Page 1

Protocol Control System (PCS) Users Manual

Document No 0709304

Date: 5/17/2005

Page 2

1. Table of Contents

TABLE OF CONTENTS......................................2

1.

2. TABLE OF FIGURES..........................................4

3. DISCLAIMER.......................................................6

4. INTRODUCTION.................................................7

4.1 ORGANIZATION ................................................7

5. PCS HARDWARE................................................8

5.1 PCS CONTROLLER ...........................................8

5.1.1 Input Power.............................................8

5.1.2 Display Contrast Adjust ..........................8

5.1.3 Status LEDs.............................................8

5.1.4 DIP Switches ...........................................8

5.1.5 Mounting .................................................9

5.1.6 Fuse.........................................................9

5.1.7 Controller Wiring....................................9

5.2 PCS EXPANSION BOARD..................................9

5.2.1 Input Power...........................................10

5.2.2 Mounting ...............................................10

5.2.3 Fuse.......................................................10

5.2.4 Expansion Board Wiring.......................10

5.3 PRESSURE TRANSDUCER ................................10

5.4 TEMPERATURE SENSOR..................................11

5.5 FIELD WIRING.................................................11

6. PCS FEATURES.................................................12

6.1 OVERVIEW .....................................................12

6.1.1 Circuit Control......................................12

6.1.2 Suction Pressure Control.......................12

6.1.3 Lighting Control....................................12

6.1.4 Discharge Pressure Control..................12

6.1.5 Alarms ...................................................12

6.1.6 Maintenance/Diagnostics......................13

7. QUICK START...................................................14

7.1.1 Display and Keypad ..............................14

7.1.2 Login......................................................14

7.1.3 Main Status Screen................................15

7.1.4 Configuration Screens...........................15

7.1.5 Viewing/Changing Suction Pressure

Setpoint 15

7.1.6 Viewing Circuit Temperatures...............16

7.1.7 Viewing/Changing Circuit Temperature

Setpoint 16

7.1.8 Determining if a Circuit is in Defrost....16

7.1.9 Forcing a Defrost..................................17

7.1.10 Alarms ...................................................17

8. CONTROLLER OPERATION......................... 19

8.1 CIRCUIT CONTROL......................................... 19

8.1.1 Defrost.................................................. 19

8.2 PRESSURE CONTROL...................................... 19

8.2.1 Switchback............................................ 19

8.2.2 Pressure Control Algorithm.................. 19

8.3 CONDENSER CONTROL .................................. 20

8.4 MENU STRUCTURE ........................................ 20

8.4.1 Status Screens....................................... 20

8.4.2 Configuration Screens .......................... 20

8.4.3 Maintenance Screens............................ 20

8.4.4 Alarm Screen ........................................ 21

8.4.5 Screen Navigation................................. 21

8.5 SCREENS........................................................ 21

8.5.1 Status Screens....................................... 21

8.5.2 Configuration Screens .......................... 22

8.5.3 Alarms................................................... 32

8.5.4 Maintenance ......................................... 32

9. PUMP STATION................................................ 33

9.1 OVERVIEW..................................................... 33

9.2 HARDWARE ................................................... 33

9.3 OPERATION ................................................... 33

9.3.1 Pump Motor.......................................... 33

9.3.2 Fluid Cooler.......................................... 33

9.4 SCREENS........................................................ 34

9.4.1 Status Screens....................................... 34

9.4.2 Configuration Screens .......................... 34

9.5 ALARMS ........................................................ 37

9.5.1 Controller Reboot................................. 37

9.5.2 Spray Pump Fail................................... 37

9.5.3 Low Speed Fan ..................................... 37

9.5.4 High Speed Fan .................................... 37

9.5.5 Pump 1.................................................. 37

9.5.6 Pump 2.................................................. 37

9.5.7 High Discharge Pressure...................... 37

9.5.8 Low Discharge Pressure....................... 37

9.5.9 Pressure Sensor Fail............................. 37

9.5.10 Inlet Temp probe Fail........................... 37

9.5.11 Outlet Temp probe Fail......................... 37

9.5.12 Ambient Temp Fail ............................... 38

9.5.13 Alarm Winter Override......................... 38

10. SUPERVISORY SYSTEM............................ 39

10.1 OVERVIEW..................................................... 39

10.2 SUPERVISORY CONNECTION WIRING............. 39

10.3 REQUIREMENTS............................................. 39

10.4 SOFTWARE INSTALLATION ............................ 39

10.5 HARDWARE INSTALLATION........................... 40

10.5.1 RS485 Adapter...................................... 40

10.5.2 PlantVisor Software Key....................... 40

10.6 REMOTE ACCESS ........................................... 41

10.7 OPERATION ................................................... 41

10.7.1 Running the PCS Supervisor................. 41

10.7.2 Navigation ............................................ 42

Page 3

Protocol Control System Users Manual 2/12/01

10.7.3

Configuration ........................................42

10.8 RUNNING THE SYSTEM...................................46

10.8.1 Troubleshooting.....................................46

10.9 PCS SUPERVISORY SYSTEM SCREENS............46

10.9.1 General Information..............................46

10.9.2 PlantVisor Engine Screens....................46

10.9.3 Supervisory Main Screen.......................47

10.9.4 Unit Main Screen...................................47

10.9.5 System Setup..........................................48

10.9.6 Suction Group/Compressor Setup.........49

10.9.7 Aux Control and Temperature Monitor.49

10.9.8 Light Ckt................................................49

10.9.9 Info ........................................................50

10.9.10 Circuits..............................................50

10.9.11 Alarms ...............................................51

11. APPENDIX A- SUPERVISORY WIRING...53

12. APPENDIX B- TROUBLESHOOTING.......54

12.1 PCS TROUBLESHOOTING ...............................54

12.2 SUPERVISORY SYSTEM TROUBLESHOOTING...54

Page 3

Page 4

Protocol Control System Users Manual 2/12/01

Figure 53- Suction Configuration Screen 2.................. 29

2. Table of Figures

Figure 1- PCS Controller.................................................8

Figure 2- Controller Wiring ............................................9

Figure 3 - PCS Expansion Board...................................10

Figure 4- Expansion Board Wiring............................... 10

Figure 5- PCS Pressure Probe.......................................11

Figure 6- PCS Temperature Probe ................................11

Figure 7- Controller Display .........................................14

Figure 8- Password Screen............................................15

Figure 9- Main Status Screen........................................15

Figure 10- Suction Group Configuration Screen...........15

Figure 11- Circuit Configuration Screen.......................16

Figure 12- Temp Setpoint Configuration Screen...........16

Figure 13- Circuit Maintenance Screen.........................17

Figure 14- Alarm Log Screen........................................17

Figure 15- Alarm Maintenance Screen..........................17

Figure 16- Alarm Confirmation Screen.........................18

Figure 17-Equal Horsepower Example.........................19

Figure 18 - PCS Menu Tree ..........................................20

Figure 19- Main Status Screen......................................21

Figure 20- Lighting Status Screen.................................22

Figure 21- Lighting Status Fields..................................22

