.

Vertical – 55 lb

Horizontal– 72 lb (Standard) 200# option

3 & 4 Fan Proto-Aire™ - 72 lb (Standard) 200# option

6 Fan Proto-Aire™ - 145 lb (Standard) 200# option

Field Supplied and Installed Water Components

The Protocol™ comes equipped with a flow control/shutoff valve for servicing the plate

heat exchanger. All other water loop components must be field supplied and installed. A

16-20 mesh strainer (1 mm) is required immediately upstream of each Protocol™.

Accessibility

All Standard Control Panel Doors require 40 inches clearance. Oversized Control Panel

Doors require 48 inches clearance. Vertical Protocol™ units must be serviceable from the

front and top of the unit. Access to either side is also recommended. Horizontal

Protocol™ units must be serviceable from three sides, the front and right side as well as the

top or back as viewed facing the removable panels. A minimum of 40 inches clearance is

recommended.

3

Page 8

Protocol™ Installation and

Service Manual

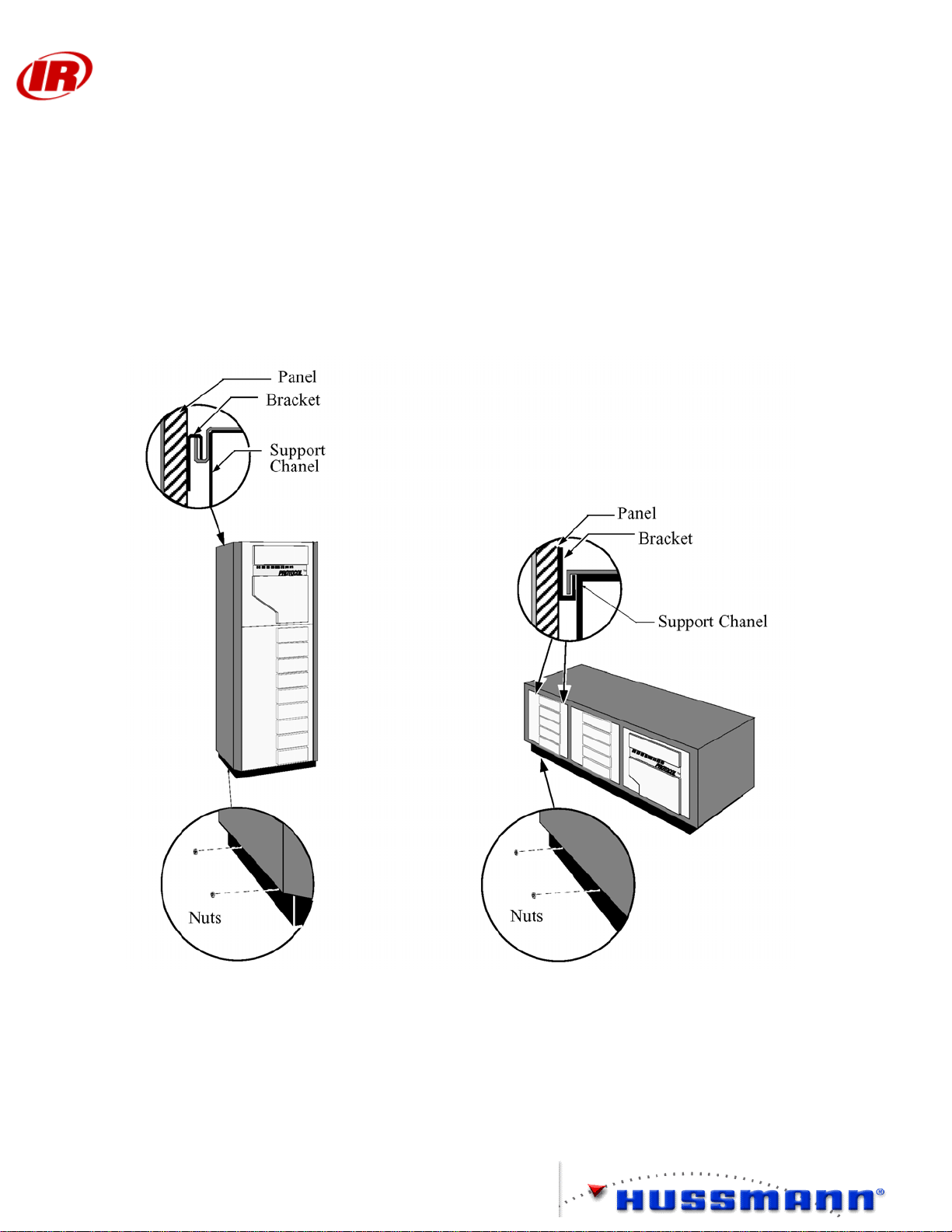

Panel Removal

Vertical Units

At the top, a bracket in a channel supports each panel. At the bottom, each panel is held in

place by two nuts. Remove the nuts at the bottom of the panel, then lift up and out.

Horizontal Units

At the top, a bracket in a channel supports each panel. At the bottom, each panel rests on

two studs and is held in place by nuts. Remove the nuts at the bottom of the panel, then

slide the panel out at the bottom and down.