Figure 22- Aux Processing Status Screen......................22

Figure 23- System Status Screen...................................22

Figure 24- System Configuration Screen 1...................22

Figure 25- System Configuration Screen 2...................23

Figure 26- System Configuration Screen 3...................23

Figure 27- System Configuration Screen 4...................23

Figure 28- System Configuration Screen 5...................23

Figure 29- System Configuration Screen 6...................24

Figure 30- System Configuration Screen 7...................24

Figure 31- System Configuration Screen 8...................24

Figure 32- System Configuration Screen 9...................24

Figure 33- System Configuration Screen 10.................24

Figure 34- System Configuration Screen 11.................25

Figure 35 - System Configuration Screen 12................25

Figure 36- System Configuration Screen 13.................25

Figure 37- Circuit Configuration Screen 1....................25

Figure 38- Circuit Configuration Screen 2....................25

Figure 39- Circuit Configuration Screen 3....................26

Figure 40- Circuit Configuration Screen 5....................26

Figure 41- Circuit Configuration Screen 6....................26

Figure 42- Circuit Configuration Screen 7....................26

Figure 43- Circuit Configuration Screen 8....................27

Figure 44- Circuit Configuration Screen 9....................27

Figure 45- Circuit Configuration Screen 10..................27

Figure 46- Circuit Configuration Screen 11..................27

Figure 47- Circuit Configuration Screen 12..................27

Figure 48- Circuit Configuration Screen 13..................28

Figure 49- Circuit Configuration Screen 14..................28

Figure 50- Circuit Configuration Screen 15..................28

Figure 51- Copy Circuit Configuration Screen .............28

Figure 52- Suction Configuration Screen 1...................29

Figure 54- Suction Configuration Screen 3.................. 29

Figure 55- Suction Configuration Screen 5.................. 29

Figure 56- Suction Configuration Screen 6.................. 29

Figure 57- Suction Configuration Screen 7.................. 30

Figure 58- Discharge Configuration Screen................. 30

Figure 59- Lighting Configuration Screen 1................. 30

Figure 60- Lighting Configuration Screen 2................. 30

Figure 61- Lighting Configuration Screen 2A.............. 30

Figure 62- Lighting Configuration Screen 3................. 30

Figure 63- Lighting Configuration Screen 4................. 31

Figure 64- Aux Configuration Screen 1 ....................... 31

Figure 65- Aux Configuration Screen 2 ....................... 31

Figure 66- Aux Configuration Screen 3 ....................... 31

Figure 67- Aux Configuration Screen 4 ....................... 32

Figure 68- Release Configuration Screen..................... 32

Figure 69- Suction Group Maintenance Screen 1......... 32

Figure 70- Suction Group Maintenance Screen 2......... 32

Figure 71- PSC Main Status Screen ............................. 34

Figure 72- PSC Pump Status Screen.............................34

Figure 73- PSC Pump Date/Time Screen..................... 34

Figure 74- PSC Release Screen.................................... 34

Figure 75- PSC Password Screen................................. 35

Figure 76- PSC Configuration Screen 1....................... 35

Figure 77- PSC Configuration Screen 2....................... 35

Figure 78- PSC Configuration Screen 3....................... 35

Figure 79- PSC Configuration Screen 4....................... 35

Figure 80- PSC Configuration Screen 5....................... 35

Figure 81- PSC Configuration Screen 6....................... 36

Figure 82- PSC Configuration Screen 7....................... 36

Figure 83- PSC Configuration Screen 8....................... 36

Figure 84- PSC Configuration Screen 9....................... 36

Figure 85- PSC Configuration Screen 10..................... 37

Figure 86- PSC Configuration Screen 11..................... 37

Figure 87- PSC Alarm Screen ...................................... 38

Figure 88- Installation Screen....................................... 39

Figure 89- RS485 Adapter............................................ 40

Figure 90- PlantVisor Software Key ............................ 40

Figure 91- PlantVisor Engine Demo Mode.................. 41

Figure 92- Plantvisor Engine Screen............................ 41

Figure 93- Logon Screen.............................................. 41

Figure 94- Main Screen................................................ 42

Figure 95- Navigation Examples.................................. 42

Figure 96- Network Management Screen.....................42

Figure 97- Site Configuration Screen........................... 43

Figure 98- Serial Line Configuration Screen................ 43

Figure 99- Modem Setup Screen.................................. 43

Figure 100- User Configuration Screen........................ 44

Figure 101- Add New User Screen............................... 45

Figure 102- Scheduler Configuration Screen ............... 45

Figure 103- Alarm Priorities Screen............................. 45

Figure 104- Device Alarm Settings.............................. 46

Figure 105- PlantVisor Engine Screen ......................... 47

Figure 106- PlantVisor Engine Detail Screen............... 47

Figure 107- PlantVisor Engine Close Screen............... 47

Figure 108- Supervisory Main Screen.......................... 47

Page 4

Page 5

Protocol Control System Users Manual 2/12/01

Figure 109- Unit Main Screen- No Alarms...................48

Figure 110- Main Screen With Alarms.........................48

Figure 111- System Setup Screen..................................49

Figure 112- Suction Group/Compressor Setup Screen..49

Figure 113- Pressure Graph...........................................49

Figure 114- Supervisory Temperature Monitor and Aux

Control Screen.......................................................49

Figure 115- Lighting Circuit Screen..............................50

Figure 116- Information Screen....................................50

Figure 117- Circuit Setup Screen..................................50

Figure 118- Defrost Setup Screen .................................51

Figure 119- Circuit Temperature Graph........................51

Figure 120- Case Size Screen........................................51

Figure 121- Case Type Screen ......................................51

Figure 122- Supervisory Alarms Screen .......................52

Figure 123 - Supervisory Wiring...................................53

Page 5

Page 6

Protocol Control System Users Manual 2/12/01

3. Disclaimer

ALL RIGHTS RESERVED

The information contained in this manual has been

carefully checked and it believed to be accurate.

However, Computer Process Controls, Inc. assumes no

responsibility for any inaccuracies that may be contained

herein. In no event will Computer Process Controls, Inc.

be liable for any direct, indirect, special, incidental or

consequential damages resulting from any defect or

omission in this manual, even if advised of the

possibility of such damages. In the interested of

continued product development, Computer Process

Controls, Inc. Reserves the right to make improvements

to this manual, and the products described herein, at any

time without notice or obligation.

Page 6

Page 7

Protocol Control System Users Manual 2/12/01

4. Introduction

This document describes the Protocol Control System

(PCS). The PCS is an electronic control system designed

specifically to control all functions of the Protocol

Refrigeration System.

4.1 Organization

This document is organized into a number of sections.

The first section is an overview of the hardware. A

“quick start” section is included next to enable users to

quickly get a minimum amount of information needed to

start using the controller. A detailed section follows.

The last section describes the PCS supervisory system.

It is recommended that the user familiarize himself with

the PCS system by reading all sections of this manual

before operation.

Page 7

Page 8

Protocol Control System Users Manual 2/12/01

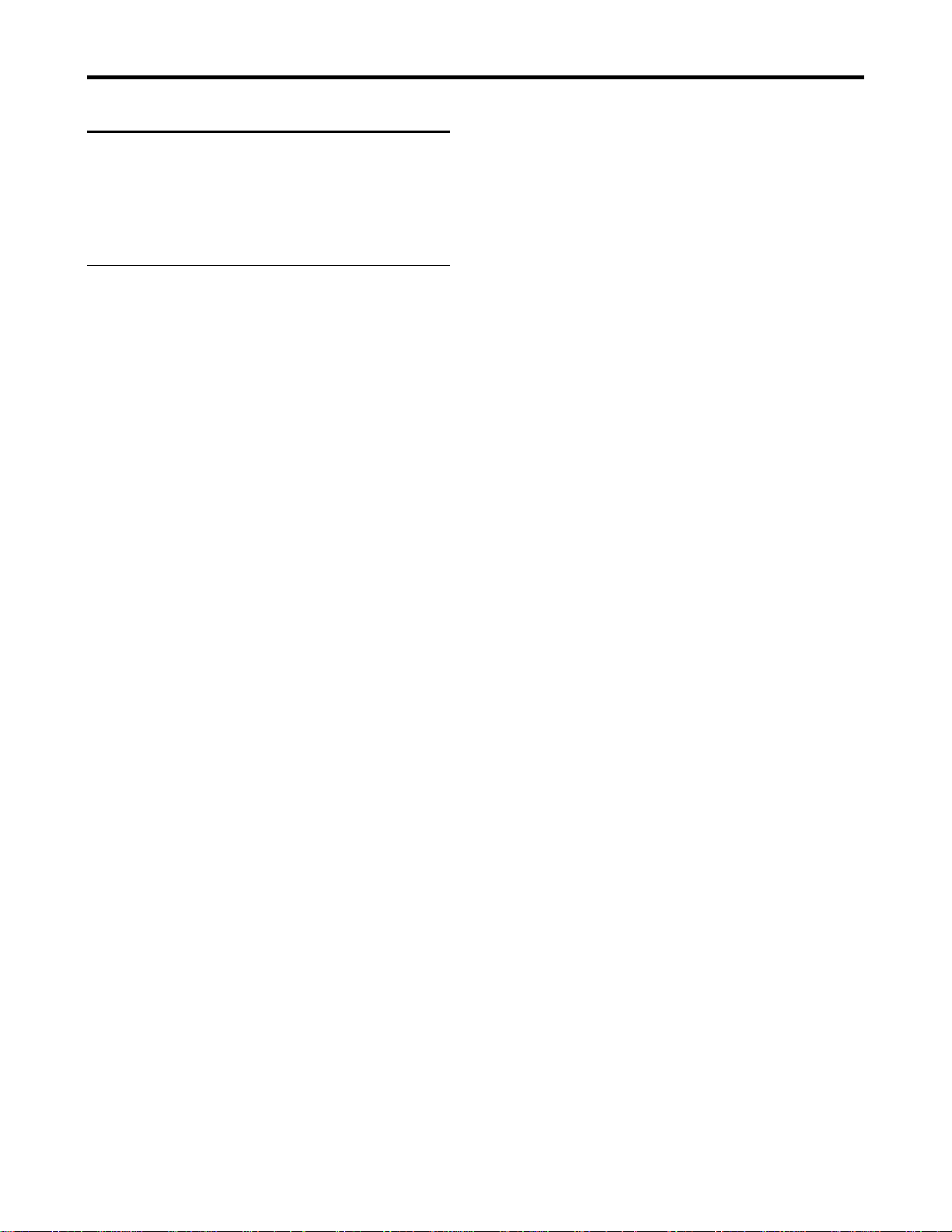

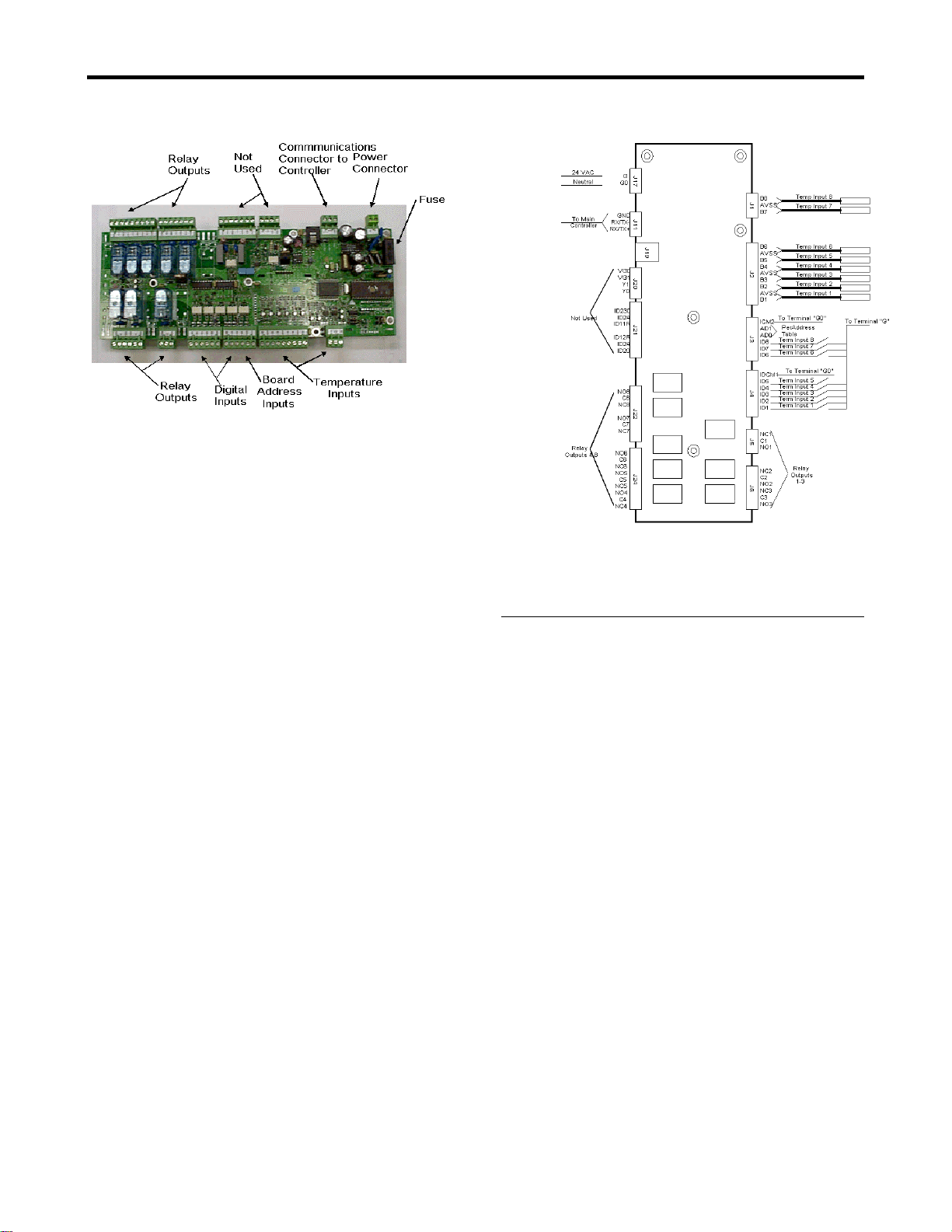

Figure 1- PCS Controller

5. PCS Hardware

The following are components of the PCS system.

1) PCS Controller

2) PCS Expansion Board

3) PCS Pressure Transducer

4) PCS Temperature Probes

This document describes the elements of the PCS

components. The schematics included with each

Protocol Refrigeration System detail the connections that

are made to the components. Refer to the schematics for

connection details.

WARNING: The Controller and Expansion board use

low voltage (24 VAC) power. However, both units have

high voltage loads connected to them. Extreme caution

should be used when servicing these units. Failure to

observe caution could lead to injury or death.

5.1.1 Input Power

The Controller uses 24 VAC (+/-15%, 50/60

Hz) (Class II) power at 50 VA.

5.1 PCS Controller

The PCS Controller is a microprocessor based system

that contains a built in display, keypad and I/O (relays

termperature inputs, pressure inputs and digital inputs).

It serves as the user interface and runs the algorithms that

control the protocol refrigeration system. Additional I/O

(relays, digital inputs and temperature inputs) can be

added using the PCS Expansion Board. The controller

contains all the I/O for all compressors in the Protocol

refrigeration system.

The temperature inputs must use the PCS temperature

sensors (described below) and the pressure inputs must

use the PCS pressure probes (described below).

Figure 1 shows a picture of the PCS Controller and

identifies the different parts of the Controller.

5.1.2 Display Contrast Adjust

The contrast of the display can be adjusted by

pressing and holding the ENTER and ESC keys

together and pressing the UP ARROW key to

increase the contrast or the DOWN ARROW

key to decrease the contrast. Refer to

paragraph 7.1.1 for an explanation of how to

identify the keys.

5.1.3 Status LEDs

There are two LED’s on the Controller that

indicate power status. If the Yellow LED is ON

this indicates that the unit is getting power. If it

is OFF, there is either no power to the unit or

the fuse is blown. The Red LED indicates the

status of the Pressure probe power output

(Connector J2 , terminals GND and +VDC). If

the Red LED is ON, there is a fault in the probe

supply. Most likely, the pressure probe is bad

or there is a short in the cable.

5.1.4 DIP Switches

Page 8

The DIP Switches on the controller should

always be in the down (OFF) position.

Page 9

Protocol Control System Users Manual 2/12/01

5.1.5 Mounting

The Controller is mounted via Din rail mount.

The Controller can be removed from the

mounting by carefully pulling on the 3 small

tabs on the bottom of the controller and rotating

the Controller up. All connectors should be

removed from the unit before removing the

Controller from the mounting.

5.1.6 Fuse

The Controller has an internal fuse. If the

Controller will not power up and you have

verified that the controller is getting input

power, you should replace the fuse. Always

replace with the same type of fuse.

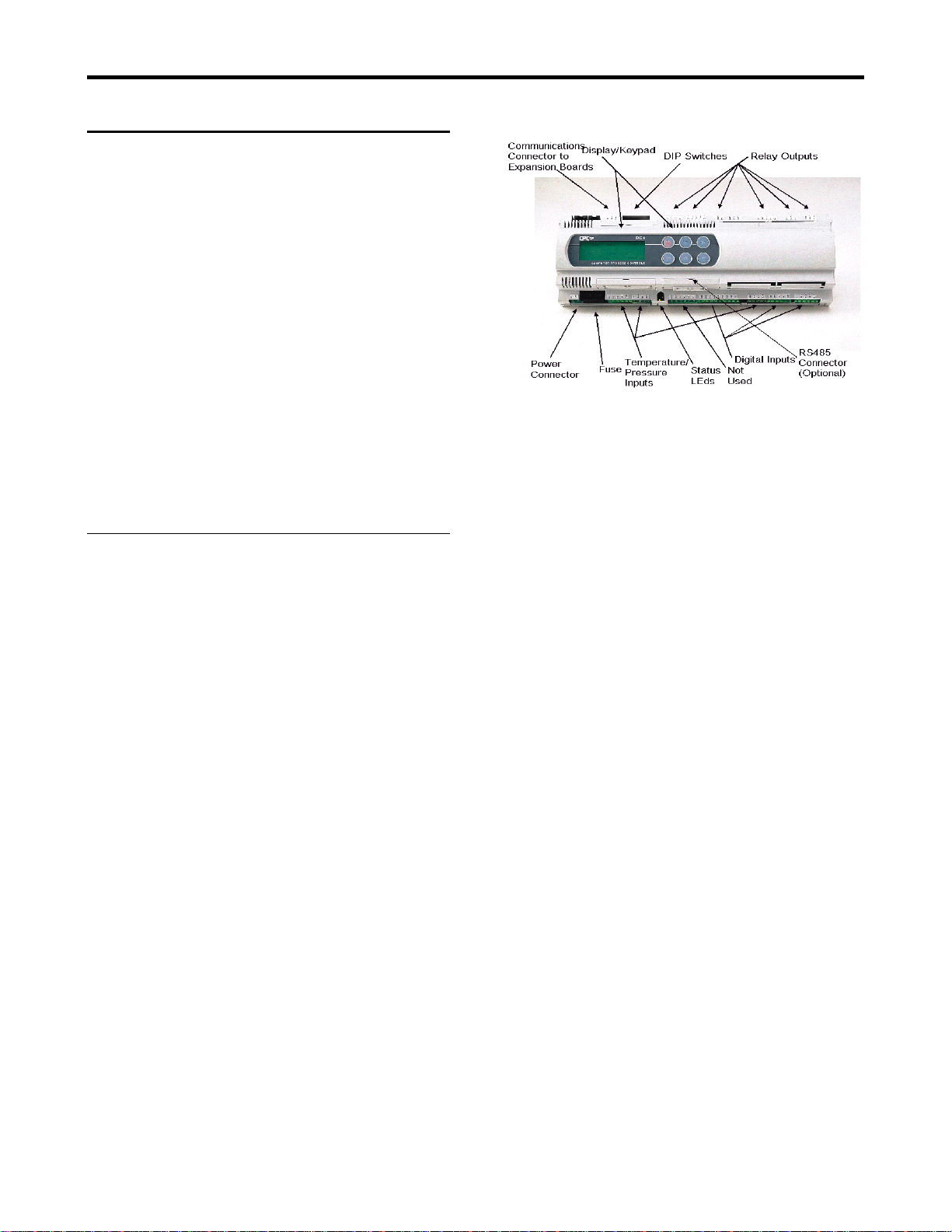

5.1.7 Controller Wiring

The field wiring for the expansion board is

shown in Figure 2. Field wiring for the

controller consists of temperature probes on

inputs 4 through 8.

Figure 2- Controller Wiring

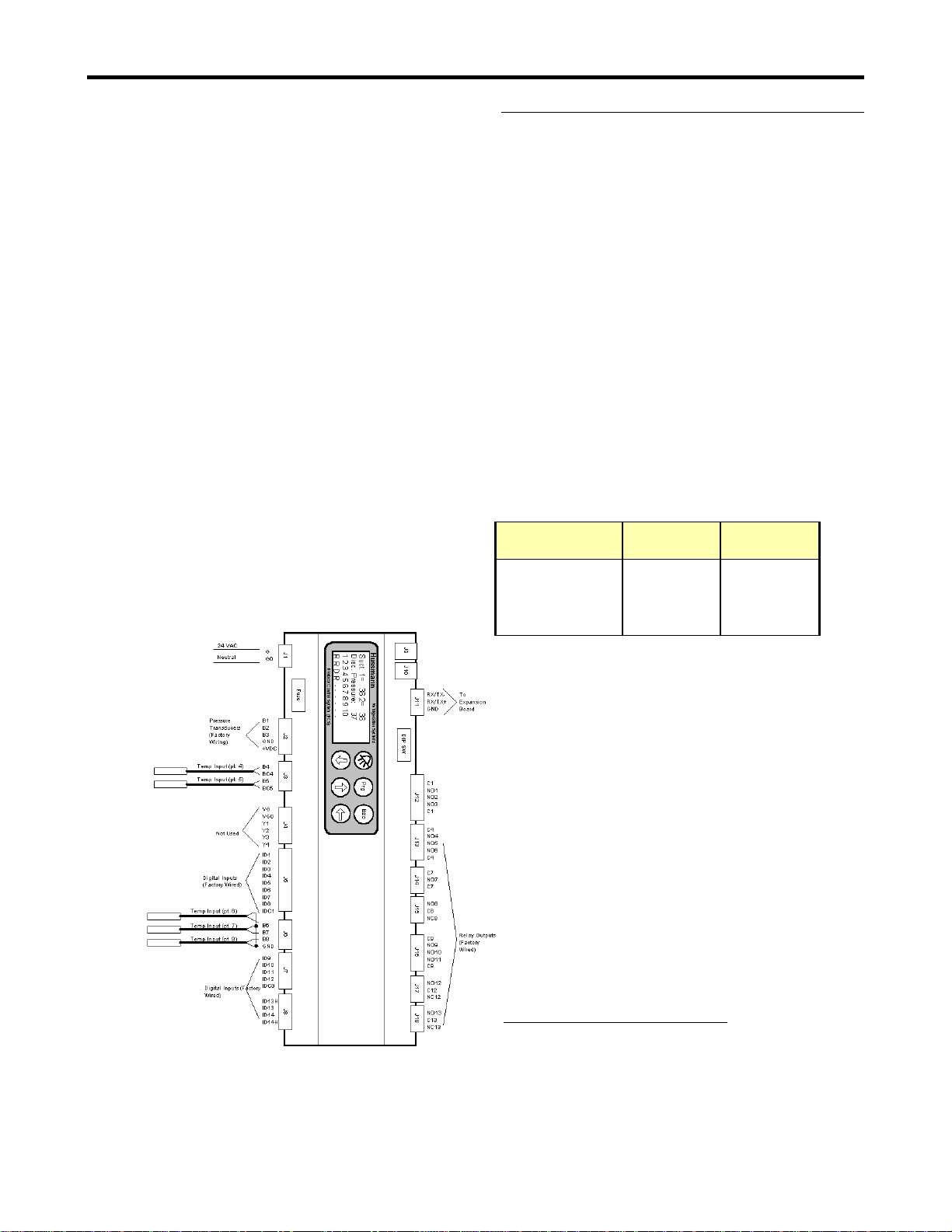

5.2 PCS Expansion Board

The PCS Expansion board is used to provide additional

I/O (relays, digital termination inputs and temperature

inputs) to the PCS Controller. Typically, the expansion

board will contain the I/O for circuits (refrigeration valve

relays, temperature inputs and defrost termination

inputs). The Expansion board contains 8 relay outputs

(Normally Open/Normally Closed outputs), 8

Temperature inputs and 8 Digital inputs.

The temperature inputs must use the PCS temperature

sensors (described below).

The Expansion board is connected to the PCS Controller

by a communications cable (Beldon 8641 or equivalent).

The PCS system supports up to 4 expansion boards. The

address of the expansion board is determined by the

wiring of inputs AD0 and AD1. Table 1 lists the

expansion board address.