4

Page 9

Protocol™ Installation and

Service Manual

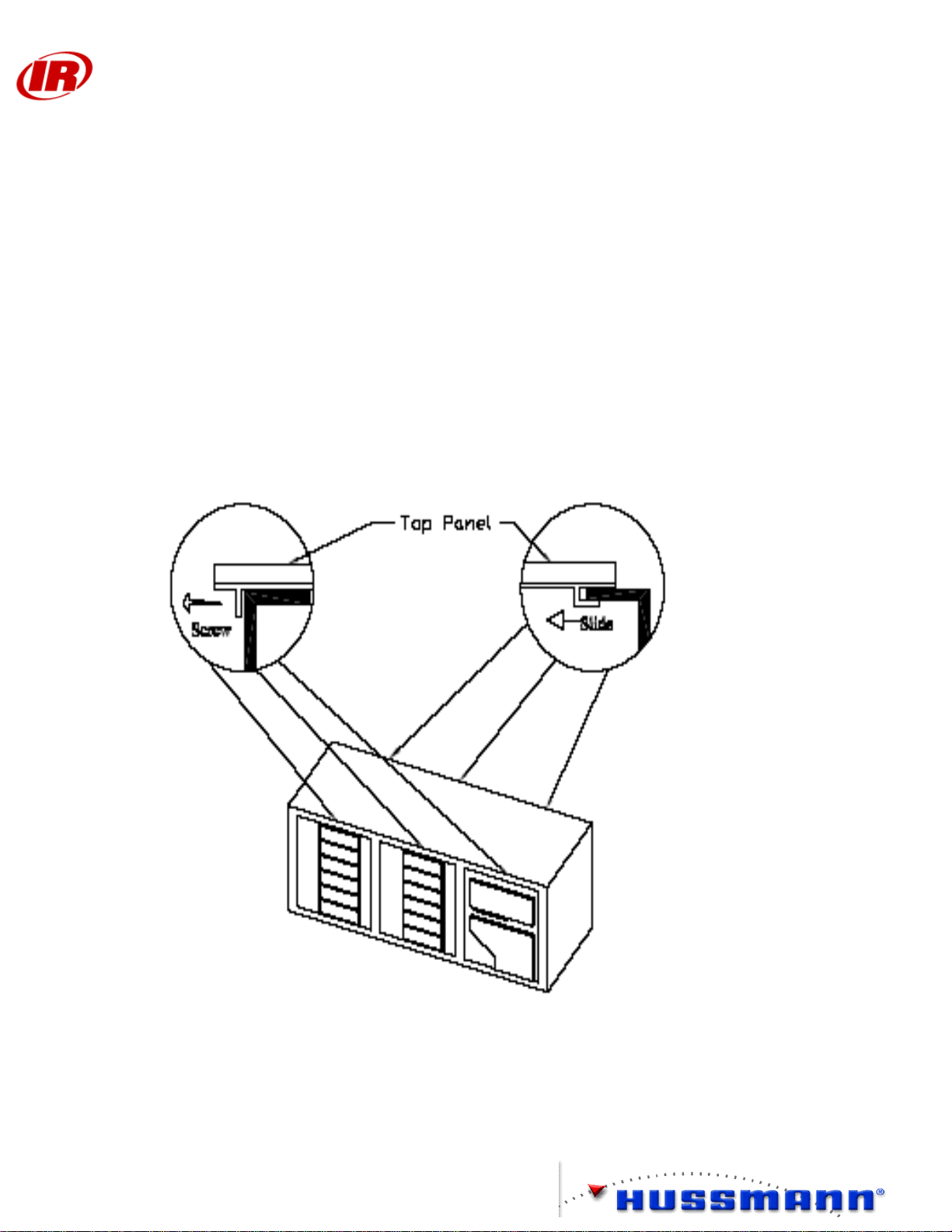

Horizontal Units – Top Removal

To remove the top assembly, first remove the front panels. Then remove the bracket screw

at top center of each panel opening and above the control panel. Slide the top assembly

forward until the back clips disengage. Lift the top off. Reverse procedure to install.

For some under-table applications, it may be desirable to remove the finished top panel to

reduce the Protocol™ unit’s height by two inches. To separate the top panel assembly,

remove it and take out the screws holding the finished top panel to the sub-panel. The subpanel MUST be installed, even when the finished top is not used.

5

Page 10

Protocol™ Installation and

Service Manual

Rigging and Hoisting

The installer is responsible for ensuring that the equipment used to move the Protocol™ is

operated within its limits. Under no circumstances should the top of the unit or the outer

panels be used for lifting or moving the unit. For strap rigging, run the straps under the top

level of compressor mounting channel.

Vibration Pads

Vibration Isolation Pads are supplied with each Protocol™ unit. To adjust for slightly

uneven floors, place 16 gauge galvanized steel shims between the vibration pads and the

floor (shims must be field supplied). One vibration pad is installed under each upright

channel. Vertical units use four pads. Horizontal units use 8 to 10 pads.