Table 1- Expansion Board Addressing

Expansion

Board

Board 2

1

Board 3 OPEN

Board 4 24 VAC OPEN

Board 5 24 VAC 24 VAC

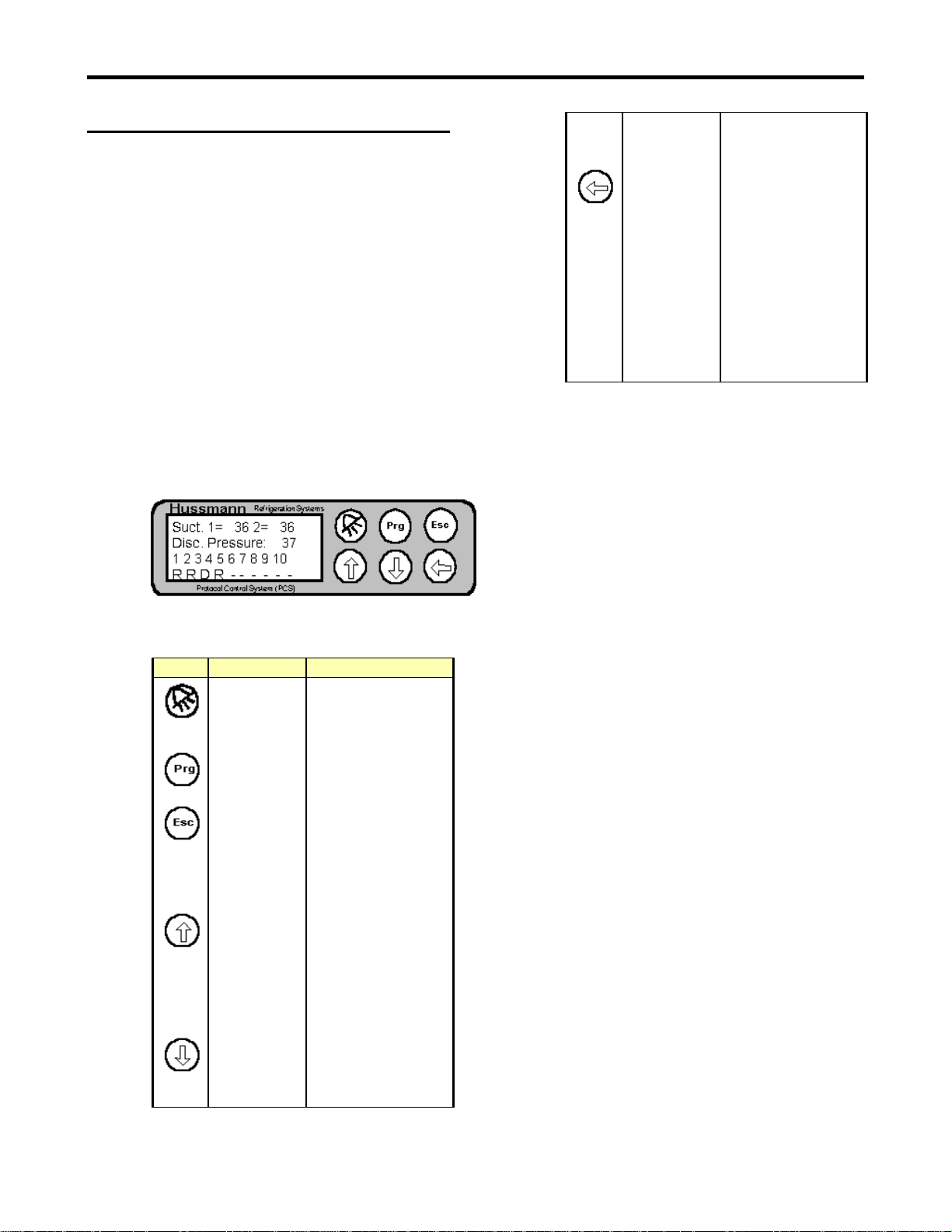

Figure 3 shows a picture of the PCS Expansion board

and identifies the different parts of the board.

AD1 AD0

OPEN OPEN

24 VAC

2

1

The first expansion board is referred to as board 2. The main

controller is referred to as board 1.

2

InTable 1, 24 VAC means tied to “G” terminal.

Page 9

Page 10

Protocol Control System Users Manual 2/12/01

Figure 3 - PCS Expansion Board

5.2.1 Input Power

The Controller uses 24 VAC (+10%/-15%,

50/60 Hz) (Class II) power at 15 VA. Note that

if using the same transformer to power the

controller and expansion board, care must be

taken to connect the G terminals on both boards

to the same side of the transformer and the G0

terminals on both boards to the same side of the

transformer.

5.2.2 Mounting

The Expansion board is mounted via standoffs.

5.2.3 Fuse

The Expansion board has an internal fuse. If the

Expansion board will not power up and you

have verified that the controller is getting input

power, you should replace the fuse. Always

replace with the same type of fuse.

Figure 4- Expansion Board Wiring

5.3 Pressure Transducer

The PCS system uses a 4/20 milliamp pressure

transducer. Inputs are provided for reading suction

pressure (optionally a second suction group pressure) and

discharge pressure. The same type of pressure

transducer is used for reading suction and discharge

pressure. The transducer is a 2 wire connection and is

polarity sensitive (refer to the Protocol schematics for

details). The system reads 0 to 362 PSI.

The wiring for the pressure transducer should not be

routed near cables carrying high voltage.

Figure 5 shows a picture of the pressure transducer.

5.2.4 Expansion Board Wiring

The field wiring for the expansion board

consists of the temperature probes and defrost

termination sensors. Refrigeration valve relays

are factory wired to terminal blocks. Figure 4

shows the connection points for the field wiring.

Page 10

Page 11

Protocol Control System Users Manual 2/12/01

Figure 5- PCS Pressure Probe

5.4 Temperature Sensor

The PCS system uses an NTC type temperature sensor to

read the temperature. The temperature sensor is not

polarity sensitive. Note that the wiring for the

temperature sensor should be routed in such a way that it

is not in close proximity to any power line cables. This

will prevent invalid readings from occurring.

The temperature sensor should be placed in the discharge

air stream to give a true indication of case temperature.

Figure 6 shows a picture of the temperature sensor.

allowing complete control of the units from the PC. For

this system each of the Controller must have a

communications card installed. The controllers must be

connected in a daisy chain fashion using Belden 8641,

24AWG, 2 conductor twisted shielded pair. This

wiring should be carefully routed away from power lines

or other high electrical noise environments

Field valve wiring should use 16/18 AWG cable

appropriate for the valve current requirements. This

wiring should not be run in close proximity to the

temperature, termination or communication wiring.

Figure 6- PCS Temperature Probe

5.5 Field wiring

All wire connections to the PCS system should be in

accordance with all applicable local and national codes.

Temperature sensors and defrost termination sensors

should be wired to the controller and expansion board

using Belden 8761, 22AWG, 2 conductor twisted

shielded pair or equivalent. This wiring should be

carefully routed away from power lines or other high

electrical noise environments.

The PCS system offers the option of using a supervisory

system where all units in the store are connected to a PC

Page 11

Page 12

Protocol Control System Users Manual 2/12/01

controller uses a PI algorithm to maintain

6. PCS Features

The PCS system has a number of features as defined in

the following paragraphs.

6.1 Overview

The PCS system has the following features:

smooth discharge pressure.

If the Protocol system uses a fluid cooler instead

of an air cooled condenser, a separate controller

will be used to control the Pump Station (refer

to the section on Pump Station Control).

The PCS controller will provide alarming on

the discharge pressure input, but will not

provide direct control in this case.

6.1.1 Circuit Control

The PCS system can control up to 10 circuits.

Control consists of controlling the defrost

schedule, controlling the circuit temperature (by

using a solenoid valve), and alarming.

The controller can schedule up to 6 defrosts per

day. The defrost can be either off cycle, electric

or hot gas. Defrost can be terminated by either

time, circuit temperature or digital (Klixon)

input.

6.1.2 Suction Pressure Control

The PCS system can control up to 6

compressors. Up to two suction groups are

supported.

Control of the pressure is by PI type algorithm

for precise pressure control. The reading from

the pressure transducer is compared to the

setpoint and the appropriate action (turning

compressors on and off) is taken to maintain the

suction pressure near the setpoint. Note that

minimum on and off times and startup delays

for the compressors can be programmed.

6.1.3 Lighting Control

Two circuits are provided for lighting control.

The lighting circuits can be turned on and off by

a 7 day schedule with one on and one off time

per day.

6.1.4 Discharge Pressure Control

The PCS system can be used to control

condensor fans. The fans are cycled in response

to the discharge pressure setpoint and the

current discharge pressure reading. The

6.1.5 Alarms

The PCS system keeps an alarm log with 16

entries. The alarm log displays the date and

time that the alarm occurred, the type of alarm

and whether the alarm is ACTIVE or has been

ACKNOWLEDGED. When an alarm occurs,

the alarm relay will activate, the ALARM key

will turn RED and the Alarm menu will

automatically be displayed. The alarm relay

will remain activated and the ALARM key will

remain RED until the alarm is

ACKNOWLEDGED.

Alarms are provided for the following

conditions:

6.1.5.1 High/Low Circuit Temperature

An alarm is signaled if the circuit temperature is

too high or too low (as determined by the alarm

setpoints).

6.1.5.2 Defrost Termination

An alarm is signaled if a defrost is set up to

terminate by temperature or digital termination,

but terminates by the maximum time instead.

This can indicate that there may be some type of

problem with the case (ice build up) or the

termination sensor.

6.1.5.3 High/Low Suction Pressure

If the suction pressure is above or below the

limits (as defined by the alarm setpoints) this

alarm will be signaled.

6.1.5.4 High Discharge Pressure

If the discharge pressure is above the limit (as

defined by the alarm setpoint) this alarm will be

signaled. Note that the discharge pressure alarm

will automatically clear (but will remain in the

Page 12

Page 13

Protocol Control System Users Manual 2/12/01

alarm log) if the discharge pressure falls below

the alarm limits.

6.1.5.5 Sensor Failures

If a temperature or pressure probe failure

occurs, this alarm will be signaled. The alarm

will provide details as to what sensor has failed.

6.1.5.6 Compressor Proof Failures

This alarm will be signaled if a compressor

proof fails. Note that proofing is optional in

the Protocol refrigeration system. Refer to the

Protocol schematics for details.

6.1.5.7 Compressor General Alarms

This alarm will be signaled if a general alarm

occurs for a compressor. A general alarm

occurs when the digital input associated with

the compressor is active. There is one digital

input for each compressor. The digital input

will be activated when the oil level sensor trips,

there is a high pressure cutout or the discharge

temperature is to high. See the Protocol

schematic for details.

will return to normal when the controller logoff

timeout occurs.

6.1.6.3 Compressor Run Time

The run time (in hours) for each compressor is

stored. The run time can be cleared if a

compressor is replaced.