6

Page 11

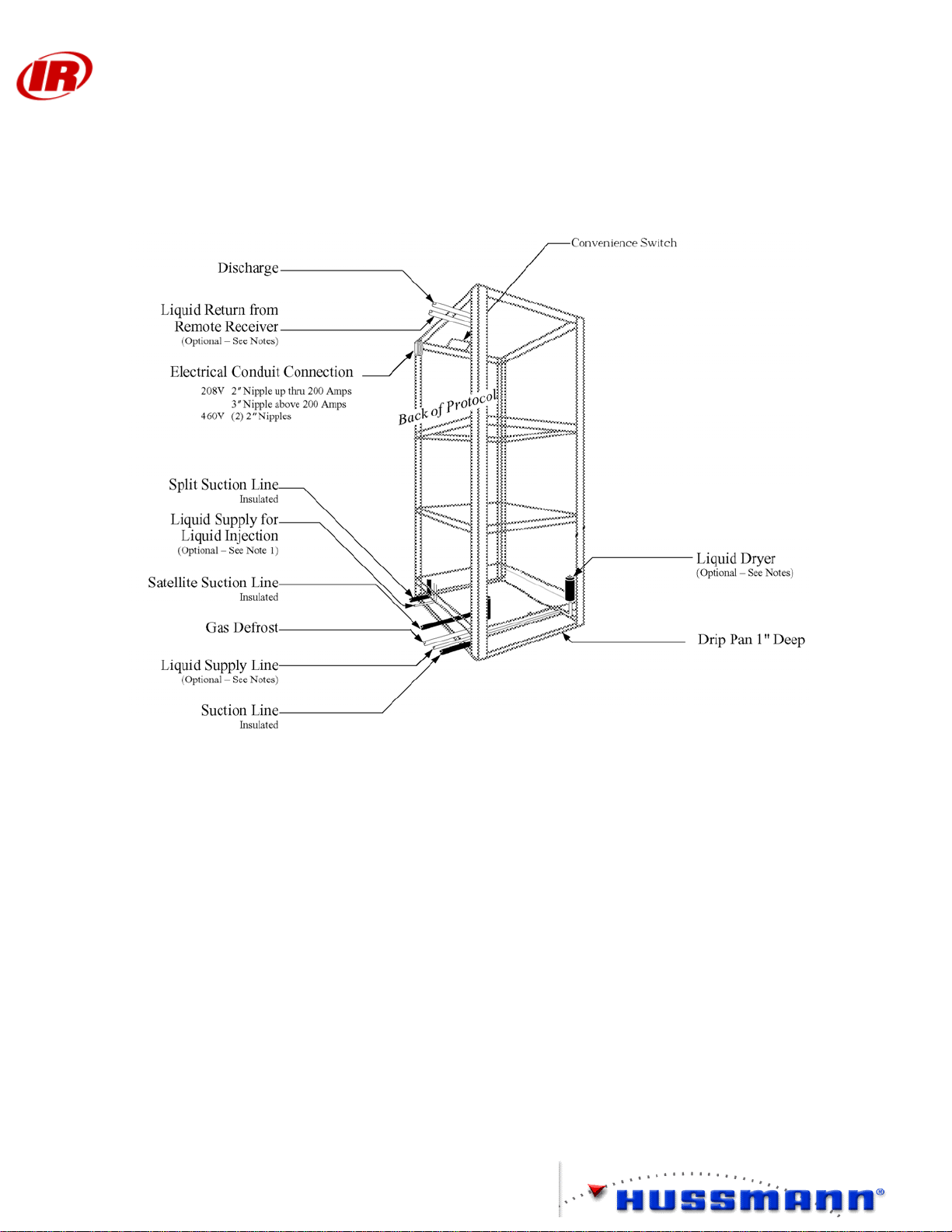

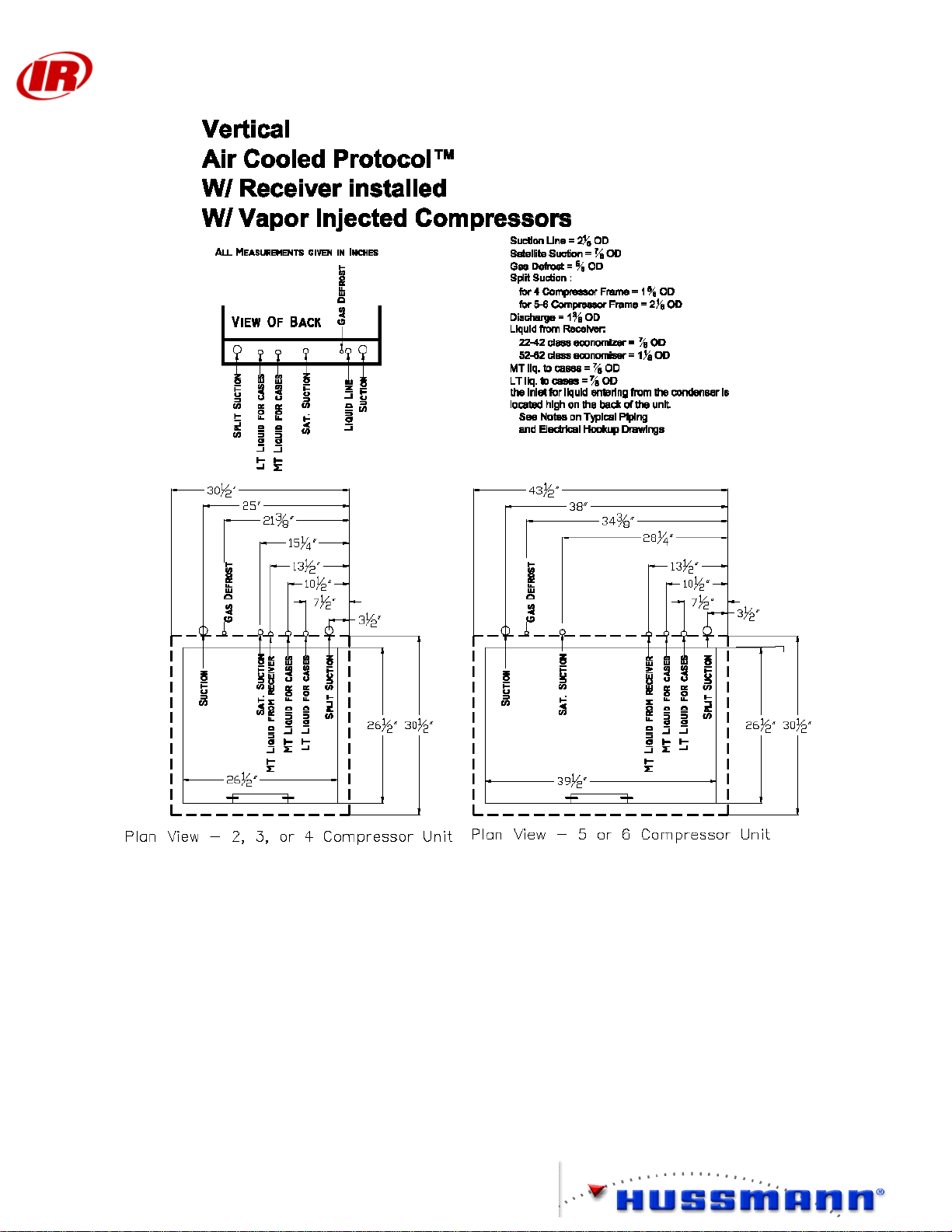

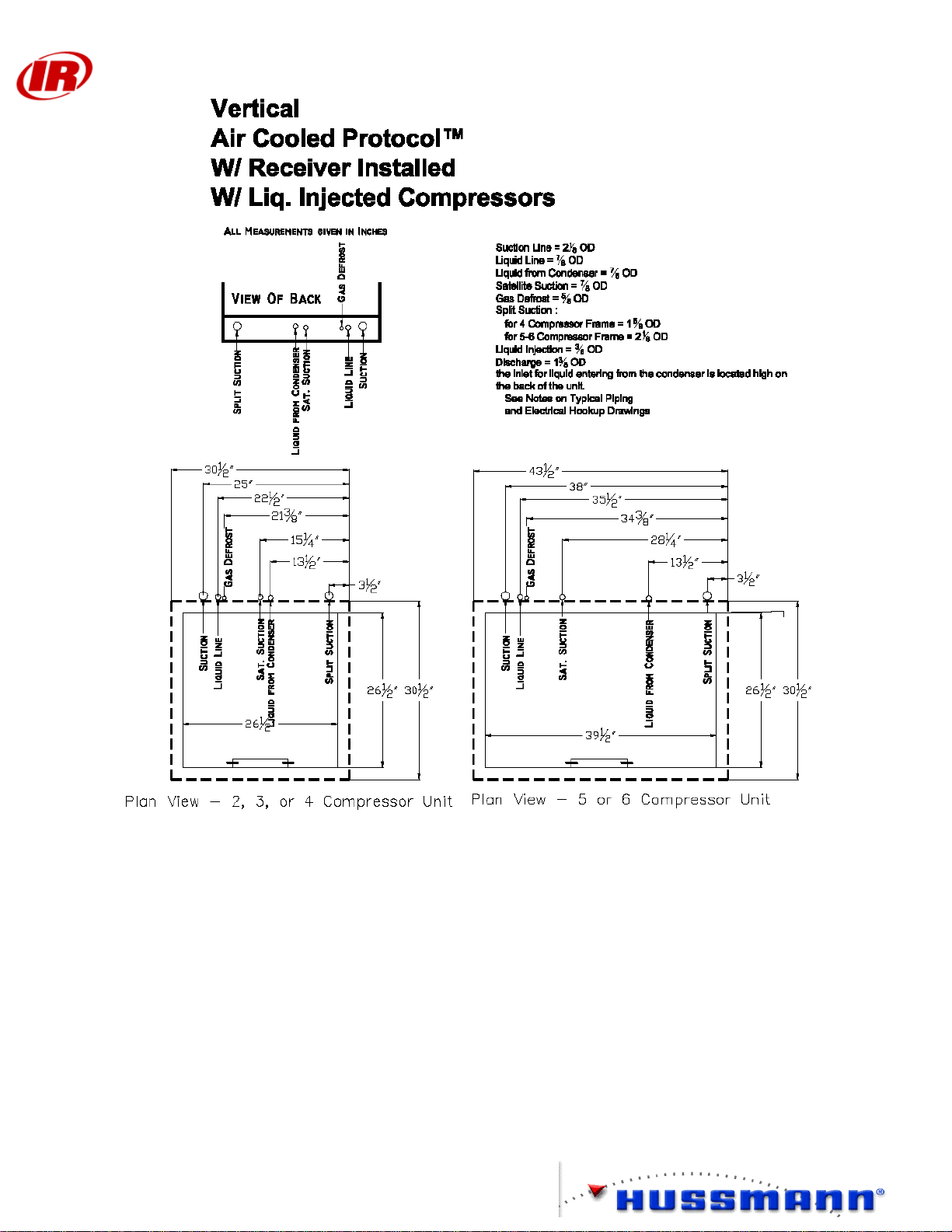

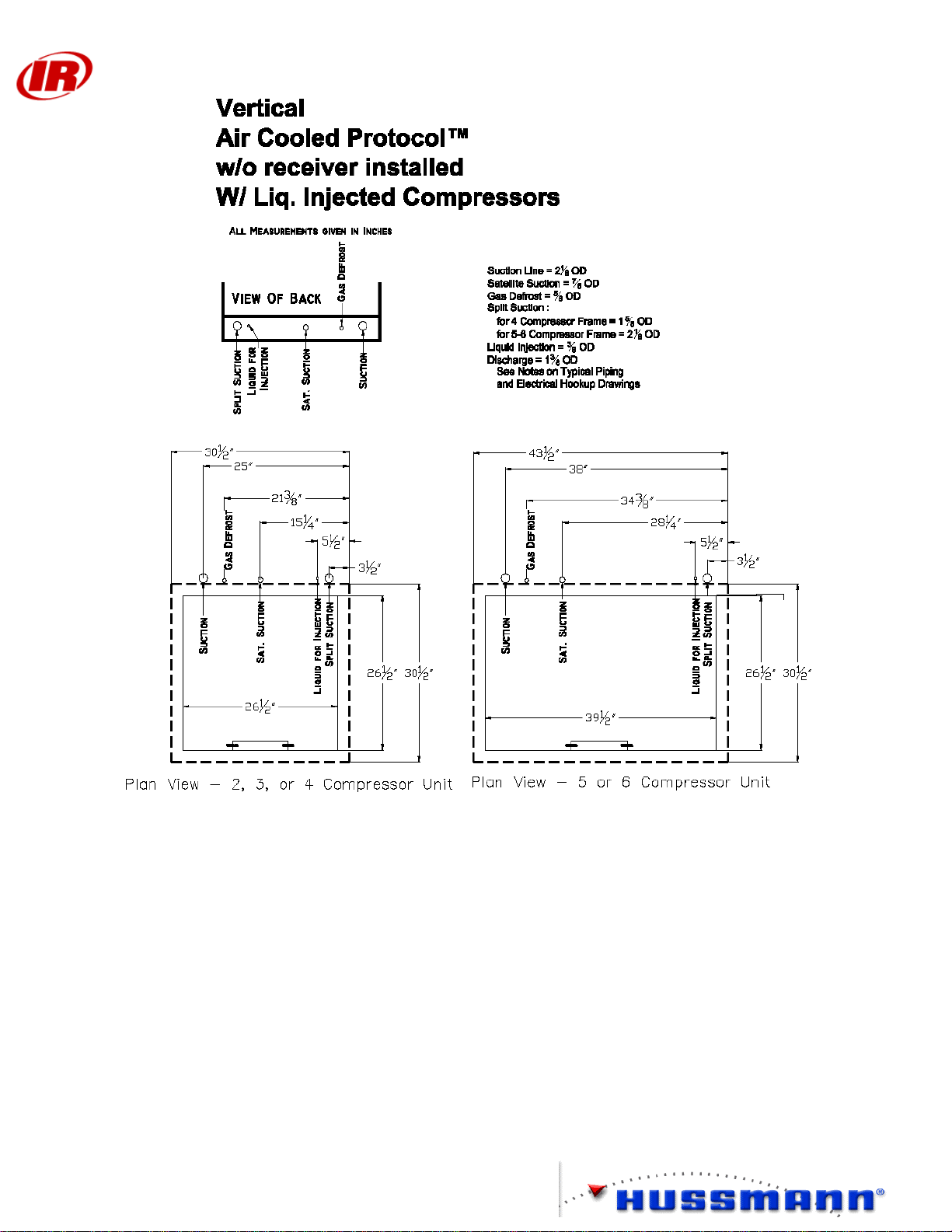

TYPICAL PIPING & ELECTRICAL HOOKUP

Vertical Units

Protocol™ Installation and

Service Manual

7

Page 12

Protocol™ Installation and

Service Manual

8

Page 13

Protocol™ Installation and

Service Manual

9

Page 14

Protocol™ Installation and

Service Manual

10

Page 15

Protocol™ Installation and

Service Manual

11

Page 16

Protocol™ Installation and

Service Manual

12

Page 17

Protocol™ Installation and

Service Manual

13

Page 18

Protocol™ Installation and

Service Manual

14

Page 19

Protocol™ Installation and

Service Manual

15

Page 20

Protocol™ Installation and

Service Manual

16

Page 21

Protocol™ Installation and

Service Manual

17

Page 22

Protocol™ Installation and

Service Manual

18

Page 23

Protocol™ Installation and

Service Manual

19

Page 24

Horizontal Units

Protocol™ Installation and

Service Manual

20

Page 25

Protocol™ Installation and

Service Manual

21

Page 26

Protocol™ Installation and

Service Manual

22

Page 27

Protocol™ Installation and

Service Manual

23

Page 28

Protocol™ Installation and

Service Manual

24

Page 29

Protocol™ Installation and

Service Manual

25

Page 30

Protocol™ Installation and

Service Manual

26

Page 31

Protocol™ Installation and

Service Manual

27

Page 32

Protocol™ Installation and

Service Manual

28

Page 33

Protocol™ Installation and

Service Manual

29

Page 34

Protocol™ Installation and

Service Manual

30

Page 35

Protocol™ Installation and

Service Manual

31

Page 36

Protocol™ Installation and

Service Manual

32

Page 37

Proto_Aire Units

Protocol™ Installation and

Service Manual

33

Page 38

Protocol™ Installation and

Service Manual

34

Page 39

Protocol™ Installation and

Service Manual

35

Page 40

Protocol™ Installation and

Service Manual

36

Page 41

Protocol™ Installation and

Service Manual

37

Page 42

Protocol™ Installation and

Service Manual

38

Page 43

Protocol™ Installation and

Service Manual

39

Page 44

Protocol™ Installation and

Service Manual

REFRIGERATION PIPING

Important: Since Hussmann has no direct control over the installation,

providing freeze-burst protection is the responsibility of the

installing contractor. Refer to Page 48

Always use a pressure regulator with a nitrogen tank. Do not exceed 2 pisg and

vent lines when brazing. Do not exceed 350 psig for leak testing high side. Do not

exceed 150 psig for leak testing low side.

Always recapture test charge in approved recovery vessel for recycling.

The Water Loop should be tested for leaks using pressurized water.

DO NOT exceed 75 psig at the lowest point in the piping.

Overview

This section details the major refrigeration components and their locations in each piping

system.