6.1.5.8 Phase Loss

This alarm will be signaled if the controller

detects a phase loss.

6.1.5.9 Controller Reset

If the controller resets due to an interruption of

power, this alarm will be signaled when power

is restored

6.1.6 Maintenance/Diagnostics

The controller provides the following

capabilities for maintenance:

6.1.6.1 Force Defrost

A circuit can be forced to perform a defrost or

to cancel a defrost in progress. Note that if a

defrost is forced, the defrost will terminate

normally as defined by the circuit setpoints.

6.1.6.2 Force Compressors

A compressor can be forced on or off. Note that

the user must be logged in to force the

compressor on or off and the compressor state

Page 13

Page 14

Protocol Control System Users Manual 2/12/01

2) On other

7. Quick Start

This section of the manual provides a quick overview of

the operation of selected features of the controller. It is

intended to provide an overview of the most used

features. Refer to the Controller operation section for

more details.

7.1.1 Display and Keypad

The controller’s user interface consist of a 4x20

LCD display with a 6 button keypad. The

display/keypad are used to see status

information on the controller and also to change

setpoints. Figure 7 shows the display and

keypad of the controller.

Figure 7- Controller Display

ENTER 1) On Main status

7.1.1.1 Cursor

Each screen can have one or more fields. The

active field will have a cursor on the first

character of the field. The cursor will alternate

between a block and the normal character for

the field.

screens- Used

to enter a value

screen- Enters

the

configuration

menus for a

given field

2) On other

screens- Used

to move

between fields

and to accept a

value.

Table 2- Controller Key Functions

Key Name Function

ALARM Enters the alarm

PROGRAM Enters maintenance

ESCAPE Return to Main

UP

ARROW

DOWN

ARROW

menu or returns to

original menu from

alarm menu

menu (depends on

current screen)

status screen (from

any screen) or move

to other status

screens (from Main

status screen)

1) On Main status

screen- Moves

between status

fields

2) On other

screens- Used

to enter a value

1) On Main status

screen- Moves

between status

fields

7.1.2 Login

Certain actions (changing setpoints, forcing

defrosts, etc.) require the user to log on to the

controller. This requires the user to enter a

password. When you must log in to perform the

action, a logon screen will pop up and you will

be prompted to enter the password. When this

happens, enter the numeric password (using the

UP or DOWN ARROW keys) then press the

ENTER key. If the password is correct the

login screen will disappear and you will be able

to perform the action. If the password is not

correct, you will not be allowed to perform the

action and the logon screen will appear again

after you press the ENTER key. Once you have

logged in, you will not have to enter the

password again unless the controller times out

and logs out. The time out will occur if you do

not press any of the keys for 5 minutes. At that

point, the controller will log you out and return

to the main status screen.

The factory default password is “0000” and it

can be changed by an authorized user.

Figure 8 shows the password screen.

Page 14

Page 15

Protocol Control System Users Manual 2/12/01

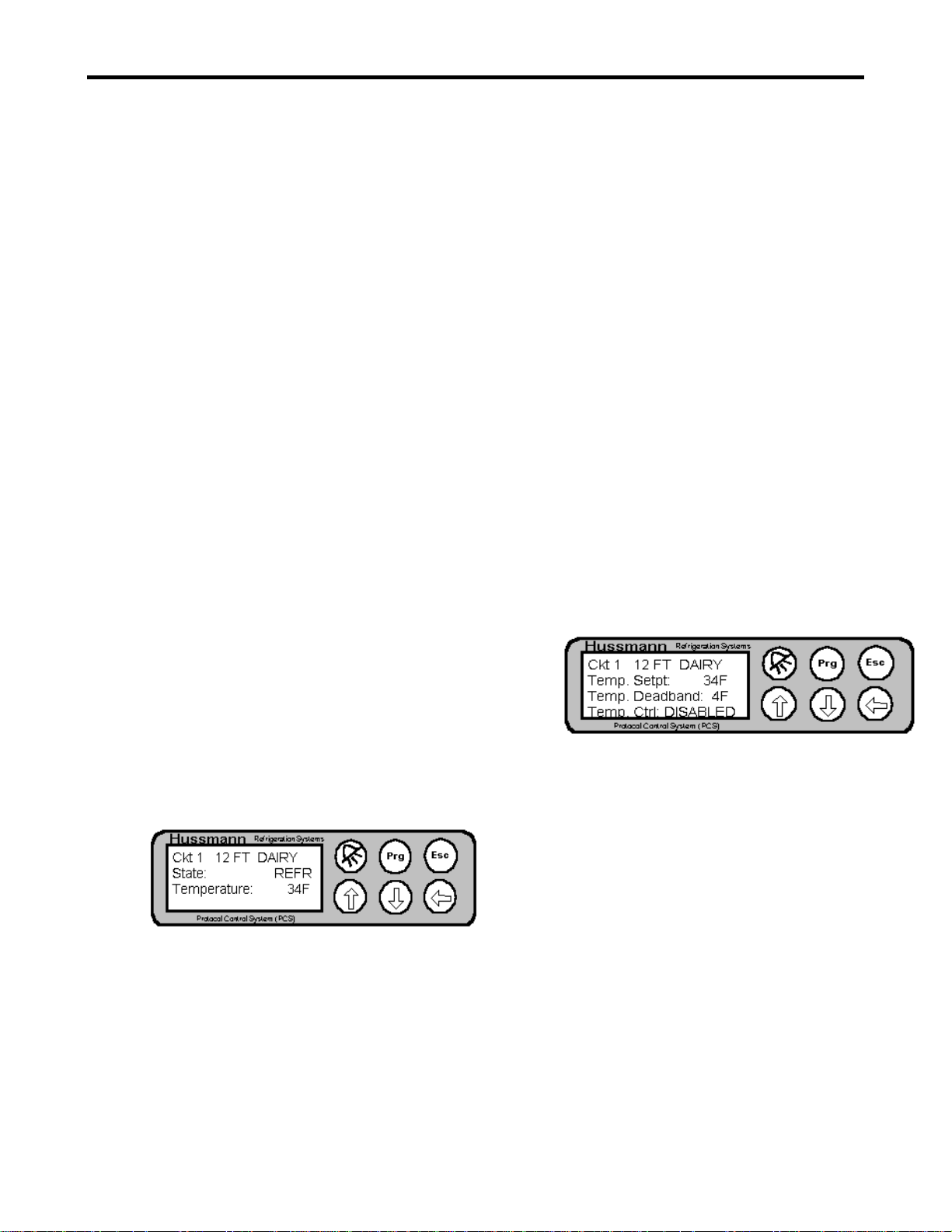

Figure 8- Password Screen

7.1.3 Main Status Screen

Figure 9 shows the main status screen. This

screen is displayed when the controller is first

powered on. This screen will also be displayed

if there are no keys pressed for a period of 5

minutes.

Figure 9- Main Status Screen

The first row on this screen shows the current

pressure reading for suction group 1 and (if

configured for two suction groups) suction

group 2. The second row shows the current

reading for the discharge pressure. The bottom

two rows show the circuit status. The numbers

1 to 10 on the third row represent circuit

numbers 1 to 10. On the last row there will be

either a “-“, “R”, “D” or “S” under each circuit

number. If a “-“ is present, this means that the

circuit has not been configured. If a “R” is

present, this means that the circuit is currently

in refrigeration mode. If a “D” if present, this

means that the circuit is in defrost. If an “S” is

present, it means that the circuit has temperature

control enabled and the circuit temperature is

currently satisfied.

To return to the main status screen from a

configuration or maintenance screen, press the

ESCAPE key once. To return to the main status

screen from another status screen, press the

ESCAPE key until the Main status screen is

displayed. Depending on which status screen

you are currently in, you might have to press the

ESCAPE key several times.

7.1.4 Configuration Screens

There are several configuration screens. In

general, these screens provide more detailed

status information and also contain setpoints.

Typically, there are several configuration

7.1.4.1 Active Fields

screens for a given function (circuit

configuration, for example). When a

configuration screen is first entered, the cursor

rests in the upper left hand corner of the screen.

If you press the UP or DOWN ARROW keys

with the cursor in the resting position, the next

or previous configuration screen will be

displayed.

Each configuration screen typically consists of a

number of fields. A field can be a setpoint or

any other area where a value can be changed.

Pressing the ENTER key with the cursor in the

resting position will advance the active field to

the first field on the screen. At this point, the

value of the field can be changed (using the

ARROW keys) or pressing the ENTER key

again will advance to the next field. If the value

of the field is changed, the ENTER key must be

pressed to accept the value and move to the next

field. Continue pressing the ENTER key until

the cursor returns to the upper left corner of the

screen.

7.1.5 Viewing/Changing Suction Pressure

Setpoint

To view or change the suction pressure setpoint,

you must enter the suction configuration screen.

To do this from the Main status screen, use the

ARROW keys to move the active field to either

Suction Group 1 or Suction Group 2. Now

press the ENTER key. The Suction Group

configuration menu will now be displayed.

Figure 10- Suction Group Configuration Screen

Page 15

Page 16

Protocol Control System Users Manual 2/12/01

The first row has the group number that you are

viewing. The name of the suction group is also

displayed on the top row. The next row has the

suction pressure reading (in PSI). The next row

has the suction setpoint (in PSI). The last row is

an indication of how many compressors (that

are assigned to this suction group) are currently

on. In this example, there are 3 compressors

assigned to the group and 1 is on.

If there are two suction groups, you can look at

the second suction group by pressing the

ENTER key to put the cursor on the group

number, then pressing the UP ARROW key to

change the value of the field to 2, then press the

ENTER key. The other active field on the

suction configuration screen is the suction

setpoint. Press the ENTER key to advance from

the suction group field to the setpoint field. The

value can now be changed by pressing the

UP/DOWN ARROW keys. After the new value

has been entered, press the ENTER key to

accept. Press the ENTER key once more to

return the cursor to the resting position. The

setpoint has now been changed.

Note that there can be up to three temperature

probes defined for a circuit and the number

displayed on this screen is the combination of

the three.

By pressing the ENTER key on this screen, you

will move the cursor to the first field which is

the circuit number. You can change the circuit

number you are currently viewing by using the

UP or DOWN ARROW keys to change the

circuit number. The temperature for the

selected circuit will automatically be displayed

(without the need to press the ENTER) key.

There may be a slight delay (up to 2 seconds)

for the display to update with the temperature

for the new circuit.

7.1.7 Viewing/Changing Circuit Temperature

Setpoint

To view or change the circuit temperature

setpoint you must enter the circuit configuration

screen. With the cursor in the resting position

(upper left hand corner), press the DOWN

ARROW key two times and a screen will be

displayed with the temperature setpoint.