Refrigeration Line Piping

Use only clean, dehydrated, sealed refrigeration grade copper tubing. Use dry nitrogen in

the tubing during brazing to prevent the formation of copper oxide. All joints should be

made with silver alloy brazing material, and use 35% silver solder for dissimilar metals.

Liquid and suction lines must be free to expand and contract independently of each other.

Do not clamp or solder them together. Run supports must allow tubing to expand and

contract freely. Do not exceed 100 feet without a change of direction or an offset. Plan

proper pitching, expansion allowance, and P-traps at the base of all suction risers. Use long

radius elbows to reduce flow resistance and breakage. Avoid completely the use of 45°

elbows. Install service valves at several locations for ease of maintenance and reduction of

service costs. These must be UL approved for 450 psig minimum working pressure.

All Protocol™ units have one-inch drip pan at the bottom of the unit. DO NOT run piping

through the bottom of this pan.

Return Gas Superheat

Return gas superheat should be 10 to 30 °F on all units.

Suction Line

1. Install a downward slope in direction of flow. A P-trap is required for all vertical

risers.

2. Line may be reduced by one size after first third of case load and again after the

second third. Do not reduce below evaporator connection size.

3. Suction returns from evaporators must enter at the top of the line.

40

Page 45

Protocol™ Installation and

Service Manual

Liquid Line

1. Take-offs to evaporators must exit the bottom of the liquid line. Provide an

expansion loop for each evaporator take-off (minimum 3-inch diameter).

2. Offtime and Electric Defrost may be reduced by one size after one half the case

load. Do not reduce below evaporator connection size.

Refrigeration Cycle

Oil Return System Not shown

Beginning with Compressors, refrigerant vapor is compressed into the Discharge Header.

The Turba-Shed oil separator effectively divides the refrigerant from the lubricant in the

system. The lubricant is then returned to the compressors. The Condenser dissipates the

unwanted heat from the refrigerant into either a water/ glycol, or, air condenser depending

on the type used. The receiver acts as a vapor trap and supplies the Liquid Line with

quality liquid refrigerant. A Liquid Line Filter/Drier removes water and other

contaminants from the refrigerant. The liquid branch line supplies liquid refrigerant to the

Thermostatic Expansion Valve (TXV), which in turn feed refrigerant to the cases

(evaporator coils). These coils pick up heat from the product stored in the cases. A

Suction Filter removes system contaminants from return vapor, which is factory supplied

but field installed. It is also a good idea to install isolation valves for ease of service. The

oil return system is not shown in the following illustration.