7.1.6 Viewing Circuit Temperatures

In order to view circuit temperatures, you must

enter the circuit configuration screen. To do

this from the Main status screen, press the

DOWN ARROW key until the cursor is on the

circuit number you would like to view. Then

press the ENTER key. The Circuit

configuration screen will now be displayed.

Figure 11- Circuit Configuration Screen

The first row displays the circuit number

(similar to the suction group number in the

suction group configuration screen) and the

name of the circuit. The next row displays the

current state of the circuit. “REFR” indicates

refrigeration. “DEFR” indicates defrost.

“SATISFIED” indicates that the circuit has

temperature control enabled and the circuit

temperature is currently satisfied. The third row

shows the current temperature for the circuit.

Figure 12- Temp Setpoint Configuration Screen

To change the circuit temperature, press the

ENTER key twice to make the Temp Setpt the

active field. Use the UP or DOWN ARROW

keys to change the value. Press the ENTER key

to accept the new value. Note that the active

field will automatically go to the Temp Ctrl

field. Press the ENTER key again to return the

cursor to the upper left corner (resting position).

7.1.8 Determining if a Circuit is in Defrost

To determine if a circuit is in defrost you can

look at the circuit’s status in the Main status

screen (“D”) or in the circuit configuration

screen (“DEFR”).

Page 16

Page 17

Protocol Control System Users Manual 2/12/01

7.1.9 Forcing a Defrost

To force a circuit into defrost, you must be in

any of the circuit configuration screens. From a

Circuit configuration screen, press the

PROGRAM key. The Circuit maintenance

screen will be displayed.

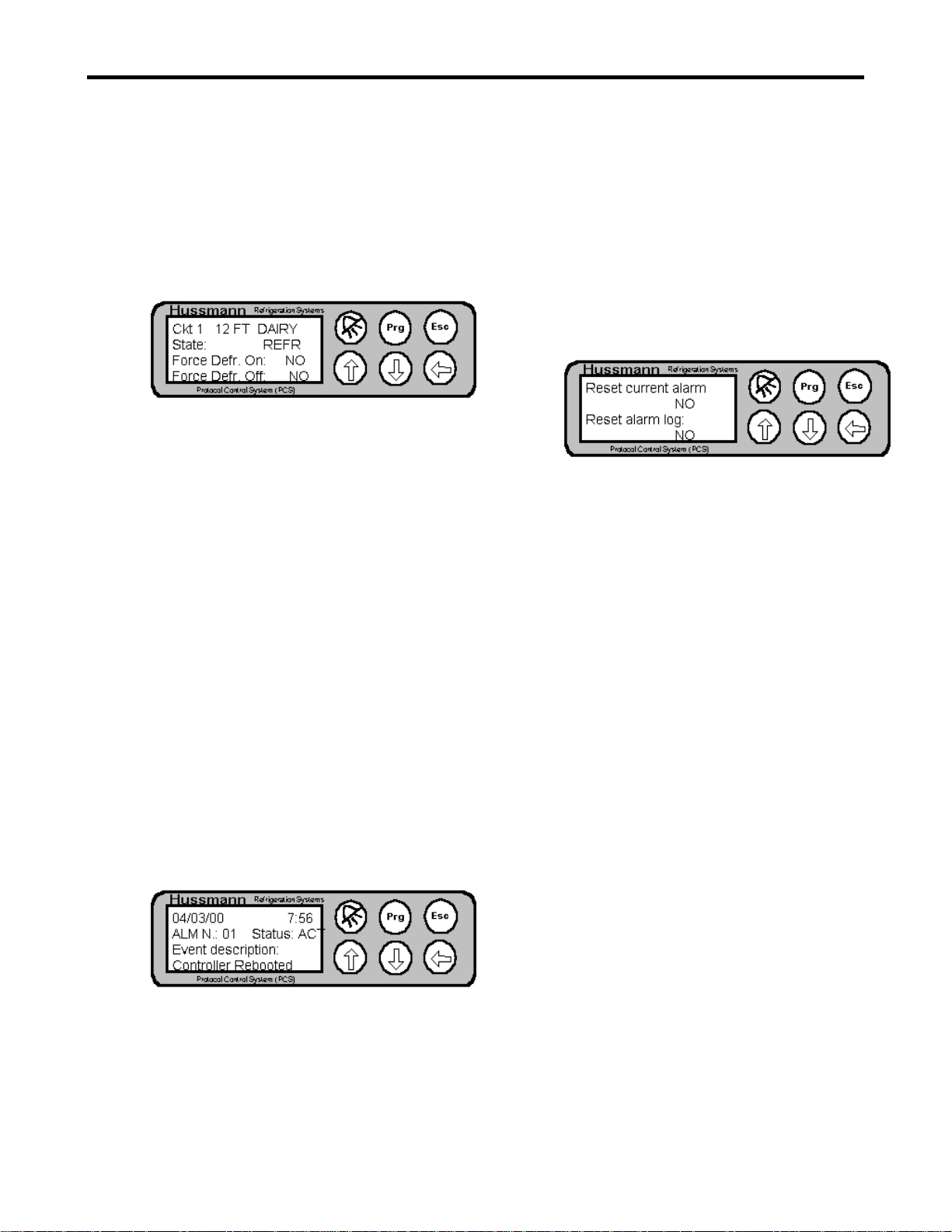

Figure 13- Circuit Maintenance Screen

The Circuit maintenance screen displays the

circuit number and name on the top row. The

current circuit state is displayed on the second

row. The third row contains a field called

“Force Defr. On:”. By moving the cursor to this

field (using the ENTER key) and pressing the

UP ARROW key the “NO” will be changed to a

“YES”. Press the ENTER key to accept the

change and a forced defrost will be started.

Note that the defrost will terminate in the

normal way (according to the circuit setpoints).

Likewise, you can cancel a defrost by moving

the cursor to the field that says “Force Defr.

Off:” and changing the “NO” to “YES” with the

ARROW key and pressing ENTER.

7.1.10 Alarms

If an alarm occurs, the controller will

automatically display the alarm log screen and

the ALARM key will turn RED. The alarm

screen can also be enter from any other screen

by pressing the ALARM key.

Figure 14- Alarm Log Screen

The Alarm screen displays the date and time

when the alarm occurred on the top row. The

next row shows the alarm number (1 to 16) and

the Status (either active (ACT) or acknowledged

(AKN). The last row gives a description of the

alarm.

To view other alarms use the UP or DOWN

ARROW keys to display other alarms that are in

the alarm log.

7.1.10.1 Acknowledging Alarms

To acknowledge an alarm you must be in the

Alarm maintenance screen. To enter the Alarm

maintenance screen, first enter the alarm screen,

then press the PROGRAM key. The Alarm

maintenance screen will be displayed.

Figure 15- Alarm Maintenance Screen

The alarm maintenance screen has two fields.

Press the ENTER key to move to the first field

that says “Reset current alarm”. Press the UP

ARROW key and the “NO” will change to

“YES”. Press the ENTER key to accept the

entry and the alarm current active alarm will be

acknowledged. The controller will

automatically return to the alarm screen.

Note that there may be more than one active

alarm. If you have cleared the alarm and the

ALARM key is still RED, use the ARROW

keys to determine if there are other alarms in the

alarm log that are active. If so, use the

ARROW keys to display the active alarm then

acknowledge the alarm as described in the

preceding paragraph.

7.1.10.2 Clearing the Alarm Log

To clear the alarm log, enter the alarm

maintenance screen as described in paragraph

7.1.10.1. Press ENTER twice to move the

cursor to the “Reset alarm log:” field. Use the

ARROW keys to change the “NO” to “YES”.

Immediately a confirmation screen will pop up

asking you to confirm that you would like to

clear the alarms. Pressing the ESCAPE key will

cancel the operation and return you to the alarm

screen. Pressing the ENTER key will result in

the alarm log being cleared.

Note: Use caution when clearing the alarm log.

Once cleared, alarm entries cannot be

retrieved.

Page 17

Page 18

Protocol Control System Users Manual 2/12/01

Figure 16- Alarm Confirmation Screen

Page 18

Page 19

Protocol Control System Users Manual 2/12/01

algorithm is used that equalizes run times

8. Controller Operation

The basic operation of the controller is described in the

following paragraphs. An overview of the menu

structure is given, the more detailed information for each

screen is presented. Where applicable, additional

information about the control algorithms, etc. are

provided.

8.1 Circuit Control

The PSC controller provides circuit control for up to 10

circuits. Each circuit can have up to 3 temperature

probes for temperature monitoring. A relay can be

assigned for temperature control. Each circuit also has a

defrost schedule that controls defrost.

8.1.1 Defrost

There are three types of defrost supported by the

controller, HOT GAS, ELECTRIC and OFF

CYCLE. Refer to the Protocol schematics for

details of the wiring for each type of defrost.

8.2.2.1 Equal Horsepower compressors

Figure 17-Equal Horsepower Example

between compressors. If there are different

horsepowers, a different algorithm is used. The

algorithms are described in the following

paragraphs.

If the compressors all have the same

horsepower, the controller uses the deadband

and setpoint to determine what compressors

should be on. “Bins” are created which

determine when a compressor is turned on and

off. One Bin is created for each compressor.

The size of the Bin is determined by the

deadband divided by the number of

compressors. An example is shown in Figure

17. In this example, the setpoint is 50 psi, the

deadband is 16 psi and there are four

compressors. As the pressure increases (going

toward the right side), more compressors are

turned on. As the pressure decreases (going

toward the left side) compressors are turned off.

8.2 Pressure Control

The PCS controller provides control of suction pressure

by cycling compressors on and off to meet the load

requirements. Up to 6 compressors are supported for a

suction group. The controller will support 1 or 2 suction

groups.

8.2.1 Switchback

Switchback is a mechanical backup mode of the

PCS. This occurs when a hard failure occurs in

the controller and it is unable to run. When this

occurs, the switchback relay (controller point 7)

will open (normally, this relay is held close).

This willcause the SBA relay to open and some

of the compressors will be powered through the

Normally Closed contacts of the SBA relay and

the Low Pressure Control. Refer to the Protocol

schematics for more detail.

8.2.2 Pressure Control Algorithm

There are two basic pressure control algorithms

used in the Controller. If all compressors have

the same horsepower, an equal horsepower

Note that there are other setpoints which affect

the minimum on and off times for the

compressors (See Figure 30 and Figure 31).

The above example shows the effect of the

Setpoint and Deadband in controlling the

suction pressure. This is basically

“Proportional” control. The controller

incorporates an additional parameter that is used

for PI (Proportional + Integral) control (See

Figure 25). This parameter is called

“Integration time” (See Figure 54). For PI

control, the controller will add (or subtract) a

Page 19

Page 20

Protocol Control System Users Manual 2/12/01

small amount to the actual pressure reading

before determining how many compressors to

turn on. The Integration time is the length of

time (in seconds) it takes for the controller to

add an error equal to the setpoint minus the

actual pressure reading.