Liquid Line

Case

Filter / Drier

Sight Glass

Receiver

Condenser

Case

Liquid Branch Line

Case

Case

Suction Line

Filter

Suction Branch Line

Discharge Header

Compressors

Suction Header

Turba-Shed

Oil Separator

41

Page 46

Protocol™ Installation and

Service Manual

Protocol™ with 3-Pipe Gas Defrost

Oil Return System Not shown

When 3-pipe gas defrost is used, hot gas is piped from the discharge line, after the oil

separator, to the cases. Solenoid valves are placed in both the suction and hot gas line so

that each system can be tuned on or off by the controller. Place a bypass line, with a check

valve ensuring that flow during defrost can bypass the TXV. A pressure differential

solenoid valve needs to be installed in the main liquid line to insure proper flow during

defrost. The pressure differential solenoid valve is factory installed in a vertical or

horizontal Protocol™. Ensure that during defrost no more than 45 lbs or 20% of the total

load is in defrost at any given time.

Liquid Line

Pressure

Differential

Solenoid Valve

Filter / Drier

Sight Glass

Receiver

Condenser

Liquid Branch Line

Case

Case

Case

Case

S

S

S

S

S

S

S

S

Suction Line

Filter

Hot Gas Line

Discharge Header

Compressors

Suction Header

Turba-Shed

Oil Separator

Check Valve

S

Solenoid Valve

42

Page 47

Protocol™ Installation and

Service Manual

Protocol™ with Heat Reclaim

Oil Return System Not shown

When heat reclaim (for water or air) is used with the Protocol™ a 3-Way Heat Reclaim

Valve should be installed after the oil separator. A bleed line should be installed from the

heat reclaim valve to the angle valve found in the suction header. A check valve is

installed in the heat reclaim return loop. This check valve ensures that back flow through

the heat reclaim coil is eliminated when heat reclaim is not used. Refer to specific

manufacturers guidelines for sizing reclaim coils. In the case of water heat reclaim, a 10#

check valve should be used to bypass the water tank in the case that the pressure drop

across the tank become excessive.

Liquid Line

Case

Filter / Drier

Sight Glass

Receiver

Condenser

Liquid Branch Line

Case

Case

Case

Suction

Filter

Suction Branch Line

Angle Valve

Heat

Reclaim

Coil

Discharge Header

Compressors

Suction Header

Check Valve

3-Way Heat Reclaim Valve

Turba-Shed

Oil Separator

Bleed Line

43

Page 48

Protocol™ Installation and

Service Manual

Protocol™ with Split Suction

Oil Return System Not shown

Split suction is used when two temperatures are required from the same Protocol™ unit. The use of split

suction allows for greater efficiency due to the fact that the compressors are operating closer to the desired

suction temperature.

Liquid Line

Filter / Drier

Receiver

Condenser

Liquid Branch Line

Case

Case

Case

Case

Suction

Filters

Suction Branch Line

Sight Glass

Discharge Header

Compressors

Turba-Shed

Oil Separator

Split Suction Headers

44

Page 49

Oil

Regulator

Protocol™ Installation and

Service Manual

Oil Cycle

Discharge refrigerant carries droplets of oil from the compressor’s outlet. The Turba-Shed

separates the oil from the refrigerant. The oil is stored in the Turba-shed until needed. The

oil returns to the system through the high-pressure line and oil filter.

The oil filter removes impurities from the oil. The high-pressure oil is distributed to the

electronic oil level control, which feeds oil into the compressor through a solenoid valve.

Electronic oil regulators monitor oil levels. The units are powered by a 24V power supply.

When the oil level in the compressor drops below ½ sightglass, the fill light comes on, and

the oil solenoid is energized. If after 90 seconds the oil level does not rise above ½

sightglass, the unit opens the compressor control circuit. If oil becomes available, the

electronic oil level control will automatically re-set and the compressor will resume

operation.

Discharge Header

Turba-Shed

Oil Separator

Oil Header

Suction Header

Oil

Filter

45

Page 50

Protocol™ Installation and

Service Manual

Liquid Injection

When operating at high compression ratios, injecting liquid partway through the

compression process is a method of cooling the scroll compressor. Hussmann applies

liquid injection on all units operating below 0 °F evaporating temperature, with the

exception of the Low-temp high efficiency Protocol™. Each compressor has its own

shutoff valve, injection solenoid valve, and supply hose. When the compressor is off, the

solenoid valve is de-energized via a current sensing relay mounted at the compressor

contactor.

Note: On units with remote air-cooled condensers, liquid refrigerant must be piped to the

liquid injection stub-out at the back of the Protocol™ unit.

Liquid Line

Filter / Drier

Receiver

Condenser

Liquid Branch Line

Case

Case

Case

Case

Suction Line

Filter

Sight Glass

Suction Branch Line

S

Liquid Injection

Header

S

Compressors

S

S

Turba-Shed

Oil Separator

Suction Header

46

Page 51

Protocol™ Installation and

Service Manual

Vapor Injection

Another method of cooling the scroll compressor is to use vapor injection. Vapor Injection

takes a small portion of liquid refrigerant from the main liquid line and runs it through a

thermostatic expansion valve and a heat exchanger, which helps to ensure vapor is sent to

the compressor as well as sub-cooling the main refrigerant before it goes to the TXV and

evaporator in the case.

Liquid Branch Line

Case

Case

Case

Case

Suction Line

Filter

Heat

Exchanger

Suction Branch Line

S

Liquid Line

F ilte r / Drie r

S Port

Sight Glass

V apor Injection

H eader

S

Receiver

S

S

Condenser

Tu rba-Shed

Compressors

Suction H eader

47

Oil Separator

Page 52

Protocol™ Installation and

Field Piping

Field Fabricated Headers are not required with Protocol™ Installations.

Example of Improper Field Piping

Protocol™

Produce Cases

Produce Islands

Produce Room

Service Manual

Produce Cases

Produce Islands

Example of Proper Field Piping

Protocol™

Produce Cases

Produce Room

Produce Islands

Produce Cases

Produce Islands

48

Page 53

Protocol™ Installation and

Service Manual

Water Loop Piping

Important: Since Hussmann has no direct control over the installation, providing

freeze-burst protection is the responsibility of the installing contractor. It is

mandatory that glycol be added to the water loop before startup to prevent

freezing. Use only non-ferrous metal or PVC for water loop piping.

The Water Loop should be tested for leaks using pressurized water.

DO NOT exceed 75 psig

Overview

This section details major water loop components, and their locations in the piping system.

Water Loop Guidelines

Pipe Connections

PVC Plastic pipe should be solvent welded (glued) together as described on the glue can.

Pipe Fittings must be clean and dry.

Cut Pipe with a guillotine type cutter to get a clean, square cut; remove any burrs.

Use Purple Primer on both pipe and fitting before gluing.

Apply glue to both pipe and fitting and join with a twisting motion.

Hold joint together for approximately 30 seconds to allow glue to set.

Allow to dry for 24 hours before putting in to service.

Where it is necessary to connect plastic and metal pipe. DO NOT USE A THREADED

CONNECTION. A compression type fitting should be used. For larger pipe sizes, a

flanged connection may be used.

Isolation Valves

Install isolation valves at inlet and outlet of each Protocol™ unit.

It is good practice to include isolation valves at several locations throughout the piping.

For example valves should be used where branches tie into main supply and return lines.

PVC plastic ball valves may be used.

Strainers

Use a 16-mesh strainer at inlet of each Protocol™ unit. Position isolation valves so that

this strainer can be opened for cleaning.