Using the example shown is Figure 17, assume

that the actual pressure reading is 52 psi and the

integration time is 10 seconds. The error is (52

psi – 50 psi) 2 psi. In 10 seconds, 2 psi will be

added to the actual pressure and the controller

will calculate the compressors to turn on based

on a pressure of (52 psi + 2 psi) 54 psi. This is

at the bottom of Bin 3 so compressor 1,2 and 3

would be turned on at this point.

8.2.2.2 Unequal Horsepower compressors

If a controller has unequal compressors, the

algorithm is slightly different than the above

example. First the controller calculates the

number of steps it has available. For example,

if there are two compressors, the first being a 2

HP and the second being a 3 HP, there are 3

steps available (2 HP, 3 HP and 5 HP). The

controller then calculates a % capacity required

which is based on the error between the actual

reading and the setpoint. This error is divided

by the deadband and converted to a percentage

(0 to 100%). The percentage is applied to the

steps and the closest match is used. No runtime

equalization is performed for unequal

horsepower compressors.

Note that if PI control is used, an integration

error amount is added to the actual reading as

described above.

8.3 Condenser Control

The controller has the capability to control an air cooled

condenser (see Figure 32 and Figure 33). The condenser

control is very similar to the equal horsepower pressure

control with the number of compressors being the

number of fans. Note that the control of the fans is

Proportional control only.

8.4 Menu Structure

screens. Each screen type is discussed in the following

paragraphs.

Figure 18 - PCS Menu Tree

8.4.1 Status Screens

Status screens are display only screens. They

provide information about a particular function

of the controller (for example, Suction

pressure). They also serve as the entry into the

configuration screens. There are 5 status

screens. They are shown on the top row of

Figure 18. They are the Main Status, Lighting

Status, Aux Processing Status, System Status

and Release Info and Status. Each of the

screens will be described in detail later in this

document.

8.4.2 Configuration Screens

Configuration screens are screens that show

more detailed status and also have setpoints.

There are six basic types of configuration

screens: Circuit, Suction Group, Discharge,

Lighting, Aux Processing and System. These

screens are shown on row 2 in Figure 18. The

configuration screens also serve as an entry to

the maintenance screens.

Note that Figure 18 only shows one block for

each type of configuration screen. Each block

may represent many screens. For example,

there are six configuration screen for Suction

Group setup.

The screens on the controller consist of 4 basic types of

screens. They are Status screens, Configuration screens,

Maintenance screens and the Alarm screen. Figure 18

shows a menu tree that shows these different types of

8.4.3 Maintenance Screens

Maintenance screens are shown on the third row

of Figure 18. Maintenance screens allow you to

Page 20

Page 21

Protocol Control System Users Manual 2/12/01

perform a maintenance action (force a circuit

into defrost, force off a compressor, etc). Note

that there are maintenance screens for Circuits,

Suction Groups and Lighting functions.

8.4.4 Alarm Screen

The Alarm screen displays the alarm log. It can

be entered from any screen by pressing the

ALARM key.

8.4.5 Screen Navigation

8.4.5.1 Status Screens

Pressing the ESCAPE key from any

configuration or maintenance screen will always

return you to the Main Status screen. If you are

on the Main Status screen, pressing the

ESCAPE key will move you to the Lighting

Status screen. Each press of the ESCAPE key

will move to the next status screen as shown on

the top row of Figure 18.

8.4.5.3 Maintenance Screens

All maintenance screens are entered from a

corresponding configuration screen. For

example, if you wan to enter the Circuit

Maintenance (to force a defrost), you must first

enter the Circuit configuration screen. Once in

the Circuit configuration screen, press the

PROGRAM key and the Circuit maintenance

screen will be displayed. Maintenance screens

are available for Circuit, Suction Group,

Lighting and Alarms.

8.5 Screens

8.5.1 Status Screens

The status screens are shown on the top row of

Figure 18. They are described in detail in the

following paragraphs.

8.5.1.1 Main Status

Figure 19- Main Status Screen

8.4.5.2 Configuration Screens

All configuration screens are entered from a

status screen. System, Lighting and Auxillary

configurations screens are entered by pressing

the enter key when in the corresponding status

menu. Circuit, Suction Group and Discharge

configurations screens are all entered from the

Main Status screen. To enter the Suction Group

configuration screen from the Main Status

screen, move the cursor to either Suction Group

1 or Suction Group 2 pressure field, then press

the ENTER key. To enter the Discharge

configuration screen, move the cursor to the

Discharge pressure field , then press the ENTER

key. To enter the Circuit configuration screen,

move the cursor to the appropriate circuit

number (see Figure 9), then press the ENTER

key.

Once in the configuration screen, you can move

to the next configuration screen by pressing the

DOWN ARROW key (with the cursor in the

upper left hand corner). You can move back to

the previous configuration screen by pressing

the UP ARROW key. Note that at any time you

can press the ESCAPE key to return to the Main

Status screen.

Table 3- Main Status Fields

Field Explanation

Suct. 1 Suction Group 1

Pressure

Reading

Suct. 2 Suction Group 2

Pressure

Reading

Disc.

Pressure

Circuit Status Circuit 1 through

Discharge

Pressure

Reading

10 Status.

“-“- Not

configured

“R”-

Refrigeration

“D”- Defrost

“S”-

Temperature is

satisfied

Page 21

Page 22

Protocol Control System Users Manual 2/12/01

8.5.1.2 Lighting Status

Figure 20- Lighting Status Screen

Figure 21- Lighting Status Fields

Field Explanation

Lighting Ckt1 Status of lighting circuit 1

Lighting Ckt1 Status of lighting circuit 1

8.5.1.3 Aux Processing

Figure 22- Aux Processing Status Screen

Date The current date

Unit Address The address of the unit on

the supervisory

communications network.

8.5.1.5 Release Info

Field Explanation

Name The name of the controller

as set by the user

Release The version number of the

software release

Date The release date of the

software.

8.5.2 Configuration Screens

Table 4- Aux Processing Status Fields

Field Explanation

Aux State State of the auxiliary relay

Aux Temp Temperature reading of the

auxiliary input

8.5.1.4 System Status

Figure 23- System Status Screen

Table 5- System Status Fields

The configuration screens are shown on the

second row of Figure 18. Note that each

8.5.2.1 System Configuration

Figure 24- System Configuration Screen 1

configuration screen block shown in Figure 18

may have several configuration screens

associated with it. The following paragraphs

detail the configuration screens. Note that all

configuration screens for a particular function

are shown. To access the different

configuration screens, enter the first

configuration screen for the desired function,

then, with the cursor in the resting position

(upper left corner), press the DOWN ARROW

key until the desired screen is displayed.

The System Configuration screens are used to

provide “System” level setup information.

These fields should be set up first when

programming a controller.

Field Explanation

Time The current time (as kept

by the controller)

Page 22

Page 23

Protocol Control System Users Manual 2/12/01

Table 6- System Configuration Screen 1

Field Explanation

Time Used to set the time of the

controller

Date Used to set the date of the

controller

Day Used to set the Day of the

week

Unit Address Used to set the address of

the unit on the supervisory

communications network.

Figure 25- System Configuration Screen 2

Table 7- System Configuration Screen 2

Field Explanation

Unit Type Used to select between an

LP2000 and Protocol

application. Note that this

will define the maximum

number of circuits and

compressors that are

supported.

TWO GROUP Field that indicates two

suction groups (TWO

GROUP) or one suction

group (ONE GROUP), or

one suction group + a

single compressor satellite

(ONE GROUP + COMP.

SAT.).

Regulation

Type

Type of pressure control

algorithm to use either

“P”- Proportional only or

“P+I”- Proportional +

Integral. It is

recommended to use P+I

for smooth pressure

control.

Figure 26- System Configuration Screen 3

Table 8- System Configuration Screen 3

Field Explanation

Maximum

Power Load

Amps

The amount of Current

draw the Protocol unit is

rated for (used for

compressor shedding

during electric defrost)

Temperature

Display Mode

The display mode for

temperature (°F or °C)

Figure 27- System Configuration Screen 4

Table 9- System Configuration Screen 4

Field Explanation

Suct Displays the

minimum/maximum range

for the suction pressure

probe (both suction

groups). This should

always be 000/362 PSI.

Disc Displays the

minimum/maximum range

for the discharge pressure

probe (both suction

groups). This should

always be 000/362 PSI.

Figure 28- System Configuration Screen 5

Table 10- System Configuration Screen 5

Field Explanation

Comp 1 2 3 … Read only field that

displays the compressor

number.

Pt Displays the relay point

number assigned to the

compressor. Note that all

compressor relays are

located on the controller.

Grp Displays the Group

Page 23

Page 24

Protocol Control System Users Manual 2/12/01

number that the

compressor is associated

with.

Figure 29- System Configuration Screen 6

There will be one screen for each compressor

(1 – 6) that is identical to the above screen.

Table 11- System Configuration Screen 6

Field Explanation

Comp1 Amps The total amp draw of

compressor 1 (used for

compressor shedding

during electric defrost)

Comp1 HP The Horsepower of

compressor 1 (used during

capacity calculations for

the pressure control

algorithm)

Comp1 Proof Used to ENABLE or

DISABLE proofing for a

compressor. Note that the

compressor proof input

points are fixed for each

compressor (refer to the

Protocol schematics for

details)

Figure 30- System Configuration Screen 7

Figure 31- System Configuration Screen 8

Table 13- System Configuration Screen 8

Field Explanation

Compressor

Setup

IntrostageDelay

Displays the minimu m

time that will elaspe before

bringing on a different

compressor. This is useful

to prevent all compressors

from coming on all at one

time (such as after a power

fail)

Min time betw.

Same comp.

starts

Displays the minimu m

amount of time that must

elaspe (beginning with the

time the compressor is

turned on) before a

compressor can be turned

on after being turned off.

(Only with version

3.0B01)

Figure 32- System Configuration Screen 9

Table 14- System Configuration Screen 9

Table 12- System Configuration Screen 7

Field Explanation

Min On Displays the minimum on

time for the compressor

Min Off Displays the minimu m off

time for the compressor

Page 24

Field Explanation

Cond Fan 1Bd

Pt

Displays the Board

number and Point (relay)

number for the condenser

fans. Applicable only for

applications using

condenser control.

Figure 33- System Configuration Screen 10

Page 25

Protocol Control System Users Manual 2/12/01

Table 15- System Configuration Screen 10

Field Explanation

Setpoint Displays the condenser

pressure setpoint

(applicable only for

condenser control)

Deadband Displays the deadband to

use for condenser control

Figure 34- System Configuration Screen 11

This screen has no fields. It is a prompt to

change the password. If you’d like to change

the password, press the ENTER key. Note that

the default password for the controller is

“0000”.

Figure 35 - System Configuration Screen 12

This screen is displayed if you press the

ENTER key on the previous screen. Changing

the value displayed will result in the password

being changed.

Figure 36- System Configuration Screen 13

8.5.2.2 Circuit Configuration

The following are the circuit configuration

screens. Note that the top row of each screen

contains the circuit number and the name of the

circuit. The circuit number in the top row is an

active field in all screens. To view the

configuration information for a different circuit,

change the circuit number to the desired circuit

and the information for the new circuit will be

displayed.

Figure 37- Circuit Configuration Screen 1

Table 16- Circuit Configuration Screen 1

Field Explanation

State Read Only field that

displays the state of the

refrigeration circuit

(REFR- Refrigeration,

STAND BY- Temperature

is satisfied, DEFR-

Circuit)

Temperature Displays the calculated

temperature for the circuit.

Note that this may be a

combination of multiple

temperature probes

assigned to the circuit.

Figure 38- Circuit Configuration Screen 2

This screen is used to completely clear all

setpoints which are in the unit. Changing the

NO field to YES and pressing ENTER will

result in an “Are You Sure?” screen being

displayed.

Note that clearing all setpoints will results in

ALL configuration information (compressors,

circuits, suction group, etc.) being lost. Use

this with caution.

Page 25

Table 17- Circuit Configuration Screen 2

Field Explanation

State Read Only field that

displays the state of the

refrigeration circuit

(REFR- Refrigeration,

STAND BY- Temperature

is satisfied, DEFR-

Circuit)

Probe 1,2,3 Displays the actual reading

Page 26

Protocol Control System Users Manual 2/12/01

of the temperature probe.

Note that “---“ will be

displayed if a input

assignment (board/point)

has not been made for the

probe.

Figure 39- Circuit Configuration Screen 3

Table 18- Circuit Configuration Screen 4

Field Explanation

Alm Low Dlt The delta (difference)

below the setpoint that is

considered an alarm. For

example, if the

temperature setpoint is 30

and the delta is 5, the low

alarm will be at 25

degrees.

Alm High Dlt The delta (difference)

above the setpoint that is

considered an alarm. For

example, if the

temperature setpoint is 30

and the delta is 5, the high

alarm will be at 35

degrees.

Alm Displays the setting

(ENABLED or

DISABLED) for the alarm

Figure 40- Circuit Configuration Screen 5

Temp Ctrl Displays the temperature

control mode of the circuit

(ENABLED- temperature

control enabled,

DISABLED- temperature

control disabled). Note

that if the circuit is a hot

gas defrost, there is not an

option for temperature

control of the circuit.

Figure 41- Circuit Configuration Screen 6

Table 20- Circuit Configuration Screen 6

Field Explanation

Temperature

Alm Delay

Displays the amount of

delay time after the

temperature goes above or

below the alarm limits

before the temperature

alarm is logged

Show Temp Displays the mode for

calculation of the circuit

tempearture. This is only

applicable if there are

multiple probes defined for

the circuit. Note that this

field can be AVG (display

the average), MIN (display

the minimum), or MAX

(displays the maximum)

Figure 42- Circuit Configuration Screen 7

Table 19- Circuit Configuration Screen 5

Field Explanation

Temp Setpt Displays the temperature

setpoint for this circuit.

Temp

Deadband

Displays the deadband to

be applied to the setpoint if

the circuit is controlling

temperature

Table 21- Circuit Configuration Screen 7

Field Explanation

Defr Time 1 Displays the time of the

first defrost

Number Defr Displays the total number

of defrosts per day

Calculate If the user fills in the Defr

Page 26

Page 27

Protocol Control System Users Manual 2/12/01

Times Time 1 field and the

Number Defr field and sets

this field to YES, the

controller will

automatically calculate all

defrost times (evenly

spaced through out the

day)

Figure 43- Circuit Configuration Screen 8

Table 22- Circuit Configuration Screen 8

Field Explanation

Defr Length Displays the amount of

time for a defrost. If there

is no termination or there

the controller does not get

the termination signal, this

is the maximum length of

time that the defrost will

last.

Alarm Delay Displays the time delay for

an alarm if the controller is

in defrost.

Defr Min Time Displays the mi nimum

time that the controller will

run a defrost for. A defrost

will run for this minimum

amount of time, even if a

termination signal occurs

before this period of time.

Figure 45- Circuit Configuration Screen 10

Table 24- Circuit Configuration Screen 10

Field Explanation

Defr Time

4,5,6

Displays the time of the

defrost (24 hour format)

Figure 46- Circuit Configuration Screen 11

Table 25- Circuit Configuration Screen 11

Field Explanation

Defr Type Displays the type of

defrost (ELECTRIC, OFF

CYCLE or HOT GAS)

Defr Term

Type

Displays the type of

termination to use (TIME,

NONE, TEMPERATURE

or DIGITAL (Klixon))

Defr Term

Temp

Displays the termination

temperature for the circuit

Figure 47- Circuit Configuration Screen 12

Figure 44- Circuit Configuration Screen 9

Table 23- Circuit Configuration Screen 9

Field Explanation

Defr Time

1,2,3

Displays the time of the

defrost (24 hour format)

Page 27

Table 26- Circuit Configuration Screen 12

Field Explanation

Temp 1,2,3 Displays input Board and

Point for the temperature

probes for this circuit.

Note that the assignment

of the board/point defines

whether a circuit is active.

Page 28

Protocol Control System Users Manual 2/12/01

Figure 48- Circuit Configuration Screen 13

Table 27- Circuit Configuration Screen 13

Field Explanation

Probe 1,2,3

offset

Displays the offset

(degrees) that will be

applied to the probe

reading.

Figure 49- Circuit Configuration Screen 14

Table 28- Circuit Configuration Screen 14

Field Explanation

Defr Relay Displays the output point

assignment for the

refrigeration relay for this

circuit. Note that if this is

an electric defrost, the

controller automatically

takes the next relay point

on the board for this circuit

as well.

Digit. Term Displays the input point

assignment (Board/Point)

for the digital termination

for the circuit.

Electric Defr Displays the Amp draw of

the circuit’s electric defrost

heaters. Used for

compressor shedding

during electric defrost.

Figure 50- Circuit Configuration Screen 15

Table 29- Circuit Configuration Screen 15

Field Explanation

Case Type Displays the case type

defined for the circuit.

This allows a circuit to be

named to better identify it.

Scroll through all the

names by selecting the

field and pressing the UP

ARROW or DOWN

ARROW keys.

Case Size Displays the case size

defined for the circuit.

Select the size by selecting

the fields and pressing the

UP or DOWN ARROW

keys.

The above screen is the last screen for circuit

configuration.

8.5.2.3 Copying Circuit Configuration

A circuit configuration can be copied from an

existing circuit to save time during the setup

process. To copy a circuit configuration, first

setup one circuit. Next go to the first

configuration screen of the circuit that you wish

to copy into. Press the UP ARROW key and

the Circuit Copy Screen (see Figure 51) will be

displayed. Go to the Copy from Circuit field

and enter the number of the circuit that you

have already set up. The controller will then

copy all setpoints from the original circuit into

the new circuit. Note that after copying it will

be necessary to make the required changes to

the circuit (defrost schedule, board/points, etc.).

Figure 51- Copy Circuit Configuration Screen

8.5.2.4 Suction Group Configuration

The following are the suction group

configuration screens. Note that the top row of

each screen contains the group number and the

name of the group. The group number in the top

row is an active field in all screens. To view the

configuration information for a different group,

change the group number to the desired group

Page 28

Page 29

Protocol Control System Users Manual 2/12/01

and the information for the new group will be

displayed.

Figure 52- Suction Configuration Screen 1

Table 30- Suction Configuration Screen 1

Field Explanation

Suct. Pressure Read Only field that shows

the current suction

pressure reading.

Suct. Setpt Displays the suctio n

pressure setpoint

X of Y comp

ON

Read Only field that shows

how many compressors for

this suction group are on

Figure 53- Suction Configuration Screen 2

This screen shows the status of all compressors.

Figure 54- Suction Configuration Screen 3

(in seconds). The larger

this number, the slower the

controller will be to

respond to and try to

correct pressure changes.

Figure 55- Suction Configuration Screen 5

Table 32- Suction Configuration Screen 5

Field Explanation

Alm Low Dlt Displays the Low pressure

alarm delta (difference) in

PSI. Note that value will

be subtracted from the

setpoint and that will be

the value that will trigger a

low suction pressure alarm

(after the delay time)

Alm High Dlt Displays the High pressure

alarm delta (difference) in

PSI. Note that value will

be added to the setpoint

and that will be the value

that will trigger a high

suction pressure alarm

(after the delay time)

Suct. Alm

Delay

Displays the delay time

before signaling a high/low

pressure alarm

Table 31- Suction Configuration Screen 4

Field Explanation

Suct. Deadband Displays the Deadband for

the P+I algorithm. Note

this deadband is used for

both P and P+I. The larger

this field, the wider the

pressure swings that will

be allowed before

switching on/off

compressors.

Integration

Time

Displays the Integration

Time for the P+I algorithm

Figure 56- Suction Configuration Screen 6

Table 33- Suction Configuration Screen 6

Field Explanation

Pressure Offset Displays the offset (PSI)

that will be applied to the

pressure probe reading.

Page 29

Page 30

Protocol Control System Users Manual 2/12/01

Figure 57- Suction Configuration Screen 7

This is the last configuration screen for the

suction group. The suction group can be named

by selecting the name field and using the UP or

DOWN ARROW keys to select a letter, then

pressing the ENTER key to move to the next

letter.

8.5.2.5 Discharge Pressure Configuration

This screen shows the configuration screen for

the discharge pressure setup. Note that the

only field on this screen is the setting of the

Alarm setpoint (in PSI).

Figure 58- Discharge Configuration Screen

Figure 60- Lighting Configuration Screen 2

Table 35- Lighting Configuration Screen 2

Field Explanation

Type Control: Displays the control mode

for the lighting circuit.

Can be either SCHEDcontrolled from a schedule

or DIG- controller from a

digital input point (ON

when the input is high)

Figure 61- Lighting Configuration Screen 2A

8.5.2.6 Lighting Configuration

The following screens show the configuration

screens for lighting control.

Figure 59- Lighting Configuration Screen 1

Table 34- Lighting Configuration Screen 1

Field Explanation

State Read Only field that

displays whether the

circuit is ON or OFF

Output 1: Displays the output point

(board/point) assignment

for the output relay.

Note that Figure 61 shows the screen in Figure

60 if the Type Control field is set to DIGITAL.

Field Explanation

Type Control Displays the control mode

for the lighting circuit.

Can be either SCHEDcontrolled from a schedule

or DIG- controller from a

digital input point (ON

when the input is high)

Dig Input: Displays the input point

(board/point) assignment