49

Page 54

Protocol™ Installation and

Service Manual

Air Vent Valves

Manual air vent valves are recommended. Air vent valves should be located at piping high

points where air will tend to collect. Momentarily open these vents and release trapped air

a few times during startup.

Tie-Ins to Supply Headers

Branch supply pipes SHOULD NOT tie into the bottom of main supply pipes. Always tie

into top of a main supply pipe; that is, the “T” fitting should point UP, NOT DOWN.

Pipe Supports

Pipe support should be provided as follows:

Nominal Pipe Size,

inches

1.0 4.5 3.5

1.5 5.0 3.5

2.0 5.0 4.0

3.0 6.0 4.5

4.0 6.5 5.0

6.0 7.5 6.0

Do not clamp supports tightly – this restricts axial movement of the pipe. Supports should

provide a smooth bearing surface that conforms to the bottom of the pipe, and should be a

minimum of 2 inches wide.

Exposure to Direct Sunlight

Piping that will be exposed to direct sunlight should be shaded or covered. A thin layer of

insulation is adequate for this.

Leak Check

Check for leaks in the piping before startup by filling with pressurized water at 50 psig.

Cleaning and Flushing

The pipe loop should be cleaned before the system is put into service. Fill the closed loop

with a solution of 1% trisodium phosphate and (99%) water, by weight.

Circulate the detergent/water solution for 24 hours.

Drain the loop and refill with fresh water. Circulate for at least 3 hours.

Drain and refill again. Repeat until all phosphate is gone.

Filling

The water loop MUST have adequate corrosion protection. In most situations, using fully

inhibited, industrial grade ethylene glycol or propylene glycol 30% by volume with water

Distance Between Supports,

feet

Schedule 40 Pipe @ 100 °F

Distance Between Supports,

feet

Schedule 80 Pipe @ 120 °F

50

Page 55

Protocol™ Installation and

Service Manual

can provide corrosion protection. For most installations, 30% glycol by volume will also

provide BURST protection to –20 °F.

If the store location has particularly hard water, with a total hardness greater than 100 ppm,

the water used to fill the loop should be softened or distilled. Local water treatment

vendors can provide information on local water quality.

If any Protocol™ unit has reverse cycle gas defrost, at least 30% glycol by volume MUST

be used to prevent condenser freezing.

Use only industrial grade, fully inhibited ethylene or propylene glycol such as Dow

Chemical’s Dowtherm SR-1 or Dowfrost. Consult local regulations as to which type –

ethylene or propylene – to use. Propylene glycol is generally considered non-toxic, while

ethylene glycol is somewhat toxic. DO NOT USE AUTOMOTIVE GRADE GLYCOL.

Use a refractometer to check the glycol concentration at least once a year.

The pumping station has a low fluid pressure switch set at roughly 10 to 20 psig, which

should be tied into an alarm. It is good practice to test the operation of this switch at least

once a year.

Balance Valve Adjustment

A flow balancing valve is located inside each Protocol™. These valves should be set at

startup using the following procedure.

Presetting The Flow Control (Balancing) Valve

(Bell & Grossett 1½ inch Circuit Setter)

51

Page 56

Protocol™ Installation and

Service Manual

Balancing the Water Loop

.

Balancing the Water Loop for Direct Return Piping

Several factors must be accounted for when balancing the water loop of a Protocol™

installation using direct return piping. Two major factors stand out:

1 – Balancing to attain the correct water flow for each Protocol™; and

2 – Balancing the system for Piping Head Loss.

Since these factors have nearly unlimited combinations, finding the appropriate setting for

each combination is unrealistic. However, if these factors are separated, their effect on the

system can easily be defined.

52

Page 57

Protocol™ Installation and

Service Manual

Balancing the Water Flow for Each Protocol™

If the store were designed so that each Protocol™ condenser was supplied from and

returned to a Very Large Box, and the piping to each condenser was identical; then flow

rate (GPM) would be proportional to the Degrees of Closure on each Circuit Setter.

53

Page 58

Very Large

Box

Protocol™ Installation and

Service Manual

Pump Station

Water Cooled Condenser

Very Large

Box

54

Page 59

Protocol™ Installation and

Service Manual

Balancing the System for Piping Head Loss

If the store were designed so that each Protocol™ condenser was identical; the flow rate

(GPM) for each condenser could be set from a simple table. Balancing Head Loss for

Length of Piping Run could be equated to Degrees of Closure on each Circuit Setter.

By accounting for Head Loss and Flow Rate (GPM) for each Protocol™ in a system, a

Preset Value for each Protocol™ unit’s Circuit Setter may be established.

Page 25 is a Preset Worksheet, which allows the installer to estimate the adjustments

required for the Circuit Setters. It is designed to provide a starting place. Since each

installation is unique, all Protocol™ units must be carefully monitored during store startup.

Once all Protocol™ units are running, the water loop must be checked, and final balancing

performed.

Table 1 shows a proportional Closure for the Circuit Setter based on Protocol™ GPM

requirements.

Table 1

GPM ° Closure GPM ° Closure GPM ° Closure

58 0 42 8 26 16

57 0 41 8 25 16

56 1 40 9 24 17

55 1 39 9 23 17

54 2 38 10 22 18

53 2 37 10 21 18

52 3 36 11 20 19

51 3 35 11 19 19

50 4 34 12 18 20

49 4 33 12 17 20

48 5 32 13 16 21

47 5 31 13 15 21

46 6 30 14 14 22

45 6 29 14 13 22

44 7 28 15 12 23

43 7 27 15

55

Page 60

Protocol™ Installation and

Service Manual

Table 2 shows a proportional Closure for the Circuit Setter based on Length of Piping Run.

Table 2

Length of Run ° Closure

1000 0

950 1

900 2

850 3

800 4

750 5

700 6

650 7

600 8

550 9

500 10

450 11

400 12

350 13

300 14

250 15

200 16

150 17

100 18

50 and below 19

56

Page 61

Protocol™ Installation and

Service Manual

Presetting the Degree of Closure

Look up flow rate (GPM) for each Protocol™. Find the closest GPM in Table 1. Log the

listed °Closure Value for each Protocol™ in the Table 1 Value row.

Establish Length of Run for each Protocol™. Find the closest Length of Run in Table 2.

Log the listed °Closure Value for each Protocol™ in the Table 2 value row.

Add the two values logged for each Protocol™.

Locate the lowest Total. Subtract it from each Protocol™ Unit’s Total, to get Presetting

°Closure.

Important Note: Length of Run includes both the supply and return piping.

Example

Protocol™ A B C D E F G H I

Table 1 Value

(+)

Table 2 Value 9 14 5 8 11 9 10 12 18

Total

(-)

Lowest Total

Presetting

°Closure

Protocol™

Table 1 Value

(+)

Table 2 Value

Total

(-)

Lowest Total

Presetting

°Closure

11 9 14 12 15 7 15 11 8

20 23 19 20 26

16 16 16 16 16 16 16 16 16

4 7 3 4 10 0 9 7 10

25 23 26

16

57

Page 62

Protocol™ Installation and

Service Manual

58

Page 63

Protocol™ Installation and

N

Service Manual

Electrical

Field Wiring

Maximum Field Wire Size

Based on the total load amperes, the largest connectable wire sizes for the terminals on the

convenience switch are listed below. (Wire size is based on the serial plate minimum

circuit ampacity.)

Total Connected

RLA

200 A (max) 3 /0 per Ø

400 A (max) 2 x (3 /0) per Ø

Refer to National Electric Code for temperature derating factors.

Sizing Wire and Overcurrent Protectors

Check the legend for Minimum Circuit Ampacity (MCA), Maximum Overcurrent

Protective Devices (MOPD), and total RLAs. Follow NEC guidelines.

ote: A convenience switch is provided as part of the unit. A Branch Circuit must

be built to the unit using information supplied on the unit data plate for Minimum

Current Ampacity (MCA) and Maximum Over Current Protective Device (MOPD).

Protocol™ components are wired as completely as possible at the factory with all work

completed in accordance with the National Electrical Code. All deviations required by

governing electrical codes will be the responsibility of the installer.

The lugs on the convenience switch in the convenience switch box are sized for copper

wire only, with 75 °C THW insulation. All wiring must be in compliance with governing

codes.

For 208-230/3/60 Compressor Units:

To each Protocol™ provide:

One 208-230/3/60 branch circuit

One 120/1/60 neutral

One ground wire to earth ground

For 380-460/3/60-50 Compressor Units with Remote Mounted Transformer:

To each Protocol™ provide

One 380-460/3/60-50 branch circuit

One ground wire to earth ground

To remote mounted transformer

One 380-460/1 or 3/60-50 branch circuit from Protocol™ Fuse Block

One ground wire to ground wire connection

From remote mounted transformer

Largest Connectable

Wire

59

Page 64

Protocol™ Installation and

Service Manual

One 240/1 or 3/60-50 connection to 240V convenience switch in panel

One derived neutral from transformer

For 380-460/3/60-50 Compressor Units without Remote Mounted Transformer:

To each Protocol™ provide

One 380-460/3/60-50 branch circuit

One ground wire to earth ground

One 208-240/1 or 3/60-50 branch circuit

One 120/1/60-50 neutral

For 575/3/60 Compressor units without Remote Mounted Transformer:

To each Protocol™ provide

One 575/3/60 branch circuit

One ground wire to earth ground

One 220/1/60 branch circuit

Consult factory for other voltages.

Alarm Wiring

Protocol™ provides one NO/NC pilot duty relay for remote alarm. The field connection

pins are located in the convenience switch panel.

Temperature Sensors and Defrost Termination Thermostats

Use shielded and grounded Belden Cable #8762, or equivalent, between control panel and

case sensors or thermostats.

Shielded cable must be used. The shield wire must be attached to the panel liner

on the control panel door.

Additional Circuits

Check the store legend for components requiring electrical circuits to the Control Panel and

Case Power Distribution Box. The Protocol™ can provide power for all case electrical

needs including:

Fan and Anti-sweat Heater Circuits

Satellite Control

Electrical Defrost Heaters

Case mounted refrigeration solenoid

Case Lighting

Unit Cooler Fan Power (electric defrost only)

Important

60

Page 65

Protocol™ Installation and

Service Manual

Evaporator Mounted Refrigeration Solenoid

Power for refrigeration solenoids at the evaporator comes from the Protocol™ case

electrical terminal pins located in the main control panel.

Cooler Door Switch Wiring

Check the store legend for door switch kits (M115 or M116). The switch is mounted to

the cooler doorframe, and controls the field installed liquid line solenoid and evaporator

fans. For Gas Defrost applications, M116 includes a check valve to bypass the liquid line

solenoid valve.

Panel Voltages

The Protocol™ Control Panels contain voltages:

24V PC Board, POWERLINK™

Control Circuits

Electronic oil level control

120V

208/230V

380V

460V or 575V Power Supply Circuits

Control Circuits

and

61

Page 66

Protocol™ Installation and

Service Manual

NOTE: The current draw required by an analog meter (Volt-Ohm Meters or VOMs)

can permanently damage electronic equipment. Never use a VOM to check computer

components or computer controlled systems. Use a Digital Multimeter (DMM) to measure

voltage, amperage, milliamperes, or ohms. If a range is exceeded the display will show OL

(overload).

Alarm LEDs

One exterior and one interior Alarm LED assist in preliminary troubleshooting.

Alarm Light on

Control Board

ON

OFF

OFF

ON

Alarm Relay

Light

ON

ON

OFF

ON

Exterior

Alarm Light

OFF

OFF

ON

ON

Condition

Okay

Monitoring

Alarm

Switchback

Compressor

Safeties Failed

62

Page 67

Protocol™ Installation and

Service Manual

Typical wiring diagram for Temperature Sensor and Klixon wiring.

Individual wiring may vary.

See page 102 for details on control types.

63

Page 68

Electrical Legend

Protocol™ Installation and

Service Manual

64

Page 69

Main Power Wiring

208V Two Wide Protocol™

Protocol™ Installation and

Service Manual

65

Page 70

208V 5 or 6 Compressor Protocol™

Protocol™ Installation and

Service Manual

66

Page 71

460V Two Wide Protocol™

Protocol™ Installation and

Service Manual

67

Page 72

460V 5 or 6 Compressor Protocol™

Protocol™ Installation and

Service Manual

68

Page 73

460V Two Wide Protocol with Factory installed transformer

Protocol™ Installation and

Service Manual

69

Page 74

460V Two Wide Protocol™ with Field supplied transformer

Protocol™ Installation and

Service Manual

70

Page 75

Protocol™ Installation and

460V 5 or 6 Compressor Protocol™ with Field supplied transformer

Service Manual

71

Page 76

600V Two Wide Protocol™

Protocol™ Installation and

Service Manual

72

Page 77

600V 5 or 6 Compressor Protocol™

Protocol™ Installation and

Service Manual

73

Page 78

600V Two Wide Protocol™ with Field supplied transformer

Protocol™ Installation and

Service Manual

74

Page 79

Protocol™ Installation and

Service Manual

Terminal Connections

Protocol™ units carrying 5 and 6 compressors, or an oversized Control Panel, do not use a

single-phase bussbar. Wire number assignments and corresponding terminal number

assignments in the Power Distribution Box differ from the smaller panel arrangement.

120V Circuit Logic

The Protocol™ includes as standard the following 120V components:

Service Receptacle (5 Amp Max)

Cabinet Exhaust Fan

120V by 24V Transformer

Compressor Contactor Coils

Valve Solenoids

External Alarm Light

24V Circuits

The printed circuit control boards with attached relay coils are 24V. The

POWERLINKS™ are powered by a 24V DC supply (used to control electric defrost

heaters). Each POWERLINK™ power supply will drive up to 5 POWERLINKS™ at

once, and require 2 seconds to recharge an internal DC capacitor between operations. If the

POWERLINK™ power supply fails, a transformer will NOT replace it.

Electronic Oil Level Control

A 24V transformer powers the electronic oil level control. All circuit logic including oil

solenoid control is 24 volt. Only the alarm contact is 120V. See next two pages for typical

wiring diagrams.

75

Page 80

Protocol™ Installation and

Service Manual

Satellite Short Cycle Control Relay

The Satellite short cycle control relay is intended to prevent rapid cycling when the

compressor goes into pumpdown mode. It is a single-shot time-delay relay. When the low

pressure control opens on a decrease in pressure, the short cycle control relay becomes

energized and starts timing. After 3 minutes (regardless of the action of the low pressure

control) this relay will close, thereby re-engaging the control circuit and allowing the

compressor to run again.

76

Page 81

Control and Compressor Wiring

PCS without Vapor Wiring

Protocol™ Installation and

Service Manual

77

Page 82

PCS with Vapor Wiring

Protocol™ Installation and

Service Manual

78

Page 83

CPC, Danfoss, Comtrol without Vapor Wiring

Protocol™ Installation and

Service Manual

79

Page 84

CPC, Danfoss, Comtrol with Vapor Wiring

Protocol™ Installation and

Service Manual

80

Page 85

Controller Wiring

PCS

Protocol™ Installation and

Service Manual

81

Page 86

CPC

Protocol™ Installation and

Service Manual

82

Page 87

CPC Einstein

Protocol™ Installation and

Service Manual

83

Page 88

Danfoss

Protocol™ Installation and

Service Manual

84

Page 89

Comtrol

Protocol™ Installation and

Service Manual

85

Page 90

Protocol™ Installation and

Service Manual

Liquid Injection

When operating at high compression ratios, injecting liquid partway through the

compression process is a method of cooling the scroll compressor. Hussmann applies

liquid injection on all units below 0 °F evaporating temperature. Each compressor has its

own Direct Thermal Control (DTC) valve, which is an all-in-one injection solenoid that

allows for a more energy efficient use of liquid.

Note: On units with remote air-cooled condensers, liquid refrigerant must be piped to the

liquid injection header inside the Protocol™ unit.

Vapor Injection

Another method of cooling compressors is to use vapor injection. The Protocol High

Efficiency (HE) series incorporates vapor injected (ZFKV) scroll compressors for low

temperature applications, and the ZBKCE series of scroll compressors for medium

temperature. The Protocol High Efficiency series systems are designed specifically for

R404A/R507 HFC refrigerants. When compared to the standard Protocol low temperature

unit at typical design conditions, the HE series has 40 % more capacity and has a 20%

improvement in EER. This is accomplished by the economizer cycle, which sub cools

liquid refrigerant through a heat exchanger and injects vapor via a port on the compressor

at a "mid-pocket" interstage pressure. The HE series is available in horizontal units and 3

wide vertical frame units with air or water cooled options. However when selecting

horizontal models, they MUST BE accessible from the Top. When sizing EVI Low Temp

compressors, DO NOT EXCEED 85% of capacity rating. Also Liquid Lines MUST BE

INSULATED.

Protocol HE horizontal units must be accessible from the top. The economizer system is

pre-installed on every Protocol HE unit. Factory settings for the EPR between the heat

exchanger and compressor injection ports in the system are the following:

R404A R507

77.0 psi 80 psi

However field adjustments of the EPR may be required at a later date, therefore horizontal

units must be accessible from the top.

The expansion valve in the economizer loop may also need to be adjusted once the system

is operating. Settings need to maintain approximately a 10 °F superheat after the heat

exchanger.

The subcooled liquid to the cases is designed to be approximately 50 °F leaving the heat

exchanger when vapor injection is activated. When liquid temperatures entering the

subcooler fall to 55 °F, the T-STAT control in the unit will open and will de-energize the

solenoid ahead of the expansion valve, thus disabling vapor injection. The T-STAT control

86

Page 91

Protocol™ Installation and

Service Manual

will re-energize the solenoid when the condensing temperature reaches 65 °F. Consult

Engineering representative if adjustment of the T-STAT control is required.

FIELD PIPING & TXV SIZING

Besides standard discharge lines, the liquid return line from the condenser must also be

piped back to the unit when remote air-cooled units are used with low temp cases.

If the unit has low and medium temp suction groups, the protocol unit will have TWO

liquid lines leaving the unit- one for medium temp cases and one for low temp cases.

Only the liquid to the low temp cases will be subcooled to 50 °F. The liquid to the

medium temp cases will be at the condensing temperature.

Units with low temp ZFKV compressors must insulate the liquid line to the low temp

cases/walk-ins coolers since the refrigerant is at a subcooled temperature. Also, suction

line sizing should take into account the lower liquid temperature.

When expansion valves are selected for the cases, they should be sized for a liquid

temperature of 50 °F due to subcooling.

SERVICE

There is a shut off valve before the TXV for service of solenoids, the TXV, or the EPR in

the Low Temp economizer loop. Shut off valves are also present at each compressor

injection port.

87

Page 92

Protocol™ Installation and

Service Manual

Defrost Schedule

Refrigeration Circuit Control

The following circuits show the electrical connections during the refrigeration cycle.

Power comes into the control board from X1A. The refrigeration solenoid valve and

thermostat (if needed) are wired to the terminal pin. The unit cooler circuit is the same as a

simple refrigeration circuit but it has an additional fan control circuit. The fan control

circuit ensures that the fans will not turn on during the defrost cycle. It should be noted

that off time defrost is achieved by turning the refrigeration valve off. For unit cooler fan

wiring see page 87.

Defrost Circuit Control

Off time Sequence of Operation

Control Board energizes the Defrost Board Relay Coil, which open the Main Liquid Line

Solenoid circuit.

Main Liquid Line Valve closes. As evaporators empty, the compressors cycle off on Low

Pressure.

Defrost my be time or temperature terminated.

88

Page 93

Protocol™ Installation and

Service Manual

Hot Gas

Control Board energizes the Aux Relay Coil, which de-energizes the Main Liquid Line

Pressure Differential Solenoid. The valve reduces liquid supply line pressure. The Control

Board also energizes the Defrost Relay coil, which open Hot Gas Solenoid valves and

closes the Suction Solenoid valves. Each case terminates defrost through individual defrost

termination thermostats, and goes into drip cycle until branch is timed off by the Control

Board.

Note: Only 20% of the cases may be defrosted at once because of the requirement to keep

a refrigeration load on the compressors to provide gas for defrost.

Electric Defrost

Control Board locks out certain compressors to cover heater Amp draw. Control Board

energizes two Defrost Board Relay Coils for each Defrost Circuit:

1) The first closes the POWERLINK™

2) The second opens the Electric Heaters are energized. Branch Liquid Line

Valve closes. Compressors not locked out maintain case refrigeration for

units not in defrost. Defrost is temperature terminated.

3) See POWERLINK™ operation diagram on Page 97. See Page 105 for

further information on defrost operation.

89

Page 94

Protocol™ Installation and

Service Manual

Special Case of Heat Reclaim with Hot Gas Defrost

When you have the special case of heat reclaim with hot gas it is necessary to interlock the

Main Liquid Line solenoid wiring with the heat reclaim valve wiring. This wiring will

ensure that heat reclaim does not take place while defrost is occurring.

90

Page 95

Protocol™ Installation and

Service Manual

Lighting Control

Control Board energizes one output relay for each lighting circuit (PCO control can have

up to two lighting circuits.) Each lighting circuit has a schedule which determines when

the output is turned on and when the output turns off.

91

Page 96

Protocol™ Installation and

Service Manual

Unit Cooler Fan Wiring

The following drawing shows the wiring to control the fans in a unit cooler.

Defrost termination by klixon may connect back to the controller relay board based on

individual customer specs. See job specific board layout sheets and wiring diagrams for

your individual installation.

92

Page 97

Protocol™ Installation and

Service Manual

Protocol™ Remote Condenser Fan Wiring

The installer must wire the condenser fan to the terminal pin that corresponds to the correct

board point in order to ensure proper control of the condenser fans. The following diagram

shows the wiring for a typical Protocol™ with a remote condenser.

In the event that the condenser is ordered with control boards attached, these boards must

be connected back to the controller with communication cable in a manner appropriate for

the individual controller. The board addressing and the controller program should be

checked to verify that the boards are addressed correctly and the controller is programmed

to recognize the boards and control the condenser through them.

93

Page 98

Protocol™ Installation and

Service Manual

Proto-Aire™ Fan Wiring

The following diagram shows the fan electrical wiring present in a Proto-Aire™. At the

bottom of the diagram the receiver and crankcase heaters are shown, which are common to

each type of Proto-Aire™.

94

Page 99

Protocol™ Installation and

Service Manual

95

Page 100

Protocol™ Installation and

Service Manual

96

Loading...

Loading...